Page 1

Operating Instructions & Parts Manual

Version B - For Reduction G016.J

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

®

4W315C

Dayton Diesel Electric

Generator

Description

Dayton professional-duty generators are rugged and compact. These models provide

dependable, trouble-free service. The alternators are brushless with revolving fields.

Yanmar diesel engines provide long life under heavy use. These engines are governed to

maintain engine speed of 3600 RPM under load. 3600 RPM engine speed provides 120/

240V, 60 Hz power. Additional features include circuit breaker protection, spark-arresting

muffler, large fuel tank, oil alert system, electric starter, and a pressurized lubrication

system.

Unpacking

1. Remove generator from carton.

2. Remove any protective packaging

applied to generator for shipment.

3. Check for loose or missing parts. Check

for shipping damage. If any parts are

missing or damaged, promptly inform

dealer where you bought generator.

4. Battery cables are supplied. These cables

are in a separate bag inside generator

carton. You must install these cables to

engine. See “Battery,” page 7 for

installation instructions.

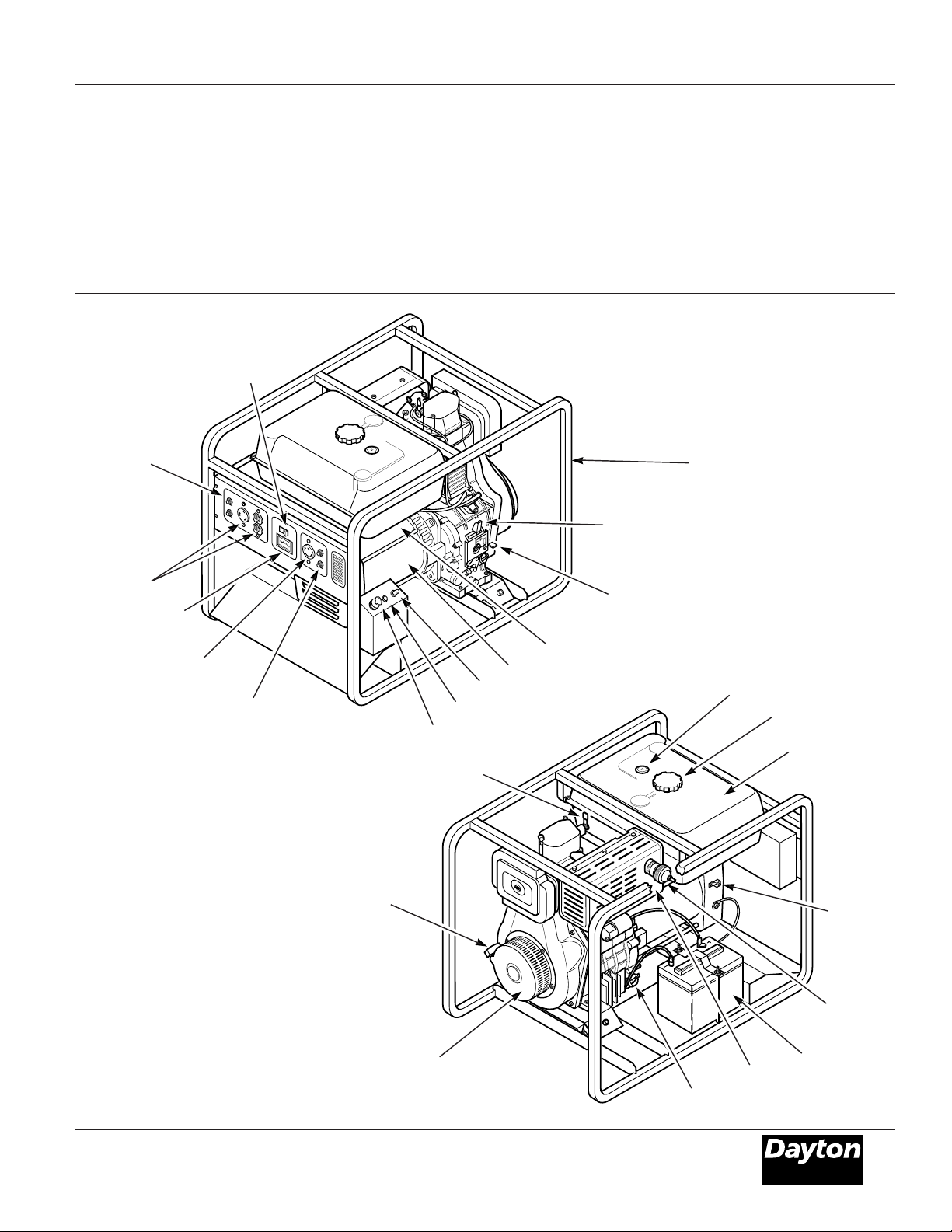

Figure 1 – Model 4W315C

Form 5S3125

®

Printed in U.S.A.

03430

0703/215/VCPVP

Page 2

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

Specifications

ELECTRICAL SPECIFICATIONS

Rated Maximum Rated Amperage Rated Amperage

Wattage* VA 120V 240V

5000 6500 41.7 20.8

4W315C

* Single-phase, 1.0 power factor

NOTE: Ratings apply to SAE standard conditions. Reduce ratings 3

Fahrenheit rise above 60°F.

GENERAL SPECIFICATIONS

Yanmar Yanmar Fuel Fuel Tank Oil Alert Electric Weight

Engine H.P. Model Type Capacity System Start (pounds)

10 L100 Diesel 4.2 gal. Yes Yes 241

RECEPTACLE SPECIFICATIONS

120V 120V, 30-Amp 120/240V, 20-Amp 120V Full

Duplex Twist-Lock Twist-Lock Power Switch

Yes Yes Yes Yes

ELECTRICAL COMPONENT SPECIFICATIONS

Resistance in Ohms

Stator Stator Rotor Rotor Capacitor,

Main Auxiliary Primary Secondary MFD Diodes (2)

Winding * Winding ∆ Winding † Winding † 450 Volt 800 Volt

0.54 1.38 0.61 2.29 50 70 Amp

1

/2% for each 1000 feet above sea level and 1% for each 10°

(*) Connect T2 (green) and T3 (black). Measure resistance between T1 (red) and T4 (yellow).

(∆) Resistance between brown and white leads.

(†) Remove diodes to check resistance.

2

107358

Page 3

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Product Identification

Full Power

Selector Switch

Control Panel

1

2

0

V

O

L

T

S

F

U

L

L

P

1

O

2

0

W

O

E

N

R

L

Y

S

E

L

E

C

T

1

O

2

R

0

/

2

4

0

V

1

0

2

1

0

0

/

2

0

4

0

2

V

0

O

0

L

T

S

A

3

C

0

V

O

L

T

S

O

U

T

P

U

T

V

O

L

T

A

G

E

120 Volt

Receptacles

Hour Meter

F

E

Roll Cage

N

U

R

P

O

T

S

Engine Run Lever

Engine Stop Lever

120/240 Volt

Receptacle

Circuit

Breaker

Figure 2 – Portable Generator

Starter Grip

Battery Discharge Lamp

Electric Start Switch

Decompression

Lever

Engine

Alternator

Oil Alert Lamp

Fuel Valve (under fuel tank)

EF

Fuel Gage

Oil Dipstick

Fuel Cap

Muffler

Fuel Tank

Ground

Lug

Spark

Arrester

Battery (Not

included, must

be purchased

separately)

107358

®

3

Page 4

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

General Safety Information

IMPORTANT: Read these instructions and

engine owner’s manual carefully. Become

familiar with generator before trying to

operate or service it. Know its uses,

limitations, and any hazards involved.

Improper use of generator can cause

severe injury or death from explosion, fire,

burns, electrical shock, or carbon monoxide poisoning.

Make certain you read and understand all

warnings. Keep these instructions for

reference. They are your guide to safe and

proper operation of this generator.

Safety information appears throughout

these instructions. Pay close attention to

them. Below are definitions for the safety

information listed throughout this manual.

Under this heading,

installation, operating, and maintenance procedures or

practices will be found that, if not carefully

followed, WILL result in IMMEDIATE

serious personal injury or death.

Under this heading,

installation, operating, and maintenance procedures or

practices will be found that, if not carefully

followed, COULD result in severe personal

injury or death.

Under this heading,

installation, operating, and maintenance procedures or

practices will be found that, if not carefully

followed, MAY result in minor personal

injury, product or property damage.

Engine exhaust

contains poisonous

carbon monoxide gas. Overexposure

will cause loss of consciousness and

will lead to death. Use only in wellvented areas. Make sure area has

plenty of free-moving, fresh, outside

air. Never run generator in an enclosed

or confined area. Never run generator

inside occupied building.

Early signs of carbon monoxide

poisoning resemble the flu, with

headaches, dizziness, or nausea. If you

have these signs, get fresh air at once!

Some people are more affected by

carbon monoxide than others. These

include pregnant women, persons with

heart or lung disease or anemia, those

under the influence of alcohol, and

those at high altitudes.

Diesel fuel pre-

sents a hazard of

fire. Diesel fuel is flammable.

• Keep fuel out of children’s reach.

• Refuel generator in a well-vented

area. Do not fill fuel tank in the dark.

Do not refuel while engine is

running. Unhook all electrical loads

and shut off engine before refueling.

• Do not overfill fuel tank. Always

allow room for fuel to expand. If you

overfill tank, fuel can overflow onto

hot generator. This can cause fire.

After refueling, tightly close fuel

tank cap.

• Do not spill fuel. If fuel spills, make

sure area is dry before starting

engine.

• Never smoke in refueling area. Never

allow open flames or sparks in area.

• Store fuel in approved container.

Store fuel in a well-vented area free

of open flames or sparks.

Guard against fire

hazard. Keep

operation area well-vented. Keep

generator at least three feet away

from any object. Do not place flammable objects near generator.

• Do not use generator where flam-

mable vapors are present. Some

vapors are heavier than air. These

vapors settle in low-lying places.

• Do not use generator in enclosed

spaces. This includes motor home or

RV generator compartments.

Guard against

electric shock.

Generator produces high voltage. This

high voltage can cause severe electric

shock. Only responsible adults should

use the generator.

•Properly ground generator before

starting.

• Never let anyone operate or service

generator without proper instructions.

•Avoid contact with live terminals or

bare wires.

• Do not use generator outdoors in

rain or snow.

• Do not use generator near standing

water or snow.

• Do not use if generator is wet or

damp.

• Do not use generator in highly

conductive areas. These areas include

metal decking and steelwork.

• Only use grounded extension cords.

• Do not use any worn or damaged

electric cords. Electric shock or

damage to generator may result.

• On construction sites, you must use a

Ground Fault Circuit Interrupter

(GFCI). This helps guard against

electric shock. OSHA and the National Electrical Code requires this.

• Do not wear damp clothing or wet

shoes when using generator.

107358

4

Page 5

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

General Safety Information

(Continued)

Guard against

burns. Hot engine

parts can cause severe injury. Use

caution and remain alert when using

generator.

• Keep children and animals away

from generator while it is running or

hot.

• Keep all covers and shields in place.

Keep them tightly secured.

• The muffler becomes very hot during

operation. The muffler remains hot

for a while after shutdown. Do not

touch muffler while it is hot. Do not

let muffler touch anything flammable. Let engine cool before

transporting or storing.

Have standby

installation to

home or building performed by a

licensed electrician. Do not let anyone

else wire into a utility circuit. Personal

injury, equipment damage, or damage

to home could occur.

Battery contains

sulfuric acid.

Battery acid is poisonous if swallowed.

Contact with skin or eyes may cause

severe burns. Do not tilt generator

with battery installed. Tilting could

cause battery acid to spill. Wear

protective clothing and face shield

when servicing. Keep out of children’s

reach.

Only a qualified

electrical service

person should service and repair

generator.

• Generator produces high voltage.

Use extreme caution when working

on electrical parts.

• When working on generator, avoid

hot muffler, exhaust manifold, and

engine parts. Severe burns may

occur.

• Do not work on generator when

tired.

• Use only factory approved replace-

ment parts.

Keep generator

and nearby areas

clean.

• Keep generator free of oil, mud, and

other foreign matter.

• Remove anything that creates

slippery areas around generator.

• Remove oily rags and other items

that create fire hazards.

• Keep a fire extinguisher nearby.

Make sure it is rated ABC by the

NFPA. They are good for all uses.

Consult your local fire department.

• Keep fire extinguisher well maintained. Be familiar with its use.

Know how to stop

engine quickly.

Know how to use all controls.

Prolonged exposure to loud noise

can cause hearing loss.

• When working around generator,

wear approved hearing protection.

• Remember neighbors when using

generator.

existing electrical circuits. The generator output will back-feed into the

utility power line. This may electrocute

a power company line repair person.

Also, if generator is powering electrical circuits, the chance of an electrical

fire exists.

Keep sparks, flames, and cigarettes

away. Do not remove or install battery

cables when engine is cranking or

running. Only service or use battery in

a well-vented area.

107358

Never connect

generator to any

Battery gives off

explosive gases.

Store generator in

a well-vented area.

Make sure fuel tank is empty. Never

store with fuel in tank.

Never operate

generator

• if engine speed changes greatly

• if engine misfires often

• if powered items overheat

• if electrical output drops

• if it is sparking

• if it produces smoke or flames

• if it vibrates at high levels

• if it has a damaged receptacle

5

Generator Features

OIL ALERT SYSTEM

The oil alert system protects the engine

from low oil damage. This system automatically shuts down the engine and

prevents engine restarting if the oil

pressure falls too low.

If this system shuts down the engine, the

engine will not start until you add oil. The

oil alert lamp is near engine starter switch

(See Figure 3, page 6). Add oil to engine

(See “Engine Oil,” page 8).

See engine owner’s manual for more

information.

®

Page 6

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

Generator Features

(Continued)

OIL

CHARGE

OFF

Battery

Discharge

Lamp

Figure 3 - Battery Discharge Lamp and Oil

Alert Lamp Location

BATTERY DISCHARGE LAMP

The battery discharge lamp (See Figure 3,

above) will light if battery charger is not

operating while engine is running. If this

happens, the battery will not charge and

will eventually run down. Have battery

charging circuit repaired by authorized

service person.

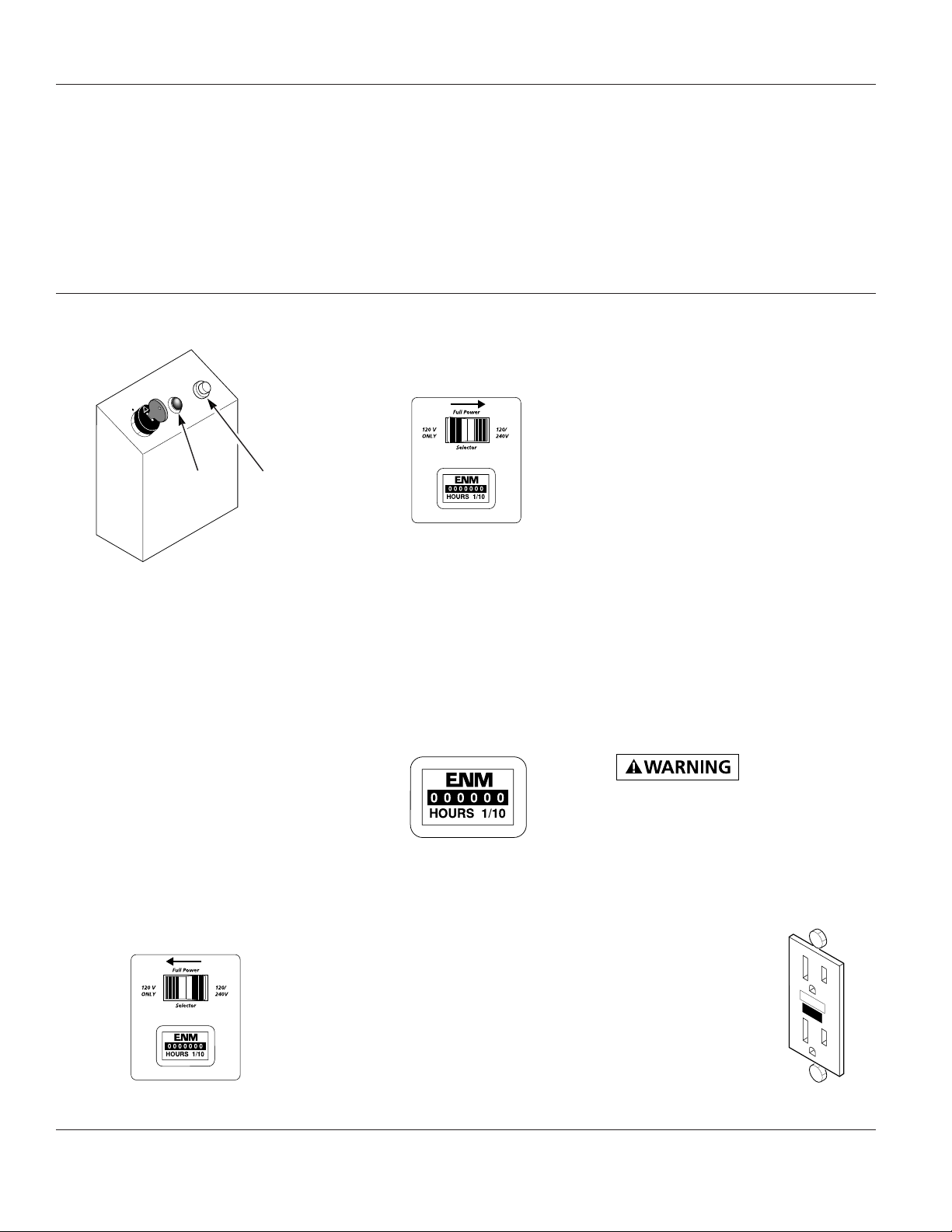

FULL POWER SELECTOR SWITCH

The full power selector switch is on the

control panel. The switch has two positions: 120 VOLT ONLY, and 120/240 VOLT.

120 VOLT ONLY: This position sends full

power to the 120V receptacles only. 240V

power is not available. Use this position

when powering 120V items only.

Figure 4 – Full Power Selector Switch in 120

Volt Only Position

Oil Alert

Lamp

120/240 VOLT: This position sends full

power to the 120/240V receptacle. It also

powers the 120V receptacles at reduced

wattage capacity.

Figure 5 – Full Power Selector Switch in

120/240 Volt Position

IMPORTANT: Do not move the full power

selector switch while powering electrical

items. Unplug all items before moving

switch. Failure to do so can damage switch.

HOUR METER

The hour meter will measure the total run

time of the generator, including all idle

time. Hour meter is accurate up to 1/10 of

an hour.

Figure 6 – Hour Meter

ELECTRIC START

A battery is not supplied with generator.

You must provide a 12-volt, 45-amp-hour

battery. For more battery information, see

“Battery,” page 7.

GROUND FAULT CIRCUIT INTERRUPTER

RECEPTACLE

This generator has a 120-volt ground fault

circuit interrupter (GFCI) receptacle. The

GFCI receptacle is on the control panel.

The GFCI protects you against hazardous

electrical shock caused when your body

becomes a path through which electricity

travels to reach ground. This could happen

when you touch an appliance or cord that

is ‘live’ through faulty mechanism, damp

or worn insulation, etc.

When protected by the GFCI, you may still

feel a shock, but the GFCI should cut it off

quickly. A person in normal health should

not receive serious injury.

NOTE: Infants and very small children may

still be affected.

TEST PROCEDURE

Check the GFCI receptacle every month.

This insures it is working right.

1. Push black TEST button. Red RESET

button should pop out. This should

trip GFCI, resulting in no electrical

power at receptacle. Verify this by

plugging test lamp with good bulb

into receptacle. If lamp does not work,

GFCI receptacle is good.

If RESET button

does not pop out,

do not use the GFCI receptacle. Contact

a qualified electrician for repairs.

2. If the GFCI receptacle tests okay, restore

power by pushing the RESET button

back in. The test lamp should work at

this time.

IMPORTANT: You

must press the RESET

button firmly and fully.

It should lock into

place. If the GFCI does

RESET

TEST

not lock into place, do

not use receptacle.

Contact a qualified

electrician for repairs.

Figure 7 – GFCI Receptacle

107358

6

Page 7

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Generator Features

(Continued)

RECEPTACLE CIRCUIT BREAKER

The circuit breakers protect the receptacles

and alternator. Overloading generator will

trip circuit breaker. A short circuit in item

being powered will also trip breaker. If this

occurs, unplug electrical load from

receptacle. Let circuit breaker cool down.

Push circuit breaker button to reset.

Electric motors need higher starting

current. They require up to 3-times their

rated wattage to start. The starting current

needed may be too high. This can cause

nuisance circuit breaker tripping. To help

prevent this, start electric motors first.

Connect additional items to generator

after starting motors. If this continues to

happen, reduce the total generator load.

20

Figure 8 – Receptacle Circuit Breaker Button

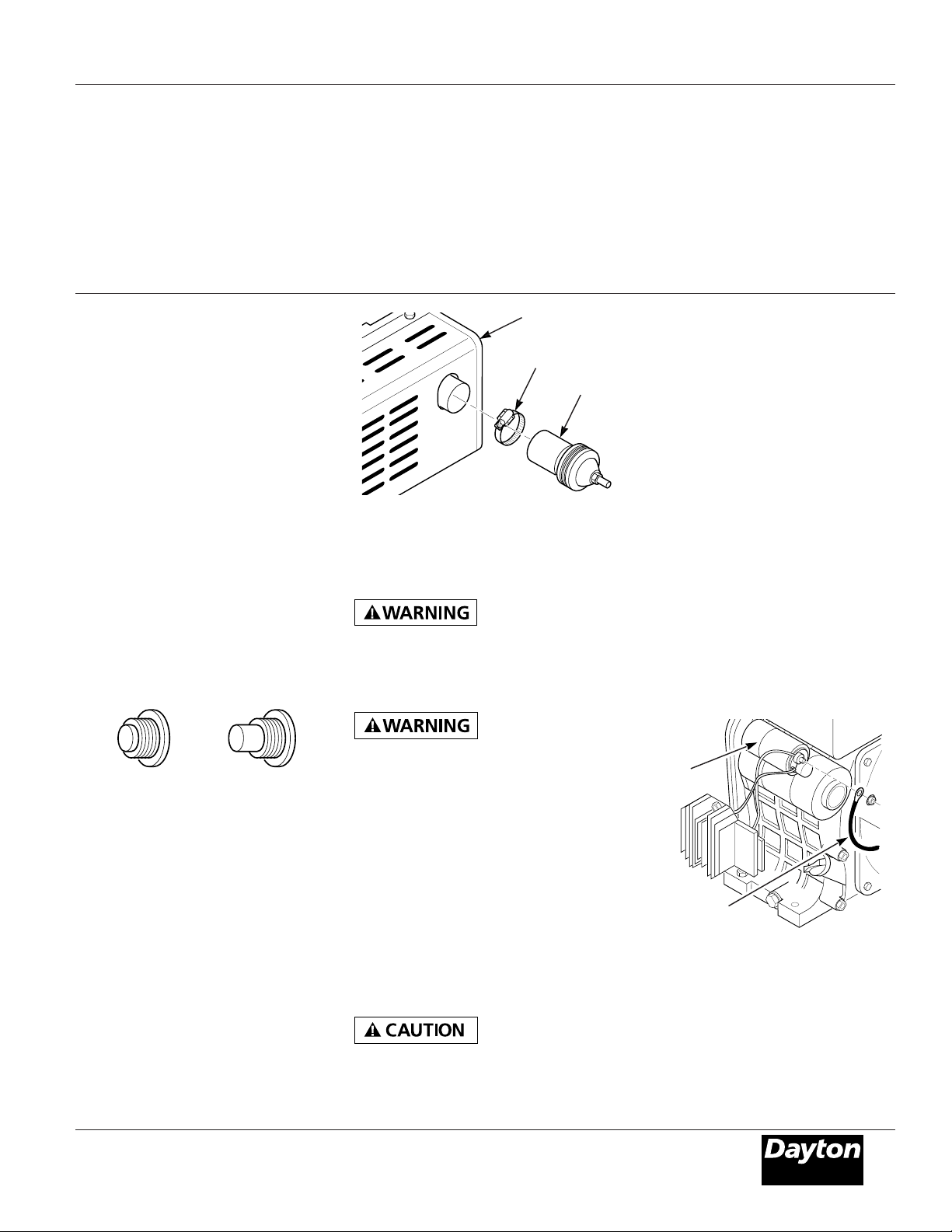

SPARK ARRESTER

We ship a spark arrester with this generator. You must install spark arrester to

muffler (See Figure 9).

A spark arrester is required if using

generator in a national forest and other

designated state and local areas. Check

local codes.

The spark arrester needs periodic cleaning.

A dirty spark arrester reduces engine

output and increases fuel consumption. It

also makes starting difficult. See engine

owner’s manual for cleaning instructions.

20

TrippedNormal

Muffler

Clamp

Figure 9 - Installing Spark Arrester

Spark

Arrester

Assembly

BATTERY

Battery gives off

explosive gases.

Keep sparks, flames, and cigarettes

away. Do not remove or install battery

cables when engine is cranking or

running. Only service or use battery in

a well-vented area.

Battery contains

Contact with skin or eyes may cause

severe burns. Do not tilt generator with

battery installed. Tilting could cause

battery acid to spill. Wear protective

clothing and face shield when servicing.

Keep out of children’s reach.

• If battery acid gets on your skin,

wash with water.

• If battery acid gets in your eyes,

flush with water at least 15 minutes.

Call a doctor at once.

Battery acid is poisonous.

• If swallowed, drink large amounts of

water or milk. Follow with milk

of magnesia or vegetable oil. Call a

doctor at once.

the red, positive (+) battery cable

terminal. Insulate with electrical tape.

Exposed terminal may spark when

generator runs.

sulfuric acid.

If you remove

battery, insulate

IMPORTANT: Make sure battery connec-

tions are the correct polarity. Electric start

generators use negative ground, 12-volt

DC starting system.

A battery is not supplied with generator. You

must provide a 12-volt, 45-amp-hour

battery. The positive and negative battery

cables are supplied with generator. You must

install these cables before mounting battery.

Always wear safety glasses when working

with battery. Make sure battery terminals are

clean. Make sure cable connections are tight.

Always shut down engine before removing

or attaching battery cables. Always remove

the negative (–) cable first. Always attach

negative (–) cable last.

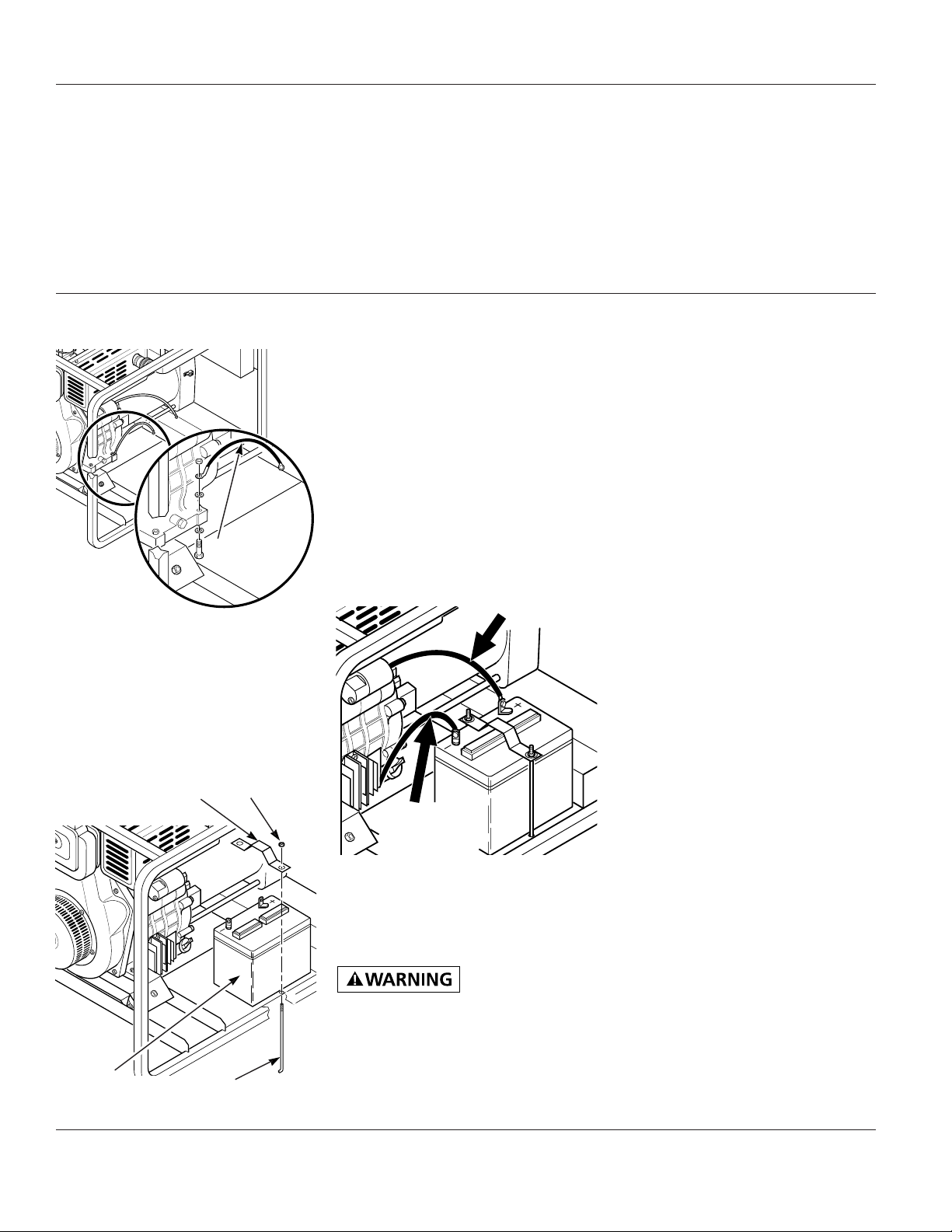

INSTALLING BATTERY CABLES TO

ENGINE

1. Attach the red, positive (+) battery cable

to the starter solenoid on engine (See

Figure 10).

Starter

Solenoid

Red, Positive (+)

Battery Cable

Figure 10 – Connecting Red, Positive (+)

Battery Cable to Starter Solenoid on Engine

2. Attach the black, negative (–) battery

cable to the engine block. Use the bolt,

nut, and two washers provided with the

battery cables. Attach cable as shown in

Figure 11, page 8.

107358

®

7

Page 8

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

Assembly (Continued)

Black, Negative (–)

Battery Cable

Figure 11 – Connecting Black, Negative (–)

Battery Cable to Engine Block

MOUNTING BATTERY TO GENERATOR

1. Secure battery to generator by battery

hold-down system. This system consists

of the battery mounting bracket, hook

bolt, and nut (See Figure 12).

Battery Mounting

Bracket

Battery

Figure 12 – Battery Hold-Down System

Nut

Hook Bolt

2. Locate the red, positive (+) battery cable

from starter solenoid. Connect it to the

positive (+) battery terminal (See Figure

13).

3. Locate the black, negative (–) battery

cable attached to engine block. Connect

it to the negative (–) battery terminal

(See Figure 13).

4. Check battery before starting engine.

Make sure fluid levels are full. Make

sure battery is charged.

See engine owner’s manual for more

information.

Red, Positive Cable

From Starter Solenoid

Black, Negative

Cable From

Engine Block

Figure 13 – Connecting Positive and

Negative Cables to Battery

Installation

FUEL

Diesel fuel pre-

fire. Diesel fuel is flammable.

• Keep fuel out of children’s reach.

• Refuel generator in a well-vented

area. Do not fill fuel tank in the dark.

Do not refuel while engine is

running. Unhook all electrical loads

and shut off engine before refueling.

sents a hazard of

• Do not overfill fuel tank. Always

allow room for fuel to expand. If you

overfill tank, fuel can overflow onto

hot engine. This can cause fire. After

refueling, tightly close fuel tank cap.

• Do not spill fuel. If fuel spills, make

sure area is dry before starting

engine.

• Never smoke in refueling area. Never

allow open flames or sparks in area.

• Store fuel in approved container.

Store fuel in a well-vented area free

of open flames or sparks.

Use clean, fresh, diesel fuel. Use diesel fuel

with cetane rating of 45 or higher. Avoid

getting dirt, dust, or water in fuel tank.

See engine owner’s manual for more

information.

ENGINE OIL

We ship the generator without oil in the

engine crankcase. You must add oil before

starting engine. See “Engine Lube Oil,”

page 9 for specific oil type.

CHECKING OIL LEVEL AND ADDING OIL

Follow steps below to check oil level.

Make sure engine is level and stopped.

1. Remove dipstick (See Figure 14). Wipe

dipstick clean.

2. Insert dipstick into oil filler neck. Do not

screw it in. Oil level should be at top of

filler neck. Oil should cover most of

dipstick.

3. If level is low, fill to top of oil filler neck

(See Figure 14). Use proper lube oil to

preserve your engine.

NOTE: If oil level is too low, oil alert

system will shutdown engine and prevent

engine from restarting.

107358

8

Page 9

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Installation (Continued)

Oil Level

At Top Of

Filler Neck

Dipstick

Oil

Figure 14 – Checking Oil Level

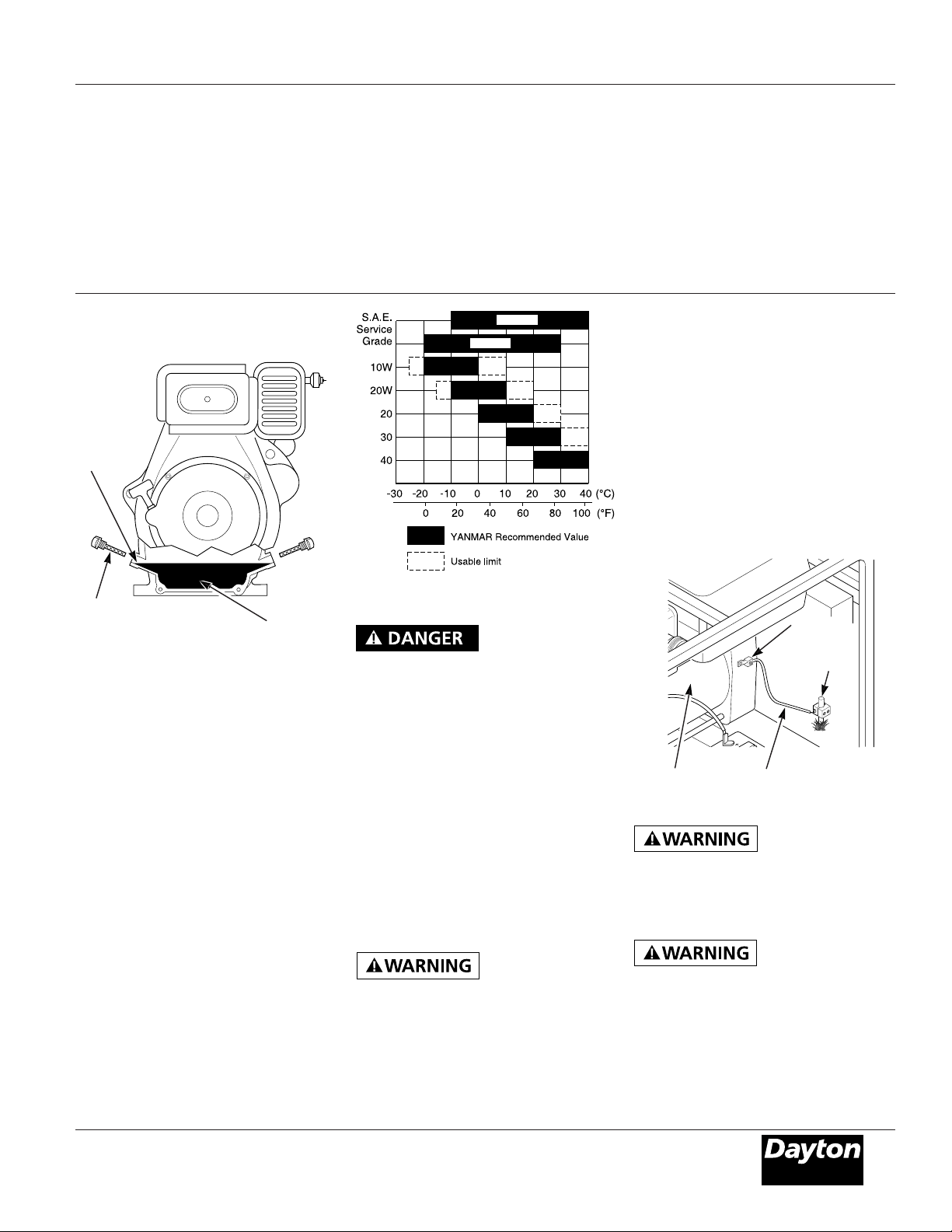

ENGINE LUBE OIL

Nothing affects the performance and

durability of your engine more than the

lube oil you use. Using inferior oil or not

changing oil regularly increases the risk of

piston seizure, piston ring sticking, and

accelerated wear of cylinder liner, bearing

and other moving parts. Your engine life

may be seriously shortened. Yanmar

recommends CC/CD oil of API engine

service classification, stock number 4ZF20.

Always use oil with the right viscosity for

the ambient temperature in which you are

using the engine. Use the chart below

when choosing your engine oil.

Lube Oil Capacity:

4W315C1.74 qt.

107358

20W 40

10W 30

VENTILATION

Use only in well-

vented areas. Make

sure area has plenty of free-moving,

fresh, outside air. Never run generator

in an enclosed or confined area. Never

run generator inside occupied building.

Engine exhaust contains poisonous

carbon monoxide gas. Overexposure

will cause loss of consciousness and

will lead to death.

This generator needs cooling air to run

properly. Never block free-flowing, cooling

air to generator. Overheating will occur

without cooling air. This will damage the

generator. Keep generator at least three

feet away from any object.

GENERATOR GROUNDING

You must properly

earth-ground

generator before starting. This will

help guard against deadly electric

shock. Only use grounded plugs with

generator. Only use grounded extension cords. Only use three-wire or

double-insulated power tools.

Grounding generator helps prevent electric

shock from a ground fault condition.

Locate ground lug on end of generator

housing (See Figure 15). Attach a #10

stranded-copper ground wire to ground

lug. Drive grounding point into ground.

Grounding point can be a stake, grounding rod, or pipe. Grounding point should

be copper or brass. Attach ground wire to

grounding point. You must supply the

ground wire and grounding point. They do

not come with generator. Follow the

National Electrical Code and all state and

local codes. Consult your power company

or a licensed electrician.

Ground Lug

Copper or

Brass

Grounding

Point

Alternator

Figure 15 – Grounding Generator

metal pipe being used to carry combustible materials or gases.

Ground Wire

For a grounding

point, do not use

DUST, DIRT, RAIN, AND SNOW

Do not use genera-

tor outdoors in

rain or snow. Do not use generator

near standing water or snow. Do not

use if generator is wet or damp.

Operating generator in these conditions increases the risk of electrocution. Severe injury or death can occur.

Do not use generator in extremely dusty or

dirty conditions. This will severely affect its

life. Keep generator clean. Do not allow

®

9

Page 10

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

Installation (Continued)

dust, dirt, rain, or snow to collect on it.

Protect generator from outdoor elements.

EXTENSION CORDS

Only use grounded extension cords. Be sure

to use extension cord with proper wire

gauge size. See chart below.

RECOMMENDED MINIMUM WIRE

GAUGES (AWG) FOR EXTENSION CORDS

Ampere AWG for AWG for AWG for

Load 50' Cord 100' Cord 150' Cord

218 18 18

318 18 18

416 16 16

516 16 16

616 16 14

816 14 12

10 16 14 12

12 14 14 12

14 14 12 10

16 12 12 10

20 10 10 8

GROUND FAULT PROTECTION

Ground Fault Circuit Interrupter (GFCI)

helps guard against electric shock. On

construction sites, you must use a GFCI.

OSHA and the National Electric Code

requires this.

STANDBY INSTALLATION TO HOME OR

BUILDING

Have standby

installation

performed by a skilled, licensed

electrician. Do not let anyone else wire

into a utility circuit. Personal injury,

equipment damage, or damage to

home could occur.

IMPORTANT: This generator will not

power your entire home. Most home

utility electric service is more than 60

amps. This will exceed generator output.

Only power needed items during a power

outage. Make sure total wattage of

electrical load does not exceed rated

wattage of generator.

You can use this generator as a standby

power source. During a power outage, the

generator will power selected items in a

building. Have generator and additional

wiring installed by a skilled, licensed

electrician. This is not a do-it-yourself job.

Follow all local codes.

The electrician must install a doublethrow transfer switch. This isolates

existing electrical circuits from the

utility power line. If not isolated,

generator output

will back-feed into

utility power line.

This may electrocute a power company

line repair person.

DETERMINING ELECTRICAL LOAD FOR

GENERATOR

You must decide what electrical load your

generator can power. Do this before using

generator. Use the following four-step

method. It will help you select a load that

is not too large. Make sure total wattage

of all electrical loads does not exceed

5000 watts. Electric motors present a

special problem when figuring load. Read

Step 3 carefully.

1. Make two lists of items you want

powered by generator. List all motors

and motor powered appliances in one.

List all lights, small appliances, etc. in

the other. For standby service to home

or building, only include items you must

power.

2. Enter running watts of each item except

motors. The light bulb or appliance

nameplate lists its wattage. Remember,

1KW = 1000 watts.

NOTE: The nameplate may not list

wattage. It may only list volts and amps.

The formula for finding wattage is: Volts x

Amps = Watts. For example: An appliance

nameplate states 3 amps at 120 volts. 3

amps x 120 volts = 360 watts.

3. Electric motors present a special

problem. They require 3 to 6 times their

rated full-load wattage to start. Chart 2,

page 11, shows starting watts (maximum volt-amperes [VA]) for different

size motors. For example: an electric

motor nameplate states 5 amps at 120

volts. 5 amps x 120 volts = 600 watts

running. Multiply this figure by 3. This

will show the starting watts (maximum

VA) needed. 600 watts x 3 = 1800

watts (VA) to start. When figuring the

generator load for motors, you must use

the starting watts (maximum VA) figure.

Do not use the running watts figure.

NOTE: Some motors require nearly the

same wattage to run as to start. These

items include saws, drills, hair dryers, and

food mixers. See Chart 1, page 11 for

typical appliance wattage examples.

4. Add watts and starting watts (maximum

VA) of all items. This total must not be

larger than 5000 watts. It is a good idea

to have up to 25% extra capacity for

future needs or extra equipment.

10

107358

Page 11

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Installation (Continued)

TYPICAL ELECTRIC APPLIANCE WATTAGES

Chart to be used as a reference. Data may vary with size, make, and/or model.

CHART 1

Equipment Watts (Max.VA)

Running Watts

Light bulb (100W) 100 100

Radio 150 150

Fan 200 600

Television 400 400

Furnace fan—1/3 HP with blower 600 1800-2400

Vacuum cleaner 600 750

Sump pump—1/3 HP 700 2100-2800

Refrigerator/freezer 800 2400-5000

6" Circular saw 800 1000

Floodlight 1000 1000

1/2" Drill 1000 1250

Toaster/coffeemaker 1200 1200

Skillet 1200 1200

14" Chain saw 1200 1500

Water well pump—1/2 HP 1000 3000-6000

Hot plate/range (per burner) 1500 1500

10" Table saw 2000 6000

Water heater (storage-type) 5000 5000

Starting

CHART 2

Motor Approximate (Max. VA) (Max. VA) (Max. VA) (Max. VA)

HP Running Universal Motors Repulsion Capacitor Split Phase

Rating Watts (small appliance) Induction Motors Motors Motors

1/8 500 625 1100 1500 2250

1/4 700 875 1550 2100 3150

1/3 800 1000 1750 2400 3600

1/2 1100 1375 2400 3300 4950

3/4 1400 1750 3100 4200 †

1 1700 2125 3750 5100 †

1

2 2450 3075 5400 7350 †

3 3600 † 7800 10800 †

(*) Always use starting watts (maximum VA), not running watts, when figuring correct electrical load.

(†) Motors of higher horsepower are not generally used.

NOTE: Please check with appliance manufacturer for maximum wattage required.

107358

Approximate Approximate Approximate Approximate

Starting Watts* Starting Watts* Starting Watts* Starting Watts*

1

/2 2100 2625 4620 6300 †

11

®

Page 12

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

Operation

HIGH AND LOW TEMPERATURE

OPERATION

Air temperature affects generator output.

Output drops 1% for each 10° temperature rise above 60° F. Very low temperatures may make the engine hard to start.

See engine owner’s manual for more

information.

GENERAL INFORMATION

This generator is not large enough to

power your entire home. Do not connect

generator to any existing electrical circuits.

Plug items directly into generator receptacles. Do not exceed amperage rating of

receptacles. Only use grounded cords.

Use only in well-

vented areas. Make

sure area has plenty of free-moving,

fresh, outside air. Never run generator

in an enclosed or confined area. Never

run generator inside occupied building.

engine exhaust contains poisonous

carbon monoxide gas. Overexposure

will cause loss of consciousness and

will lead to death.

Never connect

generator to any

existing electrical circuits. The generator output will back-feed into the

utility power line. This may electrocute

a power company line repair person.

Also, if generator is powering electrical circuits, the chance of an electrical

fire exists.

NOTE: We supply the engine owner’s

manual with generator. Refer to that

manual for questions concerning engine

operation.

USING RECEPTACLE

NOTE: Do not exceed amperage rating of

receptacles. Exceeding rating will trip

receptacle circuit breaker.

Use receptacles properly. Improper use

could damage generator. Use only

grounded extension cords. Power only

grounded or double-insulated items. Do

not overload receptacles. These generators have the following receptacles (See

Figure 16):

• 120V, 15-amp duplex receptacle

• 120V, 15-amp GFCI duplex receptacle

• 120V, 30-amp twist-lock receptacle

• 120/240V, 20-amp twist-lock receptacle

120V, 15-Amp GFCIDuplex

120V, 15-Amp Duplex

1

2

0

V

O

L

T

S

R

E

S

E

T

T

E

S

T

120

ONLY

120

240V

EN

M

0

000

000

HOURS 1/10

5

120V, 30-Amp

Twist-Lock

120/240V, 20-Amp

Twist-Lock

Figure 16 – Receptacle Locations

POWER CORD AND PLUG REQUIREMENTS

120V, 30-amp twist-lock receptacle

• NEMA L5-30P plug

• Three-wire, 30-amp cord

120/240V, 20-amp twist-lock receptacle

• NEMA L14-20P (20-amp) plug

• Four-wire, 20-amp cord

120 Volt

30 Amp

W

Ground

(Green)

(Neutral)

120/240 Volt

20 Amp

Ground

(Green)

W

Y

(Hot)

X

(Hot)

X

(Hot)

W

(Neutral)

G

Neutral

120V 120V

w

YX

G

Ground

Figure 17 – Cord and Plug Configurations

PRESTART

Operate generator on a firm, dry, and

clean surface. The surface must be level.

Protect generator from heavy dust, sand,

RES

ET

dirt, rain, or snow. Do not locate genera-

R

ES

ET

tor near standing water or snow. Make

sure area is well-vented.

Only responsible

adults should use

generator. Never let anyone operate

generator without proper instructions.

NOTE: If oil level is too low, oil alert

system will keep engine from starting (See

“Oil Alert System,” page 5). Make sure oil

level is full before starting. See Engine Oil,

page 8.

Before starting the engine, disconnect all

electric loads from generator.

You may need to bleed fuel line to remove

trapped air

• if starting engine for first time

• if starting engine after allowing

generator to run out of fuel

X

L5-30P

Plug

L14-20P

Plug

12

107358

Page 13

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Operation (Continued)

BLEEDING FUEL LINE

1. Loosen fuel line clamp and remove fuel

line from engine. Place open end of fuel

line over a clean container to catch any

fuel spilled in step 3, below.

2. Move fuel valve lever to the “O” (open)

position (See Figure 18).

3. Allow air to bleed from line. When fuel

exits fuel line in a steady stream,

reattach fuel line to engine.

4. Add spilled fuel back into fuel tank.

STARTING

Never use gaso-

line, paint thinner,

or any other flammable liquid as a

starting aid. An explosion may occur.

IMPORTANT: The engine speed is preset.

The throttle is locked in preset position. Do

not adjust throttle. Preset position lets

engine run at 3600 RPM under load. The

engine must maintain 3600 RPM for

generator to create correct voltage.

Running engine at lower speeds will

damage generator and powered items.

IMPORTANT: Never start generator with

electrical loads connected. Start engine

before adding electrical loads.

1. Make sure fuel tank is full. See “Fuel,”

page 8 for fuel information.

2. Move fuel valve lever to the “O” (open)

position (See Figure 18).

O

S

Fuel Valve

Lever

Figure 18 - Fuel Valve Lever In “O” (open)

Position

3. Move engine run lever to the RUN

position (See Figure 19).

Engine Run

Lever

RUN

STOP

Figure 19 - Engine Run Lever

You must fully

move engine run/

stop knob to the RUN position to run

engine at 3600 RPM. Do not run engine

at lower speeds. Running engine at

lower speeds will damage generator

and powered items.

4. Start the engine.

a. Electric Starter

(1) Slowly pull starter rope until you

feel strong resistance. Gently

return starter rope to engine.

(2) Push decompression lever all the

way down (See Figure 20). Decompression lever will stay in this

position until you turn starting key.

Decompression

Lever

Figure 20 - Decompression Lever

(3) Turn the starting key clockwise to

the START position (See Figure 21).

Hold it there until engine starts.

Starting Key

OIL

CHARGE

OFF

Figure 21 - Starting Key

(4) When engine starts, release key.

IMPORTANT: Do not use electric starter

more than ten seconds. Starter motor

damage may occur. If engine fails to start,

release the key and wait 15 seconds. After

15 seconds, try starting again.

107358

®

13

Page 14

Dayton Operating Instructions and Parts Manual

RUN

STOP

®

Dayton Diesel Electric Generator

4W315C

Operation (continued)

b. Recoil Starter

(1) Slowly pull starter rope until you

feel strong resistance. Gently

return starter rope to engine.

(2) Push decompression lever all the

way down (See Figure 22). Decompression lever will stay in this position until you pull starter rope.

Decompression

Lever

Figure 22- Decompression Lever

(3) Firmly grasp starter grip with both

hands. Remove slack from starter

rope by lightly pulling starter grip.

(4) To start engine, pull starter rope

briskly. You must pull the starter

rope all the way out. If not, the

engine will not start.

IMPORTANT: Do not let starter grip snap

back against engine. Return it gently. This

will prevent damage to starter.

Never use gaso-

line, paint thinner,

or any other flammable liquid as a

starting aid. An explosion may occur.

If engine does not start, repeat steps

under b. Recoil Starter on this page.

HIGH ALTITUDE OPERATION

This generator will not perform well at

high altitudes without proper adjustment. Contact a Yanmar dealer for

adjustment information.

ADDING ELECTRICAL LOADS

IMPORTANT: Do not overload generator.

Make sure total wattage of all electrical

loads does not exceed rated wattage of

generator. Overloading may shorten

generator life. It could also cause internal

damage to generator. Overloading

will trip circuit breaker.

IMPORTANT: Keep full power selector

switch in the 120 VOLT ONLY position if

only powering 120V items. Only move

switch to 120/240 VOLT position if

powering 240V items.

1. Check items to be powered. Their

nameplate lists their wattage ratings.

NOTE: The wattage ratings for some

electrical motors are misleading. They

may require 3 to 6 times their rated fullload wattage to start. You must figure

total electrical load wattage. Make sure

total wattage of all electrical loads does

not exceed rated wattage of generator.

See “Determining Electrical Load For

Generator,” page 10.

2. Start engine. Let engine reach full speed.

3. Connect electrical loads one at a time. If

the load consists of electric motors, start

them first. Always start the largest first.

Start each motor individually.

14

DISCONNECTING ELECTRIC LOADS

Remove electrical loads one at a time.

Remove voltage sensitive items first.

Voltage sensitive items include TVs, VCRs,

and other home electronic items.

STOPPING ENGINE

Follow the steps below to stop engine.

1. Remove all electrical loads from

generator (See “Disconnecting Electrical

Loads,” above). Remove electrical loads

one at a time.

2. Let engine run for two or three minutes

after removing electrical loads. This lets

engine cool slightly.

3. Push down engine stop lever (See Figure

23). This releases engine run lever and

stops engine. Do not stop engine with

the decompression lever.

4. Turn the starter key to the OFF position.

Engine Stop Lever

Figure 23 - Pushing Down Engine Stop

Lever

5. Turn fuel valve lever off. Do this by

moving valve lever to the “S” position

(See Figure 24, page 15).

6. Slowly pull starter rope until you feel

strong resistance. Gently return starter

rope to engine. This action closes the

intake and exhaust valves. This prevents

rust from forming while not using engine.

107358

Page 15

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Operation (continued)

O

S

Fuel Valve Lever

Figure 24 - Fuel Valve Lever In “S” Position

Maintenance and Repairs

Only a qualified

electrical service

person should service and repair the

alternator on this generator. Use only

factory approved replacement parts.

You must always

run the engine at

full speed. Do not run engine at lower

speeds. At full speed, the engine runs

at 3600 RPM under load. The engine

must maintain 3600 RPM for generator

to create correct voltage. Running

engine at lower speeds will damage

generator and powered items.

Shut off generator

before performing

maintenance.

IMPORTANT: Keep generator level when

servicing. Never turn generator upside

down or stand it on end to service.

NOTE: We supply the engine owner’s

manual with generator. Refer to that

manual for questions concerning engine

maintenance and repairs.

Non-engine parts require little maintenance.

Keep generator clean. Use a damp cloth to

clean outside surfaces. Never use water to

clean generator. Water can cause damage to

internal parts. Use vacuum to clean air inlet

and outlet louvers of alternator.

SERVICING THE ENGINE

For Yanmar engine replacement parts,

contact Grainger Parts at 1-800-323-0620.

Yanmar engine servicing should be

handled by your nearest authorized

Yanmar engine service firm. Contact

Yanmar at 1-847-541-1900 for nearest

authorized Yanmar engine service firm.

ENGINE MAINTENANCE

Periodic checks and maintenance are very

important for keeping the engine in good

condition and durable. The chart on page

18 indicates which checks to make and

when to make them. The mark “•”

indicates that special tools and skills are

required. Items marked “•” should be

serviced by an authorized Yanmar dealer,

unless the owner has the proper tools and

is mechanically proficient.

Consult your Yanmar dealer.

Shut off the

engine before

performing any maintenance. If the

engine must be run, make sure the area

is well ventilated. The exhaust contains

poisonous carbon monoxide gas.

After the engine

has been used,

clean the engine immediately with a

cloth to prevent corrosion and to

remove sediment.

Only use genuine

Yanmar parts. The

use of replacement parts which are

not of equivalent quality may damage

the engine.

HOW TO CHANGE YOUR ENGINE OIL

Remove the oil filler cap. Remove the drain

plug and drain the old oil while the engine

is still warm. The plug is located on the

bottom of the cylinder block. Tighten the

drain plug and refill with the recommended oil. (See the section under

“Preparations for Starting” in the engine

owner’s manual.)

CLEANING THE OIL FILTER

Loosen the fixing bolt and then pull out

the oil filter. Clean oil filter every six

months or 500 hours of operation.

CHANGING THE AIR CLEANER ELEMENT

Do not wash the air cleaner element with

detergent because this is a wet-type

element. Change air cleaner element every

six months or 500 hours of operation (or

earlier if dirty).

See the section for changing the air

cleaner element under “Preparations for

Starting” in the engine owner’s manual.

Never run the

engine without

the air cleaner element or with a

defective element.

NOTE: A clogged element hinders the

flow of air to the combustion chamber.

This reduces engine output, increases lube

oil and fuel oil consumption and makes

starting difficult. Make sure you clean your

107358

®

15

Page 16

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

4W315C

Maintenance and Repairs

(Continued)

element regularly.

CLEANING AND REPLACING THE FUEL

FILTER

The fuel filter also has to be cleaned

regularly to insure maximum engine output.

Clean fuel filter every six months or 500

hours of operation. Replace fuel filter every

year or 1000 hours of operation.

1. Drain the fuel oil from the fuel tank.

2. Loosen the nuts of the fuel cock and

pull out the filter from the fuel tank

filler port. Wash the filter thoroughly

with diesel fuel.

CLEANING THE SPARK ARRESTER

If the engine has

been running, the

muffler and the spark arrester will be

very hot. Allow these to cool before

proceeding.

Remove the lock nut, end cap and diffuser

discs and clean off the carbon deposits.

Clean spark arrester every three months or

100 hours of operation (or earlier if dirty).

Clamp

Spark

Arrester

Muffler

End Cap

Figure 25 - Spark Arrester

Diffuser

Discs

Lock Nut

A clogged spark

arrester hinders

the flow of exhaust gas. This reduces

engine output, increases fuel consumption and makes starting difficult.

Make sure you clean your spark

arrester regularly.

TIGHTEN CYLINDER HEAD BOLTS

Tightening the cylinder head bolts requires

a special tool. Don’t try it yourself. Consult

your Yanmar dealer.

CHECKING THE INJECTION NOZZLE,

INJECTION PUMP, ETC.

• Adjusting the valve head clearance for

the intake and exhaust valves.

• Lapping of intake and exhaust valves.

• Replacing piston ring.

All these require special tools and skills.

Consult your Yanmar dealer.

Do not perform the

injection nozzle

test near an open fire or any other kind

of fire. The fuel spray may ignite. Do

not expose bare skin to the fuel spray.

The fuel may penetrate the skin and

cause injury to the body. Always keep

your body away from the nozzle.

CHECKING AND REPLENISHING BATTERY

FLUID AND CHARGING THE BATTERY

Battery fluid will be lost through continuous charging and discharging.

The battery

electrolyte

contains sulfuric acid. Protect your

eyes, skin, and clothing. In case of

contact, flush thoroughly with water

and get prompt medical attention,

especially if your eyes are affected.

Batteries generate

hydrogen gas,

which can be highly explosive. Do not

smoke or allow flames or sparks near

the battery, especially during charging.

NOTE: Much more fluid is lost during

summer than in winter.

Before starting, check for physical damage

to the battery and also the electrolyte

levels, and replenish with distilled water up

to the upper mark if necessary. When

actual damage is discovered, replace the

battery. Check battery fluid monthly.

Before charging,

remove the cap

from each cell of the battery. Charge

the battery in a place where there is

plenty of ventilation. Discontinue

charging if the electrolyte temperature

exceeds 45° C (117° F).

Do not charge the

battery with the

battery cable still connected. The diodes

will be damaged by the high voltage.

Connect the (+)

lead of the charger

to the (+) terminal of the battery, and

the (–) lead to the (–) terminal. Reversed polarity will damage the

charger rectifier or the battery.

Storage

Remove all fuel

from fuel tank

before storing generator. Store fuel in

approved container. Store fuel in a

well-vented area free of open flames

or sparks.

The muffler

becomes very hot

during operation. The muffler remains

hot for a while after shutdown. Let

engine cool before storing.

IMPORTANT: Keep generator level while

in storage. Never store generator upside

down or standing on end.

Cover and store generator in a clean, dry

place. Do not expose generator to extreme

high or low temperatures during storage.

16

107358

Page 17

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Storage (Continued)

ENGINE STORAGE

If storing your engine for long periods,

make the following preparations.

1. Operate the engine for about 3 minutes

and then stop.

2. Stop the engine. Drain the engine lube

oil while the engine is still warm and fill

with new oil.

3. Pull the recoil starter slowly. Stop when

it feels tight. This closes the intake and

exhaust valves (in compression position)

and helps prevent rust from forming.

4. Wipe the oil and dirt from the engine

and store in a dry place.

CHART 3

Service Service Service Service

Item Check Monthly or 20 Hrs. or 100 Hrs. or 500 Hrs. or 1000 Hrs.

Daily Service Month 3 Months 6 Months Year

Check and replenish fuel oil

Drain fuel from fuel tank

Check and replenish lube oil

Check for oil leakage

Check and tighten engine parts

Check and tighten engine head bolts

Change lube oil (first time)

Change lube oil (each time after first)

Clean oil filter (replace if needed)

Replace air cleaner element (Service more

frequently when used in dusty areas)

Clean fuel filter

Replace fuel filter

Clean spark arrester

Check fuel injection pump

Check fuel injection nozzle

Check fuel piping (replace if needed)

Adjust valve head clearance for intake

and exhaust valves (first time at 20 hrs)

Adjust valve head clearance for intake

and exhaust valves (each time after first)

Lap intake and exhaust valves

Replace piston rings

Check battery fluid

First Every Every Every

107358

Special tools and skills required.

No special tools or skills required.

®

17

Page 18

Dayton Operating Instructions and Parts Manual

®

Dayton Diesel Electric Generator

Wiring Diagrams

4W315C

120/240V 20A

Receptacle

White

Black

Green

T2

Green

Red

Black

Red

T2

Black

Black

White

Main

Windings

Red

Black

Capacitor

White

Green/Yellow

Circuit

T1

Breaker

25A

Circuit

Breaker

25A

Yellow

Black

Red

White

T1

T3

T4

Black

T4

T3

Figure 26 - Alternator Wiring Diagram

Green/White

Charge

Coil

Green/White

White

Hour

Meter

T1

T2

Full Pwr

Selector

Switch

T3

Yellow

Red

Red

T4

Charge

Regulator

Fuse

Diode

White

Rotor

Green

Yellow

White

Black

White

120V, 15A

Receptacle

Duplex

Auxiliary

Phase

Diode

Red

White

2

3

4

1

Stator

Brown

White

120V, 15A

Receptacle

GFCI

HOT

LINE

Green

Black

Green

Green

WHITE

L1

Green

Yellow

White

White

T1

110/120V

Red

120V, 30A

Receptacle

Green

Stator

T2

T3

220/240V

110/120V

Key

Switch

T4

L2

Charge

Lamp

Circuit

Breaker

20A

Circuit

Breaker

20A

Black

Figure 27 - Engine Wiring Diagram

Green/White

Green/White

White Red

Red

Red

Bridge

Black

Starter

Motor/

Solenoid

+

-

Battery

30

86

Red White

Pressure Lamp

Black

Relay

Low Oil

Red

87

85

Shutdown

Solenoid

White

P

Yellow

Oil

Pressure

Switch

Black

18

107358

Page 19

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Model 4W315C

Troubleshooting Chart

NOTE: See engine owner’s manual for

engine troubleshooting.

Symptom

No voltage when starting generator with

no electrical load

Voltage is less than normal voltage with

no electrical load

Voltmeter reading more than 10% high

with no electrical load

Only a qualified

electrical service

person should service and repair

generator. Use only factory approved

replacement parts.

Possible Cause(s)

1. Defective capacitor

2. Winding short circuit or loose connec-

tions

3. Defective rotor diode

4. Loss of residual magnetism

1. Engine speed too low

2. Clogged spark arrester

3. Defective rotor diode

4. Partial short circuit in winding

5. Defective capacitor

Engine speed too high

Corrective Action

1. Replace capacitor

2. Check resistance of coils (See “Electrical

Component Specifications,” page 2)

3. Replace both diodes on rotor

4. Apply 12-volt battery to capacitor

terminals for 2-3 seconds

1. Set engine speed to 3720 RPM (62 Hz)

with no load

2. Clean arrester. See engine owner’s

manual

3. Replace both diodes on rotor

4. Check resistance of coils (See “Electrical

Component Specifications,” page 2)

5. Replace capacitor

Set engine speed to 3720 RPM (62 Hz)

with no load

Voltmeter reading correct with no

electrical load, but more than 10% low

when electrical load is added

Engine will not start

107358

1. Defective rotor diode

2. Electrical load too high

3. Engine not running properly

1. Fuel level too low

2. Fuel cock not in “O” (open) position

3. Diesel fuel not reaching the fuel

injection pump or nozzle

4. Speed control lever not in START

position

5. Lube oil level not correct

6. Fuel injection nozzle not working right

7. Recoil starter not pulled quickly and

firmly enough

8. Spark arrester clogged by carbon

9. Battery not discharging

19

1. Replace both diodes on rotor

2. Do not overload generator

3. Contact an authorized engine service

center

1. Add fuel to fuel tank

2. Move fuel cock to “O” (open) position

3. See qualified Yanmar service person

4. Move speed control lever to START

position

5. Add lube oil to engine

6. See qualified Yanmar service person

7. When starting engine with recoil starter,

pull starter rope quickly and firmly. You

must pull starter rope all the way out

8. Clean spark arrester. See “Cleaning the

Spark Arrester,” page 16

9. Loose battery connections, corrosion on

battery terminals, or battery dead

®

Page 20

Dayton Operating Instructions and Parts Manual

4W315C

4W315C

For Repair Parts, call 1-800-323-0620

Dayton Diesel Electric Generator

24 hours a day - 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

Grainger Parts

P.O. Box 3074

1657 Shermer Road

Northbrook, IL 60065-3074 U.S.A.

®

1

E

F

5

2

3

9

8

6

7

12

16

13

9

Figure 28 – Repair Parts Illustration for Fuel Tank and Roll Cage

11

17

15

10

9

14

4

20

14

19

19

14

18

9

8

8

9

20

107358

Page 21

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Repair Parts List for Fuel Tank and Roll Cage

Model 4W315C

Reference Part No. for

Number Description Model 4W31SC: Quantity

4W315C

1 Fuel tank assembly 099935-01 1

2 1/4-20 x 3/4" Screw * 4

3 1/4" Washer WP-4C 4

4 1/4-20 Nut 103880-01 4

5 Roll cage 099943-01 1

6 Spreader 099945-01 1

7 5/16-18 x 1

1

/2" Bolt * 2

8 5/16" Washer WP-5C 5

9 5/16-18 Nut NEC-5C 9

10 1/2-20 x 1" Screw 26302006 2

11 1/2" Lockwasher WLI-8 2

12 Shock mounts 17529000 2

13 5/16-18 x 3/4" Bolt 26007004 4

14 5/16" Washer WLE-5 3

15 Shock mount 099853-02 1

16 Battery bracket 099749-01 1

17 Hook bolt 099750-01 2

18 Ground strap 14138000 1

19 1/4-20 x 1/2" Screw * 2

20 #8-18 x 1/2" Sems screw 100410-01 4

∆ Safety information decal 099947-01 1

∆ Operation decal 099948-01 1

∆ Battery cable (positive) 099873-01 1

∆ Battery cable (negative) 099873-02 1

107358

(∆) Not shown.

(*) Standard hardware. Available from local hardware store.

®

21

Page 22

Dayton Operating Instructions and Parts Manual

4W315C

4W315C

For Repair Parts, call 1-800-323-0620

Dayton Diesel Electric Generator

24 hours a day - 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

Grainger Parts

P.O. Box 3074

1657 Shermer Road

Northbrook, IL 60065-3074 U.S.A.

®

21

23

14

19

20

22

23

9

8

7

6

5

1

2

Figure 29 – Repair Parts Illustration for Alternator Assembly

10

4

24

11

3

12

13

15

16

17

18

22

107358

Page 23

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Repair Parts List for Alternator Assembly

Model 4W315C

Reference Part No. for

Number Description Model 4W31SC: Quantity

1 End cover 099844-01 1

2 M5 x 13 Screw 099701-01 6

3 Bushing 099760-01 1

4Terminal block (4-block) 099863-01 1

5Terminal block (2-block) 099863-02 1

6Ground lug † 1

7 #10-16 x 3/8" Screw M11084-26 1

8 Stator bolt 099847-02 4

9 5/16" Lockwasher WLE-5 4

10 Bearing housing 099843-01 1

11 Capacitor 27005003S 1

12 Stator † 1

13 Fan bracket 27003002 1

14 M8 x 20 Screw * 4

15 Rotor nut 099891-01 1

16 Draw bolt 099842-02 1

17 Bearing 27003003 1

18 Diode 27003012S 2

19 Rotor † 1

20 Fan 27003008 1

21 Engine flange 101839-01 1

22 3/8-16 x 5/8" Bolt * 4

23 3/8" Lockwasher * 8

24 Foam pad 099892-01 1

∆ Alternator assembly complete 099723-02 1

4W315C

(†) Parts not available. Included in Alternator Assembly.

(∆) Includes reference numbers 1 through 24.

(*) Standard hardware. Available from local hardware store.

107358

®

23

Page 24

Dayton Operating Instructions and Parts Manual

4W315C

4W315C

For Repair Parts, call 1-800-323-0620

Dayton Diesel Electric Generator

24 hours a day - 365 days a year

®

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

Grainger Parts

P.O. Box 3074

1657 Shermer Road

Northbrook, IL 60065-3074 U.S.A.

11

2

2

1

1

2

0

V

O

L

T

S

3

14

RESET

TEST

4

5

7

FULL POWER

120 ONLY

SELECTOR

E

N

M

0000

00

H

O

05

U

R

S 1/10

8

Figure 30 – Repair Parts Illustration for Control Panel

120/240V

6

12

1

2

0

/2

4

0

V

O

L

T

S

R

E

S

E

T

R

E

S

E

T

6

12

13

9

10

24

107358

Page 25

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Repair Parts List for Control Panel

Model 4W315C

Reference Part No. for

Number Description Model 4W315C: Quantity

1 Control panel, front 103349-02 1

2 20 Amp Circuit breaker *22616009 2

3 120V, 30A Twist-lock receptacle *099833-01 1

4 120V, 15A Duplex receptacle *15342000 1

5 Full power selector switch *099956-01 1

6 25 Amp Circuit breaker *22616011 2

7 120/240V, 20A Twist-lock receptacle *099834-01 1

8 Hour Meter 101350-01 1

9 Bushing 099760-01 1

10 #8-18 x 1/2" Sems screw 100410-01 4

11 Control box, rear 100149-01 1

12 U-nut 22261000 8

13 Switch plug 099997-01 1

14 120V, 15A GFCI Duplex receptacle 100445-01 1

∆ Panel schematic decal 100177-07 1

† Control panel assembly 103348-02 1

4W315C

107358

(∆) Not shown.

(†) Includes reference numbers 1 through 14.

(*) Includes fastening hardware.

®

25

Page 26

Dayton Operating Instructions and Parts Manual

4W315C

4W315C

15

12

®

3

2

1

10

13

12

11

9

For Repair Parts, call 1-800-323-0620

Dayton Diesel Electric Generator

24 hours a day - 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

Grainger Parts

P.O. Box 3074

1657 Shermer Road

Northbrook, IL 60065-3074 U.S.A.

17

16

20

5

4

22

4

6

3

Figure 31 – Repair Parts Illustration for Switch Control Box

7

4

19

8

3

18

4

23

21

14

26

107358

Page 27

Dayton Operating Instructions and Parts Manual

Version B - For Reduction G016.J

Repair Parts List for Switch Control Box

Model 4W315C

Reference Part No. for

Number Description Model 4W315C: Quantity

1 Switch control box 101037-01 1

2 Low oil light 22721000 1

3 Key switch, lamp, and harness assembly 099936-01 1

4 1/4-28 Keps nut 101039-01 4

5 Strain relief bushing 099760-01 1

6 1/4-20 x 5/8" Hex-head sems 101040-01 2

7Relay 26498000 1

8 #10-32 Hex locknut NTF-3C 1

9 Adhesive-backed PVC foam RN12000100 1

10 Connector * 1

11 #6-32 x 1/2" Hex tapping screw * 1

12 #6 Internal-tooth lockwasher * 5

13 Full bridge 26509000 1

14 #8-32 x 3/8" Screw * 4

15 Grommet * 1

16 #10 Flat washer WP-3C 1

17 #10-32 x 3/4" Hex-head screw 26499000 1

18 Solenoid 26490000 1

19 M4 x 8 Hex-head screw * 2

20 M3 x 8 Hex-head screw * 4

21 Control box cover 101038-01 1

22 Cable 101036-01 1

23 Conduit 101035-01 1

† Switch control box assembly 101103-01 1

4W315C

107358

(†) Includes reference numbers 1 through 23.

(*) Standard hardware. Available from local hardware store.

®

27

Page 28

Dayton Operating Instructions and Parts Manual

®

4W315C

Dayton Diesel Electric Generator

NOTE: The five-year limited warranty below covers all non-engine parts of this generator including the alternator. Yanmar warrants the

engine. See engine owner’s manual for engine warranty information.

Limited Warranty

DAYTON FIVE-YEAR LIMITED WARRANTY. Professional-duty electric generator alternator, Model 4W315C, are warranted by

Dayton Electric Mfg. Co. (Dayton) to the original user against defects in workmanship or materials under normal use for five years

after date of purchase. Any part which is determined to be defective in material or workmanship and returned to an authorized

service location, as Dayton designates, shipping costs prepaid, will be, as the exclusive remedy, repaired or replaced at Dayton’s

option. For limited warranty claim procedures, see PROMPT DISPOSITION below. This limited warranty gives purchasers specific legal

rights which vary from jurisdiction to jurisdiction.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, Dayton’s liability for consequential and incidental damages is

expressly disclaimed. Dayton’s liability in all events is limited to and shall not exceed the purchase price paid.

WARRANTY DISCLAIMER. Dayton has made a diligent effort to provide product information and illustrate the products in this

literature accurately; however, such information and illustrations are for the sole purpose of identification, and do not express or imply

a warranty that the products are MERCHANTABLE, or FIT FOR A PARTICULAR PURPOSE, or that the products will necessarily conform

to the illustrations or descriptions.

Except as provided below, no warranty or affirmation of fact, expressed or implied, other than as stated in the “LIMITED WARRANTY”

above is made or authorized by Dayton.

PRODUCT SUITABILITY. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of products

for certain purposes, which may vary from those in neighboring areas. While Dayton attempts to assure that its products comply with

such codes, it cannot guarantee compliance, and cannot be responsible for how the product is installed or used. Before purchase and

use of a product, review the product applications, and all applicable national and local codes and regulations, and be sure that the

product, installation, and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products; e.g., (a) some jurisdictions do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation or exclusion may not apply to you; (b) also, some jurisdictions do not

allow a limitation on how long an implied warranty lasts, consequently the above limitation may not apply to you; and (c) by law, during

the period of this limited

warranty, any implied warranties of implied merchantability or fitness for a particular purpose applicable

to consumer products purchased by consumers, may not be excluded or otherwise disclaimed.

PROMPT DISPOSITION. Dayton will make a good faith effort for prompt correction or other adjustment with respect to any product

which proves to be defective within limited warranty. For any product believed to be defective within limited warranty, first write or

call dealer from whom the product was purchased. Dealer will give additional directions. If unable to resolve satisfactorily, write to

Dayton at address below, giving dealer’s name, address, date, and number of dealer’s invoice, and describing the nature of the defect.

Title and risk of loss pass to buyer on delivery to common carrier. If product was damaged in transit to you, file claim with carrier.

Manufactured for Dayton Electric Mfg. Co., 5959 W. Howard St., Niles, Illinois 60714 U.S.A.

Manufactured for Dayton Electric Mfg. Co.

Niles, Illinois 60714 U.S.A.

107358-01

Rev. B

07/03

®

Version B - For Reduction G016.J

Loading...

Loading...