Trebor 610NM User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

MAGNUM 610NM PUMP

Operation / Maintenance

Manual

SERIAL NUMBER (located on top of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 1/29/2014 – M610NM-D

CONTENTS

1 INSTALLATION ............................................................................................................ 3

1.1 UNPACKING ...................................................................................................... 3

1.2 TIE BOLT TORQUE ........................................................................................... 3

1.3 UTILITIES / HOOK-UP ....................................................................................... 3

1.4 CHECK MUFFLER OPERATION ....................................................................... 5

1.4.a Purpose ................................................................................................. 5

1.4.b Adjustment ............................................................................................. 5

2 OPTIONS ...................................................................................................................... 6

2.1 FLUID PORT CONNECTION OPTIONS ............................................................ 6

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP .................................... 6

3 START-UP .................................................................................................................... 7

3.1 HIGH TEMPERATURE OPERATION ................................................................ 7

3.2 PERFORMANCE CHARTS ................................................................................ 7

4 MAINTENANCE ........................................................................................................... 9

4.1 PREVENTIVE MAINTENANCE SCHEDULE ..................................................... 9

4.1.a Preventive Maintenance Record ......................................................... 11

4.2 RECOMMENDED SPARE PARTS .................................................................. 12

4.3 TOOLS .............................................................................................................. 12

4.4 PARTS ILLUSTRATION ................................................................................... 13

4.5 PARTS LIST ..................................................................................................... 14

4.6 CLEAN-UP ........................................................................................................ 14

4.7 DISASSEMBLY ................................................................................................ 14

4.7.a Master and Slave Heads ..................................................................... 15

4.7.b Body Disassembly ............................................................................... 15

4.8 ASSEMBLY ...................................................................................................... 16

4.8.a Head Assemblies ................................................................................. 16

4.8.b Body Assembly .................................................................................... 16

4.8.c Final Assembly .................................................................................... 18

4.9 TESTING .......................................................................................................... 19

4.9.a Performance Test ................................................................................ 19

4.9.b Dry Pump ............................................................................................. 19

4.9.c Dry Suction .......................................................................................... 19

5 TROUBLESHOOTING ............................................................................................... 20

6 WARRANTY ....................................................................................................... 21

7 CONTACT INFORMATION ........................................................................................ 22

7.1 GENERAL CONTACT INFORMATION ............................................................ 22

7.2 TECHNICAL SUPPORT ................................................................................... 22

7.3 REGIONAL REPRESENTATIVES ................................................................... 22

MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

Qty

Item

Description

1

610NM

Magnum 610NM Pump

1

M610NM

Operation/Maintenance Manual

1

C0135

Check Muffler Assembly

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

1.2 TIE BOLT TORQUE

The tie bolts on the pump are tightened before leaving the factory. However,

relaxation may occur due to handling, material creep, or other unforeseen

events. Trebor recommends that all eight tie bolts be re-tightened upon pump

install. The following procedure should be used.

1. Remove black tie bolt caps (Item15 in 4.4 Parts Illustration) from both

sides of all 8 tie bolts.

2. Apply 42 in-lbs. of torque to each slave side bolt while holding the master

side bolt stationary. A star-pattern is advised.

a. The master side is the left side of the pump if you are looking at

the fluid ports.

3. Replace tie bolt caps.

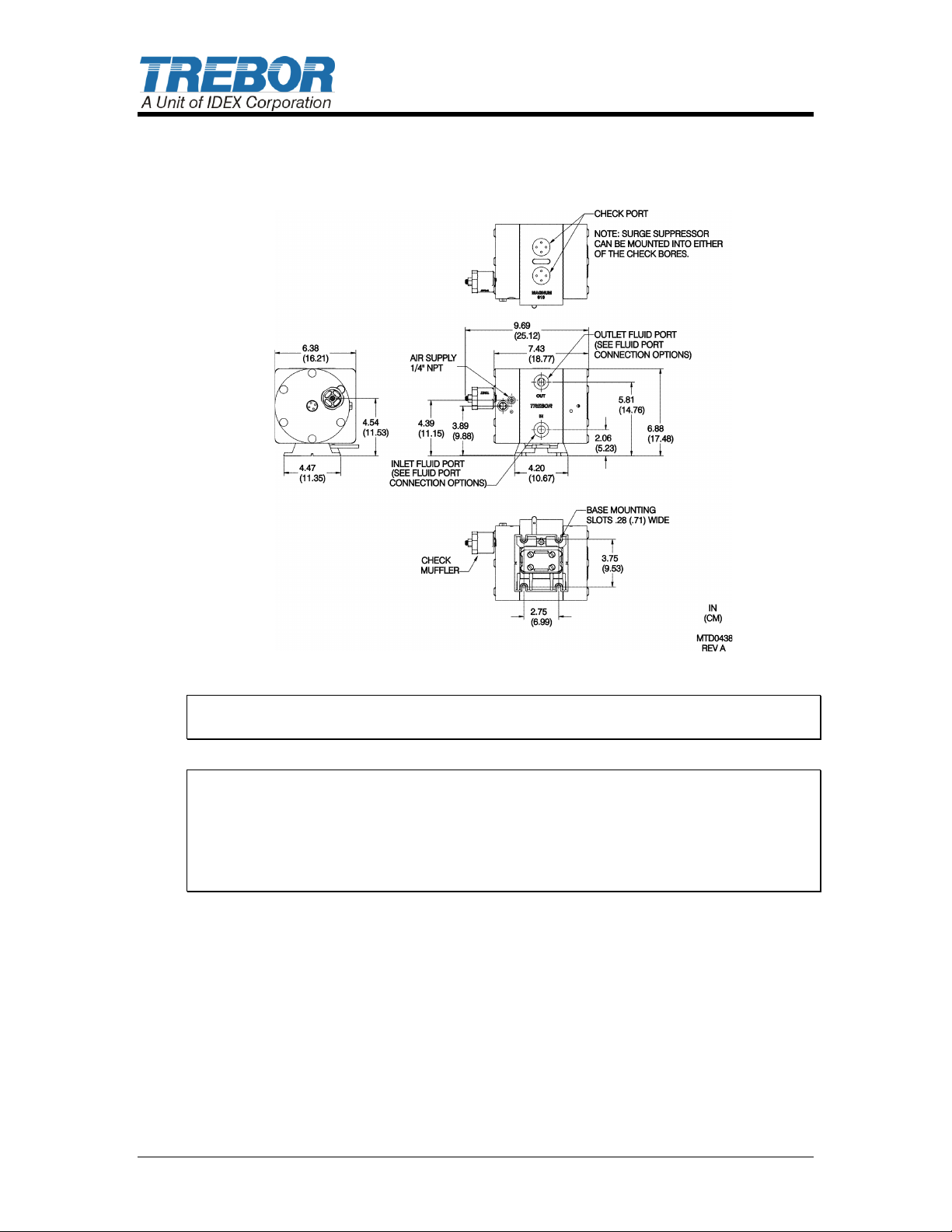

1.3 UTILITIES / HOOK-UP

It is recommended that the pump be installed no more than 15° from level to

maintain its self-priming ability and pumping efficiency. This pump mounts on a

quick release base for easy installation.

Air Inlet: 1/4” FNPT (3/8” Dia. [8mm] supply tube minimum).

Air Supply: 20-60 psig (1.4 – 4.1 bar) clean dry air or nitrogen. (See

Performance Charts, Section 3.2 for air consumption.)

Fluid Ports: 3/4” FNPT - additional adaptor port options available.

Inlet/Outlet adaptor fluid fittings and Surge Suppressor require

torqueing during pump installation. See Section 2 for hook- up

diagram and torque values

Important Requirements for Maximum Flow:

MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

1. Maximize supply line diameter.

2. Minimize supply line length.

3. Minimize supply line restrictions; valves, fittings.

4. Normal pump operation requires suction (negative fluid head)

supply.

Figure 1-1

ATTENTION: The pump should be operated with clean, dry air or nitrogen.

Particulate, water and oils in the air supply can damage the pump.

NOTE:

1. It is recommended that a filter be placed on the discharge side of the pump.

2. Although extensive efforts are made to deliver pumps to our customers

completely dry, new pumps may contain residual moisture from their final DI

water test.

Recommended Maximum Operating Levels:

Maximum supply CDA/N2 pressure: 60 psig (4.1 bar)

Maximum fluid temperature: 230°F (110°C)

See Section 4.1 Preventative Maintenance Schedule for additional requirements

for high temperature applications.

PAGE 4 MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL

1.4 CHECK MUFFLER OPERATION

1.4.a Purpose

Permits pump to operate reliably in systems that incorporate a discharge fluid

“dead head” condition. (Pump air supply remains on while discharge port is

closed.)

Permits pump to operate reliably in systems that have the pump located at an

elevation below the liquid supply level. (Pump air supply remains on.)

Effectively reduces the amount of harmful acid vapors that can enter into the

pump’s internal air circuit components while the pump air supply is off. (A

common cause of shuttle and pilot valve failures.)

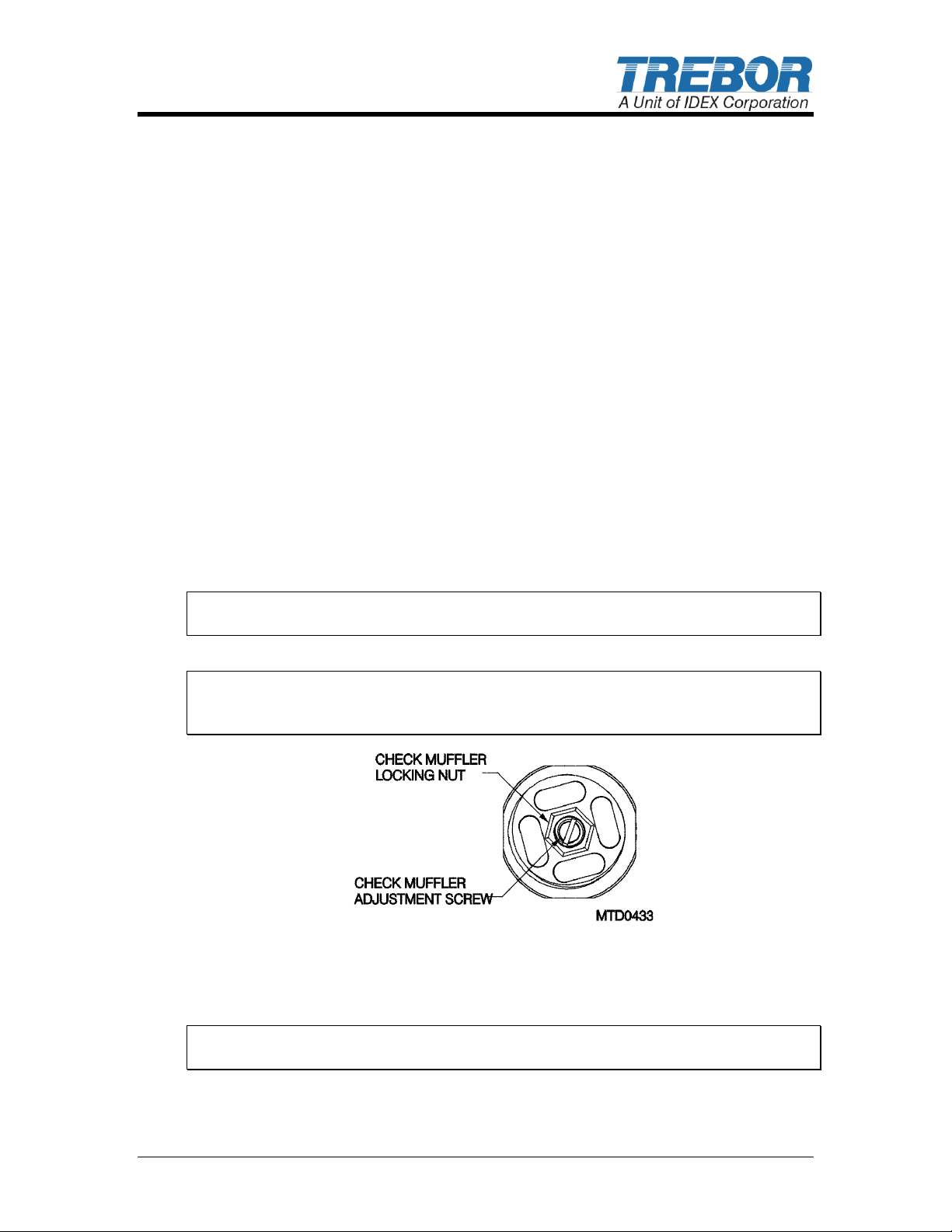

1.4.b Adjustment

The Check Muffler is preset at the factory to a setting that makes the pump

“Dead Cycle” at a slow constant rate with the fluid discharge port closed, and

the pump air supply at 45 psig. This setting also allows the pump to operate

with approximately 4 ft. (1 meter) of H2O positive fluid supply pressure.

“Deadheading” at other air supply pressure or with more positive fluid supply

pressure (fluid source above pump) may require user adjustment. The

adjustment should control the pump to a slow, steady “Dead Cycle” rate with

no erratic cycling/”machine gunning” evident.

NOTE: If pump application does not require operation in either of these

conditions, loosen check muffler adjustment for minimum restriction.

NOTE: Air consumption during “Dead Cycling” is very little since the pump

diaphragms are displacing only internal bypass. “Dead Cycling” should be

considered as a standby idle mode.

Figure 1-2

Turn adjustment screw clockwise (CW) to increase back pressure.

Turn adjustment screw counter-clockwise (CCW) to decrease back pressure.

NOTE: Loosen locking nut prior to making adjustment and tighten nut to maintain

adjustment.

MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

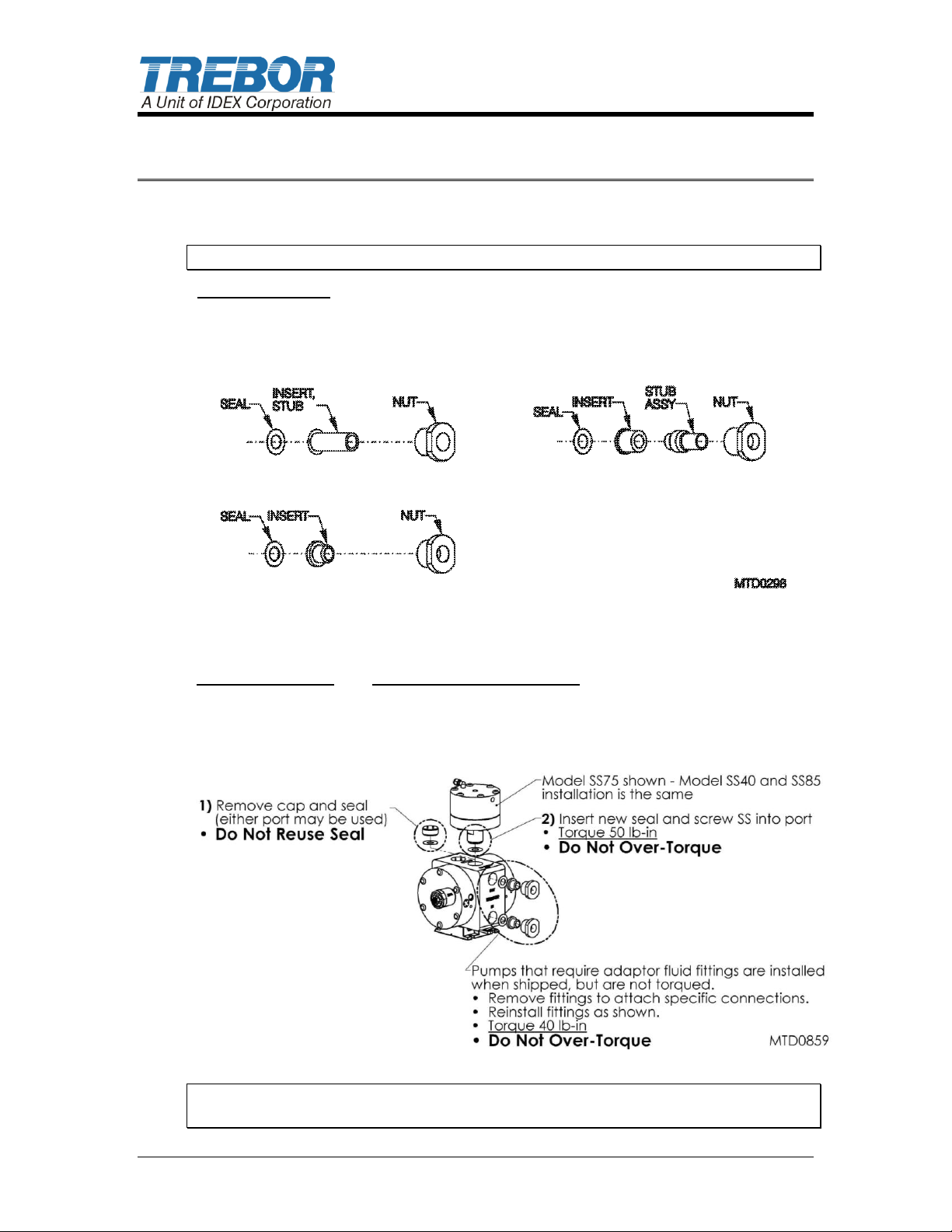

Available Options

A) PFA Weldable pipe………..1/2”

B) Flare style tube adapter.….1/2”, 3/4"

C) PFA tube stub out…………3/4”

Surge Suppressor

Assembled Height: IN (CM)

SS75

12.29 (31.21)

SS85

14.82 (37.65)

SS40

12.37 (31.43)

A)

B)

C)

2 OPTIONS

2.1 FLUID PORT CONNECTION OPTIONS

NOTE: Use O-ring to seal stainless steal or other rigid plumbing.

Figure 2-1

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP

NOTE: See Surge Suppressor Operation Manual for detailed installation

instructions.

PAGE 6 MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL

Figure 2-2

Air Supply

Pressure

(PSIG)

Discharge

Fluid

Pressure

(PSIG)

Air

Used

(SCFM)

Cycles

Per

Minute

Displacement

IN3 Per

Cycle

20 0 3.9

170

10.4

20

10

2.8

105

9.3

30 0 5.6

190

10.5

30

15

4.0

120

9.4

40 0 7.0

198

10.5

40

20

5.4

125

9.6

50 0 8.4

205

10.5

50

25

7.2

130

9.7

60 0 10.2

208

10.6

60

30

8.4

128

9.4

3 START-UP

Pump air supply pressure should be regulated.

Open the fluid suction (IN) line valve, if necessary.

Open the fluid discharge (OUT) line valve, if necessary.

Start with air regulator at low pressure setting. Increase or decrease

pressure to attain desired flow, up to 60 psig (4.1 bar) at the pump.

Table 1: Consumption / Efficiency can be used to determine approximate air

consumption.

Refer to Troubleshooting, Section , if pump fails to start.

ATTENTION: Prolonged periods (> 5 minutes) of dry running will damage critical

internal pump parts.

CAUTION: When handling potentially dangerous fluids under pressure,

the pump and its fittings should be placed in an enclosure.

3.1 HIGH TEMPERATURE OPERATION

Pump operation at temperatures above 60C requires periodic tightening of the

tie bolt nuts. The frequency of this procedure is best established by the user.

Refer to Section 4 on Maintenance.

3.2 PERFORMANCE CHARTS

Pumping capacity is a function of air supply pressure and volume, suction head,

suction line restrictions, discharge head, discharge line restriction, and fluid

specific gravity and viscosity.

Table 1: Consumption / Efficiency

NOTE: Specification to be used to size regulators and control valves.

MAGNUM 610NM PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

Loading...

Loading...