Page 1

These icons alert you to a possible risk of personal injury.

Look for this icon to find information about how to avoid damaging the

equipment while doing a procedure.

Look f

MILKSHAKE AND SOFT-SERVE MACHINES

SS 3

Model C602

Taylor Company milkshake and soft

3

Taylor Company

Milkshake and Soft-serve Machine

Daily maintenance tasks

SS 3 D1 Opening

procedures

SS 3 D2 Closing procedures

Weekly maintenance tasks

SS 3 W1 Clean and sanitize

syrup lines with

duckbill valves

SS 3 W2 Clean hot sundae

topping water baths

SS 3 W3 Clean and sanitize

hot sundae topping

pumps

Bi-weekly maintenance tasks

SS 3 B1 14 day brush

cleaning

Monthly maintenance tasks

SS 3 M1 Calibrate hopper

temperatures

SS 3 M2 Calibrate draw

temperatures

SS 3 M3 Calibrate hot

sundae topping

temperatures and

volumes

Quarterly maintenance tasks

SS 3 Q1 Replace soft-serve

mix scraper blades

SS 3 Q2 Clean non-

aluminum air filter

SS 3 Q3 Replace machine

components

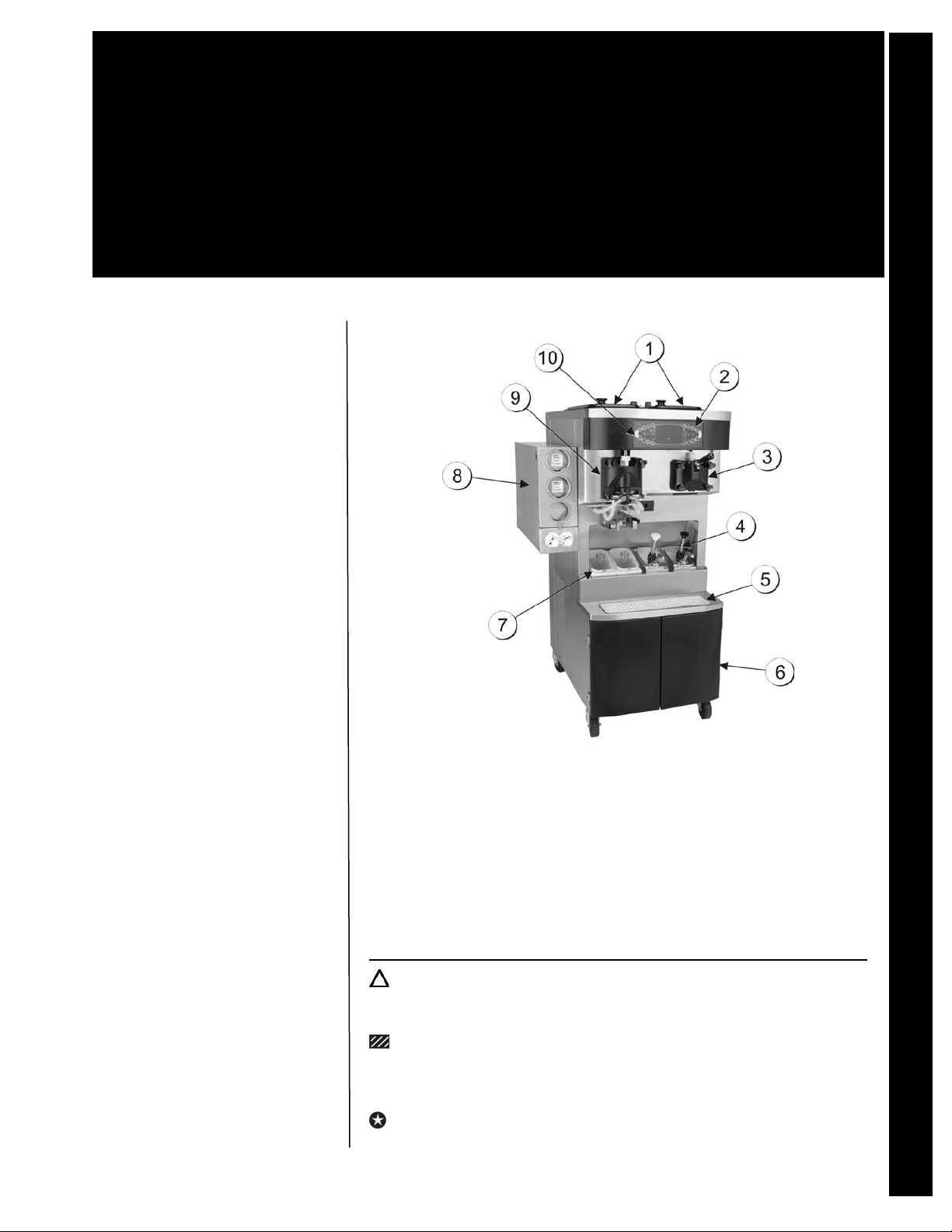

Model C602

1. Hopper Covers 6. Cabinet Doors

2. Keypad-S

3. Soft Serve Door Assembly 8. Cup & Cone Dispenser

4. Topping Pump 9. Shake Door Assembly

5. Drip Tray/Splash Shield 10. Keypad-Shake

oft Serve 7. Cold Topping Containers

-serve machine model C602 SS

Semi-annual maintenance tasks

SS 3 S1 Replace milkshake

mix scraper blades

Annual maintenance tasks

SS 3 A1 Replace syrup

pump tubes

SS 3 A2 Replace non-

aluminum air filter

Hazards

Equipment alerts

Tips

or this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021

Page 2

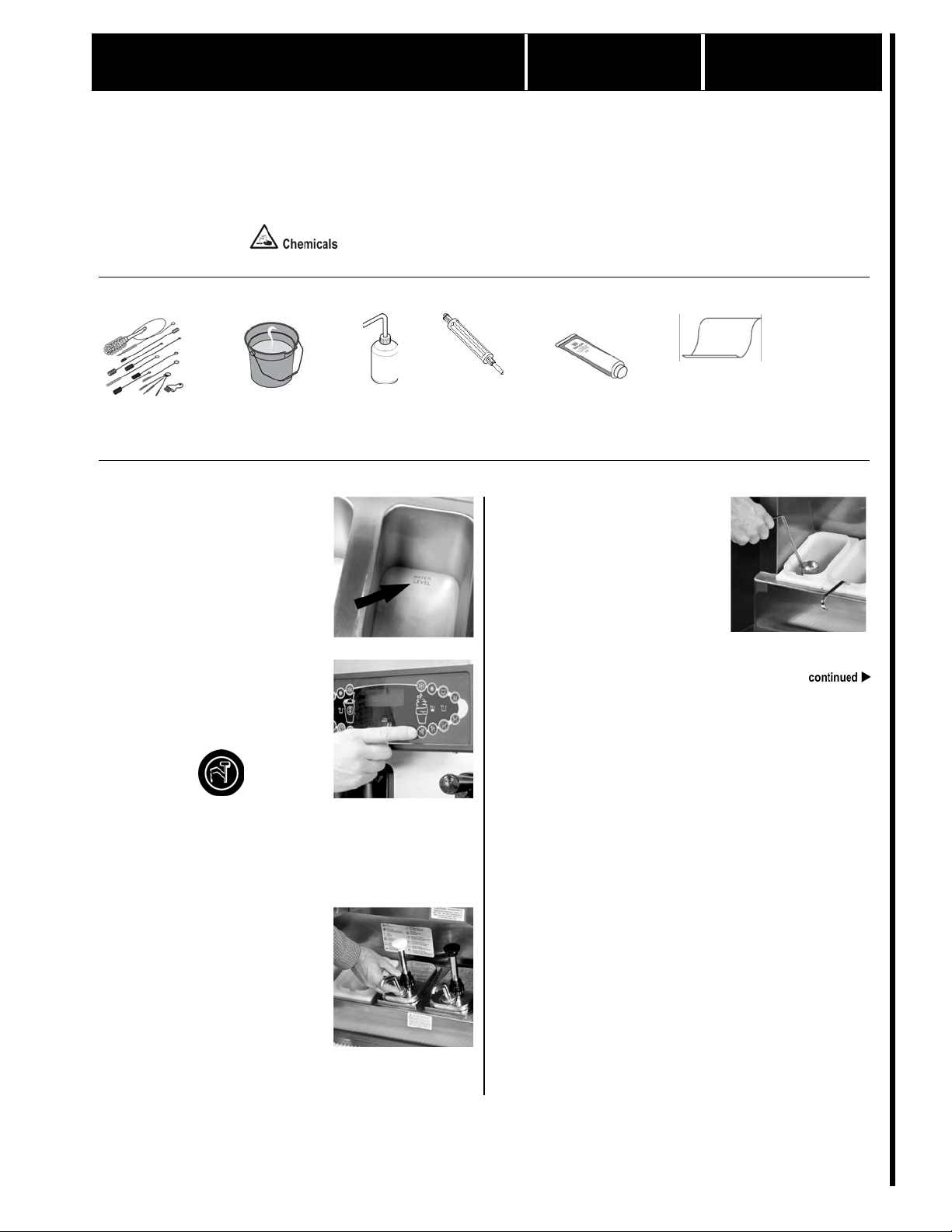

Opening Procedures Daily SS 3 D1

Taylor Company milkshake and soft

Daily

Why

Prepare Milkshake/Soft-Serve machine for serving

Time required

5 minutes to prepare

30 minutes to complete

Time of day

When store opens in the morning

24-hour restaurants: during low-volume periods

Hazard icons

Brushes

Bucket with Kay 5

Kay 5

Taylor Seal

Taylor Lube HP

Clean Sanitized

1

Fill heated topping wells with

2

Place topping heaters in ON

W2 & W3.)

3

Fill topping containers.

4

Sanitize topping ladles.

5

Fill cup dispensers, cup lid

holder and cone dispenser.

product after the heat treatment cycle is completed

Tools and supplies

-serve machine model C602

Sanitizing Solution

Sanitizing

Solution

Install /

Removal Tool

Towels

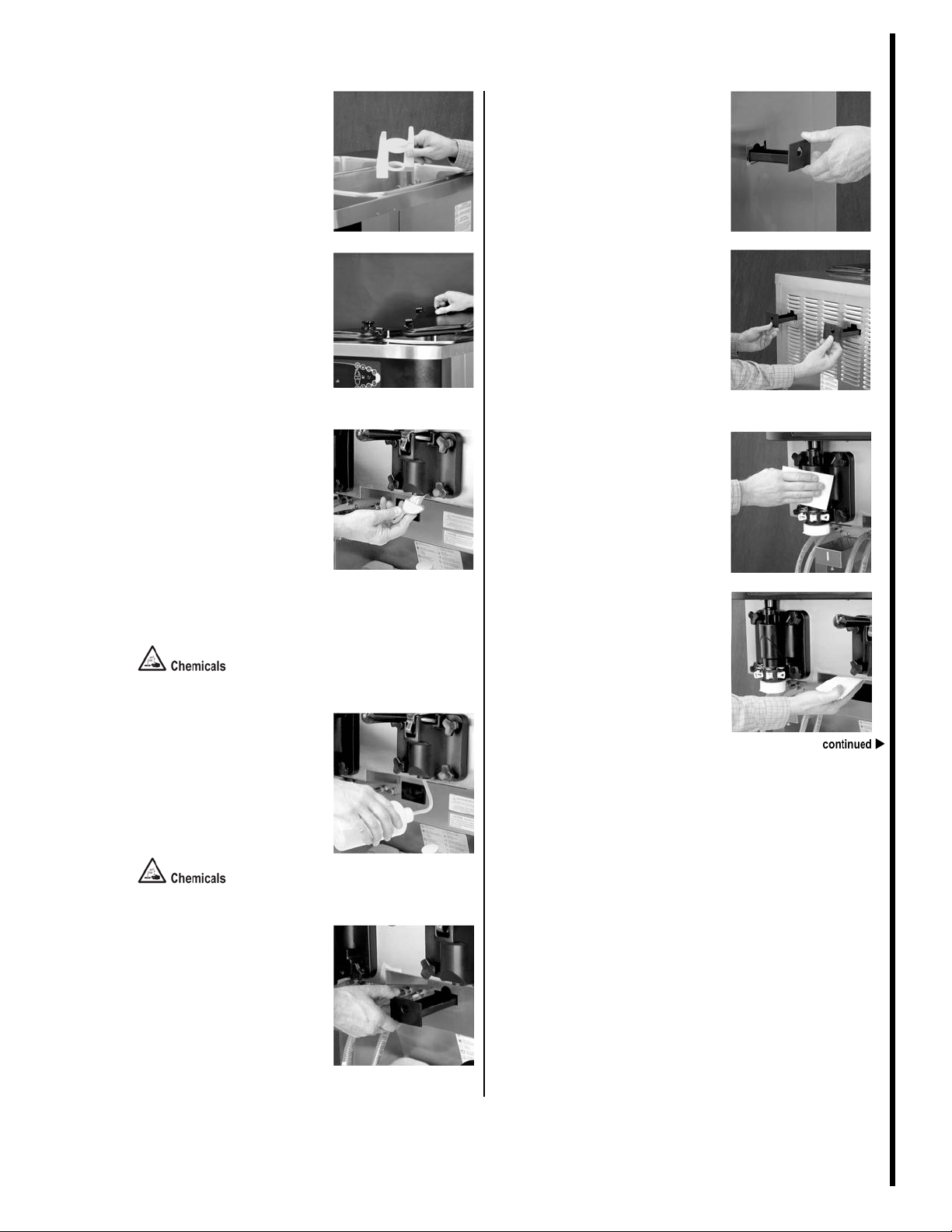

Procedure – Set Up

clean water.

Remove the topping

containers. Fill the heated

Sanitize the topping ladles

and place them in the cold

topping containers.

wells with clean water, up to

the fill line located on the

bottom of the well.

position.

Place the topping heaters in

the ON position by touching

the topping heater symbols.

Note: Clean and sanitize

topping containers, topping

pumps, and heated wells

weekly. (See PM cards SS01

Fill the topping containers.

Place the caramel and fudge

topping containers in the

heated wells and the

remaining two containers in

the unheated wells. Cover the

containers.

SS 3 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 4

Page 3

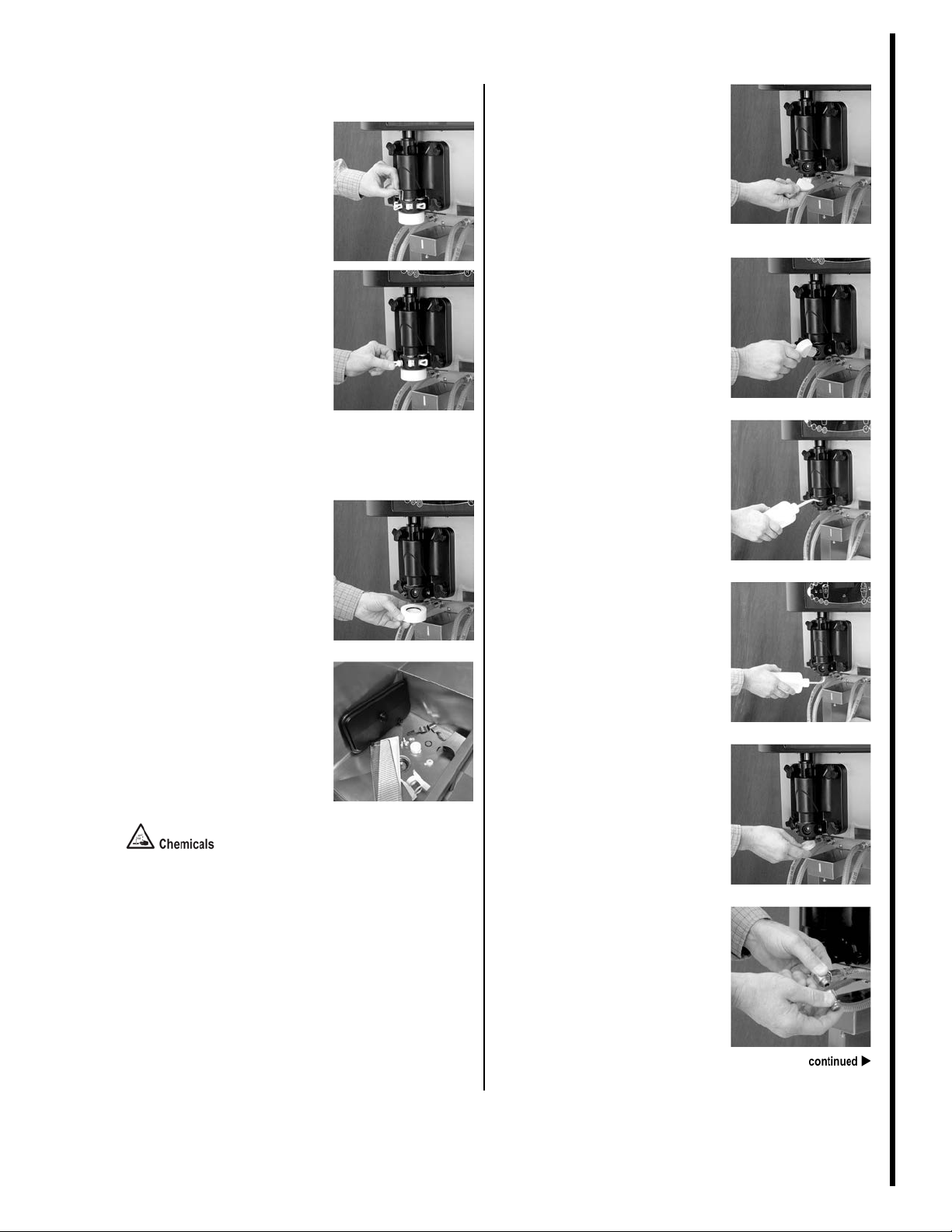

Opening Procedures (continued)

Taylor Company milkshake and soft

Daily

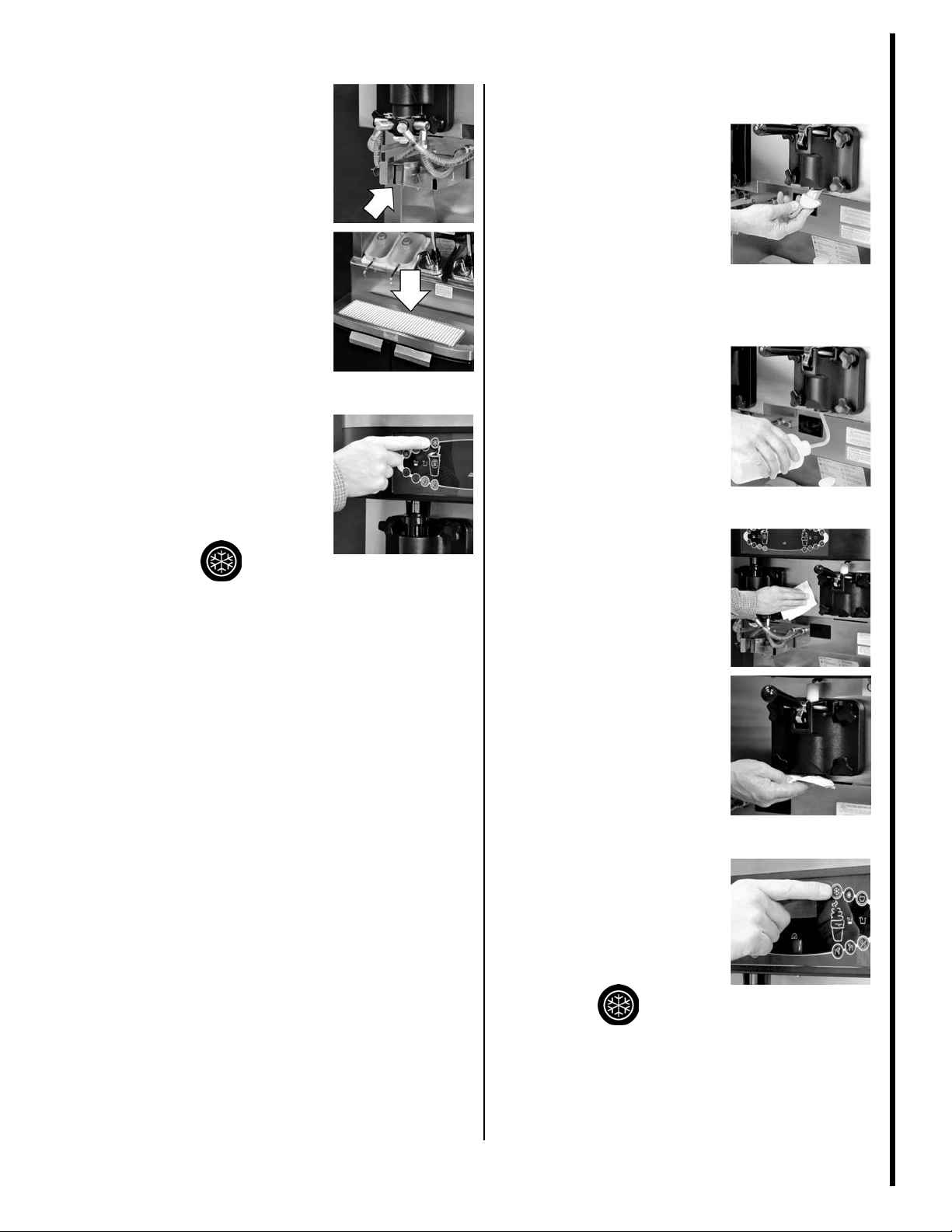

1

Remove syrup valve retainers

2

Remove draw valve cap.

3

Sanitize parts.

4

Sanitize door spout, driven

5

Sanitize syrup port holes.

6

Flush syrup port holes with

7

Flush door spout with

8

Install syrup valve retainers

9

Remove syrup nose fittings.

Procedure – Shake Side

and syrup hole plugs.

Remove the syrup valve

retainers and the syrup hole

plugs.

Remove the o-rings from the

syrup hole plugs.

Remove the draw valve cap

and remove the o-ring.

spinner, spinner blade, and

syrup line fittings.

Brush clean each item for a

total of 60 seconds,

repeatedly dipping the brush

in sanitizing solution.

Place a pail below the door

spout.

Brush each syrup port hole 10

to 15 times. Dip the brush in

sanitizing solution before

brushing ea ch port.

sanitizing solution.

Insert tube end of squeeze

bottle into each syrup port

and squeeze the bottle firmly.

Flush each port for 10

seconds.

-serve machine model C602

Prepare a small amount of

KAY-5 Sanitizer solution.

Sanitize the o-rings, restrictor

cap, syrup hole plugs, syrup

valve retainers, draw valve

cap, shake cup holder, front

drip tray, and splash shield in

this solution.

Sa

nitizer Solution

sanitizing solution.

Flush the bottom of the door

spout door with sanitizing

solution.

and restrictor cap on door

spout.

Remove the syrup nose fitting

from each syrup line by

turning the syrup nose fitting

counter-clockwise.

SS 3 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 4

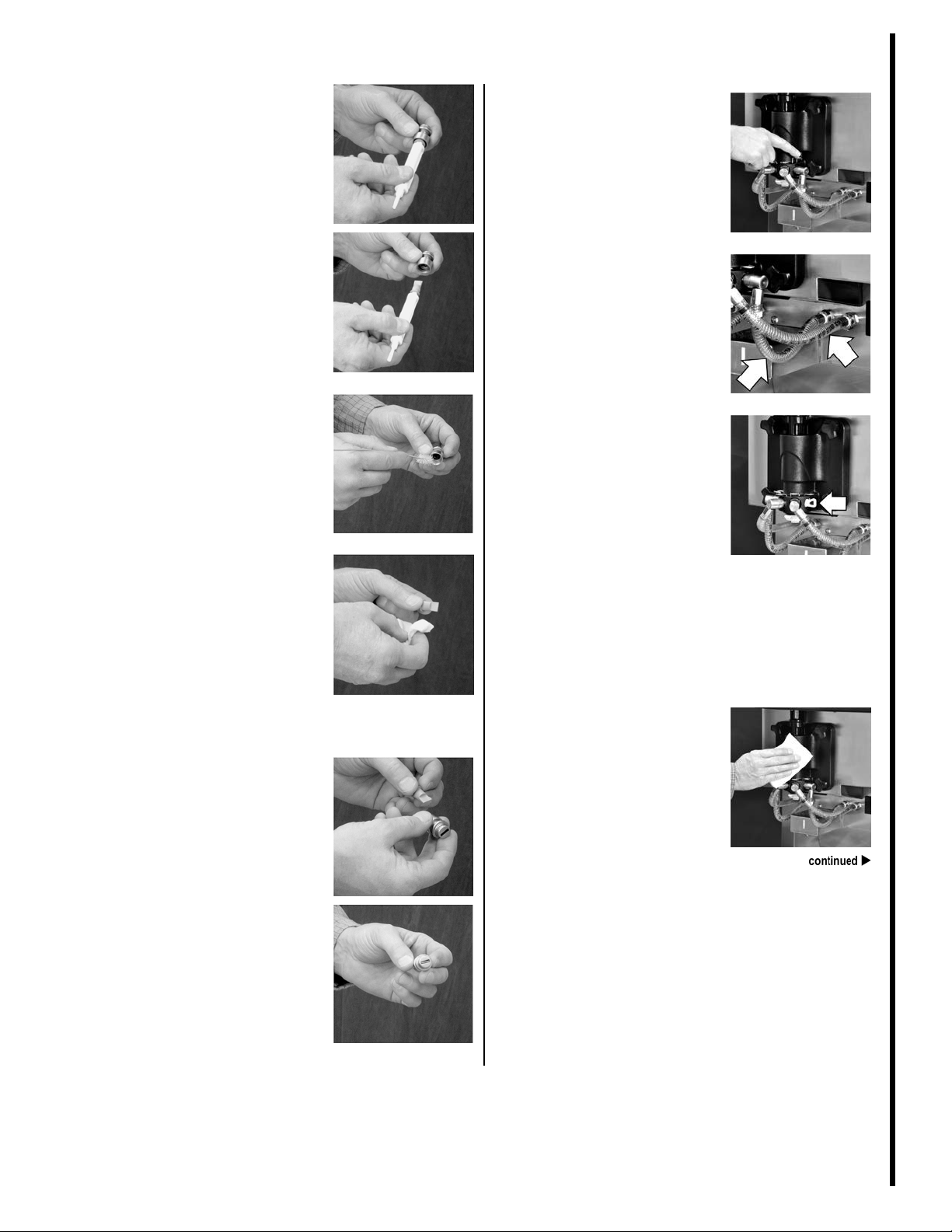

Page 4

Opening Procedures (continued)

Taylor Company milkshake and soft

Daily

10

Remove duckbill valve.

11

Clean syrup nose fitting.

12

Sanitize syrup nose fittings

fittings and duckbill valve.

13

Install duckbill valve into syrup

14

Install syrup valves.

15

Check syrup lines for air

16

Install syrup plugs for unused

(See PM card SS01 W1)

17

Wipe exterior of machine.

Remove the d uc kb ill val ve

and the o-ring from each

syrup nose fitting, by using

the seal removal tool.

Using a brush and the

sanitizing solution, brush

clean the inside of each syrup

nose fitting until there is no

remaining syrup or mix inside

the fitting.

and duckbill valve.

Using a clean, sanitized

towel, gently wipe a ny syrup

and mix fro m ea ch duckbil l

valve.

Use a milkshake cup filled

with sanitizing solution to

thoroughly rinse the nos e

Raise the syrup valve retainer

and install the syrup valve.

Push the reta iner down to

hold the valve in place.

Repeat for each syrup valve.

pockets in the line.

If air pockets are present,

prime the syrup lines. (See

Operator Manual for priming

syrup lines.)

syrup lines.

Install a syr up hole plug into

the syrup port in the door

whenever a syrup line is not

in use. (Example: When the

optional flavor shake is not

being served.)

Do not install an empty syrup

line into the syrup port of an

unused syrup line.

Note: The syrup system

must be flushed and

sanitized weekly.

-serve machine model C602

nose fitting and install syrup

nose fitting onto syrup line

fitting.

Install the duckbill valve into

the syrup nose fitting with the

flat end aligned with the open

slot in the fitting.

Install the syrup nose fitting

onto the syrup line fitting.

Tighten by hand (cloc kwise)

until snug.

Install and lubricate the o-ring

on the syrup nose fittin g.

Using a clean, sanitized

towel, wipe down the freezer

door, front panel, and other

areas that have a build up of

moistur e or food substance.

SS 3 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 4

Page 5

Opening Procedures (continued)

Taylor Company milkshake and soft

Daily

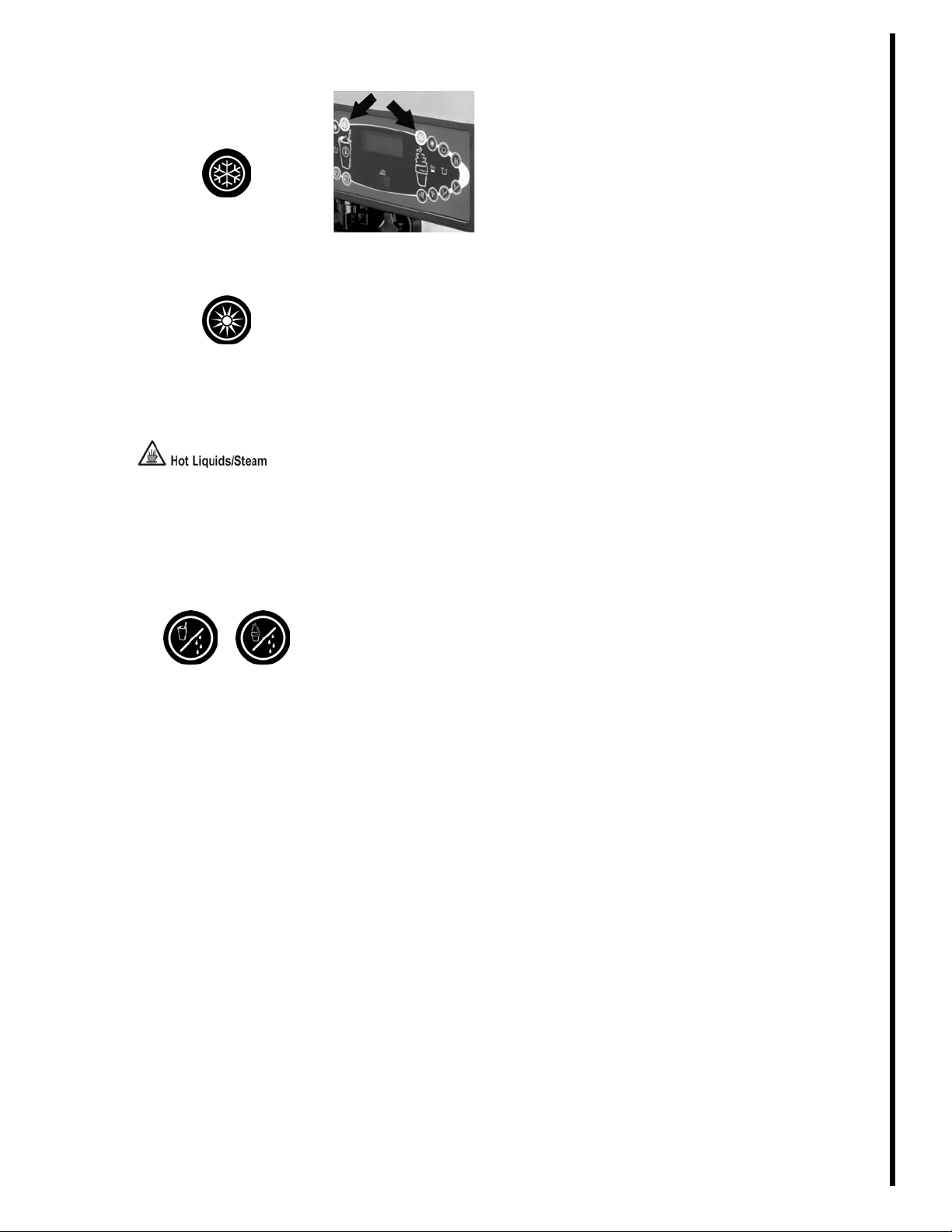

18

Install shake cup holder, front

19

Select the AUTO symbol.

product.

1

Sanitize door spout and

2

Flush door spout and bottom

3

Wipe exterior of machine.

4

Select the AUTO symbol.

product.

drip tray and splash shield.

When ready to resume normal

operation, touch the AUTO

symbol. The frozen product

should be ready to serve in

approximately 10 minutes.

Procedure – Soft Serve Side

bottom of draw valve.

With a pail placed beneat h the

soft serve door, dip the door

spout brus h in sanitizing

solution. Brush cle an the door

spout and bottom of the draw

valve. Repeatedly dip the

brush in sani tizing solution

and brush clean each item for

60 seconds.

of draw valve with sanitizing

solution.

Use the squeeze bottle filled

with sanitizing solution to

flush the door spout and

bottom of the draw valve.

-serve machine model C602

Note: This step should be

performed approximately

15 minutes prior to serving

Using a clean, sanitized

towel, wipe down the freezer

door, front panel, and other

areas that have a build up of

moistur e or food substance.

When ready to resume normal

operation, touch the AUTO

symbol. The frozen product

should be ready to serve in

approximately 10 minutes.

Note: This step should be

performed approximately

15 minutes prior to serving

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 4 of 4

SS 3 D1

Page 6

Closing Procedures Daily SS 3 D2

Taylor Company milkshake and soft

Daily

Why

Prepare Milkshake/Soft-Serve machine for the heat treatment cycle

Time required

30 minutes

Time of day

At closing

24-hour restaurants: one hour before heat treatment cycle

Hazard icons

Brushes

SolidSense All

Kay 5 Sanitizing

Valve Cap

Syrup Hole Plugs

Kay 5 Sanitizing

Clean Sanitized

1

Fill mix hopper.

must not be on.

2

Remove hopper cover.

3

Remove milkshake cup

4

Remove drip tray and splash

5

Remove agitator paddle.

performing the next steps.

With sanitized hands,

begins

Tools and supplies

-serve machine model C602

Purpose Super

Concentrate (APSC)

Solution

Procedure – Shake Side

Fill the hopper with fresh

mix, up to the l ine on the

agitator paddle. Do not fill

above the agitator paddle.

Important: The level of

mix in the hopper must be

at the line on the agitator

paddle. The mix low light

Solution

Solution

Towels

shield.

Select the calibrate symbol

to momentarily stop the

agitator paddle from

turning.

holder.

Important: Make sure

your hands are clean and

sanitized before

remove the agitator paddle

from the hopper.

SS 3 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 5

Page 7

Closing Procedures (continued)

Taylor Company milkshake and soft

Daily

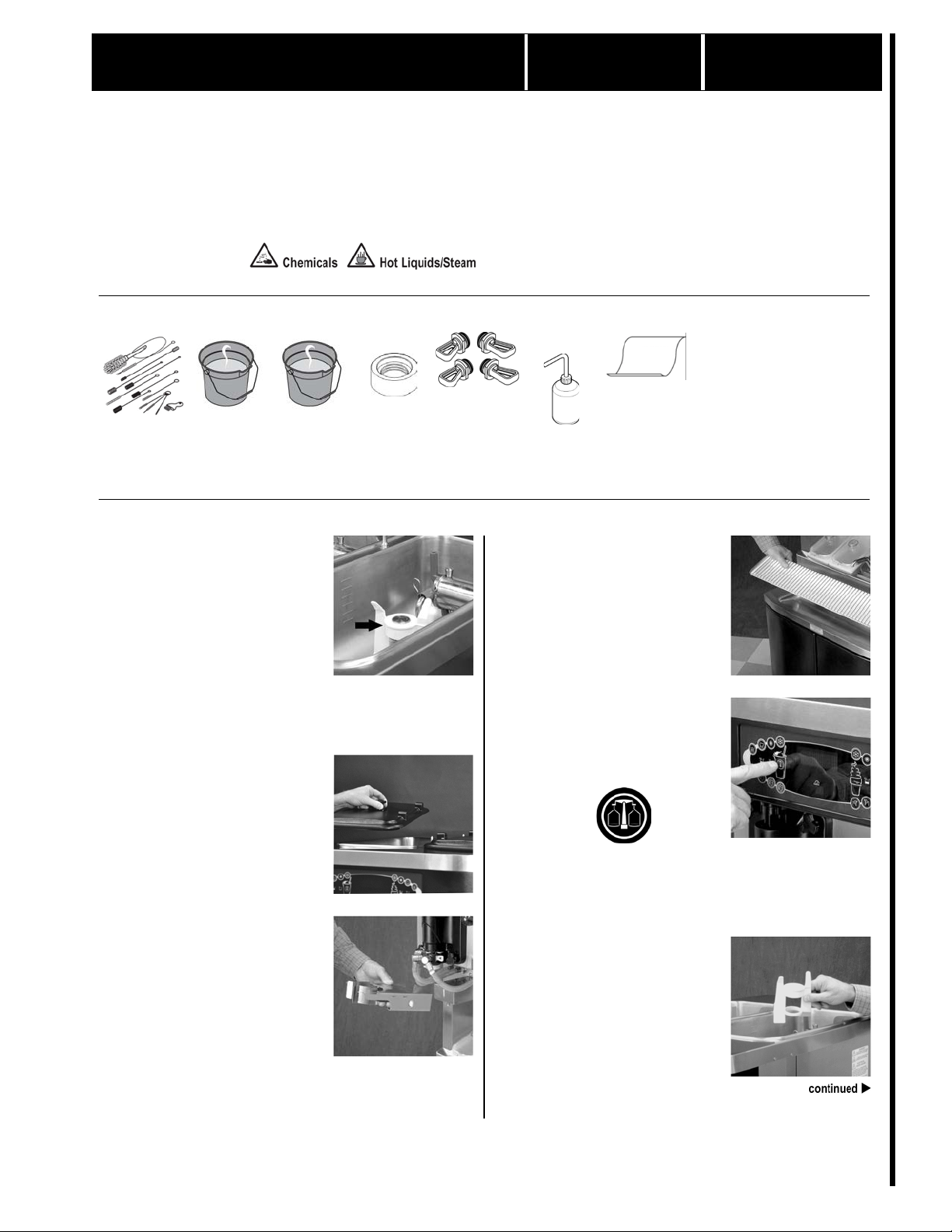

6

Remove restrictor cap.

7

Clean and sanitize parts.

APSC & Sanitizer solution

8

Install agitator paddle.

Using sanitized hands,

9

Install hopper cover.

10

Remove syrup lines.

11

Clean syrup port holes.

12

Clean door spout, bottom of

13

Clean syrup valve retainers

Remove the restrictor cap

from the door spout.

At the sink, brush clean and

sanitize:

Agitator paddle

Hopper cover

Milkshake cup holder

Milkshake restrictor cap

Drip tra y

Splash shield

Syrup hole plugs

Spout cap

Spout cap o-ring

Place the restrictor cap,

splash shield, drip tray, and

milkshake cup holder on a

clean, dry surface to air dry

overnight or until the heat

treatment cycle is complete.

Select the calibrate symbol

to momentarily stop the

agitator drive motor.

Raise the retaining pins and

remove the syrup valves.

Place a bucket beneath the

door. Brush clean each

syrup port hole 10 to 15

times. Dip t he brush in

cleaning solution before

brushing ea ch port.

Brush each item for a total

of 60 seconds.

A

PSC solution

driven spinner, spinner blade

and syrup line fittings.

Brush clean each item for a

total of 60 seconds,

repeatedly dipping the brush

in cleaning solution.

-serve machine model C602

reinstall the agitator paddle

on the drive post in the

hopper.

and holes.

With sanitized hands,

remove the syrup valve

retainers. Dip the brush in

cleaning solution and brush

clean the retainers and the

retainer holes. Reinstall the

syrup valve retainers.

SS 3 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 5

Page 8

Closing Procedures (continued)

Taylor Company milkshake and soft

Daily

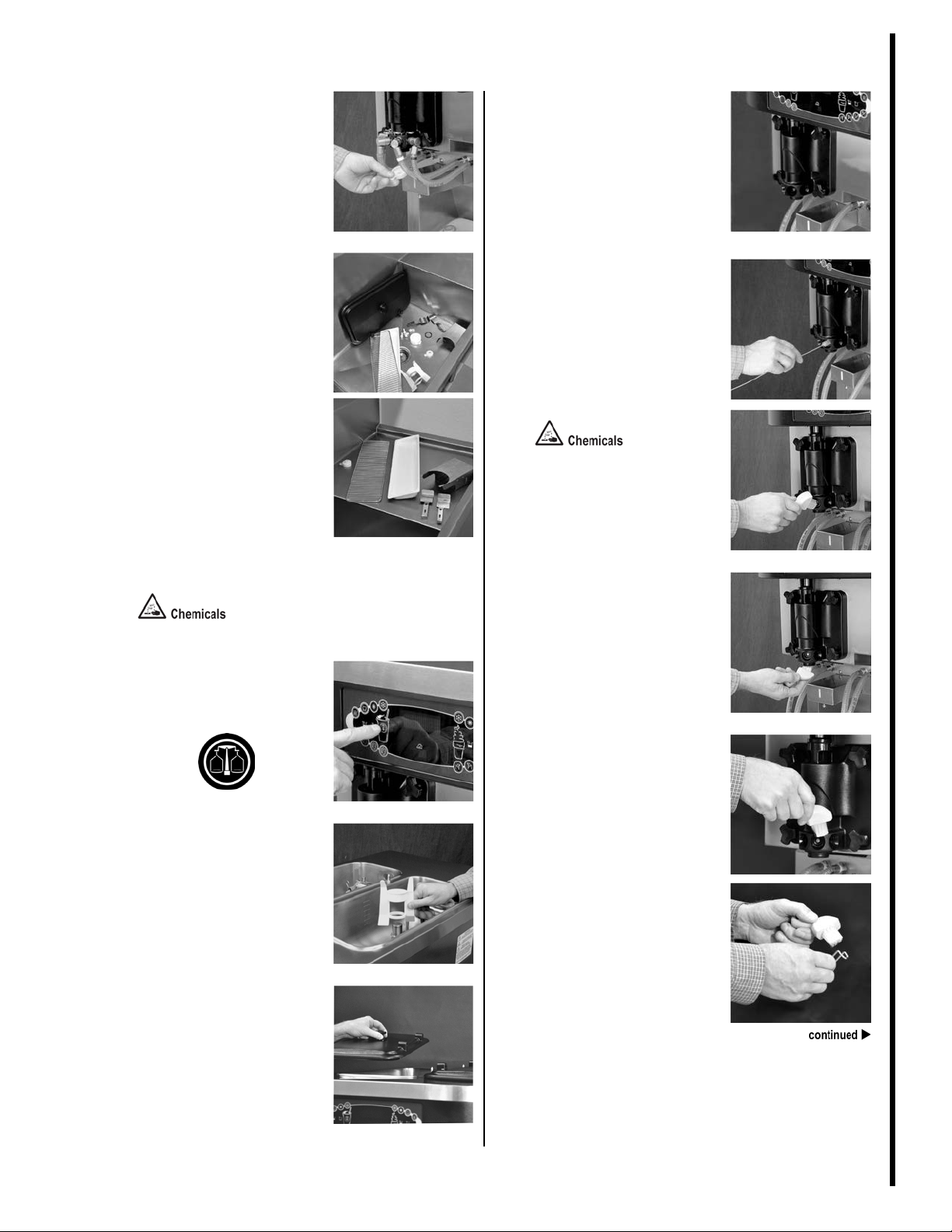

14

Flush syrup port holes with

APSC solution

15

Flush door spout with

16

Fill valve cap with sanitizing

17

Install syrup hole plugs.

18

Sanitize syrup nose fittings.

1

Fill mix hopper.

Important: The level of

2

Place topping heaters in OFF

3

Remove, clean, and sanitize

4

Remove, clean, sanitize, and

performing the next steps.

sanitizing solution.

Insert the tube end of the

squeeze bottle filled with

sanitizing solution into each

syrup port. Squeeze the

bottle firmly. Flush ea ch

port for 10 seconds.

Procedure – Soft Serve Side

Fill the hopp er with fresh

mix, up to the line on the

agitator paddle. Do not fill

the mix hopper above the

agitator paddle.

sanitizing solution.

Flush the bottom of the door

spout door with sanitizing

solution.

solution and install.

Fill the insulated valve cap

with sanitizing solution and

install the cap onto the

milkshake door spout.

Raise the retainer pins.

Install a syr up hole plug

into each syrup port. Lower

the retainer pins to secure

the syrup hole plugs.

mix in the hopper must be

at the line on the agitator

paddle. The mix low light

must not be on.

position.

Turn the topping heaters

OFF by selecting the

topping heater symbols.

hopper cover.

A

PSC & Sanitizer solution

-serve machine model C602

Hold the squeeze bottle over

a bucket. Squeeze the bottle

and thoroughly rinse the slot

of each syrup nose fitting.

Wipe the outside of the

syrup nose f ittings with a

clean, sanitized towel.

te: The syrup system

No

must be flushed and

sanitized weekly.

(See PM card SS01 W1.)

reinstall agitator paddle.

Select the calibrate symbol

to momentarily stop the

agitator paddle from

turning.

Important: Make sure

your hands are clean and

sanitized before

SS 3 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 5

Page 9

Closing Procedures (continued)

Taylor Company milkshake and soft

Daily

Remove the agitator paddle

5

Install hopper cover.

6

Clean door spout and bottom

APSC solution

7

Flush door spout with

Sanitizer solution

8

Remove, clean and reinstall

Note: Mix in the dri p pans

9

Wipe exterior of machine.

from the hopper and ta ke it

to the sink. Brush clea n,

sanitize, and reinstall the

agitator paddle.

of draw valve.

Place a bucket beneath the

soft-serve door. Dip the

door spout brush into

cleaning solution and brush

clean the door spout and

bottom of the draw valve.

Repeatedly dip the brus h in

cleaning solution and brush

clean each item for 60

seconds.

indicates there is a leak that

needs to be corrected before

damage occurs inside the

machine.

Examples:

If mix is in the front or side

drip pans, inspect/replace

the beater drive shaft seals.

If mix is in the rear drip

pan, inspect/replace the

pump drive shaft seals.

-serve machine model C602

Use a clean, sanitized towel

to wipe down the freezer

doors, front panels, and any

other areas that have a

build-up of either moisture

or food substance.

sanitizing solution.

Use the squeeze bottle filled

with sanitizing solution to

rinse the bottom of the door

spout. Rinse the spout wi th

sanitizing solution for 10

seconds.

drip pans.

Remove the drip pans and

take them to the sink. Br ush

clean, sanitize, and reinstall

the drip pans.

SS 3 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 4 of 5

Page 10

Closing Procedures (continued)

Taylor Company milkshake and soft

Daily

10 Make sure unit is in AUTO.

Note: The machine must be

in AUTO (or STANDBY) to

start the heat treatment

cycle at the programmed

time.

DO NOT attempt to draw

product or disassemble the

machine during the HEAT

cycle. The product is hot and

under extreme pressure.

hen the heat cycle is

W

complete, the control panel

will change to the

STANDBY mode. The

STANDBY symbols will be

illuminated.

-serve machine model C602

SS 3 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 5 of 5

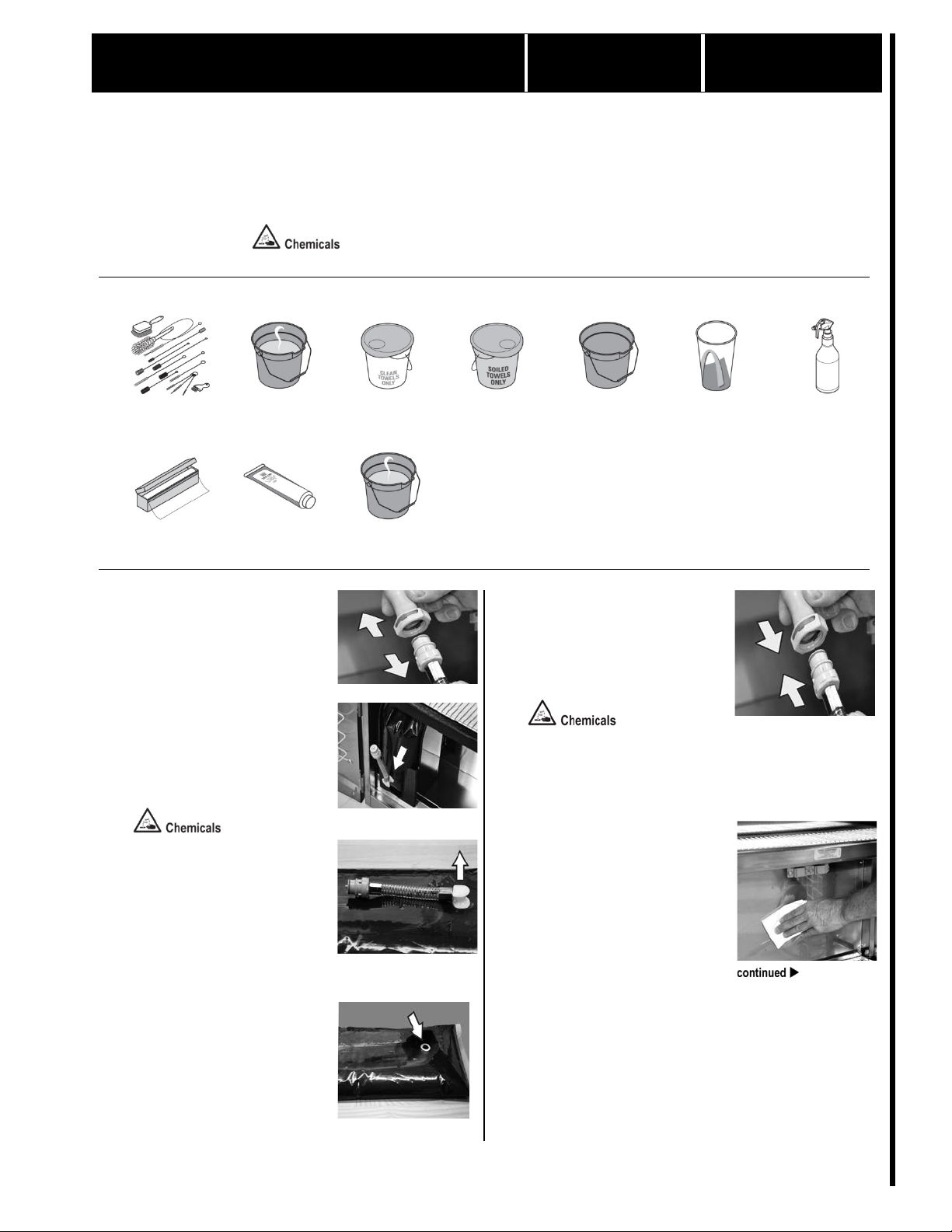

Page 11

Clean and sanitize syrup lines with duckbill

valves

Weekly SS 3 W1

Taylor Company milkshake and soft

Weekly

W1

Why

To break the bacteria cycle

Time required

5 minutes to prepare

20 minutes to complete

Time of day

At close

For 24-hour restaura nts: during breakfast menu

Hazard icons

Brushes

Bucket, SolidSense

Bucket, clean and

Bucket, soiled towels

Bucket, plastic

Cold-drink cup

Kay-5 Sanitizing

Plastic wrap

Taylor Lube HT

Kay-5 Sanitizing

solution

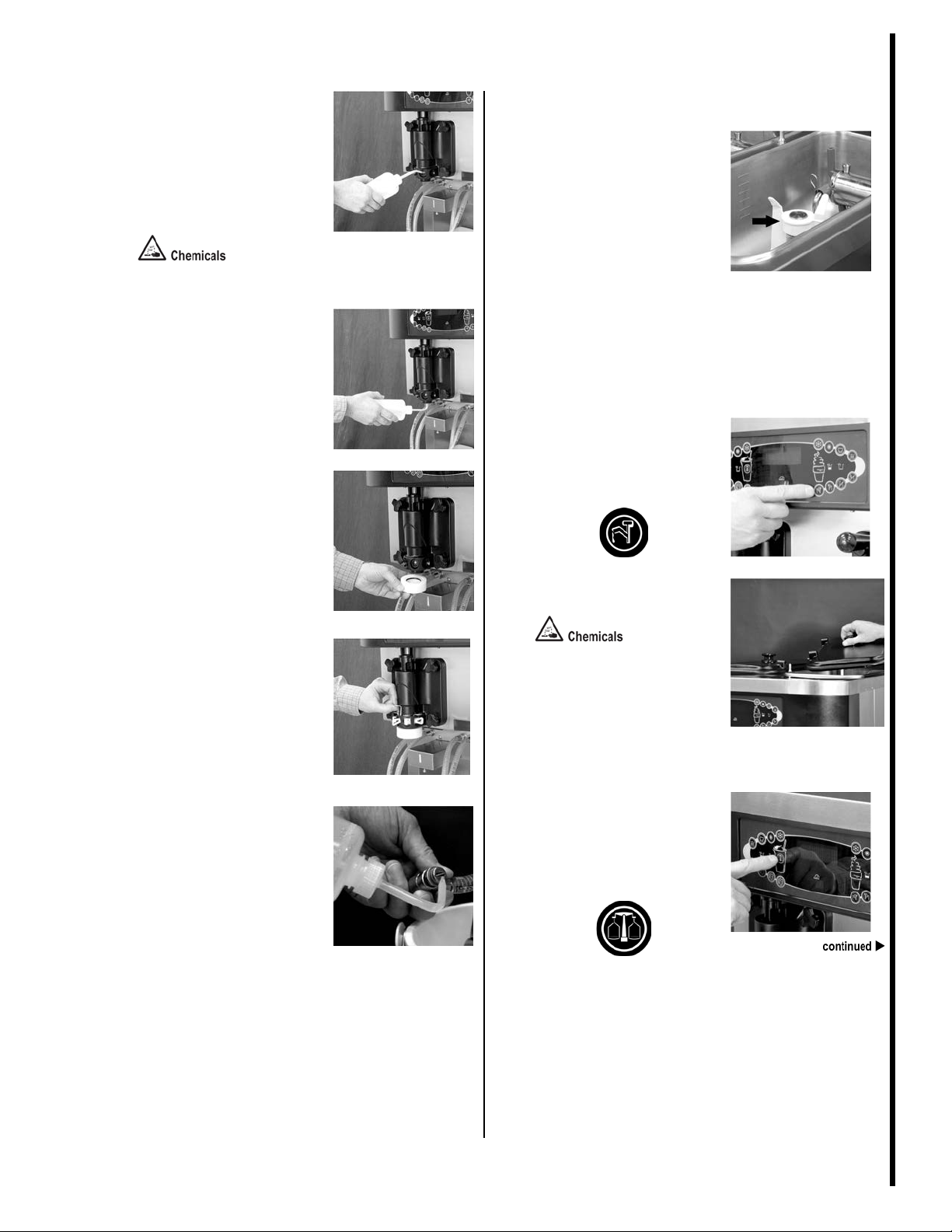

1

Disconnect the QD fitting

4

Re-connect the QD

5

Clean inside of cabinet.

Tools and supplies

-serve machine model C602

Procedure

Disconnect the QD fitting

on the syrup bag.

Remove the syrup bags wit h

the line attached from the

cabinet.

Wipe the outside of the feed

tubes or the hose connector

fittings with a clean,

sanitizer-soaked towel.

Sanitizer solution

2

Place the syrup bag on a level

surface. Remove the syrup

bag line from the syrup bag.

All Purpose Super

Concentrate (APSC)

sanitizer-soaked

towels

Fitting/Hose from the syrup

bag

Place the syrup feed hose in a

bucket of APSC solution.

AP

SC Solution

Wipe down the inside of the

syrup cabinet with a clean,

sanitizer-soaked towel. Spray

resistant areas with additional

sanitizer solution.

solution

3

Cover the syrup inlet port

with plastic wrap.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 4

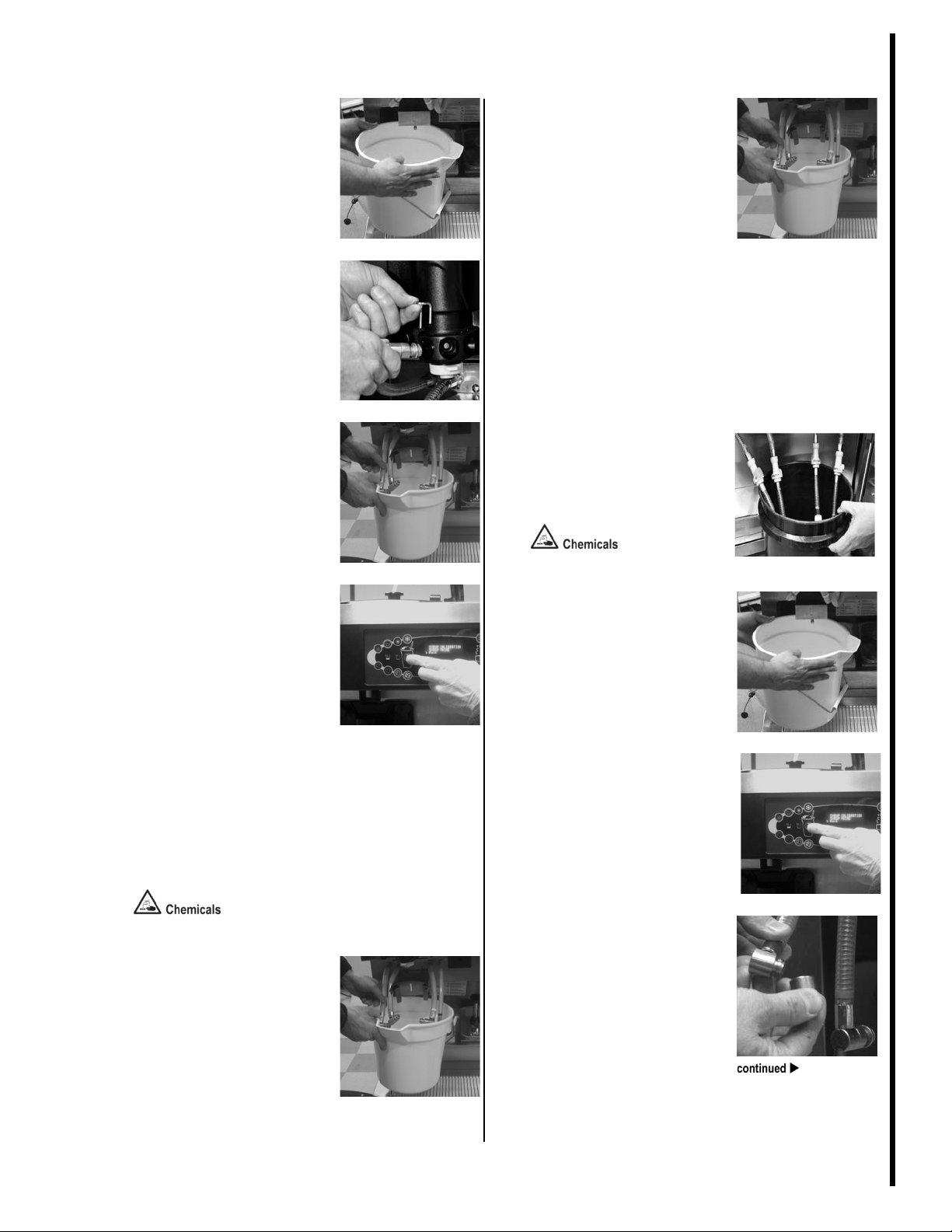

Page 12

Clean and sanitize syrup lines with duckbill valves (continued)

Taylor Company milkshake and soft

Weekly

W1

6

Place empty bucket under

7

Remove syrup line from

8

Place syrup line and valve in

9

Start flow of APSC solution.

APSC solution

10

Flush syrup line with APSC

is completely flushed.

11

Pump all liquid from syrup

line.

12

Rinse with clean, hot water

hot water.

13

Place feed tubes in sanitizer

Sanitizer solution

14

Place empty bucket under

15

Flush syrup line with sanitizer

16

Remove nose fitting.

milkshake draw valve.

Place a clean plastic bucket

under the milkshake draw

valve.

milkshake freezer door.

Disconnect the corresponding

syrup line from the milkshake

freezer door by raising the

syrup valve retainer. Pull the

valve straight out.

bucket.

Hang the syrup line and valve

in the empty bucket.

line.

Remove the syrup feed tube

from the bucket of APSC

solution and continue to run

the pump until APSC solution

no longer ru ns from the s yrup

line.

Touch the Flavor Select key

to stop the flow of APSC

solution thr ough the syrup

-serve machine model C602

Repeat steps 7-10 with clean,

solution.

Place the syrup bag connect

fittings into a bucket of

sanitizer solution.

Press the Calibration key on

the control panel to display

the menu options.

ouch the Auto ke y to move

T

the arrow to “Syrup Prime.”

T

ouch the Calibration key

again to disp lay the syrup

prime screen.

ress the Flavor Select key

P

for the correct flavor, to start

the flow of APSC through the

line.

solution.

Allow the APSC solution to

continue to flow into the

empty bucket until all the

syrup is flushed from the line.

When the liq uid from the

syrup line runs clear, the line

milkshake draw valve.

Place a clean plastic bucket

under the milkshake draw

valve.

solution.

Repeat steps 7 through 9

using sanitizer solution.

Unscrew the nose fitting from

the syrup valve in the b ucket

by turning the cap counterclockwise.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 4

Page 13

Clean and sanitize syrup lines with duckbill valves (continued)

Taylor Company milkshake and soft

Weekly

W1

17

Remove valve and o-ring.

18

Clean nose and elbow fitting.

19

Clean duckbill valves.

20

Sanitize syrup valve fittings.

Sanitizer solution

21

Insert duckbill valve.

22

Connect nose fitting.

23

Install and lubricate o-ring.

24

Reassemble remaining valves.

25

Place clean bucket under

Remove the duckbill valve

and o-ring from each syrup

nose fitting, by using the seal

removal tool.

Install the duckbill valve into

one of the no se fittings with

the flat end a ligned wit h the

open slot in the nose fitting.

Do not lubricate the duckbill

valve.

-serve machine model C602

Use the white end of the

double-ended brush to scrub

the inside of the syrup nose

fitting and the elbow fitting.

Remove any residual

particles.

Screw the nose fitting o nto

one of the s yrup valve elbows

by turning it clockwise.

Tighten it by hand until snug.

Use a clean, sanitizer-soaked

towel to wipe any syrup from

the duckbill valves.

Fill a cup with sanitizer

solution. S ubmerge the syrup

valve fittings in the sanitizer

solution in the cup. Rotate the

cup gently so the fittings are

washed thoroughly. Allo w to

soak for at least one minute.

Push one of the o-rings onto

the nose fitting and lubricate

it with Taylor Lube HP.

Repeat steps 20 through 22 to

reassemble the remaining

syrup valve s .

milkshake draw valve.

Place a clean plastic bucket

under the milkshake draw

valve. Position the sanitized

valves so t hey are hanging

over the bucket.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 4

Page 14

Clean and sanitize syrup lines with duckbill valves (continued)

Taylor Company milkshake and soft

Weekly

W1

26

Drain syrup feed tubes.

27

Replace syrup feed tubes and

28

Display syrup menu options.

29

Touch AUTO key.

30

Touch calibration key.

31

Start syrup flow.

32

Stop flow of syrup.

33

Repeat steps 27-31 for each

flavor.

34

Reconnect syrup valves.

Remove the syrup feed tubes

from the bucket of sanitizer

solution and allow them to

drain back i nto the bucket.

syrup bags.

For syrup bag systems, attach

the bag connector fittings to

the proper syrup flavors.

Return the syrup bags to the

cabinet.

Press the Calibration key on

the control panel to display

the syrup menu options.

Press the Flavor Select key to

stop the flow of syrup.

Connect the syrup valves to

the freezer door. Secure by

lowering the retainers.

-serve machine model C602

Touch the Auto ke y to move

the arrow to “Syrup Prime.”

Touch the Calibration key to

display the syrup prime

screen.

Press the Flavor Select key to

start the flow of syrup

through the l ine.

Allow the syrup to flow until

all sanitizer solution and air is

flushed from the line.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 4 of 4

Page 15

Clean hot sundae topping water bat hs Weekly SS 3 W2

Taylor Company

Weekly

2

Why

To maintain food quality

Time required

5 minutes to prepare

10 minutes to complete

Time of day

At close and after topping pumps and

containers have been removed

For 24-hour restaura nts: during breakfast menu and

after topping pumps and containers have been removed

Hazard icons

Brushes

Bucket, Sol-

Concentrate (APSC)

Bucket, tap water

Bucket, clean and

Bucket, soiled towels

Pan, prep, 1/3 size,

Paper towels

Screwdriver, flat

1

Turn off water bath heaters.

2

Remove pumps and containers

baths may be extremely hot.

3

Position prep pan under water

water bath drain tubes.

4

Drain water bath.

completely into the prep pan.

milkshake and soft-serve machine model C602

Tools and supplies

idSense™ All

Purpose Super

Procedure

Using the control panel on the

front of the machine, t urn off

both the left and right water

bath heaters.

and allow water bath to cool.

Remove both hot topping

pumps and containers. Allow

the water in the water baths to

cool for 10 minutes.

solution

sanitized towels

6 inches deep

bath drain tubes.

Place the 6 inch deep, 1/3 size

prep pan under the machine

just to the right of the center

front. The pan should b e positioned directly under the

Using a flat screwdriver,

loosen the drain screw in the

bottom of one of the baths by

turning the s crew counterclockwise. Do not remove the

screw.

Metal surfaces and water

Allow the water to drain

SS 3 W

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 2

Page 16

Clean hot sundae topping water baths (continued)

Taylor Company

Weekly

2

so the water can still drain.

5

Discard water in pan.

extremel y hot.

6

Position prep pan under

7

Tighten drain screw.

8

Clean water bath.

APSC & Sanitizer solution

9

Drain water bath.

10

Rinse water bath.

11

Drain water bath.

12

Dry interior of water bath.

13

Refill water bath.

14

Clean second water bath.

If the drain is plugged,

remove the drain screw

completely by turning it

counterclockwise. Clear the

drain using the double-ended

brush. Replace the screw

loosely, turning it clockwise,

Make sure the water has

drained completely out of the

bath and into the pan. Carefully slide the pan out from

under the machine and d iscard the water.

Water baths may be

machine.

Return the prep pan to the

same position under the water

bath drain tubes.

Repeat steps 4 through 7 to

drain and discard the APSC

solution. Remember to tighten

the drain screw before beginning the next st ep.

milkshake and soft-serve machine model C602

Using a clean, sanitized towel

and clean tap water, thoroughly rinse the interior of

the water bath.

Repeat steps 4 through 7 to

drain and discard the rinse

water. Remember to tighten

the drain screw before beginning the next step.

Use a dry paper towel to dry

the inside of the water bath

and remove any remaining

sanitizer residue.

Turn the dr ain screw clo ckwise to tighten it.

Fill the water bath with APSC

solution. U s ing a clean, sanitized towel, thoroughly wash

the inside of the water bath.

Fill the water bath with clean

tap water, up to the fill lines

marked on the sides of the

bath.

Repeat steps 3 through 13 for

the second water bath.

SS 3 W

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 2

Page 17

Clean and sanitize hot sundae topping pumps Weekly SS 3 W3

Taylor Company

Weekly

W3

Why

To break the bacteria cycle

Time required

5 minutes to prepare

30 minutes to complete

Time of day

During 14 day brush cleaning

During 14 day brush cleaning

Hazard icons

Brushes

Spatula, rubber

Taylor Lube HT

Kay-5®

SolidSense™ All

1

Remove topping pump and

The pumps may be hot.

2

Discard topping.

before starting this procedure.

3

Rinse container and pump.

spout.

4

Remove plunger assembly.

5

Remove plunger knob.

hand.

milkshake and soft-serve machine model C602

Tools and supplies

Procedure

container.

Lift the topping pump and

container from the water bath.

D

o not remove the pump by

pulling on t he spout.

Use a rubber spatula to remove and di scard the topping

from the container.

To minimize waste, run the

topping as low as possible

Sanitizer/Cleaner

Purpose Super

Concentrate (APSC

)

Transfer the pump and container to the threecompartment sink. Rinse the

container with hot water.

Spray the pump with hot water to remove any remaining

topping. Place the lower end

of the pump in a container of

water and p ush down on the

pump lever several times until

only water flows from the

Turn the plu nger nut count erclockwise to remove the

plunger assembly from the

pump body.

To remove the knob, compress the spring toward the

knob, using the washer . Compress it enough to grab onto

the plunger with your hand

for suppo rt. Begin removing

the knob with your other

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 5

SS 3

Page 18

Clean and sanitize hot sundae topping pumps (continued)

Taylor Company

Weekly

W3

6

Remove plunger nut.

7

Remove plunger tube and

8

Remove spring and washer.

9

Remove seal assembly.

10

Remove o-ring from seal.

11

Remove spout lock nut from

12

Remove lid.

13

Remove plunger cylinder from

14

Remove spout from valve

15

Remove o-rings from valve

16

Wash all pump parts.

APSC Solution

17

Clean spout.

Remove the plunger nut from

the plunger tube.

Lift the lid off the spout and

plunger c ylinder.

milkshake and soft-serve machine model C602

insert.

Remove the plunger tube and

insert from the plunger assembly.

valve body.

Turn cylinde r counterclockwise to remove.

body.

Remove the s pring and wa sher from the plunger assembly.

Turn spout counter-clockwise

to remove.

Slide the seal assembly off

the bottom of the plunger.

lid.

Loosen the spout lock nut by

turning it counterclockwise.

Remove it from the spout and

lid.

body and spout.

Remove the 15/16 inch o-ring

from the val ve body and remove the 1 inch o-ring from

the spout.

Wash all pump parts in the

three-compartment sink using

APSC solution and the

supplied b rushes.

Insert the bristle end of the

spout brus h into the tip of the

spout. Move the brush back

and forth quickly. Pus h the

brush all the way through the

spout and pull it out the opposite end.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 5

Page 19

Clean and sanitize hot sundae topping pumps (continued)

Taylor Company

Weekly

W3

18

Clean top side of inlet valve on

19

Clean top side of outlet valve.

20

Clean passageway between

the valve bo dy.

21

Rinse and sanitize pump parts.

Sanitizer solution

22

Insert seal assembly o-ring.

23

Lubricate seal assembly

24

Install seal assembly.

25

Install washer and spring.

26

Install plunger insert into

27

Install plunger nut.

28

Insert plunger with spring into

tube.

valve body.

Retrieve the valve body. Use

the bristle e nd of the brush to

scrub the top side of the inlet

valve. Be sure to scrub around

the steel ball.

Use the bristle end of the

brush to scrub the top side of

the outlet valve. Be sure to

scrub around the steel ball.

o-ring.

Lubricate the seal assembly

o-ring, using Taylor Lube.

milkshake and soft-serve machine model C602

Install the seal assembly onto

the end of the plunger that is

opposite the stem end.

valves.

Insert the non-bristle end of

the brush into the top side of

the inlet valve. Thread it

through the passageway between the valves. Pull it out

through the top side of the

outlet valve until the bristles

are in the pass ageway.

Move the brush back and

forth quickly to scrub the passageway. Pull the brush out of

Slide the washer and spr ing

onto the ste m end of the

plunger.

plunger tube.

Locate the beveled edge of

the plunger insert. Thi s end

will also have the smaller

hole. Insert this end into the

open end of the plunger tube.

Rinse and sanitize all clean

pump parts in the threecompartment sink.

ather all pump parts for

G

re-assembly.

Insert the o-ring in the seal.

Slide the plunger nut onto the

plunger tube.

plunger tube.

Insert the plunger wit h t he

spring into t he larger end of

the plunger tube assembly.

Push on the end of the plunger, compressing the spring,

until the thr eaded end of the

stem proj ects through the

opposite end of the plunger

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 5

SS 3

Page 20

Clean and sanitize hot sundae topping pumps (continued)

Taylor Company

Weekly

W3

29

Install knob.

turning it clockwise.

30

Install spout o-ring.

31

Lubricate spout o-ring.

32

Install valve body o-ring.

33

Lubricate valve body o-ring.

34

Connect spout and valve body.

valve bod y.

35

Connect plunger cylinder and

grooves on the valve bo dy.

36

Slide lid onto pump assembly.

37

Secure lid to pump assembly.

Place the knob with the knob

o-ring onto the threaded en

o

f the plunger. Push the

plunger tube down toward the

seal assembly, squeezing th

pring as far as it will go.

s

Tighten the knob secure ly by

Position the spout o-ring in

the groove s on the spout.

d

e

Lubricate the o-ring, using

Taylor Lube.

Position the valve body o-ring

in the grooves on the top side

of the inlet valve.

Insert the spout into the

smaller opening in the valve

body by aligning the flats on

the spout wi th the locki ng

grooves on the valve bo dy.

milkshake and soft-serve machine model C602

Push the spout down until it is

seated in the valve body

opening. Turn the spout

clockwise to fully engage it in

the lockin g grooves on t he

valve body.

Insert the c ylinder into the

larger opening in the valve

body by tilting the cylinder

away from the spout. Slide

the widest section of the cylinder flange under the center

locking groove on the valve

body.

Align the tabs on the cylinder

with the locking groove s on

the valve bo dy. Turn the cylinder clockwise until the tabs

fully engage in the locking

Lubricate 15/16 inch o-ring,

using Taylor Lube.

Insert the spout through the

smaller hole in the lid. Slide

the lid down until the top of

the plunger cylinder is aligned

with the larger hole.

Slide the spout lock nut over

the spout and onto lid. Tighten it securely by turning it

clockwise.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 4 of 5

Page 21

Clean and sanitize hot sundae topping pumps (continued)

Taylor Company

Weekly

W3

38

Lubricate plunger assembly.

39

Install plunger assembly.

40

Tighten plunger nut.

Lubricate bottom of the

plunger assembly, using

Taylor Lube.

milkshake and soft-serve machine model C602

Slide the plunger assembly

through the cylinder opening

in the lid and into the pump

body.

Securely tighten the p lunger

nut on to the li d by turning it

clockwise.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 5 of 5

Page 22

14 Day Brush Cleaning Every 14 Days SS 3 B1

Taylor Company milkshake and soft

Every 14 Days

B1

Why

Required Cleaning and Lubrication of Machine

Time required

5 minutes to prepare

4 hours to co mplete

Time of day

At close

For 24-hour restaura nts: during low-volume periods

Hazard icons

Procedure

1

Turn topping heaters off.

serve side.

2

Cancel AUTO mode.

3

Remove shake cup holder

4

Remove hopper cover.

SolidSense All Purpose

Kay-5 Sanitizing Solution

Pail, clean and sanitized

Taylor milkshake

Taylor soft-serve

Simplified Pump

Tool – Pump Drive Shaft

Taylor High Performance

O-Ring Removal Tool

Syrup Hole Plugs

Brushes

Tool – Seal Install &

Tools and supplies

-serve machine model C602

Super Concentrate

(APSC)

Lubricant

towels

side Parts Tray

side Parts Tray

Parts Trays

Remove

Cancel automatic operation

Draining Product From the

Freezing Cylinder

by touching the AUTO

symbol

.

Note: As parts are removed,

place them on a roll-a-cart for

transport to the sink.

(shake side only).

Place the topping heater

switches in the OFF position

by touching the heater

symbols

C

lean and sanitize the topping

.

pumps using MRC card

SS1W3.

Note: The steps to drain product

from the freezing cylinder are the

same for both sides. Therefore,

perform all draining steps for the

shake side and then duplicate

the applicable steps for the soft

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 7

Page 23

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

5

Remove the agitator.

6

Press WASH and PUMP

Shake Side: Touch any flavor

7

When the flow of product

WASH operation is cancelled.

8

Discard the product/mix.

9

Remove hopper parts.

10

Remove syrup lines and install

Insert the syrup hole plugs in

SS01W1 instructions.

11

Take cart of parts to the sink.

12

Drain the soft-serve side.

the soft serve side.

Rinsing

1

Rinse mix hopper.

syrup plugs (shake side only).

Remove the syrup lines from

the freezer door by raising the

syrup valve retainers and

pulling the valves stra ight out

of the door.

symbols and drain product.

With a pail beneath the door

spout, touch the WASH and

PUMP symbols

open the draw valve.

Drain the product from t he

freezing c ylinder and the mix

hopper.

selection symbol to open the

draw valve.

and

the syrup ports.

Lower the retainer pins to

secure the hole plugs in the

door.

Note: The syrup system

must be flushed and

sanitized weekly per MRC

Repeat the draining steps for

Note: Perform all rinsing steps for

the shake side and then

duplicate the applicable steps for

the soft serve side.

-serve machine model C602

stops, touc h the WASH and

PUMP symbols

The shake dr aw valve will

automatically close when the

Remove the locking clip , mix

feed tube, pump clip and the

assembled air/mix pump.

.

Pour two gallons (7.6 liters)

of cool, clean water into the

mix hopper. With the white

hopper brush, scrub the

hopper, mi x l evel sensing

probes, and the outside of the

agitator drive shaft ho using.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 7

Page 24

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

Using the double ended

2

Activate WASH mode.

3

Drain water and cancel WASH.

discharged is clear.

4

Rinse the soft serve side.

soft serve side of the freezer.

Cleaning, Rinsing and

1

Prepare and pour cleaning

APSC Solution

2

Brush clean mix hopper.

3

Activate WASH mode.

brush, clean the mix inl et

hole.

Sanitizing

Do not clean t he mix inlet

hole while the machine is in

the WASH mode.

With a mix pail beneath the

door spout, touch the W ASH

symbol

.

Open the draw valve and

drain the rinse water. Close

the draw valve and touc h the

WASH symbol,

cancelling the wash mode.

Repeat the rinsing procedure

until the wa t er being

Note: Perform all cleaning,

rinsing, and sanitizing steps for

the shake side and then

duplicate the applicable steps for

the soft serve side.

solution into hopper.

Draw 2 gallons (7.6 liters) of

Solid Sense All Purpose

Super Concentrate (AP SC )

(HCS) cleaning solution from

the sink proportioner.

Pour the cleaning soluti on

into the hopper and allow it to

flow into the freezing

cylinder.

Using the white hopper brush,

clean the mi x hopper, mix

level sensi ng probes and the

outside of the agitator drive

shaft housin g.

-serve machine model C602

Repeat the rinse steps for the

Using the double ended

brush, clean the mix inl et

hole.

Do not brush c lean the mi x

inlet hole while the machine

is in the WASH mode.

Touch the WASH symbol .

This will cause the cleaning

solution to come in contact

with all areas of the freezing

cylinder. Allow the solution

to agitate for 5 minutes.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 7

Page 25

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

4

Draw off cleaning solution.

Shake Side: Touch any flavor

5

Close draw valve and cancel

WASH operation is cancelled.

6

Rinse mix hopper.

mix hopper. Repeat steps 2-5.

7

Prepare sanitizing solution and

Sanitizer Solution

8

Clean, rinse, and sanitize

soft serve side.

Disassembly - Shake Side

1

Turn power switch off.

2

Remove syrup plugs.

3

Remove restrictor cap.

4

Detach spinner blade.

5

Remove freezer door.

Place an empty pail beneath

the door spout and draw off

the solution.

selection symbol to open the

draw valve.

WASH mode.

Once the cleaning solution

stops flowing from the door

spout, close the draw valve

and touch the WASH

symbol

wash mode.

, cancelling the

Note: As parts are removed,

place them on a roll-a-cart for

transport to the sink.

Be sure the power switch is

in the OFF position.

-serve machine model C602

Remove the hole plugs from

the syrup ports.

The shake dr aw valve will

automatically close when the

Pour two gallons (7.6 liters)

of cool, clean water into the

pour into hopper.

Prepare 2.5 gallons (9.5 liters)

of Kay-5 Sanitizing solution.

Use one packet in 2.5 gallons

(9.5 liters) of water (100

PPM). Pour solution into

hopper and repeat steps 3 – 5.

soft serve side.

Repeat the cleaning, rinsing,

and sanitizing steps for the

Remove the restrictor cap

from the bottom of the door

spout.

Detach the spinner blade from

the bottom of the door spout

by lifting up the locking

collar (1) on the spinner

coupling and pulling down

the blade (2).

Remove the handscre ws,

freezer door, beater assembly,

drive shaft, drive shaft seal,

and scraper blades from the

freezing cylinder.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 4 of 7

SS 3

Page 26

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

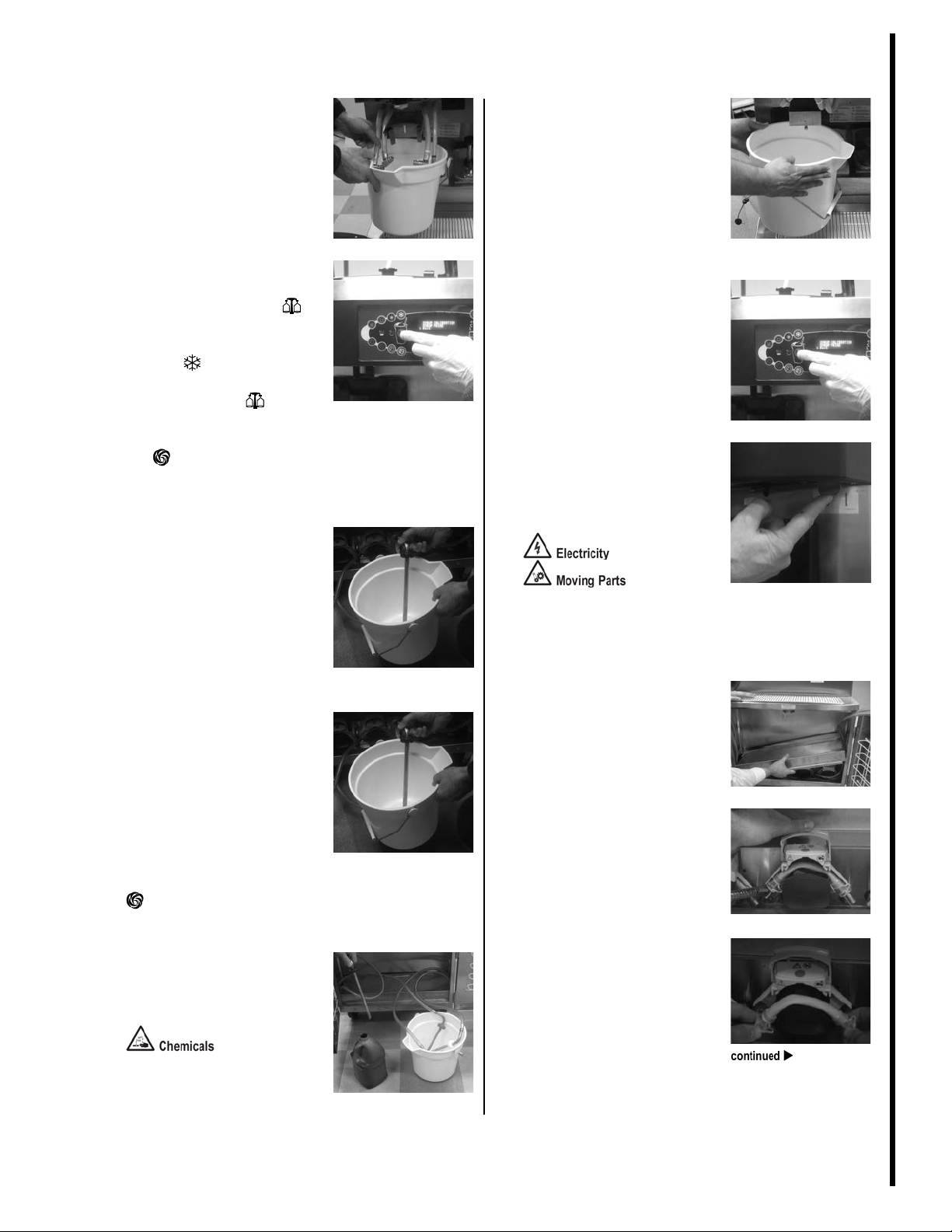

6

Take cart of parts to the sink.

7

Remove drive shaft seal.

8

Disassemble freezer door.

9

Remove spinner and seal.

Remove the s pinner shaft

10

Remove draw valve o-rings.

11

Disassemble pump cylinder.

all o-rings.

12

Remove pump drive shaft.

Disassembly - Soft Serve Side

1

Turn power switch off.

2

Remove freezer door.

3

Remove drip tray, splash

From the shake pump

cylinder, remove the retaining

pin, mix inlet adaptor, valve

cap, pump gasket, and the

piston.

Remove the check valve and

Remove the drive shaft seal

from the dr i ve shaft.

Remove the freezer door oring, front bearing, retainer

pins, and the draw valve

spinner assembly.

Remove the driven spinner

from the dr aw valve by

grasping the draw valve and

pulling the driven spinner out.

Using the pump drive shaft

removal tool, remove the

pump drive shaft from the

drive hub in t he rear wall of

the mix hopper.

Remove the o-rings.

Note: As parts are removed,

place them on a roll-a-cart for

transport to the sink.

Be sure the power switch is in

the OFF position.

-serve machine model C602

seal, using the seal install/

removal tool.

Remove the two o-rings from

the draw valve.

Remove the handscre ws,

freezer door, beater assembly,

scraper blades, and drive shaft

with drive shaft seal from the

freezing cylinder.

shield and topping ladles.

Remove the front drip tray

and splash shield. Remove the

ladles from the two cold

topping containers.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 5 of 7

SS 3

Page 27

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

4

Remove drip pans.

5

Take cart of parts to the sink.

6

Remove drive shaft seal.

7

Disassemble pump.

tube.

8

Disassemble freezer door.

removeable piece.

9

Remove pump drive shaft.

Brush Cleaning

the following ste ps.

1

Prepare cleaning solution and

Remove the long dr ip pan

from the front panel, the two

short drip pans from the rear

panel, and the two notched

drip pans from the left and

right side panels.

Remove the drive shaft seal

from the drive shaft .

Using the pump drive shaft

removal tool, remove the

pump drive shaft from the

drive hub in t he rear wall of

the mix hopper .

Remove the o-rings.

Perform all brush cleaning steps

for the shake side and place

them in the parts tray. Then

duplicate the applicable steps for

the soft serve side.

U

se parts trays to avoid

interchanging shake and soft

serve parts.

IMPORTANT: Make sure

your hands are clean and

sanitized before performing

-serve machine model C602

From the soft serve pump

cylinder, remove the retaining

pin, mix inlet adaptor, valve

cap, pump gasket, and the

piston. Re move the o-rings

and check ring from the feed

Remove the freezer door

gasket, front bearing, pivot

pin, draw handle, and draw

valve. Remove the draw valve

o-rings.

DO NOT attempt to remove

the star design from the

door. The star design is part

of the door and is NOT a

brush clean parts in the sink.

From sink proportioner draw

cleaning solution into the

sink.

horoughly brush clean all

T

disassembled parts and parts

trays in the cl eaning so l ution,

making sure all lubricant and

mix film is removed. Be sure

to brush all surfaces.

PSC Solution

A

Brush clean syrup line fittings

2

(shake side only).

Brush clea n t he syrup line

fittings using MRC car d

SS1D1.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 6 of 7

Page 28

14 Day Brush Cleaning (continued)

Taylor Company milkshake and soft

Every 14 Days

B1

3

Rinse parts.

4

Clean drive hub opening.

5

Clean rear shell bearing.

6

Soak parts in sanitizing

Sanitizer solution

7

Place parts in parts trays.

8

Brush clean soft serve side.

9

Wipe down freezer.

10

Perform equipment set-up

Equipment Manual.

Rinse all parts with clean,

warm water, one tray at a

time, includ ing the tray.

Using the bl ack brush a nd a

small amount of cleaning

solution, clean the drive hub

openings in the rear wall of

the mix hopper .

Repeat brush cleaning and

sanitizing steps for the soft

serve side of the freezer.

-serve machine model C602

Using the bl ack brush a nd a

small amount of cleaning

solution, clean the rear shell

bearing at the back of the

freezing cylinder.

Wipe all exterior surfaces of

the freezer with a clean,

sanitized towel.

solution.

Prepare a sink with sanitizing

solution. Soak the parts and

trays for a minimum o f 1

minute.

Using clean and sanitized

hands, place disassembled

parts in clean and sanitized

parts trays until the equipment

is set up.

procedures.

Perform the equipment set-up

procedures outlined in the

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 7 of 7

Page 29

Calibrate hopper temperatur es Monthly SS 3 M1

Taylor Company milkshake and soft

Monthly

M1

Why

To meet food safety standards and to maintain product quality

Time required

5 minutes to prepare

5 minutes to complete

recalibrated the machine

Time of day

At open

For 24-hour restaura nts: during breakfast menu

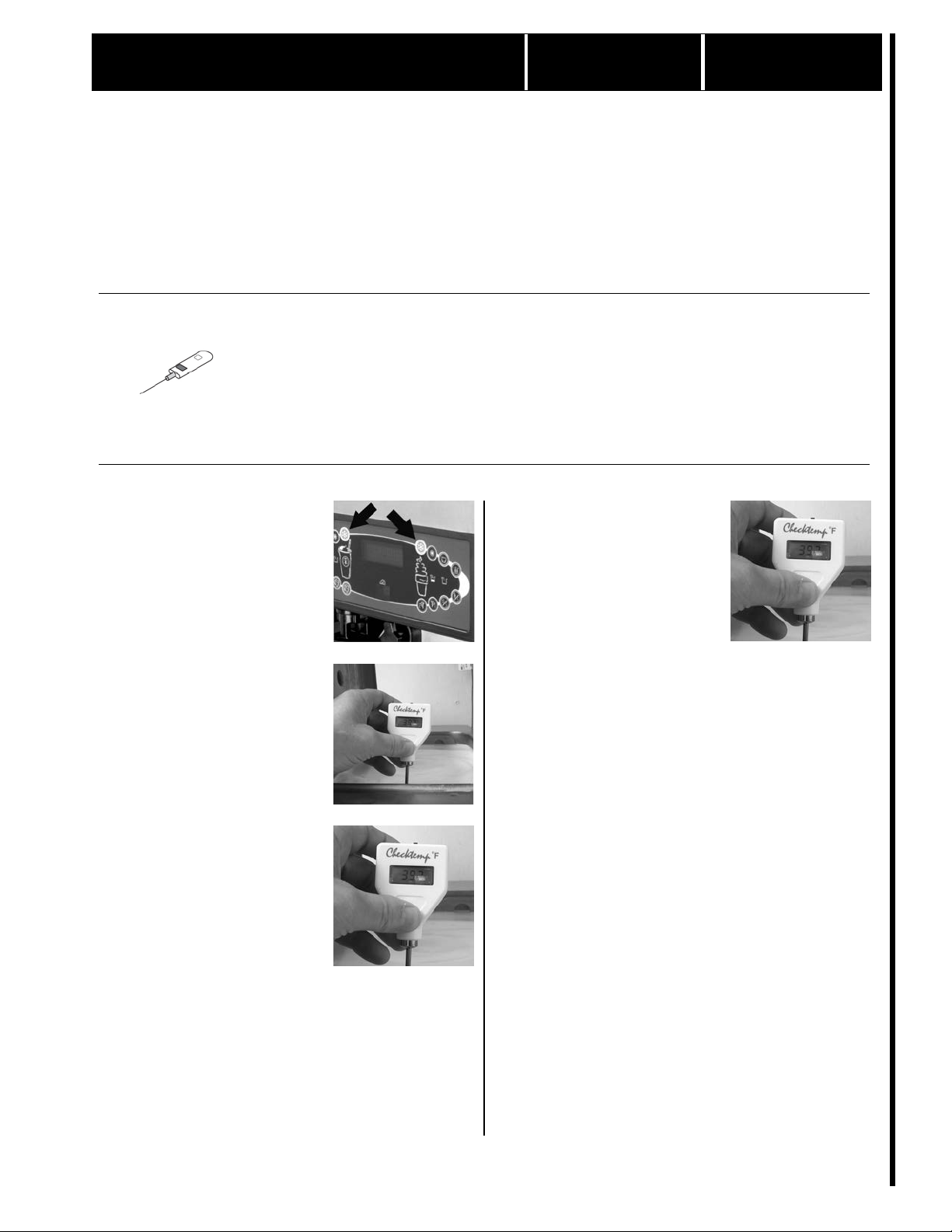

Hazard icons

Pyrometer with sanitized

needle probe

1

Turn machine to Auto or

2

Place needle probe in mix.

3

Read temperature.

the hopper cover.

4

Read temperature of mix in

the hopper cover.

30 minutes to complete if a service technician has

Tools and supplies

-serve machine model C602

Procedure

Standby.

Set both sides of the machine

to the Auto or Standby mode.

Open the hopper cover until it

is fully upright. Place the sanitized probe of a calibrated

pyrometer i nto the mix.

Allow the temperature to stabilize for 10 seconds. Read

the temperature on the pyrometer.

he temperature of the mix

T

should be between 34° and

38°F (1° and 3°C). If the temperature reading is not

between these temperatures,

contact your factoryauthorized service center.

other hopper.

Open the other hopper cover

and repeat the temperature

check.

he temperature of the mix

T

should be between 34° and

38°F (1° and 3°C). If the temperature reading is not

between these temperatures,

contact your factoryauthorized service center.

Remove the probe and close

SS 3

Remove the probe and close

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 1

Page 30

Calibrate draw temperatures Monthly SS 3 M2

Taylor Company

Monthly

M2

Why

To maintain product quality

Time required

5 minutes to prepare

5 minutes to complete

ibrated the machine

Time of day

At open

For 24-hour restaura nts: during breakfast menu

Hazard icons

Pyrometer with sanitized

Cold drink cup, child

1

Turn main power switch on.

2

Select auto function on soft-

3

Draw small portion of soft

handle all the way back.

4

Pre-cool needle probe.

5

Draw second sample of soft

30 minutes to complete if a service technician has recal-

milkshake and soft-serve machine model C602

Tools and supplies

needle probe

Procedure

serve side of machine.

serve.

Place a child-size cold-drink

cup under t he dispensing nozzle and pull t he draw handle

forward. Draw a small portion

of soft serve, and push the

size

Place the sanitized probe of a

calibrated pyrometer into the

soft serve to pre-cool it.

Leave the pyrometer in the

soft serve until you are ready

to read the temperature in the

next step.

serve.

Using a fresh child-size colddrink cup, d raw another small

sample of soft serve.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 2

Page 31

Calibrate draw temperatures (continued)

Taylor Company

Monthly

M2

6

Read temperature of soft

7

Read temperature of

serve.

Place the needle probe into

the soft serve. Allow the pyrometer to stabilize for 10

seconds, and read the temperature on the pyrometer.

The temperature should be

between 16° and 18°F (-9°

and -8°C). If the te mperature

reading is not between these

temperatures, contact your

factory-authorized service

center.

milkshake and soft-serve machine model C602

Lea

ve the pyrometer in the

soft serve until you are ready

to read the temperature in the

next step.

milkshake.

Using a fresh child-size colddrink cup, d raw a small sample of milkshake.

e proper draw temperature

Th

for Triple Thick Milks hakes

is between 22° and 24°F (-5°

and -4°C). If the temperature

reading is not between these

temperatures, contact your

factory-authorized service

center.

The proper draw temperature

for milkshakes is between 24°

and 26°F (-4° and -3°C). If

the temperature reading is not

between these temperatures,

contact your factoryauthorized service center.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 2

Page 32

Calibrate hot sundae topping temperatures

and volumes

Monthly SS 3 M3

Taylor Company

Monthly

M3

Why

To meet food quality standards and to meet Gold Standard quality descriptions

Time required

5 minutes to prepare

5 minutes to complete

30 minutes to recalibrate temperatures

Time of day

At open

For 24-hour restaura nts: during breakfast menu

Hazard icons

Bucket, clean and

Bucket, soiled towels

Calibration cup

Pyrometer with sanitized

Screwdriver, flat

Sundae cup

1

Dispense hot topping.

2

Read temperature of topping.

steps 3-8.

CAUTION! Steps 3-8 mu s t

3

Remove right panel.

4

Read water bath temperature.

may be extre mel y ho t.

milkshake and soft-serve machine model C602

Tools and supplies

sanitized towels

Procedure

Hold an empty sundae cup

under a hot topping pump

spout. Push the pump lever

down one full stroke.

Place the sanitized probe of a

calibrated pyrometer into the

topping and wait 20 seconds

for the temperature to stabilize.

The temperature should be

between 115° and 125°F (46°

and 52°C).

Remove the probe and clean

it thoroughly with a clean,

sanitized towel.

S

anitizer solution

f the temperature falls within

I

the proper range, go to step 9.

If a temperature adjustment is

needed, contact an authorized

service technician to perform

needle probe

be performed by an authorized service technician.

Temperature controls for the

water baths are located behind

the topping pumps. To access

the controls, remove the right

panel. Use a flat screwdriver

to remove the screws from the

panel. Set the panel and

screws aside.

If the topping temperature is

not within range, check the

water bath temperature.

Remove the topping pump.

Insert the probe into the water

in the water bath and wait 20

seconds for the temperature to

stabilize.

The temperature should be

between 135° and 145°F (57°

and 63°C).

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 2

Metal surfaces and water bath

Page 33

Calibrate hot sundae topping t em peratures and volumes (continued)

Taylor Company

Monthly

M3

Remove the probe and wipe it

5

Adjust water bath temperature.

and 63°C).

6

Read temperature of topping.

7

Calibrate other hot topping

8

Replace right panel.

9

Dispense hot topping into

run down the s ides of the cup.

10

Read volume of hot topping.

sink.

11

Calibrate other hot topping

thoroughl y with a clean, sanitized towel.

M

etal surfaces and water bath

may be extre mel y ho t.

There is one temperature adjustment screw for each water

bath. Use a flat screwdriver to

turn the correct screw.

f the water bath temperature

I

is below 135°F (57°C), turn

the screw clockwise.

I

f the water bath temperature

is above 145°F (63°C), turn

the screw counterclockwise.

Turn the adjustment screw in

small increments.

ait 10 minutes for the water

W

bath temperature to stabilize.

Repeat steps 4 and 5 until the

water bath temperature is

between 135° and 145°F (57°

When all hot topping temperatures have been calibrated,

reinstall the right panel. Hold

the panel in position, and use

the screwdriver to replace the

screws.

calibration cup.

Do not begin this step until

the topping temperature is

between 115° and 125°F (46°

and 52°C) or the dispensed

amounts will not be correct.

Hold the small chamber of a

calibration cup under a pump

spout. Push the pump lever

down one full stroke. Dispense the topping directly

onto the bottom of the cup.

Do not allow the topping to

Read the topping level in the

calibration cup. The amount

of dispensed topping should

be 1 fluid ounce (30 ml).

f the dispensed amount i s not

I

1 fluid ounce (30 ml), contact

an authorized service technician.

milkshake and soft-serve machine model C602

Replace the topping pump.

Wait 60 minutes for the topping temperature to stabilize.

epeat steps 1 and 2 to read

R

the topping temperature.

temperatures.

Repeat steps 1 through 6 for

each hot topping pump.

Wash and rinse the calibration

cup at the three-compartment-

volumes.

Repeat steps 9 and 10 for

each hot topping pump.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 2

Page 34

Replace soft-serve scraper blades Quarterly SS 3 Q1

Ta

Quarterly

Q1

Why

To scrape frozen mix off the cold freezing cylinder wall.

Time required

0 minutes to prepare

2 minutes to complete

Time of day

At 14 Day Brush Cleaning

Hazard icons

1

Machine must be off.

2

Inspect scraper blade.

Scraper blades are sharp.

3

Install rear scraper blade.

5

Install front scraper blade and

6

Slide beater assembly into

Procedure

IMPORTANT: The scraper blade replacement procedures must be performed during the 14 Day Brush Cleaning. Perform the 14 Day Brush

Cleaning per the Operations Manual to properly drain, disassemble, clean, rinse, assemble, sanitize, and prime the machine.

ylor Company soft serve machine model C602

Make sure the power switch

is in the off position.

Make sure scraper blade is

straight and blade opening is

clean. If bent or chipped,

replace with new blade. Brush

clean blade to remove dried

mix.

Scraper blades are sharp.

Place the rear scraper blade

over the rea r holding pi n on

the beater assembly.

Insert beater half way.

4

Insert beater half way into the

freezing cylinder to support

the rear of the beater.

beater shoes.

Place the front scraper blade

over the front holding pin.

Install beater shoes on beater.

freezing cylinder.

Slide the beater assembly into

the freezing cylinder to secure

the scraper blade on the beater.

S

craper blades are sharp.

S

craper blades are sharp.

Rock the beater.

7

ock the beater assembly

R

back and for th slightly to

make sure it is properly seated on the drive shaft. The

assembly should not stick out

beyond the front of the fr eezing cylinder.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 1

Page 35

Clean non-aluminum air filter Quarterly SS 3 Q2

Taylor Company milkshake and soft

Quarterly

Q2

Why

To prevent dust and dirt build-up on the main condenser

Time required

5 minutes to prepare

30 minutes to complete

Time of day

During 14 day brush cleaning.

For 24-hour restaura nts: Durin g 14 day brush cleaning.

Hazard icons

Bucket, clean and

Bucket, soiled towels

Brush, pot, nylon

SolidSense™ All

Concentrate (APSC)

1

Turn off and unplug machine.

turned off and unplugged.

2

Remove air filter.

3

Wash filter.

4

Rinse filter.

of normal air flow.

5

Shake filter.

6

Dry filter.

Tools and supplies

-serve machine model C602

sanitized towels

Procedure

Move the power switch to the

off position. Unplug the machine.

Do not begin c leaning the air

filter until the machine is

Remove the filter and take it

to sink.

Purpose Super

solution

Rinse the filter with hot water

from the hot water hose.

Flush the wat er through the

filter in the opposite direction

While holding the filter over

the sink, shake it to remove as

much water as possible.

Wash the filter thoroughly in

APSC solutio n.

AP

SC solution

Using a clean, sanitized towel, wipe any remaining

moisture from the filter.

S

anitizer solution

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 2

SS 3

Page 36

Clean non-aluminum air filter (continued)

Taylor Company milkshake and soft

Quarterly

Q2

7

Replace filter.

Install the new filter. Push

firmly until the filter is seated.

-serve machine model C602

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 2

Page 37

Replace machine components Quarterly SS 3 Q3

Taylor Company milkshake and soft

Quarterly

Q3

Why

To meet food safety and food quality standards and to ensure proper machine operation

Time required

5 minutes to prepare

30 minutes to complete

Time of day

During 14 day brush cleaning

For 24-hour restaura nts: During 14 day brush cleaning

Hazard icons

Taylor Tune-up Kit,

milkshake side parts

Taylor Tune-up Kit,

soft

1

Set up parts tray for milkshake

2

Replace milkshake side parts.

Discard the old parts.

3

Replace soft-serve side parts.

Tools and supplies

-serve machine model C602

-serve side parts

Procedure

side.

Place the new pa rts in the

proper location on the parts

tray.

Using the tools included with

the kit, replace the old

machine components with the

new parts.

Refer to the instructions provided with the tune-up ki t for

your equipment.

Repeat steps 1 through 2 for

the soft-serve side.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 1

Page 38

Replace milkshake mix scraper blades Semi-annually SS 3 S1

Taylor Company milkshake and soft

Semi

S1

Why

To prevent frozen milkshake mix from freezing on the cylinder wall

Time required

5 minutes to prepare

5 minutes to complete

Time of day

During low-volume periods

For 24-hour restaura nts: during low-volume periods

Hazard icons

1

Drain milkshake mix from

2

Turn off and unplug machine.

unplugged.

3

Remove freezing cylinder

door. Set aside.

4

Remove beater assembly.

Scraper blades are sharp.

5

Remove scraper blades.

Scraper blades are sharp.

6

Install new scraper blades.

Always replace both blades.

7

Slide beater assembly into

8

Replace freezing cylinder door.

Procedure

hopper and freezing cylinder.

Move the power switch to the

off position. Unplug the

machine.

Do not begin replacing the

scraper blades until the machine is tur ned off and

door.

Remove the handscre ws fr o m

the freezing cylinder door and

set aside.

Remove the freezing cyl inder

Carefully remove the scraper

blades by lifting the blades

off the holding pins.

Place each scraper blade over

the holding pins on the beater

assembly.

S

craper blades are sharp.

freezing cylinder.

Slide the beater assembly into

the freezing cylinder. Rock it

back and forth sl ightly to

make sure it is properly seated. The assembly should not

stick out beyond the fro nt of

the freezing cylinder.

-serve machine model C602

Grasp the front of the beater

assembly and carefully pull it

all the way out of the machine. Support both the front

and back of the assembly as

you remove it.

S

craper blades are sharp.

Using the stud nuts, replace

the freezing cylinder door.

I

nstall the handscrews.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 1

-annually SS 3

Page 39

Taylor Co

Annually

A1

Why

To break the bacteria cycle and to ensure proper flow of syrup to the draw valve

Time required

5 minutes to prepare

20 minutes to complete

Time of day

At open

For 24-hour restaura nts: during breakfast menu

Hazard icons

Bucket, SolidSense™ All

Bucket, KAY-5®

Bucket, plastic

Bucket, clean and

Bucket, soiled towels

Plastic wrap

Pump tube

Taylor Lube HP

1

Remove syrup feed tube and

Sanitizing Solution

2

Cover jug with plastic wrap.

3

Place syrup feed tube in

4

Place empty bucket under

5

Remove syrup line from

Replace syrup pump tubes Annually SS 3 A1

mpany milkshake and soft-serve machine model C602

Tools and supplies

Purpose Super

Concentrate (APSC)

Sanitizing Solution

Procedure

syrup jug.

Open the cabinet door. Remove the syrup feed tube

from a syrup jug. Wipe the

outside of the feed tube with a

clean, sanitized towel.

Remove the syrup jugs from

the cabinet.

sanitized towels

SolidSense APSC solution.

Place the syrup feed tube in a

bucket of APSC solution.

AP

SC Solution

milkshake draw valve.

Place a clean plastic bucket

under the milkshake draw

valve.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 1 of 4

milkshake freezer door.

Disconnect the corresponding

syrup line from the milkshake

freezer door by raising the

syrup valve retainer. Pull the

valve straight out.

SS 3

Page 40

Replace syrup pump tubes (continued)

Taylor Company milkshake and soft

A

A1

6

Place syrup line and valve in

7

Start flow of SolidSense APSC

APSC throu gh the line.

8

Flush syrup line with

pletely flushed.

9

Pump all liquid from syrup

through the syrup line.

10

Place feed tube in KAY-5

11

Place empty bucket under

12

Flush syrup line with KAY-5

13

Turn off and unplug machine.

unplugged.

14

Remove pump cover tray.

15

Open pump.

exposed.

16

Remove the pump tube.

bucket.

Hang the syrup line and valve

into the empty bucket.

solution though syrup line.

Press the calibration key

on the control panel to display

the menu op t ions. Touch the

auto key

row to “syrup prime.” Touch

the calibration key

to display the syrup p rime

screen. Press the flavor select

key

flavor to start the flow of

SolidSense APSC.

Allow the APSC solution to

continue to flow into the empty bucket until all the syrup is

flushed from the line. When

the liquid from the syrup line

runs clear, the line is com-

to move the ar-

again

for the corresponding

milkshake draw valve.

Place a clean plastic bucket

under the milkshake draw

valve.

Sanitizing solution.

Repeat steps 8 through 10

using the sanitizing solution.

Move the power switch to the

off position. Unplug the machine.

Do not begin working with

the syrup pump until the machine is tur ned off and

-serve machine model C602

line.

Remove the syrup feed tube

from the bucket of APSC

solution and continue to run

the pump until APSC solution

no longer ru ns from the s yrup

line.

T

ouch the flavo r select key

to stop the flow of APSC

Sanitizing solution.

Place the syrup feed tube in a

bucket of sanitizing solution.

San

itizing Solution

Remove the pump cover tray

in the cabinet by lifting it up

and out. Set it aside.

Open the pump for the corresponding line by pushing up

on the hinged cover. The

pump tube assembly is now

nnually

Using both hands, grasp the

pump tube assembly on both

ends and pull it up and out of

the pump body.

SS 3

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 2 of 4

Page 41

Replace syrup pump tubes (continued)

Taylor Company milkshake and soft

A

A1

17

Remove clips.

18

Remove fittings.

19

Lubricate o-rings.

20

Insert fittings into new pump

firmly into place.

21

Attach clips to collars.

22

Position the pump rollers.

23

Push the pump tube assembly

24

Close pump.

cover.

25

Flush remaining syrup lines

26

Replace the pump cover tray.

27

Replace the syrup jugs and

28

Plug in machine and turn on.

29

Prime each syrup line.

Remove the two clips attached to the pump tube

collars.

Remove the two fittings that

connect the feed tube and

syrup line to the pump tube.

Locate the o-rings on the

fittings. Lubricate each o-ring

with Taylor Lube HP.

tube.

Insert the fittings on the feed

tube and syr up line into a new

pump tube by pushing them

Push down on the hinged

cover to close the pump body.

To avoid damage to the pump

tube, make sure it is seated

properly in the pump body

before closing the hinged

and replace remaining pump

tubes.

Repeat steps 1 through 25 for

each remaining syrup flavor.

Replace the pump cover tray

by sliding the tray in ove r the

pumps.

-serve machine model C602

Attach one clip to each collar

on the new pump tube.

Using both hands, rotate the

pump rollers so they are in the

10 o’clock and 2 o’clock

positions.

into the pump body.

Make sure the syrup line i s

pushed through the rear of the

cabinet.

syrup feed tubes.

Remove the plastic wrap from

each syrup jug. Return the