UCC1858

UCC2858

UCC3858

PRELIMINARY

DESCRIPTION

The UCC3858 provides all of the control functions necessary for active

power factor corrected preregulators which require high efficiency at low

power operation. The controller achieves near unity power factor by

shaping the AC input line current waveform to correspond to the AC input

line voltage using average current mode control.

The operation of the UCC3858 closely resembles that of previously designed Unitrode PFC parts with additional features to allow higher efficiency boost converter operation at light loads. This is accomplished by

linearly scaling back the PWM frequency when the output of the voltage

error amplifier drops below a predetermined user programmable level indicating a light load condition. The frequency is scaled back by reducing

the charging current for the CT ramp (in proportion to the output power),

and increasing the dead time. There is also an instantaneous reset input

to pull the IC out of foldback mode quickly when the load comes back up.

The PWM technique used in the UCC3858 is leading edge modulation.

When combined with the more conventional trailing edge modulation on

the downstream converter, this scheme offers the benefit of reduced ripple current on the bulk storage capacitor. The oscillator is designed for

easy synchronization to the downstream converter. A simple synchronization scheme can be implemented by connecting the PWM output of

the downstream converter to the SYNC pin.

(continued)

High Efficiency, High Power Factor Preregulator

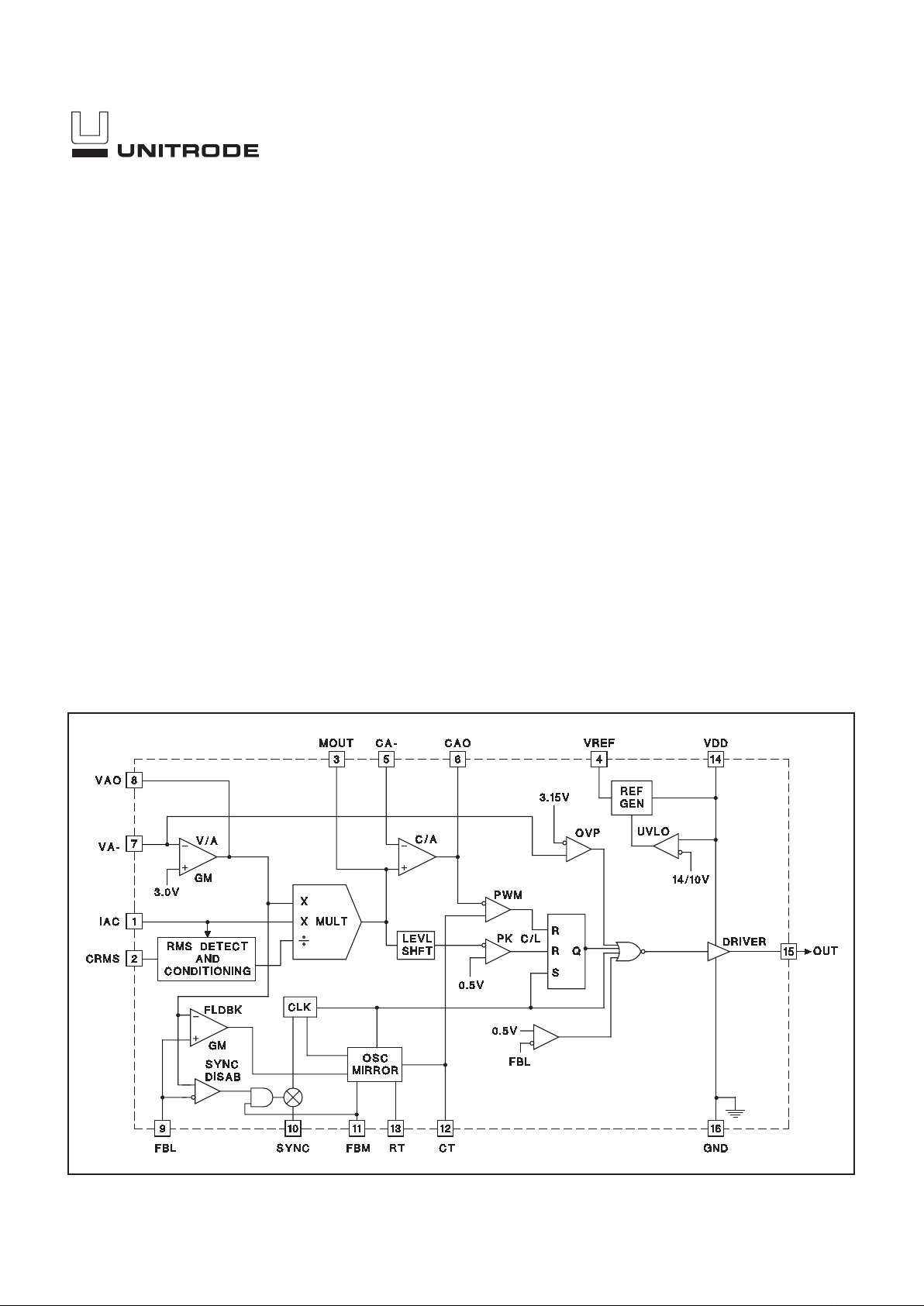

BLOCK DIAGRAM

FEATURES

• Programmable PWM Frequency

Foldback for Higher Efficiency at Light

Loads

• Leading Edge PWM for Reduced

Output Capacitor Ripple Current

• Controls Boost PWM to Near Unity

Power Factor

• World Wide Operation without

Switches

• Accurate Power Limiting

• Synchronizable Oscillator

• 100µA Startup Supply Current

• Low Power BCDMOS

• 12V to 18V Operation

03/99

UDG-96191-1

2

UCC1858

UCC2858

UCC3858

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18V

Gate Drive Current

Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2A

Pulsed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500mA

Input Current IAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200mA

Power Dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1W

Storage Temperature . . . . . . . . . . . . . . . . . . . −65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . −55°C to +150°C

Lead Temperature (Soldering, 10 Sec.). . . . . . . . . . . . . +300°C

Analog Inputs

Maximum Forced Voltage . . . . . . . . . . . . . . . . –0.3V to 11V

Unless otherwise indicated, voltages are reference to ground and currents are positive into, negative out of the specified terminal. Pulsed is

defined as a less than 10% duty cycle with a maximum duration of

500ns. Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

Controller improvements include an onboard peak detector for the input line RMS voltage, an integrated

overcurrent shutdown, overvoltage shutdown and significantly lower quiescent operating current. The peak detector eliminates an external 2-pole low pass filter for

RMS detection. This simplifies the converter design as

well as providing an approximate 6X improvement in input line transient response. The current signal is extracted from the current error amplifier input to provide a

cycle-by-cycle peak current limit. Low startup and operating currents which are achieved through the use of

Unitrode’s BCDMOS process simplify the bootstrap

supply design as well as minimize losses in the control

circuit. A transconductance voltage error amplifier allows

output voltage sensing for internal overvoltage protection.

Additional features include: undervoltage lockout for reliable off-line startup, a precision 7.5V reference, and a

precision RMS detection and signal conditioning circuit.

Chip shutdown can be attained by bringing the FBL pin

below 0.5V.

DESCRIPTION (cont.)

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TA= 0°C to 70°C for the

UCC3858, –40°C to +85°C for the UCC2858, and –55°C to +150°C for the UCC1858, V

VDD

= 12V, RT= 24k, CT= 330pF, R

FBM

=

96k, I

IAC

= 100µA, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Overall

Supply Current, Off V

CAO

, V

VAO

= 0V, VDD= UVLO – 0.3V 100 250 µA

Supply Current, On FBL = 0V 2 3.5 5 mA

VDD Turn-On Threshold 12 13.5 15.5 V

VDD Turn-Off Threshold 10 V

UVLO Hysteresis 3.2 3.5 3.8 V

Voltage Amplifier

Input Voltage T

A

= 25°C 2.95 3 3.05 V

Over Voltage Protection Volts Above VA– Input Voltage 0.12 0.14 0.16 V

VA– Bias Current –0.5 –1 µA

Open Loop Gain V

OUT

= 2V to 5V 45 50 dB

VAO High Load = –25µA 5.7 6 6.3 V

VAO Low Load = 25µA 0.3 0.5 V

Output Source Current V

VA

– = 2.8V –50 µA

Output Sink Current V

VA

– = 3.2V 50 µA

Transconductance I

OUT

= ± 50µA 400 600 1000 µS

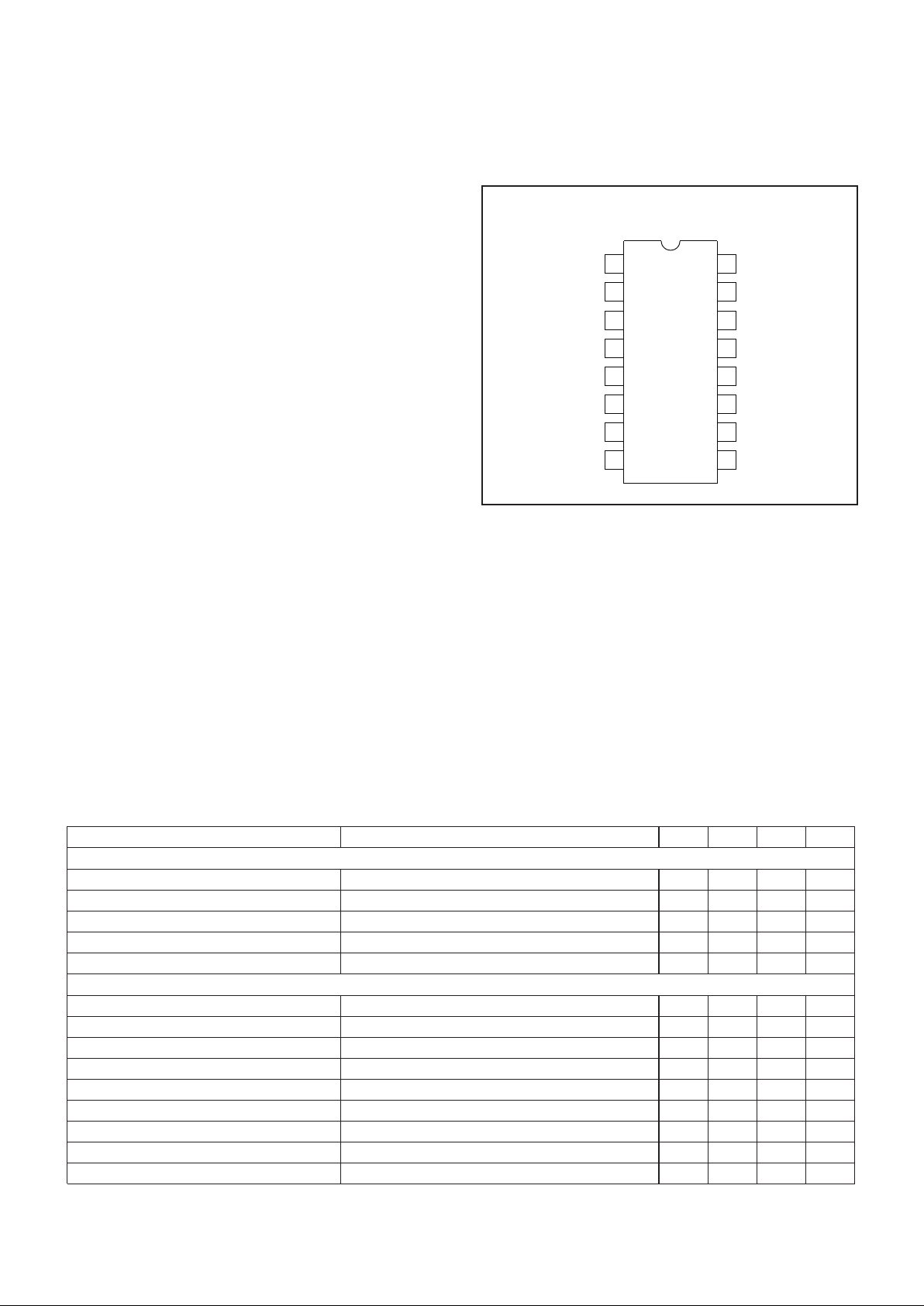

VDD

OUT

GND

RT

CT

SYNC

FBM

FBL

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

CRMS

IAC

VAO

CAO

VA–

MOUT

VREF

CA–

CONNECTION DIAGRAM

DIP-16, SOIC-16 (TOP VIEW)

J, N,DW Packages

3

UCC1858

UCC2858

UCC3858

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TA= 0°C to 70°C for the

UCC3858, –40°C to +85°C for the UCC2858, and –55°C to +150°C for the UCC1858, V

VDD

= 12V, RT= 24k, CT= 330pF, R

FBM

=

96k, I

IAC

= 100µA, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Amplifier

Input Offset Voltage V

CM

= 0V, V

CAO

= 3V –3 0 3 mV

Input Bias Current V

CM

= 0V, V

CAO

= 3V –6.5 –5 µA

Input Offset Current V

CM

= 0V, V

CAO

= 3V –0.5 0.0 0.5 µA

Open Loop Gain V

CM

= 0V, V

CAO

= 2V to 5V 80 90 dB

CMRR V

CM

= 0V to 1.5V, V

CAO

= 3V 65 80 dB

CAO High V

CA

–

= 0V, V

MOUT

= 1V, IL= –50µA 6.5 7 7.5 V

CAO Low V

CA

–

= 1V, V

MOUT

= 0V, IL= 1mA 0.2 0.3 V

Maximum Output Source Current –130 –150 µA

Voltage Reference

Output Voltage I

REF

= 0mA, TA= 25°C 7.313 7.5 7.688 V

Over Temperature, UCC3858 7.294 7.5 7.707 V

Over Temperature, UCC2858, UCC1858 7.239 7.5 7.762 V

Load Regulation I

REF

= 0mA to 2mA 3 5 mV

Line Regulation V

DD

= 12V to 16V 30 mV

Short Circuit Current V

REF

= 0V 35 50 mA

Oscillator

Initial Accuracy TA= 25°C 90 100 110 kHz

Voltage Stability V

DD

= 12V to 16V 1 %

Total Variation Line, Temperature 80 120 kHz

Ramp Amplitude (p-p) Oscillator Free Running, VAO = 5.5V 3.3 3.5 3.7 V

Ramp Peak Voltage Oscillator Free Running, VAO = 5.5V 4.4 4.6 4.8 V

Peak Current Limit

PKLMT Threshold Voltage (V

CA

–)–V

MOUT

350 450 550 mV

PKLMT Hysteresis 100 200 mV

PKLMT Propagation Delay 1 µs

Multiplier Section

High Line, Low Power I

AC

= 100µA, V

CRMS

= 3.5V, VA

OUT

= 1.25V 1 µA

High Line, High Power I

AC

= 100µA, V

CRMS

= 3.5V, VA

OUT

= 5.5V 15 µA

Low Line, Low Power I

AC

= 20µA, V

CRMS

= 0.75V, VA

OUT

= 1.25V 4 µA

Low Line, High Power I

AC

= 20µA, V

CRMS

= 0.75V, VA

OUT

= 5.5V 64 µA

IAC Limited I

AC

= 20µA, V

CRMS

= 0.4V, VA

OUT

= 5.5V 64 µA

Gain Constant I

AC

= 100µA, V

CRMS

= 3.5V, VA

OUT

= 5.5V 2.5 1/V

Zero Current I

AC

= 20µA, V

CRMS

= 0.75V, VA

OUT

= 5.5V (Note 1) 0 µA

I

AC

=100µA, V

CRMS

= 3.5V, VA

OUT

= 5.5V (Note 1) 0 µA

Power Limit (V

CRMS

• IMO)I

AC

= 20µA, V

CRMS

= 0.75V, VA

OUT

= 5.5V 45 µW

PWM Frequency Foldback

FBL Input Current –500 –100 nA

FBL Output Disable 0.5 V

Foldback Minimum Frequency R

FBM

= 100k 25 30 kHz

FBM Foldback Override 1.5 1.75 V

4

UCC1858

UCC2858

UCC3858

PIN DESCRIPTIONS

CA–: (Current Amplifier Inverting Input) This input and

the non-inverting input MOUT remain functional down to

GND.

CAO: (Current Amplifier Ouput) Output of a wide bandwidth amplifier that senses line current and commands

the pulse width modulator (PWM) to force the correct current. This output can swing close to GND, allowing the

PWM to force zero duty cycle when necessary.

CRMS: (RMS Measurement Capacitor) A capacitor connected between CRMS and GND enables averaging of

the AC line voltage over a half cycle. IAC current is internally mirrored to provide charging current for CRMS.

CT: (Oscillator Timing Capacitor) A capacitor from CT to

GND will set the free-running PWM oscillator frequency

according to:

f

RC

TT

=

•

0814.

FBL: (Frequency Foldback Level Select) Selects the level

of the voltage error amplifier output at which frequency

foldback begins. A chip shutdown can be attained by

bringing the foldback level pin to below 0.5V.

FBM: (Minimum Frequency Reference) A resistor between this pin and VREF is used to set the minimum frequency during foldback mode. Once the value of R

T

and

C

T

are determined, use

R

Cf

R

FBM

TMIN

T

=

•

−

0857.

to find the value of R

FBM

which will set the minimum

foldback frequency to f

MIN.

This pin also incorporates a

foldback override which enables the part to return quickly

to normal operating mode when the load comes back up.

To override foldback mode, force this pin below 1.5V with

an open collector.

GND: (Ground) All voltages measured with respect to

ground. VDD and VREF should be bypassed directly to

GND with a 0.1µF or larger ceramic capacitor. The timing

capacitor discharge current also returns to this pin, so

the lead from CT to GND should be as short and direct

as possible.

IAC:(Input AC Current) This input to the analog multiplier

is a current. The multiplier is tailored for very low distortion from this current input (I

IAC

) to MOUT. Requires

some bypassing to GND for noise filtering (<470pF).

MOUT: (Multiplier Output) The output of the analog multi-

plier and the non-inverting input of the current amplifier

are connected together at MOUT. As the multiplier output

is a current, this is a high impedance input so the amplifier can be configured as a differential amplifier to reject

ground noise. The voltage at this pin is also used to implement peak current limiting.

OUT: (Gate Drive Output) The output of the PWM is a totem pole MOSFET gate driver. A series gate resistor of

at least 5Ω is recommended to prevent interaction between the gate impedance and the output driver that

might cause the gate drive to overshoot excessively.

RT: (Oscillator Timing Resistor) A resistor from RT to

GND is used to program oscillator discharge current.

SYNC: (Oscillator Synchronization Input) Allows the PFC

to be synchronized to a trailing edge modulator in the

DC-DC stage. A synchronization pulse can be generated

from the positive output edge of the downstream regulator and applied to this pin. The internal clock is reset

(charged up) on the rising edge of the SYNC input.

VA–: (Voltage Amplifier Inverting Input) This pin is normally connected to the boost converter output through a

divider network. It also is an input to the overvoltage

comparator where by the output is terminated if this pin’s

voltage exceeds 3.15V.

VAO: (Voltage Amplifier Output) Output of the

transconductance amplifier that regulates output voltage.

The voltage amplifier output is internally limited to approximately 6V for power limiting. It is also used to determine the frequency foldback mode. Compensation

network is connected from this pin to GND.

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for T

A

= 0°C to 70°C for the

UCC3858, –40°C to +85°C for the UCC2858, and –55°C to +150°C for the UCC1858, V

VDD

= 12V, RT= 24k, CT= 330pF, R

FBM

=

96k, I

IAC

= 100µA, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Gate Driver

Pull Up Resistance I

OUT

= 100mA 7 Ω

Pull Down Resistance I

OUT

= –100mA 3.5 Ω

Output Rise Time C

LOAD

= 1nF, RS= 10Ω 25 ns

Output Fall Time C

LOAD

= 1nF, RS= 10Ω 20 ns

Note1: M

OUT

current with contributions form CA+ and peak limit level shift subtracted out.

5

UCC1858

UCC2858

UCC3858

The UCC3858 is designed to optimize the implementation of power factor corrected boost converters in low to

medium power applications where light load efficiency is

critical. While basic configuration of the UCC3858 is similar to the industry standard UC3854 series controllers,

several distinguishing features have been added. A typical application circuit is shown along with a diagram

showing how the UCC3858 can be used with the downstream converter to achieve optimum performance.

Chip Bias Supply and Startup

The UCC3858 is implemented using Unitrode’s

BCDMOS process allowing minimal startup (60µA typical) and operating (3.5mA typical) supply currents. This

results in significantly lower power consumption in the

trickle charge resistor used to startup the IC, increasing

the system efficiency at light loads. Lower supply currents, coupled with the wide undervoltage lockout hysteresis (13.75V on, 10V off) provide the opportunity to

operate both stages from the same startup and bootstrap

supply as shown in the typical application drawing.

Oscillator and Frequency Foldback at Light Loads

The oscillator of the UCC3858 is set up to operate either

synchronously with the downstream converter or as a

stand alone oscillator. A simplified block diagram of the

oscillator and associated circuitry is shown in Fig. 2 and

the related waveforms are shown in Fig. 3a - 3c. A rising

edge at the SYNC pin initiates the clock cycle by charging up the CT pin with a nominal internal current of

I

CHnom (=19 •IDIS). Once the high threshold of the ramp

(4.5V) is crossed, the internal latch is set and the CT pin

starts discharging at a rate (I

DIS

=3/RT) set by the resistor

on the RT pin. In the absence of a SYNC pulse, C

T

discharges all the way to the ramp low threshold (1V) and

that sets the free running frequency of the oscillator as

given by equation 1. In applications where synchronization is used, the R

T,CT

values should be chosen so that

the free running frequency is always lower than the synchronization frequency.

f

RC

TT

=• •

•

19203

351.

(1)

When VAO falls below the threshold level set by FBL, the

oscillator goes into frequency foldback mode and disables synchronization. The frequency foldback is

achieved by reducing the oscillator charging current as

the power level (and VAO voltage) falls. As shown in Fig.

2, the difference between VAO and FBL regulates current I

Csub which subtracts the current available for charg-

ing C

T

. The effective charge current into the capacitor is

given by (I

CHnom-ICsub

). To avoid converter operation in

the low frequency range (e.g. audio), the charge current

should not be allowed to go very low.Minimum frequency

of the controller is programmed by the current I

MIN flow-

ing into pin FBM which sets the minimum charging current. The value of R

FBM

to set the desired minimum

frequency is given by:

R

fC

R

FBM

MIN T

T

=•

•

3351

.

–

(2)

Fig. 4 shows the characteristic curves for the frequency

foldback. When the converter comes out of the low

power mode, the time taken to restore normal mode operation (return to nominal or synchronized frequency operation) must be minimized. Given that the voltage error

amplifier response is very slow in PFC circuits, the VAO

pin change is not the best indicator of change in load

conditions. UCC3858 provides a solution where the normal mode can be restored instantaneously when FBM is

pulled below 1.5V. A typical interface would involve the

output of the error amplifier of the downstream converter

(with proper buffering and filtering) driving an npn switch

that pulls FBM down to GND. The buffer and filter should

ensure that the switch is turned on only when the error

amplifier of downstream converter is saturated high for a

preset duration indicating a droop in output voltage from

increased load. The FBM input can also be permanently

pulled low to disable the frequency foldback mode completely, while still using the other features of UCC3858.

FBL pin also acts as a chip disable input when it is

brought below 0.5V.

APPLICATION INFORMATION

VDD: (Positive Supply Voltage) Connect to a stable

source of at least 20mA between 13V and 17V for normal

operation. Bypass VDD directly to GND to absorb supply

current spikes required to charge external MOSFET gate

capacitance. To prevent inadequate gate drive signals,

the output devices will be inhibited unless V

VDD

exceeds

the upper undervoltage lockout voltage threshold and remains above the lower threshold.

VREF: (Reference Voltage) VREF is the output of an accurate 7.5V voltage reference. This output is capable of

delivering 10mA to peripheral circuitry and is internally

short circuit current limited. VREF is disabled and will remain at 0V when V

VDD

is low.Bypass VREF to GND with

a 0.1µF or larger ceramic capacitor for best stability.

PIN DESCRIPTIONS (cont.)

6

UCC1858

UCC2858

UCC3858

Figure 1. UCC3858 Typical application circuit.

APPLICATION INFORMATION (cont.)

* Pins 4, 9 and 14 need good bypassing to GND for noise immunity. Capacitors C2, C3 and C23 should each consist of a combination of ceramic (0.47

µ

F) and tantalum (4.7µF) capacitors for best results.

* * L1 can be fabricated with an Allied Signal Amorphous Core MP4510PFC, using a 100 turn (AWG 18) primary and 5 turn secondary.Alternatively, a gapped Ferrite Choke can be used. (Coiltronics CTX-08-13679)

UDG-97120-1

7

UCC1858

UCC2858

UCC3858

BOOST

DIODE

CURRENT

V

OUT

T

S

V

CT

V

CAO

4.75V

>1V

SYNC

Figure 3a. Oscillator timing waveforms synchronized

to buck (DC/DC) PWM.

BOOST

DIODE

CURRENT

V

OUT

T

S

V

CT

V

CAO

4.75V

>1V

Figure 3b. Oscillator timing waveforms stand alone

operation.

Figure 2. Oscillator block diagram.

APPLICATION INFORMATION (cont.)

UDG-97121-1

8

UCC1858

UCC2858

UCC3858

Capacitor Ripple Reduction

For a power system where the PFC boost converter is

followed by a DC-DC converter stage, there are benefits

to synchronizing the two converters. In addition to the

usual advantages such as noise reduction and stability,

proper synchronization can significantly reduce the ripple

currents in the boost circuit’s output capacitor. Fig. 5

helps illustrate the impact of proper synchronization by

showing a PFC boost converter together with the simplified input stage of a forward converter. The capacitor current during a single switching cycle depends on the

status of the switches Q1 and Q2 and is shown in Fig. 6.

It can be seen that with a synchronization scheme that

maintains conventional trailing edge modulation on both

converters, the capacitor current ripple is highest. The

greatest ripple current cancellation is attained when the

overlap of Q1 off-time and Q2 on-time is maximized. One

method of achieving this is to synchronize the turn-on of

the boost diode (D1) with the turn-on of Q2. This approach implies that the boost converter’s leading edge is

pulse width modulated while the forward converter is

modulated with traditional trailing edge PWM. The

UCC3858 is designed as a leading edge modulator with

easy synchronization to the downstream converter to facilitate this advantage. Table 1 compares the I

CBrms

for

D1/Q2 synchronization as offered by UCC3858 vs. the

I

CB

rms

for the other extreme of synchronizing the turn-on

of Q1 and Q2 for a 200W power system with a V

BST

of

385V.

APPLICATION INFORMATION (cont.)

Figure 5. Simplified representation of a 2-stage PFC

power supply.

Figure 6. Timing waveforms for synchronization

scheme.

BOOST

DIODE

CURRENT

V

OUT

V

CT

V

CAO

4.5V

>1V

SLOPE=

I

CH

C

T

CLK

T

S

Figure 3c. Frequency foldback mode.

% NOMINAL FREQUENCY

80

60

R

FBM

= 10k

FBL = VAO(V)

–1 –2 –30

–4

40

20

100

–5 –6

R

FBM

= 25k

R

FBM

= 100k

(R

T

= 24k, CT= 330pF, NOMINALFREQUENCY 100kHz)

Figure 4. Frequency foldback characteristics.

Switch Sync

Trailing-Edge PWM for

both Boost and Buck

Inverted Switch Sync

Leading-Edge Boost PWM

Trailing-Edge Buck PWM

UDG-97131

UDG-97130-1

9

UCC1858

UCC2858

UCC3858

Table I. Effects of Sychronization on Boost

Capacitor Current

VIN= 85V VIN= 120V VIN= 240V

D(Q2) Q1/Q2 D1/Q2 Q1/Q2 D1/Q2 Q1/Q2 D1/Q2

0.35 1.491A 0.835A 1.341A 0.663A 1.024A 0.731A

0.45 1.432A 0.93A 1.276A 0.664A 0.897A 0.614A

Table 1 illustrates that the boost capacitor ripple current

can be reduced by about 50% at nominal line and about

30% at high line with the synchronization scheme facilitated by the UCC3858. The output capacitance value can

be significantly reduced if its choice is dictated by ripple

current or the capacitor life can be increased as a result.

In cost sensitive designs where hold-up time is not critical, this is a significant advantage.

An alternative method of synchronization to achieve the

same ripple reduction is possible. In this method, the

turn-on of Q1 is synchronized to the turn-off of Q2.While

this method yields almost identical ripple reduction and

maintains trailing edge modulation on both converters,

the synchronization is much more difficult to achieve and

the circuit can become susceptible to noise as the synchronizing edge itself is being modulated.

Reference Signal (I

MULT

) Generation

Like the UC3854 series, the UCC3858 has an Analog

Computation Unit (ACU) which generates a reference

current signal for the current error amplifier. The inputs to

the ACU are (signals proportional to) instantaneous line

voltage, input voltage RMS information and the voltage

error amplifier output. Unlike prior techniques of RMS

voltage sensing, UCC3858 employs a patent pending

technique to simplify the RMS voltage generation and

eliminate performance degradation caused by the prior

techniques. With the novel technique (shown in Fig. 7),

need for external two pole filter for V

RMS

generation is

eliminated. Instead, the IAC current is mirrored and used

to charge an external capacitor (C

RMS

) during a half cycle. The voltage on CRMS takes the integrated sinusoidal

shape and is given by equation 3. At the end of the halfcycle, CRMS voltage is held and converted into a 4-bit

digital word for further processing in the ACU. CRMS is

discharged and readied for integration during the next

half cycle. The advantage of this method is that the second harmonic ripple on the V

RMS

signal is virtually eliminated. Such second harmonic ripple is unavoidable with

the limited roll-off of a conventional 2-pole filter and results in a 3rd harmonic distortion in the input current signal. The dynamic response to the input line variations is

also improved as a new V

RMS

signal is generated every

cycle.

V

I

C

t

CRMS

AC

pk

RMS

=

••

•21ωω(–cos )

(3a)

Vpk

I

C

CRMS

AC

pk

RMS

()=

•ω

(3b)

For proper operation, I

ACpk

should be selected to be

100µA at peak line voltage. For universal input voltage

with peak value of 265 VAC, this means R

AC

= 3.6M. The

noise sensitivity of the IC requires a small bypass capacitor for high frequency noise filtering. The value of this capacitor should be limited to 330pF maximum. The V

CRMS

value should be approximately 1V at the peak of low line

(80 VAC) to minimize any digitization errors. The peak

value of V

CRMS

at high line then becomes 3.5V. The de-

sired C

RMS

can be calculated from equation 3 to be 90nF

for 50Hz line and 75nF for 60Hz line.

The multiplier output current is given by equation (4) with

K=0.33.

I

VIK

V

MULT

VAO AC

CRMS

=

••(–)1

2

(4)

The multiplier peak current is limited to 200µA and the

selected values for IACand V

CRMS

should ensure that

the current is within this range. Another limitation of the

multiplier is that I

MULT

can not exceed two times the I

AC

current, limiting the minimum voltage on V

CRMS

.

APPLICATION INFORMATION (cont.)

AD

MULTI

DAC

4BIT

WORD

REGISTER

A

B

C

A•B

C

VAO

IAC

R

AC

1

2

(X2)

C

RMS

CRMS

Figure 7. Novel circuit for RMS signal generation.

LINE

V

CRMS

ADC

HOLD

10

UCC1858

UCC2858

UCC3858

The discrete nature of the RMS voltage feedforward

means that there are regions of operation where the input voltage changes, but the V

RMS

value fed into the multiplier does not change. The voltage error amplifier

compensates for this by changing its output to maintain

the required multiplier output current. When the output of

the ADC changes, there is a jump in the output of the error amplifier. There is a resultant shift in the foldback frequency if the converter is at light load. However, the

impact of this change is minimal on the overall converter

operation.

Another key consideration with the RMS voltage scheme

is that it relies on the zero-crossing of the I

AC

signal to be

effective. At very light loads and high line conditions, the

rectified AC does not quite reach zero if a large capacitor

is being used for filtering on the rectified side of the

bridge. In such instances, the feedforward effect does not

take place and the controller functionality is lost. For

UCC3858, the I

AC

current should go below 10µA for the

zero crossing detection to take place. It is recommended

that the capacitor value be kept low enough for the light

load operation or the feedforward be derived directly from

the AC side of the input bridge as shown in the typical

applications circuit.

Gate Drive Considerations

The gate drive circuit in UCC3858 is designed for high

speed power switch drive. It consists of low impedance

pull-up and pull-down DMOS output stages. When operating with high bias voltages, in order to stay within the

SOA of the DMOS output stages, it is recommended that

the gate drive current be limited to 0.5A peak with the

use of external gate resistor. Please see the characteristic curve in Fig. 8 for determining the required external resistance.

Current Amplifier Set-up

The multiplier is set-up first by choosing the V

RMS

range.

The maximum multiplier output is at low line, full load

conditions. The inductor peak current also occurs at the

same point. The multiplier terminating resistor can be determined using equation 5.

R

IL R

I

MULT

PK SENSE

MULT

PK

=

•

(5)

The peak current limiting function provided by the

UCC3858 is integrated into MOUT. The signal on MOUT

is normally maintained at 0V as the (I

MULT•RMULT

) cancels the voltage drop across the sense resistor with

closed loop operation. During short circuit or transient

startup conditions, the multiplier current can not fully cancel the voltage drop across R

SENSE and the voltage at

MOUT drops below 0V. The internal peak current limit is

activated when MOUT drops below –0.5V. The peak current limit at any operating point is given by:

I

IR

R

LIM

MULT MULT

SENSE

=

•+05.

(6)

The current amplifier can be compensated using previously presented techniques, (Application Note U- 134),

summarized here. A simplified high frequency model for

inductor current to duty cycle transfer function is given

by:

Gs

idV

sL

id

LO

()=

∧

∧

=

(7)

The gain of the current feedback path at the frequency of

interest (crossover) is given by:

d

i

R

R

RV

L

SENSE

Z

ISE

∧

∧

=••

1

(8)

Where V

SE

is the ramp amplitude (p-p) which is 3.5V for

UCC3858. Combining equations 7 and 8 yields the loop

gain of the current loop and equating it to 1 at the desired crossover frequency can result in a design value for

R

Z

. The current loop crossover frequency selected using

conventional trade offs. However, it should be ensured

that the current-loop is stable at the minimum switching

frequency under foldback conditions.

APPLICATION INFORMATION (cont.)

0

10

20

30

40

10 12 14 16 18 20

VDD(V)

RS(

Ω

)

Figure 8. Reguired series gate resistance as a

function of supply voltage.

11

UCC1858

UCC2858

UCC3858

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

Figure 9. Use of the UCC3858 in a two stage converter to optimize performance.

APPLICATION INFORMATION (continued)

UDG-96192-1

Voltage Amplifier Set-up

The voltage amplifier in UCC3858 is a transconductance

type amplifier to allow output voltage monitoring for an

overvoltage condition. The gain of the amplifier, given by

APPLICATION INFORMATION (cont.)

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...