STIHL MS 192 TC, MS 192 T Owner's Manual

{

STIHL MS 192 T

Instruction Manual

Manual de instrucciones

Warning!

To reduce the risk of kickback injury use STIHL reduced kickback bar and STIHL PMMC3 (3/8" Picco) or PMC3 (3/8" Picco) chain depending on sprocket pitch or other available low kickback components.

Advertencia!

Para reducir el riesgo de lesionarse como resultado de un culatazo, utilice la barra de contragolpe reducido y la cadena PMMC3 (Picco de 3/8 pulg) o PMC3 (Picco de 3/8 pulg) de STIHL, dependiendo de la rueda dentada usada y de otros componentes reductores de contragolpe.

Read and follow all safety precautions in Instruction Manual – improper use can cause serious or fatal injury.

Lea y siga todas las precauciones de seguridad dadas en el manual de instrucciones – el uso incorrecto puede causar lesiones graves o mortales.

Instruction Manual 1 - 54

Manual de instrucciones 55 - 115

Contents

|

Guide to Using this Manual |

2 |

Main Parts |

|

|

Safety Precautions and Working |

|

Specifications |

|

Manual |

Techniques |

3 |

Special Accessories |

|

Cutting Attachment |

19 |

Ordering Spare Parts |

||

Mounting the Bar and Chain |

20 |

Maintenance and Repairs |

||

Instruction |

||||

chain tensioner) |

21 |

Emission Control Warranty |

||

|

Tensioning the Saw Chain (side |

|

STIHL Incorporated Federal |

|

Original |

Checking Chain Tension |

21 |

Statement |

|

Fuel |

22 |

STIHL Incorporated California |

||

|

Fueling |

23 |

Exhaust and Evaporative |

|

recycled. |

Chain Lubricant |

24 |

Emissions Control Warranty |

|

Filling Chain Oil Tank |

25 |

Statement |

||

be |

Checking Chain Lubrication |

25 |

Trademarks |

|

|

||||

can |

Chain Brake |

26 |

|

|

paper |

|

|||

Information Before You Start |

27 |

|

||

oils, |

Starting / Stopping the Engine |

27 |

|

|

paperfree-chlorineon vegetablecontaininks |

Operating Instructions |

30 |

|

|

|

|

|||

|

Taking Care of the Guide Bar |

31 |

|

|

|

Air Filter System |

32 |

|

|

|

Cleaning the Air Filter |

32 |

|

|

Printed Printing |

Engine Management |

33 |

|

|

Adjusting the Carburetor |

33 |

|

||

|

|

|||

|

Spark Arresting Screen in Muffler |

34 |

|

|

|

Checking the Spark Plug |

34 |

|

|

|

Replacing the Starter Rope and |

|

|

|

2011 |

Rewind Spring |

35 |

|

|

Storing the Machine |

38 |

|

||

KG, |

|

|||

Checking and Replacing the Chain |

|

|

||

ANDREAS©STIHL AG & Co. 8621-217-0458-B. VA1.J11. 0000000707011 GB |

|

|

||

Sprocket |

38 |

|

||

{ |

|

|

||

|

Maintaining and Sharpening the |

|

|

|

|

Saw Chain |

39 |

|

|

|

Maintenance and Care |

43 |

|

English

45 |

This manual contains operating and |

47 |

safety instructions for all STIHL |

Professional Tree Service Chain Saws. |

|

48 |

A professional tree service chain saw is |

49 |

|

49 |

designed especially for in-tree |

maintenance, tree surgery and other |

cutting work in confined spaces such as a lift-bucket.

49Allowonlypersonswhofullyunderstand this manual to operate your chain saw.

|

To receive maximum performance and |

51 |

satisfaction from your STIHL chain saw, |

53 |

it is important that you read, understand |

|

and follow the safety precautions and |

the operating and maintenance instructions in chapter "Safety Precautions for Chain saw Users" and "Safety Precautions" before using your chain saw. For further information you can go to www.stihlusa.com.

Contactyour STIHLdealer or theSTIHL distributor for your area if you do not understandanyoftheinstructionsinthis manual.

Warning!

Warning!

Because a chain saw is a high-speed wood-cutting tool, some special safety precautions must be observed as with any other power saw to reduce the risk of personal injury. Careless or improper use may cause serious or even fatal injury.

MS 192 T, MS 192 TC |

1 |

English

Guide to Using this Manual

Pictograms

The meanings of the pictograms attached to or embossed on the machine are explained in this manual.

Dependingonthemodelconcerned,the following pictograms may be on your machine.

Fuel tank; fuel mixture of gasoline and engine oil

Chain oil tank; chain oil

Engaging and disengag- ing the STIHL Quickstop chain brake

Direction of chain rotation

Ematic; chain oil quantity control

Tension the chain

Intake air preheating for winter operation

Intake air for summer operation

Handle heating

Operate decompression valve

Operate manual fuel pump

Symbols in Text

Many operating and safety instructions are supported by illustrations.

The individual steps or procedures describedin themanualmaybemarked in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that refers directly to an illustration may contain item numbers that appear in the illustration. Example:

N Loosen the screw (1). N Lever (2) ...

In addition to the operating instructions, this manual may contain paragraphs that require your special attention. Such paragraphs are marked with the symbols and signal words described below:

Danger!

Danger!

Indicates an imminent risk of severe or fatal injury.

Warning!

Warning!

Indicatesahazardoussituationwhich,if not avoided, could result in severe or fatal injury.

Caution!

Caution!

Indicates a risk of property damage, including damage to the machine or its individual components.

Engineering Improvements

STIHL’s philosophy is to continually improve all of its products. As a result, engineeringchangesandimprovements are made from time to time. Therefore, some changes, modifications and improvements may not be covered in this manual. If the operating characteristics or the appearance of your machine differs from those describedinthismanual,pleasecontact your STIHL dealer for assistance.

2 |

|

MS 192 T, MS 192 TC |

Safety Precautions and

Working Techniques

This top handle chain saw is designed specifically for tree surgery and maintenance in the tree.

Due to the special com- pact handle design (closely spaced handles), there is an increased risk of injury from loss of control.

The increased risk includes injuries due to uncontrolled reactive forces of the chain saw or leg injuries due to the saw "dropping" at the end of the cut.

For this reason

these special

chain saws should

chain saws should

be used only for work in a tree by persons who are trained in special cutting and work- ing techniques and who are properly secured (lift bucket, ropes, safety harness)

be used only for work in a tree by persons who are trained in special cutting and work- ing techniques and who are properly secured (lift bucket, ropes, safety harness)

Regular chain saws (with wider spaced handles) are recommended for all other cutting work at ground level.

Warning!

Warning!

Working in a tree requires the use of special cutting and working techniques which must be observed in order to reduce the increased risk of personal injury.

Never work in a tree unless you have received specific, professional training for such work, including training in the use of the safety and other climbing equipment, such as harnesses, ropes, belts, climbing irons, snap hooks, carabiners, etc.

The use of any chain saw may be hazardous. The saw chain has many sharp cutters. If the cut- ters contact your flesh, they will cut you, even if the chain is not moving.

It is important that you read, fully understand and observe the following safety precautions and warnings. Read the instruction manual and the safety instructions periodically. Careless or improper use may cause serious or fatal injury.

Warning!

Warning!

Reactiveforces,includingkickback,can be dangerous. Pay special attention to the section on reactive forces.

Have your STIHL dealer show you how to operate your power tool. All safety precautions that are generally observed whenworkingwithanaxeorahandsaw also apply to the operation of chain saws. Observe all applicable federal, state and local safety regulations, standards and ordinances.

English

Warning!

Warning!

Do not lend or rent your power tool with- out the instruction manual. Be sure that anyone using it understands the infor- mation contained in this manual.

Use your chain saw only for cutting wooden objects.

Warning!

Warning!

Do not use it for other purposes, since misuse may result in personal injury or property damage, including damage to the machine.

Warning!

Warning!

Minors should never be allowed to use this power tool. Bystanders, especially children, and animals should not be allowed in the area where it is in use.

Most of these safety precautions and warnings apply to the use of all STIHL chain saws. Different models may have different parts and controls. See the appropriate section of your instruction manual for a description of the controls and the function of the parts of your model.

Safe use of a chain saw involves 1 the operator

2the power tool

3the use of the power tool.

MS 192 T, MS 192 TC |

3 |

English

THE OPERATOR

Physical Condition

You must be in good physical condition and mental health and not under the influence of any substance (drugs, alcohol, etc.) which might impair vision, dexterity or judgment. Do not operate this machine when you are fatigued.

Warning!

Warning!

Be alert – if you get tired, take a break. Tiredness may result in loss of control. Working with any power tool can be strenuous. If you have any condition that might be aggravated by strenuous work, check with your doctor before operating this machine.

Warning!

Warning!

Prolonged use of a power tool (or other machines) exposing the operator to vibrations may produce whitefinger dis- ease (Raynaud's phenomenon) or carpal tunnel syndrome.

These conditions reduce the hand's ability to feel and regulate temperature, produce numbness and burning sensations and may cause nerve and circulation damage and tissue necrosis.

All factors which contribute to whitefinger disease are not known, but cold weather, smoking and diseases or physical conditions that affect blood vessels and blood transport, as well as high vibration levels and long periods of

exposure to vibration are mentioned as factorsinthedevelopmentofwhitefinger disease. In order to reduce the risk of whitefinger disease and carpal tunnel syndrome, please note the following:

–Most STIHL power tools are available with an anti-vibration ("AV") system designed to reduce the transmission of vibrations created by the machine to the operator's hands. An AV system is recommended for those persons using power tools on a regular or sustained basis.

–Wear gloves and keep your hands warm. Heated handles, which are available on some STIHL powerheads, are recommended for cold weather use.

–Keep the AV system well maintained. A power tool with loose components or with damaged or worn AV elements will tend to have higher vibration levels. Keep the saw chain sharp. A dull chain will increase cutting time, and pressing a dull chain through wood will increase the vibrations transmitted to your hands.

–Maintain a firm grip at all times, but do not squeeze the handles with constant, excessive pressure. Take frequent breaks.

All the above-mentioned precautions do not guarantee that you will not sustain whitefinger disease or carpal tunnel syndrome. Therefore, continual and regular users should closely monitor the condition of their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

Warning!

Warning!

The ignition system of the STIHL unit produces an electromagnetic field of a very low intensity. This field may inter- fere with some pacemakers. To reduce theriskofseriousorfatalinjury,persons with a pacemaker should consult their physician and the pacemaker manufac- turer before operating this tool.

Proper Clothing

Warning!

Warning!

Toreducetheriskofinjury,theoperator should wear proper protective apparel.

Clothing must be sturdy and snug-fitting, but allow complete freedom of movement. To reduce the risk of cut injuries, wear overalls, long pants or chaps that contain pads of cut-retardant material, depending on the indidi- vidual application. Avoid loose-fitting jackets, scarfs, neckties, jewelry, flared or cuffed pants, unconfined long hair or anything that could become caught on branches, brush or the moving parts of the unit. Secure hair so it is above shoulder level.

4 |

MS 192 T, MS 192 TC |

Good footing is very important. Wear sturdy boots with nonslip soles. Steel-toed safety boots suitable for climbing in trees are recommended.

Never operate your power tool unless wearing goggles or properly fitted protective glasses with adequate top andsideprotectioncomplyingwithANSI Z 87.1 (or your applicable national standard).

Always wear gloves when handling the machine and the cutting tool. Heavy-duty, nonslip gloves improve your grip and help to protect your hands.

Wear an approved safety hard hat to reduce the risk of injury to your head.

Chain saw noise may damage your hearing. Wear sound barriers (ear plugs or ear mufflers) to help protect your hearing. Continual and regular users should have their hearing checked regularly.

Be particularly alert and cautious when wearing hearing protection because your ability to hear warnings (shouts, alarms, etc.) is restricted.

Use proper equipment at all times to protect your- self from falling.

Any crew member in the cutting area should also wear proper protective clothing, especially hard hats, to protect their heads.

THE POWER TOOL

For illustrations and definitions of the power tool parts see the chapter on "Main Parts".

Warning!

Warning!

Never operate your power tool if it is damaged, improperly adjusted or main- tained, or not completely or securely assembled.

Warning!

Warning!

Nevermodifythispowertoolinanyway. Only attachments supplied by STIHL or expressly approved by STIHL for use with the specific STIHL model are authorized. Although certain unauthor- ized attachments are useable with STIHL powerhead, their use may, in fact, be extremely dangerous.

English

THE USE OF THE POWER TOOL

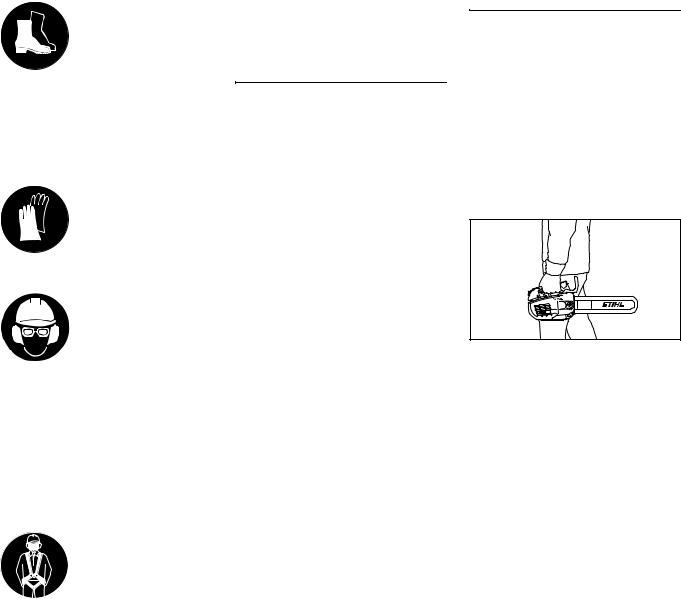

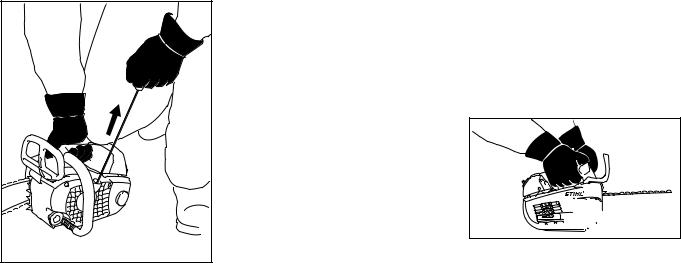

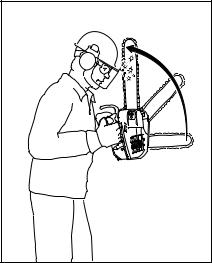

Transporting the Power Tool

Warning!

Warning!

Always stop the engine before putting a chain saw down or carrying it. Carrying a chain saw with the engine running is extremely dangerous. Accidental accel- eration of the engine can cause the chain to rotate. Always engage the chain brake when taking more than a few steps.

0012BA024 KN

By hand: When carrying your saw by hand, the engine must be switched off and the saw must be in the proper position. Grip the top handle and place the muffler away from the body. The chain guard (scabbard) should be over the chain and guide bar, which should point backwards.

By vehicle: When transporting in a vehicle,keepchainandbarcoveredwith the chain guard. Properly secure your saw to prevent turnover, fuel spillage and damage to the saw.

Fuel

Your STIHL power tool uses an oilgasolinemixtureforfuel(seechapteron "Fuel" of your instruction manual).

MS 192 T, MS 192 TC |

5 |

English

Warning!

Warning!

Gasoline is an extremely flammable fuel. If spilled and ignited by a spark or other ignition source, it can cause fire and seri-

ous burn injury or property damage. Use extreme caution when handling gasoline or fuel mix. Do notsmokeorbringanyfireorflamenear the fuel or the power tool. Note that combustible fuel vapor may escape from the fuel system.

Fueling Instructions

Warning!

Warning!

Fuel your power tool in well-ventilated areas, outdoors. Always shut off the engine and allow it to cool before refu- eling. Gasoline vapor pressure may build up inside the fuel tank depending onthefuelused,theweatherconditions and the tank venting system.

In order to reduce the risk of burns and other personal injury from escaping gas vapor and fumes, remove the fuel filler capon yourpowertool carefully so asto allow any pressure build-up in the tank torelease slowly. Neverremovethe fuel filler cap while the engine is running.

Selectbare groundforfuelingandmove at least 10 feet (3 m) from the fueling spot before starting the engine. Wipe off any spilled fuel before starting your machine.

Warning!

Warning!

Check for fuel leakage while refueling and dur- ing operation. If fuel leakage is found, do not start or run the engine untiltheleakisfixedand

any spilled fuel has been wiped away. Take care not to get fuel on your cloth- ing. If this happens, change your clothing immediately.

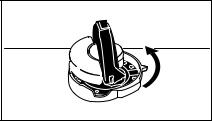

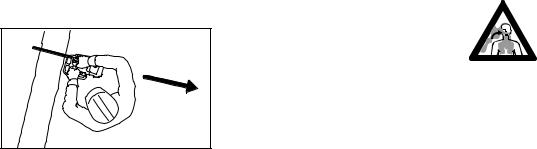

Toolless cap with grip

Warning!

Warning!

In order to reduce the risk of fuel spill- age and fire from an improperly tightened fuel cap, correctly position and tighten the fuel cap in the fuel tank opening.

001BA220 KN

To do this with this STIHL cap, raise the griponthetopofthecapuntilitisupright at a 90° angle. Insert the cap in the fuel tank opening with the raised positioning marks on the grip of the cap and on the fuel tank opening lining up. Using the grip, press the cap down firmly while turning it clockwise as far as it will go (approx. 1/4 turn).

Fold the grip flush with the top of the cap. Grip

the cap and check for tightness. If the grip does not lie completely flush

the cap and check for tightness. If the grip does not lie completely flush

with the cap and the detent on the grip does not fit in the correspond- ing recess in the filler opening, or if the cap is loose in the filler opening, the cap is not properly seated and tightened and you must repeat the above steps.

Misaligned, damaged or broken cap

NIfthecapdoesnotdropfullyintothe openingwhenthepositioningmarks line up and/or if the cap does not tighten properly when twisted, the baseofthecapmaybeprematurely rotated (in relation to the top) to the closed position. Such misalignment can result from handling, cleaning or an improper attempt at tightening.

001BA227 KN |

Left: |

Base of cap in closed posi- |

|

tion (with open space) |

Right: |

Base of cap correctly posi- |

|

tioned for installation |

6 |

MS 192 T, MS 192 TC |

001BA226 KN |

NTo return the cap to the open position for installation, turn the cap (with the grip up) until it drops fully intothetankopening.Next,twistthe capcounterclockwiseasfarasitwill go (approx. 1/4 turn) – this will twist the base of the cap into the correct position. Then, twist the cap clockwise, closing it normally.

NIf your cap still does not tighten properly, it may be damaged or broken; immediately stop use of the unit and take it to your authorized STIHL dealer for repair.

See also the "Fueling" chapter in your Instruction Manual for additional information.

Before Starting

Takeoffthechainguard(scabbard)and inspect the saw for proper condition and operation. (See the maintenance chart near the end of the instruction manual.)

Warning!

Warning!

Alwayscheckyourpowertoolforproper condition and operation before starting, particularly the throttle trigger, throttle trigger lockout, stop switch and cutting attachment. The throttle trigger must move freely and always spring back to the idle position. Never attempt to mod- ify the controls or safety devices.

Warning!

Warning!

Check that the spark plug boot is securely mounted on the spark plug – a loose boot may cause arcing that could ignite combustible fumes and cause a fire.

For proper assembly of the bar and chain follow the procedure described in the chapter "Mounting the Bar and Chain" of your instruction manual. STIHL Oilomatic chain, guide bar and sprocket must match each other in gauge and pitch. Before replacing any bar and chain, see the chapter entitled "Specifications" in the instruction manual and the section "Kickback" and the "ANSI B 175.1-2000 chain saw kickback standard" below.

Since longer bars add weight and may be more difficult to control, select the shortest bar that will meet your cutting needs. Check the throttle trigger and throttle trigger lockout for smooth action

– throttle trigger must return automatically to idle position. The Master Control lever / stop switch must move easily to STOP and 0.

English

Warning!

Warning!

Proper tension of the chain is extremely important. In order to avoid improper setting, the tensioning procedure must be followed as described in your man- ual. Always make sure the hexagonal nut(s) for the sprocket cover is (are) tightened securely after tensioning the chain in order to secure the bar. Never start the saw with the sprocket cover loose. Check chain tension once more after having tightened the nut(s) and thereafteratregularintervals(whenever the saw is shut off). If the chain becomes loose while cutting, shut off theengineandthentighten.Nevertryto adjust the chain while the engine is running!

Keep the handles clean and dry at all times; it is particularly important to keep themfreeofmoisture,pitch,oil,fuelmix, grease or resin in order for you to maintain a firm grip and properly control your power tool.

Starting

Warning!

Warning!

To reduce the risk of fire and burn inju- ries, start the engine at least 10 feet (3 m) from the fueling spot, outdoors only.

Start and operate your saw without assistance. For specific starting instructions,seethe appropriate section oftheinstructionmanual.Properstarting methods reduce the risk of injury.

MS 192 T, MS 192 TC |

7 |

English

Warning!

Warning!

To reduce the risk of injury from chain contactand/orreactiveforces,thechain brake must be engaged when starting the saw.

Warning!

Warning!

Do not drop start. This method is very dangerous because you may lose con- trol of the saw.

0012BA008 KN

Place the chain saw on firm ground or other solid surface in an open area. Maintain good balance and secure footing.

Warning!

Warning!

Besurethattheguidebarandchainare clear of you and all other obstructions andobjects,includingtheground.When the engine is started, the engine speed with the starting throttle lock engaged will be fast enough for the clutch to engage the sprocket and, if the chain brake is not activated, turn the chain. If the running chain near the upper quad- rant of the tip of the bar touches any object, it may cause kickback to occur (see section on reactive forces). To reduce this risk, always engage the chain brake before starting. Never attempt to start the chain saw when the guide bar is in a cut or kerf.

Once the engine has started, immediately blip the throttle trigger, whichshouldreleasetheMasterControl lever to the run position and allow the engine to slow down to idle.

Warning!

Warning!

When you pull the starter grip, do not wrapthe starterropearoundyourhand. Do not let the grip snap back, but guide the starter rope to rewind it properly.

Failure to follow this procedure may result in injury to your hand or fingers and may damage the starter mechanism.

Important Adjustments

Warning!

Warning!

To reduce the risk of personal injury from loss of control and/or contact with the running cutting attachment, do not use your unit with incorrect idle adjust- ment. At correct idle speed, the cutting attachment should not move. For direc- tions on how to adjust idle speed, see the appropriate section of your instruc- tion manual.

If you cannot set the correct idle speed, have your STIHL dealer check your power tool and make proper adjustments and repairs.

During Operation

Holding and Controlling the Power Tool

0012BA019 KN

0012BA019 KN

Always hold the saw firmly with both handswhentheengineisrunning.Place your left hand on the front handle bar and your right hand on the control handle and throttle trigger. Left-handers should follow these instructions too. Wrap your fingers tightly around the handles, keeping the handles cradled between your thumb and forefinger. Withyourhandsinthisposition,youcan best oppose and absorb the push, pull

8 |

MS 192 T, MS 192 TC |

and kickback forces of your saw without losing control (see section on reactive forces).

To reduce the risk of seri- ous or fatal injury to the

operator or bystanders

operator or bystanders

from loss of control, never use the saw with one hand. It is more diffi- cult for you to control reactive forces and to prevent the bar and chain from skating or bouncing along the limb or log. Even for those compact saws designed for use in confined spaces, onehanded operation is dan- gerous because the operator may lose control.

Warning!

Warning!

To reduce the risk of cut injuries, keep hands and feet away from the cutting attachment. Never touch a moving cut- ting attachment with your hand or any other part of your body.

Warning!

Warning!

Keep proper footing and balance at all times. Special care must be taken in slippery conditions (wet ground, snow) andindifficult,overgrownterrain.Watch for hidden obstacles such as tree stumps, roots, rocks, holes and ditches to avoid stumbling. There is increased danger of slipping on freshly debarked logs. For better footing, clear away fallen branches, scrub and cuttings. Be extremely cautious when working on slopes or uneven ground.

Warning!

Warning!

Take extreme care in wet and freezing weather (rain, snow, ice). Put off the workwhentheweatheriswindy,stormy or rainfall is heavy.

English

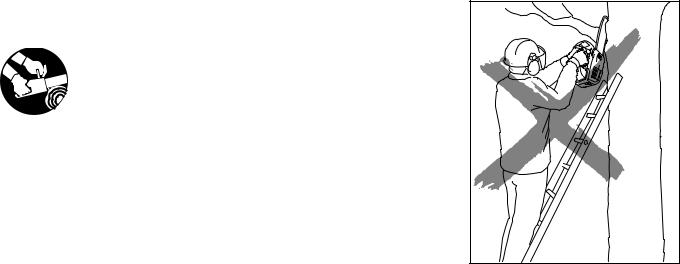

0012BA025 KN

Warning!

Warning!

To reduce the risk of injury from loss of control, never work on a ladder or any other insecure support. Never hold the machine above shoulder height. Do not overreach.

Warning!

Warning!

Never work in a tree unless you have received specific, professional training for such work, are properly secured (suchastackleandharnesssystemora lift bucket), have both hands free for operating the chain saw in a cramped environmentandhavetakenproperpre- cautions to avoid injury from falling limbs or branches.

Theuseofclimbingaids,suchasspikes or climbing irons, also require special training. Always secure the chain saw witharope(tietohingedring)andattach

MS 192 T, MS 192 TC |

9 |

English

ittothelifeline.Cordonofftheworkarea in order to reduce the risk of injuries and damage to bystanders or property (e. g. motor vehicles) from falling branches.

0012BA020 KN

Position the chain saw in such a way that your body is clear of the cutting attachment whenever the engine is running. Stand to the left of cut while bucking.

Warning!

Warning!

To reduce the risk of falls, keep rotating saw chain well clear of harness and life- lines to avoid them being severed. It is essential to use a double lifeline.

Check condition of harness, belts and ropes at regular frequent intervals. Always pull the saw out of the cut with the chain running.

After finishing a cut, activate the chain brake to lock the chain or shut down the engine before moving the saw to another position in the tree.

Never put pressure on the saw when reaching the end of a cut. The pressure may cause the bar and rotating chain to pop out of the cut or kerf, go out of control and strike the operator or some other object. If the rotating chain strikes some other object, a reactive force may cause the moving chain to strike the operator.

10

Working Conditions

Operate and start your power tool only outdoors in a well-ventilated area. Operate it under good visibility and daylight conditions only. Work carefully.

Warning!

Warning!

Your chain saw is a one-person machine. Do not allow other persons in the general work area, even when start- ing. They should stand well clear of the branches being cut. Stop the engine immediately if you are approached.

Warning!

Warning!

Eventhoughbystandersshouldbekept away from the running saw, never work alone. Keep within calling distance of others in case help is needed.

Warning!

Warning!

To reduce the risk of injury to bystand- ers and damage to property, never let yourpowertoolrununattended.Whenit is not in use (e. g. during a work break), shut it off and make sure that unauthor- ized persons do not use it.

Warning!

Warning!

As soon as the engine is running, this product generates toxic exhaust fumes containing chemi- cals, such as unburned hydrocarbons (including

benzene) and carbon monoxide, that are known to cause respiratory prob- lems, cancer, birth defects, or other reproductive harm. Some of the gases (e. g. carbon monoxide) may be color- less and odorless. To reduce the risk of serious or fatal injury/illness from inhal- ing toxic fumes, never run the machine indoorsorinpoorlyventilatedlocations. If exhaust fumes become concentrated due to insufficient ventilation, clear obstructions from work area to permit proper ventilation before proceeding and/or take frequent breaks to allow fumes to dissipate before they become concentrated.

Warning!

Warning!

Operate your chain saw so that it pro- duces a minimum of noise and emissions – do not run engine unneces- sarilyandacceleratetheengineonlyfor cutting.

MS 192 T, MS 192 TC

Warning!

Warning!

Inhalation of certain dusts, especially organic dusts such as mold or pollen, can cause susceptible persons to have an allergic or asthmatic reaction. Sub- stantial or repeated inhalation of dust andotherairbornecontaminants,inpar- ticularthose withasmallerparticlesize, may cause respiratory or other ill- nesses. This includes wood dust, especially from hardwoods, but also from some softwoods such as Western Red Cedar. Control dust at the source where possible. Use good work prac- tices, such as always cutting with a properly sharpened chain (which pro- duces wood chips rather than fine dust) and operating the unit so that the wind or operating process directs any dust raised by the power tool away from the operator. Follow the recommendations ofEPA/OSHA/NIOSHandoccupational and trade associations with respect to dust ("particulate matter"). When the inhalation of dust cannot be substan- tially controlled, i.e., kept at or near the ambient (background) level, the opera- tor and any bystanders should wear a respirator approved by NIOSH/MSHA for the type of dust encountered.

Warning!

Warning!

Breathing asbestos dust is dangerous and can cause severe or fatal illness, respiratory illness or cancer. The use and disposal of asbestos-containing productshavebeenstrictlyregulatedby OSHA and the Environmental Protec- tion Agency. If you have any reason to believe that you might be cutting asbes- tos, immediately contact your employer or a local OSHA representative.

Warning!

Warning!

To reduce risk of electro- cution, take extra precautionswhencutting near power lines. Have the power switched off before starting cutting

work in the immediate vicinity of power lines.

Operating Instructions

Warning!

Warning!

Do not operate your chain saw with the starting throttle lock engaged. Cutting with the starting throttle lock engaged does not permit the operator proper controlofthesaworchainspeed.Begin cutting with the saw at full throttle, engage the bumper spike firmly in the wood (if possible) and then continue cutting. Always work with the bumper spike so that you have better control of the saw. If you work without the bumper spike the saw may pull you forwards suddenly.

English

Warning!

Warning!

Never touch a chain with your hand or any part of your body when the engine is running, even when the chain is not rotating.

In the event of an emergency, switch off the engine immediately – move the master control lever to 0 or STOP.

Warning!

Warning!

Always stop the engine before putting a chain saw down.

Warning!

Warning!

The saw chain continues to move for a short period after the throttle trigger is released (flywheel effect).

Accelerating the engine while the saw chain is blocked increases the load and willcausetheclutchtoslipcontinuously. This may occur if the throttle is depressed for more than a few seconds when the chain is pinched in the cut or the chain brake is engaged. It can result in overheating and damage to important components (e. g. clutch, polymer housing components) – which can then increase the risk of injury, e. g., from the saw chain moving while the engine is idling.

MS 192 T, MS 192 TC |

11 |

English

Warning!

Warning!

Yourchainsawisequippedwithachain catcher.Itisdesignedtoreducetherisk of personal injury in the event of a thrown or broken chain. From time to time, the catcher may be damaged or removed.Toreducetheriskofpersonal injury,donotoperateachainsawwitha damaged or missing chain catcher.

Warning!

Warning!

Inspect antivibration elements periodi- cally. Replace damaged, broken or excessivelywornantivibrationelements immediately, since they may result in loss of control of the saw. A "spongi- ness" in the feel of the saw, increased vibration or increased "bottoming" dur- ing normal operation may indicate damage, breakage or excessive wear. Antivibration elements should always be replaced in sets. If you have any questions as to whether the antivibra- tion elements should be replaced, consult your STIHL servicing dealer.

If this tool is subjected to unusually high loadsforwhichitwasnotdesigned(e. g. heavy impact or a fall), always check that it is in good condition before continuingwork.Checkinparticularthat the fuel system is tight (no leaks) and that the controls and safety devices are working properly. Do not continue operating this machine if it is damaged. Incaseofdoubt,haveitcheckedbyyour STIHL servicing dealer.

Your saw is not designed for prying or shoveling away limbs, roots or other objects. Such use could damage the cutting attachment or AV system.

12

Warning!

Warning!

When sawing, make sure that the saw chain does not touch any foreign mate- rialssuchasrocks,fences,nailsandthe like. Such objects may be flung off, damagethesawchainorcausethesaw to kickback.

Warning!

Warning!

Take special care when cutting shat- tered wood because of the risk of injury from slivers being caught and thrown in your direction.

Warning!

Warning!

Never modify your muffler. Any modifi- cation could cause an increase in heat radiation,sparksorsoundlevel,thereby increasing the risk of fire, burn injury or hearingloss.Youmayalsopermanently damage the engine. Have your muffler serviced and repaired by your STIHL servicing dealer only.

Warning!

Warning!

The muffler and other parts of the engine (e.g. fins of the cylinder, spark plug) become hot during operation and remain hot for a while after stopping the engine. To reduce risk of burns, do not touch the muffler and other parts while they are hot. Keep the area around the muffler clean. Remove excess lubricant and all debris such as pine needles, branches or leaves. Let the engine cool down sitting on concrete, metal, bare ground or solid wood (e.g. the trunk of a felled tree) away from any combustible substances.

Warning!

Warning!

Animproperlymountedordamagedcyl- inder housing or a damaged/deformed muffler shell may interfere with the cool- ingprocessofthemuffler.Toreducethe riskoffireorburninjury,donotcontinue work with a damaged or improperly mounted cylinder housing or a dam- aged/deformed muffler shell.

Your muffler is furnished with a spark arresting screen designed to reduce the risk of fire from the emission of hot particles. Never operate your unit with a missing or damaged spark arresting screen.Ifyourgas/oilmixratioiscorrect (i.e., not too rich), this screen will normally stay clean as a result of the heat from the muffler and need no service or maintenance. If you experiencelossofperformanceandyou suspect a clogged screen, have your mufflermaintained byaSTIHL servicing dealer. Some state or federal laws or regulations may require a properly maintained spark arrestor for certain uses.Seethe"Maintenance,Repairand Storing" section of these Safety Precautions. Remember that the risk of a brush or forest fire is greater in hot or dry conditions.

MS 192 T, MS 192 TC

Warning!

Warning!

SomeSTIHL power tools are equipped with a cata- lytic converter, which is

designed to reduce the exhaust emissions of the engine by a chemical

process in the muffler. Due to this proc- ess, the muffler does not cool down as rapidly as conventional mufflers when the engine returns to idle or is shut off. To reduce the risk of fire and burn inju- ries when using a catalytic converter, always set your power tool down in the upright position and never locate it where the muffler is near dry brush, grass, wood chips or other combustible materials while it is still hot.

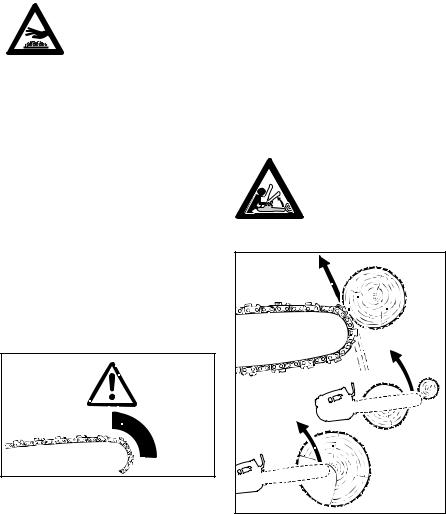

Reactive Forces Including Kickback

Warning!

Warning!

Reactive forces may occur any time the chain is rotating. Reactive forces can cause serious personal injury.

001BA093 LÄ

Thepowerfulforceusedtocutwoodcan be reversed and work against the operator.Iftherotatingchainissuddenly stopped by contact with any solid object suchasalogorbranchorispinched,the reactive forces may occur instantly. These reactive forces may result in loss

MS 192 T, MS 192 TC

of control, which, in turn, may cause serious or fatal injury. An understanding of the causes of these reactive forces may help you avoid the element of surprise and loss of control. Surprise contributes to accidents.

The most common reactive forces are:

–kickback,

–pushback,

–pull-in. Kickback

Kickback may occur when the moving saw chain near the upper quadrant of the bar nose contacts a solid object or is pinched.

0012BA021 KN

The reaction of the cutting force of the chain causes a rotational force on the chainsawinthedirectionoppositetothe chain movement. This may fling the bar

English

upandbackinalightningfastreactionin an uncontrolled arc mainly in the plane of the bar. Under some cutting circumstances the bar moves towards the operator, who may suffer severe or fatal injury.

Kickback may occur, for example, when thechainneartheupperquadrantofthe bar nose contacts the wood or is pinched during limbing or when it is incorrectly used to begin a plunge or boring cut.

The greater the force of the kickback reaction,themoredifficultitbecomesfor the operator to control the saw. Many factors influence the occurrence and force of the kickback reaction. These include chain speed, the speed at which the bar and chain contact the object, the angle of contact, the condition of the chain and other factors.

The type of bar and saw chain you use is an important factor in the occurrence andforceofthekickbackreaction.Some STIHLbarandchaintypesaredesigned to reduce kickback forces. STIHL recommends the use of reduced kickback bars and low kickback chains.

ANSI B 175.1-2000 Chain Saw Kickback Standard

§ 5.11 of ANSI standard B 175.1-2000, sets certain performance and design criteria related to chain saw kickback.

To comply with § 5.11 of ANSI B 175.1-2000:

a)Saws with a displacement of less than 3.8 cubic inches (62 cm³)

13

English

–must, in their original condition, meet a 45° computer-derived kickback angle when equipped with certain cutting attachments,

–and must be equipped with at least two devices to reduce the risk of kickback injury, such as a chain brake, low kickback chain, reduced kickback bar, etc.

b)Saws with a displacement of 3.8 cubic inches (62 cm³) and above

–must be equipped with at least one device designed to reduce the risk of kickback injury, such as a chain brake, low kickback chain, reduced kickback bar, etc.

The computer-derived angles for saws below 3.8 cubic inches (62 cm³) displacementaremeasuredbyapplying a computer program to test results from a kickback test machine.

Warning!

Warning!

The computer-derived angles of § 5.11 ofANSIB 175.1-2000maybearno rela- tionship to actual kickback bar rotation angles that may occur in real life cutting situations.

In addition, features designed to reduce kickback injuries may lose some of their effectivenesswhentheyarenolongerin their original condition, especially if they have been improperly maintained.

Compliance with § 5.11 of ANSI

B 175.1-2000 does not automatically mean that in a real life kickback the bar and chain will rotate at most 45°.

Warning!

Warning!

Inorderforpowerheadsbelow3.8 cubic inches(62 cm³)displacementtocomply with the computed kickback angle requirements of § 5.11 of

ANSI B 175.1-2000 use only the follow- ing cutting attachments:

–bar and chain combinations listed as complying in the "Specifications" section of the instruction manual or

–other replacement bar and chain combinations marked in accordance with the standard for use on the powerhead or

–replacement chain designated "low kickback saw chain".

See the section on "Low kickback saw chain and reduced kickback bars".

Devices for Reducing the Risk of Kickback Injury

STIHL recommends the use of the STIHL Quickstop chain brake on your powerhead with green labeled reduced kickback bars and low kickback chains.

Warning!

Warning!

To reduce the risk of injury, never use a saw if the chain brake does not function properly. Take the saw to your local STIHL servicing dealer. Do not use the sawuntiltheproblemhasbeenrectified.

STIHL Quickstop Chain Brake

STIHL has developed a chain stopping system designed to reduce the risk of injury in certain kickback situations. It is called a Quickstop chain brake.

0012BA022 KN

All STIHL chain saws are equipped with a Quickstop chain brake which can be activated by inertia. If the forces of an occurring kickback are sufficiently high, the hand guard is accelerated towards the bar nose even without hand contact. See the chapter entitled "Chain Brake" of your instruction manual.

Warning!

Warning!

Never operate your chain saw without a fronthandguard.Inakickbacksituation this guard helps protect your left hand andotherpartsofyourbody.Inaddition, removal of the hand guard on a saw equipped with a Quickstop chain brake will deactivate the chain brake.

14 |

MS 192 T, MS 192 TC |

Warning!

Warning!

No Quickstop or other chain brake device prevents kickback. These devices are designed to reduce the risk of kickback injury, if activated, in certain kickback situations. In order for the Quickstop to reduce the riskofkickback injury, it must be properly maintained and in good working order. See the chapter of your instruction manual enti- tled "Chain Brake" and the section "Maintenance, Repair and Storing" at theendoftheseSafetyPrecautionsand Working Techniques. In addition, there must be enough distance between the bar and the operator to ensure that the Quickstophassufficienttime toactivate and stop the chain before potential con- tact with the operator.

Warning!

Warning!

An improperly maintained chain brake may increase the time needed to stop the chain after activation, or may not activate at all.

MS 192 T, MS 192 TC

Warning!

Warning!

Never run the chain saw above idle speed for more than 3 seconds when the chain brake is engaged or when the chain is pinched or otherwise caught in the cut. Clutch slippage can cause excessive heat, leading to severe dam- age of the motor housing, clutch and oiler component and may interfere with the operation of the chain brake. If clutch slippage in excess of 3 seconds has occurred, allow the motor housing tocoolbeforeproceedingandcheckthe operation of your chain brake as described in the chapter entitled "Chain Brake" of your instruction manual. Also make sure that the chain is not turning at idle speed (see above at "Important Adjustments").

Low Kickback Saw Chain and Reduced Kickback Bars

STIHL offers a variety of bars and chains. STIHL reduced kickback bars andlowkickbackchainsaredesignedto reduce the risk of kickback injury. Other chains are designed to obtain higher cuttingefficiencyorsharpeningeasebut may result in higher kickback tendency.

STIHL has developed a color code system to help you identify the STIHL reducedkickbackbarsandlowkickback chains. Cutting attachments with green warning decals or green labels on the packaging are designed to reduce the risk of kickback injury. The matching of green decaled powerheads under

3.8 cubic inches (62 cm³) displacement with green labeled bars and green labeled chains gives compliance with the computed kickback angle requirements of ANSI B 175.1-2000

English

when the products are in their original condition.Productswithyellowdecalsor labels are for users with extraordinary cutting needs and experience and specialized training for dealing with kickback.

Warning!

Warning!

Use of other, non-listed bar/chain com- binations may increase kickback forces and the risk of kickback injury. New bar/chain combinations may be devel- oped after publication of this literature, which will, in combination with certain powerheads, comply with § 5.11 of ANSI B 175.1-2000. Check with your STIHL dealer for such combinations.

Warning!

Warning!

Reduced kickback bars and low kick- back chains do not prevent kickback, but they are designed to reduce the risk of kickback injury. They are available from your STIHL dealer.

Warning!

Warning!

Even if your saw is equipped with a Quickstop chain brake, a reduced kick- back bar and/or low kickback chain, this does not eliminate the risk of injury by kickback. Therefore, always observe all safety precautions to avoid kickback situations.

Low Kickback Chain

Some types of saw chains have specially designed components to reduce the force of nose contact kickback. STIHL has developed low kickback chain for your powerhead.

15

English

"Low kickback saw chain" is a chain which has met the kickback performance requirements of § 5.11.2.4 of ANSI B 175.1-2000 (GasolinePowered Chain Saws–Safety Requirements) when tested in its original condition on a selected representative sample of chain saws below 3.8 cubic inches (62 cm³) displacement specified in ANSI

B 175.1-2000.

Warning!

Warning!

There are potential powerhead and bar combinations with which low kickback saw chains can be used which have not beenspecificallycertifiedtocomplywith the 45° computer derived kickback angle of § 5.11 of ANSI B 175.1-2000. Some low kickback chains have not been tested with all powerhead and bar combinations.

Warning!

Warning!

A dull or improperly sharpened chain may reduce or negate the effects of the design features intended to reduce kick- back energy. Improper lowering or sharpening of the depth gauges or shaping of the cutters may increase the chance and the potential energy of a kickback. Always cut with a properly sharpened chain.

Reduced Kickback Bars

STIHL green labeled reduced kickback bars are designed to reduce the risk of kickback injury when used with STIHL green labeled low kickback chains.

16

Warning!

Warning!

Whenusedwithother,moreaggressive chains,thesebarsmaybelesseffective in reducing kickback.

Warning!

Warning!

For a properly balanced saw and in order to comply with § 5.12.1 of ANSI B 175.1-2000, use only bar lengths listedinthespecificationschapterofthe instruction manual for your powerhead.

Warning!

Warning!

Do not mount a bow guide on any STIHL chain saw. Any chain saw equippedwitha bowguideispotentially very dangerous. The risk of kickback is increased with a bow guide because of the increased kickback contact area. Low kickback chain will not significantly reduce the risk of kickback injury when used on a bow guide.

To Avoid Kickback

The best protection from personal injury that may result from kickback is to avoid kickback situations:

1.Hold the chain saw firmly with both hands and maintain a secure grip. Don’t let go.

2.Beawareofthelocationoftheguide bar nose at all times.

3.Never let the nose of the guide bar contact any object. Do not cut limbs with the nose of the guide bar. Be especially careful near wire fences and when cutting small, tough limbs,smallsizebrushandsaplings which may easily catch the chain.

4.Don't overreach.

5.Don't cut above shoulder height.

6.Begin cutting and continue at full throttle.

7.Cut only one log at a time.

8.Use extreme caution when reentering a previous cut.

9.Do not attempt to plunge cut if you are not experienced with these cutting techniques.

10.Be alert for shifting of the log or other forces that may cause the cut to close and pinch the chain.

11.Maintain saw chain properly. Cut withacorrectlysharpened,properly tensioned chain at all times.

12.Stand to the side of the cutting path of the chain saw.

A = Pull-in

A |

001BA037 KN |

|

|

Pull-in occurs when the chain on the bottom of the bar is suddenly stopped whenitispinched,caughtorencounters a foreign object in the wood. The reaction of the chain pulls the saw forward and may cause the operator to lose control.

MS 192 T, MS 192 TC

Pull-in frequently occurs when the bumper spike of the saw is not held securely against the tree or limb and when the chain is not rotating at full speed before it contacts the wood.

Warning!

Warning!

Useextremecautionwhencuttingsmall size brush and saplings which may eas- ily catch the chain, be whipped towards you or pull you off balance.

To Avoid Pull-in

1.Always start a cut with the chain rotating at full speed and the bumper spike in contact with the wood.

2.The risk of pull-in may also be reduced by using wedges to open the kerf or cut.

B = Pushback

B |

001BA038 KN |

|

|

Pushback occurs when the chain on the top of the bar is suddenly stopped when it is pinched, caught or encounters a foreign object in the wood. The reaction of the chain may drive the saw rapidly straight back toward the operator and may cause loss of saw control. Pushback frequently occurs when the top of the bar is used for cutting.

To Avoid Pushback

1.Be alert to forces or situations that may cause material to pinch the top of the chain.

2.Do not cut more than one log at a time.

3.Do not twist the saw when withdrawing the bar from a plunge cut or underbuck cut because the chain can pinch.

4.Do not underbuck freely hanging limbs because the chain may get pinched and cause pushback and loss of control.

Warning!

Warning!

This chain saw equipped with a top han- dle is designed specifically for tree surgery and maintenance. Due to the special handle design (closely spaced handles), there is an increased risk of injury from loss of control.

For this reason this special chain saw shouldbe used only forworkin atreeby persons trained in special cutting and working techniques. This type of chain saw is not designed for cutting work on the ground, such as felling and bucking. Because this chain saw is not intended for use on the ground, this manual does not contain instructions for felling or for limbing and bucking felled trees. For instructions on these techniques when using other STIHL chain saw models, see the instruction manuals for these saws or the STIHL Chain Saw Safety Manual, which is available free from your STIHL servicing dealer.

English

Cutting Techniques

2 |

KN |

|

001BA151 |

|

|

|

|

2 |

|

1 |

KN |

|

001BA152 |

|

|

Logs under strain:

Risk of pinching! Always start relieving cut (1) at compression side. Then make buckingcut(2)attensionside.Ifthesaw pinches, stop the engine and remove it from the log.

Only properly trained professionals should work in an area where the logs, limbs and roots are tangled. Working in "blow down" areas is extremely hazardous. Drag the logs into a clear area before cutting. Pull out exposed and cleared logs first.

If conditions allow, work from a lift bucket.

MS 192 T, MS 192 TC |

17 |

English

Warning!

Warning!

Be extremely cautious when cutting limbs under tension (spring poles). The limbs could spring back toward the operatorandcauselossofcontrolofthe saw and severe or fatal injury to the operator.

MAINTENANCE, REPAIR AND STORING

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. However, if you make a warranty claim for a component which has not been serviced or maintained properly or if nonapproved replacement parts were used, STIHL may deny coverage.

Warning!

Warning!

Use only identical STIHL replacement partsformaintenanceandrepair.Useof non-STIHL parts may cause serious or fatal injury.

Strictly follow the maintenance and repair instructions in the appropriate section of your instruction manual.

Please refer to the maintenance chart in this manual.

Warning!

Warning!

Always stop the engine and make sure that the cutting tool is stopped before doinganymaintenanceorrepairworkor cleaning the power tool.

Warning!

Warning!

Do not attempt any maintenance or repair work not described in your instructionmanual.Havesuchworkper- formed by your STIHL servicing dealer only. For example, if improper tools are used to remove the flywheel or if an improper tool is used to hold the fly- wheel in order to remove the clutch, structural damage to the flywheel could occurandcouldsubsequentlycausethe flywheel to burst.

Wear gloves when handling or performing maintenance on saw chains.

Warning!

Warning!

Use the specified spark plug and make sure it and the ignition lead are always clean and in good condition. Always presssparkplugbootsnuglyontospark plugterminalofthepropersize.(Note:If terminal has detachable SAE adapter nut, it must be securely attached.) A loose connection between spark plug terminal and the ignition wire connector in the boot may create arcing that could ignite combustible fumes and cause a fire.

Warning!

Warning!

Never test the ignition system with the sparkplugbootremovedfromthespark plugorwitharemovedsparkplug,since uncontained sparking may cause a fire.

Warning!

Warning!

Do not operate your power tool if the muffler is damaged, missing or modi- fied. An improperly maintained muffler will increase the risk of fire and hearing loss. Your muffler is equipped with a spark-arresting screen to reduce the risk of fire; never operate your power toolifthescreenismissing,damagedor clogged. Remember that the risk of a brushorforestfireisgreaterinhotordry weather.

In California, it is a violation of § 4442 or § 4443 or the Public Resources Code to use or operate gasoline-powered tools on forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a complying spark arrester that is maintained in effective working order. The owner/operator of this product is responsible for properly maintaining the spark arrester. Other states or governmentalentities/agencies,suchas the U.S. Forest Service, may have similar requirements. Contact your local fire agency or forest service for the laws or regulations relating to fire protection requirements.

Keep the chain, bar and sprocket clean; replace worn sprockets or chains. Keep the chain sharp. You can spot a dull chain when easy-to-cut wood becomes hard to cut and burn marks appear on the wood. Keep the chain at proper tension.

Tightenallnuts,boltsandscrewsexcept the carburetor adjustment screws after each use.

18 |

MS 192 T, MS 192 TC |

Warning!

Warning!

In order for the chain brake on your STIHL chain saw to properly perform its function of reducing the risk of kickback and other injuries, it must be properly maintained.Likeanautomobilebrake,a chainsawchainbrakeincursweareach time it is engaged.

The amount of wear will vary depending upon usage, conditions under which the sawisusedandotherfactors.Excessive wear will reduce the effectiveness of the chain brake and can render it inoperable.

Fortheproperandeffectiveoperationof the chain brake, the brake band and clutch drum must be kept free of dirt, grease and other foreign matter which may reduce friction of the band on the drum.

For these reasons, each STIHL chain saw should be returned to trained personnel such as your STIHL servicing dealer for periodic inspection and servicing of the brake system according to the following schedule:

Heavy usage – every three months, Moderate usage – twice a year, Occasional usage – annually.

The chain saw should also be returned immediately for maintenance whenever the brake system cannot be thoroughly cleaned or there is a change in its operating characteristics.

For any maintenance of the emission control system please refer to the maintenance chart and to the limited warranty statement near the end of the instruction manual.

Do not clean your machine with a pressure washer. The solid jet of water may damage parts of the machine.

Store chainsawinadry place and away from children. Before storing for longer than a few days, always empty the fuel tank (see chapter "Storing the Machine" in the instruction manual).

English

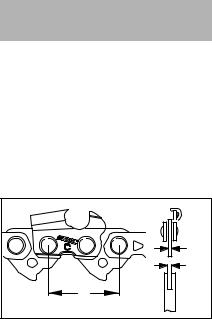

Cutting Attachment

STIHL is the only manufacturer in the industry to produce its own chain saws, guide bars, saw chains and chain sprockets.

Acuttingattachmentconsistsofthesaw chain, guide bar and chain sprocket.

The cutting attachment that comes standard is designed to exactly match the chain saw.

1 |

2 |

|

|

|

|

|

3 |

KN |

a |

001BA191 |

|

t = a : 2 |

|

–The pitch (t) of the saw chain (1), chain sprocket and the nose sprocketoftheRollomaticguidebar must match.

–The drive link gauge (2) of the saw chain (1) must match the groove width of the guide bar (3).

If non-matching components are used, thecuttingattachmentmaybedamaged beyond repair after a short period of operation.

MS 192 T, MS 192 TC |

19 |

English

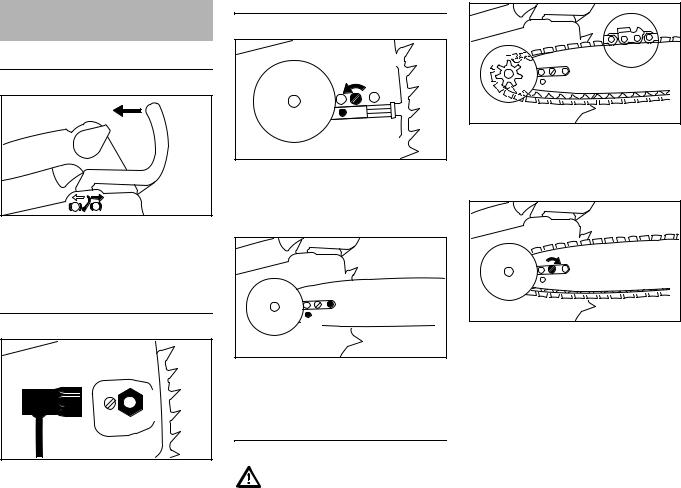

Mounting the Bar and Chain

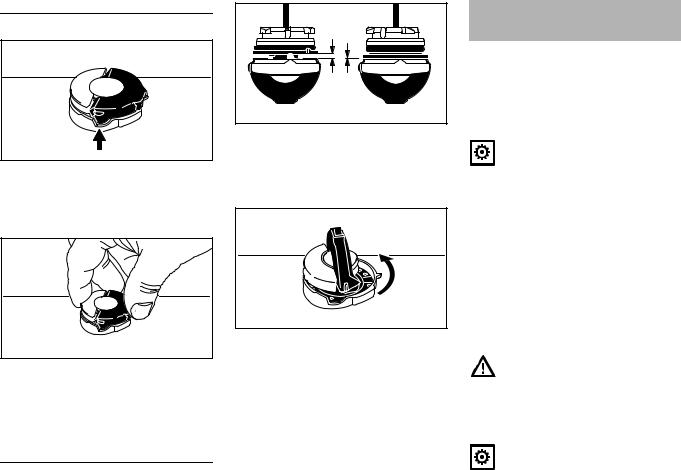

Releasing the chain brake

4

142BA057 KN

NPull the hand guard (4) toward the control handle until there is an audibleclick – the chain is disengaged.

Removing the chain sprocket cover

6

5 |

KN |

|

142BA058 |

||

|

NUnscrewthenut (5)andremovethe cover (6).

Mounting the guide bar

7

8 |

KN |

|

142BA059 |

||

|

NTurn the screw (7) counterclockwiseuntilthetensioner slide (8) butts against left end of housing slot.

11 |

142BA061 KN |

NFit chain around the sprocket (11) and over the guide bar – cutting edges on top of bar must point to bar nose.

9

10 |

KN |

|

142BA060 |

||

|

NFit the guide bar over the stud (9) andengagethepegofthetensioner slide in the locating hole (10).

Fitting the chain

7 |

KN |

|

142BA062 |

||

|

NTurn the tensioning screw (7) clockwise until there is very little chain sag on the underside of the bar – and the drive link tangs are engaged in the bar groove.

Wear work gloves to protect your hands from the sharp cutters.

20 |

MS 192 T, MS 192 TC |

NRefit the sprocket cover –

thepivotpinonthehandguardmust engagethesleeve–andthenscrew the nut onto the stud fingertight.

NGo to chapter on "Tensioning the Saw Chain"

Tensioning the Saw Chain (side chain tensioner)

|

KN |

1 |

142BA063 |

|

Retensioning during cutting work: N Switch off the engine.

N Loosen the nut.

N Hold the bar nose up.

NUse a screwdriver to turn the tensioning screw (1) clockwise until the chain fits snugly against the underside of the bar.

NWhile still holding the bar nose up, tighten down the nut firmly.

N Go to "Checking Chain Tension".

Anewchainhastoberetensionedmore often than one that has been in use for some time.

NCheck chain tension frequently – see chapter on "Operating Instructions".

English

Checking Chain Tension

142BA064 KN |

N Shut off the engine.

NWear work gloves to protect your hands.

NThe chain must fit snugly against the underside of the bar and it must still be possible to pull the chain along the bar by hand when the chain brake is released.

N If necessary, retension the chain.

Anewchainhastoberetensionedmore often than one that has been in use for some time.

NCheck chain tension frequently – see chapter on "Operating Instructions".

MS 192 T, MS 192 TC |

21 |

English

Fuel

This engine is certified to operate on unleaded gasoline and the STIHL twostroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of highquality gasoline and two-stroke air cooled engine oil.

Usemid-gradeunleadedgasolinewitha minimum octane rating of 89 (R+M/2) and no more than 10% ethanol content.

Fuel with a lower octane rating may increase engine temperatures. This, in turn, increases the risk of piston seizure and damage to the engine.

The chemical composition of the fuel is also important. Some fuel additives not only detrimentally affect elastomers (carburetor diaphragms, oil seals, fuel lines,etc.),butmagnesiumcastingsand catalytic converters as well. This could cause running problems or even damage the engine. For this reason STIHL recommends that you use only high-quality unleaded gasoline!

Gasoline with an ethanol content of more than 10% can cause running problems and major damage in engines with a manually adjustable carburetor and should not be used in such engines.

The ethanol content in gasoline affects engine running speed – it may be necessary to readjust the carburetor if you use fuels with various ethanol contents.

Warning!

Warning!

To reduce the risk of personal injury from loss of control and / or contact with the running cutting tool, do not use your unit with incorrect idle adjustment. At correct idle speed, the cutting tool should not move.

If your power tool shows an incorrect idleadjustment,haveyourSTIHLdealer check your power tool and make proper adjustments and repairs.

The idle speed and maximum speed of the engine change if you switch from a fuel with a certain ethanol content to another fuel with a much higher or lower ethanol content.

This problem can be avoided by always using fuel with the same ethanol content.

Use only STIHL two-stroke engine oil or equivalent high-quality two-stroke engine oils that are designed for use only in air cooled two-cycle engines.

WerecommendSTIHLHPUltra2-Cycle Engine Oil since it is specially formulated for use in STIHL engines.

Do not use BIA or TCW rated (twostroke water cooled) mix oils or other mixoilsthatstatetheyareforuseinboth water cooled and air cooled engines (e.g., outboard motors, snowmobiles, chain saws, mopeds, etc.).

Take care when handling gasoline. Avoid direct contact with the skin and avoid inhaling fuel vapor. When filling at the pump, first remove the container from your vehicle and place the containeronthegroundbeforefilling.To reduce the risk of sparks from static

discharge and resulting fire and/or explosion, do not fill fuel containers that are sitting in or on a vehicle or trailer.

The container should be kept tightly closed in order to limit the amount of moisture that gets into the mixture.

The machine‘s fuel tank should be cleaned as necessary.

Fuel mix ages

Only mix sufficient fuel for a few days work,nottoexceed3monthsofstorage. Store in approved fuel-containers only. When mixing, pour oil into the container first, and then add gasoline. Close the container and shake it vigorously by hand to ensure proper mixing of the oil with the fuel.

Gaso- |

Oil (STIHL 50:1 or equiva- |

line |

lent high-quality oils) |

US gal. US fl.oz.

12.6

2 1/2 |

6.4 |

512.8

Dispose of empty mixing-oil containers only at authorized disposal locations.

22 |

MS 192 T, MS 192 TC |

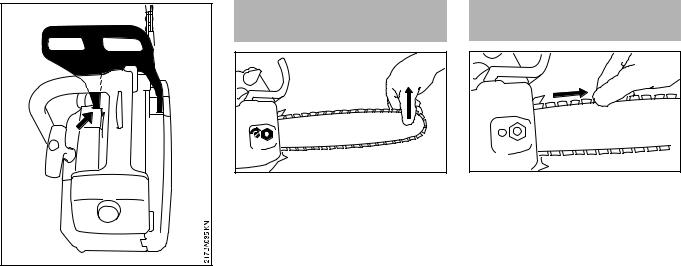

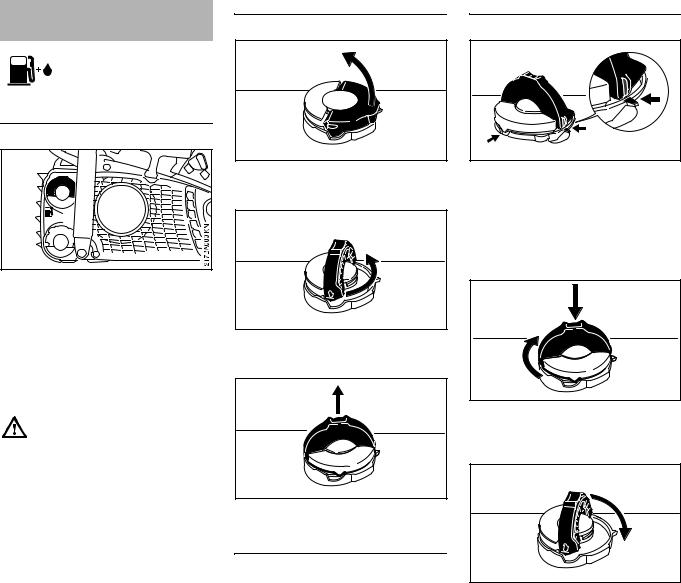

Fueling

Preparations |

NBefore fueling, clean the filler cap andtheareaaroundittoensurethat no dirt falls into the tank.

Always thoroughly shake the mixture in the canister before fueling your machine.

NPosition the machine so that the filler cap is facing up.

In order to reduce the risk of fire and personalinjuryfromescapinggas vapor and fumes, remove the fuel filler cap carefully so as to allow any pressure build-up in the tank to release slowly.

Opening |

001BA218 KN |

NRaise the grip into an upright position.

001BA219 KN |

NTurn the cap counterclockwise (approx. 1/4 turn).

001BA224 KN |

N Remove fuel filler cap.

Refueling

Take care not to spill fuel while fueling and do not overfill the tank.

English

Closing

001BA220 KN

With grip in an upright position:

NInsert the cap – positioning marks onthecapandthefueltankopening must line up.

NThe cap should drop fully into the opening in this position.

001BA221 KN |

NWhilepressingthecapdown,twistit firmly clockwise as far as it will go (approx. 1/4 turn).

001BA222 KN |

N Fold down the grip.

MS 192 T, MS 192 TC |

23 |

English

Checking for proper closure

001BA223 KN |

NThe lug on the grip must engage entirely in the recess (arrow), and the grip must lie completely flush with the top of the cap.

001BA225 KN

NGrip the cap and check for tightness.

NIf the cap can be moved, it is not properly installed.

Misalignment of the cap parts

NIfthecapdoesnotdropfullyintothe openingwhenthepositioningmarks line up and/or if the cap does not tighten properly when twisted, the base of the cap may be rotated out of position vis-à-vis the top.

NSuch misalignment can result from handling, cleaning or an improper attempt at tightening.

001BA227 KN |

Left: |

Base of improperly aligned |

|

cap (with open space) |

Right: |

Base of cap correctly posi- |

|

tioned for installation |

001BA226 KN |

NTo correct a misalignment, turn the cap (with the grip up) until it drops fully into the tank opening.

NTwist the cap counterclockwise as far as it will go (approx. 1/4 turn) – thiswilltwistthebaseofthecapinto the correct position.

NTwist the cap clockwise, closing it normally – see the sections "Closing" and "Checking for proper closure."

NIf your cap still does not tighten properly, it may be damaged or broken; immediately stop use of the unit and take it to your authorized STIHL dealer for repair.

Chain Lubricant

For automatic and reliable lubrication of the chain and guide bar – use only an environmentally compatible quality chain and bar lubricant. Rapidly biodegradable STIHL Bioplus is recommended.

Biological chain oil must be resistant to aging (e.g. STIHL Bioplus) since it will otherwise quickly turn to resin. This results in hard deposits that are difficult to remove, especially in the area of the chain drive, clutch and chain. It may even cause the oil pump to seize.

The service life of the chain and guide bar depends on the quality of the lubricant. It is therefore essential to use only a specially formulated chain lubricant.

Do not use waste oil. Renewed contact with waste oil can cause skin cancer. Moreover, waste oil is environmentally harmful.

Waste oil does not have the necessary lubricating properties and is unsuitable for chain lubrication.

24 |

MS 192 T, MS 192 TC |

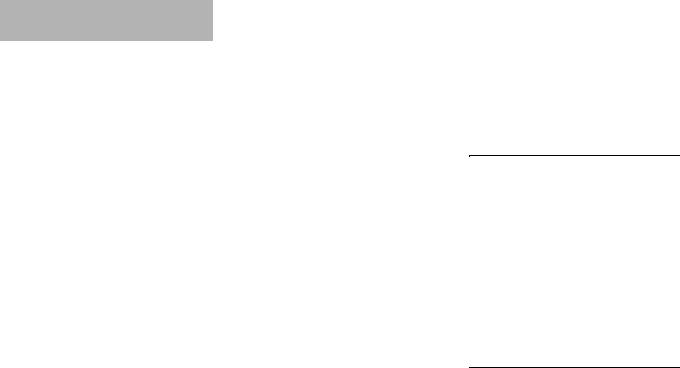

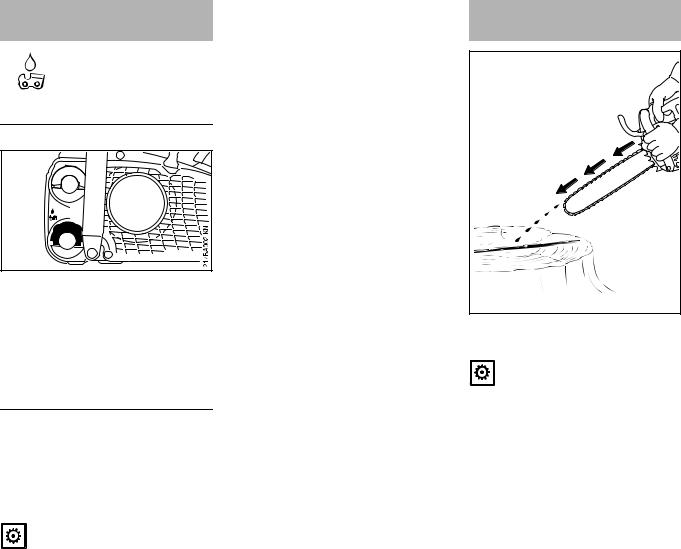

Filling Chain Oil Tank

Preparations

NThoroughly clean the oil filler cap andtheareaaroundittoensurethat no dirt falls into the tank.

NPosition the machine so that the filler cap is facing up.

N Open the filler cap.

Filling chain oil tank

NRefill the chain oil tank every time you refuel.

Take care not to spill chain oil while refilling and do not overfill the tank.

N Close the filler cap.

There must still be a small amount of oil in the oil tank when the fuel tank is empty.

If the oil level in the tank does not go down,thereasonmaybeafaultintheoil supply system: Check chain lubrication, clean the oilways, contact your dealer for assistance if necessary STIHL recommends that you have servicing and repair work carried out exclusively by an authorized STIHL servicing dealer.

English

Checking Chain Lubrication

142BA069 KN |

The saw chain must always throw off a small amount of oil.

Never operate your saw without chain lubrication. If the chain runs dry, the whole cutting attachment will be irretrievablydamagedwithinaveryshort time.Alwayscheckchainlubricationand the oil level in the tank before starting work.

Every new chain has to be broken in for about 2 to 3 minutes.

After breaking in the chain, check chain tension and adjust if necessary – see "Checking Chain Tension".

MS 192 T, MS 192 TC |

25 |

English

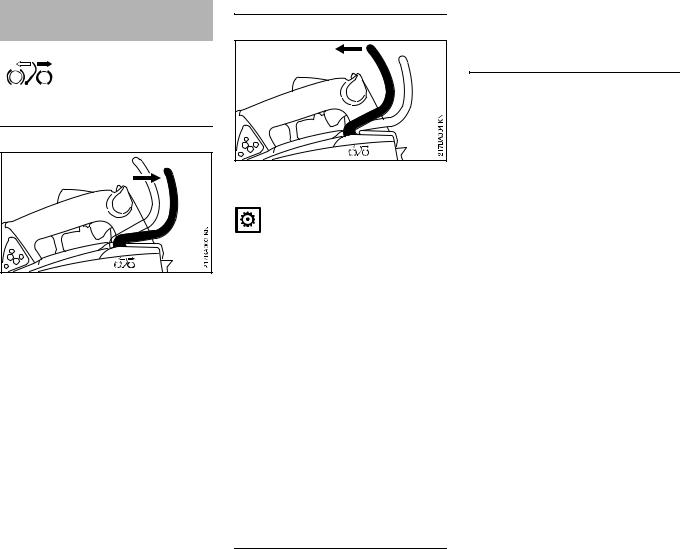

Chain Brake

Locking chain with chain brake

–in an emergency

–when starting

–at idling speed

The chain is stopped and locked when thehandguardispushedtowardthebar nose by the left hand – or when brake is activated by inertia in certain kickback situations.

26

Releasing the chain brake

NPullthehandguardbacktowardthe front handle.

Always disengage chain brake before accelerating engine and before starting cutting work. The only exception to this rule is when you check operation of the chain brake.

High revs with the chain brake engaged (chain locked) will quickly damage the powerhead and chain drive (clutch, chain brake).

The chain brake is designed to be activated also by the inertia of the front hand guard if the forces are sufficiently high. The hand guard is accelerated toward the bar nose - even if your left hand is not behind the hand guard, e.g. during a felling cut. The chain brake will operate only if it has been properly maintained and the hand guard has not been modified in any way.

Check operation of chain brake

Before starting work: Run engine at idle speed, engage the chain brake (push hand guard toward bar nose).

Accelerate up to full throttle for no more

than 3 seconds – the chain must not rotate. The hand guard must be free from dirt and move freely.

Chain brake maintenance

The chain brake is subject to normal wear. It is necessary to have it serviced and maintained regularly by trained personnel,suchasyourSTIHLservicing dealer, at the following intervals:

Full-time usage: |

every 3 |

|

months |

Part-time usage: |

every 6 |

|

months |

Occasional usage: |

every 12 |

|

months |

MS 192 T, MS 192 TC

English

Information Before You Start |

|

Starting / Stopping the |

|

|

Engine |

If the engine is cold

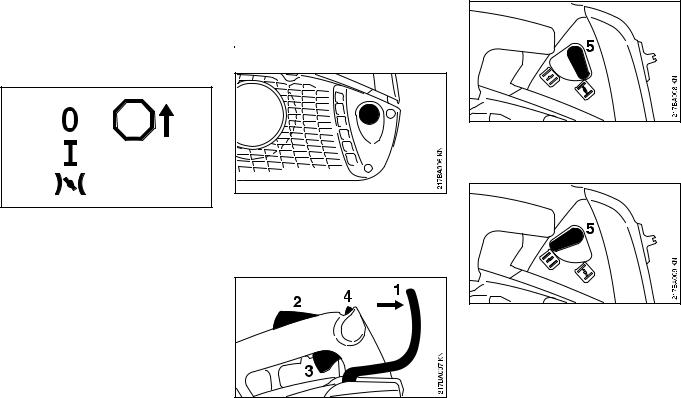

The three positions of the Master |

|

Starting the engine |

Control lever: |

|

|

151BA006 KN

Stop 0 – engine off – the ignition is switched off.

Normal run position F– engine runs or can fire.

Tomove theMaster ControlleverfromF to n, press down the throttle trigger lockout and squeeze the throttle trigger at the same time.

Starting throttle position n– this position is used to start a warm engine. The Master Control lever moves to the normal run position as soon as the throttle trigger is squeezed.

N Observe safety precautions.

NPress the fuel pump bulb at least five times – even if the bulb is already filled with fuel.

N Set the choke lever (5) to l.

If the engine is warm

NSet the choke lever (5) to j . Also use this position if the engine has been running but is still cold.

NPush the hand guard (1) forward – the chain is locked.

NPress down the throttle trigger lockout (2) and squeeze the throttle trigger (3) at the same time – hold both levers in that position.

NMovetheMasterControllever (4)to nand hold it there.

NNow release the throttle trigger, MasterControlandtriggerlockoutin that order. This is the starting throttle position.

MS 192 T, MS 192 TC |

27 |

English

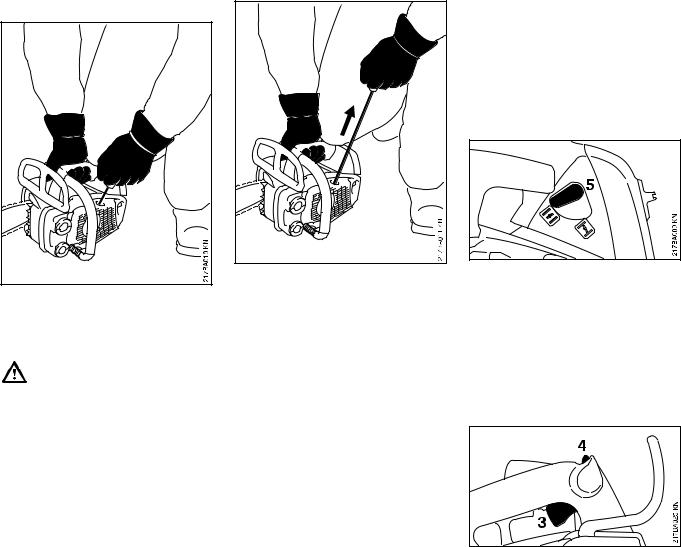

Starting

NPlace your saw on the ground. Make sure you have a firm footing – check that the chain is not touching any object or the ground.

Bystanders must be well clear of the general work area of the saw.

NHold the saw firmly on the ground with your right hand on the control handle and your right knee resting on the carburetor box cover.

Models with stardard starter

NPull the starter grip slowly with your left hand until you feel it engage – and then give it a brisk strong pull and push down the front handle at the same time. Do not pull out the starter rope to full length – it might otherwise break.

NDonotletthestartergripsnapback. Guideitslowlybackintothehousing so that the starter rope can rewind properly.

Models with Easy2Start

The Easy2Start stores the energy requiredtostartthesaw.Forthisreason there may be a delay of a few seconds between cranking the engine and it actually starting.

NPull the starter grip slowly and steadilywithyourlefthandandpush down the front handle at the same

time. Do not pullout thestarter rope all the way – it might otherwise break.

NDonotletthestartergripsnapback. Guideitslowlybackintothehousing so that the starter rope can rewind properly.

When the engine begins to fire.

If the engine is cold:

NSet the choke lever (5) to jand continue cranking until the engine runs.

If the engine is warm

NContinue cranking until the engine runs.

As soon as the engine runs

NBlip the throttle trigger (3), the Master Control lever (4) moves to the run position Fand the engine settles down to idling speed.

28 |

MS 192 T, MS 192 TC |

Loading...

Loading...