Trebor REV6 User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

This manual contains information necessary for the safe and proper use of the Rev6. Included are specifications

for the standard configurations of the pump system and instructions regarding its use, installation, operation,

adjustment, inspection, and maintenance. For special configurations of the pump system, refer to accompanying

information. Please familiarize yourself with the contents of the manual to ensure the safe and effective use of

this product. After reading this manual, please store the manual where the personnel responsible for operating

the pump system can readily refer to it at any time.

REV6

Operation / Maintenance

Manual

SERIAL NUMBER (located on the product):

06/20/2014 – REV6-A

Table of Contents

1 Safety Precautions ......................................................................................................................... 4

2 Specifications ................................................................................................................................. 5

2.1 Specification of Components ................................................................................................... 5

2.2 Standard System Configurations ............................................................................................. 7

2.2.1 Pump Only Configuration ................................................................................................. 7

2.2.2 Stand-Alone System Configuration ................................................................................... 7

2.3 General Environmental Conditions .......................................................................................... 9

2.4 Pump Performance Curves ..................................................................................................... 9

2.4.1 Pressure-Flow Curves ...................................................................................................... 9

2.4.2 NPSHr Curves .................................................................................................................10

2.4.3 Maximum Static Pressure vs. Fluid Temperature ............................................................10

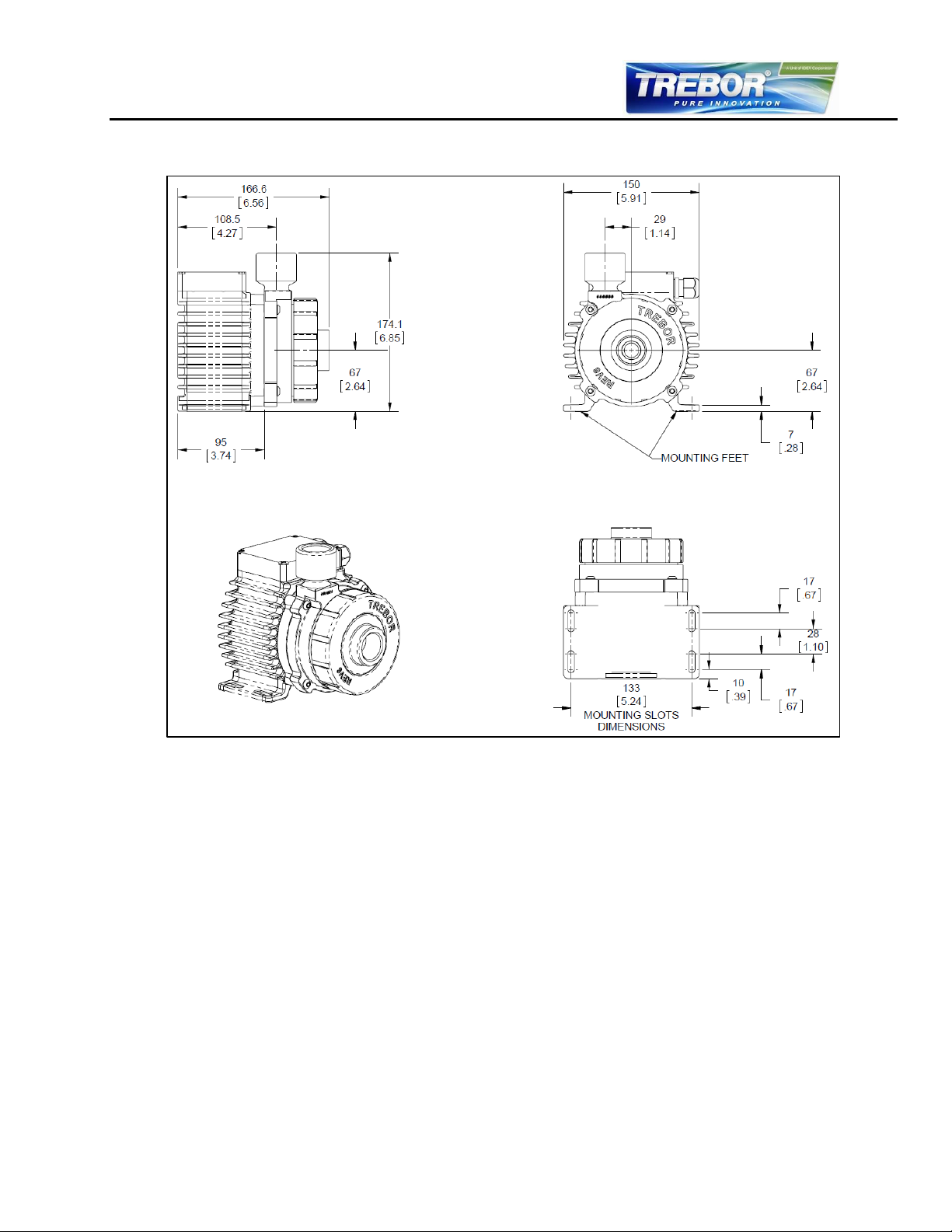

2.5 Basic Dimensions of Main Components .................................................................................11

2.6 Air Cooling Module .................................................................................................................13

2.7 Cable Minimum Bend Radius .................................................................................................14

3 Engineering Information ................................................................................................................15

3.1 Sealing and Material Concept .................................................................................................15

3.2 Power Consumption ...............................................................................................................16

3.3 Temperature Monitoring .........................................................................................................17

3.4 Thermal Management ............................................................................................................18

3.4.1 Motor Temperature ..........................................................................................................18

3.4.2 Controller Temperature ...................................................................................................20

3.5 Hydraulic Circuit Design .........................................................................................................21

4 Installation.....................................................................................................................................22

4.1 Electrical Installation of Controller ...........................................................................................22

4.1.1 Overview .........................................................................................................................22

4.1.2 General Installation Instructions ......................................................................................23

4.1.3 Electrical Installation of Standalone Operation ................................................................23

4.2 Mechanical Installation of the Pump/Motor .............................................................................25

4.3 Mechanical Installation of the Controller .................................................................................25

4.4 Mechanical Installation of Adapter/Extension Cables..............................................................25

5 Operation ......................................................................................................................................26

5.1 System Operation with Standalone Controller ........................................................................26

5.1.1 State Diagram of Standalone Controller ..........................................................................26

5.1.2 Standalone Operation (Button Control Mode) ..................................................................27

5.1.3 Extended Operation (Analog Control Mode) ....................................................................27

REV6 OPERATION / MAINTENANCE MANUAL CONTENTS

5.1.4 Error Display on the Integrated Panel ............................................................................. 28

6 Inspection and Maintenance ......................................................................................................... 29

6.1 Impeller Replacement Interval ............................................................................................... 29

6.2 Impeller Replacement Procedure ........................................................................................... 29

6.2.1 Preparation ..................................................................................................................... 29

6.2.2 Instructions for Replacement .......................................................................................... 30

7 Troubleshooting ............................................................................................................................ 31

7.1 Troubleshooting for Operation with Standalone Controller ..................................................... 31

8 Technical Support ........................................................................................................................ 32

9 Appendix ...................................................................................................................................... 33

9.1 Regulatory Status .................................................................................................................. 33

9.1.1 CE Marking ..................................................................................................................... 33

9.2 Symbols and Signal Words .................................................................................................... 34

REV6 OPERATION / MAINTENANCE MANUAL 3 CONTENTS

CAUTION

Do not open the motor or controller. Trebor does not assume responsibility

for any damage occurring under such circumstances.

CAUTION

High magnetic field strength of pump impeller

The pump system contains a rotor magnet with high field strength. This may

alter or damage the calibration of sensitive electronic devices and

measuring instruments in the immediate surroundings. Keep at a safe

distance from computers, monitors and all magnetic data storage media

(e.g. disks, credit cards, audio and video tapes etc.)

WARNING

Hazardous voltage may be present.

In case of the usage of an inadequate AC/DC power supply, mains voltages

may be present (even if the system is designed for 48VDC). The usage of a

galvanic separated power supply, which is certified by a 3rd party (UL or CE),

is highly recommended.

The controller must be grounded and placed in a spill protected

environment. Do not under any circumstances open the powered controller.

The usage of galvanic separated AC/DC supply is highly recommended.

WARNING

High magnetic field strength of pump impeller

The pump system contains a rotor magnet with high field strength.

Pacemakers may be influenced and magnetic forces may lead to

contusions. Keep distance to pace makers and handle impeller with care.

WARNING

TOXIC CHEMICALS may be present.

When using the system to pump chemicals skin contact and toxic gases

may be hazardous to your health. Wear safety gloves and other appropriate

safety equipment.

1 SAFETY PRECAUTIONS

REV6 OPERATION / MAINTENANCE MANUAL 4 CONTENTS

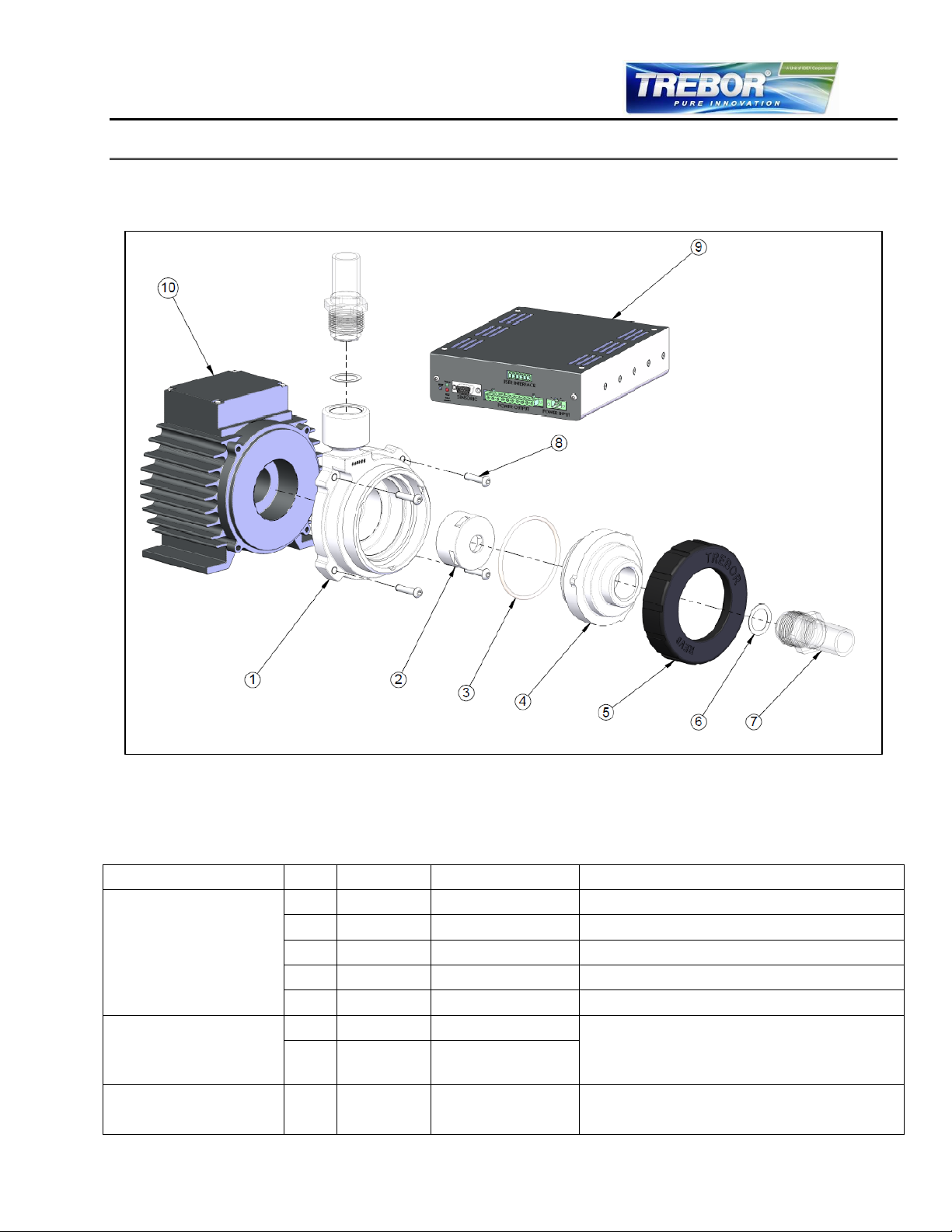

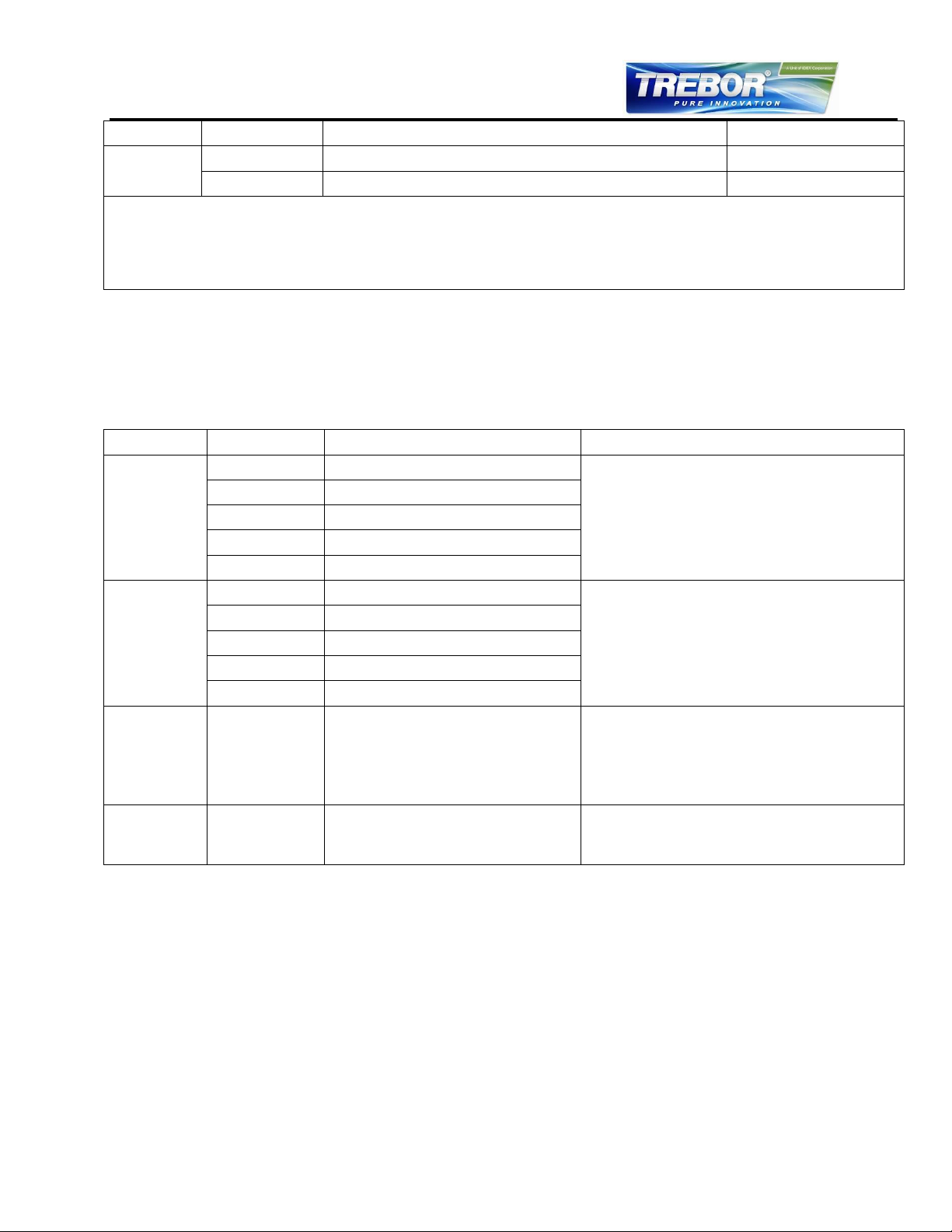

Component

Item

PN

Description

Materials of Construction

Pump

1

BM001

Pump Casing

PTFE

2

98004267

Pump Impeller

PFA flow path

3

98004268

Pump Main Seal

Semiconductor grade FFKM

4

BM002

Inlet Housing

PTFE TFM 1600

5

BM003

Union Nut

Polypropylene

Fluid Port Adapter

6 Seal

See Table 3 for details

7

Fluid Port

Adapter

Motor Attachment

Bolts

8

98004269

M6x25mm

QTY 4

316 stainless steel

2 SPECIFICATIONS

2.1 Specification of Components

Figure 1 shows the main system components. The accessories are listed below.

Each Rev6 pump system is comprised of a pump, a motor, a controller, and two fluid port adapters.

Table 1 lists each part:

REV6 OPERATION / MAINTENANCE MANUAL 5 CONTENTS

Figure 1 – Standard Components (Cables not shown)

Table 1 – Major Component Part List

Component

Item

PN

Description

Materials of Construction

Controller

9

98004271

Motor Controller

Standalone Controller

48VDC/600W Power

Panel control for motor speed

Optional PLC control

Motor

10

98004270

600W Motor

Standard 3 meter cables included (not

shown)

FEP Jacket

IP67 rated liquid and dust protected

Product

Description

Included

Additional Required

Items

REV6A0

Pump with PP union nut and 316 SS

bolts

- Pump

- Attachment

Screws

- Pump Manual

- Pump motor

- Pump controller

- Connecting cables

- Power supply

- Fluid port adapters

Seal Type

PN

Part Description

Plant Connection

PTFE Gasket

G12000-10

GROUP;ADPTR;3/4IN PIPE;PTFE GSKT

3/4” weldable pipe

G12F08-10

GROUP;ADPTR;1/2 IN FLR;PTFE GSKT

1/2” flare

G12F12-10

GROUP;ADPTR;3/4FLR;PTFE GSKT;PVDF NUT

3/4” flare

G12F16-10

GROUP;ADPTR;1IN FLR;PTFE GSKT

1” flare

G12P12-10

GROUP;ADPTR;3/4 FNPT;PTFE GSKT

3/4” female NPT

G12PL12-10

GROUP;ADPTR;3/4 PRIMELOCK;PTFE GSKT

3/4” PrimeLock

G12T12-10

GROUP;ADPTR;3/4T;PTFE GSKT

3/4” tube stub

G12X12-10

GROUP;ADPTR;3/4 PILLAR;PTFE GSKT

3/4” Pillar

FFKM O-ring

O12000

GROUP; ADPTR; 3/4 IN PIPE; FFKM O-RING

3/4” weldable pipe

O12F08

GROUP;ADPTR;1/2IN FLARE;FFKM O-RING

1/2” flare

O12F12

GROUP;ADPTR;3/4IN FLARE;FFKM O-RING

3/4” flare

O12F16

GROUP;ADPTR;1IN FLARE;FFKM 0-RING

1” flare

O12P12

GROUP;ADPTR;3/4IN FNPT;FFKM O-RING

3/4” female NPT

O12PL12

GROUP;ADPTR;3/4IN PRMLCK;FFKM O-RING

3/4” PrimeLock

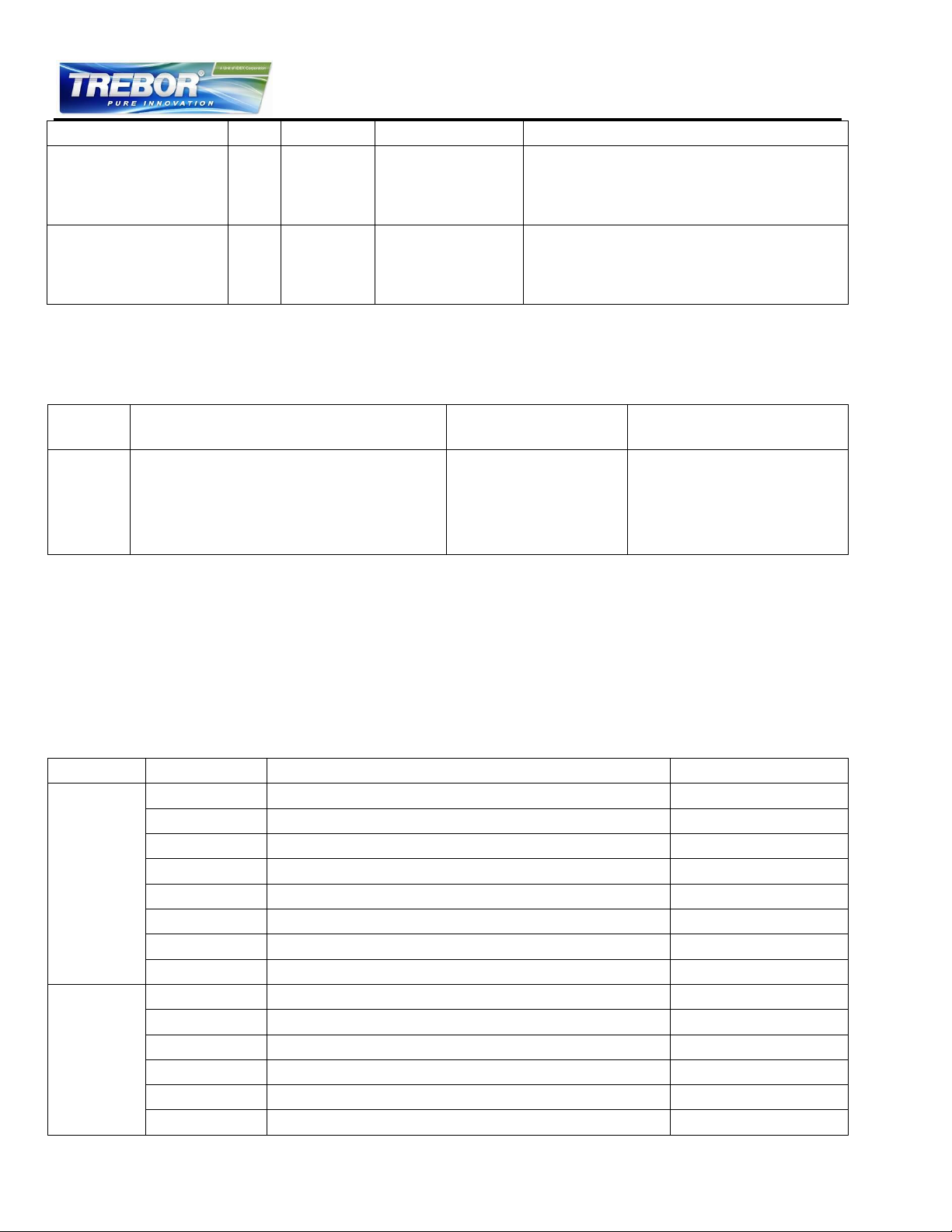

The Rev6 can be ordered as an individual pump to replace a current installation. In order to have a fully

functioning unit (i.e., for a new installation) a motor, controller, connecting cables, power supply and

fluid port adapters are required. The pump will not operate without a motor and controller.

Table 2 – Standard System Configurations

Wide varieties of industry standard fluid interfaces are available in the fluid port adapter. The fluid port

adapter assures seamless fit between plant infrastructure and the Rev6 pump. All fluid port adapters

are manufactured out of ultrapure PFA for the highest chemical compatibility and purity and can be

used interchangeable between any Rev6 pump.

Two seal types are available on the pump side. The first is a PTFE gasket seal to ensure chemical

compatibility. The second is a semiconductor grade FFKM o-ring seal. The seal is specifically designed

to maintain sealing characteristics even at elevated temperatures. The types of adapters currently

available are shown below.

Table 3 – Fluid Port Adapters

REV6 OPERATION / MAINTENANCE MANUAL 6 CONTENTS

Seal Type

PN

Part Description

Plant Connection

O12T12

GROUP;ADPTR;3/4IN TUBE;FFKM O-RING

3/4” tube stub

O12X12

GROUP;ADPTR;3/4IN PILLAR;FFKM O-RING

3/4” Pillar Super 300

If additional fluid connections are needed, contact your Trebor representative for options

All flare nuts are constructed of PVDF. PFA nuts are available on request.

PrimeLock and Pillar Super 300 are trademarks of Entegris, Inc. and Nippon Pillar Packing Co. LTD,

respectively.

Accessory

PN

Description

Comments

Power

Cable

98004272-01

CABLE;POWER;0.5m;REV6

PVC Jacket

Circular AMP and D-Sub Plastic

Connectors

98004272-02

CABLE;POWER;3m;REV6

98004272-03

CABLE;POWER;5m;REV6

98004272-04

CABLE;POWER;7m;REV6

98004272-05

CABLE;POWER;10m;REV6

Sensor

Cable

98004273-01

CABLE;SENSORS;0.5m;REV6

PVC Jacket

Circular AMP and D-Sub Plastic

Connectors

98004273-02

CABLE;SENSORS;3m;REV6

98004273-03

CABLE;SENSORS;5m;REV6

98004273-04

CABLE;SENSORS;7m;REV6

98004273-05

CABLE;SENSORS;10m;REV6

Power

Supply

98004274

POWER SUPPLY;48V;REV6

TSP-600-148-M

(M=Modified design from Traco)

Output: 48 VDC, 600 W

Input: 85-265 VAC (auto detect)

CE, CB, UL, CSA, SEMI F47

Air Cooling

Module

98004282

MODULE;AIR COOLING;REV6

PP (+40% Talc)

NPT 1/4” Connection

1-3 bar (14-43 psi) – 100 LPM @ 1 bar

Additional components are available for the Rev6. Extension cables to pair the controller to the pump

are available at several different lengths. A sensor cable and power cable are needed for each

motor/controller pair. A 48V power supply is also needed for the motor and controller. The specific

accessories and part numbers are listed below. See 2.2 below for descriptions and diagrams of

different pump setups.

Table 4 – Additional Accessories

2.2 Standard System Configurations

2.2.1 Pump Only Configuration

The Rev6 pump can be purchased without a motor or controller to replace a pump in an existing

installation. The Rev6 is a drop-in replacement for the Levitronix BPS-600. This configuration comes

with the assembled pump and four 316 stainless steel screws to attach the pump to the motor.

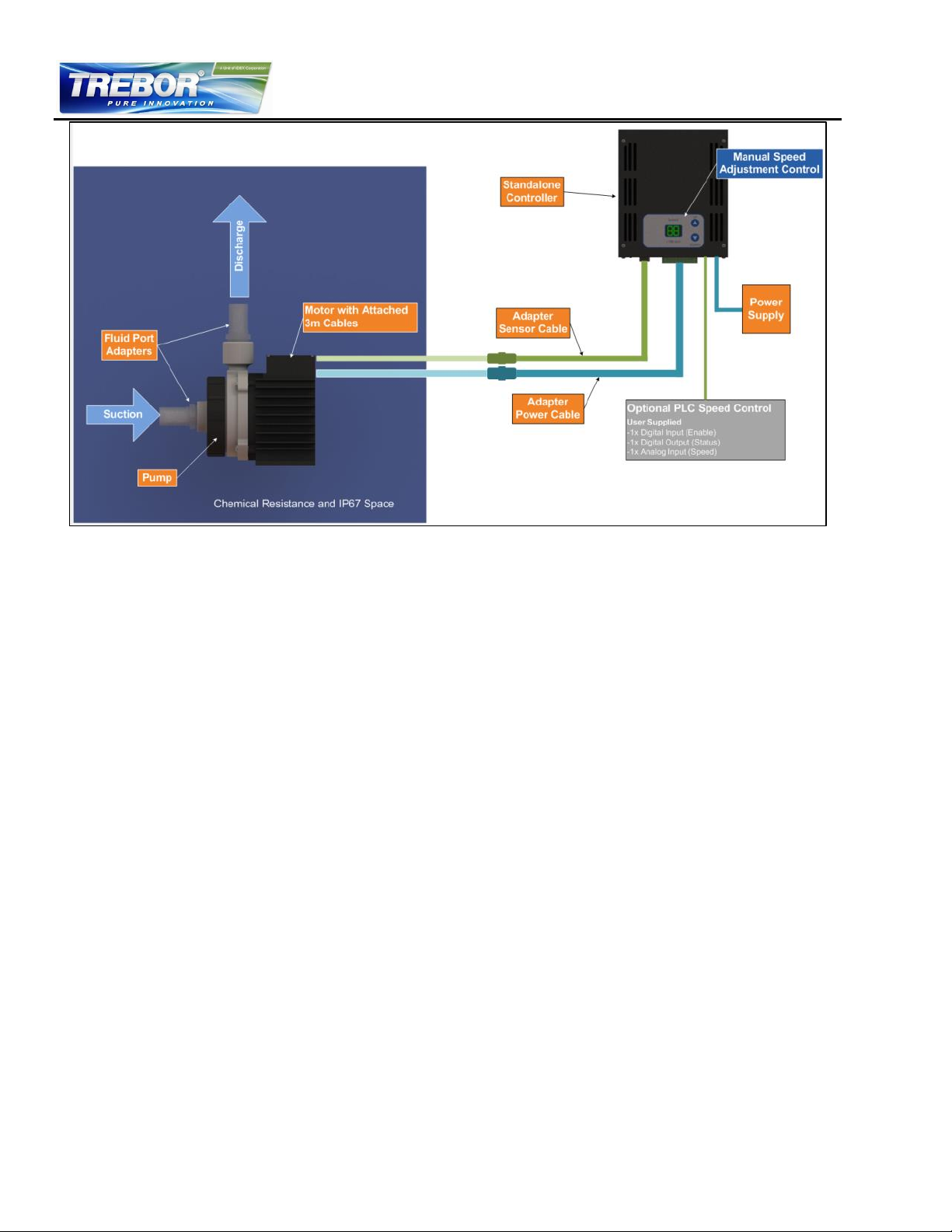

2.2.2 Stand-Alone System Configuration

The stand-alone pump system configuration (Figure 2) consists of a controller with an integrated user

panel to set the speed manually. The speed is adjusted using the buttons on the control panel and

automatically stored in the internal EEPROM of the controller. As an alternative, the pump speed can

also be set with an external analog signal.

REV6 OPERATION / MAINTENANCE MANUAL 7 CONTENTS

Figure 2 – Standard System Configuration for Standalone Control (Rev6A1)

All components in an orange box in Figure 2 are required for an operable system. The adapter cables

(sensors and power), fluid port adapters, and power supply are sold as separate line items.

REV6 OPERATION / MAINTENANCE MANUAL 8 CONTENTS

Controller usage

Indoor

Motor with pump usage

Indoor/Outdoor

Altitude

Up to 2000 m

Operating ambient temperature

0 to 40°C

Storage ambient temperature

(Extremes for transportation)

-20 to 80°C

Operating humidity range

15 to 95% relative humidity (non-condensing)

Storage humidity range

(Extremes for transportation)

15 to 95% relative humidity (non-condensing)

Normal storage conditions

Ambient temp.: 20 to 30 °C

Relative humidity: 50% (non-condensing)

Acceptable DC supply fluctuations

±5% of nominal voltage

Transient over-voltages typically

present on the mains supply

Surge immunity according to EN 61000-4-5

(tested together with certified AC/DC power supply)

Pollution degree

2

9000 RPM

8000 RPM

7000 RPM

6000 RPM

5000 RPM

4000 RPM

0.0 2.5 5.0 7.5 10.0 12.5 15.0 17.5 20.0

0

10

20

30

40

50

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0 10 20 30 40 50 60 70 80

GPM

PSI

bar

LPM

Specific gravity = 1 g/cm3

Viscosity = 1 cP

Liquid Temp.: 23°C

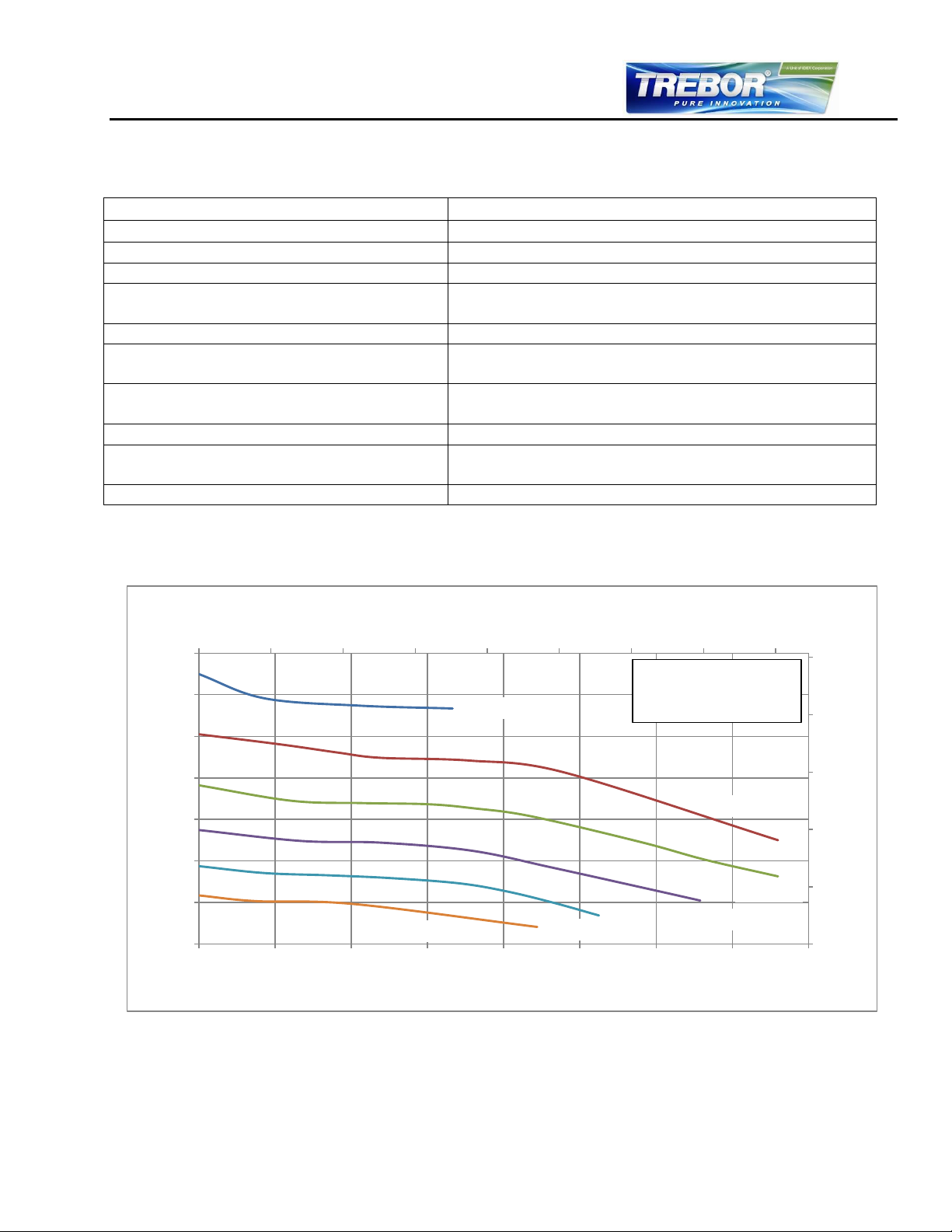

2.3 General Environmental Conditions

Table 5 – Environmental Conditions for Pump System

2.4 Pump Performance Curves

2.4.1 Pressure-Flow Curves

Figure 3 – Rev6 Flow vs Diff Pressure Curves

REV6 OPERATION / MAINTENANCE MANUAL 9 CONTENTS

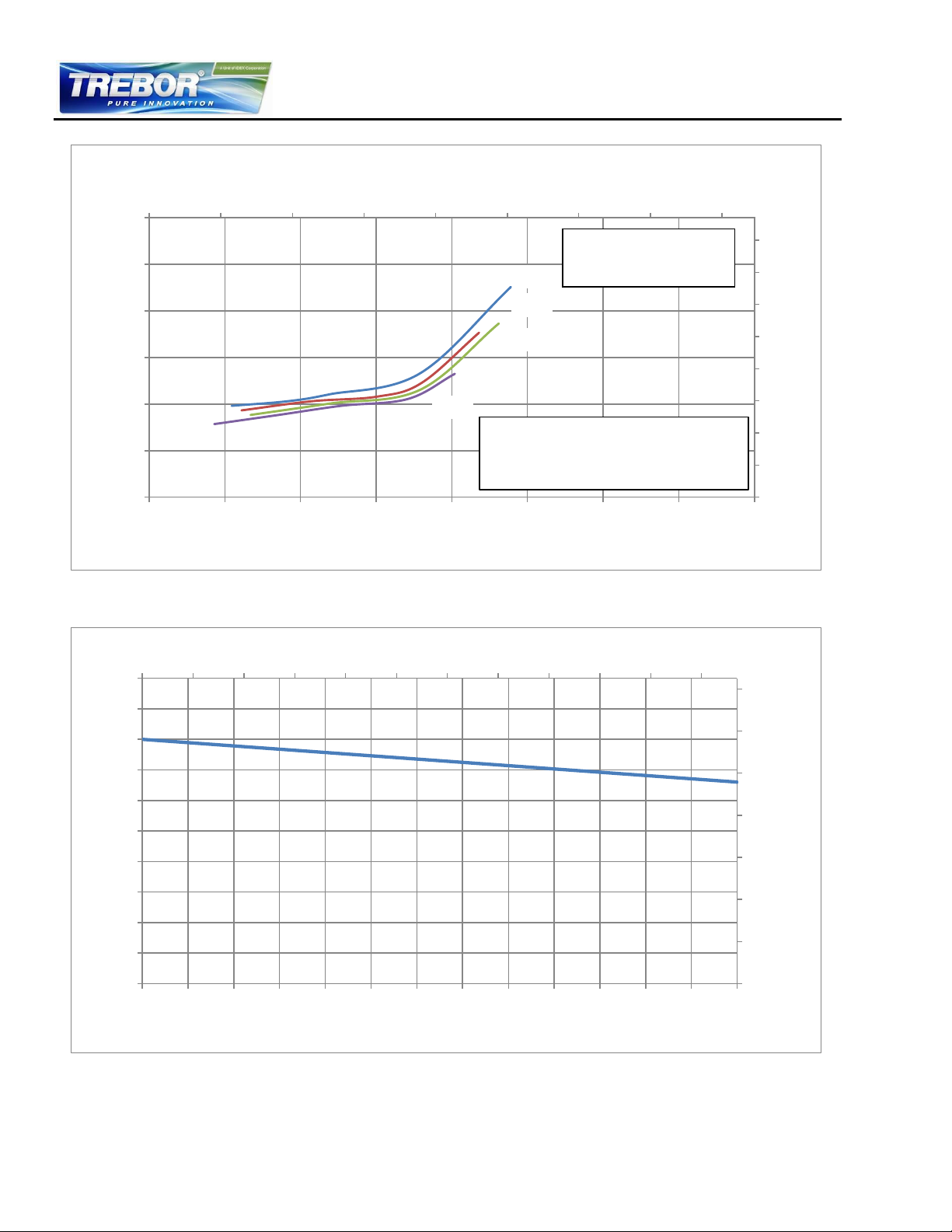

2.4.2 NPSHr Curves

8000

7000

6000

5000

0.0 2.5 5.0 7.5 10.0 12.5 15.0 17.5 20.0

0

1

2

3

4

5

6

7

8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0 10 20 30 40 50 60 70 80

GPM

PSI

bar

LPM

NPSHr Criteria ≡ The min. absolute inlet pressure

where the pump pressure is reduced by 3%

- Limitation is due to the axial limit of the

impeller

77 87 97 107 117 127 137 147 157 167 177 187

0

20

40

60

80

100

120

140

0

1

2

3

4

5

6

7

8

9

10

25 30 35 40 45 50 55 60 65 70 75 80 85 90

°F

PSI

Maximum Static Pressure

bar

°C

Fluid Temperature

Specific gravity = 1 g/cm3

Viscosity = 1 cP

Liquid Temp.: 20°C

Figure 4 – NPSHr Curves

2.4.3 Maximum Static Pressure vs. Fluid Temperature

Figure 5 – Maximum Static Pressure Allowed vs. Fluid Temperature

REV6 OPERATION / MAINTENANCE MANUAL 10 CONTENTS

2.5 Basic Dimensions of Main Components

All dimensions are given in mm and inches with the inch measurement in brackets.

Figure 6 – Basic Pump Dimensions

REV6 OPERATION / MAINTENANCE MANUAL 11 CONTENTS

Loading...

Loading...