Trebor Q-Series User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

Q-SERIES DI WATER

HEATER

Operation / Maintenance

Manual

SERIAL NUMBER:

PATENTS: U.S. 5971402, U.S. 6433319, U.S. 6479094B2, U.S. 6544583B2, 4/21/10 – MQ-B

U.S. 6580061B2, U.S. 6663914, U.S 6674053B2;

ADDITIONAL PATENTS PENDING

CONTENTS

1 INTRODUCTION ........................................................................................................................................3

2 SAFETY ......................................................................................................................................................5

2.1 SAFETY MESSAGE CONVENTIONS ............................................................................................5

2.1.a Danger ...........................................................................................................................5

2.1.b Warning ..........................................................................................................................5

2.1.c Caution ...........................................................................................................................6

2.2 EMERGENCY OFF (EMO) .............................................................................................................6

2.3 LOCKOUT / TAGOUT ....................................................................................................................7

2.3.a Preliminary .....................................................................................................................7

2.3.b Definitions ......................................................................................................................7

2.3.c Machine Lockout with access panels installed ................................................................7

2.3.d Machine Start-Up with access panels installed ...............................................................8

2.3.e Machine Lockout with access panels removed ...............................................................8

2.3.f Machine Start-Up with access panels removed ..............................................................8

2.4 SEISMIC PROTECTION ................................................................................................................9

3 INSTALLATION ........................................................................................................................................ 10

3.1 UNPACKING ................................................................................................................................ 10

3.2 LOCATION ................................................................................................................................... 10

3.3 UTILITY HOOK-UP ...................................................................................................................... 10

4 START-UP ................................................................................................................................................ 13

4.1 PRE-START INSPECTION .......................................................................................................... 13

4.1.a Verify Shipping Condition ............................................................................................. 13

4.1.b Hazardous Power Terminals ......................................................................................... 13

4.1.c Electrical Inspection ..................................................................................................... 13

4.1.d Plumbing Leak Check ................................................................................................... 13

4.2 SYSTEM POWER ........................................................................................................................ 14

4.3 HEATING WATER ....................................................................................................................... 14

5 HEATER OPERATION ............................................................................................................................. 15

5.1 BACKGROUND COLOR CONVENTIONS FOR BUILT-IN GRAPHICAL USER INTERFACE ...... 15

5.2 LOCAL OPERATION THROUGH BUILT-IN GRAPHICAL USER INTERFACE ............................ 15

5.2.a Home Page ........................................................................................................ 16

5.2.b Alarm page ......................................................................................................... 16

5.2.c Configuration Page ............................................................................................. 18

5.2.d Plot Page ........................................................................................................... 19

5.3 REMOTE OPERATION OVER AN EXTERNAL HARDWARE INTERFACE ................................. 20

6 PROCESS INTERLOCKS ......................................................................................................................... 22

7 SYSTEM SHUT DOWN ............................................................................................................................ 24

8 MAINTENANCE ........................................................................................................................................ 25

9 TROUBLESHOOTING .............................................................................................................................. 30

10 WARRANTY ............................................................................................................................................. 31

5.3.a Remote Communication via Modbus/RTU .................................................................... 20

6.1 LOW FLUID PRESSURE SENSOR ............................................................................................. 22

6.2 LIQUID LEVEL SENSOR ............................................................................................................. 22

6.3 ELEMENT OVER TEMPERATURE SENSOR .............................................................................. 23

6.4 LIQUID LEAK SENSOR ............................................................................................................... 23

6.5 OVERPRESSURE RELIEF FITTING ........................................................................................... 23

8.1 REPAIR INSTRUCTIONS ............................................................................................................ 25

8.1.a Heater Element Check ................................................................................................. 25

8.1.b Heater Replacement ................................................................................................ ..... 25

8.1.c Liquid Level Sensor Calibration .................................................................................... 27

8.1.d Draining the System ..................................................................................................... 27

8.1.e Leaks............................................................................................................................ 27

8.1.f Overpressure Relief Fitting Replacement ..................................................................... 28

8.2 PREVENTIVE MAINTENANCE SCHEDULE................................................................................ 28

See Appendix for specific system requirements.

Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL CONTENTS

1 INTRODUCTION

Q-SERIES DI WATER HEATER

TREBOR’s Q-Series DI water heater will meet your most stringent

application requirements for process cleanliness and temperature control.

Our unique heater design virtually eliminates the potential for metal

contamination due to potentially exposed metal heating elements in

immersion style heaters, while process control and reliability are designed

to outperform and outlast other available quartz heating systems.

Trebor’s DI water heater uses a revolutionary heating technology to

provide exceptional process purity and control. Heat is generated using

resistive heating elements conducted to the fluid through quartz tubes

using convective heat transfer. This conductive / convective heating

method allows the heating element to operate at a much cooler

temperature than IR heating systems and provides the basis for a

responsive heating control system.

The heater modules have smooth surfaces with minimal cracks and

crevices, reducing particle traps. Furthermore, no elastomeric O-rings

are used for sealing and the DI water is exposed only semiconductor

grade quartz and high purity polymers.

Trebor’s patented heating module technology is constructed to provide

excellent process control by minimizing hold-up volume and thermal heat

capacitance while maximizing the heat transfer. This also reduces the

consumption of DI water by minimizing temperature transition time and

bypass to drain requirements.

Many product safety features have been incorporated into the Q-Series

heater. Each system has a liquid level sensor, leak sensor, grounded

heater modules, ground fault protection, and redundant control system

interlocks. An electro-mechanical contactor disengages power to the

heaters when a fault condition occurs.

This equipment is built to semiconductor manufacturing industry

requirements of SEMI S2.

This equipment complies with the requirements of the EU guidelines:

Figure 1-1: 89/392/EEC “European Machinery Directive”

89/336/EEC “European EMC Directive”

Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL PAGE 3

Part Name

[部件名称]

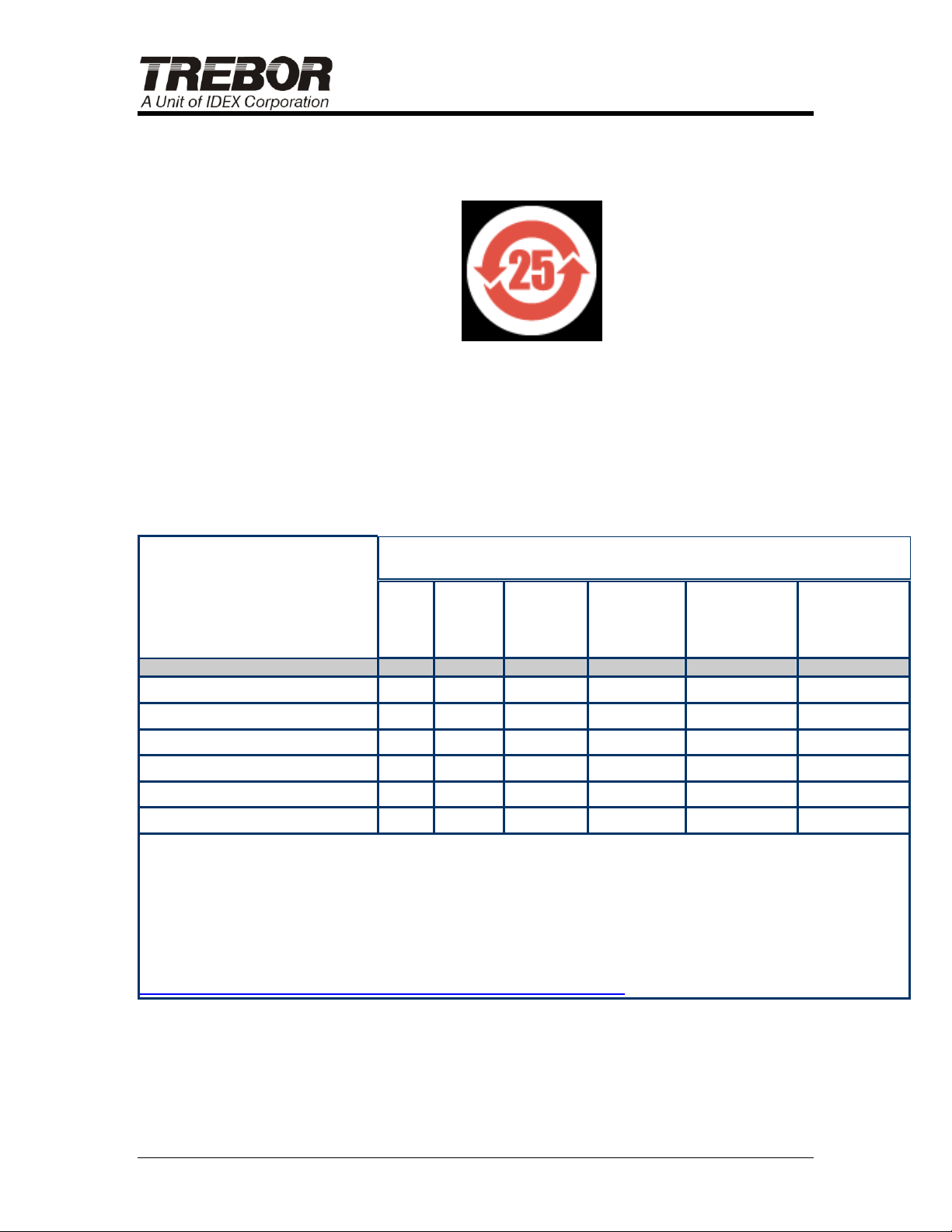

Table of Hazardous Substances and Elements

[产品中有毒有害物质或元素的名称及含量]

Lead

[铅]

(Pb)

Mercury

[汞]

(Hg)

Cadmium

[镉]

(Cd)

Hexavalent

Chromium

[六价铬]

(Cr (VI))

Polybrominated

biphenyl

[多溴联苯]

(PBB)

Polybrominated

diphenyl ether

[多溴二苯醚]

(PBDE)

QA1V208P12-AA

X

QA1V380P10-AB

X

QA1V415P10-AB

X

QA1V480P10-AD

X

QA1V480P12-AB

X

O = This substance is present at a concentration below the limit in SJ/T 11363-2006 in all of the homogeneous materials

for this part, and it has not been intentionally added to any metallic coating. (See SJ/T 11363-2006 for definition of

homogeneous materials)

X = This substance is present at a concentration above the limit in SJ/T 11363-2006, in at least one of the homogenous

materials for this part, or it has been intentionally added to a metallic coating. (See SJ/T 11363-2006 for definition of

homogeneous materials)

Notes: concentration limits of 1000 ppm (0.1% by weight) for lead, mercury, hexavalent chromium, polybrominated

biphenyls (PBB) and polybrominated diphenyls ether (PBDE), or 100 ppm (0.01% by weight) for cadmium.

Please refer to AeA’s website for an English translation of SJ/T 11363-2006 (or the latest revision of this document):

http://www.aeanet.org/governmentaffairs/gajl_MCV_SJT11363_2006ENG.asp

This equipment also complies with the requirements of the “Management

Methods for Controlling Pollution of Electronics Information Products”,

known as “China RoHS”.

Figure 1-2: China RoHS - Electronic information product pollution

control symbol

Trebor will use an EFUP (Environmental Friendly Use Period) of 25

years, which is consistent with the industry mean. The EFUP label is

located next to the main system nameplate and a declaration table is

included below.

Table [表]

PAGE 4 Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL

2 SAFETY

This section describes information that is important for safe equipment

operation. Included is a listing of message conventions used in this

manual, as well as equipment safety interlocks, push buttons, and labels.

The equipment described in this manual uses hazardous voltage

electricity that can be dangerous. Only personnel trained in the

procedures and safety messages outlined in this manual should install (if

applicable), operate, or maintain this equipment. Read and understand

this manual before installation or operation of the system. Follow all

recommended practices and procedures that apply to your actions and

conduct. All safeguard devices must be in place when equipment is in

operation. Operators, set-up operators, helpers or installation personnel

should not alter, remove or disable safety equipment. When using this

equipment, be sure to follow the safety procedures outlined by your

facility. These safety procedures should cover the two primary types of

hazard training: (1) equipment hazards and (2) facility-related hazards.

2.1 SAFETY MESSAGE CONVENTIONS

Safety messages contained in this manual; Dangers, Warnings, and

Cautions, are highlighted for quick identification.

2.1.a Danger

A Danger message indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury. Messages identified by

the word Danger are used sparingly and only for those situations

presenting the most serious hazards.

2.1.b Warning

A Warning message indicates a potentially hazardous situation that, if not

avoided, could result in serious injury. Following is a typical example of a

Warning message as it could appear:

Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL PAGE 5

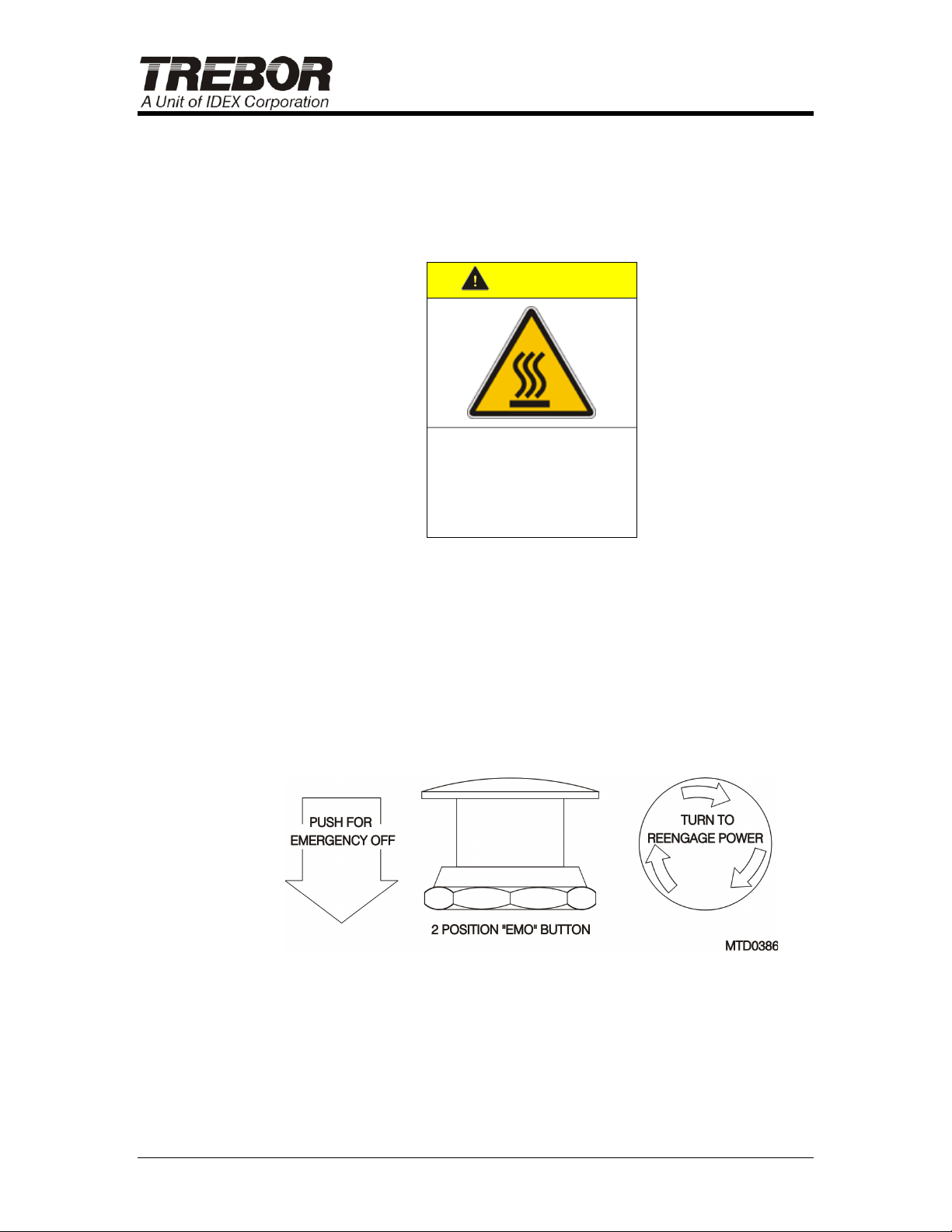

Caution

Hot Surface

Do not touch. Can cause

skin burns upon contact.

Disconnect and lockout

power and allow surface to

cool before servicing.

2.1.c Caution

A Caution message indicates a potentially hazardous situation, which, if

not avoided, could result in minor or moderate injury. It may also be used

to alert against unsafe practices. Following is a typical example of a

Caution message as it could appear:

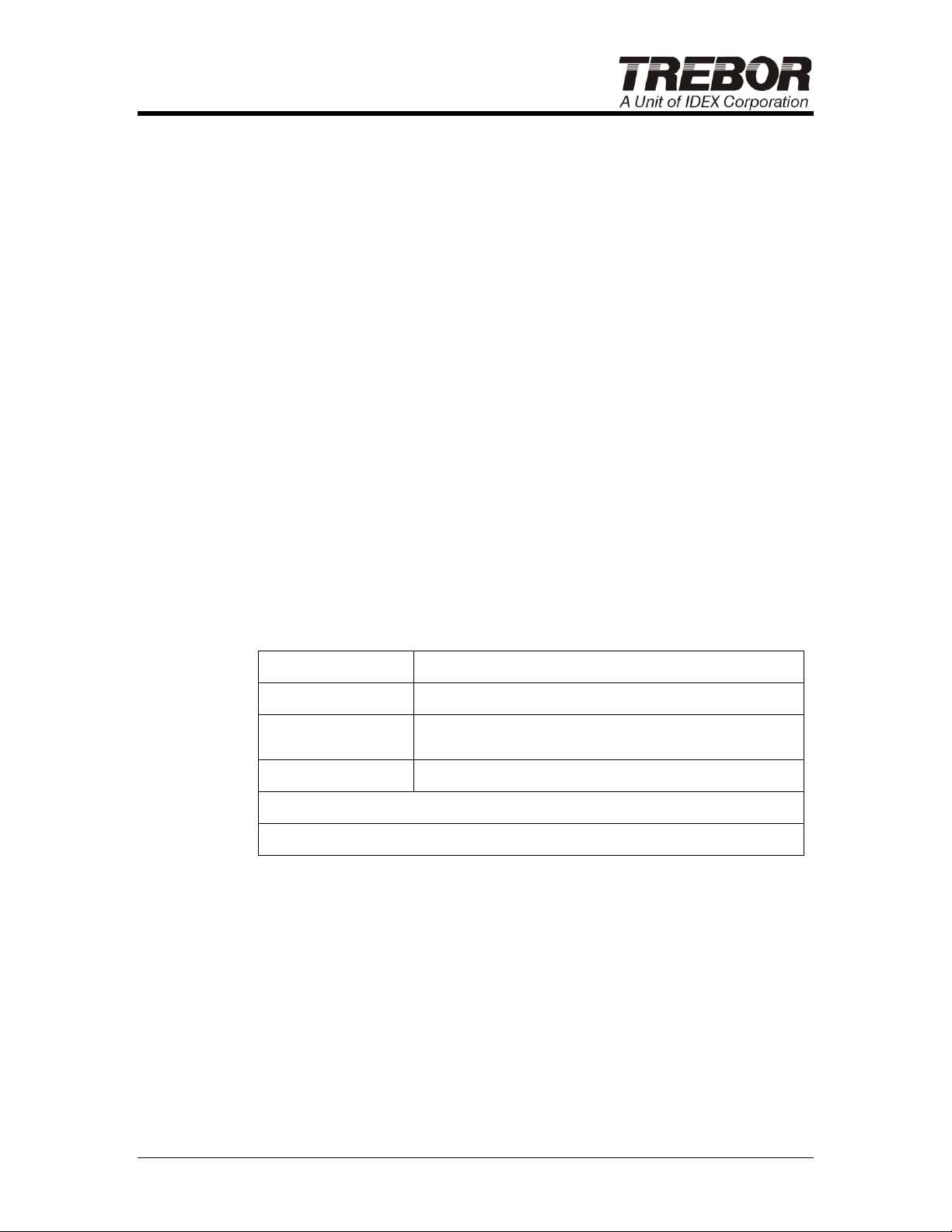

2.2 EMERGENCY OFF (EMO)

The EMERGENCY OFF button (EMO) is located on the front of the

heater. When the EMO circuit is activated by pushing the button in, the

equipment will be placed into a safe shutdown condition. The EMO will

de-energize the heaters and process interlock devices. Other devices on

the electrical panel remain energized and hazardous voltages will be

present at the power supply and power supply fuses, sub-panel circuit

breakers and contactors. Use the Main Power Disconnect Switch to

remove power altogether.

After the EMO button is disengaged, the heater must be reset by

pressing the blue RESET button located on the front of the heater near

the EMO button to reactivate the controls.

Figure 2-1

PAGE 6 Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL

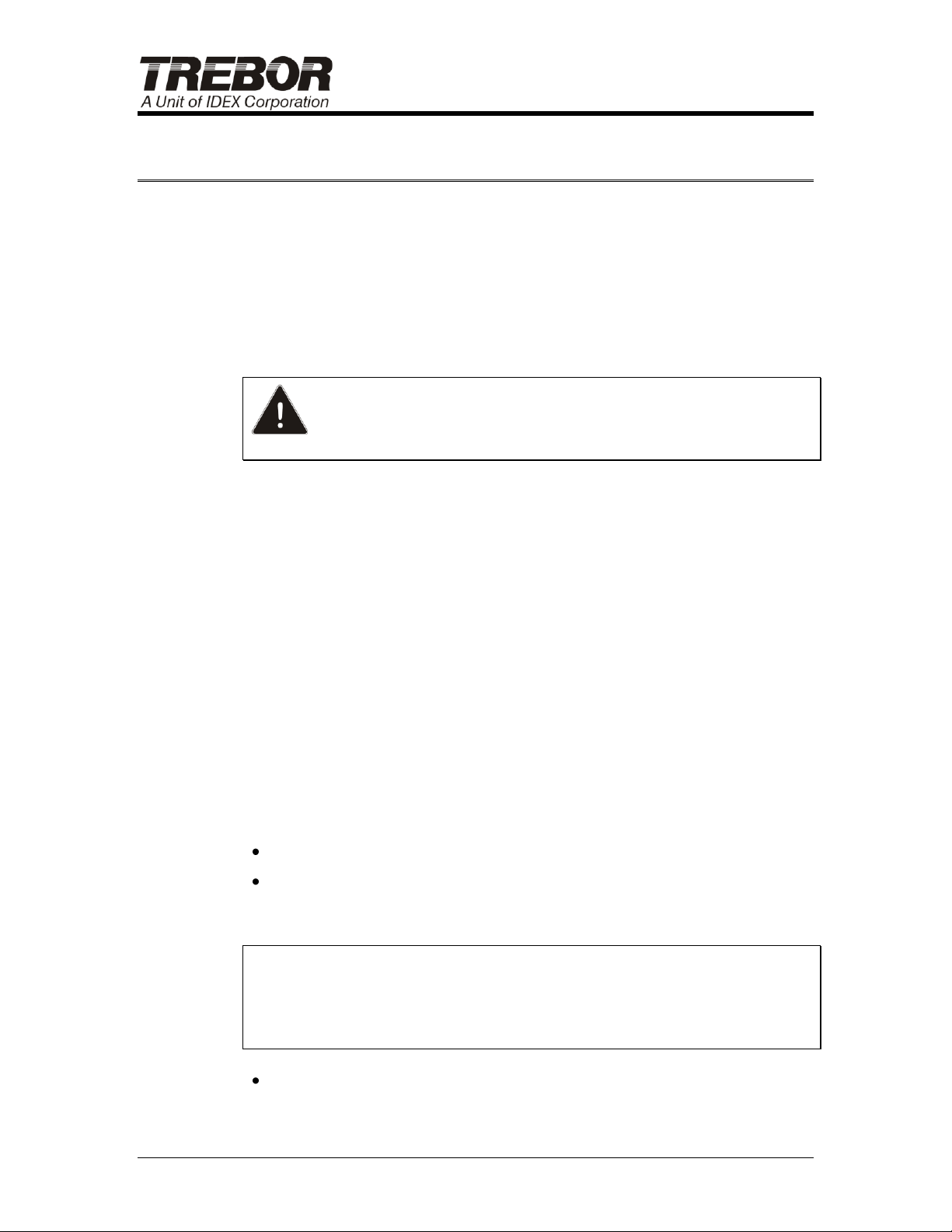

Energy Type

Electrical

Hazard:

Electrocution, electrical burns, and shock

Magnitude:

480 VAC or 415 VAC or 380 VAC or 208 VAC

See system label for exact voltage.

Control Method:

Main Power

Shutdown Procedure

Switch off main circuit breaker disconnect handle at side of system.

2.3 LOCKOUT / TAGOUT

2.3.a Preliminary

Before installation or servicing the DI water heater, the facility’s power

source to the heater must be de-energized to prevent serious injury to

personnel and equipment. An authorized employee representing the

facility installing the DI water heater must follow approved company

guidelines and lockout or use suitable means to prevent re-energizing the

electrical system during installation or servicing.

2.3.b Definitions

Lockout: the placement of a lockout device on an energy isolating

device, in accordance with established company procedures, ensures

that the energy isolating device and the equipment being controlled

cannot be operated until the lockout device is removed.

Tagout: a prominent warning device such as a tag and a means of

attachment, which can be securely fastened to an energy isolating device

in accordance with established company procedure, ensures that the

energy isolated device and the equipment being controlled may not be reenergized or operated until the tagout device is removed.

This table lists the Lockout/Tagout information for the system.

2.3.c Machine Lockout with access panels installed

Perform the following sequence of events in the order listed for electrical

energy isolation of the tool:

1. Notify personnel in the area that you are going to shut down the

equipment.

2. Shutdown the system in an orderly fashion.

3. Locate the main incoming power disconnect switch-actuating handle.

4. Move the actuating handle to the "OFF" (down) position.

Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL PAGE 7

5. Apply the locking energy isolation device (lock) through the hole in the

actuating handle and secure the lock.

6. Verify that the tool has been isolated and de-energized by attempting

to turn the main power disconnect back to the “ON” position and/or by

pressing the machine start button. The machine power must not be

reapplied and/or the machine must not start.

2.3.d Machine Start-Up with access panels installed

Perform the following sequence of events in the order listed for electrical

re-energization of the tool:

1. Ensure that all hand tools are removed from the equipment and that it

is ready for start-up.

2. Notify personnel in the area that you are going to start-up the

equipment.

3. Open the lock and remove the locking energy isolation device (lock)

from the hole in the actuating handle of the Main Disconnect Switch.

4. Move the actuating handle to the "ON" (up) position.

5. Press the machine start button. The machine should start.

2.3.e Machine Lockout with access panels removed

Perform the following sequence of events in the order listed for electrical

energy isolation of the tool:

1. Notify personnel in the area that you are going to shut down the

equipment.

2. Shutdown the system in an orderly fashion.

3. Locate the main incoming power disconnect switch-actuating handle.

4. Rotate the rotary disconnect shaft to the "OFF" of “0” (down) position.

5. Insert key and lock the rotary disconnect lock located at the top left of

rotary disconnect device (see Figure 2-2). Remove the key.

6. Verify that the Tool has been isolated and de-energized by attempting

to turn the rotary disconnect shaft back to the “ON” or “1” position

and/or by pressing the machine start button. The machine power

must not be reapplied and/or the Machine must not start.

2.3.f Machine Start-Up with access panels removed

Perform the following sequence of events in the order listed for electrical

re-energization of the tool:

1. Ensure that all hand tools are removed from the equipment and that it

is ready for start-up.

2. Notify personnel in the area that you are going to start-up the

equipment.

PAGE 8 Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL

3. Insert key and unlock the rotary disconnect lock located at the top left

of rotary disconnect device (see Figure 2-2). Remove the key.

4. Move the rotary disconnect shaft to the "ON" of “1” (up) position.

5. Press the machine start button. The machine should start.

Figure 2-2: Lockout Key Location on Main Breaker

2.4 SEISMIC PROTECTION

It is the user’s responsibility to adequately secure and anchor the

equipment to comply with local regulatory agency seismic requirements.

Mounting holes for anchors are provided at the bottom of the cabinet

enclosure. See Facility Layout in Appendix for mounting hole locations.

Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL PAGE 9

3 INSTALLATION

3.1 UNPACKING

Remove heater system from crate and inspect heater cabinet for any

signs of damage (dented panels, paint scratches, etc.). Shock indicators

on the heater cabinet should be checked for rough handling during

shipment. Any damage to the system should be reported to the carrier

immediately.

CAUTION: Heavy Object. When lifting or moving the system,

follow safe heavy object handling methods to prevent injury.

Be careful to not damage the fittings located on back of heater cabinet

when using a dolly or forklift.

3.2 LOCATION

Locate the heater near the point-of-use to reduce plumbing heat loss.

Access to the side access panels will be necessary for maintenance and

utilities hook-up.

3.3 UTILITY HOOK-UP

All utility hook-ups associated with the DI water heater are easily

accessible and are referenced in the Appendix.

After positioning heater at operating location, adjust the four leveling feet

until the heater is level and stable.

Connect the cold DI supply line to the “Cold DI Inlet” connection.

Connect the hot DI process lines to the “Hot DI Outlet” connection.

Use only hot DI compatible plumbing components. They must be

rated at a minimum of 110°C (230°F) and 414kPa (60 psig).

NOTE: It is recommended that the hot water supply line have a bleed, or

purge, at the point-of-use to reduce the possibility of stagnating the DI

water in the heaters when not in use. The amount of this bleed is best

evaluated on a case-by-case basis, taking into account each user’s

criteria and production standards.

Recommendation: Either insulate the hot DI water process line or

place a Hot Surface hazard warning (shown below) on the tubing

every 20 feet. Conform to local codes while evaluating hot water line

routing.

PAGE 10 Q-SERIES DI HEATER OPERATION / MAINTENANCE MANUAL