Page 1

Publication PB 0167

Issue 4

Installation and operating instructions

501RL, 205, 505BA

and 505L pumpheads

2

Page 2

Table of Contents

Declarations .................................................... Page 4

Two year warranty .................................................... Page 5

Information for returning pumps .................................................... Page 5

Safety .................................................... Page 5

Recommended operating procedures ............................................. Page 6

Part 1 : 501RL pumphead

Description .................................................... Page 7

Installation .................................................... Page 7

Roller adjustment .................................................... Page 7

Tube loading .................................................... Page 8

Care and maintenance .................................................... Page 8

Spares .................................................... Page 9

501RL flow rates .................................................... Page 9

Tubing range .................................................. Page 10

Part 3: 205BA & 505BA pumpheads

Description .................................................. Page 11

Installation .................................................. Page 11

Flow rates .................................................. Page 11

Tube range .................................................. Page 12

Cassette loading .................................................. Page 13

Cassette removal .................................................. Page 13

Care and maintenance .................................................. Page 13

Spares 205BA & 505BA .................................................. Page 14

Part 5 : 505L pumphead

Description .................................................. Page 15

Installation .................................................. Page 15

Flow rates .................................................. Page 16

Tubing range .................................................. Page 16

Tube loading .................................................. Page 17

Care and maintenance .................................................. Page 19

Adjustment of the track .................................................. Page 19

Spares and accessories .................................................. Page 20

Decontamination certificate .................................................. Page 21

3

Page 3

Declarations

Declaration of

incorporation

When the 501RL, 205BA, 505BA, and 505L pumpheads are to be used with

any Watson-Marlow drive unit or any customer’s drive unit, or are to be

installed into machines or assembled with other machines for installations,

they must not be put into service until the relevant machinery has been

declared in conformity with the provisions of the Machinery Directive

2006/42/EC.

Responsible person: David Cole, Managing Director,

Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009

4

Page 4

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through

either Watson-Marlow Limited, its subsidiaries, or its authorised distributors,

to repair or replace free of charge, including labour, any part of this product

which fails within two years of delivery of the product to the end user. Such

failure must have occurred because of defect in material or workmanship and

not as a result of operation of the product other than in accordance with the

instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

• Consumable items such as rollers and cassettes are excluded.

• Products must be returned by pre-arrangement carriage paid to Watson-

Marlow Limited, its subsidiaries, or its authorised distributor.

• All repairs or modifications must have been made by Watson-Marlow

Limited, its subsidiaries, or its authorised distributors or with the express

permission of Watson-Marlow Limited, its subsidiaries, or its authorised

distributors.

• Products which have been abused, misused, or subjected to malicious or

accidental damage are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any

person, including representatives of Watson-Marlow Limited, its subsidiaries,

or its distributors, which do not accord with the terms of this warranty shall not

be binding upon Watson-Marlow Limited unless expressly approved in writing

by a Director or Manager of Watson-Marlow Limited.

Information for returning pumps

Any equipment which has been contaminated with, or exposed to, body fluids,

toxic chemicals or any other substance hazardous to health must be

decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate (a suitable blank form is included at the rear of these operating

instructions), or signed statement, must be attached to the outside of the

shipping carton.

This certificate is required even if the pump is unused. If the pump has been

used, the fluids that have been in contact with the pump and the cleaning

procedure must be specified along with a statement that the equipment has

been decontaminated.

Safety

In the interests of safety, these pumpheads and the tubing selected should

only be used by competent, suitably trained personnel after they have read

and understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this

equipment should be fully competent to carry out the work. In the UK this

person should also be familiar with the Health and Safety at Work Act 1974.

5

Page 5

Recommended operating procedures

Do keep delivery and suction lines as short as possible.

Do use the minimum number of bends in rigid pipe runs. If there must be a

bend, use a swept bend and not a tight elbow.

Do use suction and delivery pipelines with a bore equal to or larger than the

bore of the tube fitted in the pumphead. When pumping viscous fluids, the

losses caused by increased friction can be overcome by using pipe runs with

a cross sectional area several times greater than the pumping element.

Do run at a slow speed when pumping viscous fluids. When using the 501RL

pumphead, a 4.8 or 6.4mm bore tube with a 1.6mm wall will give best results.

Tube smaller than this will generate a high friction pressure loss, so reducing

the flow. Tube with a larger bore will not have sufficient strength to restitute.

Flooded suction will enhance pumping performance in all cases, particularly

for materials of a viscous nature. Silicone and Marprene tubing is available

with a 2.4mm wall thickness for speeds up to 220rpm. (The rotor will require

re-setting to a roller/track gap of 3.8mm.)

Do use the largest possible bore tube running at slow speed for the longest

tube life.

Do fit an extra length of pump tube in the system so that you can move the

tube through the pumphead occasionally, without needing to break the

pumping circuit. This is particularly useful for extending tube life in long

running sterile applications.

Do keep the track and rollers clean, and ensure that the rollers are free.

Do not fit valves in the suction or delivery lines without considering that

peristaltic pumps are self priming and will hold their prime up to several

metres, so there may be no need for non-return or foot valves, nor for the

loading valves required on many other kinds of pumps.

Any valves fitted must cause no restriction. If electrically actuated valves are

fitted, they should be interlocked so that the pump will only run when the

valves are open. Fit an automatic by-pass if manual valves are installed.

When using Marprene or Bioprene tubing, after about 30 minutes of

running, re-tension the tube in the pumphead by releasing the tube clamp on

the delivery side a little and pulling the tube tight. This is to counteract the

normal stretching that occurs with Marprene or Bioprene, which can go

unnoticed, and result in poor tube life.

Tube selection The chemical compatibility list published in the WatsonMarlow catalogue is only a guide. If in doubt request a tube sample card for

immersion trials. Remember the sample will be fully immersed, but the fluid

when in use will only be in contact with the inside of the tube. If the material

swells but does not lose its strength it could be worth considering.

Viscous dispensing To overcome the common problems, of reduced

accuracy and dripping delivery pipes, the suction and delivery lines should be

kept as short as possible. Use larger bore transmission tubes than in the

pumphead to keep the friction losses to a minimum. Improvement will be

noticed if rigid or semi-rigid pipe is used on the delivery side. The rigid tube is

effective in reducing over-run because it does not expand during pumping.

6

Page 6

Part 1 : 501RL pumphead

Description

The 501RL pumphead has two spring-loaded rollers, which automatically

compensate for minor variations in tubing wall thickness, giving extended

tube life.

The 501RL is set during manufacture to accept tubing with wall thicknesses

of between 1.6mm and 2.0mm, and internal diameters of up to 8.0mm. The

501RL pumphead is equipped with a "tool lockable" guard for increased

safety, this should be locked shut whilst the pump is in use.

A major feature of the 501RL pumphead is the ability to run the pumphead

clockwise for extended tube life, or anti-clockwise to operate against higher

pressures.

The tube clamps of the 501RL are adjustable to four positions to allow varying

tube diameters to be securely held without occluding the tube.

Installation

Any one of three tubing input/output positions can be selected on cased

drives. Select the required position then fit the track over the drive shaft and

locating boss. Tighten the track retaining screw.

After checking that the shaft is clean and degreased slide the rotor on to it. Fit

the track in any one of three orientations, over the drive and locating boss.

Secure the track with the locating screw. Ensure the drive shaft is degreased

before locating the rotor onto the shaft via the split collet. Rotate rotor until

its guide rollers are alligned flush to the front edge of the track. Tighten

the rotor screw to a torque of 3Nm to prevent the collet slipping during

operation.

To reposition the track, remove any tubing from the pumphead, and swing out

the crank handle to expose the rotor retaining screw. Turn the screw

anticlockwise one turn to release the collet, and withdraw the rotor from the

shaft. Loosen the track locating screw, and pull the track clear. Rotate the

track to its new position and tighten the track locating screw.

Roller adjustment

The 501RL has a factory set gap of 2.6mm between the rollers and the track

and is suitable for tubing having wall thicknesses of between 1.6 and 2.0mm.

Adjustment of the gap will be required if tubing having a wall thickness of less

than 1.6mm is required. There is an adjusting screw on each of the two roller

arms, and each of these screws will require adjustment. The correct gap is

twice the wall thickness less twenty percent. Correct adjustment is important:

over occlusion will reduce tube life; under occlusion will reduce pumping

efficiency.

To change the gap setting, turn each adjusting screw clockwise to increase

the gap, or anticlockwise to decrease the gap. A full turn changes the gap by

0.8mm.

To restore the original settings of 2.6mm, turn the adjusting screws until both

rollers are just touching the track, then tighten each screw by three and a

quarter turns.

7

Page 7

Tube loading

Switch off the pump before loading the tube. Unlock and open the hinged

guard and swing out the rotor crank handle until it locks into position.

Select the length of tubing required, noting that approximately 240mm is

required for the track system (measured from the outside faces of the tube

clamps).

Fit one end of the tubing into one of the spring loaded clamps, and then,

whilst rotating the rotor with the crank handle, feed the tubing between the

rollers and the track, aligning it within the rotor tube guides. The tubing must

lie naturally against the track and must not be twisted or stretched.

Fit the other end of the tubing into the second spring loaded clamp, ensuring

that the tubing is not slack in the pumphead, since this can reduce tube life.

Close the crank handle and shut and lock the guard. After the pump has been

started, open the downstream clamp for a short time, so that the tube can find

its natural length.

The 501RL pumphead is fitted with four-position tube clamps, to

accommodate various tube diameters, which can be adjusted by pushing in or

pulling out the bars at the top of the upper clamp and the bottom of the lower

clamp. Set the clamps so that the minimum necessary pressure is applied to

the tubing.

Care and maintenance

If aggressive liquids are spilled on to the pumphead, the head should be

removed and cleaned using a mild solution of detergent and water. Remove

any tubing from the pumphead, and swing out the crank handle to expose the

rotor retaining screw. Turn the screw anticlockwise one turn to release the

collet, and withdraw the rotor from the shaft. Unscrew the track retaining

screw and detach the track from its spigot.

Check moving parts of the rotor regularly for freedom of movement. Lubricate

pivot points and rollers with Teflon lubricating oil. To obtain effective

lubrication of the roller spindle, remove from the pumphead and clean

thoroughly prior to applying RD-105 grease.

8

Page 8

Spares

Guard

MN 1200M For lock

MN 0017M Unlockable

Lock

FN4502

FN 2341

4 off

Hinge

MN0266M

Grey

MN0018M

Black

501RL

Rotor assembly

MNA0143A

Springs

SG 0001, 4 off Standard

SG 0002, 4 off Hard

Main rollers

MN 0011T, 2 off

Follower rollers

MN 0012T 2 off

Track assembly

MNA0311A Grey

MNA0137A Black

RD-105

OG 0034

Teflon lubricant

XX 0095

Tube clamp

assembly

MNA0114A

FN2332

2 off

If in doubt when considering spares for order, do not hesitate to contact

Watson-Marlow Technical Support for further information.

Flow rates

The flow rates given overleaf were obtained using silicone tubing, with the

pumphead rotating clockwise, pumping water at 20C with zero suction and

delivery pressures (unless otherwise stated). Where an application is critical,

the flow rate should be determined under operating conditions. The important

factors affecting flow rates are delivery pressures, temperature, and fluid

viscosity. Tube life will be reduced when pumping against pressure.

9

Page 9

501RL flow rates (ml/min)

Tube # 112 13 14 16 25 17 18

Tube bore 0.5mm 0.8mm 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm

1/50" 1/32" 1/16" 1/8" 3/16" 1/4" 5/16"

504S/U 55rpm 2.3 6.7 24 101 220 347 550

505S/U/Du 220rpm 9.2 27 94 410 892 1400 2200

505Di 220rpm 9.2 27 94 410 892 1400 2200

300*rpm 12.5 37 128 560 1210 1900 3000

503P 30rpm 1.3 3.7 13 55 120 190 300

160rpm 6.7 20 70 293 640 1010 1600

* Pumphead restricted to a maximum running speed of 300rpm.

Tubing range

Flow precision depends upon the accuracy and consistency of the tubing. All

Watson-Marlow tubing is formulated, manufactured and quality controlled to

rigorous specifications. Peristaltic pumping performance and tube life will be

affected unless tubing specifically designed for the task is used.

Ordering

Information

Tubing 501RL pumphead

Bore Tube

mm " # Marprene Bioprene Silicone Neoprene

0.5 1/50 112 902.0005.016 903.0005.016 910.0005.016

0.8 1/32 13 902.0008.016 903.0008.016 910.0008.016 920.0008.016

1.6 1/16 14 902.0016.016 903.0016.016 910.0016.016 920.0016.016

3.2 1/8 16 902.0032.016 903.0032.016 910.0032.016 920.0032.016

4.8 3/16 25 902.0048.016 903.0048.016 910.0048.016 920.0048.016

6.4 1/4 17 902.0064.016 903.0064.016 910.0064.016 920.0064.016

8.0 5/16 18 902.0080.016 903.0080.016 910.0080.016 920.0080.016

Bore Tube

mm " # Butyl Tygon Viton

1.6 1/16 14 930.0016.016 950.0016.016 970.0016.016

3.2 1/8 16 930.0032.016 950.0032.016 970.0032.016

4.8 3/16 25 930.0048.016 950.0048.016 970.0048.016

6.4 1/4 17 930.0064.016 950.0064.016 970.0064.016

8.0 5/16 18 930.0080.016 950.0080.016 970.0080.016

10

Page 10

Part 3: 205BA & 505BA pumpheads

Description

The 205BA/505BA pumpheads have eight rollers driven by planetary gearing

providing virtually pulse free flow. They are easy loading cassette pumpheads

available in 4, 8, 12 or 16 channel versions. If more channels are required, 12

or 16 channel 205BAX/505BAX extension pumpheads can be added.

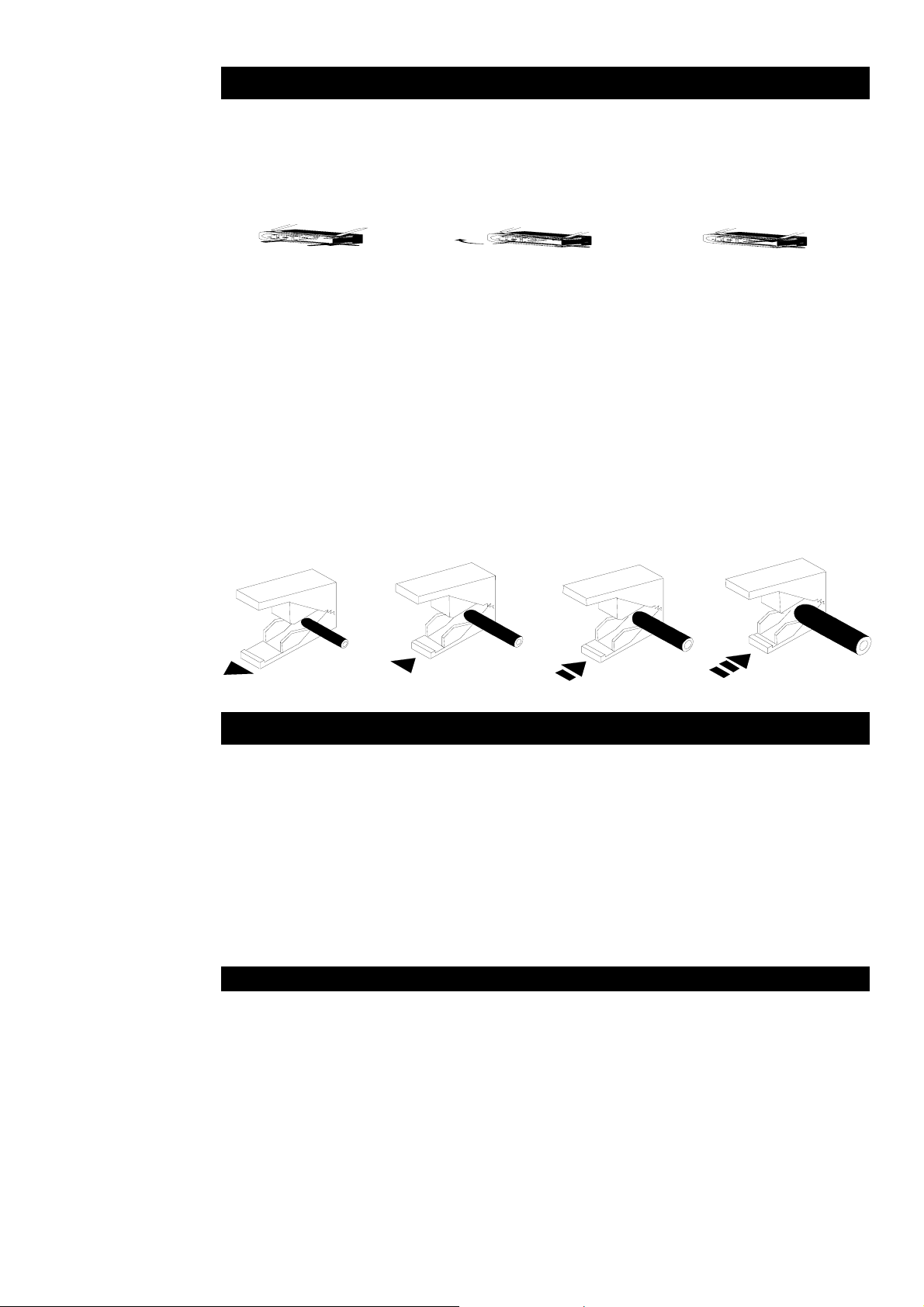

Installation

Remove the drive-shaft cover from the 205BA/505BA and fit the pumphead

over the drive "nose" (1), ensuring that the tongue on the drive shaft locates

on the slot in the pumphead centre shaft. Tighten the retaining screws (2) at

the top and bottom of the mounting plate.

2

1

4

3

Fitting an

extension

pumphead

To fit an extension pumphead, remove the end cover

plate (3) on the first pumphead, exposing the two locating

pins and the drive shaft slot. Spring off the planetary gear

system cover plate from the 205BAX/505BAX extension

pumphead.

Locate the 205BAX/505BAX extension pumphead on to the two locating pins,

ensuring that the tongue of its drive shaft engages in the slot in the shaft of

the 205BAX/505BAX. Tighten the two retaining screws (4) on the right and left

of the 205BAX/505BAX to be added. Fit the end plate to the last pumphead.

Flow rates

These flow rates were obtained using PVC tubing pumping water at 20C with

zero suction and delivery pressures. Critical flow rates should be measured

under operating conditions where the important factors are suction and

delivery, temperature and viscosity. Flow rates are given in ml/minute.

205BA flow rates (ml/min)

Tubing internal diameter (mm)

0.13 0.19 0.25 0.38 0.50 0.63 0.76 Maximum

Drive rpm 0.005" 0.007" 0.01" 0.015" 0.02" 0.025" 0.03" Channels

205S & 0.5 0.0003 0.0011 0.001 0.002 0.004 0.007 0.011 32

205U 90 0.045 0.116 0.265 0.439 0.720 1.30 1.89 32

0.88 1.02 1.14 1.29 1.42 1.47 1.52 32

Drive rpm 0.035" 0.04" 0.045" 0.05" 0.055" 0.058" 0.06" 32

205S & 0.5 0.014 0.019 0.023 0.029 0.035 0.038 0.040 32

205U 90 2.52 3.33 4.10 5.27 6.25 6.78 7.15 32

1.65 1.85 2.05 2.38 2.54 2.79 32

Drive rpm 0.065" 0.07" 0.08" 0.09" 0.1" 0.11" 32

205S & 0.5 0.046 0.057 0.069 0.089 0.010 0.117 32

205U 90 8.26 10.3 12.4 16.1 18.0 21.0 32

The 205BA pumphead is dedicated to the 205S and 205U drives.

11

Page 11

505BA flow rates (ml/min)

Tubing internal diameter (mm)

0.13 0.19 0.25 0.38 0.50 0.63 0.76 Maximum

Drive rpm 0.005" 0.007" 0.01" 0.015" 0.02" 0.025" 0.03" Channels

504U 0.5 0.0002 0.0006 0.0014 0.0024 0.004 0.008 0.010 48

504S 2.0 0.0008 0.0024 0.0056 0.0096 0.016 0.032 0.04 48

505U 55 0.03 0.07 0.16 0.27 0.44 0.79 1.16 48

505S 170 0.068 0.204 0.476 0.816 1.36 2.72 3.4 48

505Du 0.25 0.0001 0.0003 0.0007 0.0012 0.002 0.004 0.005 48

1.0 0.0004 0.0012 0.0028 0.0048 0.008 0.016 0.02 48

55 0.03 0.07 0.16 0.27 0.44 0.79 1.16 48

170 0.068 0.204 0.476 0.816 1.36 2.72 3.4 48

505Di 1.0 0.0004 0.0012 0.0028 0.0048 0.008 0.016 0.02 48

2.0 0.0008 0.0024 0.0056 0.0096 0.016 0.032 0.04 48

170 0.068 0.204 0.476 0.816 1.36 2.72 3.4 48

503P 6 0.0024 0.0072 0.0168 0.0288 0.048 0.096 0.12 48

30 0.012 0.036 0.084 0.144 0.24 0.48 0.6 48

32 0.0128 0.0384 0.0896 0.1536 0.256 0.512 0.64 48

160 0.064 0.192 0.448 0.768 1.28 2.56 3.2 48

Tubing internal diameter (mm)

0.88 1.02 1.14 1.29 1.42 1.47 1.52 Maximum

Drive rpm 0.035" 0.04" 0.045" 0.05" 0.055" 0.058" 0.06" Channels

504U 0.5 0.014 0.02 0.022 0.030 0.034 0.038 0.040 48

504S 2.0 0.056 0.08 0.088 0.12 0.136 0.152 0.16 48

505S 55 1.54 2.04 2.51 3.22 3.82 4.14 4.37 48

504U 170 4.76 6.8 7.48 10.2 11.56 12.92 13.6 48

505Du 0.25 0.007 0.009 0.011 0.015 0.017 0.019 0.020 48

1.0 0.028 0.04 0.044 0.060 0.068 0.076 0.080 48

55 1.54 2.04 2.51 3.22 3.82 4.14 4.37 48

170 4.76 6.8 7.48 10.2 11.56 12.92 13.6 48

505Di 1.0 0.028 0.04 0.044 0.060 0.068 0.076 0.080 48

2.0 0.056 0.08 0.088 0.12 0.136 0.152 0.16 48

170 4.76 6.8 7.48 10.2 11.56 12.92 13.6 48

503P 6 0.168 0.24 0.264 0.36 0.408 0.456 0.48 48

30 0.84 1.2 1.32 1.8 2.04 2.28 2.4 48

32 0.896 1.28 1.408 1.92 2.176 2.432 2.56 48

160 4.48 6.4 7.04 9.6 10.88 12.16 12.8 48

Tubing internal diameter (mm)

1.65 1.85 2.05 2.38 2.54 2.79 Maximum

Drive rpm 0.065" 0.07" 0.08" 0.09" 0.1" 0.11" Channels

504U 0.5 0.046 0.060 0.070 0.090 0.11 0.12 48

504S 2.0 0.184 0.24 0.28 0.36 0.44 0.48 48

505U 55 5.05 6.31 7.60 9.84 11.0 12.8 48

505S 170 15.64 20.4 23.8 30.6 37.4 40.8 48

505Du 0.25 0.023 0.029 0.035 0.045 0.50 0.60 48

1.0 0.092 0.12 0.14 0.18 0.22 0.24 48

55 5.05 6.31 7.60 9.84 11.0 12.8 48

170 15.64 20.4 23.8 30.6 37.4 40.8 48

505Di 1.0 0.092 0.12 0.14 0.18 0.22 0.24 48

2.0 0.184 0.24 0.28 0.36 0.44 0.48 48

170 15.64 20.4 23.8 30.6 37.4 40.8 48

503P 6 0.552 0.72 0.84 1.08 1.32 1.44 48

30 2.76 3.6 4.2 5.4 6.6 7.2 48

32 2.944 3.84 4.48 5.76 7.04 7.68 48

160 14.72 19.2 22.4 28.8 35.2 38.4 48

505BA pumpheads must not be run at rotor drive speeds greater than 170rpm

12

Page 12

Tubing range

Single segment manifold tubing for 205BA and 505BA cassette

pumpheads

Colour code Bore Bore

mm " Marprene PVC Silicone

Orange/black 0.13 0.005 980.0013.000

Orange/red 0.19 0.007 980.0019.000

Orange/blue 0.25 0.010 978.0025.000 980.0025.000

Orange/green 0.38 0.015 978.0038.000 980.0038.000

Orange/yellow 0.50 0.020 978.0050.000 980.0050.000

Orange/white 0.63 0.025 978.0063.000 980.0063.000 982.0063.000

Black/black 0.76 0.030 978.0076.000 980.0076.000 982.0076.000

Orange/orange 0.88 0.035 978.0088.000 980.0088.000 982.0088.000

White/white 1.02 0.040 978.0102.000 980.0102.000 982.0102.000

Red/red 1.14 0.045 978.0114.000 980.0114.000 982.0114.000

Grey/grey 1.29 0.050 978.0129.000 980.0129.000 982.0129.000

Yellow/yellow 1.42 0.055 978.0142.000 980.0142.000 982.0142.000

Translucent 1.47 0.058 982.0147.000

Yellow/blue 1.52 0.060 978.0152.000 980.0152.000 982.0152.000

Blue/blue 1.65 0.065 978.0165.000 980.0165.000 982.0165.000

Green/green 1.85 0.070 978.0185.000 980.0185.000 982.0185.000

Purple/purple 2.05 0.080 978.0205.000 980.0205.000 982.0205.000

Purple/black 2.38 0.095 978.0238.000 980.0238.000 982.0238.000

Purple/orange 2.54 0.100 978.0254.000 980.0254.000 982.0254.000

Purple/white 2.79 0.110 978.0279.000 980.0279.000 982.0279.000

Single segment manifold tubing for 205BA and 505BAcassette

pumpheads

Bore Bore Solvent Acid

Colour code mm " resistant resistant

Orange/black 0.13 0.005 984.0013.000

Orange/red 0.19 0.007 984.0019.000

Orange/blue 0.25 0.010 984.0025.000

Orange/green 0.38 0.015 984.0038.000

Orange/yellow 0.50 0.020 984.0050.000 986.0050.000

Orange/white 0.63 0.025 984.0063.000 986.0063.000

Black/black 0.76 0.030 984.0076.000 986.0063.000

Orange/orange 0.88 0.035 984.0088.000 986.0088.000

White/white 1.02 0.040 984.0102.000 986.0102.000

Red/red 1.14 0.045 984.0114.000 986.0114.000

Grey/grey 1.29 0.050 984.0129.000 986.0129.000

Yellow/yellow 1.42 0.055 984.0142.000 986.0142.000

Yellow/blue 1.52 0.060 984.0152.000 986.0152.000

Blue/blue 1.65 0.065 984.0165.000 986.0165.000

Green/green 1.85 0.070 984.0185.000 986.0185.000

Purple/purple 2.05 0.080 984.0205.000 986.0205.000

Purple/black 2.38 0.095 984.0238.000 986.0238.000

Purple/orange 2.54 0.100 984.0254.000 986.0254.000

Purple/white 2.79 0.110 984.0279.000 986.0279.000

13

Page 13

Cassette loading

The cassettes are designed only for use with manifold pump tubing. Place the

tube, without twisting or stretching it, into the tube retaining slots. Depress the

cam adjustment lever which will move the cassette leg inwards. Load the

cassettes into the pumphead starting at the drive end.

Ensure that both retaining lips are properly engaged, then raise the cam

adjustment lever to its vertical position to give the normal tube occlusion. The

final delivery pressure can be varied slightly by adjusting the cam lever

position.

Cassette removal

Depress the cam adjustment lever fully and lift out the cassette. There is no

need to switch off the drive to remove a cassette for tube changing.

The removal of a cassette will not disturb the pumping action of any other but

the pump must not be run for long periods of time without all the cassettes in

place.

For safety reasons, all cassettes should be in position in the pumphead during

normal running, even if some do not contain tubing.

Care and maintenance

When the pumphead needs cleaning, switch the drive off and isolate it from

the mains. Withdraw the cassettes from the pumphead and remove the

tubing. Wash the cassettes in water and mild detergent.

If fluid has been spilled into the pumphead, removal of the pumphead from

the drive will make cleaning easier. Periodically, inspect all moving parts for

wear and ensure all bearings and rollers are free to rotate.

Spares 205BA & 505BA

2

9

7

8

10

4

3

5,6

1

14

Page 14

# Description Part number Quantity

1 Cassette assembly DEA0069A 1

2 Gearbox cover DE 0293S 1

3 Roller 4 way DE 0981T 1

3 Roller 8 way DE 0982T 1

3 Roller 12 way DE 0983T 1

3 Roller 16 way DE 0984T 1

4 Roller bearing BB 0034 16

5 Centre shaft bearing BB 0038 2

6 Centre spacer bearing BB 0014 2

7 Roller gear, 35 teeth MN 0983M 6

8 Centre gear, 45 teeth MN 0982M 1

9 Friction O ring OS 0013 1

10 Head/drive adaptor 505BA 053.5021.000 1

15

Page 15

Part 5 : 505L pumphead

Description

This design of peristaltic pumphead is Watson-Marlow's most accurate dosing

and dispensing pumphead. To overcome the pulsatile effect many peristaltic

pumps exhibit, Watson-Marlow have developed the principle of twin offset

tracks. This puts the two tubes out of phase, merging a pulse from one

channel with a trough from the other.

The 505L is fitted with six stainless steel rollers and uses either silicone or

Marprene tubing up to 9.6mm bore, to further increase accuracy, 2.4mm wall

thickness is used. With a 50% greater wall thickness than standard tubing,

505L tube elements are more stable under changing conditions of pressure,

suction and viscosity. The increase of bore size compared to standard 500

series pumpheads gives increased flow rates to over 2.4 litres per minute at

220rpm.

Silicone tubing will give the highest accuracy, but Marprene or Bioprene may

be a better choice where chemical compatibility is a problem, or extra long

tube life is required. For most dispensing and low pulse applications, we

would strongly advise the use of Watson-Marlow double-Y tubing elements,

which are pre-formed to the correct length to ensure accurate merging of

flows to give the smoothest flow possible. If you do not wish to use the special

double-tube elements you will need to order a set of six tube clamps which

will enable the pumphead to be used with either twin inlet (suction) tubes or

as a two channel (totally separate) precision pumphead.

One 505LX extension pumphead can be fitted to 503P, 504S, 504U, 505Di,

505S, 505U and 505Du drives to increase flow rates still further or to provide

another individual pumping channel.

Fitting an

extension

pumphead

Installation

Remove the drive-shaft cover from the 205/505LA and fit the pumphead over

the drive "nose" (1), ensuring that the tongue on the drive shaft locates on the

slot in the pumphead centre shaft. Tighten the two retaining screws (2) at the

top and bottom of the mounting plate.

2

1

4

5

To remove the end cover plate (3) on the first pumphead, take one of the

extension pumphead fixing bolts supplied and screw into the tapped holes (4),

from the rear of the front plate, breaking the adhesion and pushing off the

cover plate. Grease the shaft tongue on the extension pumphead with the

grease supplied. Locate the tongue of the extension head drive shaft into the

slot in the centre shaft of the first pumphead and tighten the two extension

head fixing screws (5), at each side of the extension pumphead. The

extension head is supplied with two strips of industrial adhesive tape (6). Peel

off the cover strips and relocate the cover plate on the extension pumphead.

6

3

16

Page 16

Flow rates

The flow rates given below were obtained using silicone tubing, with the

pumphead rotating clockwise, pumping water at 20C with zero suction and

delivery pressures (unless otherwise stated).

Where an application is critical, the flow rate should be determined under

operating conditions. The important factors are suction and delivery

pressures, temperature, and fluid viscosity.

Tube life will be reduced when pumping against pressure.

The flow rates shown are the combined flow using the Watson-Marlow

Double-Y tubing elements. Flows for two separate channels are each

approximately half that given.

505L flow rates (ml/min)

Tube # 119 16 25 17 18 122

Tube bore 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm 9.6mm*

Drive rpm 1/16" 1/8" 3/16" 1/4" 5/16" 3/8"

504S/U

55 40 125 230 385 495 685

505Di

505S/U

220 155 500 925 1540 1980 2750

505Du

505Di 300* 245 800 1500 2450 3150 4375

ml/revolution 0.7 2.3 4.2 7.0 9.0 12.5

* 9.6mm bore through pumphead and to delivery; 12.7mm bore to source

Tubing range

Double-Y tubing elements for 505L Product codes

Tube bore

mm " Silicone Marprene

1.6 1/16 910.E016.024 902.E016.024

3.2 1/8 910.E032.024 902.E032.024

4.8 3/16 910.E048.024 902.E048.024

6.4 1/4 910.E064.024 902.E064.024

8.0 5/16 910.E080.024 902.E080.024

9.6* 3/8 910.E096.024 902.E096.024

* 9.6mm bore through pumphead and to delivery; 12.7mm bore to source. An

MNA 0345A twin tube clamp assembly, available from Watson-Marlow or its

distributors, must be purchased to enable the 9.6mm high-flow Double-Y

tubing element to be used.

17

Page 17

2.4mm wall transfer tubing Product codes

Tube Bore Tube

mm " # Silicone Marprene

1.6 1/16 119 910.0016.024 902.0016.024

3.2 1/8 120 910.0032.024 902.0032.024

4.8 3/16 15 910.0048.024 902.0048.024

6.4 1/4 24 910.0064.024 902.0064.024

8.0 5/16 121 910.0080.024 902.0080.024

9.6 3/8 122 910.0096.024 902.0096.024

Y connectors Product codes

For 1.6mm bore 999.3016.000

For 3.2mm bore 999.3032.000

For 4.8 and 6.4mm bore 999.3064.000

For 8.0mm bore 999.3080.000

For 9.6mm bore 999.3096.000

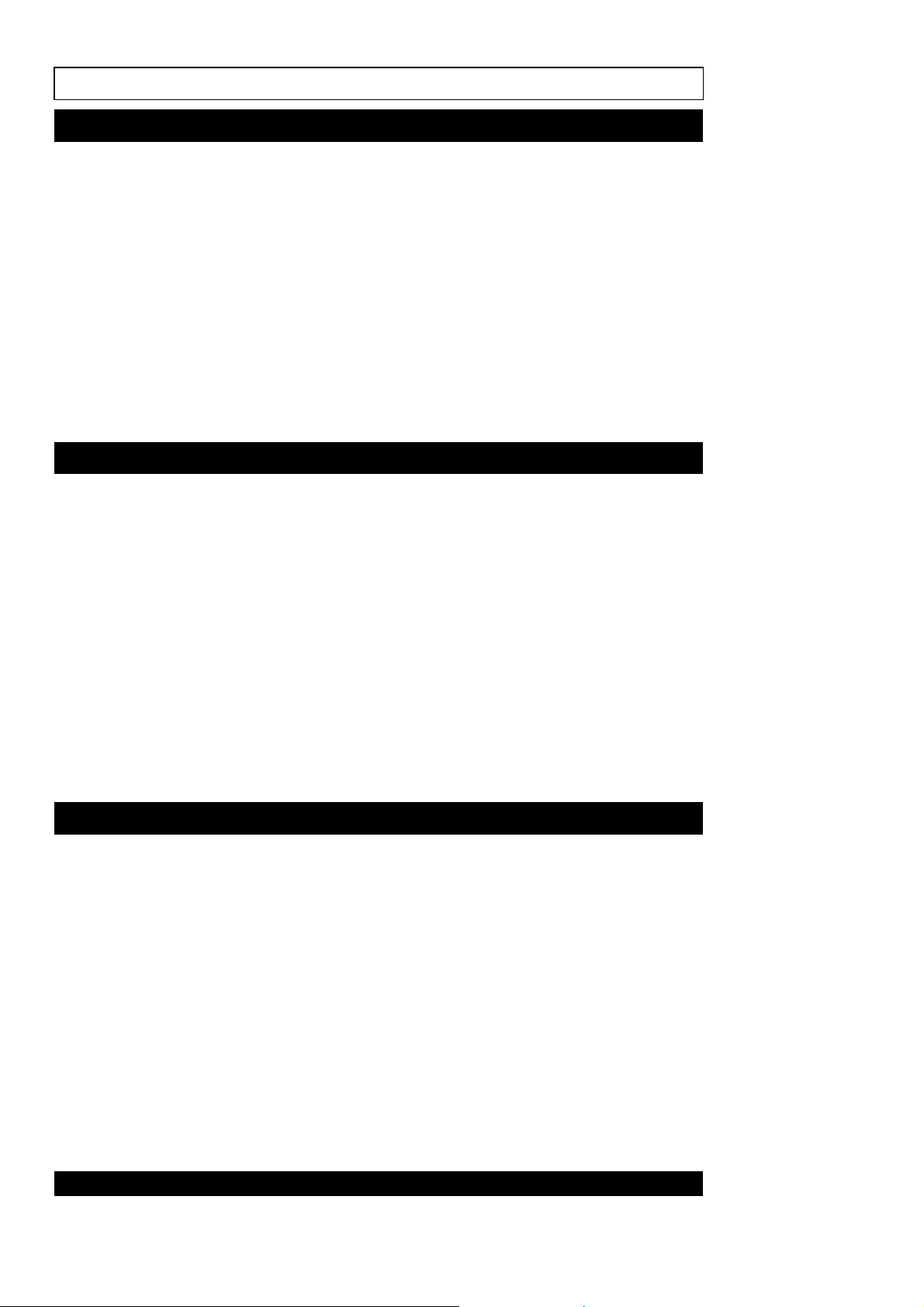

Tube loading

Tube loading instructions are given for the three possible methods of using a

505L pumphead.

For most dispensing, and any application where there must be minimal

pulsing, the use of Watson-Marlow Double-Y silicone tubing elements is

recommended.

These are pre-formed to the correct length and merge two out of phase flows

into a single smooth output. These elements fit on the retaining pegs supplied

with the pumphead.

Under certain circumstances it may be useful to run two separate inlet tubes

from your source to the pumphead. It is advisable to do this if the fluid is

particularly viscous and the single inlet tube is found to restrict the flow rate,

or if the pump is situated a long distance from the source reservoir and is

running at high speed.

A tube clamp set is available from Watson-Marlow (refer to the spares

section) to securely fix twin inlet tubes.

The 505L may also be used as a two channel, six roller, precision pumphead,

with two entirely separate tubes. The tube clamp set contains two clamps for

each size of tubing to enable both the inlet and the delivery side to be

securely fixed.

It should be noted that, when used in this way, the flow does not benefit from

the smoothing created by combining two out of phase flows, and slight

channel-to-channel variation may be found in the flow rates. Keeping suction

and discharge tubing lengths the same and will minimise this variation.

18

Page 18

Lift the two levers (1) at either side of the pumphead and remove the track.

Stretching the tubing element slightly (2), locate it over the "pegs" at either

side of the pumphead (3).

Replace the track and pull down the securing levers.

Transfer tubing (4) may now be attached to the connectors and is available

from Watson-Marlow. It is advised to use 2.4mm wall tubing for transfer tubing

(to match the double tube elements) as this will give the best performance

under suction.

Fitting WatsonMarlow DoubleY tubing

elements

Lift the two levers (1) at each side of the pumphead and remove the track, as

above. Remove the "peg" on the inlet side. Do not remove the delivery side

peg (2).

Take the two lengths (3) of tubing to be used and insert the appropriate "Y"

connector (4). Lay this assembly across the rotor, with the "Y" connector over

the end peg on the delivery side (2). Whilst pulling the tubing taught from the

inlet side, take the correct tube clamp (5) (all tube clamps are marked with the

nominal bore for their intended tubing) and firmly secure using the same fixing

as the end peg. It is found to be easier to insert the two tubes into the

"arches" of the clamp before securing the clamp itself.

Using twin inlet

tubes

Replace the track and pull down the securing levers and connect the delivery

tube (6) to the output of the "Y" connector.

19

Page 19

Using two

independent

tubes

Lift the two levers (1) at either side of the pumphead and remove the track, as

above. Remove both locating "pegs". Take the two tube lengths (2) and insert

into the "arches" of the tube clamps (3) ensuring that the nominal distance

between the clamps

9.6mm bore. All tube clamps are marked with the nominal bore for their

intended tubing and only the correct size should be used.

Take the tube assembly and secure one tube clamp. Whilst stretching the

tubing slightly, fit the second tube clamp locking it down securely.

is 145mm for bore sizes up to 8.0mm and 150mm for

Replace the track and pull down the securing levers.

When fitting new lengths of Marprene tubing, run for about half an hour and

then re-tension the tubing, making sure that the nominal lengths above are

restored. If tubing lengths greater than those given are used, the tubing may

move about within the pumphead and damage will occur.

Care and maintenance

The 505L pumphead is "maintenance free" although you should check moving

parts of the rotor from time to time for freedom of movement.

If aggressive liquids are spilled on to the pumphead, the head should be

removed and cleaned. Do not use strong solvents.

Adjustment of the track

The track is set for use with 2.4mm wall tubing with bore sizes from 1.6mm to

9.6mm. If other tubing is used, It may require the adjustment of the track/rotor

gap setting. This setting may also be used to "fine tune" each channel to

achieve identical flow rates.

Normal setting 14.3mm (0.56")

To restore the original setting, a dimension of 14.3mm (0.56") should be set

from the track to the top from the pumphead. The adjustment screw is made

with the screw between the two guide pins on the top of the track.

20

Page 20

Spares and accessories

0338A

Adapto

505LTC Tube clamp se

059.4001.000

Comprises o

each o

ube sizes

0339A

ube loca

peg

(

equired)

A

assembly

A

0333A

assembly

e sha

bea

g

(

equired)

Accessories

Complete pumphead

505

053.4001.000

505

053.40

000

t

MNA

T

2 r

f the six t

MNA

L

LX

f 2 clamps for

ting

r

11.

MNA

Track

BB 0014

Driv

ft

rin

2 r

MNA0371

Rotor

MN 1029C

End plate

:

XX 0083

dhesive tape

21

Page 21

Decontamination certificate

22

Loading...

Loading...