Trebor 620R User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

MAGNUM 620R PUMP

Operation / Maintenance

Manual

SERIAL NUMBER (located on back of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 04/11/2014– M620R-B

CONTENTS

1 INSTALLATION ............................................................................................................ 3

1.1 UNPACKING ...................................................................................................... 3

1.2 UTILITIES / HOOK-UP ....................................................................................... 3

1.3 CHECK MUFFLER OPERATION ....................................................................... 5

1.3.a Purpose ................................................................................................. 5

1.3.b Adjustment ............................................................................................. 5

1.4 REMOTE EXHAUST HOOK-UP ........................................................................ 7

2 OPTIONS ...................................................................................................................... 8

2.1 FLUID PORT CONNECTION OPTIONS ............................................................ 8

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP .................................... 8

3 START-UP .................................................................................................................. 10

3.1 PERFORMANCE CHARTS .............................................................................. 10

4 MAINTENANCE .......................................................................................................... 13

4.1 PREVENTIVE MAINTENANCE SCHEDULE ................................................... 13

4.1.a Preventive Maintenance Record .......................................................... 15

4.2 RECOMMENDED SPARE PARTS ................................................................... 16

4.3 TOOLS .............................................................................................................. 16

4.4 PARTS ILLUSTRATION ................................................................................... 17

4.5 PARTS LIST ..................................................................................................... 18

4.6 CLEAN-UP ........................................................................................................ 18

4.7 DISASSEMBLY ................................................................................................. 18

4.7.a Body Disassembly ............................................................................... 20

4.7.b Head Disassembly ............................................................................... 20

4.7.c Master Head Disassembly ................................................................... 20

4.7.d Pump Cleaning .................................................................................... 20

4.8 ASSEMBLY ....................................................................................................... 20

4.8.a Master Head Assembly ........................................................................ 20

4.8.b Pump Assembly ................................................................................... 22

4.8.c Final Assembly .................................................................................... 23

4.9 TESTING .......................................................................................................... 25

5 TROUBLESHOOTING ............................................................................................... 26

6 WARRANTY ............................................................................................................... 27

7 CONTACT INFORMATION ........................................................................................ 28

7.1 GENERAL CONTACT INFORMATION ............................................................ 28

7.2 TECHNICAL SUPPORT ................................................................................... 28

7.3 REGIONAL REPRESENTATIVES ................................................................... 28

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

Qty

Item

Description

1

620

Magnum 620 Pump

1

M620R

Operation/Maintenance Manual

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

1.2 UTILITIES / HOOK-UP

It is recommended that the pump be positioned within 15 from level to maintain

self-priming ability and pumping efficiency. Allow sufficient room for tubing

connectors. The pump mounts on a quick-change base for easy installation.

The pump has an exhaust location on the backside of the master head. The

exhaust location requires 1/2” (12mm) minimum clearance behind the master

head. Care should be taken to prevent flooding the exhaust port when the pump

is located in a wet bench plenum. For remote exhaust connection see Section 0.

Air Inlet: 1/4” FNPT (3/8” Dia. [8mm] supply tube minimum).

Air Supply: 20-80 psig (1.4 – 5.5 bar) clean dry air or nitrogen (see

Performance Charts, Section 3.1).

Fluid Ports: 1” NPSM – additional adaptor port options available.

Inlet/Outlet adaptor fittings and Surge Suppressor require

torqueing during pump installation. See Section 2 for hook-up

diagram and torque values.

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

Temperature Range

Supply Pressure Max

< 60°C

80 PSI (5.5 bar)

60°C - 110°C**

60 PSI (4.1 bar)

*110C Maximum Fluid Temperature

Figure 1-1: Dimensional Views

ATTENTION: The pump should be operated with clean, dry air or nitrogen.

Particulate, water and oils in the air supply can damage the pump.

NOTE:

1. It is recommended that a filter be placed on the discharge side of the pump.

2. Although extensive efforts are made to deliver pumps to our customers

completely dry, new pumps may contain residual moisture from their final DI

water test.

Recommended Maximum Operating Levels:

PAGE 4 MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL

1.3 CHECK MUFFLER OPERATION

1.3.a Purpose

NOTE: The check muffler is not designed to control pump speed. Use of the

check muffler for this purpose could result in serious damage to the pump.

Permits pump to operate reliably in systems that incorporate a discharge flow

less than 3 gpm.

Permits pump to operate reliably in systems that have the pump located at

an elevation below the liquid supply level and flows below 3 gpm. (Pump air

supply remains on.)

Effectively reduces the amount of harmful acid vapors that can enter into the

pump’s internal air circuit components while the pump air supply is off.

1.3.b Adjustment

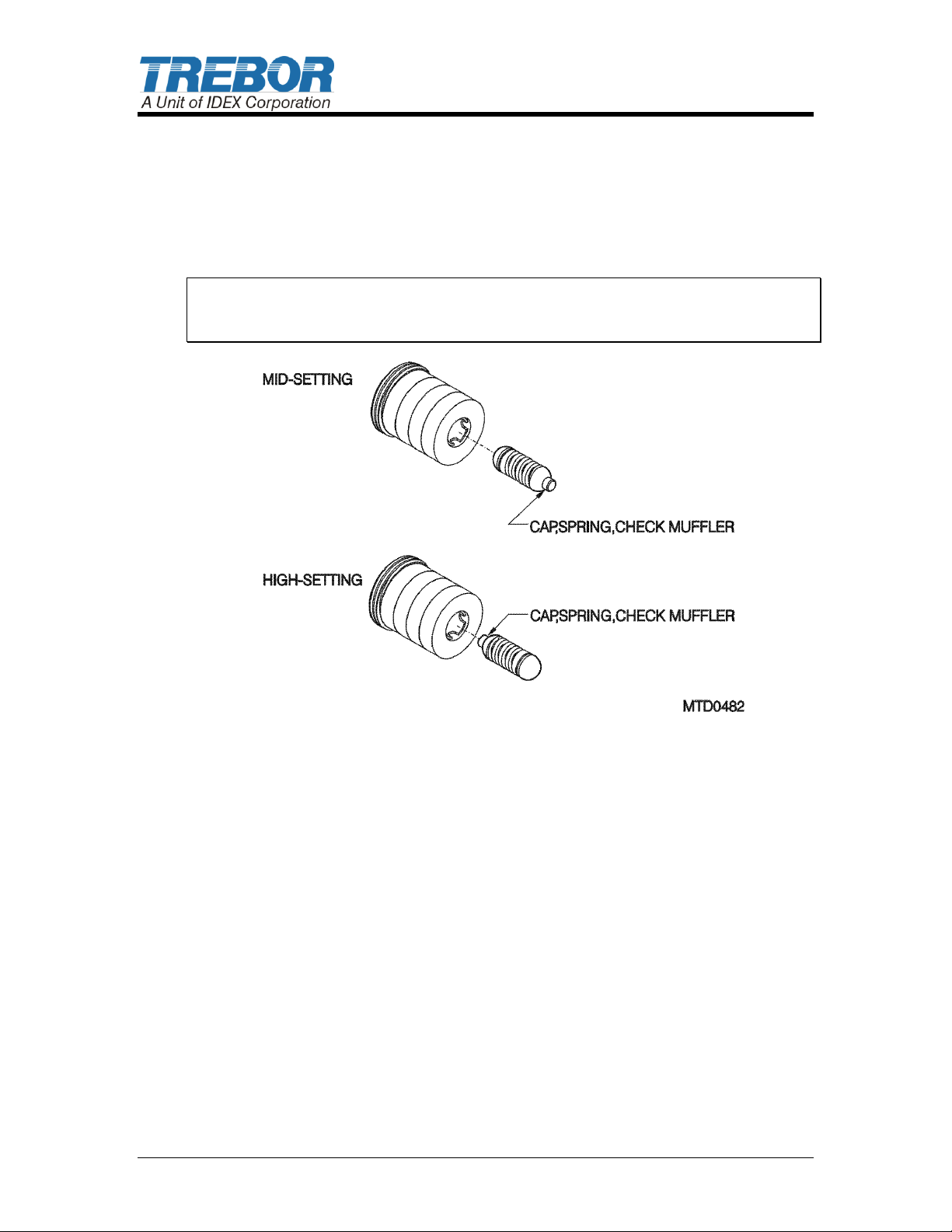

The check muffler has 3 preset arrangements. The pump is shipped from the

factory in the medium back pressure setting, see Mid-Setting in Figure 1-2:

Check Muffler.

Mid-Setting

Start pressure <15 psi

Low flow applications (flow <3 gpm)

The Check Muffler is preset at the factory at the mid-setting. This setting

protects the pump air system from caustic fumes and allows the pump to

maintain a “Dead Head” condition with supply pressures up to 35 psi. This

setting also protects the pump in conditions of positive inlet supplies up to 10

ft. above the inlet of the pump.

High-Setting

Start pressure at <30 psi

Air supply >40 psi, low flow application (flow <3 gpm)

By removing the muffler from the pump and reversing the spring assembly in

the muffler then reinstalling the muffler, the Check Muffler is now set in the

highest back pressure setting. This setting protects the pump from dead

head conditions up to 60 psi, or from positive inlet heads up to 20 ft.

However, this setting is not recommended for operating fluid temperatures

over 60C as damage to the pump shaft can occur. This setting also

diminishes the pump’s flow capacity by 15% from normal published curves.

This setting also increases the pump start pressure from 15 psi to

approximately 30 psi.

Low-Setting (no picture shown)

Spring assembly removed

Start pressure <10 psi

Low back pressure, high flow (>3 gpm) requirement

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

If none of the aforementioned conditions exist when operating the pump,

then the final setting of the check muffler may be used. To obtain maximum

flow capability and lowest start pressure (<10 psi), completely remove the

spring assembly from the check muffler assembly. This is the recommended

condition to obtain best performance and life from the pump. Most normal

open recirculation applications may be operated successfully under this

condition.

NOTE: Air consumption during “Dead Cycling” is very little since the pump

diaphragms are displacing only internal bypass. “Dead Cycling” should be

considered as a normal standby idle mode.

Figure 1-2: Check Muffler

PAGE 6 MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL

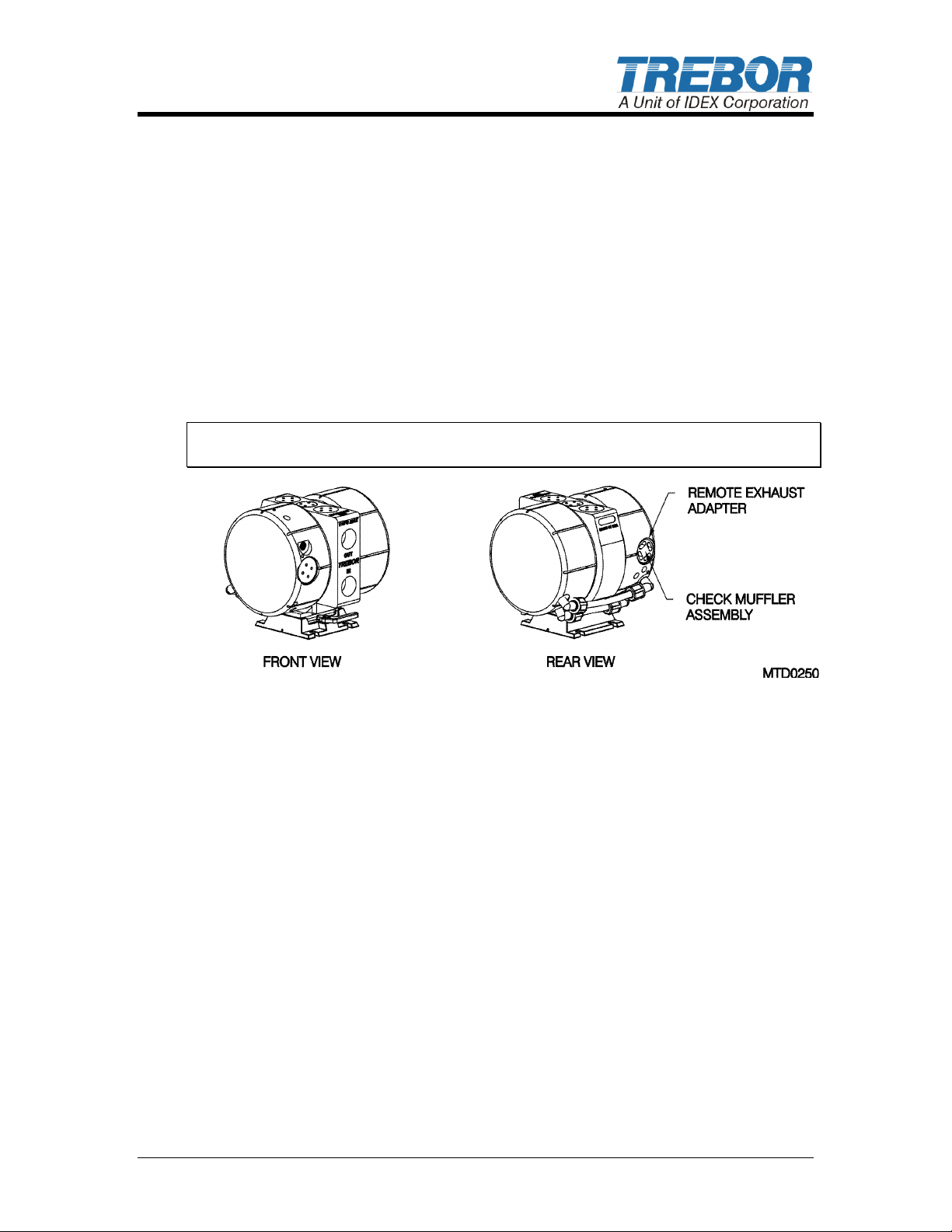

1.4 REMOTE EXHAUST HOOK-UP

Some installations may benefit from remotely exhausting air from the pump to

eliminate unwanted air turbulence or to prevent potentially damaging chemical

vapors from entering the pump air cavities.

Remove existing Muffler Assembly from the back of pump head.

Install Exhaust Plug in Exhaust Port.

Install the appropriately sized (3/8” OD) fitting and tubing (not provided) to

remote exhaust. A remote muffler assembly may be installed at the point of

exhaust if required for condition needing the check muffler (see Section

1.3.b).

NOTE: To maintain optimum pump performance use 3/8” (8mm) tubing minimum

at a length of 10 ft. (3 meters) maximum.

Figure 1-3: Remote Exhaust

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

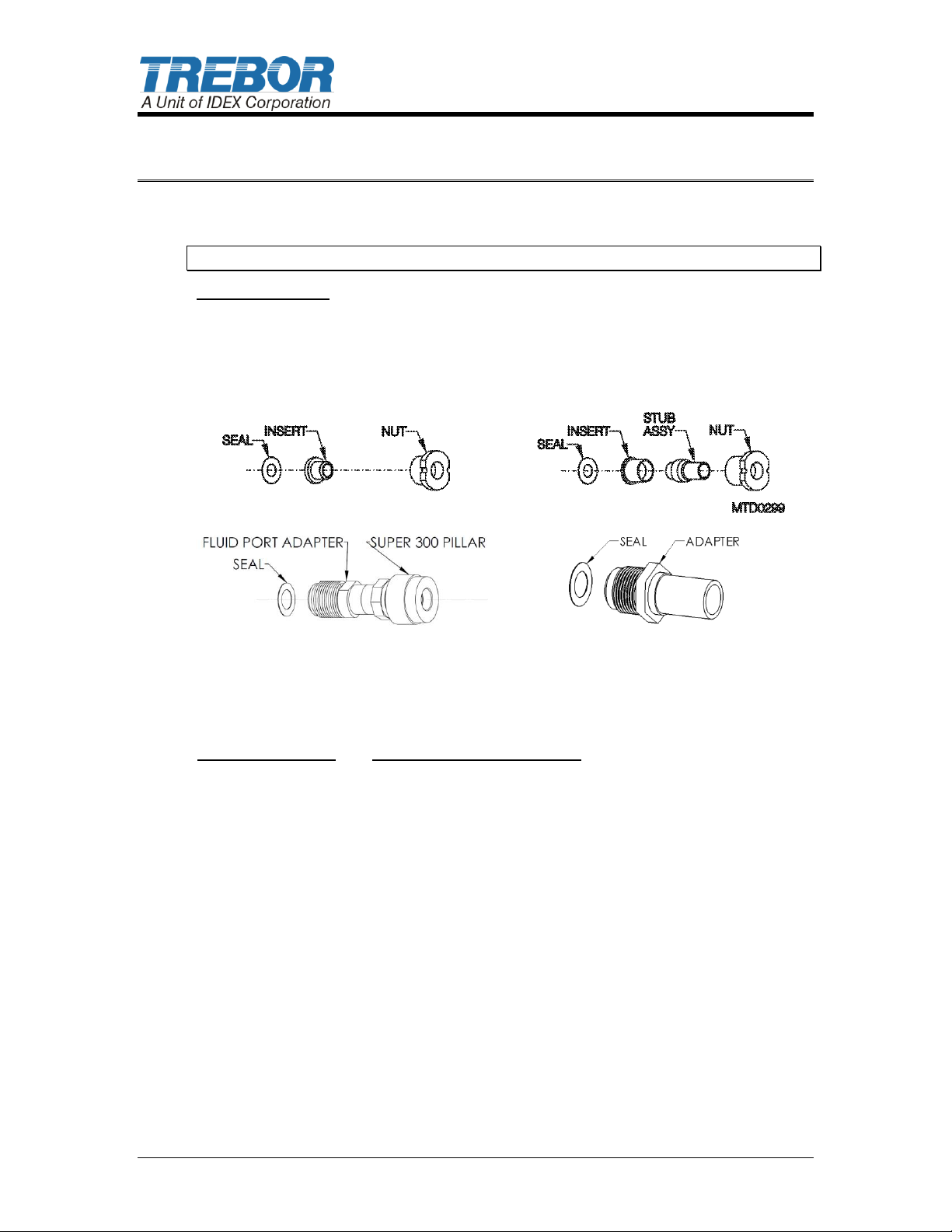

Available Options

A) Flare style tube adapter….1/2” and 3/4"

B) PFA tube stub out………...3/4"

C) Pillar Super 300…………..3/4” OR 1”

D) PFA Weldable pipe……….3/4"

Surge Suppressor

Assembled Height: IN (CM)

MODEL SS40

12.63 (32.08)

MODEL SS85

14.97 (38.02)

A)

B)

C)

D)

2 OPTIONS

2.1 FLUID PORT CONNECTION OPTIONS

NOTE 1: Use O-ring to seal stainless steel or other rigid plumbing.

Figure 2-1

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP

PAGE 8 MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL

Figure 2-2

NOTE: See Surge Suppressor Operation Manual for detailed installation

instructions.

MAGNUM 620R PUMP OPERATION / MAINTENANCE MANUAL PAGE 9

Loading...

Loading...