Whirlpool 3397616 User Manual

Large Capacity Thin Twin

Washer•Dryer – 120/240 Volt

®

Home Appliances

Installation Instructions

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

www.whirlpool.com

Part No. 3397616 Rev. B

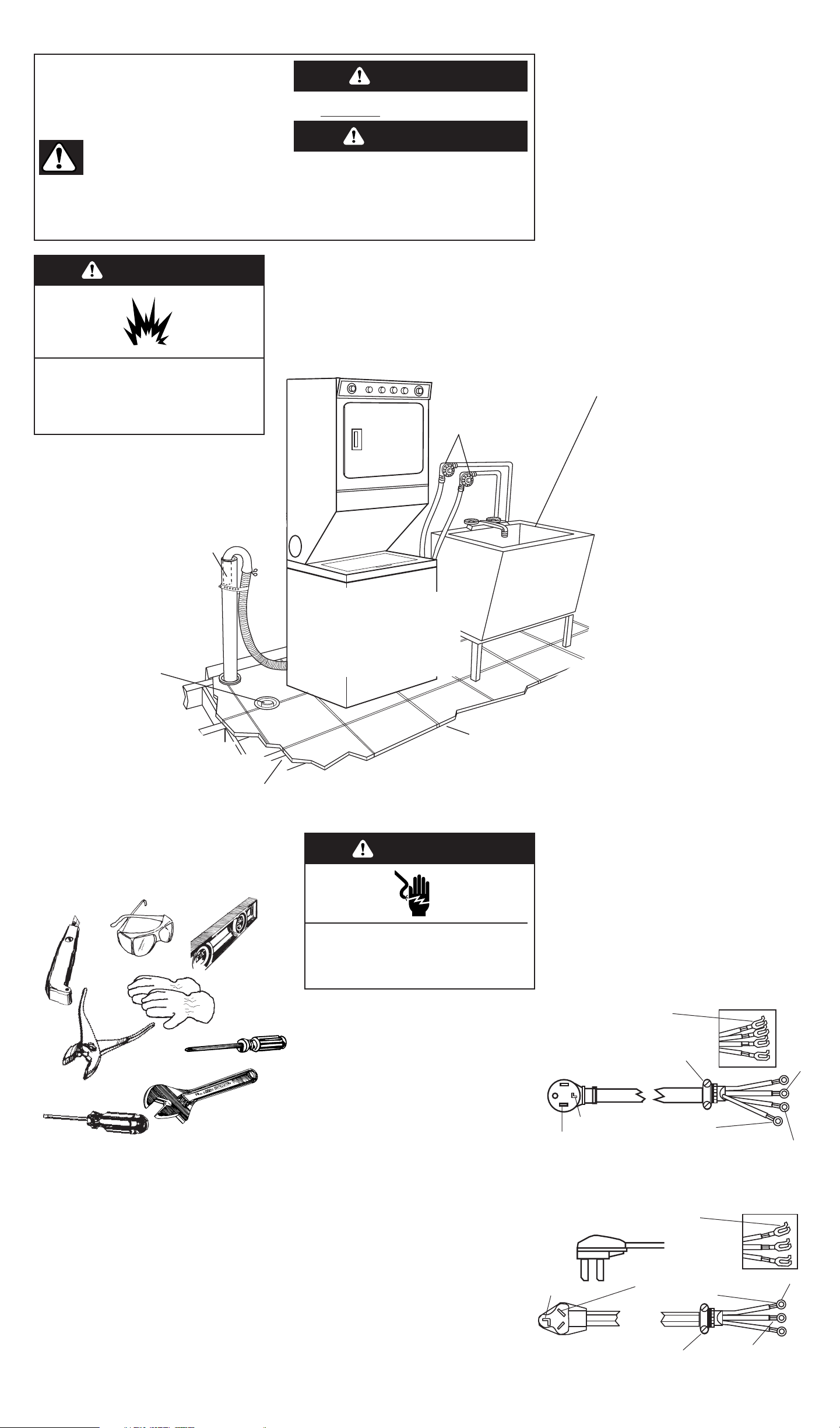

Water heater: Set to deliver 140°F

water to the washer.

Laundry tub drain system: Needs a

20-gallon laundry tub. Top of tub

must be at least 34 inches high and

no higher than 72 inches from floor.

If a longer drain hose is needed,

drain hose (Part No. 388423) and

hose extension kit (Part No. 285442)

are available from a Whirlpoolauthorized parts distributor.

Dryer may be exhausted from the

rear or left or right side. Exhausting

through the side requires Part No.

279823. See “Exhaust requirements,”

Panels C and D.

Four-inch metal exhaust vent is

required.

SEE RECESSED AREA INSTRUCTIONS

ON PANEL G.

Important: Observe all

governing codes and

ordinances.

Check location where washer/dryer will

be installed. Proper installation is your

responsibility. The washer/dryer must not

be installed or stored in an area where it

will be exposed to water and/or

weather. Make sure you have

everything necessary for correct

installation.

Panel A

Location: Should be large enough to

fully open dryer door to 90°. See Panel

G for “Recessed and closet installation

instructions” and “Product dimensions.”

Grounded electrical connection is

required. See “Electrical requirements.”

Standpipe drain system: Needs

a two-inch diameter standpipe

with minimum carry-away

capacity of 17 gallons per

minute. Top of standpipe must

be at least 34 inches high and

no higher than 72 inches from

floor.

Floor drain system requires a

siphon break, Part No.

285320, available from a

Whirlpool-authorized

parts distributor.

Do Not store or operate washer/dryer

below 32°F (some water may remain in

washer). Proper operation of dryer

cycles requires temperatures above

45°F. See Use & Care Guide for

“Winterizing” information.

Tools and materials

needed for installation:

Check code requirements: Some codes

limit or do not permit installation of

clothes dryers in garages, closets,

mobile homes and sleeping quarters.

Contact your local building inspector.

Hot and cold water

faucets: Must be within

4 feet of the back of

the washer/dryer and

provide water pressure

of 5 -100 PSI.

Electrical requirements

A four-wire or three-wire, single-phase,

120/240-volt, 60-Hz, AC-only electrical

supply (or four-wire or three-wire,

120/208-volt, if specified on the

model/serial rating plate) is required on

a separate, 30-ampere circuit, fused on

both sides of the line. A time-delay fuse

or circuit breaker is recommended. The

model/serial rating plate is located in

the door well behind the dryer door on

the front of the opening.

It is the personal responsibility and

obligation of the customer to contact a

qualified electrician to assure that the

electrical installation is adequate and in

conformance with the National

Electrical Code, ANSI/NFPA 70 — latest

edition*, and all local codes and

ordinances.

Untape and

open washer

lid. Remove

packages

and hoses

from washer.

Drain hose

may also be

installed to a

laundry tub or

floor drain

system.

See Panel F.

level

Phillips screwdriver

pliers

utility

knife

safety glasses

gloves

adjustable

wrench (two

may be

required)

flat-blade

screwdriver

Check utilities: Proper, water and

electrical supply connections must be

available.

Support: Floor must be sturdy enough to

support washer/dryer weight, with water

and clothes, of 500 pounds.

Level floor:

1-inch maximum

slope under entire

washer/dryer.

Copies of the standards listed above may be

obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

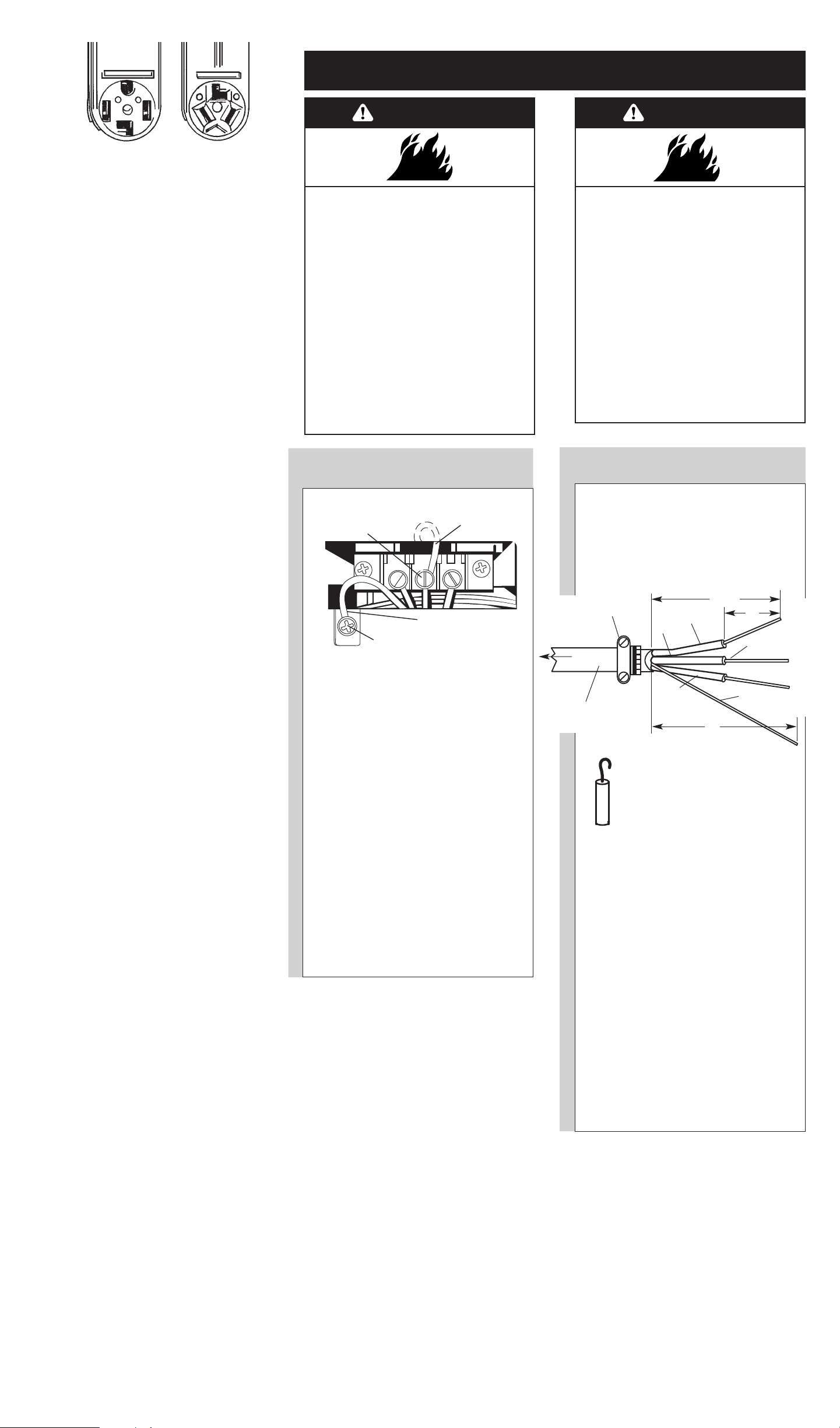

Power supply cord

Local codes may permit the use of a

U.L.-listed, 120/240-volt minimum, 30ampere, dryer power supply cord kit

(pigtail). Power supply cord should be

Type SRD or SRDT and be at least four

feet long. The wires that connect to the

dryer must end with ring terminals or

spade terminals with upturned ends.

A 3/4", U.L.-listed strain relief must be

installed where the power supply cord

connects to the dryer (see Figures 1

and 2).

Four-wire power supply cord

NEMA 14-30P

Figure 1

NEUTRAL

NEUTRAL

(white or center)

3/4" U.L.-listed

strain relief

This blade connected

to this conductor.

ring terminals

spade

terminals with

upturned ends

spade

terminals with

upturned ends

Three-wire power supply cord

NEMA 10-30P

Figure 2

NEUTRAL

NEUTRAL

(white)

3/4" U.L.-listed

strain relief

ground prong

ground wire

(green)

ring

terminals

WARNING

Explosion Hazard

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Failure to do so can result in death,

explosion, or fire.

Your safety and the safety of others are

very important.

We have provided many important safety messages

in this manual and on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential

hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert

symbol and either the word “DANGER” or

“WARNING”. These words mean:

All safety messages will tell you what the potential

hazard is, tell you how to reduce the chance of

injury, and tell you what can happen if the

instructions are not followed.

You can be killed or seriously injured if you

don’t immediately

follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

WARNING

Before you start...

D ANGER

Electrical Shock Hazard

Plug into a grounded 4-prong outlet.

Failure to do so can result in death or

electrical shock.

WARNING

Electrical connection

Panel B

Direct wire

The washer/dryer can be connected

directly to fused disconnect or circuit

breaker box with four-wire or three-wire

flexible armored or non-metallic

sheathed copper cable (with ground

wire). Do Not use two-wire with bare

ground wire. All current-carrying wires

must be insulated.

A conduit connector must be installed

at junction box. USE ONLY 10-GAUGE

SOLID COPPER WIRE. DO NOT USE

ALUMINUM WIRE. Allow four feet of slack

in the line so dryer can be moved if

servicing is ever necessary.

This dryer is manufactured with the

cabinet-ground conductor connected

to the NEUTRAL (center) of the wiring

harness at the terminal block. If local

codes do NOT permit this type of

connection, use “Four-wire connection”

instructions.

GROUND INSTRUCTIONS: This appliance

must be grounded. In the event of

malfunction or breakdown, ground will

reduce the risk of electric shock by

providing a path of least resistance for

electric current.

If using a power supply cord, the plug

must be plugged into an appropriate

outlet that is properly installed and

grounded in accordance with all local

codes and ordinances.

If using a direct wire connection, this

appliance must be connected to a

grounded metal, permanent wiring

system; or an equipment-ground

conductor must be run with the circuit

conductors and connected to the

equipment-ground terminal or lead on

the appliance.

WARNING - Improper connection of the

equipment-ground conductor can

result in a risk of electric shock. Check

with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded. Do not modify the power

supply cord plug. If it will not fit the

outlet, have a proper outlet installed by

a qualified electrician.

If the house has aluminum wiring, follow

the procedure below:

a) Connect a section of 8 gauge solid

copper wire to the connector block.

b) Connect the aluminum wiring to the

added section of copper wire using

special connectors designed and

Underwriters Laboratories Listed for

joining copper to aluminum. Follow

the electrical connector

manufacturer's recommended

procedure.

c) Aluminum/copper connection must

conform with local codes and

industry accepted wiring practices.

three-wire

receptacle(10-30R)

Figure 4

For use where

local codes

permit use of

flexible power

supply cord.

four-wire

receptacle(14-30R)

Figure 3

Four-wire installation is recommended

(required for mobile homes): The power

supply cord must have four, No.-10

copper wires and match a four-wire

receptacle of NEMA Type 14-30R (see

Figure 3). The fourth wire (ground

conductor) must be identified with a

green cover and the neutral conductor

by a white cover.

Three-wire installation (if a four-wire

system is not available): The power

supply cord must have three, No.-10

copper wires to match a three-wire

receptacle of NEMA Type 10-30R (see

Figure 4).

Panel B

Four-wire connection...

A.

DIRECT WIRE

1. Disconnect the power supply.

2. Remove terminal block cover.

3. Strip 5 inches of outer covering from

end of cable. Leave bare ground

wire at 5 inches. Cut 1-1/2 inches

from 3 remaining insulated wires.

Strip insulation back 1 inch (see

Figure 6).

3/4" U.L.-listed

strain relief

red

white

black

to disconnect

box

NEUTRAL

10-gauge, 3-wire

with ground wire

(Romex)

Direct wire preparation

Figure 6

5"

1"

3-1/2"

Figure 7

Shape the end of each

wire into a “U” shaped

hook (see Figure 7). The

bare ground wire must

be 4-1/2" long after

forming the hook.

u-shaped

hook

bare ground

wire

1. Disconnect the power supply.

2. Remove terminal block cover.

3. Install copper, four-wire power

supply cord through strain relief.

4. Remove the ground wire (green

with yellow stripes) from the external

ground connector and fasten

under center, silver-colored

terminal block screw.

5. Connect the ground wire (green) of

the copper, four-wire power supply

cord to the external ground

connector.

6. Connect the neutral wire (white) of

the power supply cord to the

center, silver-colored terminal screw

of the terminal block. Connect the

other wires to the outer terminals.

Tighten screws firmly.

7. Tighten strain relief screws.

8. Replace the terminal block cover.

power supply cord

ground wire (green)

external ground

connector

center silvercolored terminal

block screw and

neutral white wire

ground wire (green

with yellow stripes)

Figure 5

POWER SUPPLY CORD

4. Install copper, four-wire power

supply cable through strain relief.

5. Remove the ground wire (green with

yellow stripes) from the external

ground connector and fasten under

center, silver-colored terminal block

screw.

6. Slide the hook end of the ground

wire (bare) of the four-wire power

supply cable under the external

ground connector screw. Squeeze

hook end of wire together. Tighten

screw.

7. Connect the neutral wire (white) of

the power supply cable to the

center, silver-colored terminal screw

of the terminal block using the same

method. Connect the other wires to

the outer terminals. Tighten screws

firmly.

8. Tighten strain relief screws.

9. Replace the terminal block cover.

wires stripped

of insulation

WARNING

Fire Hazard

Use a new UL approved 30 ampere

power supply cord.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire) must

be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire) must

be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

Loading...

Loading...