Weinmann WM 22460, WM 22440, WM 22400 Service Manual

MODUL CapnoVol

Device for measuring respiratory parameters

Servicing and repair instructions

WM 22400

WM 22440

WM 22460

Content

Introduction

1.

Overview

2.

Description of device

2.1

2.2

3.

Hygiene treatment

3.1

3.2

3.3

4.

Test the device

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

5.

Servicing

5.1

5.2

5.3

5.4

5.5

5.6

5.7

6.

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . 4

Intended purpose

Description of function

Intervals

MODUL CapnoVol and sensor cable

Individual parts

Test material required

Preparation for testing

Enter device data

Test leaktightness

Test device self-test

Test the infrared interface

Test display elements

Test input elements

Test battery charging

Test flow measurement

Test occlusion alarm

Test CO2 measurement

Test system clock

Documentation

. . . . . . . . . . . . . . . . . . . . . . . . 15

Intervals and scope

Change battery

Change O-rings of plug connection

Change O-rings of

Calibrate O2 sensor

Storage

Disposal

. . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . .

. .

oxygen duct inlet. 17

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . 20

10

10

10

11

11

12

12

13

14

14

15

16

16

17

19

19

7.

Repair information and repair instructions 22

7.1

General

7.2

Open the device

7.3

5

5

6

6

7

8

8

9

9

8.

9.

10. Technical data . . . . . . . . . . . . . . . . . . . . 39

11. Service record . . . . . . . . . . . . . . . . . . . . . 41

Close the device

7.4

Replace the Capno connecting

adapter

7.5

Replace Nafion tube

7.6

Replace main circuit board and/or

CAP 100 circuit board

7.7

Replace fuses

7.8

Replace connecting tube for oxygen

duct

7.9

Replace display circuit board

7.10

Replace infrared circuit board

7.11

Replace top part of housing

7.12

Replace bottom part of housing

Replacement parts

8.1

Replacement parts list

8.2

Parts to be changed when servicing

Tools and testing equipment

9.1

General tools

9.2

Special tools. . . . . . . . . . . . . . . . . 37

9.3 Testing equipment . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . . . .

. . . . . . .

. . . .

. . . . . . . . . . . . . . . . . 35

. . . . . . . . . . .

.

. . . . . . . . . . 37

. . . . . . . . . . . . . . . .

22

22

23

24

25

25

28

29

31

32

33

34

35

36

37

© Copyright WEINMANN GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised WEINMANN Service Partners in

the course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with WEINMANN.

2

Introduction

WEINMANN has been developing, manufacturing

and selling devices for emergency medicine, for

oxygen therapy and for inhalation therapy for

decades.

The objective of these servicing and repair

instructions is to make you, an expert, familiar with

the function, technology and repair of

MODUL CapnoVol. In conjunction with the training

session you have already received from

WEINMANN, you are now considered a “trained

expert specialist”, so can properly instruct your

customers, eliminate faults independently and

perform the function checks specified in the

instructions for use and any repairs in accordance

with these servicing and repair instructions.

In the event of a claim under warranty, send

MODUL CapnoVol to WEINMANN.

Please enclose the end-customer’s proof of

purchase (invoice) to enable us to process

warranty or goodwill claims.

Repairs and servicing work may only be

performed by WEINMANN or by trained

specialists.

You are responsible for repairs carried out yourself

and for guaranteeing them!

Use only genuine WEINMANN replacement parts

for repairs.

Please remember:

your customer trusts you and is relying on your

capability in the same way as you rely on

WEINMANN.

Note

The following information can be found in the instructions for use for MODUL CapnoVol:

• safety instructions

• assembly of accessories

• operating MODUL CapnoVol

• hygiene treatment

• function check

• warranty

Introduction 3

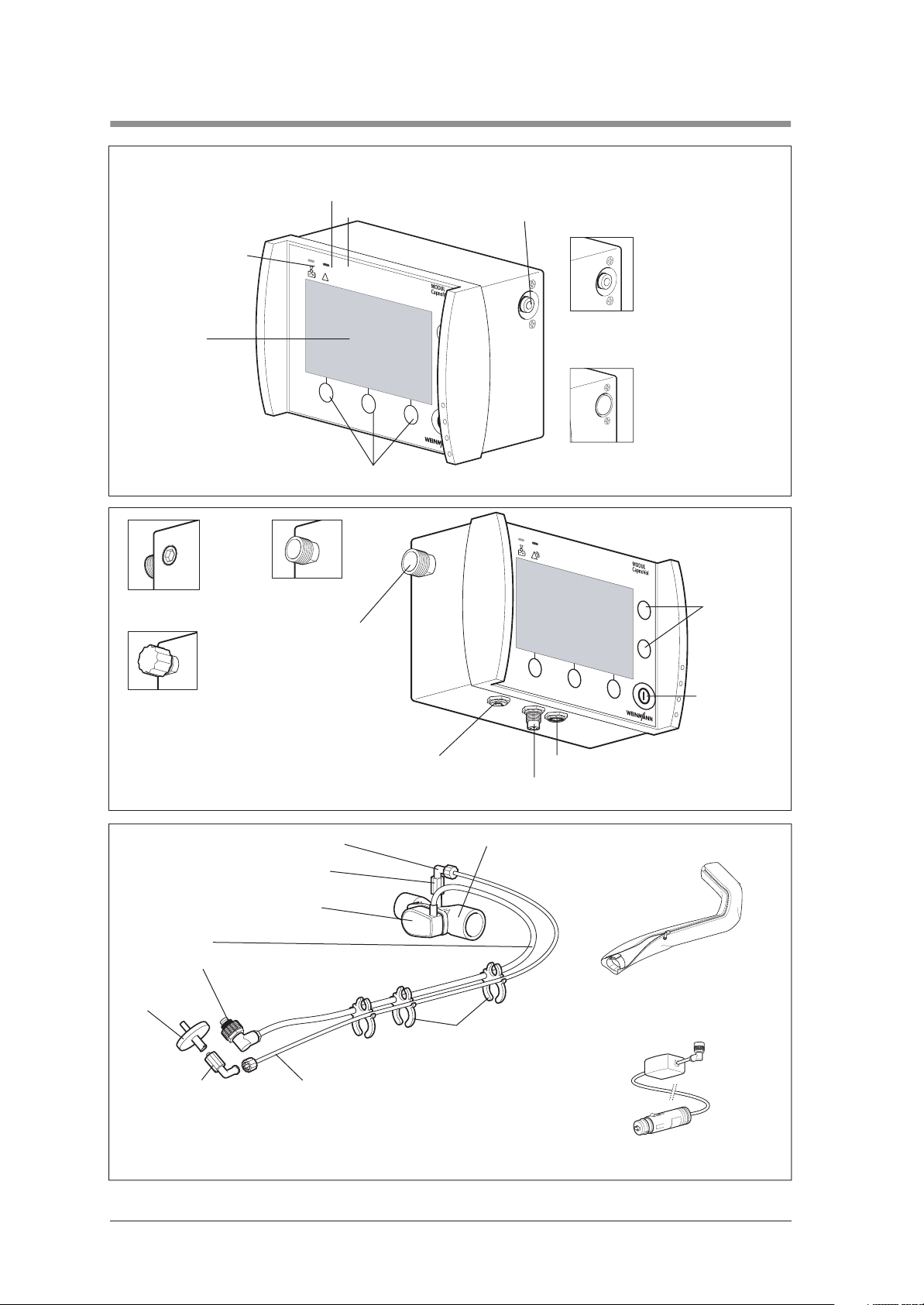

1. Overview

MODUL CapnoVol

6 Green charging

indicator (battery

charging)

5 Display

LIFE-BASE Mini II

LIFE-BASE II

LIFE-BASE III

11 Inlet for

1 Red alarm indicator

2 IR interface

4 Operating key

oxygen duct

3 Outlet for

oxygen duct

LIFE-BASE II

LIFE-BASE III

LIFE-BASE Mini II

LIFE-BASE Micro

stand-alone

4 Operating

key

Stand-alone

LIFE-BASE Micro

12 Luer lock elbow adapter

20 Connection for CO2 extraction tube

19 Connector for BiCheck flow sensor

18 Sensor cable

17 Connector for sensor cable

16 Water filter

12 Luer lock elbow

adapter

15 CO2extraction tube

10 Intake opening

for respiratory gas CO2

measurement

13 BiCheck flow sensor

14 Clip for securing

patient tube

system

7 On/Off key

8 Connection for BiCheck flow sensor

9 Connection for power supply

21 Tube protection sleeve

4 Overview

22 Power supply cable 12 V

2. Description of device

2.1 Intended purpose

MODUL CapnoVol is a device for measuring

respiratory parameters on exhalation.

The following are shown as figures:

• tidal volume (TVe)

• minute volume (MVe)

• respiratory frequency (AF)

• ratio of inspiration to exhalation (I:E)

• carbon dioxide concentration at the end of

exhalation (etCO2)

The following is shown in the form of a graph:

• current carbon dioxide concentration

(capnogram).

MODUL CapnoVol can be used in a permanent

location or on a mobile basis both indoors and

outdoors.

2.2 Description of function

Measuring volume flow

Volume flow is measured on the principle of heat energy transmission (hot-wire method). This method

measures the time taken to transfer heat from one central transmission wire to the lateral reception wires. Tidal

volume (TV), minute volume (MV), respiratory frequency (AF) and the ratio of inspiration to exhalation (I:E) are

determined from the values measured.

Sampling and gas analysis

A small pump inside the device extracts respiratory gas from the patient's respiratory flow at an adjustable

gas flow rate (secondary flow method). The respiratory gas is fed to a measuring cell via a water filter. The

CO2 concentration of the dry gas is determined in the measuring cell. The measuring method used in the

process is based on infrared absorption spectrometry.

CO2 measurement and display of measured values

The patient's exhalation gas is dried for technical reasons before it enters the measuring device. So that the

measured values still reflect actual conditions in the moist respiratory air, MODUL CapnoVol incorporates

the water vapor partial pressure of moisture-saturated air in its calculation. The value displayed thus includes

the water vapor in the exhaled gas (water vapor correction).

Several measured values are determined for each breath. The CO2 concentration measured can be

displayed in vol %, in mmHg or in kPa. Barometric altitude pressure is taken into account and compensated

accordingly.

The CO2 concentration determined is shown in the form of a capnogram. The maximum value at the end of

exhalation is called the end-tidal CO2 value (etCO2) or also final concentration of carbon dioxide on

exhalation. It is displayed as a figure.

Description of device 5

3. Hygiene treatment

3.1 Intervals

You must subject MODUL CapnoVol and any

accessories used to a hygiene treatment after every

use.

After that, always perform a function check (see

Section “8. Function check” in the instructions for

use).

3.2 MODUL CapnoVol and sensor cable

Warning!

Never immerse MODUL CapnoVol or the sensor

cable in disinfectant or other liquids, otherwise

damage to the device and thus a hazard to users

and patients may result.

MODUL CapnoVol and the sensor cable are kept

clean by simply washing or wiping with

disinfectant.

Parts Cleaning

Housing for

MODUL CapnoVol

Sensor cable with

securing clips

Wipe with a damp

cloth

Wipe with a damp

cloth

Rinse cycle in a

washing machine

Not permitted

Not permitted

We recommend the use of suitable gloves (e.g.

household or disposable gloves) for disinfecting.

See the instructions for use for the disinfectant used.

For disinfecting by wiping, we recommend

TERRALIN.

Disinfecting Sterilizing

Disinfect by

wiping

Disinfect by

wiping

Not

permitted

Not

permitted

6 Hygiene treatment

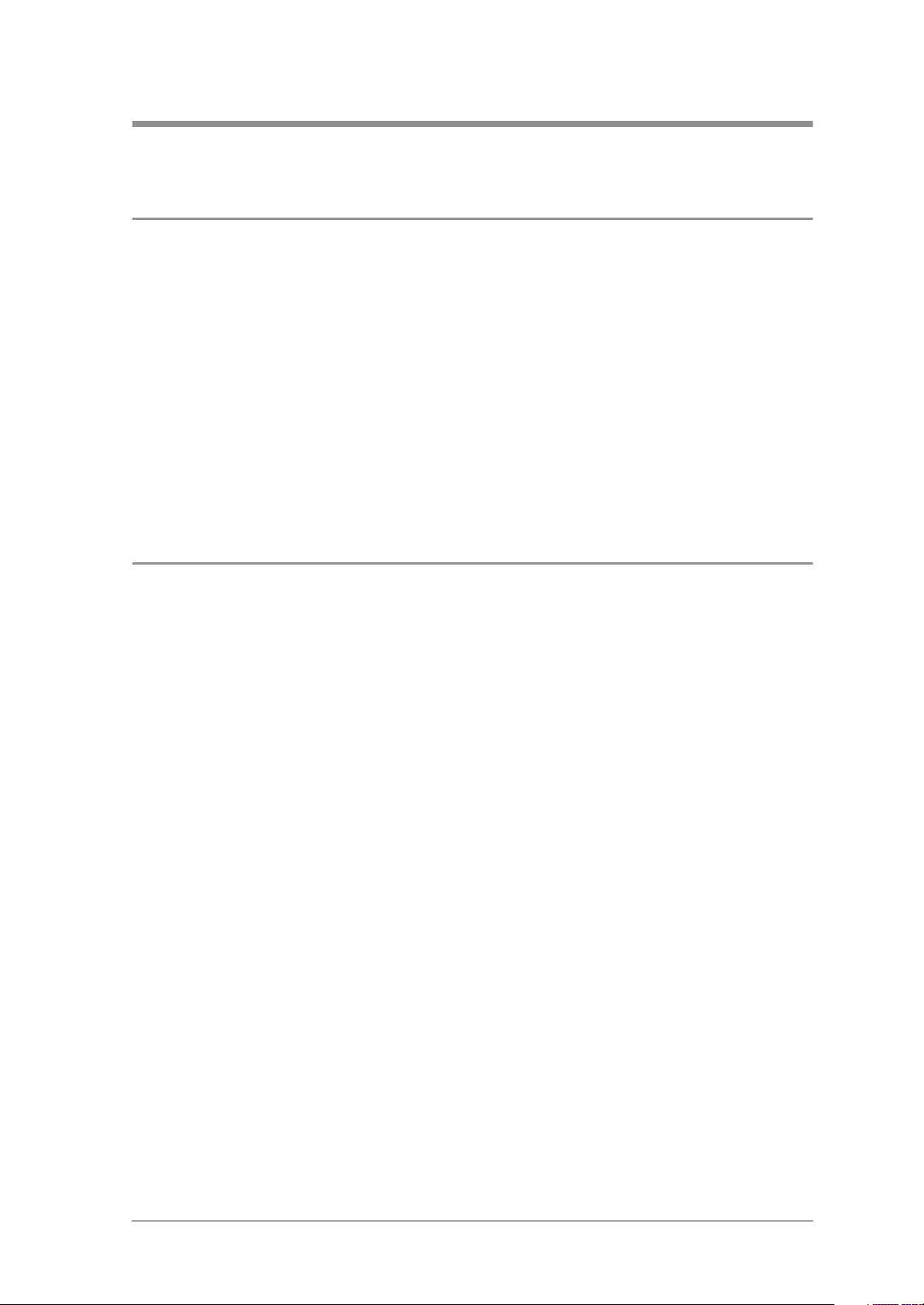

3.3 Individual parts

Individual parts should be cleaned, disinfected or

sterilized as listed in the following table.

We recommend the use of suitable gloves (e.g.

household or disposable gloves) for disinfecting.

Parts Cleaning

BiCheck flow sensor 13

(1)

Tube protection sleeve 21

In hot water with a

mild detergent

Wipe with a damp

cloth

Rinse cycle in a

washing machine

Wash in a

dishwasher at 65 ˚C.

Then dry thoroughly.

Rinse cycle 30 ˚C, no

spin

See the instructions for use for the disinfectant used.

We recommend GIGASEPT FF for disinfecting by

immersion.

Warning!

The BiCheck flow sensor 13 may not be flushed

through with a high-pressure water jet or compressed

air, as this may damage the measuring wires.

Disinfecting Sterilizing

Disinfect by

immersing (2)

Possible during

rinse cycle (4)

Steamsterilize (3)

Not

permitted

CO2 extraction tube 15

Water filter 16

Not permitted, as disposable

Luer lock elbow adapter

12

(1): You must remove sensor cable 18, CO2 extraction tube 15 and the ventilation tube from the BiCheck

flow sensor 13, as these cannot be autoclaved.

(2): Immerse the component in dilute solution so that all surfaces, both internal and external, are wetted

without bubbles. Allow full time for product to take effect. Following disinfecting, rinse all parts inside

and out thoroughly with distilled water and then leave them to dry.

(3): Hot steam sterilization with devices to EN 285, temperature 134 ˚C, retention time 5 minutes.

(4): Add a suitable disinfectant additive to the rinse cycle (30 ˚C in the washing machine, no spin).

Hygiene treatment 7

4. Test the device

Important!

Perform the following test on the device in accordance with test instruction WM 22401 after every repair and on

servicing. The device test can also be used for troubleshooting.

If you find faults or deviations from specified values during testing, you may not use MODUL CapnoVol until

the faults have been rectified.

The potential causes of the fault and how to eliminate the malfunction can be found in Section “6.

Troubleshooting” on page 20.

We recommend always keeping the following in stock:

• replacement seals for device connections WM 22468, WM 22469

• Ni-Mh battery WM 22458

4.1 Test material required

• Ventilation device, e.g. MEDUMAT with the associated test set, e.g. WM 15382

• KAL Check gas WM 97061 with pressure reducer WM 97062

• PC with installed software WM 22480 from the following set WM 15681

• Set of IR adapter plus software and bracket WM 15681

• Power supply cable, 12 V, WM 22895

• Connecting cable for flow measurement WM 22420

• Measuring and leaktightness adapter WM 22868

• Current measuring adapter MODUL CapnoVol WM 22817

• CO2 absorber WM 22172

• Set for testing power supply MEDUMAT/MODULES WM 15440

• Set of tools for MEDUMAT Standard WM 15349 or syringe set WM 15359

• Volume flow measuring device (e.g. PF-300), breath volume measurement with O2 in STP mode

• Digital multimeter

• Patient tube with patient valve

• Pall filter

4.2 Preparation for testing

1. Fit MODUL CapnoVol together with a

MEDUMAT ventilation device to a LIFE-BASE

carrying system.

2. Connect the external power supply.

3. Connect sensor cable 18.

4. Connect 12 V power supply cable 22.

8 Test the device

5. Connect the power supply testing set

MEDUMAT/MODULES WM 15440.

6. Connect CO2 extraction tube 15 with water

filter.

4.3 Enter device data

Enter the device number and the date of

manufacture in the test record.

4.4 Test leaktightness

4.4.1 Test oxygen duct

1. Apply a pressure of 6 bar to the inlet side of

both devices when they are switched off.

2. Shut off outlet pressure.

Requirement: the drop in pressure must be

≤ 200 mbar/min.

4.4.2 Test CO2 measuring section

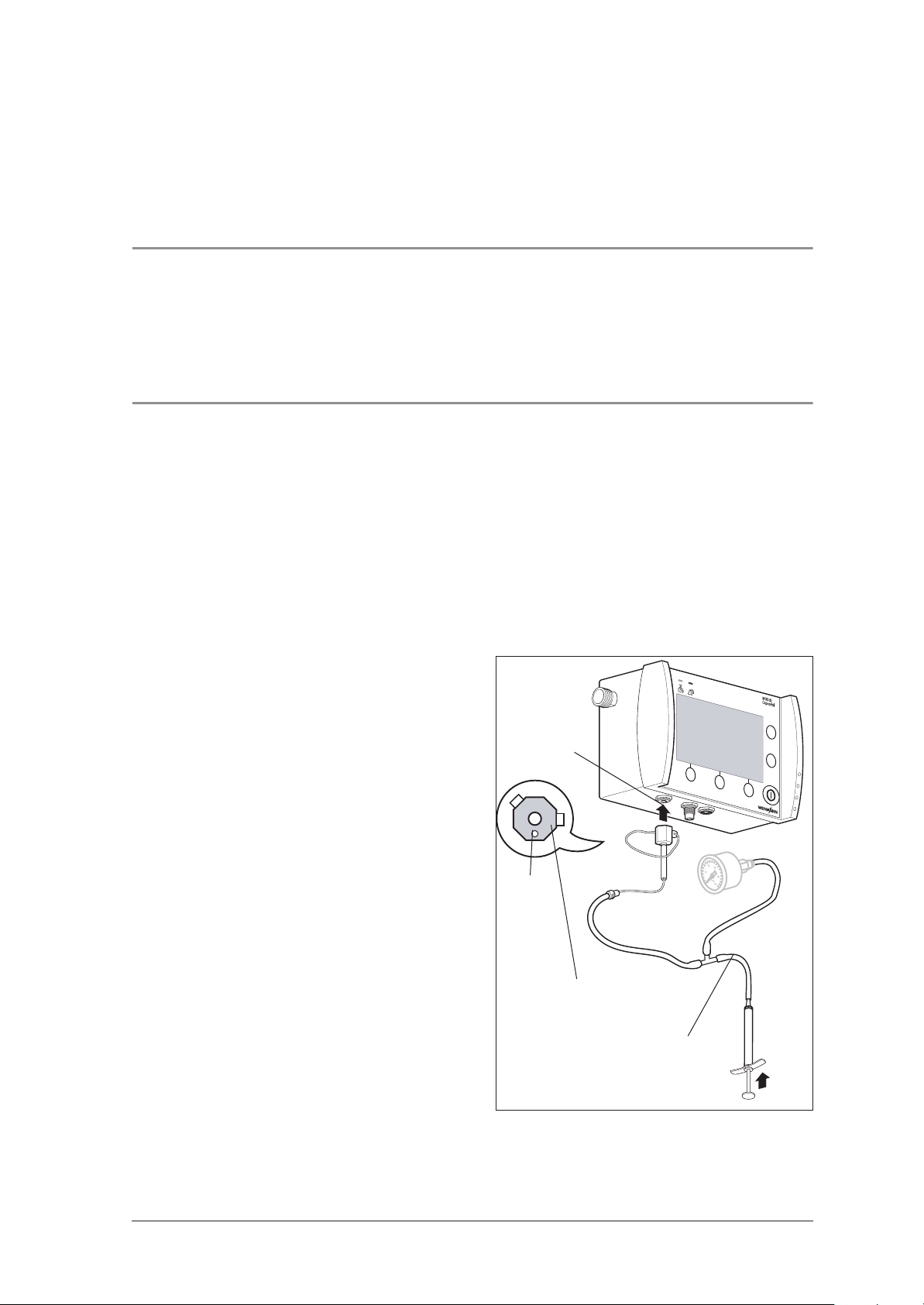

1. Push the CO2 measuring and leaktightness

adapter onto the intake opening for respiratory

gas CO2 measurement 10. In the process,

ensure that the CO2 measuring and

leaktightness adapter is correctly positioned

(the pin must be in the position shown in

relation to the device).

2. Put the T-tube with syringe from set

WM 15349/WM 15359 onto the CO2

measuring and leaktightness adapter.

3. Detach the test pressure gage from the T-tube.

4. Connect the volume flow measuring device at

the same point.

5. Push the CO2 measuring and leaktightness

adapter against the intake opening for

respiratory gas CO2 measurement 10 of the

device to ensure leaktightness.

6. Apply a pressure of 60 mbar to the intake

opening for respiratory gas CO2

measurement 10 with the device switched off.

Requirement: the drop in pressure must be

≤ 2 mbar/min.

10

Pin

CO2 measuring and

leaktightness adapter

T-tube with syringe

Test the device 9

4.5 Test device self-test

1. Ensure that water filter 16 has been correctly

fitted before switching on.

2. Switch on MODUL CapnoVol.

Requirement: after 10 seconds, there should

not be any system alarm and the capnometry

pump should have audibly started up.

4.6 Test the infrared interface

1. Align the infrared sensor above the infrared

interface of MODUL CapnoVol.

2. Start the “CAPNOVOL.EXE” program as

described in “Manual CapnoVol

Software.pdf” on CD WM 22480.

3. Follow the instructions for reading out

measured data from MODUL CapnoVol.

Requirement: the measured data read out must

result in meaningful characters as described in

Section 4 “Measured data file” on CD

WM 22480.

4.7 Test display elements

4.7.1 Test power supply LED, alarm LED and alarm transmitter

1. Switch on the device.

2. Switch off the device and then switch back on.

Requirement: the green and red LEDs must light

up one after the other. At the same time, the

alarm transmitter must be triggered once.

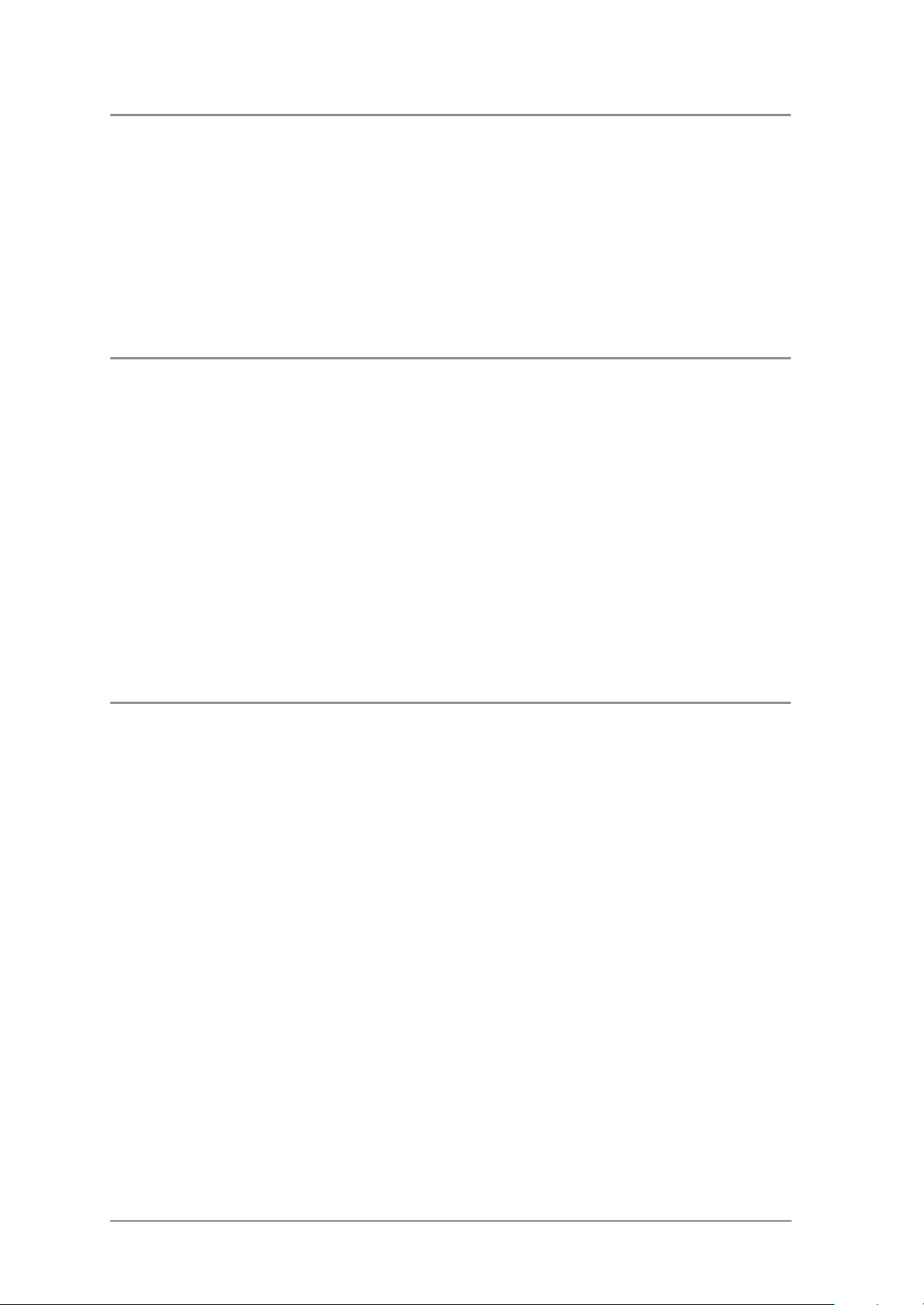

4.7.2 Test display

1. Press the “Menu” key.

2. Use the arrow keys to select the menu item

“Default settings”. Press the ↵ key.

3. Use the arrow keys to select the menu item

“Display”. Press the ↵ key.

10 Test the device

4. Use the arrow keys to select the menu item

“Normal Inverse”. Press the ↵ key.

5. You can now use the + and – keys to switch

the display between normal display and

inverse display. Confirm your entries in each

case by pressing ↵.

Requirement: no image elements may be

permanently on or off in either display.

4.8 Test input elements

Press all the operating keys of MODUL CapnoVol

within the menu.

Requirement: all keys are detected correctly and

initiate the appropriate actions.

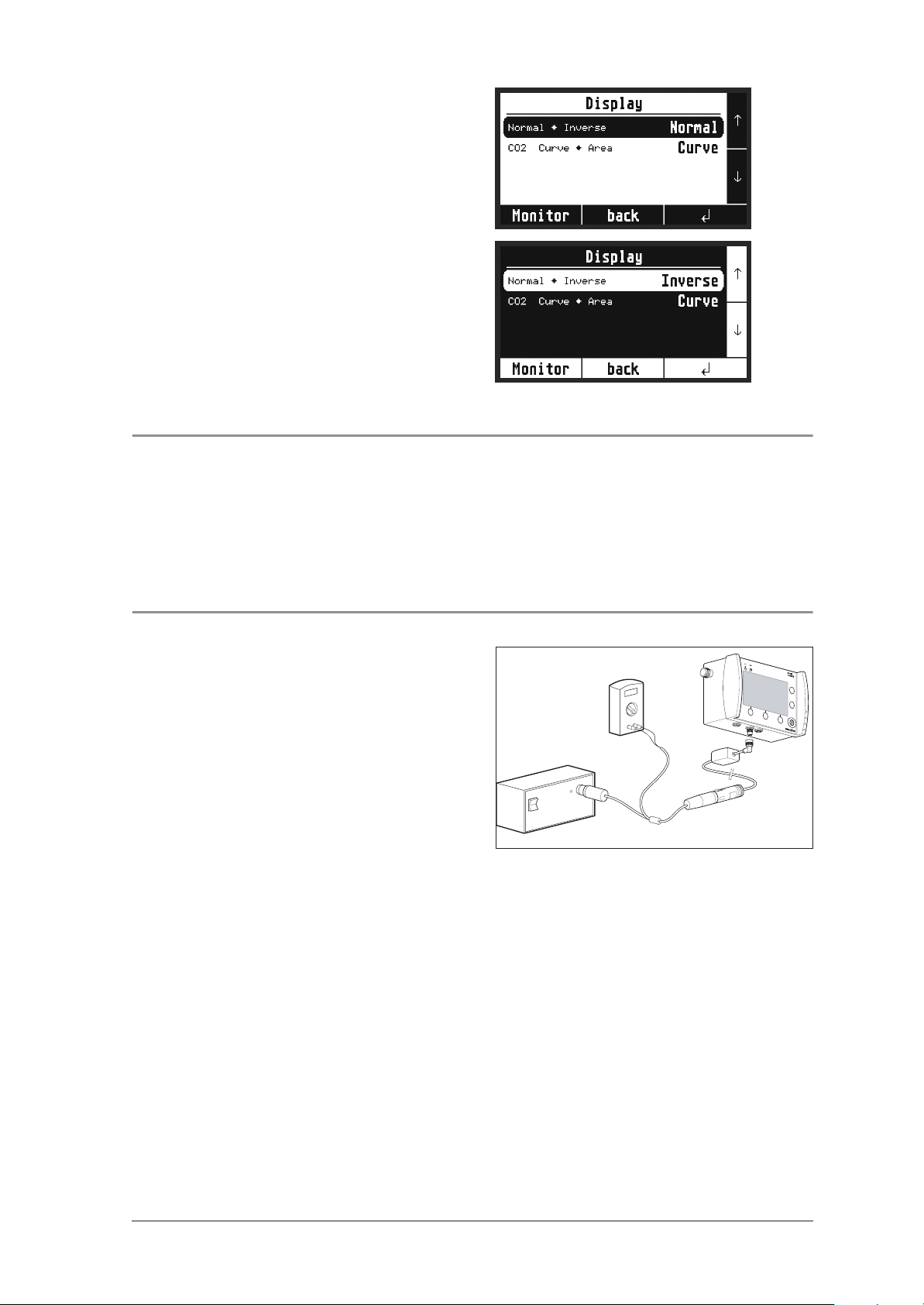

4.9 Test battery charging

1. Connect current measuring adapter

MODUL CapnoVol WM 22817, 12 V

power supply and multimeter to the device.

2. Switch on MODUL CapnoVol.

3. Switch on the power supply and measure

current consumption in charging mode.

Requirement: charging current at 12 V must be

1.7 A ± 0.2 A.

The power supply of mains charging devices

WM 2645 and WM 2610 is higher (13.8 V). If

these devices are used, the charging current

should be 1.4 A ± 0.2 A.

Note

If the battery is fully charged, the device will

not switch to charging mode. In other words,

the above-mentioned requirement cannot be

met. In this event, leave the device switched on

for approx. 10 minutes and then repeat the

test.

Test the device 11

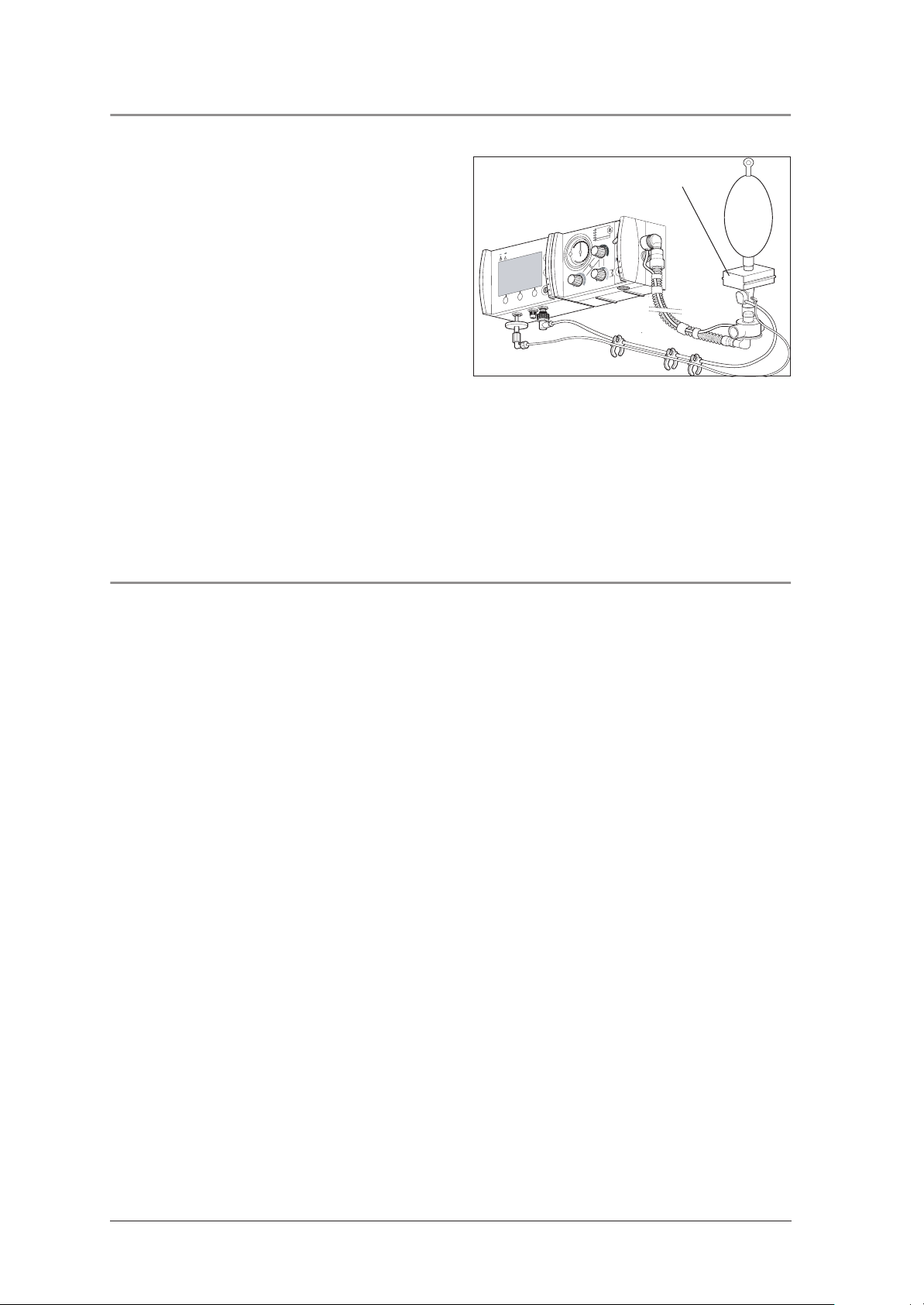

4.10 Test flow measurement

1. Connect MODUL CapnoVol together with a

MEDUMAT ventilation device to BiCheck flow

sensor 13.

2. Set breath volume on the MEDUMAT (f =

approx. 20/min, AMV = approx. 9 l/min;

pressure limit p = 60 mbar).

3. Switch on the compressed gas supply.

4. Switch on MEDUMAT.

5. Put the Pall filter on the test bag (for filtering

flow peaks).

6. Plug BiCheck flow sensor 13 between the

patient valve and the test bag with the Pall

filter.

7. Start ventilating with the MEDUMAT.

Requirement: MODUL CapnoVol must display

an exhalation volume TVe = 450 ± 70 ml.

Pall filter

I

I

4.11 Test occlusion alarm

1. Take CO2 extraction tube 15 off

MODUL CapnoVol and seal the water filter

with a finger.

Requirement: the device displays an occlusion

alarm.

2. Take your finger off the water filter again.

Requirement: the device no longer displays an

occlusion alarm.

12 Test the device

4.12 Test CO2 measurement

4.12.1 Preparation

1. Plug water filter 16 onto the intake opening for

respiratory gas CO2 measurement 10.

2. Connect CO2 absorber WM 22172 to water

filter 16.

3. Press the CO2 absorber at least 20 times to

ensure that CO2-free air is in the system.

4.12.2 Method

Important!

Use only the following components:

10

16

• the KAL Check gas (WM 97061) supplied by WEINMANN

• a suitable pressure reducer (WM 97062)

Observe an ambient temperature of approx. 20 ˚C to guarantee adequate precision in this test. It is essential

to follow the instructions for use and the warning information enclosed with the KAL CHECK gas.

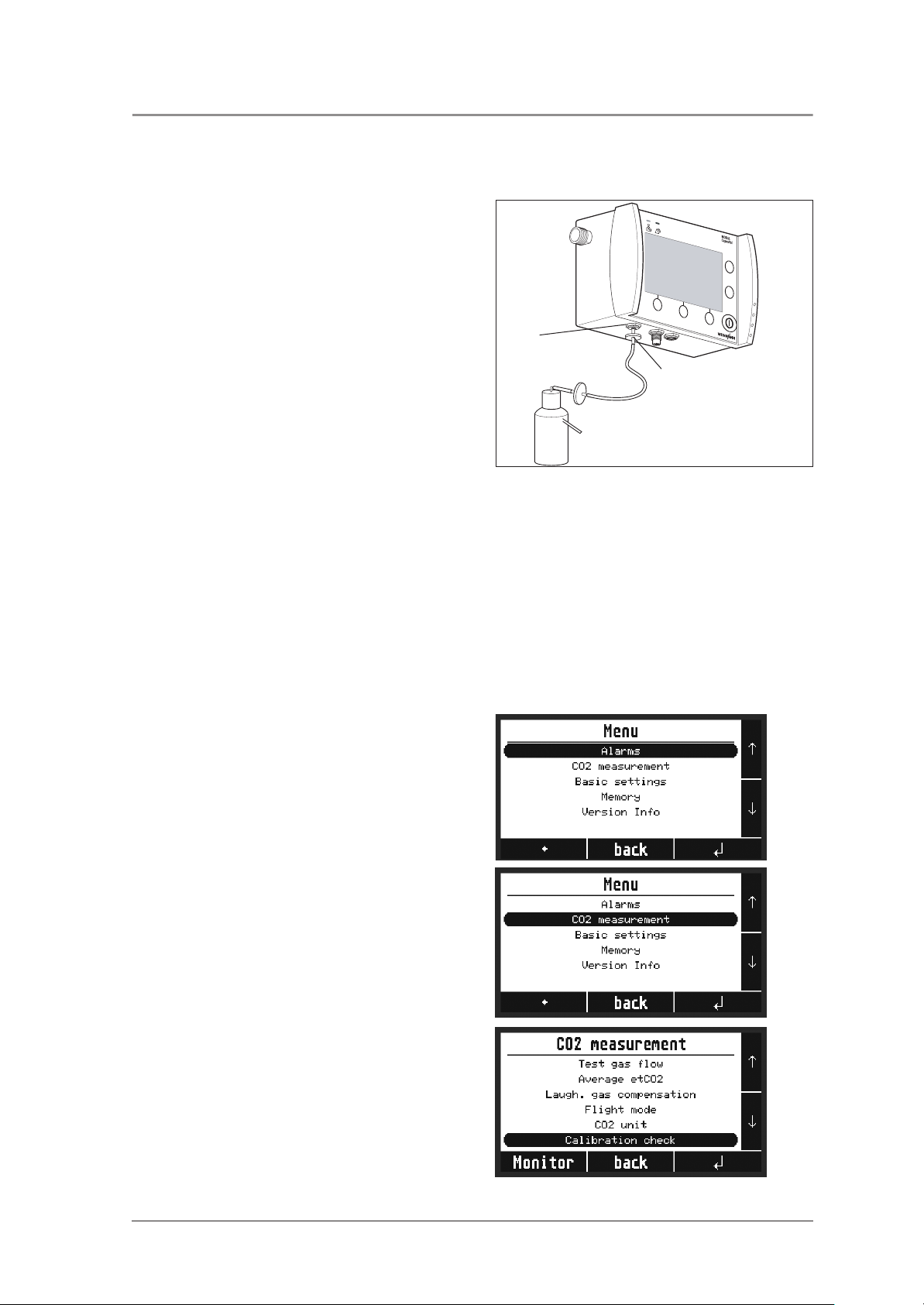

1. Switch on the device.

Leave MODUL CapnoVol to run for approx.

15 minutes in normal mode.

2. Press the “Menu” key. The main menu

appears.

3. Use the arrow keys to select the menu item

“CO2 measurement”.

4. Press the ↵ key to reach the submenu for CO2

measurement.

5. Use the ‹ key to select the “Calibration check”

submenu.

6. Press the ↵ key to reach the submenu.

7. Disconnect CO2 extraction tube 15 from

BiCheck flow sensor 13.

Test the device 13

8. Connect CO2 extraction tube 15 to the Y–

piece of the KAL CHECK device.

Important: the other end of the Y-piece must

remain open.

9. Open the valve of the KAL CHECK gas

canister far enough for the ball on the flow

measuring device to be between the first and

second marking ring.

Important: the gas canister must be upright for this.

10.Press the ↵ key to start the calibration check.

Remaining time is displayed while the

calibration check is performed.

When the calibration check has been

completed successfully, you will receive the

corresponding message.

4.13 Test system clock

1. Check whether the date and time are correct

in the display.

2. If necessary, set date and time as described in

the instructions for use, Section “5.4 Menu

default settings”.

4.14 Documentation

1. Record performance of the test on the repair

and test record (copy of the form).

2. Following any repairs, send a copy of the

record to WEINMANN.

14 Test the device

Loading...

Loading...