Page 1

Model 990 Computer

Model

DS10

Cartridge Disk System

~~~n'"'

<.~

Installation and Operation

Part No. 946261-9701 * B

15 December

1980

TEXAS

INSTRUMENTS

Page 2

© Texas Instruments Incorporated 1977, 1978, 1979, 1980

All Rights Reserved, Printed in U.S.A.

The

information

and/or

drawings

set

forth

in

this

document

and all

rights

in and

to

inventions

disclosed

herein and

patents

which

might

be granted thereon

disclosing

or

employing

the materials,

methods,

techniques

or apparatus

described

herein, are the

exclusive

property

of

Texas

Instruments

Incorporated.

MANUAL REVISION HISTORY

Model 990 Computer Model DS10 Cartridge Disk System

Installation

and Operation (946261-9701

*8)

Original Issue

..................................

. 1 December 1977

Change 1

....................................

. 15 January 1978 (ECN 419819)

Change 2

....................................

. 15 August 1978 (ECN 437233)

Change 3

.....................................

15 March 1979 (ECN 449602)

Change 4

....................................

. 15 August 1980 (MCR 000297)

Revision .

......................................

. 15 December 1980 (MCR 000440)

I The total number

of

pages in this publication

is

126.

I

I

I

l

________________________

J

Page 3

"i1"

946261-9701

~-------

PREFACE

This manual provides detailed instructions for installing a Texas Instruments Model DSIO

Cartridge Disk System in conjunction with a properly installed Model 990 Computer. In addition,

it

contains information required

description

information

Section

1 General Description - This section briefly describes the features and major com-

of

the disk system with specific attention to the controls and indicators. The

is divided

ponents

of

into

the

the

disk system

to

program the computer

following sections:

to

acquaint the reader with the system.

to

use the disk system and a

2 Installation -

ing

a Model DSIO Cartridge Disk System. Information is also provided

the site for the installation

The procedures given in

digital electronics.

3

Programming

in

designing a service routine

4

Operation - This section describes

disk system operators, and describes the use

operation

Model 990/5 Computer System Hardware User's Manual

Model

Model

Model

Depot Maintenance Manual

This section contains step-by-step procedures for unpacking and install-

is properly prepared prior

this section presuppose

~

This section presents interfacing information for use

to

control the disk system's activity.

of

the

disk system.

Title

990/10 Computer System Hardware Reference Manual

990/12 Computer Hardware User's Manual

990 Computer Model DSIO Cartridge Disk System

to

that

the

controls and indicators

of

those controls and indicators in the

installation

the reader

of

Part Number

946294-9701

945417

2264446-9701

946262-9701

to

ensure that

of

the disk system.

is

not

familiar with

by

a programmer

the

disk system for

-9701

Model

Model

Language Programmer's Guide

990 Computer Programming Card

990 Computer TMS 9900 Microprocessor Assembly

iii/iv

943440-9701

943441-9701

Digital Systems Division

Page 4

Page 5

~-------

'iY

946261-9701

TABLE

OF

CONTENTS

Pangrapb

Title Page

SECTION 1.

GENERAL

DESCRIPTION

1.1 General

.....................................................................

-

...

1-1

1.2 System Configuration

............................................................

1-1

1.2.1

TILINE

Bus

....... ' ...........................................................

1-2

1.2.2 Disk Controller

...............................................................

1-5

1.2.3 Disk Drives

..................................................................

1-5

1.3 System Operation

...............................................................

1-6

1.4 System Specifications

...........................................................

1-10

2.1

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.5.1

2.3.5.2

2.3.5.3

2.3.6

2.4

2.4.1

2.4.2

2.4.3

2.4.3.1

2.4.3.2

2.4.3.3

2.4.3.4

2.4.4

2.4.4.1

2.4.5

2.4.6

2.4.7

2.4.8

2.4.8.1

2.4.8.2

SECTION 2.

INSTALLATION

General

........................................................................

2-1

Site Requirements

...............................................................

2-2

Mounting

Space Requirements for Rack

Mount

Disk Drive

..........................

2-2

Mounting

Space Requirements for Cabinet

Mount

Disk Drive

........................

2-2

Ac Power Requirements

........................................................

2-5

Model

990

Computer

..........................................................

2-5

Supportive Environment

.......................................................

2-6

Cabling Restrictions

...........................................................

2-6

Unpacking Instructions

.....................

'

.....................................

2-6

Unpacking Rack

Mount

Disk Drive

..............................................

2-6

Unpacking Disk Controller

....................................................

2-12

Unpacking Cabinet

Mount

Disk Drive

...........................................

2-17

Unpacking Accessories

.. ~ .....................................................

2-21

Unpacking, Handling,

and

Storing Disk Cartridges

................................

2-21

Unpacking Disk Cartridges

..................................................

2-22

Handling Disk Cartridges

...................................................

2-22

Storing Disk Cartridges

.....................................................

2-23

Voltage Conversion Procedures

................................................

2-24

Installation

....................................................................

2-24

Installation

of

Rack

Mount

Disk Drive

..........................................

2-24

Installation

of

Cabinet

Mount

Disk Drive

........................................

2-28

Computer

Chassis

Preparation

for Disk Controller

................................

2-29

Reconfiguring Access

Granted

Circuit

for

New Chassis Slot

(6-

and

13-Slot Chassis)

...................................................

2-29

Reconfiguring Access

Granted

Circuit for New Chassis Slot

(17-Slot

Chassis)

.........................................................

2-34

Interrupt Connections

for 6-and

13-S10t Chassis

................................

2-37

Interrupt Connections

for

17-Slot Chassis

......................................

2-39

Preparation

of

Disk Controller

.................................................

2-42

Selecting Disk

TILINE

Address

..............................................

2-42

Installation

of

Disk Controller

.................................................

2-42

Installing Disk System Interconnection Cables

....................................

2-42

Connection

of

Disk Drive

to

Ac

Power

Source

....................................

2-49

Disk Cartridge Installation

and

Removal

.........................................

2-51

Purging

the

Disk Drive

Air

Filtering System

....................................

2-51

Disk Cartridge Installation

..................................................

2-52

v Digital Systems Division

Page 6

~-------

'iY'

946261-9701

Paragraph

2.4.8.3

2.4.8.4

2.5

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.4.2.1

3.4.2.2

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

3.5.7

3.5.8

3.5.9

3.5.9.1

3.5.9.2

3.5.9.3

3.5.9.4

3.5.9.5

3.5.9.6

3.5.9.7

3.5.9.8

3.6

3.6.1

3.6.2

3.6.2.1

3.6.2.2

3.6.2.3

3.6.2.4

3.6.2.5

3.6.2.6

3.6.2.7

3.6.2.8

TABLE OF CONTENTS (Continued)

Tide

Page

Disk Cartridge Removal

.....................................................

2-56

Removal

of

Disk Cartridge Following Power Failure

or

for Emergency

.............

2-58

System Operational Checkout

....................................................

2-59

SECTION 3. PROGRAMMING

General

........................................................................

3-1

Programming the Disk Controller

.................................................

3-1

Command Control

......................................................

,

.......

3-1

Command Completion

...........................................................

3-1

Command Completion without Interrupts

........................................

3-3

Command Completion with Interrupts

...........................................

3-3

Command Completion Interrupts

..............................................

3-3

Seek and Restore Completion Interrupts

........................................

3-3

Control Words Content and Formats

...............................................

3-3

Disk Status, Control Word 0 ,

...................................................

3-3

Command Control, Control Word 1

.............................................

3-4

Format and Sector, Control Word 2

..............................................

3-5

Cylinders, Control Word 3

.....................................................

3-6

Word Count, Control Word 4

...................................................

3-6

LSB Memory Address, Control Word 5

...........................................

3-7

Unit Select and MSB Memory Address, Control Word 6

.............................

3-7

Interrupt and Controller Status, Control Word 1

...................................

3-8

Disk Commands

.............................................................

3-10

Store

Registers Command

...................................................

3-10

Write Format Command

....................................................

3-10

Read Data Command

.......................................................

3-12

Write Data Command

......................................................

3-13

Read Unformatted Command

................................................

3-14

Unformatted Write Command

...............................................

3-15

Seek Command

............................................................

3-15

Restore Command

.........................................................

3-15

Formats and DefInitions

........................................................

3-16

Definition

of

Terms

..........................................................

3-16

Sector Format

...............................................................

3-16

Gap 1

....................................................................

3-11

Synchronization (Sync) Character

............................................

3-17

Identification (ID) Words

...................................................

3-11

Error Detection Code (EDC) Number 1

........................................

3-18

Gap2

.....................................................................

3-18

Data

.....................................................................

3-18

Error Detection Code (EDC) Number 2

........................................

3-18

Gap 3

....................................................................

3-18

SECTION 4. OPERATION

4.1 General

........................................................................

4-1

4.2 Controls and Indicators

..........................................................

4-1

4.2.1 Ac Circuit ·Breaker

............................................................

4-1

vi

Digital Systems Division

Page 7

~-------

~

946261-9701

Paragraph

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

4.3

4.3.1

4.3.2

4.3.3

4.3.3.1

4.3.3.2

4.3.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.3.1

4.5.3.2

Table

TABLE OF CONTENTS (Continued)

Title

Page

Dc Circuit Breaker

............................................................

4-1

START/STOP

Switch/Indicator

...............................................

.4-1

READY Indicator

.............................................................

4-2

ACTIVE

Indicator

............................................................

4-2

F

AUL T /RESET

Indicator/Switch

...............................................

4-2

WRITE/PROTECT

CART

Indicator/Switch

....................................

.4-3

WRITE/PROTECT

FIXED

Indicator/Switch

.....................................

4-3

BRU~H

Indicator

.............................................................

4-3

Operating Instructions

...........................................................

4-3

Operating Precautions

.........................................................

4-3

Power Application for Online Operation

..........................................

4-4

Disk Cartridge Installation

and

Removal

..........................................

4-4

Disk Cartridge Installation

...................................................

4-4

Disk Cartridge Removal

......................................................

4-5

Removal

of

Disk Cartridge Following Power Failure

or

for

Emergency

..............

4-6

Write

Protect

.................................................................

4-6

Stop

and

Power

Removal

.......................................................

4-6

Changing Disk Assignments

....................................................

4-7

Fault

Operating Procedures

.....................................................

4-7

Operator

Preventive Maintenance

...............................................

4-7

Maintenance Aids

...............................................................

4-7

Preventive Maintenance

.....................

~

...................................

4-11

Preventive Maintenance

for

the

Rack

Mount

Disk Drive

............................

4-11

Preventive Maintenance

for

the

Cabinet

Mount

Disk Drive

.........................

4-11

Preventive Maintenance

for

the

Cartridge Disk

...................................

4-12

General

...........................................

'

........................

4-12

Maintenance Procedures

....................................................

4-13

LIST OF ILLUSTRATIONS

TItle Page

1-1

Model

DSI0

Cartridge Disk System

................................................

1-0

1-2 Model

DSI0

Cartridge Disk

Unit

Subsystem Simplified Diagram

.......................

1-2

1-3

TILINE

Master-to-Slave Write Cycle Timing

........................................

1-3

1-4

TILINE

Master-to-Slave

Read

Cycle Timing

........................................

1-4

1-5

Interconnection

of

Disk Controller

and

Two Disk Drives

..............................

1-6

1-6 Model

DSI0

Cartridge Disk Controller (PWB)

.......................................

1-7

1-7 Model

DSI0

Cartridge Disk Controller (Fine Line PWB)

..............................

1-8

1-8 Model

DSI0

Cartridge Disk Drive (Cabinet Mount)

...................................

1-9

1-9 Rack

Mount

Disk Drive Physical Dimensions

.......................................

I-II

1-10 Cabinet

Mount

Disk Drive Physical Dimensions

....................................

1-12

2-1

Model

DSI0

Cartridge Disk System Components

.....................................

2-3

2-2 Recommended Rack Dimensions for Model

DSI0

Cartridge Disk Drive

..................

2-4

2-3

Physical Dimensions

of

Cabinet

Mount

Model DSIO Cartridge Disk Drive

...............

2-5

2-4 Rack

Mount

Disk Drive Shipping Configuration

.....................................

2-7

2-5 Cabinet

Mount

Disk Drive Shipping Configuration

...................................

2-8

2-6 Placement

of

Disk Drive for Shipping Bolt Removal

..................................

2-9

vii

Digital Systems Division

Page 8

)175\

______

_

~

946261-9701

LIST OF ILLUSTRATIONS (Continued)

Figure

Title

Page

2-7

Location

of

Electronics Cover Screws

.............................................

2-10

2-8

Carriage Lock Pin Location

.....................................................

2-11

2-9 Card Cage Cover and Clamp Location

.............................................

2-12

2-10 Disk Drive PWB Locations

......................................................

2-13

2-11

Control PWB Switch Settings

....................................................

2-14

2-12 Sector PWB Switch Settings

.....................................................

2-15

2-13

Servo PWB Switch Settings

......................................................

2-16

2-14 Data Recovery PWB Switch Settings

..............................................

2-17

2-15

R/W

/E

PWB Resistor Module Orientation

.........................................

2-18

2-16 Disk Controller Shipping Configuration

...........................................

2-19

2-17

Disk Controller Standard Jumpers

................................................

2-20

2-18

Disk Cartridge

.................................................................

2-23

2-19 Voltage Jumper Plug and Connector

..............................................

2-25

2-20 Rack Slide Assembly Mounting

...................................................

2-27

2-21

Rack Mount Slide Configuration (Right Side Only)

..................................

2-28

2-22 TILINE Access Granted Jumper Locations for

6-S10t

Chassis (Current Production)

......

2-31

2-23

TILINE Access Granted Jumper Locations for

13-S10t

Chassis (Current Production)

.....

2-32

2-24 TILINE Access Granted Jumpers (P2-5 to P2-6) on the Model

990

Backpanel

............

2-33

2-25

Interrupt Plug and TLAG Jumper Switches in the

17-S10t

Chassis

......................

2-35

2-26

17-S10t

Chassis TLAG Jumper Switch Settings

......................................

2-36

2-27

Location

of

Interrupt Jumpers

(6-

and

13-S10t

Chassis)

...............................

2-37

2-28

6-S10t

Chassis Interrupt Jumper Plugs

.............................................

2-39

2-29

13-S10t

Chassis Interrupt Jumper Plugs

............................................

2-40

2-30

17-S10t

Chassis Interrupt Jumper Connector

........................................

2-41

2-31

Model DSI0 Cartridge Disk Controller (PWB)

......................................

2-43

2-32 TILINE Slave Address Switches

..................................................

2-44

2-33

Interconnection Cable Connector Mating

..........................................

2-45

2-34 Interconnection Cable Dressing in Computer Chassis

................................

2-46

2-35

Cable Adapter. , ,

.... , .........................................................

2-47

2-36 Cable Arrangement on Cable Carriers

.............................................

2-48

2-37

XRM (n) Resistor Packs to be Removed from Primary Rack

Mount Disk Drive

I/O

Board

..................................................

2-50

2-38

XRM (n) Resistor Packs to be Removed from Primary Cabinet

Mount Disk Drive

I/O

Board

..................................................

2-50

2-39 Switches and Settings for Rack Mount Primary Disk Drive

............................

2-53

2-40 Switches and Settings for Cabinet Mount Primary Disk Drive

.........................

2-54

2-41

Disk Drive Circuit Breakers

......................................................

2-55

2-42 Brush Indicator

................................................................

2-56

2-43

Disk Cartridge Installation

......................................................

2-57

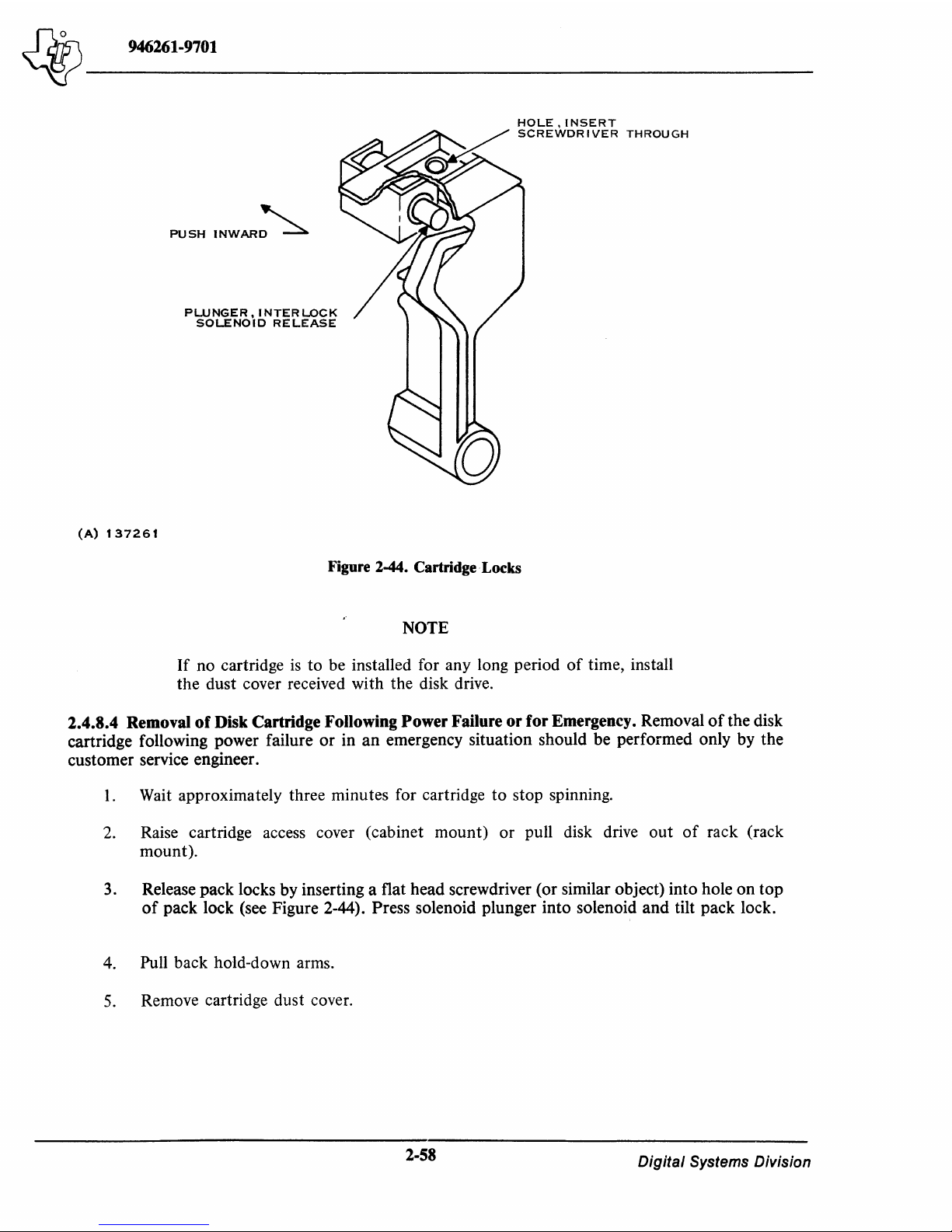

2-44 Cartridge Locks

................................................................

2-58

3-1

Model DSI0 Disk System Control Word Formats

....................................

3-2

3-2

Control Word 0

.................................................................

3-3

3-3

Control Word 1

.................................................................

3-4

3-4 Control Word 2

.................................................................

3-6

3-5

Control Word 3

.................................................................

3-6

3-6

Control Word 4

.................................................................

3-6

3-7

Control Word 5

.................................................................

3-7

3-8

Control Word 6

.................................................................

3-7

viii

Digital Systems Division

Page 9

~-------

~

946261-9701

LIST OF ILLUSTRATIONS (Continued)

Figure

Title

Page

3-9

Control Word 7

.................................................................

3-8

3-10

Command Format

.............................................................

3-10

3-11

Store Registers Data Format

.....................................................

3-11

3-12

Header Data Format

............................................................

3-12

3-13

Format

of

a Sector Record Bit Stream

.............................................

3-17

4-1

Disk Drive Controls and Indicators

................................................

4-2

4-2

Disk Designation Jumper

.........................................................

4-8

4-3

Disk Controller LEOs (pWB Version)

..............................................

4-9

4-4

Disk Controller LEOs (Fine Line PWB Version)

....................................

4-10

4-5

Disk Contaminants

.............................................................

4-13

LIST

OF

TABLES

Table

nde

Page

1-1

Disk Drive Specifications

........................................................

1-10

1-2

General Characteristics

of

Model OSlO Cartridge Disk System

........................

1-11

1-3

Ac

Power Requirements for Disk Drive (Both

50-

and

6O-Hertz

Drives)

.................

1-13

2-1

Model

OSlO

Cartridge Disk System Components

.....................................

2-2

2-2

Site Environmental Requirements for Model

OSlO

Cartridge Disk System

................

2-6

2-3

Disk Drive Input Voltage Jumper Connections

......................................

2-26

2-4

TILINE Slave Address Switch Settings and Addresses

................................

2-44

3-1

Disk Command Bits

.............................................................

3-5

3-2

Example

of

List Words in a Store Registers Command

...............................

3-11

3-3

Write Format Command

........................................................

3-11

3-4

Example

of

Read Data

..........................................................

3-12

3-5

Read Unformatted Command Example

............................................

3-14

3-6

Example

of a Seek

Command

..................................

~

.................

3-15

ix

Digital Systems Division

Page 10

...-

6

(A)

143663

Figure 1-1. Model OSlO Cartridge Disk System

Page 11

Jdls-\

______

_

~

946261-9701

SECTION 1

GENERAL DESCRIPTION

1.1

GENERAL

The Model DSI0 Cartridge Disk System (Figure

1-1)

is

a moving-head random-access magnetic disk

data storage system for the Model

990

Computer. The system consists

of

a printed wiring board disk

controller and up

to

two Model DSI0 Cartridge Disk Drives as shown in Figure 1-2. A Model DSI0

Cartridge Disk System consisting

of

one disk controller and two disk drives

is

capable

of

storing

25.2 million unformatted bytes

of

data, 12.6 million per disk drive (20 million,

10

million per disk

drive, when formatted).

The disk system features include:

•

•

•

•

•

•

•

Single printed wiring board controller capable

of

supporting two disk drives.

Transfer rate

of

312K bytes per second

A fixed and a removable disk

Automatic track switching across head and cylinder boundaries

Variable record formats, from one sector to full track

Efficient disk formatting and double-frequency recording for high percentage use

of

storage

Controller self-diagnostic capability

The Model

DSI0 Cartridge Disk System uses a magnetic medium-density (2200 bits per inch) disk

(one fixed, one removable) and flying heads that move laterally over the disk surfaces

to

select dif-

ferent cylinders. Control for up

to

two disk drives resides

on

a disk controller printed wiring board

(PWB) located in a Model 990 Computer chassis. The controller uses

an

on-board microprocessor

to

handle all time-critical events in the transfer

of

data between the computer and the disk drive. The

disk drive assembly includes the mechanical, e1etromechanical, and electronic components required

to rotate the disks, perform track selection, and read and write data on the disk.

1.2

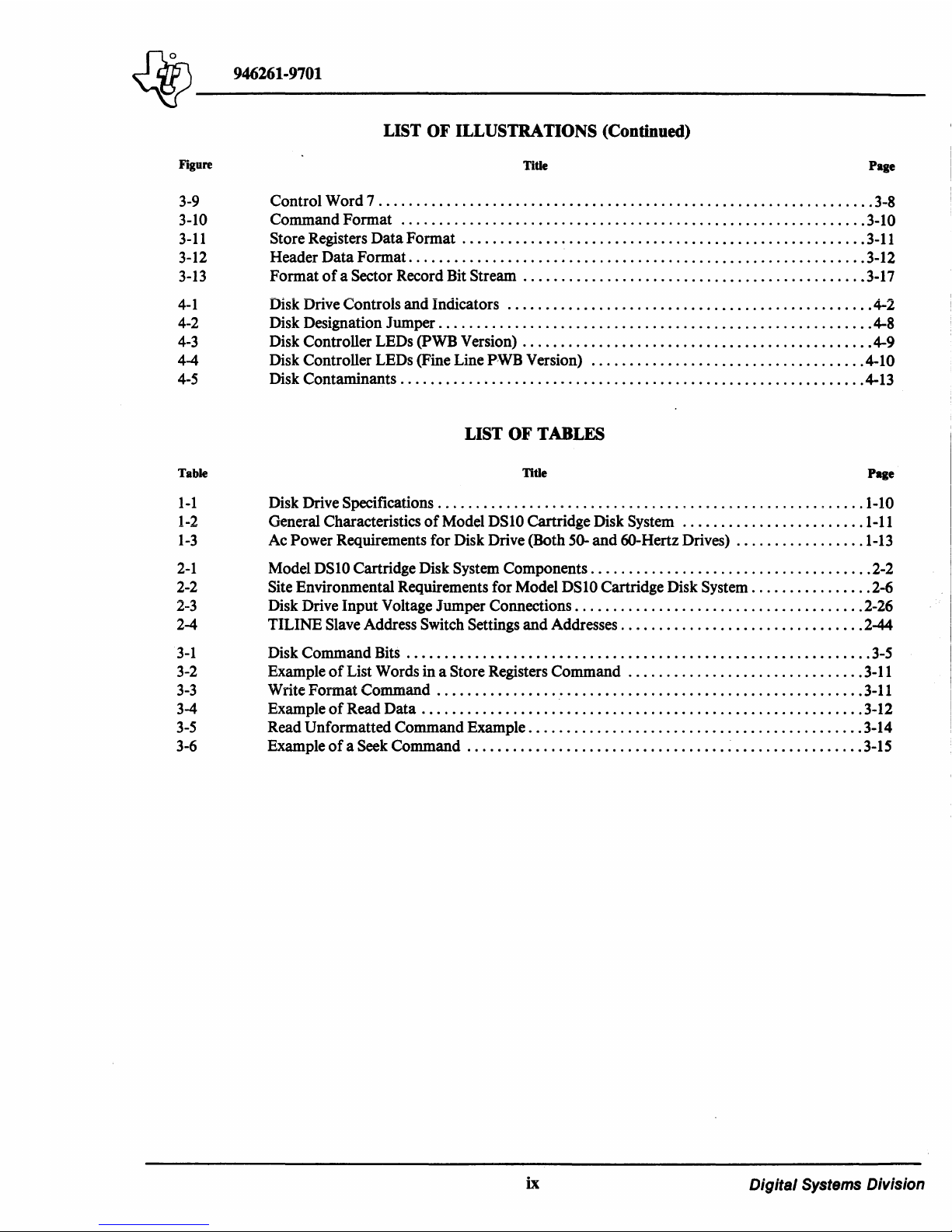

SYSTEM CONFIGURATION

Figure

1-2

illustrates the relationship

of

the major components

of

the Model DSI0 Cartridge Disk

System. The disk controller

is

a full-width PWB that

is

installed in the computer chassis to interface

with the computer's high-speed TILINE* data bus.

Two cables are required

to

connect the controller

to

the primary disk drive. One cable carries control signals and serial data from the controller to the primary disk drive, and the other cable carries

status signals and serial data from the primary disk drive

to

the disk controller. When a second disk

drive

is

installed into a system, the disk drive

is

daisy-chained to the first disk drive with two addi-

tional cables. The cables that interconnect the two disk drives perform the same functions as the

*Trademark

of

Texas Instruments Incorporated.

1-1

Digital Systems Division

Page 12

~-------

~

946261·9701

r

I

---

---

I

MEMORY

I

I

I

L

AU

-

~

--

~

-

A)

137221

I

COM

MANOS

AND

SERIAL

DATA

..

-

PARALLEL

~

I

..

DISK

STATUS

AND

CONTROLLER

SERIAL

DATA

TILINE

...

I-

INTERFACE

I

PRIMARY

TILINE

DISK

DRIVE

DATA

..

~

BUS

...

I

--

-

~

I

_J

COMMANDS

-

-

-

-

-

-

AND

SERIAL

DAT~_

...

STATUS

AND

SERIAL

DATA

-

SECONDARY

DISK

DRIVE

~-

TERM I NA

TOR

------"

-I-

Figure

1-2.

Model

OSlO Cartridge

Disk

Unit Subsystem Simplifred

Diagram

cables that interconnect the disk controller with the first disk drive. The second disk drive functions

as though it were connected directly to a disk controller.

The cables connect to

an

adapter board at each disk drive. The adapter board mates the flat

ribbon cable connectors to the Winchester connector on the disk drive.

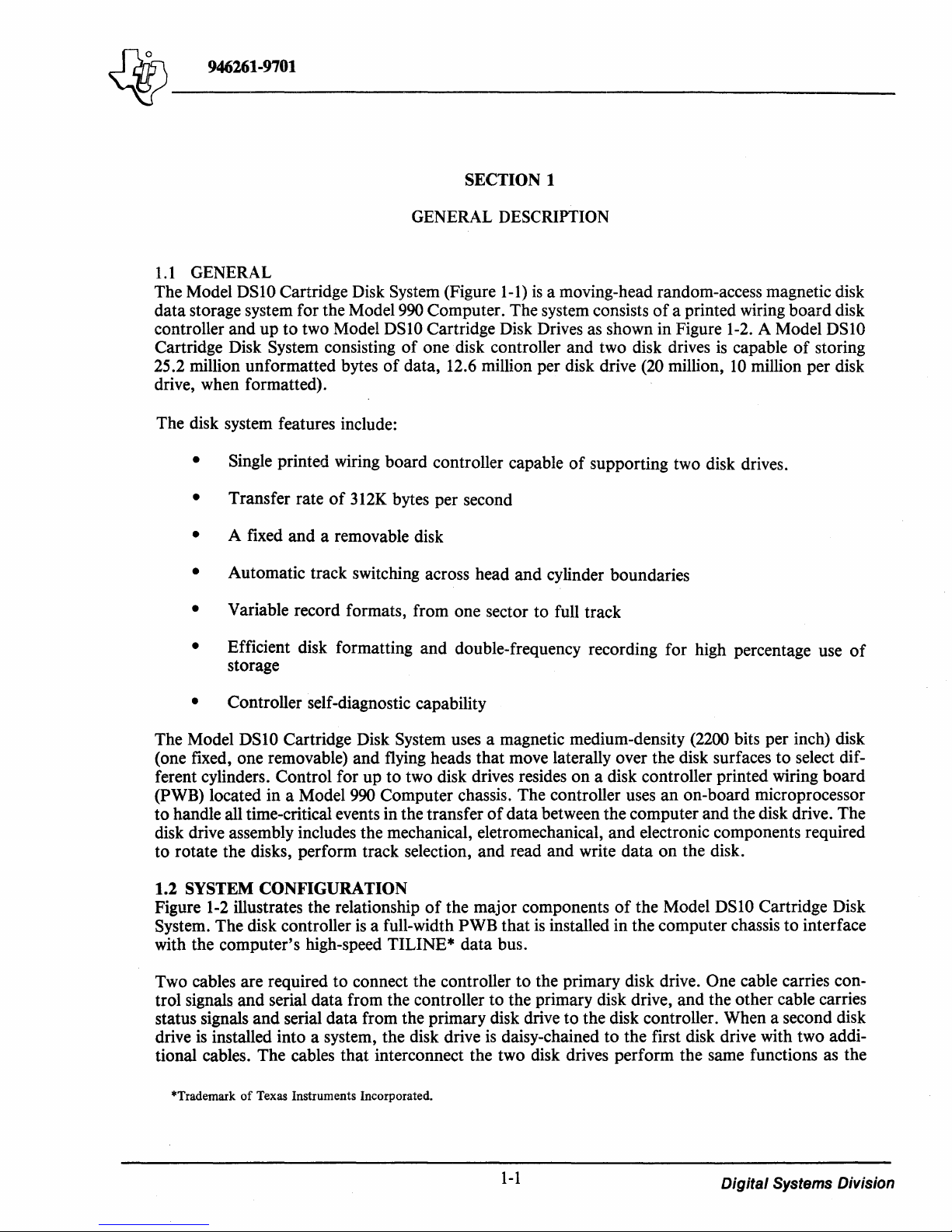

1.2.1 TILINE

BUS.

The TILINE bus

is

an

asynchronous, high-speed, 16-bit parallel data bus

used to transfer data between the central processing unit

(CPU) of the computer, the computer's

memory, and any TILINE device installed in the computer, such

as

magnetic tape and disk

storage systems. Any full-sized

990 circuit board plugged into the Model 990 Computer chassis

may engage the TILINE bus and participate in data transfers. The TILINE bus

is

divided

between two chassis connector slots, PI and P2, in a full-width chassis slot.

Two classes

of

TILINE users interface with the TILINE bus. Users

of

the bus that contend for con-

trol

of

the bus are called TILINE masters, and users that only accept data from the bus are called

TILINE slaves. The disk controller

is

both a master and a slave, depending on the operation being

conducted. The disk controller

is

a slave when receiving commands from the CPU and a master

when contending for the bus to transfer data to or from the computer's memory.

Data

is

transferred between the TILINE bus and the disk controller as parallel, 16-bit words. The

associated address information

is

transferred as parallel, 20-bit words. In addition, a number

of

control lines are used to synchronize TILINE bus transfers and to indicate data parity errors.

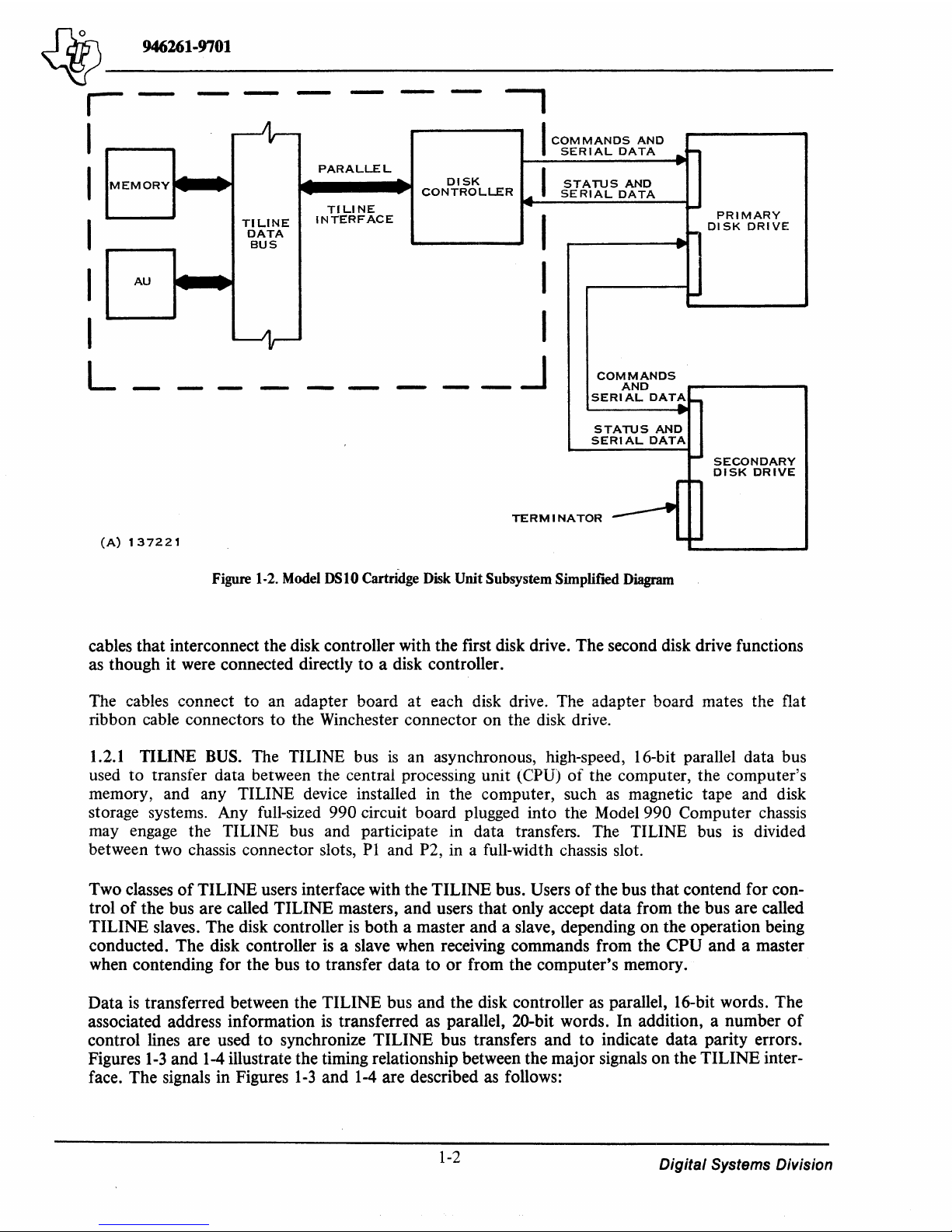

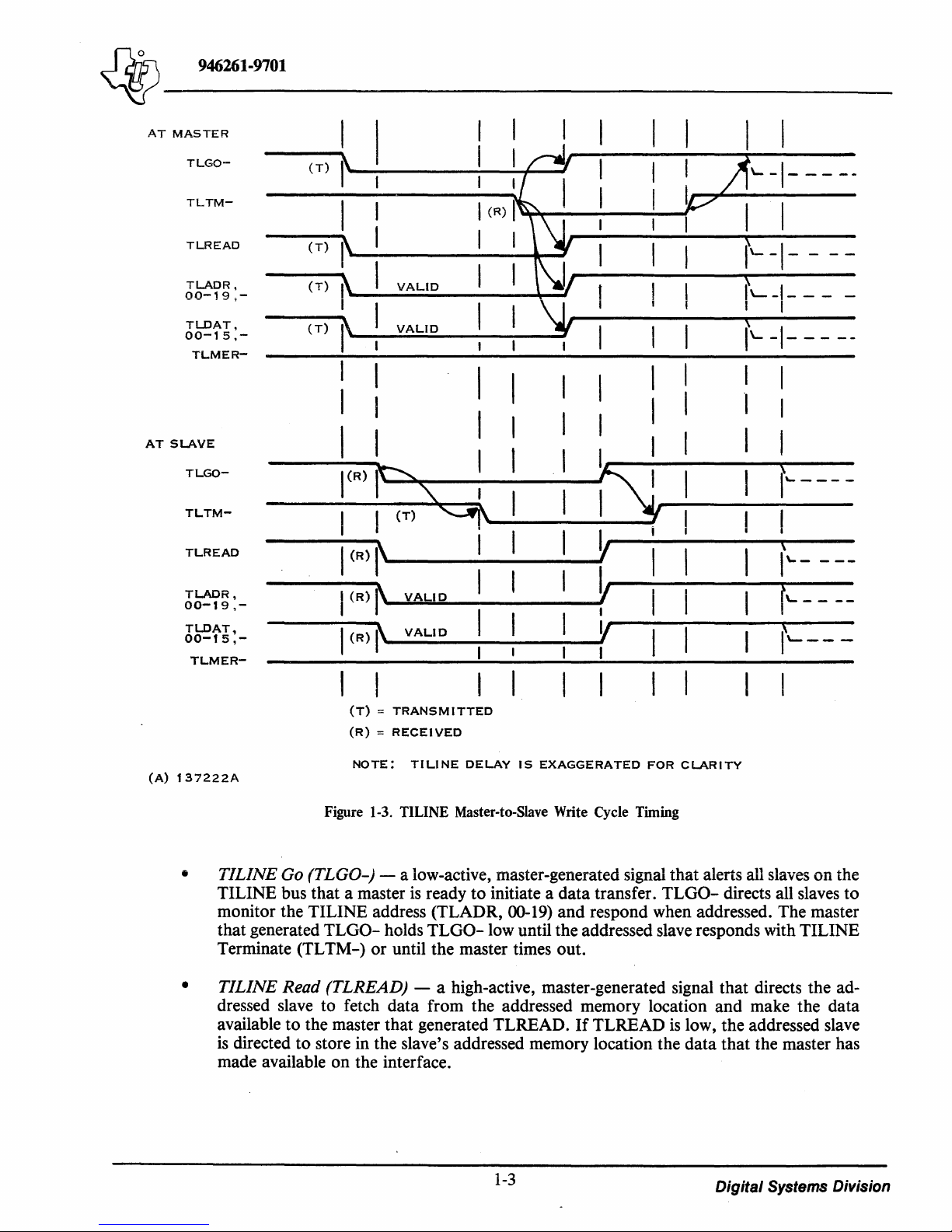

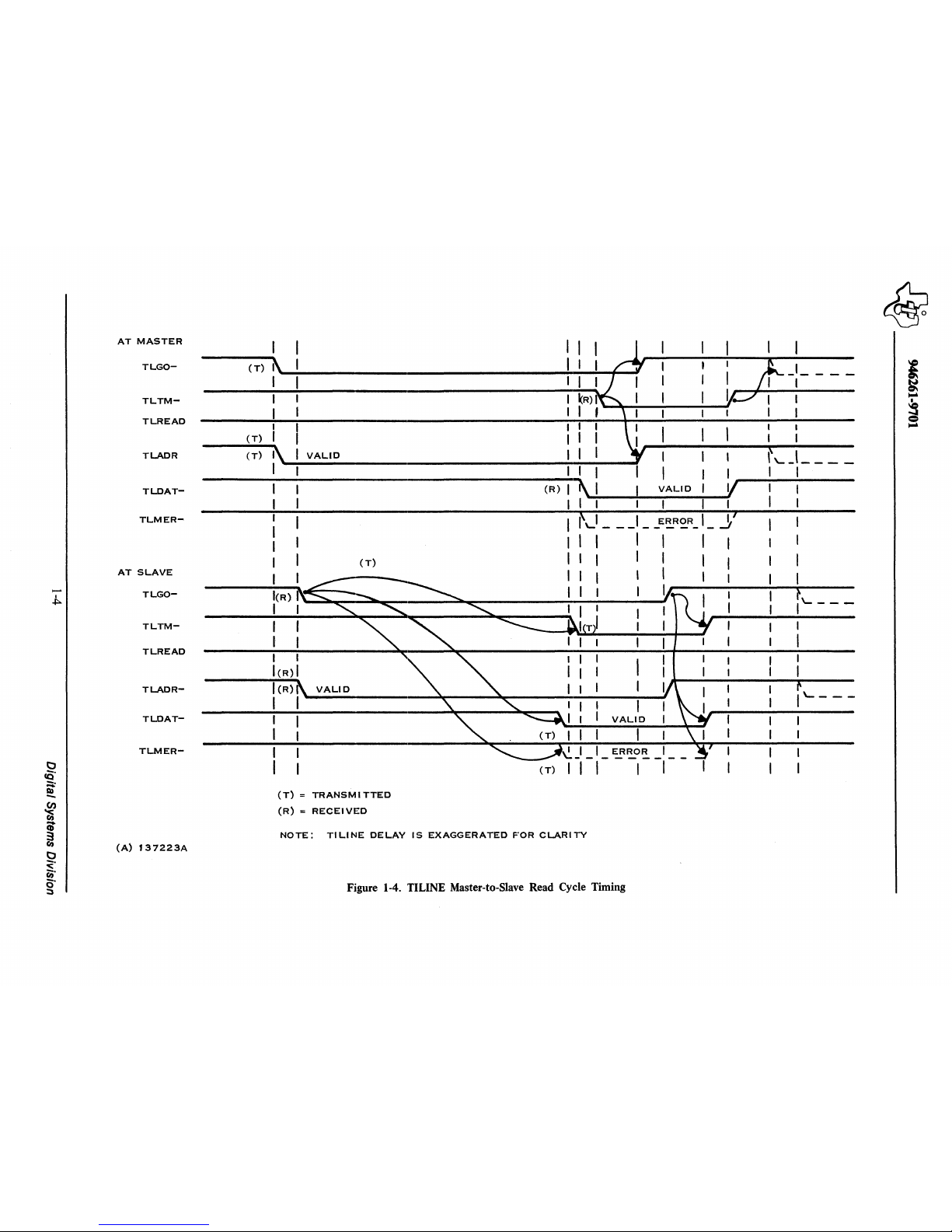

Figures

1-3

and

1-4

illustrate the timing relationship between the major signals on the TILINE inter-

face. The signals in Figures

1-3

and

1-4

are described as follows:

1-2

Digital Systems Division

Page 13

~-------

~

946261-9701

AT

MASTER

TLGO-

TLTM-

TLREAD

TLADR,

00-19,-

TLDAT,

00-15,-

TLMER-

AT

SLAVE

TLGO-

TLTM-

TLREAD

TLADR,

00-19,-

TLDAT,

00-15,-

TLMER-

(A)

137222A

(

T)

I

I

I

(R)

I

(T)

I

I

(T)

VALID

I

I

I

I

~

(T)

I'

VALID

I

I

I

I

I

\

I

I

,

I

I

I

I

I

I

I I

I

\(R)

~

~

I

S

I

I

I

I

(T)

9'

I

I

Y

I

1

(R)

~

I

I

,

I

Y

I

(R)

I'

VALID

I

I

I

I

I

(R)

I'

VALID

Y

I

I

I

I

I

I

I

(T) = TRANSMITTED

(R) = RECEI

VED

NOTE:

TILINE

DELAY

IS

EXAGGERATED

FOR

CLARITY

Figure 1-3. TILINE Master-to-Slave Write Cycle Timing

I

I

L-I-----

I

I

1'--

-I-

IL--I---

-

I

I

\

1'--

-1-

----

I

I

I

\

I~

----

I

\

\\.-

---

f'---

--

X

1\--- -

•

TILINE

Go (TLGO-) - a low-active, master-generated signal that alerts all slaves on the

TILINE bus that a master

is

ready to initiate a data transfer.

TLGO-

directs all slaves to

monitor the TILINE address (TLADR, 00-19) and respond when addressed. The master

that generated

TLGO- holds

TLGO-

low until the addressed slave responds with TILINE

Terminate (TL TM-) or until the master times out.

• TILINE Read (TLREAD) - a high-active, master-generated signal that directs the ad-

dressed slave to fetch data from the addressed memory location and make the data

available to the master that generated TLREAD.

If

TLREAD

is

low, the addressed slave

is

directed to store in the slave's addressed memory location the data that the master has

made available on the interface.

1-3

Digital Systems Division

Page 14

AT

MASTER

TLGO-

TLTMTLREAD

TLADR

TLDAT-

TLMER-

AT

SLAVE

-

TLGO-

I

.J:>..

TLTM-

TLREAD

TLADR-

TLDAT-

TLMER-

0

cO'

::;:

Q)

-

(I)

~

CD

3

en

(A)

137223A

0

~.

~.

O·

:::s

(T)

(T)

(T)

VALID

~R)

1

I I

I I

I

,'-J

___

_

I I I

--------------------------------------------(-R-)~~~

_________

VA_L_I_D~--~Vr----

----------

I I

(R)

I I

I I

I I

I(R)

VALID

1 1

(T)

(T) = TRANSMI

TTED

(R)

::

RECEI

VED

K 1

ERROR

I;

'-

_________

...:1

I

1

I

I

I

VALID

ERROR

,

- - - -

-1--

NOTE:

TILINE

DELAY

IS

EXAGGERATED

FOR

CLARITY

Figure 1-4. TILINE Master-to-Slave Read Cycle Timing

1'----

1'----

Page 15

~

946261-9701

~~------------------

TILINE

•

master that generated

memory write or that the slave's memory data

(TLDAT, 00-15). The slave that generated

removes

TILINE

•

dress the slave memory location to be accessed for the read or write operation.

TILLVE Data

provide two-way data transfer over the TILINE interface.

TILINE

•

the master that the active slave detected a parity error when data was fetched from the

slave's memory. The slave performs no parity check on data fetched from its registers.

1.2.2

DISK CONTROLLER. The disk controller

control ROMs (read only memories) implemented on a full-sized Model 990 PWB. The disk controller can be installed into any standard TILINE chassis slot. The controller slave address

switches located on the controller

two disk drives connected

All disk controller operations are initiated by instructions (commands) from the computer. These instructions are directed to the slave address assigned to the controller.

Terminate

TLGO-.

Address

Memory Error

(TLTM-)

(TLADR,

(TLDAT,

as

shown in Figure

- a low-active, slave-generated signal that informs the

TLGO-

00-19-) -

00-15-) -

(TLMER-)

PWB

as

that the slave has accepted the master's data during a

is

valid on the interface

TLTM-

20

low-active, master-generated signals that ad-

16

low-active master- or slave-generated signals that

- a low-active, slave-generated signal that informs

is

a microprocessor-based controller with a set

described in Section

1-5.

holds

TLTM-

2.

The disk controller supports up to

as

TILINE Data

low until the master

of

is

set by

After a disk controller command has been initiated by the computer, the computer cannot read or

write to the slave address

controller

is

forced to zero.

After initiation

The controller contends for TILINE access on a positional priority basis by cycle-stealing with the

CPU and with any other TILINE master devices that are active. After gaining access to the TILINE

bus, the disk controller transfers 16-bit parallel data words to and from the slave it has addressed (in

most cases, a computer memory module). The disk controller

CPU action after it has been activated).

Figure

PWB).

1.2.3 DISK DRIVES. The Model

actuated disk drive with four moving heads (two each for a fixed and a cartridge disk). The disk

drive assembly contains the read/write heads, voice coil, analog and digital circuit boards, power

supply, power amplifier, cartridge receiver, spindle and drive motor, one fixed disk, filter, air

blower and cooling system.

The disk drive operates at 2400 revolutions per minute (rpm) and has an unformatted storage

capacity

tridge to double its storage capacity. The disk drive

482.60-millimeter (19.00-inch) rack with 266.70 millimeters

1-1)

characteristics

is

busy and a slave request

of

a command by the computer, the disk controller may become a TILINE master.

1-6

shows the disk controller (PWB) and Figure

of

100

million bits

or

mounted in its own standalone cabinet (Figure 1-8). Table

of

the disk drive.

of

the designated controller until the command

is

initiated, the request

DSIO

Cartridge Disk Drive (Figures

of

data. Each drive contains one fixed disk and accepts a removable car-

is

is

terminated normally and the idle bit

is

autonomous (not dependent on any

1-7

shows the disk controller (fine line

available for slide mounting in a standard

(10.50 inches)

is

completed. When the

1-1

and

1-2)

is

a voice coil-

of

panel space (Figure

1-1

lists the performance

1-5

Digital

Systems Division

Page 16

~~------------------

~

946261-9701

50-WIRE

CABLE

937516-0001

-

CABINET

MOUNT

937516-0003

-

RACK

MOUNT

40-WIRE

CABLE

937515-0001

-

CABINET

MOUNT

937515-0003

-

RACK

MOUNT

~--~---~{--------~

6.1

M

(20

FT)

CABLE

(CABINET

MOUNT)

3.05

M

(10FT)

CABLE

(RACK

MOUNT)

CABLE

ADAPTER

,.83

M

(6

FT)

DAISY

CHAIN

CABLES

(A)142127A

CABLE

ADAPTER

937510-0001

P3

P4

DISK

CONTROLLER

ASSEMBLY

(COMPONENT

SIDE)

PI

937505-0001

2262100-0001

P2

NOTES:

1.

WHEN

ONLY

ONE

DISK

DRIVE

IS

USED

THE

TERMINATING

RESISTORS

ARE

LOCATED

ON

THE

PRIMARY

DISK

DRIVE.

2.

STANDARD

CONFIGURATION.

PRIMARY

DISK

DRIVE

(LOGICAL

UNIT

O-FIXED

LOGICAL

UNIT

1-REMOVABLE)2

937513-0001

(RACK

MOUNT)

937513-0005

(CABINET

MOUNT)

SECONDARY

DISK

DRIVE

(LOGICAL

UNIT

2-FIXED

LOGI

CAL

UNI T 3-REMOVABLE)2

TERMINATING

RESISTORS

1

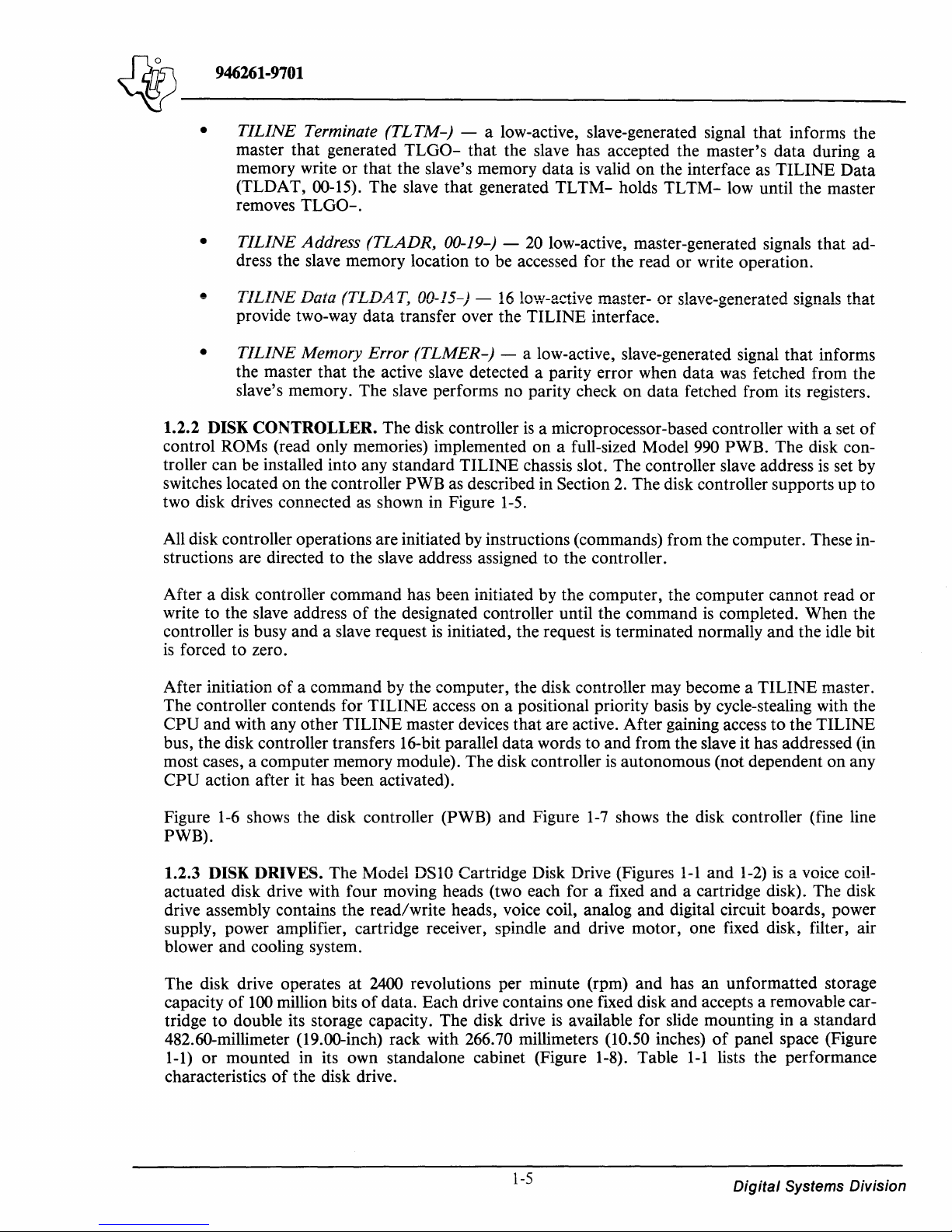

Figure 1-5. Interconnection of Disk Controller and Two Disk Drives

1.3 SYSTEM

OPERATION

The

Model DS 10 Cartridge Disk System provides an auxiliary mass storage facility for

the

Model990

Computer

system. The disk system performs disk-to-memory transfers

between

TILINE

memory

and disk memory. The

data

transfer,

whether

read

or

write,

is

initiated

by

software executing in

the

computer's

central processing

unit

(CPU) and controlled

by

firmware

executing

in

the

microprocessor

of

the

disk controller

after

receipt

of a command

from

the

computer.

The computer addresses the disk system via the disk controller's slave address. The disk controller

then functions as a TILINE master and relieves the computer

of

direct responsibility for the data

transfer. The disk controller fetches parallel data from TILINE memory (write) or transfers serial

data

from disk (read); converts the data to serial or parallel, depending upon the direction

of

the

data

transfer; and completes the transfer. The disk operates under complete control

of

the disk con-

troller.

1-6

Digital

Systems Division

Page 17

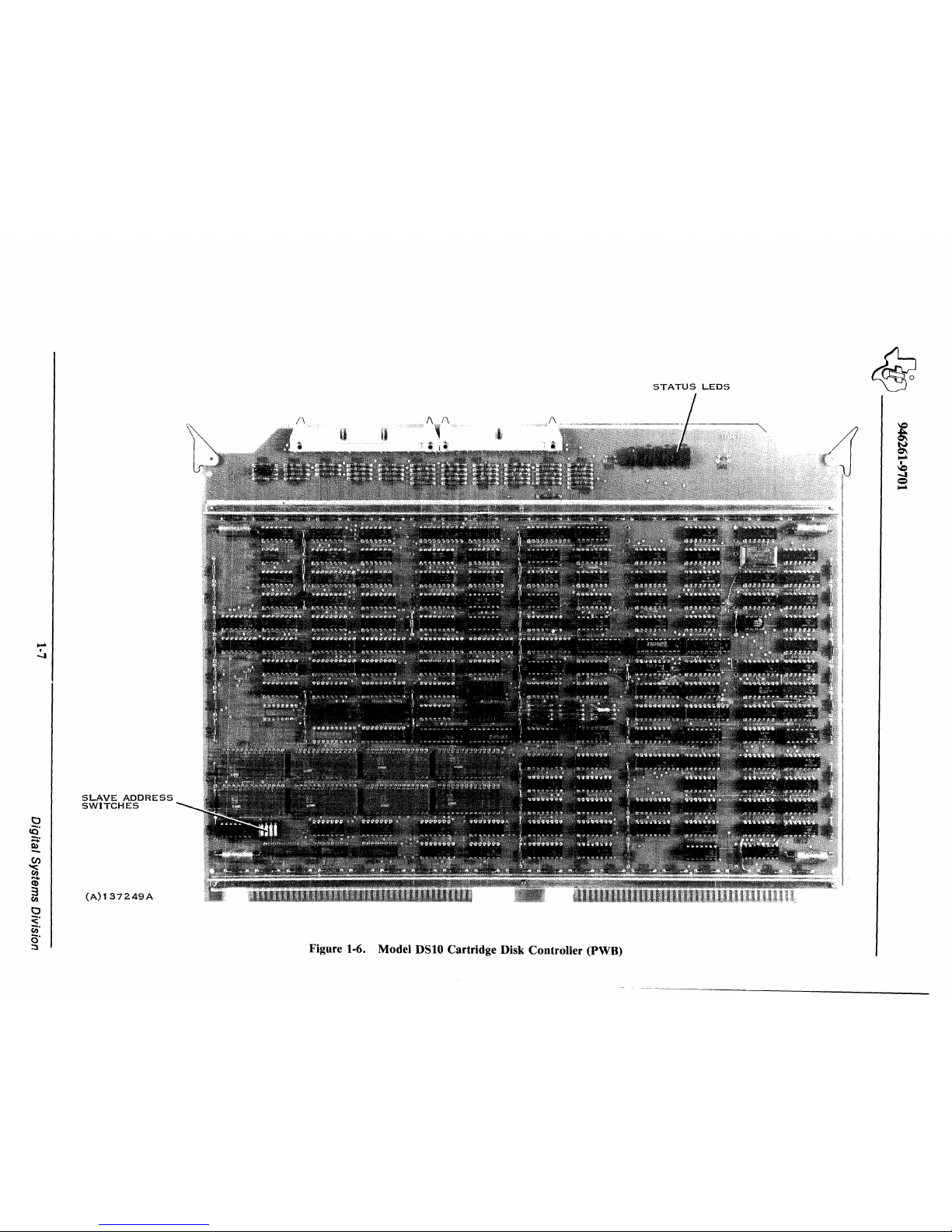

SLAVE

ADDRESS

SWITCHES

(A)137249A

STATUS

LEOS

Figure 1-6. Model DSI0 Cartridge Disk Controller (PWB)

Page 18

~

I

QO

(A)

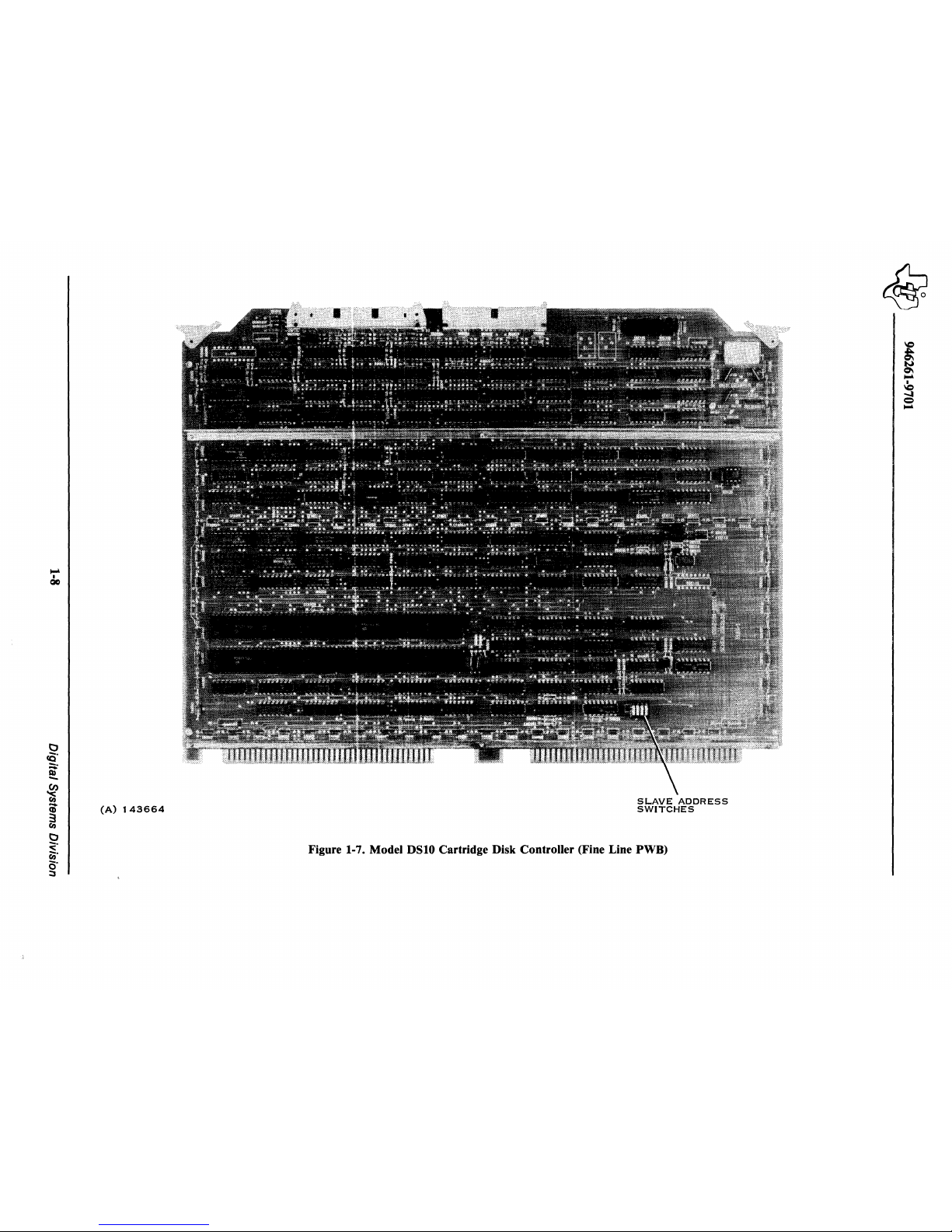

143664

SLAVE

ADDRESS

SWITCHES

Figure 1-7. Model

DSI0

Cartridge Disk Controller (Fine Line PWB)

Page 19

"'ij/

Jd7)\

______

946261-9701

_

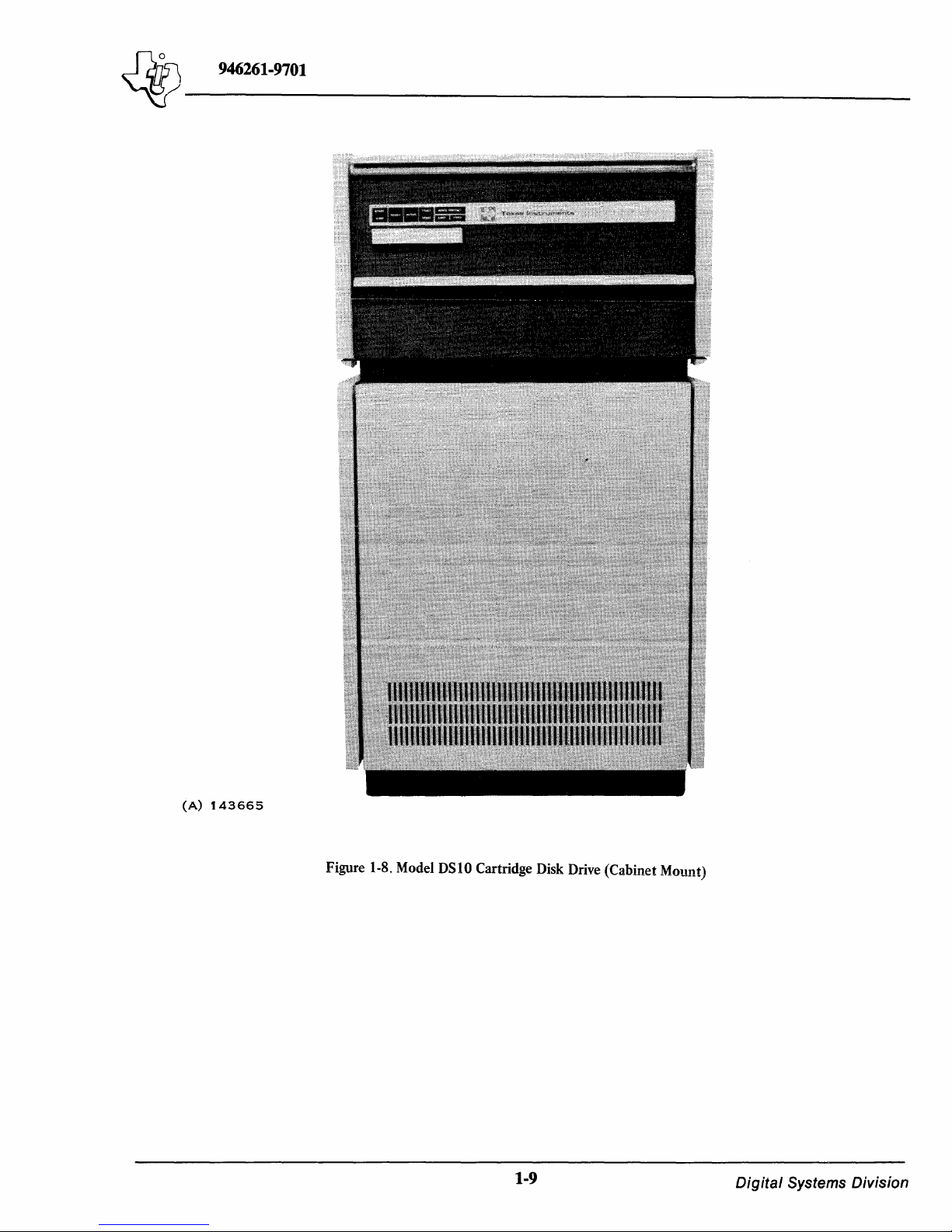

(A)

143665

Figure 1-8. Model OSlO Cartridge Disk Drive (Cabinet Mount)

1-9

Digital

Systems Division

Page 20

~-------

~

946261-9701

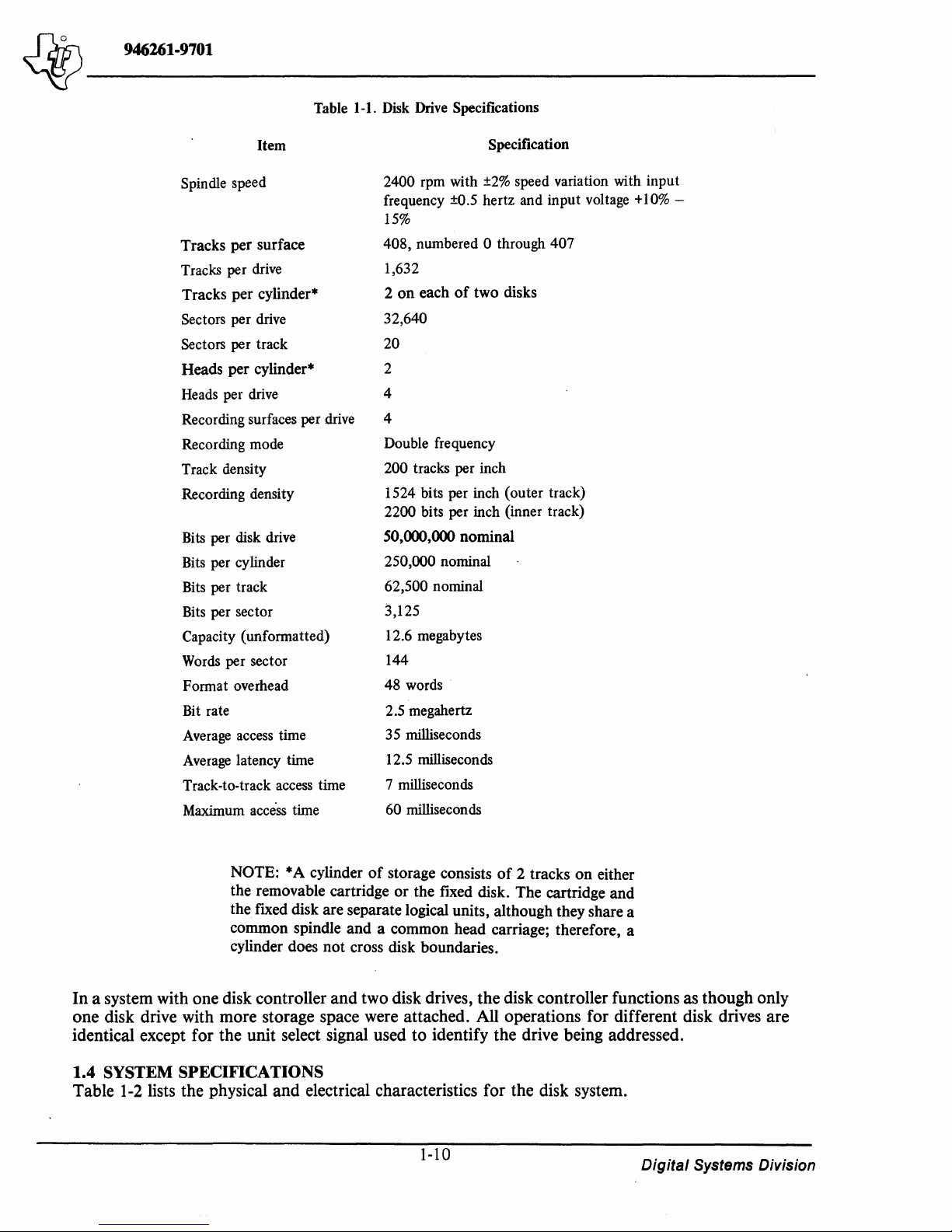

Table

I-I.

Disk Drive Specifications

Item

Specificati on

Spindle speed

2400 rpm with

±2%

speed variation with input

frequency

±0.5 hertz and input voltage +10% -

15%

Tracks per surface

Tracks per drive

Tracks per cylinder*

Sectors per drive

Sectors per track

Heads per cylinder*

Heads per drive

Recording surfaces per drive

Recording mode

Track density

Recording density

Bi

ts

per disk drive

Bits per cylinder

Bits per track

Bits per sector

Capacity (unformatted)

Words

per sector

Format overhead

Bit rate

Average access time

Average latency time

Track-to-track access time

Maximum access time

408, numbered 0 through 407

1,632

2

on

each

of

two disks

32,640

20

2

4

4

Double frequency

200 tracks per inch

i 524 bits per inch (outer track)

2200 bits per inch (inner track)

50,000,000 nominal

250,000 nominal

62,500 nominal

3,125

12.6 megabytes

144

48 words

2.5 megahertz

35 milliseconds

12.5 milliseconds

7 milliseconds

60 milliseconds

NOTE: * A cylinder

of

storage consists

of

2 tracks on either

the removable cartridge

or

the fixed disk. The cartridge and

the fixed disk are separate logical units, although they share a

common spindle and a common head carriage; therefore, a

cylinder does not cross disk boundaries.

In a system with one disk controller and two disk drives, the disk controller functions as though only

one disk drive with more storage space were attached. All operations for different disk drives are

identical except for the unit select signal used to identify the drive being addressed.

1.4 SYSTEM SPECIFICATIONS

Table

1-2

lists the physical and electrical characteristics for the disk system.

1-10

Digital Systems Division

Page 21

'i:Y

946261-9701

~-------

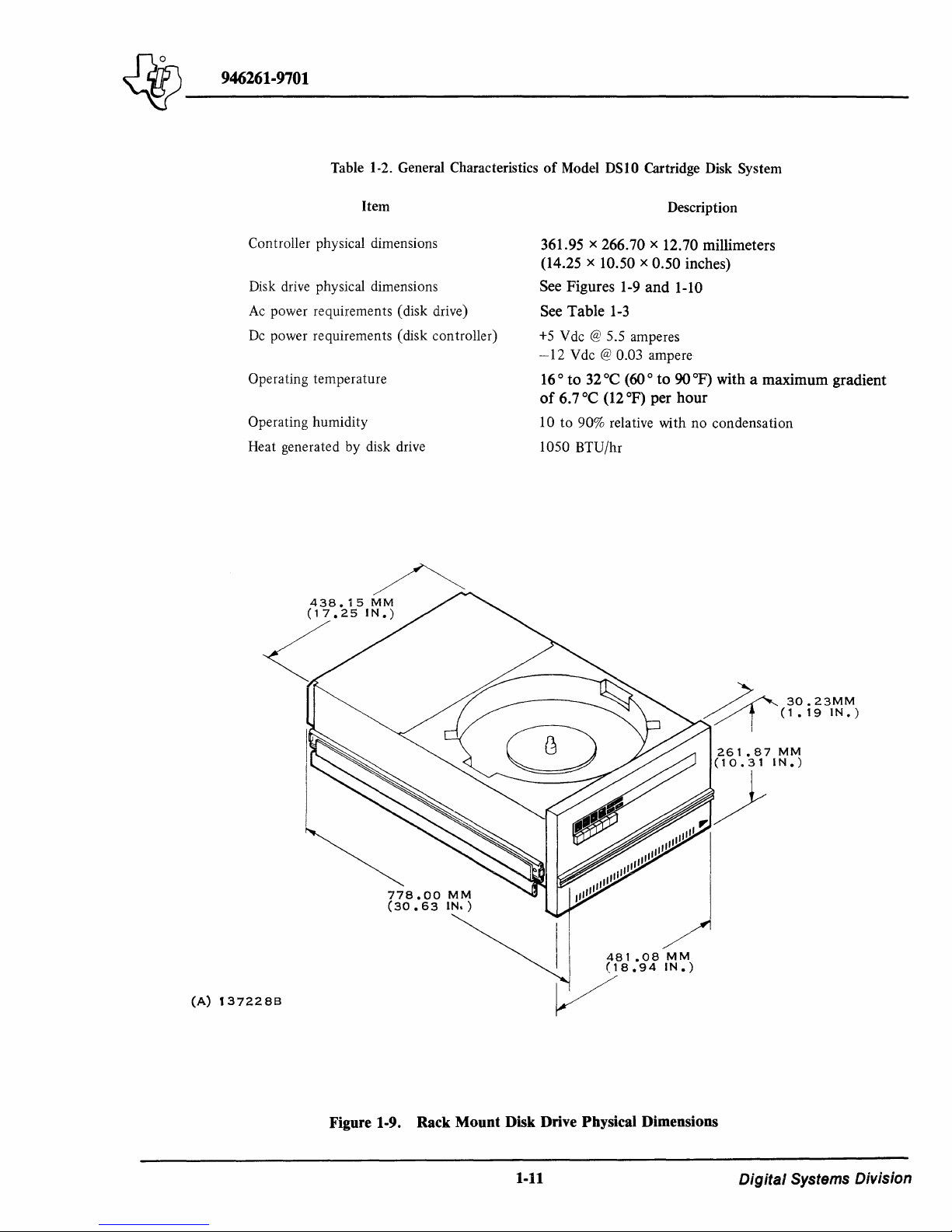

Table 1-2. General Characteristics

Item

Controller physical dimensions

Disk drive physical dimensions

Ac power requirements (disk drive)

Dc power requirements (disk controller)

Operating

Operating

Heat generated

temperature

humidity

by

disk drive

of

Model DSI0 Cartridge Disk System

Description

361.95 x 266.70 x 12.70 millimeters

(14.25 x

See Figures

See

+5

-12

16 ° to

of

10

1050

10.50 x 0.50 inches)

1-9

and 1-10

Table

1-3

V dc @ 5.5 amperes

Vdc

@ 0.03 ampere

32°C (60 °

6.7

°C

(12

to

90% relative

BTU/hr

OF)

to

per

with

90

OF)

with a maximum gradient

hour

no

condensation

(A)

1372288

778.00

(30.63

MM

IN.)

I ,

I

481.08

(18.94

MM

IN.)

V

Figure 1-9. Rack Mount Disk Drive Physical Dimensions

1-11

Digital Systems Division

Page 22

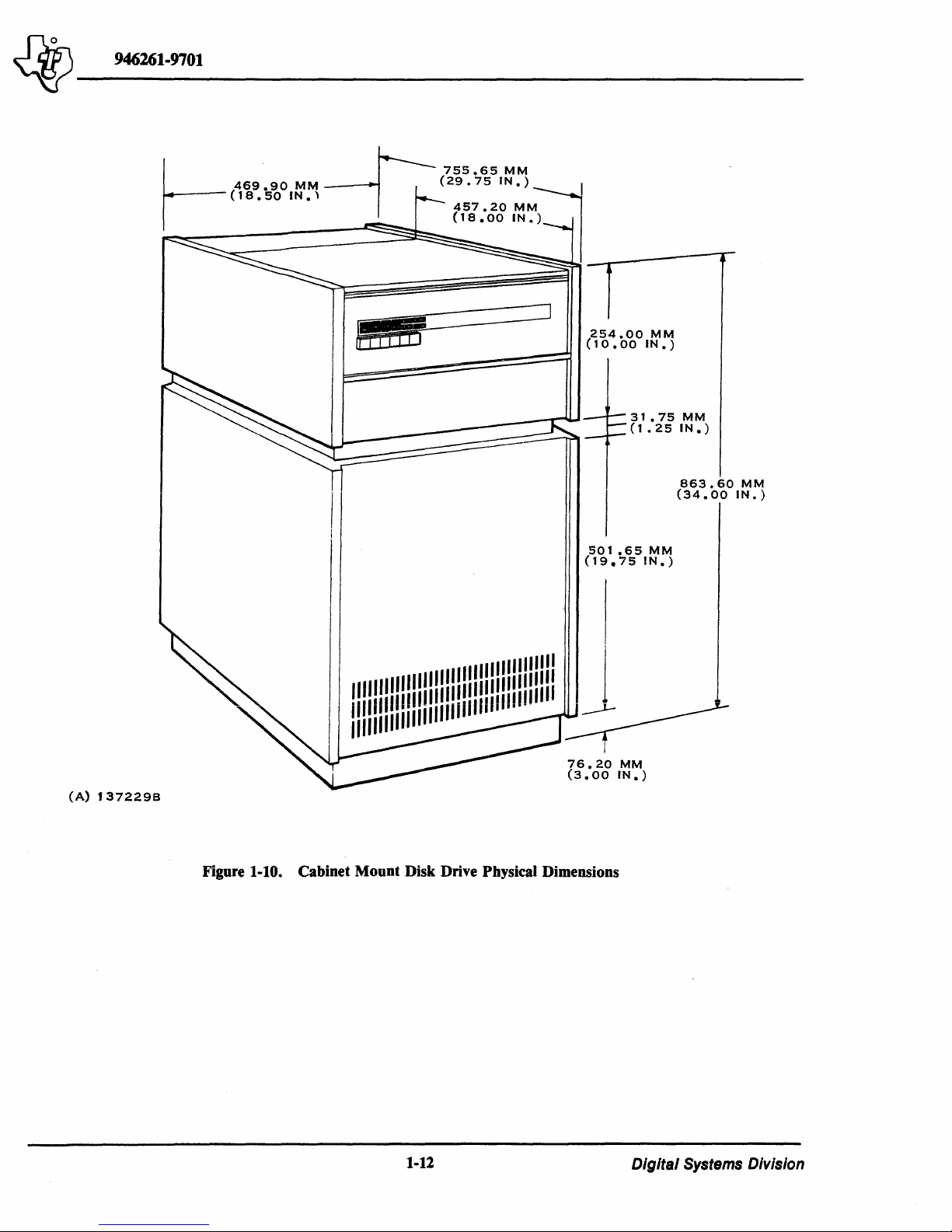

~

946261·9701

~-------

469".90

(18.50

MM---j;(~~~7~51~~;---1

IN.)

457.20MM

~

~~~~~======~~~~~(~'8~.~0~0~IN~·)~111

____

254.00

(10.00

501.65

(19.75

------~

MM

IN.)

31.75

(1.25

MM

IN.)

MM

IN.)

863.60MM

(34.00

IN.)

(A) t 372298

11111111111111

1II111111II1II111111!!!!!111111I1111111

11111111111111

I

76.20

(3.00

Figure 1-10. Cabinet Mount Disk Drive Physical Dimensions

MM

IN.)

1-12

DlgltaJ Systems Division

Page 23

~

946261-9701

~-------

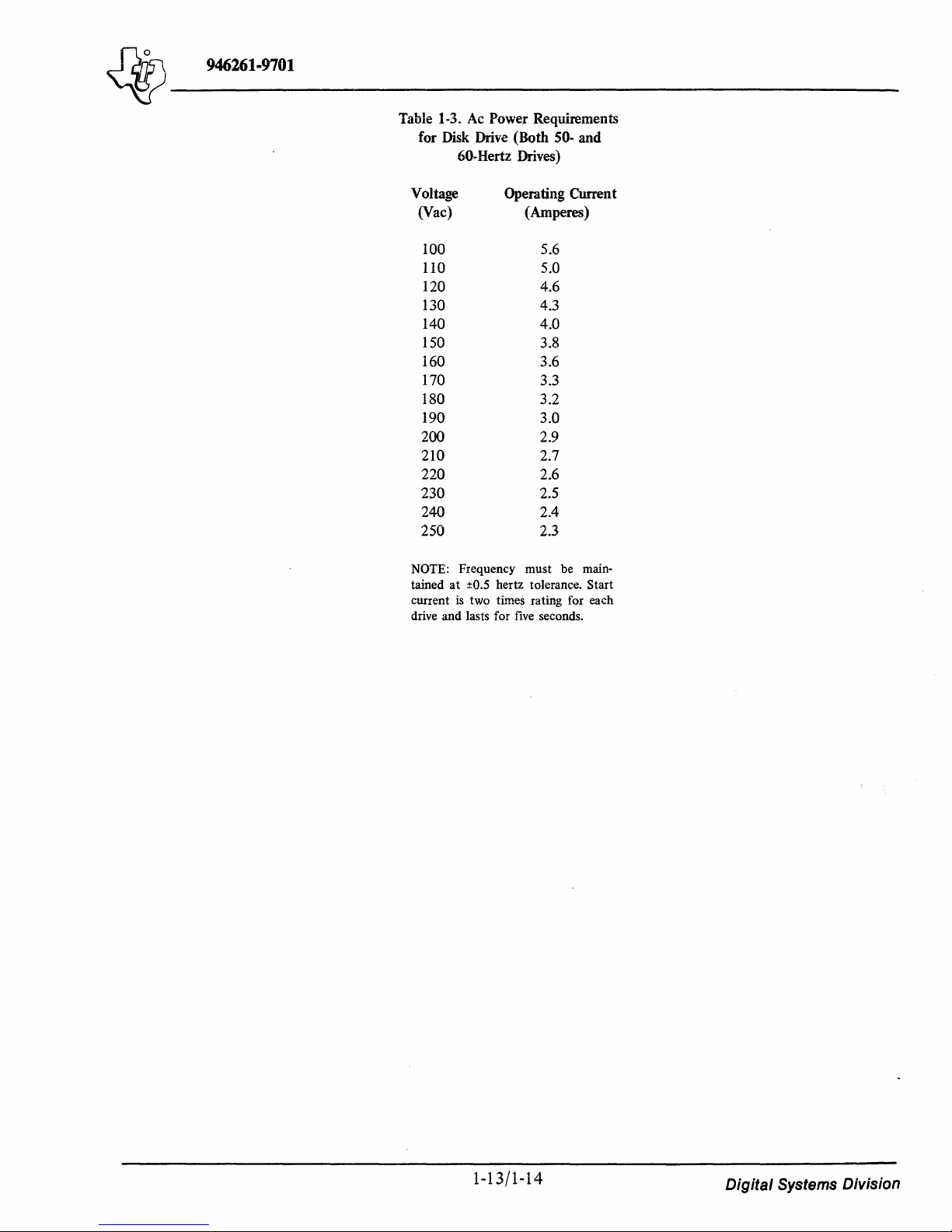

Table 1-3.

for Disk Drive (Both

Voltage Operating Current

(Vac)

NOTE: Frequency must be maintained

current

drive and lasts for

Ac

Power Requirements

60-Hertz Drives)

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

at

:to.S hertz tolerance. Start

is

two times rating for each

50- and

(Amperes)

5.6

5.0

4.6

4.3

4.0

3.8

3.6

3.3

3.2

3.0

2.9

2.7

2.6

2.5

2.4

2.3

five

seconds.

1-13/1-14

Digital Systems Division

Page 24

Page 25

~

946261-9701

~---~---

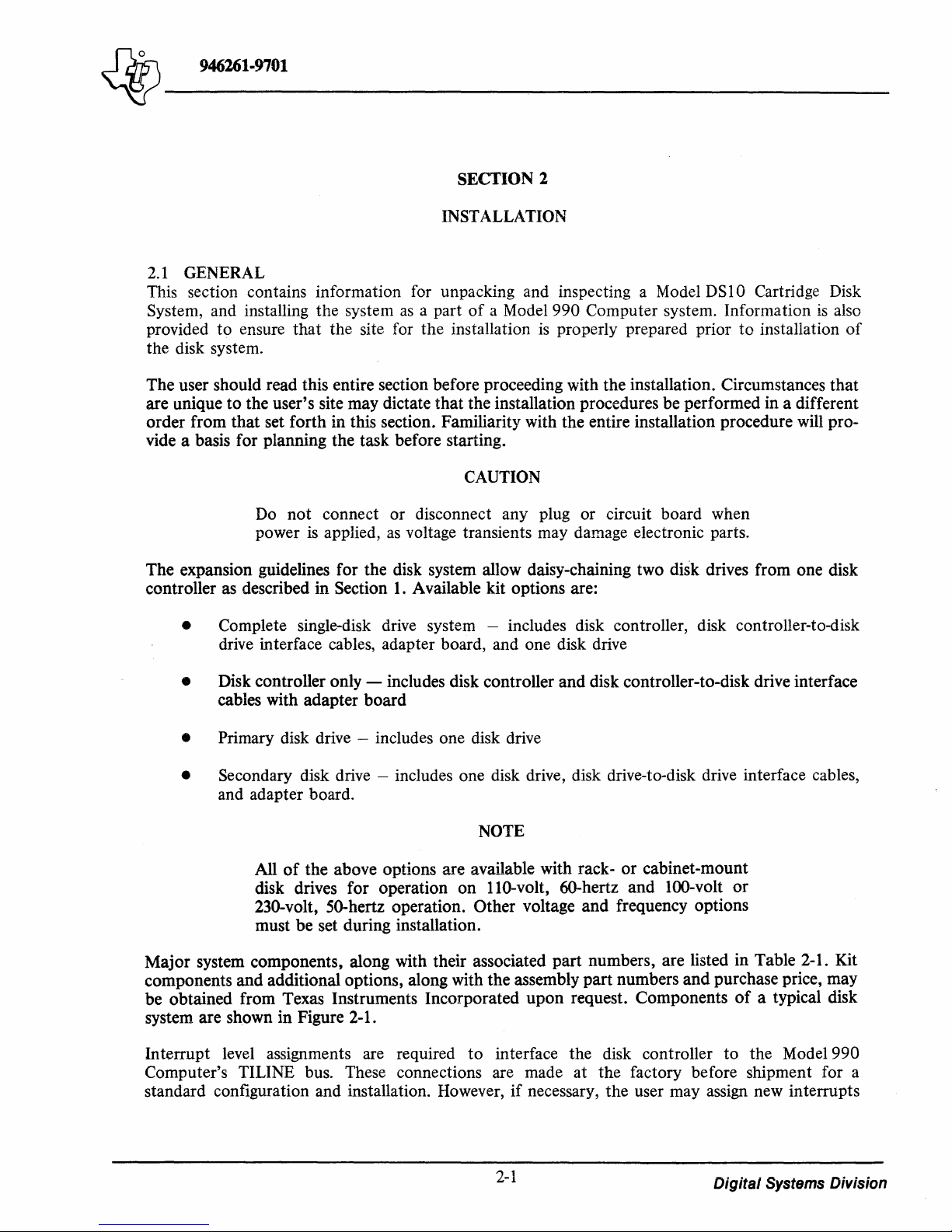

SECTION 2

INSTALLATION

2.1

GENERAL

This section contains information for unpacking and inspecting a Model

System, and installing the system

provided

the disk system.

The user should read this entire section before proceeding with the installation. Circumstances that

are unique

order from that set forth in this section. Familiarity with the entire installation procedure will pro-

vide a basis for planning the task before starting.

to

ensure that the site for the installation

to

the user's site may dictate that the installation procedures be performed in a different

Do

not connect or disconnect any plug or circuit board when

power

is

applied,

as

a part

as

voltage transients may damage electronic parts.

of

a Model 990 Computer system. Information

is

properly prepared prior

CAUTION

DS

10 Cartridge Disk

to

installation

is

also

of

The expansion guidelines for the disk system allow daisy-chaining two

controller as described in Section

• Complete single-disk drive system - includes disk controller, disk controller-to-disk

drive interface cables, adapter board, and one disk drive

• Disk controller only - includes disk controller and disk controller-to-disk drive interface

cables with adapter board

• Primary disk drive - includes one disk drive

• Secondary disk drive - includes one disk drive, disk drive-to-disk drive interface cables,

and adapter board.

All

of

the above options are available with rack- or cabinet-mount

disk drives for operation

230-volt, 50-hertz operation. Other voltage and frequency options

must be set during installation.

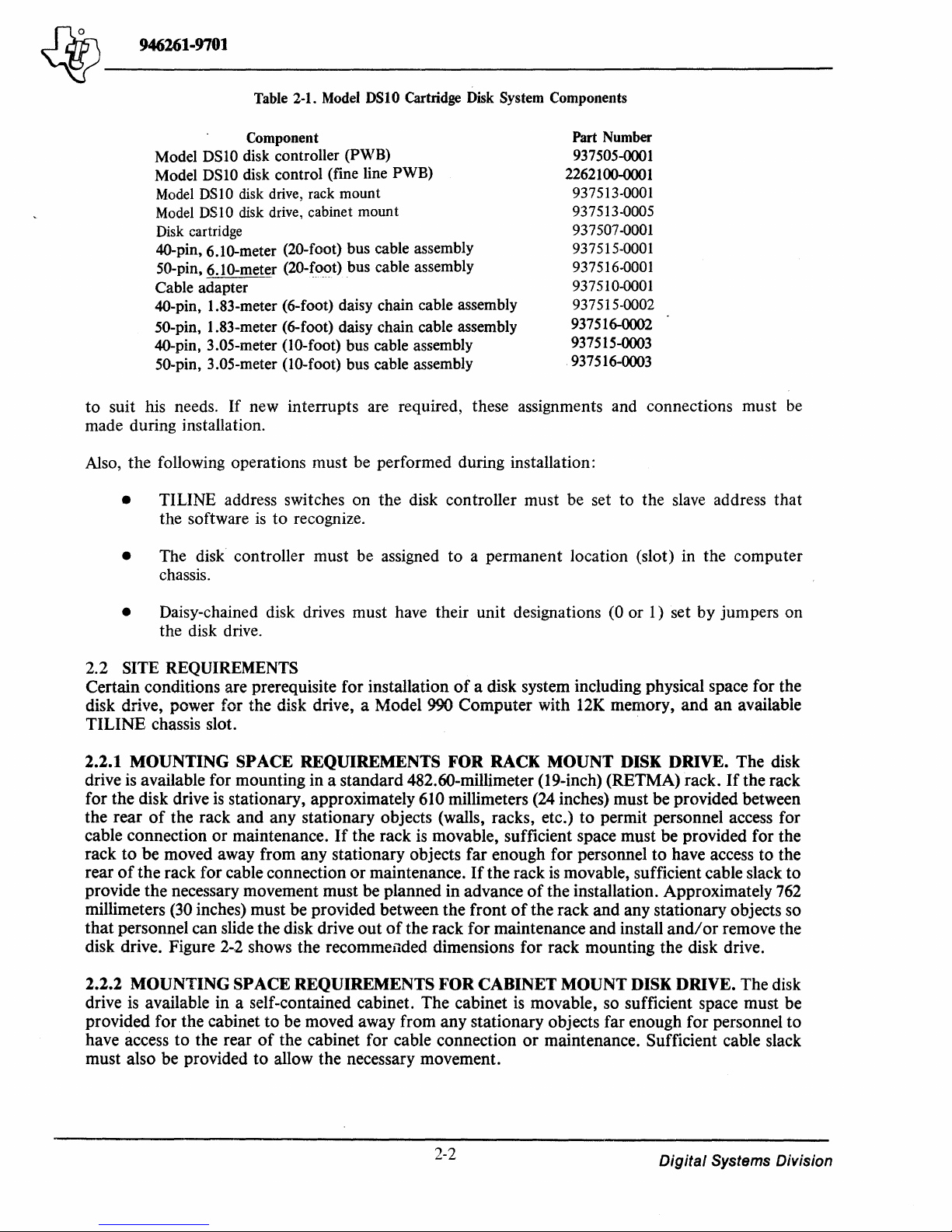

Major system components, along with their associated part numbers, are listed in Table 2-1. Kit

components and additional options, along with the assembly part numbers and purchase price, may

be obtained from Texas Instruments Incorporated upon request. Components

system are shown in Figure 2-1.

1.

Available kit options are:

NOTE

on

110-volt, 6O-hertz and l00-volt

disk drives from one disk

or

of

a typical disk

Interrupt level assignments are required

Computer's TILINE bus. These connections are made at the factory before shipment for a

standard configuration and installation. However,

to

interface the disk controller

if

necessary, the user may assign new interrupts

2-1

to

the Model 990

Digital Systems Division

Page 26

~

946261-9781

~-------

Model

Model

Model

Model

Disk cartridge

4O-pin,

SO-pin,

Cable

4O-pin, 1.83-meter

50-pin,

4O-pin,

50-pin,

DS

DS10 disk

DSI0

DSI0

6.10-meter

6.10-meter

adapter

1.83-meter

3.05-meter

3.05-meter

to suit his needs.

Table 2-1. Model

Component

10 disk

controller

control

disk drive, rack

disk drive, cabinet

(20-foot)

(20-~~-<>t)

(6-foot)

(6-foot)

(10-foot)

(10-foot)

If

new interrupts are required, these assignments and connections must

(PWB)

(fine

mount

bus

bus

daisy

daisy

bus

bus

DSI0

Cartridge Disk System Components

line

PWB)

mount

cable

assembly

cable

assembly

chain

cable

assembly

chain

cable

assembly

cable

assembly

cable

assembly

Part Number

937505-0001

2262100-0001

937513-0001

937513-0005

937507-0001

937515-0001

937516-0001

937510-0001

937515-0002

937516-0002

937515-0003

.937516-0003

made during installation.

Also, the following operations must be performed during installation:

• TILINE address switches on the disk controller must be set to the

the software

is

to recognize.

slave

be

address that

• The disk controller must be assigned to a permanent location (slot) in the computer

chassis.

• Daisy-chained disk drives must have their unit designations (0 or 1) set by jumpers on

the disk drive.

SITE REQUIREMENTS

2.2

Certain conditions are prerequisite for installation

disk drive, power for the disk drive, a Model 990 Computer with

of

a disk system including physical space for the

12K

memory, and

an

available

TILINE chassis slot.

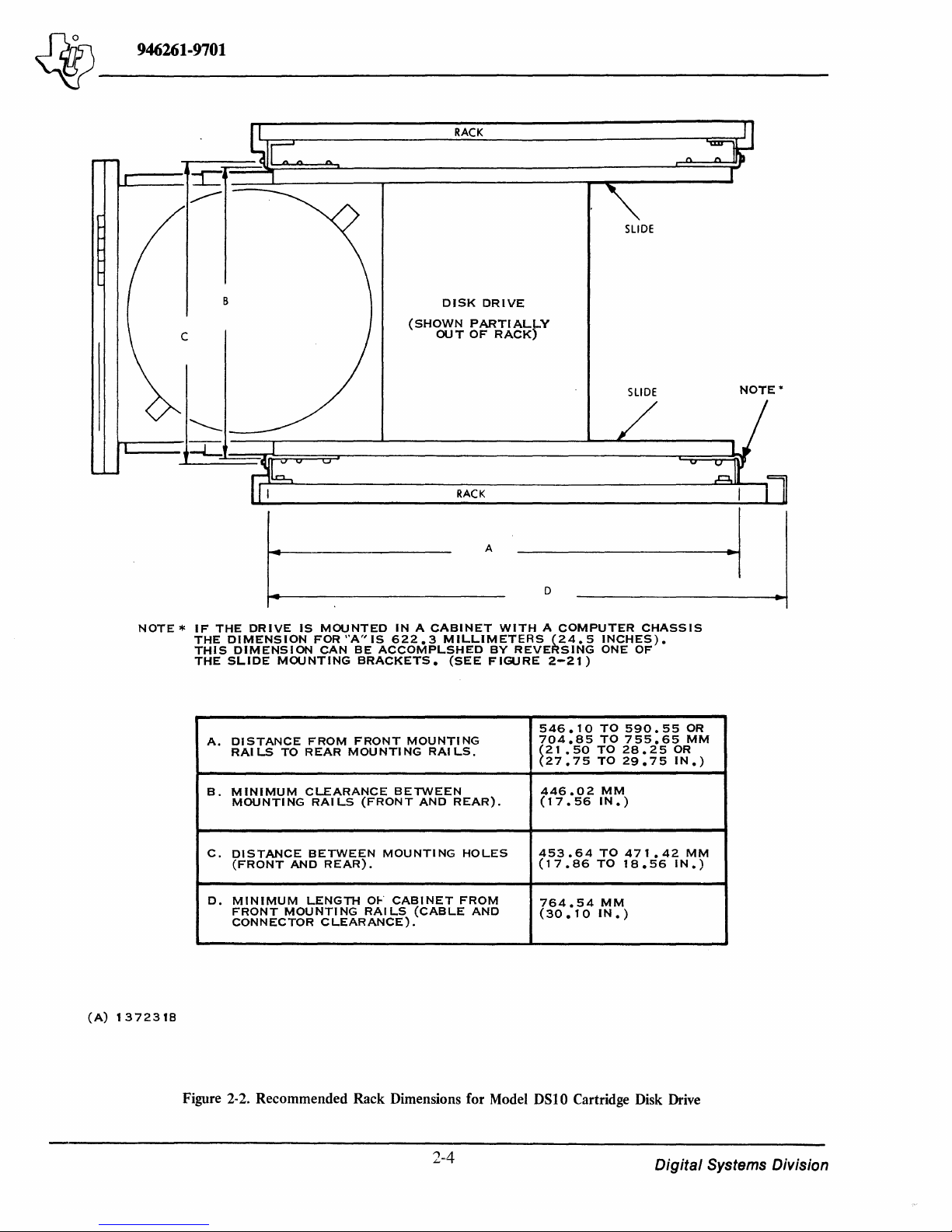

MOUNTING SPACE REQUIREMENTS FOR RACK MOUNT DISK DRIVE. The disk

2.2.1

drive is available for mounting in a standard 482.60-millimeter (19-inch) (RETMA) rack.

for the disk drive

the rear

of

cable connection or maintenance.

rack

to

be moved away from any stationary objects far enough for personnel

rear

of

the rack for cable connection

provide the necessary movement must be planned in advance

millimeters (30 inches) must be provided between the front

that

personnel can slide the disk drive

is

stationary, approximately 610 millimeters (24 inches) must be provided between

the rack and any stationary objects (walls, racks, etc.) to permit personnel access for

If

the rack

or

out

is

movable, sufficient space must be provided for the

maintenance.

of

the rack for maintenance and install

If

the rack

is

movable, sufficient cable slack

of

the installation. Approximately

of

the rack and any stationary objects so

to

have access to the

and/or

If

the rack

remove the

disk drive. Figure 2-2 shows the recommended dimensions for rack mounting the disk drive.

2.2.2

MOUNTING SPACE REQUIREMENTS

drive

is

available in a self-contained cabinet. The cabinet

provided for the cabinet

have access

to

the rear

must also be provided

to

be moved away from any stationary objects far enough for personnel to

of

the cabinet for cable connection

to

allow the necessary movement.

FOR

CABINET MOUNT DISK DRIVE. The disk

is

movable, so sufficient space must be

or

maintenance. Sufficient cable slack

to

762

2-2

Digital

Systems Division

Page 27

N

•

I:H

(A)

143663

Figure 2-1. Model

DSI0

Cartridge Disk System Components

Page 28

~

946261-9701

~-------

RACK

SLIDE

B

DISK

(SHOWN

OUT

DRIVE

PARTIALJ-,Y

OF

RACK)

SLIDE

NOTE

*

~--~-L-==~~~~=u~--------------------------~~~~

RACK

A

~I

D

NOTE * IF

THE

THIS

THE

A.

THE

DRIVE

DIMENSION

DIMENSION

SLIDE

DISTANCE

RAI

MOUNTING

LS

TO

IS

MOUNTED

FOR"A"IS

CAN

FROM

REAR

IN A CABINET

622.3

BE

ACCOMPLSHED

BRACKETS.

FRONT

MOUNTING

MILLIMETERS

(SEE

MOUNTING

RAI

LS.

WITH A COMPUTER

BY

FIGURE

(24.5

REVERSING

2-21)

546.10

704.85

~21

.50

27.75

INCHES).

ONE

OF

TO

590.55

TO

755.65

TO

28.25

TO

29.75

CHASSIS

OR

IN.)

OR

MM

(A)

1372318

MINIMUM

B.

MOUNTING

C.

DISTANCE

(FRONT

MINIMUM

D.

FRONT

CONNECTOR

CLEARANCE

RAILS

BETWEEN

AND

LENGTH

MOUNTING

Figure 2-2. Recommended Rack Dimensions for Model DSIO Cartridge Disk Drive

(FRONT

REAR).

CLEARANCE).

MOUNTI

OF

RAILS

BETWEEN

AND

CABINET

(CABLE

2-4

REAR).

NG

HOLES

FROM

AND

446.02

(17.56

453.64

(17.86

764.54

(30.10

MM

IN.)

TO

TO

MM

IN.)

471.42

18.56

MM

IN.)

Digital

Systems Division

Page 29

~-------

~

946261-9701

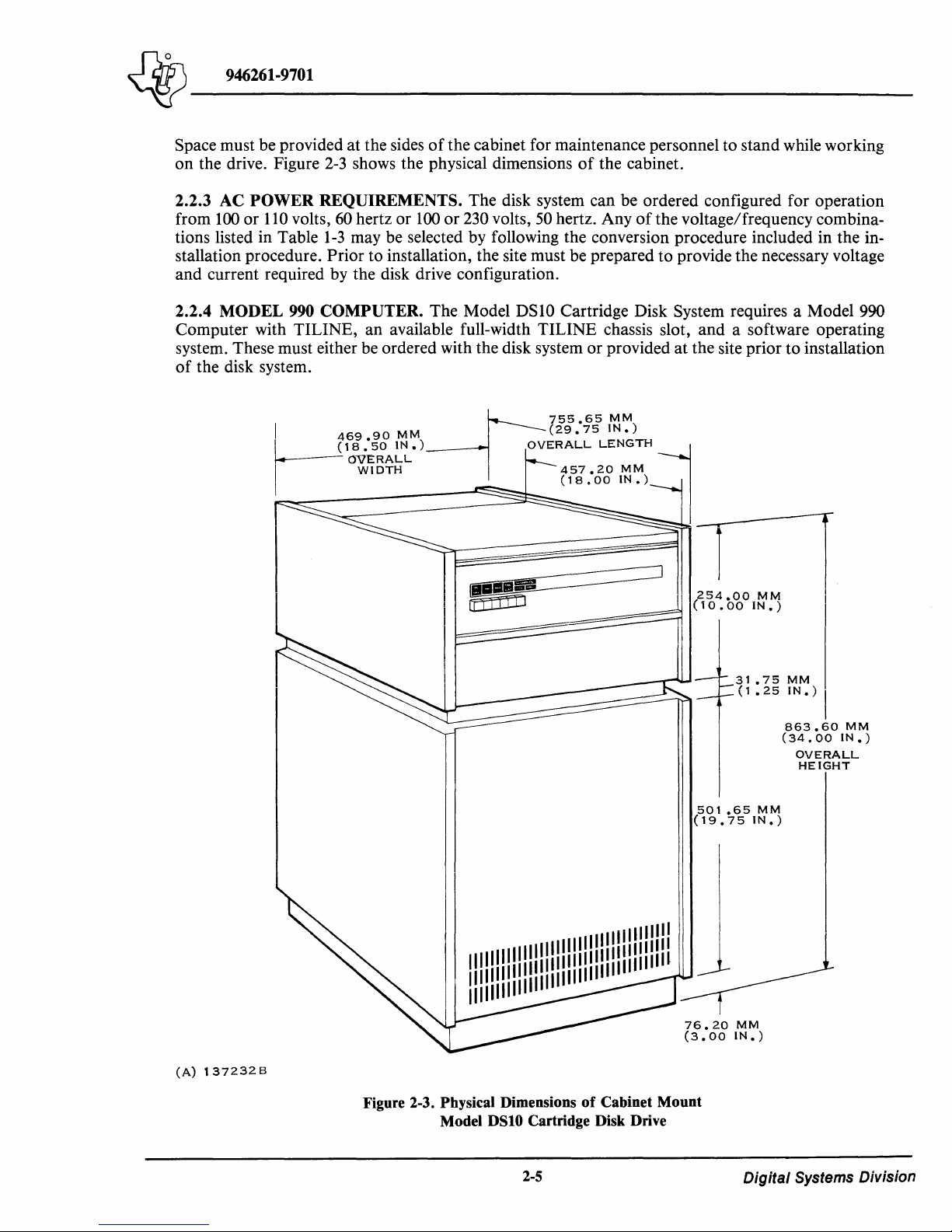

Space must be provided at the sides

of

the cabinet for maintenance personnel to stand while working

on the drive. Figure

2-3

shows the physical dimensions

of

the cabinet.

2.2.3 AC POWER REQUIREMENTS. The disk system can be ordered configured for operation

from

100

or

110

volts,

60

hertz or

100

or

230

volts,

50

hertz. Any

of

the voltage/frequency combina-

tions listed in Table

1-3

may be selected by following the conversion procedure included in the in-

stallation procedure.

Prior to installation, the site must be prepared to provide the necessary voltage

and current required by the disk drive configuration.

2.2.4 MODEL

990

COMPUTER. The Model DS10 Cartridge Disk System requires a Model 990

Computer with TILINE, an available full-width TILINE chassis slot, and a software operating

system. These must either be ordered with the disk system or provided at the site prior to installation

of

the disk system.

(A)

1372326

--17

755.65

MM

I

469

90

MM

(29.75

IN.)

r

18

:50

IN.)

OVERALL

LENGTH

j

OVERALL

WIDTH

457.20

MM

(18,00

IN.)

31.75MM

(1.25

IN.)

I

863.60

MM

(34.00

IN.)

OVERALL

HEIGHT

501.65MM

(19.75

IN.)

I I

11111111111111

I 1

11111

11111

11111

I!!

IIII!

11111111111111

1111111111111111

Figure 2-3. Physical Dimensions

of

Cabinet Mount

Model

DSIO

Cartridge Disk Drive

2-5

Digital Systems Division

Page 30

~

946261-9701

~-------

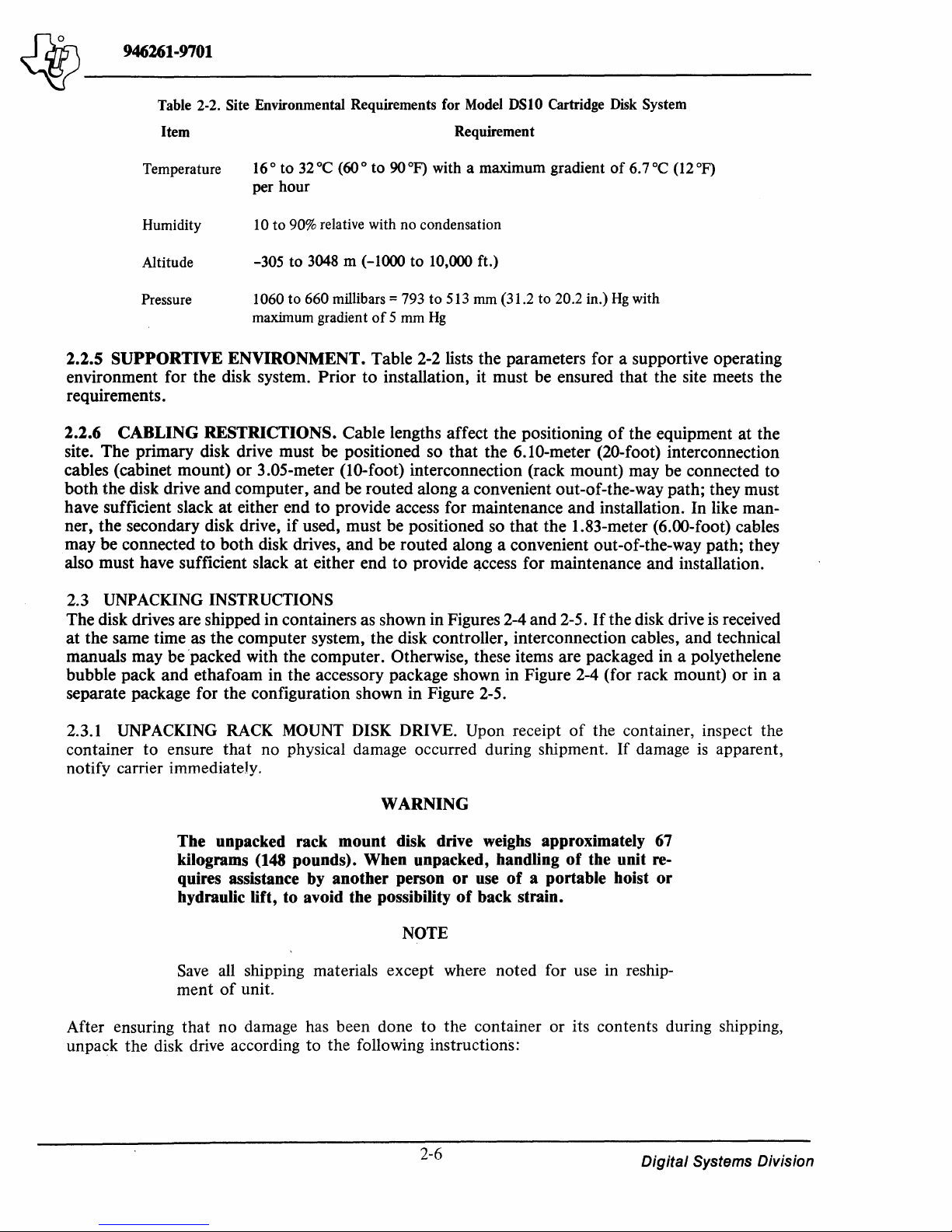

Table 2-2. Site Environmental Requirements for Model DSIO Cartridge

Item

Temperature

Humidity

Altitude

Pressure

16°

to

32°C

(60°

to 90°F) with a maximum gradient

per hour

10

to

90% relative with no condensation

-305 to

1060

maximum gradient

3048

m (-1000 to 10,000 ft.)

to

660 millibars = 793

of

5 mm

Requirement

to

513 mm

Hg

(3l.2

to

20.2 in.)

Disk

of

Hg

System

6.7°C

with

(12

oF)

2.2.5 SUPPORTIVE ENVIRONMENT. Table 2-2 lists the parameters for a supportive operating

environment for the disk system. Prior to installation, it must be ensured that the site meets the

requirements.

2.2.6 CABLING

RESTRICTIONS. Cable lengths affect the positioning

of

the equipment at the

site. The primary disk drive must be positioned so that the 6.10-meter (20-foot) interconnection

cables (cabinet mount) or 3.05-meter (lO-foot) interconnection (rack mount) may be connected to

both the disk drive and computer, and be routed along a convenient out-of-the-way path; they must

have sufficient slack at either end to provide access for maintenance and installation. In like manner, the secondary disk drive,

if

used, must be positioned

so

that the 1.83-meter (6.00-foot) cables

may be connected to both disk drives, and be routed along a convenient out-of-the-way path; they

also must have sufficient slack at either end to provide

~ccess

for maintenance and installation.

2.3

UNPACKING INSTRUCTIONS

The disk drives are shipped in containers as shown in Figures 2-4 and

2-5.

If

the disk drive

is

received

at the same time as the computer system, the disk controller, interconnection cables, and technical

manuals may be

bubble pack and ethafoam in the accessory package shown in Figure

'packed with the computer. Otherwise, these items are packaged in a polyethelene

2-4

(for rack mount) or in a

separate package for the configuration shown in Figure 2-5.

2.3.1

container

notify carrier immediately.

UNPACKING RACK MOUNT DISK DRIVE. Upon receipt

to

ensure

that

no physical damage occurred during shipment.

of

the container, inspect the

If

damage

is

apparent,

WARNING

The unpacked rack mount disk drive weighs approximately

kilograms

(148

quires assistance by another person

hydraulic lift, to avoid the possibility

Save

all shipping materials except where noted for use in reship-

ment

of

unit.

After ensuring

unpack the disk drive according

that

no damage has been done

pounds). When unpacked, handling

or

use

of

a portable hoist

of

back strain.

NOTE

to

the container

to

the following instructions:

or

of

the unit re-

its contents during shipping,

67

or

2-6

Digital

Systems Division

Page 31

~

946261-9701

~-------

(A)

137233

Figure 2-4. Rack Mount Disk Drive Shipping Configuration

2-7

Digital Systems Division

Page 32

4r

---------------------------------------------------------------------------------------------------------------------------------------

946261-9701

(A)

137234A

Figure 2-5. Cabinet Mount Disk Drive Shipping Configuration

2-8

Digital

Systems Division

Page 33

~

Jd7s\

______

946261-9701

(A)

_

137235

Figure 2-6. Placement

1.

Position container so

2. Cut and discard metal bands around shipping container.

3.

Open

assembly.

4. Remove manual from top

5.

Grasp accessory package

6.

Lift cardboard inner tube

top

flaps

that

of

shipping container and lift shipping container

by

of

Disk Drive for Shipping Bolt Removal

address label is upright.

of

accessory package and read unpacking instructions.

its sides, lift

off

disk drive and set aside.

WARNING

it

out

of

inner tube, and set it aside.

The following step requires at least two persons.

7. Grasp disk drive by placing fingers underneath sides

Rotate unit 90 degrees as shown in Figure 2-6

ing

bolt

heads underneath

wood

base.

and

of

set unit

unit

on

and

foam

by

flaps

lift clear

base

to

up

of

foam

expose

and

off

base.

mount-

9. Open plastic bag surrounding disk drive; press bag

now

be

lifted free

10. Remove three screws (Figure 2-7)

tronics cover.

11.

Remove carriage lock pin (Figure 2-8) by rotating

and

pulling straight up. Store pin

of

wood base

and

plastic protective bag.

that

hold electronics cover in place

head

on

side

of

magnet as shown in Figure 2-8.

2-9

down

of

around

pin 90 degrees counterclockwise

disk drive sides.

and

Digital Systems Division

Unit

remove elec-

can

Page 34

~

946261-9701

~~------------------

(A)

137236

12.

(990-1077-15-5)

Press in on outboard end

ward until free

side

of

card cage.

13. Lift card cage cover

The following steps are necessary only

installation.

14.

Remove control PWB and verify that SI settings are as shown in Figure 2-11.

15.

Replace control PWB.

Figure 2-7. Location

of

card cage cover clamp (Figure

of

screw. Lift up

off

and set aside.

on

free end

of

Electronics Cover Screws

NOTE

Refer to Figure 2-10 for steps

NOTE

2-9)

and move clamp end for-

of

clamp to release end hooked onto inboard

14

through 23.

if

a problem occurs during

16.

Remove sector PWB and verify that switch settings are as shown in Figure 2-12.

17.

Replace sector PWB.

18.

Remove servo PWB and verify that switch settings are

2-10

as

shown in Figure 2-13.

Digital

Systems Division

Page 35

~

946261-9701

~~------------------

TO

INSTALL:

INSERT

HOLE

COUNTERCLOCKWISE,

ALLOW

TO

TWIST

STRAIGHT

IN

AClUATOR

PIN

REMOVE:

90°

LEG

OF

PRES!:)

TO

PIN

NORMAL

FRAME;.

TO

RElURN

COUNTERCLOCKWISE

INTO

TWIST

DOWN

SMALL

900

AND

POSITION.

AND

PULL

UP.

CARRIAGE

BE

STORED

MAGNET

AS

LOCK

ON

SHOWN

PIN

SIDE

MAY

OF

(A)

137237

19.

20.

21.

22.

(990-977-35-11)

Replace servo PWB.

Remove data recovery PWB and verify that switch settings are

Replace data recovery PWB.

Remove r

/w

/ e PWB and verify that resistor modules are in orientation shown in Figure

2-15.

23.

Replace

r/w/e

PWB.

Figure 2-8. Carriage Lock Pin Location

2-11

as

shown in Figure 2-14.

Digital

Systems Division

Page 36

~'{j~o

_________________

_

~

946261-9701

(A)137238A

Figure 2-9. Card

Cage

Cover and Clamp Location

24. Replace card cage cover and clamp.

CLAMP

OUTBOARD

END

CARD

CAGE

COVER

25. Reinstall electronics cover. Disk drive

is

now ready for

attachment

of

slides.

2.3.2 UNPACKING DISK CONTROLLER. The disk controller

is

packaged in the special two-

piece ethafoam package shown in Figure 2-16. For the rack mount disk drive, the controller

is

shipped inside the accessory package shown in Figure 2-4. For the cabinet mount disk drive, the controller

is

shipped in a separately shipped accessory package similar to the one for the rack mount

disk drive. The unpacking procedures for the controller are the same for all configurations once the

accessory package has been separated from the rest

of

the shipping materials. The instructions are as

follows:

2-12

Digital

Systems Division

Page 37

~

946261-9701

~~------------------

DATA

RECOVERY

PWB

(A)

137239

1.

2.

(990-977-35-11)

Use

a utility knife

Remove disk controller package.

3. Remove tape holding two pieces

that

is

on top. Either the circuit board or the ethafoam spacer

4.

If

circuit board

package and turn it over.

Figure 2-10. Disk

to

slit tape holding down

is

exposed (it

is

Drive

PWB

Locations

top

flaps

of

accessory package.

of

ethafoam together and carefully lift

is

inside the ethafoam piece

2-13

you

off

the half

now exposed.

have lifted), reassemble

Digital

Systems Division

Page 38

~

j}r1.s\

946261-9701

______

_

~

INDICATES

SWITCH

POSITION

0000000

0000000

0000000

0000000

0000000

0000000

~

o 0 51 0 0 0

~r

INVALID

CYL. A DO.

DROP

READY

(DENSITY

NO

ACTIVE

ACTIVE

R. T .Z.S.

SPARE

(A)

137240

STATUS

FIXED D 15K

LOW

HIGH

RESETS

INTERRUPT

WIT H FAULT

)

100

ERRUPT

INT

TERRUPT

IN

FAULT

Figure 2-I

TPI

I.

Control

0

N

X

Y

X

0

5

1

8

'X

7

6

X

5

X

4

3

2

1

Xi

PWB

2-14

F

F

X.

READY

STAYS

FAULT

DISK

HIGH

LOW

INTER

DOESN'T

TRUE

INTE

DURING

200

TPI

FIXED

ACTIVE

ACTIVE

R.

T.Z.S.

SPARE

Switch Settings

NDITION

CO

RRUPT

RUPT

RESET

FAULT

Digital

Systems Division

Page 39

~

946261-9701

~

INDICATES

SWITCH

POSITION

..-

S4

rttB-B

0 0

0

.....

0

0

0

0

0

ONLY ONE

SWITCH

FROM

THIS

GROUP

CAN

BE

ON.

0

5

F

4

F

r

)(

1

2

'Y

)

3

4

1;(

5

'l

IX

6

7

I

I

-l

0

N

:)(

X

+ 1

+

+

+ S

74

+ 2

X 1

X2

32

16

FIX

FI

FI

FIX

FIX

FIX

FIX

FIX

ED

XED

XED

ED

ED

ED

ED

ED

DYNAMIC

FUTURE

2400

FIXED

FIXED

INDEX

2400

NO

DYNAN\IC

it.

INDEX

DELAYED

&

INDEX

SECTOR.e'

0 0

0 0

0 0

0

0 0

0

51

BRAKE

FIXED

INDEX

RPM

INDEX

TIMING &

INDEX

TIMING &

ANGLE

5O~'

RPM

BRAKE

TIMING

INDEX

TIMING

DIRECT

0 0

~

5 ..

.....

0 0

o 5

: 3

')

)

)(

-X

X

MULTI

SECTOR,

SINGLE

SECTOR

fiXED

INDEX

0

0

0

n n n

U U U

0 0 0

0 0

0

N

, 1

2

3

4

IX

5

X

6

7

8 IX

INDEX

OR

INDEX

NO

DYNAMIC

FUTURE

1500

RPM

FIXED

FIXED

INDEX

1500

RPM

DYNAN\IC

AT

SECTOR.t

PRIOR

INDEX

INDEX

ANGLE

FIXED

TIMING &

TIMING &

BRAKE

TO

ONLY ONE

SWITCH

THIS

GROUP

CAN

BE

BRAKE

INDEX

JOl0'

FROM

ON.

INDEX

INDEX

HARD

SOFT

-

TIMING

TIMING

SECTOR

SECTOR

I

~

F 2

X2

) 3

~

4

) 5

6

~

)(8

&.

.&

0

5

N

1

IX

7

IX

I~

F

Ix

+ 1

+

32

+

16

7

SCA

+

4C

+

2C

X 1 C

X 2 C

5 0

1 N

1

IX

2

IX

3

4

IX

CA

RT

ART

C

ART

C

RT

ART

ART

ART

ART

INDEX

INDEX

SOFT

HARD

TIMING &

TIMING &

SECTOR

SECTOR

(A)

137241

Figure 2-12. Sector

PWB

Switch Settings

2-15

Digital Systems Division

Page 40

~-------

"'iY

946261-9701

NORMAL

OPERATION

FEOT

ADJUST

~.

INDICATES

SWITCH

POSITION

ADDRESS

INTERlOCK

....

______________

....

CD

ON

CYLINDER

GOES

FALSE

X 3

ADDRESS

INTERLOCK

PULSE

DDDDDD~

0000000

0000000

0000000

0000000

0000000

I.'

52~:

II

I

51

I

-

II.

I I

III

I I I

III

II

II

I

l

200

TPI

I

I I

SPARE

ON

IXIXIX

X X X

.xXIX

5 1 1 2 3 4 5 6 7 8 9

1t*i

v -

OFF X

I'--

__

~---~JSPARE

I

100

TPI

TO

CURRENT

CYLINDER

BUT

V 2

NO

CHANGE

IN

ON

11\

NOT

FOR

ILLEGAL

AD

DR

ES:-.-S

"-+----t'o-I

CYLINDER

WITH

ILLEGAL

DURING

STROBE

FOR

SEEK

J-

\!I

ON

CYLINDER

GOES

FALSE

AD~ESS

OR