Foreword

G700B

OPERATOR’S MANUAL

This Operator’s Manual is intended as a guide for the correct

use and maintenance of the machine. Therefore, study it

carefully before starting and operating the machine, or before carrying out any preventive maintenance.

Keep the manual in the manual box in the cab so that it is always at hand. Replace it immediately if it is lost.

NOTE: The manual describes the applications for which

the machine is primarily intended, and is written to apply for all markets. We therefore ask you to disregard the

sections that are not applicable to your machine or to

the work for which you use your machine.

Many hours are spent on design and production to make a

machine that is as efficient and safe as possible. The accidents that occur in spite of this are mostly caused by the human factor. A safety-conscious person and a well maintained

machine make a safe, efficient and profitable combination.

Therefore, read the safety instructions and follow them.

Every new Volvo Motor Grader is shipped with a CIMA Grad-

er Safety Manual published by the Construction Industry

Manufacturers’ Association. Read it carefully before operating or servicing your grader.

We continually strive to improve our products and to make

them more efficient through changes to their design. We retain the right to make these changes without committing ourselves to introducing these improvements on products that

have already been delivered.

We also retain the right to change data and equipment, as

well as instructions for service and maintenance, without prior notice.

Contents

Presentation

Instrument panels

Controls

Operating instructions

Operating techniques

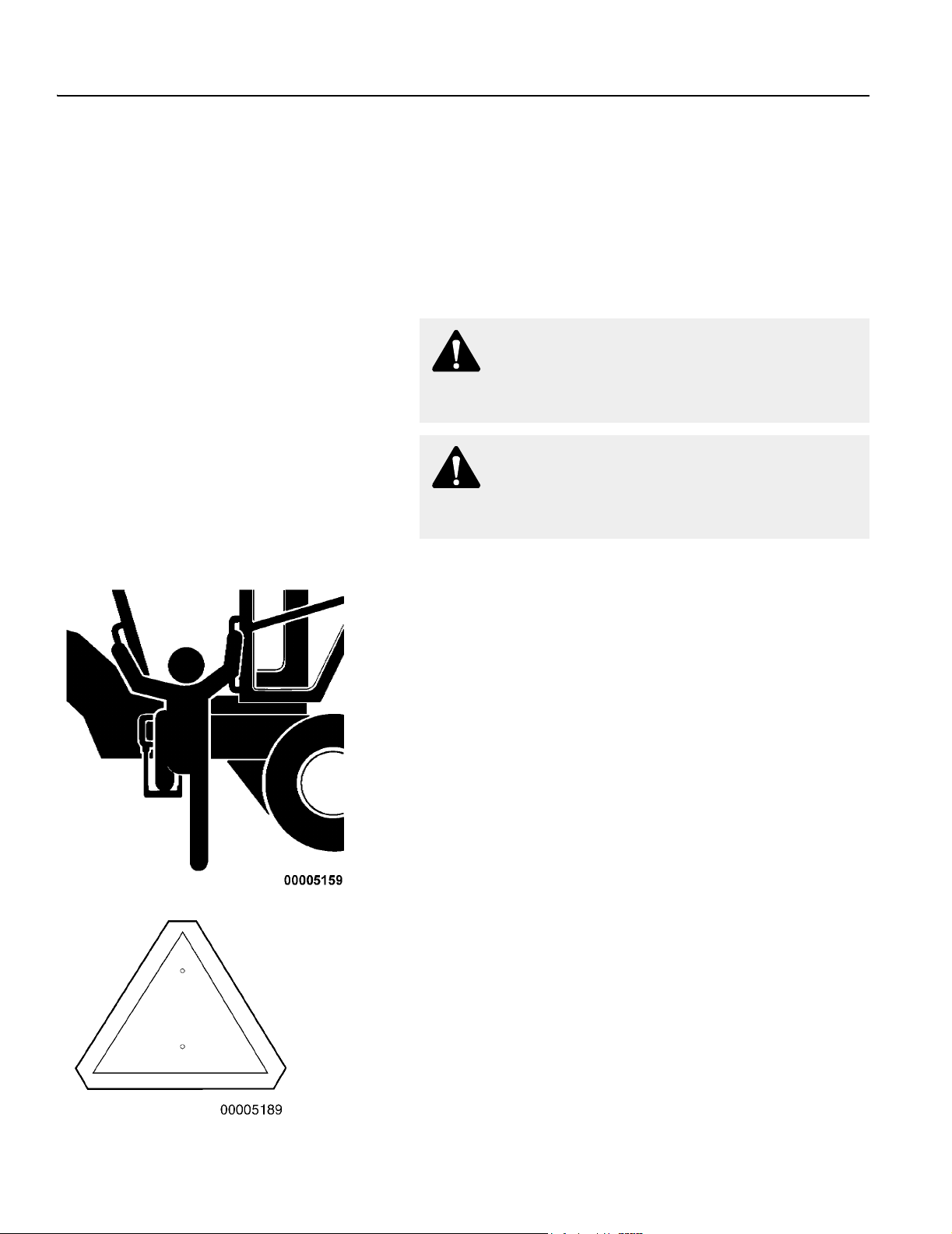

SAFETY REGULATIONS

It is the operator’s obligation to know and follow the applicable national and local safety regulations. The safety instructions in this manual only apply to cases when there are no

national or local regulations.

WARNING!

The symbol above appears at various points in the

manual together with warning text. It means – Warning,

be alert! Your safety is involved. It is the obligation of

the operator to make sure that all warning decals are in

place on the machine and that they are readable.

Accidents may otherwise occur.

Know the capacity and limits of your machine!

This manual applies to Serial Number 35000 and up.

Safety when servicing

Service and maintenance

Specifications

Alphabetical index

Ref. No.: 21 1 434 4006

Printed in Canada

Foreword

2

State the PIN number of the machine (serial number) below. Always state this information when contacting the manufacturer and when ordering spare parts. It is also a good idea to note the serial number of the components.

Manufacturer Volvo Motor Graders Limited

160 Maitland Road,

Goderich, Ontario, Canada N7A 3Y6

The PIN number of the

machine (serial number)

Engine

Transmission

Final drive

Foreword

Operation and maintenance of the machine 3

Operation and maintenance of the machine

Volvo Motor Graders Limited is only responsible if:

n the machine has been used in a correct way and has been maintained

in accordance with the instructions in the Operator’s Manual and

Service Manual.

n prescribed service and prescribed inspections have been carried out

at the stated points of time.

n the recommended lubricants according to the manual have been

used.

n no security seals have been broken other than by authorized persons.

n all modifications and repairs have been carried out and methods have

been used in the way prescribed by Volvo Motor Graders Limited.

n only genuine Volvo spare parts/accessories, or genuine spare parts/

accessories that meet Volvo’s requirements, have been used.

WARNING!

The operator of a motor grader must have sufficient knowledge

and instructions before he/she operates the machine. Untrained

operators may cause severe injuries or even fatalities. Therefore,

it is important that you read and follow the instructions of this

Operator’s Manual. Never use a motor grader that has no

Operator’s Manual available. Learn and understand the safety

signs and symbols on the machine and the operator instructions

before you begin to use the machine.

Foreword

4 Communication equipment, installation

Communication equipment,

installation

IMPORTANT!

All installations of electronic communication equipment must be

performed by trained professionals and in accordance with Volvo

Construction Equipment instructions applicable to the specified

machine.

Protection from electromagnetic interference

The Volvo Motor Grader is equipped with multiple ECUs that were tested

for Electro Magnetic Compliance. This means that the ECUs are immune

to electromagnetic interference at the levels prescribed in the international standards. However, if improper installation and use of communication

equipment exceed the limits of these components, the machine may malfunction. Therefore, it is very important that all non-approved electronic

accessories, such as communication equipment, be tested before the

machine is put into service.

Mobile telephones

To obtain the best functionality, mobile telephones should be permanently installed in the electrical system of the grader with a permanently fixed

antenna on the cab, installed as advised by the manufacturer.

If a portable mobile telephone is used, note that it can constantly transmit

information to its base station, even when the telephone is not used. For

this reason, it should not be located beside electronic equipment in the

machine, such as directly on a control panel, etc.

Guidelines

The following guidelines must be followed during installation:

– The antenna placement must be chosen to give good adaptation to

the surroundings.

– The antenna cable must be of the coaxial type. Be careful to ensure

the cable is undamaged, that the sheath and braid are not split at the

ends, and the braid covers the connector ferrules and has good galvanic contact with them.

– The mating surface between the antenna mounting bracket and the

bodywork must have clean metal surfaces, with all dirt and oxide removed. Protect the mating surfaces against corrosion after installation

to maintain good galvanic contact.

– Remember to separate interfering and interfered cables physically. In-

terfering cables consist of the communication equipment’s supply cables and antenna cable. Interfered cables are those which are

connected to electronic devices in the machine. Install the cables as

close as possible to grounded sheet metal surfaces, since the metal

has a shielding effect.

Contents

Contents

Foreword.................................................................1

Operation and maintenance of the machine ......................3

Communication equipment, installation..............................4

Contents..................................................................5

Presentation ...........................................................7

General...............................................................................7

CE Marking and Declaration of Conformity ......................10

Plates and decals .............................................................12

Service .............................................................................16

General Information..........................................................17

Instrument panels ................................................21

General.............................................................................21

Center instrument panel ...................................................22

Pedestal instrument panel................................................28

Side console instrument panel .........................................45

All Wheel Drive control panel ...........................................52

Other ................................................................................54

5

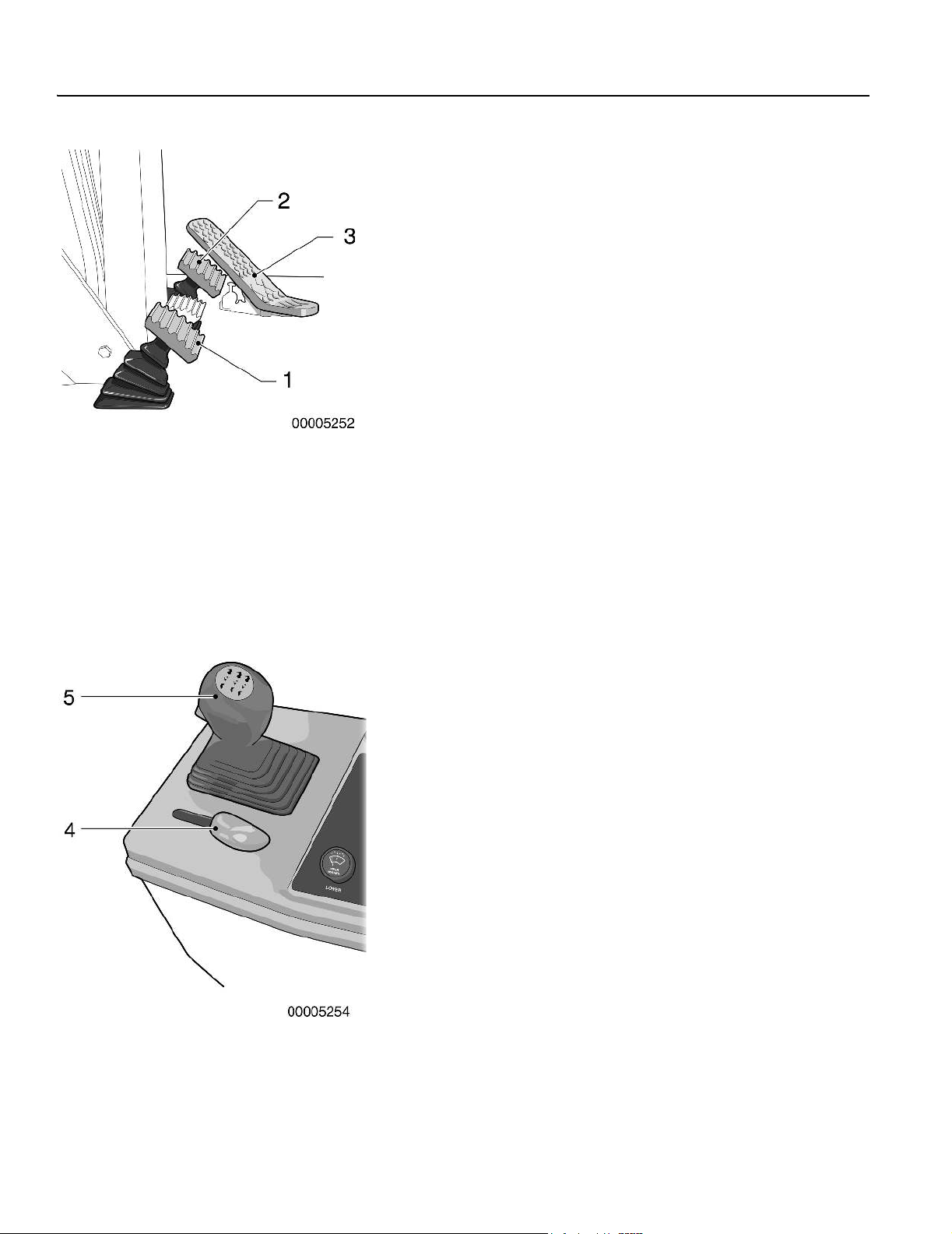

Controls ................................................................55

Operator controls..............................................................55

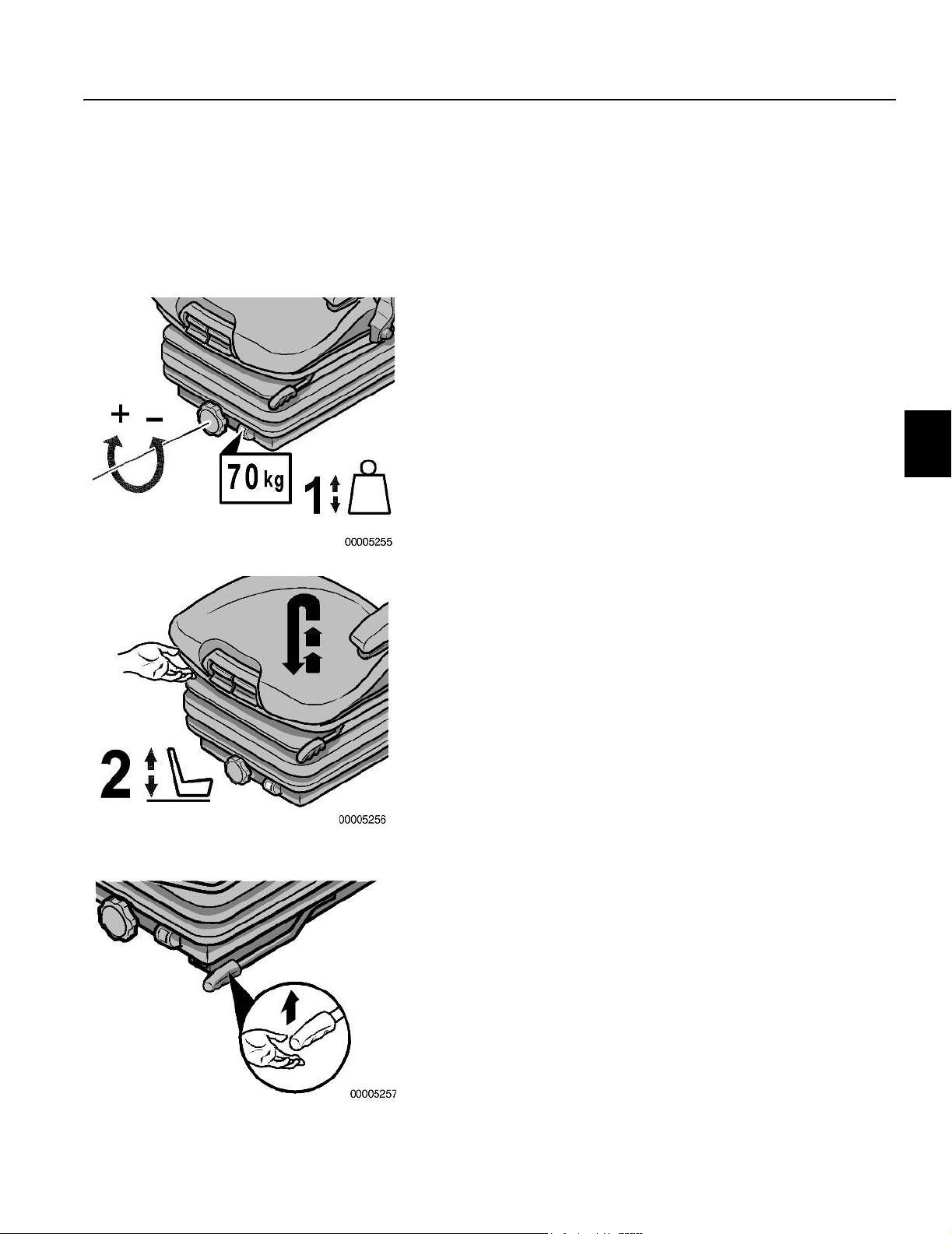

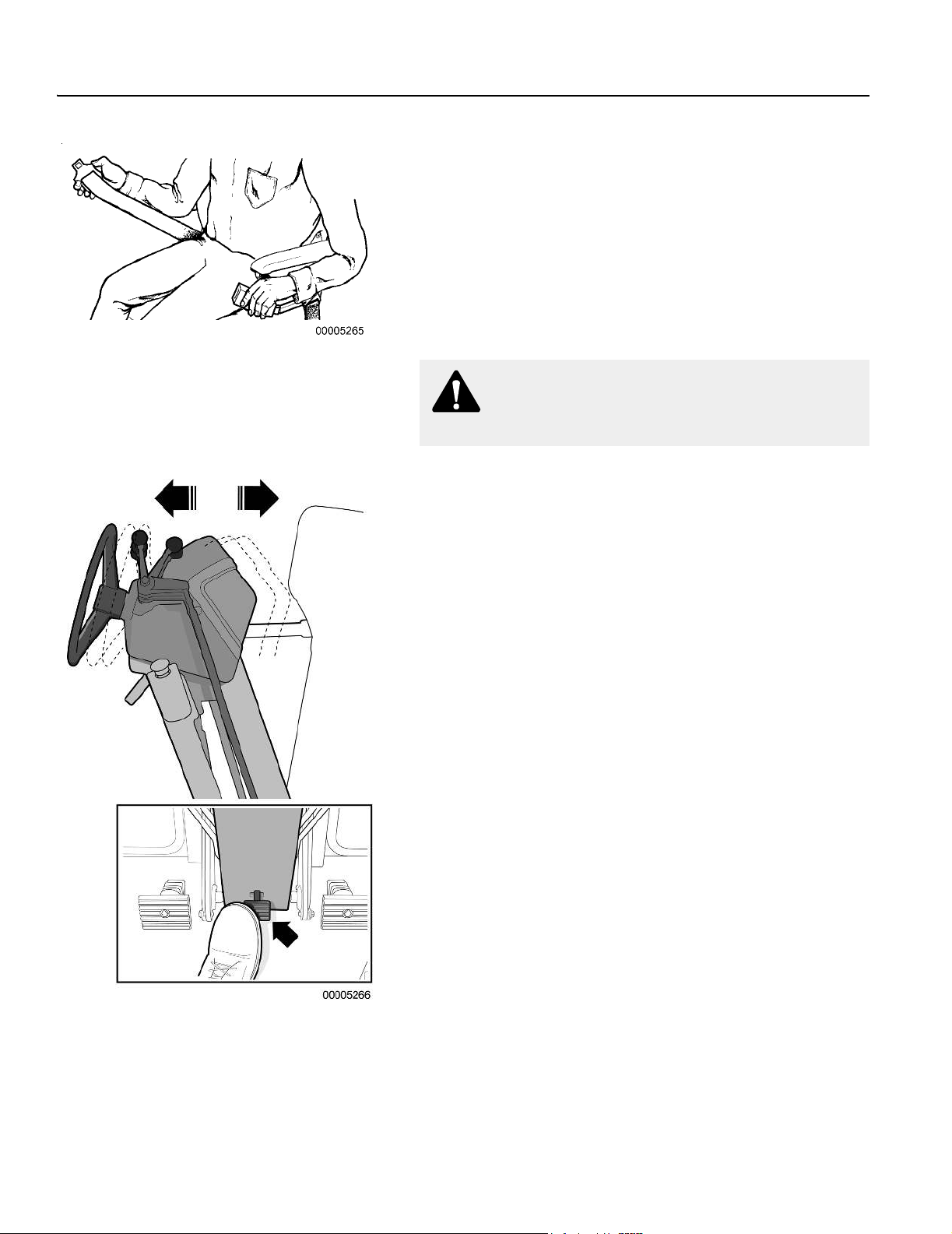

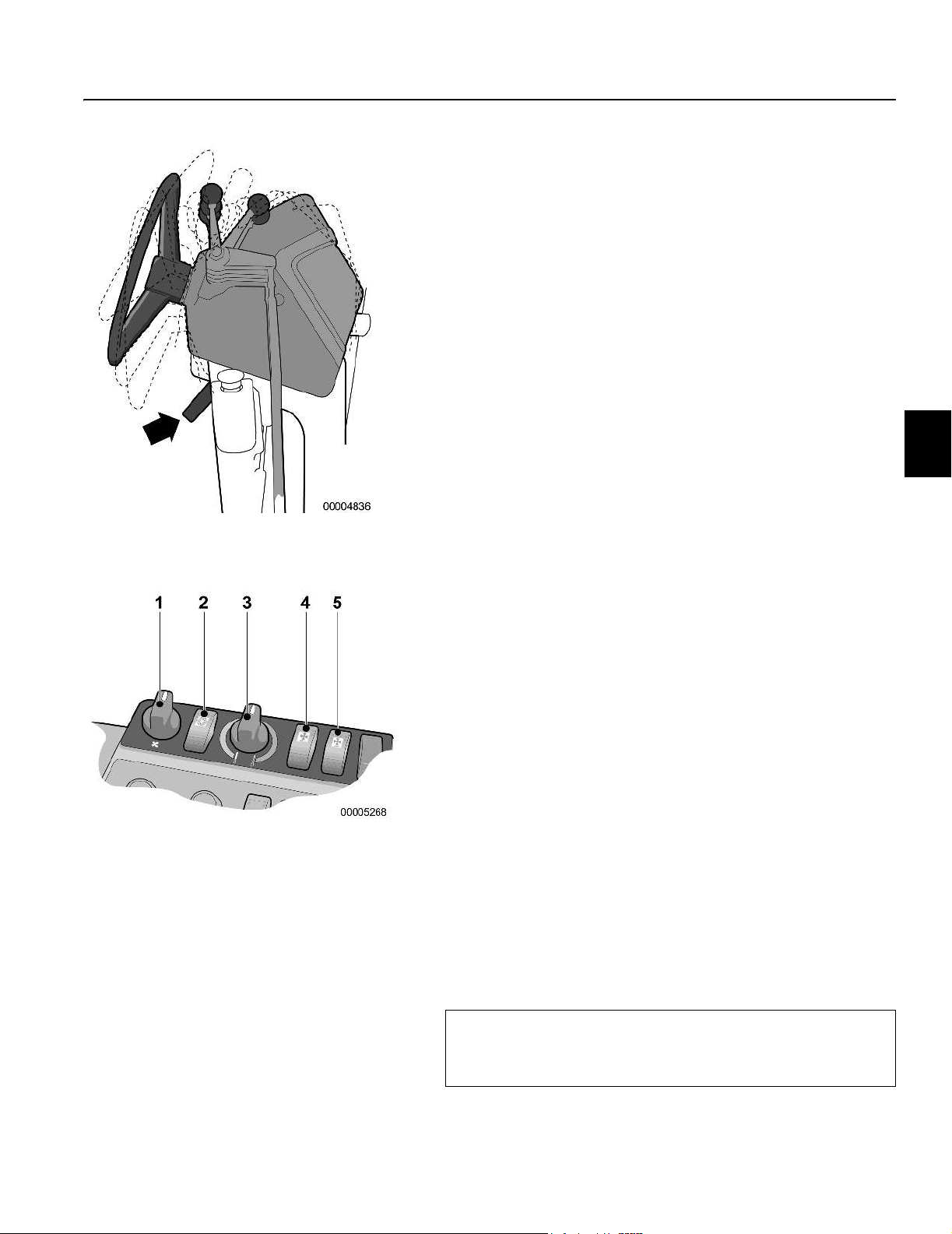

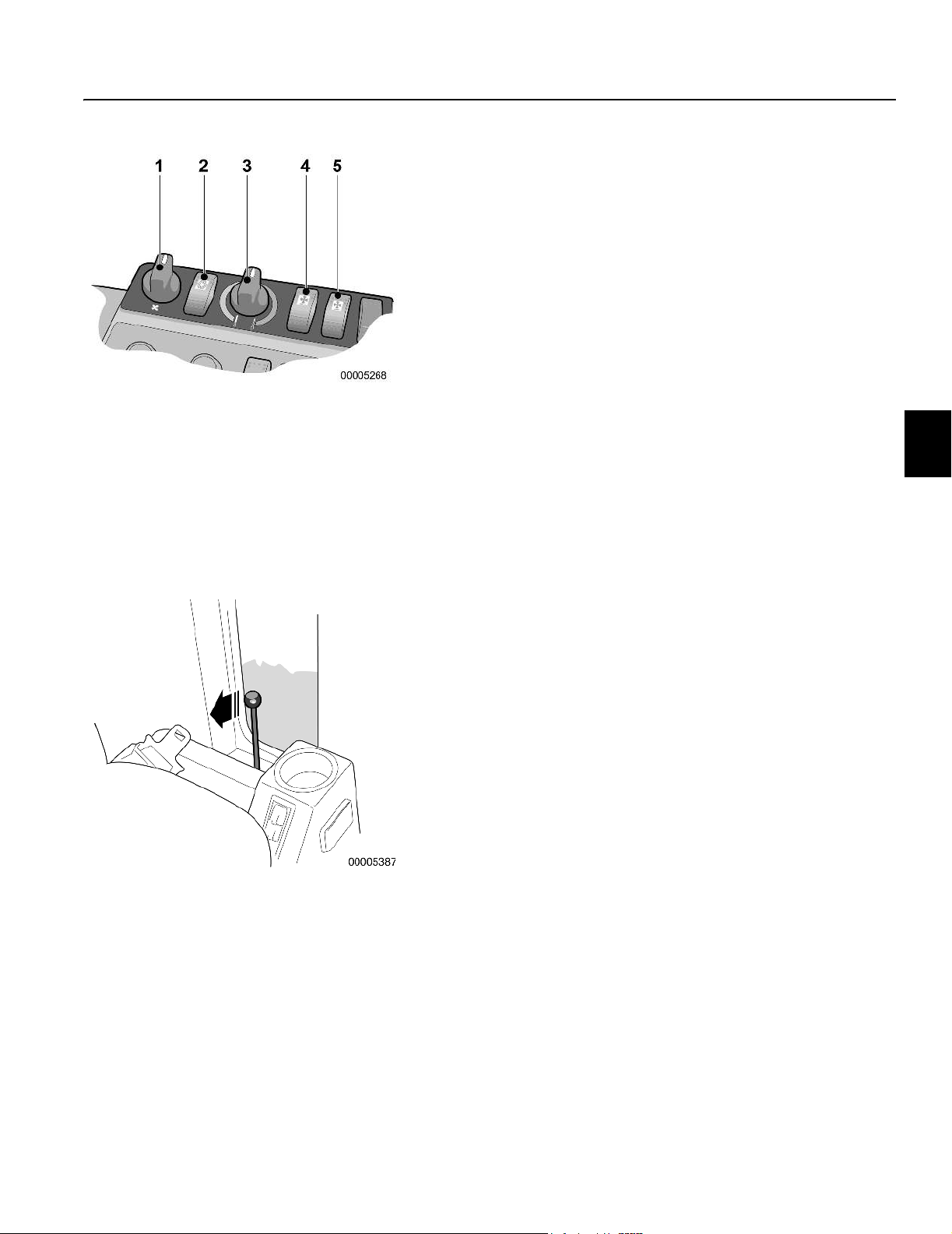

Operator comfort ..............................................................57

Hydraulic controls .............................................................64

Other controls ...................................................................71

Operating instructions.........................................73

Introduction.......................................................................73

Running-in period .............................................................74

Safety and responsibility ..................................................75

Before operating ...............................................................80

Ignition switch ...................................................................83

Starting the engine ...........................................................85

Shifting gears ...................................................................87

Steering ............................................................................93

Braking .............................................................................95

Differential lock .................................................................97

After operating ..................................................................98

Towing............................................................................101

Transporting the machine...............................................103

Manual release of parking brake ....................................106

Moveable Blade Control System ....................................107

Scarifier ..........................................................................115

Ripper.............................................................................116

Windrow eliminator .........................................................117

Dozer blade/V-plow ........................................................119

One way plow.................................................................120

Hydraulic snow wing.......................................................121

Operating techniques ........................................123

Introduction.....................................................................123

Moldboard ......................................................................124

Turning around using articulation ...................................125

Making a three point turn................................................126

6

Contents

Grading around an object.............................................. 127

Grading on an ‘S’ curve shoulder .................................. 128

Right-hand leveling........................................................ 130

Left-hand leveling .......................................................... 131

Road construction.......................................................... 132

Scarifier and ripper operation ........................................ 143

Safety when servicing ...................................... 145

Introduction.................................................................... 145

Service position ............................................................. 146

General ......................................................................... 148

Fire prevention measures.............................................. 152

Hydraulic system ........................................................... 156

Electrical system............................................................ 159

Tires............................................................................... 160

Air conditioning unit ....................................................... 161

Fuel handling ................................................................. 162

Service and maintenance ................................. 163

Fuel system ................................................................... 165

Turbocharger ................................................................. 169

Engine air cleaner.......................................................... 170

Radiators and coolers.................................................... 172

Engine cooling system................................................... 174

Drive belt tension........................................................... 178

Electrical system............................................................ 179

Transmission ................................................................. 185

Engine clutch ................................................................. 187

Final drives .................................................................... 188

Tandems........................................................................ 190

Brake system................................................................. 191

Hydraulic system ........................................................... 193

All Wheel Drive .............................................................. 195

Tires............................................................................... 196

Climate control system .................................................. 197

Miscellaneous ................................................................ 200

Maintenance schedule................................................... 201

Grease points ................................................................ 202

Symbol key, lubrication and service chart ..................... 203

Lubrication and service chart......................................... 204

Specifications.................................................... 217

Recommended lubricants.............................................. 217

Capacities...................................................................... 219

Intervals between changes ............................................ 219

Engine ........................................................................... 221

Fuel system ................................................................... 223

Cooling system .............................................................. 224

Electrical system............................................................ 225

Power transmission ....................................................... 227

Brake system................................................................. 229

Hydraulic/Steering system ............................................. 230

Critical mounting torques ............................................... 231

Dimensional drawing ..................................................... 233

Noise and vibration levels.............................................. 234

Alphabetical index ......................................................... 235

Presentation

Presentation

General 7

General

Intended use

The machine is intended to be used under normal conditions for

the operations described in the Operator’s Manual. If it is used for

other purposes or in potentially dangerous environments, for example, an explosive atmosphere, areas with dust containing asbestos, etc., special safety regulations must be followed and the

machine must be equipped for such use. Contact the manufacturer or dealer for further information.

Engine

The engine is a four stroke cycle, in line six cylinder, turbocharged

diesel with overhead valves and air-to-air charge air cooler. These

engines are of the low emission type and all models have VHP

(Variable horsepower).

VHP

All Volvo grader models have engines that provide 2 different power levels depending on the gear selected by the operator.

– For non-All Wheel Drive equipped graders, forward gears 1,

2, and reverse 1, have reduced power to minimize wheel slip.

In forward gears 3 through 8, and reverse gears 2 through 4,

engine power is automatically increased.

– For All Wheel Drive equipped models with the All Wheel Drive

system turned OFF, the function of the VHP is the same as

above.

– For All Wheel Drive equipped models with the All Wheel Drive

turned ON, the engine power is increased for all gears.

– There is no operator selectable control over the VHP system.

Presentation

8 General

Electrical system

The electrical system is a 24VDC, negative-ground system. Power is supplied by two 12VDC batteries connected in series. Battery

charging is accomplished using a standard 75 amp alternator and

an optional 100 amp alternator. Electrical power can be disconnected using a ground isolation switch.

Clutch

A multiple wet disc clutch is mounted to the engine flywheel and

connected to the transmission with a driveshaft. The clutch must

be used when starting to move or when changing direction.

Transmission

The transmission has eight forward and four reverse speeds. It is

a fully sequential, direct drive, powershift unit utilizing a countershaft design.

Final drive/tandems

Final drives are single reduction in models G710B to G746B and

double reduction in the G780B. Each has an operator controlled

lock/unlock differential. Rear axles are case hardened, full floating

design, supported on double row spherical roller bearings. Tandem wheels are chain-driven.

Brakes

Hydraulically actuated, oil disc service brakes are located at the

four tandem drive wheels. The crossover dual braking circuits provide even braking on both sides of the grader.

If the engine stalls, or hydraulic boost pressure becomes unavailable, full braking capability is available through a reserve system.

An electric motor supplies the power required to bring the grader

to a safe stop.

The parking brake is a spring apply/hydraulic release, disc-type

brake. It is driveline-mounted to the transmission output shaft. An

accumulator in the circuit stores system pressure allowing the

brakes to remain released in the event of system pressure loss for

about 15 minutes.

Steering

The steering system is a closed-center dynamic signal load sensing system. The hydraulic steering system incorporates two steering cylinders. The leaning wheel feature and articulated frame can

be used to decrease turning radius. There is no manual steering.

Cab and frame

Both the canopy and fully-enclosed cab are equipped according to

the ROPS standard. FOPS approved structures are optional. Enclosed cabs are also provided with air conditioning and/or heating

systems as options. All controls are housed in the fully adjustable

steering pedestal and the right-hand side console. Ergonomic

seating and hydraulic control lever placement ensure operator

comfort and efficiency. The frame articulates 22° to the left or to

the right and uses anti-drift lock valves to ensure stable operation.

Presentation

General 9

MBCS (Moveable Blade Control System)

Blade mobility permits steep ditch cutting angles and back sloping

outside of overall machine width. The circle is held in place by adjustable clamp plates and guide shoes. Bearing surfaces are DURAMIDE™-faced to maximize service life. Hardened teeth are cut

on the outside of the circle. Oil is directed to the two drive cylinders

by a circle timing valve. The cylinders are arranged 90° out of

phase to ensure consistent power. The moldboard is provided with

replaceable cutting edge and end-bits. The drawbar is a narrow

“T” design for optimum visibility to the work area.

Hydraulic system

The closed-center hydraulic system uses a pressure and flow

compensated (load-sensing) variable displacement piston pump.

The pump supplies oil to the implements, the steering and the engine cooling fan system.

The cooling fan is driven by a fixed displacement vane-type motor.

Fan speed is variable and is determined by various cooling requirements. The fan operates between pre-determined minimum

and maximum speeds. The fan remains at its minimum speed until

there is a demand for cooling. Fan speed will automatically increase with the demand for cooling.

Lock valves (counterbalance valves) are incorporated into the

blade lift, moldboard tilt, circle shift, wheel lean and articulation circuits to prevent cylinder drift. The control levers are short throw,

feathering type located on an adjustable steering pedestal.

All Wheel Drive

G726B and G746B are All Wheel Drive models. The system operates in gears 1 through 7. It is powered by two electronically controlled, variable displacement hydraulic pumps in a closed loop

system. Each pump supplies one front wheel motor.

Front wheel motors are two-speed, high torque, radial piston, cam

lobe type. Each wheel motor has a separate speed sensor.

The system has a 16-speed aggression control dial.

Equipment and attachments

The circle, drawbar and moldboard equipment is fully maneuverable using hydraulic cylinders. Optional attachments include:

– Dozer blade

– Rear-mounted ripper-scarifier

– Mid-mounted scarifier

– Front-mounted scarifier

– Windrow eliminator

– Push block (counterweight for ripper)

– One-way plow

–V-plow

– Hydraulic snow wing (high and low bench)

– A-frame (used with V-plow and One-way plow only)

Presentation

10 CE Marking and Declaration of Conformity

CE Marking and Declaration of Conformity

(Only applies to machines marketed within the EU/EEA).

This machine is CE marked. This means that when delivered the

machine meets the applicable “Essential Health and Safety Requirements”, which are given in the EU Machinery Safety Directive.

If changes are made that affect the safety of the machine, the person carrying out the changes is responsible for the same.

As proof that the requirements are met, the machine is supplied

with an EU Declaration of Conformity, issued by Volvo Motor

Graders Limited for each separate machine. This EU Declaration

also covers attachments made by Volvo Motor Graders Limited.

This documentation is a valuable document, which should be kept

safe and retained for at least 10 years. The document should always accompany the machine when it is sold.

If the machine is used for other purposes or with other attachments than described in this manual, safety must at all times and

in each separate case be maintained. The person carrying out

such action is also responsible for the action that, in some cases,

may require a new CE marking and the issue of a new EU Declaration of Conformity.

EU EMC Directive

The electronic equipment of the machine may in some cases

cause interference to other electronic equipment, or suffer from

external electromagnetic interference, which may constitute safety risks.

The EU EMC directive on “Electromagnetic conformity” provides a

general description of what demands can be made on the machine out of a safety point of view, where permitted limits have

been determined and given according to international standards.

A machine or device, which meets the requirements, should be

CE marked. Our machines have been tested particularly for electromagnetic interference. The CE marking on the machine and the

declaration of conformity also covers the EMC directive.

If other electronic equipment is fitted to this machine, the equipment must be CE marked and tested on the machine as regards

to electromagnetic interference.

Presentation

CE Marking and Declaration of Conformity 11

Modifications

Modifications of any kind to this product including the fitting of unauthorized attachments, accessories, assemblies or parts could

affect the integrity of the product and/or the ability of the product

to perform as designed or intended.

It is policy that no modification of any kind is to be made to this

product unless officially approved by Volvo Motor Graders. A modification includes, but is not restricted to, the use of attachments,

accessories, assemblies and parts not approved by Volvo Motor

Graders and/or not installed in a factory approved manner.

Modifications are officially approved if at least one of the following

conditions is met:

1 The attachment, accessory, assembly or part is manufactured

or distributed by Volvo and installed in a factory approved manner as described in the publications available from Volvo; or

2 The modification has been approved in writing by the Engineer-

ing Department of Volvo Motor Graders.

Volvo Motor Graders disclaims responsibility for any situation that

may arise as a result of a non-approved modification. If any person or organization modifies or contributes in any way to a nonapproved modification, the person or organization will be deemed

to have assumed all the risks associated with such a modification,

including but not limited to, product failure, product damage, property damage, loss of production, injury or death.

If any claims result from a non-approved modification, Volvo Motor

Graders will protect its interest by taking whatever action is appropriate.

Volvo Motor Grader warranty shall not apply to any product or part

which fails or is damaged by, or whose functioning or operation is

adversely affected by non-approved modification.

Unauthorized modifications of the ROPS (Roll Over Protective Structure)

Never make any unauthorized alterations to the ROPS such as

lowering the height of the ceiling, drilling or welding to it.

Such unauthorized modifications will affect the structural limits of

the ROPS cab and will void the certification.

The ROPS has been approved after testing and meets the standard according to ISO 3471 1994 and SAE 1040 APR 88.

An optional cab has also been tested and approved according to

the FOPS (Falling Object Protective Structure) standard as defined by ISO 3449 1992, SAE J231 JAN 81 and meets the requirements for “Overhead guards for high-lift rider trucks” ISO 6055

1979 and “Operator seat belt requirements” SAE J386 JUN 93.

All planned alterations must be reviewed in advance by our Engineering Department to determine whether the alteration can be

made within the limits of the certifying tests.

It is important that all persons in your organization, including management, be made fully aware of these rules involving the ROPS.

Whenever anyone sees a machine ROPS with unauthorized alterations, both the customer and manufacturer should be notified in

writing.

Presentation

12 Plates and decals

Plates and decals

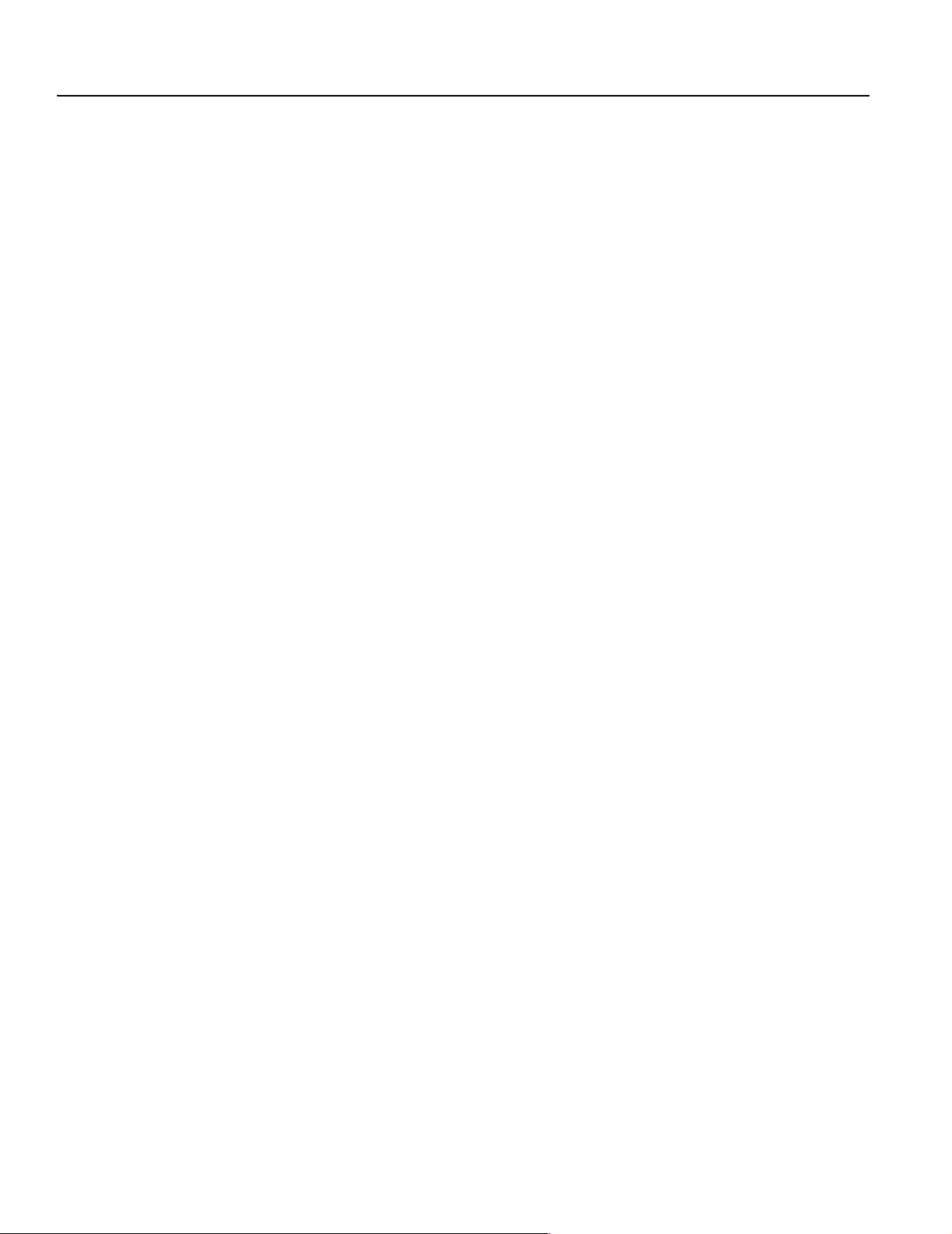

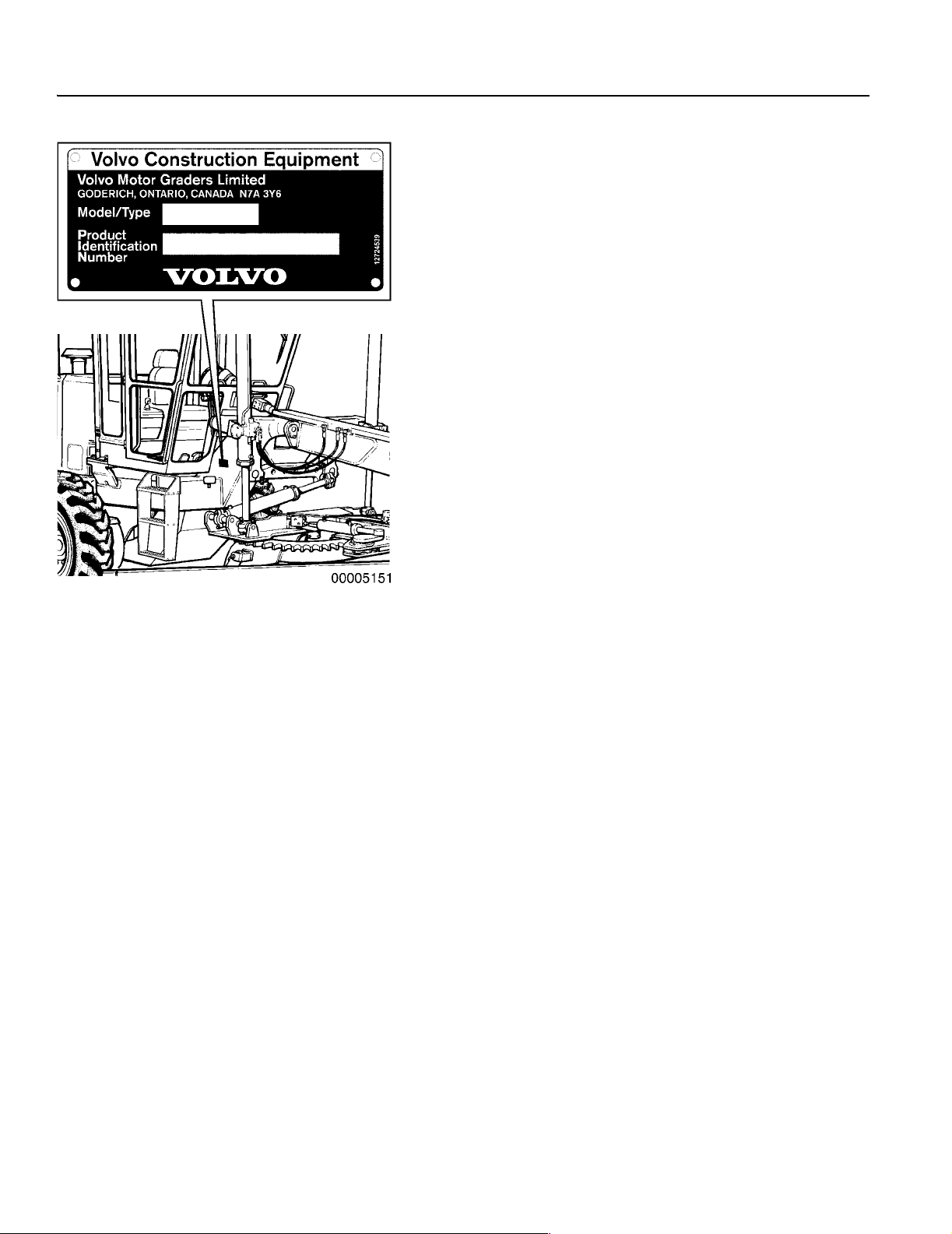

Product plates

The following illustrations and text show which product plates are

installed on the machine. These numbers are recorded at the factory.

Always quote the motor grader Model Number and the Product

Identification Number when ordering spare parts, and in all telephone inquiries or correspondence.

1 Engine

The engine serial numbers are found on a plate on the left-hand

side of the engine on models G710B to G730B. G740B, G746B

and G780B models have the serial number stamped into the righthand side of the engine block.

2 Cab

The ROPS and FOPS serial number plates are found inside the

cab on the left-hand post behind the operator’s seat. The ROPS

plate states the model and serial number, specification, maximum

machine mass, and bolt torque. The FOPS plate states the model,

serial number and specification.

3 Product identification plate

This plate is found on the right-hand side of the frame in front of

the cab. It has the Model Number and PIN (Product Identification

Number) stamped on it. The Model Number is broken down as follows: the first digit designates G700 Models; the next two digits indicate weight and horsepower range.

The Model Number and PIN must be used in conjunction with the

Parts Catalog to order correct replacement parts.

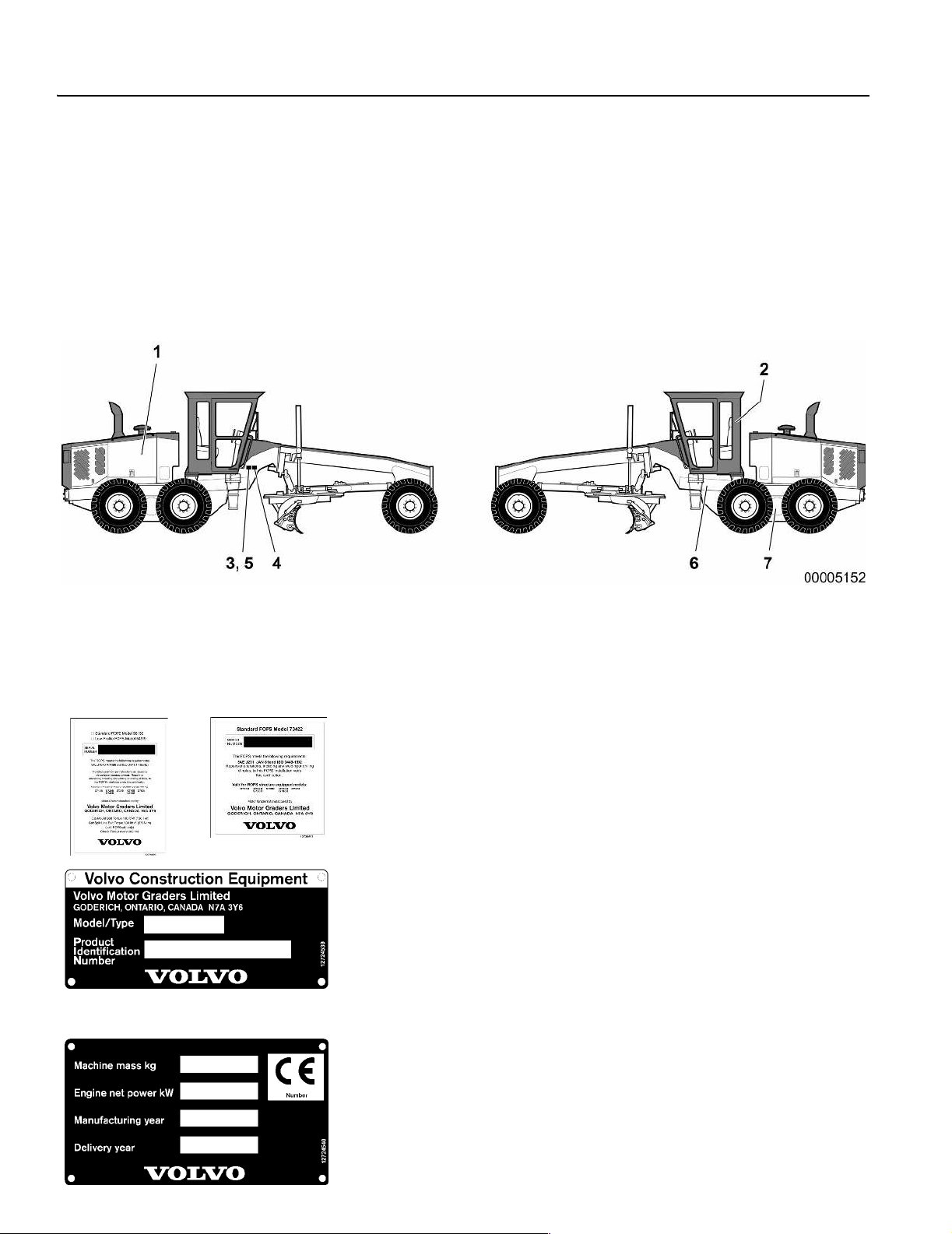

4 Product identification plate (EU/EEA countries)

In addition to the above information, this plate shows machine

weight, engine power, year of manufacture and has a space for

the CE mark. It also is positioned on the right-hand side of the

frame in front of the cab.

Presentation

Plates and decals 13

5 Product identification plate for TUV (Germany)

This plate is found on the right-hand side of the frame in front of

the cab.

6 Transmission

The transmission serial number is located on the lower front of the

housing.

7 Final drive

The final drive serial number is found on the right-hand side on the

rear of the final drive on models G710B to G746B. On G780B

models it is found on the top of the center housing.

Presentation

14 Plates and decals

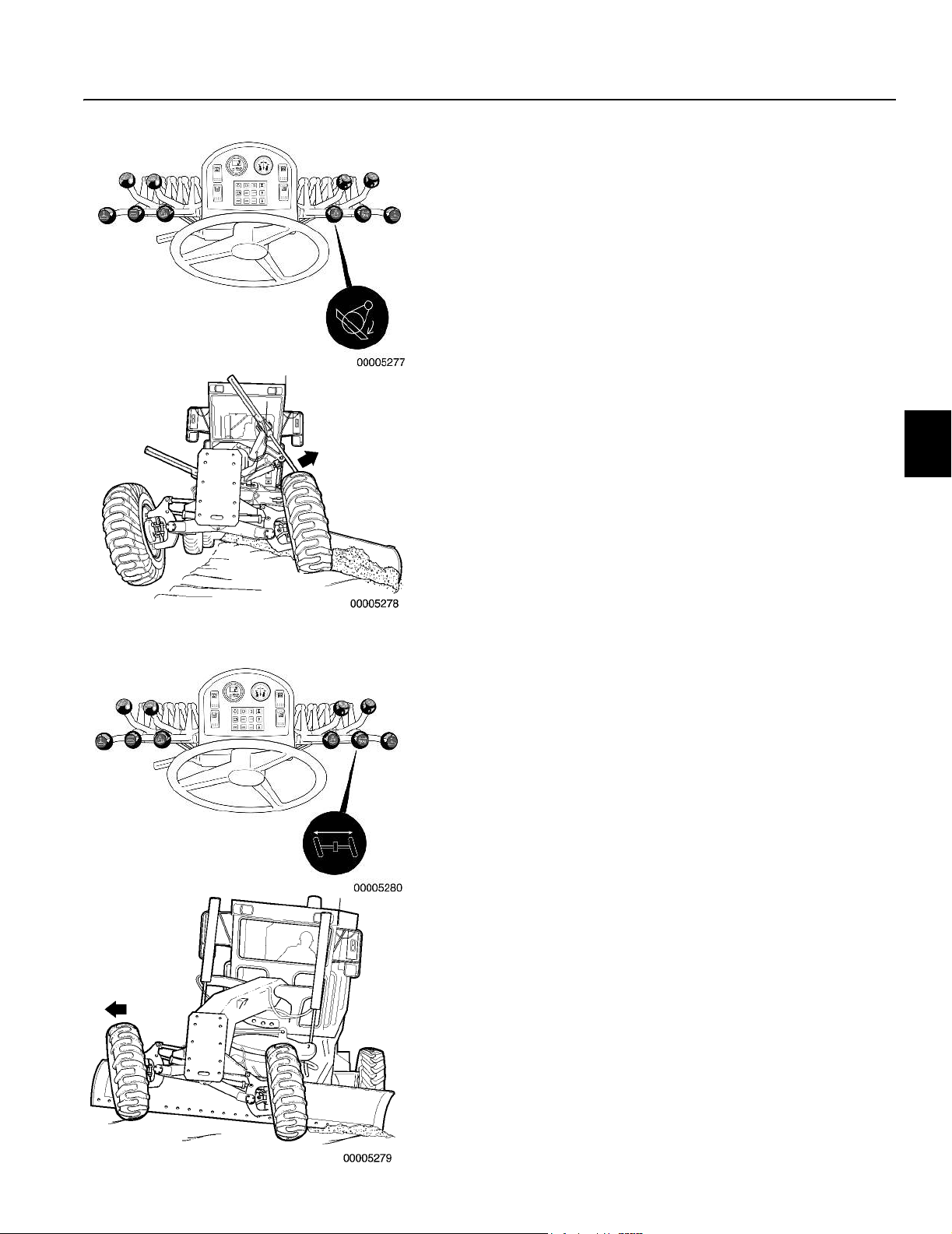

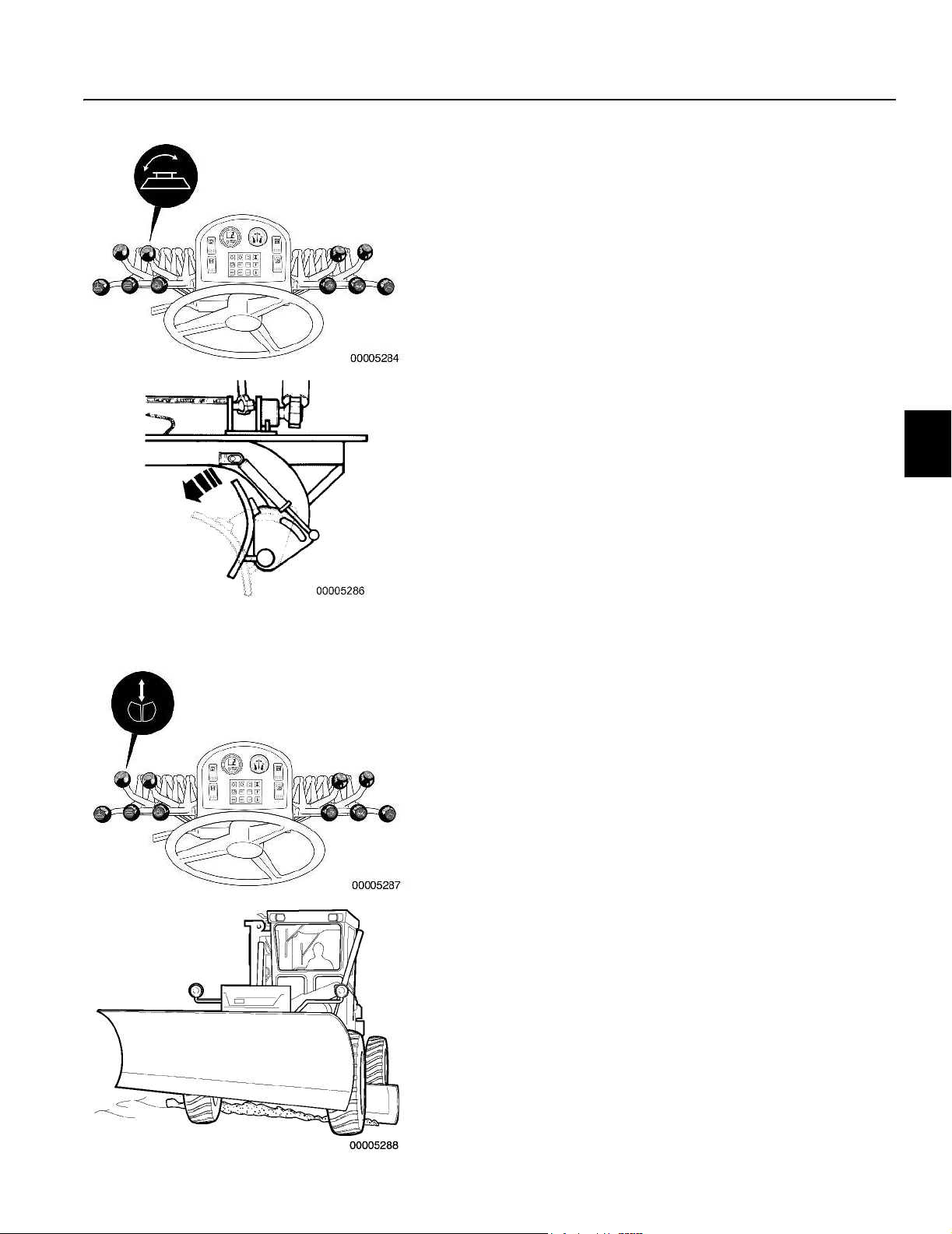

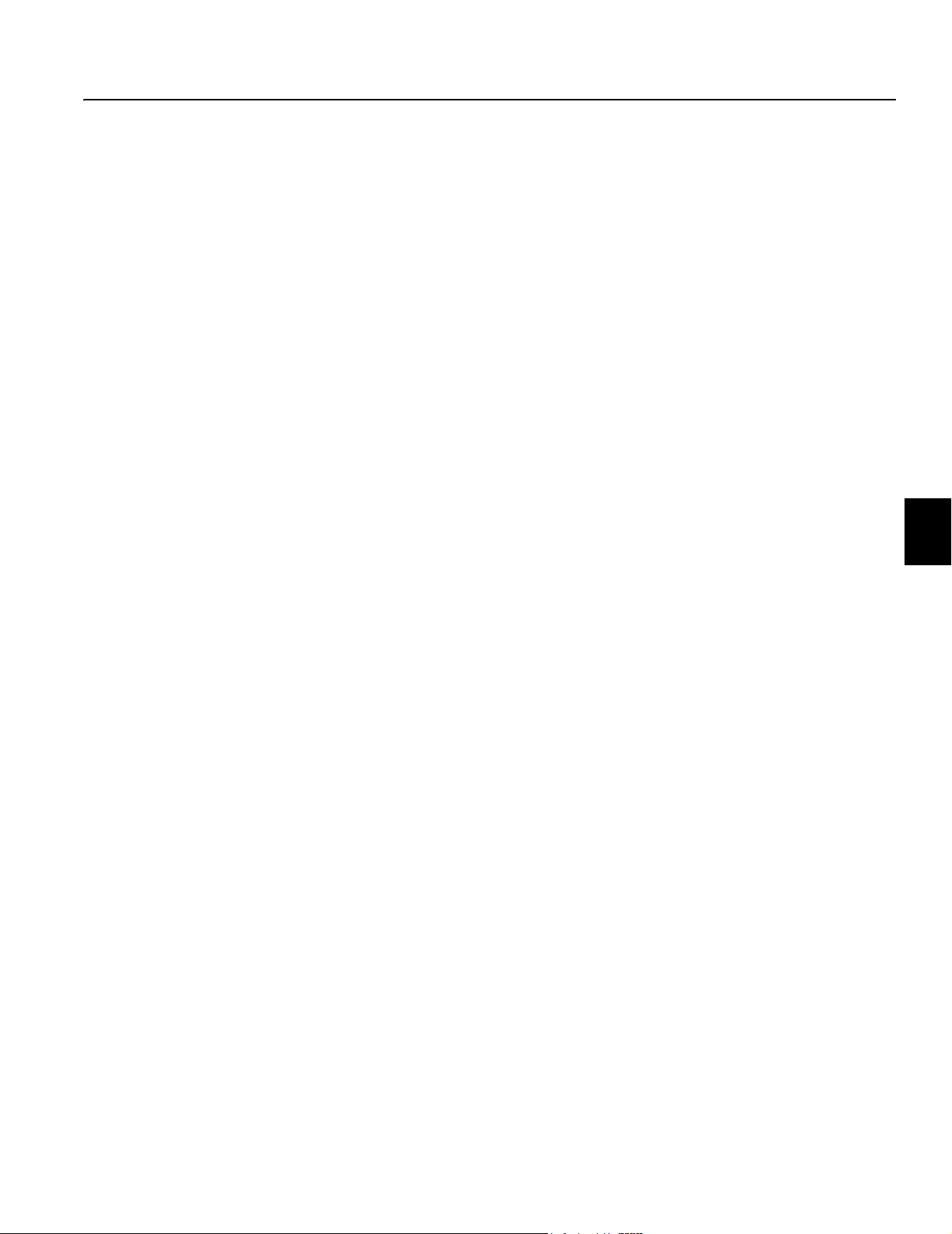

Information and warning plates

The following illustrations and text show which safety signs can be

found on the machine. The operator of the machine must know

and follow warnings and information given on safety signs.

Safety signs that have been damaged, painted over, disappeared,

or for any other reason are no longer legible, must be replaced immediately.

The part number of the respective safety sign can be found in the

Parts Catalog.

Presentation

Plates and decals 15

Item Description Location

1 Warning! Hot components. Right-hand side, under the door latch of the engine compart-

ment door.

2 Warning! Never Short across starter

terminals.

3 24V Start On the starter, inside the engine compartment, right-hand side.

4 Warning! Hot pressurized coolant. On the top of the engine hood.

5 Warning! Crush zone. Both sides of the cab.

6 Parking brake decal Right-hand side of pedestal.

7 Warning! Wear seat belt when operat-

ing machine.

7 Warning! Read the operator’s manual

first!

8 Warning! Accumulator contents under

pressure.

9 Warning! Use only petroleum base fluid

in brake reservoir.

10 Warning! Crush zone. Both sides below the engine compartment door.

11 Differential lock operating instructions On the front windshield.

12 Anti-freeze coolant tag. On the steering wheel.

On the starter, inside the engine compartment, right-hand side.

Front of the pedestal.

Front of the pedestal.

Over the barrel of the accumulator (if equipped).

Rear right-hand side of cab.

13 Warning! Use no ether. On the engine hood beside the air intake.

14 Warning! Explosive gases. Inside the battery box, left-hand tandem case.

15 24V Start Inside the battery box, left-hand tandem case.

16 Safety instructions: Use handholds and

steps.

17 Warning! Keep clear of moldboard. On the left, right and rear faces of the drawbar.

18 Lubrication and service chart Left-hand side under the cab on the frame.

19 Warning! Rotating components. Right-hand side below engine compartment door. Both sides

20 Warning! Rotating fan. Inside of the rear radiator cowling door.

21 Sound decal

(Statement of exterior noise measurement of the machine)

Both sides of the cab.

inside the cooling compartment door.

On the right-hand side of the frame in front of the cab. (TUV,

EU/EEA countries only.)

Presentation

16 Service

Service

If the machine is to operate as economically as possible, it must

be properly maintained. Intervals of maintenance and lubrication

apply to the machine under normal environmental and operating

conditions. The maintenance work described in this manual can

be carried out by the operator. For further adjustments and repairs, the machine should be taken to an authorized dealer.

Delivery inspection

Before the machine left the factory it was tested and adjusted. In

addition to this, your dealer has carried out a further check – the

“Delivery Inspection” – according to our instructions before the

machine was handed over to you.

Inspection

It is especially important, however, that during the first period of

operation, the machine is subjected to further checks. Retightening of bolts, checking adjustments and other minor measures have

to be carried out. Carry out this inspection within 100 operating

hours.

Maintenance service

Condition Test and Maintenance Programs

In addition to the maintenance listed in the Maintenance Schedule

in this manual, your authorized dealer offers a maintenance system based on tests which give an indication of the general condition of your machine. Further information about this maintenance

system can be obtained from your nearest authorized dealer.

Presentation

General Information 17

General Information

The USA federal clean air act

The Federal Clean Air Act Section 203 (a) (3) states that the removal of air pollution control devices or the modification of an

EPA-certified non road engine to a non certified configuration.

The Federal regulations implementing the Clean Air Act for nonroad engines, 40 C.F.R. section 89.1003(a)(3)(i) reads as follows:

The following acts and the causing thereof are prohibited:

For a person to remove or render inoperative a device or ele-

ment of design installed on or in a non road engine vehicle or

equipment in compliance with regulations under this part prior to its sale and delivery to the ultimate purchaser or for a

person knowingly to remove or render inoperative such a device or element of design after the sale and delivery to the ultimate purchaser.

The law provides a penalty of up to $2,500 for each violation.

An example of a prohibited modification is the recalibration of the

fuel system so that the engine will exceed the certified horsepower

or torque.

You should not make a change to an EPA-certified non-road engine that would result in an engine that does not match the engine

configuration certified to meet the Federal Standards.

Customer assistance

Volvo Construction Equipment wishes to assure that the Emission

Control System Warranty is properly administered. In the event

that you do no receive the warranty service to which you believe

you are entitled under the Emission Control System Warranty, you

should contact your nearest Volvo Construction Equipment Regional office for assistance.

Presentation

18 General Information

Normal non-road engine use

The Maintenance Instructions are based on the assumption that

this conventional machine will be used as designated in the Operator's Instruction Manual and operated only with the specified fuel

and lubrication oils.

Non-road engine maintenance

The non-road engine is of conventional design and any local dealer may perform the necessary non-road engine emission control

maintenance defined in this manual.

Volvo recommends that the purchaser use the service program for

the non-road engine, known as Preventative Maintenance, including the recommended engine emission control maintenance.

In order to document that the proper regular maintenance has

been performed on the non-road engine, Volvo recommends that

the owner keep all records and receipts of such maintenance.

These records and receipts should be transferred to each subsequent purchaser of the non-road engine.

Service performed by your local dealer

Your local dealer is best qualified to give you good, dependable

service since he has trained service technicians and is equipped

with genuine original manufacturer's parts and special tools, as

well as the latest technical publications. Discuss your servicing

and maintenance requirements with your local dealer. He can tailor a maintenance program for your needs.

For regular scheduled service or maintenance, it is advisable to

contact your local dealer in advance to arrange for an appointment

to ensure availability of the correct equipment and service technician to work on your machine. This will aid your local dealer in efforts to decrease service time on your machine.

Presentation

General Information 19

Preventive maintenance program

To retain the dependability, noise level and exhaust emission control performance originally built into your conventional non-road

engine, it is essential that the non-road engine receive periodic

service, inspections, adjustments and maintenance.

Fuel system

Fuel Recommendations:

The fuel used must be clean, completely distilled, stable and noncorrosive. Distillation range, cetane level and sulfur content are

most important when selecting fuel for optimum combustion and

minimum wear.

Engine working conditions and ambient temperature influence the

selection of the fuel with respect to cold handling properties and

cetane levels.

In cold weather conditions, below 32 ºF (0 ºC), the use of lighter

distillate or higher cetane level fuel are recommended. (Final boiling point max. 660 ºF (349 ºC) and cetane min 45.)

To avoid excessive deposit formation and to minimize the emissions of sulfur dioxide into the ambient air, the sulfur content of the

fuel should be the lowest available. The diesel fuels recommended for use in Volvo engines should meet ASTM designation: D 975

No. ID (C-B) or No. 2D (T-T); with a cetane level above 42 and sulfur content not exceeding 0.5 percent by weight.

Check for fuel leaks (with the engine running at fast idle):

n Visually check unions and hose connections.

Check the condition of the fuel hoses for:

n Ageing

n Cracks

n Blisters

n Scuffing

Check the condition of the fuel tank:

n Drain water condensation.

n Check for cracks.

n Check for leaks.

n Check the mounting.

Check the turbocharger:

n Visually check for leaks in the intake hoses and exhaust pipe

of the turbocharger.

Presentation

20 Notes

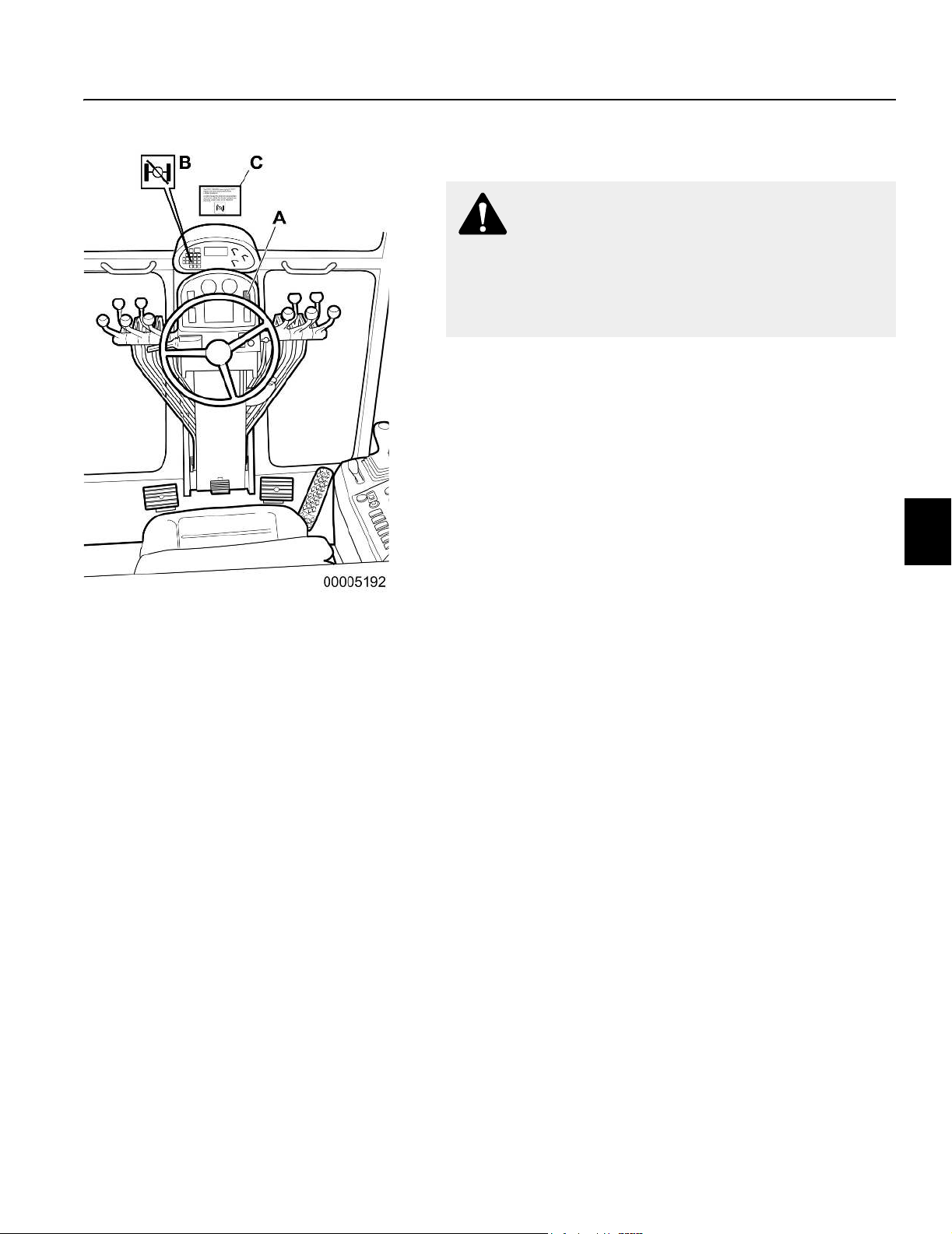

Instrument panels

General 21

Instrument panels

General

WARNING!

Do not operate the machine until you are thoroughly

familiar with the position and function of the various

instruments and controls. Read this manual carefully.

Your safety is involved!

Glance at the instruments now and then. Doing so will alert you to

any abnormal readings and allow necessary action to prevent serious damage.

If any warning lamps or buzzers energize, park the machine and

shut down the engine immediately. Report the problem to your supervisor.

The battery isolation switch must be in the ON (I) position and the

ignition switch in the “I” position (running position) when checking

the function of the instruments and warning devices.

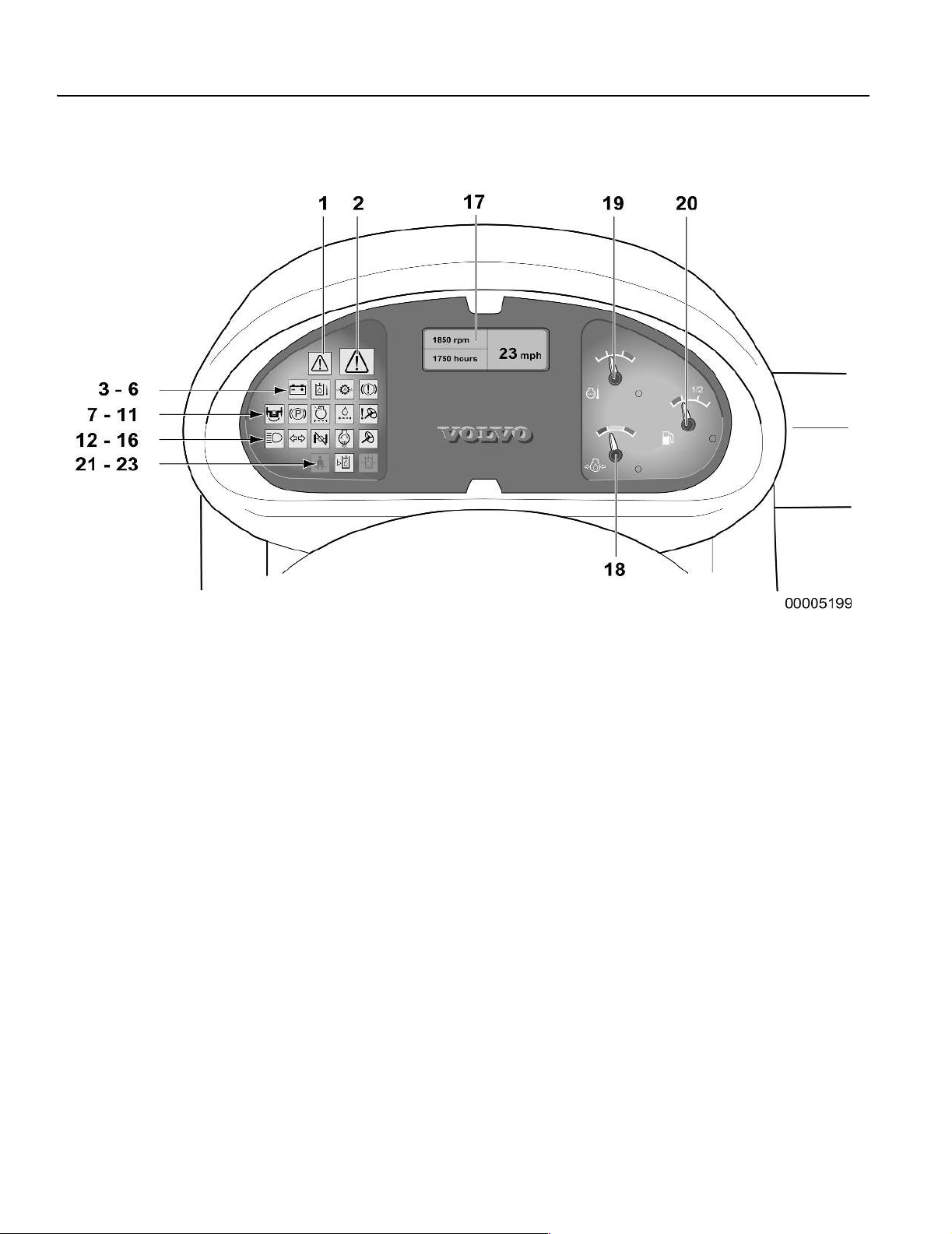

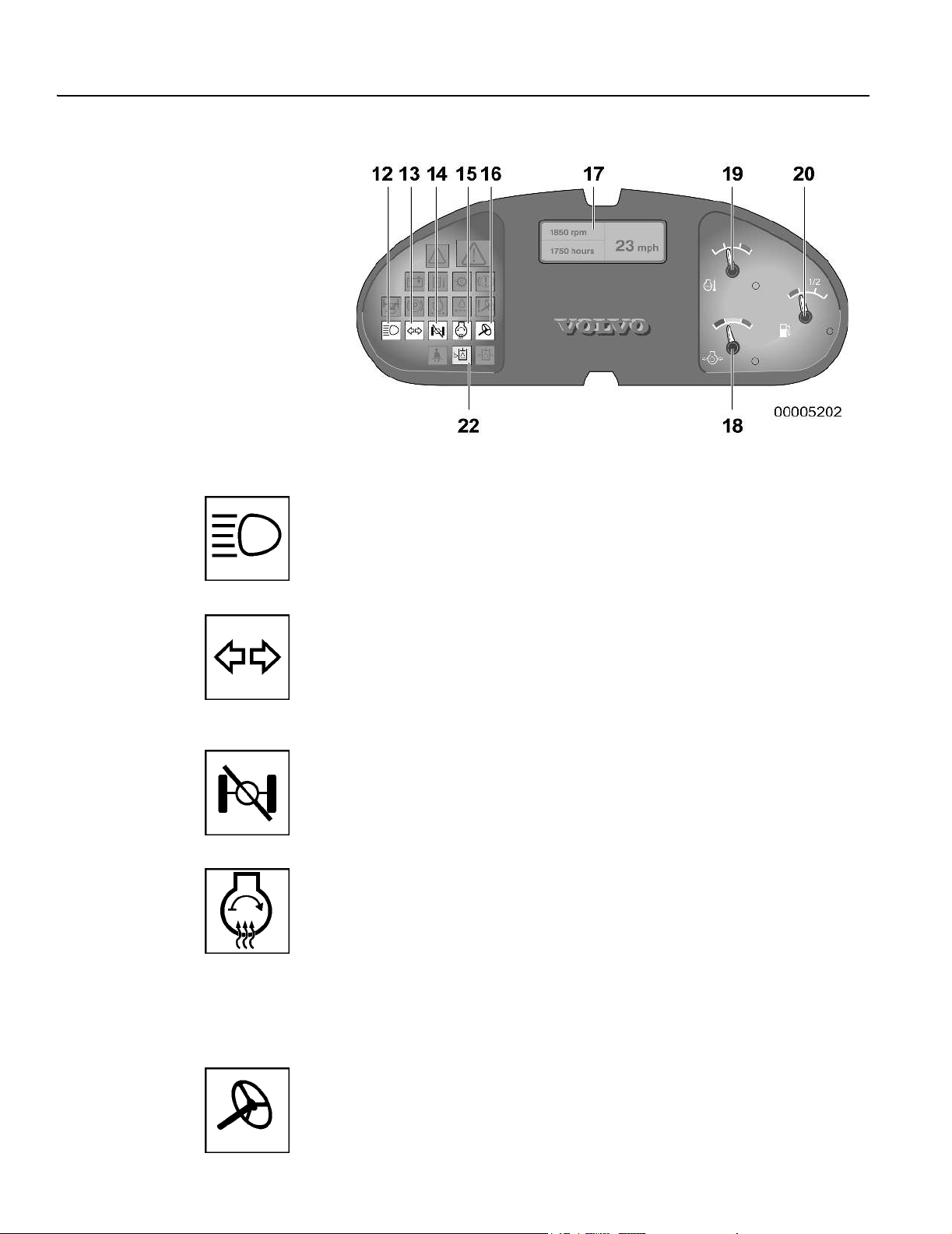

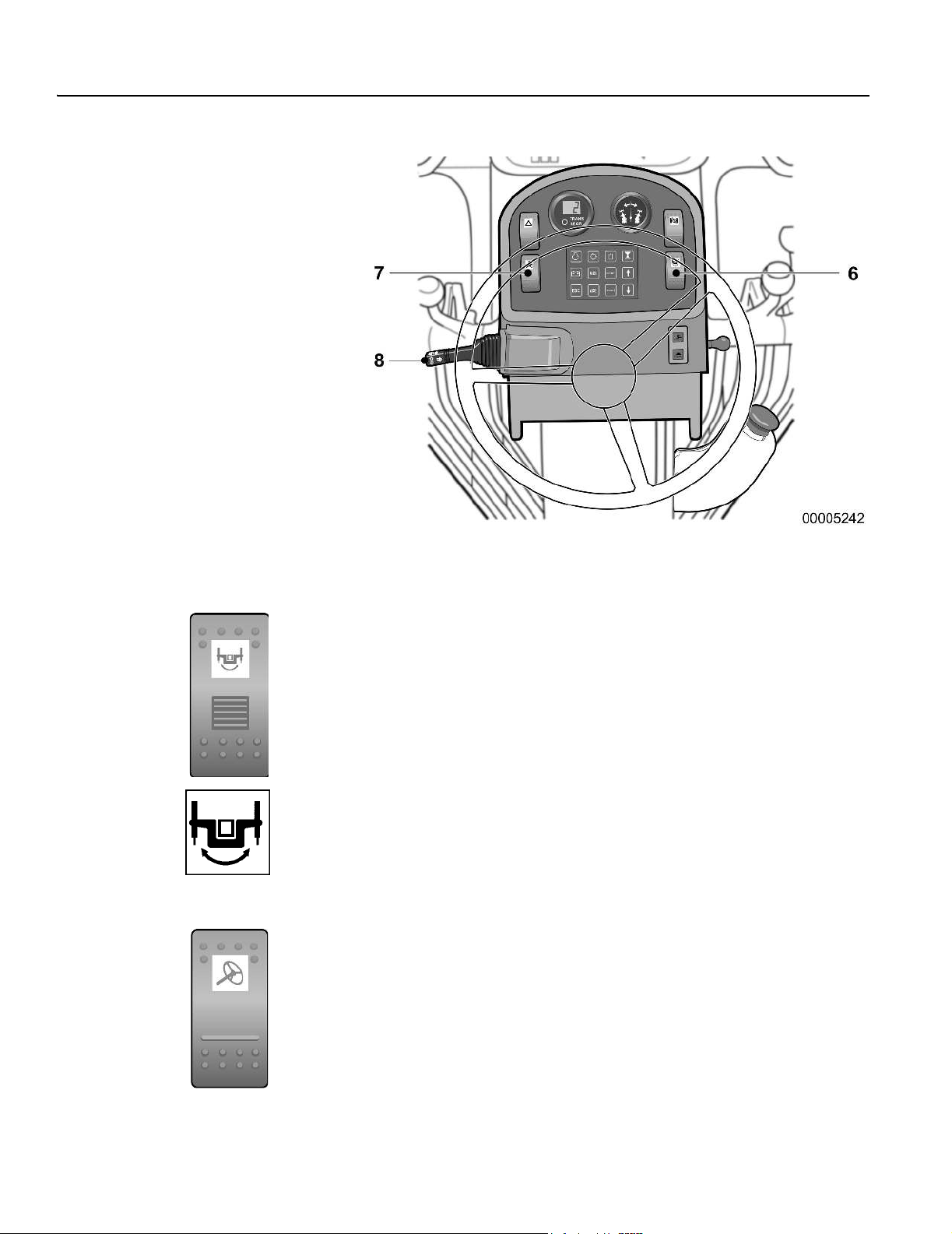

1 Center instrument panel (display unit, control lamps, gauges)

2 Pedestal head instrument panel (switches, warning lights, gauges)

3 Side console instrument panel (switches, warning lights/buzzers)

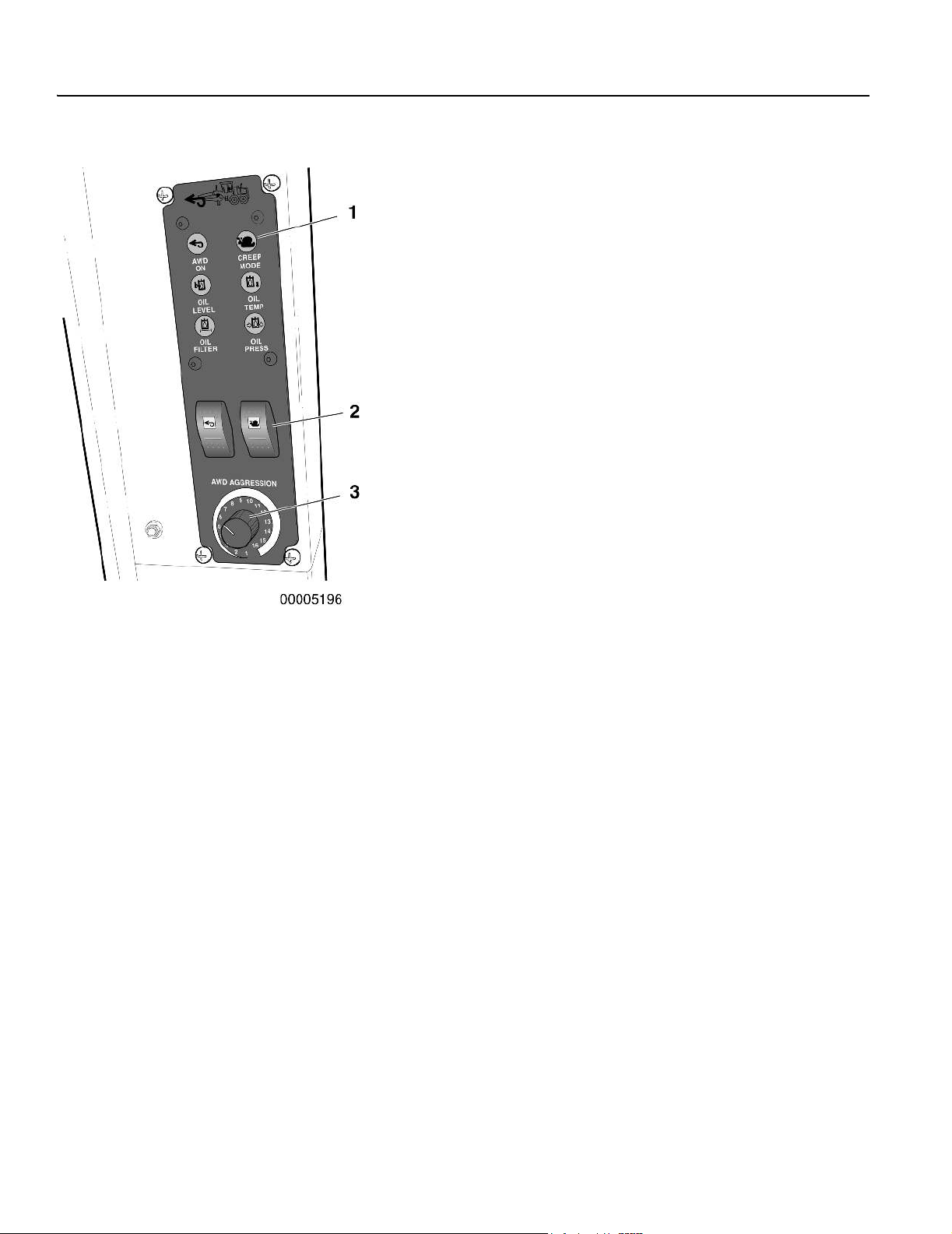

4 All Wheel Drive control panel (switches, warning/information lights, aggression dial)

Instrument panels

22 Center instrument panel

Center instrument panel

1 Information (amber) 12 High beams

2 Central warning (red) 13 Turn signal indicator

14 Differential locked

3 Charging battery 15 Engine preheat

4 High Hydraulic oil temperature 16 Secondary steering

5 Low transmission oil pressure

6 Brake warning 17 Display unit (speedometer optional)

7 Blade control system unlocked 18 Engine oil pressure

8 Parking brake applied 19 Engine coolant temperature

9 Engine air filter restriction 20 Fuel level

10 Filter bypass warning

11 Primary steering system 21 (not used)

22 Hydraulic oil level

23 (not used)

General

If red control lamps light up – stop the machine immediately!

If amber lamps light up – an abnormal condition exists and mea-

sures may be required depending on the function concerned.

The remaining lamps – indicate that the respective function is

engaged/connected.

Instrument panels

Center instrument panel 23

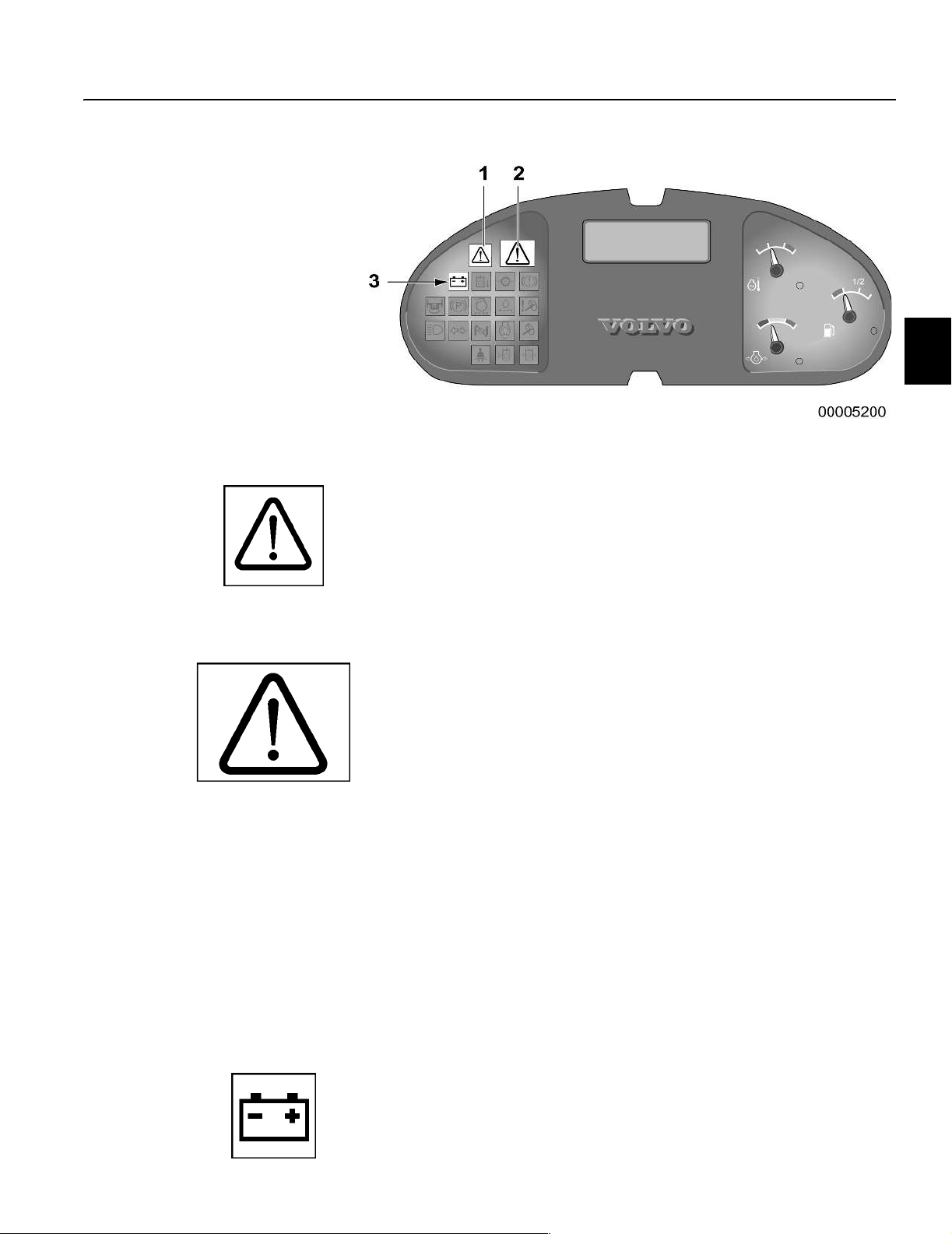

1

Information (amber)

The amber central warning lamp flashes when system errors occur for less critical warnings. It informs the operator that a function

is engaged/disengaged or that a function needs to be kept under

observation (for example low fuel). It is accompanied by another

warning lamp and/or message display to clarify the warning/error.

2

Central warning (red)

The central warning lamp flashes when critical warnings or errors

occur. It is accompanied by a buzzer, another indicator lamp and/

or message on the display unit. It informs the operator that immediate attention is required.

Buzzer

The buzzer sounds at the same time the red central warning lamp

illuminates if any of the following faults are indicated:

– Low engine oil pressure

– Low transmission oil pressure

– Low parking/service brake pressure

– Parking brake (if applied in gear)

– Low hydraulic oil level

– Low steering system pressure

– High engine coolant temperature

– High hydraulic oil temperature

3

Battery charge warning (red)

This lamp is energized if the alternator is not charging. A message

is shown on the display unit if the electrical system voltage drops

below 21 volts or rises above 31 volts.

Instrument panels

24 Center instrument panel

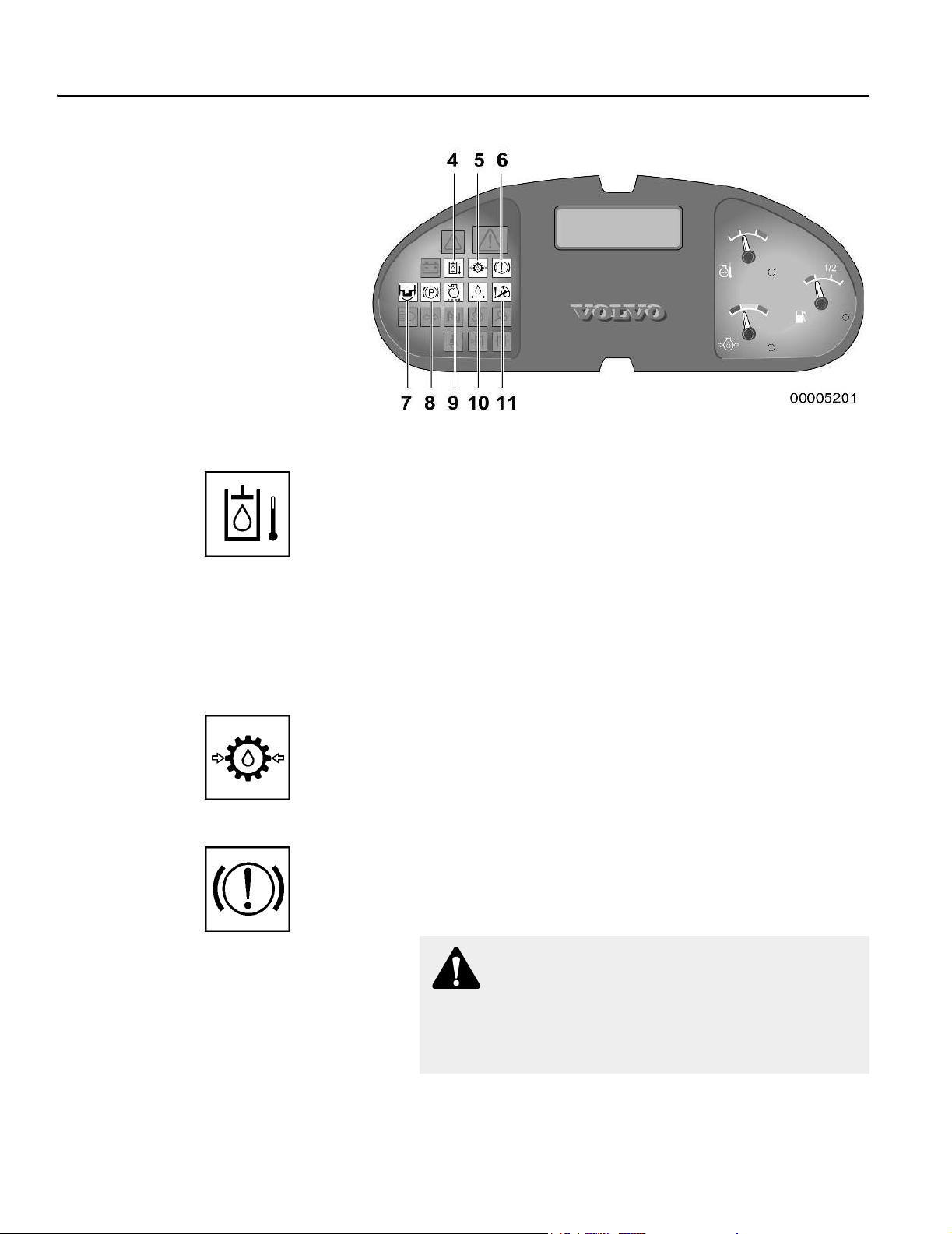

4

Hydraulic oil temperature warning (red)

(optional)

This lamp indicates the hydraulic oil temperature in the reservoir

is too high. It is accompanied by the red central warning lamp,

buzzer, and display message.

Fluid temperature must be kept within acceptable limits in order to

retain its viscosity and other properties necessary for satisfactory

operation between oil change intervals. Refer to Service and

maintenance, Hydraulic system page 193 for further information.

5

Transmission pressure warning (red)

This lamp indicates low transmission oil pressure. It is accompanied by the red central warning lamp, buzzer, and display message.

6

Service brake warning (red)

This lamp indicates low brake system pressure or one of the brake

circuits is not functioning. It is accompanied by the red central

warning lamp, buzzer, and display message.

WARNING!

If the brake warning lamp and alarm energize during

grader operation, the brake system is faulty and must be

repaired by a qualified service technician. Do not drive the

grader.

Instrument panels

Center instrument panel 25

7

MBCS status lamp (amber)

The lamp indicates the MBCS (Moveable Blade Control System)

lock is disengaged.

107.

8

Parking brake applied (red)

This lamp indicates the parking brake is applied. If the brake is applied when the transmission is in gear, the lamp is accompanied

by the red central warning lamp, buzzer, and display message.

9

Engine air filter restriction (amber)

This lamp indicates restricted air flow through the engine air filter

and is accompanied by the amber central warning lamp. If this

lamp lights up, service or clean the engine air filter. Refer to Service and maintenance, Engine air filter elements page 170.

Refer to Moveable Blade Control System page

WARNING!

Operate the system only long enough

to make a steering correction –

maximum two minutes.

10

Filter bypass warning (amber)

(optional)

This lamp indicates either the transmission or hydraulic filter is

clogged. It is accompanied by a message in the display panel

identifying which filter is bypassing and the amber central warning

lamp.

11

Primary steering system (red)

(Secondary steering option only)

This lamp indicates low steering system hydraulic pressure. It is

accompanied by the red central warning, buzzer, and display message.

The Secondary steering option is an auxiliary hydraulic system

that allows the operator to make steering corrections more easily

in the event of loss of hydraulic flow to the steering unit. The ignition key must be in the “I” (running) position for this system to function. The system will also turn on when the test switch is activated,

see below.

Secondary steering system check

Refer to Secondary steering system test switch page 42.

Instrument panels

26 Center instrument panel

12

High beam (blue)

The blue control lamp is on when the high beam lights are on. Refer to the Directional indicator/High beam/Horn button page 43.

13

Directional indicators (green)

This lamp flashes when the directional indicator lever is moved for

turning left or right and when the 4-way hazard flasher switch is

activated.

14

Differential lock status (amber)

This lamp energizes when the differential lock is in the LOCK position.

15

Engine preheat (amber)

This lamp indicates the engine preheating element is on. Refer to

Side console instrument panel, Engine preheat switch page 49.

After 10 to 50 seconds (the time depends on the coolant temperature) the preheating element will be disconnected and the lamp

extinguished.

For cold starting instructions, refer to Starting the engine page 85.

16

Secondary steering system status (amber)

(Secondary steering option only)

This lamp will energize simultaneously with the Primary steering

system lamp. It indicates the secondary steering system has been

activated.

Instrument panels

Center instrument panel 27

17

Display unit

For display information, refer to the Pedestal head instruments,

Keypad, display unit page 30.

18

Engine oil pressure gauge

The pointer displays the current engine oil pressure. If the pointer

enters the red sector, the lamp beside the gauge will illuminate

along with the red central warning, buzzer, and display message.

19

Engine coolant temperature gauge

The pointer displays the current engine coolant temperature. If the

pointer enters the red sector, the lamp beside the gauge will illuminate along with the red central warning, buzzer, and display

message.

20

Fuel gauge

The gauge shows the current level in the fuel tank. Check your fuel

supply when the grader is on level ground. If the pointer moves

into the red area, the warning lamp will illuminate indicating the

machine should be refuelled. In this situation, there is approximately 17% of fuel capacity left. Refuel the machine to avoid air

entering the system.

If the tank has been run empty, see Bleeding the fuel system page

168

under Service and maintenance.

Fill the tank at the end of each shift. This reduces the chance of

condensation forming in the fuel tank.

For the capacity of the fuel tank, see Specifications, Capacities

page 219.

21

(not used)

22

Hydraulic oil level (red)

(optional)

This lamp illuminates when the hydraulic oil level is too low in the

reservoir. It is accompanied by the red central warning lamp, buzzer, and display message.

23

(not used)

Instrument panels

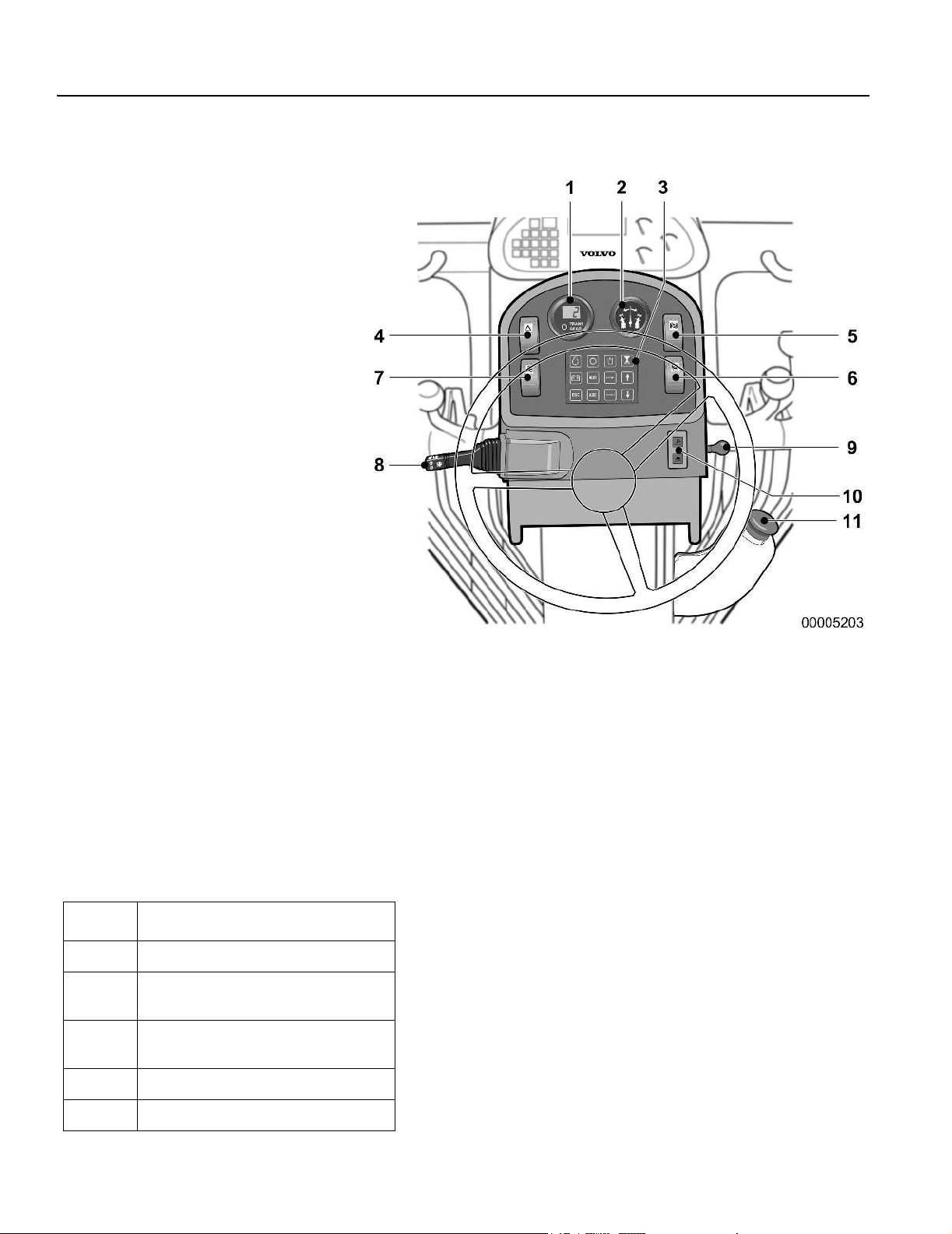

28 Pedestal instrument panel

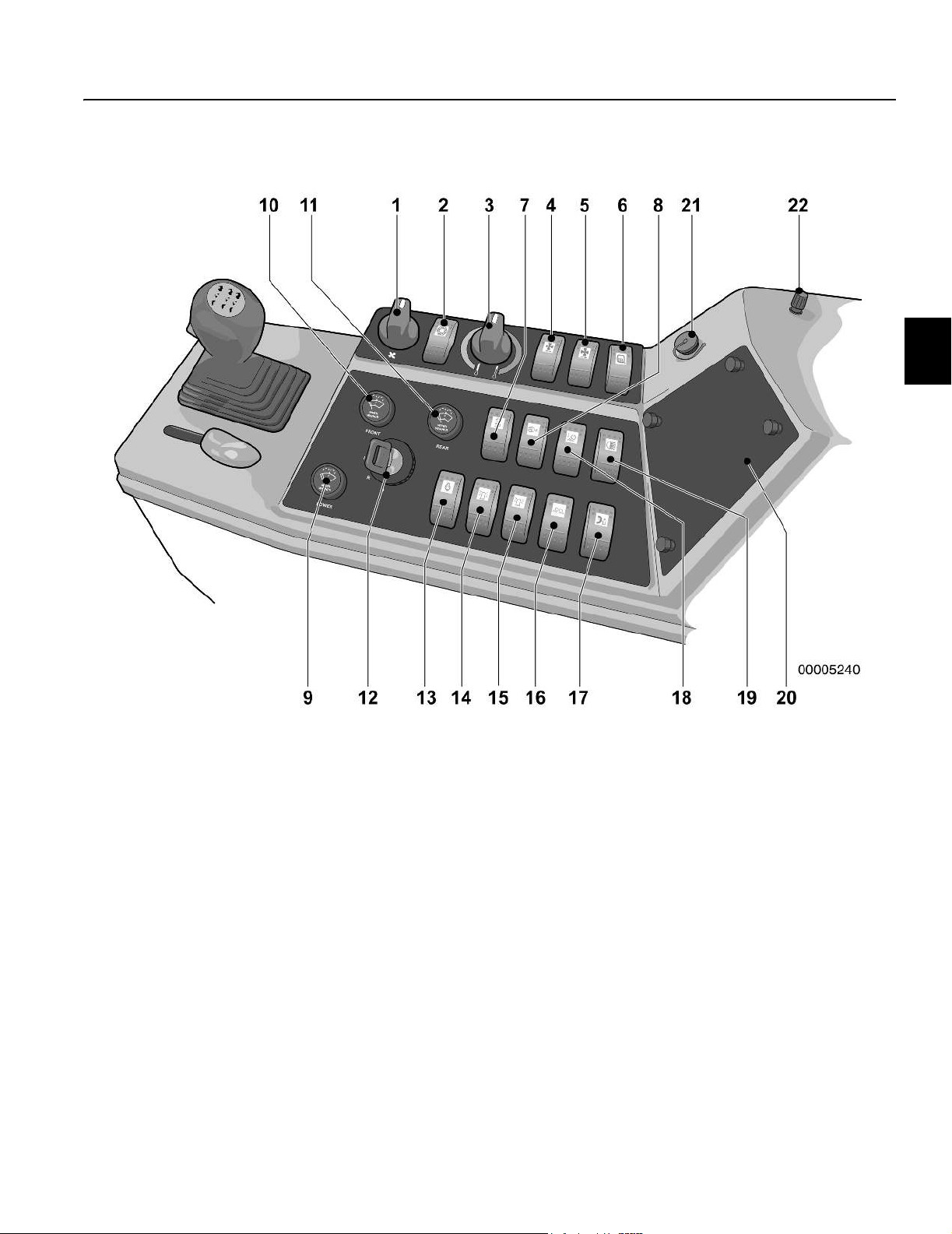

Pedestal instrument panel

1 Transmission gear display 7 Secondary steering system test

2 Articulation indicator gauge 8 Directional indicator/ High beam/Horn

3 Keypad, display unit 9 Float valves power switch

4 Four-way hazard flasher 10 Float valves system indicator lights

5 Differential lock switch 11 Parking brake switch

6 MBCS lock pin

Code Meaning

.8.8 LCD (Liquid Crystal Display) test

7.8 ECU (Electronic Control Unit)

identification

8.4 ECU identification (All Wheel

Drive)

1 Last gear memorized* (example)

1

Transmission gear display

The transmission gear display is located in the top left-hand side

of the pedestal. It displays the transmission gear selected.

With the shift lever in the FORWARD position, the display shows

the number of the forward gear, for example ‘3’.

With the shift lever in the REVERSE position, the display shows a

negative number, for example ‘-2’.

Refer to Shifting gears page 87.

The gear display can also provide other information:

n It indicates a Start code sequence on start-up.

n It shows an error code if there is a fault in the transmission or

All Wheel Drive electrical system.

-1 Opposite gear* (example)

* Alternating display while in neutral

Start code sequence

When you start the engine, the transmission gear display will show

a series of codes called the Start code sequence.

Instrument panels

Pedestal instrument panel 29

Error codes

The transmission ECU (electronic control unit) continuously monitors the transmission and the AWD (All Wheel Drive) electrical

system. In the event of a malfunction in either of these systems,

an error code is shown in the gear display. Record any error

codes and have the electrical system repaired by a qualified

service technician. For further information on Error Codes,

see the Service manual.

Transmission error codes

If a malfunction occurs in the transmission electrical system, the

gear display shows the letter ‘E’ followed by a two-digit numeric

code. Multiple error codes are possible. The ECU disables the

transmission shifter and places the transmission in NEUTRAL.

The display alternates between ‘E’ and the code until the operator

returns the shift lever to the NEUTRAL position.

n “1.0” series error codes indicate insufficient power available

for transmission solenoids. The transmission will not operate until this problem has been resolved.

n “2.0” or “3.0” series error codes indicate either an open or

short circuit in a transmission solenoid. An alternate gear

can be selected by returning the transmission to NEUTRAL. This will allow the grader to be moved.

n “2.8” or “3.8” series error codes indicate either an open or

short circuit in the parking brake solenoid. The grader will not

operate until this problem has been resolved.

n “4.2” error code indicates the fault may be corrected by plac-

ing the shifter in NEUTRAL then back into gear.

n “4.4” error code indicates a multiple shift command error.

More than one proximity switch has been energized simultaneously. The circuit board must be replaced to correct this

problem.

n “4.6” error code indicates there is a problem with the shift le-

ver. The shift lever is out of neutral with no signal to the forward or reverse solenoids.

n “P” series error codes indicate a malfunction in the parking

brake electrical system.

AWD (All Wheel Drive) error codes

The transmission ECU continuously monitors the AWD electrical

system. It is able to detect abnormal conditions and alert the operator of a problem by displaying a code that will aid in correcting

the problem.

If a malfunction occurs:

1 The transmission gear display shows the letter “E” followed by

a 2-digit alphanumeric code. Multiple error codes are possible.

2 The display alternates between “E” and the error code until the

malfunction is corrected. The transmission is not disabled.

Record the error codes and have the AWD electrical system repaired by a qualified service technician. Some error codes will disable the AWD system.

NOTE! “L1”, “L2” and “L4” Series error codes indicate a serious

problem with hydraulic oil temperature, level or pressure. Shut the

grader down immediately and correct the problem.

Instrument panels

30 Pedestal instrument panel

2

Articulation indicator gauge

The indicator needle displays the degree the grader frame is articulated. The frame is straight with the needle in the center position.

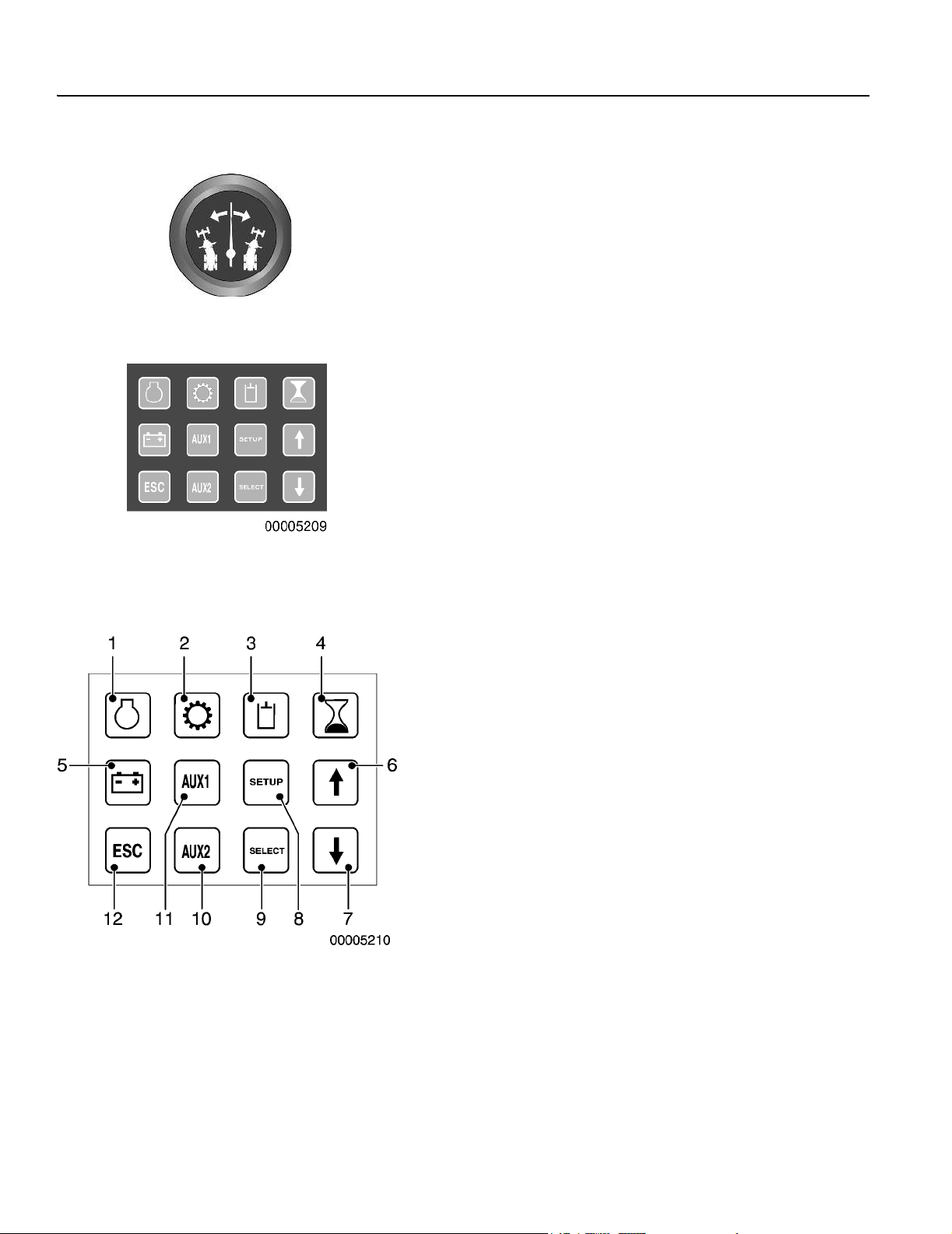

3

Keypad, display unit

The keypad allows access to information in different areas of the

grader. The information is organized into systems (function

groups).

Engine

Engine speed, Coolant temperature, Oil pressure, Air inlet temperature, Boost temperature, Boost pressure, Fuel temperature,

Fuel pressure (G740B, G746B and G780B only), Coolant level.

1Engine 7 Arrow down

2Transmission 8Setup

3Hydraulics 9Select

4 Hourmeter 10 Auxiliary 2

5 Electrical system 11 Auxiliary 1

6 Arrow up 12 Esc

Transmission

Transmission oil pressure, Filter bypass (optional), VHP status

Hydraulics

Brake pressure, Hydraulic filter bypass (optional), Hydraulic oil

temperature (optional), Hydraulic oil level (optional).

Electrical system

System voltage

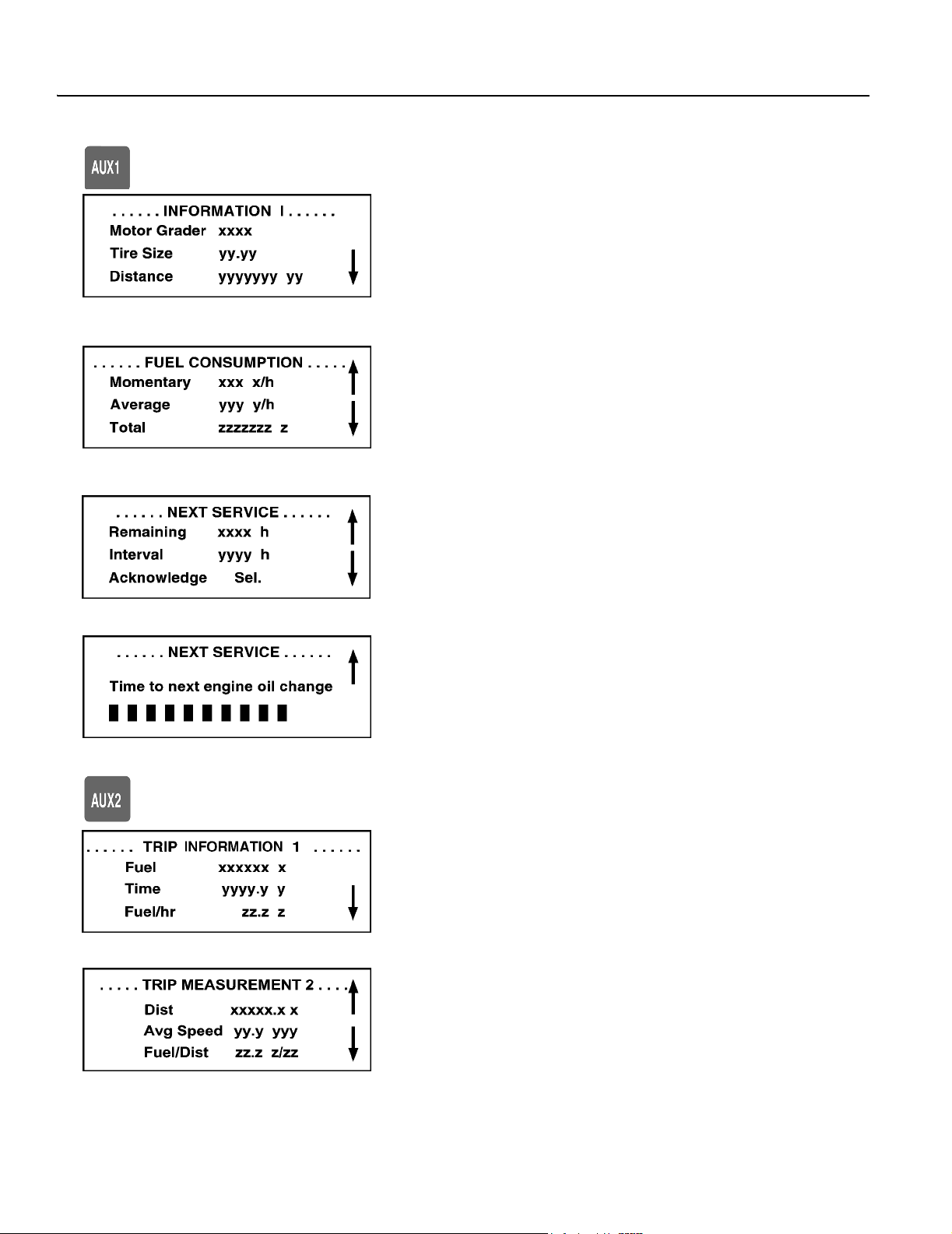

AUX1 (Grader information)

Model, Tire size, Distance (only with speedometer option), Instantaneous fuel consumption, Average fuel consumption, Total fuel

consumption, Time to next service, Next service interval.

AUX2 (Trip measurement information)

Fuel used, Time, Fuel/hour, Distance, Average speed, Fuel/distance, Reset (changes fuel, time and distance values to zero).

Instrument panels

Pedestal instrument panel 31

The following functions can be controlled from the keypad:

– Selecting function group by direct selection (function key)

– Browsing within a function group (the arrow keys)

– Activating/deactivating functions (on/off)

– Setting to zero/acknowledge (time/distance/cycles)

– Numerical settings (the arrow keys)

– Alpha-numerical settings (the arrow keys)

– Simpler settings (e.g. increase/reduce)

Engine, Transmission, Hydraulics, Hourmeter, Electrical,

Auxiliary 1 and Auxiliary 2 keys, display information about the

respective function group.

SETUP key displays the menu for making changes to units and

language. Refer to Setup, language and units page 34.

Arrow Up and Arrow Down keys are used to scroll in a function

group menu. Select key is used to change and confirm settings.

ESC key returns the display to “Operating display”, regardless of

which menu is showing.

When in the SETUP mode, pressing ESC will bring you back to

the top of the selected menu.

Refer to Setup, language and units page 34.

Instrument panels

32 Pedestal instrument panel

Display unit

Starting sequence (initial display)

(Ignition key in the “I” position)

The starting sequence takes about 4 to 5 seconds. At this time, a

test program runs to verify the system.

The progress of this test is indicated on the display unit by the appearance of black squares from 1 to 7.

During the first part of the test, the control lamps will light up and

the gauges will indicate (at twelve o’clock).

Displayed information

The display unit provides information to the operator. This information is divided into three groups:

1 Operating information, etc.

2 Warning displays (low pressure etc.)

Operating information display

3 ERROR displays (sensor and control device check)

1 Engine speed

2 Machine hours

3 Travel speed (optional)

4 Units for travel speed

Operating information display

n This is the default display.

n Obtain different information – engine, transmission, hydrau-

lics, hourmeter, electrical, auxiliary 1 and auxiliary 2 – by selecting buttons on the keypad.

Warning display

n Alerts the operator to a malfunction in machine systems (en-

gine, hydraulics, transmission, etc.).

n Applies to various areas of the grader.

Error display

n Alerts the operator to malfunction in the monitoring system.

n Applies to various areas of the grader.

Operating information (default display)

– Operating Information will be displayed after starting (unless

the operator had another display screen showing when the

power was switched off).

– At a speed above 20 km/h (12.4 mph) the Operating Informa-

tion will show the current travel speed (even if another display

screen was selected).

– If a display screen other than the Operating Information was

selected, the system will revert to that display screen when

the travel speed drops below 20 km/h (12.4 mph).

– Changing the display screen using the keyboard is only pos-

sible if the travel speed is below 20 km/h (12.4 mph).

Instrument panels

Pedestal instrument panel 33

Changing display screen

Move from one function group to another using the keys on the

keypad. When changing function group, the first menu of that

group will be displayed. To return to the Operating Information display, press the ESC key.

Setup

Settings of language and units are done in Setup, language

and units page 34.

Display classes

The information shown on the display for the operator is organized

into the following classes:

Class 1: WARNING

Shown regardless of which display is selected. “WARNING” display is shown for 2 seconds, then the previous display for 3 seconds. This is repeated for as long as the malfunction remains.

Generally, the red central warning lamp flashes while the alarm

text is shown.

Class 2: INFORMATION

Shown regardless of which display is selected. “INFO” display is

shown for 2 seconds, then the previous display for 3 seconds. This

is repeated until the info display has been shown 3 times.

Generally, the amber central warning lamp flashes while the info

display is shown.

The next time the machine is started, the info display is repeated

if it is still active.

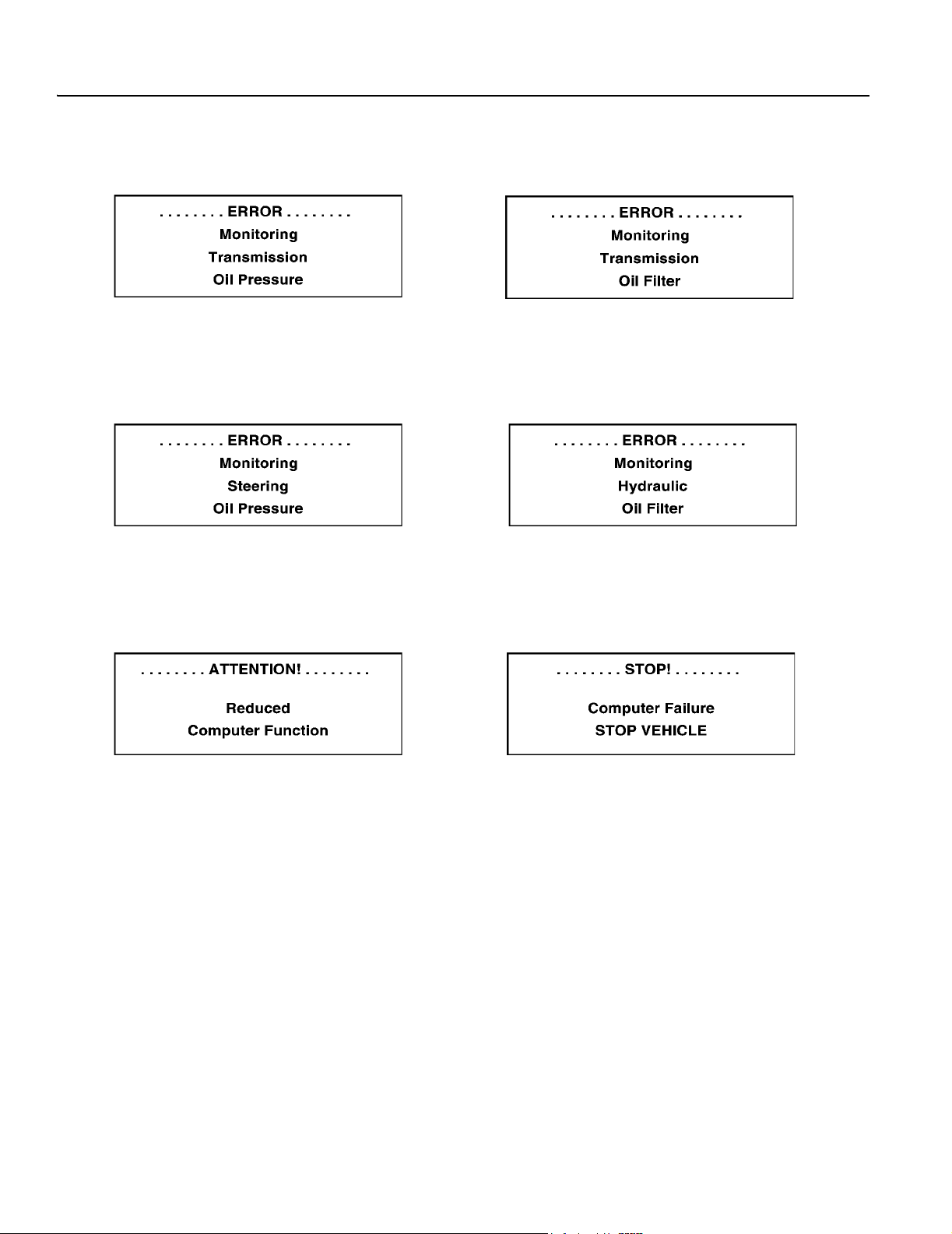

Class 3: ERROR

Shown regardless of which display is selected. “ERROR” display

is shown for 2 seconds, then the previous display for 3 seconds.

This is repeated as long as the malfunction remains.

Generally, the amber central warning lamp flashes while the error

display is shown.

Class 4: SERVICE INFO

Shown regardless of which display is selected. “SERVICE INFO”

display is shown for 2 seconds, then the previous display for 3

seconds. This is repeated until acknowledged by “reset”.

Generally, the amber central warning lamp flashes while the service info display is shown.

Multi-info/warning/error display:

If several info/warning/error displays are active simultaneously,

they are shown one after the other.

Machines with the optional speedometer

At vehicle speeds greater than 20 km/h (12.4 mph), the info/warning/error display is shown first, then “Operating info” is shown,

then the next info/warning/error display, etc. At speeds less than

20 km/h (12.4 mph), the display information follows the sequence

described in its class, with the “previous” display shown between

the alternating multiple displays.

For machines not equipped with a speedometer, the information

displayed follows the sequence described in its class above, with

the “previous” display shown between the alternating multiple displays.

Instrument panels

34 Pedestal instrument panel

Setup, language and units

Language

– Depress the SETUP key, then depress the SELECT key to

– Select the required language with up or down arrow keys.

– After the language has been chosen, press SELECT. If no

Units

– By pressing the SELECT key, the display will change from the

– Choose the required units with the arrow keys and press SE-

– Press ESC to return to the main menu.

To cancel a setting, press ESC. The SETUP menu will appear.

Press ESC again to return to the main menu.

show the language menu. Available languages are English,

French, Spanish, Swedish, and German.

change of the setting is required, just press SELECT.

language menu to the menu for “Units”.

LECT. If no change of the setting is required, just press

SELECT.

Information display screens

Function groups

Each function group consists of one or more display screens. If

there is more than one screen for each function group, an arrow

pointing downward will be displayed in the bottom, right-hand

corner of the display. Arrows pointing upward and downward

indicate there are screens above and below the current one.

To browse within a function group, press the down or up arrow

keys.

NOTE! If “Er” is shown for a value in any display screen, it in-

dicates an error in the signal monitoring that information.

x = Engine speed (revolutions per minute).

y = Engine coolant temperature, units are °C or °F. Shown down

to 0 °C, below that shown as < 0 °C or < 0 °F.

z = Engine oil pressure, units are in bar or psi.

x = Intake air temperature, units are °C or °F. Indicates actual

temperature down to 0 °C, below that shown as < 0 °C or <

0 °F.

y = Charge air temperature, units are °C or °F. Indicates actual

temperature down to 0 °C, below that shown as < 0 °C or <

0 °F.

z = Charge air pressure, units are in bar or psi.

x = Fuel temperature, units are °C or °F. Indicates actual tem-

perature down to 0 °C, below that shown as < 0 °C or < 0 °F.

y = Fuel pressure, units are bar and psi.

z = Coolant level (normal or low).

Instrument panels

Pedestal instrument panel 35

x = Transmission oil pressure (indicates normal or low).

y = Transmission oil filter (indicates normal, clogged).

z = VHP status (indicates ON or OFF).

x = Brake system pressure (indicates normal or low).

y = Hydraulic oil filter (indicates normal or clogged).

z = Hydraulic oil temperature (indicates normal or high).

x = Time in hours, up to 99999.9.

x = Electrical system voltage (real time) in volts DC.

Instrument panels

36 Pedestal instrument panel

x = Machine model

y = Tire size designation

y = Distance travelled, units in km or mi. Shown up to

NOTE! Values for distance are only shown if the speedometer

option is installed on the machine.

x = Current fuel consumption, shown in L/h or g/h (liters per

y = Average fuel consumption per hour, shown in L/h or g/h (li-

z = Total fuel consumption, calculated up to 9999999 liters or

999,999 km or 621,372 miles.

hour or US gallons per hour).

ters per hour or US gallons per hour). Calculated by dividing

total fuel consumed by engine hours.

2641720 US gal, in one unit increments.

x = Time remaining to next service interval.

y = Service interval, shown as 250, 500, 1000, 2000. When 8

hours remain to next service, display shows “Time for service”.

To acknowledge and remove information, press SELECT.

The bars indicate the total time left until the next service interval.

Each one represents 25 hours.

When 8 hours remain to next service, the display shows “Time to

change engine oil”.

To acknowledge and remove information, press SELECT.

x = Fuel consumption since resetting, in liters or US gal up to

999,999 liters or 264,200 US gal.

y = Time since resetting in hours up to 9999.9

z = Fuel consumption per hour since resetting, up to 99.9 L/h or

26.4 US gal/hr.

NOTE! To reset, see Trip information reset to follow.

x = Total distance since resetting in km (or mi) up to 9999.9 km

(6213.6 mi), alternatively –

y = Average speed since resetting up to 99.9 kmh (62.1 mph)

shown in kmh (kilometre/hour) or mph (miles/hour), alternatively –

z = Fuel consumption per unit distance since resetting, up to

99.9 in L/km or US mi/gal, alternatively –

NOTE! Values based on distance only available with speedometer option. If speedometer not available, value displays

as “n/a”.

Instrument panels

Pedestal instrument panel 37

Trip information reset:

– Press AUX 2, display shows “TRIP INFORMATION 1”.

– Press the down arrow, display shows “TRIP

INFORMATION 2”.

– Press the down arrow, display shows “TRIP RESET”.

– Press SELECT to reset. The display shows “TRIP RESET –

RESETTING”.

– Trip data is now set to zero.

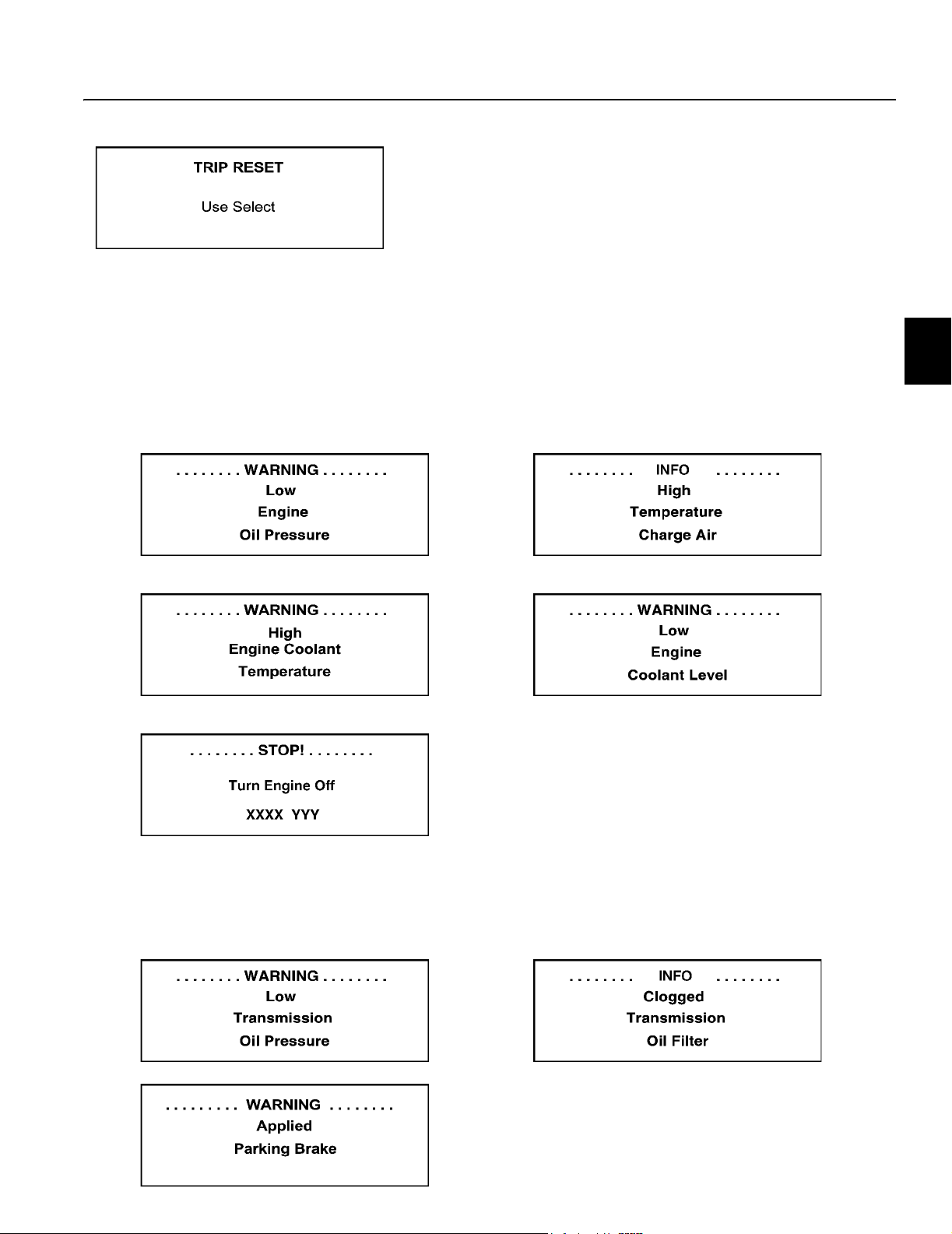

Warning displays

The following alarm texts may appear on the display unit.

ENGINE, warning and information displays

XXXX = PPID, PID, or SID

YYY = Numeric value 1 - 999

TRANSMISSION, warning and information displays

Instrument panels

38 Pedestal instrument panel

HYDRAULICS, warning and information displays

ELECTRICAL SYSTEM, warning and information displays

WARNING DISPLAYS, other

Instrument panels

Pedestal instrument panel 39

ERROR DISPLAYS, sensor and actuator switches, engine

XXXX = PPID, PID, or SID

YYY = Numeric value 1 - 999

Instrument panels

40 Pedestal instrument panel

ERROR DISPLAYS, sensor and actuator switches, transmission

ERROR DISPLAYS, sensor and actuator switches, hydraulics

ERROR DISPLAYS, sensor and actuator switches, other

Instrument panels

Pedestal instrument panel 41

4

4-way hazard flasher switch

Depress the top of the rocker switch to turn on the 4-way flashers.

Depress the bottom of the switch to turn them off.

The directional indicator lamp in the center display will flash when

the 4-way flashers are activated. The red indicator lamp on the

switch will flash when the flashers are activated.

5

Differential lock/unlock switch

The top of the rocker switch is depressed to activate the differential lock; the bottom of the switch is depressed to deactivate.

The differential lock status lamp in the center display panel and the

lamp on the switch energize when the differential lock is in the

LOCK position.

Put the control switch in the LOCK position for normal grading operations when maximum traction is required. Put the control

switch in the UNLOCK position when differential action is required.

This will reduce the turning radius and decrease tire scuffing when

operating on paved surfaces.

WARNING!

Lock or unlock the differential ONLY when driving at slow

speeds, in a straight line or if the grader is stopped. Do

not lock or unlock the differential while making a turn or

when the tandem wheels on one side are spinning.

Damage to the differential could result.

Instrument panels

42 Pedestal instrument panel

6

MBCS (Moveable Blade Control System)

lock pin switch

The switch has a secondary release to activate it and prevent involuntary release of the MBCS lock pin. Push up on the secondary

release and the top of the rocker switch to retract the pin. The

MBCS status lamp in the center display energizes to indicate that

the lock pin is retracted.

Push the bottom of the switch to engage the MBCS lock pin.

See also

Moveable Blade Control System page 107.

7

Secondary steering system test switch

(optional)

This is a momentary style switch. Push on the top of the switch to

activate and deactivate the system. The switch defaults to the off

position.

To test the Secondary steering system:

n Turn the ignition key to the “I” (running) position. Do not start

the engine.

n Depress the top of the rocker switch to activate the system.

The Red central warning lamp, Primary steering system lamp

and the Secondary steering lamp in the center instrument

panel will energize accompanied by a buzzer and display

message.

Instrument panels

Pedestal instrument panel 43

n Check the system by turning the steering wheel.

WARNING!

Do not operate the supplementary steering system longer

than two minutes. Equipment damage will result.

n If the steering wheel does not turn easily, there is a fault in the

system. Have the system repaired by a qualified service technician.

8

Directional indicator/High beam/Horn but-

ton

Directional indicator

Move the turn signal switch lever UP to activate the right-hand turn

signal. Move the turn signal switch lever DOWN to activate the

left-hand turn signal.

High beam

Pull the lever back towards the operator to change the headlights

from low beam to high beam and back. A blue lamp illuminates in

the display panel to indicate high beam.

Horn button

Push in on the end of the lever to sound the horn.

Instrument panels

44 Pedestal instrument panel

9

Float valves power switch

The float valve switch arms the float system for the moldboard and

attachments. This is a momentary style switch.

Push the power switch up to activate the system; push down to deactivate. Lights mounted on the front of the pedestal indicate that

the system is activated. See below.

WARNING!

Do not use float control to lower moldboard. Loss of

control of grader could result.

10

Front float valves system indicator lights

(control lamp amber)

These indicator lamps are mounted on the front right-hand side of

the pedestal. They illuminate when the Front float valve system is

active. If the option is not installed on the grader, the lamp will not

illuminate.

NOTE! If the valve is already in the float position (4th position

detent), and the floats have not been activated, move the lever out of the float position in order to activate the system.

11

Parking brake switch

Push in the knob to apply the parking brake; pull out to release it.

The switch must be pushed in (parking brake applied) to start the

grader.

Instrument panels

Side console instrument panel 45

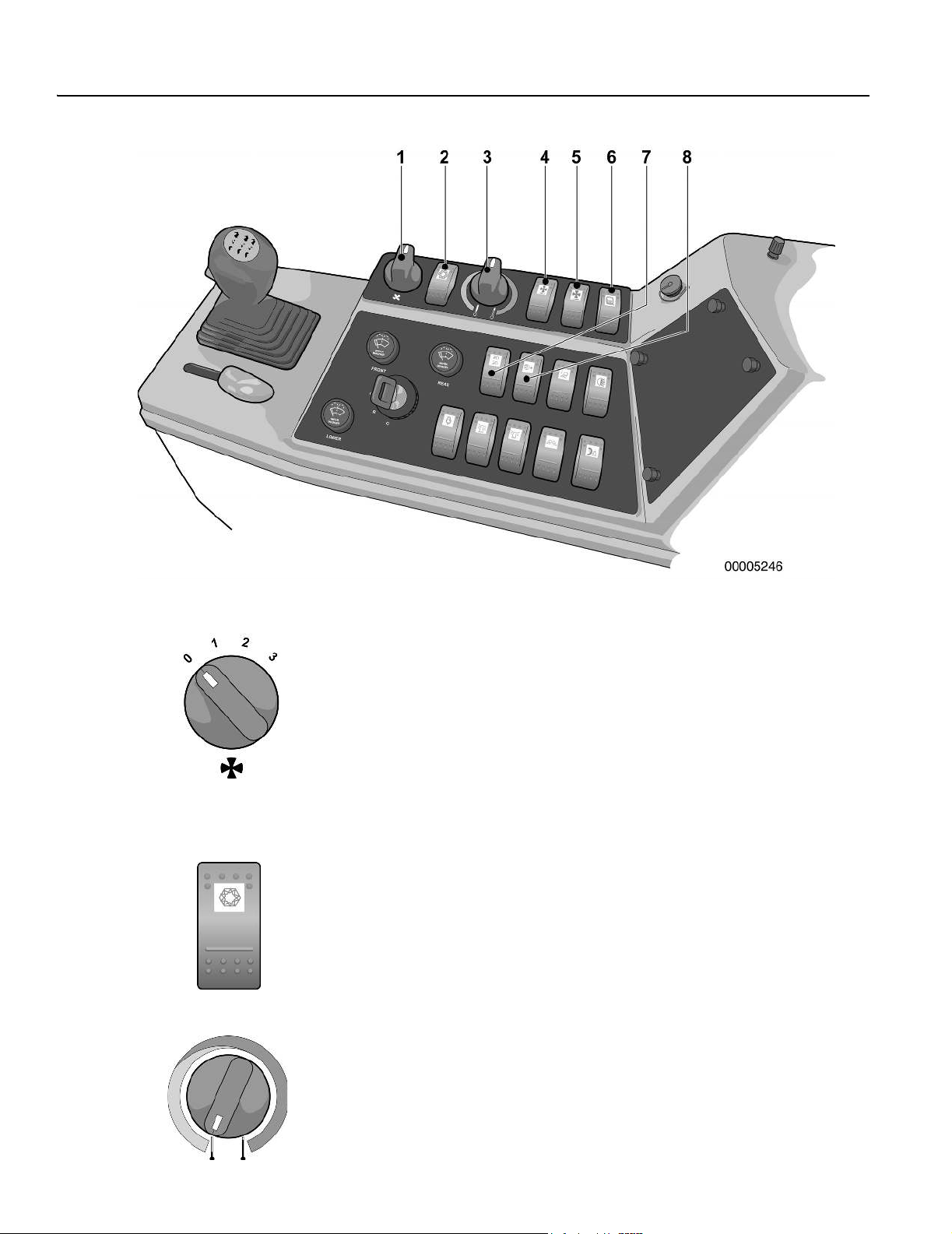

Side console instrument panel

1 Heater/air conditioner fan speed switch 12 Ignition switch

2 Air conditioner switch 13 Engine preheat switch

3 Heater/air conditioner temperature control 14 Amber revolving beacon switch

4 Front defroster fan switch 15 Blue revolving beacon switch

5 Rear defroster fan switch 16 Wing lights switch

6 Heated mirrors switch 17 Tire pump switch

7 Headlights and parking light switch 18 Moldboard lights switch

8 Extra headlights or EEC headlights and parking lights switch 19 Rear flood lights switch

9 Lower windows wiper/washer 20 Fuse and relay center access panel

10 Front windshield wiper/washer 21 Socket for service display unit

11 Rear windshield wiper/washer 22 Instrument lighting level

23 24V Remote electrical receptacle (not

shown)

Instrument panels

46 Side console instrument panel

1

Heater air conditioner fan speed switch

(optional)

Turn the knob to increase or decrease the heater air/conditioner

fan speed.

0 = System off

1 = Low fan speed

2 = Medium fan speed

3 = High fan speed

2

Air conditioner switch

(optional)

The air conditioning system is turned on and off using the rocker

switch. Depress the top of the switch to turn the system on. Depress the bottom of the switch to turn it off. An indicator lamp in the

switch illuminates when the switch is activated.

3

Heater/air conditioner temperature control

(optional)

Turn the knob clockwise to raise the air temperature (warmer).

Turn it counterclockwise to lower the air temperature (cooler).

Instrument panels

Side console instrument panel 47

4

Front defroster fan switch

(optional)

This is a three position switch. Depress the top of the switch to position two to activate low speed. Depress the top of the switch

again to position three to activate high fan speed. Depress the bottom of the switch to turn it off.

5

Rear defroster fan switch

(optional)

This is a three position switch. Depress the top of the switch to position two to activate low speed. Depress the top of the switch

again to position three to activate high fan speed. Depress the bottom of the switch to turn it off.

6

Heated mirrors switch (optional)

Depress the top of the switch to activate the heated external cab

mirrors. An indicator lamp in the switch illuminates to show the

switch has been activated. Depress the bottom of the switch to

turn them off.

7

Headlights, EEC headlights and parking

lights switch

This is a three position rocker switch. Depress the top of the switch

to position two to turn on the parking lights only. Depress the top

of the switch to position three to turn on the front headlights along

with the parking lights. If the high beam lights are on, the blue control lamp in the center display panel will be on.

8

Extra headlights switch

(optional)

This switch is used for extra headlights. Depress the top of the

rocker switch to turn on these lights. Depress the bottom of the

switch to turn them off.

Instrument panels

48 Side console instrument panel

9

Lower windows wiper/washer

(optional)

The wiper switch has three positions. Move it clockwise one indexed position for normal speed. Move it two indexed positions for

fast speed. The windshield washer activates when the switch is

pushed (spring return). See also Windshield washer fluid reser-

voir, front and rear windows page 200

10

Front windshield wiper/washer

(optional)

The wiper switch has three positions. Move it clockwise one indexed position for normal speed. Move it two indexed positions for

fast speed. The windshield washer activates when the switch is

pushed (spring return).

11

Rear windshield wiper/washer

(optional)

The wiper switch has three positions. Move it clockwise one indexed position for normal speed. Move it two indexed positions for

fast speed. The windshield washer activates when the switch is

pushed (spring return).

Instrument panels

Side console instrument panel 49

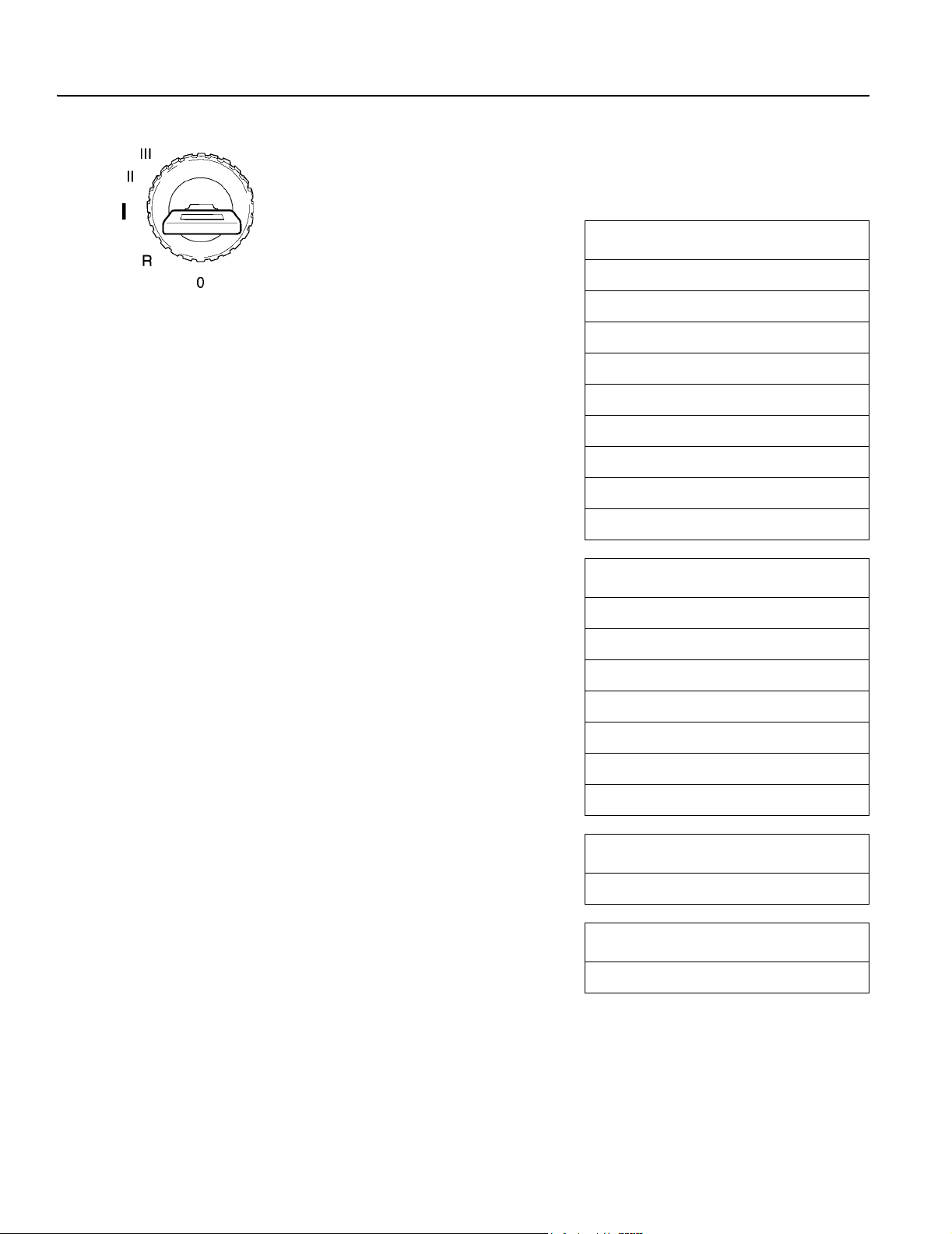

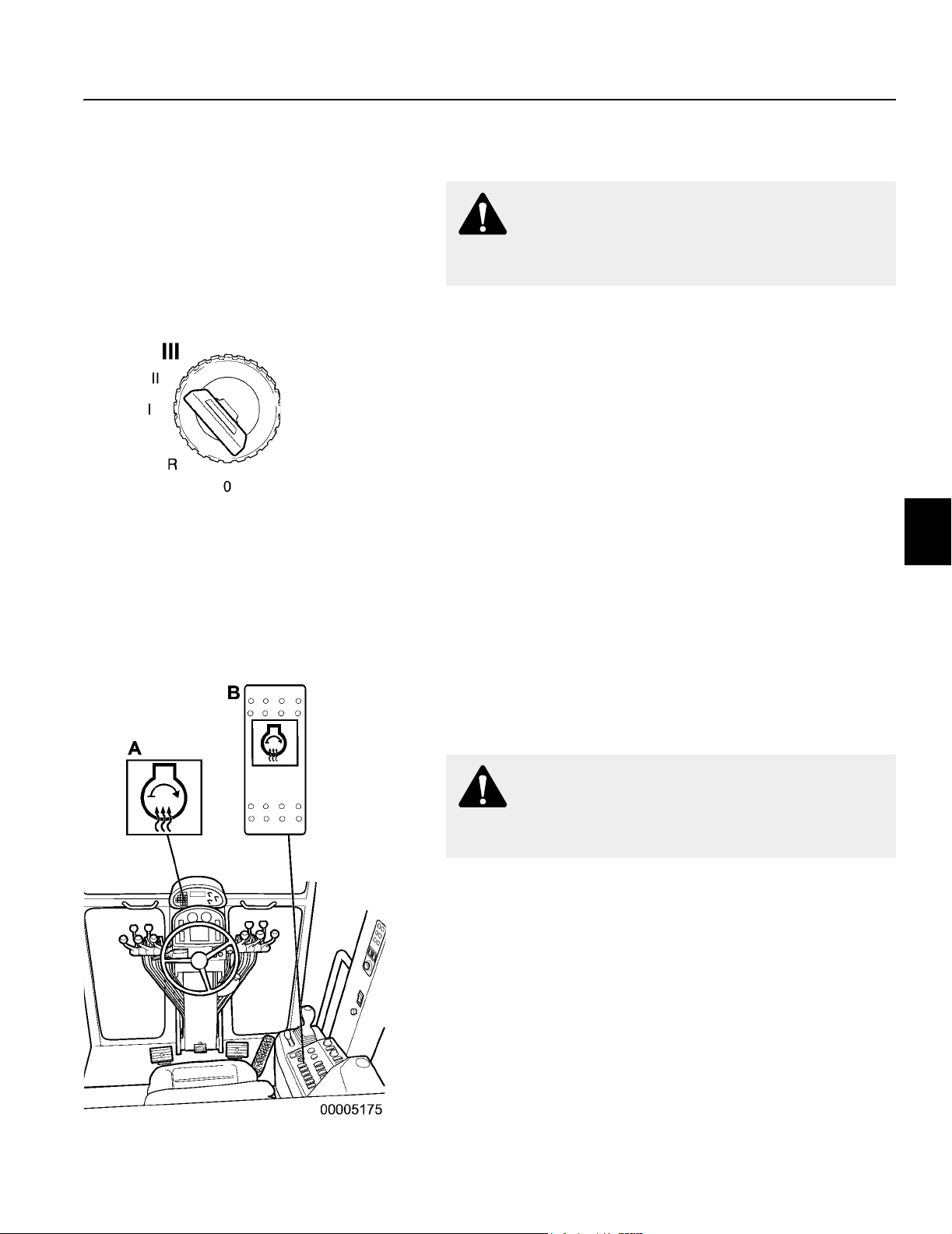

12

Ignition switch

The Ignition switch has four positions.

O Turned off

R Radio position

I Running position and preheating position

II (not used)

III Starting position

See also Ignition switch page 83.

13

Engine preheat switch

This momentary style switch is used for connecting a heating element in the intake manifold.

To turn on the preheating element, turn the ignition key to the “I”

position. Depress and release the switch. The lamp in the center

instrument panel illuminates to indicate the element is connected.

Refer to Starting the engine page 85.

14 and 15 Amber and blue revolving beacon light

switches

(optional)

Depress the top end of the rocker switch to turn on the revolving

beacon. Depress the bottom end of the rocker switch to turn it off.

An indicator lamp on the switch illuminates when the switch is activated.

16

Wing lights switch (optional)

Depress the top end of the rocker switch to turn on the wing lights.

Depress the bottom of the switch to turn them off. An indicator

lamp on the switch illuminates when the switch is activated.

17

Tire pump switch (optional)

Depress the top end of the rocker switch to activate the tire pump.

Depress the bottom of the switch to turn it off. An indicator lamp

on the switch illuminates when the switch is activated.

Instrument panels

50 Side console instrument panel

18

Moldboard lights switch

(optional)

Depressing the top of the rocker switch turns on the moldboard

work lights. Depress the bottom of the switch to turn them off. An

indicator lamp on the switch illuminates when the switch is activated.

19

Rear flood lights switch

(optional)

Depressing the top of the rocker switch turns on the floodlights on

the rear of the machine. Depress the bottom of the switch to turn

them off. An indicator lamp on the switch illuminates when the

switch is activated.

Instrument panels

Side console instrument panel 51

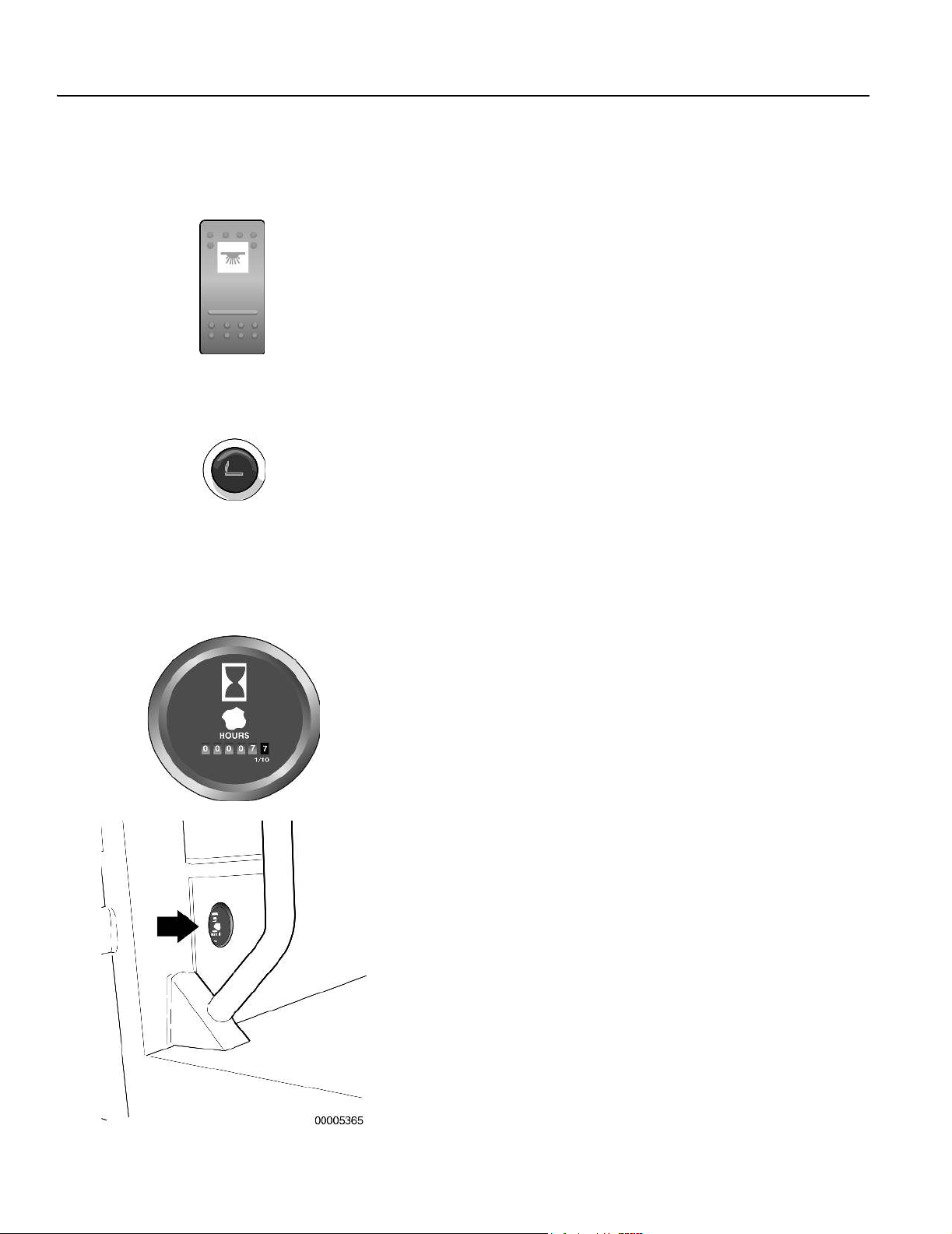

20