Trebor 50U User Manual

Phone: 800-669-1303 or 801-561-0303

Fax: 801-255-2312

e-mail: treborservice@idexcorp.com

MAXIM 50E/U PUMP

External Controlled

Operation / Maintenance

Manual

SERIAL NUMBER (located on top of product):

PATENTS: U.S. 09642426, U.S. 06106246, U.S. 05971402, U.S. 05370507 07/27/2012 – MM50EU-F

CONTENTS

1 INSTALLATION ............................................................................................................ 3

1.1 UNPACKING ...................................................................................................... 3

1.2 UTILITIES / HOOK-UP ....................................................................................... 3

1.3 PROBE ASSEMBLY INSTALLATION (E MODEL ONLY) ................................. 5

1.4 PLC CONTROL SCHEMATIC ............................................................................ 5

1.5 REMOTE EXHAUST HOOK-UP ........................................................................ 6

2 OPTIONS ...................................................................................................................... 7

2.1 FLUID PORT CONNECTION OPTIONS ............................................................ 7

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP .................................... 7

2.3 OPTIONAL LEAK SENSING .............................................................................. 8

2.3.a Installation.............................................................................................. 8

2.3.b Sensor Signal Specifications ................................................................. 8

3 START-UP .................................................................................................................... 9

3.1 PERFORMANCE CHARTS ................................................................................ 9

4 MAINTENANCE ......................................................................................................... 11

4.1 PREVENTIVE MAINTENANCE SCHEDULE ................................................... 11

4.1.a Preventive Maintenance Record ......................................................... 13

4.2 RECOMMENDED SPARE PARTS .................................................................. 14

4.3 TOOLS .............................................................................................................. 14

4.4 PARTS ILLUSTRATION ................................................................................... 15

4.5 PARTS LIST ..................................................................................................... 16

4.6 CLEAN-UP ........................................................................................................ 16

4.7 DISASSEMBLY ................................................................................................ 16

4.7.a Body Disassembly ............................................................................... 18

4.7.b Control Base Disassembly .................................................................. 18

4.7.c Cleaning............................................................................................... 18

4.8 ASSEMBLY ...................................................................................................... 18

4.8.a Control Base Assembly – Quick Exhaust ............................................ 18

4.8.b Body Assembly .................................................................................... 19

4.8.c Final Assembly .................................................................................... 20

4.9 TESTING .......................................................................................................... 22

4.9.a Performance Test ................................................................................ 22

4.9.b 80/80 Leak Test ................................................................................... 22

4.9.c Dry Pump ............................................................................................. 22

4.9.d Dry Suction .......................................................................................... 22

4.10 MAXIM PUMP LADDER LOGIC CONTROL EXAMPLE .................................. 23

4.10.a Oscillator Control (No Probes Required) ............................................. 23

4.10.b End-Of-Stroke Control ......................................................................... 25

4.10.c Combination End-Of-Stoke & Oscillator Reset ................................... 27

5 TROUBLESHOOTING ............................................................................................... 31

6 WARRANTY ............................................................................................................... 32

7 CONTACT INFORMATION ........................................................................................ 33

7.1 GENERAL CONTACT INFORMATION ............................................................ 33

7.2 TECHNICAL SUPPORT ................................................................................... 33

7.3 REGIONAL REPRESENTATIVES ................................................................... 33

MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL CONTENTS

Qty

Item

Description

1

M50E/U

Maxim 50E/U Pump

1

MM50E/U

Operation/Maintenance Manual

2

DP-C-12

End-of-Stroke Probe (E Model only)

1

98002986

Fiber Optic Cable Cutter

1 INSTALLATION

1.1 UNPACKING

After unpacking, the pump should be checked for any damage that may have

occurred during shipment. Damage should be reported to the carrier

immediately.

The following items should be included within the shipping container:

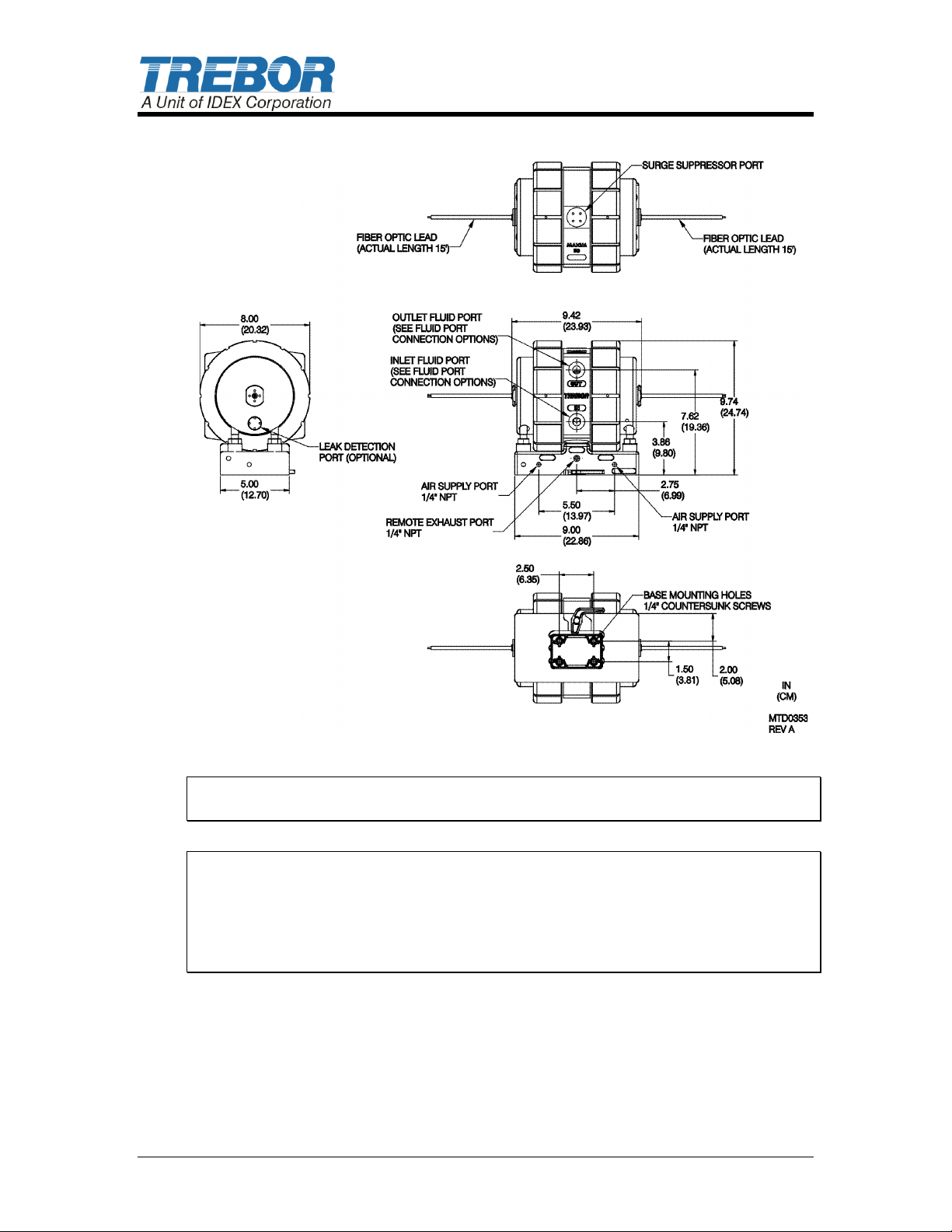

1.2 UTILITIES / HOOK-UP

It is recommended that the pump be positioned within 15° from level to maintain

self-priming ability and pumping efficiency. Allow sufficient room for tubing

connectors. The pump mounts on a quick-change base for easy installation.

The pump has dual exhaust locations on the backside of the base. The exhaust

locations require 1/2” (12mm) minimum clearance behind the control base. Care

should be taken to elevate the pump whenever possible to help prevent flooding

when the pump is located in a wet bench plenum. For remote exhaust

connection see Section 1.5.

Air Inlet: 1/4” FNPT (3/8” Dia. [8mm] supply tube minimum).

Fluid Ports: Inlet/Outlet Fluid Fittings and Surge Suppressor require torqueing

during pump installation. See Section 2 for hook- up diagram and

torque values.

Air Supply: 20-80 psig (1.4 – 5.5 bar) clean dry air or nitrogen (see

Performance Charts, Section 3.1).

MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL PAGE 3

Figure 1-1

ATTENTION: The pump should be operated with clean, dry air or nitrogen.

Particulate, water and oils in the air supply can damage the pump.

NOTE:

1. It is recommended that a filter be placed on the discharge side of the pump.

2. Although extensive efforts are made to deliver pumps to our customers

completely dry, new pumps may contain residual moisture from their final DI

water test.

Recommended Maximum Operating Levels: See Error! Reference source

not found.

PAGE 4 MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL

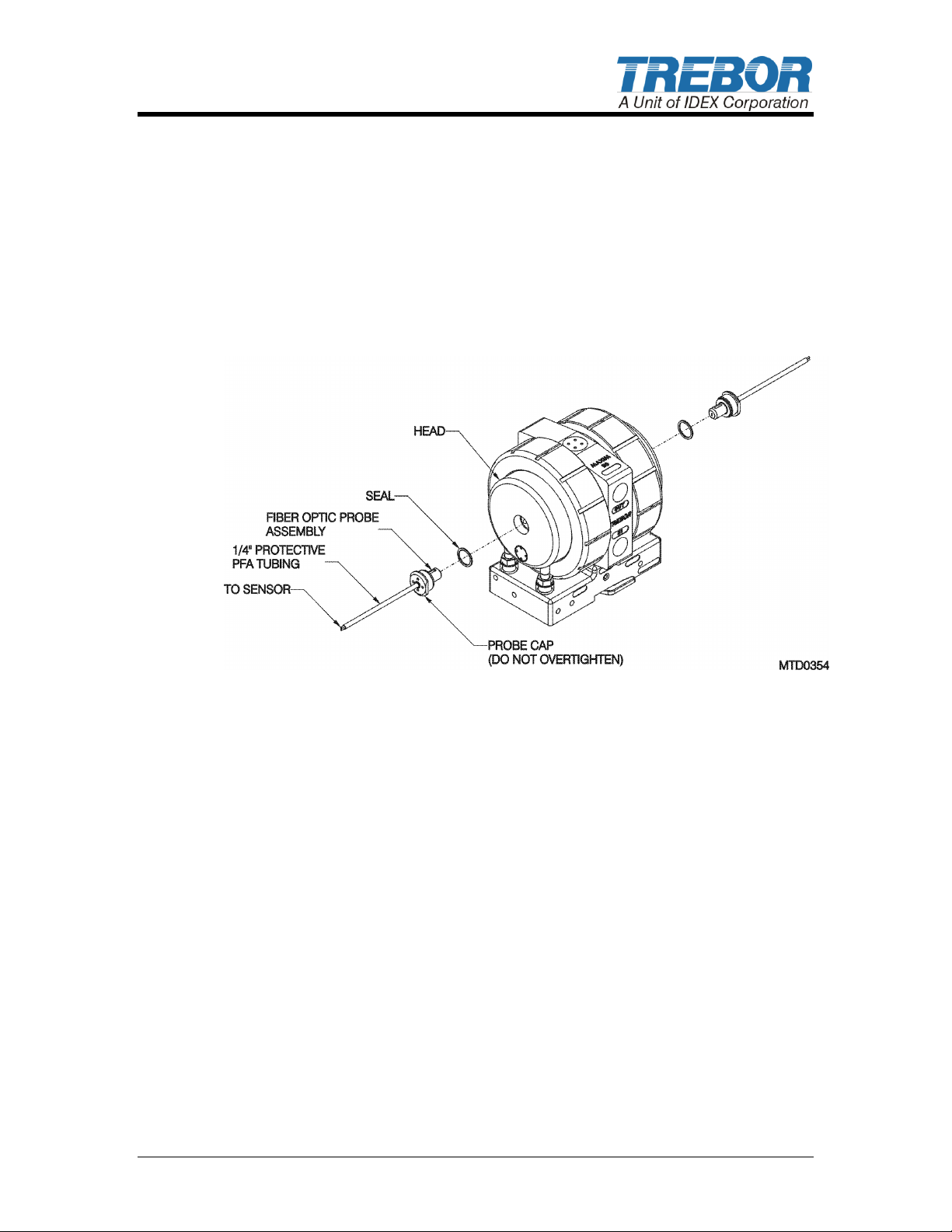

1.3 PROBE ASSEMBLY INSTALLATION (E MODEL ONLY)

Optic Cable: 1mm core; 1/4” PFA protective tubing.

Install seal into head.

Install probe assembly into head.

Thread probe cap into head hand tight only, no tool needed.

Connect fiber optic cable to sensor. NOTE: Minimize bends in fiber optic

cable to 2” radius minimum to help ensure optimum signal strength. NOTE:

Standard cable length is 15 ft. [4.57 meters].

Figure 1-2

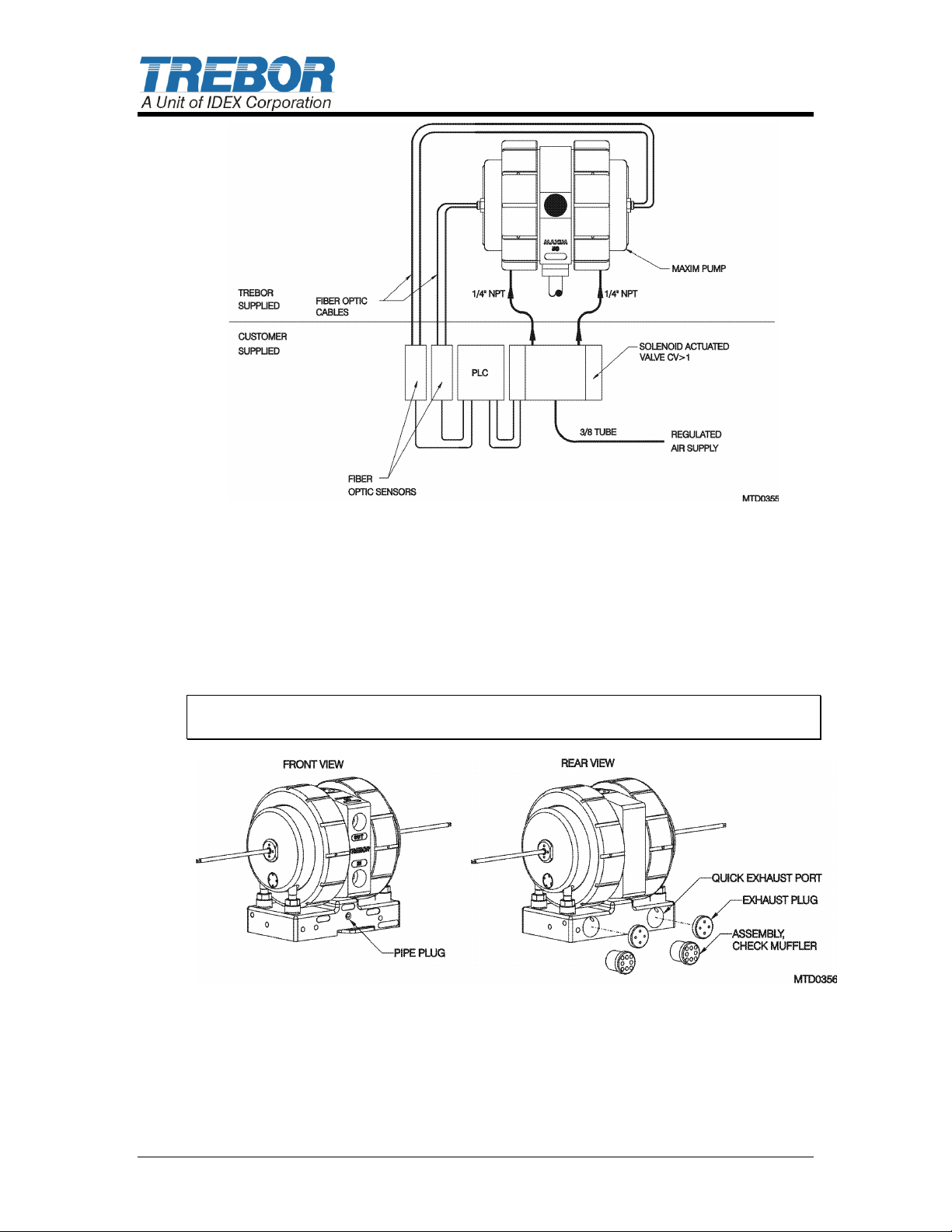

1.4 PLC CONTROL SCHEMATIC

Shown below is an example of the fiber optic end of stroke detection for a Maxim

Pump. The Programmable Logic Controller (PLC) control schematic shown will

allow the Maxim to be controlled by a PLC. Some of the features that can be

programmed are:

Start and stop pump

Monitoring approximate flow rate

Leak sensing

High and low flow rate detection

Preventative maintenance counter

Cycle counting

Oscillator control override

NOTE: See examples of ladder logic programs in Section 4.10.

MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL PAGE 5

Figure 1-3

1.5 REMOTE EXHAUST HOOK-UP

Remove existing Muffler Assembly from pump base.

Install Exhaust Plugs in Quick Exhaust Ports.

Remove Pipe Plug (1/4” NPT) from the pump base. Install the appropriately

sized fitting and tubing (not provided) to remote exhaust.

NOTE: To maintain optimum pump performance use 3/8” tubing minimum at a

length of 10 ft. maximum.

Figure 1-4

PAGE 6 MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL

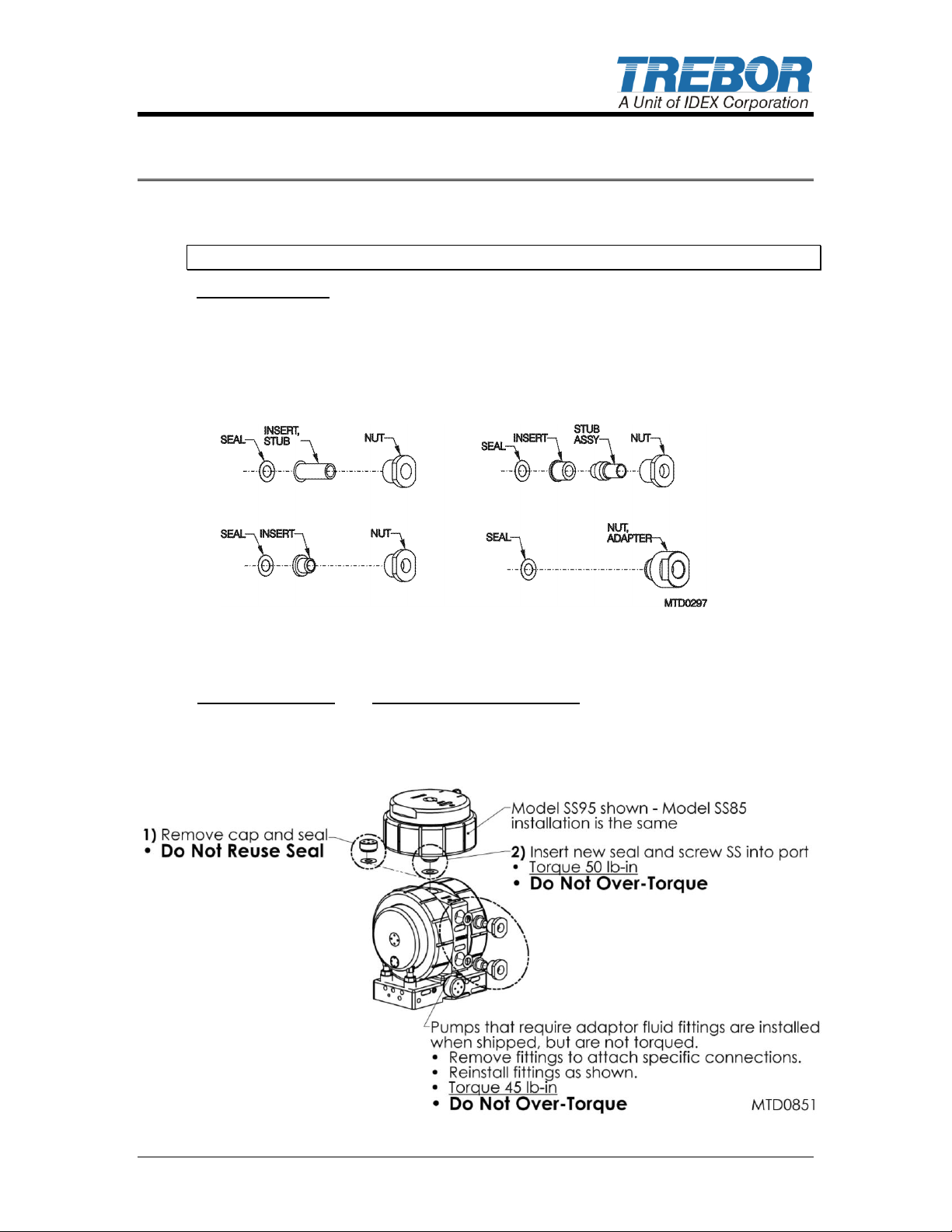

Available Options

A) PFA Weldable pipe…………...1/2”

B) Flare style tube adapter.….1/2”, 3/4" and 1”

C) PFA tube stub out…………3/4”

D) NPT adapter nut.………….3/4”

Surge Suppressor

Assembled Height: IN (CM)

SS85

17.12 (43.49)

SS95

13.97 (35.48

C)

D)

A)

B)

2 OPTIONS

2.1 FLUID PORT CONNECTION OPTIONS

NOTE: Use O-ring to seal stainless steel or other rigid plumbing.

Figure 2-1

2.2 FLUID FITTINGS / SURGE SUPPRESSOR HOOK-UP

MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL PAGE 7

Figure 2-2

NOTE: See Surge Suppressor Operation Manual for detailed installation

instructions.

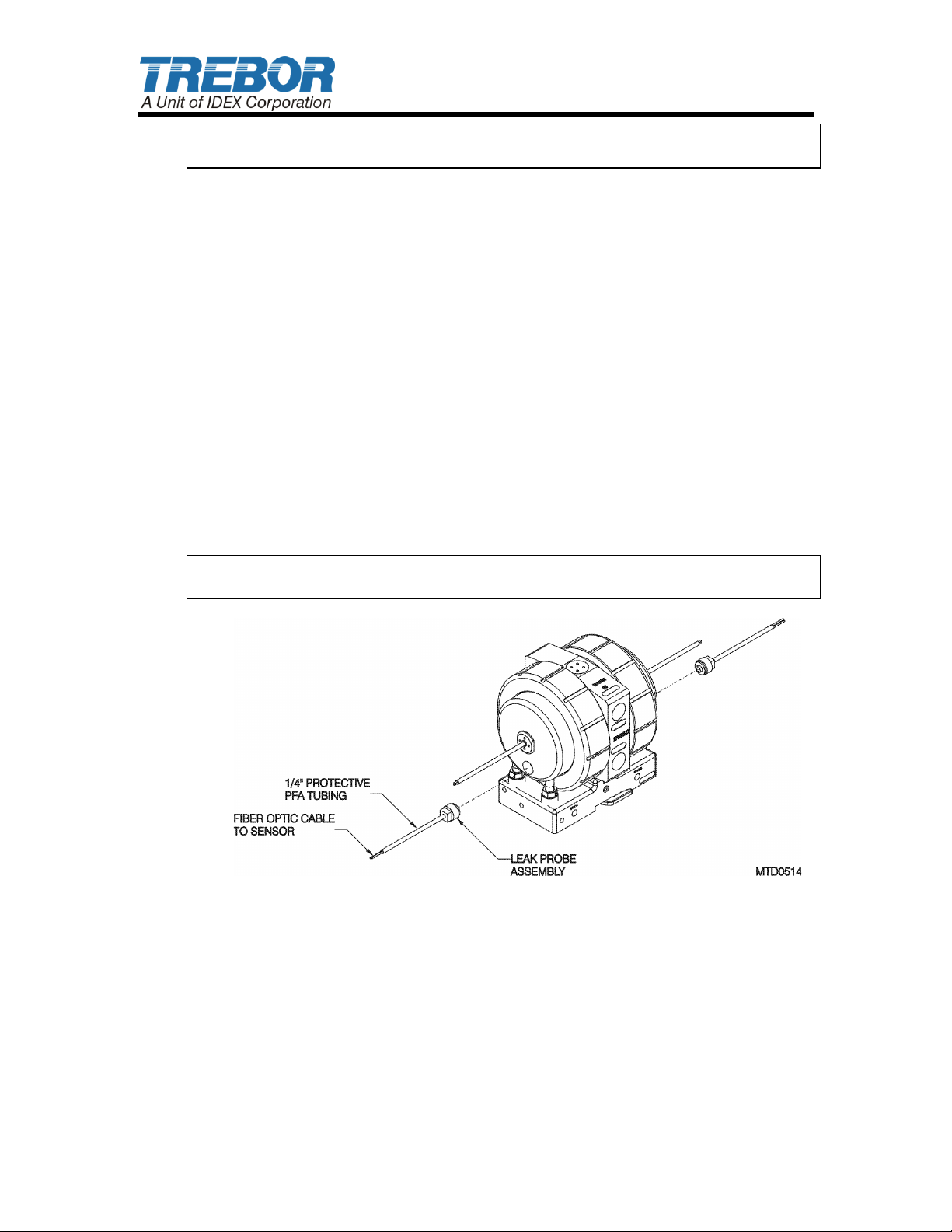

2.3 OPTIONAL LEAK SENSING

2.3.a Installation

Remove plug and seal from port. Probe is self-sealing.

Install probe assembly into leak sensor port.

Thread probe cap into port. (NOTE: Do not over tighten; damage to threads

will occur.)

Push protective tubing into probe cap.

Connect fiber optic cable to sensor (NOTE: Minimize bends in fiber optic

cable to 2” radius minimum to help ensure optimum signal strength.) Fiber

optic cable can be cut to desired length using the cable cutter provided.

2.3.b Sensor Signal Specifications

The sensor signal is normally closed. In the event of a leak, no light signal is

returned to the sensor.

NOTE: See your fiber optic sensor installation instructions for proper hook-up

and adjustment.

Figure 2-3

PAGE 8 MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL

Air Supply

Pressure

(PSIG)

Discharge

Fluid Pressure

(PSIG)

Air

Used

(SCFM)

20 0 4.3

20

10

3.2

30 0 6.6

30

15

5.1

40 0 9.3

40

20

6.8

50 0 12.0

50

30

8.2

60 0 15.3

60

40

9.7

80 0 19.0

80

50

12.6

3 START-UP

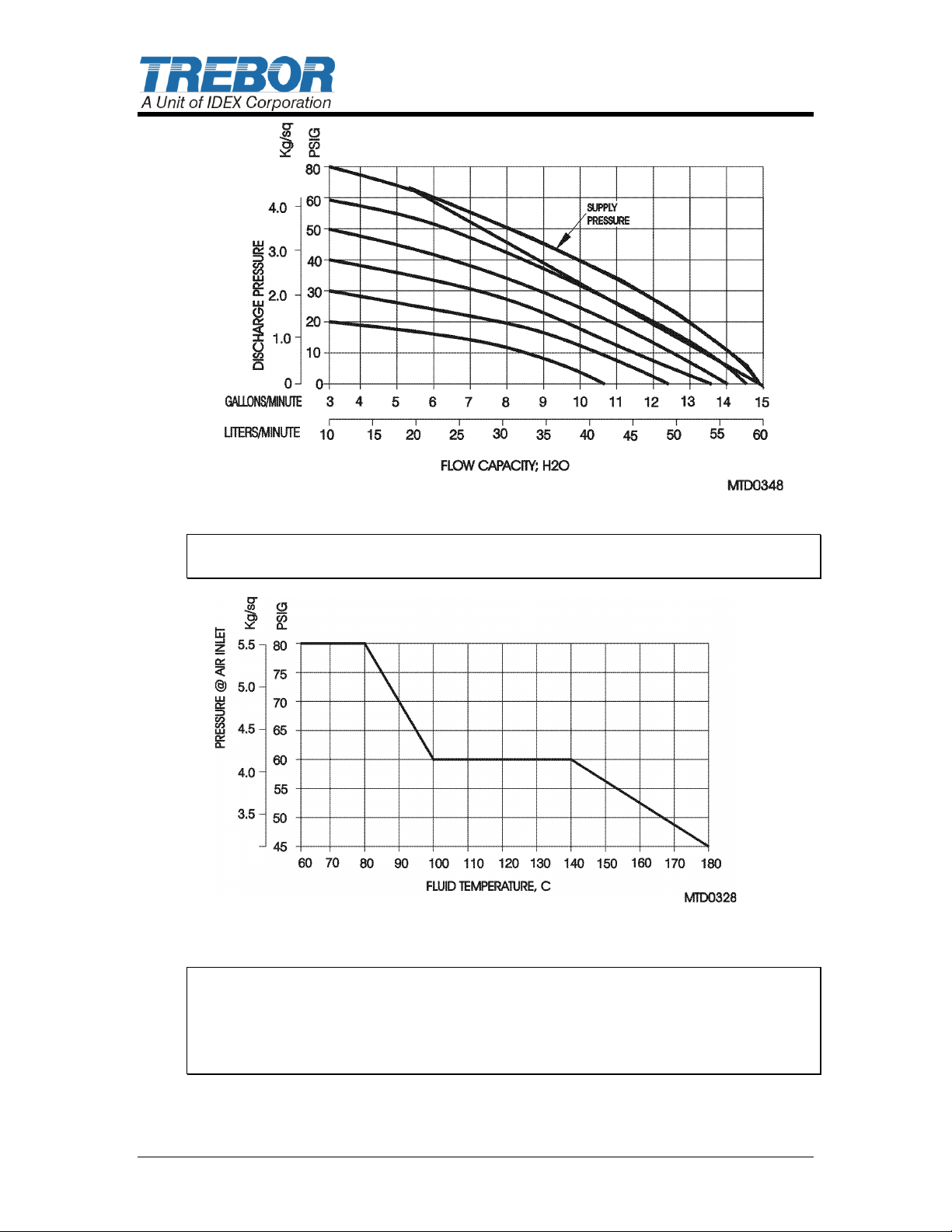

Pump air supply pressure should be regulated. (See : Pressure vs. Fluid

Temperature Chart)

Open the fluid suction (IN) line valve, if necessary.

Open the fluid discharge (OUT) line valve, if necessary.

Start with air regulator at low (> 20 psi) pressure setting. Increase pressure

to attain desired flow, up to the maximum rating (See Section 3.1).

Table 1: Consumption / Efficiency can be used to determine approximate air

consumption.

Refer to Troubleshooting, Section 5, if pump fails to start.

ATTENTION: Prolonged periods (>5 minutes) of dry running can damage critical

internal pump parts.

CAUTION: When handling potentially dangerous fluids under pressure,

the pump and its fittings should be placed in a compatible enclosure.

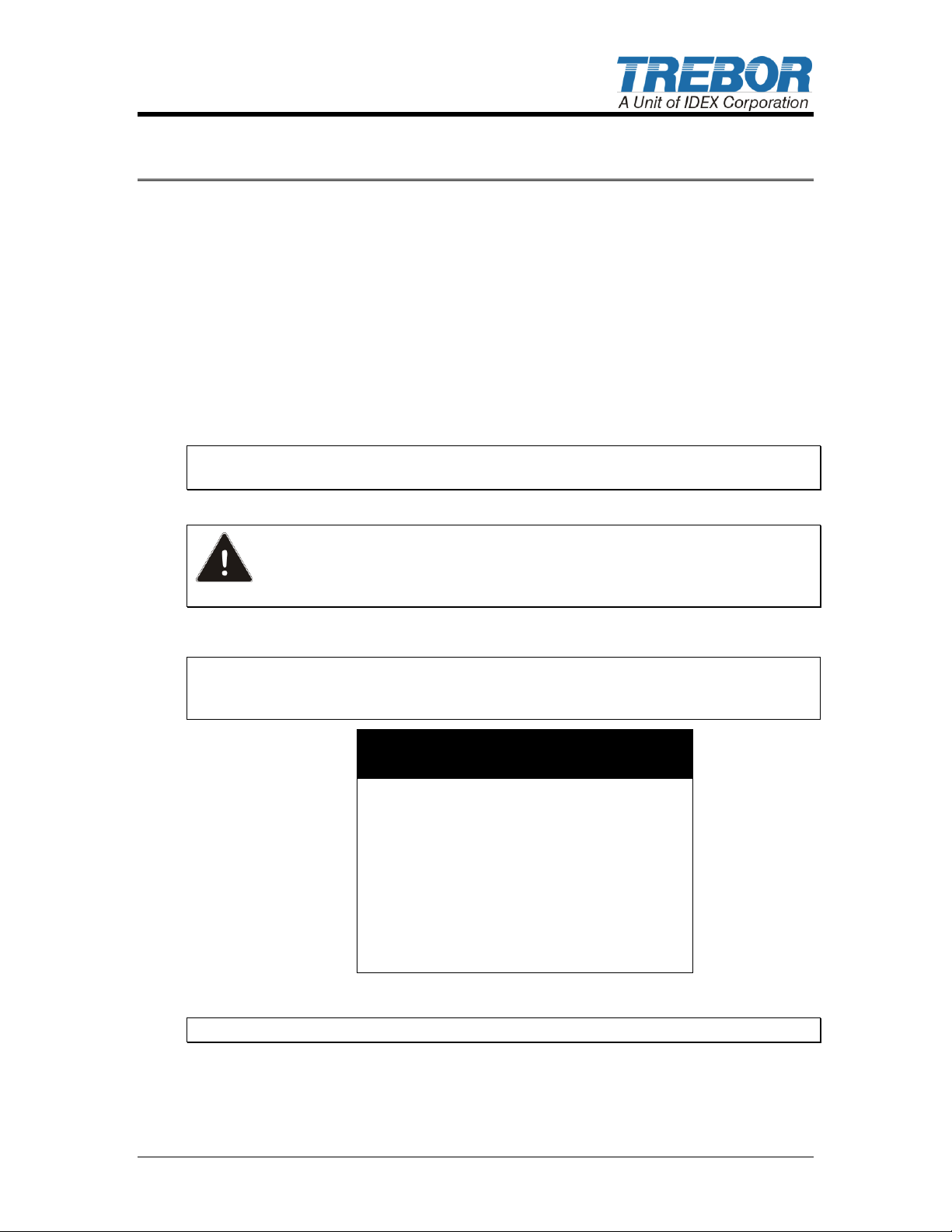

3.1 PERFORMANCE CHARTS

Pumping capacity is a function of air supply pressure and volume, suction head,

suction line restrictions, discharge head, discharge line restriction, and fluid

specific gravity and viscosity.

Table 1: Consumption / Efficiency

NOTE: Specification to be used to size regulators and control valves.

MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL PAGE 9

Figure 3-1: Pressure & Capacity Chart

NOTE: Test information is based on specific conditions and limited sampling.

Use for general reference only.

Figure 3-2: Pressure vs. Fluid Temperature Chart

Recommended Maximum Pump Operating Pressure

NOTE:

1. This graph is not representative of all operating conditions - customer’s

specific application results may vary.

2. Be sure that fittings and tubing used are capable of these operating

conditions.

PAGE 10 MAXIM 50E/U PUMP OPERATION / MAINTENANCE MANUAL

Loading...

Loading...