Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

testo 330 · Flue gas analyzer

Instruction manual

Page 2

2

Page 3

1 Contents

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 6

2.1. About this document ........................................................................ 6

2.2. Ensure safety................................................................................... 7

2.3. Protecting the environment .............................................................. 8

3 Specifications .......................................................................................... 9

3.1. Use .................................................................................................. 9

3.2. Technical data ............................................................................... 10

3.2.1. Examinations and licenses ...............................................................................10

3.2.2. Bluetooth® module (option) ...............................................................................10

3.2.3. Declaration of Conformity .................................................................................12

3.2.4. Measuring ranges and resolution .....................................................................13

3.2.5. Accuracy and response time ............................................................................14

3.2.6. Other instrument data .......................................................................................15

4 Product description ............................................................................... 17

4.1. Case 0516 3300 (accessory) ......................................................... 17

4.1.1. Bottom level view ..............................................................................................17

4.1.2. Top level view ...................................................................................................18

4.2. Case 0516 3301 (accessory) ......................................................... 19

4.2.1. Bottom level view ..............................................................................................19

4.2.2. Middle level view ...............................................................................................20

4.2.3. Top level view ...................................................................................................21

4.3. Measuring instrument .................................................................... 22

4.3.1. Overview ...........................................................................................................22

4.3.2. Keypad ..............................................................................................................23

4.3.3. Display...............................................................................................................24

4.3.4. Device connections ...........................................................................................25

4.3.5. Interfaces ..........................................................................................................25

4.3.6. Components ......................................................................................................26

4.3.7. Carrying strap (0440 0581) ...............................................................................27

4.4. Modular flue gas probe .................................................................. 28

3

Page 4

1 Contents

First steps .............................................................................................. 29

5

5.1. Commissioning ............................................................................. 29

5.2. Getting to know the product .......................................................... 29

5.2.1. Mains unit / rechargeable battery ..................................................................... 29

5.2.1.1. Changing the battery.......................................................................... 29

5.2.1.2. Charging batteries .............................................................................. 30

5.2.1.3. Mains operation ................................................................................. 30

5.2.2. Connecting probes / sensors ............................................................................ 31

5.2.3. Switching on ..................................................................................................... 32

5.2.4. Calling up a function ......................................................................................... 32

5.2.5. Entering values ................................................................................................. 32

5.2.6. Show graphic .................................................................................................... 33

5.2.7. Printing / saving data ........................................................................................ 34

5.2.8. Remembering data (clipboard) ......................................................................... 34

5.2.9. Confirming an error message ........................................................................... 34

5.2.10. Switching off ..................................................................................................... 35

5.3. Address/Location .......................................................................... 35

5.4. Measurement records ................................................................... 37

5.5. Instrument diagnosis ..................................................................... 38

6 Using the product ................................................................................. 40

6.1. Performing settings ....................................................................... 40

6.1.1. Assigning the right function key ........................................................................ 40

6.1.2. Instrument settings ........................................................................................... 40

6.1.2.1. Readings display ................................................................................ 40

6.1.2.2. Alarm limits ......................................................................................... 42

6.1.2.3. Units ................................................................................................... 42

6.1.2.4. Date / time .......................................................................................... 43

6.1.2.5. Energy management.......................................................................... 43

6.1.2.6. Display brightness .............................................................................. 43

6.1.2.1. Choose measurement type ................................................................ 43

6.1.2.2. Printer ................................................................................................. 44

6.1.2.3. Bluetooth® .......................................................................................... 44

6.1.2.4. Language ........................................................................................... 45

6.1.2.5. Country version .................................................................................. 45

6.1.2.6. Password protection .......................................................................... 46

6.1.3. Sensor settings ................................................................................................. 46

6.1.3.1. NO2 addition ....................................................................................... 46

6.1.3.2. O2 reference ....................................................................................... 47

6.1.3.3. Sensor protection ............................................................................... 47

6.1.3.4. Recalibration / adjustment ................................................................. 48

6.1.4. Fuels ................................................................................................................. 49

6.1.5. Programs .......................................................................................................... 50

4

Page 5

1 Contents

6.2. Measuring ...................................................................................... 51

6.2.1. Preparing for measurement ..............................................................................51

6.2.1.1. Zeroing phases ...................................................................................51

6.2.1.2. Using the modular flue gas probe ......................................................52

6.2.1.3. Configuring the reading display .........................................................53

6.2.1.4. Setting location and fuel .....................................................................53

6.2.2. Flue gas ............................................................................................................53

6.2.3. Draught-Measurement ......................................................................................56

6.2.4. Micro pressure probe ........................................................................................56

6.2.5. CO undiluted .....................................................................................................57

6.2.6. Smoke No. / HCT ..............................................................................................57

6.2.7. Differential pressure ..........................................................................................58

6.2.8. Differential temperature ....................................................................................59

6.2.9. O2 air.................................................................................................................59

6.2.10. Gas flow ............................................................................................................60

6.2.11. Oil flow...............................................................................................................60

6.2.12. CO ambient .......................................................................................................61

6.2.13. CO2 ambient .....................................................................................................62

6.2.14. Automatic furnaces ...........................................................................................63

6.2.15. Solid fuel measurement ....................................................................................64

6.2.16. Gas pipe tests ...................................................................................................65

6.2.16.1. Tightness test 1 ..................................................................................65

6.2.16.2. Tightness test 2 ..................................................................................66

6.2.16.3. Let By Test .........................................................................................67

6.2.16.4. Leak detection ....................................................................................68

6.3. Transferring data ........................................................................... 69

6.3.1. Report printer ....................................................................................................69

6.3.2. PC / Pocket PC .................................................................................................69

7 Maintaining the product ........................................................................ 70

7.1. Cleaning the measuring instrument ............................................... 70

7.2. Replacing sensors ......................................................................... 70

7.3. Recalibrating / adjusting sensors ................................................... 71

7.4. Replacing additional filter .............................................................. 71

7.5. Cleaning the modular flue gas probe ............................................. 72

7.6. Replacing the probe module .......................................................... 72

7.7. Changing the thermocouple .......................................................... 73

7.8. Condensate container ................................................................... 73

7.9. Checking / replacing the particle filter ............................................ 74

8 Tips and assistance............................................................................... 75

8.1. Questions and answers ................................................................. 75

8.2. Accessories and spare parts ......................................................... 76

8.3. Updating the instrument software .................................................. 80

5

Page 6

2 Safety and the environment

Minor physical injury or damage to the

2 Safety and the environment

2.1. About this document

This document describes the products testo 330-1 LL and

testo 330-2 LL with the instrument setting Country version |

Great Britain.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

Symbols and writing standards

Representati

Explanation

on

Warning advice, risk level according to the

signal word:

Warning! Serious physical injury may occur.

Caution!

equipment may occur.

> Apply the specified precautionary measures.

Note: Basic or further information.

testo 330-1 LL

The description only applies for the specified

instrument model testo 330-1 LL or

testo 330-2 LL.

1. ...

2. ...

Action: several steps, the sequence must be

followed.

> ... Action: one step or optional step.

- ... Result of an action.

Menu

Elements of equipment , equipment display or

program interface.

6

Page 7

2 Safety and the environment

Representati

Explanation

on

[OK]

Control keys on equipment or control buttons in

program interface.

... | ... Functions / paths within a menu.

“...” Example entries

2.2. Ensure safety

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Testo.

> Any further or additional work must only be carried out by

authorised personnel. Testo will otherwise refuse to accept

responsibility for the proper functioning of the measuring

instrument after repair and for the validity of certifications.

> Only use the device in closed, dry rooms and protect it from rain

and moisture.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

are expressly permitted for higher temperatures.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

area when performing the measurements.

7

Page 8

2 Safety and the environment

For products with Bluetooth

®

(optional)

Changes or modifications that have been made without the explicit

consent of the responsible approval authority, may cause the

retraction of the type approval.

Data transfer may be disturbed by equipment that uses the same

ISM-band, e.g. WLAN, microwave ovens, ZigBee.

The use of radio communication links is not permitted, among

others, in aeroplanes and hospitals. For this reason the following

points must be ensured before entering:

> Switch off the device:

> Isolate the device from any external power sources (mains

2.3. Protecting the environment

cable, external rechargeable batteries, ...).

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

8

Page 9

3 Specifications

warranty or guarantee claims relating to functionality that

3.1. Use

The testo 330 is a handheld measuring device for the professional

flue gas analysis of furnace systems:

• Small furnaces (burning oil, gas, wood, coal)

The solid fuel measurement adapter (0600 9765) is

required for measurements on solid fuel systems. The

adapter protects the measuring instrument from harmful

substances (dust, organic compounds, etc.).

• Low-temperature and condensing boilers

• Gas water heaters

These systems can be adjusted using the testo 330 and checked

for compliance with the applicable limit values.

The following tasks can also be carried out with the testo 330:

• Regulating the O2-, CO- and CO2-, NO-, NOx- values in

furnace systems for the purpose of ensuring optimal operation.

• Draught measurement.

• Measuring and regulating the gas flow pressure in gas water

heaters.

• Measuring and optimising the flow and return temperatures of

heating systems.

• CO and CO2 environment measurement.

• Detection of CH4 (methane) and C3H8 (propane).

• The testo 330 can be used for measurements on CHP stations

in accordance with the first German Federal Immission Control

Ordinance (BImschV).

• In principal, the CO sensor can also be used for

measurements on CHP stations. If you should carry out

more than 50 measurements on CHP stations per year,

please contact your nearest testo service centre or send the

testo 330 for checking to testo Service.

A worn NOx filter of the CO sensor can be ordered as a

spare part (order no. 0554 4150) and replaced.

Testo guarantees the functionality of its products when

used in accordance with their intended purpose. This

guarantee does not apply to features of Testo products in

combination with unauthorised third-party products.

Competitor products are not authorised by Testo.

As is common practice, Testo generally excludes support,

3 Specifications

9

Page 10

3 Specifications

has not been guaranteed by Testo as part of the product

offered. Claims shall also be excluded in the event of

improper use or handling of the products, e.g. in

combination with unauthorised third-party products.

testo 330 must not be used:

• as a safety (alarm) instrument

The Bluetooth

3.2. Technical data

is type approved.

®

option may only be operated in countries in which it

3.2.1. Examinations and licenses

As declared in the certificate of conformity, this product complies

with Directive 2014/30/EC.

3.2.2. Bluetooth® module (option)

• Bluetooth® type: BlueGiga WT 11 / WT 11i-A (from

October 2013)

• Bluetooth® product note: WT 11

• Bluetooth

B017633 (WT11i-A)

• Bluetooth

®

identification: B017401 (WT 11) /

®

company: 10274

10

Certification

Belgium (BE), Bulgaria (BG), Denmark (DK), Germany (DE),

Estonia (EE), Finland (FI), France (FR), Greece (GR), Ireland (IE),

Italy (IT), Latvia (LV), Lithuania (LT), Luxembourg (LU), Malta (MT),

Netherlands (NL), Austria (AT), Poland (PL), Portugal (PT),

Rumania (RO), Sweden (SE), Slowakia (SK), Slowenia (SI), Spain

(ES), Czech Republic (CZ), Hungary (HU), United Kingdom (GB),

Republic of Cypres (CY).

EFTA countries

Iceland, Liechtenstein, Norway and Switzerland.

Other countries

USA, Canada, Turkey, Colombia, El Salvador, Ukraine, Venezuela,

Ecuador, Australia, New Zealand, Bolivia, Dominican Republic,

Peru, Chile, Cuba, Costa Rica, Nicaragua, Korea

Page 11

3 Specifications

Information of the FCC (Federal Communications

Commission)

This device fulfils part 15 of the FCC-guidelines. Commissioning is

subject to the two following conditions: (1) This device must not

generate any dangerous interferences and (2) this device must be

able to receive interferences, even if these could have undesired

effect on the operation.

Changes

The FCC demands that the user is to be informed that with any

changes and modifications to the device, which have not been

explicitly approved by testo AG, the right of the user to use this

device will become null and void.

11

Page 12

3 Specifications

3.2.3. Declaration of Conformity

12

Page 13

1

3.2.4. Measuring ranges and resolution

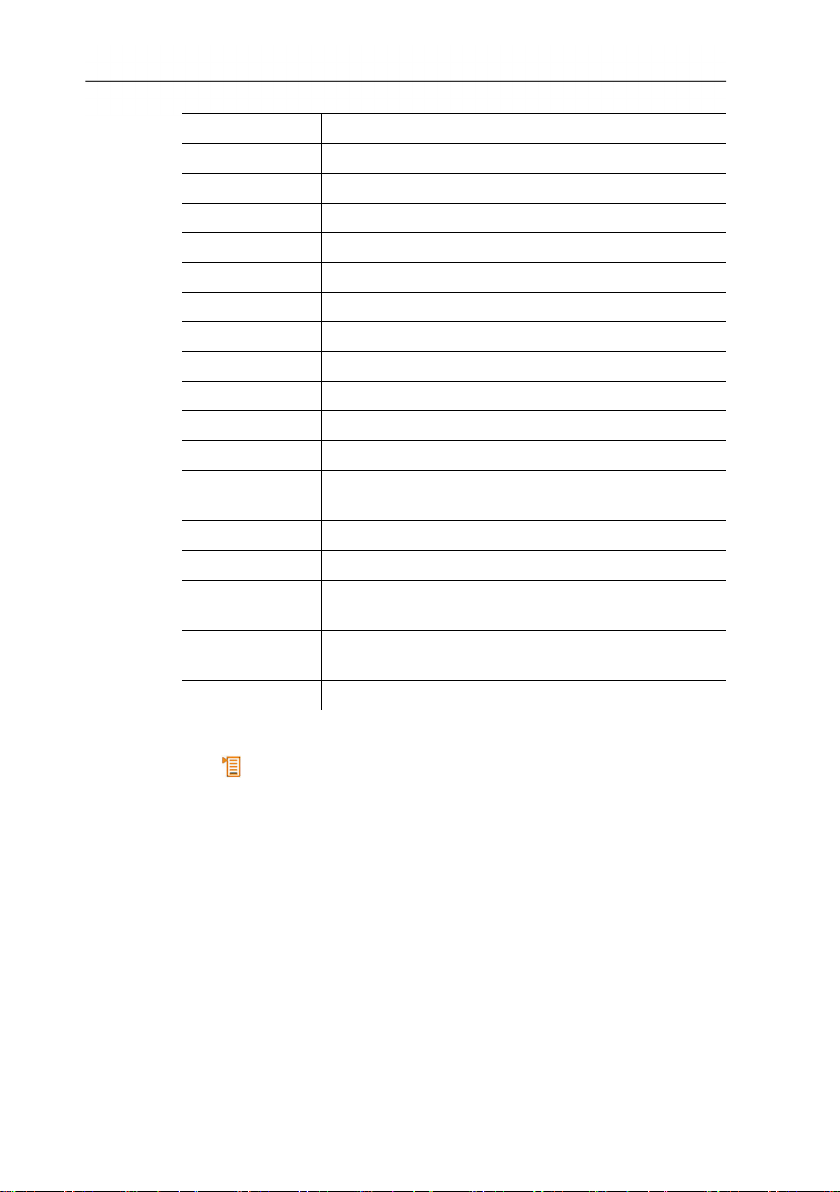

Parameter Measuring range Resolution

O2 0...21 Vol.% 0.1 vol.%

CO 0...4000 ppm 1 ppm

CO, H2-comp.

COlow 0...500 ppm 0.1ppm

AmbCO

through flue gas

probe

AmbCO with

probe 0632 3331

NO 0...3000 ppm 1 ppm

NOlow 0...300 ppm 0.1 ppm

Draught -9.99...40 hPa 0.01 hPa

ΔP 0...300 hPa 0.1 hPa

Temperature -40...1200 °C 0.1°C (-40.0...999.9 °C)

Efficiency net 0...120 % 0.1 %

Flue gas loss 0...99.9 % 0.1 %

AmbCO2 with

probe 0632 1240

Gas leak testing

with probe

0632 3330

0...8000 ppm 1 ppm

0...2000 ppm 1 ppm

0...500 ppm 1 ppm

1°C (rest of range)

0...1 vol.

-

0...10000 ppm

0...10000 ppm

-

CH4 / C3H8

3 Specifications

1

above the sensor protection threshold: Resolution 1 ppm (up to max. 30,000

ppm)

13

Page 14

3 Specifications

3.2.5. Accuracy and response time

Parameter Accuracy Response

O2 ±0.2 vol.% < 20s (t90)

CO ±20 ppm (0...400 ppm)

±5% of mv (401...2000 ppm)

±10% of mv (2001...4000 ppm)

CO, H2-comp. ±10 ppm or ±10 % of mv2

(0...200 ppm)

±20 ppm or ±5 % of mv

(201...2000 ppm)

±10% of mv (2001...8000 ppm)

only testo 330-2:

8000...30000 ppm

(automatic dilution)

COlow ±2 ppm (0…39.9 ppm)

±5 % of mv (rest of range)

AmbCO through

flue gas probe

AmbCO with

0632 3331

NO ±2 ppm (0…39,9 ppm)

NOlow

Draught4 ±0.02 ppm or ±5% of mv2

±10 ppm (0...100 ppm)

±10 % of mv (101….2000 ppm)

±5 ppm (0...100 ppm)3

±5 % of mv ( >101 ppm)

±5 % of mv (40….2000 ppm)

±10 % of mv (2001...3000 ppm)

±2 ppm (0…39,9 ppm)

±5% of mv (rest of range)

(-0.50...0.60 hPa)

± 0.03 hPa (0.61...3.00 hPa)

±1.5 % of mv (3.01...40.00 hPa)

time

< 60s (t90)

< 60s (t90)

2

< 40s (t90)

< 35s (t90)

approx. 35s

(t90)

< 30s (t90)

< 30s (t90)

-

2

higher value is valid

3

at 10...30 °C, outside this range additionally ±0.2 % of mv / °C

4

with fine draught measurement option: Measuring range 0...100, 0Pa,

resolution 0.1Pa

14

Page 15

Parameter Accuracy Response

ΔP ± 0.5 hPa (0.0...50.0 hPa)

±1 % of mv (50.1...100.0 hPa)

±1.5 % of mv (rest of range)

Temperature ± 0.5 °C (0.0...100.0 °C)

±0.5 % of mv (rest of range)

Efficiency - -

Flue gas loss - -

AmbCO2,

through

0632 1240

±75 ppm + 3 % of mv

(0...5000 ppm)

±150 ppm + 5 % of mv

(5001...10000 ppm)

Gas leak testing

- < 2s (t90)

with 0632 3330

3.2.6. Other instrument data

3 Specifications

time

-

probe

dependent

approx. 35s

(t90)

Flue gas analyser

Characteristic Values

Storage / and

-20...50 °C

transport

temperature

Operating

-5...45 °C

temperature

Ambient humidity 0…90 % rH, not condensing

Power supply Battery: 3.7 V / 2.6 Ah

Mains unit: 6 V/1.2 A

Protection class IP40

Weight 600 g (excluding battery)

Dimensions 270 x 90 x 65 mm

Memory 500,000 readings

Display Graphic colour display, 240 x 320 pixels

Flue gas

max. 50 mbar

overpressure

Negative pressure max. 80 mbar

15

Page 16

3 Specifications

Characteristic Values

Gas leak testing

probe

Storage

temperature battery

Battery charge time approx. 5-6 h

Battery operation

time

Bluetooth® (option) Range < 10 m

Warranty Measuring instrument: 48 months

visual indication (LED)

audible indication by buzzer

±0...35 °C

6h (pump on, 20 °C ambient temperature)

LL-sensors O2, CO: 48 months

NOlow sensor: 12 months

Other sensors: 24 months

Flue gas probe: 48 months

Thermocouple: 12 months

Battery: 12 months

Further warranty terms: see

website

16

Page 17

4 Product description

4.1. Case 0516 3300 (accessory)

Recommended for stowing away the measuring instrument and

accessories (example)

4.1.1. Bottom level view

4 Product description

1 Sealing clip

2 testo 330-1 /-2 LL flue gas analyzer

3 Repository for printer accessories

• Spare batteries for IRDA printer

• 1 roll of spare thermal paper (0554 0568)

4 Repository for printer

• IRDA printer (0554 0549)

• Bluetooth

17

®

/IRDA printer (0554 0620)

Page 18

4 Product description

5. Instruction manual

6 Lock

7 Probes

• Flue gas probe (e.g. 0600 9741)

• Pitot tube for heating check (0635 2050)

8 Large storage compartment

• Mains unit for testo 330-1 /-2 LL (0554 1096)

• Differential temperature set (0554 1208)

• Spare dirt filter (0554 0040)

9 Round storage compartment

• Hose connection set with pressure adapter (0554 1203)

4.1.2. Top level view

18

1 Soot pump set (0554 0307)

2 Storage compartment

• Fine pressure probe (0638 0330)

Page 19

3 Storage compartment

• Capillary hose set for fine pressure probe (0554 1215)

• Connecting cable for surface probe (0430 1215)

4 Combustion air temperature probe (0600 9787)

5. Surface temperature probe Type K (0604 0994)

4.2. Case 0516 3301 (accessory)

Recommended for stowing away the measuring instrument and

accessories (example)

4.2.1. Bottom level view

4 Product description

1 Fine pressure probe (0638 0330)

2 testo 308 smoke tester (0632 0308)

19

Page 20

4 Product description

4.2.2. Middle level view

1 Sealing clip

2 testo 330-1 /-2 LL flue gas analyzer

3 Repository for printer accessories

• Spare batteries for IRDA printer

• 1 roll of spare thermal paper (0554 0568)

4 Repository for printer

• IRDA printer (0554 0549)

• Bluetooth

®

/IRDA printer (0554 0620)

5. Instruction manual

6 Lock

7 Probes

• Flue gas probe (e.g. 0600 9741)

• Pitot tube for heating check (0635 2050)

20

Page 21

8 Large storage compartment

• Mains unit for testo 330-1 /-2 LL (0554 1096)

• Differential temperature set (0554 1208)

• Spare dirt filter (0554 0040)

9 Round storage compartment

• Hose connection set with pressure adapter (0554 1203)

4.2.3. Top level view

4 Product description

1 Soot pump set (0554 0307)

2 Storage compartment

• Fine pressure probe (0638 0330)

3 Storage compartment

• Capillary hose set for fine pressure probe (0554 1215)

• Connecting cable for surface probe (0430 1215)

4 Combustion air temperature probe (0600 9787)

5. Surface temperature probe Type K (0604 0994)

21

Page 22

4 Product description

CAUTION

4.3. Measuring instrument

4.3.1. Overview

22

1 Switch on/off

2 Interfaces: USB, PS2, infrared

Risk of injury from infrared beam!

> Do not direct infrared beam at human eyes!

3 Condensate trap (on rear)

4 Fixing eyelets for carrying strap (left and right)

5 Display

Page 23

6 Magnetic holders (on rear)

WARNING

Function key (orange, 3x), relevant function is shown on

Magnetic field

May be harmful to those with pacemakers.

> Keep a minimum distance of 15 cm between pacemaker and

instrument.

ATTENTION

Magnetic field

Damage to other devices!

> Keep a safe distance away from products which could be

damaged by the effects of magnetism (e.g. monitors,

computers or credit cards).

7 Keypad

8 Service cover (on rear)

9 Gas outlet

10 Unit connections: flue gas probe, sensor, pressure probe, mains

4.3.2. Keypad

unit

Ke y Functions

[ ]

[OK]

Example

[▲]

[▼]

[esc]

[ ]

[ i ]

[ ]

4 Product description

Switch measuring instrument on / off

the display

Scroll up, increase value

Scroll down, reduce value

Back, cancel function

Open main menu

Open instrument diagnosis menu

Transmit data to the Testo protocol printer.

23

Page 24

4 Product description

4.3.3. Display

1 Status bar (dark grey background):

• Warning symbol (only if there is a device error, display

of error in instrument diagnosis menu), otherwise:

Instrument designation.

• Symbol (only if data are stored in the temporary

memory).

• Display of date and time.

• Indication of Bluetooth

capacity of the battery:

Icon Feature

2 Info field of register tabs: Indication of selected

Address / Location, chosen fuel, chosen measurement type

3 Selection field for functions (chosen function appears against a

white background, unavailable functions are identified by grey

characters) or display of measuring values.

4 Function display for function keys.

®

status, power supply and remaining

blue symbol = Bluetooth® on,

grey symbol = Bluetooth

Battery operation

®

off

Indication of remaining capacity of the rech. batt.

by colour and filling degree of the battery symbol

(green = 5-100 %, red = < 5 %)

Mains operation

Indication of remaining capacity of battery: see

above

24

Page 25

4.3.4. Device connections

1 Probe socket

2 Flue gas socket

3 Mains unit socket

4 Pressure socket

4.3.5. Interfaces

4 Product description

1 USB interface

2 PS2-interface

3 Infrared interface (IrDA)

4 Bluetooth interface (optional)

25

Page 26

4 Product description

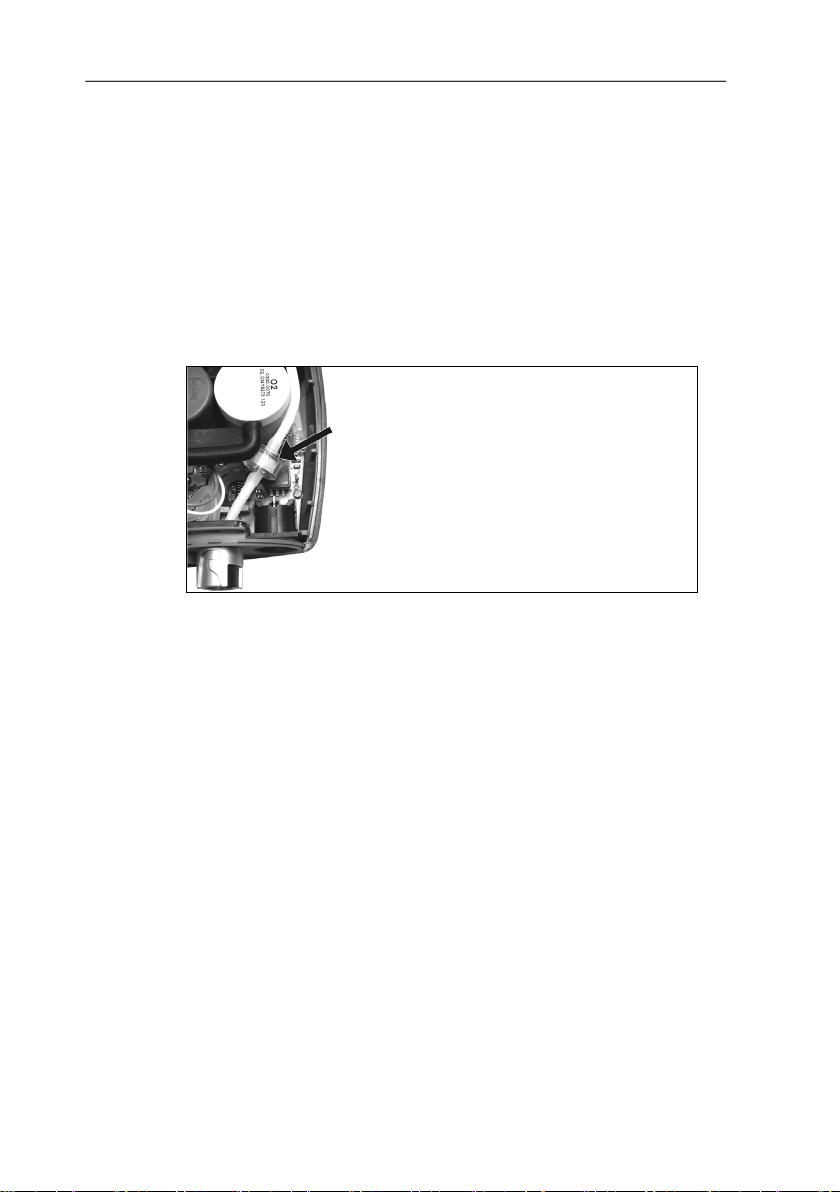

4.3.6. Components

1 Rechargeable battery

2 Measuring gas pump

3 Slot for CO-sensor or COlow-sensor

4 Slot O2-sensor

5 Slot NO-sensor or NOlow-sensor

6 Additional filter

26

Page 27

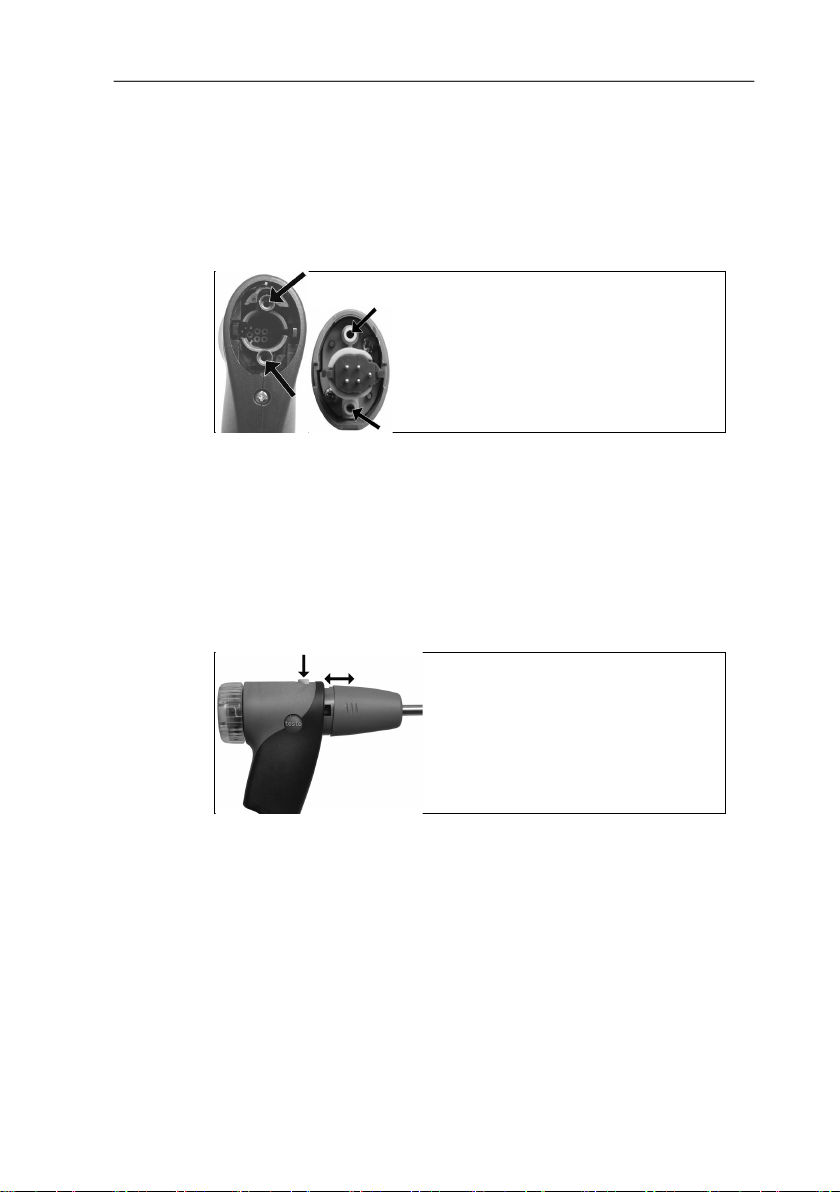

4.3.7. Carrying strap (0440 0581)

To secure the carrying strap:

> Remove the sealing caps from the sides of the housing.

Fix the sealing caps on the inside of the service cover:

1. Place the measuring instrument on its front.

2. Pick the service cover up at the markings (arrows) using your

index finger and thumb and press gently to release the lock.

3. Fold up the service cover and remove it.

4. Secure the sealing caps in the two holders on the inside of the

service cover (1).

5. Attach the service cover and engage it in place.

4 Product description

> Engage the carrying strap clip in the fixing eyelets on the sides

of the device. Note the guide groove, the strap must point

"down" (2).

27

Page 28

4 Product description

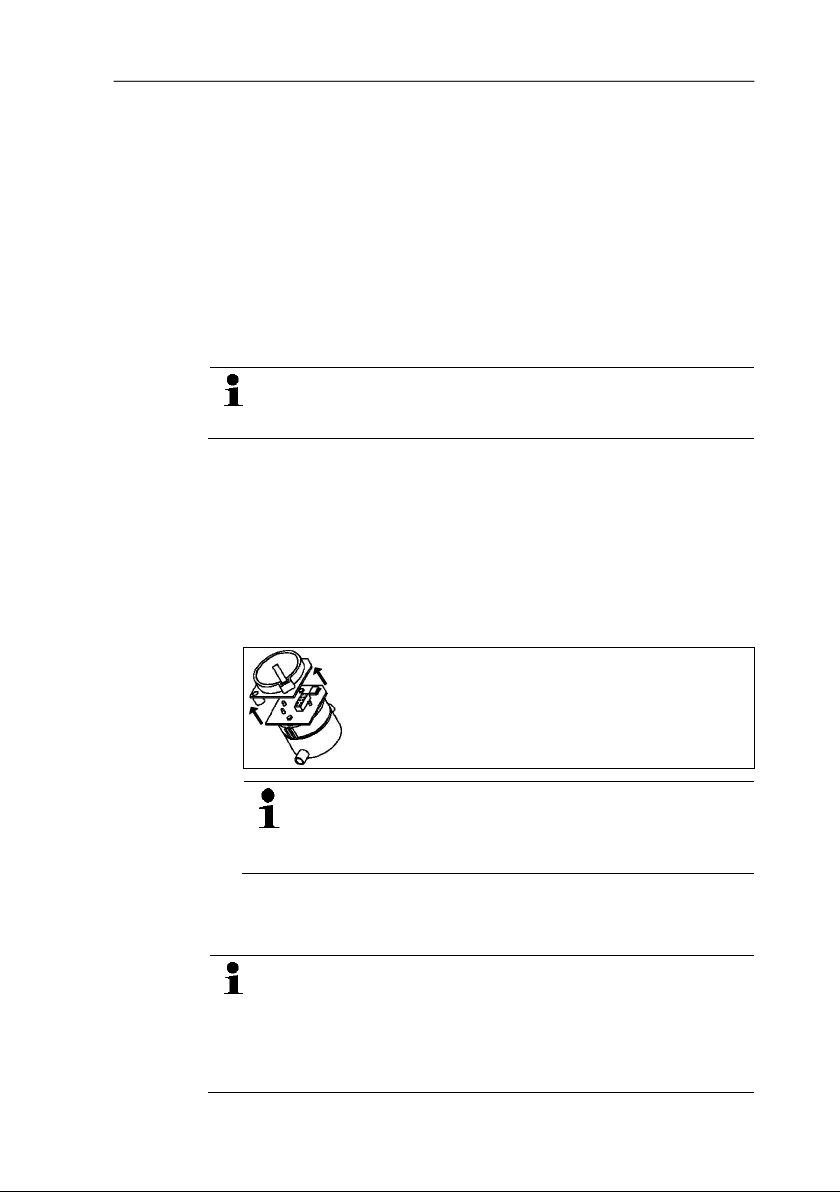

4.4. Modular flue gas probe

1 Removable filter chamber with window and particle filter

2 Probe handle

3 Connecting cable

4 Connector plug for measuring instrument

5 Probe module lock release

6 Probe module

28

Page 29

5 First steps

5.1. Commissioning

The measuring instrument is supplied with a rechargeable battery

already fitted.

> Charge the battery fully before using the measuring instrument,

5.2. Getting to know the product

see Charging batteries, page 30.

5.2.1. Mains unit / rechargeable battery

If the mains unit is connected, the measuring instrument is

5.2.1.1. Changing the battery

automatically powered from the unit.

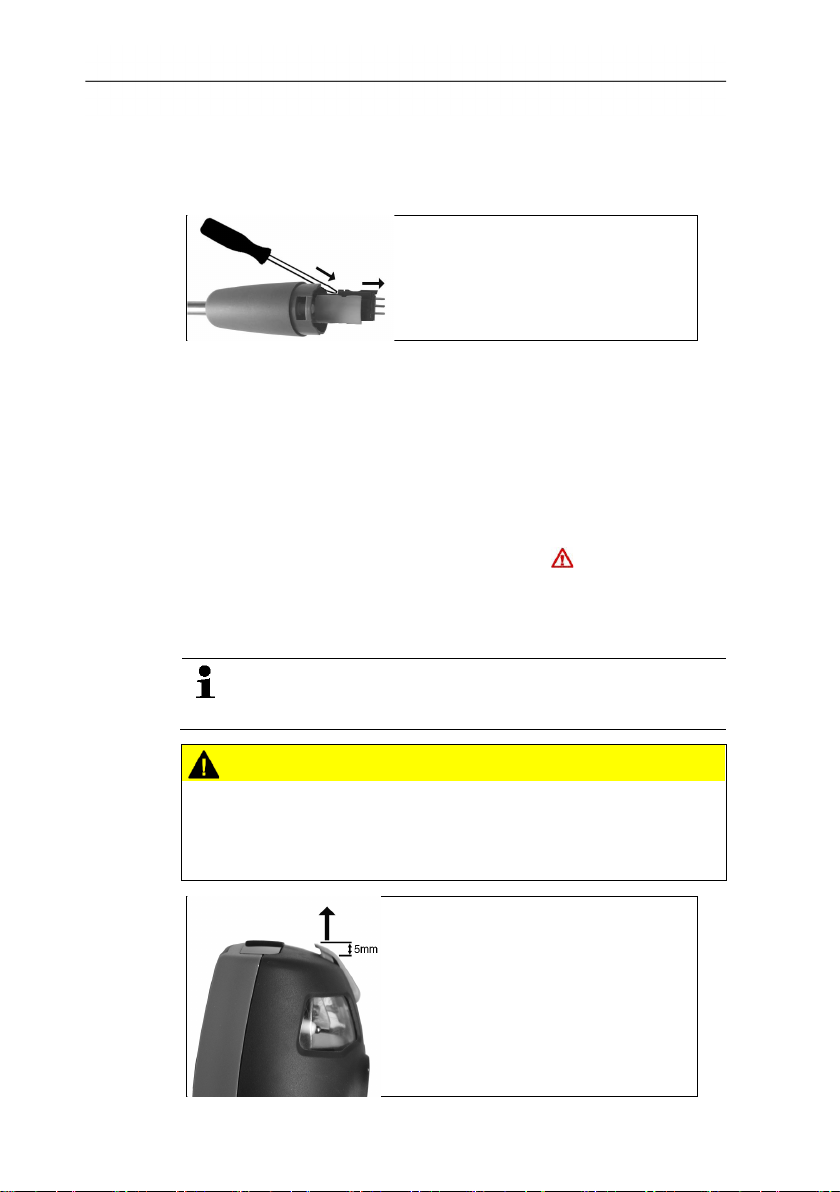

✓ The measuring instrument must not be connected to a mains

socket via the mains unit. The instrument must be switched off.

Change the rechargeable battery within 3 minutes so that device

settings (e.g. date / time) are not lost.

5 First steps

1. Place the measuring instrument on its front.

2. Remove the service cover: Take hold of it at the markings

(arrows) using the index finger and thumb, press slightly, fold

up and remove.

3. Open the battery lock: Press the grey key and push in direction

of arrow.

4. Remove the battery and insert a new rechargeable battery.

Only use the Testo rechargeable battery 0515 0107!

5. Close the battery lock: Press the grey key and push against

direction of arrow until the battery engages.

6. Attach the service cover and engage it in place.

29

Page 30

5 First steps

5.2.1.2. Charging batteries

The rechargeable battery can only be charged at an ambient

temperature of ±0...+35 °C. If the battery has been discharged

completely, the charging time at room temperature is approx. 5-6

hrs.

Charging in the measuring instrument

1. Connect the plug of the mains unit to the mains unit socket on

the measuring instrument.

2. Connect the mains plug of the mains unit to a mains socket.

- The charging process will start. The charge condition will be

shown in the display. The charging process will stop

automatically when the battery is fully charged.

Charging in the charging station (0554 1087)

> Refer to the documentation enclosed with the charging station.

Battery care

> Do not fully exhaust rechargeable batteries.

> Store rechargeable batteries only in charged condition and at

low temperatures, but not below 0 °C (best storage conditions

with a charge level of 50-80 %, at an ambient temperature of

10-20 °C, recharge completely before use).

> For longer breaks you should discharge and recharge the

batteries every 3- months. Trickle charging should not exceed 2

days.

5.2.1.3. Mains operation

1. Connect the plug of the mains unit to the mains unit socket on

the measuring instrument.

2. Connect the mains plug of the mains unit to a mains socket.

- The measuring instrument is powered by the mains unit.

- If the measuring instrument is switched off and a rechargeable

battery is inserted, the charging process will start automatically.

Switching the measuring instrument on has the effect of

stopping battery charging and the measuring instrument is then

powered via the mains unit.

For longer measurements that are mains-operated, Testo

recommends using a combustion air temperature probe

with connecting cable. Self-heating of the instrument

during mains operation may influence the combustion air

temperature measurement with a mini ambient air probe.

30

Page 31

5.2.2. Connecting probes / sensors

Probe/sensor detection at the flue gas socket is carried out

continuously. New probes are recognised automatically.

Connect a probe to the probe socket before switching on

the measuring instrument or start sensor detection

manually after changing the probe: [Options] → Sensor

detection.

Connecting flue gas probes / gas pressure adapters / temperature adapters

> Insert the connector plug into the flue gas socket and lock by

slightly turning it clockwise (bayonet lock).

There must be no more than one extension lead (0554

1201) between measuring instrument and flue gas probe.

5 First steps

Connecting other sensors

> Insert the connector plug of the probe into the probe socket.

31

Page 32

5 First steps

5.2.3. Switching on

> press [ ] .

- The start screen is displayed (duration: about 5 s).

- If the voltage supply was interrupted for a longer period: The

menu Date / Time is opened.

- The pressure sensors are set to zero.

- There is a device error: The Error Diagnosis is displayed.

- The menu Measurements is displayed.

5.2.4. Calling up a function

1. Select function: [▲], [▼].

- The chosen function appears in a frame.

2. Confirm selection: [OK].

- The chosen function is opened.

5.2.5. Entering values

Some functions require values (numbers, units, characters) to be

entered. Depending on the function that is chosen, the values are

entered via either a list field or an input editor.

List field

32

1. Select the value to be changed (numerical value, unit): [▲],

[▼], [◄], [►] (depending on the selected function).

2. Press [Edit] .

3. Set value: [▲], [▼], [◄], [►] (depending on the selected

function).

4. Confirm the entry: [OK].

5. Repeat steps 1 and 4 as required.

6. Save the entry: [Finished].

Page 33

5 First steps

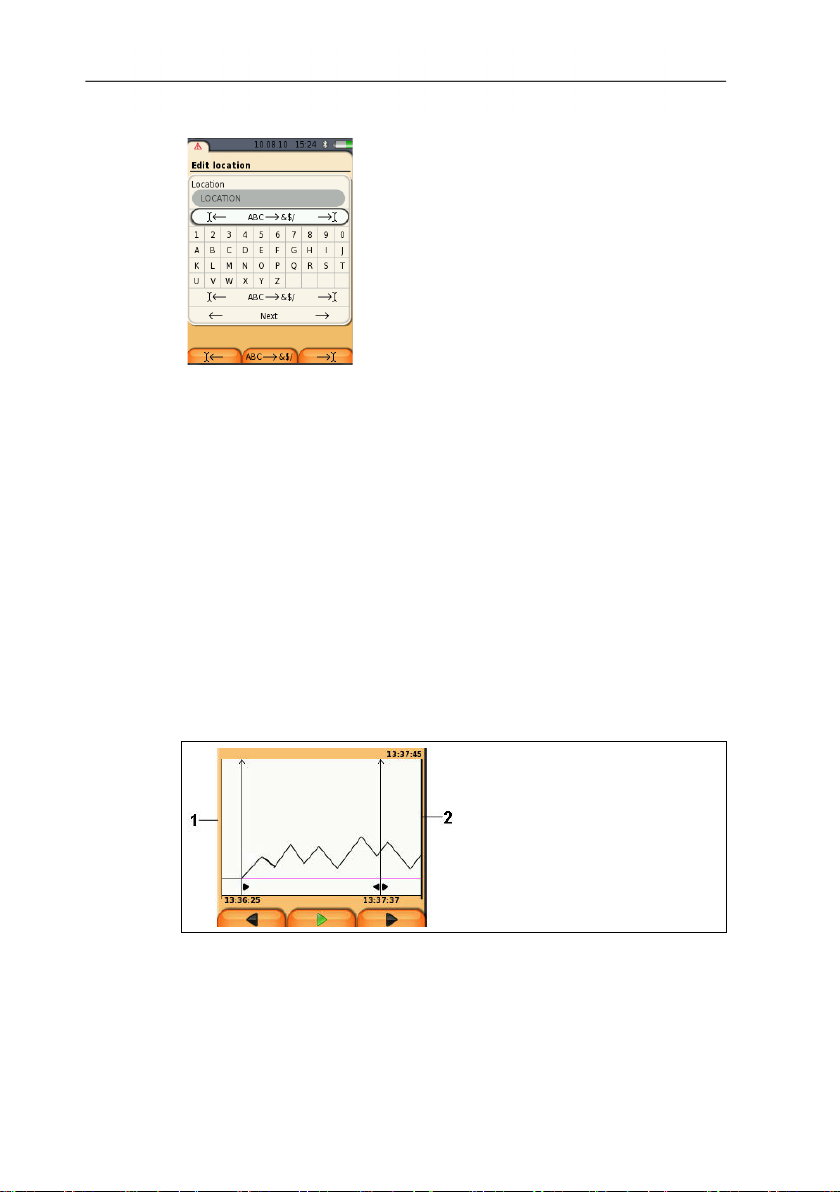

Input editor

1. Select the value to be changed (character): [▲], [▼], [◄], [►].

2. Accept value: [OK].

Options:

> Toggle between upper / lower case characters:

Select Ι← ABC→&$/ →Ι : [▲], [▼] → [ABC→&$/].

> Position the cursor in the text:

Select Ι

[

> Delete character before or after the cursor:

Select

3. Repeat steps 1 and 2 as required.

4. Save the entry: Select

← ABC→&$/ →Ι : [▲], [▼] → [Ι←] or

→Ι].

← next → : [▲], [▼] → [←] or [→].

← next → : [▲], [▼] → [Next].

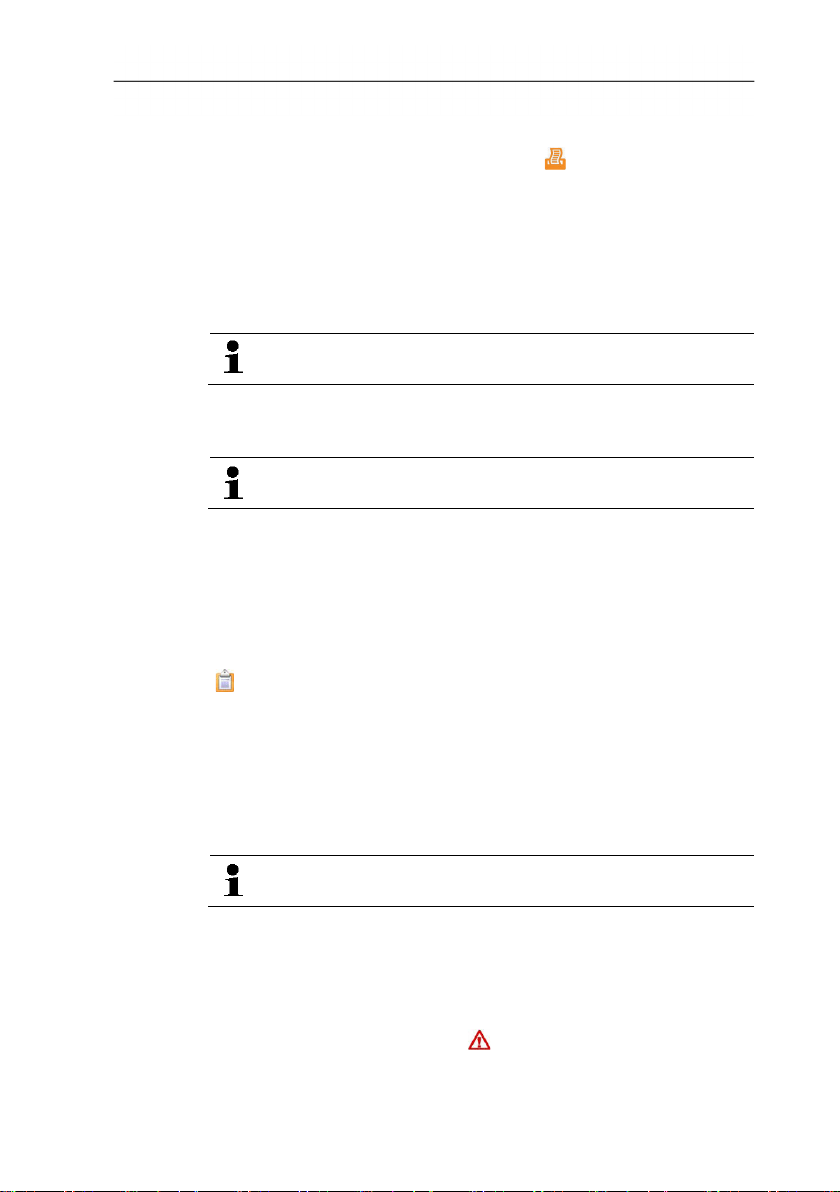

5.2.6. Show graphic

1 Current measuring value

2 End time of the displayed period.

The time is not displayed if no measuring value was recorded for

this period.

33

Page 34

5 First steps

5.2.7. Printing / saving data

Data are printed out via the function key [ ] or the menu Options.

Data are saved via the menu Options. The menu Options is

accessed via the left function key and is available in many different

menus.

Assignment of the right function key with the function Save or

Print, see Assigning the right function key page 40 .

Only measuring values, which have a display field in the

measurement view assigned, will be saved / printed out.

The measurement data can be printed out parallel to the

saving process, while a measurement program is running.

To be able to transmit data via infrared or Bluetooth interface to a

report printer, the printer to be used must have been activated, see

Activating the printer:, page 44.

Graph charts can be printed out using the Bluetooth® /

IRDA printer 0554 0620.

5.2.8. Remembering data (clipboard)

With the help of the clipboard measuring results from various

measurement types can be combined to a common record, which

can then be printed out (see above). Data are saved to the

clipboard via the menu Options and the command Clipboard.

If there are data in the clipboard, the status bar shows the symbol

.

If there are data in the clipboard and the command Print is

triggered, all data in the clipboard will be printed out.

Only one set of measuring data can be recorded per measurement

type (e.g. Flue Gas or Draught). Repetitive saving of test data of

one measurement type overwrites the previously saved data. When

changing the measurement place or the fuel, the clipboard is

deleted.

> [Options] → Delete clipboard: Any data saved to the

clipboard is deleted.

5.2.9. Confirming an error message

If an error occurs, an error message is shown in the display.

> Confirming an error message: [OK].

Errors which have occurred and have not yet been rectified are

indicated by a warning symbol ( ) in the header.

Not yet rectified error messages can be displayed in the menu

Error Diagnosis, see Instrument diagnosis, page 38.

34

Page 35

5.2.10. Switching off

function can also be used to find a series of several

Unsaved measuring values will be lost when the flue gas

analyser is switched off.

> Press [ ] .

- Possibly: The pump starts and the sensors are rinsed until the

switch-off thresholds (O2 > 20 %, other measurement

parameters < 50 ppm) are reached. The maximum rinsing

period is 3 minutes.

- The measuring instrument switches off.

5.3. Address/Location

All measuring values can be saved under the currently active

location. Measuring values that have not been saved are lost when

the measuring instrument is switched off!

Addresses and locations can be created, edited, copied and

enabled. Addresses and locations (incl. protocols) can be deleted.

Call up function:

> [ ] → Address/Location → [OK].

There are various options for opening address.

1. Edit search setting: [Edit].

2. Select search setting: [▲], [▼] → [OK].

Possible settings:

• Show all: All address/location are displayed.

• Search: A search text only brings up address/location that

contain characteristics of the search text.

• Filter: Individual letters or numbers can be selected. All data

beginning with the relevant letter/number is displayed.

The initial letter is the determining factor for the filter

function, and this can only be selected individually. The

search

letters within the address!

3. Carry out search according to search setting: [Search]

5 First steps

Show all

1. Select address: [▲], [▼].

2. Show details: [Details].

3. Enable a location: select the location → [OK].

- The location is activated.

> Open measurements menu: press [OK] again.

35

Page 36

5 First steps

Search

1. Edit search criteria: [►] → [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Address

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Call up entry field for search text: [►] or [▼]

> Enter search text → [Finished]

Do not use the special character * as a placeholder.

Filter

1. Edit search criteria: [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Address

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Enable tab: [▼]

4. Select the required tab: [▲], [▼] and sometimes [◄], [►]→

[Filter].

- The search result for the relevant letter or number is displayed.

36

Create a new measuring location:

A location is always created under an address.

1. Select the address in which the location is to be created.

2. [Options] → New/Location → [OK].

3. Enter values or make settings.

4. Finalise the entry: [Finished].

Page 37

Other location options:

> [Options] → Edit location: make changes to an existing

location.

> [Options] → Copy location: make a copy of an existing

location in the same address.

> [Options] → Delete location: delete an existing location.

Create new address:

1. [Options] → New address → [OK].

2. Enter values or make settings.

3. Finalise the entry: [Finished].

Other address options:

• Edit address: make changes to an existing folder.

• Copy address: make a copy of an existing folder.

• Delete address: delete an existing folder, including the

locations created therein.

• Delete All addresses: delete all existing folders, including the

locations created in them.

5.4. Measurement records

Calling up the function:

> [ ] → Measurement Records → [OK].

5 First steps

There are various options for opening protocols, see Address/Location, page 35

Displaying a record:

1. Choose the required record from the detailed view.

2. Print [Data].

Printing all records for a location:

1. Select measuring location: [▲], [▼]

2. Start printout: [ ].

- All records for the location are printed out.

37

Page 38

5 First steps

Options:

> [Options] → Show Graphic: Display saved record data as

graphic.

> [Options] → Print Data: Transmit data of the chosen record to

a record printer.

> [Options] → Delete Record: Delete the chosen record.

> [Options] → Number of Lines: Change the number of

measuring values per display page.

> [Options] → Delete all Records: Delete all saved records for a

location.

5.5. Instrument diagnosis

Important operating values and instrument data are displayed. A

gas path check (testo 330-2 LL) can be carried out. The status of

the sensors and any device errors not yet rectified can be

displayed.

Calling up the function:

> [ ] → Instrument Diagnosis → [OK].

or

> [ i ].

Carrying out a gas path check (testo 330-2 LL)

1. Gas Path Check → [OK]

2. Place the black sealing cap on the tip of the flue gas probe.

- The pump flow is displayed. If the volumetric flow rate is less

than 0.02 l/min, the gas paths are not leaking.

3. End of check: [OK].

38

Viewing device errors:

> Error Diagnosis → [OK].

- Unrectified errors are displayed.

> View next / previous error: [▲], [▼].

Page 39

5 First steps

View sensor diagnosis:

1. > Sensor Diagnosis → [OK].

2. Select sensor. [▲], [▼].

- The status of the sensor is indicated by a lamp.

A sensor is able to recover. It is therefore possible that the

sensor status indication changes from yellow to green or

from red to yellow.

View instrument information:

> Device Information → [OK].

- Information is displayed.

39

Page 40

6 Using the product

6 Using the product

6.1. Performing settings

6.1.1. Assigning the right function key

The right function key can have a function from the Options menu

assigned to it. The menu Options is accessed via the left function

key and is available in many different menus. This assignment is

only valid for the currently opened menu / the opened function.

✓ A menu / function is opened in which the Options menu is

6.1.2. Instrument settings

displayed on the left function key.

1. Press [Options] .

2. Select option: [▲], [▼].

Depending on the menu / function from which the Options menu

was opened, the following functions are available.

3. Assign the selected function to the right function key: Press

[Config. Key].

It is assumed that the contents of the chapter First steps

(see First steps, page 29) are known.

Calling up a function:

> [ ] → Device Settings.

see First steps, page 29

6.1.2.1. Readings display

The parameters / units and the display representation (number of

readings displayed per display page) can be set.

The settings are only valid for the currently chosen measurement

type, which is indicated by the symbol in the info field.

Total overview of selectable parameters and units (available

selection depends on the chosen measurement type):

Display Parameter

FT

AT

ltemp

Pump

40

Flue gas temperature

Combustion air temperature

Instrument temperature

Pumping capacity

Page 41

Display Parameter

O2

CO2

CO

uCO

NO

NOx

λ

amCO

amCO2

O2ref

Edrft

E-ΔP

Oxygen

Carbon dioxide

Carbon monoxide

Carbon monoxide undiluted

Nitrogen monoxide

Nitrogen oxide

Air ratio

Ambient carbon monoxide

Ambient carbon dioxide

Oxygen reference

external draught (micro pressure probe)

external differential pressure (micro pressure

probe)

ExAir

Ratio

η+

Air ratio

Poison index

Efficiency under due consideration of the heat

value range

η

Efficiency without consideration of the heat value

range

Dew/a

Flue gas dew point temperature

6 Using the product

Calling up the function:

> [ ] → Instrument Settings → [OK] → Readings Display →

[OK]

Changing parameter / unit in a line:

1. Select the line where you want to position the selected

measurement parameter: [▲], [▼] → [Edit]

2. Select the parameter: [▲], [▼] → [OK]

3. Select the unit: [▲], [▼] → [OK]

4. Save changes: [OK]

- The measurement parameter is now in the selected position on

the reading display.

41

Page 42

6 Using the product

Options:

> [Options] → Number of Lines: Change the number of

measuring values per display page.

> [Options] → Insert Empty Lines: Insert the empty line before

the selected line.

> [Options] → Delete Line: Delete the selected line.

> [Options] → Factory Setting: Reset the readings display to

factory setting

6.1.2.2. Alarm limits

Alarm limits can be set for several display parameters. An audible

alarm signal is triggered when the alarm limit is reached.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Alarm Limits → [OK]

Switching alarm signals on / off, changing alarm limits:

1. Select function or parameter: [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Finished].

> Reset the enabled value to the factory setting: [Standard].

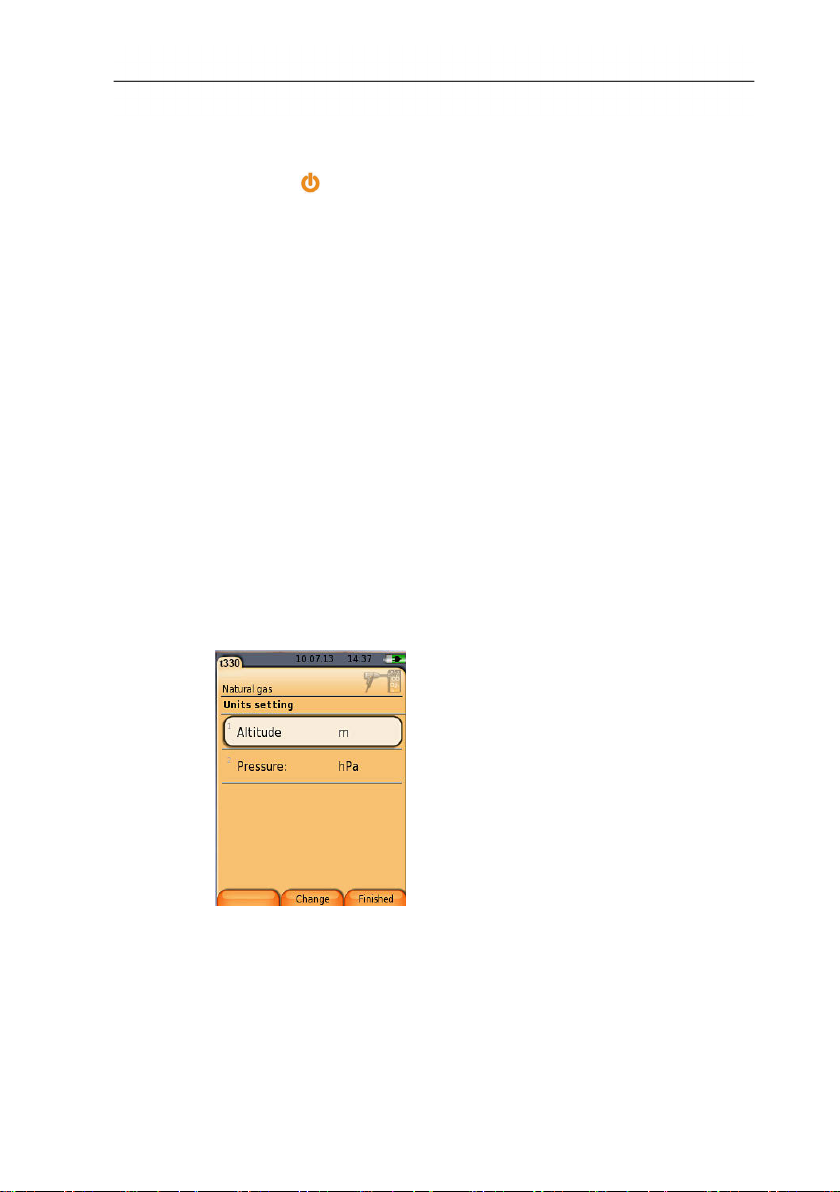

6.1.2.3. Units

The units used for parameters in configuration menus can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Units → [OK]

42

Adjustable units

Parameter Unit

Altitude m, ft

Pressure mbar, hPa

1. Select the line: [▲], [▼]→ [Edit].

2. Select the unit to be changed: [▲], [▼] → [OK].

3. Confirm the entry: [Finished].

Page 43

6.1.2.4. Date / time

Date, time mode and time can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Date/Time → [OK]

Setting date/time:

1. Select parameter: [◄], [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Save].

6.1.2.5. Energy management

Automatic instrument shutdown (Auto-Off) and switching off of the

display light in battery operation can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Energy Management

→ [OK]

Making settings:

1. Select function or parameter: [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Finished].

6 Using the product

6.1.2.6. Display brightness

The intensity of the display illumination can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Display Brightness →

[OK]

Performing settings

> Set parameter: [◄], [►] → [OK].

6.1.2.1. Choose measurement type

Individual measurement types can be shown or hidden. These are

displayed or hidden accordingly under Measurement options.

Call up function:

> [ ] → Device settings → [OK] → Choose measurement

type → [OK].

43

Page 44

6 Using the product

Show or hide measurement types:

1. Select measurement type: [▲], [▼]

2. Enable / disable measurement type: [ ] (enabled), [ ]

(disabled)

3. Save selection: [Finished].

6.1.2.2. Printer

The headers (lines 1-3) and the footers for the printout can be set.

The printer that is used can be activated.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Printer → [OK]

Activating the printer:

1. Select Printer → [OK].

2. Select the printer: [▲], [▼] → [OK].

- The printer is activated and the menu Printer is opened.

Configuring the print text:

1. Print text → [OK].

2. Select function: [▲], [▼] → [Edit].

> Enter values for Line 1, Line 2, Line 3 and the Footnote

> Print out system data and/or customer data: [ ]

3. Save the entry: select [Finished].

see Bluetooth

The printer 0554 0543 can only be selected after the

Bluetooth

Bluetooth

®

-interface has been activated, see

®

, page 44.

®

, page 44

6.1.2.3. Bluetooth®

This menu is only available if the instrument is equipped with

Bluetooth. The Bluetooth module can be switched on / off.The relay

44

can now be tested.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Bluetooth → [Edit].

Making settings:

> Set parameter → [OK].

Page 45

6.1.2.4. Language

The menu language can be set. The number of available

languages depends on the activated country version, see Country

version, page 45.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Language → [OK]

Activating the language:

> Select the language → [OK].

see Country version, page 45

6.1.2.5. Country version

Changing the country version may alter the basis for calculation

and therefore also the displayed measurement parameters, fuels,

fuel parameters and calculation formulas.

The selection of the country version influences the menu languages

that can be enabled.

For information concerning the assignment table, the basis for

calculation and the country version, see website.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Country Version →

[OK]

This action can be password protected. A password is

specified in the menu Password Protection, see

Password protection, page 46.

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

6 Using the product

Setting the country version:

1. Select the country version: [▲], [▼] → [OK].

2. Confirm the confirmation request: Yes → [OK]

- The system is restarted.

see Password protection, page 46

45

Page 46

6 Using the product

6.1.2.6. Password protection

The password protection is only valid for functions identified by the

following symbol: or .

Password protection can be activated / deactivated, the password

can be changed.

To deactivate the password protection change the password to

0000 (factory setting).

Calling up the function:

> [ ] → Instrument Settings → [OK] → Password Protection

→ [OK]

Possibly:

> Enter the currently valid password:

[Enter] → Enter password → [Next] → [OK].

Changing the password:

1. [Edit].

2. Enter the new password → [Next].

3. [Edit].

4. Enter the new password again to confirm → [Next].

5. Save changes: [Finished].

6.1.3. Sensor settings

6.1.3.1. NO2 addition

The NO2 addition parameter can be set.

The setting of the NO2-addition can be password protected, see

Password protection, page 46.

Calling up the function:

> [ ] → Sensor Settings → NO2 Addition → [Edit].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

Setting the NO

> Set parameter → [OK].

46

addition:

2

Page 47

6.1.3.2. O2 reference

The O2 reference value can be set.

The setting of the O2 reference value can be password protected,

see Password protection, page 46.

Calling up the function:

> [ ] → Sensor Settings → O2 Reference→ [Edit].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

6 Using the product

Setting the O

reference:

2

> Set parameter → [OK].

6.1.3.3. Sensor protection

Protection limits can be set to protect the sensors against overload.

Sensor protection switch-off is available for the following sensors:

CO, NO.

The sensor protection is activated when the threshold is exceeded.

• testo 330-1 LL: Switch-off.

• testo 330-2 LL: Dilution, if exceeded again: Switch-off.

To deactivate sensor protection the thresholds must be set to 0

ppm.

Calling up the function:

> [ ] → Sensor Settings → Sensor Protection → [OK].

Setting sensor protection thresholds:

1. Select parameter: [Edit].

2. Set parameter → [OK].

3. Save changes: [Finished].

47

Page 48

6 Using the product

WARNING

6.1.3.4. Recalibration / adjustment

CO and NO sensors can be recalibrated and adjusted.

For recalibration / adjustment Testo recommends the use of the

calibration adapter 0554 1205.

If obviously unrealistic readings are displayed, the sensors

should be checked (calibrated) and, if required, adjusted.

Have the recalibration / adjustment carried out by a

qualified service centre approved by Testo.

Adjustments made with low gas concentrations can lead to

accuracy deviations in the upper measuring ranges.

Calling up the function:

> [ ] → Sensor Settings → Recalibration → [OK].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

- Gas zeroing (30 s).

Performing recalibration / adjustment:

Dangerous gases

Danger of poisoning!

> Observe safety regulations / accident prevention regulations

when handling test gas.

> Use test gases in well ventilated rooms only.

1. Connect the calibration adapter to the flue gas socket.

2. Select the parameter: [▲], [▼] → [OK].

3. [Edit] → Enter the test gas concentration (nominal value).

4. Attach the connecting line of the test gas bottle to the

calibration adapter.

5. Apply test gas to the sensor.

6. Start recalibration: [Start].

7. Accept the nominal value once the actual value is stable

(adjustment): [OK].

-orAbort (no adjustment): [esc].

8. Save changes: [Finished].

48

Page 49

6.1.4. Fuels

Correct representation of measuring results is only assured

The fuel can be selected. The fuel-specific coefficients and limits

can be set.

Apart from the pre-configured fuels, 10 more customer

specific fuels can be configured.

Calling up the function:

> [ ] → Fuels → [OK].

Activating fuels:

> Select the fuel → [OK].

- The fuel is activated and the main menu is opened.

Setting coefficients:

1. Select the fuel → [Coeff.].

2. Select the coefficients: [Edit].

Possibly:

Enter the password: [Enter] → Enter password → [Next] →

>

[OK].

3. Set values → [OK].

4. Save changes: [Finished].

6 Using the product

In order to maintain the measuring accuracy of the

instrument one must choose or configure the correct fuel.

if the threshold values for the ideal range of the

corresponding measurement task have been set correctly.

The pre-set threshold values are typical values for the

selected system type and the chosen type of fuel.

Setting limits:

1. Select limit → [Edit].

2. Set values → [OK].

3. Save changes: [Finished].

49

Page 50

6 Using the product

6.1.5. Programs

Five measuring programs for different measurement types can be

configured and activated. The measuring programs serve the

purpose of saving and representing measuring sequences. After

the end of the measuring process the readings of a measuring

program are automatically saved in a record.

Only one measuring program can be activated in the instrument.

Calling up the function:

> [ ] → Programs → [OK].

Activating / deactivating a program:

> Select the program: [▲], [▼] → [Enable] or [Disable].

- When activating a program: The program is activated and the

measurement type matching the program is opened.

Configuring the program:

The measuring cycle takes 1s and cannot be changed.

An activated program cannot be configured.

1. Select the program: [▲], [▼] → [Edit].

2. Select parameters program name, measurement type, gas

phase: [▲], [▼] → [Edit].

3. Set parameters or enter values: [▲], [▼] and partly [◄], [►]→

[OK].

4. Save changes: [Finished].

50

Page 51

6.2. Measuring

6.2.1. Preparing for measurement

It is assumed that the contents of the chapter First steps

(see First steps, page 29) are known.

6.2.1.1. Zeroing phases

Measuring the ambient air temperature (AT)

If no combustion air temperature probe is connected, the

temperature measured by the thermocouple of the flue gas probe

during the zeroing phase is used as the combustion air

temperature. All dependent parameters are calculated using this

value. This method of measuring combustion air temperature is

sufficient for systems dependent on ambient air. However, ensure

that the flue gas probe is near the intake duct of the burner during

the zeroing phase.

If a combustion air temperature probe is connected, the combustion

air temperature is measured continuously via this probe.

Gas zeroing

When the instrument is switched on the measurement menu is

opened and the gas sensors are zeroed.

testo 330-1 LL: The flue gas probe must be in the open air

during the zeroing phase!

testo 330-2 LL: The flue gas probe can be in the flue gas

duct even during the zeroing phase, if a separate VTsensor is plugged in.

6 Using the product

Draught / pressure zeroing

The pressure sensors are zeroed when a pressure measuring

function is called up.

testo 330-1 LL: The flue gas probe must be in the open air

during the zeroing phase / the instrument must not be

pressurised during zeroing!

testo 330-2 LL: The flue gas probe can be in the flue gas

duct even during the zeroing phase, if a separate VTsensor is plugged in. The pressure socket of the instrument

must be free (i.e. unpressurized, not closed).

51

Page 52

6 Using the product

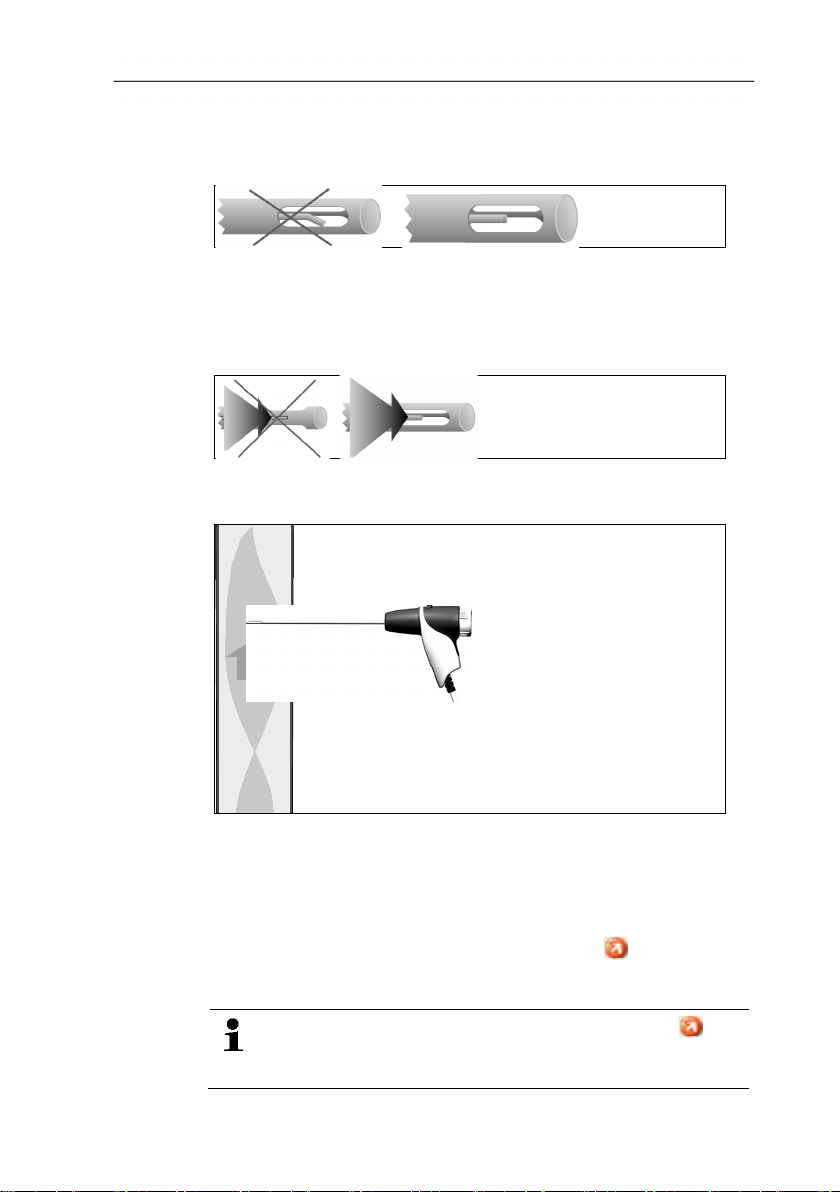

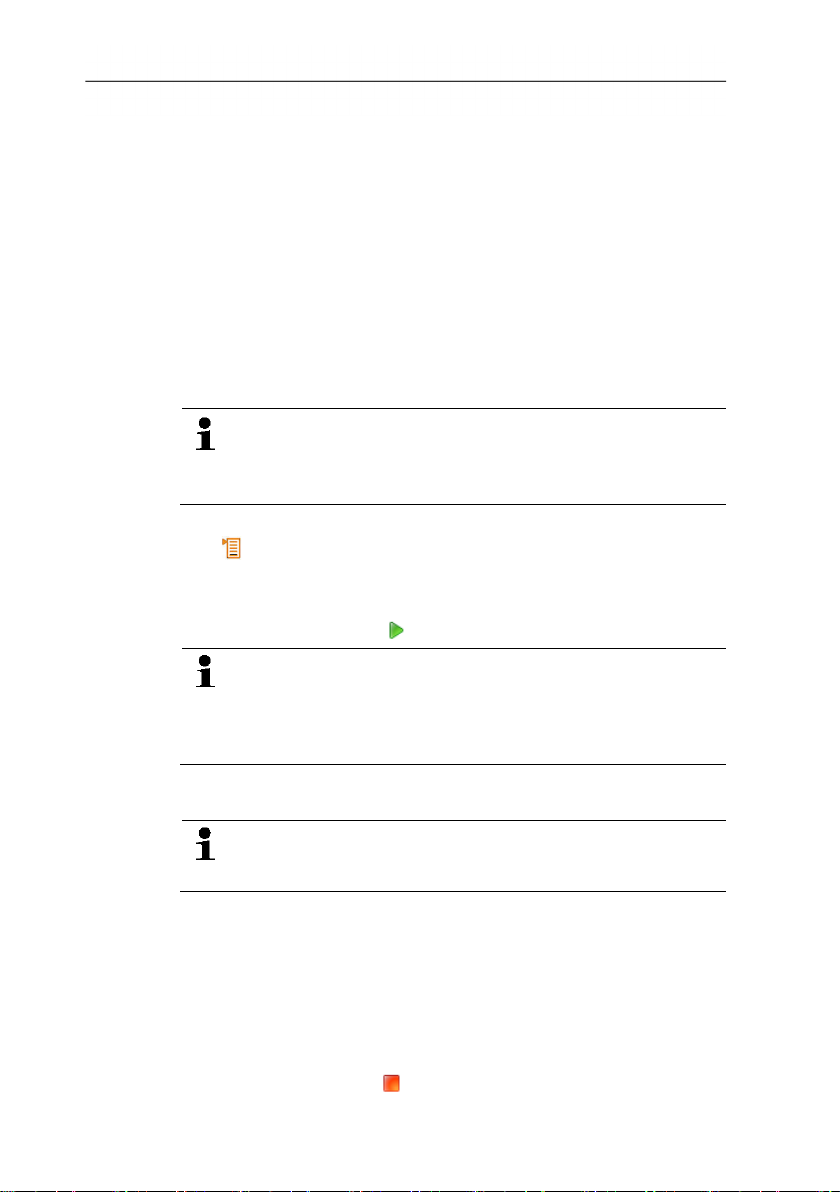

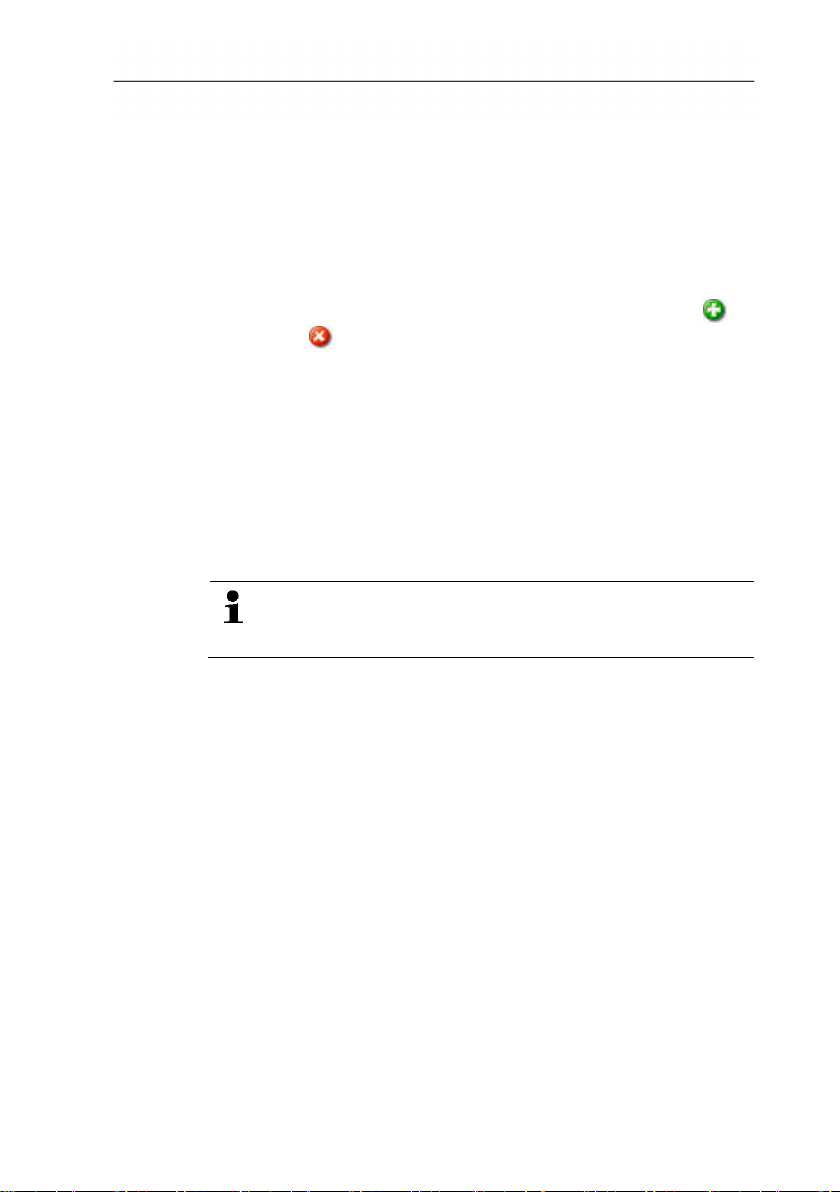

6.2.1.2. Using the modular flue gas probe

Checking the thermocouple

The thermocouple of the flue gas probe must not lie against the

probe cage.

> Check before use. Bend the thermocouple back if necessary.

Aligning the flue gas probe

The flue gas must be able to flow freely past the thermocouple.

> Align the probe by turning it as required.

The tip of the probe must be in the hot spot of the flue gas flow.

> Align the flue gas probe in the flue gas duct so that the tip is in

the hotspot (area of the highest flue gas temperature). As a

visual aid, the display shows the current temperature with a

green bar. The red marking indicates the maximum measured

temperature during the hotspot search. If the symbol

appears, the temperature is outside the measuring range of the

flue gas probe.

The measuring value of the red marking and the

symbol can only be cancelled by restarting the flue gas

menu.

52

Page 53

6.2.1.3. Configuring the reading display

been carried out, this value is calculated using the readings

If CO undiluted has already been measured separately, the

Only those parameters and units, which are activated in the reading

display, appear in the reading display, the saved measurement

protocols and the record printouts.

> Before performing measurements set up the reading display in

such a way, that the required parameters and units are

activated, see Readings display, page 40.

6.2.1.4. Setting location and fuel

Before carrying out measurements, the measurement location and

the fuel must be correctly selected, see Address/Location, page 35

6.2.2. Flue gas

and Fuels, page 49.

To achieve usable measurement results, the measurement

period of a flue gas measurement should be approx. 3 min

and the measuring instrument should display stable

measured values.

Calling up the function:

1. [ ] → Measurements → [OK] → Flue Gas → [OK].

2. Select the fuel → [OK].

Performing the measurement:

1. Start measurement: [ ].

If a separate measurement of CO undiluted has not yet

of the flue gas probe and is updated continuously.

6 Using the product

value obtained is adopted.

- The readings are displayed.

> [Options] → Draught measure start/stop

The draught measurement option is only available if the

measurement parameter Draught is enabled in the reading

display.

- Draught measurement zeroing

- Draught measurement begins automatically

> Hold the draught measurement value displayed: [Drgt stop]

- The measurement stops automatically.

- The readings are automatically displayed and saved in a record.

Option

Restart the draught measurement: [Drgt start]

2. Quit measurement: [ ].

53

Page 54

6 Using the product

Options

> [Options] → Clipboard: Data are saved to the clipboard

> [Options] → Delete clipboard: Any data saved to the clipboard

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

> [Options] → Configure Graphic: The measurement

> [Options] → Draught measure start/stop: The measurement

> [Options] → Flue Gas Matrix: The readings are displayed as

> [Options] → Number of Lines: Change the number of

> [Options] → Accept measuring values from 315-3:

is deleted.

form of a line graph.

parameters to be represented (max. 4) can be displayed ( ) or

hidden ( ).

view is opened and a draught measurement can be carried out.

flue gas matrix, see below.

measuring values per display page.

Ambient CO/CO2 values measured with the testo 315-3 can be

accepted by the testo 330. Data is transferred via Bluetooth® or

via the IrDA interface.

For data transfer via Bluetooth®, the testo 315 - 3 and the

testo 330 - 2 must have this option, otherwise data is

transferred via the IrDA interface.

✓ A measurement was carried out with the testo 315-3.

54

✓ testo 330-2 is on.

✓ Data transfer at the testo 315-3 has been enabled.

- The testo 330 accepts the instrument-specific information

and measurement data sent from the testo 315-3. The

measurement data is displayed under ppm AmbCO or ppm

AmbCO2.

> [Options] → Recalibrate: The gas sensors are set to zero.

> [Options] → Measurement view: (This function is not available

during a measurement): The readings display menu is opened.

Page 55

3.

6 Using the product

Show flue gas matrix

This function is only available if the measurement parameter CO

has been activated in the readings display.

Calling up the function:

✓ The flue gas function is opened.

> [Options] → Flue Gas Matrix:

Options

> [Options] → Clipboard: Data are saved to the clipboard:

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

> [Options] → Show Numerical Values: Data are displayed as

numerical values.

> [Options] → System Type: (This function is not available

during a measurement). Set the system type to be able to

configure the ideal zone (green) of the flue gas matrix, using the

limits pre-configured for each system type.

> [Options] → Reset Graphic: The displayed graphical values

are deleted.

> [Options] → Limits: (This function is not available during a

measurement). Enter limits to be able to configure the ideal

zone (green) of the flue gas matrix.

> [Options] → CO + O2 or CO + CO2: Choose which parameter

should be assigned to the x-axis of the display matrix (O2 or

CO2).

> [Options] → Measurement view: (This function is not available

during a measurement). Open the readings display menu.

55

Page 56

6 Using the product

6.2.3. Draught-Measurement

Calling up the function:

✓ A flue gas probe must be connected.

1. [ ] → Measurements → [OK] → Draught → [OK].

Performing the measurement:

The pressure socket of the instrument must be free (i.e.

unpressurized, not closed).

Do not measure for longer than 5 min, as the drift of the

pressure sensor means that the readings could be outside

the tolerance limits.

1. Start measurement: [ ].

- Draught zeroing.

2. Position the flue gas probe in the hot spot (area of the highest

flue gas temperature).

The display showing the maximum measured flue gas

temperature (FT max) helps when positioning the probe.

- The reading is displayed.

3. Quit measurement [ ].

Options:

> [Options] → Clipboard: Data are saved to the clipboard.

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

> [Options] → Configure Graphic: The measurement

parameters to be represented (max. 4) can be displayed ( ) or

hidden ( ).

> [Options] → Measurement view: (This function is not available

4.

6.2.4. Micro pressure probe

during a measurement): The readings display menu is opened.

The following measurements can be performed using the micro

pressure probe (0638 0330):

• Ext-Draught

• Ext-Delta-P Single meas.

• Ext-Delta Program

See instruction manual for micro pressure probe.

56

Page 57

5.

6.2.5. CO undiluted

Calling up the function:

✓ A multi-hole probe (0554 5762) must be connected.

> [ ] → Measurements → [OK] → CO undiluted → [OK].

Performing the measurement:

1. Start measurement: [ ]

- The reading is displayed.

2. Quit measurement: [ ]

Options:

> [Options] → Clipboard: Data are saved to the clipboard.

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

6.2.6. Smoke No. / HCT

Calling up the function:

> [ ] → Measurements → [OK] → Smoke No. / HCT → [OK].

The parameters Smoke No. and Oil derivatives are only

available for oil fuels.

6 Using the product

Determining smoke tester no. / smoke nos. / oil derivative with the smoke pump and entering manually:

1. Select parameter → [Edit].

2. Enter data or values → [Next] or [OK].

Determining smoke tester no. / smoke nos. / oil derivative with the smoke tester testo 308 and transferring wireless:

- The testo 308 must be in data transfer mode ( lights up).

> [Options] → t308.

- The values recorded by the smoke tester are transferred to the

testo 330.

Entering the heat carrier temperature:

> Heat carrier → [Edit] → Enter value → [OK].

57

Page 58

6 Using the product

WARNING

Options:

> [Options] → Clipboard: Data are saved to the clipboard

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Reset values: The entered values are deleted.

6.2.7. Differential pressure

Dangerous mixture of gases

Danger of explosions.

> Make sure there are no leaks between the sampling point and

the measuring instrument.

> Do not smoke or use naked flames during measurement.

Do not measure for longer than 5 min, as the drift of the

pressure sensor could have the effect that the readings are

outside the tolerance limits.

✓ The gas pressure set (0554 1203) must be connected.

Calling up the function:

> [ ] → Measurements → [OK] → Differential Pressure →

[OK].

58

Performing the measurement:

✓ At the start of the measurement, the instrument's pressure

socket must be unpressurised (e.g. instrument must not be

connected to the system to be tested), as the pressure sensor

has to be zeroed first.

1. Start measurement: [ ].

- Pressure zeroing.

2. Connect a silicone hose to the testo 330-2 and the system to be

tested.

- The reading is displayed.

3. Quit measurement: [ ].

Options:

> [Options] → Clipboard: Data are saved to the clipboard

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

Page 59

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

> [Options] → Measurement view: (This function is not available

during a measurement): The readings display menu is opened.

6.2.8. Differential temperature

✓ The differential temperature set (0554 1204) must be

connected.

Calling up the function:

> [ ] → Measurements → [OK] → Differential Temperature→

[OK].

Performing the measurement:

1. Start measurement: [ ].

- The readings and the calculated differential temperature

(T1 T2) are displayed.

2. Quit measurement: [ ].

Options:

> [Options] → Clipboard: Data are saved to the clipboard.

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

> [Options] → Measurement view: (This function is not available

during a measurement): The readings display menu is opened.

6 Using the product

6.2.9. O2 air

✓ An O2 dual wall clearance probe (0632 1260) must be

59

connected.

Calling up the function:

> [ ] → Measurements → [OK] → O2 Air→ [OK].

Performing the measurement:

1. Start measurement: [ ].

- The reading is displayed.

2. Quit measurement: [ ].

Page 60

6 Using the product

Options:

> [Options] → Clipboard: Data are saved to the clipboard.

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The readings are saved in a record.

> [Options] → Show Graphic: The readings are displayed in

form of a line graph.

6.2.10. Gas flow

The function is only available if the chosen fuel is a gas.

Calling up the function:

> [ ] → Measurements → [OK] → Gas Flow→ [OK].

Performing the measurement:

1. Start measurement: [ ].

- The measuring duration is displayed.