Page 1

Models C801, C801R, F802, P802, C803, C803R, C804

Wendy's Grills

Operating Instructions

072493-M

5/22/09 (Original Publication)

(Updated 6/5/12)

Page 2

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Installer Safety 1........................................................

Electrical Connections 1.................................................

Installation 2...........................................................

Setup and Checkout Instructions 3........................................

Ventilation and Clearance 3..............................................

Grease Disposal Container 3.............................................

Section 2 To the Operator 4...........................................

Section 3 Safety 5....................................................

Section 4 Operator Parts Identification 7...............................

C801 7................................................................

C801 Reverse 8........................................................

F802 Front Unit 9.......................................................

P802 Pick Up Window Unit 10.............................................

C803 11................................................................

C803 Reverse 12........................................................

C804 13................................................................

Accessories - Supplied By T aylor Company 14..............................

Accessories Not Supplied By Taylor Company -

Obtain From Wendy's Small Wares Vendors 15..............................

Section 5 Important: To the Operator 16.................................

C801 16................................................................

C801 Reverse 17........................................................

F802 Front Unit 18.......................................................

P802 Pick Up Window Unit 19.............................................

C801/C801R/F802/P802/C803/C803R/C804 Table of Contents

Page 4

Table of Contents - Page 2

C803 20................................................................

C803 Reverse 21........................................................

C804 22................................................................

Section 6 Operating Procedures 26.....................................

Morning Procedures 26...................................................

Operating Procedures 31.................................................

Cook to Order Mode 33...................................................

Nightly Cleaning Procedures 34............................................

Section 7 Troubleshooting Guide 36....................................

Section 8 Warranty Explanation 40......................................

Parts 40................................................................

Labor 40................................................................

Section 9 Parts List 41.................................................

Wiring Diagrams 56......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of instructions.

E May, 2009 Taylor (Original Publication)

(Updated June, 2012)

072493-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Table of Contents C801/C801R/F802/P802/C803/C803R/C804

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 5

Section 1 To the Installer

The following are general installation instructions.

For complete installation details, please see the

check out card.

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only Taylor authorized service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

cause severe injuries.

Electrical Connections

Electrical connections to the grill must be provided

and arranged by Wendy's, with their preferred

licensed electrician. This must be completed

immediately following grill installation and prior to the

grill Start Up and Checkout by the local Taylor

representative.

Check the data plate on the grill for voltage, cycle,

phase and electrical specifications. The power

connections are located behind the access cover of

the control box under the front staging side of the

grill.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

This unit has many sharp edges that can

The Proper Wire Size and Branch Circuit

The main power supply(s) to the equipment

must be disconnected prior to performing any

repairs. Failure to follow this instruction may result in

personal injury or death from electrical shock or

hazardous moving parts as well as poor

performance or damage to the equipment.

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

C801/C801R/F802/P802/C803/C803R/C804 To the Installer

Overcurrent Device shall be selected according to

the data label information and in accordance with

CEC Part I 2006, Section 14-100(e)(i). Incoming

power must be connected to the line side of the

power contactor.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

1

Page 6

Installation

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipments frame.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

These machines are designed for indoor use

only.

The C801 grill and the C801 Reverse grill must be

lifted and positioned in place with the aid of a lift

device. They are suspended between the adjacent

sandwich counter and the meat well.

The F802,C803, C803 Reverse, and C804 grills are

mounted on carts. They are wheeled into position in

the store.

The P802 grill is installed into the sandwich counter.

The items to be installed / connected by the

distributor include:

S Node board modules

S Lane dividers

S Miscellaneous accessory brackets

DO NOT installthemachineinanarea

where a water jet could be used to clean or rinse the

machine. Failure to follow this instruction may result

in serious electrical shock.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

2

C801/C801R/F802/P802/C803/C803R/C804To the Installer

Page 7

Setup and Checkout Instructions

Step 1

Install the panels, starting with the bottom. Install the

panels under the node board modules, the lane

dividers (staging side) and the accessory brackets.

Step 2

Install the node board modules.

Step 9

Once the gaps are set, install the cook side back

splash, lane divider, and the release sheets.

Step 10

Cook one run of product on each platen to check the

product appearance and the finished product

temperature. (Internal temperature must be above

175°F / 79°C.)

Step 3

Tighten all screws.

Step 4

Once the electrical connections are completed,

install the box cover and turn the grill on.

Step 5

Wait for 45 minutes for the grill to reach stable

temperatures before proceeding to the next step.

The grill will indicate it is ready to cook in

approximately 15 - 20 minutes.

CAUTION: The grill will be hot. Wear

proper protective equipment to avoid severe burns

from high temperatures.

Step 6

Check the platen lift mechanism and adjust, if

needed (not applicable to P802). (See Lift/Latch

Instructions in the Service Manual.)

Step 7

Install the back panel.

Step 8

The platen should be lowered onto the lower plate

and the gap settings should be properly calibrated.

To close the platen, touch and hold the red button

corresponding to the desired platen. A cook cycle

will not start and the display will read “Standby”.

Release the button after the platen has closed. (See

Platen Gapping Procedures in the Service

Manual.)

Step 11

Check the “cook to order” and back up staging.

Step 12

Fill out the checkout card and the work order /

invoice.

Ventilation and Clearance

To ensure proper operation of this appliance, it must

be installed so that the products of combustion are

efficiently removed.

After set up, do not store anything on top of

the grill. Failure to follow this instruction may result

in a fire hazard.

Grease Disposal Container

In order to comply with NSF Standard 4

requirements, an appropriate grease disposal

container must be provided. This container is

supplied by the KES, not the Taylor Company.

C801/C801R/F802/P802/C803/C803R/C804 To the Installer

3

Page 8

Section 2 To the Operator

The grill you have purchased has been carefully

engineered and manufactured to provide

dependable operation.

This grill, when properly operated and maintained,

will produce a consistent quality product. Like all

mechanical products, they require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures in

this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment's operation and

cleaning, review these procedures for proper training

and assurance that no misunderstandings exist.

In the event that you require technical assistance,

please call 877-222-7010 for authorized service.

Note: Warranty is valid only if the parts are

authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required

service work is provided by an authorized Taylor

service technician. Taylor reserves the right to deny

warranty claims on equipment or parts if

non-approved parts or refrigerant were installed in

the machine, system modifications were performed

beyond factory recommendations, or it is determined

that the failure was caused by neglect or abuse.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

4

C801/C801R/F802/P802/C803/C803R/C804To the Operator

Page 9

Section 3 Safety

We at Taylor Company are deeply concerned about

the safety of the operator when he or she comes in

contact with the grill and its parts. Taylor has gone

to extreme efforts to design and manufacture built-in

safety features to protect both you and the service

technician. As an example, warning labels have

been attached to the grill to further point out safety

precautions to the operator.

Please call 877-222-7010 for authorized service.

To Operate Safely:

DO NOT operate the grill without reading

this operator's manual. This manual should be kept

in a safe place for future reference.

Per IEC 60335-1 and its part 2 standards,

“This appliance is to be used only by trained

personnel. It is not intended for use by children or

people with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning

the use of the appliance by a person responsible for

their safety.”

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord, (Code designation

60245 IEC 57), installed with the proper

cord anchorage to relieve conductors from

strain, including twisting, at the terminals

and protect the insulation of the conductors

from abrasion.

IMPORTANT: DO NOT use a water jet or

spray excessive water on or anywhere near the

grill. Failure to follow this instruction may result in

serious electrical shock and cause permanent

electrical and mechanical damage to internal parts.

Failure to follow this instruction may result in:

Failure to follow the instructions below may

result in severe injury or death from electrocution:

S DO NOT operate the grill unless it is

properly grounded.

S serious electrical shock

S DO NOT attempt any repairs unless the

power supply to the grill has been

disconnected (must be performed by an

authorized service technician).

S DO NOT operate the grill unless all service

panels are restrained with screws.

C801/C801R/F802/P802/C803/C803R/C804 Safety

5

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

120605

Page 10

DO NOT use cold water or ice to cool the

upper cook surface, the lower cook surface, or the

staging grill plate. Failure to follow this instruction

may result in:

Appropriate grill clearance must be

maintained from all combustible materials. Failure to

comply could result in a fire hazard.

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

Failure to follow the instructions below may

result in severe burns from high temperatures:

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

S USE EXTREME CAUTION when cleaning

the grill.

Take caution to protect eyes, lungs, and all

parts of the body from potential harm when using

any chemical cleaner. Failure to follow this

instruction may result in a chemical burn.

DO NOT use any abrasives or cleaners

other than approved food service cleaners and

degreasers. Failure to comply may cause illness to

the consumer and may also damage grill surfaces.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

6

C801/C801R/F802/P802/C803/C803R/C804Safety

Page 11

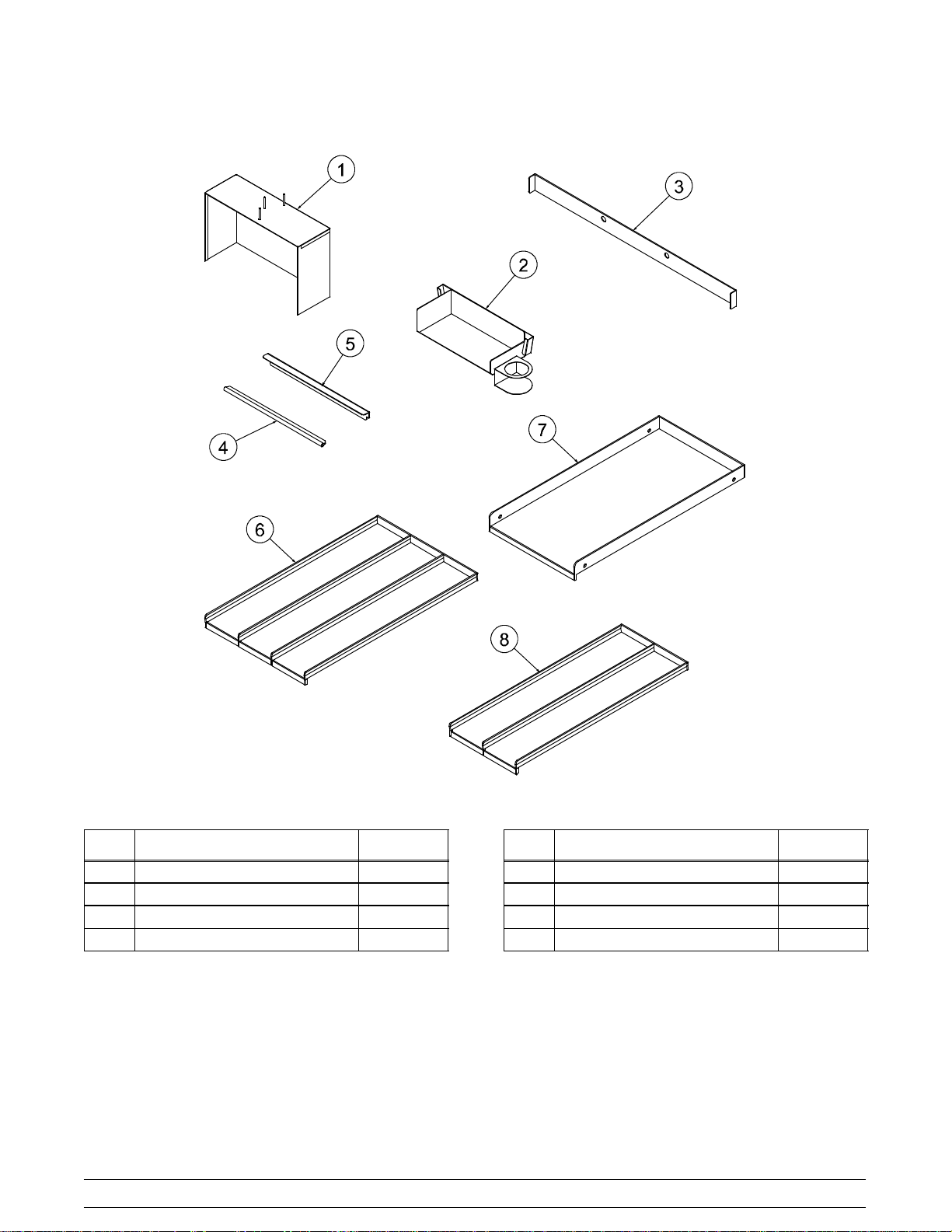

Section 4 Operator Parts Identification

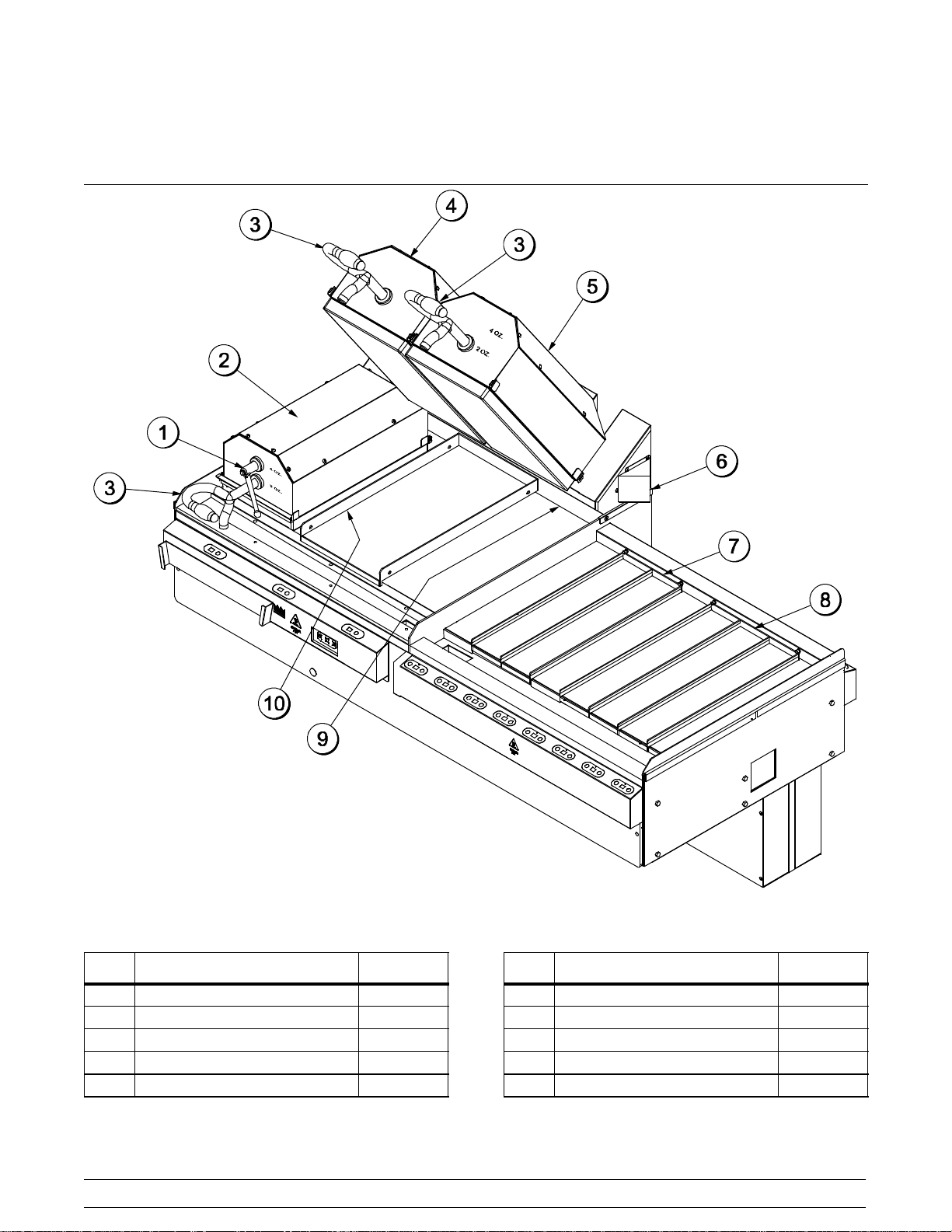

C801

Figure 1

ITEM DESCRIPTION PART NO.

1 HANDLE-ADJUST-PLATEN 070647

2 PLATEN A.-ADJUSTABLE X71825-23

3 HANDLE-LIFT-PLATEN 072711

4 PLATEN A.-4OZ X71824-23

5 PLATEN A.-2OZ X71823-23

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

ITEM DESCRIPTION PART NO.

6 PANEL A.-SPLASH SHLD W/SP X70783

7 DIVIDER A.-2 LANE 070847

8 DIVIDER A.-3 LANE *STAGE 070848

9 SHIELD-BACKSPLASH 070765

10 DIVIDER A.-COOK 070851

7

Page 12

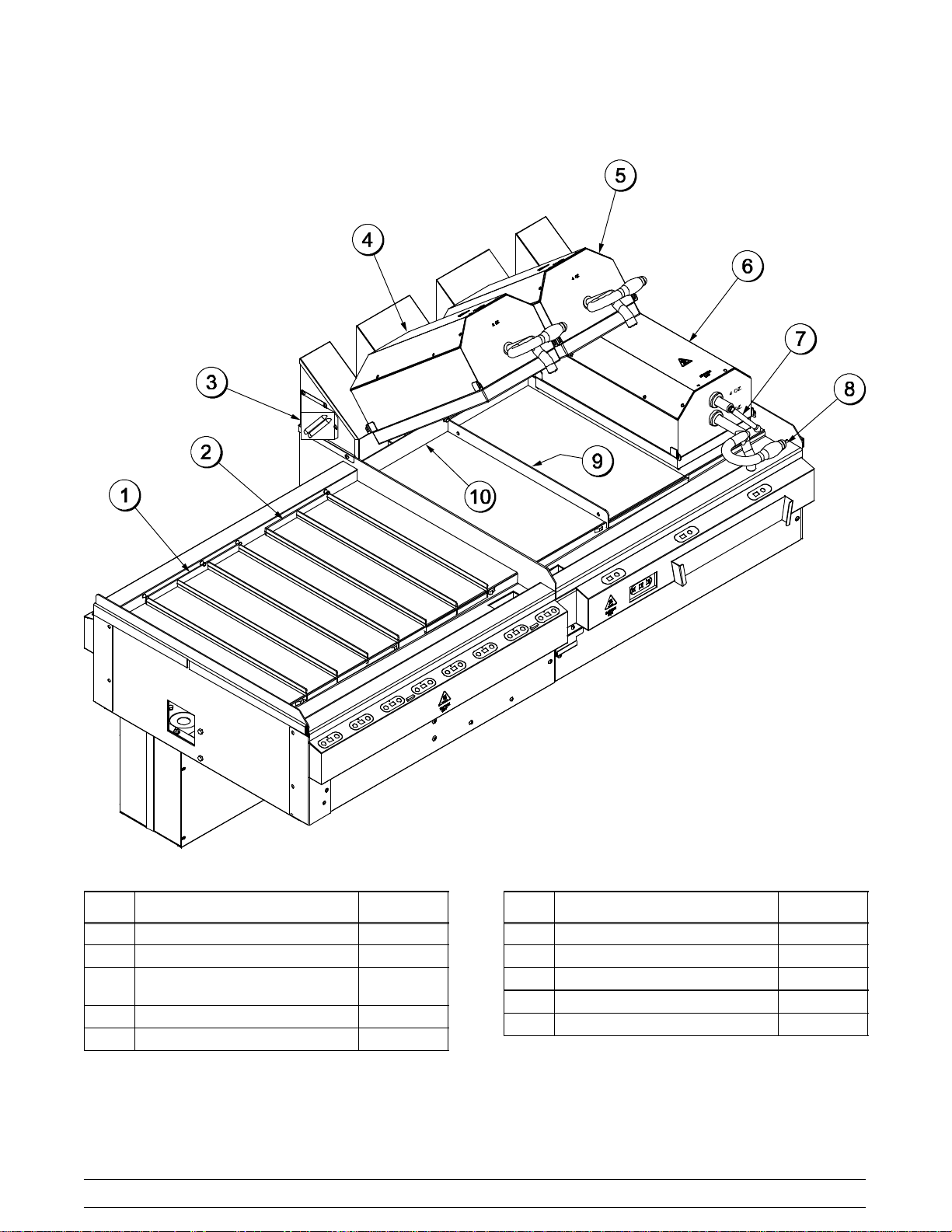

C801 Reverse

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-3 LANE *STAGE 070848

2 DIVIDER A.-*2 LANE*STAGE 070847

3 PANEL A.-SPLASH SHIELD

W/SPEAKER

4 PLATEN A.-*C801*2 OZ SERV X71823-23

5 PLATEN A.-*C801* 4 OZ X71824-23

X72247

Figure 2

8

ITEM DESCRIPTION PART NO.

6 PLATEN A.-ADJUSTABLE SERV X71825-23

7 HANDLE-ADJUST-PLATEN 070647

8 HANDLE-LIFT-PLATEN 072711

9 DIVIDER A.-COOK 070851

10 SHIELD-BACKSPLASH 070765

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

Page 13

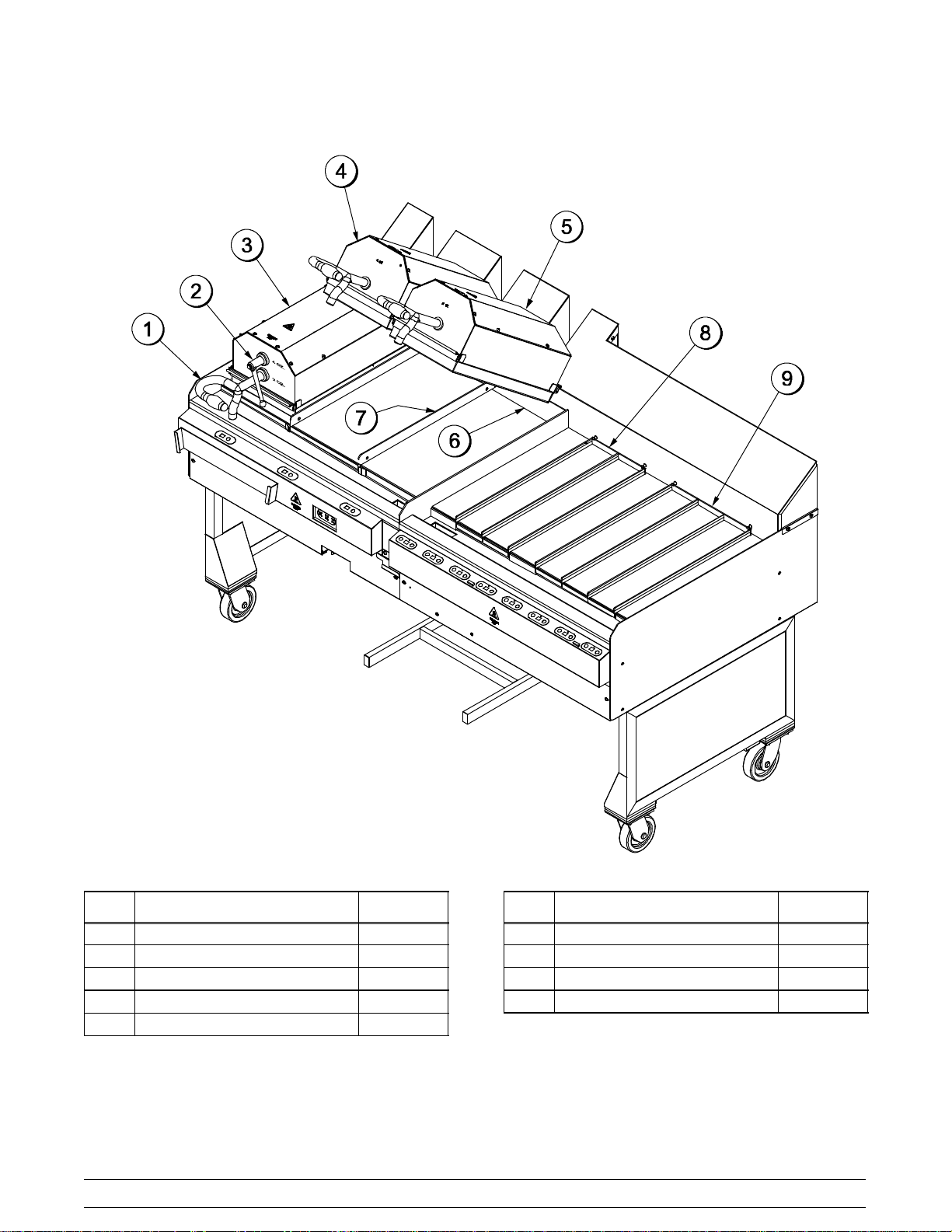

F802 Front Unit

Figure 3

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-2 LANE 070847

2 HANDLE-LIFT-PLATEN 072711

3 HANDLE-ADJUST-PLATEN 070647

4 PLATEN A.-SERVICEADJ LEFT X72669-23

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

ITEM DESCRIPTION PART NO.

5 PLATEN A.-SERVICEADJ X71825-23

6 SHIELD-BACKSPLASH 071732

7 DIVIDER A.-COOK 070851

9

Page 14

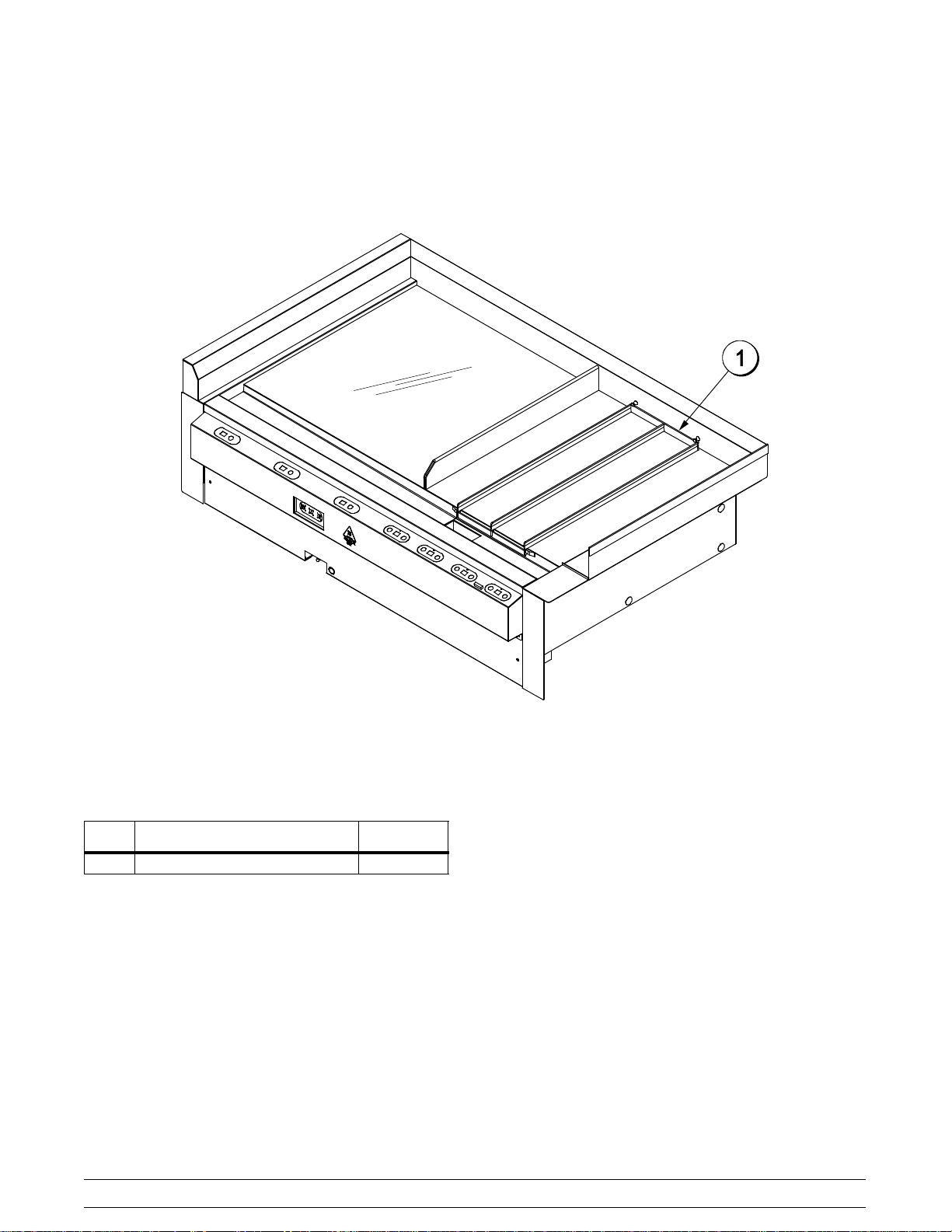

P802 Pick Up Window Unit

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-*2 LANE 070847

Figure 4

10

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

Page 15

C803

Figure 5

ITEM DESCRIPTION PART NO.

1 HANDLE-LIFT-PLATEN 072711

2 HANDLE-ADJUST-PLATEN 070647

3 PLATEN A.-ADJUSTABLE SERV X71825-23

4 PLATEN A.-*C801*4 OZ SERV X71824-23

5 PLATEN A.-*C801*2 OZ SERV X71823-23

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

ITEM DESCRIPTION PART NO.

6 SHIELD-BACKSPLASH 070765

7 DIVIDER A.-COOK 070851

8 DIVIDER A.-2 LANE STAGE 070847

9 DIVIDER A.-3 LANE STAGE 070848

11

Page 16

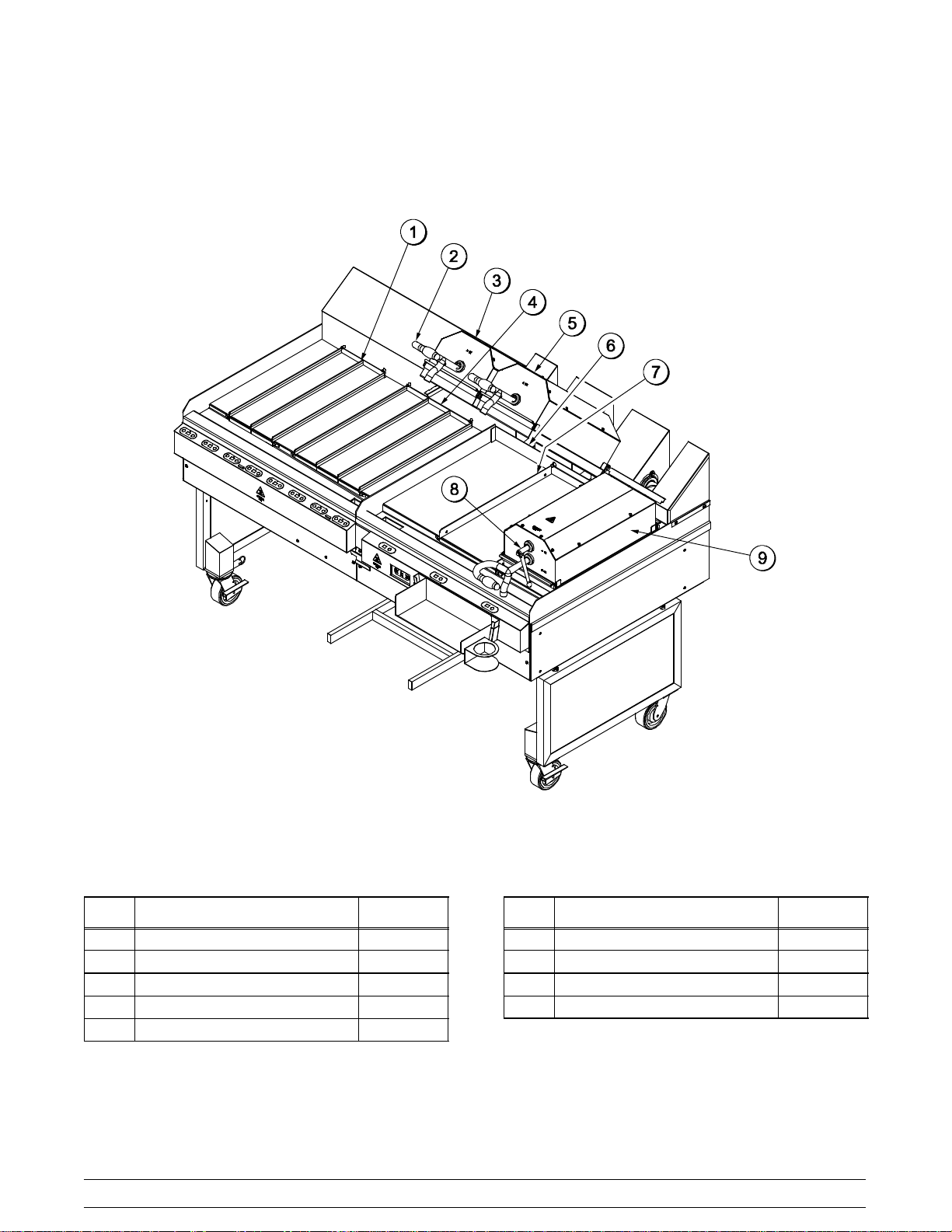

C803 Reverse

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-2 LANE 070847

2 HANDLE-LIFT-PLATEN 072711

3 PLATEN A.-2 OZ X71823-23

4 DIVIDER A.-3 LANE STAGE 070848

5 PLATEN A.-4 OZ X71824-23

Figure 6

12

ITEM DESCRIPTION PART NO.

6 SHIELD-BACKSPLASH 070765

7 DIVIDER A.-COOK 070851

8 HANDLE-ADJUST-PLATEN 070647

9 PLATEN A.-ADJUSTABLE X71825-23

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

Page 17

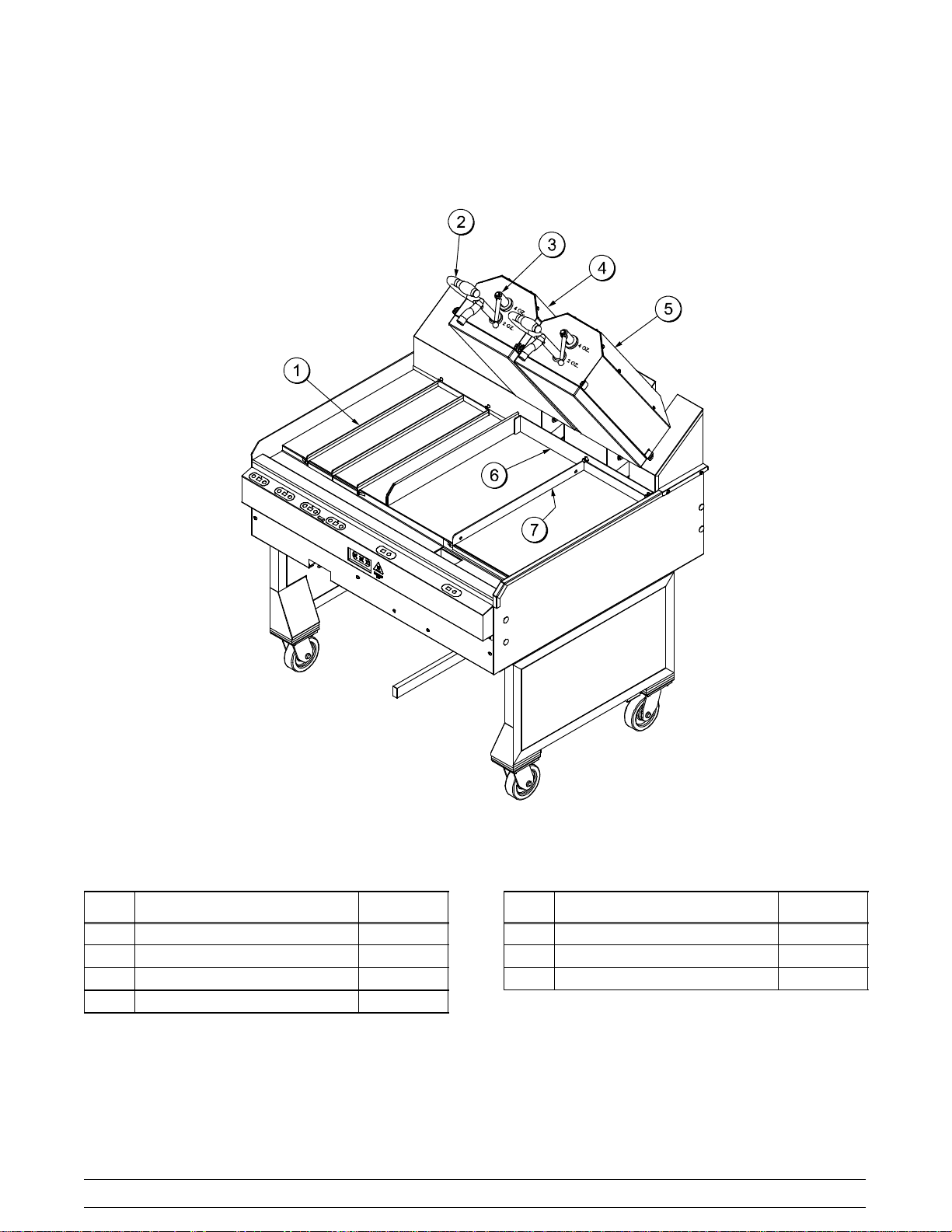

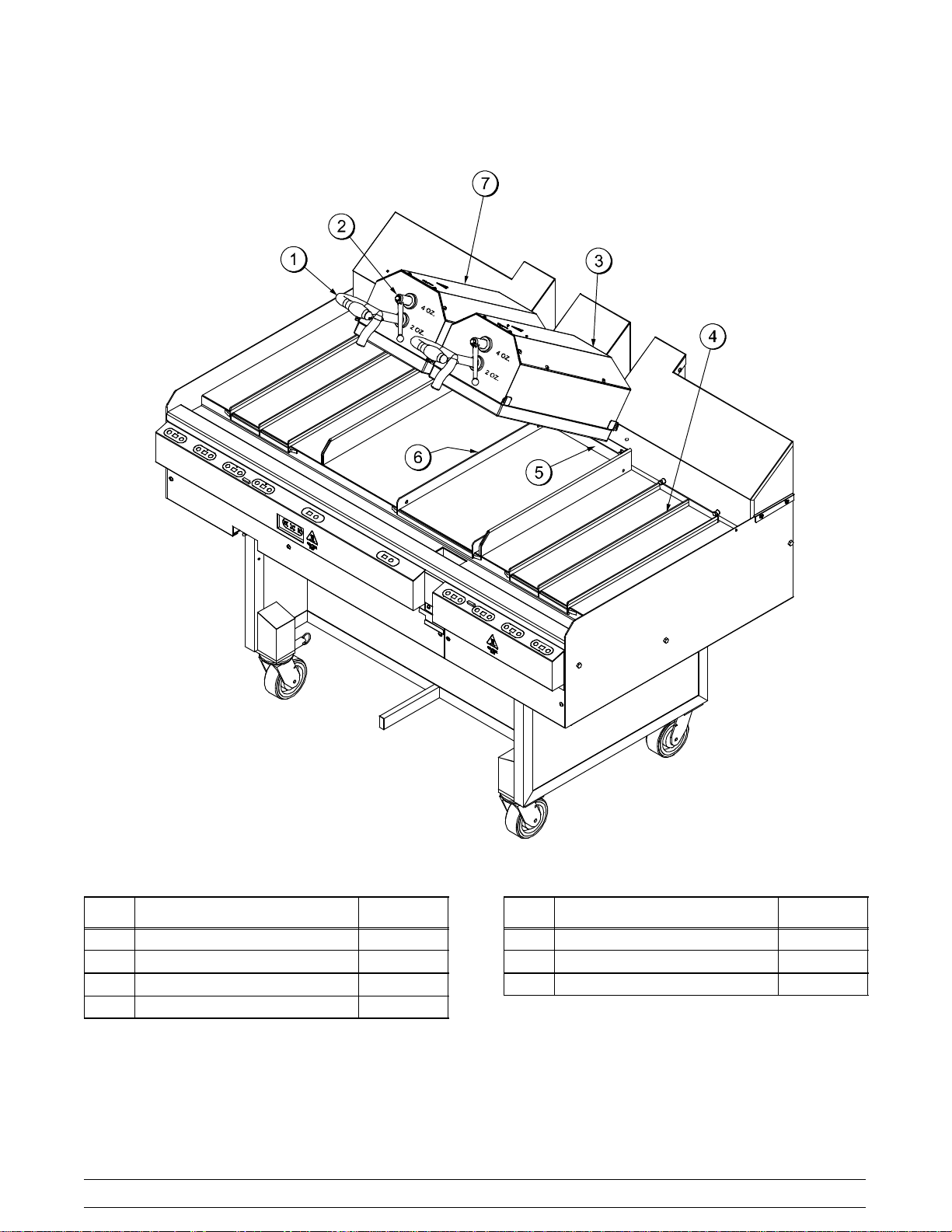

C804

Figure 7

ITEM DESCRIPTION PART NO.

1 HANDLE-LIFT-PLATEN 072711

2 HANDLE-ADJUST-PLATEN 070647

3 PLATEN A.-SERVICE ADJ X71825-23

4 DIVIDER A.-2 LANE 070847

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

ITEM DESCRIPTION PART NO.

5 SHIELD-BACK SPLASH 071732

6 DIVIDER A.-COOK 070851

7 PLATEN A.-SERVICE ADJ LEFT X72669-23

13

Page 18

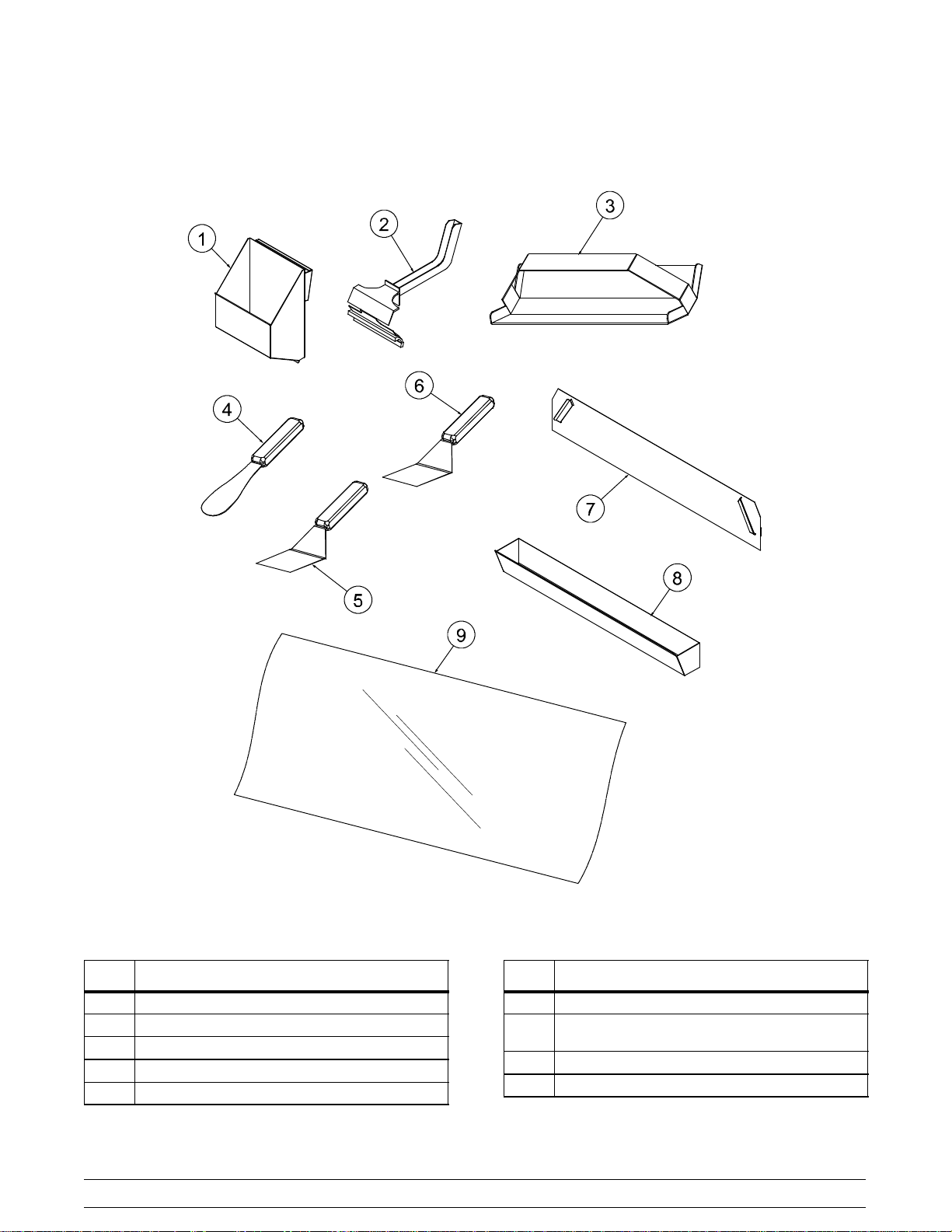

Accessories - Supplied By Taylor Company

ITEM DESCRIPTION PART NO.

1 SHIELDA.-LOCATING BUCKET X71284

2 SHELF A.-MEAT LOADING X70944

3 SHIELD-BACKSPLASH 070765

4 CLIP-RELEASE SHEET 070709

Figure 8

14

ITEM DESCRIPTION PART NO.

5 BRACKET-RELEASESHEET 070707

6 DIVIDER A.-3 LANE *STAGE 070848

7 DIVIDER A. *COOK 070851

8 DIVIDER A. *2 LANE 070847

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

Page 19

Accessories Not Supplied By Taylor Company Obtain From Wendy's Small Wares Vendors

Figure 9

ITEM DESCRIPTION

1 HOLDER-SQUEEGEE

2 HANDLE-SQUEEZE

3 TOOL-TRANSFER

4 SPATULA-REDHANDLE-SERRATED

5 SPATULA-REDHANDLE-SERVING

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

ITEM DESCRIPTION

6 SPATULA-WHITE HANDLE-SERVING

7 HOLDER-WHITE HANDLED SERVING

SPATULA

8 TROUGH

9 SHEET-RELEASE

15

Page 20

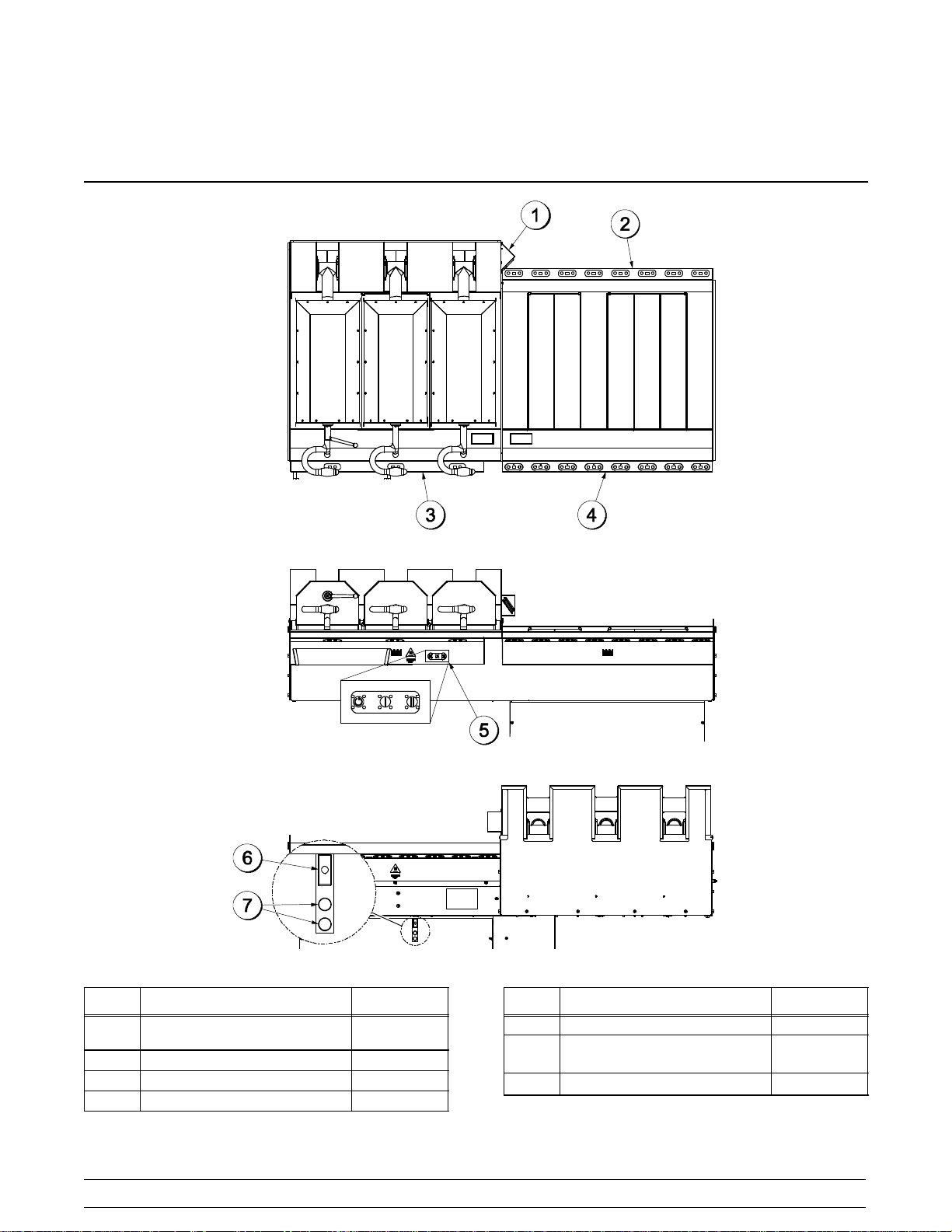

Section 5 Important: To the Operator

C801

ITEM DESCRIPTION PART NO.

1 PANEL A.-SPLASH SHIELD

W/SPEAKER

2 KIT A.-NODE-REAR W/HARN X72136

3 KIT A.-NODE-COOK W/HARN X72134

4 KIT A.-NODE-FRONT W/HARN X72135

X70783

Figure 10

16

ITEM DESCRIPTION PART NO.

5 CONTROL-C801 NODE I/O 071242-SER

6 CONTROL-RESET SWITCH

10A/230

7 LIGHT-RED 230V 070880-27

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

070717

Page 21

C801 Reverse

Figure 11

ITEM DESCRIPTION PART NO.

1 KIT A.-NODE REAR C801

W/HARN

2 PANEL A.-SPLASH SHIELD

W/SPEAKER

3 CONTROL-RESET SWITCH

10A/250

4 LIGHT-RED 230V 070880-27

X72136

X72247

070717

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

ITEM DESCRIPTION PART NO.

5 NODE A.-COMPLETE C801R

COOK

6 NODE A.-COMPLETE C801R

STG F

7 CONTROL C801 MODEI/O 071242-SER

17

X72254

X72243

Page 22

F802 Front Unit

ITEM DESCRIPTION PART NO.

1 NODE A.-COMPLETE F802

STAGE/COOK

2 CONTROL-C801 MODE I/O 071242-SER

X71550-SER

Figure 12

18

ITEM DESCRIPTION PART NO.

3 LIGHT-RED 230V 070880-27

4 CONTROL-RESET SWITCH

10A/250

070717

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

Page 23

P802 Pick Up Window Unit

Figure 13

ITEM DESCRIPTION PART NO.

1 NODE A.-COMPLETE P802

STAGE/COOK

2 CONTROL C801 MODEI/O 071242-SER

X71593-SER

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

ITEM DESCRIPTION PART NO.

3 LIGHT-RED-230V 070880-27

4 CONTROL-RESET SWITCH

10A/250

19

070717

Page 24

C803

ITEM DESCRIPTION PART NO.

1 NODE A.-COMPLETE C803

COOK

2 KIT A. NODE-FRONT C801

W/HARN

3 CONTROL-C801 MODE I/O 071242-SER

X72062

X72135

Figure 14

20

ITEM DESCRIPTION PART NO.

4 LIGHT-RED 230V 070880-27

5 CONTROL-RESET SWITCH

10A/230

070717

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

Page 25

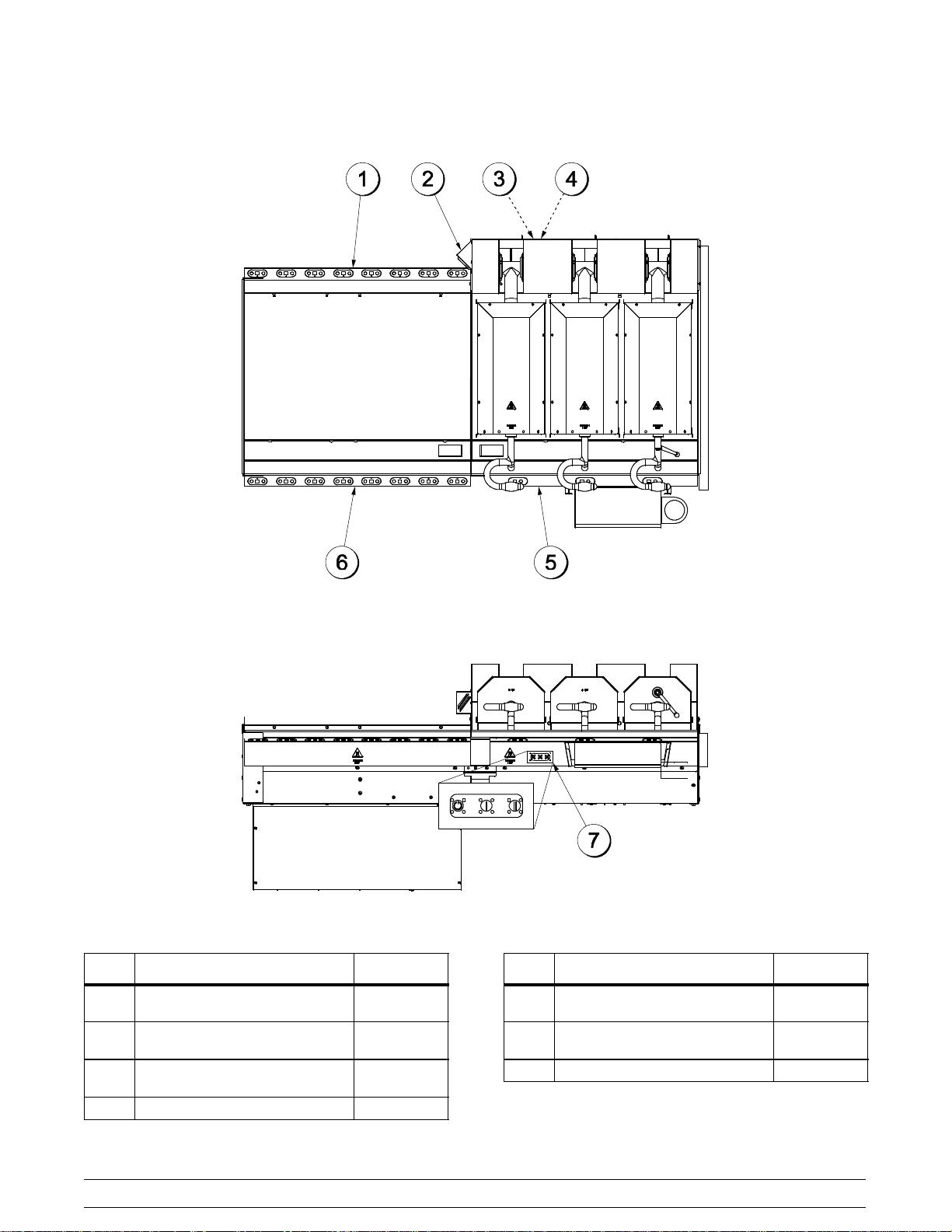

C803 Reverse

Figure 15

ITEM DESCRIPTION PART NO.

1 NODE A.-COMPLETE

*STAGING

2 NODE A.-COMPLETE *COOK X72254

3 CONTROL-C801 MODE I/O 071242-SER

X72243

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

ITEM DESCRIPTION PART NO.

4 LIGHT-RED 230V 070880-27

5 CONTROL-RESET-SWITCH

10A/250

21

070717

Page 26

C804

ITEM DESCRIPTION PART NO.

1 NODE A.-COMPLETE X73057

2 HARNESS-NODE 073154

3 CONTROL-MODE I/O 071242-SER

Figure 16

22

ITEM DESCRIPTION PART NO.

4 LIGHT-RED 230V 070880-27

5 CONTROL-RESET SWITCH 070717

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

Page 27

The following symbols are used on the control mode

display:

= Idle (blue illumination)

= Cook Only (amber illumination)

= Cook and Stage (green illumination)

The IDLE symbol will be illuminated when the

control mode is in the OFF mode.

The COOK AND STAGE symbol will be illuminated

when the control mode is in the LUNCH COOK AND

STAGE mode.

Figure 19

The COOK ONLY and COOK AND STAGE symbols

will be illuminated when the control mode is in the

BREAKFAST mode.

Figure 17

The COOK ONLY symbol will be illuminated when

the control mode is in the LUNCH COOK ONLY

mode.

Figure 18

Figure 20

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

23

Page 28

The following symbols are used on the cook and

serve displays.

=4oz.

=2oz.

= Eggs

= Sausage

= Hot Meat

situation, any cooked meat in the staging section

and any meat in the cooking section must be

removed from the grill. The cooked meat from the

staging section is placed in the chili meat pan and

the partially cooked meat is discarded.

To restart the grill, push in on the master power

switch to restore power to the controls. If the back

up memory has expired, turn on the grill per

standard procedures. When the switch is pushed in,

the red lights will extinguish.

The master power switch is located on the Line 2

side of the grill, beneath the node panel.

Grill Operation

Each grill has a lower cook surface. Excluding the

Model P802, they also have two or more upper

platens. One or more of the upper platens is

adjustable. Adjustable platens can be adjusted to

cook either 2 oz. or 4 oz. patties.

= Chicken

= Red Chef Hat

Master Power Switch

The Double-Sided Grill (DSG) is equipped with a

master power switch, which is only used when the

grill needs to be quickly shut down.

In this situation, pulling out on the switch

immediately removes power from the control

circuits. Two red lights illuminate to indicate that the

power to both power circuits has been interrupted.

There is a one minute memory backup that allows

the grill to maintain all timing control states in the

event of a power loss. Once this backup period

expires, all timing control functions are lost. In this

To change the product size on the adjustable platen,

shift the lever on the front of the platen up or down

so that the display shows the desired patty size.

Place the lever in the up position for 4 oz. patties

and in the down position for 2 oz. patties.

Figure 21

A minimum of one patty and a maximum of eight 4

oz. or ten 2 oz. patties may be cooked under one

grill platen.

24

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

Page 29

Health and Safety

Follow proper procedures to prevent

food contamination and health hazards!

Wash hands before and after handling raw meat or

the grill operator utensils to prevent contamination

and health hazards.

Cooked ground beef must reach a minimum internal

temperature of 175ºF (79.4_C).

CAUTION: Be careful not to touch the grill

or splash hot meat juices while scraping or cleaning

the grill. The top grill platens are extremely hot

(380ºF / 193_C) and can easily cause burns.

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

25

Page 30

Section 6 Operating Procedures

Approximately half of each grill is dedicated to

cooking and the other half is used for staging cooked

meat.

Each model has a lower cook surface. Excluding the

P802, each model also has two or more upper

platens. The two-sided cooking concept ensures

quick, even cooking of both sides of the products

placed on the lower surface. The upper platens are

labeled to indicate which patty size can be cooked

under that platen (2 oz. or 4 oz.).

One or more of the upper platens is adjustable. This

adjustable platen can be adjusted to cook either 2

oz. or 4 oz. patties.

If an adjustable platen is chosen, rotate the lever up

for 4 oz. patties and down for 2 oz. patties. The lever

is attached to an over-center device to ensure a

positive selection of the proper gap.

Sensors detect the lever position They indicate “2

oz.” or “4 oz.” on the display and make all

appropriate timing adjustments.

Morning Procedures

The top platens and release sheets are cleaned

during theMorning Procedures.

Assemble the following tools:

S Blue scrub

S DCT Heavy Duty Degreaser

S Dry white towel

S 1/6-sized, 4-inch deep pan of water

S Vinyl gloves

CAUTION: The grill must remain in the

OFF position for cleaning. (The grill should be

cool.) Failure to follow this instruction may result in

severe burnsfrom high temperatures.

Removing Platen Release Sheets

Step 1

The upper platen must be in the UP position in order

to remove the platen release sheet.

Figure 22

A minimum of one patty and a maximum of eight 4

oz. or ten 2 oz. patties may be cooked under one

grill platen.

We begin our instructions with the Morning

Procedures.

Note: The Model C801 has been selected to

illustrate the step-by-step operating procedures.

Step 2

Pull the retainer clip off of the release sheet bracket

located on the front of the platen. The release sheet

will drop loose.

Step 3

Remove the release sheet bracket from the front of

the platen. Set it aside on the staging side of the

grill.

Step 4

Lift the rear release sheet bracket assembly off the

rear of the platen. The release sheet and the bracket

assembly will come off of the platen together.

Step 5

Remove the retainer clip and the release sheet

bracket from the release sheet and set them aside

on the staging side of the grill.

Step 6

Lay the release sheet flat on the staging side of the

grill.

26

C801/C801R/F802/P802/C803/C803R/C804Operating Procedures

Page 31

Step 7

Repeat these steps for the remaining platens.

Replace release material sheets if:

S Release sheetis torn

S Release sheet is worn

S Product sticksto the release sheets

Cleaning Platens

Step 1

Wearing vinylgloves, spraya light layer of DCT

Heavy Duty Degreaser on the platen surface.

Step 2

Using the blue scrub pad, scrub the platen surface

with an up and down motion.

IMPORTANT: G rill screens and Scotch Bricks

must NOT be used to clean the top platens. They

will damage the cooking surfaces.

Step 3

Continue scrubbing until the entire platen grill

surface isclean and no carbon build-up is visible.

Reinstall the Platen Release Sheets

Step 1

Lay the sheet outflat on the staging side of the grill.

Step 2

Lay the release sheet bracket on the top edge of the

release sheetwith the notches on the bar facing up

and the inside of the angle facing toward you.

Step 4

Clean the sides and top of the platen as necessary.

Step 5

Wipe the platen surface with a damp towel. Rinse

the toweland re-wipe several times to remove any

remaining residue.

Cleaning Platen Release Sheets

Step 1

Wipe the platen sheet using a damp towel. To

remove heavycarbon build-up, spray DCT Heavy

Duty Degreaser on the platen sheet and scrub

thoroughly with a damp towel.

Step 2

Wipe the platen sheet dry and re-install it on the

platen surface.

Note: When re-installing the platen sheet, reverse it

every day to prolong the life of the sheet.

Step 3

Repeat these steps for the remaining platen

release sheets.

Figure 23

Step 3

Fold the end of the sheet in toward the bend of the

release sheetbracket. Center the sheet between the

notches. Placethe edge of the sheet flush against

the inside angle.

Figure 24

C801/C801R/F802/P802/C803/C803R/C804 Operating Procedures

27

Page 32

Step 4

Hold the release sheet in place using downward

pressure. Roll the release sheet bracket forward 90°.

Re-attach the retainer clip, making sure the clip is

centered on the release sheet bracket.

Figure 25

Step 6

Close the platen while pulling back on the release

sheet.

Figure 27

Step 7

Lift the release sheet up against the front of platen

and hold it in place.

Step 5

With the release sheet bracket notches facing down

and the retainer clip facing the back of the grill, slide

the notchesof the release sheet bracket onto the

rear release sheet bracket.

Figure 26

Figure 28

Step 8

Install therelease sheet bracket onto the front

release sheetbracket.

Note: Lower the platen(s) next to the platen being

worked on to ease the installation of the rear release

sheet bracket.

28

Figure 29

C801/C801R/F802/P802/C803/C803R/C804Operating Procedures

Page 33

Step 9

Pull the release sheet tight and fold it over the top of

the release sheet bracket.

Figure 30

Step 10

Hold the sheet in place and re-install the retainer

clip.

Step 11

Make sure the platen sheet is firmly positioned

between the front and rear holding brackets. The

platen sheet must fit flat to the bottom and sides of

the platen. Never fold or crease the platen sheet

while handling. It should not be wrinkled or bowed

when properlyinstalled.

Figure 32

The platen sheet helps keep residue from

accumulating between the platens, which adversely

impacts cooking performance.

Figure 31

Step 12

Repeat these steps on the remaining platens to

reinstall the release sheets.

Step 13

After all the platens and the release sheets are

cleaned and reinstalled, wipe the cooking and

staging sides of the grill surface with a damp towel.

This will remove any residue that may have fallen

while cleaning the platens and release sheets.

C801/C801R/F802/P802/C803/C803R/C804 Operating Procedures

29

Page 34

Grill Start-Up

Step 1

Before turning on the grill, ensure that the rear

splash guard and the cook divider are installed and

that the platens are closed.

Figure 35

CAUTION: The grill surfaces will become

hot. (See the “Safety” section on page 5.)

Step 4

While the grill is heating, the display on the cooking

Figure 33

Step 2

Install the staging lane dividers.

Figure 34

side will be red and will show

until the cooking section reaches the proper cooking

temperature.

Note: Refer to page 24 for examples of other menu

items.

Step 5

The displaywill turn green and read

(depending on the platen setting) when the

cooking side reaches the correct temperature.

Step 6

While the grill is heating, the display on the staging

side will be red and show

section reaches the proper cooking temperature.

Step 7

The staging side displays will turn green and read

or

or

until the staging

Step 3

Touch the COOK/STAGE button on the main control

switch located on the front of the grill below the

cooking controls.The lights around the button will

illuminate green. Allow the grill to pre-heat for 20

minutes.

when the staging side reaches the correct

temperature.

Step 8

Make sure the grease bucket is directly under the

grease chutes.

30

C801/C801R/F802/P802/C803/C803R/C804Operating Procedures

Page 35

Step 9

Set up the grill area as directed by Wendy's

Operating Procedures.

Operating Procedures

Cooking Patties

Figure 36

Step 1

Following Wendy's Operating Procedures,quickly

lay the patties on the section of the grill selected for

the meat size being cooked. The display indicates

either

Step 2

Lay the patties between the holes on the cook

divider, 1/2 inch in from the sides of the dividers.

HOT! (See the “Safety” section on page 5.)

Step 3

Immediately closethe lid to start the cook cycle.

The display will change to orange

, and a bar graph will indicate the cook cycle

progress.

or .

CAUTION: The top platen is extremely

or

Note: If the platen doesn't automatically raise,the

platen can be lifted manually with a sharp upward

tug.

Step 5

An orange display flashes

cycle finishesand the platen is raising.

Step 6

Follow Wendy's procedures to transfer the cooked

patties to the staging lanes.

Step 7

Confirm the patty transfer by touching the

appropriate buttons(

stage lane display.

Note: The red buttons are reserved for the cook

and the white buttons are reserved for those

handling ready-to-serve food.

Step 8

Use the squeegee scraper after each run of product

to remove excess juice from the grill platens and the

cooking surface.

when the cook

or )onthe

Step 4

At the end of the cook cycle, an alarm will sound

once and the platen will automatically raise.

C801/C801R/F802/P802/C803/C803R/C804 Operating Procedures

IMPORTANT: DO NOT use the metal side of the

scraper on the platen or the release sheet.

Damage will occur!

31

Page 36

Cleaning Between Product Runs

Standby

After each run of product, the grill should be cleaned

to ensure proper cooking.

Step 1

Using a grill scraper, scrape the residue from the

lower cooksurface.

Figure 37

When not in consistent use, the grill platens should

be closed to reduce heat in the grill area and to

conserve energy.

Figure 38

Step 1

Touch and hold the red

corresponding to the desired platen while closing the

button

Step 2

Use a rubber wiper squeegee to clean the release

material on the upper cook surface. Hold the handle

at a slight upward angle with the wiper end facing

downward. Wipe the material using a downward

motion. DO NOT use extreme pressure or force.

Improper procedures will tear or crease the release

material.

Note: DO NOT use a scraper, sharp utensils, or

abrasives to clean the upper cook surface.

Step 3

When necessary, use a grill cloth to clean the back

splash shield and the strike plate areas. When

necessary, use the spatula to clean the front grease

trough. Periodically check thegrease bucket for

excess grease and empty it as needed.

Temporary Staging

platen. The display will indicate

to orange.

Step 2

Release the button after closing the platen. The

display will change to green.

Step 3

Open the platen to begin a cook cycle by touching

and holding the corresponding red button. The

platen will automatically raise.

, and change

Follow Wendy's Operating Procedures to manage

the staging process.

32

Figure 39

C801/C801R/F802/P802/C803/C803R/C804Operating Procedures

Page 37

Cook Cycle Interrupted

Cook to Order Mode

Step 1

If the cook cycle is interrupted, the product that was

cooking must be discarded. The platen display will

turn red and an alarm will sound.

Step 2

The displayreads

close.

Step 3

To deactivate the alarm, touch and hold the red

button for approximately one second, until the

display clears.

and the platen will not

Step 1

During operating hours, water clean the cook side

grill surface as needed, using standard Wendy's

procedures.

Step 2

A “Cook to Order” mode is provided for times when

it is desirable to shut down the staging side. Follow

Wendy's operating procedures when using this

function.

Figure 40

Step 4

Remove the meat from the grill and discard.

CAUTION: DO NOT use this meat for chili

meat as it cannot be assured that it has been

properly cooked.

Figure 41

Step 3

The grill may be placed in the “Cook to Order“ mode

by touching and holding the “COOK ONLY“ button.

Amber lights will illuminate around the button.

Step 4

Before the “Cook to Order” mode can be entered, all

timing functions must be cleared on the staging side,

and the staging side must be emptied.

C801/C801R/F802/P802/C803/C803R/C804 Operating Procedures

33

Page 38

Nightly Cleaning Procedures

CAUTION! Before proceeding with the nightly

cleaning procedures, follow the safety

.

precautions stated in the Safety Section,

starting on page 5. Failure to follow those

instructions may result in severe personal

injury or death.

IMPORTANT: To prevent damage to the grill,

please note the warnings below.

DO NOT apply water or cleaner/degreaser to any

part of the grill other than the cook surfaces.

Improper procedures will cause permanent electrical

and mechanical damage to internal parts.

DO NOT attempt to clean the release material

sheets by using a hot hose or by soaking them in

liquid. Failure to follow these instructions may result

in damage to the release material sheets.

DO NOT fold, crease or touch the release material

sheets with sharp objects. Failure to follow this

instruction mayresult in torn or creased release

material sheets.

DO NOT allow the grill scraper or any abrasive

cleaning materials to come in contact with the

release material sheets. Failure to follow these

instructions may result in damage to the release

material sheets.

DO NOT use grill screens on the upper cook

surface, the lower cook surface, or the staging grill

plate. Failure to follow this instruction may result in

damage to the grill surfaces.

Step 1

Insure all timing functions have been cleared.

Step 2

Raise the grill platens by touching the platen button.

Figure 42

Step 3

Turn off the grill cooking and staging sections by

touching and holding the “IDLE“ button on the main

control switch.The lights around the button will

illuminate blue.

CAUTION: The grill surfaces are hot.

(See the “Safety” section on page 5.)

Step 4

Put on safety equipment (gloves) and follow

Wendy's Nightly Cleaning Procedures.

34

C801/C801R/F802/P802/C803/C803R/C804Operating Procedures

Page 39

Step 5

Remove the following items to be washed, rinsed

and sanitized at the dish sink:

S Grill cookdividers

S Grill staging lane divider

S Rear splash guard

S Meat loading shelf

Step 6

Water clean the grill surface per Wendy's standard

procedures. Use a Scotch Brick instead of a grill

screen.

Step 7

Leave the platens in the raised position overnight.

Step 9

Apply a light coat of shortening to the entire lower

cook surface.

Step 8

Since the platens are very hot, cleaning the

platens and the release sheets will be completed the

next morning as a part of the Morning Procedures.

Figure 43

Step 10

Empty the grease bucket into the appropriate

container.

ALWAYS FOLLOW LOCAL HEALTH CODES.

C801/C801R/F802/P802/C803/C803R/C804 Operating Procedures

35

Page 40

Section 7 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

1. Grill will not heat. a. Circuit breaker is tripped. a. Reset the circuit breaker.

2. One heat zone will not heat.

(A fault message will be

displayed.)

4. One heat zone is overheating.

(The cook display will be blank

and illuminated in red.)

5. The upper cook surface will not

stay in the raised position.

b. Master Power Switch (reset) is in

the OFF position.

c. Master Power Switch is faulty. c. Contact a service technician.

d. A cook mode button has not been

pressed. The grill is still in the

IDLE mode.

a. Heater is faulty. a. Contact a service technician.

b. The thermocouple is faulty. b. Contact a service technician.

c. Thermo overload is faulty. c. Contact a service technician.

a. Thermocouple is faulty. a. Contact a service technician.

a. Defective springs. a. Contact a service technician.

b. Place the Master Power Switch in

the ON position.

d. Press the appropriate cook mode

button (COOK ONLY or COOK &

STAGE).

6. Product is under-cooked,

overcooked, or cooking unevenly.

a. Release material sheet is worn. a. Replace the release material

sheet.

b. The adjustable platen handle is in

the wrong position.

c. Heat zone is not heating. c. Contact a service technician.

d. Upper cook surface has carbon

build-up.

e. An incorrect item was placed on

the lower cook surface (example:

4 oz. patty placed in 2 oz. cook

position).

b. Place the adjustable platen handle

in the correct position

(2 oz. or 4 oz.).

d. Closing procedures must be

followed to remove carbon

build-up.

e. Place the item on the proper lower

cook surface.

36

C801/C801R/F802/P802/C803/C803R/C804Troubleshooting Guide

Page 41

The following information is from the Wendy's Troubleshooting Guide (part no. 064274). The “Checklist Before

Calling the Taylor Company Call Center” indicates the symptoms and appropriate action to take. The “After Hours

Service Call Protocol” lists the questions to expect when calling 877-222-7010 after 10:00 pm Central Time and

on weekends.

Checklist Before Calling the Taylor Company Call Center

SYMPTOM CHECK ACTION TO TAKE

Raw, Undercooked or

Overcooked, Burned

Patties

a. Interference between platen or other object

(back splash, lane divider, release clips).

b. Space between platen and grill surface to

appear equal all the way around platen.

a. Install parts correctly to remove

obstructions.

b. If gap is visibly unequal, Call for Service.

Cook Cycle Won't Start

(timing bar does not

display)

c. Proper size patty (2 oz./4 oz.) placed under

correct platen.

d. Patties spaced and positioned correctly to

insure full coverage by platen front, back

and sides.

e. Meat temperature before laying patties

34°-40°F(1.1°C-4.4°C) as stored.

f. Any residue or carbon build-up on grill

surface.

g. Release sheet condition. g. Replace if worn or has pinholes.

h. Any residue or carbon build up on platen

surface behind sheet.

i. Cook a full test run under adjustable and

corresponding fixed platen.

j. From full test run take internal meat

temperatures following operations manual

procedures (insure thermometer is

accurate).

Is display green with meat size displayed?

a. If yes, does display change to timing bar

when platen is closed?

c. Insure consistent use of the proper size

patties.

d. Insure consistent, correct orientation and

placement of patties.

e. Only use meat stored within the proper

pre-cook temperature range.

f. Water scrape more frequently.

h. Insure daily cleaning procedures are

thoroughly and consistently followed.

i. Compare same size patty from each platen.

If significantly different visually, Call for

Service.

j. If temperatures 185°F - 200°F(85°C-

93°C), no grill adjustment tobe made.

Escalate to supervisor. If temperature is

below 175°F(79°C), Call for Service.

a. Normal operation, no action required.

b. If no, or timing bar does not display. b. Press & Hold buttonfive seconds. If normal

green display appears, close platen to start

cook cycle. If not, insure grill has preheated

for 30 minutes. Call for Service.

Platen Closed and Will

Not Open

C801/C801R/F802/P802/C803/C803R/C804 Troubleshooting Guide

a. Is there a timer being displayed? a. Let timing finish before proceeding.

b. Press & Hold button five seconds. b. If platen won't open, and Up Arrow is

displayed, large font text or small font text,

note which and Call for Service.

37

Page 42

SYMPTOM ACTION TO TAKECHECK

Controls Don't Work

Code Displayed a. Error code displayed as 2 lines of letters

All cook displays show green with meat size?

a. If no. a. Press & Hold button five seconds.

b. If yes AND stage displays show empty or

“--”.

c. If “a” or “b” are still no. c. Press & Hold active stage button five

d. If controls will not function as normal. d. Do Hard Reset by pulling out white master

and numbers.

b. Do Hard Reset by pulling out white master

switch for a full 60seconds. Push White

switch in and restart grill.

seconds toclear the lane.

switch for a full 60seconds. Push White

switch in and restart grill.

a. Accurately note the display location and the

error code by line. Call for Service.

Platen Opens Before

Cook Cycle Ends

a. Was gap selector handlemoved or not

completely seated on Adjustable Platen

during Cook Cycle?

b. Was grill preheated for 30 minutes prior to

start of cook cycle?

c. Above does not resolve issue. c. Call for Service.

a. Cook cycle will not complete if gap selector

is moved.

b. Allow grill temperature to stabilize prior to

starting a cook cycle.

38

C801/C801R/F802/P802/C803/C803R/C804Troubleshooting Guide

Page 43

After Hours Service Call Protocol

Note: The “Checklist Before Calling the Taylor Company Call Center” form must be completed before

starting the “After Hours Service Call Protocol” side of the form.

1. Name 5. Serial Number

2. Company 6. Phone Number

3. Grill or Frosty Machine Issue 7. City, State

4. Wendy's Corp. Assigned Site Number 8. Are you a Taylor Technician?

1. Is this a meat cooking issue?

a. If yes, go to question #2 for 2 oz. meat or question #3 for 4 oz. meat.

b. If no, is it regarding grill operations/controls?

1. If yes: go to question 4.

2. If no: a follow up service call will be made the next business day.

2. 2 oz. Meat Cooking Issue

a. Do you have one platen that will cook 2 oz. meat?

1. If yes: a service call will be dispatched the next business day.

2. If no: an emergency callwill be dispatched.

3. 4 oz. Meat Cooking Issue

a. Do you have one platen that will cook 4 oz. meat?

1. If yes: a service call will be dispatched the next business day.

2. If no: an emergency callwill be dispatched.

4. Grill Operations / Controls

a. Does the grill respond to controls … change modes, turn off, turn on?

b. If no:

1. Go to the back of the grill and pull white switch outward and see how many of the two red lights are

lit. If one or none light up, go to main breaker panel and turn both grill breakers off and then back on.

Check grill and make sure both lights are lit. If both are lit, go to next step. If not, call your local

maintenance person or electrician to find out root cause of power loss at grill.

2. Do a hard reset by leaving the white switch pulled out and both red lights lit for one full minute (60

seconds). Push the white switch back inward. The two red lights should go out. Restart the grill.

c. Is grill working properly now?

1. If yes: the store will be called the next business day to resolve any further points.

2. If no: an emergency callwill be dispatched.

5. Calls that will receive a follow up the next business day.

a. Meat quality issues with meattemperatures above 175°F(79°C).

b. Issues effecting a single platen. (Cook cycle interrupt, platen comes up too fast, platen won't open, etc.)

c. Requests for grill parts. (Release sheets are ordered with food order and smallwares are ordered from

Kitchen Equipment Supplier - KES.)

C801/C801R/F802/P802/C803/C803R/C804 Troubleshooting Guide

39

Page 44

Section 8 Warranty Explanation

Parts

Class 103 Parts

The warranty for new equipment is one year, with a

replacement parts warranty of three months.

Class 000 Parts

Wear items -- no warranty.

Class 212 Parts

The warranty for new equipment parts is two years,

with a replacement parts warranty of 12 months. This

includes the heater/timer boards, lift solenoids, lower

plate heater, and the upper platen assemblies

(aluminum casting and shroud).

Labor

The Taylor warranty is valid only if the required service

work is performed by an authorized Taylor technician.

For more details, see the warranty/checkout card.

Contact your local Taylor Distributor regarding

Extended Service Contract options.

40

C801/C801R/F802/P802/C803/C803R/C804Warranty Explanation

Page 45

Section 9 Parts List

REMARKS

WARR.

CLASS

QTY.

C804

QTY.

C803R

QTY.

C803

P802

C802

F802

QTY.

C801R

QTY.

C801

QTY.

QTY.

USE WITH 072711HANDLE

2-3/16 DIA X 06310/5/07

USE WITH X73187ARM - REF

S/B 0162SG

USE WITH 071324HANDLE

USE WITH 071324HANDLE

USE WITH X70670ARM ASSY-

SEE S/B 0162SG

USE WITH X70670ARM ASSY-

SEE S/B 0162SG

NUMBER

DESCRIPTION PART

ARM-PLATEN *C801* 072712 1 1 1 1 1 2 103

BEARING-CAM *C801* 070623 2 2 4 2 2 2 103

HINGE-PLATE-PLATEN *C801* 070644 4 4 8 4 4 4 103

PIN-ROLL .250D X 2.500 LONG ZP 070648 4 4 8 4 4 8 103

PIN-STOP-CAM *C801* 070656 1 1 2 1 1 2 103

PLATE-OVER CENTER *C801* 071476 1 1 2 1 1 2 103

PULLEY-PLATEN CABLE 072662 4 4 8 4 4 8 103 REPLACES 070641 PULLEY

SHAFT-CAM-PLATEN *C801* 070640 1 1 2 1 1 2 103

ARM A.-PLATEN ADJUSTABLE X73187-SER 1 1 2 1 1 2 103 S/N K8124744 & UP - MUST

C801/C801R/F802/P802/C803/C803R/C804

SPRING-EXTENSION.500X.063X3.00 070657 1 1 2 1 1 2 103

SWITCH A.-POSITION *C801* X70701-SER 2 2 2 2 2 4 103

+SCREW-1/4-20X2 SERRATED H 070675 4 4 8 4 4 8 000

+HANDLE-LIFT-PLATEN *C801* 072711 1 1 2 1 1 2 103 S/N K8124744& UP - MUST

ARM-PLATEN *C801* NON-ADJ. 072712-1 2 2 2 2 103 S/N K8124744 & UP

41

ARM-PLATEN *C801* 070671 * * * * * 103 S/N K8124743 & PRIOR - MUST

+HANDLE-LIFT-PLATEN *C801* 071324 * * * * * 103 S/N K8124743 & PRIOR-MUST

ARM A.-PLATEN *C801*ADJUSTABE X70670-SER * * * * * 103 S/N K8124743 & PRIOR - MUST

ARM-PLATEN *C801* NON-ADJ 070671-1 * * * 103 S/N K8124743 & PRIOR-MUST

BEARING-ARM 071935 6 6 4 6 6 4 103

+SCREW-3/8-16X3/4 SERRATED HWH 017328 12 12 8 12 12 8 103

+SEAL-BEARING-ARM *C801* 070658 6 6 4 6 6 4 000

+NUT-5/8-11HEXGRADE 5 047922 * * * * 000

+SCREW-5/8-11 X2 070739 * * * * 000

+WASHER-5/8 LOCK SS 070740 * * * * 000

BEARING-PILLOW BLOCK 2" SHAFT 070728 * * * * 000 K6047081 & PRIOR

Parts List

Page 46

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

LIMIT X71752-SER

3PH

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

BLOCK-POWER DIST 3POLE 6-WIR 070719 1 103

BLOCK-POWER DIST 3 POLE 8-WI 070718 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

CONTACTOR-60A 3PH 208/240VA 070741 2 103

FILTER-CORCOM 2VR1 032567 2 103

SUPPLY-POWER-24VAC IN-DUAL OUT 070519-SER 2 103

TRANS.-100VA 120/208/240 PRI 079800 2 103

BLOCK-POWER DIST 3 POLE 8-WIRE 070718 1 103

BLOCK-POWER DIST 3POLE 6-WIRE 070719 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

CONTACTOR-60A 3PH 208/240VAC 070741 2 103

FILTER-CORCOM 2VR1 032567 2 103

BLOCK-TERMINAL 6 POLE 071320 3 3 2 3 3 2 103

BLOCK-TERMINAL 7P GREEN 024156 1 1 1 1 1 1 103

BUSHING-SNAP 15/16 ID X 1-3/32 023396 6 6 6 6 6 6 9 103

BUSHING-SNAP 1-3/8ID X 1-3/4OD 027712 6 6 9 6 6 6 12 000

BUSHING-SNAP 1-31/32ID - 2-1/2 039152 2 2 1 1 2 2 1 000

BUSHING-SNAP 1-5/8ID X 2 OD 043637 4 4 2 3 4 5 2 000

BUSHING-NONPOROUS 3/8IDX5/8OD 071193 12 12 8 12 12 8 103

BRACKET-RELEASE SHEET *C801* 070707 8 8 6 8 8 6 103

BRACKET-SEASONING HOLDER *C801 070667 1 1 1 1 1 103

CABLE-ADJUST-PLATEN *C801* 070622 4 4 8 4 4 8 103

CABLE A.-COMMUNICATION 072536 1 103

CLIP-RELEASE SHEET *C801* 070709 8 8 6 8 8 6 000

COVER-BACKSPLASH *P802* 072515 1 103

COVER-PLATEN *C801* 070935 3 3 2 3 3 2 103

CONTROL-C801CURRENTMONITOR 070518-SER 2 2 2 2 2 2 2 103

CONTROL-C801MAIN TIMER/HEATER 070514-SER 2 2 2 2 2 2 2 212

CONTROL-HI-LIMIT 450F NO RES * * * * * * * SEE- KIT A.-CONTROL-HI

CONTROL-RESET-SWITCH-10A/250 070717 1 1 1 1 1 1 1 103 208V 60HZ 3PH & 240V 60HZ

CONTROL A.-CONTACTOR *C801* X70743-23 1 103

Parts List C801/C801R/F802/P802/C803/C803R/C804

42

CONTROL A.-CONTACTOR *C801R* X72206-23 1 103

SUPPLY-POWER-24VAC IN-DUAL OUT 070519-SER 2 103

Page 47

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

TRANS.-100VA 120/208/240 PRI 079800 2 103

BLOCK-POWER DIST 3 POLE 8-WIRE 070718 1 103

BLOCK-POWER DIST 3POLE 6-WIRE 070719 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

CONTACTOR-60A 3PH 208/240VAC 070741 2 103

CONTROL-RESET-SWITCH-10A/250 070717 1 103

HARNESS-RESET SWITCH "A"*C803 072075 1 103

HARNESS-RESET SWITCH "B"*C803 072076 1 103

JUMPER A.-CONTACTOR COIL*C803 071738 2 103

LIGHT-RED-230V 070880-27 2 103

CONTROL A.-CONTRACTOR *C803* X72046-23 1 103

CONTROL A.-CONTRACTOR *C803R* X73210-23 1 103

C801/C801R/F802/P802/C803/C803R/C804

BLOCK-POWER DIST 3 POLE 8-WIRE 070718 1 103

BLOCK-POWER DIST 3POLE 6-WIRE 070719 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

43

CONTACTOR-60A 3PH 208/240VAC 070741 2 103

CONTROL-RESET-SWITCH-10A/250 070717 1 103

HARNESS-RESET SWITCH "A"*C803" 072075 1 103

HARNESS-RESET SWITCH "B"*C803" 072076 1 103

JUMPER A.-CONTACTOR COIL*C801* 071738 2 103

LIGHT-RED-230V 070880-27 2 103

CONTROL A.-CONTRACTOR *F802* X71783-23 1 103

BLOCK-POWER DIST 3 POLE 8-WIRE 070718 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

CONTACTOR-60A 3PH 208/240VAC 070741 1 103

JUMPER A.-CONTACTOR COIL*C80 071738 1 000

CONTROL A.-CONTRACTOR *C804* X73054-23 1 103

BLOCK-POWER DIST 3 POLE 8-WIRE 070718 1 103

BLOCK-TERMINAL 7P GREEN 024156 1 103

CONTACTOR-75A 3PH 208/240VAC 073091 1 103

JUMPER A.-CONTACTOR COIL*C803 071738 1 103

Parts List

CORD A.-POWER-250V-4 WIRE 072330 1 1 103

DAMPER-OIL FILLED-4.5 STROKE 071153 3 3 2 3 3 2 103 K5012546 & UP

DIAGRAM-WIRING *C801* 071488-23 1 000 208V 60HZ 3PH

Page 48

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

USE WITH X73187ARM

USE WITH X70670ARM ASSY-

SEE S/B 0162SG

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

DIAGRAM-WIRING *C801R* 072260-23 1 000 208V 60HZ 3PH

DIAGRAM-WIRING *C803* 072159-23 1 1 000 208V 60HZ 3PH

DIAGRAM-WIRING *F802* STD 072333-23 1 000 208V 60HZ 3PH

DIAGRAM-WIRING *P802* V1-1-1 071860-23 1 000 208V 60HZ 3PH

DIAGRAM-WIRING *C804* 073137-23 1 000 208V 60HZ 3PH

DIVIDER A.-*C801* 2 LANE 070847 1 1 1 1 1 1 2 103

DIVIDER A.-*C801* COOK 070851 1 1 1 1 1 1 103

DIVIDER A.-3 LANE *C801* STAGE 070848 1 1 1 1 103

FUSE-2A 32VDC MINI-BLADE 071664 6 6 6 3 6 6 6 000

FUSE-3A 32VDC MINI-BLADE 071665 2 2 2 1 2 2 2 000

GASKET-CONTROL *C801* 070747 2 2 000

GASKET-CONTROL *C801* 070748 2 2 000

GASKET-PLATEN COVER *C801* UPP 070943 3 3 2 3 3 2 000

GUIDE-TROUBLESHOOT-WENDY'S 064274 1 1 1 1 000

HANDLE-ADJUST-PLATEN*C801* 070647 1 1 2 1 1 2 103

HANDLE-LIFT-PLATEN *C801* 072711 3 3 2 3 3 2 103 S/N K8124744 & UP - MUST

HANDLE-LIFT-PLATEN *C801* 071324 * * * * 103 S/N K8124743 & PRIOR-MUST

Parts List C801/C801R/F802/P802/C803/C803R/C804

44

HARNESS-12VDC *C801* 070867 1 1 103

HARNESS-12VDC *C803* 072081 1 1 103

HARNESS-12VDC *F802 071842 1 1 103

HARNESS-12 VDC *P802* 071863 1 103

HARNESS A.-PLATEN-CLU *C801* 071631 1 1 1 1 103

HARNESS A.-PLATEN-CRU *C801* 071632 1 1 1 103

HARNESS A.-PLATEN-CMU *C801* 071633 1 103

HARNESS A.-PLATEN-CMU *C801R 072250 1 103

HARNESS A.-PLATEN CRU *C803* 072201 1 1 103

HARNESS A.-PLATEN CMU *C803* 072202 1 1 1 103

HARNESS-CAN BUS *C801* 071364 1 1 103

HARNESS-CAN BUS *C801R* 072251 1 1 103

HARNESS-CAN BUS *F802* 072683 1 103

HARNESS-CAN BUS *P802* 072688 1 103

HARNESS-CAN BUS *C804* 073134 1 103

Page 49

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

HARNESS-CURRENT SENSE-MC1 070795 1 1 1 1 103

HARNESS-CURRENT SENSE-MCO 070844 1 1 1 103

HARNESS-CURRENT SENSE-MCI 072077 1 1 103

HARNESS-CURRENT SENSE-MC1 071849 1 1 103

HARNESS-CURRENT SENSE-MC0 071850 1 1 103

HARNESS-FEED B-L1/L2 MAIN IN 071494 1 1 103

HARNESS-FEED A-L1 MAIN IN 071495 1 1 103

HARNESS-FEED A-L2/L3 MAIN IN 071496 1 1 103

HARNESS-FEED B-L3 MAIN IN 071497 1 1 103

HARNESS-FEED L1 MAIN IN 071864 1 103

HARNESS-FEED B-L2/L3 MAIN IN 071865 1 103

HARNESS-FEED A-L2/L3 MAIN IN 072079 1 1 103

C801/C801R/F802/P802/C803/C803R/C804

HARNESS-FEED B-L3 MAIN IN 072080 1 1 103

HARNESS-FEED A-L1 MAIN IN 072082 1 1 103

HARNESS-FEED B-L1/L2 MAIN IN 072083 1 1 103

45

HARNESS-FILTER *C801* 070858 2 2 2 1 2 2 2 103

HARNESS-HIGH LIMIT *C801*CLL 071614 1 1 1 1 103

HARNESS-HIGH LIMIT *C801*CML 071613 1 1 1 103

HARNESS-HIGH LIMIT *C801*CRL 071612 1 1 1 103

HARNESS-HIGH LIMIT *C803*CLL 072199 1 1 103

HARNESS-HIGH LIMIT *C803*CLU 072200 1 1 103

HARNESS-HIGH LIMIT *C803*CML 072198 1 1 103

HARNESS-HIGH LIMIT *C803*CRL 072197 1 1 103

HARNESS-HIGH LIMIT *P802* 071868 1 103

HARNESS-HIGH LIMIT *P802*L 071869 1 103

HARNESS-MODE 1/0-LG *C801* 070803 1 1 1 1 1 1 103

HARNESS-MODE I/0-SHT *C801* 070865 1 1 1 1 1 1 103

HARNESS-MODE I/0-LG 073177 1 103

HARNESS-MODE I/0-SHT 073178 1 103

HARNESS-NODE *C801* 071363 4 4 3 3 1 103

HARNESS-NODE *F802* 072682 1 103

Parts List

HARNESS-NODE-RIGHT *P802* 072685 1 103

HARNESS-NODE-LEFT *P802* 072686 1 103

HARNESS-NODE *C804* 073154 3 103

Page 50

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

HARNESS-RELAY LOW VOLTAGE 071866 1 103

HARNESS-RELAY LOW VOLTAGE MCO 072078 1 103

HARNESS-RELAY-LOW VOLTAGE -MC1 072376 1 103

HARNESS-RELAY-LOW VOLTAGE -MCI 072377 1 103

HARNESS-RELAY-LOW VOLTAGE-MC 073136 1 103

HARNESS-RELAY-LOW VOLTAGE-MC 073135 1 103

HARNESS-RELAY-LOW VOLTAGE-MC1 071492 1 1 103

HARNESS-RELAY-LOW VOLTAGE-MC1 072320 1 103

HARNESS-RELAY-LOW VOLTAGE-MCO 071493 1 103

HARNESS-RELAY-LOW VOLTAGE-MCO 072321 1 103

HARNESS-RELAY-LOW VOLTAGE-MC1 073243 1 103

HARNESS-RELAY-LOW VOLTAGE-MC0 073244 1 103

HARNESS-RESET SWITCH "A"*C801* 071736 1 1 103

HARNESS-RESET SWITCH "B"*C801* 071737 1 1 103

HARNESS-RESET SWITCH *F802* 071853 1 1 1 103

HARNESS-RESET SWITCH "A"*C803* 072075 1 1 103

HARNESS-RESET SWITCH "B"*C803* 072076 1 1 103

HARNESS-SOLENOID MAIN IN 072361 1 1 103

HARNESS-SOLENOID *F802* 071852 1 1 103

HARNESS-SOLENOID *C801* 071627 1 1 1 1 103

HARNESS-SPEAKER *C801* 2 PLUG 072177 1 1 103

HARNESS-SPEAKER *C803*2 PLUG 072203 1 1 1 1 103

HARNESS-SPEAKER*P802*2 PLUG 072362 1 103

HARNESS-STAGE-HIGH LIMIT*C801* 071630 1 1 1 103

HARNESS-STAGE-HIGH LIMIT*C801R 072319 1 103

HARNESS-STAGE-HIGH LIMIT*F802* 071851 1 1 103

HARNESS-STAGE HIGH LIMIT*P802* 071867 1 103

HARNESS-STAGE R-HIGH LIM*C804* 073139 1 103

HARNESS-T.C. JUMPER *C801* 071362 1 1 1 1 103

HARNESS-T.C. JUMPER *F802 MCO 071840 1 103

HARNESS-T.C.JUMPER *F802* MC 072383 1 1 103

HARNESS-T.C.JUMPER *F802* MC 072384 1 1 103

HARNESS-TRANSFORMER-L1 *F802* 072749 1 1 103

HARNESS-TRANSFORMER-L3 *F802* 072750 1 1 103

Parts List C801/C801R/F802/P802/C803/C803R/C804

46

Page 51

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

GASKET-CONTROL *C801* 070747 2 000

GASKET-CONTROL *C801* 070748 2 000

LENS-CONTROL *C801* 070746 1 103

+WASHER-#8 INTERNAL TOOTH LOC 007543 80 80 52 28 80 80 56 000

+SCREW-8-32X1/4 PHILLIPS 071700 80 80 52 28 80 80 56 000

HEATER-CAST 208V-4350 WATTS 070634-23 3 3 2 2 3 3 2 212 PLATE LOW-COOK SIDE

HEATER-CAST 208V-2400 WATTS 070665-23 2 2 212 PLATE LOW-STAGE SIDE

HEATER-CAST 208V-2400 WATTS 072212-23 1 1 2 2 2 212

KIT A.-CONTROL-HI-LIMIT 450F X71752-SER 20 20 13 7 20 20 14 103 KIT A.-CONTROL-HI-LIMIT

KIT A.-PLATE A.-DEC-REAR*C801* X70630-SER 1 103

GASKET-CONTROL *C801* 070747 2 000

KIT A.-PLATE A.-DEC-REAR*C801R X77235-SER 1 103

C801/C801R/F802/P802/C803/C803R/C804

GASKET-CONTROL *C801* 070748 2 000

LENS-CONTROL *C801* 070746 1 103

KIT A.-NODE-COOK C801W/HARN X72134 1 103

47

CONTROL-GRILLCOOK SIDE 071180-SER 3 103

CONTROL-C801MODE I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 4 103

HARNESS-NODE *C801* 071363 3 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

LENS-NODE *C801* COOK 071458 3 103

LENS-NODE *C801*MODE I/0 071460 1 103

KIT A.-NODE-FRONT C801W/HARN X72135 1 1 103

CONTROL-C801STAGE NODE W/LED 070951-SER 2 2 103

GASKET-NODE *C801* 070908 8 8 103

HARNESS-NODE *C801* 071363 3 3 103

LENS-NODE-FRONT*C801*STAGE 071457 8 8 103

KIT A.-NODE-REAR C801W/HARN X72136 1 1 103

CONTROL-C801STAGE NODE W/LED 070951-SER 2 2 103

GASKET-NODE *C801* 070908 8 8 103

Parts List

HARNESS-NODE *C801* 071363 2 1 103

LENS-NODE-REAR STAGE *C801* 071459 8 8 103

LIFTER A.-ARM *C801* 071663 6 6 4 6 4 103

Page 52

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

212 K5114439

X72134

W/HARN X72135

W/HARN - X72136

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

BEARING-OPEN END NEEDLE-5/8 070805 9 9 6 9 6 103

BEARING-SELF ALIGN-TIE ROD 071262 3 3 2 3 2 103

BLOCK-LINKAGE STOP *C801* 070752 12 12 8 12 4 103

LINKAGE-PIVOT-LOWER *C801* 071266 3 3 2 3 2 103

PULLEY-SHIELDED BEARING 071477 12 12 8 4 8 103

SHAFT-PLATEN LINKAGE *C801* 071154 6 6 4 6 4 103

SOLENOID-PLATEN LIFT *C801* 070654-23 3 3 2 3 2 112 WARRANTY CHANGED FROM

TURNBUCKLE *C801* 071265 3 3 2 3 2 103

LIGHT-RED-230V 070880-27 2 2 1 2 1 103

LINKAGE A.*C801* X71276-SER 3 3 2 3 2 103

Parts List C801/C801R/F802/P802/C803/C803R/C804

MAN-OPER C801 071261-M 1 000

MAN-OPER 801REVERSE/C802 072493-M 1 1 1 1 000

NODE A.-COMPLETE *C801* COOK X71166 1 USE KIT A.-NODE-COOK

NODE A.-COMPLETE-STAGE-FRONT X71198 1 1 USE KIT A.-NODE-FRONT C801

NODE A.-COMPLETE-STAGE-REAR X71201 1 1 USE KIT A.-NODE-REAR C801

48

NODE A.-COMPLETE *F802* X71550-SER 1 103

CONTROL-C801STAGE NODE W/LE 070951-SER 1 103

CONTROL-GRILLCOOK NODE 071180-SER 2 103

CONTROL-C801MODEL I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 7 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

HARNESS-NODE-COMPLETE *F802* 072682 1 103

LENS-NODE-FRONT STAGE *C802* 071461 4 103

NODE A.-COMPLETE *P802* X71593-SER 1 103

CONTROL-C801STAGE NODE W/LED 070951-SER 1 103

CONTROL-GRILLCOOK NODE 071180-SER 3 103

CONTROL-C801MODEL I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 8 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

Page 53

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

HARNESS-NODE-RIGHT *P802* 072685 1 103

HARNESS-NODE-LEFT *P802* 072686 1 103

LENS-NODE-FRONT*C801*STAGE 071457 4 103

LENS-NODE *C801* COOK 071458 3 103

LENS-NODE *C801*MODE I/0 071460 1 103

CONTROL-GRILLCOOK NODE 071180-SER 3 103

CONTROL-C801MODEL I/O 071242 -SER 1 103

GASKET-NODE *C801* 070908 4 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

HARNESS-NODE *C801* 071363 2 103

NODE A.-COMPLETE *C803* COOK X72062 1 103

C801/C801R/F802/P802/C803/C803R/C804

LENS-NODE *C801* COOK 071458 3 103

LENS-NODE *C801*MODE I/0 071460 1 103

NODE A.-COMPLETE *C801R* COOK X72254 1 1 103

49

CONTROL-GRILLCOOK NODE 071180-SER 3 3 103

CONTROL-C801MODEL I/O 071242-SER 1 1 103

GASKET-NODE *C801* 070908 4 4 103

HARNESS-MODE I/0-LG *C801* 070803 1 1 103

HARNESS-MODE I/O-SHRT *C801 070865 1 1 103

HARNESS-NODE *C801* 071363 2 2 103

LENS-NODE *C801* COOK 071458 3 3 103

LENS-NODE *C801*MODE I/0 071460 1 1 103

NODE A.-COMPLETE *C801R*STG F X72243 1 1 103

CONTROL-C801STAGE NODE W/LED 070951-SER 2 2 103

GASKET-NODE *C801* 070908 8 8 103

HARNESS-NODE *C801* 071363 1 1 103

LENS-NODE-FRONT STAGE *C802* 071461 8 8 103

NODE A.-COMPLETE *C803* COOK X72062 1 103

CONTROL-GRILLCOOK NODE 071180-SER 3 103

CONTROL-C801MODEL I/O 071242-SER 1 103

Parts List

GASKET-NODE *C801* 070908 4 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

Page 54

CLASS

CLASS

QTY.

QTY.

C804

C804

QTY.

QTY.

C803R

C803R

QTY.

QTY.

C803

C803

P802

C802C801R

F802

QTY.

QTY.

C801R

QTY.

QTY.

C801

C801

QTY.

QTY.

PART

PART

NUMBER

NUMBER

DESCRIPTION REMARKSWARR.

DESCRIPTION REMARKSWARR.

HARNESS-NODE *C801* 071363 2 103

CONTROL-C801STAGE NODE W/LED 070951-SER 1 103

CONTROL-GRILLCOOK NODE 071180-SER 3 103

CONTROL-C801MODEL I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 8 103

CONTROL-C801STAGE NODE W/LED 070951-SER 1 103

CONTROL-GRILLCOOK NODE 071180-SER 2 103

CONTROL-C801MODEL I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 7 103

HARNESS-MODE I/0-LG *C801* 070803 1 103

HARNESS-MODE I/O-SHRT *C801* 070865 1 103

HARNESS-NODE-COMPLETE *F802* 072682 1 103

LENS-NODE *C801* COOK 071458 2 103

LENS-NODE *C801*MODE I/0 071460 1 103

LENS-NODE-FRONT STAGE *C802* 071461 4 103

CONTROL-C801STAGE NODE W/LED 070951-SER 1 103

CONTROL-GRILLCOOK SIDE 071180-SER 2 103

CONTROL-C801MODE I/O 071242-SER 1 103

GASKET-NODE *C801* 070908 7 103

HARNESS-NODE *C801* 071363 1 103

HARNESS-NODE *C804* 073154 2 103

HARNESS-MODE I/0-LG 073177 1 103

HARNESS-MODE I/0-SHT 073178 1 103

LENS-NODE-FRONT*C801*STAGE 071457 4 103

LENS-NODE *C801* COOK 071458 2 103

LENS-NODE *C801*MODE I/0 071460 1 103

CONTROL-C801STAGE NODE W/LED 070951-SER 1 103

GASKET-NODE *C801* 070908 4 103

HARNESS-NODE *C801* 071363 1 103

LENS-NODE-FRONT STAGE *C802* 071461 4 103

NODE A.-COMPLETE *P802* X71593-SER 1 103

Parts List C801/C801R/F802/P802/C803/C803R/C804