Page 1

INSTRUCTION HANDBOOK

FS10, FS32

FS32 & FS10

(example; exact model may vary)

This instruction handbook is for the daily users of the equipment.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 1 of 17

Page 2

INSTRUCTION HANDBOOK

FS10, FS32

Table of Contents

1 Introduction .............................................................................................................................. 3

1.1 FS10 / FS32 ............................................................................................................................ 3

1.2 Abbreviations in this manual .................................................................................................... 3

1.3 Symbols on the machine ......................................................................................................... 3

1.4 Caution and employee safety .................................................................................................. 4

1.5 Essential training before daily use ........................................................................................... 4

1.6 References .............................................................................................................................. 4

1.7 Dismantling and disposal ......................................................................................................... 4

2 General information ................................................................................................................. 5

2.1 Unpacking and inspection ........................................................................................................ 5

2.2 Receiving and storing the FS10/FS32 ..................................................................................... 5

2.3 Mounting of capping head ....................................................................................................... 5

2.4 Technical specifications ........................................................................................................... 6

2.4.1 Dimensions .............................................................................................................................. 6

2.4.2 Buttons / Connections.............................................................................................................. 7

2.4.3 Services .................................................................................................................................. 8

2.4.4 Bottles and caps ...................................................................................................................... 8

2.4.5 Ingress protection .................................................................................................................... 8

2.4.6 Weight ..................................................................................................................................... 8

2.4.7 Materials .................................................................................................................................. 8

3 Installation ............................................................................................................................... 9

3.1 Connections ............................................................................................................................ 9

3.2 Mounting of capping head ..................................................................................................... 10

3.3 Mounting of bottle tool ........................................................................................................... 11

4 Adjustments ........................................................................................................................... 11

4.1 Adjustment of the height of the capping head ........................................................................ 11

4.2 Adjustment of the stroke length of piston in capping head ..................................................... 12

5 Daily Use ............................................................................................................................... 13

5.1 Production START and STOP ............................................................................................... 13

5.2 Starting-up and running ......................................................................................................... 13

6 Malfunctioning ....................................................................................................................... 14

6.1 Function errors / Trouble shooting ......................................................................................... 14

7 Cleaning ................................................................................................................................ 15

7.1 Cleaning Frequency .............................................................................................................. 15

7.2 Preparations for cleaning ....................................................................................................... 15

7.3 Cleaning Guidance ................................................................................................................ 15

7.4 Detergents or cleaning agents ............................................................................................... 15

8 Maintenance & service .......................................................................................................... 16

8.1 Service .................................................................................................................................. 16

8.2 Methods and frequency of inspections for safety functions .................................................... 16

9 Accessories ........................................................................................................................... 16

10 Declaration of conformity ....................................................................................................... 17

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 2 of 17

Page 3

INSTRUCTION HANDBOOK

App.

Approximately

Hz

Hertz

IH

Instruction Handbook

Max.

Maximum

PE

Protective Earth (electrical units safety measure)

SOP

Standard Operating Procedure

VAC

Volt Alternating Current

WMF

Watson-Marlow Flexicon a/s

FS10, FS32

1 Introduction

1.1 FS10 / FS32

FS10 and FS32 are both semi-automatic capping machines designed for crimping aluminium caps.

FS10 is designed for crimping 8 mm, 13 mm and 20 mm standard crimp caps* with or without flip-off

plastic disc.

FS32 is mainly designed for 20mm and 32 mm caps*, also with or without flip-off plastic disc.

Crimping is performed by pressing the bottle or vial against the bottle holder. This causes the crimp

head to move down onto the bottle, the jaws close around the cap, pressure is applied, the jaws

release and the head lifts again.

All used compressed air is collected and can be removed through a hose mounted on the side of the

cabinet.

*ISO 8362

1.2 Abbreviations in this manual

1.3 Symbols on the machine

Warning against touching Warning against high voltage

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 3 of 17

Page 4

INSTRUCTION HANDBOOK

WM-Flexicon machines may not be disposed using normal refuse

*

FS10, FS32

1.4 Caution and employee safety

This manual should be read before using the FS10/FS32.

It is strongly advised that

- Any kind of maintenance or cleaning of the machine not is carried out while power is

connected

- Unauthorised / non-trained personnel should not maintain the electrical parts

- The machine is placed in such a way that it is not exposed to high humidity, high temperatures

or other abnormal operating environment.

- FS10 / FS32 is used for capping bottles, only

1.5 Essential training before daily use

Read the section with Daily Use, thoroughly before using the machine.

Protective equipment and protective devices are installed:

If fingers accidently are placed on the top of the bottle while the crimp head is going down,

crimping will not take place. If the inner side of crimp head is prohibited to “rest” on the top of

the cap it will return to top position.

Always respect the warning symbols on the machine.

Cleaning must be performed as described in this IH.

1.6 References

N/A

1.7 Dismantling and disposal

Prior to dismantling, it must be observed that all services are disconnected, and connections to other

equipment are removed.

collection. The machines must be collected and disposed separately as

they contain electrical components such as batteries, electrolyte

capacitors, liquid crystal displays and printed circuit boards.

Further information is available on www.wmflexicon.dk.

* (WEEE) DS/EN 50419

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 4 of 17

Page 5

INSTRUCTION HANDBOOK

FS10, FS32

2 General information

2.1 Unpacking and inspection

Please check that all ordered items have been received and that no items are damaged during

transport. In case of any defects or omissions, please contact WMF or your supplier immediately.

2.2 Receiving and storing the FS10/FS32

Before unpacking or storing of the FS10/FS32 it should be checked if the crate is damaged.

In case of long -term stor age of t he FS10/FS32 before installation, the machine must be stored in the

crate, and placed in a dry room. The crate is not water resistant.

2.3 Mounting of capping head

If the capping head has been removed during shipping it is mounted as described in section 3.2

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 5 of 17

Page 6

2.4 Technical specifications

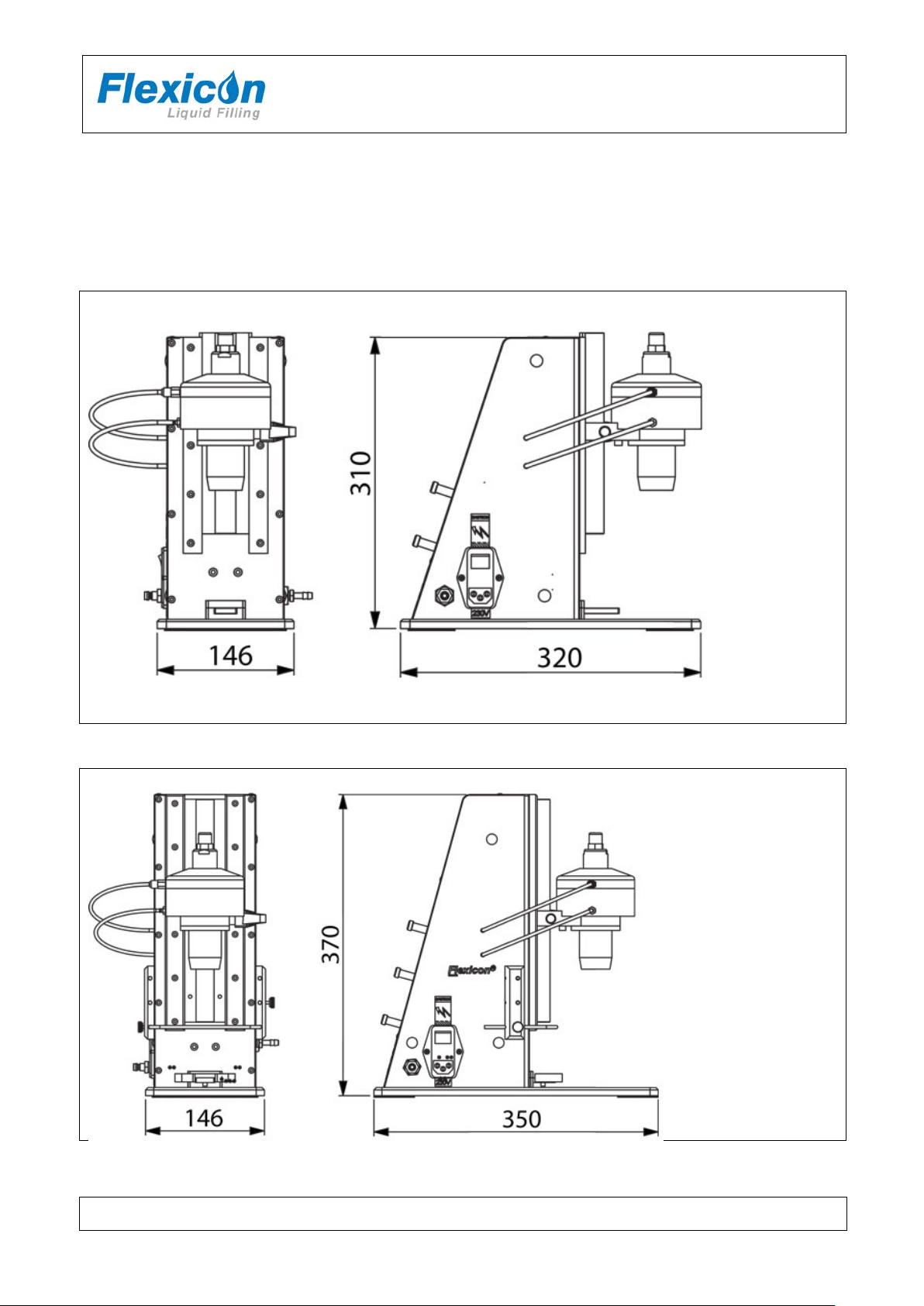

2.4.1 Dimensions

FS10

INSTRUCTION HANDBOOK

FS10, FS32

FS32

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 6 of 17

Page 7

2.4.2 Buttons / Connections

INSTRUCTION HANDBOOK

FS10, FS32

ON/OFF Button / Emergency stop

Power indicator; lights when power is on.

OFF is used for emergency stopping.

Power supply connection

Compressed air connection

Exhaust filter and air collection

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 7 of 17

Air tubes for the crimp head

Page 8

50/60Hz

Note:

Only authorised personnel can gain access to the installations. The main

installations are touched.

DIN standard

flip-top

Cabinet

Anodised aluminium

Closing head

Hardened steel jaws

housing

2.4.3 Services

All electrical systems are placed inside the machine.

INSTRUCTION HANDBOOK

FS10, FS32

Power supply:

Consumption: 50 W

Compressed air: 6 bar, clean and dry air

Consumption, FS10:

Consumption, FS32:

110/230 VAC earthed,

35 L/min. free air

50 L/min. free air

power cable must be removed completely from power supply before the

2.4.4 Bottles and caps

Bottle sizes

Max. Diameter 55 mm 95 mm

Max. Height 180 mm 240 mm

Cap sizes

FS10 FS32

FS10 FS32

With or without

8-20 mm 20-32 mm

2.4.5 Ingress protection

Ingress protection IP31

2.4.6 Weight

Weight, FS10 app. 12 kg

Weight, FS32 App. 16 kg

2.4.7 Materials

Anodised aluminium

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 8 of 17

Page 9

INSTRUCTION HANDBOOK

2 1

3 Installation

3.1 Connections

FS10 / FS32 must be placed on a stable and horizontal bedplate.

The mains cable (1) is

connected to a singlephase power supply with

earth.

The plug box (1) contains 2

fuses. When the cover of fuse

box is removed 1 more fuse is

found inside the machine.

Compressed air is

connected to (2) by use

of the supplied quick

release clutch.

FS10, FS32

Please contact your supplier or WMF IF the machine is not made for your local power supply. The sign on the machine indicates the

value of power (110/120 VAC or 220/240 VAC). The frequency has no influence.

or

If the delivered power cable does not match your socket,

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 9 of 17

Page 10

3

4

All exhaust air is collected

and exhausted through the

air exhaust filter (2)

A hose connection can be

mounted in order to

“remove” the process air

form the capping area; but

the machine will function

even if no hose is mounted.

INSTRUCTION HANDBOOK

FS10, FS32

The tubes (4) are mounted

on the capping head.

The upper tube on the

upper connection and the

lower on the lower

connection

3.2 Mounting of capping head

Loosen the

handle on the

side of the

capping head and

mount the head

gently on the

slide bar.

Tighten the

handle.

Re-mount the air

tubes on the

capping head

Changing of capping head is done the opposite way as mounting.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 10 of 17

Page 11

INSTRUCTION HANDBOOK

IN

OUT

FS10, FS32

3.3 Mounting of bottle tool

Place the bottle

tool on the

bracket and

mount the screw.

Note: If the bottle tool is mounted too close to the machine the switch function will not work, see

section 4.1

4 Adjustments

4.1 Adjustment of the height of the capping head

Before starting the production the initial height of the capping head and the bottle tool should both be

adjusted.

Begin with the bottle tool; for safety reasons switch the power OFF

Place a bottle on the base plate under the capping head.

Loosen the handle “B” and lower the capping head until it is just above the bottle neck.

Now adjust the bottle tool so the bottle is centred under the capping head – WHEN THE BOTTLE

TOOL IS PUSHED “IN”

Now FS10 is ready for height adjustment.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 11 of 17

Page 12

INSTRUCTION HANDBOOK

FS10, FS32

Connect compressed air and power. Turn power ON.

Choose the spacer (D) which best fits the capping head on the machine.

Place a bottle under the capping head – With NO stopper or cap in place.

Place the spacer on the capping head, so that it fits on the capping head.

Loosen the handle (B), press the capping head down until it rests firmly on the bottle.

It should be so firm, that the bottle can only be removed by the use of some force.

Tighten the handle (B) again. Remove bottle and spacer. The height is now roughly adjusted.

For final adjustment, a few vials should be capped and crimped.

Examine the results and if necessary make adjustments according to trouble shooting table, see

section 6.1

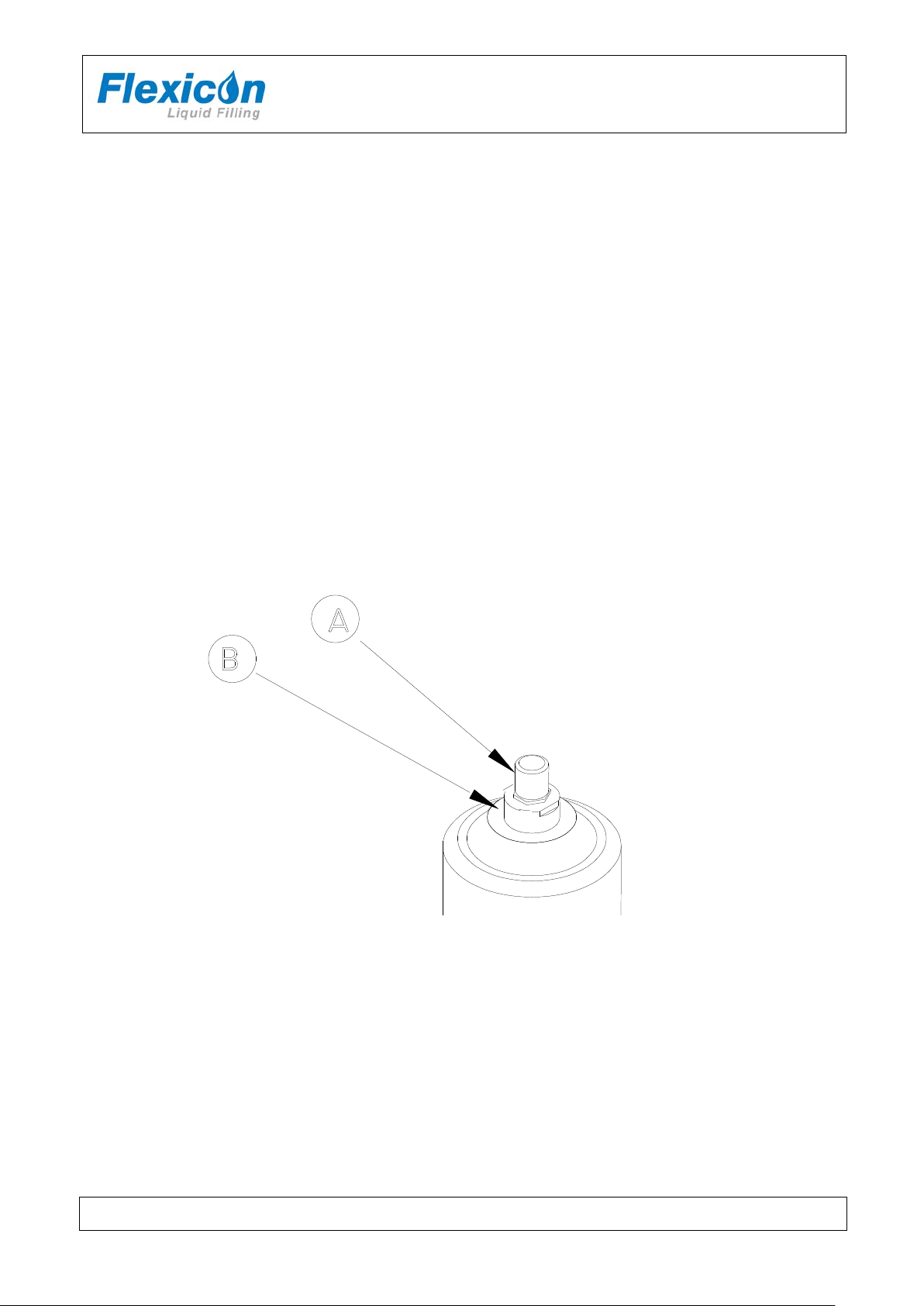

4.2 Adjustment of the stroke length of piston in capping head

Under normal condition it is possible to operate with full stroke length on the piston, but in certain

combination of cap and bottle ring tolerances, the cap might fold when hitting the bottle neck.

If this happens, the stroke length can be adjusted as following:

1. Loosen the nut (A) and screw down the piston cap (B).

2. While holding contra on the piston cap with the key surface, the nut is tightened.

3. Repeat the procedure until the cap is crimped satisfactorily.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 12 of 17

Page 13

INSTRUCTION HANDBOOK

FS10, FS32

5 Daily Use

5.1 Production START and STOP

FS10/FS32 is ready for production start when:

Section 3 has been completed

The height of the capping head has been set (section 4.2.1)

and the Power signal is ON

5.2 Starting-up and running

The bottle with cap is placed in the bottle tool, which is activated by pressing it towards the rear of the

machine. The capping head moves down onto the cap and bottle.

The bottle tool activates a micro switch which releases the compressed air; the capping head then

descends on the cap by its own weight. In case something prevents the capping head (e.g. a finger)

in encircling the cap, a stroke will not be achieved. When the capping head is in position over the cap,

a micro switch is activated in order to activate the jaws.

The jaws crimp the cap on the bottle and then the capping head returns to its upper position.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 13 of 17

Page 14

INSTRUCTION HANDBOOK

Problem:

Crimping leaves marks on the cap skirt, and crimping is not tight.

Reason:

Capping head is too high.

Action:

Lower capping head.

Problem:

Caps are closed on the bottle neck.

Caps skirts are too long for stopper-vial combination.

Too long stroke.

Check combination of rubber stopper, vial and cap.

Adjust the stroke. (see section 4.2)

Problem:

Crimping is done on the rim of caps.

Too short stroke.

Cap skirt is too short.

Make an adjustment of the stroke.

Check rubber stopper’s head for thickness.

Cap is not crimped tight. Cap is crimped too tight.

Incorrect height of crimp head.

Dirty/worn jaws.

Adjust the crimp head height slightly. Lower is tighter – Higher is looser.

Clean and polish the jaws; please contact your supplier or WMF

FS10, FS32

6 Malfunctioning

6.1 Function errors / Trouble shooting

FS10/FS32 is a relatively simple machine to operate and normally errors will be due to incorrect

adjustment of certain functions.

In the table below, the most common faults are described and what causes it.

Or the caps are deformed. (harmonica deformation)

Reason:

Action:

Reason:

Action:

Problem:

Reason:

Stroke length incorrect.

Action:

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 14 of 17

Make an adjustment of the stroke.

Page 15

INSTRUCTION HANDBOOK

Cleaning of parts

May

autoclaved

Can be cleaned

alcohol 70%

Can be cleaned with

wiped off with dry a cloth

Anodized aluminium

Nylon

(Compressed Air tubes)

FS10, FS32

7 Cleaning

7.1 Cleaning Frequency

As FS10/FS32 is not in direct contact with the dispensed product, daily cleaning might not be

necessary.

Cleaning might be determined by local SOP’s and cleaning validations; but must never be with

detergents more potent than the ones below.

7.2 Preparations for cleaning

Before cleaning the machine:

Turn off the power

Remove the capping head and the air tubes

7.3 Cleaning Guidance

Correct cleaning of the FS10/FS32 is carried out by washing it off with water or deter gents, using a

lint-free firmly wrung cloth or lint-free paper towel; subsequently the machine is wiped off with a dry

cloth.

7.4 Detergents or cleaning agents

Normal cleaning agents such as tepid/medium hot water, ethyl alcohol (ethanol) 70% and may be

used all over the machine.

The FS10/FS32 can be cleaned in several ways:

made of:

Recommendation: Keep a log on the cleaning in order to keep a sense of perspective.

be

X X X

X

with ethyl

water and afterwards

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 15 of 17

Page 16

INSTRUCTION HANDBOOK

FS10, FS32

8 Maintenance & service

8.1 Service

Should service be needed, please contact W-M Flexicon or your local supplier.

8.2 Methods and frequency of inspections for safety functions

Safety functions should be tested once a year:

Emergency switch

When pressed the compressed air is switched off

Keep a log and read the previous log recordings to present an overview of the machines state.

After testing the safety functions the results must be recorded in the log.

9 Accessories

For FS10/FS32 a number of standard capping heads are made as well as capping heads for special

purposes. The mounted standard bottle tool covers most bottle sizes, but customised bottle tools can

also be delivered.

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 16 of 17

Page 17

INSTRUCTION HANDBOOK

Flex Seal type

Item no

Model

FS10

93-100-100

63-100-020

FS32

93-100-110

63-100-050

DS EN/ISO 12100

Safety of machinery - Basic concepts, general

principles of design

DS/EN 60204

Safety of machinery – Electrical equipment of

machines

2006/42/EC

On the approximation of the laws of the Member

States relating to machinery

2006/95/EC

On the harmonization of the laws of Member

for use within certain voltage limits

2004/108/EC

On the approximation of the laws of the Member

States relating to electromagnetic compatibility

Ringsted, Denmark

10 Declaration of conform ity

We Watson-Marlow Flexicon A/S

Frejasvej 2-6

DK-4100 Ringsted

Declare on our sole responsibility that the flex seal:

to which this declaration relates is in conformity with the following standard(s):

FS10, FS32

According to the provisions in the Directives:

States relating to electrical equipment designed

Signature:

October, 2012

Jørn Jeppesen, Development Manager

FS10-32 IH EN 74-215-021 v1.02.doc Version: 1.02 Page 17 of 17

Loading...

Loading...