Trebor SL20 User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

CHAMPION SL20

Slurry/Booster Pump

Operation / Maintenance

Manual

SERIAL NUMBER (located on top of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 NOVEMBER, 2007 – MSL20-C

CONTENTS

1 PREFACE.....................................................................................................................3

1.1 INTRODUCTION TO TREBOR SL20 SLURRY/BOOSTER PUMP ..................3

2 INSTALLATION............................................................................................................4

2.1 UNPACKING ......................................................................................................4

2.2 UTILITIES / HOOK-UP FOR CHAMPION SL20 PUMP.....................................4

2.3 UTILITIES / HOOK-UP FOR REMOTE CONTROLLER....................................5

2.3.a Trebor’s PC20 Electronic Oscillator ......................................................5

3 START-UP....................................................................................................................7

3.1 CONTROLLER OPERATION.............................................................................8

3.1.a The PLC outputs are shown in Table 2.................................................9

3.1.b Changing a pump function listed in Table 3:.........................................9

3.1.c Turning Pump On and Off ...................................................................10

3.1.d Auto Tune Mode..................................................................................10

3.1.e Manual Tune Mode (Auto Tune-OFF).................................................10

3.1.f Booster Mode......................................................................................11

3.1.g Preventative Maintenance (PM) Counter............................................11

3.1.h Changing PLC data stores listed in table 3:........................................11

3.1.i Tune Optics .........................................................................................12

3.2 PERFORMANCE CHARTS – PUMPING WITH INLET SUCTION REQUIRED12

3.3 PERFORMANCE CHARTS – BOOSTER PUMPING......................................13

4 MAINTENANCE .........................................................................................................15

4.1 PREVENTIVE MAINTENANCE SCHEDULE...................................................15

4.1.a Preventive Maintenance Record.........................................................17

4.2 RECOMMENDED SPARE PARTS ..................................................................18

4.3 TOOLS..............................................................................................................18

4.4 PARTS ILLUSTRATION...................................................................................19

4.5 PARTS LIST.....................................................................................................20

4.6 CONTROLLER PARTS LIST – PC20..............................................................21

4.7 CLEAN-UP........................................................................................................21

4.8 DISASSEMBLY ................................................................................................21

4.8.a Body Disassembly...............................................................................21

4.8.b Control Base Disassembly ..................................................................22

4.8.c Cleaning...............................................................................................22

4.9 ASSEMBLY ......................................................................................................22

4.9.a Control Base Assembly.......................................................................22

4.9.b Pump Assembly...................................................................................22

4.9.c Final Assembly....................................................................................23

5 TROUBLESHOOTING ...............................................................................................24

6 WARRANTY .......................................................................................................25

PAGE 2 CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL

1 PREFACE

1.1 INTRODUCTION TO TREBOR SL20 SLURRY/BOOSTER

PUMP

We are pleased that you have chosen the Trebor SL20 pump for your high purity

application.

This innovative, dual chamber, vacuum fill pump offers near pulse-less flow –

typically 5 PSI or less in most applications. This is the result of Cross Phase

Discharge™, or overlapping pump strokes, that eliminates the momentary pump

pressure drop-off between strokes, typical of all other internally connected

reciprocating pumps. This improves filter life, provides consistent process

results, and eliminates the need for large and costly pulsation dampeners.

The SL20 utilizes very few moving parts, thereby improving reliability, reducing

particle generation, and lowering maintenance costs. As a matter of fact, the

only regularly scheduled serviceable parts are the PTFE diaphragms, externally

accessible check balls and seats, air quick exhaust valves, and exhaust media.

Configured with all fluoropolymer wetted components, the SL20 is compatible

with virtually all aggressive ultra-pure chemicals. There are absolutely no

elastomer O-rings or metal parts (including no coated metal parts) that could

contaminate your critical chemistries. Plus, the pump is fully plenum compatible.

Vacuum filled pumping chambers and Cross Phase Discharge™ are key to the

SL20’s unmatched particle cleanliness and low pulsation. Fluid chambers are

filled by passing positive air pressure through vacuum generators installed in the

pump base. Optic sensors in the pump heads determine when the fluid

chambers are filled and ready to pump. These sensors signal the PC20 Pump

Controller to pressurize the fluid chamber and discharge the fluid, which is

isolated by a PTFE diaphragm. The PC20’s control algorithm regulates the fill

and discharge strokes for constant overlap and optimum performance.

The rated flow of the SL20 (20 LPM or 5.3 GPM) is only limited by the vacuum fill

capability. Positive inlet head will greatly increase the chamber fill rate, and

subsequently the discharge flow rate, providing a maximum flow rate of 45 LPM

or 12 GPM when inlet pressure exceeds 15 PSI (.1 MPa). The high discharge

capacity creates very flat flow curves in low flow ranges. This means that spray

processes that benefit from constant line pressure will stay that way as inline

valves are opened and closed. The SL20 also utilizes Trebor’s patented floating

ring check seats for exceptional suction lift of even viscous chemicals.

Thanks again for purchasing Trebor products. We are confident that you will be

pleased with the performance and reliability of the SL20 pump. In the rare event

you do experience difficulty with this product; you can be assured that Trebor will

quickly respond with knowledgeable solutions and comprehensive warranty

service.

CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

2 INSTALLATION

2.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

Qty

Item Description

1 SL20 Champion SL20 Slurry/Booster Pump

1 MSL20 Operation/Maintenance Manual

2 DP-C-12 End-of-Stroke Probe

1 PC20 Pump Controller **

**Controller equipped with 12-ft. pump interconnect air line package.

2.2 UTILITIES / HOOK-UP FOR CHAMPION SL20 PUMP

It is recommended that the pump be installed no more than 15° from level to

maintain its self-priming ability and pumping efficiency. This pump mounts on a

quick release base for easy installation. We recommend 1/4 - 20 x 3/4” flat head

counter sink screws.

Air Inlet: 2 each 1/4” OD (6mm) Tube (Pump Air Supply).

2 each 5/16” OD (8mm) Tube (Vacuum Generator Supply).

Fluid Ports: 2 each 3/4” OD Flare Tube Port.

Exhaust: Muffler Standard w/2 each 1/2” NPTF (optional) upon removal of

muffler media.

Sensor: 2 each DP-C-12 EOS probes and seals

PAGE 4 CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL

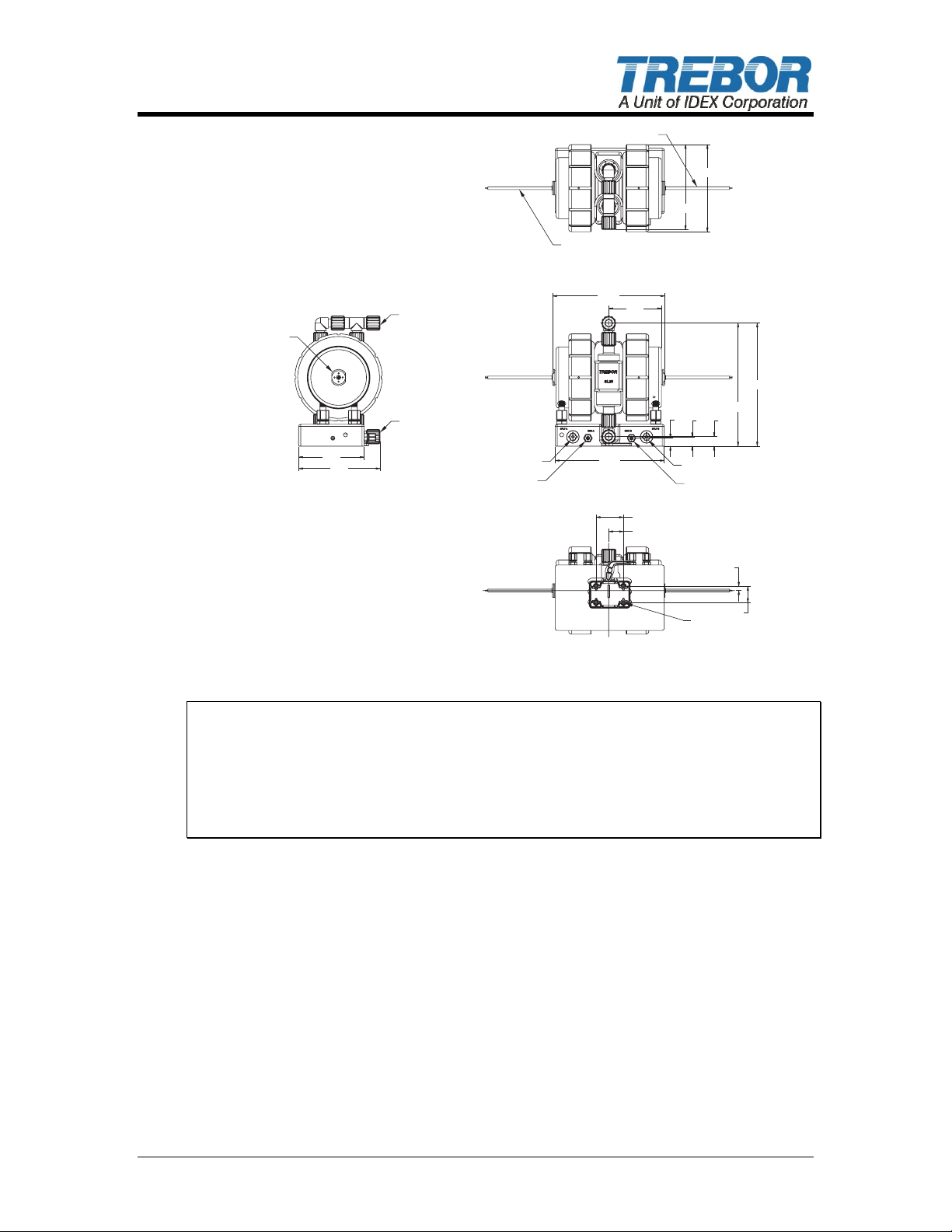

END-OF-STROKE

PROBES

8.00

7.80

END-OF-STROKEEND-OF-STROKE

PROBES

10.29

10.00

4.83

2.50

1.25

.73

11.28

.85

.87

PUMP SUPPLY LINESPUMP SUPPLY LINES

1/4" TUBE FITTING1/4" TUBE FITTING

VACUUM SUPPLY LINESVACUUM SUPPLY LINES

5/16" TUBE FITTING5/16" TUBE FITTING

11.28

END-OF-STROKE

PROBE PORTPROBE PORT

6.00

7.46

OUTLET FLUID PORTOUTLET FLUID PORT

(STD 3/4" FLARE)(STD 3/4" FLARE)

INLET FLUID PORTINLET FLUID PORT

(STD 3/4" FLARE)(STD 3/4" FLARE)

VACUUM SUPPLY LINESVACUUM SUPPLY LINES

5/16" TUBE FITTING5/16" TUBE FITTING

PUMP SUPPLY LINESPUMP SUPPLY LINES

1/4" TUBE FITTING1/4" TUBE FITTING

4x %%c4x %%c.28

Figure 2-11

ATTENTION: Although extensive efforts are made to deliver pumps to our

customers completely dry, new pumps may contain residual moisture from their

final DI water test. It is also recommended that a filter be placed on the

discharge side of the pump.

The pump should be operated with clean, dry air or nitrogen. Particulate, water

and oils in the air supply can damage the pump.

2.3 UTILITIES / HOOK-UP FOR REMOTE CONTROLLER

The Champion SL20 pump will work with many types of external control devices.

Trebor’s electronic Pump Control Module, the PC20, is recommended for its

proven, reliable performance. Please consult factory for assistance with other

external control devices.

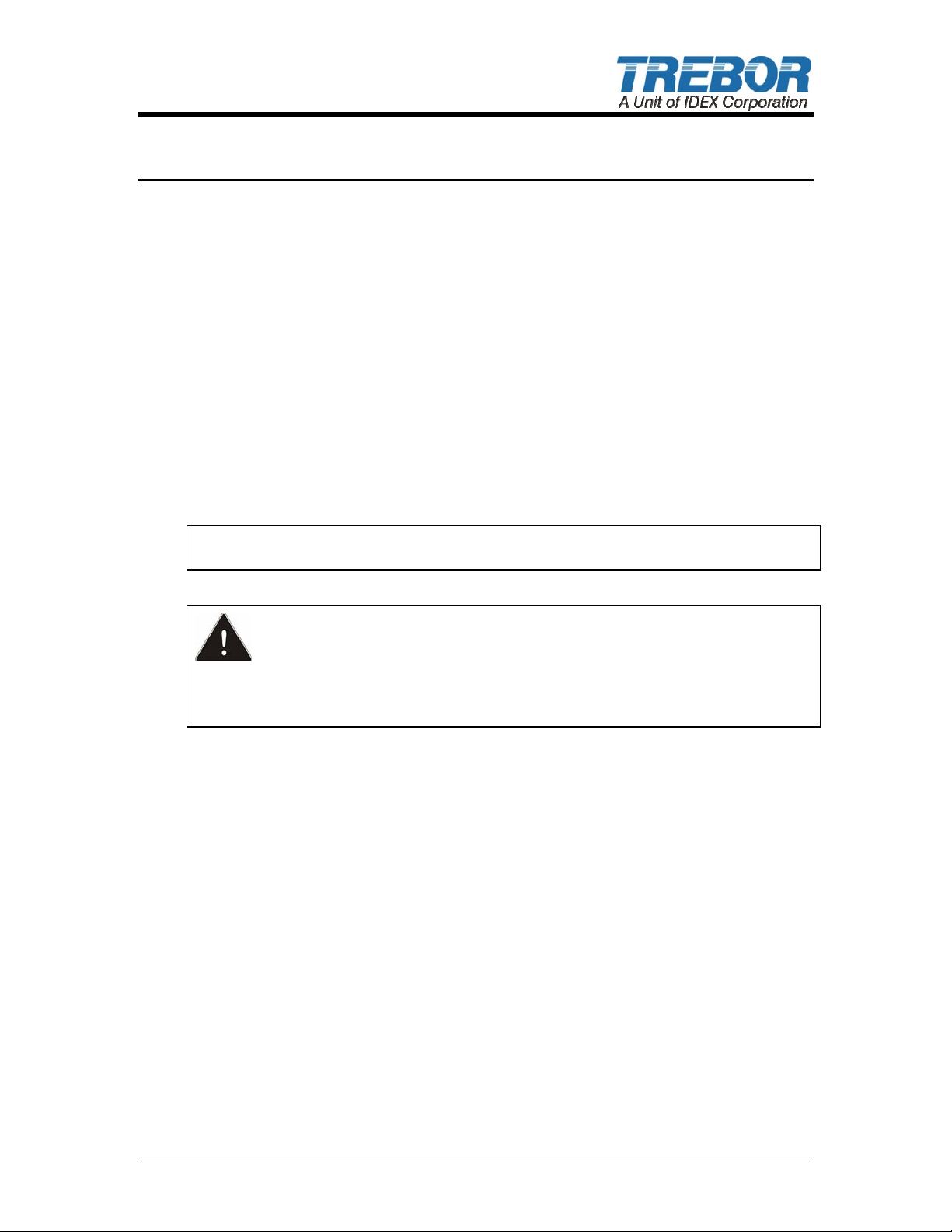

2.3.a Trebor’s PC20 Electronic Oscillator

.39

1.50

MTD0381

The PC20 Series external pump controller requires two separately regulated air

supplies; one to drive the vacuum generator, which fills the pump fluid chambers,

and one that controls pump discharge pressure.

In most booster pump applications the vacuum generators are not required and

may be turned off. (See sect, 2.1)

CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

Air Inlet: 1/4” Diameter (6mm) supply tube – 20-80 psig (.14 – .55 MPa)

pump supply.

3/8” Diameter (9mm) supply tube – 80 psig (.42 – .55 MPa)

vacuum supply.

Air Supply: 20-80 psig (.14 – .55 MPa) clean dry air or nitrogen (see

Performance Charts, Section 3.2 for air consumption).

Exhaust: Internal Muffler (1/2” Diameter [13mm] tube optional for remote

exhaust after removing muffler on SL20).

Electronics: +24VDC @ 500ma

TB1: +24VDC

TB2: +0VDC

Sensor: Connect each end-of-stroke probe optic pair to one of the two

optic amplifiers.

Figure 2-22

NOTE: To minimize pump pressure surge use separate air regulators to feed the

pump and ejector supplies.

PAGE 6 CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL

3 START-UP

• Pump discharge air supply pressure should be regulated between 20 psig

(.14 MPa) minimum and 80-psig (.55 MPa) maximum.

• Pump Vacuum Air Supply should be regulated at 80 psig (.55 MPa). (Note:

Not required for booster pump installations.)

• Open the fluid suction (IN) line valve, if necessary.

• Open the fluid discharge (OUT) line valve, if necessary.

• Start with pump air supply regulator at low (≈ 20 psi) pressure setting.

• Tune Optics per Section 3.1.i

• Table 33: Consumption / Efficiency in Section 3.2 can be used to determine

approximate air consumption. Air consumption in booster pump applications

will be much less, see Section 3.3.

• Refer to Troubleshooting, Section 5, if pump fails to start.

NOTE: When operating pump as a booster pump, vacuum air supply may be

turned off, conserving air.

CAUTION: When handling potentially dangerous fluids under pressure,

the pump and its fittings should be placed in an enclosure. NOTE: When

operating pump as a booster pump, vacuum air supply may be turned off,

conserving air.

CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

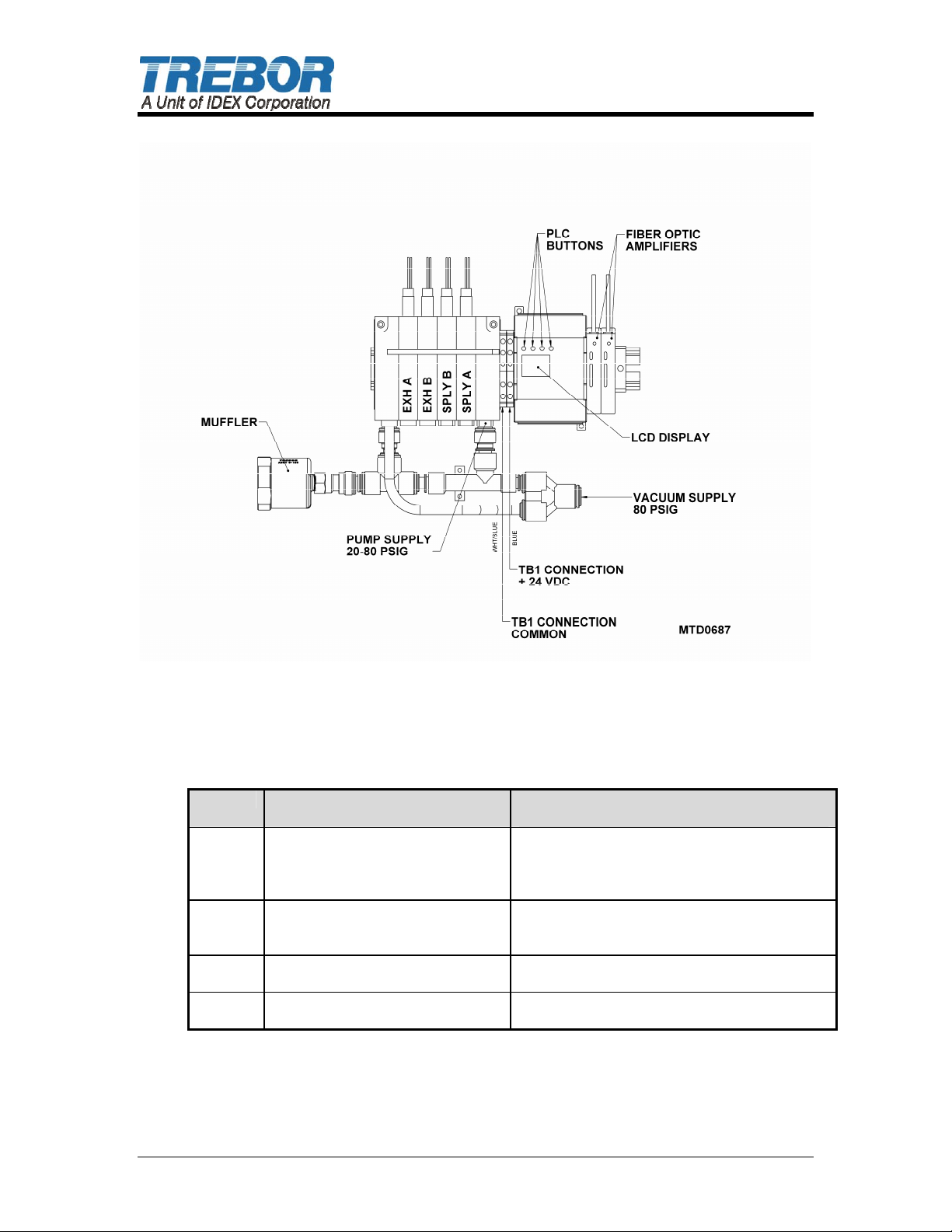

Figure 3-11

3.1 CONTROLLER OPERATION

The controller is operated using the display and buttons on the PLC. See Table

11 for a description of the PLC button functions.

Button Normal mode Numeric value change mode

3

V

U

⇔

Enables numeric value change

mode. (hold for ~3 sec)

Activates desired device change

(hold for ~3 sec)

Scroll backward through devices

to select the desired device

Scroll forward through devices to

select the desired device

Selects a device type (left side of

display) “DM” “RLY”

Table 11: PLC Buttons

(while digit is flashing)

- Activates desired change when pressed

and held for >3 seconds.

- Cancels change when pressed and held

for < 3 seconds

- Decreases value of flashing digit.

-Toggles the “current device value” (“off” to

“on” or from “on” to “off.”)

Increases value of flashing digit

Allows selection of digit to be changed

PAGE 8 CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL

Loading...

Loading...