Page 1

501CC

501cc-gb-02.pdf

Page 2

501DF, 501DP, 501DFX, 501DV ATEX II 2 G T4

9

501F, 501P, 501X, 501V ATEX

8

2

Page 3

Declarations

Declaration of

conformity

Declaration of

Incorporation

Responsible person: David Cole, Managing Director, Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009.

When this pump unit is used as a stand alone pump it complies with:

Machinery Directive 2006/42/EC, EMC Directive 2004/108/EC.

.

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 2006/42/EC.

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either Watson-Marlow Limited, its subsidiaries, or its

authorised distributors, to repair or replace free of charge, including labour, any part of this product which fails within two years of

delivery of the product to the end user. Such failure must have occurred because of defect in material or workmanship and not as

a result of operation of the product other than in accordance with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

• Consumable items such as tubing and rollers are excluded.

• Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited, its subsidiaries, or its authorised

distributor.

• All repairs or modifications must have been made by Watson-Marlow Limited, its subsidiaries, or its authorised distributors or

with the express permission of Watson-Marlow Limited, its subsidiaries, or its authorised distributors.

• Products which have been abused, misused, or subjected to malicious or accidental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person, including representatives of Watson-Marlow

Limited, its subsidiaries, or its distributors, which do not accord with the terms of this warranty shall not be binding upon WatsonMarlow Limited unless expressly approved in writing by a Director or Manager of Watson-Marlow Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals or any other substance hazardous to health

must be decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside of the shipping

carton.

This certificate is required even if the pump is unused. If the pump has been used, the fluids that have been in contact with the pump

and the cleaning procedure must be specified along with a statement that the equipment has been decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained personnel after they

have read and understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out the work. In the

UK this person should also be familiar with the Health and Safety at Work Act 1974.

Fundamental work with regard to lifting, transportation, installation, starting-up, maintenance

and repair should be performed by qualified personnel only. Make absolutely sure that no voltage is applied at all whilst work is being carried out on the geared motor. The motor must be

secured against accidental start up.

Recommended operating procedures

ON variable speed models please note that the mechanical speed variator must not be adjusted whilst the pump is stationary.

DO keep delivery and suction lines as short and direct as possible using a minimum number of swept bends

DO site the pump just above the level of the product to be pumped.

DO keep the pipework at least equal in size to the bore size of the pump. Increase the bore size when fluids have a high

viscosity or high inertia, thus keeping losses to a minimum.

3

Page 4

DO use valves with a straight fluid path.

DO use slow sweeping bends with minimum radius equal to four to five times the tubing diameter.

DO keep the pumphead rollers and track clean.

The self-priming nature of peristaltic pumps means valves are not required. Any valves fitted must cause minimum restriction to flow

in the pumping circuit.

When using Marprene tubing, after the first 30 minutes of running, re-tension the tube in the pumphead by releasing the tube clamp

on the delivery side a little and pulling the tube tight. This is to counteract the normal stretching that occurs with Marprene which can

go unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the Watson-Marlow catalogue is only a guide. If in doubt about the

compatibility of a tube material and the duty fluid, request a tube sample card for immersion trials.

Installation

Pump

• Site the pump on a flat, horizontal, vibration-proof surface allowing a free flow of air around it. Ensure there is 0.5m of straight

tubing before the pumphead inlet and after the pumphead outlets. Close coupled simplex pumps will require bolting down with four

M8 bolts through the gearbox foot mounting holes.

AC Motor

• Ensure that mains voltage/frequency are in accordance with motor nameplate information.

• Secure protective conductor connections.

• If the motor is running in the wrong direction, interchange any two phases.

• Close unused cable entrance holes and the terminal box itself in a dust and watertight manner.

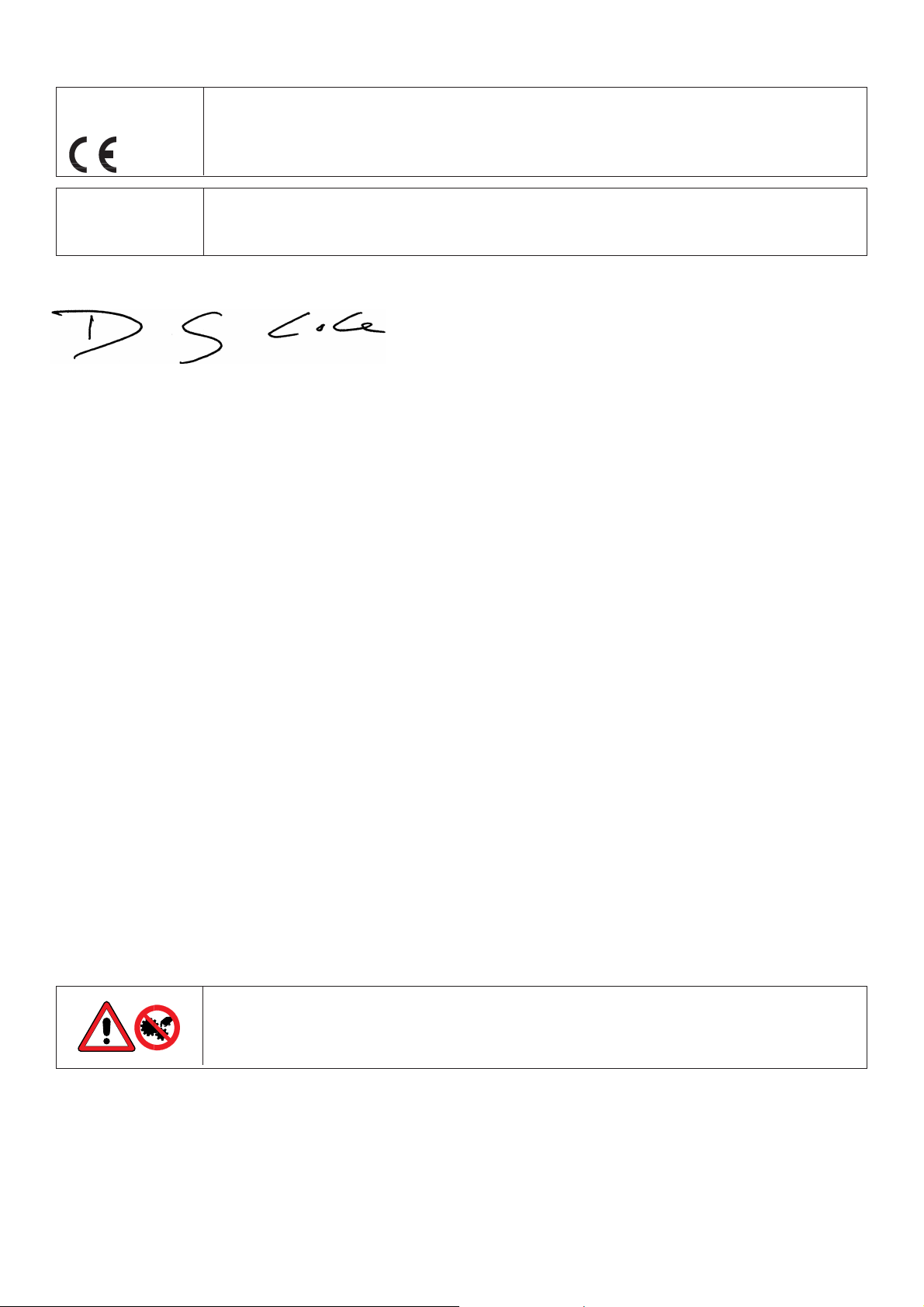

• A current overload relay should be fitted to a contact breaker. Connect the motor in accordance with the wiring diagram which will

be found in the motor terminal box.

• When a thermal protection switch is fitted in the motor, the leads will be found in the motor terminal box. They should be connected

to stop the pump if the switch operates. The switch will open circuit at an over temperature condition. See below for the connection

of the drive motor showing possible ancillary switches and protections.

1 Emergency stop 2 Start 3 Stop

The ancillary switches are rated to 220/240V 1ph 50Hz. The Start contact should have a sprung return which will disengage following

energisation of the coils C1 and C1/1.

Do not under any circumstances wire switches directly across any of the phases of a 3 phase supply. If in

doubt disconnect the pump immediately!

Do not connect ancillary switches to the terminal box of a flame proof motor unless the switch has a

suitable Exd rating for the zone area in which it is to be mounted.

4

Page 5

Start up

Before starting and after prolonged storage of the gear units, remove the plug from the vent screw on top of the casing to avoid

excessive pressure in the gearbox, which may cause leakage at the shaft seals.

Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not servicing is required.

• Check the electrical supply is available at the pump.

• Check that the pump is not stalled by incorrect fitting of tubing.

Always check to ensure that an Exd motor gearbox is suitably rated for the hazardous zone area in which it

is to be mounted. Exd motors should only be installed by Exd qualified personnel.

Any deviation from normal operating conditions (increased power consumption, temperature,

vibrations, noise) or warning signals by monitoring equipment suggest malfunction. Inform the

responsible maintenance personnel at once to prevent the trouble from worsening. If in doubt

disconnect the pump immediately.

AC Motor maintenance

• Remove any dust deposits from the fan cover to avoid overheating.

• Ensure that the bearing cage is packed to about 1/3 with evenly distributed lubricating grease.

• Select the correct lubricating grease from the table in the back of this operating instruction.

Gearbox maintenance - Simplex (single pumphead) units

• Change lubricant every 10,000 working hours or after 2 years.

• Combine a lubricant change with a thorough cleaning of the gear unit.

• Extreme working conditions (high air humidity, aggressive media and large temperature variations) will reduce the interval between

lubricant changing intervals.

• Select the correct lubricating oil from the table in the back of this operating instruction.

Gearbox maintenance - Duplex (twin pumphead) units

The gearbox is filled for life with synthetic lubricant so no maintenance is required.

Belt variator maintenance

• Pulleys are supplied with a permanent grease packing. No refill is necessary. The variator should occasionally be run over its full

range to apply a grease coating to the full track.

• The control spindle should be cleaned and greased occasionally.

Replacement of the V-belt

• Unscrew socket head screws and remove cover with the entire speed control mechanism.

• Remove V-belt

• Wrap new V-belt around open adjustable pulley and let it slip over the spring loaded pulley. The V-belt can be easily attached if the

adjustable pulley is opened. Ensure that the adjustable pulley is opened carefully.

• Replace the removed cover with complete speed control mechanism and re-assemble.

• When positioning the top (adjustable pulley closed) speed limiting lock nut, ensure that the adjustable pulley has a gap of 0.5-

1.0mm to prevent damage to the pulley and motor bearings.

• The V-belt should not be in contact with the bottom of the adjustable pulley.

Air Motors

The air motor is designed for air only. Do not allow corrosive, flammable or explosive gases or

particulate material to enter the motor. Water vapour, oil-based contaminants, or other liquids

must be filtered out. The recommended air pressure should not exceed 7 bar, 100 PSIG.

Always disconnect the air supply before servicing.

5

Page 6

Installation

A muffler is supplied with the air motor, but not installed. Install a moisture trap and filter in the air line ahead of the motor. If

condensates need to be flushed out of the motor, use clean, dry air at low pressure. For efficiency of output and speed control, use

air lines of the same size or next pipe size larger than the intake port of the motor. A 4 way valve which can be connected by piping

to both air ports of the motor will make reversing possible. Use a pressure regulator or a simple shut off valve to obtain desired power

and conserve air to regulate speed and torque.

Lubrication

Use a detergent SAE #10 automotive engine oil. Lubrication is necessary for all moving parts and rust prevention. We recommend

that an automatic air lubricator be installed in the air line just ahead of the motor. The lubricator should be adjusted to feed one drop

of oil for every 25-35 l/sec, 50-75 CFM, of air going through the motor.

• Manual lubrication-Add 10-20 drops of oil every eight hours of operation through the inlet port while the pump is shut down.

• Automatic lubrication- An In-line oiler should be adjusted to feed one drop per minute for high speed or continuous duty use. Do

not overfeed oil as contamination of the exhaust air may occur.

Troubleshooting

Reason Low torque Low speed Won’t run Runs hot Runs good then

slows down

Dirt, Foreign material x x x

Internal rust x x x

Misalignment x x x x x

Insufficient air pressure x x

Air line too small x

Restricted exhaust x x

Poor lubrication x x x x

Jammed machine x x x x

Compressor too small x x

Compressor too far from unit x x

Pump Specifications

Control range See pump specification label

Voltage/frequency See pump specification label

Power consumption See pump specification label

Operating temperature range 5C to 40C

Storage temperature range -40C to 70C

Noise <75dB(A) at 1m

Standards IEC 335-1, EN60529 (IP55)

Machinery Directive 98/37/EC EN60204-1

Low Voltage Directive 73/23/EEC EN61010-1

EMC Directive 89/336/EEC EN50081-1/EN50082-1

Specific drive performance details such as loaded drive speed variation against mains supply voltage fluctuation and drive stability

from a cold start to normal operating temperature are available on request. For further information please contact Watson-Marlow

Technical Support Centre.

501RLC Pumphead

The 501RLC pumphead has two spring-loaded working rollers, which automatically compensate for minor variations in tubing wall

thickness, giving extended tube life. The 501RLC is set during manufacture to accept tubing with wall thicknesses of between 1.6mm

and 2.0mm, and internal diameters of up to 8.0mm. It is equipped with a “tool lockable” guard for increased safety. This should be

locked shut whilst the pump is in use.

The pumphead can be run clockwise for extended tube life, or anti-clockwise to operate against higher pressures.

501RLC Flow rates

Flow rates for the 501RLC were obtained using silicone tubing with the pumphead rotating clockwise, pumping water at 20C with zero

suction and delivery pressures. For critical applications determine flow rates under operating conditions.

6

Page 7

501RLC Installation. Simplex (single pumphead) units and duplex (twin pumphead) units

Isolate motor from mains supply.

Fit the track in any one of three orientations, over the drive shaft and locating boss. Secure the track with the four locating screws.

Ensure the drive shaft is degreased before locating the rotor onto the shaft via the split collet. Rotate the rotor until its guide rollers are

aligned flush to the front edge of the track. Tighten the rotor screw to a torque of 3Nm to prevent the collet slipping during operation.

Swing in the crank handle.

To reposition the track, swing out the crank handle to expose the rotor retaining screw. Turn the screw anticlockwise one turn to release

the collet, and withdraw the rotor from the shaft. Remove the four track locating screws, and pull the track clear. Rotate the track to its

new position and tighten the track locating screws.

Photographs show duplex pumps

501RLC Tube loading simplex (single pumphead) units)

Isolate pump from mains supply. Unlock and open the hinged guard and swing out the rotor crank handle until it locks into position.

Select the length of tubing required, noting that approximately 240mm is required for the track systems.

Fit one end of the tubing into one of the spring loaded clamps, and then, whilst rotating the rotor with the crank handle, feed the tubing

between the rollers and the track, aligning it within the rotor tube guides. The tubing must lie naturally against the track and must not

be twisted or stretched. Note: For units with mechanical variators follow the Duplex tube loading procedure.

Fit the other end of the tubing into the second spring loaded clamp, ensuring that the tubing is not slack in the pumphead, since this can

reduce tube life.

Close the crank handle and shut and lock the guard.

The 501RLC pumphead is fitted with four-position tube clamps, to accommodate various tube diameters, which can be adjusted by

pushing in or pulling out the bars at the top of the upper clamp and the bottom of the lower clamp. Set the clamps so that the minimum

necessary pressure is applied to the tubing.

After the pump has been started, open the delivery clamp for a short time, so that the tube can find its natural length.

7

Page 8

501RLC tube loading. Duplex (twin pumphead) units

Isolate the pump from mains supply. Unlock and open the hinged guard. Swing out the rotor crank handle until it locks into position.

Loosen the rotor screw and give the rotor a sharp tap to release it. Pull the rotor slightly forward from its seated position on the drive

shaft so that the pinned collet clears the drive shaft dog and it can rotate freely . Select the length of tubing required, noting that

approximately 240mm is required for the track systems.

Due to the common gearbox, the two pump rotors run in opposite directions. This means that one rotor

runs in a clockwise direction and the other runs in an anti-clockwise direction. Please consider this and the

effect on the piping arrangements (suction and discharge) during installation.

Fit one end of the tubing into one of the spring loaded clamps, and then, whilst rotating the rotor with the crank handle, feed the tubing

between the rollers and the track, aligning it within the rotor tube guides. The tubing must lie naturally against the track and must not

be twisted or stretched.

Fit the other end of the tubing into the second spring loaded clamp, ensuring that the tubing is not slack in the pumphead, since this can

reduce tube life.

Rotate the rotor until it sits back slightly onto the shaft and guide rollers are aligned flush to the front edge of the track and the pinned

collet is locked to the drive shaft dog. Tighten the rotor screw to a torque of 3Nm to prevent the collet slipping during operation. Clip the

crank handle back into position. Lock the pumphead guard.

After the pump has been started, open the delivery clamp for a short time, so that the tube can find its natural length.

The 501RLC pumphead is fitted with four-position tube clamps, to accommodate various tube diameters, which can be adjusted by

pushing in or pulling out the bars at the top of the upper clamp and the bottom of the lower clamp. Set the clamps so that the minimum

necessary pressure is applied to the tubing.

501RLC Roller adjustment

The 501RLC has a factory set gap of 2.6mm between the rollers and the track and is suitable for tubing having wall thicknesses of

between 1.6 and 2.0mm. Adjustment of the gap will be required if tubing having a wall thickness of less than 1.6mm is required. There

is an adjusting screw on each of the two roller arms, and each of these screws will require adjustment. The correct gap is twice the wall

thickness less twenty percent. Correct adjustment is important: over occlusion will reduce tube life; under occlusion will reduce pumping efficiency.

To change the gap setting, turn each adjusting screw clockwise to increase the gap, or anticlockwise to decrease the gap. A full turn

changes the gap by 0.8mm.To restore the original settings of 2.6mm, turn the adjusting screws until both rollers are just touching the

track, then tighten each screw by three and a quarter turns. The 501RLC2 has a factory set gap of 3.8mm between the wall and the

track and is suitable for tubing having wall thickness of between 2.1 and 2.5mm.

Check moving parts of the rotor from time to time for freedom of movement. Lubricate pivot points and rollers occasionally with Teflon

lubricating oil. For rollers with oilite bushes, use a low viscosity mineral oil in low ambient temperature, or a high viscosity mineral oil for

high ambient temperatures.

8

Page 9

501RLC Pumphead spares

Number Spare Description

1 MN 1200M Lockable guard

2 FN 4502 Lock

3 FN 2341 Hinge screw

4 MN 0266M Hinge grey

5 MNA0114A Tube clamp assembly

6 FN 2332 Screw

7 FN 0422 Screw (x 4)

8 MN 0011T Main roller

9 MNA0143A 501RLC Rotor assembly

9 MNA0511A 501RL2C Rotor assembly

10 SG0001 Spring standard (1.6)

10 SG0002 Spring hard (2.4)

11 MN 0012T Follower roller

9

Page 10

Technical Data

##

#

##

English Tube number Tube bore rpm Pressure(+) Suction Counter-clockwise Clockwise (rpm)

Gearbox lubricant

Mineral Oil Energol GR-XP 220 Mobil-gear 630 Shell Omala Oel 220

EnergolGR-XP 100 Mobil-gear 629 Shell Omala Oel 100

Bartran HV15 Mobil DTE 11M Shell Tellus Oel T 15

501F/RL, 501I/RL, 501TI/RL - 100ml

601F/R, 601I/R, 601TI/R - 250ml

Motor wiring

(165)

(165)

10

Page 11

501RLC, 501RLC2 (ml/min)

Flow rates

# 112 13 14 16 25 17 18

m m 0.5 0.8 1.6 3.2 4.8 6.4 8.0

“ 1/50 1/32 1/16 1/8 3/16 1/4 5/16

60 2.5 7.4 26 110 240 380 600

213 8.9 26 91 400 860 1400 2100

291 12 36 120 540 1200 1900 2900

62 2.6 7.6 26 120 250 390 620

223 9.3 27 95 410 900 1400 2200

281 12 34 120 520 1100 1800 2800

6 - 60 0.25-2.5 0.74-7.4 2.6-26 11-110 24-240 38-380 60-600

21 - 213 0.88-8.9 2.6-26 9.0-91 39-400 85-860 130-1400 210-2100

29 - 291 1.2-12 3.6-36 12-120 54-540 120-1200 180-1900 290-2900

6 - 62 0.25-2.6 0.74-7.6 2.6-26 11-120 24-250 38-390 60-620

22 - 223 0.92-9.3 2.7-27 9.4-95 41-410 89-900 140-1400 220-2200

28 - 281 1.2-12 3.4-34 12-120 52-520 110-1100 180-1800 280-2800

12 - 60 0.50-2.5 1.5-7.4 5.1-26 22-110 48-240 76-380 120-600

43 - 213 1.8-8.9 5.3-26 18-91 80-400 170-860 270-1400 430-2100

13 - 64 0.54-2.7 1.6-7.9 5.6-27 24-120 53-260 83-410 130-640

40 - 201 1.7-8.4 4.9-25 17-86 74-370 160-810 250-1300 400-2000

11

Page 12

501RLC, 1.6mm

Product codes

mm “ # Marprene Bioprene Pumpsil

0.5 1/50 112 902.0005.016 903.0005.016 913.0005.016

0.8 1/32 13 902.0008.016 903.0008.016 913.0008.016

1.6 1/16 14 902.0016.016 903.0016.016 913.0016.016

3.2 1/8 16 902.0032.016 903.0032.016 913.0032.016

4.8 3/16 25 902.0048.016 903.0048.016 913.0048.016

6.4 1/4 17 902.0064.016 903.0064.016 913.0064.016

8.0 5/16 18 902.0080.016 903.0080.016 913.0080.016

mm “ # Tygon Fluorel Neoprene

0.8 1/32 13 920.0008.016

1.6 1/16 14 950.0016.016 970.0016.016 920.0016.016

3.2 1/8 16 950.0032.016 970.0032.016 920.0032.016

4.8 3/16 25 950.0048.016 970.0048.016 920.0048.016

6.4 1/4 17 950.0064.016 970.0064.016 920.0064.016

8.0 5/16 18 950.0080.016 970.0080.016 920.0080.016

501RL2C, 2.4mm

Product codes

mm “ # Marprene Bioprene Pumpsil

0.5 1/50 913.A005.024

0.8 1/32 913.A008.024

1.6 1/16 119 902.0016.024 903.0016.024 913.A016.024

3.2 1/8 120 902.0032.024 903.0032.024 913.A032.024

4.8 3/16 15 902.0048.024 903.0048.024 913.A048.024

6.4 1/4 24 902.0064.024 903.0064.024 913.A064.024

8.0 5/16 121 902.0080.024 903.0080.024 913.A080.024

mm “ # Chem-Sure Sta-Pure

1.6 1/16 119 965.0016.024 960.0016.024

3.2 1/8 120 965.0032.024 960.0032.024

4.8 3/16 15 965.0048.024 960.0048.024

6.4 1/4 24 965.0064.024 960.0064.024

8.0 5/16 121 965.0080.024 960.0080.024

Note: 2.4mm wall Chem-Sure and Sta-Pure tubing are supplied in 355mm lengths

12

Page 13

501RLC

Flow rates

13

Page 14

501F/R

501DF/R

62rpm model 223 rpm model

501FX/RL

250

220

230

345

75

85

340

14

Page 15

Switch

Watson-Marlow, Bioprene, Pumpsil and Marprene are trademarks of Watson-Marlow Limited.

Tygon is a trademark of the Saint-Gobain Performance Plastics Company. Fluorel is a trademark of 3M.

Sta-Pure and Chem-Sure are trademarks of W.L Gore and Associates.

Warning, These products are not designed for use in, and should not be used for patient connected applications.

The information contained in this document is believed to be correct but Watson-Marlow Limited accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

15

Page 16

16

Page 17

Product use and decontamination declaration

In compliance with the UK Health & Safety at Work Act and the Control of Substances Hazardous to Health

Regulations you, the user are required to declare the substances which have been in contact with the product(s) you

are returning to Watson-Marlow or any of its subsidiaries or distributors. Failure to do so will cause delays in servicing

the product. Therefore, please complete this form to ensure that we have the information before receipt of the

product(s) being returned. A FURTHER COPY MUST BE ATTACHED TO THE OUTSIDE OF THE PACKAGING

CONTAINING THE PRODUCT(S). You, the user, are responsible for cleaning and decontaminating the

product(s) before returning them.

Please complete a separate Decontamination Certificate for each pump returned.

RGA No: .......................

1 Company

Address ........................................ Postcode ........................................

Telephone ........................................ Fax Number ....................................

3.4 Cleaning fluid to be used if residue of chemical is found during

2 Product servicing;

2.1 Serial Number ................................

(a)

2.2 Has the Product been used? (b) ……………………………………………

YES NO

If yes, please complete all the following

Sections

If no, please complete Section

5 only

3 Details of substances pumped 4 I hereby confirm that the only substances(s) that the equipment

specified has pumped or come into contact with are those named, that the

information given is correct, and the carrier has been informed if the

3.1 Chemical names: consignment is of a hazardous nature.

(a) ....................................................... 5 Signed ……………………………………………….. ...........

(b) ....................................................... Name …………………………………………………

(c) ....................................................... Position ……………………………………………….

(d) ....................................................... Date …………………………………………………..

3.2 Precautions to be taken in

handling these substances:

(a) ........................................................

(b) .......................................................................................................

(c) ........................................................

(d) ........................................................

(c) ……………………………………………

(d) ……………………………………………

Note: To assist us in our servicing

please describe any fault condition you

have witnessed.

3.3 Action to be taken in the event of human contact:

(a) ………………………………………………………………….

(b) ………………………………………………………………….

(c) ………….………………………………………………………

(d) ………….………………………………………………………

Watson-Marlow Limited Falmouth Cornwall TR11 4RU England Tel: 01326 370370 Fax: 01326 376009

17

Loading...

Loading...