FILE NO. A05-012

O WNER’S MANUAL / INSTALLATION MANU AL

R410A

System air conditioner

The indoor unit in Super Heat Recovery Multi System is common to one in Super Modular Multi System air conditioner.

Therefore refer to the service manuals for A03-009, A03-010, and A03-011 separately issued.

Heat Recovery T ype

Indoor Unit

<4-way Air Discharge Cassette Type>

MMU-AP0091H, AP0121H, AP0151H,

MMU-AP0181H, AP0241H, AP0271H,

MMU-AP0301H, AP0361H, AP0481H

MMU-AP0561H

<2-way Air Discharge Cassette Type>

MMU-AP0071WH, AP0091WH, AP0121WH,

MMU-AP0151WH, AP0181WH, AP0241WH,

MMU-AP0271WH, AP0301WH, AP0481WH*

* CHINA market only

<1-way Air Discharge Cassette Type>

MMU-AP0071YH, AP0091YH, AP0121YH,

MMU-AP0151SH, AP0181SH, AP0241SH,

MMU-AP0152SH, AP0182SH, AP0242SH

<Concealed Duct Standard Type>

MMD-AP0071BH, AP0091BH, AP0121BH, AP0151BH,

MMD-AP0181BH, AP0241BH, AP0271BH, AP0301BH,

MMD-AP0361BH, AP0481BH, AP0561BH

<Concealed Duct High Static Pressure Type>

MMD-AP0181H, AP0241H, AP0271H,

MMD-AP0361H, AP0481H

<Slim Duct Type>

MMD-AP0071SPH, AP0091SPH, AP0121SPH,

MMD-AP0151SPH, AP0181SPH

<Under Ceiling Type>

MMC-AP0151H, AP0181H, AP0241H,

MMC-AP0271H, AP0361H, AP0481H

<High Wall Type>

MMK-AP0071H, AP0091H, AP0121H,

MMK-AP0151H, AP0181H, AP0241H,

MMK-AP0072H, AP0092H, AP0122H

<Floor Standing Cabinet Type>

MML-AP0071H, AP0091H, AP0121H,

MML-AP0151H, AP0181H, AP0241H

<Floor Standing Concealed Type>

MML-AP0071BH, AP0091BH, AP0121BH,

MML-AP0151BH, AP0181BH, AP0241BH

<Floor Standing Type>

MMF-AP0151H, AP0181H, AP0241H,AP0271H,

MMF-AP0361H, AP0481H, AP0561H

Outdoor Unit

Flow Selector Unit (FS unit)

<Inverter Unit>

MMY-MAP0802FT8

MMY-MAP1002FT8

MMY-MAP1202FT8

RBM-Y1122FE

RBM-Y1802FE

RBM-Y2802FE

PRINTED IN JAPAN, Aug, 2005 ToMo

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the con ventional

refrigerant R22 in order to prevent destruction of the oz one layer .

Thank you very much for purchasing TOSHIBA Air Conditioner.

Please read this owner's manual carefully before using your Air Conditioner.

• Be sure to obtain the “Owner’s manual” and “Installation manual” from constructor (or dealer).

Request to constructor or dealer

Please clearly explain the contents of the Owner’ s man ual and hand ov er it.

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the con ventional

refrigerant R22 in order to prevent destruction of the oz one layer .

Thank you very much for purchasing TOSHIBA Air Conditioner.

• This manual describes the installation method at the outdoor unit side.

• Before installation, please read this Manual thoroughly to perform correct installation.

• For pipe connection for the indoor and outdoor units, flow selector unit Y-shape branching joint or branch

header required sold separately. Select it according to the capacity.

• For pipe connection between the outdoor units, T-shape branching joint which is sold separately is required.

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the con ventional

refrigerant R22 in order to prevent destruction of the oz one layer .

Thank you very much for purchasing TOSHIBA Air Conditioner.

• This manual describes the installation method at the outdoor unit side.

• Before installation, please read this Manual thoroughly to perform correct installation.

• For pipe connection for the indoor and outdoor units, flow selector unit Y-shape branching joint or branch

header required sold separately. Select it according to the capacity.

• For pipe connection between the outdoor units, T-shape branching joint which is sold separately is required.

ADOPTION OF NEW REFRIGERANT

This SUPER HRM Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the

conventional refrigerant R22 in order to pre vent destruction of the ozone layer.

Be sure to use an indoor or outdoor unit in combination with the new refrigerant.

Thank you very much for purchasing TOSHIBA SUPER HRM Air conditioner.

Please read this manual carefully before using y our Flow Selector unit.

• When installing an indoor or outdoor unit, follow the installation man ual supplied with the unit.

• To connect the Flow Selector unit to an outdoor unit with pipes, a branching joint or header is required.

Choose one according to the capacity of the units.

• Nitrogen gas is filled in the selection unit. Be careful when removing flare nuts.

CONTENTS

OWNER’S MANUAL (EH99920601-R)

PRECA UTIONS FOR SAFETY ........................................................................................................... 1

NAME OF EACH PART ....................................................................................................................... 3

PARTS NAME OF REMOTE CONTROLLER...................................................................................... 6

CORRECT USA GE.............................................................................................................................. 8

ADJUSTMENT OF WIND DIRECTION ............................................................................................... 9

TIMER OPERATION .......................................................................................................................... 16

INSTALLATION.................................................................................................................................. 17

MAINTENANCE................................................................................................................................. 18

AIR CONDITIONER OPERATIONS AND PERFORMANCE ............................................................ 22

RE-INSTALLATION ........................................................................................................................... 23

WHEN THE FOLLOWING SYMPTOMS ARE FOUND...................................................................... 24

INSTALLATION MANUAL <OUTDOOR UNIT> (EH99842501-Q)

VOLUME-1

ACCESSORY PARTS ........................................................................................................................ 26

SAFETY CA UTION............................................................................................................................ 26

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER ............................................ 28

2

SELECTION OF INSTALLATION PLACE................................................................................ 29

3

OUTDOOR UNIT CARRYING IN ............................................................................................. 30

4

INSTALLATION OF OUTDOOR UNIT ..................................................................................... 31

5

REFRIGERANT PIPING........................................................................................................... 33

OWNER’SINSTALLATION

OUTDOOR (VOLUME-1)

INSTALLATION MANUAL <OUTDOOR UNIT> (EH99842601-Q)

VOLUME-2

SAFETY CA UTION............................................................................................................................ 43

6

ELECTRIC WIRING.................................................................................................................. 44

7

ADDRESS SETUP ...................................................................................................................50

8

SETTING WHEN CONNECTING MULTIPLE INDOOR UNITS TO A FS UNIT ....................... 59

9

HOW TO SET UP THE COOLING ONLY INDOOR UNIT......................................................... 60

10

TEST OPERATION................................................................................................................... 61

11

TROUBLESHOOTING ............................................................................................................. 63

INSTALLATION MANUAL <FLOE SELECTOR UNIT> (EH99842401-Q)

Accessory parts and Parts to be procured locally ....................................................................... 65

1

PRECAUTIONS FOR SAFETY................................................................................................ 65

2

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER ............................................ 67

3

SELECTION OF INSTALLATION PLACE................................................................................ 68

4

INATALLATION OF FLOW SELECTOR UNIT ......................................................................... 70

5

REFRIGERANT PIPING........................................................................................................... 72

6

ELECTRIC WORK.................................................................................................................... 76

INSTALLATION

OUTDOOR (VOLUME-2)

INSTALLATION

FLOW SELECTOR UNIT

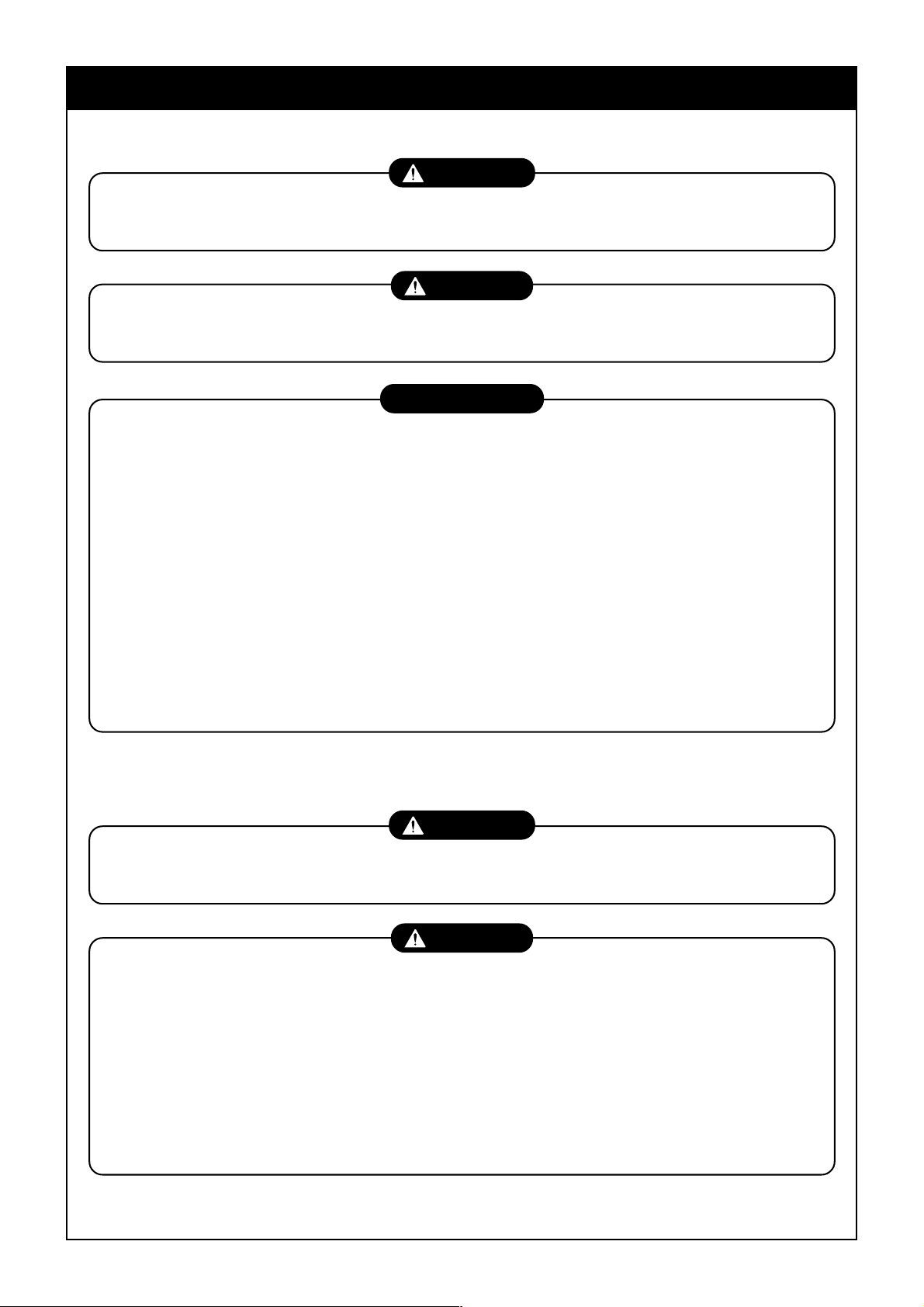

PRECAUTIONS FOR SAFETY

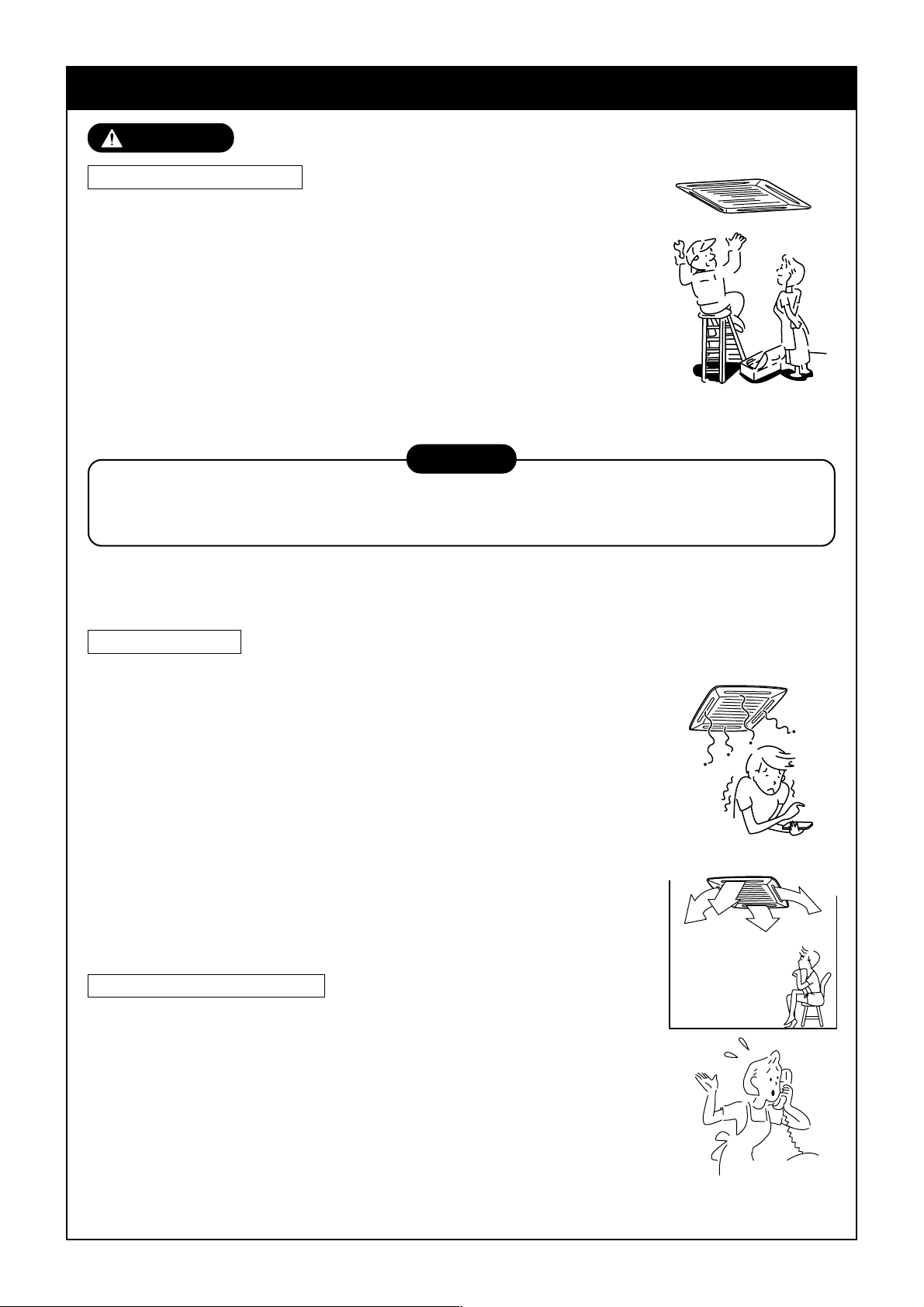

WARNING

Warning on installation

Be sure to leave the installation work to the dealer or a store

specializing.

The exclusive kno wledge and technology are required for installation work.

Do not perform installation by yourself. If an incomplete installation is perf ormed,

a fire, electric shock, injury, or water leakage may be caused.

Be sure to use the products sold separately which are specified b y us.

For the products sold separately, be sure to use those specified by us. Otherwise ,

a fire, electric shock, or water leakage ma y be caused. For installation work,

leave it to special engineer.

When installing the units in a small room, take measures so that the

refrigerant will not exceed the critical concentration if it leaks.

CAUTION

Related to countermeasures against the critical concentration, perform the installation work upon consultation with the dealer. If the refrigerant leaks and exceeds the critical concentration, oxygen deficiency

may be caused.

Check whether earthing work is performed correctly.

A grounding is necessary. If the earthing work is incompletely , an electric shock may be caused.

(For details, conf orm to the local regulation in each area.)

Warning on use

Do not expose your body directly in cool air for a long time, or do not

cool you excessively.

It causes the worse of physical condition or trouble on health.

Never insert a finger or bar into the air inlet port or air outlet port of

air.

Since the fan rotates in high speed inside of the unit, an injury may be caused.

When a trouble (burnt smell, etc.) is felt, stop the operation, turn off

the power switch, and contact the dealer who you have

purchased the air conditioner.

If keeping operation as the air conditioner is def ective, a fire, electric shock, or

trouble may be caused.

Do not use “Super HRM” for other than personal usage where the

ambient temperature may go down below –5°C.

For e xample , OA equipment/Electric device/Food/Animals and plants/Art object.

Warning on moving/repair

Never modify the air conditioner.

A fire or electric shock may be caused.

For repair, leave it to the dealer which you have purchased the air

conditioner.

If an incomplete repair is performed, a fire or electric shock may be caused.

When moving or re-installing the air conditioner, contact the dealer

which you have purchased the air conditioner or the special engineer.

If an incomplete installation is performed, a fire, electric shock, injury, or water

leakage may be caused.

1

CAUTION

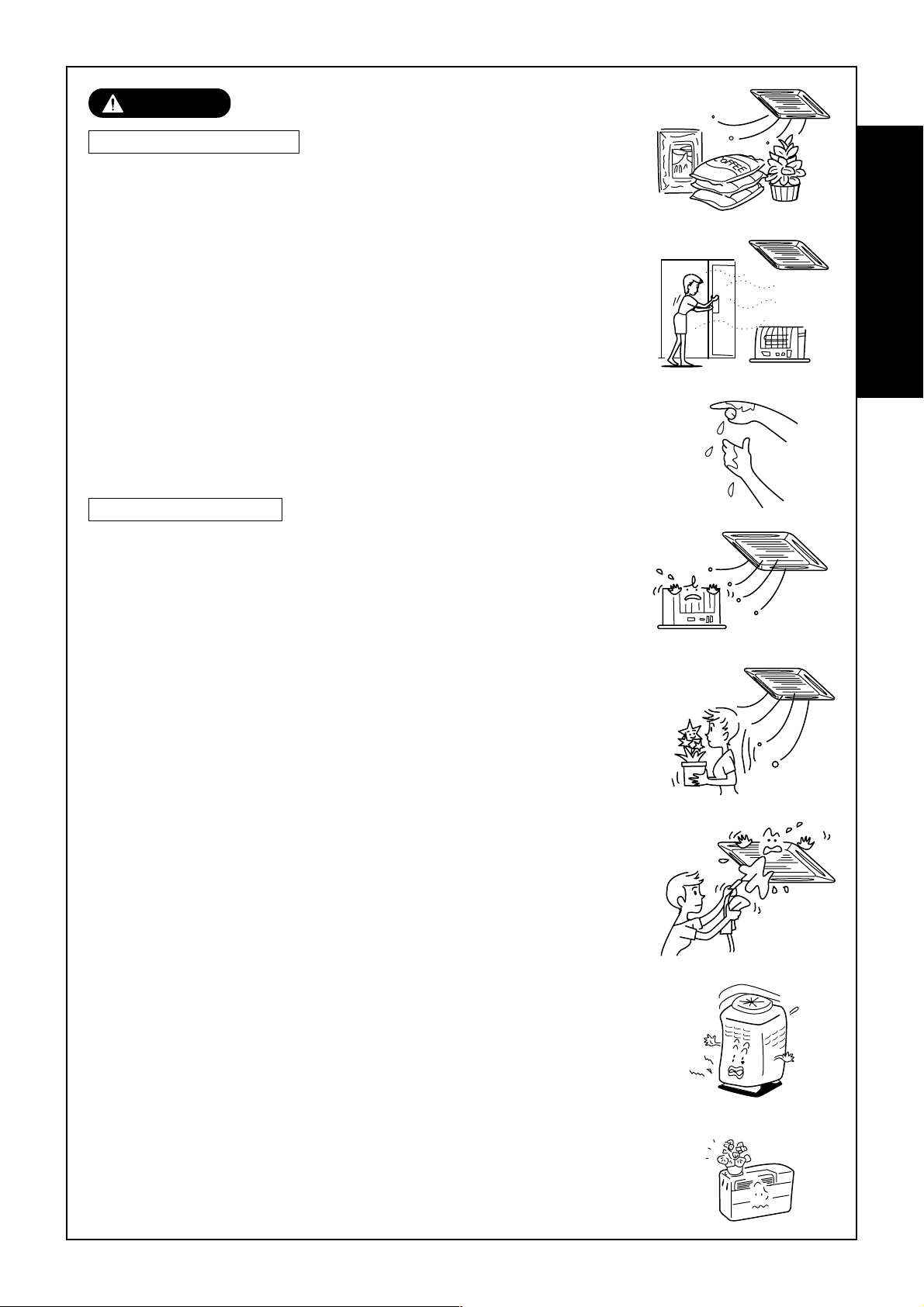

Caution on installation

Check the drain pipes are installed so that they can drain water

securely.

If the piping is incomplete, water leakage occurs resulted in moisture on

furniture.

Check the earth leakage breaker is attached.

It is necessary to attach an earth leakage breaker . Otherwise, it causes an

electric shock.

Check the air conditioner is installed at a place where flammable gas will not leak.

If gas leaks and accumulates in the unit surroundings, an outbreak of fire

may be caused.

Check the outdoor unit is fixed on the base.

If it is not fixed securely on the base, an accident such as falling may be

caused.

Check fixing method

Do not clean the air conditioner with water.

An electric shock may be caused.

OWNER’S

Do not put the combustible devices at a place where air from

the air conditioner flows directly.

Imperfect combustion of the combustible devices may be caused.

Diligently ventilate the room when operating the air conditioner

with the combustible devices.

If ventilation is incomplete, shortage of oxygen may be caused.

Check the installation plate, etc. is not damaged by use for a

long time.

If leaving them damaged, the unit may fall resulted in injury, etc.

Do not put plants and animals at a place where air from the air

conditioner flows directly.

Cause to affect on plants and animals may gener ate.

Do not put flammable spray, etc. near the air conditioner, or do

not spray directly on the air conditioner.

A fire may be caused.

Do not put vessels including water such as a vase on the unit.

Moisture floods in the unit, the electric isolation deteriorates, and an electric

shock may be caused.

Do not handle the switches with wet hands.

An electric shock may be caused.

Do not use the air conditioner for special purpose such as

storage of foods, plants and animals, precise equipment, and

art works.

Deterioration of quality may be caused.

2

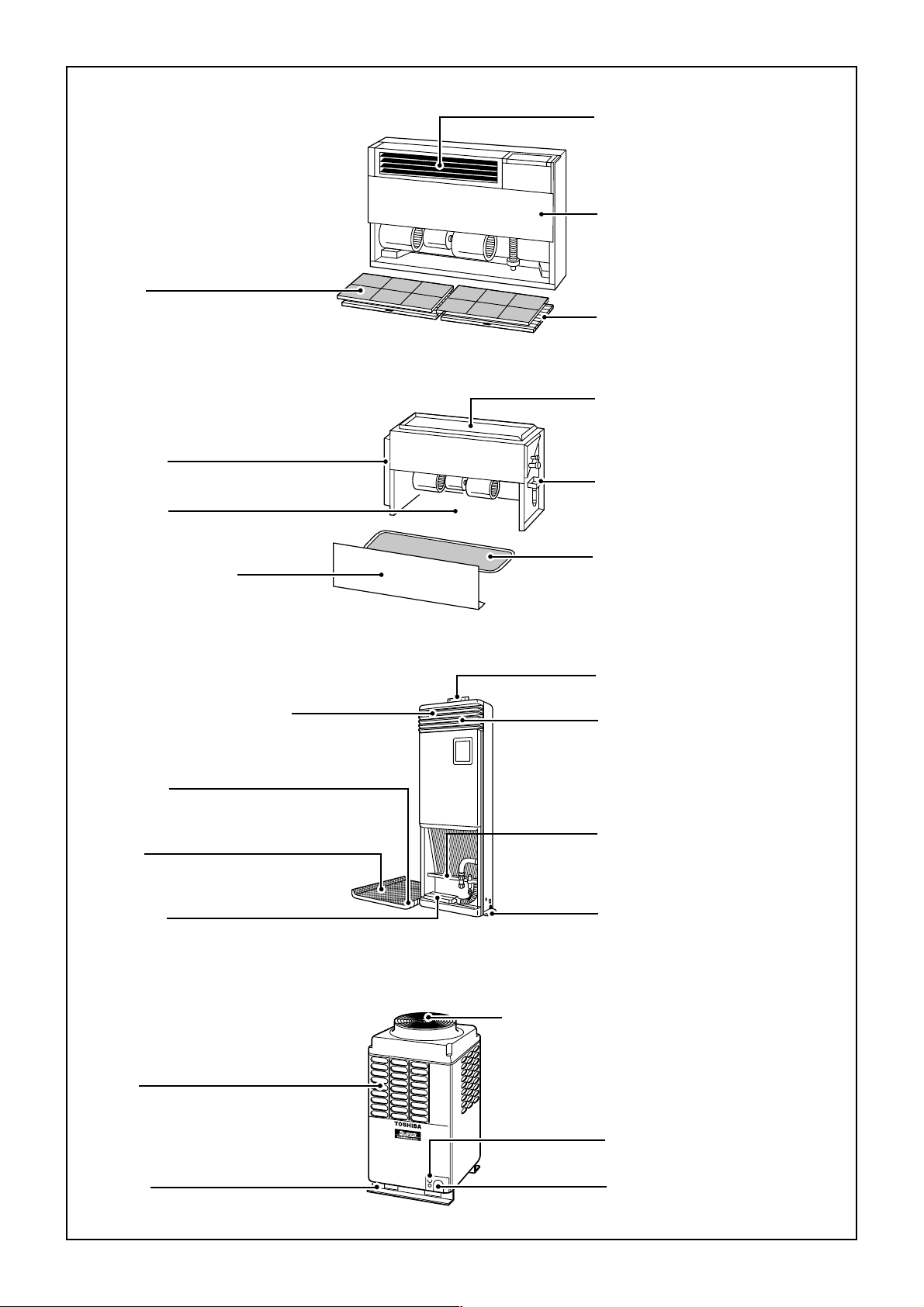

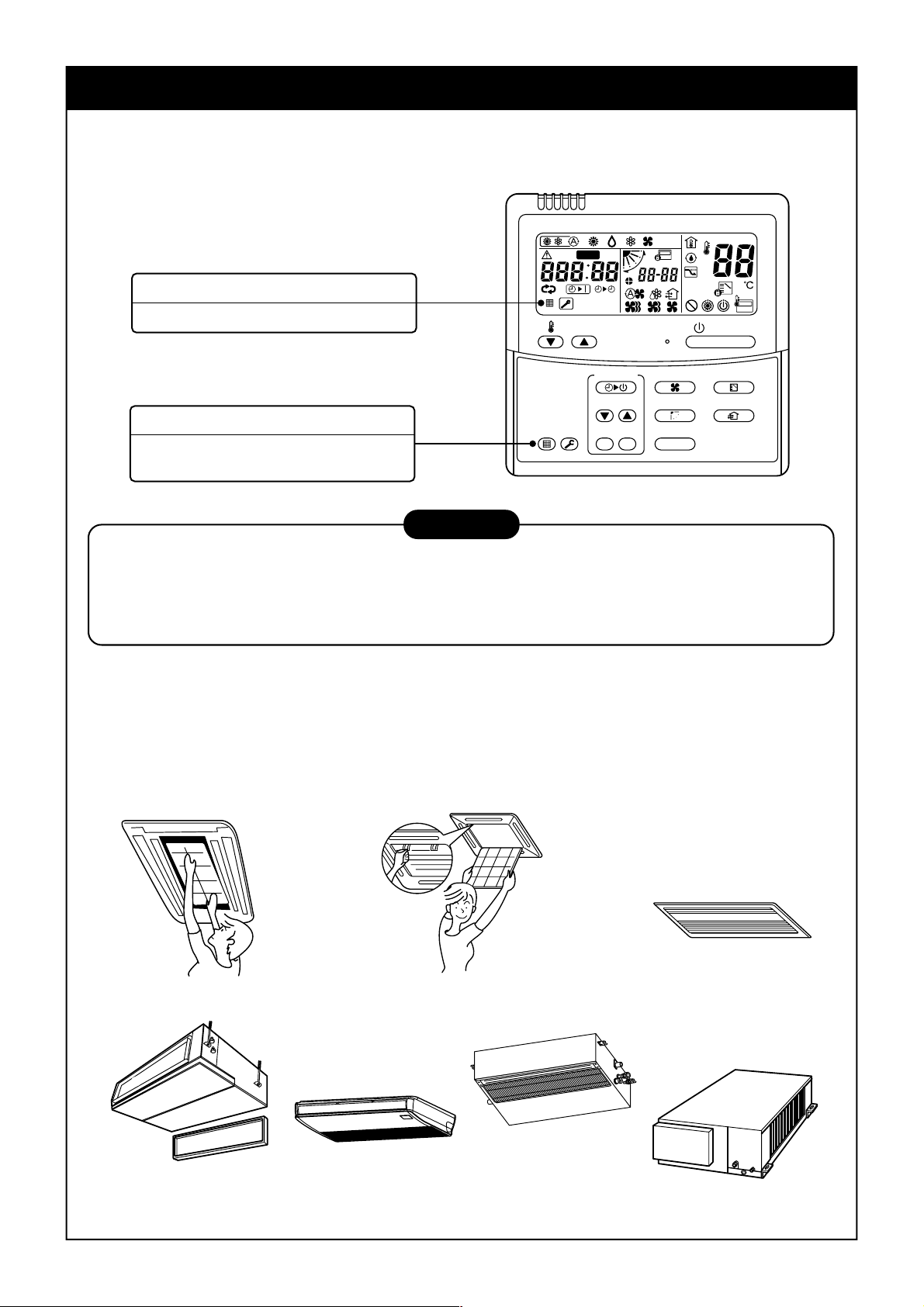

NAME OF EACH PART

Indoor unit

[4-way Air Discharge Cassette Type]

Air outlet/Air outlet flap

Select air blow direction in cooling or

heating operation each.

Earth screw

It is included in the electric

parts box.

Clip

The clip is to open/close the

air inlet grille.

[2-way Air Discharge Cassette Type]

Earth screw

It is included in the electric parts box.

Center panel

2-way discharge/3-way discharge

2-way discharge or 3-way discharge can be

selected according to the shape or

arrangement of the room.

For details, consult with the dealer which you

have purchased the air conditioner.

Air filter

Removes dust and trash.

(Air filter is provided in the air grille.)

Air inlet grille

Air in the room is sucked from here.

Air outlet/Air outlet flap

Select air blow direction in cooling or

heating operation each.

Sold Separately P arts

UNIT No.

R.C. No.

CODE No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

FILTER

RESET

RBC-AMT31E

Main remote controller

DATA

SET

TEST

SETTING

H

TEMP .

TIMER SET

TEST

Air inlet

Air in the room is

sucked from here.

Air filter

Removes dust and trash.

(Air filter is provided in the center panel.)

[1-way Air Discharge Cassette Type]

MMU-AP0071YH to AP0121YH MMU-AP0151SH to AP0241SH

Air outlet/

Select air blow direction in

cooling or heating operation each.

Earth screw

It is included in the

electric parts box.

Air inlet grille

Air in the room is sucked from here.

Air filter

Removes dust and trash.

(Air filter is provided in the air inlet grille.)

Air outlet flap

Earth screw

It is included in the electric parts box.

Air outlet/

Air outlet flap

Select air blow direction in cooling

or heating operation each.

Air inlet grille

Air in the room is sucked

from here.

Air filter

Removes dust and trash.

(Air filter is provided in the air inlet grille.)

MMU-AP0152SH, AP0182SH, AP0242SH

Button

Button to open/close

suction port

Air outlet/Air outlet flap

Change the direction of the air to be

discharged according to cool/heat mode.

RBC-AS21E2

Sub-remote controller

TEST

SETTING

˚C

Air filter

Removes dust or trash.

(Provided on the suction port.)

Suction port

Sucks air inside of the room from here.

Earth screw

It is included in the electric parts box.

Air filter

Removes dust or trash.

(Provided on the suction port.)

3

Wireless remote controller kit

TCB-AX21E2 RBC-AX22CE2 RBC-AX21U(W)-E2

[Concealed Duct Type]

Air outlet flange

Discharge duct is connected.

Air filter

Removes dust and trash.

(Air filter is provided in the air inlet grille.)

Air inlet

Air in the room is sucked from here.

[Concealed Duct, High Static Pressure Type]

Air outlet

Discharge duct is connected.

Earth screw

Earth screws are provided

in the electric parts box.

[Slim Duct Type]

Air inlet

Suction duct is

connected.

Air filter

(Air filter is not provided to

some models in the series.)

[Under Ceiling Type]

Button

Button to open/close the

suction port

Earth screw

Earth screws are provided

in the electric parts box.

Air inlet

Suction duct is connected.

Drain pan

Earth screw

It is included in the

electric parts box.

Air outlet

Discharge duct is connected.

Air inlet port

The air in the room is sucked

in from this port.

PROGRAM1

PROGRAM2

PROGRAM3

WEEKLY TIMER

Weekly timer

RBC-EXW21E2

ZONE

ALL

ZONE

GROUP

1234

SET DATA

SETTING

R.C.

SELECT ZONE

TCB-SC642TLE2

Central remote controller

UNIT No.

SuMoTuWeTh Fr Sa

ERROR

CODE

TEST

No.

CL

SET

No.

GROUP

Air filter

Removes dust or trash.

(Provided on the suction port.)

[High Wall T ype]

MMK-AP0071H to AP0241H

Air inlet grille

Air in the room is sucked from here.

Air filter

Removes dust and trash.

(Air filter is provided in

the air inlet grille.)

MMK-AP0072H to AP0122H

Air inlet grille

Air in the room is

sucked from here.

Air filter

Removes dust and trash.

(Air filter is provided in

the air inlet grille.)

Earth screw

Earth screws are provided in

the electric parts box.

Air outlet/Air outlet flap

Change the direction of the air

to be discharged according to

cool/heat mode.

Earth screw

Earth screws are provided

in the electric parts box.

Air outlet/Air outlet flap

Change the direction of the air

to be discharged according to

cool/heat mode.

Earth screw

Earth screws are provided

in the electric parts box.

Air outlet/Air outlet flap

Change the direction of the air

to be discharged according to

cool/heat mode.

4

[Floor Standing Cabinet Type]

Air filter

Removes dirt or dust.

(It is included in the suction port.)

Air outlet/Air outlet flap

Exchanges the air direction according to

cooling or heating time.

Earth screw

It is prepared in the electric parts box.

Air inlet port

Sucks air inside of the room from here.

[Floor Standing Concealed Type]

Earth screw

It is prepared in the electric parts box.

Air inlet port

Sucks air inside of the room from here.

Front panel (Lower side)

[Floor Standing Type]

Horizontal flap/Air outlet port

Exchanges the air direction according

to cooling or heating time.

Air inlet port

Sucks air inside of the room from here.

Air filter

Removes dirt or dust.

Air outlet port

Drain pan (With drain filter)

This accessory is installed at the local site.

Air filter

Removes dirt or dust.

(It is included in the suction port.)

Fixing metal holder

Vertical flap

The air can be automatically discharged

rightward/leftward at stated periods.

Drain pan

Water accumulated in the drain pan is

drained from here through the drain pipe.

Earth screw

It is prepared in the electric parts box.

Outdoor unit

Air inlet

They are provided at front, rear, left,

and right sides.

Fixing leg

Fixing metal holder (Right and left)

Air outlet (Discharge)

Hot air is discharged when cooling operation is performed.

Cold air is discharged when heating operation is performed.

Power source hole

Refrigerant pipe connecting hole

Connecting valve is included inside here.

5

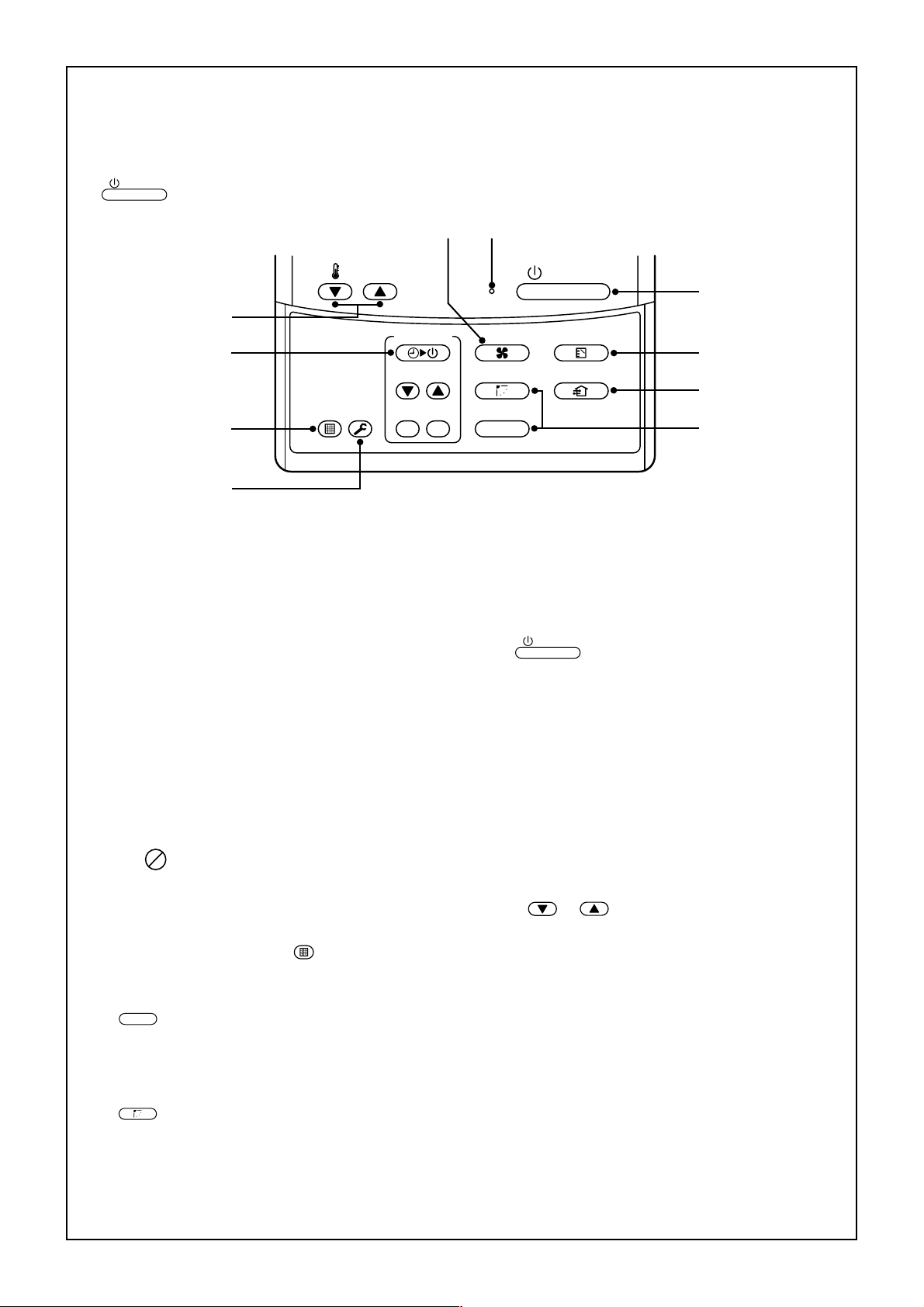

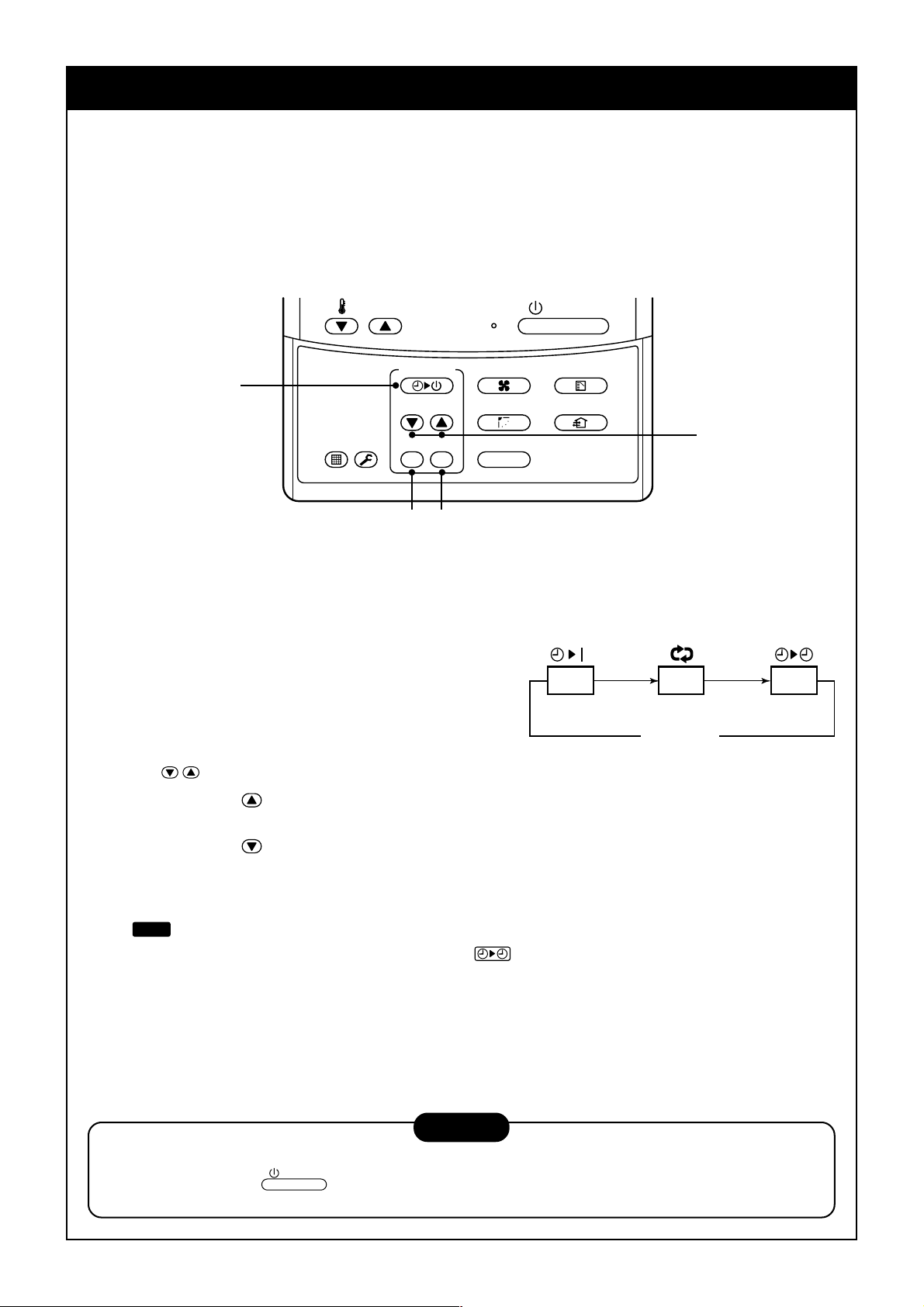

PARTS NAME OF REMOTE CONTROLLER

Display section

In the display example, all indicators are displayed for the explanation.

In reality only, the selected contents are indicated.

• When turning on the leak breaker at the first time, [SET DATA] flashes on

the display part of the remote controller. While this display is flashing, the

model is being automatically confirmed. Accordingly, wait for a while after

[SET DATA] display has disappeared, and then use the remote controller.

78 9

2

1

4

3

5

SET

H

DATA

SETTING

TEST

UNIT No.

R.C. No.

CODE No.

6

15

1

SET DATA display

Displayed during setup of the timer.

2

Operation mode select display

The selected operation mode is displayed.

3

CHECK display

Displayed while the protective device works or

a trouble occurs.

4

Timer time display

Time of the timer is displayed.

(When a trouble occurs, the check code is

displayed.)

5

Timer SETIN setup display

When pushing the Timer SETIN button, the

display of the timer is selected in order of

[OFF]

[ON]

6

Filter display

If “FILTER ” is displayed, clean the air filter.

7

TEST run display

Displayed during a test run.

8

Flap position display

(for 4-W ay Air Discharge Cassette Type

and Under Ceiling Type model only)

Displays flap position.

9

SWING display

Displayed during up/down movement of the

flap.

10

Set up temperature display

The selected set up temp. is displayed.

11

Remote controller sensor display

Displayed while the sensor of the remote

controller is used.

→ [OFF] repeat OFF timer →

→ No display.

12

PRE-HEAT display

Displayed when the heating operation starts or

defrost operation is carried out.

While this indication is displayed, the indoor fan

stops or the mode enters in LOW.

13

Operation ready display

Displayed when cooling or heating operation is

impossible because the outdoor temperature goes

out of the operable range.

14

No function display

Displayed if there is no function even if the button is

pushed.

15

Air volume select display

The selected air volume mode is displayed.

(AUTO)

(MED.) (LOW)

In the Concealed Duct High Static Pressure type

models, [HIGH] only is displayed for the air speed.

16

Mode select control display

Displayed when pushing “Operation mode select ”

button while the operation mode is fixed to heating

or cooling by the system manager of the air conditioner.

17

Central control display

Displayed when using the remote controller together

with the central control remote controller, etc.

If Remote controller is prohibited at the

centralcontrol side,

ON / OFF

,

the change is not accepted.

(The contents available to be set up on the remote

controller differ according to the central control

mode. For details, refer to Owner’s Manual of the

central control remote controller.)

DATA

SET

TEST

SETTING

H

TEMP .

TIMER SET

FILTER

TEST

RESET

10

11

12

(HIGH)

MODE

flashes when operating

, / buttons and

UNIT No.

R.C. No.

CODE No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

Display

section

Operation

section

17

16

13

14

6

Operation section

ON / OFF

Push each button to select a desired operation.

This remote controller can operate the maximum 8 indoor units.

• The details of the operation needs to be set up once, afterward, the air conditioner can be used by pushing

ON / OFF

button only.

1

7

TEMP.

10

2

FIL TER

TEST

RESET

5

3

1

Air volume select button

Selects the desired air volume mode.

The Concealed Duct High Static Pressure type

models cannot be operated.

2

Timer set button

TIMER SET button is used when the timer is

set up.

3

Check button

The CHECK button is used for the check

operation. During normal operation, do not

use this button.

4

Fan button

FAN button is used when a fan which is sold on

the market or etc. is connected.

• If is displayed on the remote controller

when pushing the FAN button, a fan is not

connected.

5

Filter reset button

Resets (Erases) “FILTER ” display.

TIMER SET

ON / OFF

8

FAN

SWING/FIXTIME

MODE

VENT

9

4

UNITSET CL

6

7

Operation lamp

Lamp is lit during the operation. Lamp is off

when stopped.

Although it flashes when operating the protection device or abnormal time.

8

When the button is pushed, the operation

starts, and it stops by pushing the button

again.

When the operation has stopped, the operation

lamp and all the displays disappear.

9

Operation select button

Selects desired operation mode.

10

Set up temperature button

Adjusts the room temperature.

Set the desired set temperature by pushing

button

or .

6

Wind direction and Swing

UNIT

:

If the multiple indoor units are operated by only

one remote controller, select the units when

the air direction is adjusted.

SWING/FIX

:

Set up the auto swing and angle of the flap .

• This function is not provided to Concealed

Duct Standard Type, High Static Pressure

Type, Floor standing Cabinet Type, Floor

Standing Concealed Type, or Slim Duct Type.

OPTION :

Remote controller sensor

Usually the TEMP. sensor of the indoor unit senses

the temperature. The temperature on the surrounding of the remote controller can also be sensed.

For details, contact the dealer from which you have

purchased the air conditioner.

• In case that one remote controller controls the

multiple indoor units, the setup operation is

unavailab le in g roup control.

7

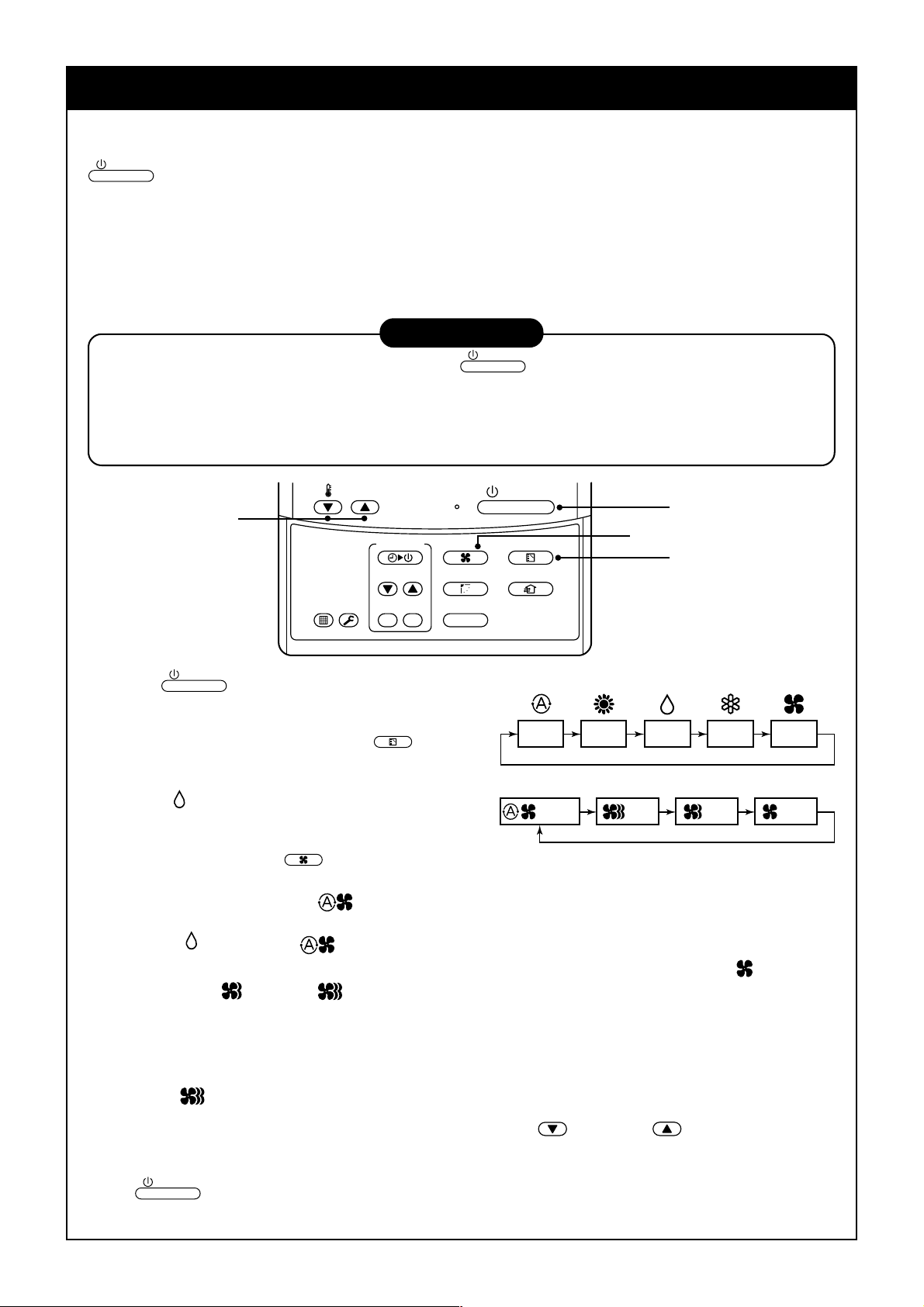

CORRECT USAGE

When you use the air conditioner for the first time or when you change the SET DATA value, f ollow the procedure below. From the next time, the operation displa yed on the remote controller will start by pushing the

ON / OFF

Preparation

Turn on the main power switch and/or the leakage breaker.

• When the power supply is turned on, a partition line is displayed on the display part of the remote controller.

After the power supply is turned on, the remote controller does not accept an operation for approx. 1 minute,

*

but it is not a failure.

• While using the air conditioner, operate it only with

• Do not turn off the leak breaker while the air conditioner is used.

• Turn on the leak breaker 12 hours or more before start of operation after the air conditioner has stopped

button only.

switch and the leak breaker.

for a long time.

REQUIREMENT

ON / OFF

button without turning off the main power

TEMP.

4

TIMER SET

SWING/FIXTIME

FIL TER

TEST

RESET

1

Push

The operation lamp goes on, and the operation starts.

2

Select an operation mode with the

One push of the button, and the display

changes in the order shown on the right.

•“DRY mode” function is not pro vided to

Concealed Duct High Static Pressure Type.

3

Select air volume with

One push of the button, and the display changes in the order shown on the right.

• When air volume is “AUTO ”, air volume differs according to the temperature difference between

set temperature and room temperature.

• In DRY mode, “AUTO ” is displayed and the air volume is LOW.

• In heating operation, if the room temperature is not heated sufficiently with volume “LOW ” oper ation,

select “MED. ” or “HIGH ” operation.

• The temperature which the temperature sensor detects is one near the air inlet of the indoor unit.

Therefore it slightly differs from the room temperature according to the installation status . The setup

value is a criterion of the room temperature. (Automatic air speed cannot be selected in FAN mode.)

• Air volume of function is not provided to “Concealed Duct High Static Pressure Type” but air speed

“HIGH ” only is displayed.

ON / OFF

button.

FAN

button.

MODE

button.

FAN

UNITSET CL

ON / OFF

MODE

VENT

1

3

2

HEAT DRYAUTO COOL FAN

(Dehumidity)

AUTO

LOW MED. HIGH

4

Determine the set up temperature by pushing the “TEMP. ” or “TEMP. ” button.

Stop

Push

The operation lamp goes off, and the operation stops.

ON / OFF

button.

8

REQUIREMENT

[In Cooling operation]

• The operation starts after approx. 1 minute.

[In Heating operation]

• In heating operation, the fan operation may continue for approx. 30 seconds after the air conditioner has

stopped.

• The indoor fan continues preheat operation for 3 to 5 minutes under stop condition, and then blows out

the hot air.

( display on the remote controller display part goes on.)

• When temperature of the room has reached the setup temperature and the outdoor unit stops, the air

speed becomes super low and the air volume extremely is lessened.

• In the defrost mode, the fan stops so that cool air is not discharged and PRE-DEF is displayed.

[In Automatic operation]

• Using the difference between the setup temperature and the room temperature , the heating or cooling

operation is automatically performed.

ADJUSTMENT OF WIND DIRECTION

To increase the cooling or heating effect, be sure to use the discharge flap in the different

directions in cooling or heating operation.

As the characteristics of the air, the cold air accum ulates at lower side and hot air at upper side, respectively.

CAUTION

Set the louver horizontally in cooling operation.

If cooling operation is performed with downward discharge, the surface of the discharge port or louver will

be wet with dew, and dewdrop may fall down.

REQUIREMENT

• If heating operation is performed with horizontal discharge, une venness of temperature may increase in

the room.

4-way Air Discharge Cassette Type

• While the air conditioner stops, the discharge flap automatically directs downward.

• While the air conditioner is in ready status for heating,

the discharge flap directs upward.

The swinging operation starts after heating ready status

has been cleared, but “SWING

remote controller even if the status is ready to heating.

” is displayed on the

[In Cooling operation]

Use the discharge flap with horizontal set point.

[In Heating operation]

Use the discharge flap with downward set point.

9

How to set up the air direction

SWING/FIX

Push

1

Every pushing the button, the air direction c hanges.

In Heating operation

Set the air outlet flap downward.

If directing it upward, the hot air may not come to the f oot.

In Cooling / Dry operation

Set the air outlet flap upward.

If directing it downward, the dew may fall on near the air discharge port or it drips.

button.

Initial setup

Initial setup

How to start swinging

2

SWING/FIX

Push

button.

Set direction of the air outlet flap to the

lowest position and then push

SWING/FIX

again.

• [SWING ] is displayed and the air direction

automatically changes upward/downward.

In case when one remote controller controls

the multiple indoor units, each indoor unit can

be selected and its air direction can be set up.

How to stop swinging

3

SWING/FIX

Push

button again during swinging of

the air outlet flap.

• The air outlet flap can be stopped at the

desired position. After then the air direction

can be again set up from the uppermost

position by pushing

SWING/FIX

button.

* While the air outlet flap is set downward in

cooling/drying operation, it does not stop.

If stopping the air outlet flap which directs

downward during swinging, it stops after

moving to the 3rd position from the top

position.

UNIT

4

• To set up the air direction individually, push

UNIT

button to display each indoor unit No. in

a group control. Then set up the air direction to

a displayed indoor unit.

• If there is no display, all the indoor units can be

operated collectively.

• Every pushing

exchanges as shown in the figure.

UNIT

button, the display

button

FIL TER

RESET

TEMP.

TEST

TIMER SET

SWING/FIXTIME

UNITSET CL

FAN

ON / OFF

MODE

VENT

1, 2, 3 4

In FAN operation

Initial setup

Display when stopping the swing

Fan/Heat

operation

Unit No. 1-1No display Unit No. 1-2

Unit No. 1-4 Unit No. 1-3

In all modes

Series of

operation

Cool/Dry

operation

10

According to the shape or arrangement of the room, the cold air and hot air can be discharged for two directions or three directions. For details, contact the dealer.

INFORMATION

• If cooling operation is performed with downward discharge, dew may fall on surface of the cabinet or the

horizontal flap resulted in dripping.

• If heating operation is performed with horizontal discharge, une venness of temperature may increase in

the room.

• Do not move the horizontal flap directly with hands; otherwise a trouble is caused. Select direction of the

horizontal flap using flap operation switch on the remote controller. The horizontal flap does not stop

immediately ev en if the switch is pushed. Adjusting the stop position, push the switch.

2-way Air Discharge Cassette Type

[In Cooling operation]

Use the air outlet flap with horizontal set point.

[In Heating operation]

Use the air outlet flap with downward set point.

Setup of air direction and swinging

1

2

3

SWING/FIX

Push

button during operation.

• [SWING ] is displayed and the air direction automatically changes upward/downw ard.

In case when one remote controller controls the multiple indoor units, each indoor unit can be selected

and its air direction can be set up.

Push

SWING/FIX

button again during s winging of the air

TEMP.

ON / OFF

outlet flapp.

• The air outlet flap can be stopped at the desired

position.

UNIT

• To set up the air direction individually, push

UNIT

FILTER

RESET

TEST

TIMER SET

FAN

SWING/FIXTIME

UNITSET CL

MODE

VENT

button to display each indoor unit No. in a group

control. Then set up the air direction to a displayed

indoor unit.

1, 2 3

• If there is no display, all the indoor units can be operated collectively.

• Every pushing

UNIT

button, the display exchanges as

Unit No. 1-1No display Unit No. 1-2

shown in the figure.

Unit No. 1-4 Unit No. 1-3

1-way Air Discharge Cassette Type (1H Series)

Adjustment of air direction upward/downward

[In Cooling operation]

In cooling operation, use the air outlet flap with horizontal set point so that the

cold air diffuses in whole room.

[In Heating operation]

In heating operation, use the air outlet flap with downward set point so that

the hot air blows at the f oot.

Adjustment of air direction rightward/leftward

To change the discharge direction to right or left side, set the vertical grille

inside of the air outlet flap to the desired direction.

Setup of air direction and swinging

Refer to description of “2-w ay Air Discharge Cassette Type”.

11

Under Ceiling Type, 1-way Air Discharge Cassette Type (2SH Series)

• While the air conditioner stops, the horizontal flap (Up/Down air direction adjustment plate)

automatically directs upward.

• While the air conditioner is in ready status for heating, the horizontal flap (Up/Down air direction adjustment plate) directs upward. The swinging operation starts after heating ready status

has been cleared, but “SWING

” is displayed on the remote controller even if the status is

ready to heating.

How to set up the air direction

SWING/FIX

Push

button during operation.

1

Every pushing the button, the air direction changes.

In Heating operation

Set the horizontal flap (Up/Down

air direction adjustment plate)

downward. If directing it upward,

the hot air may not come to the

foot come to the foot.

Initial setup

How to start swinging

2

SWING/FIX

Push

button.

Set direction of the horizontal flap (Up/Down air

direction adjustment plate) to the lowest position and then push

SWING/FIX

button again.

• [SWING ] is displayed and the air direction

automatically changes upward/downward.

In case when one remote controller controls the

multiple indoor units, each indoor unit can be

selected and its air direction can be set up.

How to stop swinging

3

4

SWING/FIX

Push

button again during swinging of the

horizontal flap.

• The horizontal flap can be stopped at the desired

position. After then the air direction can be again

set up from the uppermost position by pushing

SWING/FIX

button.

* While the horizontal flap is set downw ard in

cooling/drying operation, it does not stop.

If stopping the horizontal flap which directs

downward during swinging, it stops after moving

to the 3rd position from the top position.

UNIT

• To set up the air direction individually, push

button to display each indoor unit No. in a group

control. Then set up the air direction to a displayed indoor unit.

• If there is no display, all the indoor units can be

operated collectively.

• Every pushing

UNIT

button, the display ex-

changes as shown in the figure.

UNIT

In Cooling / Dry operation

Set the horizontal flap (Up/Down

air direction adjustment plate)

upward. If directing it downward,

the dew may fall on near the air

air outlet port or it drips.

TEMP.

FAN

SWING/FIXTIME

UNITSET CL

FIL TER

RESET

TIMER SET

TEST

1, 2, 3 4

In FAN operation

Initial setup

Display when stopping the swing

Fan/Heat

operation

Initial setup

ON / OFF

MODE

VENT

In all modes

Series of

operation

Cool/Dry

operation

Unit No. 1-1No display Unit No. 1-2

Unit No. 1-4 Unit No. 1-3

12

Right/Left air direction adjustment

To change the air outlet direction to right or left side, set the vertical flap inside of the horizontal flap to the

desired direction.

INFORMATION

• If cooling operation is performed with downward discharge,

dew may fall on surface of the cabinet or the horizontal flap

resulted in dripping.

• If heating operation is performed with horizontal discharge,

unev enness of temper ature may increase in the room.

High Wall T ype

Adjustment of air direction upward/downward

[In Cooling operation]

In cooling operation, use the horizontal flap with horizontal set point

so that the cold air diffuses in whole room.

[In Heating operation]

In heating operation, use the horizontal flap with downward set point

so that the hot air blows at the f oot.

REQUIREMENT

• If cooling operation is performed with downward air outlet, de w

may f all on surface of the cabinet or the horizontal flap resulted

in dripping.

• If heating operation is performed with horizontal air outlet,

unev enness of temper ature may increase in the room.

• Do not move the horizontal flap directly with hands; otherwise a

trouble is caused. Select direction of the horizontal flap using

SWING/FIX

switch on the remote controller. The horizontal flap does

not stop immediately ev en if the switch is pushed. Adjusting the

stop position, push the switch.

Adjustment of air direction rightward/leftward

To change the air outlet direction to right or left side, set the vertical

flap inside of the horizontal flap to the desired direction.

Setup of air direction and swinging

1H series: Refer to description of “2-way Air Discharge Cassette

Type”.

2H series: Refer to description of “Under Ceiling Type, 1-way Air

Discharge Cassette Type (2SH Series)”.

13

Floor Standing Cabinet Type

[In Cooling operation]

In cooling operation, use the air outlet flap with horizontal set

point so that the cold air diffuses in whole room.

[In Heating operation]

In heating operation, use the air outlet flap with downward set

point so that the hot air blows at the f oot.

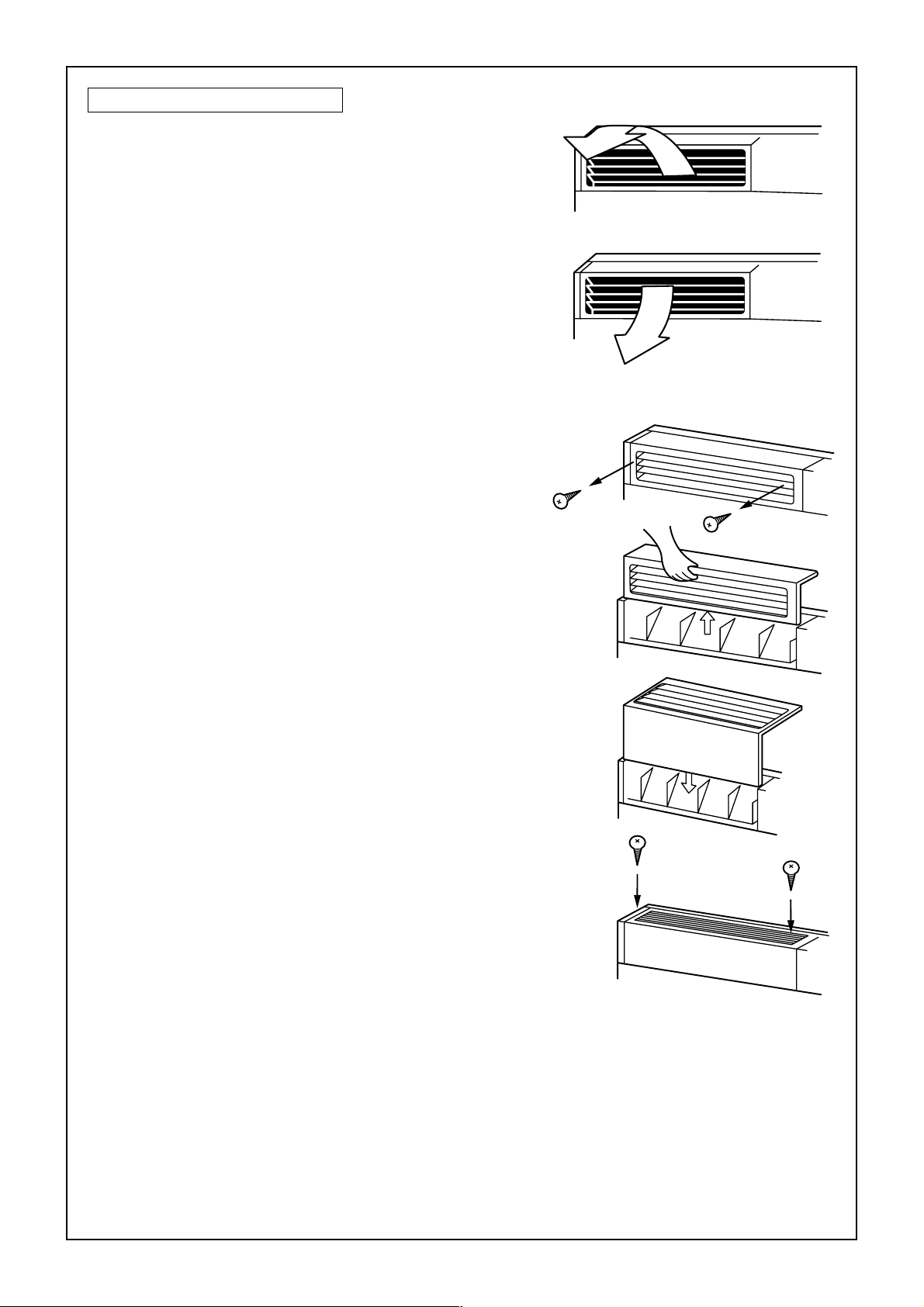

How to change the air outlet port

Change the air outlet port in the following procedure.

1

Take off two fixing screws of the air outlet port.

(The fixing screws are reused.)

2

Insert the hand into the air outlet port and push up it

a little, and then remove the air outlet port from the

claw hook at rear side.

3

Lift up the air outlet port upward and remove it.

4

Reverse the air outlet port and attach it to the main

unit.

Pay attention so that four claw hooks (two at rear and

lower sides each) are hooked at mounting position.

5

Be sure to tighten the air outlet port with the removed fixing screws so that the air outlet port does

not come off.

14

Floor Standing Type

Adjustment of air direction upward/downward

[In Cooling operation]

In cooling operation, move the flap with hands and use it with horizontal air outlet

point so that the cold air diffuses in whole room.

[In Heating operation]

In heating operation, move the flap with hands and use the horizontal flap with

downward set point so that the hot air blows at the foot.

Adjustment of air direction rightward/leftward

[In case of using unsymmetrical air directions]

Lift up the vertical flap lightly, direct it toward the desired

direction, and lower it.

In this case, do not use the Swing function.

2

1

[In case of automatic swing]

1

2

3

SWING/FIX

Push

button during operation.

• [SWING ] is displayed and the air direc-

tion automatically changes rightward/

leftward.

In case when one remote controller controls

the multiple indoor units, each indoor unit

can be selected and its air direction can be

set up.

SWING/FIX

Push

button again during swinging

of the horizontal flap.

• The horizontal flap can be stopped at the

desired position.

Swing button

• To set up the air direction individually, push

UNIT

button to display each indoor unit No.

UNIT

in a group control. Then set up the air

direction to a displayed indoor unit.

• If there is no display, all the indoor units can

be operated collectively.

• Every pushing

UNIT

button, the display

exchanges as shown in the figure.

In this case, do not use the

swing function.

TEMP.

FAN

SWING/FIXTIME

UNITSET CL

FIL TER

RESET

TIMER SET

TEST

1, 2 3

Unit No. 1-1No display Unit No. 1-2

Unit No. 1-4 Unit No. 1-3

ON / OFF

MODE

VENT

INFORMATION

• If cooling operation is performed with downward air outlet, dew may fall on surface of the cabinet or the

horizontal flap resulted in dripping.

• If heating operation is performed with horizontal air outlet, une venness of temperature may increase in

the room.

• Do not move the flap directly with hands during swing operation; otherwise a trouble is caused.

The vertical flap does not stop immediately even if the

position, push the

SWING/FIX

button.

15

SWING/FIX

button is pushed. Adjusting the stop

TIMER OPERATION

A type of timer operation can be selected from the following three types .

OFF timer : The operation stops when the time of timer has reached the set time.

Repeat OFF timer : Every time, the operation stops after the set time has passed.

ON timer : The operation starts when the time of timer has reached the set time.

Timer operation

1

FILTER

RESET

1

Push TIMER SET button.

• The timer display (type) changes for every

push of the button.

• SET DATA and timer time displays flash.

2

Push

TIME

to select “SET TIME”.

TEMP.

TEST

TIMER SET

3

4

ON / OFF

FAN

SWING/FIXTIME

UNITSET CL

MODE

VENT

2

OFF

(OFF timer) (Repeat OFF timer)

OFF ON

No display

(ON timer)

For e very push of button, the set time increases in the unit of 0.5 hr (30 minutes).

The maximum set time is 72.0 hr.

For e very push of button, the set time decreases in the unit of 0.5 hr (30 minutes).

The minimum set time is 0.5 hr.

3

Push SET button.

SETTING

•

display disappears and timer time displa y goes on.

(When ON timer is activated, timer time, ON timer are displayed and other displays disappear.)

Cancel of timer operation

4

Push CL button.

• TIMER display disappears.

NOTICE

• When the operation stops after the timer reached the preset time, the Repeat OFF timer resumes the

operation by pushing

the set time.

ON / OFF

button and stops the operation after the time of the timer has reached

16

INSTALLATION

Installation location

WARNING

• Select a location for installation that will be able to safely bear the weight of the unit.

If the installation location is not strong enough to support the unit and the unit falls, injury could result.

CAUTION

• Do not install the unit in a location where combustible gases could conceivably leak.

Leaking gases that accumulate in the vicinity of the unit could be ignited by the unit.

REQUIREMENT

• A location that permits level installation of the unit

• A location that provides enough space to service the unit safely

• A location where water draining from the unit will not pose a problem

Avoid the following types of locations :

• Locations where salt is present in large amounts (seaside areas), or where sulfuric gases are present in

large amounts (hot springs areas)

(If the unit is to be used in such areas, special maintenance is necessary.)

• Locations that generate oils (including machine oils), steam, oily smoke, or corrosive gases

• Locations where organic solvents are used

• Locations in the vicinity of equipment that generates high frequency signals

• Locations where the outdoor unit will blow in the direction of a neighbor's window

• Locations where the noise of the outdoor unit will pose a problem

• Locations with poor air circulation

Electric wiring

WARNING

Check that earthing practice is correctly performed.

Grounding is necessary . If earthing practice is incomplete, an electric shock may be caused.

CAUTION

Check the circuit breaker is fitted.

Attaching the earth leakage breaker is necessary. Otherwise, an electric shock may be caused.

Make sure that correct capacity Fuses are used.

Using wire or copper wire may cause a fire or trouble .

For the power supply, use a circuit with rated voltage exclusive for air conditioner.

To disconnect the appliance from the main power supply.

This appliance must be connected to the main power supply b y means of circuit breaker or a switch with a

contact separation of at least 3mm.

17

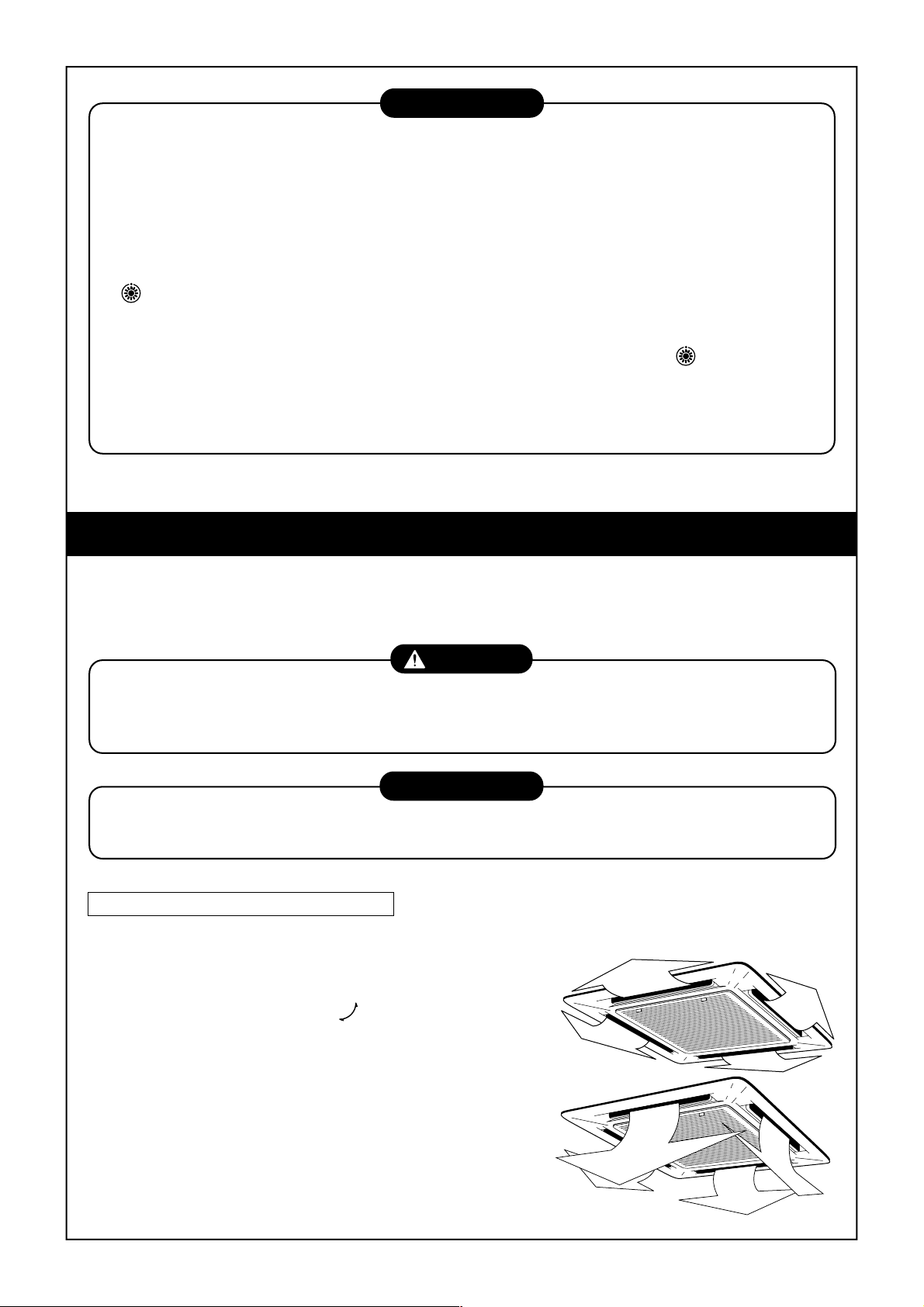

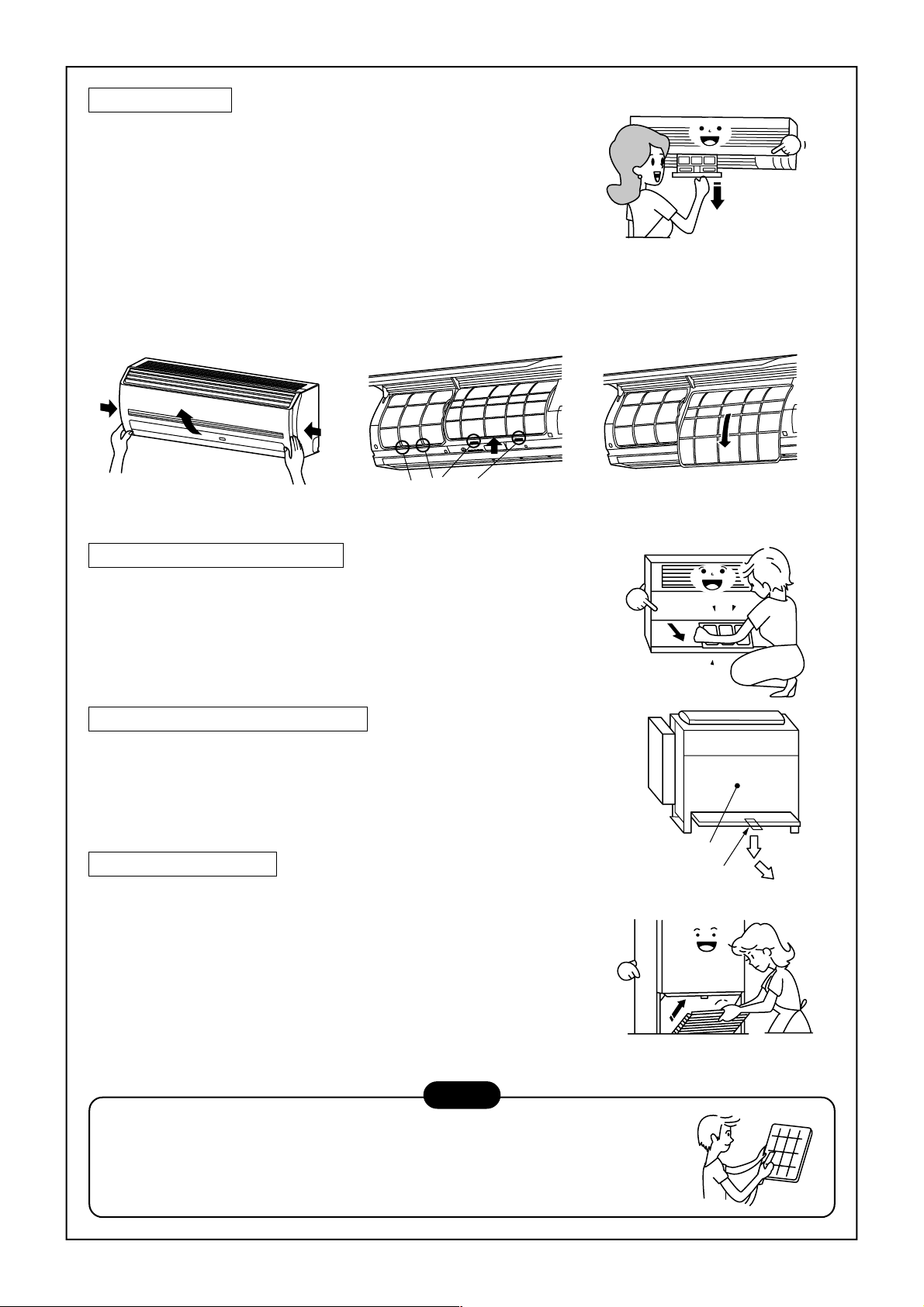

MAINTENANCE

Cleaning of air filter

• When [FILTER] is displayed on the remote controller, maintain the air filter.

• Clogging of air filter decreases cooling/heating effect.

CODE No.

ON / OFF

MODE

VENT

FILTER display

Notifies the time to clean the air filter.

FILTER reset

Push the FILTER switch after cleaning.

“FILTER” display disappears.

SET

FILTER

RESET

DATA

H

TEMP.

TEST

SETTING

TEST

TIMER SET

UNIT No.

R.C. No.

FAN

SWING/FIXTIME

UNITSET CL

WARNING

Be sure to turn off the main power switch prior to the maintenance.

• Please do not intend to do the daily maintenance and/or Air Filter cleaning by yourself.

Cleaning of the air filter and other parts of the air filter involves dangerous work in high places, so be

sure to have a service person do it. Do not attempt it yourself.

<Daily maintenance>

• For daily maintenance including Air Filter cleaning, make sure to ask the qualified service person particularly following models;

4-way Air Discharge Cassette Type Concealed Duct Type Under Ceiling Type

2-way Air Discharge Cassette Type Slim Duct Type

1-way Air Discharge Cassette Type Concealed Duct, High Static Pressure Type

NO GOOD

NO GOOD

2-way Air Discharge

Cassette Type

4-way Air Discharge

Cassette Type

NO GOOD

NO GOOD NO GOOD

Concealed Duct Type

Under Ceiling Type Slim Duct Type

18

NO GOOD

1-way Air Discharge

Cassette Type

NO GOOD

Concealed Duct,

High Static Pressure Type

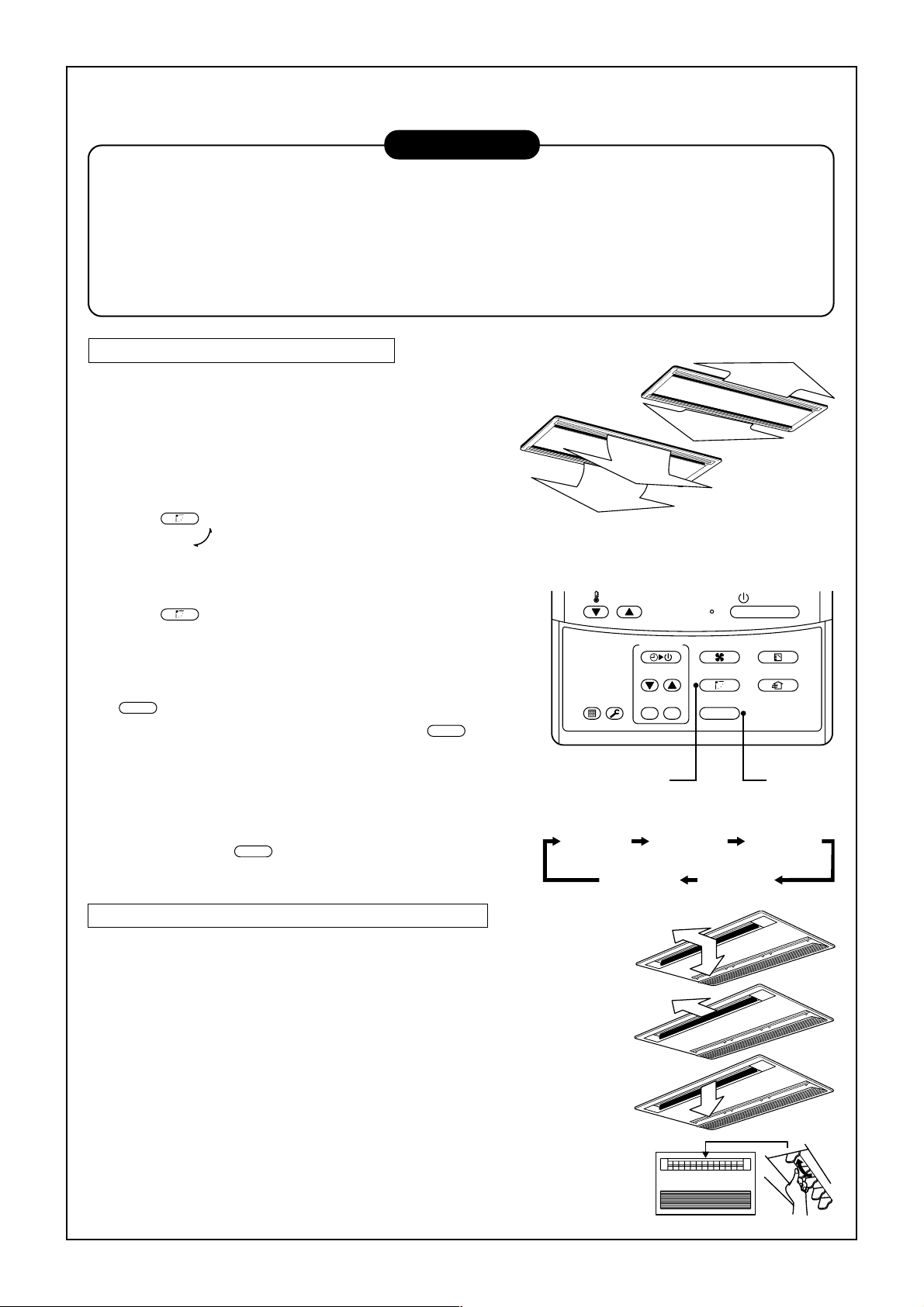

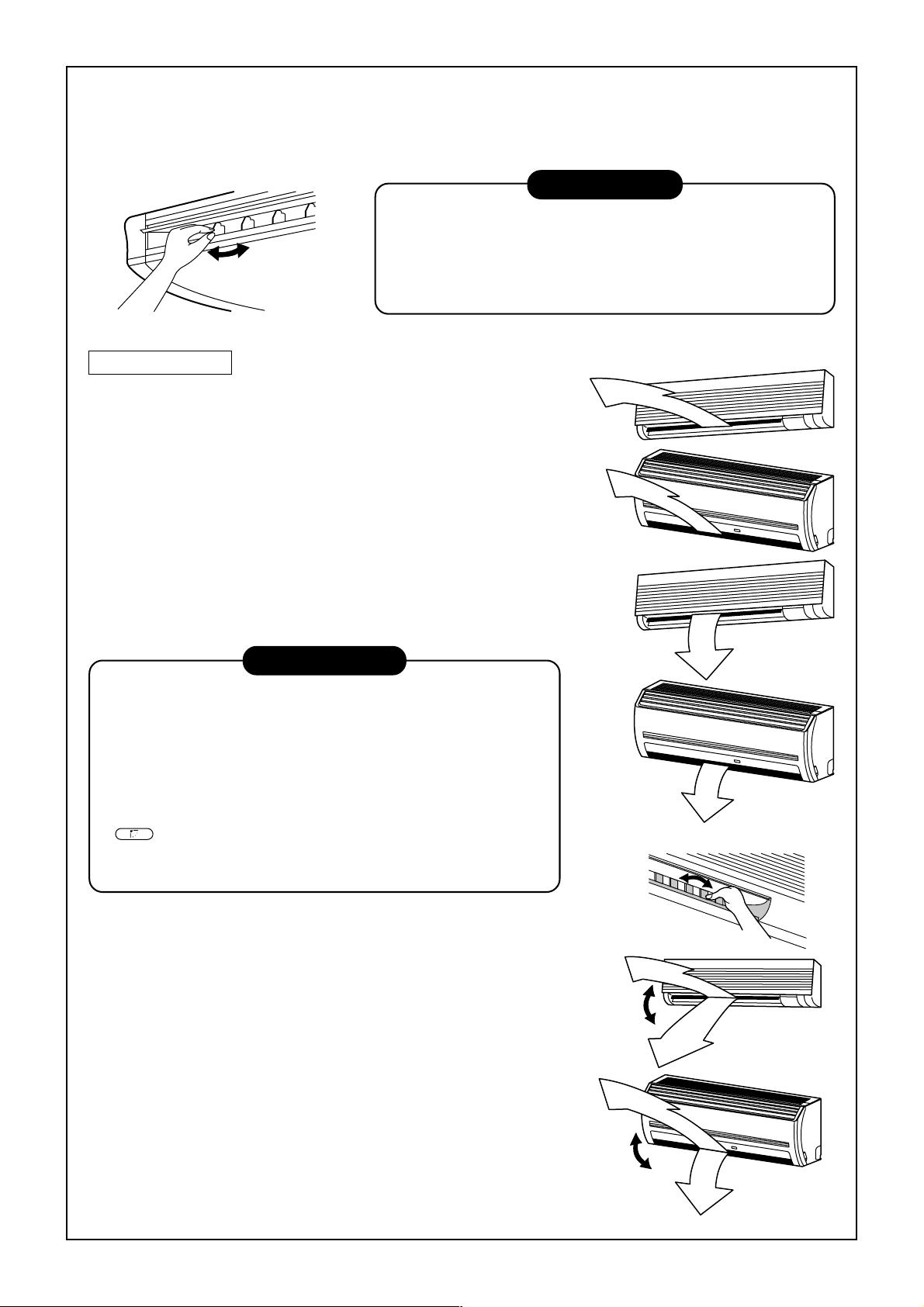

High Wall T ype

(Model : 1H series)

• Push the projection at the center of air filter. Clip is out.

• Undo the clip of air filter, pull the air filter downward while pushing it

toward the main unit side.

(Model : 2H series)

• Open the air inlet grille.

Lift the air inlet grille up to the horizontal position.

• Take hold of the left and right handles of the air filter and lift it up

slightly, then pull downward to take it out from the filter holder.

Filter holder

Push the air filter,

and pull it downward.

Floor Standing Cabinet Type

• Push down the upper part of the suction port a little, and then pull

toward you to remo ve it.

• Take out the air filter inside of the suction port.

Floor Standing Concealed Type

• Push down hook of the air filter on the front panel (Lower side).

• Pull the air filter toward you to remove it.

Floor Standing Type

Removal / Attachment of air filter

• Pull the air filter toward you.

• To attach the air filter, insert it into the main body

and push in it.

Front panel

(Lower)

Air filter knob

NOTE

• For cleaning of air filter, use a cleaner or brush clean. If stain is heavy,

it is effectiv e to w ash the air filter in tepid w ater mixed with neutral detergent.

• After washing, rinse it well, and dry it in the shade.

• Install again the air filter which has been cleaned.

19

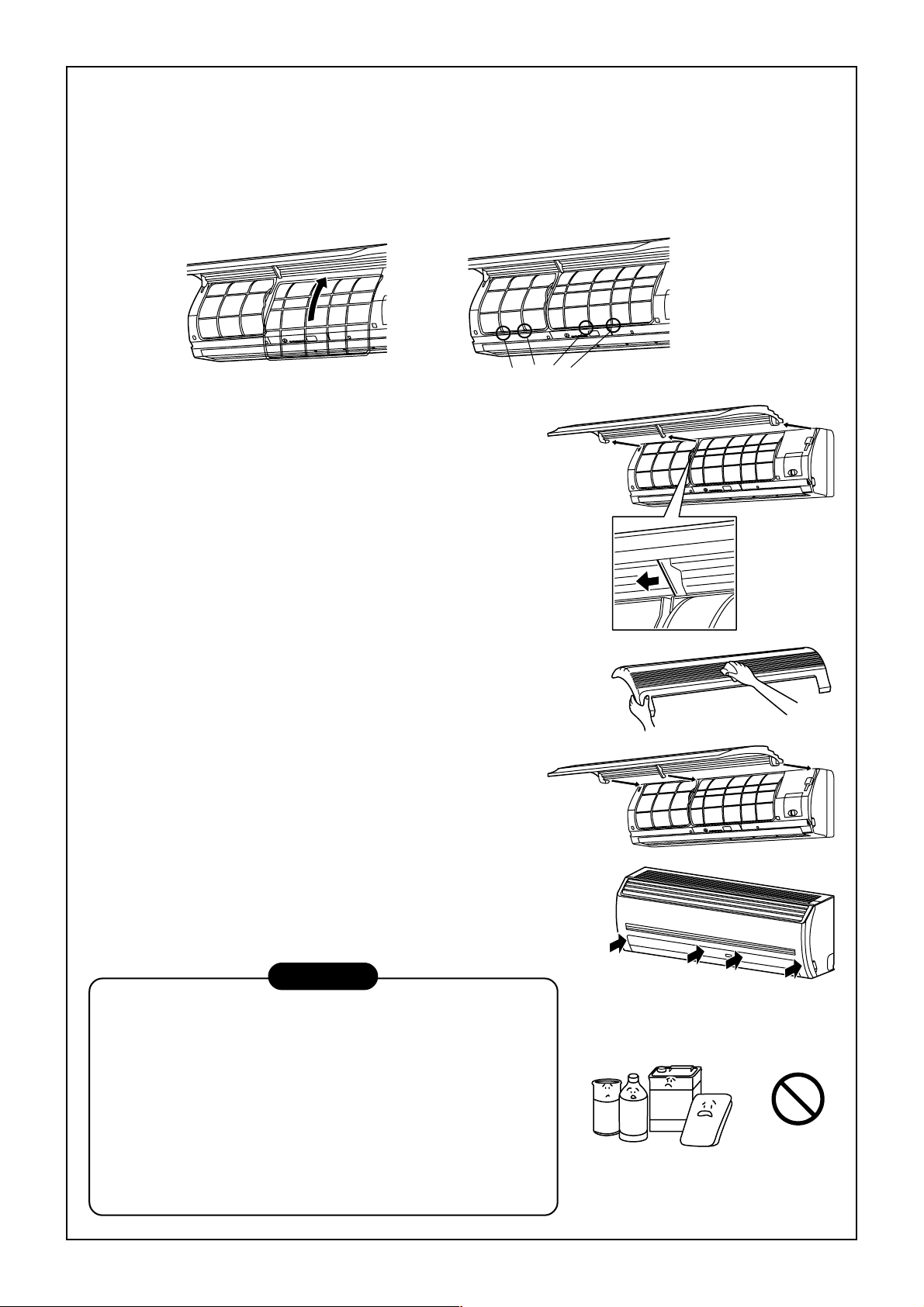

Return the air filter

• Insert the upper portion of air filter confirming to fit it is right and left edges on the indoor unit until it is firmly

set.

• Close the air inlet grille.

If the FILTER lamp on the indoor unit is indicated, press the FILTER button on the remote controller or the

TEMPORARY button on the indoor unit to turn off the lamp.

Filter holder

Cleaning the air inlet grille

1. Remove the air inlet grille.

Hold the two sides of the air inlet grille and open upwards.

Move the center arm to the left and remove the g rille.

2. Wash it with water using a soft sponge or towel.

(Do not use metallic scrubbing brush or other hard brushes.)

• Use of such hard objects will cause scratches on the

surface of the grille, and the metal coating to peel off.

• If very dirty, clean the air inlet g rille with a neutral detergent

for kitchen use, and rinse it off with water.

3. Wipe out water from the air inlet grille and dry it.

4. Fit the left and right arms of the air inlet grille to the shafts on

the two sides of the air conditioner and push in completely,

and then push in the center arm.

5. Chec k that the center arm has been completely inserted and

close the air inlet grille.

• Push the arrow locations (Four) at the bottom of the air

inlet grille to check whether the grill is completely closed.

Cleaning of main unit / remote controller

CAUTION

• Wipe them with soft and dry cloth.

• A cloth dampened with cold water may be used on the indoor

unit if it is very dirty.

• Never use a damp cloth on the main unit and remote controller.

• Do not use a chemically-treated duster for wiping or leave such

materials on the unit for long. It may damage or fade the

surface of the unit.

• Do not use benzine, thinner , polishing po wder, or similar

solvents f or cleaning. These may cause the plastic surface to

crack or def orm.

20

Polishing

powder

Benzene

Thinner

Chemical

floor-cloth

Do not use.

If you do not plan to use the unit for more than 1 month

1. Operate the fan for 3 to 4 hours to dry inside the unit

• Operate “FAN” mode.

2. Stop the air conditioner and turn off the main power switch

or the circuit breaker.

I will wipe soft

and dry cloth!

Checks before operation

1. Chec k that the air filters are installed.

2. Chec k that the air outlet or inlet is not blocked.

3. Turn on the main power switch or the circuit breaker for the

main power supply to the air conditioner.

Use after drying

when it has not been

used for a long time!

NOTE

For Air conditioning system which is operated regularly, cleaning and maintenance of the indoor/outdoor

units are strongly recommended.

As a general rule, if an indoor unit is operated for about 8 hours daily, the indoor/outdoor units will need to

be cleaned at least once every 3-MONTH. This cleaning and maintenance shall be carried out by a

qualified person.

Failure to clean the indoor/outdoor units regularly will result in poor performance, icing, water leaking and

ev en compressor failure.

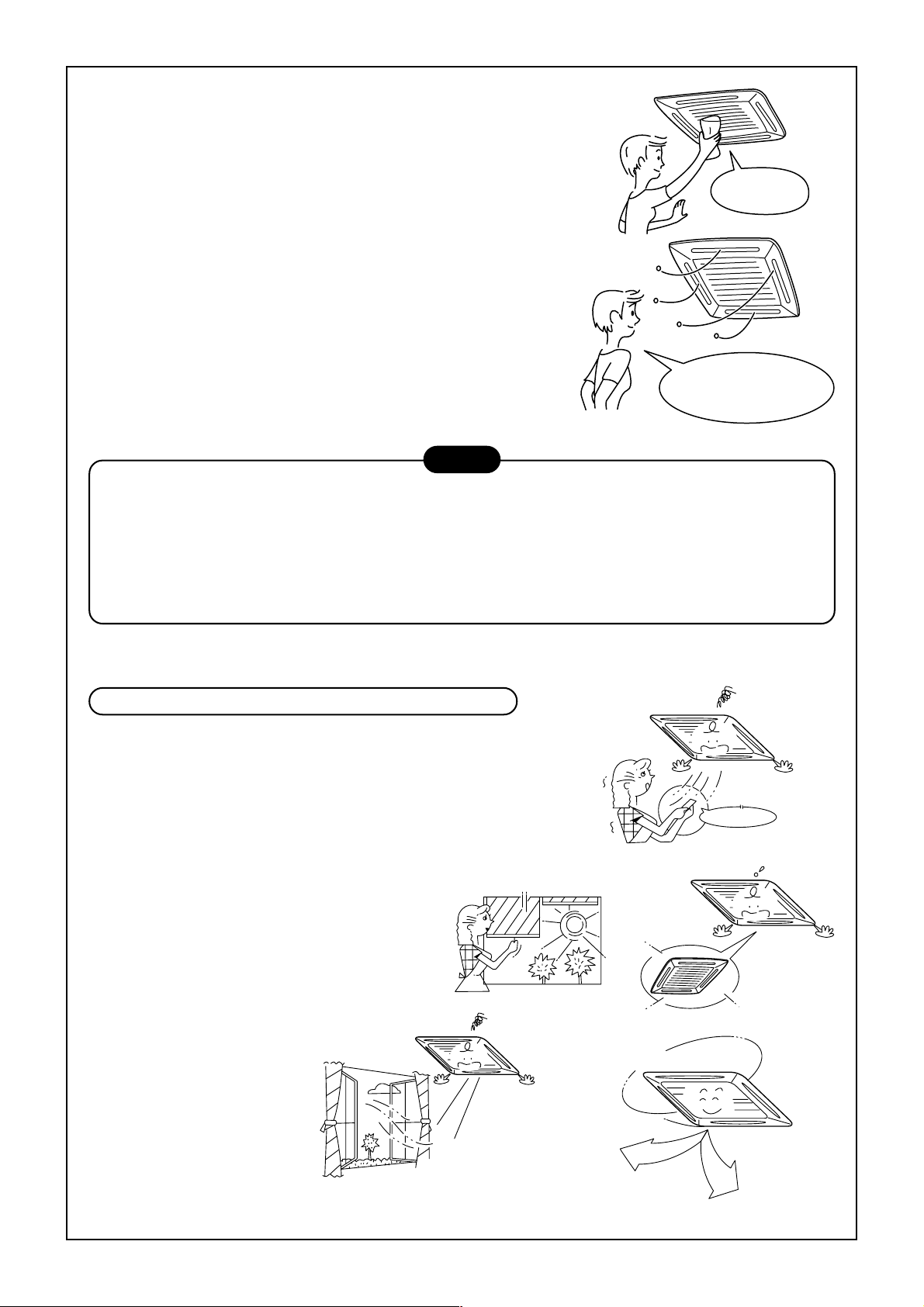

HINTS FOR ECONOMICAL OPERATION

Maintain room temperature at comfortable level

Clean air filters

The clogged air filter impairs the performance of the air conditioner.

Never open doors and windows more often than necessary

To keep cool or warm air in the room, never open doors and

windows more often than necessary.

Window curtains

In cooling, close the curtains to avoid direct sunlight.

In heating, close the curtains to keep the heat in.

Get uniform circulation of room air

Adjust the air flow direction for the even

circulation of room air.

Please close

Clean, please.

Blows upward

Cool and

dry air

Gee, chilly

Control

Air flow adjustment

Warm

air

21

Blows downward

AIR CONDITIONER OPERATIONS AND PERFORMANCE

Check before operation

• Check whether earth wire is disconnected or out of place.

• Check that air filter is installed to the indoor unit.

Heating capacity

• For heating, a heat pump system which sucks in outside heat air

and discharges it into the room is adopted.

If temperature of the outside air lowers, the heating capacity decreases.

• When temperature of the outside air is low, it is recommended to use other heating equipment together.

Turn on the power switch

12 hours or more before

starting before operation.

WARNING

Defrost operation during heating operation

• If the outdoor unit has some frost during heating operation, the operation mode changes automatically to

defrost mode to increase the heating effect (f or approx. 2 to 10 minutes).

• During defrost operation, fans of the indoor and the outdoor units stop.

Protection for 3 minutes

• The outdoor unit does not operate for approx. 3 minutes after air conditioner has been immediately restarted

after stop, or power switch has been turned on. This is to protect the system.

Main power failure

• If a power failure occurred during the operation, all operations stop.

• When restarting the operation, push ON/OFF button again.

Fan rotation of stopped unit

• While other indoor units operate, the fan on indoor units on “stand-by” rotates to protect the machine once

per approx. 1 hour for several minutes.

Protective device (High pressure switch)

The high pressure switch stops the air conditioner automatically when excessive load is applied to the air

conditioner.

If the protective de vice w orks, the operation lamp keeps lit but the operation stops.

When the protective device w orks, check characters “ ” in the remote controller display part flash.

The protective device may work in the following cases.

• When suction or discharge port of the outdoor unit closed.

• When strong wind blows continuously against discharge port of the outdoor unit.

• When dust or dirt is excessively adhered to air filter of the indoor unit.

• When discharge port of the indoor unit is blocked.

Cooling/heating operation of Heat Recovery Multi air conditioner

• When the outdoor temperature goes out of the operable range, cooling or heating operation may not be

performed in order to protect the equipment. In this case, “ ” goes on.

Characteristics of heating operation

• Hot air is not out immediately after the operation has started. After 3 to 5 minutes (differs according to room

or outside temperature) has passed and the indoor heat exchanger has been warmed up, hot air blows out.

• During operation, the outdoor unit may stop if outside temperature becomes high.

• When other outdoor unit performs heating operation while the fan is operating, the f an oper ation may be

stopped temporarily to prevent b l owing of hot air.

Characteristics of cooling/heating simultaneous operation

• If the outdoor temperature drops during operation, the fan of the outdoor unit may stop.

22

Air conditioner operating conditions

For proper perf ormance, operate the air conditioner under the f ollo wing temperature conditions:

Cooling Outdoor temperature : –10°C to 43°C (Dry-bulb temp.)

operation

Heating Outdoor temperature : –15°C to 21°C (Dry-bulb temp.), –15°C to 15.5°C (Wet-bulb temp.)

operation

• If air conditioner is used outside of the above conditions, safety protection may work.

* Do not use “Super HRM” for other than personal usage where the ambient temperature may go down below

–5°C. (For example, OA equipment/Electric device/Food/Animals and plants/Art object)

Room temperature : 21°C to 32°C (Dr y-bulb temp.), 15°C to 24°C (Wet-bulb temp.)

CAUTION

Room temperature : 15°C to 28°C (Dry-bulb temp.)

Room relative humidity – less than 80 %. If the air conditioner operates

in excess of this figure, the surface o f the air conditioner may cause dewing.

CAUTION

When outdoor temperature goes out of specified range, “ or ” mark is indicated on the Wired remote

controller display and required operation will stop .

“ & ” : When heating operation. “ ” : When cooling operation.

Notice :

• This indication is not failure.

• When outdoor temperature goes back to specified range , “ or ” disappear and start normal operation.

• Operation stops because concurrent operation can not be kept in the condition of out of specification for

Super HRM.

(Outdoor temp. (DB) < –10°C : Cooling, > 21°C : Heating)

RE-INSTALLATION

DANGER

Ask the dealer or an installation professional to re-install the air conditioner to a new place or

move it to another place and to observe the following items.

If the air conditioner is inappropriate installed by yourself, it ma y cause electric shock or fire.

Do not install the air conditioner in the following places

• Do not install the air conditioner in any place within 1 m from a TV, stereo, or radio set. If the unit is installed in

such place, noise transmitted from the air conditioner affects the operation of these appliances.

• Do not install the air conditioner near a high frequency appliance (sewing machine or massager for business

use, etc.), otherwise the air conditioner may malfunction.

• Do not install the air conditioner in a humid or oily place, or in a place where steam, soot, or corrosive gas is

generated.

• Do not install the air conditioner in a salty place such as seaside area.

• Do not install the air conditioner in a place where a great deal of machine oil is used.

• Do not install the air conditioner in a place where it is usually exposed to strong wind such as in seaside area or

on the roof or upper floor of a building.

• Do not install the air conditioner in a place where sulfureous gas generated such as in a spa.

• Do not install the air conditioner in a vessel or mobile crane.

Be careful with noise or vibrations

• Do not install the air conditioner in a place where noise by outdoor

unit or hot air from its air outlet annoys your neighbors.

• Install the air conditioner on a solid and stable foundation so that it

prevents transmission of resonating, operation noise and vibration.

• If one indoor unit is operating, some sound may be audible from

other indoor units that are not operating.

23

WHEN THE FOLLOWING SYMPTOMS ARE FOUND

Check the points described below before asking repair servicing.

Symptom

Outdoor unit • White misty cold air or

water is out.

• Sometimes, noise

“Pushu !” is heard.

Indoor unit •“Swish” sound is

heard sometimes.

• Slight “Pishi!” sound is

heard.

• Discharge air smells.

•“

” indication is lit.

It is not a failure.

• Sound or cool air is

output from the stand

by indoor unit.

• When power of the air

conditioner is turned

on, “Ticktock” sound is

heard.

Cause

• Fan of the outdoor unit stops automatically and performs defrost

operation.

• Solenoid valve works when defrost operation starts or finishes.

• When the operation has started, during the operation, or immedi-

ately after the operation has stopped, a sound such as water flows

may be heard, and the operation sound may become larger for 2 or

3 minutes immediately after the operation has started. They are

flowing sound of refrigerant or draining sound of dehumidifier.

• This is sound generated when heat exchanger, etc. expand and

contract slightly due to change of temperature.

• Various smell such as one of wall, carpet, clothes, cigarette, or

cosmetics adhere to the air conditioner.

• Do not the outdoor temperature go out of the specified range?

• When the manager of the air conditioner has fixed the operation to

COOL or HEAT, and an operation contrary to the setup operation is

performed.

• When fan operation stopped to prevent discharge of hot air.

• Since refrigerant is flowed temporarily to prevent stay of oil or

refrigerant in the stand by indoor unit, sound of flowing refrigerant,

“Kyururu” or “Shaa” may be heard or white steam when other indoor

unit operates in HEAT mode, and cold air in COOL mode may be

blow-out.

• Sound is generated when the expansion valve operates when

power has been turned on.

Operates or stops automatically.

Does not operate.

Silent

Air is not cooled or warmed sufficiently.

Check again.

It’s strange.

• Is the timer “ON” or “OFF”?

• Is it a power failure?

• Is the power switch turned off?

• Is the power fuse or breaker blown?

• Has the protective device operated? (The operation lamp goes on.)

• Is the timer “ON”? (The operation lamp goes on.)

• Do not the outdoor temperature go out of the specified range?

• Is the suction port or discharge port of the outdoor unit obstructed?

• Are any door or window open?

• Is the air filter clogged with dust?

• Is discharge louver of the indoor unit set at appropriate position?

• Is air selection set to “LOW” “MED”, and is the operation mode set

to “FAN”?

• Is the setup temp. the appropriate temperature?

• Do not the outdoor temperature go out of the specified range?

When the following symptoms are found, stop the operation immediately, turn off the power switch, and

contact the dealer which you hav e purchased the air conditioner.

• Activation of switch is unstable.

• The main power fuse often blo ws out, or circuit breaker is often activated.

• Foreign matters or water entered b y mistake.

• When if activation cause of the protective device has been removed, the operation is not performed.

• Other unusual status occurred.

24

Confirmation and check

When a trouble occurred in the air conditioner, the

check code and the indoor unit No . appear on the

display part of the remote controller.

The check code is only displayed during the operation.

If the display disappears, operate the air conditioner according to the following “Confirmation of

error history” for confirmation.

Confirmation of error history

When a trouble occurred on the air conditioner, the

trouble history can be confirmed with the following

procedure. (The trouble history is stored in memory

up to 4 troubles.)

The history can be confirmed from both operating

status and stop status.

2

Check code

TEMP.

FILTER

TEST

RESET

UNIT No.

R.C. No.

Indoor unit No. in which

an error occurred

TIMER SET

FAN

SWING/FIXTIME

UNITSET CL

CODE No.

ON / OFF

MODE

VENT

Procedure

1

2

3

Description

When pushing

seconds or more, the following display appears.

If [Service check] is displayed, the mode enters in the

trouble history mode.

• [01 : Order of trouble history] is displayed in CODE No.

window.

• [Check code] is displayed in CHECK window.

• [Indoor unit address in which an error occurred] is

displayed in UNIT No.

Every pushing of [ , ] button used to set temperature, the trouble history stored in memory is

displayed in order.

The numbers in CODE No. indicate CODE No. [01] (latest) → [04] (oldest).

CAUTION

Do not push

SET

CL

TEST

and

button because all the trouble history of the indoor unit will be deleted.

buttons at the same time for 4

UNIT No.

R.C. No.

CODE No.

1

3

After confirmation, push

TEST

button to return to the usual display.

1. Chec k the troubles according to the above procedure.

2. Ask an authorized dealer or qualified service (maintenance) professional to repair or maintain the air

conditioner.

3. More details of the service code are explained in Service Manual.

25

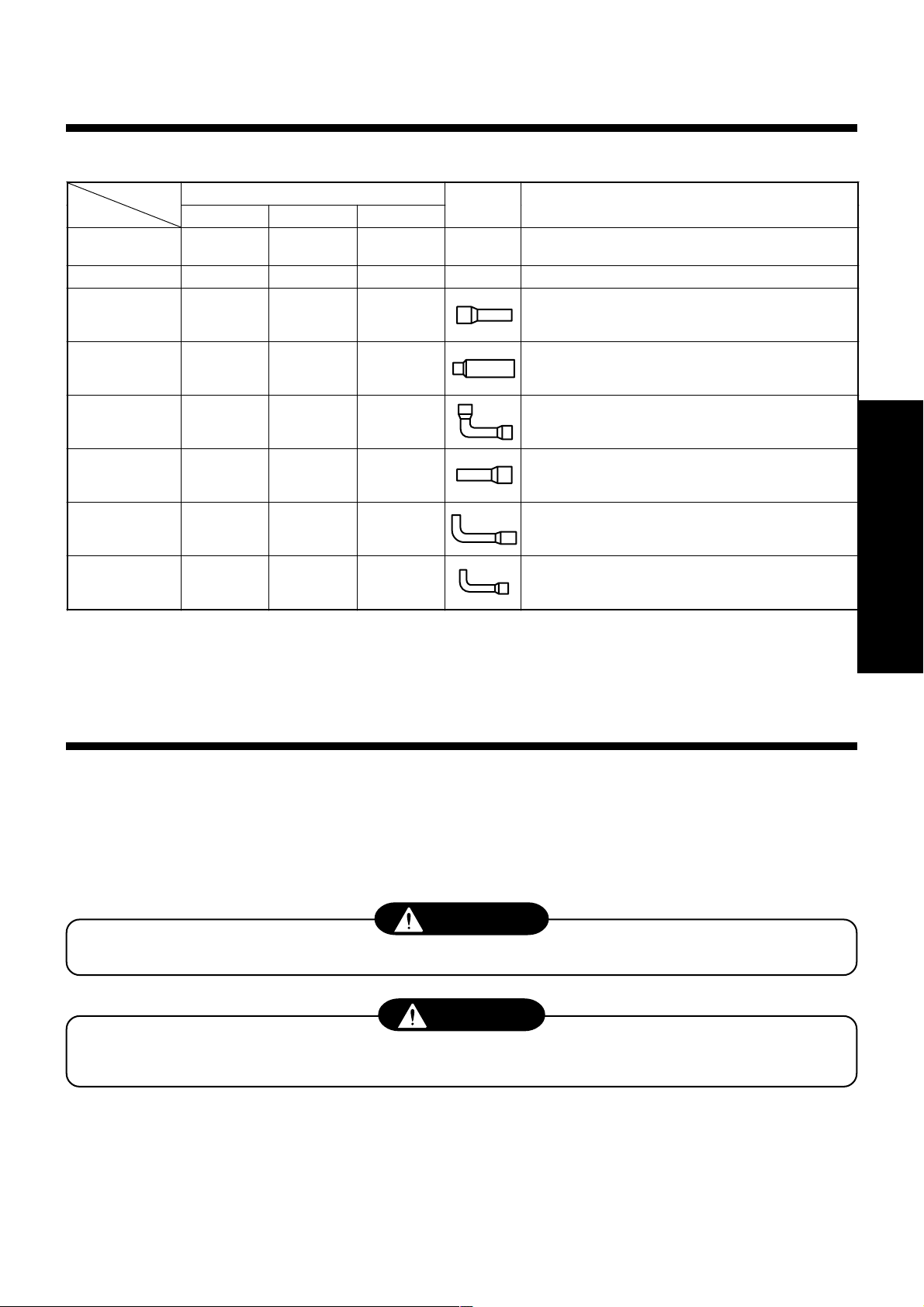

ACCESSORY PARTS

r Accessory parts

MMY-

Part name

Installation Manual 2 2 2

Owner’s Manual 1 1 1 — (Be sure to handover to customers.)

Attached pipe 1 1 —

Attached pipe ——1

Attached pipe ——1

Attached pipe 1 1 1

Attached pipe 1 1 1

Attached pipe 1 1 1

MAP0802FT8 MAP1002FT8 MAP1202FT8

Q’ty

Shape Use

Volume-1

Volume-2

(Be sure to handover to customers.)

Suction gas pipe Ø25 to Ø22 special-form connecting pipe

(For drawing out forward, downward)

Suction gas pipe Ø25 to Ø28.6 special-form connecting pipe

(For drawing out forward)

Suction gas pipe Ø25 to Ø28.6 special-form connecting pipe

(For drawing out downward)

Discharge gas pipe Ø15.9 to Ø19.1 special-form connecting

pipe (For drawing out downward)

Discharge gas pipe Ø15.9 to Ø19.1 special-form connecting

pipe (For drawing out forward)

Liquid pipe Ø12.7 connecting pipe

(For drawing out forward)

n This air conditioner requires the indoor unit, remote controller, Flow selector unit, and

Y-shape branching joint or branching header. Select one according to the capacity.

INSTALLATION

OUTDOOR (VOLUME-1)

SAFETY CAUTION

• Please read this “Safety Cautions” thoroughly before installation to install the air conditioner

and flow selector correctly.

• The important contents concerned to the safety are described in the “Safety Cautions”.

Be sure to keep them. For Indications and their meanings, see the following description.

n Explanation of indications

WARNING

Indicates possibilities that a death or serious injury of personnel is caused by an incorrect handling.

CAUTION

Indicates contents that an injury (∗1) or property damage (∗2) only may be caused when an incorrect work has

been executed.

*1 : “Injury” means a hurt, a burn, or an electric shock which does not require hospitalization or a long-term going to

the hospital.

*2 : “Property damage means an enlarged damage concerned to property, or breakage of materials.

• After installation work has finished, check there is no trouble by a test operation, and explain

using method and maintenance method to the customers based on the Owner’s Manual.

Please ask the customers to keep this Installation Manual together with the Owner’s Manual.

26

SAFETY CAUTION

WARNING

Ask a shop or a professional dealer to install the air conditioner.

If you will install by yourself, a fire, an electric shock, or water leak is caused.

Using the tool or piping materials exclusive to R410A, install the air conditioner surely

according to this Installation Manual.

The pressure of the used HFC system R410A refrigerant is higher approx. 1.6 times of that of the former refrigerant.

If the exclusive piping materials are not used, or there is imperfection in installation, a crack or an injury is

caused and also a water leak, an electric shock, or a fire may be caused.

Take measures so that the refrigerant does not exceed the limit concentration even if it leaks

when installing the air conditioner in a small room.

For the measures not to exceed the limit of concentration, contact the dealer. If the refrigerant leaks and it

exceeds the limit of concentration, an accident of oxygen shortage is caused.

Install the air conditioner at a place which is satisfactorily bearable to weight.

If strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work against a strong wind such as typhoon or earthquake.

If the air conditioner is imperfectly installed, an accident by falling or dropping may be caused.

If refrigerant gas leaks during installation work, ventilate the room.

If the leaked refrigerant gas approaches to fire, noxious gas may generate.

After installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks in the room, and approaches to fire such as fan heater, stove or kitchen range,

generation of noxious gas may be caused.

Never recover refrigerant in the outdoor unit.

Be sure to use a refrigerant recovery device to recover refrigerant in reinstallation or repair work.

Recovery of refrigerant in the outdoor unit is unavailable; otherwise a serious accident such as crack or human

injury is caused.

A person qualified for the electric work should deal with the electric construction conforming

to the regulations of the local electric company and the Installation Manual. Be sure to use the

exclusive circuit.

If there is capacity shortage of the power supply circuit or incomplete installation, a fire or an electric shock is

caused.

For cabling, use the specified cables and connect them securely so that external force of

cable does not transmit to the terminal connecting section.

If connection or fixing is incomplete, a fire, etc may be caused.

Be sure to connect earth wire.

Do not connect earth wire to gas pipe, water pipe, lightning rod, nor earth wire of telephone.

If grounding is incomplete, an electric shock is caused.

CAUTION

Do not install the air conditioner at a place where combustible gas may leak.

If gas leaks and is collected at surrounding the unit, the production of fire may be caused.

Be sure to attach an earth leakage breaker; otherwise an electric shock may be caused.

Using a torque wrench, tighten the flare nut in the specified method.

If the flare nut is exceedingly tightened, the flare nut is broken and a refrigerant leakage may be caused after a

long time has passed.

27

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

• R410A refrigerant is apt to be affected by impurity such as water, oxidizing membrane, or oils because the

pressure of R410A refrigerant is higher than that of the former refrigerant by approx. 1.6 times. Accompanied with

adoption of the new refrigerant, refrigerating oil has been also changed. Therefore pay attention so that water,

dust, former refrigerant, or refrigerating oil does not enter into the refrigerating cycle of the new refrigerant air

conditioner during installation work.

• To prevent from mixing of refrigerant or refrigerating oil, the size of charge port of the main unit or connecting

section of installation tool differs from that of the air conditioner for the former refrigerant. Accordingly the

exclusive tools are required for the new refrigerant (R410A) as shown below.

• For connecting pipes, use the new and clean piping materials so that water or dust does not enter.

Required tools and cautions on handling

It is necessary to prepare the tools and parts as described below for the installation work.

The tools and parts which will be newly prepared in the following items should be restricted to the exclusive use.

Explanation of symbols