Page 1

- Data Brochure

D 083

Duct Sensor 083

The tekmar Duct Sensor 083 is designed to measure the average temperature of the air

stream in a heating, cooling, or ventilation duct. The 083 has a 6” (150 mm) long probe

connected to a 2” x 4” electrical box for easy wiring.

Installing the Sensor

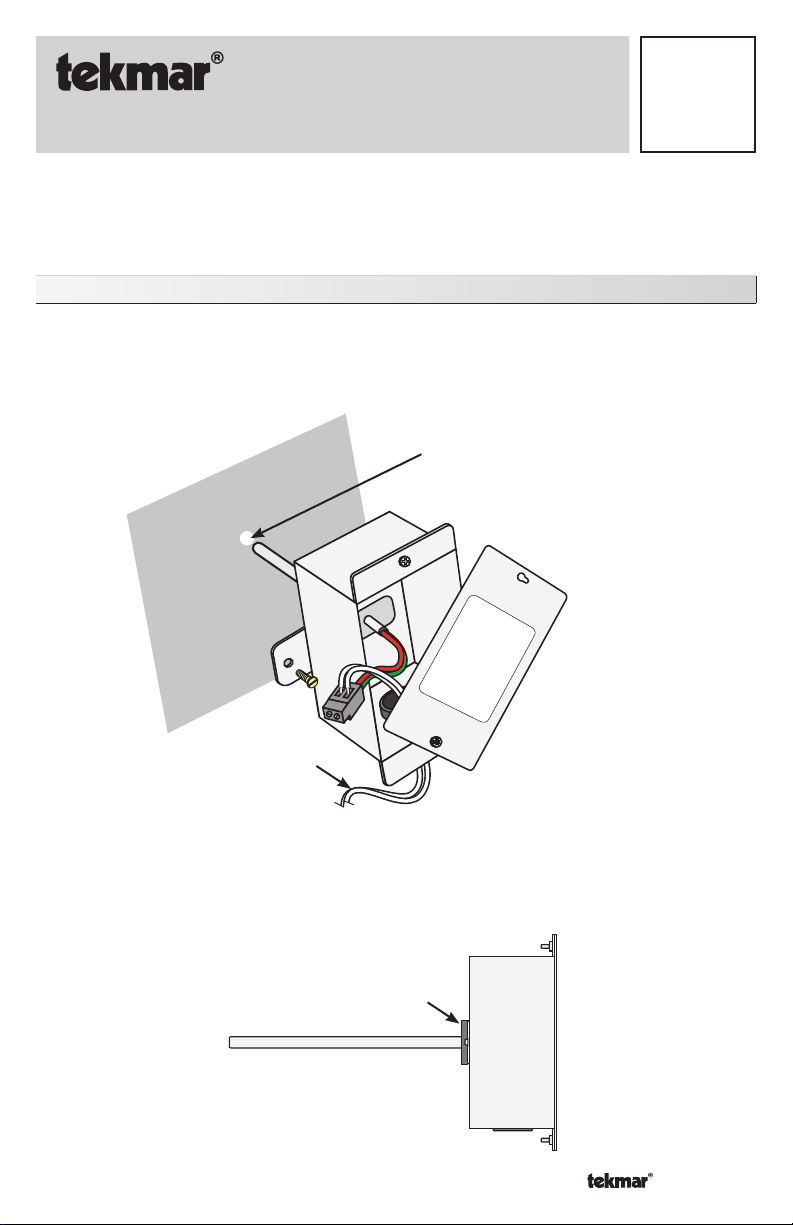

The Duct Sensor 083 probe should be located in the middle of the air stream in order to

measure the average temperature of the duct. Drill a 3/8” (10 mm) hole in the duct and

place the probe through the hole.

drill 3/8” (10 mm) diameter

hole in duct

05/07

18 AWG or

similar wire

Ensure that the foam ring on the electrical box around the probe fits tight against the

duct.

Foam ring

1 of 4 © 2007 D 083 - 05/07

Page 2

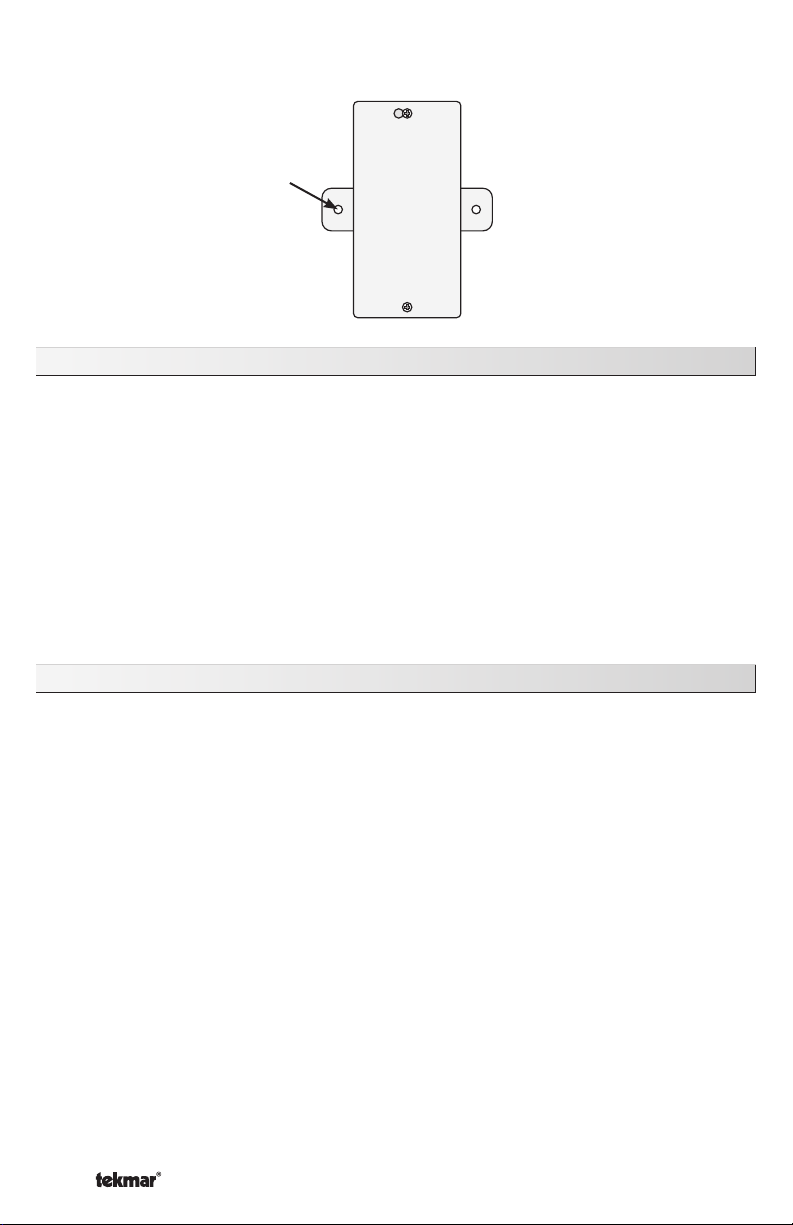

A 4” (102 mm) flange mounted on the electrical box has two holes to allow sheet metal screws

(not included) to fasten the sensor to the duct.

Wiring the Sensor

Open the electrical box by unscrewing the top screw.

Connect 18 AWG or similar wire to the two terminals provided in the enclosure and run

the wires from the 083 to the control. Do not run the wires parallel to telephone or power

cables. If the sensor wires are located in an area with strong sources of electromagnetic

interference (EMI), shielded cable or twisted pair should be used or the wires can be run

in a grounded metal conduit. If using shielded cable, the shield wire should be connected

to the Com Sen terminal on the control and not to earth ground.

Follow the sensor testing instruction in this brochure and connect the wires to the control.

Close the electrical box by tightening the top screw.

Testing the Sensor

A good quality test meter capable of measuring up to 5,000 kΩ (1 kΩ = 1000 Ω) is required to

measure the sensor resistance. In addition to this, the actual temperature must be measured

with either a good quality digital thermometer, or if a thermometer is not available, a second

sensor can be placed alongside the one to be tested and the readings compared.

First measure the temperature using the thermometer and then measure the resistance of

the sensor at the control. The wires from the sensor must not be connected to the control

while the test is performed. Using the chart on the following page, estimate the temperature

measured by the sensor. The sensor and thermometer readings should be close. If the test

meter reads a very high resistance, there may be a broken wire, a poor wiring connection

or a defective sensor. If the resistance is very low, the wiring may be shorted, there may

be moisture in the sensor or the sensor may be defective. To test for a defective sensor,

measure the resistance directly at the sensor location.

Do not apply voltage to a sensor at any time as damage to the sensor may result.

© 2007 D 083 - 05/07 2 of 4

Page 3

Temperature vs. Resistance Table

°F °C Ω °F °C Ω °F °C Ω °F °C

-50 -46 490,813 20 -7 46,218 90 32 7,334 160 71 1,689

-45 -43 405,710 25 -4 39,913 95 35 6,532 165 74 1,538

-40 -40 336,606 30 -1 34,558 100 38 5,828 170 77 1,403

-35 -37 280,279 35 2 29,996 105 41 5,210 175 79 1,281

-30 -34 234,196 40 4 26,099 110 43 4,665 180 82 1,172

-25 -32 196,358 45 7 22,763 115 46 4,184 185 85 1,073

Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance

3 of 4 © 2007 D 083 - 05/07

-20 -29 165,180 50 10 19,900 120 49 3,760 190 88 983

-15 -26 139,402 55 13 17,436 125 52 3,383 195 91 903

-10 -23 118,018 60 16 15,311 130 54 3,050 200 93 829

-5 -21 100,221 65 18 13,474 135 57 2,754 205 96 763

10 -12 62,465 80 27 9,299 150 66 2,045 220 104 598

15 -9 53,658 85 29 8,250 155 68 1,857 225 107 553

0 -18 85,362 70 21 11,883 140 60 2,490 210 99 703

5 -15 72,918 75 24 10,501 145 63 2,255 215 102 648

Page 4

Technical Data

DUCT SENSOR 083

Literature D 083

Packaged weight 1 lb (454 g)

Dimensions 4” W x 8” H x 5” L (100 mm x 203 mm x 127 mm)

Probe 1/4” (6.33 mm) O.D., 0.020” (.5 mm) Wall, 6” (150 mm) 304 Stainless Steel

Enclosure NEMA 1 / IP30, 18 Gauge Galvanized Steel

Approvals CSA C US Listed

Operating Range -40 to 250°F (-40 to 121°C)

Sensor NTC thermistor, 10 kΩ @ 77°F (25°C ± 0.2°C), ß = 3892

Limited Warranty and Product Return Procedure

Limited Warranty The liability of tekmar under this warranty is limited. The Purchaser, by taking receipt of

any tekmar product (“Product”), acknowledges the terms of the Limited Warranty in effect at the time of

such Product sale and acknowledges that it has read and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold hereunder is a manufacturer’s passthrough warranty which the Purchaser is authorized to pass through to its customers. Under the Limited

Warranty, each tekmar Product is warranted against defects in workmanship and materials if the Product

is installed and used in compliance with tekmar’s instructions, ordinary wear and tear excepted. The passthrough warranty period is for a period of twenty-four (24) months from the production date if the Product is

not installed during that period, or twelve (12) months from the documented date of installation if installed

within twenty-four (24) months from the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at tekmar’s sole discretion: the cost of parts

and labor provided by tekmar to repair defects in materials and / or workmanship of the defective product; or to

the exchange of the defective product for a warranty replacement product; or to the granting of credit limited to the

original cost of the defective product, and such repair, exchange or credit shall be the sole remedy available from

tekmar, and, without limiting the foregoing in any way, tekmar is not responsible, in contract, tort or strict product

liability, for any other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondary, incidental or consequential, arising from ownership or use of the product, or from defects in workmanship

or materials, including any liability for fundamental breach of contract.

The pass-through Limited Warranty applies only to those defective Products returned to tekmar during the warranty period. This Limited Warranty does not cover the cost of the parts or labor to remove or transport the defective Product, or to reinstall the repaired or replacement Product, all such costs and expenses being subject to

Purchaser’s agreement and warranty with its customers.

Any representations or warranties about the Products made by Purchaser to its customers which are different from

or in excess of the tekmar Limited Warranty are the Purchaser’s sole responsibility and obligation. Purchaser shall

indemnify and hold tekmar harmless from and against any and all claims, liabilities and damages of any kind or

nature which arise out of or are related to any such representations or warranties by Purchaser to its customers.

The pass-through Limited Warranty does not apply if the returned Product has been damaged by negligence by

persons other than tekmar, accident, fire, Act of God, abuse or misuse; or has been damaged by modifications,

alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the Product was not installed in compliance with tekmar’s instructions and / or the local codes and ordinances; or if due to

defective installation of the Product; or if the Product was not used in compliance with tekmar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHICH THE GOVERNING

LAW ALLOWS PARTIES TO CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE PRODUCT, ITS NON-INFRINGEMENT OF ANY RELEVANT PATENTS OR TRADEMARKS, AND

ITS COMPLIANCE WITH OR NON-VIOLATION OF ANY APPLICABLE ENVIRONMENTAL, HEALTH OR SAFETY

LEGISLATION; THE TERM OF ANY OTHER WARRANTY NOT HEREBY CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT EXTEND BEYOND TWENTY-FOUR (24) MONTHS FROM THE PRODUCTION

DATE, TO THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to have defects in workmanship or materials must be returned, together with a written description of the defect, to the tekmar Representative assigned to

the territory in which such Product is located. If tekmar receives an inquiry from someone other than a tekmar

Representative, including an inquiry from Purchaser (if not a tekmar Representative) or Purchaser’s customers,

regarding a potential warranty claim, tekmar’s sole obligation shall be to provide the address and other contact

information regarding the appropriate Representative.

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head Office: 5100 Silver Star Road

Vernon, B.C. Canada V1B 3K4

(250) 545-7749 Fax. (250) 545-0650

Web Site: www.tekmarcontrols.com

All specifications are subject

to change without notice

Product design, software and literature

are Copyright © 2007 by:

tekmar Control Systems Ltd. and tekmar

Control Systems, Inc.

4 of 4 D 083 - 05/07.

Loading...

Loading...