Trebor PC7 User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

PC7 PUMP

CONTROLLER

Operation / Maintenance

Manual

SERIAL NUMBER (located on top of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 02/16/05 – MPC7-PRJ0305

CONTENTS

1 INSTALLATION............................................................................................................3

1.1 UNPACKING ......................................................................................................3

1.2 UTILITIES / HOOK-UP.......................................................................................3

2 OPTIONS......................................................................................................................5

2.1 UNIT IS AVAILABLE IN BOTH PFA AND PP CONSTRUCTION......................5

3 START-UP....................................................................................................................6

3.1 PERFORMANCE CHARTS................................................................................7

4 MAINTENANCE ...........................................................................................................8

4.1 PREVENTIVE MAINTENANCE SCHEDULE.....................................................8

4.1.a Preventive Maintenance Record...........................................................9

4.2 RECOMMENDED SPARE PARTS ..................................................................10

4.3 TOOLS..............................................................................................................10

4.4 PARTS ILLUSTRATION – PC7........................................................................10

4.5 PARTS LIST – PC7F........................................................................................11

4.6 PARTS LIST – PC7P........................................................................................11

4.7 CLEAN-UP........................................................................................................12

4.8 DISASSEMBLY ................................................................................................12

4.9 ASSEMBLY ......................................................................................................12

5 TROUBLESHOOTING ...............................................................................................15

6 WARRANTY .......................................................................................................16

PC7 CONTROLLER OPERATION / MAINTENANCE MANUAL CONTENTS

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

Qty Item Description

1 PC7F or PC7P PC7 PUMP CONTROLLER

1 PC7-Manual Manual, PC7 Pump Controller

1.2 UTILITIES / HOOK-UP

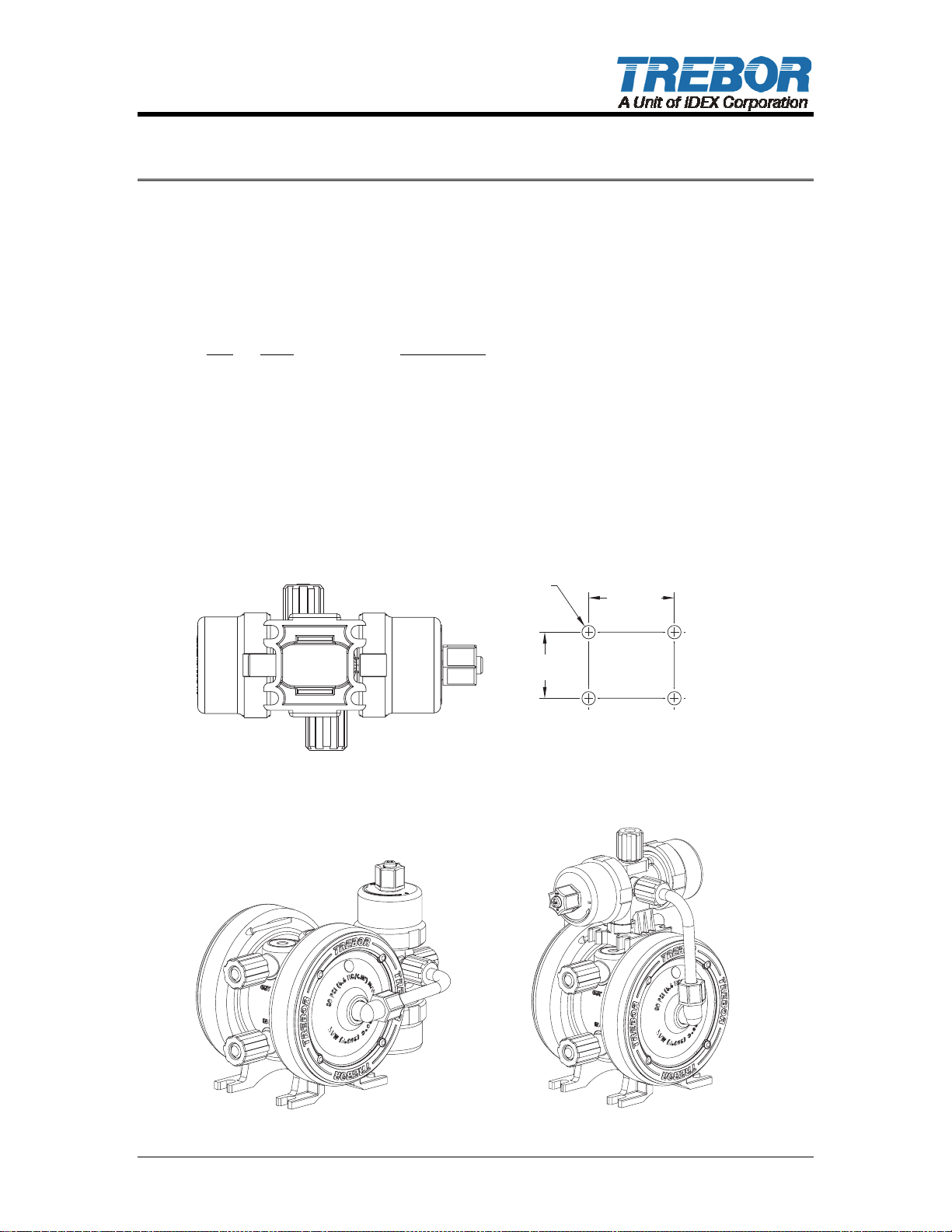

The controller can be mounted by any of three methods. It can be bolted to a wall

or deck using the snap on base slots as shown below using four ¼”(6mm) bolts

in the pattern shown below.

CONTROLLER - BOTTOM VIEW

5/16"

DIA

4X

1 7/16"1 7/16"

BOLT PATTERNBOLT

MTD0616

1 7/8"1 7/8"

PATTERN

MTD0617

MTD0618

PUMP INSTALLATION - BACK PUMP INSTALLATION - TOP

PC7 CONTROLLER OPERATION / MAINTENANCE MANUAL PAGE 3

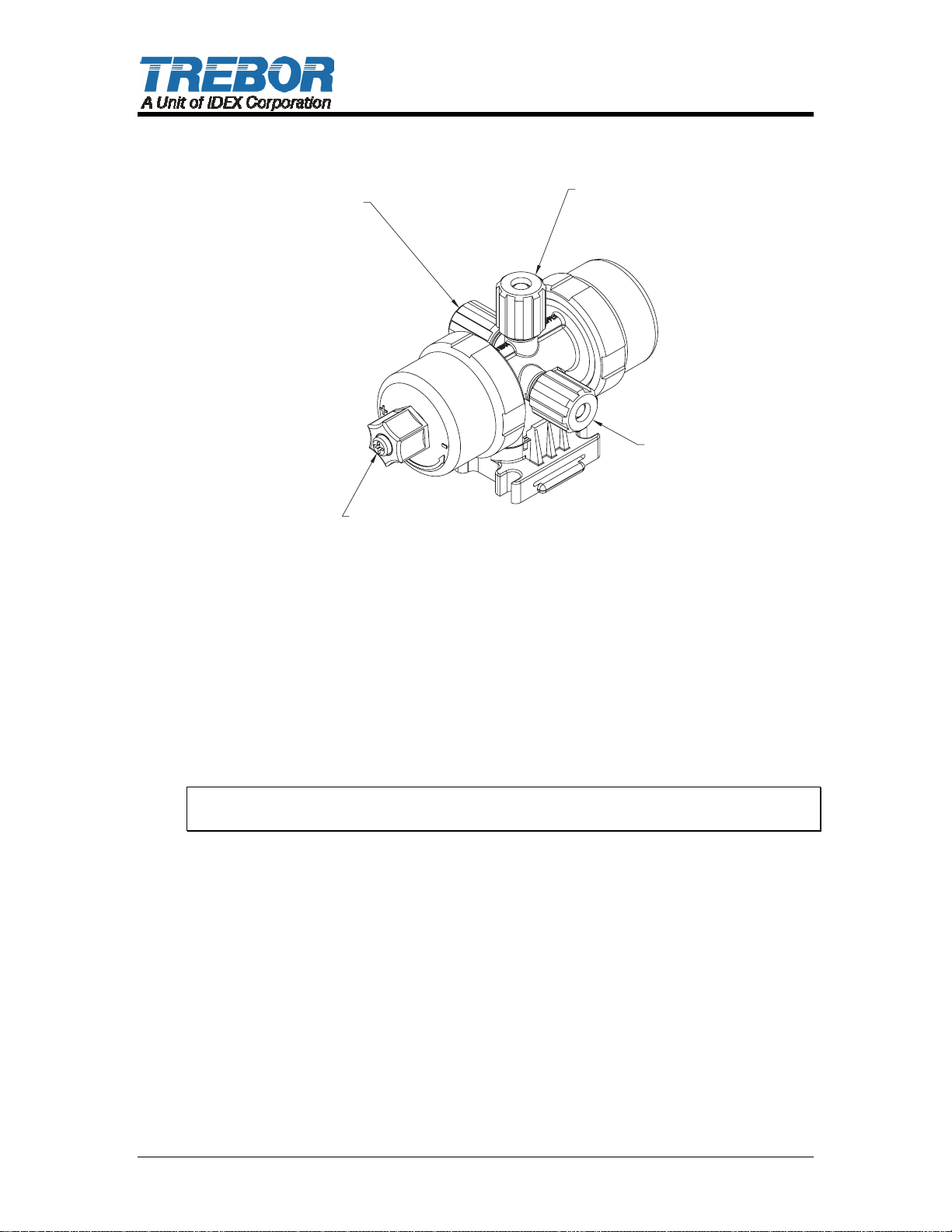

HEAD 1HEAD 1

CONNECTION

SPEED

ADJUSTMENT

SCREW

AIR INLETAIR INLET

CONNECTION

HEAD 2HEAD 2

CONNECTION

MTD0619

Air Inlet: 3/8” Flaretek (3/8” OD TUBING)

Air Supply: 20-80 PSIG (1.4 – 5.4 BAR), CLEAN DRY AIR OR NITROGEN.

Head Ports: 3/8” Flaretek (3/8” OD PFA TUBING)

Recommended Maximum Operating Levels: 80 psig (5.4 bar)

ATTENTION: The controller should be operated with clean, dry air or nitrogen.

Particulate, water and oils in the air supply can damage the controller.

PAGE 4 PC7 CONTROLLER OPERATION / MAINTENANCE MANUAL

2 OPTIONS

2.1 UNIT IS AVAILABLE IN BOTH PFA AND PP CONSTRUCTION

The PFA unit exterior parts are molded using PFA (Fluoroplastic) and the shuttle

assembly is constructed of PEEK & PPS. The PFA unit is intended for severe

applications and for compliance with FM4910.

The PP unit exterior parts are molded using Polypropylene (Polyolefin) and the

shuttle assembly is constructed of PEEK & PPS. This unit is intended as a lower

cost option with similar service life where exposure to oxidizing acids is limited.

PC7 CONTROLLER OPERATION / MAINTENANCE MANUAL PAGE 5

Loading...

Loading...