Page 1

Servicing and

repair instructions

Module System

Oxygen

WM 22200

Suction

WM 22220

Combi

WM 22210

Interface

WM 22230

MODULE

MODULE

MODULE

MODULE

Page 2

Contents

Introduction

1.

Overview

2.

Description

2.1

2.2

2.3

3.

Final Check

3.1

3.2

3.3

3.4

3.5

3.6

3.7

4.

Servicing

4.1

4.2

4.3

5.

Troubleshooting

6.

Repair information and repair instructions

6.1

6.2

6.3

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Uses

. . . . . . . . . . . . . . . . . . . . . . . . . .

Module combinations

Storage

Test resources required

Preparations for final check

Entering device data

Check for leaks in the system

Checking inhalation function

Testing vacuum

Checking aspiration function

Intervals

Servicing

Disposal

General

Oxygen MODULE

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

6.2.10

6.2.11

6.2.12

Suction

6.3.1

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Replacing the sieve in the

oxygen inlet

Replacing the O-ring in the

oxygen outlet

Dismantling the housing

Assembling the housing

Replacing the non-return valve

in the distributor block

Replacing the pressure gauge

Replacing the tubes

Replacing the toggle switch

Replacing the quick-release

coupling

Replacing O-ring of Walther

coupling

Replacing the pressure regulator

(

MODULE Oxygen: up to Device

No. 1616;

up to Device No. 1075;

MODULE Suction: up to

Device No. 1010)

Replacing the pressure regulator

(

MODULE Oxygen: from Device

No. 1617;

from Device No. 1076;

MODULE Suction: from

Device No. 1011)

MODULE

Replacing the sieve in the

oxygen inlet

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

MODULE Combi:

. . . . . . . .

MODULE Combi:

. . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. .

. . . . .

. . . . .

. . . . . .

.

. .

10

11

11

11

12

12

13

13

13

13

14

14

16

19

20

21

22

22

23

24

24

26

26

4

5

6

6

6

6

7

7

7

7

7

9

9

10. Technical Changes . . . . . . . . . . . . . . . . . . . . 44

6.3.2

6.3.3

6.3.4

6.3.5 Replacing the non-return valve

6.3.6 Replacing the pressure gauge . 27

6.3.7 Replacing the tubes . . . . . . . . 27

6.3.8 Replacing the toggle switch . . 28

6.3.9 Replacing the quick-release

6.3.10 Replacing the pressure regulator 28

6.4 Combi MODULE . . . . . . . . . . . . . . . . . 29

6.4.1 Replacing the sieve in the

6.4.2 Replacing the O-ring in the

6.4.3 Dismantling the housing . . . . . 29

6.4.4 Assembling the housing . . . . . 29

6.4.5 Replacing the non-return valve

6.4.6 Replacing the pressure gauge . 30

6.4.7 Replacing the tubes . . . . . . . . 30

6.4.8 Replacing the toggle switch . . 30

6.4.9 Replacing the quick-release

6.4.10 Replacing the pressure regulator 31

6.5 Interface MODULE. . . . . . . . . . . . . . . .32

6.5.1 Replacing the sieve in the

6.5.2 Replacing the O-ring in the

6.5.3 Dismantling the housing . . . . . 32

6.5.4 Assembling the housing . . . . . 32

6.5.5 Replacing the non-return valve

6.5.6 Replacing the pressure gauge . 33

6.5.7 Replacing the tubes . . . . . . . . 33

6.5.8 Replacing the quick-release

7. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Spare parts list . . . . . . . . . . . . . . . . . .35

7.2 Spare parts required for servicing . . . . . .37

8. Tools and test equipment . . . . . . . . . . . . . . . 39

8.1 General tools . . . . . . . . . . . . . . . . . . .39

8.2 Special tools. . . . . . . . . . . . . . . . . . . .39

8.3 Test equipment . . . . . . . . . . . . . . . . . .40

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . 41

9.1 External oxygen flow volume . . . . . . . . . 42

9.2 Oxygen flow volume from inhalation

connection . . . . . . . . . . . . . . . . . . . . .42

9.3 Aspiration efficiency. . . . . . . . . . . . . . .43

Replacing the O-ring in the

oxygen outlet

Dismantling the housing

Assembling the housing

in the distributor block . . . . . . 27

coupling . . . . . . . . . . . . . . . 28

oxygen inlet . . . . . . . . . . . . . 29

oxygen outlet . . . . . . . . . . . . 29

in the distributor block . . . . . . 30

coupling . . . . . . . . . . . . . . . 30

oxygen inlet . . . . . . . . . . . . . 32

oxygen outlet . . . . . . . . . . . . 32

in the distributor block . . . . . . 33

coupling . . . . . . . . . . . . . . . 34

. . . . . . . . . . . .

. . . . .

. . . . .

26

26

26

© Copyright Weinmann GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised Weinmann Service Partners in the

course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with Weinmann.

2

Page 3

11. Repair and inspection log . . . . . . . . . . . . . . 45

11.1Oxygen MODULE . . . . . . . . . . . . . . . 45

11.2Suction MODULE . . . . . . . . . . . . . . . . 46

11.3Combi MODULE . . . . . . . . . . . . . . . . 47

11.4Interface MODULE . . . . . . . . . . . . . . . 48

3

Page 4

Introduction

For decades, Weinmann has developed, manufactured and distributed equipment for oxygen and

inhalation therapy and for emergency medicine.

In 1980, Weinmann launched the first MODULES

on the market.

The MODULES were permanently installed in a vehicle or alternatively, for mobility purposes, mounted on the support plates LIFE-BASE II and LIFE-BASE

Mini II.

You can use the Modules individually, connect up

to three Modules in series, or combine them with

the MEDUMAT respirator. In this way, you need

only one oxygen connection, and where space is

limited, several functions are available simultaneously.

The modules serve the following purposes:

• Oxygen MODULE:

Oxygen inhalation 0 to 15 l/min.

• Suction MODULE:

Extraction, infinitely variable from

0 to -0.5 bar.

• Combi MODULE:

Oxygen inhalation 0 to 15 l/min, extraction

preset at -0.5 bar.

• Interface MODULE:

Connection to an external oxygen supply 2.7

to 6.0 bar.

The aim of these service and repair instructions is

to familiarise you, as a knowledgeable expert, with

the Module in terms of function, technology and repairs. In conjunction with the training you have already received from Weinmann, you are now a

"trained, qualified expert" and are able to instruct

your clients correctly, rectify faults yourself, and

perform the functional checks described in the instructions for use, as well as conduct any repairs

which may be necessary, as outlined in these service and repair instructions.

In the event of a guarantee claim, the module should

be returned to Weinmann.

To enable us to process any guarantee or goodwill

claims, please return the consumer's proof of purchase (invoice) together with the appliance.

Repair and maintenance work must be carried out

only by Weinmann or by knowledgeable expert

staff.

You are responsible for repairs performed by yourself

and for the warranty thereof!

Only original Weinmann spare parts should be used

for repair purposes.

Please remember:

Your customer trusts you and relies on your expertise, just as you rely on Weinmann.

Note:

The following information can be found in the instructions for use of the MODULE system:

• Safety instructions

• Mounting with accessories

• Operation of the individual modules and

extraction of secretions

• Hygienic preparation

• Warranty.

4 Introduction

Page 5

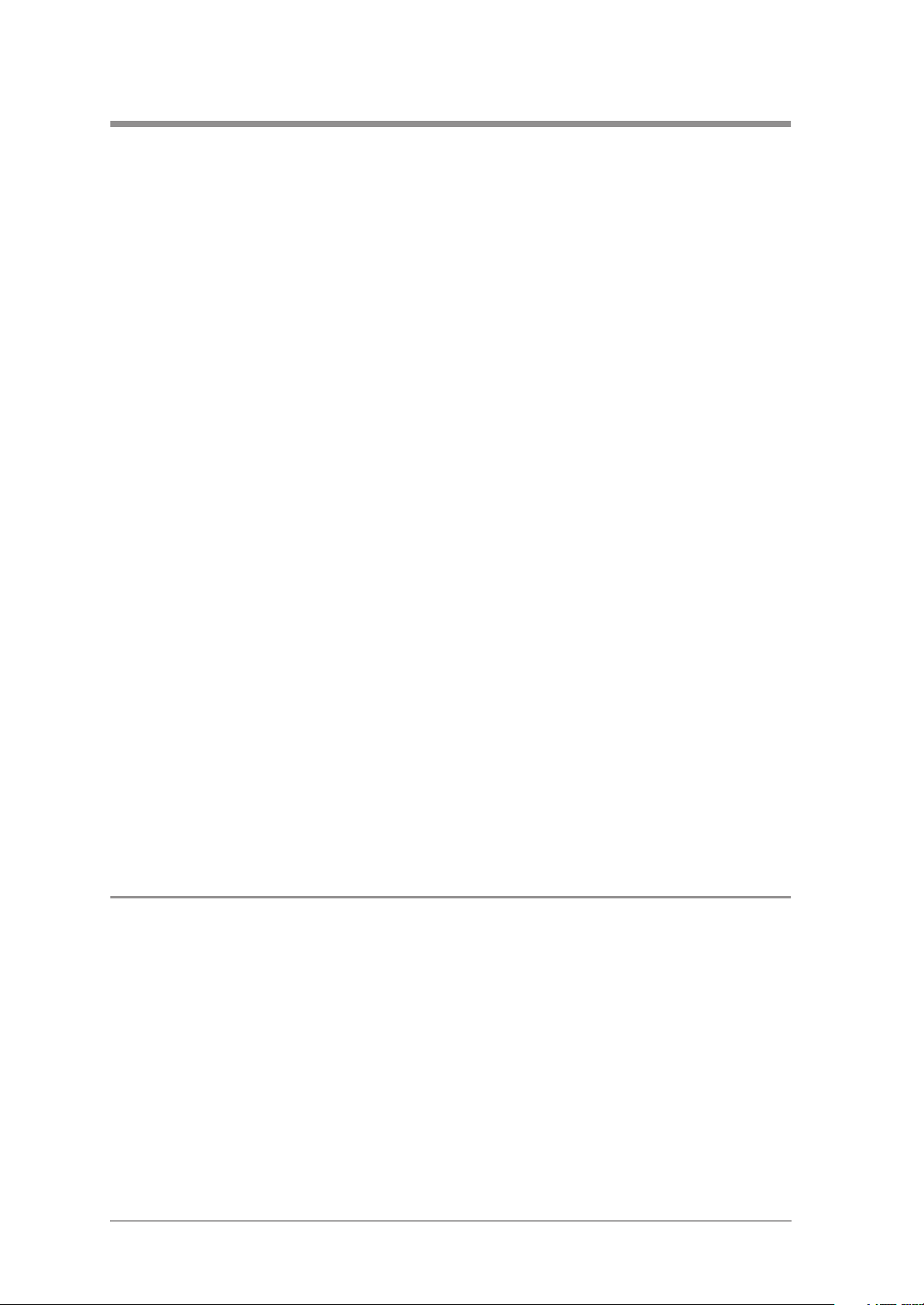

1. Overview

Module

O

1 Oxygen MODULE

1 Suction MODULE

MODUL

Interface

0

1

5

5

1

bar

0

O

2

O

2

3 Combi MODULE 4 Interface MODULE

Connections and controls (on the Combi MODULE)

5 Oxygen inlet with non-return valve 6 Flow dial 7 Oxygen outlet

1

5

5

1

0

2

O

12 External oxygen

8 ON/OFF switch13 ON/OFF switch

9 Regulator

connection

11 Inhalation

connection

10 Vacuum connection

Overview 5

Page 6

2. Description

-1,0

bar

O

2

-0,8

-0,6

-0,4

-0,2

0

0

5

10

15

l/min

O

2

0

5

10

15

l/min

O

2

2.1 Uses

Use

Increase of percentage oxygen volume in

inspiratory air

Creation of a vacuum to aspirate large

accumulations of blood, mucus, saliva and solid or

viscous food from the mouth, the pharyngonasal

cavity and the bronchial system.

Transmission of oxygen supply via couplings to

other equipment

Provision of external oxygen supply via coupling

head

The modules are not suitable for hyperbaric use

(pressure chamber).

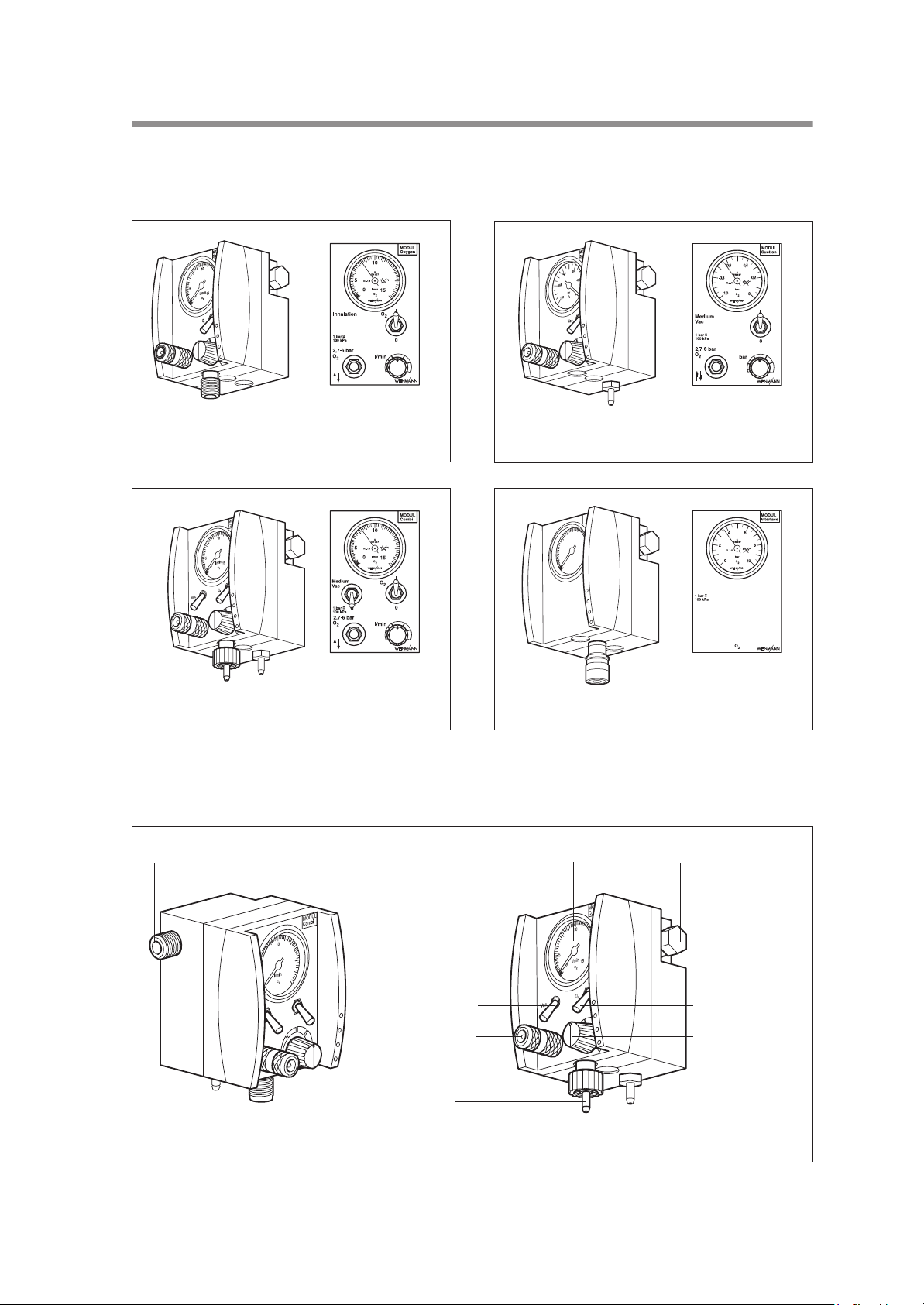

2.2 Module combinations

You can use modules either individually or in series

of up to three modules.

Oxygen

MODULE

Suction

MODULE

Combi

MODULE

Interface

MODULE

X – X –

– X X –

X X X X

X X X X

It is also possible to connect up to three modules to

the MEDUMAT ventilator.

MODUL

Suction

MODUL

Oxygen

MODUL

Interface

2

O

2

O

Oxygen

Vac

Suction

O/I

MEDUMAT

Interface

2.3 Storage

If you are not intending to use a module for a long period, we recommend the following storage precautions:

1. Clean and disinfect the module (see ”9. Hygienic preparation“ in the operating

instructions).

2. Store the module in a dry place.

6 Description

Page 7

3. Final Check

If the final check reveal defects or deviations from the specified parameters, neither the modules nor the

OMNIVAC should be used until these defects have been repaired.

We recommend you hold reserve stocks of the following items:

• washers for the tube connections

and inhalation connections WM 1145/31

• washers for connection socket WM 1145/68

3.1 Test resources required

• Blind plug G 3/8 WM 1231

• Cap WM 22204

• Set, supply test Medumat /

Modules WM 15440

• Set of test pressure gauges,

vacuum WM 15294

3.2 Preparations for final check

1. Connect module to 4.5 - 6 bar pressure supply

of the cylinder system.

2. Fully close pressure regulator (turn to left until it

meets the stop).

3.3 Entering device data

• Set, test Walther coupling,

module WM 15441

• Pressure gauge 0 – 6.3 bar, class 1.6

• Flowmeter 0 – 20 litres e.g.: Yokogawa or

EKU Vip-Ventilator / Pf 300

3. Set toggle switch to position 0.

4. If the lateral oxygen connection is not closed,

close it with cap WM 22204.

• Enter the device number and date of manufacture in the Test Record.

3.4 Check for leaks in the system

MODULE Oyxgen / Combi

1. Apply 6 bar to device and close pressure outlet.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

2. Screw blind plug onto inhalation outlet.

Final Check 7

Page 8

3. Apply approx. 4.5 bar to the input.

4. Set toggle switch to position “1”.

5. Slowly turn pressure regulator until it reads 15 l/min.

6. Close pressure supply.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

7. Close pressure regulator again and remove blind plug.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

8. Set toggle switch on device to position “0” and open pressure regulator.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

MODULE Interface

1. Apply 6 bar to device and close pressure outlet.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

2. Set toggle switch to position “1”.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

The O2 pressure indication for the module must not deviate by more than ± 0.2 bar /min.

MODULE Suction

1. Apply 6 bar to device and close pressure outlet.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

2. Set toggle switch to position “1”.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

Checking non-return valve for leaks (Oxygen, Combi and Suction module)

1. Set toggle switch to position “0”.

2. Connect pressure supply to external supply, e.g. Walther coupling (testing tube WM 15441), apply

6 bar pressure and close.

Requirement: Pressure indication must not fall by more than 0.1 bar/min.

Repairing leaks

Always keep a stock of washers for the connections available

1. Prepare a soap/water solution using nonperfumed soap.

2. Wet all the screw and hose connections with

the solution. Bubbles will form at the site of the

leak.

3. Depressurise the system (To do this, first close

the oxygen bottle. Switch on the module briefly and then switch it off again.)

4. Change the defective washers.

5. Recheck for leaks.

8 Final Check

Page 9

3.5 Checking inhalation function

MODULE Oyxgen / Combi

1. Connect inhalation outlet to a flowmeter and apply 4.5 bar pressure to the module.

2. Set flow at module to 6 l/min.

Requirement: Reading must not deviate by more than ±0.6 l/min.

3. Set flow at module to 10 l/min.

Requirement: Reading must not deviate by more than ±1.0 l/min.

4. Set flow at module to 15 l/min.

Requirement: Reading must not deviate by more than ±1.5 l/min.

5. Reduce input pressure to 2.7 bar (dynamically, at 80 l/min).

6. Switch on module and fully open pressure regulator.

Requirement: Pressure gauge reading must reach an output of at least 10 l/min.

7. Close pressure regulator and set toggle switch to position “0”.

3.6 Testing vacuum

MODULE Combi/ Suction

1. Screw the pressure supply onto the pressure inlet.

2. Reduce input pressure to 2.7 bar (dynamically, at 80 l/min).

3. Connect vacuum gauge to vacuum outlet.

4. Set toggle switch to vacuum.

Requirement: The vacuum reading must reach at least 0.35 bar.

5. Set inlet pressure to 4.5 bar.

Requirement: The vacuum reading must reach at least 0.55 bar. The device reading must not deviate

from the test gauge reading by more than ±0.05.

6. Connect vacuum connection to Rotameter.

Requirement: The suction performance must be greater than 8 l/min (flowmeter).

MODULE Suction

1. Set toggle switch to position “1”.

2. Set pressure regulator to maximum vacuum.

Requirement: See vacuum testing in section MODULE Combi/Suction.

Final Check 9

Page 10

3.7 Checking aspiration function

Necessary with the Suction MODULE and the Combi MODULE

1. Open the valve of the oxygen bottle slowly.

2. Switch on aspiration.

3. Suction MODULE:

Turn the regulator knob 9 as far right as it will

go. Remove the vacuum tube and hold vacuum connection 10 closed.

Combi MODULE:

The vacuum is locked at ≥ – 0.5 bar (at

4.5 bar O2 input pressure) and cannot be read

off the manometer 6 directly. In this case it is necessary to connect the Weinmann test manometer

WM 15294 to vacuum connection 10.

4. When the manometer 6 on the Suction

MODULE or the test manometer connected to

the Combi MODULE are showing a constant

reading, this should be not less than – 0.5 bar

at an O2 input pressure of 4.5 bar.

5. To check the OMNIVAC aspirate collection

set for leaks, replace the vacuum tube and

hold the opening of the end piece closed.

6. A reading of at least – 0.5 bar must be obtained within 30 seconds.

If this level is not reached, the connections must

be checked for leaks.

10 Final Check

Page 11

4. Servicing

Important:

Remember: a functional check must be performed after every repair.

We recommend having all maintenance work, servicing and repairs carried out either by the manufacturer

Weinmann or by a qualified technician.

4.1 Intervals

The following checks must be carried out to ensure that the modules always function correctly.

Before each use:

• Carry out a final check (see sections 3.4 to

3.7).

After each use

• Clean, disinfect or sterilise the device and its

components (see “9. Hygienic preparation” in

the operating instructions).

• Carry out a final check (see sections 3.4 to

3.7).

4.2 Servicing

The devices must be serviced every 4 years.

The following points must be covered:

At least every 6 months, if the equipment has not been used in the intervening period:

• Carry out a final check (see sections 3.2 to

3.4).

After every repair:

• Clean, disinfect or sterilise the device and its

components (see “9. Hygienic preparation” in

the operating instructions);

• Carry out a final check (see sections 3.4 to

3.7).

• Visual inspection:

– mechanical damage;

– labelling of components.

• Pressure indicator accuracy;

• Freedom from leaks;

• Oxygen delivery rate and aspiration capacity;

• Renewal of parts subject to wear / mandatory

change parts (see “7.2 Spare parts required

for servicing” on page 37);

• Functional check in accordance with Test In-

structions / Test Record WM 22248 (see “3.

Final Check” on page 7 and see “11. Repair

and inspection log” on page 45 to 48).

Servicing 11

Page 12

Every 4 years:

• Servicing of oxygen fittings (e.g. pressure reducers) by the manufacturer or by specialist personnel specifically authorised by the manufacturer.

Every 10 years:

• Repeat testing of the conventional steel or aluminium oxygen bottles by the the responsible testing organization. The test deadline can be found on the shoulder of the cylinder.

4.3 Disposal

Do not dispose of the unit with domestic waste. For proper disposal of the device and its components, please contact a certified waste disposal site for electronic goods. Ask your Environmental

Officer or local council for the address. Appliance packaging (cardboard and inserts) may be disposed of in the paper recycling bin.

5. Troubleshooting

Problem Cause of defect Elimination

Module will not switch on Module defective Arrange for repair

Oxygen bottle empty Replace oxygen bottle

Module will not function

Exceptionally high oxygen

consumption

No vacuum or vacuum too weak

or inadequate O2 flow for inhalation

Noisy inhalation/aspiration Moisture in block Replacement by Weinmann

Toggle Switch does not stay in

switch position

Pressure gauge does not reach zero

position

Module incorrectly assembled Check assembly

Tubes wrongly connected Check connections

Find and repair leak

Leak in oxygen tubes

Leak in system

Moisture in block Replacement by Weinmann

Module defective or clogged

internally.

Toggle Switch pressure plate

worn

Pressure gauge defective

(pressure hammer through open

pressure regulator 9 when switching on)

(see “3.4 Check for leaks in the

system” on page 7)

Eliminate leak

(see “3.4 Check for leaks in the

system” on page 7)

Arrange for repair

Replace toggle switch

(see “6.2.8 Replacing the toggle

switch” on page 22)

Replace the pressure gauge

(see “6.2.6 Replacing the pressure gauge” on page 20)

12 Troubleshooting

Page 13

6. Repair information and repair instructions

6.1 General

• Please observe the safety instructions in the instructions for use of the Module system.

• All handling of the device pre-supposes a precise knowledge of and compliance with the instructions for use and the service and repair

instructions.

• Please carry out only the repairs described in

these service and repair instructions. Otherwise, perfect functioning of the Modules cannot be guaranteed.

• When you replace components or individual

parts, please use original Weinmann parts

only.

6.2 Oxygen MODULE

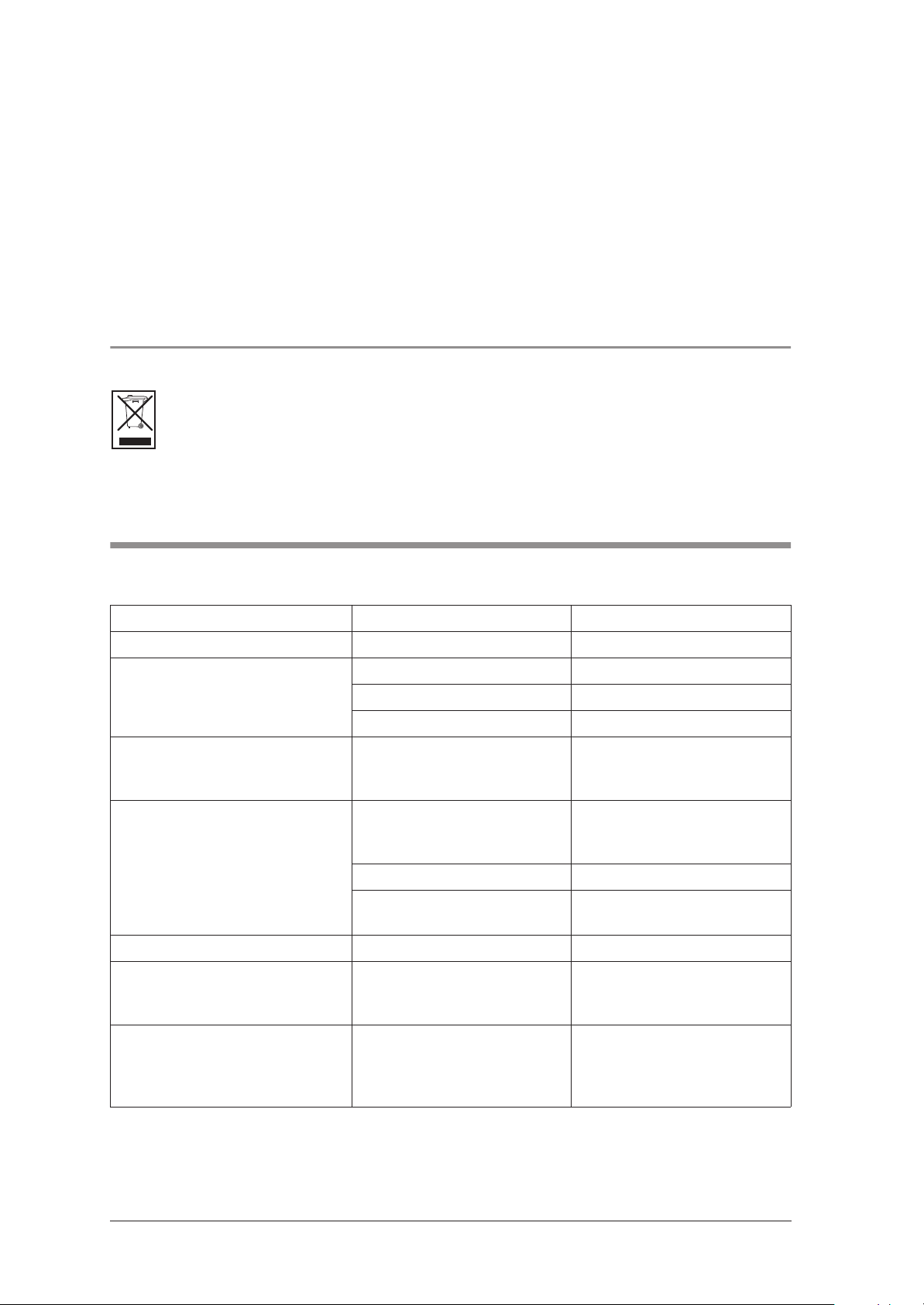

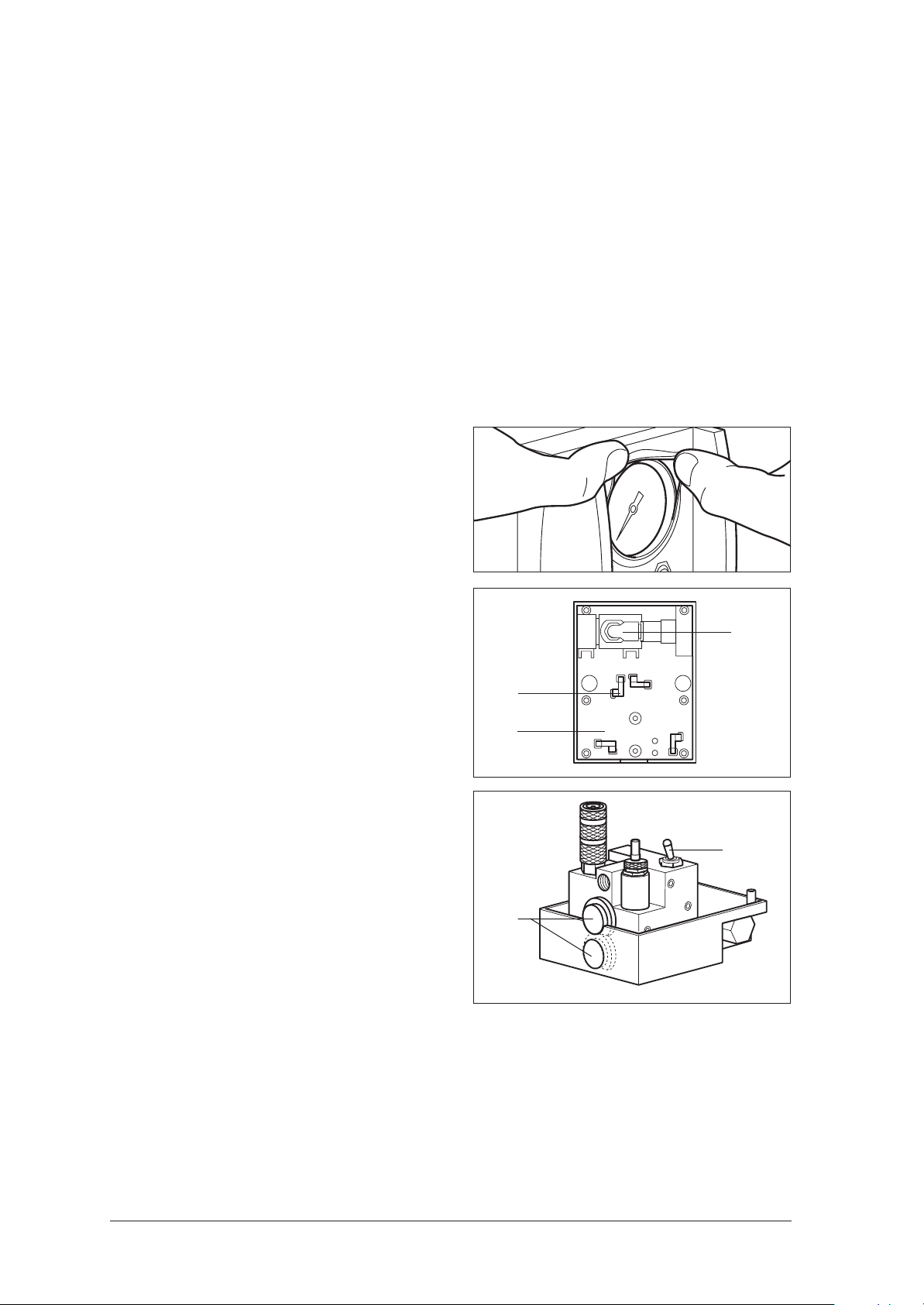

6.2.1 Replacing the sieve in the oxygen inlet

Tools required:

• Please ensure that your hands and workplace

are clean when carrying out repairs.

• Under no circumstances should you open the

screw connection in the inhalation outlet 11,

otherwise the set parameters will be altered!

• After each repair, please perform a final check

(see „3. Final Check“ on page 7).

• Note:

The item numbers used in the following text

match the item numbers in the spare parts list

on page 29 and the overview on page 4.

• Slotted screwdriver,

• Tweezers.

1. Unscrew pressure screw 49 from oxygen

inlet 5.

2. Using the tweezers, remove the sieve set 27.

3. Carefully insert a new sieve set 27 into the

oxygen inlet.

4. Screw pressure screw 49 firmly into oxygen inlet again.

2749

Repair information and repair instructions 13

Page 14

6.2.2 Replacing the O-ring in the oxygen outlet

Tools required:

• Open-ended spanner SW 16 (only necessary if the oxygen outlet 7 is sealed with the cap 47).

1. If the oxygen outlet 7 is sealed with the

cap 47, remove the cap using the open-ended

spanner (SW 16).

2. Pull the O-ring 39 from the connection.

3. Wet a new O-ring using the oxygen lubricant

Belerub (WM 14902) and push it onto the

connection.

O

4. Using open-ended spanner SW 16, gently

tighten cap 47. Do not over-tighten!

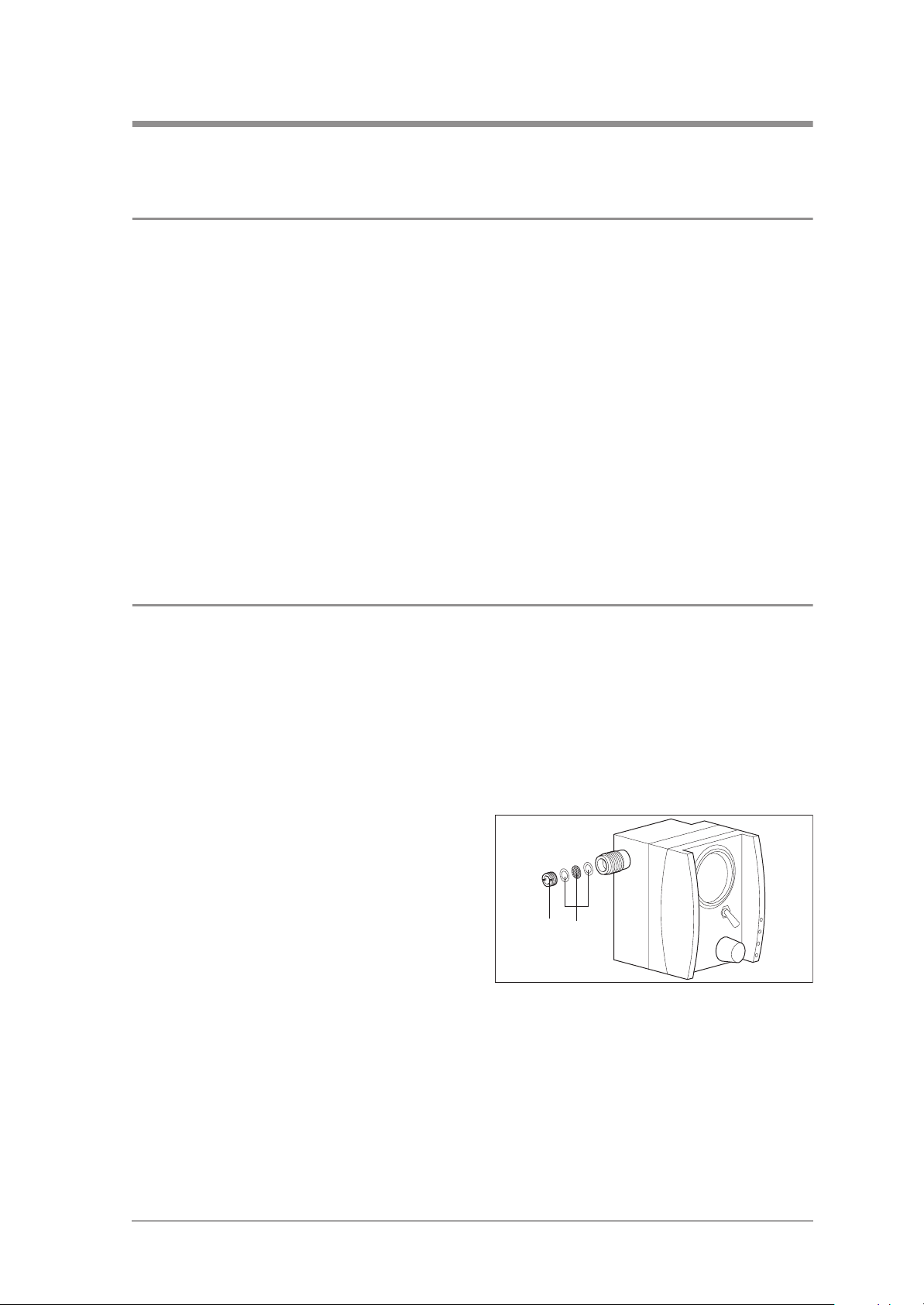

6.2.3 Dismantling the housing

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 7,

• Open-ended spanner SW 19 (only with AGA coupling),

• Open-ended spanner SW 22,

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special tool from Set WM 15348.

47

39

1. Twist the knob 45 as far as it will go to the left

so that you will have a reference point later on

when assembling.

2. Release the lid 46 from the knob 45.

3. Hold the knob steady using the special tool to

stop it from turning, and loosen the lock screw.

Note:

Do not unscrew the screw completely; otherwise,

the knob will be dismantled into its component

parts.

4. Pull off the knob 45.

5. If your Module is equipped with an AGA coupling, loosen it with an open-ended spanner

(SW 19).

6. Unscrew union nut at inhalation

connection 11.

7. Screw the special locknut tool onto the inhalation connection 11.

45

46

14 Repair information and repair instructions

Page 15

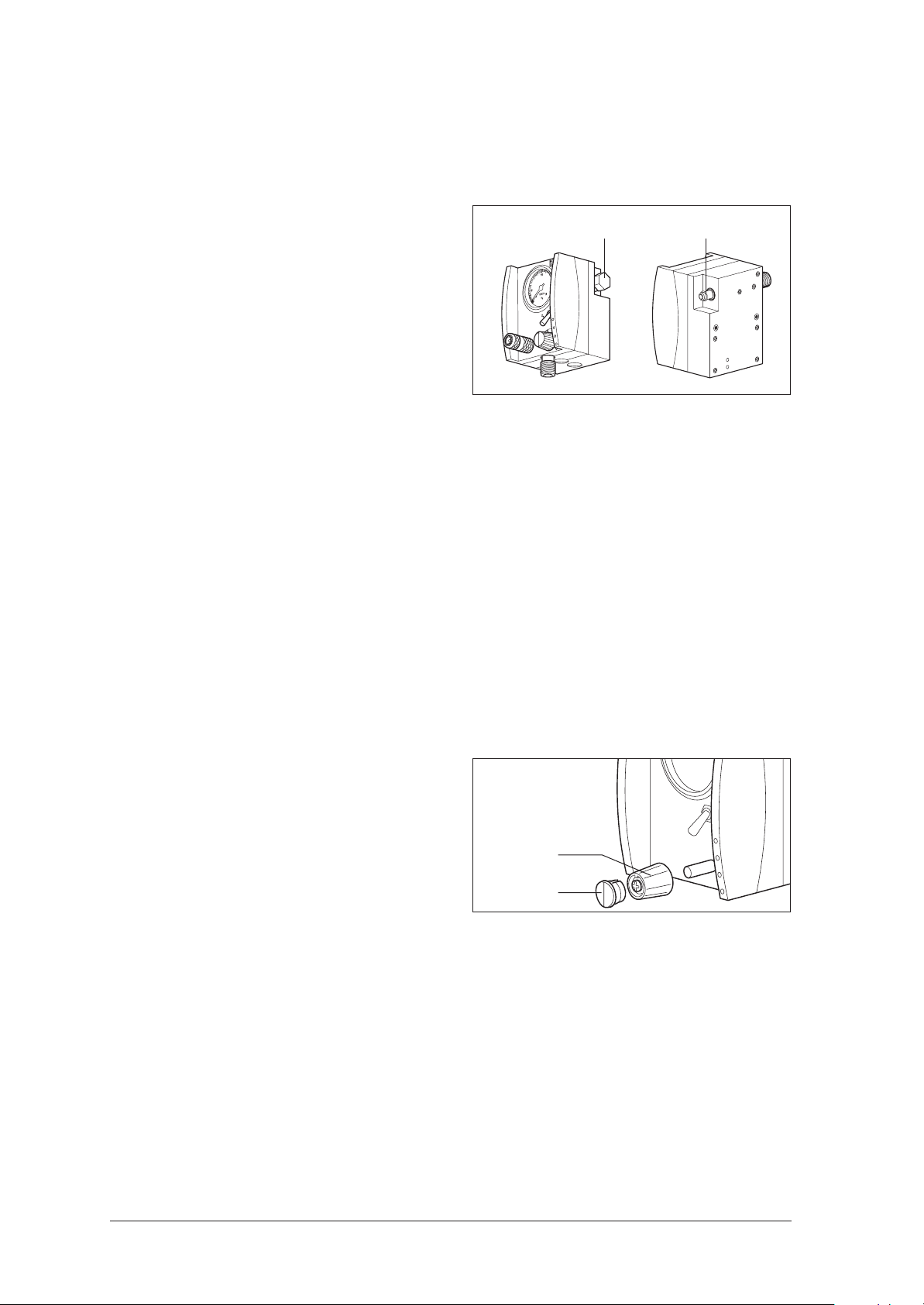

8. Clamp the special locknut tool in a vice with

protective jaws.

9. Tighten the nuts of the special locknut tool

against the inhalation connection 11 using an

open-ended spanner (SW 22).

10. Turn entire housing to left to undo connection 11.

If it is not possible to undo connection 11, pro-

11

ceed as described from step 11. onwards and

pull the housing apart. Clamp the special locknut tool in the vice again and use an open-ended spanner SW 22 to undo the block as

shown in the diagram.

11. Place the device on a non-slip surface and unscrew the six screws 32 from the rear panel of

the housing.

12. Pull off the housing base section 16 and fold it

away.

13. Next, remove the supply tube from the distributor block by pushing back the sleeve of the

angular bush 40 and pulling out the tube.

32

16

14. Unscrew the threaded connection for inhalation 11 at the handle of the special locknut

tool.

15. Next, lift off the upper housing section 15.

16. Using an open-ended spanner (SW 7), release the swivel screw connection 42 from the

pressure gauge 6.

17. Press the pressure gauge 6 out of the

mounting 14.

Tip:

You will find the pressure gauge easier to remove

if you dribble a small amount of spirit between

the pressure gauge and the mounting.

14

40

6

42

Repair information and repair instructions 15

Page 16

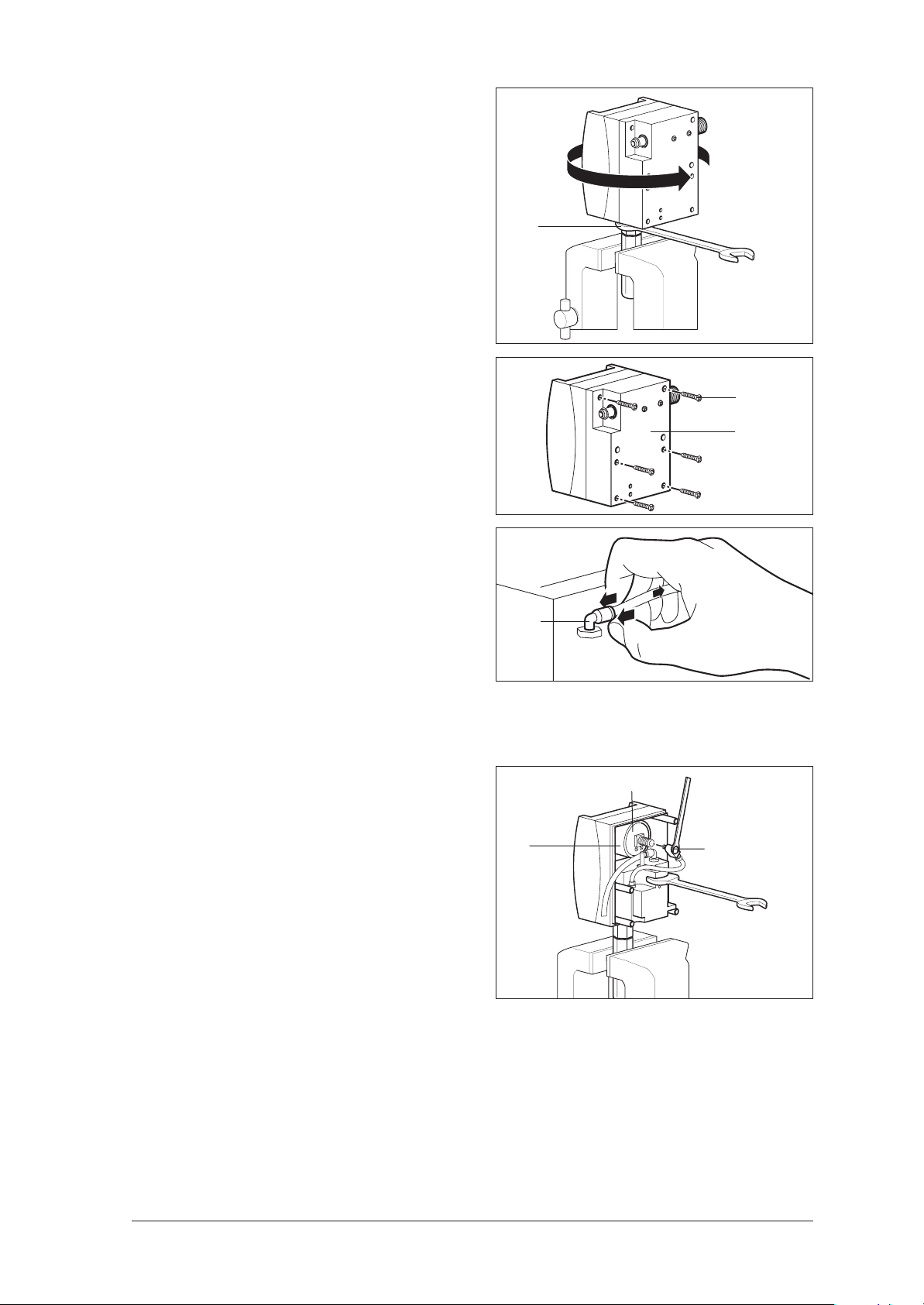

6.2.4 Assembling the housing

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 7,

• Open-ended spanner SW 19 (only with AGA coupling),

• Open-ended spanner SW 22,

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special tool from Set WM 15348.

1. Wet the edge of the pressure gauge 6 with a

little spirit and press it into the mounting 14.

Observe the installation position so that the display remains clearly legible!

2. Pass the rubber bead over the pressure gauge

with your fingers.

3. Make sure that the four rubber buffers 36 in the

housing base section 16 are firmly seated (insert with a little spirit if necessary).

4. Carefully insert the two blind plugs 35 into the

holes on the underside of the housing. The flattened sides should be pointing towards the

base of the device.

5. Carefully insert the pneumatic block into the

housing base section.

6. For easier movement, disconnect the supply

tube 25 from the pnuematic block.

7. Push the supply tube into the angular bush 40

as far as it will go.

8. Rotate the angular bush 40 in the opposite direction of the oxygen inlet 5.

40

36

16

20

35

9. Push the supply tube into the bush 40 of the

pneumatic block as far as it will go.

16 Repair information and repair instructions

Page 17

10. Screw the swivel screw connection 42 onto the

pressure gauge 6 using an open-ended spanner (SW 7).

Take care to ensure the correct installation position. The tube must not protrude beyond the housing afterwards.

11. Move the toggle switch 20 to the central position and place the guide pipe over it. The

guide pipe holds the toggle switch in position,

allowing you to fit the upper housing section

more easily.

12. Carefully push the upper housing section over

the guide pipe onto the base section.

Make sure the tubes are not pinched.

Illustration of subsequent installation position

6

42

Pneumatic block

Guide pipe

20

13. Remove the guide pipe.

14. Turn the device round and screw the housing

together using the six screws 32.

15. Clean the threaded connection for

inhalation 11 and the threaded hole.

16. Connect the module to the O2 supply and

switch the toggle switch to I. Turn up the pressure control so that the threaded hole is blown

clean.

17. Wet the threaded connection 11 with Loctite

245, and screw it into the pneumatic block using the special locknut tool.

32

11

Repair information and repair instructions 17

Page 18

18. Clamp the special locknut tool in a vice.

19. Loosen the nuts of the special locknut tool using

an open-ended spanner (SW 22).

20. Remove the module from the vice and unscrew

the special locknut tool.

21. Fasten the knob 45 onto the front of the device:

– Slide the knob onto the spindle as far as it

will go.

– Twist the knob so that it is pointing to the

lowest value for "l/min".

– Hold the knob steady with the special tool

and screw it tight.

22. Check the display of the knob. At the left limit,

the white line must be pointing to the lowest

value of the arrow.

If this is not the case, loosen the screw on the

control knob, and align the knob.

23. Place the lid 46 on the control knob 45.

24. If your module is equipped with an AGA coupling, please tighten it using the open-ended

spanner (SW 19).

25. Perform a final check (see “3. Final Check” on

page 7).

11

46

45

18 Repair information and repair instructions

Page 19

6.2.5 Replacing the non-return valve in the distributor block

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 22,

• Brass brush,

• Thread tapper M 10 x 1 for internal thread,

• Special locknut tool G 3/8, special spanner SW 20 with handle bar from Set WM 15348.

1. Unscrew the base section of the housing (see

steps 11. to 13. in chapter ”6.2.3 Dismantling

the housing“ on page 14).

2. Screw the special locknut tool onto the oxygen

inlet 5.

3. Clamp the special locknut tool in a vice.

4. Tighten the nuts of the special locknut tool

against the pressure connection using an

open-ended spanner (SW 22).

5. Place the special spanner (SW 20) onto the

distributor block.

6. Next, screw the special spanner with the housing in an counter-clockwise direction until the

oxygen inlet 5 has been loosened.

7. Open the vice, and unscrew the special locknut tool with the oxygen inlet 5 in a counterclockwise direction.

8. You can now remove the non-return valve 48.

9. Remove any adhesive residue from the thread

surfaces:

– Clean the outer thread with a brass brush.

– If necessary, re-cut the inner thread (fine

thread M 10 x 1).

10. After removing cap 47, use oxygen to blow

out any residues etc. from the distributor block.

11. Insert the new non-return valve 48.

Ensure the correct installation position: The sealing surface of the non-return valve must be pointing towards the oxygen inlet 5!

5

12. Wet the cleaned thread of the oxygen inlet 5

with Loctite 245 and screw it tight using the

special locknut tool.

13. Clamp the special locknut tool in a vice.

14. Loosen the nuts of the special locknut tool using

an open-ended spanner (SW 22).

15. Remove the Module from the vice and unscrew

the special locknut tool.

16. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

17. Fit cap 47 (see „6.2.2 Replacing the O-ring in

the oxygen outlet“ on page 14).

18. Perform a final check (see “3. Final Check” on

page 7).

Special spanner

SW 20

Repair information and repair instructions 19

Page 20

6.2.6 Replacing the pressure gauge

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 7.

1. Unscrew the base section of the housing (see

steps 11. to 13. in chapter ”6.2.3 Dismantling

the housing“ on page 14).

2. Using an open-ended spanner (SW 7), release the swivel screw connection 42 from the

pressure gauge 6.

3. Press the pressure gauge 6 out of the

mounting 14.

Tip:

You will find the pressure gauge easier to remove

if you dribble a small amount of spirit between

the pressure gauge and the mounting.

4. Wet the edge of the new pressure gauge 6

with a little spirit and press it into the

mounting 14.

Important:

Observe the installation position so that the display remains clearly legible!

5. Pass the rubber bead over the pressure gauge

with your fingers.

14

6

42

Pneumatic block

6. Screw the swivel screw connection 42 to the

pressure gauge 6.

Take care to ensure the correct installation position. The tube must not protrude beyond the housing.

7. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

8. Perform a final check (see “3. Final Check” on

page 7).

6

42

20 Repair information and repair instructions

Page 21

6.2.7 Replacing the tubes

Tools required:

• Crosstip screwdriver, size 1,

• Bulldog end cutting nippers,

• Open-ended spanner SW 7,

• Small slotted screwdriver or flat object for bending the single-lug clips.

1. Unscrew the base section of the housing (see

steps 11. to 13. in chapter ”6.2.3 Dismantling

the housing“ on page 14).

2. Disconnect the supply tube 25 from the pneumatic block by pushing back the sleeve of the

angular bush 40 and pulling out the tube.

3. Using an open-ended spanner (SW 7), unscrew the swivel screw connection 42 from the

pressure gauge 6.

6

40

25

42

4. Open both single-lug clips 26 on the pressure

gauge tube 23:

– First, open the clips with the bulldog end cut-

ting nippers.

– Then carefully bend them open using a

small screwdriver.

5. Pull the tube from the connection on both sides.

6. Replace the pressure gauge tube 23 (150 mm

long):

– Slide a new single-lug clip 26 onto the new

pressure gauge tube 23.

– Slide the tube onto the bush 43 on the pneu-

matic block.

– Align the clip and squeeze it together using

the bulldog end cutting nippers.

– In the same way, connect the tube to the

swivel screw connection 42.

7. Push the new supply tube 25 into the angular

bush 40 on the pneumatic block as far as it will

go.

Take care to ensure the correct installation position:

The angular bush should be pointing towards the

centre of the device.

The tube runs beneath the pressure gauge tube.

6

43

23

42

26

8. Screw the swivel screw connection 42 securely

to the pressure gauge 6.

Take care to ensure the correct installation position: The tube must not protrude beyond the

housing.

9. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

10. Perform a final check (see “3. Final Check” on

page 7).

Repair information and repair instructions 21

Page 22

6.2.8 Replacing the toggle switch

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 7,

• Open-ended spanner SW 17,

• Open-ended spanner SW 19 (only with AGA coupling),

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special tool from Set WM 15348.

1. Remove the housing (see “6.2.3 Dismantling

the housing” on page 14).

2. Use an open-ended spanner (SW 17) to unscrew counter nut 51, then remove the faulty

toggle switch 20.

3. Screw in the new toggle switch 20 using the

existing counter nut 51 and the new seals.

Take care with the installation position:

The toggle switch should drop automatically into

its end position. It must not become stuck in an intermediate position.

Note:

The toggle switch will tend to drop into the upper

position.

4. Re-assemble the housing (see “6.2.4 Assembling the housing” on page 16).

5. Perform a final check (see “3. Final Check” on

page 7).

51

20

50

6.2.9 Replacing the quick-release coupling

Tools required:

• Crosstip screwdriver, size 1,

• Open-ended spanner SW 7,

• Open-ended spanner SW 14 (with Walther coupling),

• Open-ended spanner SW 19 (with AGA coupling),

• Brass brush,

• Thread tapper for internal thread G 1/8,

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special tool from Set WM 15348.

1. Remove the housing (see “6.2.3 Dismantling

the housing” on page 14).

2. Carefully clamp the pneumatic block in a vice

with protective jaws.

22 Repair information and repair instructions

Page 23

3. Remove the coupling:

– Unscrew the Walther coupling using an

open-ended spanner (SW 14). As the

coupling is secured with Loctite 245, this

will take a little strength.

– If your Module is equipped with an AGA

coupling, unscrew it using the open-ended

spanner (SW 19).

4. Remove any adhesive residue from the thread

surfaces:

– Clean the outer thread with a brass brush.

– If necessary, re-cut the inner thread (G 1/8).

– Blow out the residue in the pneumatic block

with oxygen via the tube connection of the

main supply.

5. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

6. Perform a final check (see “3. Final Check” on

page 7).

50

6.2.10 Replacing O-ring of Walther coupling

1. Lift the faulty O-ring 50 out of the coupling.

2. Insert the new O-ring 50 in the coupling so that

the O-ring is properly seated in its groove.

Note:

Check that the nipple fits easily into the coupling,

and check for leaks in the external pressure supply (see “ Checking non-return valve for leaks

(Oxygen, Combi and Suction module)” on

page 8).

50

O

Repair information and repair instructions 23

Page 24

6.2.11 Replacing the pressure regulator (MODULE Oxygen: up to Device No. 1616;

MODULE

No.

Tools required:

• Crosstip screwdriver, size 1,

• Hex spanner, 2.5 mm,

• Open-ended spanner SW 7,

• Open-ended spanner SW 19 (with AGA coupling),

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special spanner SW 14.2 from Set WM 15348,

• Special socket wrench with cross-bar for pressure regulator WM 22392.

1. Remove the housing (see “6.2.3 Dismantling

the housing” on page 14).

2. Use the special socket wrench with cross-bar

to unscrew the pressure regulator by the hexagonal nut.

3. Screw down the new pressure regulator 17 to-

gether with the seal in the pneumatic block.

4. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

5. Perform a final check (see “3. Final Check” on

page 7).

Combi: up to Device No. 1075; MODULE Suction: up to Device

1010)

20

6.2.12 Replacing the pressure regulator (MODULE Oxygen: from Device No. 1617;

MODULE

No.

Tools required:

• Crosstip screwdriver, size 1,

• Hex spanner, 2.5 mm,

• Open-ended spanner SW 7,

• Open-ended spanner SW 19 (with AGA coupling),

• Guide pipes, for toggle switches (from Weinmann),

• Special locknut tool G 3/8 and special spanner SW 14.2 from Set WM 15348.

1. Remove the housing (see “6.2.3 Dismantling

the housing” on page 14).

2. Unscrew and remove the lock nut for the pres-

sure regulator fixing nut.

Combi: from Device No. 1076; MODULE Suction: from Device

1011)

24 Repair information and repair instructions

Page 25

3. Place the special spanner SW 14.2 over both

nuts of the pressure regulator and unscrew

them.

4. Screw down the new pressure regulator 17 together with the seal in the pneumatic block.

5. Fit the spindle limiter screw cap 18 as follows:

– Screw the pressure regulator nuts as far

down as they will go.

– Screw in regulator spindle by hand until it

meets noticeable spring pressure; then unscrew a quarter of a turn .

– Screw the fixing nuts onto the pressure reg-

ulator housing as far as possible.

– Secure the pressure regulator fixing nuts

with the lock nut.

6. Join the two halves of the housing together

(see “6.2.4 Assembling the housing” on

page 16).

7. Perform a final check (see “3. Final Check” on

page 7).

20

51

Repair information and repair instructions 25

Page 26

6.3 Suction MODULE

6.3.1 Replacing the sieve in the oxygen inlet

See ”6.2.1 Replacing the sieve in the oxygen inlet“ on page 13.

6.3.2 Replacing the O-ring in the oxygen outlet

See ”6.2.2 Replacing the O-ring in the oxygen outlet“ on page 14.

6.3.3 Dismantling the housing

See ”6.2.3 Dismantling the housing“ on page 14.

6.3.4 Assembling the housing

See ”6.2.4 Assembling the housing“ on page 16, apart from three exceptions:

1. Re: tools required:

In addition, you will need an open-ended

spanner SW 14.

2. Re: step 10.:

The swivel screw connection must be at an angle

of approximately 45° to the horizontal.

Illustration of subsequent installation position

6

42

3. Re: step 4.:

The installation position of the two blind

plugs 35 is different:

– In the housing base section 16, the flattened

side is pointing towards the vacuum connection,

– In the upper housing section 15, the flat-

tened side is pointing towards the second

blind plug.

≈ 45°

Pneumatic block

15

35

16

26 Suction MODULE

Page 27

6.3.5 Replacing the non-return valve in the distributor block

See “6.2.5 Replacing the non-return valve in the distributor block” on page 14.

Important!

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

6.3.6 Replacing the pressure gauge

See ”6.2.6 Replacing the pressure gauge“ on page 20.

Important!

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

6.3.7 Replacing the tubes

See ”6.2.7 Replacing the tubes“ on page 21, but with three exceptions:

1. Re: step 6.:

The pressure gauge tube 24 is 80 mm long.

2. Re: steps 4. to 6.:

On the pneumatic block, the pressure gauge

tube 24 is held by an angular bush 40, not a

single-lug clip.

– To release the tube, push back the sleeve of

the angular bush 40 and pull out the tube.

– To secure the tube, push it into the angular

bush 40 as far as it will go.

40

3. Re: step 8.:

In the Suction MODULE, the pressure gauge

tube 24 has a different installation position:

The swivel screw connection 42 must be lying at

an angle of approx. 45° to the horizontal.

Important!

42

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

≈ 45°

24

40

Suction MODULE 27

Page 28

6.3.8 Replacing the toggle switch

See ”6.2.8 Replacing the toggle switch“ on page 22.

Important!

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

6.3.9 Replacing the quick-release coupling

See ”6.2.9 Replacing the quick-release coupling“ on page 22.

Important!

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

6.3.10 Replacing the pressure regulator

See ”6.2.11 Replacing the pressure regulator (MODULE Oxygen: up to Device No. 1616;

MODULE Combi: up to Device No. 1075; MODULE Suction: up to Device No. 1010)“ on page 24.

Important!

Please observe the exceptions for assembling the housing under

• ”6.3.4 Assembling the housing“ on page 26.

28 Suction MODULE

Page 29

6.4 Combi MODULE

6.4.1 Replacing the sieve in the oxygen inlet

See ”6.2.1 Replacing the sieve in the oxygen inlet“ on page 13.

6.4.2 Replacing the O-ring in the oxygen outlet

See ”6.2.2 Replacing the O-ring in the oxygen outlet“ on page 14.

6.4.3 Dismantling the housing

See ”6.2.3 Dismantling the housing“ on page 14, with one exception:

Re: Combi MODULE has two toggle switches:

6.4.4 Assembling the housing

See ”6.2.4 Assembling the housing“ on page 16, with two exceptions:

1. Re: step 4.:

Combi MODULE only requires one blind

plug 35.

2. Re: step 11.:

As Combi MODULE has two toggle switches,

please use a guide pipe over both toggle switches when mounting the upper housing

section 15.

35

15

20

Combi MODULE 29

Page 30

6.4.5 Replacing the non-return valve in the distributor block

See ”6.2.5 Replacing the non-return valve in the distributor block“ on page 19.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

6.4.6 Replacing the pressure gauge

See ”6.2.6 Replacing the pressure gauge“ on page 20.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

6.4.7 Replacing the tubes

See ”6.2.7 Replacing the tubes“ on page 21.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

6.4.8 Replacing the toggle switch

See ”6.2.8 Replacing the toggle switch“ on page 22.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

6.4.9 Replacing the quick-release coupling

See ”6.2.9 Replacing the quick-release coupling“ on page 22.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

30 Combi MODULE

Page 31

6.4.10 Replacing the pressure regulator

See ”6.2.11 Replacing the pressure regulator (MODULE Oxygen: up to Device No. 1616;

MODULE Combi: up to Device No. 1075; MODULE Suction: up to Device No. 1010)“ on page 24.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.4.3 Dismantling the housing“ on page 29,

• ”6.4.4 Assembling the housing“ on page 29.

Combi MODULE 31

Page 32

6.5 Interface MODULE

6.5.1 Replacing the sieve in the oxygen inlet

See ”6.2.1 Replacing the sieve in the oxygen inlet“ on page 13.

6.5.2 Replacing the O-ring in the oxygen outlet

See ”6.2.2 Replacing the O-ring in the oxygen outlet“ on page 14.

6.5.3 Dismantling the housing

See ”6.2.3 Dismantling the housing“ on page 14, with two exceptions:

1. Steps 1. to 4. do not apply, since Interface

MODULE does not have a knob.

2. Step 14. do not apply, since Interface MODULE does not have a connection for inhalation.

6.5.4 Assembling the housing

See ”6.2.4 Assembling the housing“ on page 16, with six exceptions:

1. Re: step 10.:

The swivel screw connection 42 must be lying at

an angle of approx. 45° to the horizontal.

2. Re: step 4.:

A blind plug 35 is placed into both the top side

and the underside of the device. The flattened

side of the blind plug must be pointing towards

the base of the device in both cases.

3. Step 11. does not apply, since Interface

MODULE does not have a toggle switch.

4. Re: step 12.:

During assembly of the two halves of the housing, the two pins on the upper section of the

housing must snap into the holes in the housing

base section.

5. Steps 13. to 23. do not apply, since Interface

MODULE does not have a knob.

6. As Interface MODULE does not have a toggle

switch, the upper housing section 15 may be

mounted on the housing base section 16

without guide pipes.

Illustration of subsequent installation position

42

Pneumatic block

35

≈ 45°

32 Interface MODULE

Page 33

6.5.5 Replacing the non-return valve in the distributor block

See ”6.2.5 Replacing the non-return valve in the distributor block“ on page 19.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.5.3 Dismantling the housing“ on page 32,

• ”6.5.4 Assembling the housing“ on page 32.

6.5.6 Replacing the pressure gauge

See ”6.2.6 Replacing the pressure gauge“ on page 20.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.5.3 Dismantling the housing“ on page 32,

• ”6.5.4 Assembling the housing“ on page 32.

6.5.7 Replacing the tubes

See ”6.2.7 Replacing the tubes“ on page 21, but with three exceptions:

1. Re: step 6.:

The pressure gauge tube 22 is 60 mm long.

2. Re: steps 4. to 6.:

On the pneumatic block, the pressure gauge

tube 22 is held by an angular bush 40, rather

than a single-lug clip.

– To release the tube, push back the sleeve of

the angular bush 40 and pull out the tube.

– To secure the tube, push it into the angular

bush 40 as far as it will go.

3. Re: step 8.:

In the Interface MODULE, the pressure gauge

tube 22 has a different installation position:

The swivel screw connection 42 must be lying at

an angle of approx. 45° to the horizontal.

40

42

≈ 45°

22

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.5.3 Dismantling the housing“ on page 32,

• ”6.5.4 Assembling the housing“ on page 32.

40

Interface MODULE 33

Page 34

6.5.8 Replacing the quick-release coupling

See ”6.2.9 Replacing the quick-release coupling“ on page 22.

Important!

Please observe the exceptions for dismantling and assembling the housing under

• ”6.5.3 Dismantling the housing“ on page 32,

• ”6.5.4 Assembling the housing“ on page 32.

34 Interface MODULE

Page 35

7. Spare parts

7.1 Spare parts list

Note:

The item numbers in the following table match the numbers in the text of these service and repair instructions

and the instructions for use.

Item no. Designation Order No.

5

6

14 Pressure gauge mounting WM 22223

15

16

17

Threaded connection, pre-assembled WM 22339

Pressure gauge

– 0 to 15 l/min.

– Pressure gauge 0 to 10 bar

– Pressure gauge -1.0 to 0 bar

Upper housing section with film

– Oxygen

– Suction

– Combi

– Interface

Housing base section*

consisting of housing and notice

– Oxygen/Interface Module

– Combi/Suction Module

Set of spare parts, pressure regulator

– Pressure regulator

– Sealing washer

WM 22261

WM 22262

WM 10754

WM 22355

WM 22375

WM 22365

WM 22385

WM 22358

WM 22359

WM 15183

WM 22238

WM 52380

18 Fixing nut M12 x 0.75 WM 22234

Pneumatic block**

19

20

21

22

23

24

25

26

– Oxygen, with Walther coupling, replacement

– Oxygen, with AGA coupling, replacement

– Suction, with Walther coupling, replacement

– Suction, with AGA coupling, replacement

– Combi, with Walther coupling, replacement

– Combi, with AGA coupling, replacement

Set of spare parts, toggle switch

– Oxygen/Combi

– Suction/Combi

Coupling

– DIN 13260

– AGA

– Set of spare parts, bayonet

– Walther

Set of spare parts, tubes

consisting of:

– Tube, PU 2/4 60

– Tube, PU 2/4 150

– Tube, PU 2/4 80

– Tube, PU 4/6 118

– Single-lug clip

WM 22351

WM 22354

WM 22352

WM 22357

WM 22353

WM 22356

WM 15184

WM 15193

WM 22325

WM 5944

WM 15195

WM 3798

WM 15264

Spare parts 35

Page 36

Item no. Designation Order No.

27

Sieve set

consisting of 2 seals and 1 sieve

WM 15284

Set of fixing components

consisting of:

28

29

30

31

– O-ring 8 x 4

– Raised countersunk head screw M4 x 10 DIN 966

– Protective washer Ø 4

– Raised countersunk head screw M4 x 8 DIN 966

WM 15288

Set of spare parts, screws

consisting of:

32

33

34

– Fillister-head screw KB 30 x 20, 6 off

– Raised countersunk head screw M 3 x 6 DIN 966

– Countersunk screw M 3 x 10 DIN 965

WM 15194

Set of spare parts, rubber parts

consisting of:

35

36

37

– Blind plugs

– Rubber buffer, receptacle

– O-ring 8 x 4

WM 15266

Set of spare parts, seals

38

39

consisting of:

– Seal 7 x14 x 2

– O-ring 6 x 2

WM 15283

40 Angular bush 4/6 WM 22552

41 Swivel screw connection 2/4 WM 22588

42 Swivel screw connection for pressure gauge WM 4699

43 Straight screw-in bush WM 7526

44 Seal 5 x 8 x 1 WM 1145/64

45 Knob Ø 15 WM 4897

46 Lid, matt blue, Ø 15 WM 4899

47 Cap, chrome-plated WM 22204

48 Non-return valve, assembled WM 22232

49 Pressure screw WM 1158

50 O-ring 8-1.3 WM 1145/94

51 Counter nut WM 22226

52 Fixing nut M12 x 0.75 WM 22234

Service label:

53

– 2008

– 2009

– 2010

– 2011

– 2012

– 2013

– 2014

– 2015

WM 0498

WM 0499

WM 0300

WM 0609

WM 0610

WM 0366

WM 0301

WM 0302

Distributor block, assembled WM 22263

Loctite, 245 WM 14920

Oxygen lubricant Berulub WM 14902

36 Spare parts

Page 37

* When ordering, please specify the model, device number and year of construction

** When ordering, please specify the device number

7.2 Spare parts required for servicing

Overview

Years 4 8

Service pack Suction Module WM 15559 WM 15407

Service pack Oxygen Module WM 15559 WM 15409

Service pack Combi Module WM 15559 WM 15411

Service pack Interface Module WM 15559 WM 15413

Service pack Suction, Oxygen, Combi, Interface Module 4 years

Set WM 15559

comprising:

• Sieve

• Seal 3.5x6x0.5

• Non-return valve, assembled

Service pack Suction Module 8 years

Set WM 15407

comprising:

• Sieve

• Seal 3.5x6x0.5

• Non-return valve, assembled

• 2 port / 2 position valve

• Seal 4x8x0.8

• Seal 4x8x0.5

• O-ring 6x2

• Set of tubes

Service pack Oxygen Module 8 years

Set WM 15409

comprising:

• Sieve

• Seal 3.5x6x0.5

• Non-return valve, assembled

• 2 port / 2 position valve

• Seal 4x8x0.8

• Seal 4x8x0.5

• O-ring 6x2

• Set of tubes

Spare parts 37

Page 38

Service pack Combi Module 8 years

Set WM 15411

comprising:

• Sieve

• Seal 3.5x6x0.5

• Non-return valve, assembled

• 2 port / 2 position valve

(WM 22258 MODULE Oxygen)

• 3 port / 2 position valve

(WM 22590 MODULE Oxygen)

• Seal 4x8x0.8

• Seal 4x8x0.5

• O-ring 6x2

• Set of tubes

Service pack Interface Module 8 years

Set WM 15413

comprising:

• Sieve

• Seal 3.5x6x0.5

• Non-return valve, assembled

• Set of tubes

38 Spare parts

Page 39

8. Tools and test equipment

Below is a list of all tools and test equipment used in these service and repair instructions.

The particular tools and test equipment required are outlined in each respective chapter.

Special tools can be purchased from the manufacturer Weinmann.

8.1 General tools

• Slotted screwdriver size 0.5 x 3 x 100

• Crosstip screwdriver, size 1

• Crosstip screwdriver, size 2

• Open-ended spanner SW 7

for tube connection on pressure gauge

• Open-ended spanner SW 14

for vacuum connection 10

• Open-ended spanner SW 16

for cap WM 22204 on oxygen outlet 7

• Open-ended spanner SW 17

for toggle switch

• Open-ended spanner SW 19

for connection coupling AGA

• Open-ended spanner SW 22

for special tool G 3/8

• Tweezers

for sieve set

• Bulldog end cutting nippers

for single-lug clips

• Pliers.

8.2 Special tools

The following tools are available from the manufacturers Weinmann:

• Special tool set, consisting of: WM 15348

– Special spanner SW 14.2 WM 22396

– Special socket wrench with cross-bar WM 22392

(for pressure regulator WM 15138)

– Special spanner SW 20 with handle bar WM 22391

– Special tool G 3/8 WM 22827

(for unlocking the AGA coupling

and the oxygen inlet 5

and inhalation 11 connections)

– Special tool WM 22397

(for holding the knob 9 steady)

– Guide pipes, for toggle switch. WM 22398

• Set, supply test Medumat / Modules WM 15440

• Set, supply test Modules WM 15441

• Set, test set respiration and pressure reducer flow WM 15443

Tools and test equipment 39

Page 40

8.3 Test equipment

• Set of test pressure gauges,

vacuum WM 15294

• Pressure gauge 0 – 6,3 bar, class 1.6

Type WIKA

obtainable from:

Alexander Wiegand GmbH & Co.

Alexander-Wiegand-Strasse 30

D-63911 Klingenberg am Main

Tel. +49 9372/1320

• Flowmeter 0 - 20l,

e.g. Yokogawa

or

Type EKU VIP-Ventilatortester

obtainable from:

EKU Elektronik GmbH

Feldstrasse 9a

D-56291 Leiningen

Tel.: +49 6746-1018

Fax: +49 6746-8484

www.eku-elektronik.de

40 Tools and test equipment

Page 41

9. Technical data

Oxygen MODULE Suction MODULE Combi MODULE Interface MODULE

Product category

according to

93/42/EEC

Dimensions

L x B x H in mm

Weight 0.9 kg 0.9 kg 0.95 kg 0.65 kg

Temperature range

for

– operation

– storage

Gas input medicinal oxygen

Operating pressure 2.76 bar possible, 4.5bar recommended

Minimal gas volume

required.

Pressure gas

connection

Oxygen flow

Tolerance limits

– at 0 – 3.9 l/min

– at 4 – 15 l/min

DIN ISO 10079-3

classification

100 x 125 x 90 100 x 130 x 90 100 x 172 x 90

–18 °C to +60 °C

–40 °C to +70 °C

External thread G3/8; NIST adapter available on request

variable from

0 to 15 l/min

±15%

±10%

IIa

≥ 80 l/min O

variable from

0 to 15 l/min

±15%

±10%

medium vacuum

2

Technical data 41

Page 42

9.1 External oxygen flow volume

The following flow volumes apply when oxygen is supplied to other equipment.

Interface MODULE

Oxygen input External oxygen flow volume

2.7 bar dynamic operating

pressure at 80 l/min

from Weinmann pressure reducer

O

2

WM 1102/106

not less than 70 l/min

not less than 100 l/min

from Weinmann pressure

reducer WM 30301

More than one module

When several modules are connected in series,

the flow volume decreases with the module’s distance from the oxygen input. This is due to the high

flow resistance arising when the oxygen passes

through more than one module.

2.7 bar dynamic operating

pressure at 80 l/min

from Weinmann pressure reducer

WM 1102/106

from Weinmann pressure reducer

WM 30301

The figures are based on the assumption that oxygen is being supplied only from one module at a

time.

Oxygen input

not less than 90 l/min

External oxygen flow volume

A B C

not less

than

76 l/min

not less

than

100 l/min

not less

than

91 l/min

not less

than

73 l/min

not less

than

95 l/min

not less

than

88 l/min

not less

than

70 l/min

not less

than

90 l/min

not less

than

85 l/min

9.2 Oxygen flow volume from inhalation connection

Input pressure 2.7 bar 3.0 bar 3.5 bar 6.0 bar

Maximal oxygen flow volume 11 l/min 12 l/min 15 l/min 15 l/min

Tolerance ±10%

42 Technical data

Page 43

9.3 Aspiration efficiency

Maximal suction

The maximal suction exerted by the Combi and Suction MODULES depends on the input pressure of the

oxygen supply. The data below are valid for a 2 litre aspirate bottle.

Input pressure p2 Max. vacuum Maximal suction Oxygen consumption

2.7 bar - 0.40 bar 8.4 l/min 9.3 l/min

3.0 bar - 0.44 bar 8.6 l/min 10.1 l/min

3.5 bar - 0.53 bar 8.8 l/min 11.4 l/min

4.0 bar - 0.58 bar 9.0 l/min 12.2 l/min

4.5 bar - 0.60 bar 9.0 l/min 14.0 l/min

5.0 bar - 0.60 bar 9.0 l/min 15.0 l/min

5.5 bar - 0.60 bar 8.7 l/min 17.0 l/min

6.0 bar - 0.60 bar 8.5 l/min 19.0 l/min

Tolerance limits ±10%. If a bacterial filter is used,

the aspiration efficiency will diminish by between

1 and 3 l/min, depending on the atmospheric

humidity.

Aspiration efficiency of Suction MODULE

The suction exerted by the Suction MODULE varies according to the degree of vacuum selected at any given

time. The data below are valid for a 2 litre aspirate bottle.

Selected vacuum Suction Oxygen consumption

- 0.2 bar 5.3 l/min 6.5 l/min 2.7 – 6 bar

- 0.3 bar 6.5 l/min 7.7 l/min 2.7 – 6 bar

- 0.4 bar 8.4 l/min 9.3 l/min 2.7 – 6 bar

- 0.5 bar 8.3 l/min 10.5 l/min 3.5 – 6 bar

- 0.6 bar 9.0 l/min 14.0 l/min 4.5 bar

Tolerance limits ±10%. If a bacterial filter is used,

the aspiration efficiency will diminish by between

1 and 3 l/min.

Required input

pressure p2

Technical data 43

Page 44

10. Technical Changes

Technical change From Device No. Date

With screw cap WM 20522 1618 17.08.98

White cap 2396 15.01.99

Counter nut V2A WM 22226 2896 07.05.99

New screw cap WM 22234 4096 10.01.00

Reinforcement for lower part of housing 14101 17.05.04

44 Technical Changes

Page 45

11. Repair and inspection log

11.1 Oxygen MODULE

Date Signature

with MODULE service instructions

Service performed in accordance

Company

_____________ __________________

Company

Measures / Comments

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Inspections and repairs carried out in accordance with the service instructions

Manufacturer: Weinmann GmbH + Co.

Device model: Oxygen MODULE

❐ WM 22200 with Walther coupling

❐ WM 22240 with AGA coupling

Serial no.: _________________________

Date of manufacture: ________________

Before each use ____________________

Functional check:

After each use _____________________

Repair and inspection log 45

Every 6 months ____________________

After every repair __________________

Page 46

11.2 Suction MODULE

Date Signature

with MODULE service instructions

Service performed in accordance

Company

_____________ __________________

Company

Measures / Comments

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Inspections and repairs carried out in accordance with the service instructions

Manufacturer: Weinmann GmbH + Co.

46 Repair and inspection log

Device model: Suction MODULE

❐ WM 22220 with Walther coupling

❐ WM 22260 with AGA coupling

Serial no.: _________________________

Date of manufacture: ________________

Before each use ____________________

Functional check:

After each use _____________________

Every 6 months ____________________

After every repair __________________

Page 47

11.3 Combi MODULE

Date Signature

with MODULE service instructions

Service performed in accordance

Company

_____________ __________________

Company

Measures / Comments

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Inspections and repairs carried out in accordance with the service instructions

Manufacturer: Weinmann GmbH + Co.

Device model: Combi MODULE

❐ WM 22210 with Walther coupling

❐ WM 22250 with AGA coupling

Serial no.: _________________________

Date of manufacture: ________________

Before each use ____________________

Functional check:

After each use _____________________

Repair and inspection log 47

Every 6 months ____________________

After every repair __________________

Page 48

11.4 Interface MODULE

Date Signature

with MODULE service instructions

Service performed in accordance

Company

_____________ __________________

Company

Measures / Comments

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Inspections and repairs carried out in accordance with the service instructions

Manufacturer: Weinmann GmbH + Co.

48 Repair and inspection log

Device model: Interface MODULE

❐ WM 22290 with Walther coupling

❐ WM 22280 with AGA coupling

❐ WM 22270 with Shraeder-Valve coupling

❐ WM 22230 with Dräger coupling

Serial no.: _________________________

Date of manufacture: ________________

Before each use ____________________

Functional check:

After each use _____________________

Every 6 months ____________________

After every repair __________________

Page 49

Page 50

Page 51

Page 52

For decades Weinmann has been

developing, producing and marketing

medical devices for markets around

the world. In cooperation with our

partners we design economic health

systems for diagnosis and therapy in

Sleep Medicine, Home Mechanical

Ventilation, Oxygen Medicine

and Emergency Medicine.

Weinmann

Geräte für Medizin GmbH + Co. KG

P.O. Box 540268 · D-22502 Hamburg

Phone +49/40/5 47 02-0

Fax +49/40/5 47 02-461

E-mail int.sales@weinmann.de

Internet www.weinmann.de

WM 16289c · 10/07

Loading...

Loading...