Page 1

STEP/DIR

Step size

nFAULT

4 to 18 V

Controller

M

+ t

+ -

DRV8846

Stepper

Motor Driver

1 A

1 A

Decay Mode

1/32 µstep

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

DRV8846 Dual H-Bridge Stepper Motor Driver

1 Features 3 Description

1

• PWM Microstepping Motor Driver

– Built-In Microstepping Indexer

– Up to 1/32 Microstepping

– Step/Direction Control

• Multiple Decay Modes

– Adaptive Decay

– Mixed Decay

– Slow Decay

– Fast Decay

• Configurable Off-Time PWM Chopping

– 10-, 20-, or 30-μs Off-Time

• Adaptive Blanking Time for Smooth Stepping

• 4- to 18-V Operating Supply Voltage Range

• 1-A Continuous/RMS Output Current per H-Bridge

(at 25°C)

• Low-Current Sleep Mode

• 3-Bit Torque DAC to Scale Motor Current

• Thermally Enhanced Surface Mount Package

• Protection Features

– VM Undervoltage Lockout (UVLO)

– Overcurrent Protection (OCP)

– Thermal Shutdown (TSD)

– Fault Condition Indication Pin (nFAULT)

2 Applications

• Printers

• Scanners

• Video Security Cameras

• Projectors

The DRV8846 provides a highly-integrated stepper

motor driver for cameras, printers, projectors, and

other automated equipment applications. The device

has two H-bridges and a microstepping indexer and

is intended to drive a bipolar stepper motor. The

output block of each H-bridge driver consists of Nchannel and P-channel power MOSFETs configured

as full H-bridges to drive the motor windings. The

DRV8846 is capable of driving up to 1-A full scale

output current (with proper heatsinking and TA=

25°C).

A simple STEP/DIR interface allows easy interfacing

to controller circuits. Pins allow configuration of the

motor in full-step up to 1/32-step modes. Decay mode

is configurable so that adaptive decay, slow decay,

fast decay, and mixed decay can be used. The PWM

current chopping off-time can also be selected. A lowpower sleep mode is provided which shuts down

internal circuitry to achieve very-low quiescent current

draw. This sleep mode can be set using a dedicated

nSLEEP pin.

Internal protection functions are provided for UVLO,

overcurrent protection, short circuit protection, and

overtemperature. Fault conditions are indicated via a

nFAULT pin.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

DRV8846 QFN (24) 4.00 × 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

DRV8846

SLLSEK2 –JUNE 2014

(1)

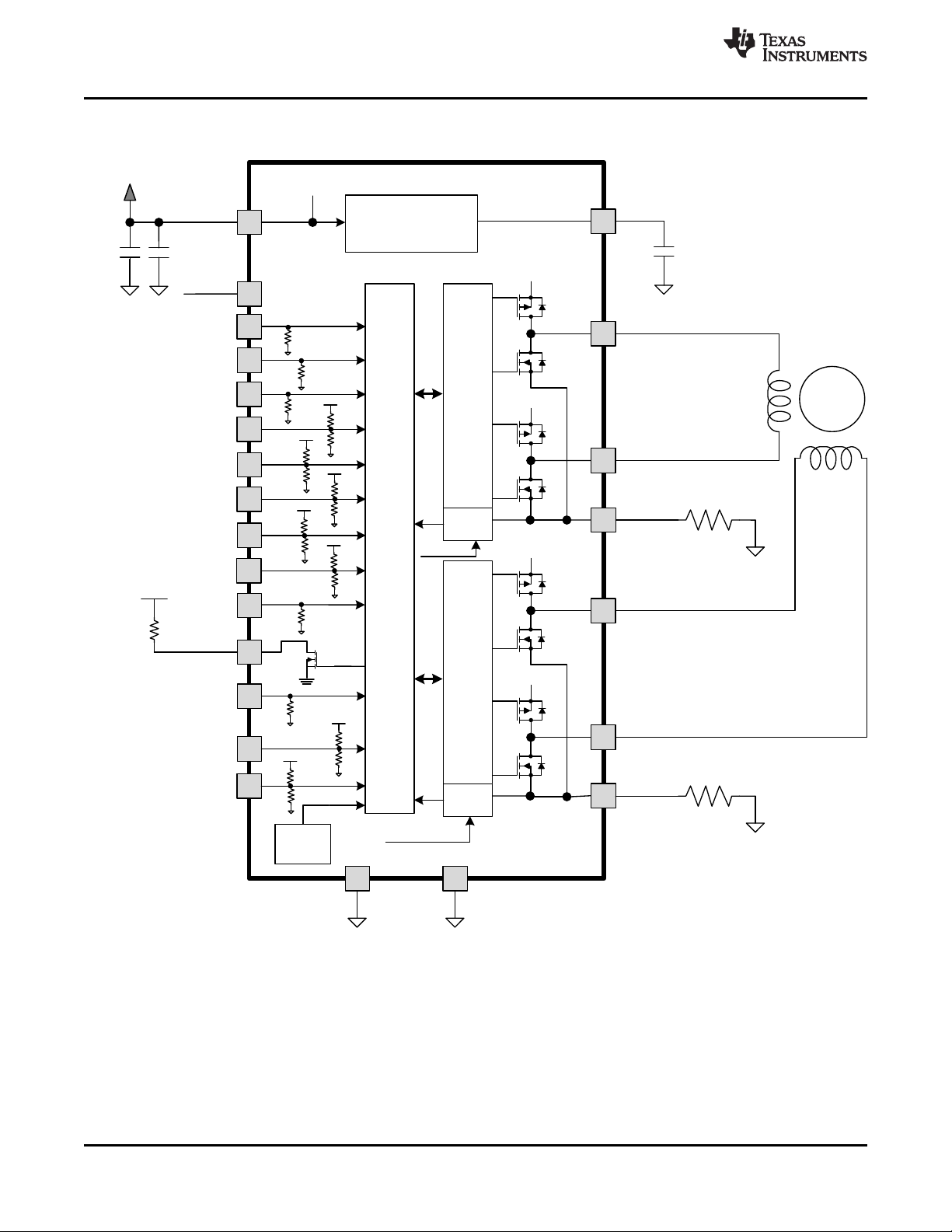

4 Simplified Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Simplified Schematic............................................. 1

5 Revision History..................................................... 2

6 Pin Configuration and Functions......................... 3

7 Specifications......................................................... 5

7.1 Absolute Maximum Ratings ...................................... 5

7.2 Handling Ratings....................................................... 5

7.3 Recommended Operating Conditions....................... 5

7.4 Thermal Information.................................................. 5

7.5 Electrical Characteristics........................................... 6

7.6 Timing Requirements................................................ 7

7.7 Typical Characteristics.............................................. 8

8 Detailed Description .............................................. 9

8.1 Overview ................................................................... 9

5 Revision History

DATE REVISION NOTES

June 2014 * Initial release.

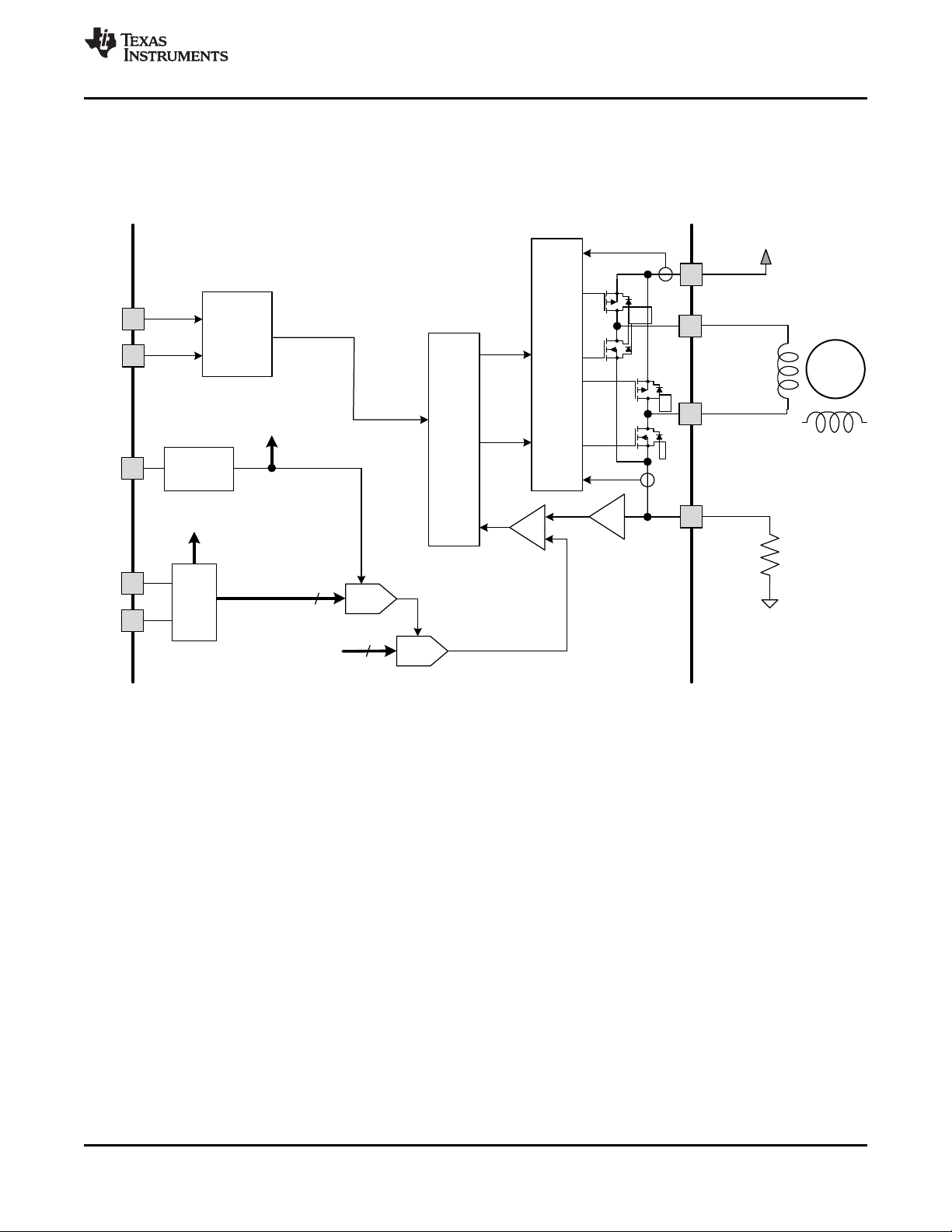

8.2 Functional Block Diagram....................................... 10

8.3 Feature Description................................................. 11

8.4 Device Functional Modes........................................ 22

9 Application and Implementation........................ 23

9.1 Application Information............................................ 23

9.2 Typical Application ................................................. 23

10 Power Supply Recommendations ..................... 26

11 Layout................................................................... 26

11.1 Layout Guidelines ................................................. 26

11.2 Layout Example .................................................... 26

12 Device and Documentation Support................. 27

12.1 Trademarks ........................................................... 27

12.2 Electrostatic Discharge Caution............................ 27

12.3 Glossary ................................................................ 27

13 Mechanical, Packaging, and Orderable

Information........................................................... 27

2 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

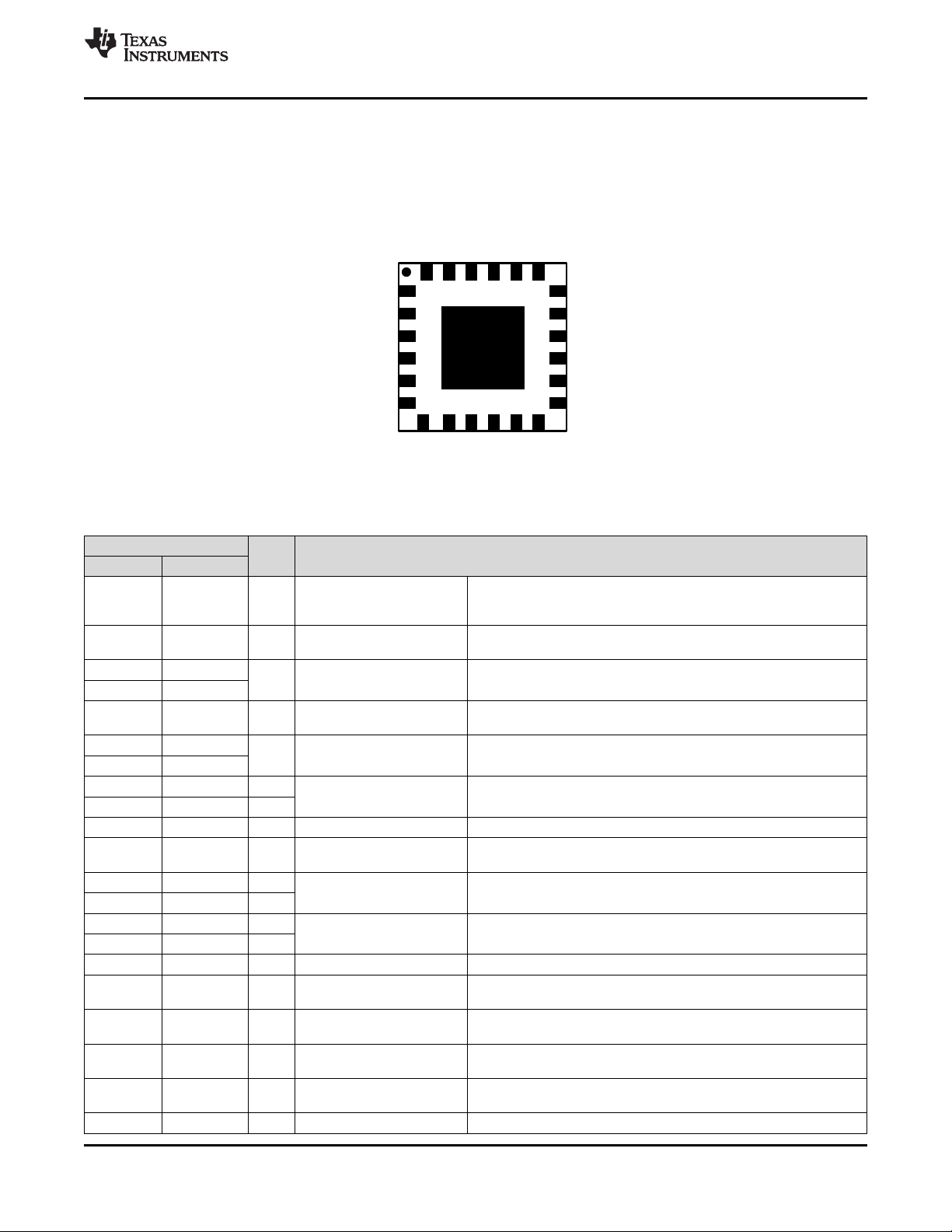

Page 3

1

2

3

4

5

6

18

17

16

15

14

13

24

23

22

21

20

19

7

8

9

10

11

12

AOUT1

AISEN

AOUT2

BOUT2

BISEN

BOUT1

GND

VINT

NC

VM

VREF

DIR

nFAULT

M0

M1

nENBL

STEP

ADEC

I0

I1

DEC0

nSLEEP

DEC1

GND

(PPAD)

www.ti.com

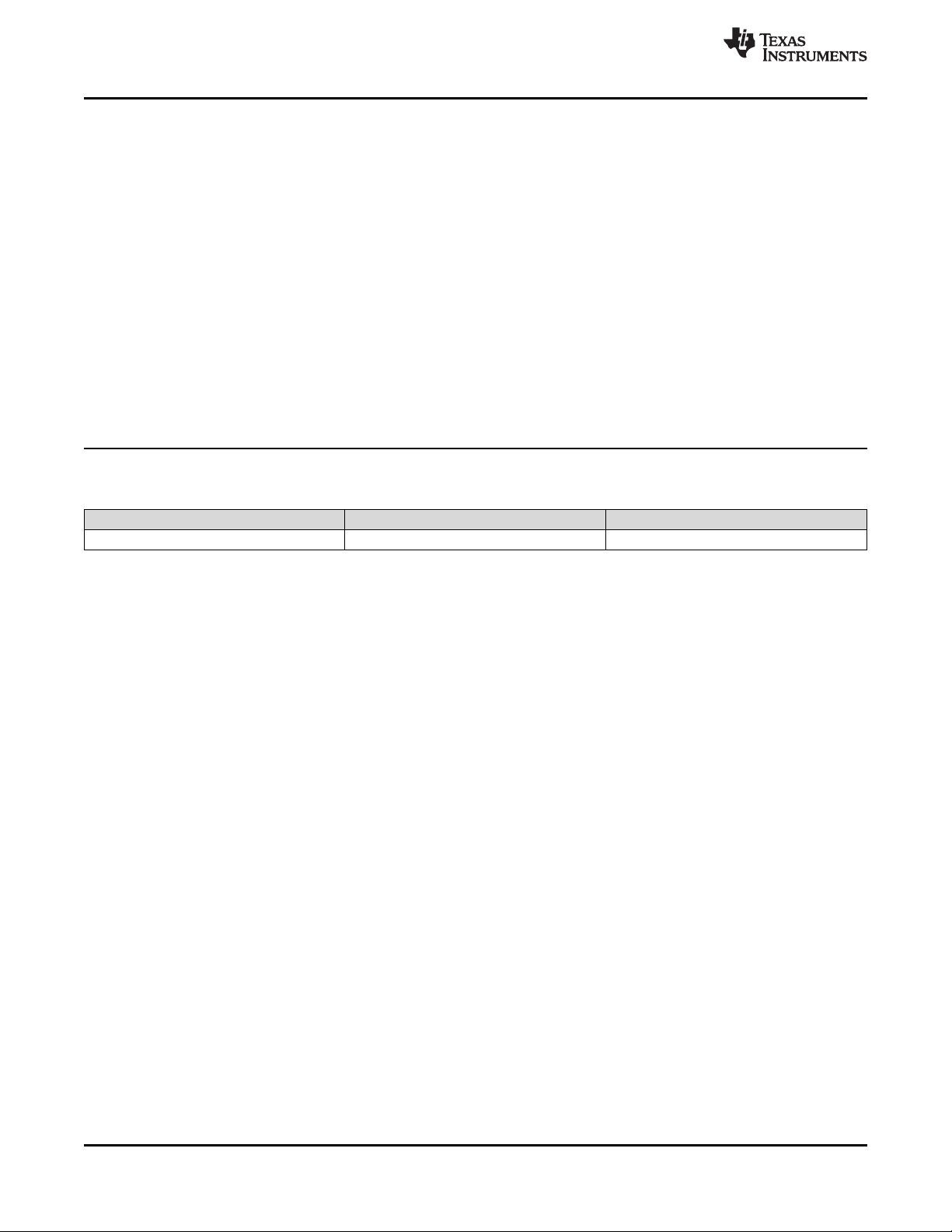

6 Pin Configuration and Functions

DRV8846

SLLSEK2 –JUNE 2014

RGE (VQFN) Package

24 Pins

(Top View)

Pin Functions

PIN

NAME NO.

ADEC 19 I Adaptive decay enable adaptive decay operation is enabled; must be set prior to coming out

AISEN 2 O Winding A sense

AOUT1 1

AOUT2 3

BISEN 5 O Winding B sense

BOUT1 6

BOUT2 4

DEC0 22 I

DEC1 24 I

DIR 13 I Direction input Logic level sets the direction of stepping; internal pulldown

GND 18, PPAD PWR Device ground

I0 20 I

I1 21 I

MO 8 I

M1 9 I

NC 16 — No connect Unused pin not connected internally

nENBL 11 I Enable driver output

nFAULT 7 OD Fault indication pin

nSLEEP 23 I Sleep mode input

STEP 12 I Step input

TOFF_SEL 10 I Decay mode off time set Sets the off-time during current chopping; tri-level pin

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 3

I/O DESCRIPTION

Logic low sets decay modes by DEC0 and DEC1 pins; logic high –

of sleep; internal pulldown

Connect to current sense resistor for bridge A, or GND if current

regulation is not required

O Winding A output

Connect to current sense resistor for bridge B, or GND if current

regulation is not required

O Winding B output

Decay mode setting pins Sets the decay mode; see description section; tri-level pin

Both the GND pin and device PowerPAD™ must be connected to

ground

Torque DAC current scalar Scales the current from 100% to 12.5% in 12.5% steps; tri-level pin

Microstepping mode setting Controls step mode (full, half, up to 1/32-step) and single- or dualpins edge clocking; tri-level pin

Logic low to enable device outputs and internal indexer; logic high to

disable; internal pulldown

Pulled logic low with fault condition; open-drain output requires

external pullup

Logic high to enable device; logic low to enter low-power sleep mode;

internal pulldown

A rising edge (or rising and falling depending on step mode) advances

the indexer one step; internal pulldown

Product Folder Links: DRV8846

Page 4

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

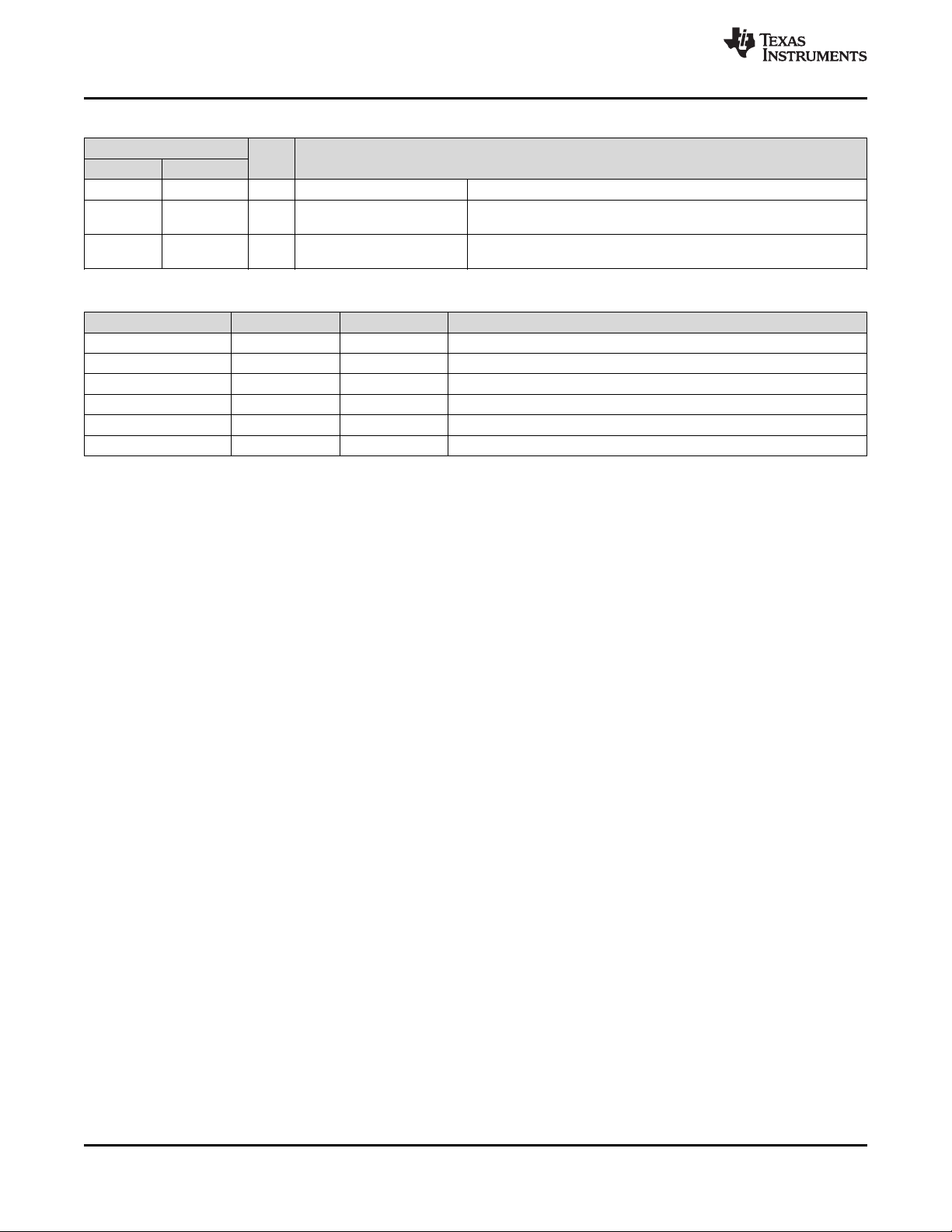

Pin Functions (continued)

PIN

NAME NO.

VINT 17 — Internal regulator Internal supply voltage; bypass to GND with 2.2-μF, 6.3-V capacitor

VM 15 PWR Power supply

VREF 14 I

I/O DESCRIPTION

Connect to motor power supply; bypass to GND with a 0.1- and 10-μF

(minimum) ceramic capacitor rated for VM

Full-scale current reference Voltage on this pin sets the full scale chopping current; short to VINT

input if not supplying an external reference voltage

Table 1. External Components

Component Pin 1 Pin 2 Recommended

C

VM

C

VM

C

VINT

R

nFAULT

R

AISEN

R

BISEN

(1) VCC is not a pin on the DRV8846, but a VCC supply voltage pullup is required for open-drain output nFAULT; nFAULT may be pulled

up to VINT through a resistor R

VM GND 10-µF (minimum) ceramic capacitor rated for VM

VM GND 0.1-µF ceramic capacitor rated for VM

VINT GND 6.3-V, 2.2-µF ceramic capacitor

(1)

VCC

nFAULT >5 kΩ

AISEN GND Sense resistor, see applications section for sizing

BISEN GND Sense resistor, see applications section for sizing

nFAULT

4 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 5

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

7 Specifications

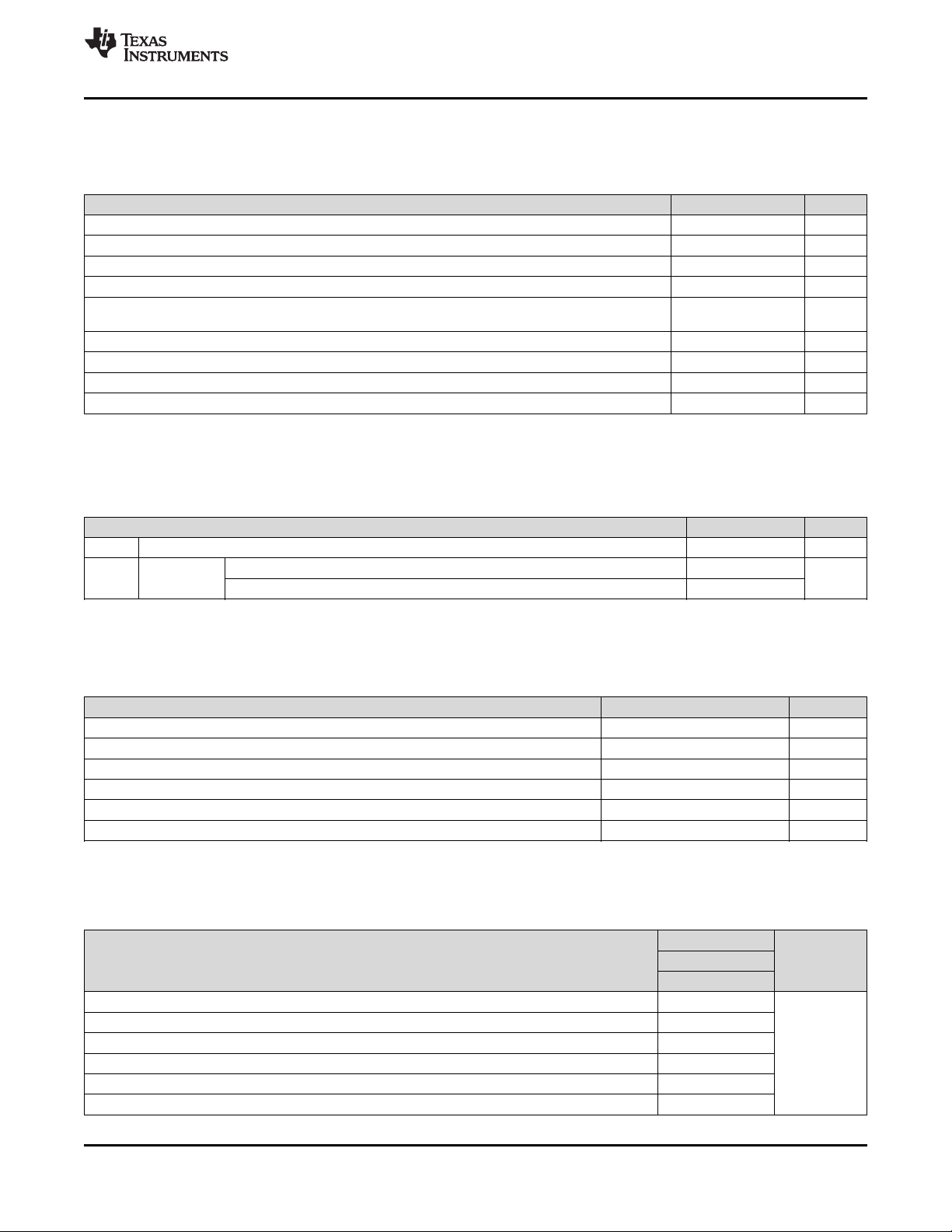

7.1 Absolute Maximum Ratings

over operating free-air temperature referenced with respect to GND (unless otherwise noted)

Power supply voltage (VM) –0.3 20 V

Power supply voltage ramp rate (VM) 0 2 V/µs

Internal regulator voltage (VINT) –0.3 3.6 V

Analog input pin voltage (VREF) –0.3 3.6 V

Control pin voltage (nENABLE, STEP, DIR, I0, I1, M0, M1, DEC0, DEC1, TOFF_SEL, nSLEEP,

nFAULT, ADEC)

Continuous phase node pin voltage (AOUT1, AOUT2, BOUT1, BOUT2) –0.3 VM + 0.6 V

Continuous shunt amplifier input pin voltage (AISEN, BISEN)

(2)

Peak drive current (AOUT1, AOUT2, BOUT1, BOUT2, AISEN, BISEN) Internally limited A

T

Operating junction temperature –40 150 °C

J

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) Transients of ±1 V for less than 25 ns are acceptable.

7.2 Handling Ratings

T

V

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Storage temperature range –65 150 °C

stg

(ESD)

Electrostatic

discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins

Charged device model (CDM), per JEDEC specification JESD22-C101, all pins

(1)

(1)

MIN MAX UNIT

–0.3 7.0 V

–0.6 0.6 V

MIN MAX UNIT

–4 4

(2)

–1.5 1.5

kV

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

VM Power supply voltage range

VREF Reference rms voltage range

ƒ

PWM

I

VINT

I

rms

T

A

(1) Note that R

(2) Operational at VREF between 0 to 1 V, but accuracy is degraded

Applied STEP signal 0 250 kHz

VINT external load current 1 mA

Motor rms current per H-bridge

Operating ambient temperature –40 85 °C

increases and maximum output current is reduced at VM supply voltages below 5 V

DS(ON)

(3) Power dissipation and thermal limits must be observed

(1)

(2)

(3)

4 18 V

1 3.3 V

0 1 A

7.4 Thermal Information

DRV8846

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 34

Junction-to-case (top) thermal resistance 36.9

Junction-to-board thermal resistance 12.5

Junction-to-top characterization parameter 0.4

Junction-to-board characterization parameter 12.5

Junction-to-case (bottom) thermal resistance 2.5

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 5

(1)

Product Folder Links: DRV8846

QFN UNIT

24 PINS

°C/W

Page 6

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

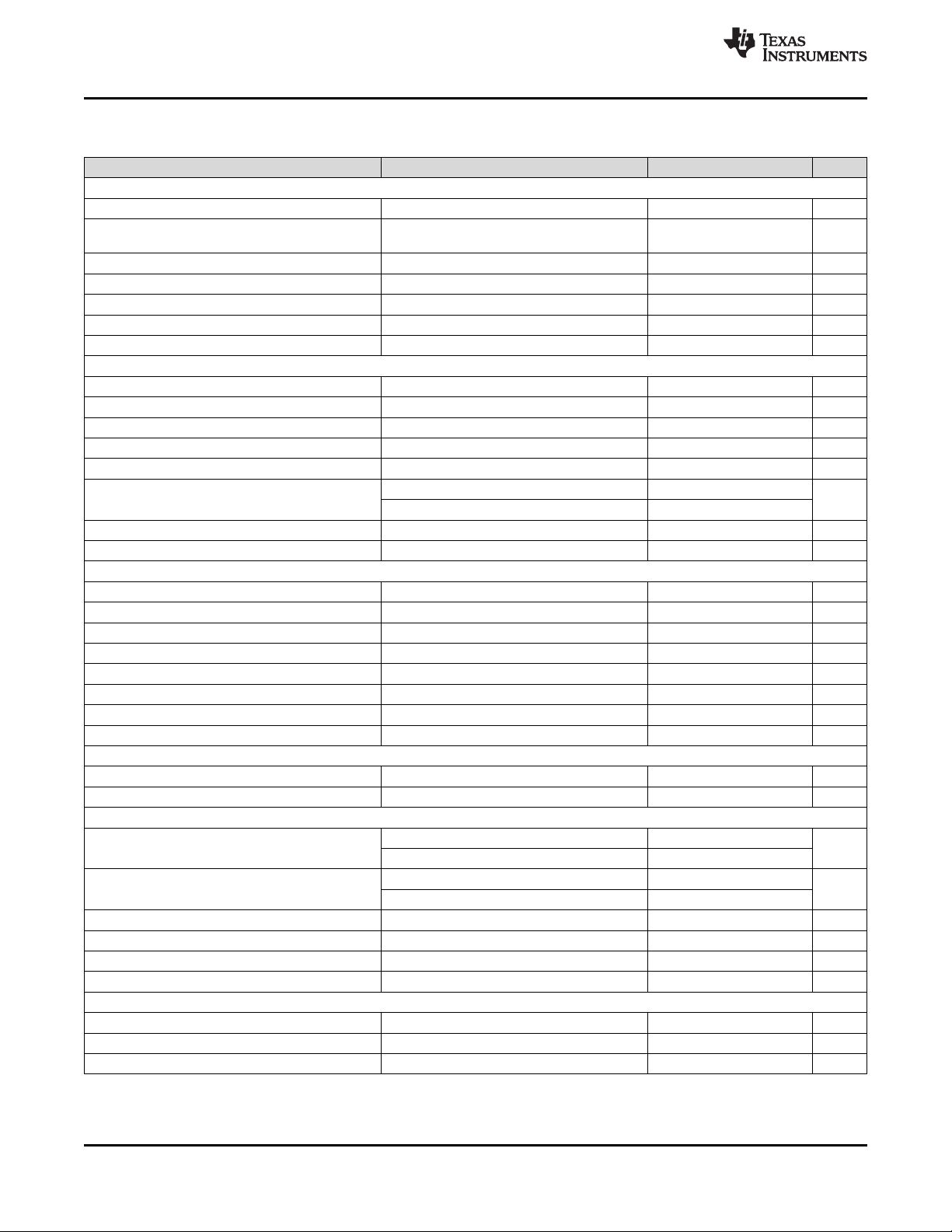

7.5 Electrical Characteristics

TA= 25°C, over recommended operating conditions unless otherwise noted

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

POWER SUPPLIES (VM, VINT)

VM VM operating voltage 4 18 V

I

VM

I

VMQ

t

SLEEP

t

WAKE

t

ON

VM operating supply current 3.5 4.5 5.5 mA

VM sleep mode supply current VM = 12 V, nSLEEP = 0, nENBL = 0 or 1 0.5 1.2 3 μA

Sleep time nSLEEP = 0 to sleep mode 1 ms

Wake time nSLEEP = 1 to output transition 1 ms

Power-on time VM > V

VINT VINT voltage VM > 4 V, I

LOGIC-LEVEL INPUTS (STEP, DIR, nENBL, nSLEEP, ADEC)

V

IL

V

IH

V

HYS

I

IL

I

IH

R

PD

t

DEG

t

PROP

Input logic low voltage 0 0.7 V

Input logic high voltage 1.6 5.5 V

Input logic hysteresis 100 mV

Input logic low current VIN = 0 V –1 1 μA

Input logic high current VIN = 5 V 1 30 μA

Pulldown resistance kΩ

Input deglitch time 200 ns

Propagation delay STEP edge to current change 600 ns

TRI-LEVEL INPUTS (I0, I1, M0, M1, DEC0, DEC1, TOFF_SEL)

V

IL

V

IZ

V

IH

V

HYS

I

IL

I

IH

R

PD

R

PU

Tri-level input logic low voltage 0 0.7 V

Tri-level input Hi-Z voltage 1.1 V

Tri-level input logic high voltage 1.6 5.5 V

Tri-level input hysteresis 100 mV

Tri-level input logic low current VIN= 0 V –30 –1 μA

Tri-level input logic high current VIN= 5 V 1 30 μA

Tri-level pulldown resistance To GND 170 kΩ

Tri-level pullup resistance To VINT 340 kΩ

CONTROL OUTPUTS (nFAULT)

V

OL

I

OH

Output logic low voltage IO= 5 mA 0.5 V

Output logic high leakage VO= 3.3 V –1 1 μA

MOTOR DRIVER OUTPUTS (AOUT1, AOUT2, BOUT1, BOUT2)

R

DS(ON)

R

DS(ON)

I

OFF

t

RISE

t

FALL

t

DEAD

High-side FET on resistance Ω

Low-side FET on resistance Ω

Off-state leakage current VM = 5 V, TJ= 25°C –1 1 μA

Output rise time 60 ns

Output fall time 60 ns

Output dead time Internal dead time 200 ns

PWM CURRENT CONTROL (VREF, AISEN, BISEN)

I

REF

V

TRIP

A

ISENSE

Externally applied VREF input current VREF = 1 to 3.3 V 1 μA

xISEN trip voltage For 100% current step with VREF = 3.3 V 500 mV

Current sense amplifer gain Reference only 6.6 V/V

VM = 12 V, excluding winding current,

nSLEEP = 1, nENBL = 0 or 1

rising to output transition 1 ms

UVLO

= 0 A to 1 mA 3.13 3.3 3.47 V

OUT

nENBL, STEP, DIR, ADEC 200

nSLEEP 500

VM = 12 V, I = 0.5 A, TJ= 25°C 550

VM = 12 V, I = 0.5 A, TJ= 85°C

(1)

660

VM = 12 V, I = 0.5 A, TJ= 25°C 350

VM = 12 V, I = 0.5 A, TJ= 85°C

(1)

420

(1) Not tested in production; limits are based on characterization data

6 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 7

STEP

2

3

1

4

5

www.ti.com

SLLSEK2 –JUNE 2014

Electrical Characteristics (continued)

TA= 25°C, over recommended operating conditions unless otherwise noted

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TOFF_SEL = GND 20

t

OFF

PROTECTION CIRCUITS

V

UVLO

I

OCP

t

OCP

t

RETRY

T

TSD

T

HYS

Current control constant off time TOFF_SEL = Hi-Z 10 μs

TOFF_SEL = VINT 30

VM undervoltage lockout V

VM falling; UVLO report 2.9

VM rising; UVLO recovery 3

Overcurrent protection trip level 2 A

Overcurrent deglitch time 2.8 μs

Overcurrent protection period 1.6 ms

Thermal shutdown temperature Die temperature T

Thermal shutdown hysteresis Die temperature T

J

J

150 160 180 °C

50 °C

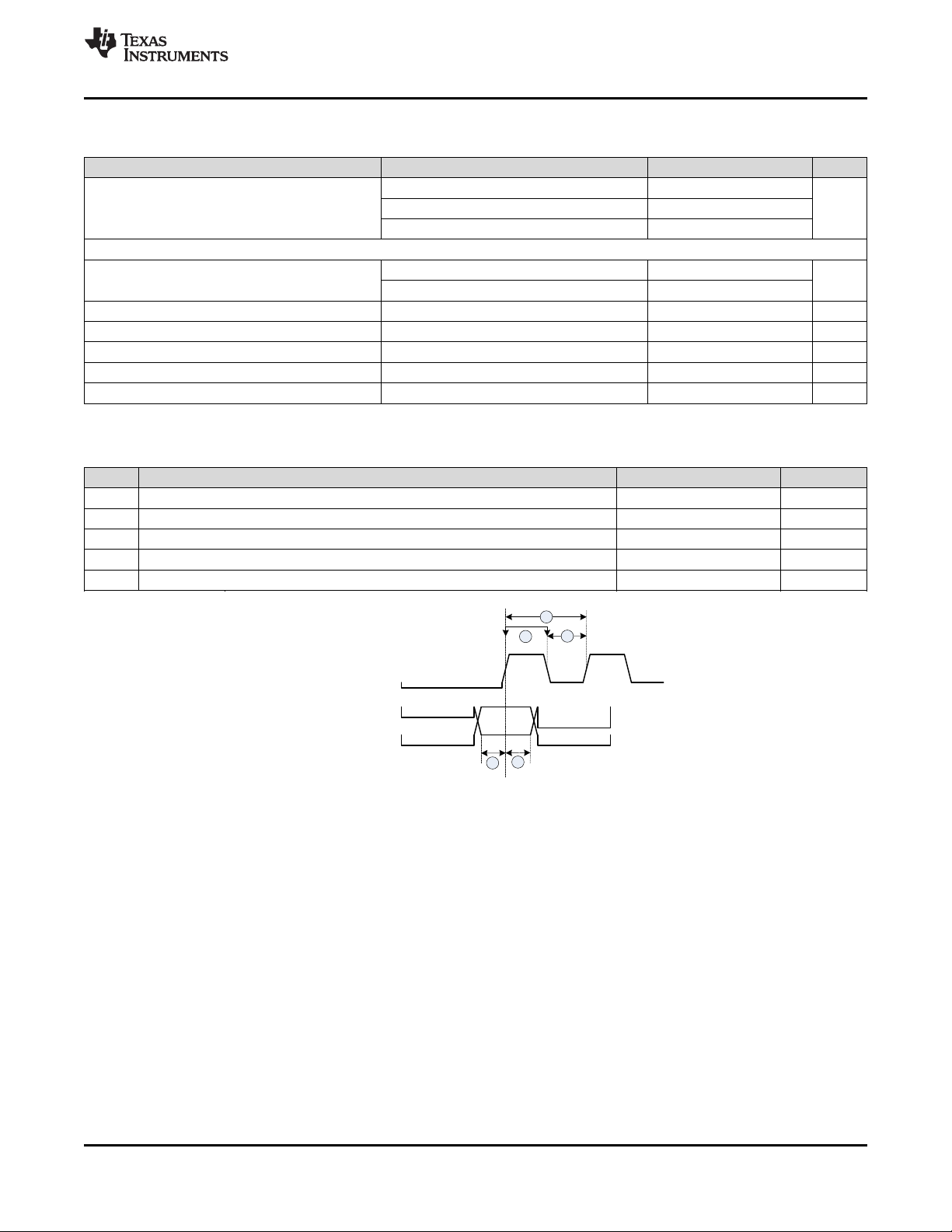

7.6 Timing Requirements

TA= 25°C, over recommended operating conditions unless otherwise noted

NO. PARAMETER MIN MAX UNIT

1 ƒ

2 t

3 t

4 t

5 t

STEP

WH(STEP)

WL(STEP)

SU(STEP)

H(STEP)

Step frequency 250 kHz

Pulse duration, STEP high 1.9 μs

Pulse duration, STEP low 1.9 μs

Setup time, DIR or Mx to STEP rising 200 ns

Hold time, DIR or Mx to STEP rising 200 ns

DRV8846

Figure 1. Timing Diagram

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: DRV8846

Page 8

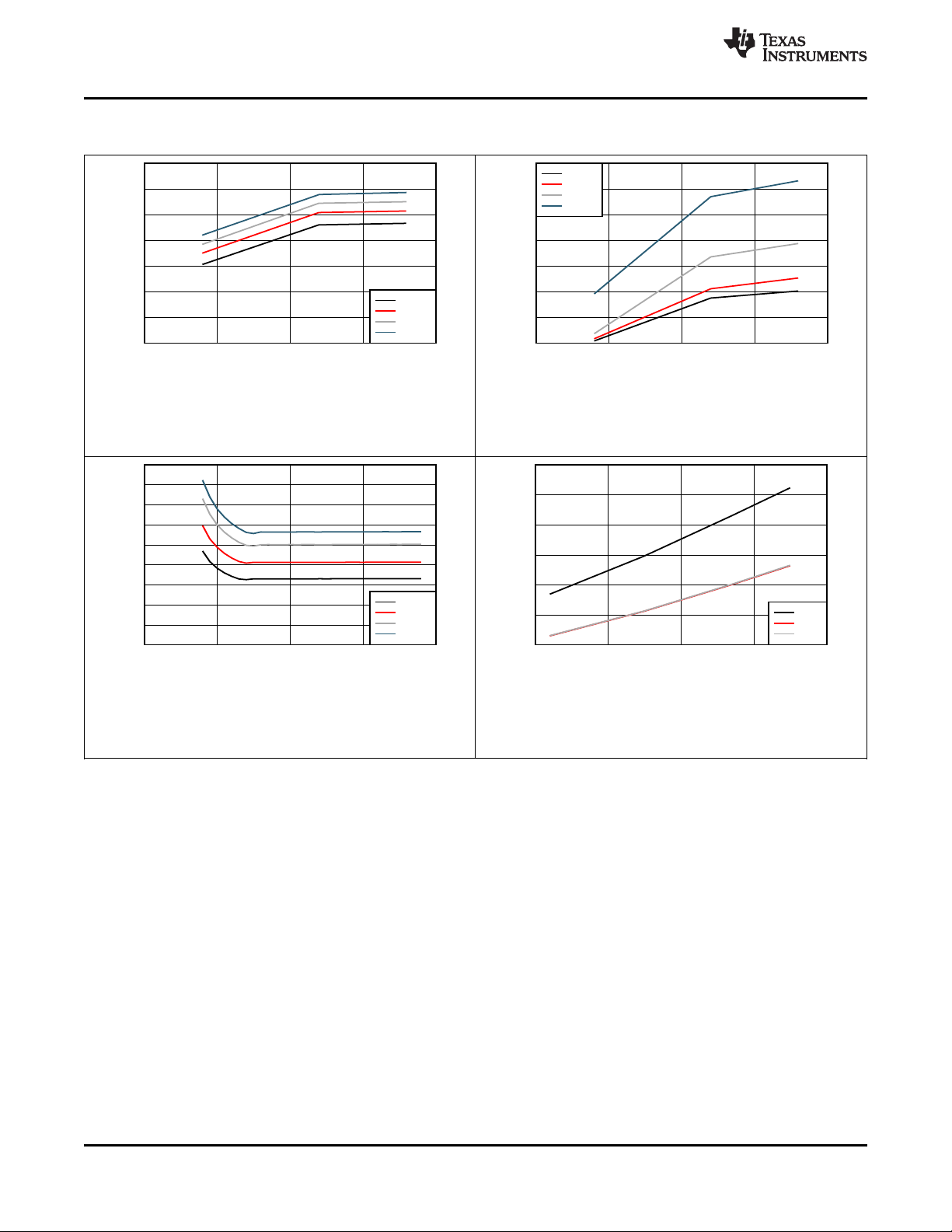

VM (V)

R

DSON

HS + LS (:)

0 5 10 15 20

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

D001

-40qC

25qC

85qC

125qC

TA (qC)

R

DSON

HS + LS (:)

-50 0 50 100 150

0.6

0.8

1

1.2

1.4

1.6

1.8

D004

4 V

12 V

18 V

VM (V)

I

VM

(mA)

0 5 10 15 20

2

2.5

3

3.5

4

4.5

5

5.5

D001

-40qC

25qC

85qC

125qC

VM (V)

I

VMQ

(PA)

0 5 10 15 20

0

0.5

1

1.5

2

2.5

3

3.5

D001

-40qC

25qC

85qC

125qC

DRV8846

SLLSEK2 –JUNE 2014

7.7 Typical Characteristics

www.ti.com

Figure 2. IVMvs VM Figure 3. I

Figure 4. R

vs VM Figure 5. R

DSON

VMQ

vs Temperature

DSON

vs VM

8 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 9

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

8 Detailed Description

8.1 Overview

The DRV8846 is an integrated motor driver solution for bipolar stepper motors. The device integrates 2 H-bridges

that use NMOS low-side drivers and PMOS high-side drivers, current sense regulation circuitry, and a

microstepping indexer. The DRV8846 can be powered with a supply range between 4 to 18 V and is capable of

providing an output current to 1.4-A full scale or 1-A rms.

A simple STEP/DIR interface allows easy interfacing to the controller circuit. The internal indexer is able to

execute high-accuracy microstepping without requiring the processor to control the current level.

The PWM off-time, t

The DRV8846 has an adaptive decay feature that automatically adjusts the decay setting to minimize current

ripple while still reacting quickly to step changes. This feature allows the DRV8846 to quickly be integrated into a

system.

A torque DAC feature allows the controller to scale the output current without needing to scale the analog

reference voltage input VREF. The torque DAC is accessed using digital input pins. This allows the controller to

save power by decreasing the current consumption when not required.

A low-power sleep mode is included, which allows the system to save power when not driving the motor.

can be adjusted to 10, 20, or 30 μs.

OFF

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: DRV8846

Page 10

OverTemp

AOUT1

GND

STEP

VM

Logic

AOUT2

VM

Gate

Drive

and

OCP

BOUT1

VM

BOUT2

VM

Gate

Drive

and

OCP

BISEN

AISEN

Step

Motor

ISEN

ISEN

DIR

M1

VM

VM

Internal Ref and

Regs

nFAULT

nSLEEP

nENBL

M0

10 µF

+

VM

I0

I1

PPAD

VINT

2.2 µF

VREF

DEC0

VREF

VREF

VINT

TOFF_SEL

DEC1

VINT

VINT

VINT

VINT

VINT

VINT

VINT

ADEC

DRV8846

SLLSEK2 –JUNE 2014

8.2 Functional Block Diagram

www.ti.com

10 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 11

xOUT1

xOUT2

VM

xISEN

Pre-

drive

VM

PWM

OCP

OCP

Optional

Step

Motor

SIN

DAC

5

+

±

DAC

3

I1

VREF

I0

A = 6.6

3level

Input

buffer

To other

channel

From Indexer

Internal

reference

To other

channel

DIR

STEP

Indexer

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

8.3 Feature Description

8.3.1 PWM Motor Drivers

DRV8846 contains two identical H-bridge motor drivers with current-control PWM circuitry. Figure 6 shows a

block diagram of the circuitry.

Figure 6. PWM Motor Driver Circuitry

8.3.2 Micro-Stepping Indexer

To allow a simple step and direction interface to control stepper motors, the DRV8846 contains a microstepping

indexer. The indexer controls the state of the H-bridges automatically. When the correct transition is applied at

the STEP input, the indexer moves to the next step, according to the direction set by the DIR pin. In 1/8, 1/16,

and 1/32 step modes, both the rising and falling edges of the STEP input may be used to advance the indexer,

depending on the M0 / M1 setting.

The nENBL pin disables the output stage in indexer mode. When nENBL = 0, the indexer inputs are still active

and respond to the STEP and DIR input pins; only the output stage is disabled.

The indexer logic in the DRV8846 allows a number of different stepping configurations. The M0 and M1 pins

configure the stepping format (see Table 2).

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: DRV8846

Page 12

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

Table 2. Step Mode Settings

M1 M0 STEP MODE

0 0 Full step (2-phase excitation), rising-edge only

0 Z 1/2 step (1-2 phase excitation), rising-edge only

0 1 1/4 step (W1-2 phase excitation), rising-edge only

Z 0 8 microsteps/step, rising-edge only

Z Z 8 microsteps/step, rising and falling edges

Z 1 16 microsteps/step, rising-edge only

1 0 16 microsteps/step, rising and falling edges

1 Z 32 microsteps/step, rising-edge only

1 1 32 microsteps/step, rising and falling edges

Note that the M0 and M1 pins are tri-level inputs. These pins can be driven logic low, logic high, or highimpedance (Z), like the I0 and I1 pins described previously.

For 1/8, 1/16, and 1/32-step modes, selections are available to advance the indexer only on the rising edge of

the STEP input, or on both the rising and falling edges.

The step mode may be changed on-the-fly while the motor is moving. The indexer advances to the next valid

state for the new M0 / M1 setting at the next rising edge of STEP.

The home state is 45°. The indexer enters the home state after power-up, after exiting UVLO, or after exiting

sleep mode (see the yellow-shaded cells in Table 3 also indicated with a table note).

Table 3 shows the relative current and step directions for different step mode settings. At each rising edge of the

STEP input, the indexer travels to the next state in the table. The direction is shown with the DIR pin high; if the

DIR pin is low, the sequence is reversed. Positive current is defined as xOUT1 = positive with respect to xOUT2.

Table 3. Relative Current and Step Directions

1/32 STEP 1/16 STEP 1/8 STEP 1/4 STEP 1/2 STEP

1 1 1 1 1 100% 0% 0

2 100% 5% 3

3 2 100% 10% 6

4 99% 15% 8

5 3 2 98% 20% 11

6 97% 24% 14

7 4 96% 29% 17

8 94% 34% 20

9 5 3 2 92% 38% 23

10 90% 43% 25

11 6 88% 47% 28

12 86% 51% 31

13 7 4 83% 56% 34

14 80% 60% 37

15 8 77% 63% 39

16 74% 67% 42

(1)

17

18 67% 74% 48

19 10 63% 77% 51

20 60% 80% 53

21 11 6 56% 83% 56

22 51% 86% 59

(1)

9

(1)

5

(1)

3

(1)

2

FULL STEP WINDING WINDING ELECTRICAL

70% CURRENT A CURRENT B ANGLE

(1)

1

71% 71% 45

(1) The indexer enters the home state after power-up, after exiting UVLO, or after exiting sleep mode.

12 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 13

www.ti.com

Table 3. Relative Current and Step Directions (continued)

1/32 STEP 1/16 STEP 1/8 STEP 1/4 STEP 1/2 STEP

23 12 47% 88% 62

24 43% 90% 65

25 13 7 4 38% 92% 68

26 34% 94% 70

27 14 29% 96% 73

28 24% 97% 76

29 15 8 20% 98% 79

30 15% 99% 82

31 16 10% 100% 84

32 5% 100% 87

33 17 9 5 3 0% 100% 90

34 –5% 100% 93

35 18 –10% 100% 96

36 –15% 99% 98

37 19 10 –20% 98% 101

38 –24% 97% 104

39 20 –29% 96% 107

40 –34% 94% 110

41 21 11 6 –38% 92% 113

42 –43% 90% 115

43 22 –47% 88% 118

44 –51% 86% 121

45 23 12 –56% 83% 124

46 –60% 80% 127

47 24 –63% 77% 129

48 –67% 74% 132

49 25 13 7 4 2 –71% 71% 135

50 –74% 67% 138

51 26 –77% 63% 141

52 –80% 60% 143

53 27 14 –83% 56% 146

54 –86% 51% 149

55 28 –88% 47% 152

56 –90% 43% 155

57 29 15 8 –92% 38% 158

58 –94% 34% 160

59 30 –96% 29% 163

60 –97% 24% 166

61 31 16 –98% 20% 169

62 –99% 15% 172

63 32 –100% 10% 174

64 –100% 5% 177

65 33 17 9 5 –100% 0% 180

66 –100% –5% 183

67 34 –100% –10% 186

68 –99% –15% 188

69 35 18 –98% –20% 191

FULL STEP WINDING WINDING ELECTRICAL

70% CURRENT A CURRENT B ANGLE

DRV8846

SLLSEK2 –JUNE 2014

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: DRV8846

Page 14

DRV8846

SLLSEK2 –JUNE 2014

Table 3. Relative Current and Step Directions (continued)

1/32 STEP 1/16 STEP 1/8 STEP 1/4 STEP 1/2 STEP

70 –97% –24% 194

71 36 –96% –29% 197

72 –94% –34% 200

73 37 19 10 –92% –38% 203

74 –90% –43% 205

75 38 –88% –47% 208

76 –86% –51% 211

77 39 20 –83% –56% 214

78 –80% –60% 217

79 40 –77% –63% 219

80 –74% –67% 222

81 41 21 11 6 3 –71% –71% 225

82 –67% –74% 228

83 42 –63% –77% 231

84 –60% –80% 233

85 43 22 –56% –83% 236

86 –51% –86% 239

87 44 –47% –88% 242

88 –43% –90% 245

89 45 23 12 –38% –92% 248

90 –34% –94% 250

91 46 –29% –96% 253

92 –24% –97% 256

93 47 24 –20% –98% 259

94 –15% –99% 262

95 48 –10% –100% 264

96 –5% –100% 267

97 49 25 13 7 0% –100% 270

98 5% –100% 273

99 50 10% –100% 276

100 15% –99% 278

101 51 26 20% –98% 281

102 24% –97% 284

103 52 29% –96% 287

104 34% –94% 290

105 53 27 14 38% –92% 293

106 43% –90% 295

107 54 47% –88% 298

108 51% –86% 301

109 55 28 56% –83% 304

110 60% –80% 307

111 56 63% –77% 309

112 67% –74% 312

113 57 29 15 8 4 71% –71% 315

114 74% –67% 318

115 58 77% –63% 321

116 80% –60% 323

FULL STEP WINDING WINDING ELECTRICAL

70% CURRENT A CURRENT B ANGLE

www.ti.com

14 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 15

FS

ISENSE

VREF

6.6 R

u

u

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

Table 3. Relative Current and Step Directions (continued)

1/32 STEP 1/16 STEP 1/8 STEP 1/4 STEP 1/2 STEP

117 59 30 83% –56% 326

118 86% –51% 329

119 60 88% –47% 332

120 90% –43% 335

121 61 31 16 92% –38% 338

122 94% –34% 340

123 62 96% –29% 343

124 97% –24% 346

125 63 32 98% –20% 349

126 99% –15% 352

127 64 100% –10% 354

128 100% –5% 357

FULL STEP WINDING WINDING ELECTRICAL

70% CURRENT A CURRENT B ANGLE

8.3.3 Current Regulation

The current through the motor windings is regulated by an adjustable fixed-off-time PWM current regulation

circuit. When an H-bridge is enabled, current rises through the winding at a rate dependent on the DC voltage,

inductance of the winding, and the magnitude of the back EMF present. After the current reaches the current

chopping threshold, the bridge enters a decay mode for a fixed period of time to decrease the current, which is

configurable between 10 to 30 µs through the tri-level input TOFF_SEL. After the time expires, the bridge is reenabled, starting another PWM cycle.

Table 4. Fixed Off-Time Selection

TOFF_SEL TOFF Duration

0 20 μs

Z 10 μs

1 30 μs

The PWM chopping current is set by a comparator which compares the voltage across a current sense resistor

connected to the xISEN pin, with a reference voltage. The reference voltage can be supplied by an internal

reference of 3.3 V (which requires VINT to be connected to VREF), or externally supplied to the VREF pin. The

reference voltage is then scaled first by the 3-bit torque DAC, then by the output of a sine lookup table that is

applied to a sine-weighted DAC (sine DAC). The voltage is attenuated by a factor of 6.6.

The full-scale (100%) chopping current is calculated as follows:

where

• IFSis the full scale regulated current

• VREF is the voltage on the VREF pin

• R

is the resistance of the sense resistor

ISENSE

• TORQUE is the scaling percentage from the torque DAC. (1)

Example: Using VREF is 3.3 V, torque DAC = 100%, and a 500-mΩ sense resistor, the full-scale chopping

current is 3.3 V / (6.6 × 500 mΩ) × 100% = 1 A.

The current for both motor windings is scaled depending on the I0 and I1 pins, which drive a 3-bit linear DAC, as

in Table 5.

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: DRV8846

Page 16

DRV8846

SLLSEK2 –JUNE 2014

Table 5. Torque DAC Settings

I1 I0 CURRENT SCALING (TORQUE)

0 0 100%

0 Z 87.5%

0 1 75%

Z 0 62.5%

Z Z 50%

Z 1 37.5%

1 0 25%

1 Z 12.5%

1 1 0% (outputs disabled)

Table 6 gives the xISEN trip voltage at a given DAC code and I[1:0] setting.

Table 6. Torque DAC xISENS Trip Levels (VREF = 3.3 V)

Sine DAC

Code

31 500 mV 438 mV 375 mV 313 mV 250 mV 188 mV 125 mV 63 mV

30 500 mV 438 mV 375 mV 313 mV 250 mV 188 mV 125 mV 63 mV

29 495 mV 433 mV 371 mV 309 mV 248 mV 186 mV 124 mV 62 mV

28 490 mV 429 mV 368 mV 306 mV 245 mV 184 mV 123 mV 61 mV

27 485 mV 424 mV 364 mV 303 mV 243 mV 182 mV 121 mV 61 mV

26 480 mV 420 mV 360 mV 300 mV 240 mV 180 mV 120 mV 60 mV

25 470 mV 411 mV 353 mV 294 mV 235 mV 176 mV 118 mV 59 mV

24 460 mV 403 mV 345 mV 288 mV 230 mV 173 mV 115 mV 58 mV

23 450 mV 394 mV 338 mV 281 mV 225 mV 169 mV 113 mV 56 mV

22 440 mV 385 mV 330 mV 275 mV 220 mV 165 mV 110 mV 55 mV

21 430 mV 376 mV 323 mV 269 mV 215 mV 161 mV 108 mV 54 mV

20 415 mV 363 mV 311 mV 259 mV 208 mV 156 mV 104 mV 52 mV

19 400 mV 350 mV 300 mV 250 mV 200 mV 150 mV 100 mV 50 mV

18 385 mV 337 mV 289 mV 241 mV 193 mV 144 mV 96 mV 48 mV

17 370 mV 324 mV 278 mV 231 mV 185 mV 139 mV 93 mV 46 mV

16 355 mV 311 mV 266 mV 222 mV 178 mV 133 mV 89 mV 44 mV

15 335 mV 293 mV 251 mV 209 mV 168 mV 126 mV 84 mV 42 mV

14 315 mV 276 mV 236 mV 197 mV 158 mV 118 mV 79 mV 39 mV

13 300 mV 263 mV 225 mV 188 mV 150 mV 113 mV 75 mV 38 mV

12 280 mV 245 mV 210 mV 175 mV 140 mV 105 mV 70 mV 35 mV

11 255 mV 223 mV 191 mV 159 mV 128 mV 96 mV 64 mV 32 mV

10 235 mV 206 mV 176 mV 147 mV 118 mV 88 mV 59 mV 29 mV

9 215 mV 188 mV 161 mV 134 mV 108 mV 81 mV 54 mV 27 mV

8 190 mV 166 mV 143 mV 119 mV 95 mV 71 mV 48 mV 24 mV

7 170 mV 149 mV 128 mV 106 mV 85 mV 64 mV 43 mV 21 mV

6 145 mV 127 mV 109 mV 91 mV 73 mV 54 mV 36 mV 18 mV

5 120 mV 105 mV 90 mV 75 mV 60 mV 45 mV 30 mV 15 mV

4 100 mV 88 mV 75 mV 63 mV 50 mV 38 mV 25 mV 13 mV

3 75 mV 66 mV 56 mV 47 mV 38 mV 28 mV 19 mV 9 mV

2 50 mV 44 mV 38 mV 31 mV 25 mV 19 mV 13 mV 6 mV

1 25 mV 22 mV 19 mV 16 mV 13 mV 9 mV 6 mV 3 mV

0 0 mV 0 mV 0 mV 0 mV 0 mV 0 mV 0 mV 0 mV

00 - 100% 0Z - 87.5% 01 - 75% Z0 - 62.5% ZZ - 50% Z1 - 37.5% 10 - 25% 1Z - 12.5%

Torque DAC I[1:0] Setting

www.ti.com

16 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 17

xOUT1

xOUT2

1

2

3

Drive Current

Slow decay

Fast decay

xVM

1

2

3

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

8.3.4 Decay Mode

After the chopping current threshold is reached, the drive current is interrupted, but due to the inductive nature of

the motor, current must continue to flow for some period of time (called recirculation current). To handle this

recirculation current, the H-bridge can operate in two different states, fast decay or slow decay (or a mixture of

fast and slow decay).

In fast-decay mode, after the PWM chopping current level is reached, the H-bridge reverses state to allow

winding current to flow through the opposing FETs. As the winding current approaches 0, the bridge is disabled

to prevent any reverse current flow. For fast-decay mode, see number 2 in Figure 7.

In slow-decay mode, winding current is recirculated by enabling both of the low-side FETs in the bridge. For

slow-decay mode, see number 3 in Figure 7.

Figure 7. Decay Modes

The DRV8846 supports fast, slow, mixed, and adaptive decay modes. With stepper motors, the decay mode is

chosen for a given stepper motor and operating conditions to minimize mechanical noise and vibration.

In mixed decay mode, the current recirculation begins as fast decay, but at a fixed period of time (determined by

the state of the DEC1 and DEC0 pins shown in Table 7) the current recirculation switches to slow decay mode

for the remainder of the fixed PWM period. Note that the DEC1 and DEC0 pins are tri-level inputs; these pins

can be driven logic low, logic high, or high-impedance (Z).

Figure 8 shows the current waveforms in slow, fast, and 25% and 1 t

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: DRV8846

mixed decay modes.

BLANK

Page 18

Slow Decay

Fast Decay

25%

1 t

BLANK

PWM

ON

PWM OFF (t

OFF

)

PWM CYCLE

25% of cycle

1 t

BLANK

Itrip

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

Figure 8. Decay Behavior

Table 7. Decay Pins Configuration

DEC1 DEC0 Decay Mode (Increasing Current) Decay Mode (Decreasing Current)

0 0 Slow decay Slow decay

0 Z Slow decay Mixed decay: 25% fast

0 1 Slow decay Mixed decay: 1 t

Z 0 Mixed decay: 1 t

Z Z Mixed decay: 50% fast Mixed decay: 50% fast

Z 1 Mixed decay: 25% fast Mixed decay: 25% fast

1 0 Slow decay Mixed decay: 50% fast

1 Z Slow decay Mixed decay: 12.5% fast

1 1 Slow decay Fast decay

BLANK

BLANK

Mixed decay: 1 t

BLANK

18 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 19

t

BLANK

t

ON

t

OFF

(fixed)

t

BLANK

t

ON

t

OFF

(fixed)

t

BLANK

t

ON

t

OFF

(fixed)

FET Drive On (FWD or REV)

Slow Decay

AOUT Current

STEP Input

Increasing

Decreasing

Increasing

Decreasing

BOUT Current

STEP Input

Decreasing

Increasing

Decreasing

Increasing

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

Figure 9 shows increasing and decreasing current. When current is decreasing, the decay mode used is fast,

slow, or mixed as commanded by the DEC1 and DEC0 pins. Three DEC pin selections allow for mixed decay

during increasing current.

Adaptive decay mode simplifies the decay mode selection by dynamically changing to adjust for current level,

step change, supply variation, BEMF, and load. To enable adaptive decay mode, pull the ADEC pin to logic high

and pull DEC0 and DEC1 pins to logic high. The state of the ADEC pin is only evaluated when exiting sleep

mode.

Adaptive decay adjusts the time spent in fast decay to minimize current ripple and quickly adjust to current-step

changes. If the drive time is longer than the minimum (t

mode applied is slow decay (see Figure 10).

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 9. Increasing and Decreasing Current

), in order to reach the current trip point, the decay

BLANK

Figure 10. Adaptive Decay – Slow Decay Operation

Product Folder Links: DRV8846

Page 20

t

BLANK

t

BLANK

t

OFF

(fixed)

t

BLANK

t

BLANK

t

OFF

(fixed) t

BLANK

t

BLANK

t

OFF

(fixed)

t

BLANK

t

OFF

(fixed)

t

BLANK

t

BLANK

t

BLANK

t

off

25%

t

BLANK

STEP

Slow Decay

Fast Decay

FET Drive On (FWD or REV)

t

BLANK

t

off

25%

t

BLANK

t

off

25%

t

BLANK

t

BLANK

t

OFF

(fixed)

t

BLANK

t

BLANK

t

BLANK

t

OFF

(fixed) t

BLANK

t

off

25%

t

OFF

(fixed)

t

OFF

(fixed)

t

BLANK

Slow Decay

Fast Decay

FET Drive On (FWD or REV)

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

When the minimum drive time (t

applied. If the second drive period also provides more current than the regulation point, fast decay of 2 t

) provides more current than the regulation point, fast decay of 1- t

BLANK

BLANK

BLANK

applied. If a third (or more) consecutive period provides more current than the regulation point, fast decay using

25% of t

time is applied. When the minimum drive time is insufficient to reach the current regulation level,

OFF

slow decay is applied until the current exceeds the current reference level (see Figure 11).

Figure 11. Adaptive Decay – Mixed Decay Operation

Figure 12 shows a case for adaptive decay where a step occurs. The system starts with 1 t

and works up to 25% of t

time for fast decay until the current is regulated again.

OFF

BLANK

of fast decay

is

is

8.3.5 Blanking Time

After the current is enabled in an H-bridge, the voltage on the xISEN pin is ignored for a period of time before

enabling the current sense circuitry. Note that the blanking time also sets the minimum drive time of the PWM.

The time, t

t

BLANK

20 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

BLANK

is given in Table 8.

Figure 12. Adaptive Decay – Step Operation

, is determined by the sine DAC code and the torque DAC setting. The timing information for

Product Folder Links: DRV8846

Page 21

www.ti.com

DRV8846

SLLSEK2 –JUNE 2014

Table 8. t

Sine DAC

Code

31 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

30 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

29 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

28 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

27 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

26 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

25 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

24 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

23 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

22 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

21 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

20 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

19 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

18 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

17 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

16 1.80 µs 1.80 µs 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 0.90 µs

15 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

14 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

13 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

12 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

11 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

10 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

9 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

8 1.50 µs 1.50 µs 1.50 µs 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs

7 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

6 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

5 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

4 1.20 µs 1.20 µs 1.20 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

3 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

2 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

1 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

0 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs 0.90 µs

00 - 100% 0Z - 87.5% 01 - 75% Z0 - 62.5% ZZ - 50% Z1 - 37.5% 10 - 25% 1Z - 12.5%

Torque DAC I[1:0] Setting

BLANK

Settings

8.3.6 Protection Circuits

The DRV8846 is fully protected against undervoltage, overcurrent, and overtemperature events.

8.3.6.1 Overcurrent Protection (OCP)

An analog current limit circuit on each FET limits the current through the FET by limiting the gate drive. If this

analog current limit persists for longer than the OCP deglitch time t

the nFAULT pin is driven low. The device remains disabled until the retry time, t

, all FETs in the H-bridge are disabled and

OCP

, occurs. The OCP is

RETRY

independent for each H-bridge.

Overcurrent conditions are detected independently on both high-side and low-side devices; that is, a short to

ground, supply, or across the motor winding all result in an OCP event. Note that OCP does not use the current

sense circuitry used for PWM current control, so OCP functions without the presence of the xISEN resistors.

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: DRV8846

Page 22

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

8.3.6.2 Thermal Shutdown (TSD)

If the die temperature exceeds safe limits, all FETs in the H-bridge are disabled and the nFAULT pin is driven

low. After the die temperature falls to a safe level, operation automatically resumes. The nFAULT pin is released

after operation has resumed.

8.3.6.3 Undervoltage Lockout (UVLO)

If at any time the voltage on the VM pin falls below the UVLO falling threshold voltage, V

, all circuitry in the

UVLO

device is disabled, and all internal logic is reset. Operation resumes when VM rises above the UVLO rising

threshold. The nFAULT pin is driven low during an undervoltage condition and is released after operation has

resumed.

Table 9. Fault Behavior

Fault Error Report H-Bridge Internal Circuits Recovery

VM UVLO nFAULT unlatched Disabled Shut down System and fault clears on recovery

OCP nFAULT unlatched Disabled Operating

TSD nFAULT unlatched Disabled Operating System and fault clears on recovery

System and fault clears on recovery and motor is driven

after time, t

RETRY

8.4 Device Functional Modes

The DRV8846 device is active unless the nSLEEP pin is driven low. In sleep mode, the VINT regulator is

disabled and the H-bridge FETs are disabled (Hi-Z). The time t

nSLEEP pin before the device enters sleep mode. The DRV8846 is brought out of sleep mode by bringing the

nSLEEP pin high. The time t

must elapse, after nSLEEP is brought high, before the outputs change state.

WAKE

If the nENBL pin is brought high, the H-bridge outputs are disabled, but the internal logic is still active. An

appropriate edge on STEP (depending on the step mode) advances the indexer, but the outputs do not change

state until nENBL is driven low.

When VM falls below the VM UVLO threshold, V

, the output driver, internal logic, and VINT regulator are

UVLO

reset.

must elapse after a falling edge on the

SLEEP

Table 10. Operating Modes

Mode Condition H-Bridge VINT Indexer

Operating nSLEEP pin = 1 Operating Operating Operating

Disabled nSLEEP pin = 1 Disabled Operating Operating

Sleep Disabled Disabled Disabled

Fault Any fault condition met Disabled Depends on fault Depends on fault

4 V < VM < 18 V

nENBL = 0

4 V < VM < 18 V

nENBL = 1

4 V < VM < 18 V

nSLEEP pin = 0

22 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 23

AOUT1

AISEN

AOUT2

BOUT2

BISEN

BOUT1

nFAULT

M0

M1

TOFF_SEL

nENBL

STEP

GND

VINT

NC

VM

VREF

DIR

DEC1

nSLEEP

DEC0

I1

I0

ADEC

Step

Motor

DRV8846

VM

18

17

16

15

14

13

VCC

logic supply

500 P

500 P

10 N

GND

(PPAD)

2.2 µF

10 µF

0.1 µF

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

9 Application and Implementation

9.1 Application Information

The DRV8846 is used in stepper motor control. The following design procedure can be used to configure the

DRV8846.

9.2 Typical Application

9.2.1 Design Requirements

Table 11 gives design input parameters for system design.

Nominal supply voltage 12 V

Supply voltage range 4 to 18 V

Motor winding resistance R

Motor winding inductance L

Motor full step angle θ

Design Parameter Reference Example Value

Table 11. System Design Input Parameters

VM

step

L

L

3.0 Ω/phase

330 µH/phase

1.8°/step

Target stepping level nm 1/8 step

Target motor speed v 400 rpm

Target chopping current I

Chopping current reference voltage VREF 3.3 V

CHOP

500 mA

Current scaling TORQUE 100%

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: DRV8846

Page 24

CHOP

L DS(ON) SENSE

VM (V)

R ( ) 2 R ( ) R ( )

: u : :

CHOP

ISENSE

VREF

6.6 R

u

u

m

step

step

v(rpm) n (steps) 6

¦ VWHSV V

( / step)

u u

T q

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

9.2.2 Detailed Design Procedure

9.2.2.1 Stepper Motor Speed

The first step in configuring the DRV8846 requires the desired motor speed and stepping level. The DRV8846

can support from full step to 1/32 step mode.

If the target motor speed is too high, the motor will not spin. Make sure that the motor can support the target

speed.

For a desired motor speed (v), microstepping level (nm), and motor full step angle (θ

θ

can be found in the stepper motor data sheet or often written on the motor itself.

step

step

),

(2)

For DRV8846, the microstepping levels are set by the M0/M1 pins and can be any of the settings in Table 2.

Higher microstepping means a smoother motor motion and less audible noise, but increases the switching losses

and requires a higher ƒ

to achieve the same motor speed.

step

9.2.2.2 Current Regulation

The chopping current (I

the sense resistor value (R

) is the maximum current driven through either winding. This quantity will depend on

CHOP

XISEN

).

(3)

I

is set by a comparator which compares the voltage across R

CHOP

to a reference voltage. Note that I

XISEN

CHOP

must follow Equation 4 to avoid saturating the motor.

where

• VM is the motor supply voltage.

• RLis the motor winding resistance. (4)

9.2.2.3 Decay Modes

The DRV8846 supports four different decay modes: slow decay, fast decay, mixed decay, and adaptive decay.

The first selection to try is the adaptive decay mode, which adjusts the decay mode automatically to improve

current regulation. The current through the motor windings is regulated using a fixed-off-time PWM scheme. This

means that after any drive phase, when a motor has reached the current chopping threshold (I

CHOP

), the

DRV8846 places the motor in one of the four decay modes until the PWM cycle has expired. Afterward, a new

drive phase starts.

The blanking time, t

, defines the minimum drive time for the current chopping. I

BLANK

is ignored during t

CHOP

BLANK

so the winding current may overshoot the trip level during this blanking period.

,

24 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 25

www.ti.com

9.2.3 Application Curves

DRV8846

SLLSEK2 –JUNE 2014

Figure 13. Microstepping Waveform, Phase A, Adaptive

Decay

Figure 14. Microstepping Waveform, Adaptive Decay, Step

Current Regulation

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: DRV8846

Page 26

2.2 µF

AOUT1

AISEN

AOUT2

BOUT2

BISEN

BOUT1

nFAULT

VINT

VM

NC

VREF

DIR

R

AISEN

R

BISEN

GND

10 µF

M1

M0

nENBL

TOFF_SEL

STEP

ADEC

I1

I0

nSLEEP

DEC0

DEC1

0.1 µF

DRV8846

SLLSEK2 –JUNE 2014

www.ti.com

10 Power Supply Recommendations

The DRV8846 is designed to operate from an input voltage supply (VM) range between 4 and 18 V. A 0.1-μF

ceramic capacitor rated for VM must be placed as close to the DRV8846 as possible. In addition, a bulk 10-μF

capacitor must be included on VM.

11 Layout

11.1 Layout Guidelines

The VM terminal should be bypassed to GND using a low-ESR ceramic bypass capacitor with a recommended

value of 10 μF rated for VM. This capacitor should be placed as close to the VM pin as possible with a thick trace

or ground plane connection to the device GND pin.

Bypass VINT to ground with a ceramic capacitor rated 6.3 V. Place this bypassing capacitor as close to the pin

as possible.

11.2 Layout Example

26 Submit Documentation Feedback Copyright © 2014, Texas Instruments Incorporated

Product Folder Links: DRV8846

Page 27

DRV8846

www.ti.com

SLLSEK2 –JUNE 2014

12 Device and Documentation Support

12.1 Trademarks

PowerPAD is a trademark of Texas Instruments.

12.2 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

12.3 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

13 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Copyright © 2014, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: DRV8846

Page 28

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

DRV8846RGER ACTIVE VQFN RGE 24 3000 Green (RoHS

DRV8846RGET ACTIVE VQFN RGE 24 250 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-3-260C-168 HR -40 to 85 DRV8846

CU NIPDAU Level-3-260C-168 HR -40 to 85 DRV8846

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

1-Jul-2014

Samples

Addendum-Page 1

Page 29

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

1-Jul-2014

Addendum-Page 2

Page 30

PACKAGE MATERIALS INFORMATION

www.ti.com 18-Aug-2014

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

DRV8846RGER VQFN RGE 24 3000 330.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

DRV8846RGET VQFN RGE 24 250 180.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 31

PACKAGE MATERIALS INFORMATION

www.ti.com 18-Aug-2014

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

DRV8846RGER VQFN RGE 24 3000 367.0 367.0 35.0

DRV8846RGET VQFN RGE 24 250 210.0 185.0 35.0

Pack Materials-Page 2

Page 32

Page 33

Page 34

Page 35

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Page 36

Loading...

Loading...