Page 1

User's Guide

SLOU287–January 2010

DRV8412EVM Motor Drive Evaluation Board

The DRV8412 customer evaluation module demonstrates the operation and performance of the DRV8412

device from Texas Instruments. The EVM can be used with a MCU controller module or can be wired into

an existing system.

Contents

1 Introduction .................................................................................................................. 2

2 Operation ..................................................................................................................... 4

3 Schematics, PCB Layers, and Bill of Materials ......................................................................... 6

List of Figures

1 The TI DRV8412EVM Motor Drive Evaluation Board – Top View.................................................... 3

2 The TI DRV8412EVM Motor Drive Evaluation Board – Bottom View................................................ 3

3 DRV8412EVM Schematic.................................................................................................. 6

4 DRV8412EVM – Top Layer Composite.................................................................................. 7

5 DRV8412EVM – Top Layer Copper...................................................................................... 7

6 DRV8412EVM – Bottom Copper.......................................................................................... 8

List of Tables

1 Key Parameters............................................................................................................. 2

2 Power Supply Requirements .............................................................................................. 4

3 Mode Pin Configurations................................................................................................... 5

4 Bill of Materials ............................................................................................................. 8

SLOU287–January 2010 DRV8412EVM Motor Drive Evaluation Board

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

1

Page 2

Introduction

1 Introduction

1.1 Description

The DRV8412 is a dual full bridge PWM motor driver. It has a maximum recommended supply voltage

of 50V with an absolute maximum of 70V. The DRV8412 is capable of delivering 2x3A continuous

output current and 2x6A peak current per device. The DRV8412 has an advanced protection system

consisting of short-circuit protection, overcurrent protection, undervoltage protection, and two-stage

thermal protection.

The DRV8412EVM can be operated with either two full bridge outputs or 4 half bridge outputs. It can

also be used in parallel mode to double the current capability. The unit can be operated with external

PWM inputs using a MCU controller module or signal generator, etc. The outputs and power supplies

can be connected using stripped wires by connecting them to the on-board terminal blocks. The EVM

module also has hardware switches to control the modes and to allow a manual reset.

1.2 DRV8412EVM Features

• PWM input motor driver module

• Self-contained protection system (short-circuit and thermal)

• Double-side, plated-through PCB layout

1.3 DRV8412EVM Specifications

www.ti.com

Table 1. Key Parameters

Output Stage Voltage 0 to 50 Vollts

System Supply Voltage 12 Volts

Number of Output 4 × Half Bridge, 2 × Full Bridge

Output Current per Output Pin Up to 6A peak, 3 A continuous

2

DRV8412EVM Motor Drive Evaluation Board SLOU287–January 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

Introduction

Figure 1. The TI DRV8412EVM Motor Drive Evaluation Board – Top View

Figure 2. The TI DRV8412EVM Motor Drive Evaluation Board – Bottom View

SLOU287–January 2010 DRV8412EVM Motor Drive Evaluation Board

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

3

Page 4

Operation

2 Operation

2.1 Quick Start List for Stand-Alone Operation

Follow these steps to use the DRV8412EVM stand-alone or when connecting it into existing circuits or

equipment. Connections to the EVM module can be made by inserting stripped wire for the power supplies

and output connections.

2.1.1 Power Supply

Two power supplies are required to power up the EVM. One is needed for system power, logic and gate

drive, while the second is for the output stage power supply. Please use enough wire gauge such that the

impedance is relatively low. The output stage supply should use at least AWG 22 wire.

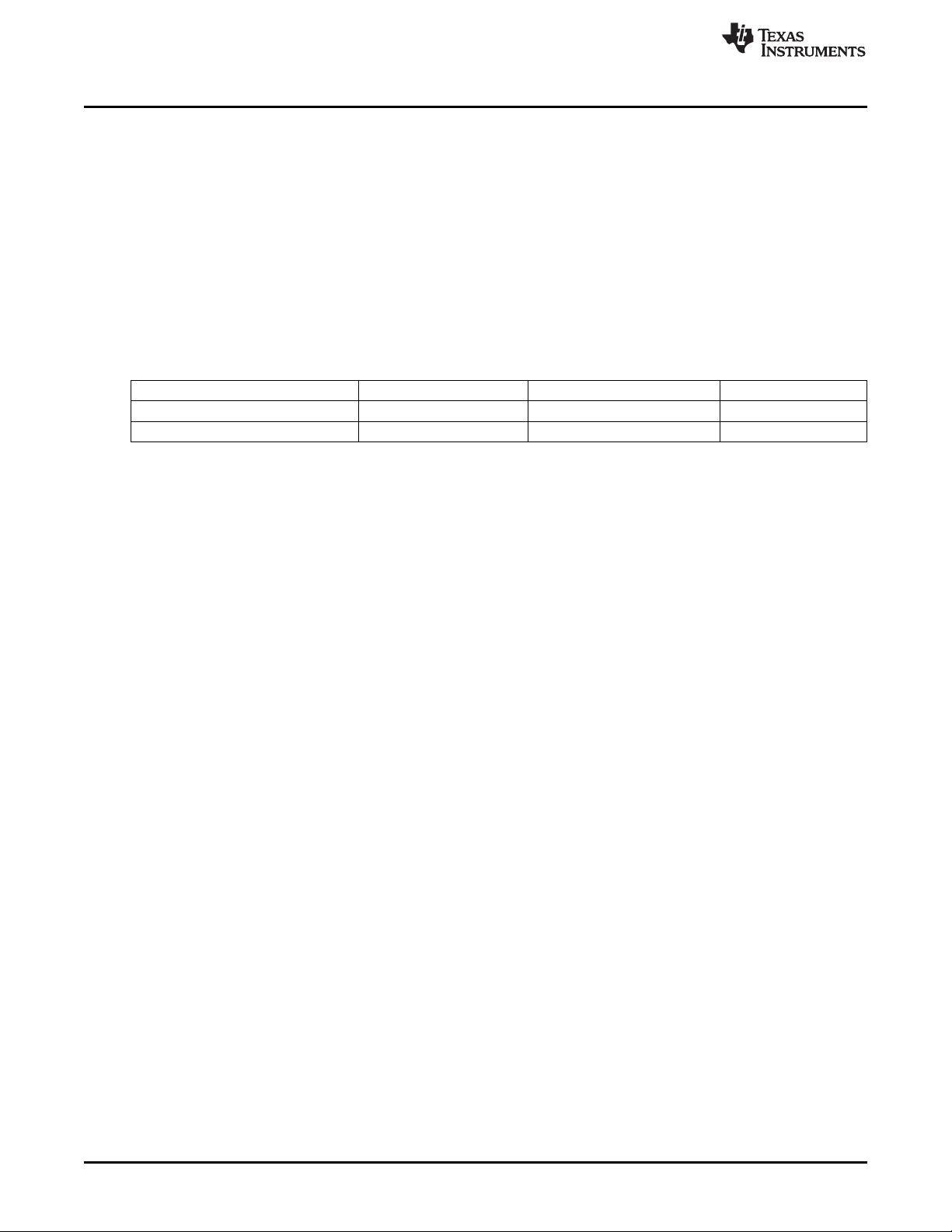

Table 2. Power Supply Requirements

Description Voltage Range Current Requirements Wire Size

System Power Supply 12 V 1 A 26 AWG

Output Stage Power Supply 0 – 50 V 6 A 22 AWG

2.1.2 Evaluation Module Preparation Inputs and Outputs

1. Ensure that all external power sources are set to OFF.

2. Connect load(s) across the outputs (OUTX) or between the outputs and ground depending on the

configuration requirement.

3. Connect an external 12V power supply to the terminal block marked GVDD and GND (J2). Make sure

the wires are connected with correct polarities.

4. Connect an external regulated power supply adjustable from 0V - 50V to the terminal block marked

PVDD and GND (J5). Make sure the wires are connected with correct polarities.

Control Signals

1. Install the mode jumpers on M3, M2, and M1 depending on the mode desired. See "Mode Pin

Configurations" table for detail.

2. Set RESET_AB (S1) and RESET_CD (S2) switches to low (RESET) position.

3. Prepare the PWM signals needed to control the power stage and make sure that PWM logic is 3.3V

not 5V.

www.ti.com

2.1.3 Power Up

The DRV8412 device doesn't require a special power up sequence, but the following sequence is

recommended for the EVM.

1. Turn on GVDD (12V) power supply.

2. Enable PWM signals.

3. Set RESET_AB (S1) and RESET_CD (S2) switches to high (NORMAL OPERATION) position.

4. Turn on the external PVDD power supply to the desired voltage gradually.

5. Adjust the duty cycle of PWM input signals to the desired value. The EVM should begin to operate

normally.

2.1.4 Fault Conditions

When device shuts down due to any fault conditions, flip RESET_AB and/or RESET_CD switches back

and forth to clear the fault and reset the device. If this doesn't work for any reason, turn 12V GVDD power

supply off and on again to clear the latch. Please inspect the board and test condition carefully to

understand the problem before next operation.

4

DRV8412EVM Motor Drive Evaluation Board SLOU287–January 2010

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

Operation

Table 3. Mode Pin Configurations

MODE PINS OUTPUT DESCRIPTION

M3 M2 M1

0 0 0 2 FB or 4 HB Dual Full Bridges (two PWM inputs each full bridge) or four half bridges with cycle-by-cycle

0 0 1 2 FB or 4 HB Dual full bridges (two PWM inputs each full bridge) or four half bridges with OC latching

0 1 0 1 PFB Parallel full bridge with cycle-by-cycle current limit

0 1 1 1 FB Dual Full Bridges (one PWM input each full bridge with complementary PWM on second half

1 x x Reserved

CONFIGURATION

current limit

shutdown (no cycle-by-cycle current limit)

bridge) with cycle-by-cycle current limit

SLOU287–January 2010 DRV8412EVM Motor Drive Evaluation Board

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

5

Page 6

GND

Green

0805

LED4

GND

GND

GND

GND

GND

Orange

OUT_D

Orange

OUT_C

Orange

OUT_B

Orange

OUT_A

Orange

OUTD

Orange

OUTC

Orange

OUTB

Orange

OUTA

GND

GND

GND

GND

Black

Black

Black

Black

GND

GND

0.875in

0.875in

0.875in

0.875in

0.875in

0.875in

Yellow

0805

LED2

GND

Yellow

0805

LED3

GND

GND

30V/2.3A

IRLMS5703TRPBF

Q1

D

G

S

3

2

1

M1

M2

1

2

3

3

2

1

M3

Orange

Orange

Orange

Orange

Orange

Orange

Orange

Orange

25A/300V

Green

J5

1

2

GND

GND

GND

Green

0805

LED1

GND

6A/250V

GRAY

J2

1

2

GVDD

GND

GND

GND

GND

GVDD

GND

GND

GVDD

GND

GVDD

GND

GVDD

GND

GND

GND

GND

GND

GND

GND

GND

GND

357

0603

R6

+3.3V

0.1ufd/100V

0805

C16

0.1ufd/100V

0805

C19

0.1ufd/100V

0805

C21

0.1ufd/100V

0805

C24

PVDD

PVDD

PVDD

PVDD

0.68ufd/100V

1210

C25

0.68ufd/100V

1210

C26

0.68ufd/100V

1210

C27

0.68ufd/100V

1210

C28

392

0603

R2

392

0603

R3

+3.3V

+3.3V

2

3

1

S1

S2

1

3

2

47K

0603

R5

0.1ufd/16V

0603

C10

PVDD

0.1ufd/100V

0805

C2

3.31/4W

1206

R1

0.01ufd/100V

0805

C3

PVDD

PVDD

4.99K

0603

R4

PVDD

0.1ufd/16V

0603

C5

330ufd/16V

M

C4

+

+3.3V

0.1ufd/16V

0603

C7

1.0ufd/16V

0603

C8

1.0ufd/16V

0603

C9

1.0ufd/16V

0603

C14

1.0ufd/16V

0603

C13

47ufd/50V

SU

C29

47ufd/50V

SU

C30

47ufd/50V

SU

C31

47ufd/50V

SU

C32

1000ufd/63V

VZ

C1

+

15A/250V

BLUE

1

2

J3

15A/250V

BLUE

2

1

J4

30V/2.3A

Q2

IRLMS5703TRPBF

D

G

S

4.7uH/8.7A

L1

931AS

4.7uH/8.7A

931AS

L2

4.7uH/8.7A

931AS

L3

4.7uH/8.7A

931AS

L4

GND

GND

GND

GND

GVDD

47ufd/16V

FC

C17

+

0.1ufd/16V

0603

C22

+5V

+5V

J1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

5.0V/500mA

SOT223-DCY

UA78M05CDCY

VR2

3

2

1

GND

VIN

VOUT

3.3V/500mA

SOT223-DCY

1

2

3

VR1

UA78M33CDCY

GND

VIN

VOUT

47ufd/16V

FC

C11

+

0.1ufd/100V

0805

C15

0.1ufd/100V

0805

C18

0.1ufd/100V

0805

C20

0.1ufd/100V

0805

C23

1.01/4W

0805

R7

0.1ufd/16V

0603

C12

47ufd/16V

FC

C6

+

HTSSOP44-DDW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22 23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

DRV8412DDW

U1

HTSSOP44-DDW

U1

PowerPad

DRV8412DDW EVALUATION BOARD REV D

(DEFAULT)

STUFFOPTION

FOR DCOUTPUT

STUFFOPTION

FOR DCOUTPUT

OUTD

OUTC

OUTA

OUTB

Flat RibbonCable = DIGI-KEY# MB30R

IDC Connector (2) = DIGI-KEY # MSC30A

IDC RibbonCable AssemblyRequired toMate to ControllerBoard

GROUND TESTPOINTS

STANDOFFS

BOM ONLY

Mode Selection Matrix

M3 M2 M1 OUTPUT DESCRIPTION

NA

1PFB

2FB

4HB/2FB

4HB/2FB

XX1

0 1 1

010

0 0 1

000 HALF/FULLBRIDGE,CYCLE BY CYCLECURRENTLIMIT

HALF/FULLBRIDGE,OC LATCHINGSHUTDOWN

PARALLELFULL BRIDGE,(A+B ANDC+D) WITH CYCLEBY CYCLE CURRENTLIMIT

RESERVEDFOR TESTMODE

FULLBRIDGE WITHONE PWM INPUTAND CYCLE BYCYCLE CURRENTLIMIT

STUFFOPTION

FOR DCOUTPUT

HIGH VOLTAGE WARNING

FOR VOLTAGE POTENTIALS

OF 50V OR GREATER

HIGH VOLTAGE

POWERINPUTS

PVDD

NOM =50V

MAX= 52.5V

EMI

SNUBBER

GVDD =12V

STUFFOPTION

FOR DCOUTPUT

HIGH

VOLTAGE

WARNING

Schematics, PCB Layers, and Bill of Materials

3 Schematics, PCB Layers, and Bill of Materials

3.1 DRV8412EVM Schematic

www.ti.com

DRV8412EVM Motor Drive Evaluation Board SLOU287–January 2010

6

Figure 3. DRV8412EVM Schematic

Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

3.2 DRV8412EVM PCB Layers

Schematics, PCB Layers, and Bill of Materials

Figure 4. DRV8412EVM – Top Layer Composite

Figure 5. DRV8412EVM – Top Layer Copper

SLOU287–January 2010 DRV8412EVM Motor Drive Evaluation Board

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

7

Page 8

Schematics, PCB Layers, and Bill of Materials

Figure 6. DRV8412EVM – Bottom Copper

www.ti.com

3.3 Bill of Materials for DRV8402DKD_EVM

Table 4. Bill of Materials

QTY REF DES Description Vendor Vendor Part No. MANU MANU Part No.

1 U1 MOTOR DRIVE POWER AMP Texas DRV8412DDW Texas DRV8412DDW

1 VR1 VOLT REG 3.3V 500mA SOT223-DCY Digi-Key 296-13424-1 Texas UA78M33CDCYR

2 VR2 VOLT REG 5.0V 500mA SOT223-DCY Digi-Key 296-12290-1 Texas UA78M05CDCYR

2 Q1, Q2 MOSFET, P-Chan 30V 2.3A, Digi-Key IRLMS5703PBFCT International IRLMS5703TRPBF

2 LED1, LED4 LED, GREEN 2.0V SMD0805 ROHS Digi-Key 67-1553-1 Lumex Opto SML-LXT0805GW-TR

2 LED2, LED3 LED, YELLOW 2.0V SMD0805 ROHS Digi-Key 67-1554-1 Lumex Opto SML-LXT0805YW-TR

1 C3 CAP SMD0805 CERM 0.01UFD 100V Digi-Key PCC1991CT Panasonic ECJ-2VB2A103K

5 C5, C7, C10, CAP SMD0603 CERM 0.1UFD 16V 10% Digi-Key PCC1762CT Panasonic ECJ-1VB1C104K

C12, C22 X7R ROHS

9 C2, C15, C16, CAP SMD0805 CERM 0.1UFD 100V 10% Digi-Key 445-1418-1 TDK C2012X7R2A104K

C18, C19, C20, X7RROHS

C21, C23, C24

4 C8, C9, C13, CAP SMD0603 CERM 1.0UFD 16V 10% Digi-Key PCC2224CT Panasonic ECJ-1VB1C105K

C14 X5R ROHS

3 C6, C11, C17 CAP 47UFD 16V RAD ALUM ELEC FC Digi-Key P11196 Panasonic EEU-FC1C470

1 C4 CAP 330UFD 16V RAD ALUM ELEC M Digi-Key P10371TB Panasonic ECA-1CM331B

1 C1 CAP 1000UFD 63V RAD ALUM ELEC VZ Digi-Key 493-1359 Nichicon UVZ1J102MHD

1 R7 RESISTOR SMD0805 1.0 OHM 1/4W 1% Digi-Key RHM1KCT ROHM ESR10EZPJ1R0

1 R1 RESISTOR SMD1206 3.3 OHM 1/8W 5% Digi-Key P3.3PCT Panasonic ERJ-8RQJ3R3V

HTSSOP44-DDW ROHS Instruments Instruments

ROHS Instruments

ROHS Instruments

SOT23-DBV6 ROHS Rectifier

10% X7R ROHS

ROHS

20% ROHS

ROHS

ROHS

ROHS

8

DRV8412EVM Motor Drive Evaluation Board SLOU287–January 2010

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

Page 9

www.ti.com

Schematics, PCB Layers, and Bill of Materials

Table 4. Bill of Materials (continued)

QTY REF DES Description Vendor Vendor Part No. MANU MANU Part No.

1 R6 RESISTOR SMD0603 357 OHM 1% Digi-Key P357HCT Panasonic ERJ-3EKF3570V

2 R2, R3 RESISTOR SMD0603 392 OHM 1% Digi-Key P392HCT Panasonic ERJ-3EKF3920V

1 R4 RESISTOR SMD0603 4.99K OHM 1% Digi-Key P4.99KHCT Panasonic ERJ-3EKF4991V

1 R5 RESISTOR SMD0603 47K OHMS 5% Digi-Key P47KGCT Panasonic ERJ-3GEYJ473V

4 L1, L2, L3, L4 INDUCTOR SMD 4.7UH 8.7A TYPE TOKO 931AS-4R7M TOKO 931AS-4R7M

3 M1, M2, M3 HEADER THRU MALE 3 PIN 100LS Digi-Key S1011E-03-ND Sullins PBC03SAAN

1 J1 HEADER THRU MALE 2X15 100LS Digi-Key S2011E-15 Sullins PBC15DAAN

1 J5 TERMINAL BLOCK 2PIN 25A/300V Digi-Key ED2677 On Shore OSTT7022150

1 J2 TERMINAL BLOCK 2PIN 6A/250V GRAY Digi-Key ED1534 On Shore ED655/2DS ED600/2DS

2 J3, J4 TERMINAL BLOCK 2PIN 15A/250V Digi-Key ED1627 On Shore

2 S1,S2 Switch,SPST Vert-PCB on-off-on Digi-Key 563-1159 Copal ATE1E-2M3-10-Z

16 OTW, FAULT PC testpoint, orange, ROHS Digi-Key 5003K Keystone 5003

PWMA, PWMB, Electronics

PWMC, PWMD,

OUTA, OUT_A,

OUTB, OUT_B,

OUTC, OUT_C,

OUTD, OUT_D,

RESET_AB,

RESET_CD

4 GNDx4 PC TESTPOINT, BLACK, ROHS Digi-Key 5001 Keystone 5001K

2 S1, S2 SWITCH,SPST VERT-PCB ON-OFF-ON Digi-Key ATE1E-2M3-10-Z Copal 563-1159

3 M1(2-3), M2(2-3), SHUNT, BLACK AU FLASH 0.100LS Digi-Key S9001 Sullins SPC02SYAN

M3(2-3)

6 N/A 4-40 SCREW, STEEL 0.250 IN Digi-Key H342 Building PMS 440 0025 PH

6 N/A STANDOFF,4-40,1.0INx1/4IN,ALUM RND Digi-Key 2031K Keystone 2031

THICK FILM 1/10W ROHS

THICK FILM 1/10W ROHS

THICK FILM 1/10W ROHS

1/10W ROHS

D128C ROHS

GOLD ROHS

GOLD ROHS

GREEN 9.52mm PITCH 12-24AWG Technology

ROHS

7mm PITCH 16-28AWG ROHS Technology

BLUE 10mm PITCH 14-22AWG ROHS Technology

miniature toggle ROHS Electronics

Electronics

MINIATURE TOGGLE ROHS Electronics

Fasteners

F-F Electronics

SLOU287–January 2010 DRV8412EVM Motor Drive Evaluation Board

Submit Documentation Feedback

Copyright © 2010, Texas Instruments Incorporated

9

Page 10

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DLP® Products www.dlp.com Communications and www.ti.com/communications

DSP dsp.ti.com Computers and www.ti.com/computers

Clocks and Timers www.ti.com/clocks Consumer Electronics www.ti.com/consumer-apps

Interface interface.ti.com Energy www.ti.com/energy

Logic logic.ti.com Industrial www.ti.com/industrial

Power Mgmt power.ti.com Medical www.ti.com/medical

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Space, Avionics & www.ti.com/space-avionics-defense

RF/IF and ZigBee® Solutions www.ti.com/lprf Video and Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2010, Texas Instruments Incorporated

Telecom

Peripherals

Defense

Wireless www.ti.com/wireless-apps

Page 11

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

DRV8412DDWEVM

Loading...

Loading...