Trebor IQ Chemical Heater User Manual

IQ CHEMICAL

HEATER

Operation / Maintenance

Manual

SERIAL NUMBER:

PATENTS: U.S. 5971402, U.S. 6433319, U.S. 6479094B2, U.S. 6544583B2, 01/25/13 – MIQ-B

U.S. 6580061B2, U.S. 6663914, U.S 6674053B2;

ADDITIONAL PATENTS PENDING

CONTENTS

1 INTRODUCTION ........................................................................................................... 3

1.1 INTENDED USE AND AUDIENCE ..................................................................... 4

1.2 HEATER SIZING ................................................................................................ 4

2 SAFETY ........................................................................................................................ 5

2.1 SAFETY PRECAUTIONS ................................................................................... 5

2.1.a General Safety ....................................................................................... 5

2.2 SAFETY MESSAGE CONVENTIONS ............................................................... 5

2.2.a Caution .................................................................................................. 5

2.2.b Warning ................................................................................................. 6

2.2.c Danger ................................................................................................... 6

2.3 HEATER INTERLOCKS ..................................................................................... 6

2.3.a Leak Sensor........................................................................................... 6

2.3.b Element Over-Temperature Protection ................................................. 7

2.3.c Liquid Over-Temperature Protection ..................................................... 7

2.3.d Internal Over-Temperature Protection ................................................... 8

2.3.e Liquid Level Sensor Interlock ................................................................ 8

3 INSTALLATION ............................................................................................................ 9

3.1 UTILITY REQUIREMENTS .............................................................................. 10

3.2 UNPACKING .................................................................................................... 10

3.3 ORIENTATION ................................................................................................. 10

3.4 FLUID CONNECTIONS .................................................................................... 10

3.4.a Inlet & Outlet ........................................................................................ 10

3.4.b Liquid Drain .......................................................................................... 10

3.5 ELECTRICAL CONNECTIONS ........................................................................ 11

4 OPERATION ............................................................................................................... 12

4.1 GENERAL ......................................................................................................... 12

4.2 LIQUID START-UP ........................................................................................... 12

4.3 TEMPERATURE CONTROL ............................................................................ 13

4.4 SHUT DOWN .................................................................................................... 13

5 MAINTENANCE .......................................................................................................... 14

5.1 SPARE PARTS ................................................................................................. 14

5.2 PREVENTIVE MAINTENANCE SCHEDULE ................................................... 14

5.3 REMOVAL AND REPLACEMENT INSTRUCTIONS ....................................... 14

5.3.a Heater Replacement ............................................................................ 14

5.3.b Heater Decommissioning .................................................................... 14

5.3.c Heater Disposal ................................................................................... 14

6 TROUBLESHOOTING ............................................................................................... 15

6.1 IRREGULAR TEMPERATURE CONTROL ...................................................... 15

6.2 HEATER ELEMENT CHECK ........................................................................... 15

6.3 INTERLOCK SENSORS .................................................................................. 16

7 WIRING SCHEMATIC ................................................................................................ 17

8 OPTIONS .................................................................................................................... 20

8.1 FLUID CONNECTIONS (IQL04V208SB08AAA00): ......................................... 20

8.2 LIQUID LEVEL SENSOR (IQL04V208SB08AAA00): ...................................... 20

8.3 LEAK SENSOR (IQL04V208SB08AAA00): ..................................................... 20

8.4 INTERLOCK TEMPERATURE SENSORS (IQL04V208SB08AAA00): ........... 20

9 WARRANTY AND EXCLUSIONS .............................................................................. 21

10 CONTACT INFORMATION ........................................................................................ 22

10.1 GENERAL CONTACT INFORMATION ............................................................ 22

10.2 TECHNICAL SUPPORT ................................................................................... 22

10.3 REGIONAL REPRESENTATIVES ................................................................... 22

MODEL IQ QUARTZ HEATER OPERATION / MAINTENANCE MANUAL CONTENTS

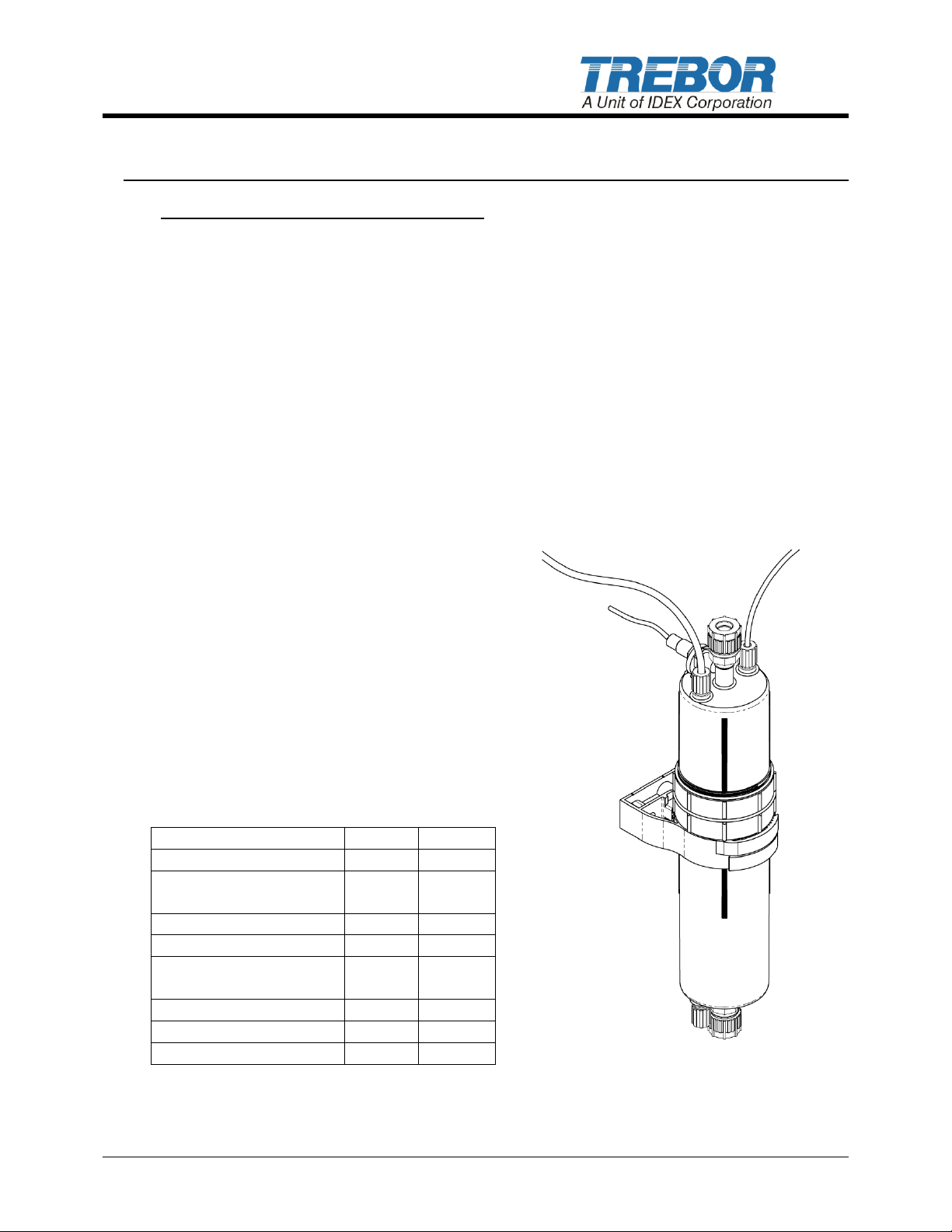

Shown with Optional Capacitive

Fluid Connections and Drain

IQL — Low Temperature

Metric

English

Maximum Pressure

.55 MPa

80 psig

Maximum Chemical

Operating Temperature

100 °C

212 °F

IQH — High Temperature

Maximum Pressure

.31 MPa

45 psig

Maximum Chemical

Operating Temperature

200 °C

392 °F

IQL/IQH

Minimum Pressure

.10 MPa

15 psig

Minimum Flow Rate

2 LPM

.53 GPM

1 INTRODUCTION

IQ Chemical Heater - The Smart Choice!

Trebor’s IQ in-line quartz chemical heater provides the ultra-high purity you demand, with

the reliability you expect.

The IQ’s flow path is smooth, free of particle traps and constructed entirely of GE 214

quartz and PFA, making it compatible with all non-combustible chemistries, except HF &

KOH. The PFA enclosure ensures plenum compatibility and resists corrosion or

discoloration. Most importantly, unlike immersion style resistive heaters your application is

free from metal ion contamination risk if the external thin-film heating element should fail.

Trebor’s patented sealing technology not only protects against liquid leaks, but eliminates

the breakage commonly associated with fragile quartz fluid connections. Plus, there are no

O-rings to service or replace.

Simplicity and flexibility are key elements of the IQ heater. The modular design allows

heaters to be connected in parallel or series. Heaters are available in multiple voltages

and with multiple fluid fitting options to accommodate your heating needs.

Features

Quartz/PFA liquid path

Multiple fluid fitting options

No metal contamination risk

No particle traps

Efficient heat transfer and small thermal

volume for fast response

SEMI S2, S3, and CE compliant

Performance Summary

MODEL IQ QUARTZ HEATER OPERATION / MAINTENANCE MANUAL PAGE 3

Fluid Sensor and Pillar Super 300

1.1 INTENDED USE AND AUDIENCE

The IQ chemical heater is designed to safely heat acids, DI water, and other

noncombustible quartz-compatible liquid solutions up to 200°C. The IQ chemical

heater is not intended for use with combustible or flammable chemistries, such

as solvents, or chemistries such as HF or KOH with accelerated quartz etch

rates.

This manual only covers the Trebor IQ chemical heater and heater accessories

provided by Trebor. The user is responsible for the external control system and

all necessary connections required to safely operate the heater (see Sections 4.3

and 7)

The Trebor IQ chemical heater is not to be used for proposes other than that

which is designed for. The heater and optional components are to be used only

with liquids and parameters stated within this manual. This manual assumes

personnel are familiar with the installation, operation and maintenance

requirements of chemical heaters.

The IQ chemical heater is intended for use by properly trained personnel. Read

and understand this manual prior to installation and/or operation of the heater.

Do not use this equipment until familiar with its operation and safety features.

1.2 HEATER SIZING

Sizing Formula

Required kW = 0.264(Flow)(Temp Delta)

Conversion Calculations:

GPM = LPM/3.8

°C = 5/9(°F - 32)

Heater Sizing Formula Example

Temperature delta per pass = 15 °C

Required kW=0.264(1 GPM)(15 °C) = 3.96 kW

For optimal temperature response and to compensate for overshoot; Trebor

recommends adding 25% excess heating capacity.

3.96 kW(1.25) = 4.95 kW.

Trebor recommends a 6 kW heater for this application.

PAGE 4 MODEL IQ CHEMICAL HEATER OPERATION / MAINTENANCE MANUAL

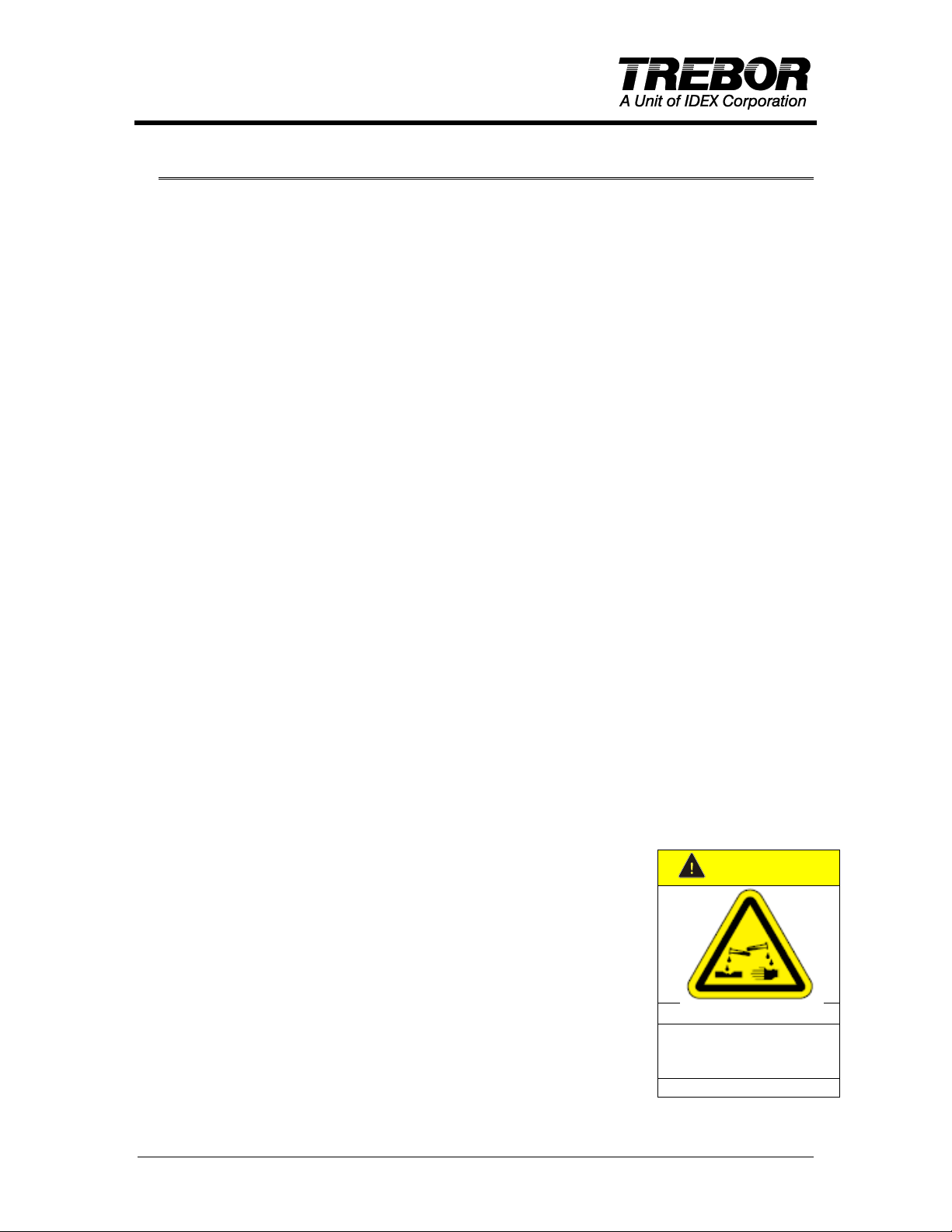

Caution

Corrosive Chemical

Product may contain

hazardous corrosive

liquids.

Handle with care.

2 SAFETY

2.1 SAFETY PRECAUTIONS

This section provides important information for safe operation of the IQ chemical

heater.

The equipment described in this manual uses hazardous voltage electricity that

can be dangerous. Local policies and procedures for safely operating any Trebor

chemical heater(s) supersede the safety considerations listed below. It is the

responsibility of all personnel to follow such policies and procedures. All safety

guard devices must be in place when equipment is in operation. Operators, setup operators, helpers or installation personnel should not alter, remove or disable

safety devices or equipment.

2.1.a General Safety

There are no serviceable parts inside the heater assembly; never open or

disassemble. Attempting to do so will void the product warranty.

Do not attempt to work on or with hazardous chemicals or electrical

equipment without proper safety training and certification, understand first aid

for electrical shock and hazardous chemicals spills.

Lockout and tag the electrical and chemical systems prior to installation or

replacement. Refer to company safety policies and procedures prior to

installation or replacement.

Always disengage the heater and optional equipment from electrical sources

prior to installation or replacement.

Always refer to company safety policies and procedures for flushing and

decontamination prior to removal.

2.2 SAFETY MESSAGE CONVENTIONS

2.2.a Caution

A Caution message indicates a potentially

hazardous situation, which, if not avoided,

could result in minor or moderate injury. It

may also be used to alert against unsafe

practices. A typical Caution message:

MODEL IQ CHEMICAL HEATER OPERATION / MAINTENANCE MANUAL PAGE 5

Warning

Hazardous Voltage

Voltage or current

hazard sufficient to

cause shock, burn or

death. Disconnect and

lockout power before

servicing.

2.2.b Warning

A Warning message indicates a potentially

hazardous situation that, if not avoided,

could result in serious injury. A typical

example of a Warning message:

2.2.c Danger

A Danger message indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury. Messages identified by

the word Danger are used sparingly and only for those situations

presenting the most serious hazards

2.3 HEATER INTERLOCKS

2.3.a Leak Sensor

The Trebor IQ chemical heater is supplied with a 24Vdc conductive liquid

leak sensor. Note, two modes of operation are available – NPN (normally

open) and PNP (normally closed).

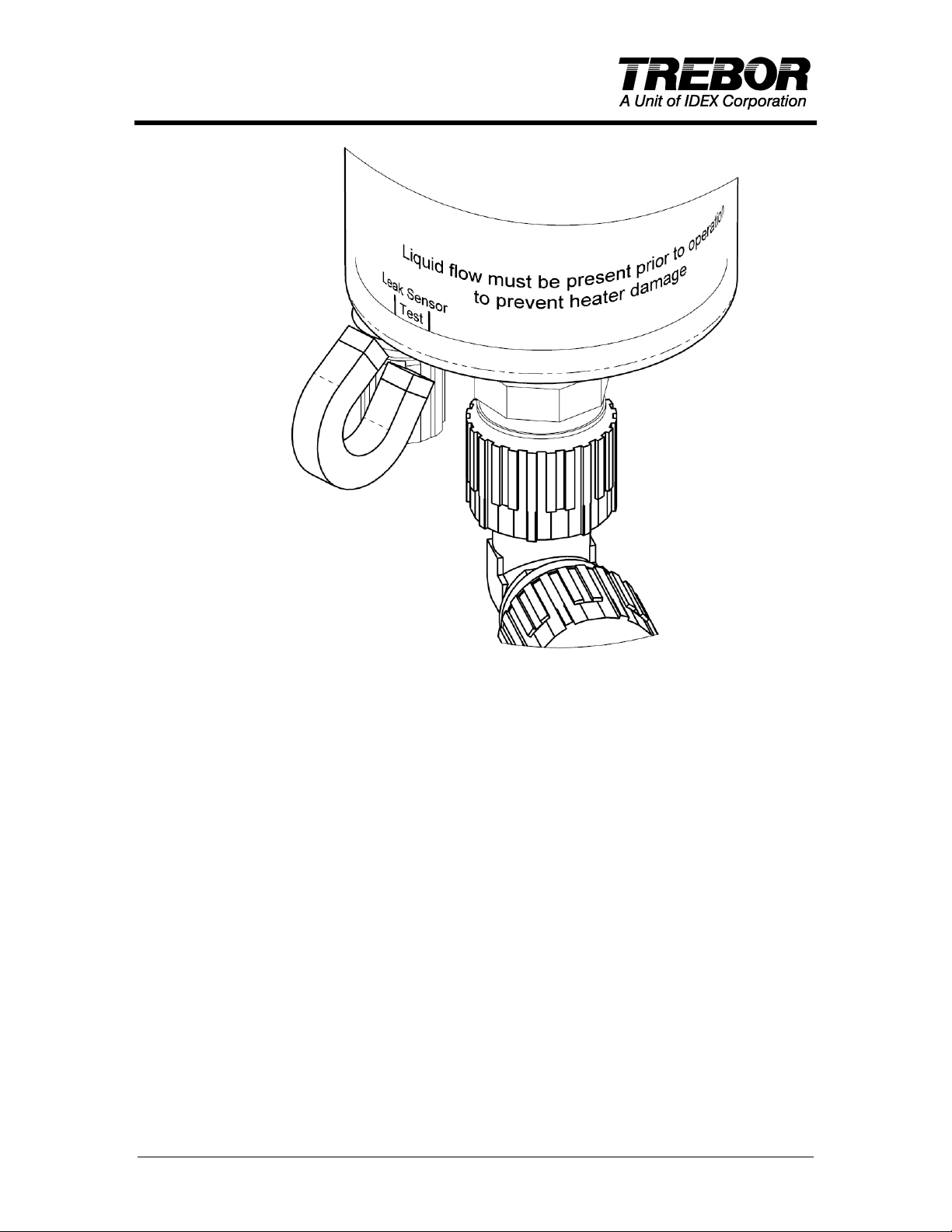

An integrated magnetic reed switch allows a non-intrusive method for

verification of sensor operation. Pass a magnet next to the area near the

heater bottom, labeled “LEAK SENSOR TEST” to engage the reed switch

and alarm the leak sensor, see Figure 2-1. See Section 7 for wiring

instructions.

PAGE 6 MODEL IQ CHEMICAL HEATER OPERATION / MAINTENANCE MANUAL

Figure 2-1

Note: The heater has no provision for monitoring or controlling flow rates

or provisions to turn off flow to the heater during a leak alarm. It is

recommended that the user incorporate a separate interlock to isolate

flow and power from the heater in the event of an alarm.

2.3.b Element Over-Temperature Protection

The Trebor IQ chemical heater is supplied with a temperature sensor(s)

located on the heater element. The element temperature sensor(s) must

be used with an interlock to ensure the element temperature does not

exceed 250°C. Note, two types of sensors are available – thermocouple

and RTD. See Section 7 for wiring instructions.

2.3.c Liquid Over-Temperature Protection

The maximum liquid temperature (T

element temperature (Te°C), heater power rating (P - i.e. 3-kW, 4-kW, 6kW, etc.) and duty cycle (duty %). Te = T

Example 1: Given a maximum allowable liquid temperature of 140°C, a

heater rated at 6 kW and a 100% duty cycle, the maximum

element temperature limit is:

°C) can be estimated from the

max

max

+ P * duty * 16.1

Te = 140°C + (6)*(1.00)*(16.1)

MODEL IQ CHEMICAL HEATER OPERATION / MAINTENANCE MANUAL PAGE 7

Loading...

Loading...