Stryker FL28EX Service manual

MAINTENANCE MANUAL

ELECTRIC MED/SURG BED

Model FL28EX

TECHNICAL ASSISTANCE AND PARTS

Canada: 1 888 233-6888

United States: 1 800 327 0770

Outside Canada and the United States: Contact your local representative

Manufactured by Stryker

72-0905E REV A MM FL28EX |

December 2005 |

F15-44-B |

Printed in Canada |

|

TABLE OF CONTENTS |

|

1. INTRODUCTION................................................................................................................... |

5 |

|

1.1 |

Specifications ................................................................................................................. |

5 |

1.2 |

Technical Support........................................................................................................... |

6 |

1.3 |

Warning, Caution, Note Definition................................................................................... |

6 |

1.4 |

Static Discharge Precautions.......................................................................................... |

6 |

1.5 |

Warranty......................................................................................................................... |

7 |

|

Limited Warranty .......................................................................................................... |

7 |

|

To Obtain Service and/or Parts .................................................................................... |

7 |

|

Return Authorization..................................................................................................... |

8 |

|

Damaged Merchandise ................................................................................................ |

8 |

1.6 |

Symbols.......................................................................................................................... |

8 |

2. PREVENTATIVE MAINTENANCE ........................................................................................ |

9 |

|

2.1 |

Bed Cleaning and Mattress Care .................................................................................... |

9 |

2.2 |

Lubrication Requirements ............................................................................................. |

10 |

|

Actuator Screw Lubrication......................................................................................... |

10 |

2.3 |

Preventative Maintenance Program.............................................................................. |

12 |

|

Annual Checklist......................................................................................................... |

12 |

|

Recommended Spare Parts ....................................................................................... |

13 |

3. TROUBLESHOOTING ........................................................................................................ |

15 |

|

3.1 |

Troubleshooting Guide.................................................................................................. |

15 |

4. MAINTENANCE PROCEDURES ........................................................................................ |

18 |

|

4.1 |

Siderail Maintenance Procedures ................................................................................. |

18 |

|

Head Siderail Assembly Replacement........................................................................ |

18 |

|

Head Rail Replacement.............................................................................................. |

19 |

|

Head Siderail Mechanism Replacement..................................................................... |

19 |

|

Foot Siderail Assembly Replacement ......................................................................... |

19 |

|

Foot Rail Replacement ............................................................................................... |

20 |

|

Foot Siderail Mechanism Replacement ...................................................................... |

20 |

|

Siderail Control Fascia Replacement.......................................................................... |

21 |

|

Siderail Outer Control Board Replacement................................................................. |

22 |

|

Siderail Inner Control Board Replacement.................................................................. |

23 |

|

Speakerphone Replacement (Optional)...................................................................... |

24 |

4.2 |

Foot Board Maintenance Procedures............................................................................ |

25 |

|

Foot End Control Fascia Replacement ....................................................................... |

25 |

|

Weigh System LCD Display Replacement.................................................................. |

25 |

|

Foot End Control Board Replacement ........................................................................ |

26 |

4.3 |

Mattress Support Maintenance Procedures .................................................................. |

27 |

|

Foot Section Replacement ......................................................................................... |

27 |

|

Thigh Section Replacement........................................................................................ |

28 |

|

Seat Section Replacement ......................................................................................... |

28 |

|

Head Section Replacement........................................................................................ |

29 |

|

Fowler Actuator Replacement .................................................................................... |

30 |

|

Knee Gatch Actuator Replacement ............................................................................ |

32 |

Hi-Lo Actuator Replacement ....................................................................................... |

33 |

Motor Control Board Replacement.............................................................................. |

35 |

Nurse Call (Optional)/GEN lll Pendant Control (Optional) Control Board Replacement |

|

................................................................................................................................... |

36 |

Power Connector Replacement .................................................................................. |

37 |

Power Connector Fuse Replacement.......................................................................... |

37 |

Scale Control Board/Bed Exit Buzzer (Optional) Replacement.................................... |

38 |

Toroidal Transformer Replacement (100/200/220/240V International Series Beds -) .. |

39 |

Load Cell Replacement............................................................................................... |

40 |

Scale Calibration......................................................................................................... |

41 |

Verifying the Scale Accuracy .................................................................................... |

41 |

Scale Calibration ...................................................................................................... |

42 |

Cardiac Chair and Auto Contour Micro Switch Replacement ...................................... |

44 |

Cardiac Chair Micro Switch....................................................................................... |

44 |

Micro Switch Common to the Cardiac Chair and Auto Contour Mechanisms ............ |

45 |

Auto Contour Micro Switch ....................................................................................... |

45 |

CPR Micro Switch Replacement ................................................................................. |

46 |

Micro Switch Attached to the Head Section Lever .................................................... |

46 |

Micro Switch Attached to the Frame. ........................................................................ |

47 |

CPR Activation Cable Replacement............................................................................ |

47 |

CPR Pneumatic Cylinder ............................................................................................ |

47 |

4.4 Base Maintenance Procedures...................................................................................... |

49 |

Brake/Steer Pedal Replacement ................................................................................. |

49 |

Steer Wheel Caster Replacement............................................................................... |

50 |

Steer Wheel Assembly Replacement.......................................................................... |

50 |

Steer Wheel Swing Arm Assembly Replacement........................................................ |

51 |

Bed Caster Replacement ............................................................................................ |

52 |

Brake Rod Replacement............................................................................................. |

53 |

Appendix A: Circuit Diagrams ................................................................................................... |

54 |

Appendix B: Maintenance Menu: Signification of Error Codes and Digital Inputs ...................... |

59 |

Introduction Chapter 1

1. INTRODUCTION

This manual is designed to assist in the servicing of the Stryker's FL28EX Med/Surg Beds. Read it thoroughly before beginning any service on the bed. Qualified maintenance personnel should be able to refer to this manual at all time when servicing the bed.

This Maintenance Manual is an integral part of the bed and should be included if the bed is sold or transferred.

1.1 SPECIFICATIONS *

Safe Working Load** |

500 lb (227 kg) |

Scale System |

|

- Capacity |

Patients weighing up to 500 lb (227 kg) |

- Accuracy |

± 2 % for weight from 100 to 500 lb (45.3 to 227 kg) |

|

± 2 lb for weight under 100 lb (45.3 kg) |

- Operating Angular Range |

-12° to +12° |

|

|

Overall Length/Width |

|

- Siderails Up |

94 5/8 x 40" (240.34 cm x 101.6 cm) |

- Siderails Down |

94 5/8 x 39" (240.34 cm x 99.06 cm) |

|

|

Weight w/Boards |

472 lb (214.1 kg) |

|

|

Patient Sleep Surface |

35 x 80" (89 x 203 cm) adjustable to 82" (208 cm) and |

|

84" (213 cm) |

|

|

Recommended Mattress Size |

35 x 80" (89 x 203 cm); 35 x 82" (89 x 208 cm); 35 x |

Mattress Maximum Thickness |

84" (89 x 213 cm) |

6" (15.24 cm) |

|

|

|

Min/Max Bed Height |

14 1/2 to 29" (36.8 to 73.7 cm) |

|

|

Fowler Angle |

0 to 61° |

|

|

Knee Gatch Angle |

0 to 24° |

- with Auto Contour |

|

- without Auto Contour |

0 to 32° |

|

|

Trendelenburg/Reverse Trendelenburg |

+14 to -14° |

|

|

Environmental Conditions |

|

- Transport and Storage |

|

- Ambient Temperature |

-40 to 70°C (-40 to 158°F) |

- Relative Humidity |

10 to 100% |

- Atmospheric Pressure |

500 to 1060 hPa |

- Operating *** |

|

- Ambient Temperature |

18.3 to 26.7°C (65 to 80°F) |

- Relative Humidity |

20 to 80% without condensation |

- Atmospheric Pressure |

700 to 1060 hPa |

|

|

Electrical Requirements**** - all electrical |

100V , 50-60Hz, 7.5A - Two 250V, 10A Fuses |

requirements meet CSA C22.2 No. 601.1, |

120V , 50-60Hz, 4.0A (9.8A w/120V Optional Auxiliary |

UL 60601-1 and IEC 60601-1, 60601-2-38 |

Outlet) - Two 250V, 10A Fuses |

specifications. |

200V , 50-60Hz, 3.2A -Two 250V, 6.3A Fuses |

|

220V , 50-60Hz, 2.9A -Two 250V, 6.3A Fuses |

|

240V , 50-60Hz, 2.7A -Two 250V, 6.3A Fuses |

|

|

*Stryker pays special attention to product improvement and reserves the right to change specifications without notice.

**The Safe Working Load specified is the sum of the mattress and accessory weight (100 lb/45.4 kg) and the patient's weight.

***Operating environment recommended to ensure the scale system precision.

****The device has a 10% duty cycle.

5

Maintenance Manual

1.2 TECHNICAL SUPPORT

For questions regarding this product, contact the following Technical Service department or your local representative:

Stryker Canada |

Stryker Medical |

1 888 233-6888 |

1 800 327-0770 |

45, Innovation Drive |

3800, East Centre Avenue |

Hamilton, Ontario, L9H 7L8 |

Portage, MI 49002 |

Canada |

USA |

1.3 WARNING, CAUTION, NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the equipment.

NOTE

Notes provide special information to make maintenance easier or important instruction clearer.

1.4 STATIC DISCHARGE PRECAUTIONS

The electronic circuits of the bed are protected from static electricity damage only while the bed is assembled. It is extremely important that all service personnel always use adequate static protection when servicing the electronic components of the bed.

Static Protection Equipment

The necessary equipment for a proper static protection is:

•1 static wrist strap

•1 grounding plug

•1 test lead with a banana plug on one end and an alligator clip on the other.

Static Protection Procedure

1. Unplug the bed power cord from the wall outlet.

2. Insert the grounding plug into a

properly grounded hospital grade wall receptacle. Plug the banana plug of the test lead into the receptacle on the grounding plug. Connect the

alligator clip on the other end of the test lead to a ground point on the bed.

3.Place the static control wrist strap on your wrist. Connect the clip at the other end of the wrist strap cord to a ground point on the bed.

6

Introduction Chapter 1

1.5 WARRANTY

LIMITED WARRANTY

All Stryker products are guaranteed against material or manufacturing defects, improper operation of mechanisms, and premature wear of bed components under normal use conditions.

For questions regarding warranty, please contact the Technical Service department (see section 1.2) or your local representative.

TO OBTAIN SERVICE AND/OR PARTS

•To Require Service

For an on-site diagnosis of a malfunction by one of our Field Service Representative, contact the Technical Service department (see section 1.2) or your local representative.

•To Order Parts

Contact the Technical Service department (see section 1.2) or your local representative and provide the following information that can be found on the serial number plate and the manufacturer's nameplate affixed respectively to the right side of the frame at the foot end of the bed, and on the right side of the head end casing:

HEAD END

B

C

D

FOOT END

MANUFACTURER NAMEPLATE

SERIAL NUMBER PLATE

A

Figure 1.5

•From the serial plate, write down the serial number (A).

•From the manufacturer's nameplate, write down the bed model (B), the production number (C), ex. FL28-XXXX, and the Customer's Guide number (D).

•Consult the parts lists and the drawings contained in the Customer Guide third section, “Parts Lists”, to identify the defective part. Write down the information.

•Write down a description of the problem encountered while using the equipment.

NOTE

It is very important that you refer to the parts lists and drawings of the Parts Lists manual specific to the bed needing repair.

The Technical Service representative can help you identify the parts to be replaced. However, if an error occurs when ordering, the user remains responsible for the parts ordered.

Stryker will take back wrong parts ordered but will not assume shipping charges, and restocking fees will be charged to the user unless a Field Service Representative has been requested for an on-site diagnosis of the malfunction.

7

Maintenance Manual

RETURN AUTHORIZATION

Merchandise cannot be returned without approval from the Technical Service department. An authorization number will be provided, which must be clearly printed on the returned merchandise. Stryker reserves the right to charge shipping and restocking fees on returned items.

DAMAGED MERCHANDISE

Claims for damaged merchandise must be made with the carrier within fifteen (15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt notification, Stryker will file a freight claim with the appropriate carrier for damages incurred. Claims will be limited in amount to the actual replacement cost. In the event that this information is not received by Stryker within the fifteen (15) day period following the delivery of the merchandise, or the damage was not noted on the delivery notice at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within five (5) days of invoice.

1.6 SYMBOLS

Warning, refer to accompanying documents

10A 250V

10A 250V

6.3A 250V

6.3A 250V

Fuse rating for 100V and 120V electric systems

Fuse rating for 200V , 220V and 240V electric systems

Protective Earth (ground)

Alternating Current

Type B Equipment

IPX4 Protection from liquid splash

8

Preventative Maintenance Chapter 2

2. PREVENTATIVE MAINTENANCE

2.1 BED CLEANING AND MATTRESS CARE

WARNING

When large fluid spills occur in the area of the circuit boards, cables and motors, immediately unplug the bed power cord from the wall outlet, remove the patient from the bed and clean up the fluid. Have maintenance completely check the bed. Fluids can have an adverse effect on operational capabilities of any electrical product. DO NOT put the bed back into service until it is completely dried and has been thoroughly tested for safe operation. Ensure, among other things, that the plastic components being used as covers for the siderail mechanism arms and the foot end casing are removed and that the parts they cover are thoroughly dried.

CAUTION

Do not use harsh cleaners, solvents or detergents. Equipment damage could occur. Do not steam clean, hose off or ultrasonically clean the bed. Do not immerse any part of the bed. The bed electrical parts may be damaged by exposure to water.

Germicidal disinfectant, used as directed, and/or Chlorine Bleach products are not considered mild detergents. These products are corrosive in nature and may cause damage to your bed if used improperly. If these types of products are used, ensure the beds are wiped with clean water and thoroughly dried following cleaning. Failure to properly rinse and dry the beds will leave a corrosive residue on the surface of the bed, possibly causing premature corrosion of critical components. Failure to follow the above directions when using these types of cleaners may void this product warranty.

CLEANING BEDS

Hand wash all surfaces of the bed with a soft cloth moistened with a solution of lukewarm water and a mild detergent.

Wipe the bed clean and dry thoroughly to avoid build up of cleaning solution.

MATTRESS CARE

WARNING

Inspect the mattress after each use. Discontinue use if any cracks or rips, which may allow fluid to enter the mattress, are found in the mattress cover. Failure to properly clean the mattress, or dispose of it if defective, may increase the risk of exposure to pathogenic substances and may bring about diseases to the patient and user.

•Inspection

Implement local policies to address regular care, maintenance, and cleaning of mattresses and covers. The cover cleaning procedure can be found below and on the bed label.

Inspect the mattress cover inner and outer surfaces and the zip fasteners regularly for signs of damage. If the mattress cover is heavily stained or soiled, or is torn, remove the mattress from service.

•Cleaning

Stains: Wash with lukewarm water using a mild detergent. Rinse with water and let dry. For tough stains, use bleach diluted with ten parts of water.

9

Maintenance Manual

2.2 LUBRICATION REQUIREMENTS

The only components of the bed needing periodic verification and lubrication are the four actuator screws and the clevis pin holding the head actuator to the head section lever. They should be checked every year and lubricated every two years.

CAUTION

The bed uses oil-impregnated shoulder spacers at hinge points. Do not lubricate these shoulder spacers. When shoulder spacers are found worn, replace them.

ACTUATOR SCREW LUBRICATION

Required Tools:

No. 2 Phillips Screwdriver |

1/4" Ratchet (w/6" extension) and 5/16" socket |

|

OG2 Grease |

Brush |

Bungee Cord |

Procedure:

A

B |

B |

Figure 2.2

Clevis Pin

1.Raise the bed fully up and apply the brakes.

2.Remove if applicable the head section plastic cover (optional).

3.Fully raise the head section.

4.Remove the head board.

5.Unplug the bed power cord from the wall outlet.

6.Apply grease all over the clevis pin.

10

Preventative Maintenance Chapter 2

7. Fully raise and lower the head section several times to spread the grease.

Head and Thigh Actuators

8.Raise the bed fully up and apply the brakes.

9.Remove if applicable the head and foot section plastic covers (optional).

10.Fully raise the head section and flatten the thigh section. Lower the four siderails.

11.Unplug the bed power cord from the wall outlet.

12.Lift and fold back the foot section toward the head end of the bed. Secure the foot section to the bed using a bungee cord.

13.Using a no. 2 Phillips screwdriver, remove the four screws (A) holding the cover plate to the frame and remove the plate. Remove the optional night light if present.

14.Using a 1/4" ratchet (w/6" extension) and a 5/16" socket, remove the two screws (B) holding the dust tube of each actuator. Push the tube back to uncover the screw threads.

15.Using a brush, apply grease on the screw threads. Make sure the grease reaches the bottom of the threads.

16.Replace the dust tubes.

17.Replace the cover plate.

18.Lower the foot section.

19.Plug in the bed power cord and, using the electric controls, raise and lower several times the Fowler and Knee Gatch to spread the grease evenly.

Hi-Lo Actuators

1.Lower the bed completely and apply the brakes. Flatten the mattress support.

2.Lower the four siderails.

3.Remove if applicable the head and foot section plastic covers (optional), to reach the Hi-Lo actuators. Otherwise, fully raise the head section, and lift and fold back the foot section toward the head end of the bed. Secure the foot section to the bed using a bungee cord.

4.Unplug the bed power cord from the wall outlet

5.Using a brush, apply grease on the threads through the dust tube side openings of both HiLo actuators. Make sure the grease reaches the bottom of the threads.

6.Lower the foot section.

7.Plug in the bed power cord and, using the electric controls, raise and lower the bed several times to spread the grease evenly.

11

Maintenance Manual

2.3 PREVENTATIVE MAINTENANCE PROGRAM

WARNING

When servicing use only identical replacement parts provided by Stryker.

ANNUAL CHECKLIST

All fasteners secure.

Inspect for excessive wear the oil-impregnated bronze shoulder spacers found at the bed hinge points. Do not lubricate these spacers. Replace as needed.

Check the grease present on the components detailed in section 2.2, lubricate if needed (see section 2.2). Lubricate them at least every two years.

On both sides of the bed, depress fully down the side of the pedal identified with a red sticker and ensure that the brakes are applied and the bed is immobilized. Toggle the pedal to neutral and ensure the brakes are released.

On both sides of the bed, depress fully down the side of the pedal identified with a green sticker and ensure that the steer wheel is engaged. Toggle the pedal to neutral and ensure that the steer wheel disengages.

Siderails move, latch and stow properly.

All controls of the foot end panel working properly, including LED's.

Calibrate the scale (see the scale calibration procedure on page 41).

All siderail controls working properly.

Ensure that the nurse call (optional) alarm sounds in the nurse station.

Ensure that the Communication Package (optional) controls operate properly.

Verify the CPR emergency release using both CPR release handles: raise the Fowler fully up and, using the CPR handle, lower the Fowler gradually to flat position by pulling, holding and releasing the handle several times. Ensure the Knee Gatch (if raised) also starts flattening when the Fowler is completely down. Following the complete lowering of the Fowler, wait approximately 30 seconds - the time for the Fowler actuator to reset - and verify that the actuator has indeed reset itself by raising the Fowler fully up.

Verify the Fowler, Knee Gatch and Hi-lo movements to ensure that the motion interrupt switch integrated to the four electric actuators is operating properly.

Auxiliary outlet (option available only with 120V beds) working properly.

Night light (optional) working properly.

No cracks in the boards, siderails, wheel covers, steer wheel hood (optional) and plastic covers (optional) of the head and foot sections.

Head end bumpers tightly secured to frame and working properly.

No rips or cracks in mattress cover. Replace if so.

Power cord intact.

No cables pinched or worn.

All electrical connections tight.

All grounds secure to the frame.

All casters roll properly. Check caster for cuts, wear, etc.

Measure current leakage and grounding continuity of the bed and the auxiliary outlet (optional). Check with our Technical Service (see section 1.2) for the acceptable values.

12

Preventative Maintenance Chapter 2

RECOMMENDED SPARE PARTS

The following is a list of recommended on hand spare parts for the FL28EX bed.

Description |

Part Number |

Parts List |

•Electric/Electronic Components

Motor Control Board |

QDF25-0592 |

OL250001/010 |

|

Scale Control Board |

QDF25-0593 |

L28-008 |

|

S.A. Scale Display |

QDF25-0463 |

L28-008 |

|

Nurse Call (Optional)/ Gen lll Control Board (Optional) |

QDF21-1163 |

OL280002 |

|

|

|

|

|

Foot Board Control Board |

QDF21-1154 |

L28-014 |

|

|

|

|

|

Micro Switch |

1325P003 |

L28-013 |

|

Push Button Micro Switch |

QDF9159 |

L28-013 |

|

Power Connector |

QDF2034 |

OL28001/010 |

|

|

|

|

|

Fuse - Fast Acting 10A, 250V for 100/120V Electric Systems |

QDF8078 |

OL280001/011 |

|

|

|

|

|

Fuse - Slow Blow 6.3A, 250V for 200/220/240V Electric Systems |

QDF8068 |

OL280012/013 |

|

|

|

|

/014 |

Power Cord with Straight N A Molded Plug |

QDF8066 |

OL250053 |

|

Power Cord with 90° N A Molded Plug (Optional) |

QDF8066-90D |

OL250055 |

|

Foot Board/Control Board Cable |

QDF28-0258 |

OL28001/010 |

|

|

|

|

|

Speakerphone w/Connectors (Optional) |

QDF26-0111 |

OL280020 |

|

|

|

|

|

Night Light (Optional) |

QDF9539 |

OL250018 |

|

Load Cell w/Long Cable |

QDF14-1367 |

L28-028 |

|

Load Cell w/Short Cable |

QDF25-0218 |

L28-028 |

|

|

|

|

|

Auxiliary Power Outlet (Optional) |

QDF8024 |

OL250029 |

|

|

|

|

|

5A Circuit Breaker (for Optional Auxiliary Power Outlet) |

QDF9025 |

OL250029 |

|

Hi-Lo Actuator |

25-0567 |

OL280001/010 |

|

Head Section Actuator |

28-0403L |

OL280001/010 |

|

Thigh Section Actuator |

28-0377 |

OL280001/010 |

|

|

|

|

|

Toroidal Transformer (International Series Bed) |

14-1160 |

OL280001/010 |

|

|

|

|

|

Stand Off Pins: Motor Control Board |

QP23-0258 |

OL280001/010 |

|

Stand Off Pins: Scale Control Board |

QDF8011 |

L28-008 |

|

Strain Relief Bushing |

QDF9541 |

OL280001/010 |

|

Female Screw Lock |

QDF2047 |

|

|

|

|

|

|

• |

Foot Board Components |

|

|

|

|

|

|

Foot End Control Panel Self-Sticking Fascia w/Scale and Bed |

QDF25-0461 |

OP250002 |

|

Exit 3 Zone (optional) |

|

|

|

Foot End Control Panel Self-Sticking Fascia w/Scale and Bed |

QDF25-0528 |

OP250003 |

|

Exit 1 Zone (optional) |

|

|

|

Foot End Control Panel Self-Sticking Fascia w/Scale w/o Bed |

QDF25-0529 |

OP250004 |

|

Exit (optional) |

|

|

|

Round Self-Sticking Screw Cover |

QDF28-0334 |

L28-014 |

|

Head/Foot Board Leg Caps |

QPC21-3855 |

L28-011-014 |

|

|

|

|

|

• |

Siderail Components |

|

|

|

|

|

|

Siderail Right Patient Ctrl Self-Sticking Fascia w/o Nurse Call |

QDF28-0248 |

OL280019 |

|

nor Communications Package (Optional) |

|

|

|

13

Maintenance Manual

Siderail Left Patient Ctrl Self-Sticking Fascia w/o Nurse Call nor |

QDF28-0249 |

OL280019 |

|

Communications Package (Optional) |

|

|

|

|

|

|

|

Siderail Right Patient Ctrl Self-Sticking Fascia w/Nurse Call, w/o |

QDF28-0252 |

OL280020 |

|

Communications Package (Optional) |

|

|

|

Siderail Left Patient Ctrl Self-Sticking Fascia w/Nurse Call, w/o |

QDF28-0253 |

OL280020 |

|

Communications Package (Optional) |

|

|

|

Siderail Right Patient Ctrl Self-Sticking Fascia w/Nurse Call and |

QDF28-0250 |

OL280021 |

|

Communications Package (Optional) |

|

|

|

Siderail Left Patient Ctrl Self-Sticking Fascia w/Nurse Call and |

QDF28-0251 |

OL280021 |

|

Communications Package (Optional) |

|

|

|

Outer Right Ctrl Panel Self-Sticking Fascia |

QDF28-0139 |

L28-001 |

|

Outer Left Ctrl Panel Self-Sticking Fascia |

QDF28-0140 |

L28-001 |

|

Outer Ctrl Panel Control Board |

QDF21-1151 |

L28-001 |

|

Inner Ctrl Panel Control Board |

QDF21-1169 |

L28-001 |

|

"Lift To Release" Self-Sticking Sticker |

QDF28-0146 |

L28-001 |

|

|

|

|

|

Oblong Self-Sticking Screw Cover |

QDF28-0145 |

L28-001 |

|

|

|

|

|

• |

Mattress Support Components |

|

|

|

|

|

|

Head Section Plastic Cover (optional) |

28-0101 |

OL280032 |

|

Foot Section Plastic Cover (optional) |

28-0103 |

OL280032 |

|

|

|

|

|

Steel Head Section (Optional) |

28-0197L |

OL280007 |

|

|

|

|

|

Steel Foot Section (Optional) |

28-0196L |

OL280007 |

|

|

|

|

|

Seat Section |

28-0345L |

OL280032 |

|

Thigh section |

28-0034L |

OL280032 |

|

|

|

|

|

CPR Mechanism Long Cable |

QDF19-0815 |

OL280034 |

|

|

|

|

|

CPR Mechanism Short Cable |

QDF19-0354 |

OL280034 |

|

|

|

|

|

CPR Mechanism Pneumatic Cylinder |

QDF5090 |

OL280034 |

|

Foot End Mattress Retainer |

17-0211L |

OL250022/023 |

|

|

|

|

|

• Hi-Lo Mechanism Components |

|

|

|

|

|

|

|

Right "Stub-Acme" Nut |

QP13-0677-05 |

OL280001/010 |

|

|

|

|

|

Nut Support |

QPA25-0380 |

OL280001/010 |

|

• |

Base Components |

|

|

Foot End Casing Plastic Cover |

QP28-0111 |

L28-005 |

|

|

|

|

|

Plastic Base Tube Cover |

QP25-0023 |

L28-020 |

|

|

|

|

|

6" Caster w/Locking Mechanism |

R25-0388-13 |

OL280003 |

|

|

|

|

|

5th Steer Wheel |

RL5 |

L28-006 |

|

Right Wheel Cover |

QP28-0299-13 |

L28-020 |

|

Left Wheel Cover |

QP28-0300-13 |

L28-020 |

|

|

|

|

|

Brake/Steer Pedal |

QP28-0130 |

L28-006 |

|

|

|

|

|

• |

Miscellaneous |

|

|

|

|

|

|

OG2 Grease |

M0027 |

|

|

Touch-Up Paint - Opal |

PD018 |

|

|

|

|

|

|

Ty-rap |

QDF9518 |

|

|

|

|

|

|

Nylon Cable Dia. 3/4" |

QDF9532 |

|

|

Coupling for Ty-rap |

QDF9533 |

|

|

14

Troubleshooting Chapter 3

3. TROUBLESHOOTING

Please consult the following troubleshooting guide before calling the Technical Service department (see section 1.2).

3.1 TROUBLESHOOTING GUIDE

PROBLEM/FAILURE |

WHAT TO CHECK |

|

No power to bed |

• Is the power cord connected to the power |

|

|

connector and plugged into the wall outlet? |

|

|

• Is the bed power switch at the head end of |

|

|

the bed turned on? |

|

|

• Is the power cord severed? Replace if |

|

|

needed. |

|

|

• Are the two fuses inside the power |

|

|

connector still operational (see page 37)? |

|

|

• Verify power at wall outlet. |

|

|

|

|

No bed up or down motion when: |

• Is the total lockout activated (LED (padlock) |

|

• the siderail command is used |

on)? If so, deactivate it. |

|

• the foot board command is used |

• Is the cable of the siderail control panel |

|

properly connected to the bed receptacle |

||

|

||

|

under the mattress support? |

|

|

• Check points of the “No power to bed” |

|

|

problem described above. |

|

|

|

|

No Fowler up or down motion when: |

• Is the Fowler lockout activated (LED |

|

• the siderail command is used |

(padlock) on)? If so, deactivate it. |

|

• the foot board command is used |

• Is the total lockout activated (LED (padlock) |

|

on)? If so, deactivate it. |

||

|

||

|

• Is the cable of the siderail control panel |

|

|

properly connected to the bed connector |

|

|

under the mattress support? |

|

|

• Check points of the “No power to bed” |

|

|

problem described above. |

|

|

|

|

The Fowler does not fully raise |

This situation happens when the CPR handle |

|

|

is used to partly lower the Fowler. The use of |

|

|

the CPR mechanism for this purpose creates a |

|

|

situation where the Fowler motor is out of sync |

|

|

with the actual position of the Fowler. To |

|

|

correct the situation: |

|

|

• Completely lower the Fowler using the |

|

|

CPR handle or the Fowler down control to |

|

|

enable the Fowler motor to reset itself. |

|

|

Refer to the "Emergency CPR Release" |

|

|

section of the Operations Manual for more |

|

|

information. |

|

|

|

15

Maintenance Manual

No Knee Gatch up or down motion when: |

• Is the Knee Gatch lockout activated (LED |

|

• the siderail command is used |

(padlock) on)? If so, deactivate it. |

|

• the foot board command is used |

• Is the total lockout activated (LED (padlock) |

|

on)? If so, deactivate it. |

||

|

||

|

• Is the cable of the siderail control panel |

|

|

properly connected to the bed connector |

|

|

under the mattress support? |

|

|

• Check points of the “No power to bed” |

|

|

problem described above. |

|

|

|

|

No Auto Contour motion |

• Is the Knee Gatch or total lockout activated |

|

|

(LED (padlock) on)? If so, deactivate it. |

|

|

• Check and replace if needed the two Auto |

|

|

Contour limit switches (see page 45). |

|

|

|

|

Improper operation of the cardiac chair: Fowler |

• Check and replace if needed (see pages |

|

and Knee Gatch raise but final step of the |

44 and 45) the two Cardiac Chair limit |

|

cardiac chair position not reached (reverse |

switches. |

|

Trend). |

|

|

Improper operation of the CPR positioning: |

• Check and replace if needed (see pages |

|

Knee Gatch does not lower and/or the Fowler |

46 and 47) the two CPR limit switches. |

|

actuator does not reset. |

|

|

The weight shown on the scale display is |

• Zero the bed without the patient in it (see |

|

incorrect. |

the "Scale System Usage" section in the |

|

|

Operations Manual). |

|

|

• Calibrate the scale (see page 41). |

|

|

|

|

Scale display reads OVERLOAD or shows |

• The weight present on the bed is superior |

|

incorrect weight. |

to the scale capacity, which is 500 lb (227 |

|

|

kg). If the patient weight is superior to 500 |

|

|

lb (227 kg), do not use the scale. |

|

|

If not the case, zero the scale after having |

|

|

removed the patient from the bed. This |

|

|

situation often results from equipment |

|

|

added to the bed without using the |

|

|

add/remove equipment procedure (see the |

|

|

Operations Manual). The weight of this |

|

|

equipment is then added to the patient's |

|

|

weight. |

|

|

• One or more load cell cable not properly |

|

|

connected or completely disconnected from |

|

|

the scale control board (see figure 4.3E, |

|

|

page 38 for the connecting positions of the |

|

|

load cell cable). |

|

|

|

|

Angle shown on the scale display is incorrect |

• Calibrate the scale (see page 41). |

|

|

|

16

|

|

Troubleshooting Chapter 3 |

|

|

|

|

|

|

Scale display does not turn on when the scale |

• Press ENTER key twice. |

|

|

is activated. |

• Turn the main power switch off and turn it |

|

|

|

on. |

|

|

|

• Lift the foot board and gently replace it into |

|

|

|

position taking care to completely push it |

|

|

|

down so that the connectors match |

|

|

|

correctly. |

|

|

|

• Check points of the “No power to bed” |

|

|

|

problem described above. |

|

|

|

• Scale user interface cable not properly |

|

|

|

connected or completely disconnected from |

|

|

|

the scale control board (J6 connector, see |

|

|

|

drawing L28-008 in the parts list manual). |

|

|

|

|

|

|

Scale displays "No scale found". |

• Press the ENTER key. If message |

|

|

|

persists, contact our Technical Service |

|

|

|

(see section 1.2). |

|

|

|

If message disappears, data displayed is |

|

|

|

correct and current procedure can be |

|

|

|

resumed. |

|

|

|

|

|

|

All lockout LEDs (padlock icons) flash or the |

• The scale is unable to measure the |

|

|

word Error appears at the bottom of the LCD |

weight due to an electrical problem. |

|

|

display. |

Please contact our Technical Service |

|

|

|

(see section 1.2). |

|

|

|

|

|

|

Bed Exit system (optional) does not operate |

• Verify that the load cell cables are properly |

|

|

properly. |

connected to the scale control board (see |

|

|

|

figure 4.3E, page 38 for the illustration of |

|

|

|

the load cell cable connecting positions). |

|

|

|

|

|

|

Bed Exit system (optional) does not work at all |

• Check points of the “No power to bed” |

|

|

or alarm goes off when Bed Exit is activated. |

problem described above. |

|

|

|

• One or more load cell cable are not |

|

|

|

properly connected or are completely |

|

|

|

disconnected from the scale control board |

|

|

|

(see figure 4.3E, page 38 for the load cell |

|

|

|

cable connecting positions). |

|

|

|

|

|

|

Nurse call (optional) or Bed Exit (optional) |

• Check points of the “No power to bed” |

|

|

signal does not reach the nurse desk. |

problem described above. |

|

|

|

• Check the connecting cable. |

|

|

|

• Check the wall outlet. |

|

|

|

• Contact the Technical Service (see 1.2) |

|

|

|

|

|

17

Maintenance Manual

4. MAINTENANCE PROCEDURES

WARNING

Only field technicians from Stryker or service personnel trained by Stryker should perform the procedures detailed in this maintenance manual, especially those related to the Scale (option) and Bed Exit (option) systems. Failure to observe this restriction can result in serious damage to material and/or severe injury to people.

To prevent injury when working under the bed with the bed in the high position, always place blocks under the mattress support frame and apply the brakes.

Always unplug the bed power cord from the wall outlet when servicing or cleaning the bed.

NOTE

Throughout this maintenance manual, the words “right” and “left” refer to the right and left sides of a patient lying face up on the bed.

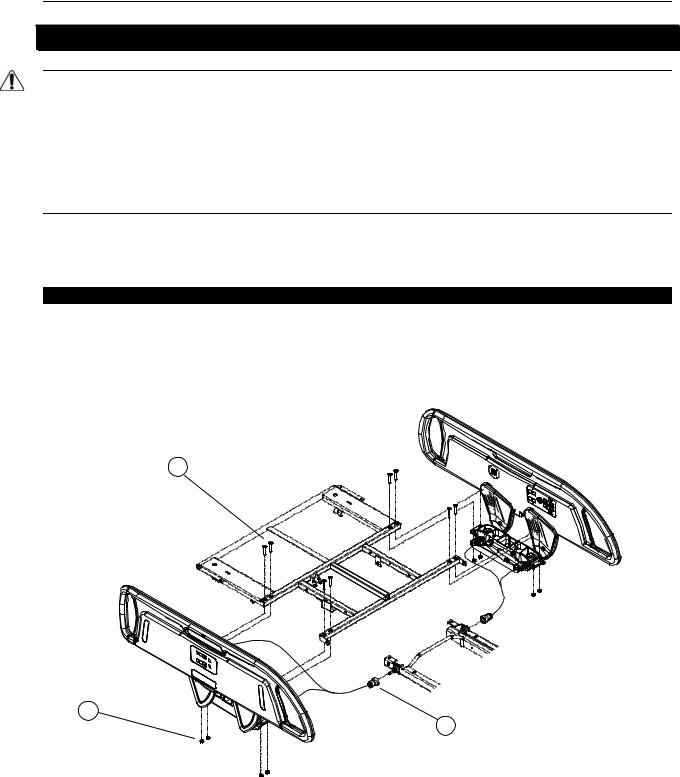

4.1 SIDERAIL MAINTENANCE PROCEDURES

HEAD SIDERAIL ASSEMBLY REPLACEMENT

Required Tools: |

|

|

1/2" Wrench |

3/16" Allen Key |

Cutting Pliers |

Procedure: |

|

|

B

B

A

Figure 4.1A

1.Run the bed fully up and apply the brakes.

2.Remove the head section plastic cover (optional). Fully raise the head section and raise the siderail needing repair.

3.Unplug the power cord from the wall receptacle.

4.Loosen the lock ring (A) and unplug the siderail cable.

5.Using cutting pliers, remove the Ty-raps holding the siderail cable to the frame.

6.Using a 3/16" Allen key and a 1/2" wrench, remove the four locknuts/bolts (B) holding the siderail assembly to the head section and remove the assembly. Support the assembly when removing the last bolts.

18

Loading...

Loading...