tekmar 665 Installation

- Data Brochure

Snow Detector & Melting Control 665

D 665

04/12

Replaces: 12/08

The Snow Detector & Melting Control 665 is a microprocessor-based control which operates a single zone snow melting system.

The control can operate automatically when a Snow / Ice Sensor 090 is installed or the user can manually enable and/or disable the

system. When the control is in the melting mode, the slab is maintained at a “Melting” temperature through an on/off output which

operates a contactor for electrical cables, a boiler, an injection pump or an injection valve. When the control is not in the melting mode,

the melt system can either be shut down or it can be maintained at an idle temperature for faster response and improved safety. The

665 control includes a large Liquid Crystal Display (LCD) in order to view system status and operating information.

Additional features include:

• Slab Outdoor Reset

• Automatic snow detection and melt control (with 090 sensor)

• Temporary Idle

• Manual Override

• Warm Weather Shut Down

• Cold Weather Cut Out

• Remote display and adjustment capabilities

• Test sequence to ensure proper component operation

• Equipment Exercising

• CSA C US certifi ed (approved to applicable UL standards)

Snow/Ice Sensor

090 installed with

Input

Sensor Socket

091 Optional

or

Input

Slab Sensor

Optional

Start

Stop

Menu Item

Snow Detector & Melting Control 665

Pulse Width Modulation

Do not apply power

1

Red2Blk3Blu4Yel5Brn/

Do not apply power

6

Out7Com8tN2

Slab

Melt Demand

Idle Demand

WWSD

Water

Melting

Idle Demand

Melt Demand

900-03

Designed and assembled in Canada by

tekmar Control Systems Ltd.

Power 115 V ± 10% 50/60 Hz 600 VA

Relays 230 V (ac) 5 A 1/3 hp

Demand 20 to 260 V (ac) 2 VA

Signal wiring must be rated at least 300 V.

9

10 11

12 13

Melt/Idle

Heat

Demand

Tes t

14 15 17

Melting

Sys

P1

off

not testing

red

testing

red

testing paused

For maximum heat,

press and hold Test

button for 3 seconds.

Meets Class B:

Canadian ICES

FCC Part 15

16

Power

L

N

Date Code

H2028D

Input

115 V (ac)

Power

Supply

Output

System

Pump

Input

Outdoor

Sensor

Included

OR

Remote Display Module (RDM)

Remote Start / Stop Module

1 of 28

© 2012 D 665 - 04/12

Input

or

Input

Melt/Idle

Demand

Output

Boiler

OR

Output

Turn on injection

pump

OR

Output

Turn on relay for

electric cables

Output

Melt Relay

How to Use the Data Brochure

This brochure is organized into four main sections. They are: 1) Sequence of Operation, 2) Installation, 3) Control Settings, and

4) Tro u b leshooti ng. The Sequence of Operation section has 5 sub-sections. We recommend reading Section A: General of the

Sequence of Operation, as this contains important information on the overall operation of the control. Then read to the sub-sections

that apply to your installation.

The Control Settings section (starting at DIP Switch Settings) of this brochure describes the various items that are adjusted and

displayed by the control. The control functions of each adjustable item are described in the Sequence of Operation.

Table of Contents

User Interface ..................................................Pg 2

Description of Display Elements ..................Pg 3

Sequence of Operation ..................................Pg 4

Section A: General Operation .............. Pg 4

Section B: Snow Melting .......................Pg 4

Section C: Melting Enable / Disable ....Pg 6

Section D: Melting Operation ............... Pg 8

Section E: Idling Operation ..................Pg 9

Installa tion ....................................................... Pg 10

Electrical Connections .......................... Pg 12

Testing The Wiring .................................Pg 14

DIP Switch Settings ........................................Pg 16

Access Levels .................................................Pg 16

Control Settings ..............................................Pg 17

View Menu ..............................................Pg 17

Adjust Menu ...........................................Pg 18

Monitor Menu .........................................Pg 19

Schedule Menu ......................................Pg 20

Miscellaneous Menu ............................. Pg 20

Testing and Troubleshooting ........................Pg 21

Error Messages ...................................... Pg 23

Technical Data .................................................Pg 27

Limited Warranty ............................................Pg 28

User Interface

The 665 uses a Liquid Crystal Display (LCD) as the method of supplying information. You use the LCD in order to setup and monitor

the operation of your system. The 665 has four push buttons (Menu, Item, ▲ (Star t), ▼ (Stop)) for selecting and adjusting settings. As

you program your control, record your settings in the ADJUST Menu table which is found in the second half of this brochure.

Menu

All of the items displayed by the control are organized into various menus. These menus

are listed on the left hand side of the display (Menu Field). To select a menu, use the

Menu button. By pressing and releasing the Menu button, the display will advance to

the next available menu. Once a menu is selected, there will be a group of items that

can be viewed within the menu.

Item

The abbreviated name of the selected item will be displayed in the item field of the

display. To view the next available item, press and release the Item button. Once you

have reached the last available item in a menu, pressing and releasing the Item button

will return the display to the first item in the selected menu.

Adjust

To make an adjustment to a setting in the control, begin by selecting the appropriate

menu using the Menu button. Then select the desired item using the Item button. Finally,

use the ▲ and / or ▼ button to make the adjustment.

Additional information can be gained by observing the Status fi eld of the LCD. The status

fi eld will indicate which of the control’s outputs are currently active. Most symbols in the

status fi eld are only visible when the VIEW Menu is selected.

2 of 28

© 2012 D 665 - 04/12

Menu Item

Menu Item

Menu Item

Display

Item Field

Displays an abbreviated

name of the selected item

Menu Field

Displays the

current menu

Status Field

Displays the

current status

of the control's

inputs, outputs

and operation

Number Field

Displays the current value of the selected item

Melt Demand

Idle Demand

WWSD

Water

Melting

Buttons

Selects Menus, Items

and adjust settings

Symbol Description

Pump

Displays when the system pumps are

operating.

Override

Displays when the control is in override mode.

Warning

Displays when an error exists or when a limit

has been reached.

Lock / Unlock

Displays when the access levels are locked or

unlocked.

Pointer

Displays the control operation as

indicated by the text.

°F, °C, min, hr, sec

Units of measurement.

Heat

Displays when the Heat relay is

turned on.

Definitions

The following defined terms and symbols are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important information concerning the life of the product.

- Warning Symbol: Indicates presence of hazards which can cause severe personal injury, death or

substantial property damage if ignored.

INSTALLATION

CATEGORY II

© 2012 D 665 - 04/12

3 of 28

- Double insulated

- Local level, appliances

Sequence of Operation

Section A

General

Operation

Page 4

Section B

Snow

Melting

Page 4 - 5

Section C

Melting Enable

/ Disable

Page 6 - 8

Section D

Melting

Operation

Page 8 - 9

Section E

Idling

Operation

Page 9

Section A: General Operation

POWERING UP THE CONTROL

When the Snow Detector & Melting Control 665 is powered up, the control displays all LCD segments for 2 seconds, then the control type number in the LCD for 2 seconds. Next, the software version is displayed for 2 seconds. Finally, the control enters into the

normal operating mode and the LCD defaults to displaying the current outdoor air temperature.

EXERCISING (EXERCISE)

The 665 has a built-in pump exercising function. The exercising period is adjustable and is factory set at 70 hours. If a pump output

has not been operated at least once during every exercising period, the control turns on the output for 10 seconds. This minimizes

the possibility of a pump or valve seizing during a long period of inactivity.

Note: The exercising function does not work if power to the control or pumps is disconnected.

Section B: Snow Melting

Section B1

General

Snow Melting

Section B1: General Snow Melting

WARM WEATHER SHUT DOWN (WWSD)

The control has a warm weather shut down that prevents the control from entering the melt or idle modes in order to conserve energy.

While in WWSD, the word WWSD is displayed in the STATUS item in the VIEW menu and the WWSD pointer is on the display. The

WWSD item in the ADJUST menu can be either set to Automatic or it can be set to a temperature.

Automatic (Auto)

When the WWSD is set to AUTO, the WWSD occurs when the slab temperature and

the outdoor temperature exceed the Melting setting by 2° F (1°C). The control exits the

WWSD when the slab or outdoor temperature falls to the Melting setting temperature.

Adjustable WWSD

When the WWSD is set to a temperature, the WWSD occurs when the outdoor air

temperature exceeds the WWSD setting by 1°F (0.5°C) and when the slab temperature

exceeds 34°F (1°C). The control exits WWSD when the outdoor air temperature falls 1°F

(0.5°C) below the WWSD setting or if the slab temperature falls below 34°F (1°C). This

allows the Melting Temperature setting to be set higher than the WWSD. This is useful

where high slab temperatures are required to melt the snow or ice. A good example of

this is installations using paving bricks on top of sand and concrete layers.

COLD WEATHER CUT OUT (CWCO)

Maintaining the system at either the melting or idling temperature during extremely cold temperatures can be expensive or impossible.

The control turns the snow melting system off when the outdoor air temperature drops below the Cold Weather Cut Out (CWCO)

temperature. While the control is in CWCO, the word CWCO is displayed in the STATUS item in the VIEW menu. The heater in the

sensor is kept on during CWCO until the control detects moisture. If water is detected, the heater is turned off but the control retains

the moisture detected information. When the outdoor temperature rises above the CWCO temperature, the control exits CWCO and

if the Snow / Ice Sensor 090 detected moisture during CWCO, the control initiates Melting mode. If the control has been started prior

to the CWCO, it resumes the Melting mode once the outdoor air temperature rises above the CWCO temperature.

Outdoor

Temperature

WWSD

Control enters

Idle and waits

for Melt Enable

CWCO

Slab

Temperature

MELT

IDLE

4 of 28

© 2012 D 665 - 04/12

RUNNING TIME (RUN TIME)

The running time is the length of time that the system operates once it has reached its slab target temperature. During the time that

the system is approaching its slab target temperature, the RUN TIME does not decrease. Once the system reaches its slab target

temperature, the RUN TIME begins counting down. When the RUN TIME reaches 0:00 as displayed in the Status item in the VIEW

menu, the system has finished melting.

Note: The running time is only applicable when a manual melting enable signal star ts the snow melting system. Refer to Section C1 for

a description of a manual melting enable.

STATUS (STATUS)

While in the VIEW menu there are a number of items available to determine the current status of the system. To view the current

status of the system, select the STATUS item in the VIEW menu.

• STRT The word STRT is displayed after the snow melting system has been manually enabled. It is displayed until the

zone reaches its slab target temperature. If the zone is at its slab target temperature, STRT is displayed for fi ve

seconds after the snow melting system has started operation. This is to verify that the control has entered into the

Melting mode.

• STOP The word STOP is displayed for fi ve seconds after the snow melting system has been manually disabled. The

word STOP is also displayed if either a Remote Start / Stop Module 039, Remote Display Module 040 or the Stop

on the control stops the snow melting system and an external melt demand is still present.

• IDLE The word IDLE is displayed as long as the zone is operating at its idling temperature.

•

“IDLE” The word IDLE is fl ashed on the display as long as the zone is operating in temporary idle.

• EXT The word EXT is displayed when the RUN TIME has reached 0:00 and the control still has an external melt demand.

In this situation, the zone continues melting until the melt demand is removed or the control is stopped.

• DET The word DET is displayed after the snow melting system has been automatically enabled by the

Snow / Ice Sensor 090 and the zone is at its slab target temperature. DET is also displayed once the control is

manually enabled after automatic detection by the 090 and the running time has counted down to 0:00.

• 0:00 to 23:59 hr While the zone is up to temperature and melting, the remaining RUN TIME is displayed.

• INF If an infi nite RUN TIME is selected and the zone is melting, INF is displayed.

• WWSD When the zone is in Warm Weather Shut Down, WWSD is displayed.

• CWCO When the control is in Cold Weather Cut Out, CWCO is displayed.

SNOW MELTING OVERRIDE

If the AWAY setting is selected in the SCHEDULE menu, the snow melting system is shut

down. Both the Melting and Idling temperatures are ignored as long as the control remains

in the Away mode.

SYSTEM PUMP OPERATION (SYS P1)

The system pump (Sys P1) contact closes and remains closed as long as the system is either in the Melting or Idling mode. The

system pump contact shuts off if the control is in CWCO, WWSD, or if there is no call for Melting or Idling.

HEAT CONTAC T OPERATIO N

The control uses the Heat contact to control the temperature of the slab.

When the control is either Melting or Idling, the Heat contact operates

on a 20 minute cycle. If the slab requires more heat, the on time in each

cycle is increased. If the slab requires less heat, the on time of each

cycle is decreased. The Heat contact shuts off if the control is in Cold

Weather Cut Out (CWCO), Warm Weather Shut Down (WWSD), or if

Relay On Time Relay Off Time

Cycle (20 minutes)

Relay On Time Relay Off Time

Less Heat

Relay On Time

More Heat

there is no call for Melting or Idling.

MELTING CONTACT OPERATION

The Melting contact (terminals 13 and 14) closes and remains closed as long as the system is in the melting mode. This contact

can be used as an external signal to indicate that the system is currently in the melting mode. This contact can also be used as a

means of prioritizing or enabling multiple snow melting controls.

PURGE

The system pump (Sys P1) and zoning device continue to operate for 20 seconds after the last demand is removed. This purges

the residual heat from the boiler(s) into the snow melting slab.

© 2012 D 665 - 04/12

5 of 28

Section C: Melting Enable / Disable

Section C1

Snow Melting

Enable

Section C2

Snow Melting

Disable

Section C1: Snow Melting Enable

The snow melting system can be enabled manually or automatically. A melting enable signal applied to the control places the system

into the melting mode. If a melting enable signal is applied once the system is already in the melting mode, the control responds to

the last command received.

MANUAL MELTING ENABLE

A manual melting enable signal requires the user to manually start the snow melting system and can be provided from the Start

button on the control, Remote Start / Stop Module 039, Remote Display Module 040, or an external melt demand.

Start Button on the Control

The snow melting system is enabled by pressing the Start button on the control while

in the VIEW menu. The control then displays the RUN TIME setting to allow the user to

adjust it. Once the snow melting system is enabled, the word STRT is displayed for at

least 5 seconds in the STATUS item while in the VIEW menu. If the Start button on the

control is pressed while the system is already melting and up to temperature, the running

time counter is reset to the RUN TIME setting.

Remote Start / Stop Module 039

The snow melting system is enabled by pressing the button on the front of the 039. While

the zone is coming up to temperature, a green indicator light flashes on the front of the

039. Once the zone is up to temperature and the RUN TIME is counting down, the green

indicator light on the front of the 039 is on solid.

Remote Display Module 040

The snow melting system is enabled by pressing the ▲ button on the 040 while in

the VIEW menu. The 040 then displays the RUN TIME setting to allow the user to

adjust it. Once the snow melting system is enabled, the word STRT is displayed for at

least 5 seconds in the STATUS item while in the VIEW menu.

7

9

8

Start / Stop

StopStart

6 of 28

© 2012 D 665 - 04/12

External Melt Demand (DIP switch set to Melt Demand)

The snow melting system is enabled when a voltage between 24 and 240 V (ac) is applied

across the Melt/Idle Demand terminals (9 and 10). An external melt demand must be

present for at least 4 seconds in order to start the snow melting system. If the RUN TIME

reaches 0:00 and the external melt demand is still present, the control continues melting

until the external melt demand is removed or the system is otherwise stopped.

Note: This operation only occurs if the Idle Demand / Melt Demand DIP switch is set to

the Melt Demand position.

AUTOMATIC MELTING ENABLE (Snow / Ice Sensor 090)

The 665 uses the Snow / Ice Sensor 090 to provide an automatic melting enable signal to

start the snow melting system. The control continually monitors the 090 for the presence

of moisture. Once moisture is detected, the water pointer is displayed in the LCD and the

snow melting system is enabled.

Water Detection Sensitivity (SENSTVTY)

The 665 has a Sensitivity setting which compensates for varying outdoor conditions which

could affect how the moisture detector in the 090 interprets the presence of moisture.

This adjustable setting is available through the SENSTVTY item in the ADJUST menu of

the control. As snow becomes contaminated with dirt, and as the sensor itself becomes

dirty, the control may incorrectly indicate the presence of water. If this condition occurs,

clean the surface of the sensor and / or turn down the SENSTVTY setting. If the snow in

your area is very clean, the SENSTVTY setting may need to be increased before snow

is detected. If AUTO is selected, the control automatically adjusts the sensitivity level

used to detect moisture.

24 to 240 V (ac)

L

N

10

9

Melt / Idle

Demand

Idle Demand

Melt Demand

Section C2: Snow Melting Disable

The snow melting system can be disabled manually or automatically. A melting disable signal applied to the control takes the zone

out of the melting mode. Once the snow melting system is disabled, the zone operates in the idling mode. The idling mode allows the

zone to be operated at either a lower temperature or turned off.

MANUAL MELTING DISABLE

A manual melting disable signal requires the user to manually stop the snow melting system and can be provided from the Stop

button on the control, Remote Start / Stop Module 039, Remote Display Module 040, or an external idle demand.

Stop Button on the Control

The Stop button on the control can be used to stop the snow melting system. The snow melting system is disabled by pressing

the Stop button on the control while in the VIEW menu. Once the snow melting system is disabled, the word STOP is displayed

for 5 seconds in the STATUS item of the appropriate zone while in the VIEW menu.

Remote Start / Stop Module 039

A Remote Start / Stop Module 039 can be used to stop the snow melting system. The snow melting system is disabled by pressing the button on the face of the 039. When the system is stopped, a solid Red Indicator Light is displayed on the face of the 039

for five seconds. If the snow melting system is disabled while there is still an external melt demand for snow melting, the 039

displays a solid red indicator light until the external demand is removed.

Remote Display Module 040

A Remote Display Module 040 can be used to stop the snow melting system. The snow melting system is disabled by pressing

the ▼ button on the 040 while in the VIEW menu. Once the snow melting system is disabled, the word STOP is displayed for 5

seconds in the STATUS item while in the VIEW menu.

© 2012 D 665 - 04/12

7 of 28

External Idle Demand (DIP switch set to Idle Demand)

The snow melting system is disabled when a voltage between 24 and 240 V (ac) is

applied across the Melt/Idle Demand te rmi nal s (9 and 10). A n ex ternal idle demand must

be present for at least 4 seconds in order to stop the snow melting system.

Note: This operation only occurs if the Idle Demand / Melt Demand DIP switch is set to

the Idle Demand position.

If the snow melting system is placed into Idling mode by an external idle demand, then

a manual melting enable signal is applied, the idle demand is overridden until either the

running time has expired, a stop signal is given, or the external idle demand is removed

and reapplied.

24 to 240 V (ac)

L

N

10

9

Melt / Idle

Demand

Idle Demand

Melt Demand

AUTOMATIC MELTING DISABLE (Snow / Ice Sensor 090)

Once the 090 is dry, the Water pointer turns off in the LCD. The system slab temperature has to be at least the slab target

temperature for a minimum of thirty minutes in order for the system to turn off. If a manual melting disable signal is applied the snow

melting system turns off immediately.

Section D: Melting Operation

Section D1

General Melting

Operation

Section D1: General Melting Operation

In order for the snow melting system to be started, one of the methods described in section D1 must be used. Once a melting enable

signal is applied and the system is not in WWSD or CWCO, the Melting mode begins. When the control is in the Melting mode, the

Melting pointer is visible in the VIEW menu. The MELT setting in the ADJUST menu sets the slab surface temperature. When the

system is melting and the slab temperature is warming up to the slab target temperature, STRT is displayed in the STATUS item while

in the VIEW menu. The system finishes melting when the slab temperature has been at least the slab target temperature for a period

of time. This period of time is based on whether an automatic or manual melting enable signal starts the snow melting system.

If an automatic melting enable signal starts the snow melting system and the slab temperature reaches the slab target temperature,

DET is displayed in the STATUS item while in the VIEW menu. The system continues to melt until the 090 becomes dry and any

additional running time has expired. Once the Melting mode is complete, the system operates in the Idling mode.

If a manual melting enable signal starts the snow melting system, the Running Time is displayed in the STATUS item while in the VIEW

menu and begins counting down once the slab temperature reaches the slab target temperature. The system continues to melt until

the running time counts down to 0:00 and there is no external melt demand. Once the Melting mode is complete, the system operates

in the Idling mode. The table on page 14 describes how the control responds to enable and disable signals.

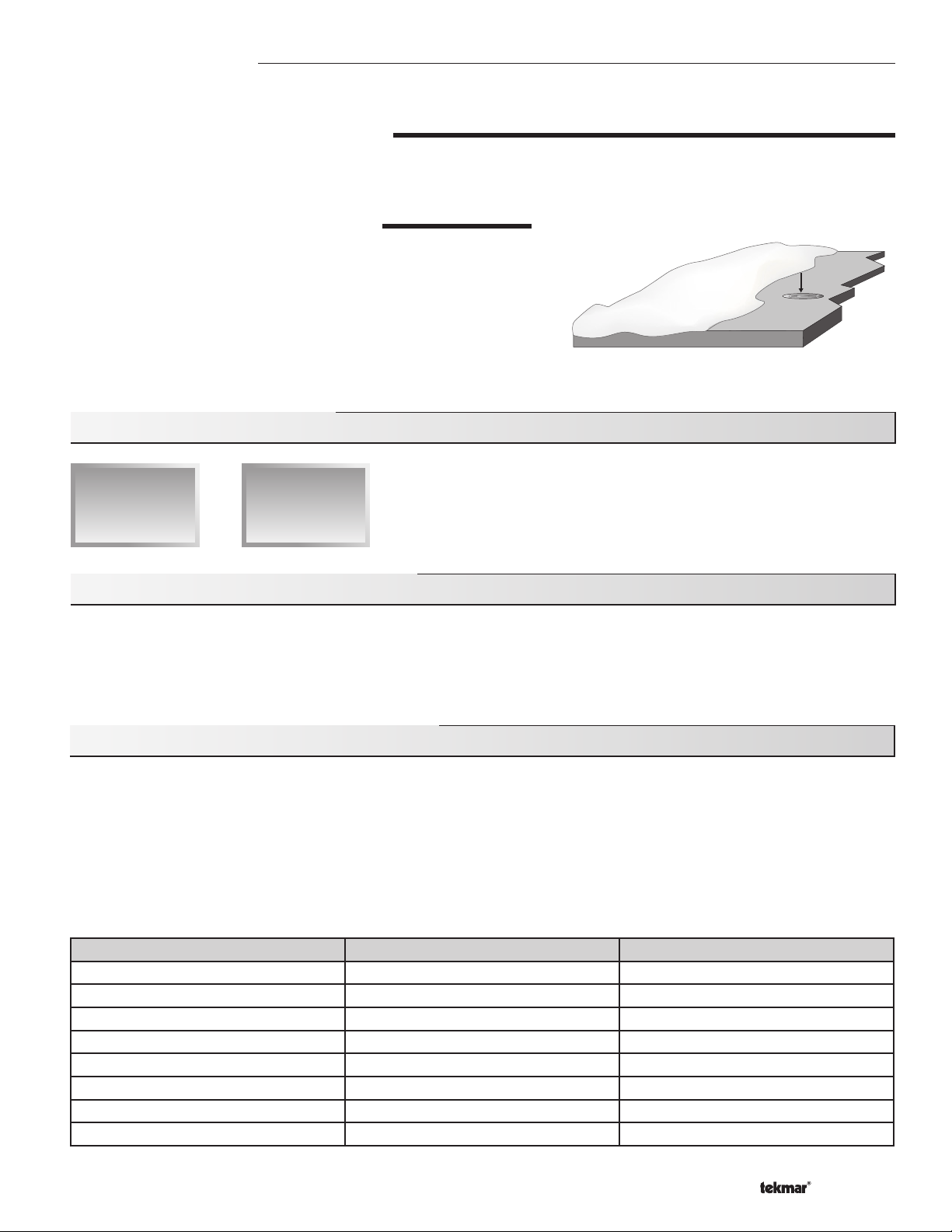

SLAB TEMPERATURE CONTROL

The 665 uses a snow / ice sensor or slab sensor to provide slab

temperature control.

Slab Sensor

If a Slab Sensor is used, the control assumes that the sensor is

approximately 1 inch below the surface of the snow melting slab. Since

this point is closer to the source of the heat, this point is warmer than

the surface of the slab. Therefore, the sensor must be maintained at

a higher temperature in order to ensure that the surface of the slab

is maintained at the correct temperature. The amount of temperature

difference between the surface of the slab and the slab sensor changes

with the outdoor temperature. Therefore, the slab core temperature

is increased as the outdoor air temperature drops. The temperature

displayed as SLAB is the temperature of the slab sensor.

Surface temperature = 35°F

Core (sensor)

is warmer

Slab Outdoor ResetSlab Outdoor Reset

Increasing Slab Core Temperature

Decreasing Air Temperature

Slab Surface Temperature is Constant

8 of 28

© 2012 D 665 - 04/12

Snow / Ice Sensor 090

The slab temperature is displayed as SLAB in the VIEW menu. This temperature is calculated from the edge and center sensors

built into the 090.

SLAB TARGET TEMPERATURE (SLB TRG)

The SLAB TRG temperature is determined from the Melting setting, or Idle setting and the outdoor air temperature. The control

displays the temperature that it is currently trying to maintain at the slab sensor. If the control does not presently have a requirement

for heat, it displays “– – –“ in the STATUS item while in the VIEW menu.

ADDITIONAL MELTING TIME (ADD MELT)

In cases where areas of the snow melting system haven’t completely

melted after the melting mode has finished and the 090 is dry, the 665

has a function in which additional time can be added to melt the zone.

This is an adjustable time through the ADD MELT item in the ADJUST

menu of the control. The ADD MELT time is calculated into a running

time and is displayed in the STATUS item while in the VIEW menu. Once

the 090 becomes dry and the slab temperature is at least the slab target

temperature, the ADD MELT time starts counting down.

Snow Ice Sensor

Dry

Section E: Idling Operation

Section E1

General Idling

Operation

Section E2

Temporary

Idle

Section E1: General Idling Operation

When the snow melting system starts from a cold temperature, the time required for the system to reach the melting temperature

may be excessive. To decrease this start up time, the 665 has an idling feature which can maintain the zone at a lower temperature.

This feature is also useful for preventing frost and light ice formation. The IDLING setting in the ADJUST menu sets the slab surface

temperature while the control is in the idling mode. When in the idling mode, IDLE is displayed in the STATUS item of the VIEW menu.

If idling is not desirable, the IDLING setting may be set to OFF.

Section E2: Temporary Idle (TMPY IDL)

The temporary idle allows the control to enter the idle state for a set amount of time. If the snow ice detector does not detect snow

during the temporary idle period, the control then leaves the idle state and returns to the OFF state. This is useful in applications

where there is the possibility of snow and the slab can be pre-heated in order to have a short heat up time if snow is detected.

To enable a temporary idle, the Te m p o r a r y I d l e setting in the ADJUST menu must be set from OFF to the length of the temporary idle.

The DIP Switch must be set to IDLE DEMAND and the IDLING must be set to a temperature. To activate a temporary idle, a voltage

between 24 and 240 V (ac) must be applied across the Melt/Idle Demand terminals for at least 4 seconds.

When a Tem p orar y I d l e time is selected, the control has three available states: OFF, Temporary Idle, and Melting. The table below

describes the action of the control:

Control State Action Result

OFF External Idle Demand Temporary Idle

OFF Manual or Auto Melt Start Melting

Melting External Idle Demand Melting

Melting Manual or Auto Melt Start Melting

Melting Manual or Auto Melt Stop OFF

Temporary Idle Temporary Idle Expires OFF

Temporary Idle Manual or Auto Melt Start Melting

Temporary Idle Manual Melt Stop OFF

© 2012 D 665 - 04/12

9 of 28

Loading...

Loading...