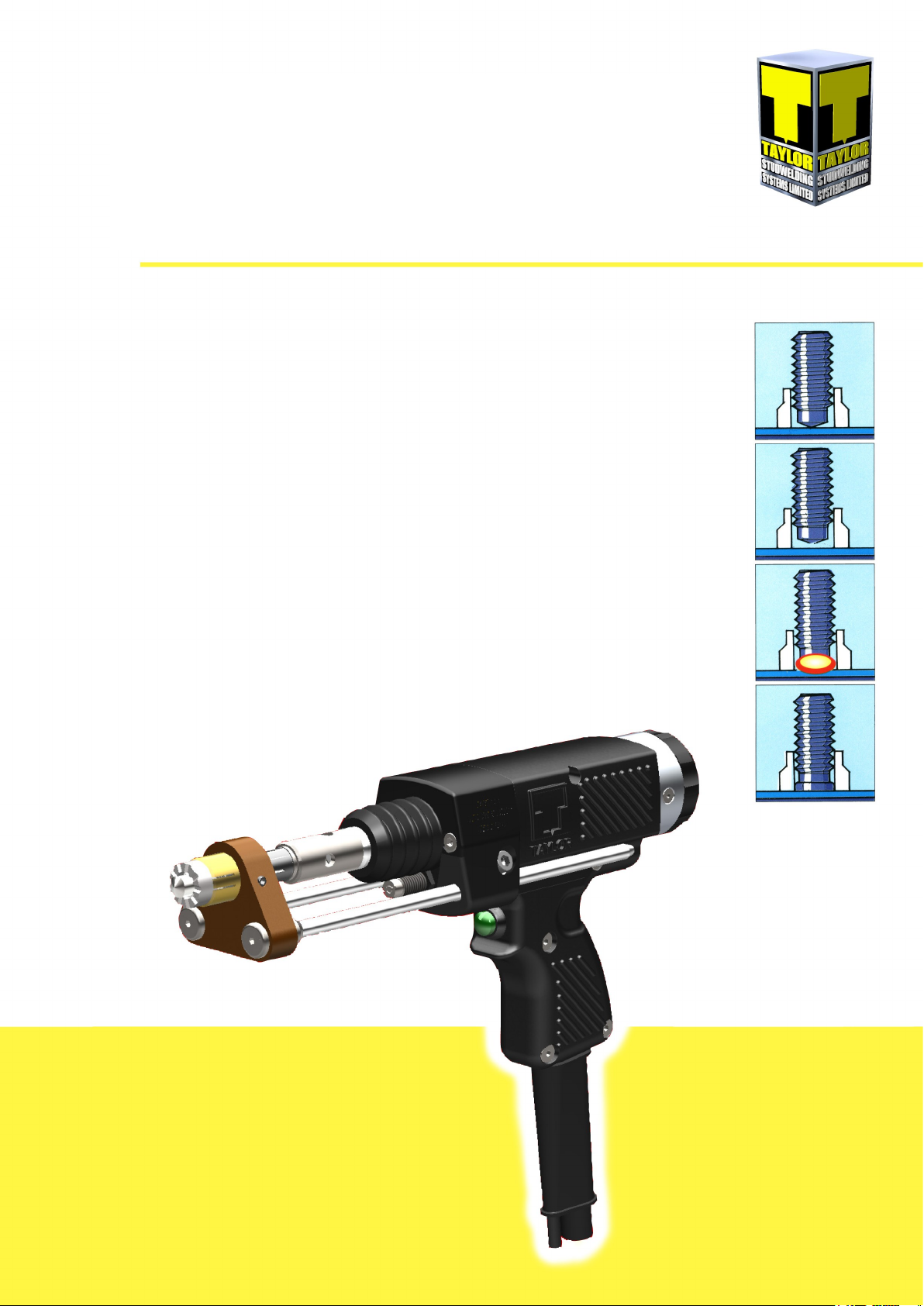

Page 1

V-2U

OPERATING GUIDE

FOR

TYPES DA1-A,

DA2-A & DA3-A

DRAWN ARC PISTOLS

TAYLOR STUDWELDING

SYSTEMS LIMITED

A TAYLORMADE DRAWN ARC STUD WELDING PISTOL

Page 2

V-2U

INDEX

PAGE No. CONTENT

3 USEFUL INFORMATION.

5 IMPORTANT SAFETY INFORMATION.

7 INTRODUCTION TO STUDWELDING.

8 SETTING UP AND WELDING.

12 EXPLODED DIAGRAMS AND PARTS LISTINGS.

17 ACCESSORIES - STANDARD FOOT ASSEMBLIES.

19 ACCESSORIES - GAS FOOT ASSEMBLY.

20 ACCESSORIES - CHUCKS - EUROPEAN SCREW-ON TYPE.

21 ACCESSORIES - CHUCKS - EUROPEAN SCREW-ON GAS TYPE

UK TAPER FIT - ADJUSTABLE

22 ACCESSORIES - FERRULE GRIPS

BENDING BAR

23 EC DECLARATION OF CONFORMITY.

2

Page 3

V-2U

USEFUL INFORMATION

3

MANUFACTURERS DETAILS

TAYLOR STUDWELDING SYSTEMS LIMITED

COMMERCIAL ROAD

DEWSBURY

WEST YORKSHIRE

WF13 2BD

ENGLAND

TELEPHONE : +44 (0)1924 452123

FACSIMILE : +44 (0)1924 430059

email : sales@taylor-studwelding.com

WEB : www.taylor-studwelding.com

SALES DIRECT TEL : +44 (0)1924 487703

TECHNICAL HELPLINE : +44 (0)1924 487701

You may wish to record the details of your controller below as this informaon will help

with any technical assistance you may require:

PURPOSE AND CONTENT OF THIS GUIDE

This guide has been wrien for :

• The personnel of the end-user responsible for the installaon and maintenance of the

pistol.

• The operator of the welding pistol.

This guide contains informaon relang to :

• Installaon and connecon.

• Operaon.

• Technical specicaons and parameters.

• Spare parts.

PISTOL SERIAL No.

DATE PURCHASED.

Page 4

V-2U

USEFUL INFORMATION

4

FURTHER INFORMATION

Should you require addional technical informaon, please contact us directly (details

on previous page) or our local agent / distributor (details of agents etc. can be obtained

from us).

This guide contains important informaon which is a pre-requisite for safe Operaon

of the pistol. The operang personnel must be able to consult this guide when necessary. In

the interests of safety, make this guide available to your personnel in good me.

If the pistol is sold / passed on, please hand over this manual to the new owner and if

possible please inform us of the name and address of the new owner, in case we need to

contact him regarding the safety of the machine.

PLEASE READ THIS GUIDE CAREFULLY BEFORE INSTALLING OR OPERATING THE

PISTOL.

PLEASE OBSERVE CAREFULLY ALL SAFETY PROCEDURES/INSTRUCTIONS.

DUE TO THE POWER REQUIREMENTS AND ELECTROMAGNETIC EMISSIONS

PRODUCED DURING NORMAL USE, THIS PISTOL MUST ONLY BE OPERATED IN

AN INDUSTRIAL ENVIRONMENT.

NEVER REMOVE ANY PORTION OF THE UNIT HOUSING WITHOUT FIRST

ISOLATING THE PISTOL FROM THE CONTROLLER.

Taylor Studwelding Systems Limited reserves the right to amend the contents of this guide without nocaon.

Page 5

V-2U

IMPORTANT SAFETY INFORMATION !

5

PROTECT YOURSELF AND OTHERS !

Read and understand these safety notes.

1. ELECTRICAL

No poron of the outer cover of the welding pistol should be removed by anyone other

than suitably qualied personnel and never whilst mains power is connected.

ALWAYS DISCONNECT THE MAINS LEAD BEFORE ATTEMPTING ANY

MAINTENANCE.

BEWARE - RISK OF ELECTRIC SHOCK !

Do not use any uids to clean electrical components as these may penetrate into the

electrical system.

Installaon must be according to the seng up procedure detailed on page 8 of this guide

and must be in line with naonal, regional and local safety codes.

2. FIRE

During welding small parcles of very hot metal are expelled. Ensure that no combusble

materials can be ignited by these.

3. PERSONNEL SAFETY

Arc rays can burn your eyes and skin and noise can damage your hearing. Operators and

personnel working in close proximity must wear suitable eye, ear and body protecon.

Fumes and gases can seriously harm your health. Use the equipment only in a suitably

venlated area. If venlaon is inadequate, then appropriate fume extracon equipment

must be used.

Hot metal spaer can cause re and burns. Appropriate clothing must be worn. Clothing

made from, or soiled with, combusble materials must NOT be worn.

Have a re exnguisher nearby and know how to use it.

Magnec elds from high currents can aect heart pacemakers or other electronically

controlled medical devices. It is imperave that all personnel likely to come into the vicinity

of any welding plant are warned of the possible risks before entering the area.

4. MAINTENANCE

All cables must be inspected regularly to ensure that no danger exists from worn or

damaged insulaon or from unsound electrical connecons. Special note should be made

of the cables close to the pistol, where maximum wear occurs. As well as producing

inconsistent welds, worn cables can overheat or spark, giving rise to the risk of re.

Page 6

V-2U

IMPORTANT SAFETY INFORMATION !

6

5. TRAINING

Use of the equipment must be limited to authorised personnel only who must be suitably

trained and must have read and understood this manual. This manual must be made

available to all operators at all mes. Further copies of this manual may be purchased from

the manufacturer. Measures must be taken to prevent the use of this equipment by

unauthorised personnel.

6. INSTALLATION

Ensure that the site chosen for the equipment is able to support the weight of the

equipment and that it will not fall or cause a danger in the course of its normal operaon.

Do not hang connecng cables over sharp edges and do not install connecng cables near

heat sources or via trac routes where people may trip over them or they may be

damaged by the passage of vehicles (forklis etc).

7. INTERFERENCE

During welding operaons, intense magnec and electrical elds are unavoidably produced

which may interfere with other sensive Electronic equipment.

All Taylor Studwelding equipment is designed, manufactured and tested to conform the

current appropriate European standards and direcves regarding electromagnec

emissions and immunity and as such is safe to use in any normal environment.

8. DISPOSAL

The equipment either wholly or any of its component parts may be disposed of as part of

general industrial waste or passed to a scrap merchant. None of the components used in

the manufacture are toxic, carcinogenic or harmful to health in their “as supplied”

condion.

Page 7

V-2U

INTRODUCTION TO STUDWELDING

7

The Taylor Studwelding DA2-A studwelding pistol when matched with an appropriate

controller and earth cables is intended for precision stud welding up to 20 mm diameter full

base studs. The pistol is lightweight, ergonomic and has been designed to operate with a

minimum amount of maintenance.

The energy required to carry out the welding operaon is derived from an appropriate

studwelding controller.

Taylor Studwelding Systems Ltd controllers are modern, robustly designed and oer

maximum reliability combined with an easy to understand operator interface.

THE PROCESS

The process of drawn arc studwelding is long established and well proven. The basic steps

are as follows :

• A measured amount of weld stud protrusion is set at the welding pistol.

• Once in posion, the pistol lis the stud away from the work-piece, simultaneously

striking an arc between the two.

• Both the p of the weld stud and the surface of the work-piece melt as the arc is

sustained for a pre-determined interval.

• At the compleon of the pre-determined interval, the pistol returns the weld stud to

the molten pool on the work-piece, thus forming a weld.

The most common and tradional drawn arc welds have a weld duraon greater than

100ms and employ the use of a single use ceramic arc shield, commonly referred to as a

ferrule. This ferrule helps to protect the arc during the weld and assists in formaon of the

nal llet. Post welding the ferrule is removed and disposed of.

It is possible to stud weld without a ferrule. When using this method it is recommended

pracce to employ a suitable shielding gas to reduce the amount of porosity in the

completed weld and improve weld quality.

Page 8

V-2U

SETTING UP AND WELDING

8

As standard, the DA2-A pistol comes ed with standard

legs and a standard foot adaptor. The pistol has a standard

UK and American taper adaptor ed to the M10 thread on

the weld sha. This enables the use of standard UK tapered

DA chucks, enabling studs up to 20mm in diameter to be

welded (see g.1).

Other arrangements are available as shown in gs. 2 & 3.

In g.2 the adapter is not ed to the weld sha to

enabling standard European screw-on chucks to be used,

enabling studs up to 20mm in diameter to be welded.

In g.3 a 35mm gas foot arrangement using long legs and

an extended form of screw-on chuck allows for welding,

with or without gas.

Please refer to the accessories secon of this guide for

informaon regarding chucks and other accessories for the

pistol.

The DA2-A pistol is commonly referred to as a “ring li” pistol. This means the pistol has an

internal clutch, allowing for moderate inconsistencies in the length of the studs being

welded, without aecng weld quality.

1

2

3

Page 9

V-2U

SETTING UP AND WELDING

9

Once you have selected the type and size of

stud you wish to weld and obtained the

correct chuck (see the accessories secon of

this guide for a list of available sizes), you will

need to set up the chuck and t it to the pistol.

On the page “An introducon to studwelding”,

under the heading “The Process” it explains that a measured amount of stud protrusion is

set at the welding pistol.

To ensure that the correct amount of

protrusion will be available once the chuck is

ed to the pistol, it is important to set the

chuck correctly in the rst place. Some chucks

have a pre-determined depth (see right) which

will only allow a certain amount of the stud to

be inserted.

Other chucks have a backstop arrangement

that allows the depth of engagement to be

adjusted.

Regardless of which type of chuck is employed,

when welding with ceramic ferrules, it is

important that sucient stud length is

exposed to allow more than the “burn-o”

allowance of the stud to pass completely

through the ferrule. Insucient allowance may

result in the leading edge of the chuck hing

the back of the ferrule during welding. This

would result in failed welds.

In non-ferrule welding it is only necessary to

set the chuck so that sucient stud length is

exposed to prevent damage to the leading edge of the chuck during welding.

Having set up the chuck, you are now ready to t it into the pistol.

Page 10

V-2U

SETTING UP AND WELDING

10

Fit the chuck into the tapered sha

adaptor (g.1) and secure in place by

gently tapping the chuck to lock the taper.

The chuck may be subsequently removed

using a twist dri (see page 22 for tools)

inserted through the cross-drilled holes in

the taper adaptor.

Fit the ferrule grip into the foot adaptor

(g.2) and secure in place using the 2 set

screws in the foot adaptor. Do not overghten the set screws as this may result in

damage to either the ferrule grip or the

foot adaptor or both.

Place a stud and ferrule into the chuck

and grip (g.3). Ensure the stud is pressed

fully home and that the ferrule is properly

seated in the grip.

Centre the ferrule over the stud (g.4).

Use the 2 countersunk socket screws set

in the foot washers to loosen and adjust

the posion of the foot adaptor on the

pistol legs. It is very important that the

ferrule does not bind on the stud as this

will cause poor, inconsistent and failed

welds.

1

2

3

4

Page 11

V-2U

SETTING UP AND WELDING

11

Set the correct protrusion (g.5) by

loosening the two socket cap screws ed

at an angle in the sides of the front end

cap.

Slide the foot/leg assembly in/out (g.6)

to achieve the desired stud protrusion,

which should be around 2 - 4mm

depending on the diameter of stud being

welded. Protrusion is the distance from

the front face of the ferrule to the front

edge of the stud, not including the coned

p.

IMPORTANT! Please note that it is

necessary to check/reset the protrusion

when changing the stud length/diameter.

Adjustment of the pistol li is achieved by

turning the rear end cap of the pistol

(g.7). The cap has a “click” detent where

one “click” is approx’ equal to a 0.25mm

change in li. Turning the cap clockwise

(CW) will reduce li, whilst turning the

cap an-clockwise (ACW) will increase li.

Upon rst use when the li posion is

unknown, it is good pracce to zero the

pistol by turning the adjuster fully CW,

then in stages turning the adjuster ACW,

pulling the trigger between adjusts to observe the li, adjust unl the pistol begins to li. Once the

pistol begins to li, one click CW is the zero posion and the desired li can be set from this point.

PLEASE NOTE! It is possible to use

European type screw-on chucks with this

pistol. This is achieved by removing and

discarding the tapered chuck adaptor.

The adaptor can be removed by using a

pair of bars through the cross-drilled

holes in the adaptor and the front sha

adaptor (check under the rubber

protecon bellows for the sha hole).

Likewise the chuck is then ed (g.8) by

bracing the sha using this hole and an

appropriate wrench. It is IMPORTANT that the sha is properly braced when ng or removing

screw-on chucks. Failure to do so may result in damage to the pistol.

IMPORTANT! Informaon contained in this operang guide is intended to assist in seng up the

pistol. The suggested sengs are intended as a starng point only. Fine tuning the sengs to

achieve the most sasfactory results is essenal and is the responsibility of the user of the pistol.

5

6

7

8

2 - 4mm

Page 12

V-2U

EXPLODED DIAGRAMS & PARTS LISTINGS

12

ITEM QTY. PART No. DESCRIPTION

1 5½ 71-300-009 CONTROL CABLE

2 5 71-300-004 WELDING CABLE

3 1 71-101-030 CONTROL PLUG

4 1 81-101-051 WELDING PLUG

5 9 71-101-032 CABLE TIE (NOT SHOWN)

1 3

2 4

SEE PAGES 13 TO 16 FOR COMPLETE STAGED

BREAKDOWN OF PISTOL.

Page 13

V-2U

ITEM QTY PART No. DESCRIPTION

1 SEE PAGE 18 FOOT ASSEMBLY

2 SEE PAGE 18 CHUCK & GRIP

3 1 81-101-005 CHUCK GRIP

4 2 Z105-05-040 SCREW

5 1 81-101-298 BEARING BUSH

6 1 81-101-190 FRONT END CAP

7 1 81-101-297 A R PLATE

EXPLODED DIAGRAMS & PARTS LISTINGS

13

2

1

7 8 9

5 6

3 4

14 15

12 13

10 11

8 2 Z120-05-025 SCREW

9 2 81-101-191 LEG GRIP

10 2 Z100-05-025 SCREW

11 2 Z615-05-000 WASHER

12 1 81-111-044 BELLOWS

13 1 81-101-293 DAMPER

14 2 Z600-06-000 WASHER

15 2 Z105-06-010 SCREW

Page 14

V-2U

ITEM QTY PART No. DESCRIPTION

1 1 81-101-299 SHAFT SPRING

2 1 81-101-014 RING RET. PLATE

3 1 81-101-015 LIFTING RING

4 1 81-101-018 RING SPRING

5 1 81-101-286 LIFTING HOOK

6 4 Z100-04-008 SCREW

7 1 81-101-345 HOOK SPRING

8 1 Z120-06-016 SCREW

EXPLODED DIAGRAMS & PARTS LISTINGS

14

3 4 5

1 2

SEE BELOW FOR SHAFT

BREAKDOWN

6 7 8

COMPLETE SHAFT ASSEMBLY IS AVAILABLE UNDER PART No. : 81-101-134

13 14 15

11 12

9 10

17

16

ITEM QTY PART No. DESCRIPTION

9 1 81-101-192 SHAFT ADAPTOR

10 1 Z105-05-040 SCREW

11 1 81-101-194 INSULATOR

12 1 81-101-195 SHAFT BLOCK

13 1 81-101-197 INSULATOR

14 1 81-101-073 LIFTING SLEEVE

15 1 81-101-269 GUIDE ROD

16 1 81-101-193 INSULATOR

17 1 81-101-196 INSULATOR

Page 15

V-2U

ITEM QTY PART No. DESCRIPTION

1 2 Z100-04-016 SCREW

2 1 81-101-275 BODY (PART OF)

3 1 81-101-284 BODY RING

4 3 Z120-04-008 SCREW

5 1 81-101-285 REAR END CAP

6 2 Z120-05-012 SCREW

7 1 81-101-267 RETAINING RING

8 1 81-101-039 WASHER

9 2 Z650-05-016 PIN

EXPLODED DIAGRAMS & PARTS LISTINGS

15

1 2 3 4 5 6

12

10 11

8 9

7

18

16 17

14 15

13

ITEM QTY PART No. DESCRIPTION

10 3 Z400-03-008 SET SCREW

11 1 81-101-281 BACKSTOP

12 1 81-101-283 DETENT CAP

13 1 81-101-170 COIL

14 2 81-111-039 DETENT

15 2 Z400-04-012 SET SCREW

16 1 81-101-280 COIL HOUSING

17 1 81-101-282 BACKSTOP DRIVER

18 2 Z120-05-010 SCREW

Page 16

V-2U

1

2

3 4

5 6

7

8 9 10

11

12

13

14

EXPLODED DIAGRAMS & PARTS LISTINGS

ITEM QTY PART No. DESCRIPTION

1 1 81-101-275 BODY (PART OF)

2 1 81-101-288 FLEXI-BRAID

3 1 81-101-279 PUSHBUTTON

4 2 Z600-06-000 WASHER

5 2 Z615-06-000 WASHER

6 2 Z115-06-010 SCREW

7 3 Z120-05-020 SCREW

8 1 81-101-278 TERMINAL PLATE

9 1 Z800-04-026 PIN

10 1 Z600-04-000 WASHER

11 1 Z225-08-914 SCREW

12 1 81-101-275 BODY (PART OF)

13 1 Z700-06-S38 TERMINAL

14 1 81-101-287 CABLE SLEEVE

16

Page 17

V-2U

ACCESSORIES

17

SEE PAGES 20 - 22 FOR OUR STANDARD DRAWN ARC, EUROPEAN AND GAS CHUCKS,

FERRULE GRIPS AND ACCESSORIES RANGE

1 2

3 4

5 6 7 8 9

10 11 12

SEE NEXT PAGE FOR COMPLETE

FOOT ASSEMBLY PART NUMBERS

ITEM QTY. PART No. DESCRIPTION

1 2 Z400-05-008 GRUB SCREW

2 1 81-101-002 STANDARD FOOT ADAPTOR (M3 - M12)

3 2 81-101-004 STANDARD LEG (230mm)

4 2 89-101-081 EXTENDED LEG (330mm)

5 2 Z125-05-035 SCREW

6 2 81-101-003 FOOT WASHER

7 2 81-101-001 FOOT WASHER

8 1 81-101-063 STANDARD FOOT ADAPTOR (M16 - M20)

9 1 81-101-131 TRIPOD FOOT ADAPTOR (M16 - M20)

10 2 Z415-08-050 GRUB SCREW

11 2 Z510-08-000 LOCKNUT

12 1 81-101-126 TRIPOD FOOT ADAPTOR (M3 - M12)

Page 18

V-2U

ACCESSORIES

18

STANDARD FOOT ADAPTOR

ASSEMBLY (M3 - M12,

STANDARD LEGS)

COMPLETE ASSEMBLY :

81-101-158

STANDARD FOOT ADAPTOR

ASSEMBLY (M16 - M20,

STANDARD LEGS)

COMPLETE ASSEMBLY :

81-101-159

TRIPOD FOOT ADAPTOR

ASSEMBLY (M3 - M12,

STANDARD LEGS)

COMPLETE ASSEMBLY :

81-101-140

STANDARD FOOT ADAPTOR

ASSEMBLY (M16 - M20,

STANDARD LEGS)

COMPLETE ASSEMBLY :

81-101-141

Page 19

V-2U

ACCESSORIES

19

COMPLETE ASSEMBLY (NO LEGS)

PART NUMBER : 89-101-414

1 2 3 4 5 6 7 8 9

ITEM QTY. PART No. DESCRIPTION

1 1 89-101-249 Ø35mm NOSE CONE

2 3 Z400-05-006 GRUB SCREW

3 1 89-101-246 GAS CONE

4 1 89-101-245 FOOT ADAPTOR

5 1 PFS-P06-U1M-INT GAS FITTING

6 1 89-101-244 BELLOWS

7 2 Z400-05-010 GRUB SCREW

8 5.5 71-200-043 GAS PIPE

9 1 71-200-067 GAS PLUG

Page 20

V-2U

ACCESSORIES - CHUCKS

EUROPEAN SCREW-ON TYPE

20

Ø D PART NUMBER

3 5 89-101-003

4 5 89-101-004

5 6 89-101-005

6 7 89-101-006

8 9 89-101-008

10 11 89-101-010

12 13 89-101-012

Ø D PART NUMBER

4 25 89-101-021

6 15 89-101-022

6 25 89-101-023

8 6 89-101-024

8 25 89-101-025

10 4 89-101-026

10 6 89-101-027

12 6 89-101-028

TABLE 1 TABLE 1

LISTS OUR STANDARD STOCK RANGE OF CHUCKS.

TABLE 2 TABLE 2

LISTS OUR NON STOCK RANGE OF CHUCKS.

NOTE! NON STOCK CHUCKS WILL REQUIRE ADDITIONAL

DELIVERY LEAD TIMES AND MAY BE SUBJECT TO

MINIMUM ORDER QUANTITY.

PLEASE NOTE.

IF THE CHUCK THAT YOU REQUIRE IS NOT SHOWN HERE,

PLEASE CHECK WITH US.

Page 21

V-2U

ACCESSORIES - CHUCKS

UK TAPER FIT - ADJUSTABLE

ACCESSORIES - CHUCKS

EUROPEAN SCREW-ON GAS TYPE

21

Ø D PART NUMBER

5 4 89-101-035

6 4 89-101-036

6 7 89-101-037

8 4 89-101-038

8 9 89-101-039

10 11 89-101-040

12 13 89-101-042

Ø PART NUMBER

M3 89-101-203

M4 89-101-204

M5 89-101-205

M6 89-101-206

M8 89-101-208

M10 89-101-210

M12 89-101-212

M16 89-101-216

M20 89-101-220

PLEASE NOTE. OTHER CHUCK SIZES ARE AVAILABLE.

PLEASE CHECK WITH US IF THE SIZE YOU WANT IS NOT

LISTED HERE.

ACCESSORIES - CHUCKS

UK TAPER FIT - RECTANGULAR

SIZE PART NUMBER

6 x 30mm 89-101-203

6 x 19mm 89-101-204

3 x 16mm 89-101-205

PLEASE NOTE. OTHER CHUCK SIZES ARE AVAILABLE.

PLEASE CHECK WITH US IF THE SIZE YOU WANT IS NOT

LISTED HERE.

Page 22

V-2U

ACCESSORIES - BENDING BAR & TOOLS

ACCESSORIES - FERRULE GRIPS

22

Ø PART NUMBER

M3 89-101-051

M4 89-101-051

M5 89-101-052

M6 89-101-052

M8 89-101-053

M10 89-101-054

M12 89-101-055

M16 89-101-056

M20 89-101-057

ITEM PART NUMBER

BENDING BAR 79-101-121

M3 NOZZLE 79-101-123

M4 NOZZLE 79-101-124

M5 NOZZLE 79-101-125

M6 NOZZLE 79-101-126

M8 NOZZLE 79-101-127

M10 NOZZLE 79-101-128

COMPLETE SET 79-101-120

TOOL PART No.

KEY SET (2, 2.5, 3, 4, 5, 6, 8) 98-100-003

UK CHUCK EJECTOR TOOL

(TWIST DRIFT)

98-100-001

17mm A/F CHUCK SPANNER 98-100-006

Page 23

V-2U

TAYLOR STUDWELDING SYSTEMS LIMITED

COMMERCIAL ROAD

DEWSBURY

WEST YORKSHIRE TEL : +44 (0)1924 452123

ENGLAND FAX : +44 (0)1924 430059

WF13 2BD EMAIL : sales@taylor-studwelding.com

This is to cerfy that the machinery listed below is designed and manufactured in conformance

with all applicable health and safety regulaons.

This statement is invalid if any modicaons are carried out on the machinery without the prior

wrien approval of Taylor Studwelding Systems Ltd.

————————————————————————————————

DESCRIPTION OF MACHINE : Drawn Arc Studwelding Pistol

TYPE : DA1-A DA2-A DA3-A

PART NUMBER : 99-101-051 99-101-052 99-101-053

————————————————————————————————

Applicable EC direcves and corresponding standards:

- Low voltage direcve 2006/95/EC:

EN60204-1 Safety of machinery - Electrical equipment of machines.

- EMC direcve 2004/108/EC (electromagnec compability):

EN50081 Electromagnec compability - Generic emission standard

EN50082 Electromagnec compability - Generic immunity standard

EN50199 Electromagnec compability (EMC) Product standard for

Arc welding equipment

- Machine guidelines 2006/42/EC:

EN60974-1 Arc welding equipment : Electromagnec compability (EMC)

EC DECLARATION

SIGNED

DAVID TAYLOR

MANAGING DIRECTOR

Loading...

Loading...