WAGNER PRO DUTY POWER PAINTER Owner's Manual

i

PRO DUTY POWER PAINTER'"

OWNER'S MANUAL • Read this manual for complete instructions

MANUEL DE L'UTILISATEUR • Lire ce manuel contient les instructions completes (_:

MANUAL DEL PROPRIETARIO • Lea este manual para obtener instrucciones corn

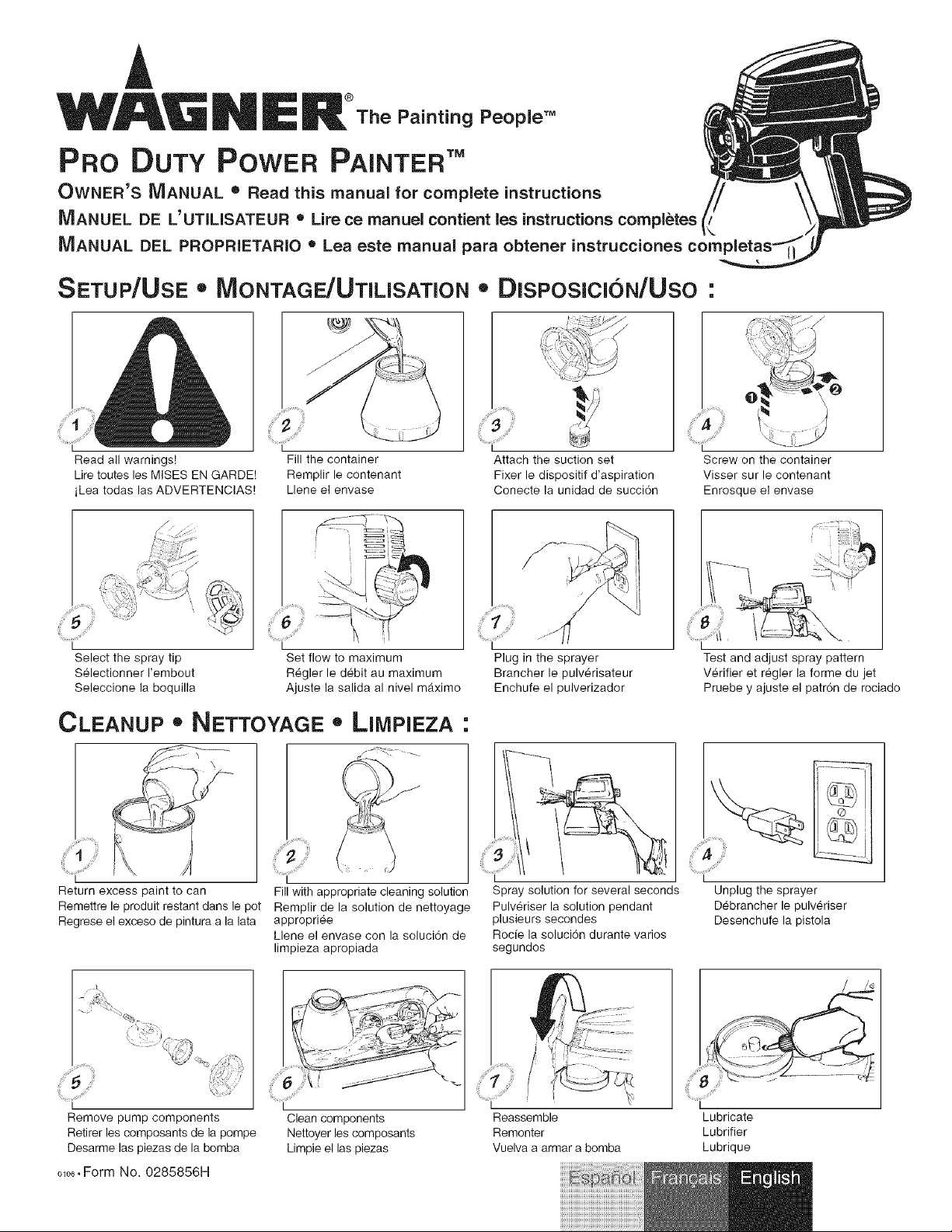

SETUP/USE " MONTAGE/UTILISATION " DISPOSICI6N/USO :

I

Read all warnings!

Lire toutes les MISES EN GARDE!

iLea todas las ADVERTENCIAS!

I

Select the spray tip

S_lectionner rembout

Seleccione la boquilla

Fill the container

Remplir le contenant

Llene el envase

i

Set flow to maximum

Regler le debit au maximum

Ajuste la salida al nivel mdtximo

CLEANUP o NETTOYAGE o LllVlPIEZA :

\

I

Return

excess paint to can

Remettre le produit restant dans le pot Remplir de la solution de nettoyage

Regrese el exceso de pintura a la lata appropri_e

I

Fill with appropriate cleaning solution

Llene el envase con la soluci6n de

limpieza apropiada

I

Attach the suction set

Fixer le dispositif d'aspiration

Conecte la unidad de succi6n

¸¸¸--4(

Plug in the sprayer

Brancher le pulv#risateur

Enchufe el pulverizador

Spray solution for several seconds

Pulv_riser la solution pendant

plusieurs secondes

Rocie la soluci6n durante varios

segundos

Screw on the container

Visser sur le contenant

Enrosque el envase

! iiiiii

I

Test and adjust spray pattern

V_rifier et regler la forme du jet

Pruebe y ajuste el patr6n de rociado

Unplug the sprayer

Debrancher le pulv_riser

Desenchufe la pistola

I

Remove pump components

Retirer les composants de la pompe

Desarme las piezas de la bomba

o_o_oForm No. 0285856H

I

Clean components

Nettoyer les composants

Limpie el las piezas

Reassemble

Remonter

Vuelva a armar a bomba

I

Lubricate

Lubrifier

Lubrique

SAFETY

[IkWARNING 1

HAZARD: INJECTmON iNJURY ° A high pressure stream of

DO NOT TREAT AN mNJECTmON iNJURY AS A SmMPLE CUT!

injection can lead to amputation. See a physician immediately.

NOTE TO PHYSICIAN:

injection into the skin is a traumatic injury, it is important to

treat the injury surgically as soon as possible. DO NOT delay

treatment to research toxicity. Toxicity is a concern with some

coatings injected directly into the blood stream. Consultation

with a plastic surgeon or reconstructive hand surgeon may be

advisabme.

PREVENTION:

• NEVER aim the gun at any part of the body•

• NEVER allow any part of the body to come in contact with the

• NEVER put your hand in front of the gun. Gloves will not

• Always unplug the spray gun before servicing, cleaning tip

• ALWAYS have the tip guard in place while spraying• The tip

HAZARD: EXPLOSmON OR FIRE ° Solvent and paint fumes can

PREVENTION:

• Exhaust and fresh air introduction must be provided to keep the

• Avoid all ignition sources such as static electricity sparks, open

HAZARD: EXPLOSION DUE TO INCOMPATIBLE MATERmALS -

PREVENTmON:

• Do not use bleach.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

PREVENTION

• Use a respirator or mask whenever there is a chance that

HAZARD: GENERAL - May cause property damage or severe

PREVENTION:

• Read all instructions and safety precautions for equipment and

paint produced by this equipment can pierce the

skin and underlying tissues, leading to serious

injury and possible amputation.

fluid stream.

provide protection against an injection injury.

guard, changing tips, or leaving unattended.

guard provides some protection against injection injuries but is

mainly a warning device.

expmode or ignite, causing property damage and/or

severe injury.

air within the spray area free from accumulation of flammable

vapors.

flames, pilot lights, hot objects, cigarettes, and sparks from

connecting and disconnecting power cords or working light

switches.

Fire extinguishing equipment must be present and in good

working order.

Follow the material and solvent manufacturer's safety

precautions and warnings.

May cause property damage or severe injury.

Do not use halogenated hydrocarbon solvents such as

methylene chloride and 1,1,1 - trichloroethane. They are not

compatible with aluminum and may cause an explosion. If you

are unsure of a material's compatibility with aluminum, contact

your coating supplier.

insecticides, and other materials may be harmful if

inhaled, causing severe nausea, fainting, or

poisoning.

vapors may be inhaled. Read all instructions with the spray

mater!a! and mask to ensure that it will provide the necessary

protection against the inhalation of harmful vapors.

injury.

spray material before operating any equipment.

Comply with all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

Keep sprayer out of the reach of children.

Hearing protection is recommended for extended use=

Use eye protection to keep particles out of eyes=

HAZARD: ELECTRmC SHOCK HAZARD - May cause severe

PREVENTION:

• Keep electrical cord plug and spray gun trigger free from paint

injury.

and other liquids. Never hold cord at plug connections to

support cord= Failure to observe may result in an electrical

shock=

CAUTION i

Use only a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. For

lengths less than 50 feet, use a No. 18 AWG extension cord.

For lengths more than 50 feet, use a No. 14 or No. 16 AWG

extension cord. An undersized cord will cause a drop in Hne

voltage resulting in loss of power and overheating.

Wagner Spray Tech accessory extension cords recommended:

P/N 0090241 20 foot extension cord.

P/N 0090242 35 foot extension cord.

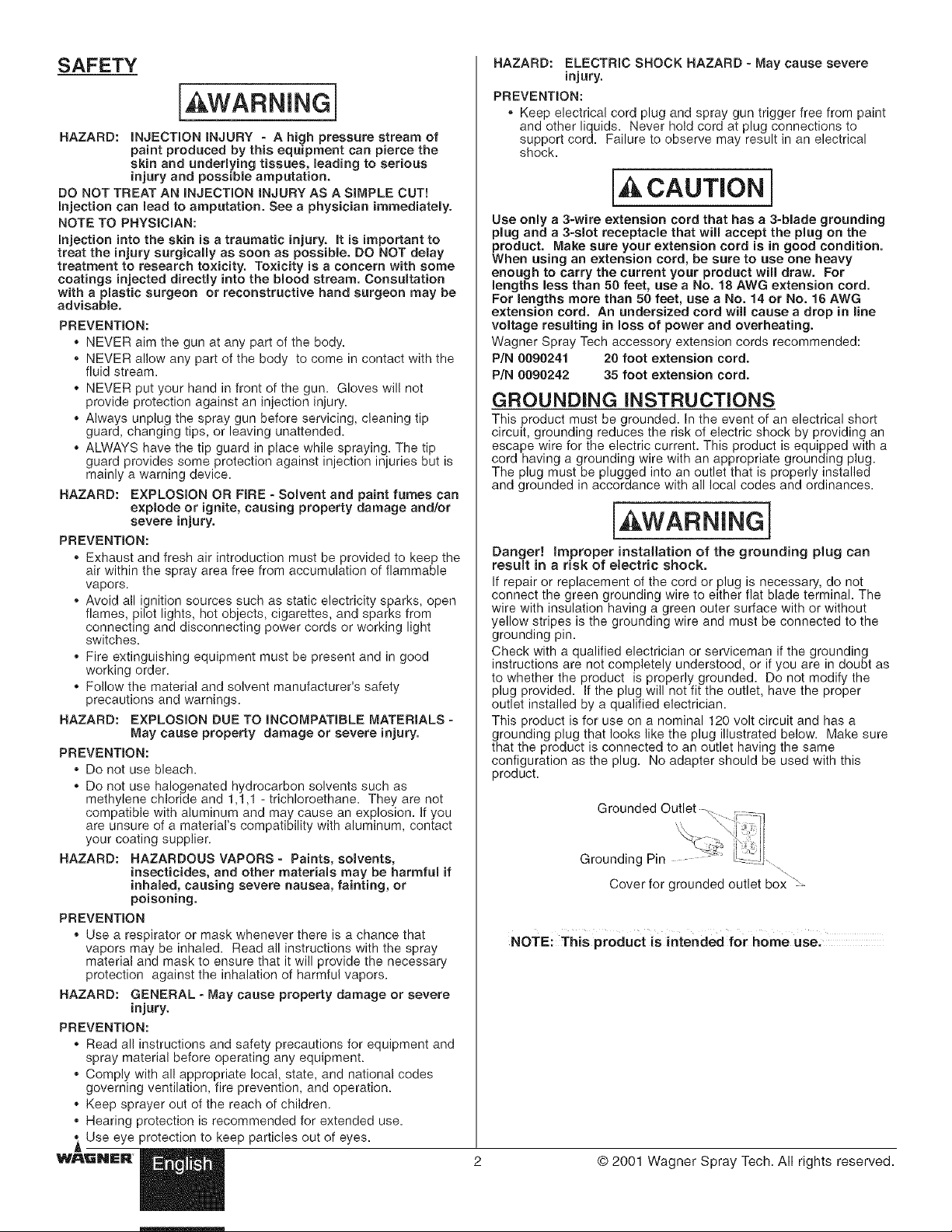

GROUNDING iNSTRUCTiONS

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

[ wAR.t.GI

Danger! improper installation of the grounding plug can

result in a risk of electric shock,

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal. The

wire with insulation having a green outer surface with or without

yellow stripes is the grounding wire and must be connected to the

grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not fit the outlet, have the proper

outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make sure

that the product is connected to an outlet having the same

configuration as the plug. No adapter should be used with this

product.

Grounded Out et _

Grounding Pin _ ........

Cover for grounded outlet box ....

NOTE: This product is intended for home use.

© 2001 Wagner Spray Tech. All rights reserved.

, i!

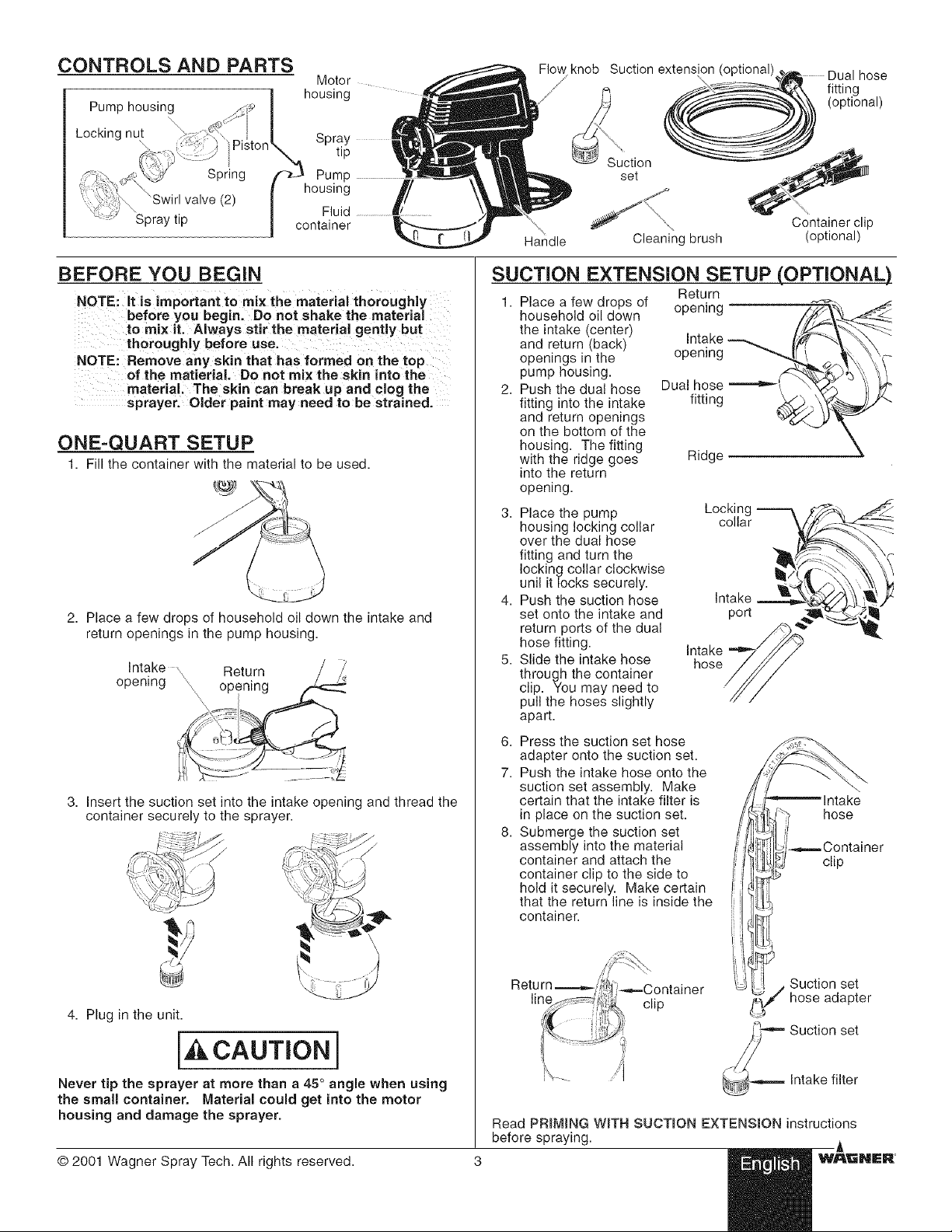

CONTROLS AND PARTS

Pump housing

Locking nut

Spring /_ Pump

\

Spray tip

(2) | Fluid

Motor

housing

Spray

housing

container

Flow knob Suction extension (optional)

tip

Handle Cleaning brush

Suction

set

Dual hose

fitting

(optional)

Container clip

(optional)

BEFORE YOU BEGIN

NOTE: Itis important tomix the material thoroughly

before you begin. Do not shake the material

to mix it. Always stir the matedal gently but

thoroughly before use.

NOTE: Remove any skin that has formed on the top

of the matietial. Do not mix the skin into the

material. The skin can break up and clog the

sprayer, older paint may need to be strained.

ONE=QUART SETUP

1. Fill the container with the material to be used.

2. Place a few drops of household oil down the intake and

return openings in the pump housing.

Intake ,, Return

opening ",,

3. Insert the suction set into the intake opening and thread the

container securely to the sprayer.

SUCTION EXTENSION SETUP (OPTIONAL)

Place a few drops of

household oil down

the intake (center)

and return (back)

openings in the

pump housing.

2,

Push the dual hose

fitting into the intake

and return openings

on the bottom of the

housing. The fitting

with the ridge goes

into the return

opening.

3. Place the pump Locking

housing locking collar collar

over the dual hose

fitting and turn the

locking collar clockwise

unil it locks securely.

4. Push the suction hose Intake

set onto the intake and port

return ports of the dual

hose fitting. Intake

5. Slide the intake hose hose

through the container

clip. You may need to

pull the hoses slightly

apart.

6. Press the suction set hose

adapter onto the suction set.

7. Push the intake hose onto the

suction set assembly. Make

certain that the intake filter is

in place on the suction set.

8. Submerge the suction set

assembly into the material

container and attach the

container clip to the side to

hold it securely. Make certain

that the return line is inside the

container.

Return

opening

Intake _

opening

fitting

Dual hose ======_i

Ridge

"""'--'Intake

['l hose

4. Plug in the unit.

Never tip the sprayer at more than a 45° angle when using

the small container. Material could get into the motor

housing and damage the sprayer.

© 2001 Wagner Spray Tech. All rights reserved.

iiiiiii

Suction set

Intake filter

Read PRIMING WiTH SUCTION EXTENSION instructions

before spraying.

3 WA_NER"

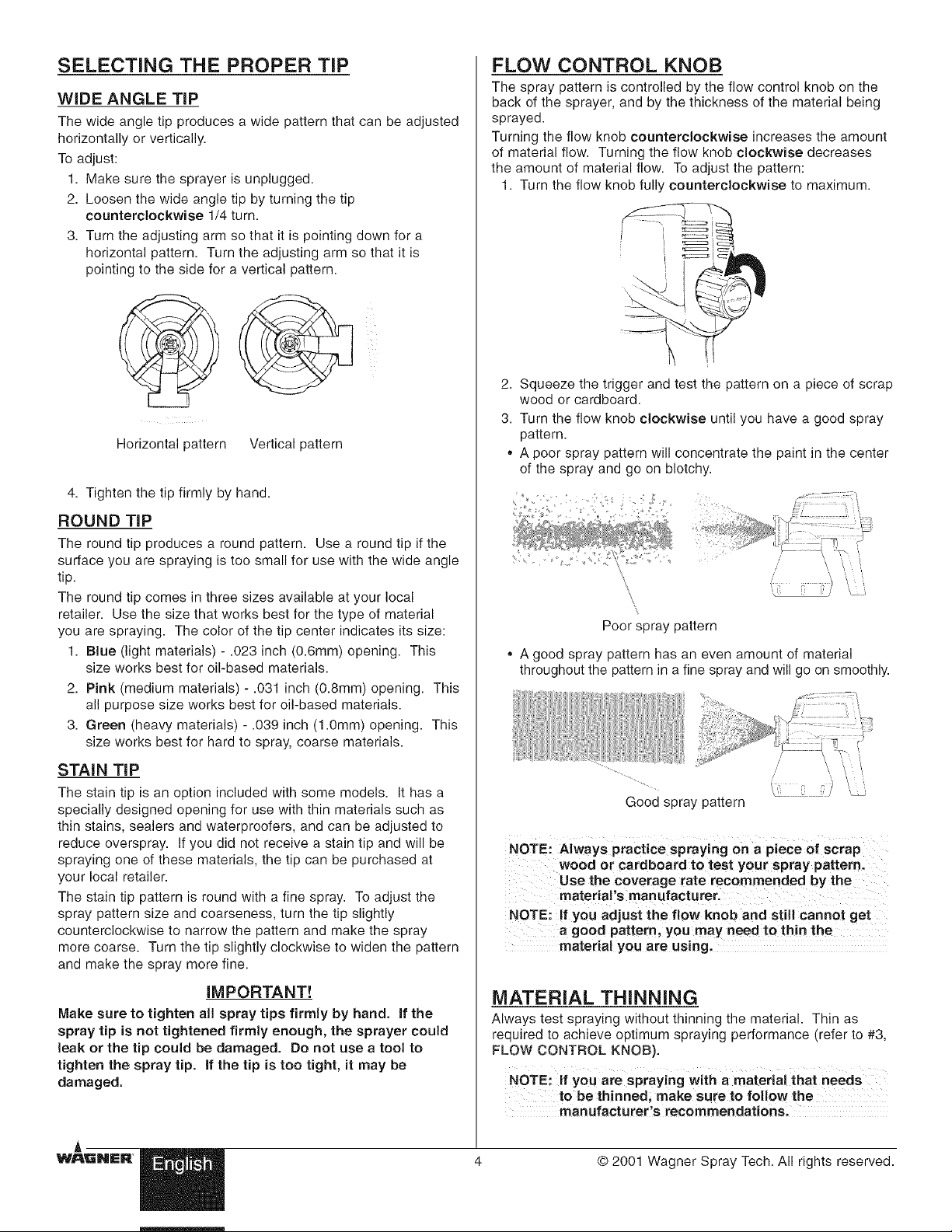

SELECTING THE PROPER TiP

WiDE ANGLE TiP

The wide angle tip produces a wide pattern that can be adjusted

horizontally or vertically.

To adjust:

1. Make sure the sprayer is unplugged•

2. Loosen the wide angle tip by turning the tip

counterclockwise 1/4 turn.

3. Turn the adjusting arm so that it is pointing down for a

horizontal pattern• Turn the adjusting arm so that it is

pointing to the side for a vertical pattern•

Horizontal pattern Vertical pattern

4. Tighten the tip firmly by hand•

ROUND TIP

The round tip produces a round pattern• Use a round tip if the

surface you are spraying is too small for use with the wide angle

tip.

The round tip comes in three sizes available at your local

retailer• Use the size that works best for the type of material

you are spraying• The color of the tip center indicates its size:

1. Blue (light materials) - .023 inch (0.6mm) opening• This

size works best for oil-based materials•

2. Pink (medium materials) - .031 inch (0.8mm) opening• This

all purpose size works best for oil-based materials•

3. Green (heaw materials) - .039 inch (1.0mm) opening• This

size works best for hard to spray, coarse materials•

STAIN TiP

The stain tip is an option included with some models• It has a

specially designed opening for use with thin materials such as

thin stains, sealers and waterproofers, and can be adjusted to

reduce overspray. If you did not receive a stain tip and will be

spraying one of these materials, the tip can be purchased at

your local retailer•

The stain tip pattern is round with a fine spray• To adjust the

spray pattern size and coarseness, turn the tip slightly

counterclockwise to narrow the pattern and make the spray

more coarse• Turn the tip slightly clockwise to widen the pattern

and make the spray more fine.

iMPORTANT!

Make sure to tighten all spray tips firmly by hand. if the

spray tip is not tightened firmly enough, the sprayer could

leak or the tip could be damaged. Do not use a too! to

tighten the spray tip. If the tip is too tight, it may be

damaged.

FLOW CONTROL KNOB

The spray pattern is controlled by the flow control knob on the

back of the sprayer, and by the thickness of the material being

sprayed•

Turning the flow knob counterclockwise increases the amount

of material flow. Turning the flow knob clockwise decreases

the amount of material flow. To adjust the pattern:

1. Turn the flow knob fully counterclockwise to maximum•

2. Squeeze the trigger and test the pattern on a piece of scrap

wood or cardboard•

3. Turn the flow knob clockwise until you have a good spray

pattern•

A poor spray pattern will concentrate the paint in the center

of the spray and go on blotchy•

_ _ _ ,,2 •

II

\

..' \

\

\

Poor spray pattern

A good spray pattern has an even amount of material

throughout the pattern in a fine spray and will go on smoothly•

Good spray pattern

NOTE: AlwaYs practice spraying on a piece of scrap

wood or cardboard to test Y0Ur spray pattern.

Use the coverage rate recommended by the

matet!a!'s man ufactu rer.

NOTE: if you adjust the flow knob and still cannot get

a good pattern, you may need to thin the

mater!a! you are using,

MATERIAL THINNING

Always test spraying without thinning the material• Thin as

required to achieve optimum spraying performance (refer to #3,

FLOW CONTROL KNOB).

NOTE: If you are spraying with a material that needs

to be thinnedi make sure to follow the

manufacturer,s recommendations,

A

WA_INllER

© 2001 Wagner Spray Tech. All rights reserved•

Loading...

Loading...