Stryker Vertier Service manual

Vertier™ Surgical Table

Service Manual

February 2010 |

1004-400-177 REV E |

www.stryker.com |

Vertier™ Surgical Table

Service Manual

This manual contains confidential information that shall not be disclosed or duplicated for any reason other than to use and maintain a Stryker Surgical Table. This restriction does not limit the right to use information contained in this manual, if it is obtained from another source without restriction. The information subject to this restriction is contained in all pages of this manual.

© February 2010 Stryker Communications. All rights reserved. Information in this document is subject to change without notice. Stryker, and Stryker logo are registered trademarks of Stryker.

All rights reserved.

Stryker Vertier™ Surgical Table Service Manual

1004-400-177 REV E

|

|

|

|

|

|

Contents |

|

1. Warnings, Cautions, and Notes ............................................................................................... |

11 |

||

1.1 |

Warnings ............................................................................................................................ |

11 |

|

1.2 |

Cautions ............................................................................................................................. |

13 |

|

1.3 |

Notes .................................................................................................................................. |

14 |

|

1.4 |

Table Pinch Points .............................................................................................................. |

15 |

|

1.4.1 |

Pinch Point Zones ..................................................................................................... |

16 |

|

2. Product Symbol Definition ...................................................................................................... |

19 |

||

2.1 |

EMC Precautions................................................................................................................ |

21 |

|

3. Indications for Use .................................................................................................................. |

23 |

||

3.1 |

Prior to Servicing Tables..................................................................................................... |

23 |

|

3.2 |

Following any Table Service ............................................................................................... |

24 |

|

3.3 |

Operating Characteristics ................................................................................................... |

24 |

|

4. Main Components Structure................................................................................................... |

25 |

||

4.1 |

Base and Column Casings ................................................................................................. |

26 |

|

4.1.1 |

Base Cover Removal ................................................................................................ |

27 |

|

4.1.2 |

Column Casings........................................................................................................ |

29 |

|

4.1.3 |

Bellows Frame Replacement .................................................................................... |

42 |

|

4.1.4 |

Castor Removal......................................................................................................... |

47 |

|

4.2 |

Inner Column ...................................................................................................................... |

52 |

|

4.2.1 |

upper Energy Chain Assembly, 50mm (0788-200-038) ............................................ |

52 |

|

4.2.2 |

Upper 50mm Energy Chain Replacement ................................................................ |

54 |

|

4.3 |

Table Top & Sections .......................................................................................................... |

62 |

|

4.3.1 |

Lever Assembly (0788300067) Replacement/Preventive Maintenance .................... |

62 |

|

4.3.2 |

Threaded Lever Spring (0788400000) Replacement................................................ |

63 |

|

4.4 |

Seat Section and Assemblies............................................................................................. |

63 |

|

4.4.1 |

Center Rail Section ................................................................................................... |

67 |

|

4.4.2 |

Tilt Frame Assembly.................................................................................................. |

68 |

|

4.4.3 |

Tilt Frame Lower Parts Assembly (view from underside) .......................................... |

70 |

|

4.4.4 |

Slide Motor Assembly ............................................................................................... |

70 |

|

4.4.5 |

Right Sledge Assembly (0788-300-066) ................................................................... |

87 |

|

5

4.4.6 |

Left Sledge Assembly (0788-300-065)...................................................................... |

88 |

|

4.4.7 |

Left Seat Section Tube - One Piece .......................................................................... |

89 |

|

4.4.8 |

Right Seat Section Tube - One Piece........................................................................ |

93 |

|

4.4.9 |

Left Back Section Cylinder ........................................................................................ |

96 |

|

4.4.10 |

Left Leg Section Cylinder .......................................................................................... |

98 |

|

4.4.11 |

Right Back Section Cylinder.................................................................................... |

100 |

|

4.4.12 |

Right Leg Section Cylinder...................................................................................... |

102 |

|

4.4.13 |

Left Joint Shields Assembly (0788300068)............................................................. |

104 |

|

4.4.14 |

Right Joint Shields Assembly (0788300069) .......................................................... |

105 |

|

4.4.15 |

Replacement of the Column Sealing Kit ................................................................. |

108 |

|

5. Technical Data ...................................................................................................................... |

124 |

||

5.1 |

Identification Plate ............................................................................................................ |

124 |

|

5.1.1 |

Illustrated Designations and Symbols ..................................................................... |

125 |

|

5.2 |

Properties and Materials .................................................................................................. |

125 |

|

5.2.1 |

Surface Materials .................................................................................................... |

125 |

|

5.3 |

Specifications ................................................................................................................... |

125 |

|

5.3.1 |

Environmental Specifications .................................................................................. |

125 |

|

5.3.2 |

Electrical Specifications .......................................................................................... |

126 |

|

5.3.3 |

Microcontroller......................................................................................................... |

126 |

|

5.3.4 |

Classification Data .................................................................................................. |

126 |

|

5.3.5 |

Adjustment Ranges................................................................................................. |

127 |

|

5.3.6 |

Power Supply (0788-205-002) ................................................................................ |

127 |

|

5.3.7 |

MPC - Motion Process Controller (0788-205-001).................................................. |

128 |

|

5.3.8 |

Hydraulic Unit Specifications (0788-203-000)......................................................... |

128 |

|

5.3.9 |

Weights and Dimensions ........................................................................................ |

128 |

|

6. Electronics |

............................................................................................................................ |

130 |

|

6.1 |

Special User Attention ...................................................................................................... |

130 |

|

6.1.1 |

Warnings ................................................................................................................. |

130 |

|

6.2 |

Battery .............................................................................................................................. |

130 |

|

6.2.1 |

Replacing the Battery.............................................................................................. |

131 |

|

6.2.2 |

Battery Charge........................................................................................................ |

132 |

|

6.2.3 |

Battery Indicators......................................................................................................... |

132 |

|

6.2.4 |

Storage of batteries....................................................................................................... |

132 |

|

6.3 |

Power Supply (0788205002) ............................................................................................ |

133 |

|

6

|

|

|

|

6.3.1 |

Specifications .......................................................................................................... |

133 |

|

6.3.2 |

Replacing the Power Supply ................................................................................... |

134 |

|

6.3.3 |

Setting the Secondary Voltage................................................................................ |

135 |

|

6.4 |

Main Switch Panel ............................................................................................................ |

136 |

|

6.4.1 |

Replacing the fuses................................................................................................. |

137 |

|

6.4.2 |

Replacing the Power Entry Module Assembly (0788205011) ................................. |

137 |

|

6.4.3 |

Replacing the Main Switch (0788305046) .............................................................. |

138 |

|

6.5 |

Remote Control ................................................................................................................ |

139 |

|

6.5.1 |

Corded Hand Control (0788305001)....................................................................... |

139 |

|

6.5.2 |

IR-Controller (0788-305-002) .................................................................................. |

141 |

|

6.5.3 |

Device Address ....................................................................................................... |

142 |

|

6.5.4 |

Programming........................................................................................................... |

143 |

|

6.5.5 |

IR Receiver Replacement Kit (0788205010)........................................................... |

144 |

|

6.6 |

Override Panel Assembly (0788205000).......................................................................... |

149 |

|

6.6.1 |

Override Panel Replacement .................................................................................. |

149 |

|

6.7 |

Override Logic .................................................................................................................. |

159 |

|

6.8 |

Foot Switch (0788-305-005) ............................................................................................. |

160 |

|

6.9 |

Hydraulic Pressure Sensor Assembly (0788203003) ....................................................... |

160 |

|

6.9.1 |

Hydraulic Pressure Sensor (0788305016) .............................................................. |

161 |

|

6.9.2 |

Hydraulic Pressure Sensor Replacement ............................................................... |

161 |

|

6.10 |

Tilt/Trend Sensors (0788305012) .................................................................................... |

165 |

|

6.10.1 |

Replacement of Tilt/Trend Sensor ........................................................................... |

166 |

|

6.11 Inductive Leg Sensor Assembly (0788205005) ................................................................ |

175 |

||

6.11.1 |

Replacement of Inductive Leg Sensor .................................................................... |

176 |

|

6.12 Seat Section Sensor Cable Harness Assembly (0788305025) ........................................ |

184 |

||

6.12.1 |

Replacement of Seat Section Sensor Cable Harness Assembly............................ |

185 |

|

6.13 |

Potentiometers.................................................................................................................. |

196 |

|

6.13.1 |

Potentiometer Testing and Calibration..................................................................... |

196 |

|

6.13.2 |

Replacement of Potentiometers .............................................................................. |

198 |

|

6.14 |

Safety Edge Sensors........................................................................................................ |

244 |

|

6.14.1 |

Replacement of Safety Edge Sensor ...................................................................... |

244 |

|

6.14.2 |

Routing Lower Wire Harness of Safety Edge Sensor Assembly with Quick Connect .. |

||

|

(0788205009)...................................................................................................................... |

251 |

|

6.15 |

Sensor Connections ......................................................................................................... |

260 |

|

7

6.16 MPC (Motion Process Controller, 0788-205-001)............................................................. |

261 |

||

6.16.1 |

General ................................................................................................................... |

261 |

|

6.16.2 |

Communication ....................................................................................................... |

261 |

|

6.16.3 |

PC Connection ........................................................................................................ |

262 |

|

6.16.4 |

Connectors.............................................................................................................. |

262 |

|

6.16.5 |

MPC Connections ................................................................................................... |

262 |

|

6.16.6 |

Replacement of the MPC ........................................................................................ |

263 |

|

6.17 |

Vertier Wiring Diagram...................................................................................................... |

265 |

|

6.18 Solenoid Pin Connector Configuration ............................................................................. |

267 |

||

6.19 MPC Motor Outputs and Power Inputs ............................................................................. |

268 |

||

6.19.1 |

MPC Motor Output and Power Input Cable Replacement....................................... |

268 |

|

6.19.2 |

Slide Motor - MPC Cable Replacement (0788305024) .......................................... |

271 |

|

6.20 |

Valve Block Control........................................................................................................... |

279 |

|

6.20.1 |

Features .................................................................................................................. |

279 |

|

6.21 |

Cables .............................................................................................................................. |

279 |

|

6.21.1 |

AC Voltage............................................................................................................... |

279 |

|

6.21.2 |

DC Voltage .............................................................................................................. |

279 |

|

6.21.3 |

Hook and Loop Fastener Placement....................................................................... |

279 |

|

7. Hydraulics ............................................................................................................................. |

|

282 |

|

7.1 |

Safety Information............................................................................................................. |

282 |

|

7.1.1 |

Lift column .............................................................................................................. |

282 |

|

7.1.2 |

Warnings ................................................................................................................. |

282 |

|

7.2 |

Hydraulic Unit (0788-203-000) ......................................................................................... |

283 |

|

7.2.1 |

Removing the Hydraulic Unit................................................................................... |

284 |

|

7.2.2 |

Hydraulic Oil (0788-303-008) .................................................................................. |

285 |

|

7.3 |

Main Valve Block TLC3 (0788-203-001) ........................................................................... |

286 |

|

7.3.1 |

Hose Connections................................................................................................... |

287 |

|

7.3.2 |

Hydraulic Circuit Diagram ....................................................................................... |

288 |

|

7.3.3 |

Valve Block TLC3 .................................................................................................... |

289 |

|

7.3.4 |

Replacement of TLC3 Manifold............................................................................... |

289 |

|

7.3.5 |

Exchange of TLC3 Valve ......................................................................................... |

290 |

|

7.3.6Changing the Solenoid Coil at SP1 (Valve Block Floor Lock) and TLC3 (Valve

System) ............................................................................................................................... |

292 |

7.4 Top Manifold ..................................................................................................................... |

293 |

8

|

|

|

|

7.4.1 |

Top Manifold............................................................................................................ |

295 |

|

7.4.2 |

Top Manifold Hose Repair and Replacement.......................................................... |

296 |

|

7.5 |

Cylinder Types .................................................................................................................. |

305 |

|

7.6 |

Floor Lock Cylinder Type LF16 ............................................................................................. |

307 |

|

7.6.1 |

Connections ............................................................................................................ |

307 |

|

7.6.2 |

Cylinder Type........................................................................................................... |

308 |

|

7.6.3 |

Pressure Switch and Valve Block (0788203002)..................................................... |

316 |

|

7.7 |

5th Wheel Assembly ......................................................................................................... |

316 |

|

8. Service Software .................................................................................................................. |

318 |

||

8.1 |

General............................................................................................................................. |

318 |

|

8.2 |

Login................................................................................................................................. |

319 |

|

8.2.1 |

Password................................................................................................................. |

319 |

|

8.2.2 |

Table Configuration Data......................................................................................... |

319 |

|

8.2.3 |

Update MPC SW..................................................................................................... |

320 |

|

8.2.4 |

Update Sidne™ IDAM SW ...................................................................................... |

320 |

|

8.3 |

Identification ..................................................................................................................... |

321 |

|

8.3.1 |

Software Versions ................................................................................................... |

321 |

|

8.3.2 |

Serial Number ......................................................................................................... |

321 |

|

8.3.3 |

IR Address .............................................................................................................. |

321 |

|

8.3.4 |

Assembly Options ................................................................................................... |

322 |

|

8.4 |

Motions ............................................................................................................................. |

322 |

|

8.4.1 |

Motion Parameters .................................................................................................. |

322 |

|

8.4.2 |

Motions Limits ......................................................................................................... |

322 |

|

8.5 |

Preset Positions................................................................................................................ |

324 |

|

8.5.1 |

Preset Position ........................................................................................................ |

325 |

|

8.5.2 |

Cycle Drive Time ..................................................................................................... |

325 |

|

8.6 |

Timings & Voltages ........................................................................................................... |

325 |

|

8.6.1 |

Battery Voltage........................................................................................................ |

326 |

|

8.6.2 |

Valve Timing............................................................................................................ |

326 |

|

8.6.3 |

Motion Maximum Duration ...................................................................................... |

326 |

|

8.6.4 |

Automatic Shut off Time .......................................................................................... |

326 |

|

8.6.5 |

System Time ........................................................................................................... |

327 |

|

8.6.6 |

Total Motion Time .................................................................................................... |

327 |

|

8.7 |

Cycle Test ......................................................................................................................... |

327 |

|

9

|

8.7.1 |

Read From File ........................................................................................................ |

328 |

|

|

8.8 |

Logged Data ..................................................................................................................... |

329 |

|

|

8.8.1 |

Identified Error Situations ........................................................................................ |

330 |

|

9. Cleaning and Disinfecting ..................................................................................................... |

332 |

|||

|

9.1 |

Cleaning ........................................................................................................................... |

332 |

|

|

9.2 |

Disinfection ....................................................................................................................... |

332 |

|

|

9.3 |

Mattresses and Pads ........................................................................................................ |

332 |

|

10. |

Troubleshooting................................................................................................................... |

334 |

||

11. |

Maintenance |

....................................................................................................................... |

338 |

|

|

11.1 |

Safety During Maintenance Procedures........................................................................... |

338 |

|

|

11.2 |

Daily ............................................................................................................Maintenance |

338 |

|

|

11.3 |

Monthly .......................................................................................................Maintenance |

338 |

|

|

11.4 |

Annual .........................................................................................................Maintenance |

339 |

|

|

11.5 |

Repair .........................................................................................................Maintenance |

340 |

|

12. |

Recycling ............................................................................................................................ |

|

342 |

|

|

12.1 |

Metals ...........................................................................................................and Plastics |

342 |

|

|

12.2 |

Hydraulic ...............................................................................Cylinders and Gas Springs |

342 |

|

|

12.3 |

Oil ..................................................................................................................................... |

|

342 |

|

12.4 |

Electronic .........................................................................................Waste and Batteries |

342 |

|

13. |

Replacement ...............................................................................................Part Numbers |

344 |

||

14. |

Stryker Limited ....................................................................................................Warranty |

352 |

||

15. |

Contact Information ............................................................................................................ |

354 |

||

10

1. Warnings, Cautions, and Notes

Please read this manual and follow its instructions carefully. The words WARNING, CAUTION, and Note carry special meanings and should be carefully reviewed:

WARNING |

The personal safety of the patient or user may be involved. Disregarding |

|

this information could result in injury to the patient. |

Caution |

Special service procedures or precautions must be followed to avoid damag- |

|

ing the instrument. |

WARNING |

A lightening bolt within a triangle is intended to warn of the presence of |

|

hazardous voltages. Refer all service to authorized personnel. |

Note Special information to make maintenance easier or important information more clear.

1.1Warnings

To avoid potential serious injury to the user and the patient and/or damage to this device, the user must:

1.Read this manual thoroughly, and be familiar with its contents prior to using this equipment.

2.Be qualified medical personnel, having complete knowledge of the use of this equipment.

3.Always wear disposable gloves and a mask when working on used tables, due to risk of infection or disease. If the table appears to have an excess of biowaste, you may need to clean and disinfect the table prior to service.

4.Test this equipment prior to a surgical procedure. This product was fully tested at the factory before shipment.

5.Disconnecting any of the hydraulic hoses can cause uncontrolled and dangerous movement of the table. Support the table parts before disconnecting any hoses. Only trained personnel should maintain hydraulic components.

6.Avoid removing covers on the product to avoid electric shock.

7.Attempt no internal repairs or adjustments unless specifically instructed to do so in this operating manual.

8.The table weighs 600 lbs (300 kg), as such it is necessary to have two people to unpack/pack it. Use work gloves when handling the crate to avoid injury.

9.NEVER PLACE ITEMS ON THE TABLE BASE DURING ARTICULATION. THIS WILL CAUSE DAMAGE TO THE TABLE.

10.The Vertier™ Surgical Table should only be used in facilities made for medical purposes.

11.Connect the Mains Cord only to a grounded power supply.

12.The Vertier™ shall be operated from its internal battery if the integrity of the protective grounding conductor arrangement is in doubt.

13.Place the patient in the longitudinal center line of the table top.

11

14.In NORMAL mode maximum patient weight is 275 kg (600 lbs).

15.In REVERSE mode maximum patient weight is 180 kg (400 lbs).

16.DO NOT attempt to clear errors and troubleshooting during surgery. Use the Override Panel.

17.Adjust the table top to the horizontal position (0-position) with the Hand Control Unit before transporting a patient on the surgical table.

18.Transporting of patients weighing up to 180 kg (400 lbs) is only allowed when table top is in horizontal position (0-position) and the height of the table is max 900mm (3 ft).

19.Transporting of patients weighing 180-225 kg (400-500 lbs) is only allowed when the table is in NORMAL mode, in horizontal position (0-position), and in the lowest position.

20.Transporting of patients weighing 225-275 kg (500-600 lbs) is not allowed.

21.Use extreme caution when transporting the table with a patient. Transporting of the table with a patient requires two persons. To maximize patient safety utilize proper restraint methods during transport.

22.To avoid endangering the patient’s respiratory system, nerve pathways, and circulatory system, the patient should be positioned properly and kept under observation!

23.Check that table top sections catches lock correctly. Incorrect attachment of table sections is dangerous and can cause personal injury or equipment damage!

24.Use only accessories recommended by the table manufacturer.

25.To avoid injury to the patient or user, do not attach large accessories to the rails of the head rest.

26.Do not use worn or damaged accessories. When using the table, ensure that all accessories are properly mounted and check the function of accessory locking and adjustments.

27.Do not attempt to remove or attach more than one section at a time.

28.When adjusting the surgical table, take care that fingers, hands, or other parts of the patient’s body are not placed between edges of back, leg, or seat section frames and pivoting points.

29.Always handle sections by the rains on the side, especially the head rest.

30.Use care when attaching sections, fingers or appendages can be trapped between two sections, causing harm to the patient or user.

31.The head rest utilizes pressurized gas springs to assist in movement of the head. Use extreme caution while articulating to avoid patient or user injury. Never press the release bar while the head rest is not connected to the table. Always keep fingers away from articulating pins.

32.To avoid injury to the patient and user, keep fingers, hands and body parts clear of the pinch points.

33.Use only permitted table top configurations illustrated in the user manual.

34.Before adjusting the surgical table ensure that table top will not hit external obstacles.

35.Before adjusting the surgical table ensure that NORMAL/REVERSE mode has been chosen correctly and is the same as patient’s orientation on the table top. After use of Main Switch, the NORMAL mode is set by default.

36.Always follow manufacturer instructions when using diathermy or defibrillation equipment.

37.When using high frequency surgical equipment take care to prevent the patient coming into contact with metal parts of the surgical table or accessories. Do not place the patient on wet or damp surfaces or electrically conductive pads due to hazard of burn injuries!

38.Combustible anaesthetic gases must not be used with the Vertier™ Surgical Table.

39.Use potential equalization conductor with patient monitoring equipment. Connector placed at

12

the table base.

40.When recharging the battery, plug the Mains Cord to table receptacle, and then to the wall socket.

41.When recharging is completed, disconnect the Mains Cord first from the wall socket, and then from the table receptacle.

42.The Main Switch can be used as an emergency stopping device (demanded by the standards). Normally the switch lever is in up position. When the lever is turned down (in the STOP position) all table functions are cancelled and table movement stops immediately.

43.Disconnect the Mains Cord from the table and turn the Main Switch to STOP position before cleaning the table.

44.Disconnect the Mains Cord from the table before any service procedures. 100-240 V~ is used in power unit placed in the table base. Hazard of electric shock!

45.The Vertier™ Surgical Table has been tested to IEC601-1-2 to ensure proper electromagnetic compatibility. Other products used in the vicinity of the Vertier™ Surgical Table should also comply with this standard. If they do not comply, interference between products in unintended responses may occur. Please contact the appropriate manufacturer if any problems arise.

46.Portable and mobile RF-communications equipment can affect the Vertier™ Surgical Table.

47.Do not attempt to remove or attach more than one section at a time.

48.Always handle sections by the rails on the side, especially the head rest.

To avoid injury to the patient or user, do not attach large accessories to the rails of the head rest.

1.2Cautions

1.If the surgical table has been in the cold, allow it to warm up at room temperature for at least 6 hours before recharging the battery or switching on, to allow any condensation formed to evaporate.

2.Recharge the battery prior to use. See the starting instructions attached to table base panel.

3.Take care to not catch the edges of the table or contents while packing/unpacking the crate.

4.If the table is not plugged in when a solid red light is illuminated, the batteries may be damaged by a complete discharge.

5.When adjusting the surgical table, take care to avoid collision between accessories and the surgical table.

6.Take precautions while using the Override Panel. None of the software limitations are active during manipulations.

7.Always remember to disconnect the power cord prior to moving the table.

8.Static charges can harm sensitive electronic components. Ground yourself to metallic parts of the table before touching components.

9.The Override panel is only for returning the table top to the horizontal position in the case of electronic malfunction. Override makes it possible to adjust the table without the controlling processor if any of the programmed restrictions are not functioning.

10.If the surgical table surface is not raised high enough when trendelenburg and side tilt are in their extreme positions, the back section may impact the table base casing, damaging the surgical table and creating pinching hazard.

11.The best place to store the Hand Control Unit, especially during transport, is the lever under the head section. Be careful not to smash the hand controls on doors or walls during transport.

13

12.The surgical table has been classified as splash proof equipment. Use of pressurized water to clean the table is not allowed.

13.Cleaning and disinfecting should be performed according to the user manual.

14.Do not pull or push the shields of back and leg section joints. Check during adjustment that there are no foreign obstacles between shields.

15.It is possible to adjust the Slide adjustment only when back or leg section are in horizontal or above horizontal position. Slide adjustment will stop automatically before collision if back or leg section is under the horizontal position.

16.Slide adjustment is only possible when table top is in horizontal position. Use of Slide adjustment is restricted with tilted table top.

17.Mattresses should be cleaned only with neutral detergent (pH 7-8).

18.The antistatic properties of the surgical table require the use of original brand mattresses and antistatic flooring.

1.3Notes

1.It is recommended to recharge the battery overnight after one day’s use to ensure the table will be always ready for use, and to maintain the battery life.

2.If the Main Switch is turned to STOP position (downward), all table functions are blocked, including the battery recharging ability. Check that the green LED above the charging inlet lights up when the Mains Cord is connected to the table.

3.When Mains Cord is connected to the surgical table, the cooling fan of the power unit is activated causing a humming sound. After disconnecting the Mains Cord, the cooling fan will continue to run for a few seconds.

4.Turn the Main Switch to the STOP position (downward) when the table is not in use or stored for a long period of time. This eliminates the possibility of unintended use and also saves the battery capacity.

5.Activate the floor lock before adjusting the table. Only the trendelenburg and back rest adjustments will function if floor lock is not activated. A red LED will blink on the Hand Control Unit if another button is pressed. Press the ON/OFF button to stop the blinking.

6.Cardboard packing material should be recycled. Wood and plastics are energy waste.

7.Batteries contain lead and need to be recycled in accordance with local environmental regulations if replaced.

8.Hook and loop tapes on table top plates can be cleaned with pressurized air. Hook and loop tape can also be replaced; spare parts and instructions are available from Stryker Technical Support.

9.Floor lock can be deactivated with a release lever placed at the table base if normal deactivating with Hand Control Unit or Override Panel can’t be done. Turn the lever or knob located at the front side of the base 90° clockwise and the table will descend on to its castors. Turn the lever back to its original position after releasing.

10.Only trendelenburg and back rest adjustments are possible when the floor locks are deactivated.

11.To articulate the legs down a full -105°, press Slide Reverse until the table reaches a preset stop about half way through the full range of slide motion. Once past this position, a full -105° can be reached.

12.The individual leg manipulation is only possible when the optional separate leg sections are at-

14

tached to the foot end of the seat section, or when no section is attached.

13.Memory buttons are dependant on orientation. The buttons can be programmed in both the normal and reverse orientation and pertain to the particular orientation mode, respectively.

14.Simultaneous maximum angles of trendelenburg/reverse trendelenburg and side tilt are limited with software.

15.Head section gas spring can be disposed of as metal waste after nitrogen gas and oil have been removed.

16.Instructions for gas releasing are available from your sales representative.

1.4Table Pinch Points

WARNING To avoid injury to the patient and user, keep fingers, hands, and body parts clear of pinch points.

7

5

1

2

6

4

3

8

9

Figure 1.1 - Pinch Point Locations

15

1.4.1Pinch Point Zones

A pinch point exists at the connection interface of all modular sections when the sections are attached to each other or to the table.

A pinch point exists on the top edge of both head rest joints when the head rest is articulated upward. This pinch point also exists when the head rest is disconnected from the table. Keep fingers and hands clear of this zone at all times. Do not press the release bar when the head rest is disconnected from the table.

A pinch point exists on the bottom edge of both head rest joints when the head rest is articulated downward.

Pinch Points exist under the four articulating joints of the table behind the joint shields. Do not put fingers or hands underneath the joints of the table.

A pinch point exists at all four articulating joints of the table as a gap between the joint and the main body of the table. Keep fingers away from the articulating joints of the table during movement.

16

Pinch points exist between all accessory rails of a 25cm section and a 40cm section. Keep fingers and hands clear when connecting a 25cm section to a 40cm section.

Pinch points exist between the sections and the column of the table while the table is sliding. Keep hands and body parts out of this area during articulation of the table.

Pinch points exist under all column casing edges when it is articulated downward toward the base of the table.

A crush zone exists beneath all four floor locks. Do not position fingers, feet, or hands underneath the floor locks.

Pinch points exist on both sides of the table at the accessory rails when the leg section is articulated downward to the maximum 105°.

17

Pinch points exist at any zone where the table top collides with the base of the table or the floor. Keep all body parts out of these zones when articulating the table.

Pinch points exist inside the flexible bellows of the table column. Keep fingers and hands away from the bellows during table articulation.

18

2. Product Symbol Definition

The following symbols may be found on the Vertier related equipment:

An exclamation mark within a triangle is intended to alert the user to the presence of important operating and maintenance (service) instructions in the literature accompanying the product.

Denotes the presence of a pinch point.

A lightning bolt within a triangle indicates the presence of hazardous voltage. Refer all service to authorized personnel.

Denotes earth ground.

Denotes equipotentiality.

Denotes temperature limits.

Denotes humidity limits.

Denotes pressure limits.

Denotes a load limitation.

Denote electrical shock hazard.

Denotes oxygen explosion hazard.

Denotes potential electromagnetic interference (EMI).

Denotes usage tips and useful information.

Denotes compliance to European Community Directive 93-42-EEC.

Indicates the product is compliant “Medical Electrical Equipment with Respect to

Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1.

EDS (29AZ)

19

Indicates the product is compliant “Medical Electrical Equipment with Respect to Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1, CAN/CSA C22.2 No601.1.

(13PZ)

Indicates hot surfaces.

Denotes compliance to CSA Standard C22.2, 60601.1 - M90, AS 3200, IEC 60601, IEC 60601-2-46, UL 60601, EN 60601

Denotes the date the equipment was manufactured.

Denotes the manufacturer of the device.

A yellow box with a hand within a triangle is intended to warn the user of the presence of an electrostatic sensitive device. Follow ESD prevention procedures.

Denotes product/part number.

Denotes product/serial number.

Denotes lot or batch number.

Denotes European Representative.

For U.S. audience only - Caution: Federal Law (USA) restricts this device to sale by or on the order of a physician.

Denotes quantity.

Denotes Class 1 and Type B Equipment.

Class 1 Equipment: equipment in which the protection against electric shock does not rely on Basic Insulation only, but includes an additional safety precaution in such a way that means are provided for the connection of Accessible Conductive

Parts to Protective (ground) Conductor in the fixed wiring of the installation in such a way that Accessible Conductive Parts cannot become Live in the event of a failure of the Basic Insulation.

Type B Equipment: equipment is suitable for international external and internal application to the patient excluding Direct Cardiac Application.

20

In accordance with European Community Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this symbol indicates that the product must not be disposed of as unsorted municipal waste but should be collected separately.

Note: The device does not contain any hazardous materials.

Legal regulations may include specifications regarding the disposal of this product. We request that you contact Stryker when planning to withdraw this device from service for discard.

Denotes the device contains more than .002% cadmium.

Denotes the device contains more than .0005% mercury.

Denotes the device contains more than .004% lead.

2.1EMC Precautions

This device is considered medical electrical equipment and requires special precautions regarding EMC and needs to be installed and put into service according to the information provided.

Portable and mobile RF communications equipment can affect the performance of this device and must be used in accordance with the information in this manual.

21

3. Indications for Use

Stryker conforms to the quality certification ISO13485. In addition, the Vertier™ Surgical Table meets the requirements of UL 60601-1, IEC 601-1-2, and IEC 601-2-46, as certified by Intertek ETL Semko.

The Vertier™ Surgical Table is intended for general surgical use. It is also well suited for:

•Day surgery

•ENT surgery

•Plastic surgery

•Orthopedics

•Arthroscopy

•Gynecology

•Urology

•Pediatrics

•Neurosurgery

3.1Prior to Servicing Tables

WARNING Always wear disposable gloves and a mask when working on used tables due to a risk of infection or disease. If the table appears to have an excess of biomaterial, it may need to be cleaned and disinfected the table prior to service.

•Connect to the table via the USB-B service port located at the bottom of the Override Panel. See Section 8 for details.

•Launch the PC Service software and log into the program; see Section 8 Service Software on how to login to the service software.

•Verify the Software version. To ensure usage of the most up-to-date version, log on to Agile and view Document Number 0100223109. For instructions on how to identify the software/ firmware revisions on the table, see Section 8.3 Service Software Identification.

•Save the table configuration data as a safety step in the event that the MPC becomes corrupted during service. For instructions on saving the table configuration data, see Section 8 Service Software.

•View and capture the error data.

-Go to the Logged Data tab and click on “Read from MPC” and then “Write to File.”

Note The error log can be opened in Notepad or WordPad. Notice the Serial Number is captured and included at the top of the error log; this will only appear if data has been read from the MPC as outlined in the above step. This step is very important when error data is sent and analyzed later.

•Verify the table functionality before taking any actions; click on the Cycle Test tab. Click on the ‘Read from File key’ and load the file “Test_Cycle_Field”. Remove all sections, pads, and accessories from the table except for the 40CM pelvic extension and the 40CM lower back sections. If the column casings are damaged, remove them and the base covers prior to executing the cycle test. Ensure the table is free from obstruction and then click on the “Play” button to execute the cycle test.

23

Note If any malfunctions are encountered during this cycle test, investigate and attempt to resolve the issue before proceeding.

•Update the MPC software if necessary by going to Agile as specified above and view Document Number 0100223108 for the most up-to-date version. For detailed instructions see Section 8.

3.2Following any Table Service

•Verify the Vertier Table Default MPC Settings are correct. Updating software, changing MPC, or updating to Sidne™ compatibility can corrupt settings if a problem is encountered during update. To ensure the settings are correct, go to Agile (For instructions on how to get to Agile see Section 3.1), retrieve document number 0788307000, compare the default settings to the actual settings, and make changes as necessary. To make changes, see Section 8 Service Software.

•Run the “Test_Cycle_Field” cycle test program on the table again to verify there are no errors or malfunctions. See Section 8.7 for details on how to execute this program.

•Complete the field service form per SOP1902

3.3Operating Characteristics

•Vertier™ is a transportable, electrohydraulic battery and Mains operated surgical table. It is microprocessor controlled and its function parameters are reprogrammable with a special PC-operated service program. The table can be connected to 100–240 VAC Mains power, and its secondary voltage is 24 VDC. The table electronics are safely grounded and it has an equipotential connection.

•The table top consists of sliding Seat Section and detachable 25 and 40-sections. The sections can be rearranged depending on the surgical concept and operation. The width of the table top is 540mm, (21 1/4 inches) without rails, and the length is 2100mm (82 inches). The table-top plate is radiotranslucent material.

•Vertier™ can be adjusted with a cable connected Hand Control Unit, an IR Hand Control Unit, the foot switch, or through Sidne™. The surgical table can also be adjusted with the Override Panel in case of electronic malfunction (i.e., if the Hand Control Unit or table microprocessor becomes defective).

•Safe and fault-free use and maintenance of the equipment requires careful adherence to these instructions. When mounting accessories to the equipment, the instructions provided with them must be followed closely. Always keep the instructions for accessories together with this manual.

24

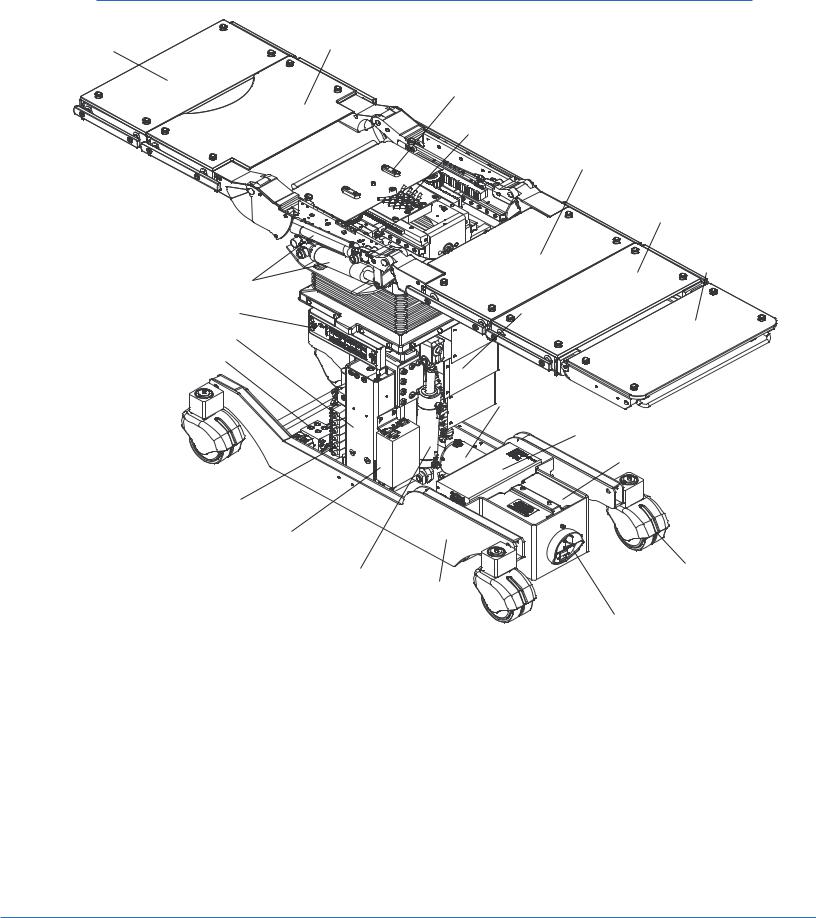

4. Main Components Structure

25cm Section

0788300011

Back and Leg Section

Cylinders

Override Panel

Lifting Column

Floor Lock Valve Block

TLC3 Valve Block

40cm Pelvic Extension Section

0788300004

Seat and Sliding Section

Valve Top Manifold

40cm Lower Back section 0788300008

25cm Section

0788300011

Head Basic Rest

0788300012

Casing Column

Hydraulic Unit

Power Supply

Battery

MPC

Cylinder for |

Castor |

|

Trendelenburg |

||

|

Base Frame

Main Switch, Fuses

and Charging Socket

Figure 4.1 - Main Components Structure

25

IR-Remote Control |

Foot Switch Control |

Remote Control |

0788305002 |

0788305005 |

0788305001 |

|

Sidne™ |

|

Figure 4.2 - Control Devices

4.1Base and Column Casings

9

8

6

|

7 |

10 |

4 |

|

2 |

3 |

5 |

|

1 |

|||

|

|

Figure 4.3 - Base

Part |

Code |

Part Name |

Additional Information |

Qty. |

26

|

|

|

|

|

|

|

|

|

|

|

|

1 |

A11533000 |

Base Frame |

|

|

1 |

2 |

0788300064 |

Castor Assembly |

|

|

4 |

3 |

0788203000 |

Hydraulic Unit Assembly |

|

|

1 |

4 |

A11521700 |

Column Offset Plate |

|

|

1 |

5 |

A1152900 |

Floor Lock Assembly |

|

|

1 |

6 |

0788205002 |

Power Charger Assembly |

|

|

1 |

7 |

0788505016 |

EMI, Filter Unit |

Medical B-type |

|

1 |

8 |

A41763300 |

5th Wheel Assembly |

|

|

1 |

|

A41767000 |

5th Wheel Mechanical Parts |

|

|

1 |

|

A41766700 |

5th Wheel Hydraulic Components |

|

|

1 |

9 |

0788205007 |

Battery Assembly |

|

|

1 |

10 |

A21549400 |

Main Switch Panel |

|

|

1 |

4.1.1 Base Cover Removal

1b

1a

3

2

1c

Figure 4.4 - Table Base Casings

Part |

Code |

Part Name |

Additional Information |

Qty. |

1 |

0788200000 |

Base Cover Set |

Includes items a, b, c, d, and e |

1 |

1a |

0788300045 |

Vertier, Base Cover Leg |

|

1 |

1b |

0788300046 |

Vertier, Base Cover Back |

|

1 |

1c |

0788300044 |

Vertier, Base Cover Screw, Plastic Head |

|

4 |

1d |

0788400006 |

Base Cover Clip |

Not shown |

4 |

1e |

0788400076 |

Base Cover Hook and Loop Tape |

Not shown |

1 |

2 |

0788400004 |

Column Case-to-Base Screw |

M4.2X13 A2 F-H DIN 7982 |

4 |

27

3 |

0788400025 |

Machined Column Case-to-Base |

|

4 |

|

|

Washer |

|

|

|

Caution |

Disconnect the Mains Cord from the table and turn the Main Switch to the |

||

|

|

OFF position before removing any base covers. |

|

|

Note If replacing either base cover, order Base Cover Set 0788200000.

Note If replacing either base cover, order Base Cover Set 0788200000.

1.Articulate the table to the highest position.

2.Turn Main Switch to the OFF position and disconnect the Mains Cord.

3.Remove the M4.2X13 column case-to-base screws (Item 2, Figure 4.4) and the machined column case-to-base washers (Item 3, Figure 4.4) from the lowest protective casing shroud.

4.Remove plastic head screws (Item 1c, Figure 4.4) from both sides of the base covers.

5.Lift up the lower column casing shroud slightly and then pull up on the base covers (Items 1a and 1b, Figure 4.4) to disconnect the hook and loop tape (Item 1e, Figure 4.4).

6.Pull the base covers toward the end of the table to remove. See Figure 4.5 for the location of the base cover hook and loop tape.

7.Repeat steps 1-6 in reverse order to reinstall the base covers.

Hook and

Loop Tape

Hook and

Loop Tape

Figure 4.5 - Base Cover Removal and Hook and Loop Tape Location

28

4.1.2Column Casings

|

28 |

29 |

|

|

|

|

|

|

27 |

|

|

|

|

|

|

|

|

16 |

17 |

|

|

|

|

|

|

|

|

17a |

|

|

|

|

14 |

13 |

17c |

17b |

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

4 |

|

11 |

|

|

|

|

30 |

6 |

25 |

10 |

19 |

20 |

21 |

22 |

|

|

|

9 |

|

|

|

|

7 |

26 |

|

8 |

18 |

23 |

5 |

|

|

15 |

3 |

24 |

4 |

|

2 |

|

1

Figure 4.6 - Column Casing Reference

29

Part |

Code |

Part Name |

Additional Information |

Qty. |

1 |

0788399014 |

Bellows Fixing Plate |

Long |

7 |

2 |

0788400008 |

Screw Protecting Cap |

Black |

32 |

3 |

0788400032 |

Plastic Washer |

|

32 |

4 |

0788400007 |

Screw |

M4X16 ISO 7380 |

27 |

5 |

0788300049 |

Column Bellows |

|

1 |

6 |

0788399013 |

Bellows Fixing Plate |

Short |

2 |

7 |

0788400012 |

Screw |

M6X100 DIN 7991 |

2 |

8 |

7105801 |

Strap |

|

20 |

9 |

3761800 |

Column Casing Spacer |

|

19 |

10 |

0788300078 |

Lower Bellows Frame |

Right |

1 |

11 |

0788300079 |

Lower Bellows Frame |

Left |

1 |

12 |

A00767 |

Compression Nut |

M3 |

20 |

13 |

3761800 |

Column Casing Spacer |

|

1 |

14 |

A41609500 |

Hook and loop tape |

|

28 |

15 |

A21543500 |

Casing Half |

Right |

1 |

16 |

A41617700 |

Casing Half |

Left |

1 |

17 |

0788205010 |

IR-Receiver Assembly |

Includes a, b, and c |

2 |

17a |

0788305052 |

IR ABS Cover |

|

2 |

17b |

A41921000 |

IR PCB |

|

2 |

17c |

0788400084 |

Fixing Screws |

M2.5X5 |

4 |

18 |

0788400011 |

Screw |

M3X4 Column casing screw |

20 |

19 |

A21543100 |

Protective Casing |

IV |

1 |

20 |

A21542900 |

Protective Casing |

III |

1 |

21 |

A21542600 |

Protective Casing |

II |

1 |

22 |

A21542300 |

Protective Casing |

I |

1 |

23 |

0788400005 |

Machined Column Case-to-Base |

|

4 |

|

|

Washer |

|

|

24 |

0788400004 |

Screw |

4,2X13 A2 F-H DIN 7982 |

4 |

25 |

0788399007 |

Cable Chain Guidance Bracket |

|

1 |

26 |

0788400014 |

Bracket-to-Column Case Screw |

M3X16 |

1 |

27 |

0788205000 |

Override Panel Assembly |

Includes cables |

1 |

28 |

0788400028 |

OR Panel Nut Cover |

|

4 |

29 |

0788400027 |

OR Panel Nut |

M3X15 (5.5MS/NI) |

4 |

30 |

0788400037 |

Screw |

M4X6 (located where the |

4 |

|

|

|

Override Panel wires are |

|

|

|

|

routed) |

|

30

Loading...

Loading...