Trebor 610E User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

MAGNUM 610E PUMP

Oscillator Controlled

Operation / Maintenance

Manual

SERIAL NUMBER (located on top of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 1/29/2014 – M610E-B

CONTENTS

1 INSTALLATION ............................................................................................................ 3

1.1 UNPACKING ...................................................................................................... 3

1.2 TIE BOLT TORQUE ........................................................................................... 3

1.3 UTILITIES / HOOK-UP FOR 610E PUMP ......................................................... 3

1.4 UTILITIES / HOOK-UP FOR REMOTE CONTROLLER .................................... 5

1.4.a Trebor’s Remote Oscillator .................................................................... 5

1.4.b Electronic Oscillation Controller (example) ........................................... 5

1.4.c Fiber Optic End-of-Stroke Detection ..................................................... 6

2 OPTIONS ...................................................................................................................... 7

2.1 FLUID PORT CONNECTION OPTIONS ............................................................ 7

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP .................................... 7

3 START-UP .................................................................................................................... 8

3.1 HIGH TEMPERATURE OPERATION ................................................................ 8

3.2 OSCILLATOR/CONTROLLER CYCLE RATE ................................................... 8

3.2.a Adjustment Instructions for Trebor Pneumatic Oscillator ...................... 8

3.3 PERFORMANCE CHARTS ................................................................................ 8

4 MAINTENANCE ......................................................................................................... 10

4.1 PREVENTIVE MAINTENANCE SCHEDULE ................................................... 10

4.1.a Preventive Maintenance Record ......................................................... 12

4.2 RECOMMENDED SPARE PARTS .................................................................. 13

4.3 TOOLS .............................................................................................................. 13

4.4 PARTS ILLUSTRATION ................................................................................... 14

4.5 PARTS LIST ..................................................................................................... 15

4.6 CLEAN-UP ........................................................................................................ 15

4.7 DISASSEMBLY ................................................................................................ 15

4.7.a Body Disassembly ............................................................................... 16

4.8 ASSEMBLY ...................................................................................................... 16

4.8.a Body Assembly .................................................................................... 16

4.8.b Final Assembly .................................................................................... 18

4.9 TESTING .......................................................................................................... 19

4.9.a Performance Test ................................................................................ 19

4.9.b Dry Pump ............................................................................................. 19

4.9.c Dry Suction .......................................................................................... 19

5 TROUBLESHOOTING ............................................................................................... 20

6 WARRANTY ....................................................................................................... 21

7 CONTACT INFORMATION ........................................................................................ 22

7.1 GENERAL CONTACT INFORMATION ............................................................ 22

7.2 TECHNICAL SUPPORT ................................................................................... 22

7.3 REGIONAL REPRESENTATIVES ................................................................... 22

MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

Qty

Item

Description

1

610E

Magnum 610E Pump

1

M610E

Operation/Maintenance Manual

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

1.2 TIE BOLT TORQUE

The tie bolts on the pump are tightened before leaving the factory. However,

relaxation may occur due to handling, material creep, or other unforeseen

events. Trebor recommends that all eight tie bolts be re-tightened upon pump

install. The following procedure should be used.

1. Remove black tie bolt caps (Item 22 in 4.4 Parts Illustration) from both

sides of all 8 tie bolts.

2. Apply 42 in-lbs. of torque to each slave side bolt while holding the master

side bolt stationary. A star-pattern is advised.

a. The master side is the left side of the pump if you are looking at

the fluid ports.

3. Replace tie bolt caps.

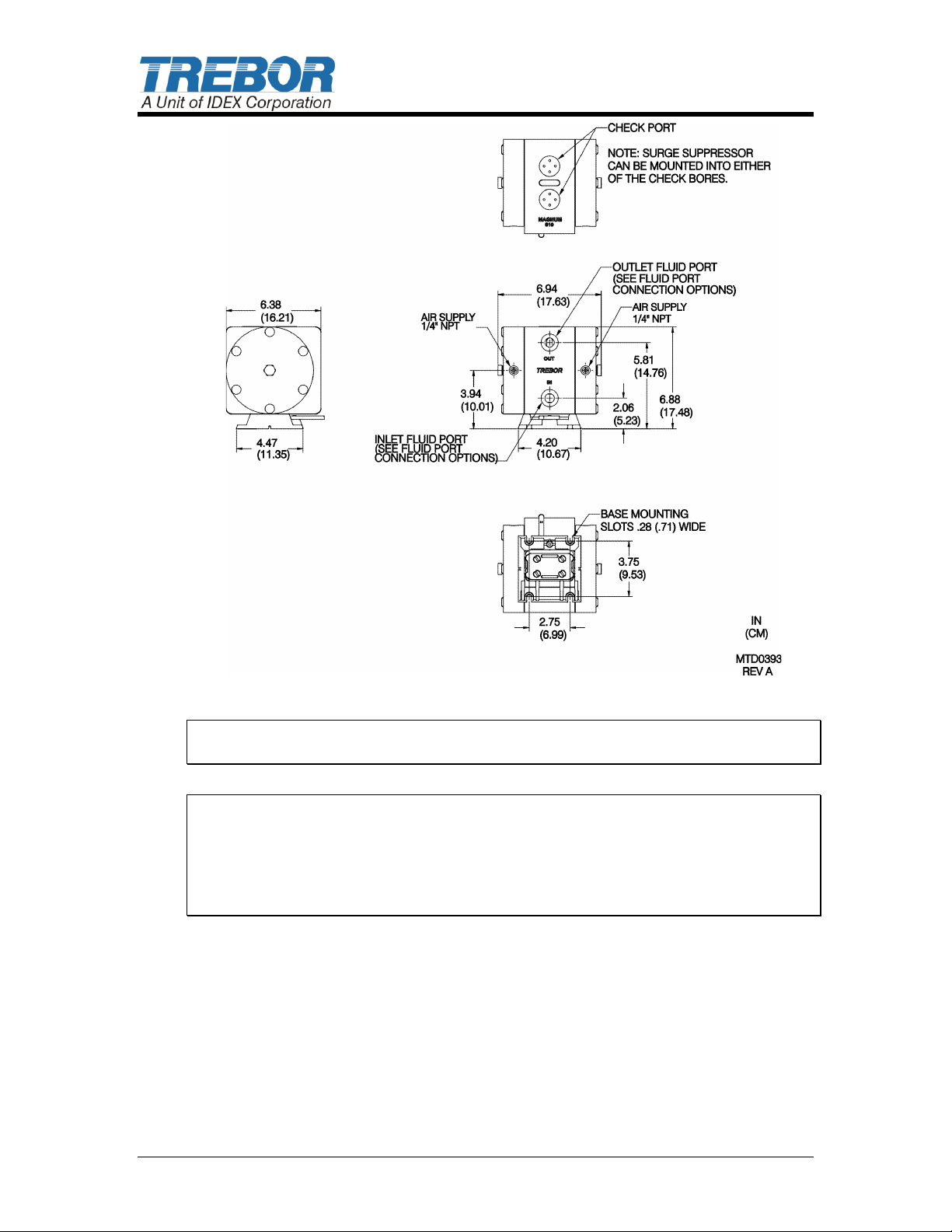

1.3 UTILITIES / HOOK-UP FOR 610E PUMP

It is recommended that the pump be installed no more than 15° from level to

maintain its self-priming ability and pumping efficiency. This pump mounts on a

quick release base for easy installation.

Air Inlet: 1/4” FNPT (3/8” Dia. [8mm] supply tube minimum).

Fluid Ports: 3/4” FNPT - additional adaptor port options available.

Inlet/Outlet adaptor fluid fittings and Surge Suppressor

require torqueing during pump installation. See Section 2

for hook- up diagram and torque values

MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

Figure 1-1

ATTENTION: The pump should be operated with clean, dry air or nitrogen.

Particulate, water and oils in the air supply can damage the pump.

NOTE:

1. It is recommended that a filter be placed on the discharge side of the pump.

2. Although extensive efforts are made to deliver pumps to our customers

completely dry, new pumps may contain residual moisture from their final DI

water test.

Recommended Maximum Operating Levels:

Maximum supply CDA/N2 pressure: 80 psig (5.2 bar)

Maximum fluid temperature: 212°F (100°C)

See Section 4.1 Preventative Maintenance Schedule for additional requirements

for high temperature applications.

PAGE 4 MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL

1.4 UTILITIES / HOOK-UP FOR REMOTE CONTROLLER

The Magnum 610E pump will work with many types of external control devices.

TREBOR’s pneumatic Pump Control Module is recommended for its proven,

reliable performance. Please consult factory for assistance with other external

control devices.

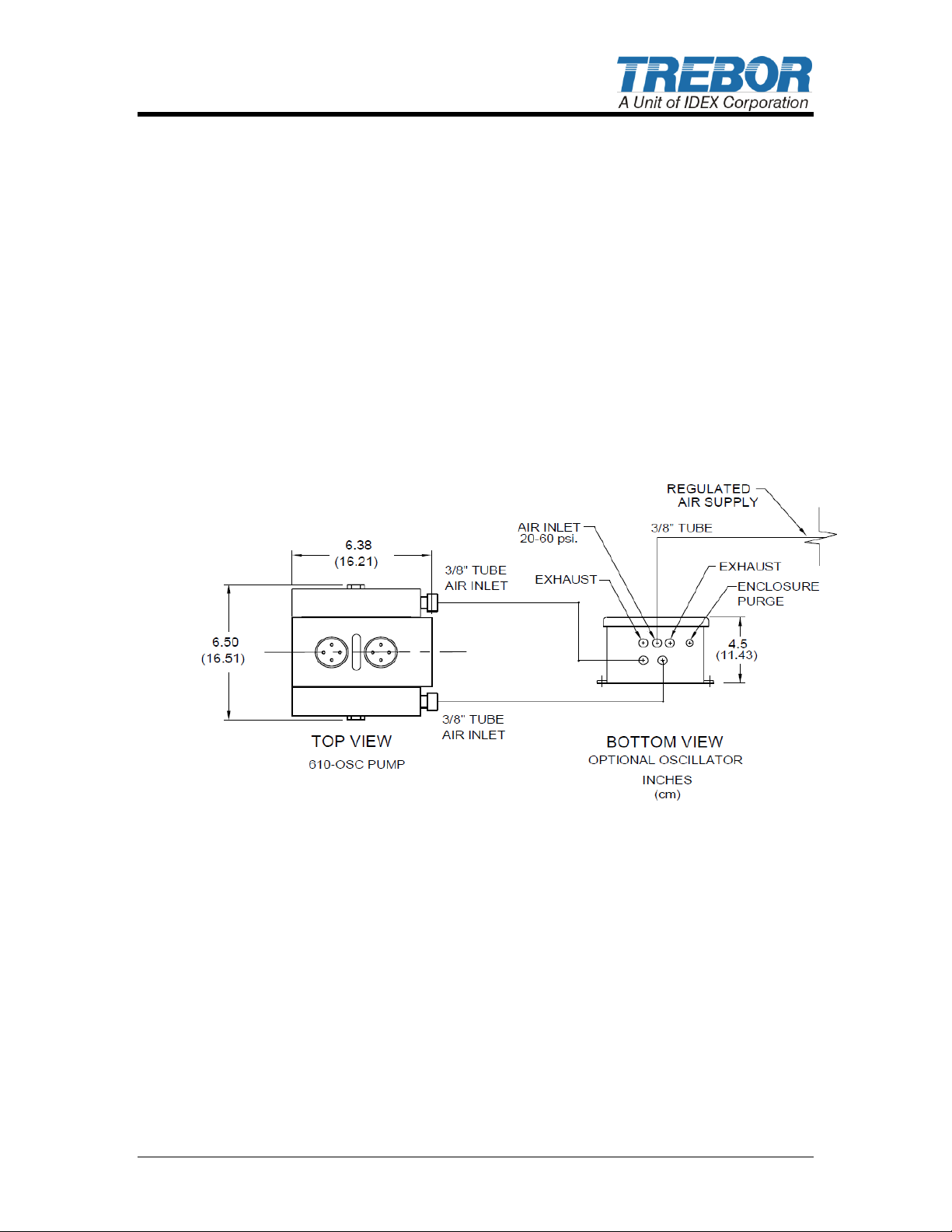

1.4.a Trebor’s Remote Oscillator

Air Inlet: 3/8” Dia. (8mm) supply tube (Use in-line 10µ air filter).

Air Supply: 20-80 psig (1.4 – 5.2 bar) clean dry air or nitrogen (see

Performance Charts, Section 3.1, for air consumption).

The mufflers on the optional Oscillator Control Module can be removed for

remote exhaust and purge connections.

Exhaust: 1/4” FNPT

Purge: 1/4” FNPT

Figure 1-2

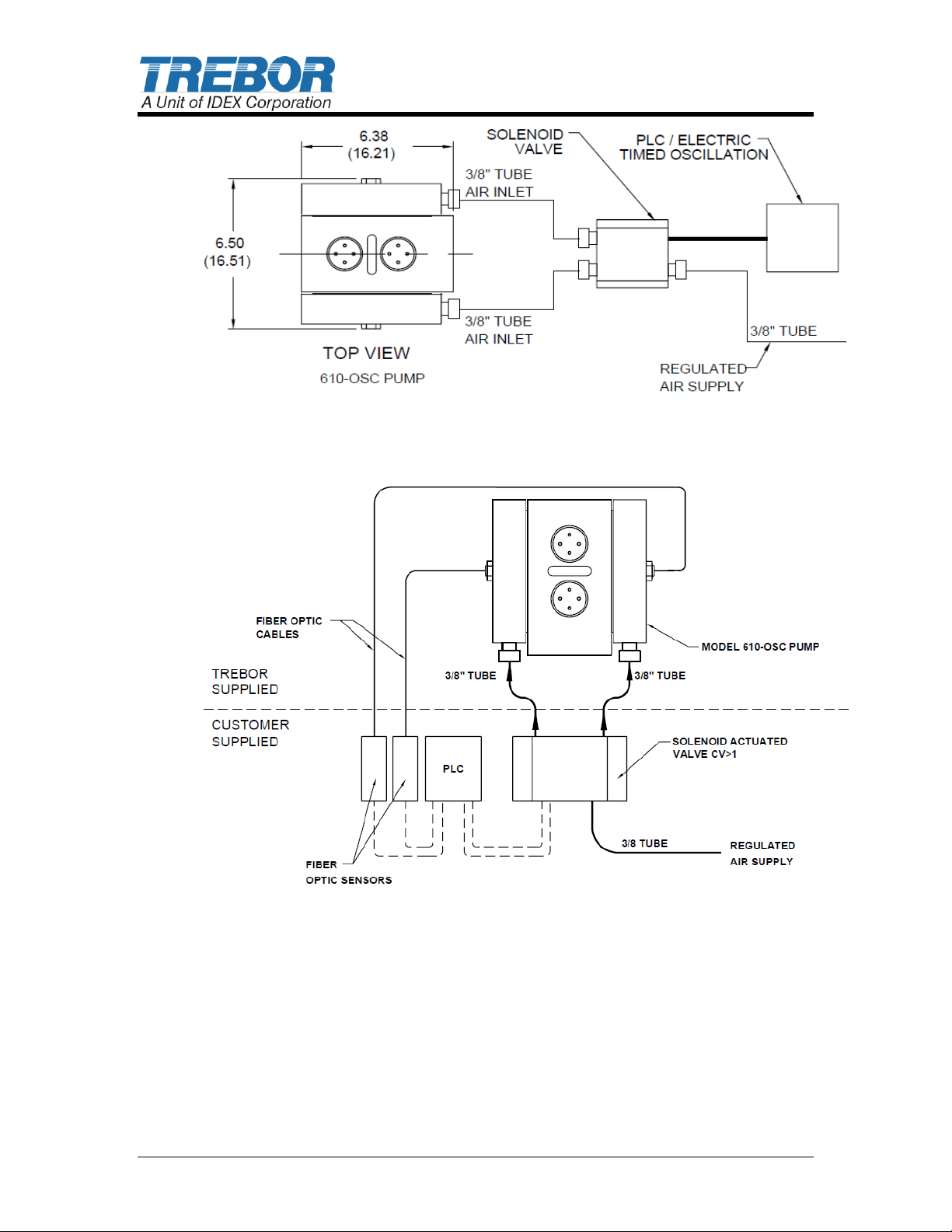

1.4.b Electronic Oscillation Controller (example)

Air Inlet: 3/8” Dia. (8mm) supply tube (Use in-line 10µ air filter).

Air Supply to Pump: 20-80 psig (1.4-5.2 bar) clean dry air.

Solenoid Valve: Cv greater than .80, 3 position.

PLC/Electric Circuit: For timed oscillation up to 260 cpm

MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

Figure 1-3

1.4.c Fiber Optic End-of-Stroke Detection

Figure 1-4: Shown with Sensors and PLC Connection

PAGE 6 MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL

Available Options

A) PFA Weldable pipe………..1/2”

B) Flare style tube adapter.….1/2”, 3/4"

C) PFA tube stub out…………3/4”

Surge Suppressor

Assembled Height: IN (CM)

SS75

12.29 (31.21)

SS85

14.82 (37.65)

SS40

12.37 (31.43)

A)

B)

C)

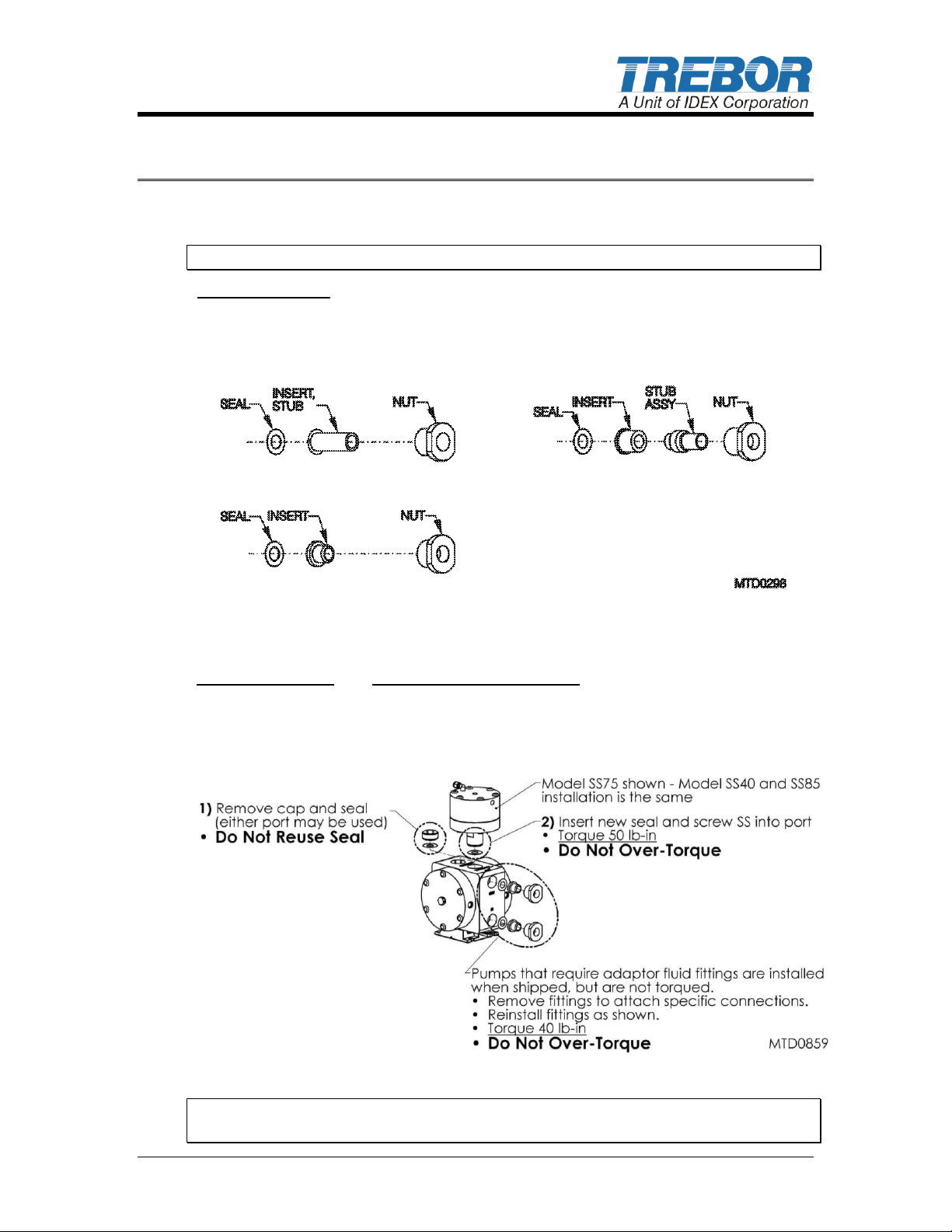

2 OPTIONS

2.1 FLUID PORT CONNECTION OPTIONS

NOTE: Use O-ring to seal stainless steel or other rigid plumbing.

Figure 2-1

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP

NOTE: See Surge Suppressor Operation Manual for detailed installation

instructions.

MAGNUM 610E PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

Figure 2-2

Loading...

Loading...