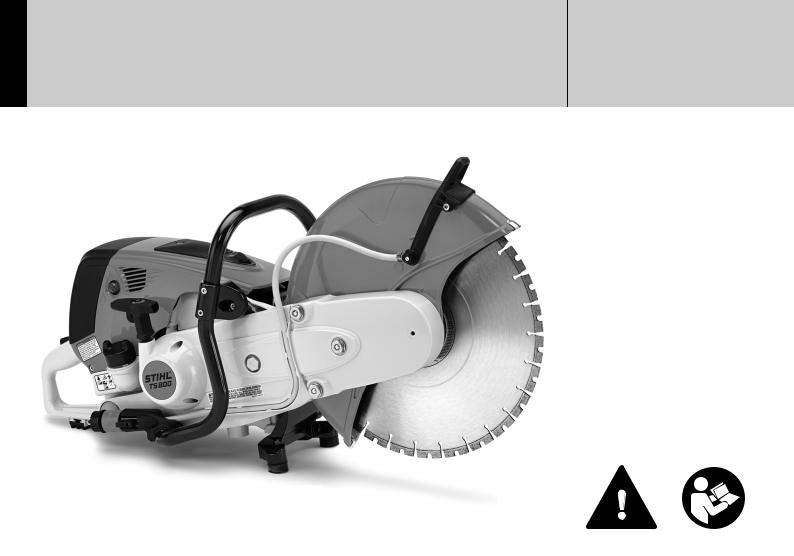

STIHL TS 700, TS 800 Instruction Manual

{

STIHL TS 700, 800

Instruction Manual

Manual de instrucciones

WARNING

WARNING

Read Instruction Manual thoroughly before use and follow all safety precautions – improper use can cause serious or fatal injury.

ADVERTENCIA

ADVERTENCIA

Antes de usar la máquina lea y siga todas las precauciones de seguridad dadas en el manual de instrucciones – el uso incorrecto puede causar lesiones graves o mortales.

Instruction Manual 1 - 52

Manual de instrucciones 53 - 108

English

Contents

Printing inks contain vegetable oils, paper can be recycled.

Printed on chlorine-free paper Original Instruction Manual

© ANDREAS STIHL AG & Co. KG, 2014 0458-572-8621-D. VA3.L14. 0000006706_002_GB

Guide to Using this Manual |

2 |

Safety Precautions and Working |

|

Techniques |

3 |

Sample applications |

16 |

Cutting wheels |

20 |

Composite resin cutting wheels |

20 |

Diamond cutting wheels |

21 |

Assembling the bearing and guard |

24 |

Tensioning the ribbed V-belt |

30 |

Fitting / replacing an abrasive |

|

wheel |

31 |

Fuel |

32 |

Fueling |

33 |

Starting / Stopping the Engine |

34 |

Air Filter System |

36 |

Engine Management |

37 |

Adjusting the Carburetor |

37 |

Spark Arresting Screen in Muffler |

38 |

Spark Plug |

39 |

Rewind Starter |

40 |

Replacing the V-belt |

41 |

Cut-off machine cart |

41 |

Storing the Machine |

42 |

Maintenance and Care |

43 |

Main Parts |

45 |

Specifications |

48 |

Maintenance and Repairs |

49 |

Disposal |

49 |

STIHL Incorporated Federal |

|

Emission Control Warranty |

|

Statement |

50 |

Trademarks |

52 |

Allowonlypersonswhofullyunderstand this manual to operate your cut-off machine.

To receive maximum performance and satisfaction from your STIHL Cutquik cut-off machine, it is important that you read, understand and follow the safety precautions and the operating and maintenance instructions in the chapter "Safety Precautions and Working Techniques" before using your cut-off machine.Forfurtherinformationyoucan go to www.stihlusa.com

Contactyour STIHLdealer or theSTIHL distributor for your area if you do not understandanyoftheinstructionsinthis manual.

WARNING

WARNING

Because a cut-off machine is a highspeed cutting tool, some special safety precautionsmustbeobservedtoreduce the risk of personal injury. Careless or improperusemaycauseseriousoreven fatal injury.

{This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process with electronic systems.

TS 700, TS 800 |

1 |

English

Guide to Using this Manual

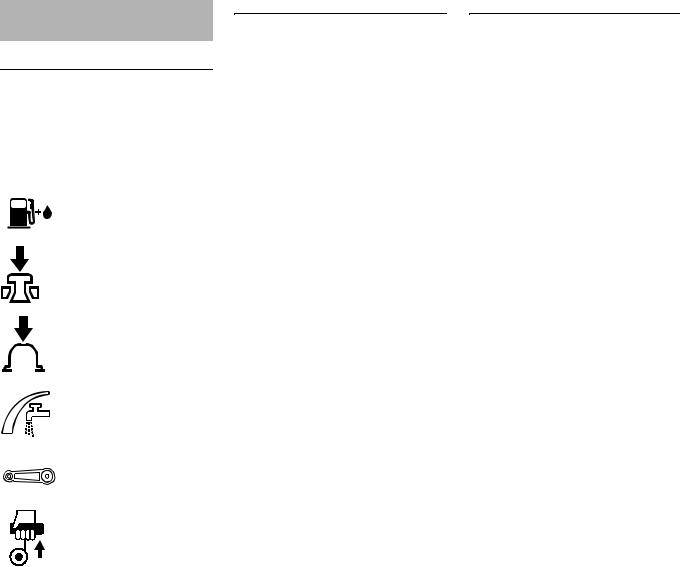

Pictograms

The meanings of the pictograms attached to or embossed on the machine are explained in this manual.

Dependingonthemodelconcerned,the following pictograms may be on your machine.

Fuel tank for gasoline and engine oil mixture

Press to operate decom- pression valve

Press to operate manual fuel pump

Water attachment, flow control

Tensioning nut for engag- ing drive belt

Pull starter grip

Symbols in Text

Many operating and safety instructions are supported by illustrations.

The individual steps or procedures describedin themanualmaybemarked in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that refers directly to an illustration may contain item numbers that appear in the illustration. Example:

N Loosen the screw (1). N Lever (2) ...

In addition to the operating instructions, this manual may contain paragraphs that require your special attention. Such paragraphs are marked with the symbols and signal words described below:

DANGER

DANGER

Indicates an imminent risk of severe or fatal injury.

WARNING

WARNING

Indicates a hazardous situation which, if not avoided, could result in severe or fatal injury.

NOTICE

Indicates a risk of property damage, including damage to the machine or its individual components.

Engineering Improvements

STIHL’s philosophy is to continually improve all of its products. As a result, engineeringchangesandimprovements are made from time to time. Therefore, some changes, modifications and improvements may not be covered in this manual. If the operating characteristics or the appearance of your machine differs from those describedinthismanual,pleasecontact your STIHL dealer or the STIHL distributor for your area for assistance.

2 |

TS 700, TS 800 |

Safety Precautions and

Working Techniques

The use of any cut-off machine may be hazard- ous. Because a cut-off

machine is a high-speed, fast-cutting power tool, special safety precau- tions must be observed to reduce the risk of per- sonal injury and fire.

It is important that you read, fully understand and observe the following safety precautions and warnings. Read the instruction manual and the safety precautions periodically.

WARNING

WARNING

Careless or improper use of any cut-off machine may cause serious or fatal injury.

Have your STIHL dealer show you how to operate your cut-off machine. Observe all applicable national, state and local safety regulations, standards and ordinances.

WARNING

WARNING

Your cut-off machine is for professional use only. Do not lend or rent your cut-off machine without the instruction manual. Be sure that anyone using it understands the information contained in this manual.

A first-time operator should obtain practical instruction before using the machine. Employers should establish a training program for operators of gasoline-powered, hand-held portable cut-off machines to assure safe operation of these machines and proper choice of cutting attachments. These safety precautions and warnings apply to the use of all current STIHL Cutquiks.

WARNING

WARNING

Use your cut-off machine only for authorized uses. For instance, it is not suitable for cutting wood or wooden objects. Misuse may result in personal injury or property damage, including damage to the machine.

WARNING

WARNING

Minorsshouldneverbeallowedtousea cut-off machine. Bystanders, especially children, and animals should not be allowed in the area where a cut-off machine is in use. Never let the cut-off machine run unattended.

Different models may have different parts and controls. See the appropriate section of your instruction manual for a description of the controls and function of the parts of your model cut-off machine.

Safe use of a cut-off machine involves

1.the operator

2.the power tool

3.the use of the power tool.

English

THE OPERATOR

Physical Condition

You must be in good physical condition and mental health and not under the influence of any substance (drugs, alcohol, etc.) which might impair vision, dexterity or judgment. Do not operate a cut-off machine when you are fatigued. Be alert – if you get tired while operating your cut-off machine, take a break; tiredness may result in loss of control. Workingwithanycut-offmachinecanbe strenuous.Ifyouhaveanyconditionthat mightbeaggravatedbystrenuouswork, check with your doctor before operating a cut-off machine.

WARNING

WARNING

Prolonged use of cut-off machines (or other machines) exposing the operator to vibrations may produce whitefinger disease (Raynaud's phenomenon) or carpal tunnel syndrome. These conditions reduce the hand's ability to feel and regulate temperature, produce numbness and burning sensations and causenerveandcirculationdamageand tissue necrosis. All factors which contribute to whitefingerdiseaseare not known, but cold weather, smoking and diseases or physical conditions that affectbloodvesselsandbloodtransport, as well as high vibration levels and long periods of exposure to vibration are mentionedasfactorsinthedevelopment of whitefinger disease. In order to reduce the risk of whitefinger disease and carpal tunnel syndrome, please note the following:

TS 700, TS 800 |

3 |

English

–STIHL cut-off machines are equipped with an anti-vibration ("AV") system designed to reduce the transmission of vibrations created by the machine to the operator's hands. An AV system is recommended for those persons using cut-off machines on a regular or sustained basis.

–Wear gloves and keep your hands warm.

–Keep the AV system well maintained. A cut-off machine with loosecomponentsorwithdamaged or worn AV elements will tend to have higher vibration levels.

–Maintain a firm grip at all times, but do not squeeze the handles with constant, excessive pressure. Take frequent breaks.

All the above-mentioned precautions do not guarantee that you will not sustain whitefinger disease or carpal tunnel syndrome. Therefore, continual and regular users should monitor closely the condition of their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

WARNING

WARNING

The ignition system of your unit produces an electromagnetic field of a very low intensity. This field may interfere with some pacemakers. To reduce the risk of serious or fatal injury, persons with a pacemaker should consult their physician and the pacemaker manufacturer before operating this tool.

Proper Clothing

WARNING

WARNING

To reduce the risk of injury, the operator should wear proper protective apparel.

Clothing must be sturdy and snug-fitting, but allow complete freedom of movement. Avoid loosefitting jackets, scarfs, neckties, jewelry, flared or cuffed pants, uncon- fined long hair or anything that could become caught on any obstacles or moving parts of the unit. Wear overalls or long pants to protect your legs. Do not wear shorts.

WARNING

WARNING

When cutting metal, a cut-off machine generates sparks that can ignite clothing. Most fabrics used in clothing are flammable – even flame-retardant fabricswilligniteathighertemperatures. To reduce the risk of burn injury STIHL recommends wearing clothing made of leather, wool, flame-retardant-treated cotton or a tightly woven, heavier cotton such as denim. Some flame-retardant synthetic fabrics are also suitable, but others such as polyester, nylon, rayon and acetate can melt during a fire into a tar-like matter that burns into the skin. Check the clothing manufacturer's instructions. Keep clothing free of oil, fuel, grease and other flammable substances.

Always wear heavy duty work gloves (e.g. made of leather or other wear resistant material) when handling the cutt-off machine. Heavy-duty, nonslip gloves improve your grip and help to pro- tect your hands.

Good footing is important in cut-off machine work. Wear sturdy boots with nonslip soles. Steel-toed safety boots are recommended.

WARNING

WARNING

Looseobjectsmaybethrowntowardthe operator by the cutting tool.

To reduce the risk of injury to your eyes never operate a cut-off machine

unless wearing goggles

or properly fitted safety glasses with adequate top and side protection complying with

ANSI Z87 "+". Proper eye protection is a must.

Wear an approved safety hard hat to protect your head. Cut-off machine noisemaydamageyourhearing.Always wear sound barriers (ear plugs or ear mufflers) to help protect your hearing. Regularusersshouldhave theirhearing checked regularly.

4 |

TS 700, TS 800 |

WARNING

WARNING

When wet cutting at the recommended flow rate is not utilized, the opera-

tor should always wear a

respirator approved by NIOSH/MSHA for the material being cut to reduce the risk of serious or fatal respiratory illness. For additional details and warnings on this subject, see information under "Working Conditions" in this instruction manual.

THE POWER TOOL

For illustrations and definitions of the parts of the cut-off machine, see the chapter "Main Parts."

WARNING

WARNING

Never modify a cut-off machine in any way. Only STIHL branded parts and cutting attachmentsexpresslyapproved bySTIHLforusewiththespecificSTIHL cut-off machine models are recommended. Although certain other parts or attachments may be useable with the STIHL powerhead, their use may, in fact, be extremely dangerous.

Abrasive Wheels

WARNING

WARNING

Before mounting the cutting wheel, make sure that the maximum operating wheel speed is above or equal to the spindlespeedofyourcut-offmachineas

TS 700, TS 800

provided in the specifications of this manual.Awheelthatisnotsoratedmay shatter or break and poses a threat of seriousorfatalinjurytotheoperatorand other nearby persons.

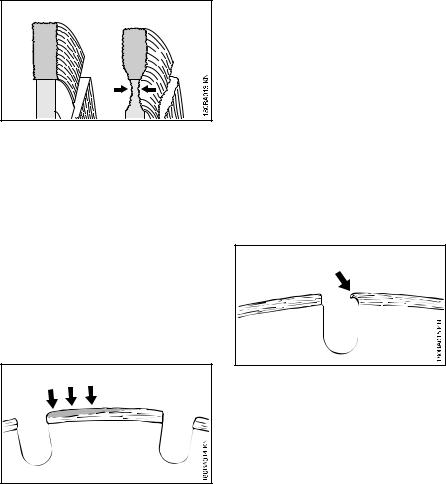

Abrasive wheels for free-hand cutting are subjected to particularly high bending and compression stresses.

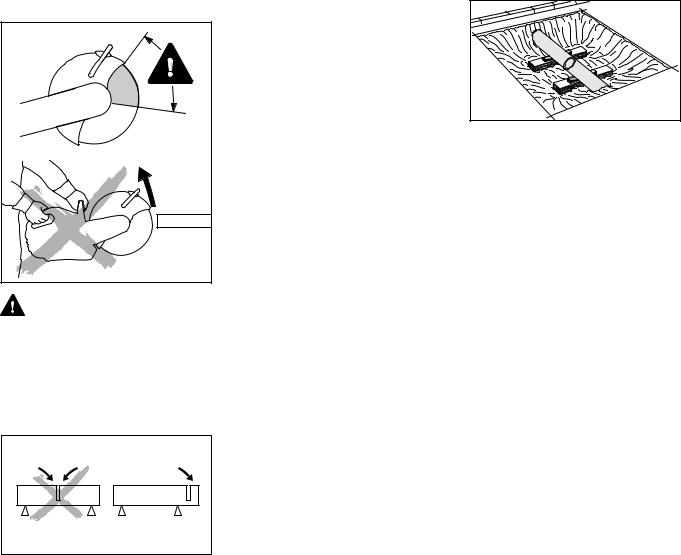

WARNING

WARNING

Never use a reducer bushing inserted into the wheel to reduce the diameter of the arbor hole. It may slip out of place, causing out-of-roundness, vibration and wheel breakage.

WARNING

WARNING

WheelsthatarenotSTIHLbrandedmay be more likely to shatter or break or createotherhazards,suchasincreased reactive forces. Use only wheels with approved RPM ratings. Read and follow any addional safety precautions that accompany the wheel.

WARNING

WARNING

Inspect the abrasive wheel frequently and

replace immediately if the

abrasive wheel is cracked or warped. Cracked or warped wheels may shatter or break and cause serious or fatal personal injury. Out-of-round or unbal- anced abrasive wheels increase vibration and reduce the service life of the cut-off machine.

English

Somediamondabrasivewheelsthatare not STIHL branded utilize poor quality steel cores, are not properly tensioned, or have other design or manufacturing defects. As a result, they may begin to wobble during use, which can cause wheel breakage. Such wobbling can also lead to a severe binding of the wheel in the kerf, that, under certain circumstances, can then result in serious or fatal injury from reactive forces. See the section entitled "Reactive Forces including Kickback." Never use a wheel that wobbles or that has ever wobbled. Even though such a wheelmaytemporarilyceasetowobble, e.g., if run without load, it will always be prone to wobble again under certain conditions. Replace it immediately before further use.

Composite abrasive wheels are heat sensitive. Always store your cut-off machine in a place where a composite wheelisnotexposedtodirectsunlightor other sources of heat. Store spare composite wheels flat on a level surface in a dry place where there is no risk of frost damage. Failure to follow these directions may cause the wheel to shatter or crack in use causing serious or fatal injury.

5

English

WARNING

WARNING

Never use circular saw blades, carbide tipped blades, rescue blades, wood-cutting blades or toothed blades of any nature. They can cause severe personal injury

from blade contact, thrown objects and/or reactive forces, including kickback. See section on "Reactive Forces." Your STIHL dealer stocks a range of special abrasive wheels for the many applications of the cut-off machine.

WARNING

WARNING

Use of the wrong abrasive wheel or the cutting of material for which the wheel was not designed may cause the wheel to wobble, shatter or increase reactive forces, causing serious or fatal injury. See below and section "Reactive Forces."

Only use the abrasive wheel approved for the type of material to be cut. There are different types of abrasive wheels, each specially marked. With respect to STIHL composite wheels, for example:

1.Stone

Also can be used for concrete, masonry, reinforced concrete and brick cutting.

2.Steel

Can be used for all ferrous metal cutting.

6

3.Asphalt

Also can be used for aggregate concrete cutting.

4.Ductile iron

Also can be used for certain grades of cast iron (SG 17-24), bronze and copper cutting.

For cutting composite materials please ask your STIHL dealer.

Diamond Abrasive Wheels

Diamond abrasive wheels have a much better cutting performance than composite abrasive wheels. The diamondwheelsare steelcentered,and diamond particles are imbedded in their cutting edges.

They can be used for concrete, asphalt, natural stone, clay pipe, brick and the like. STIHL also offers diamond wheels for cutting ductile iron and some structural steel.

They are not, however, suitable for cutting all metals and other materials.

Wet or dry cutting is possible. Water attachments are included with your STIHL cut-off machine. See the appropriate section of your instruction manual.

WARNING

WARNING

Do not remount a used diamond abrasive wheel without first inspecting for under-cutting, flatness, core fatigue, segment damage or loss, signs of overheating(discoloration)andpossible arbor hole damage. See the chapter "Diamond Cutting Wheels." Check the wheel for cracks and make sure that no pieces have broken off the wheel before use.

Alwaysfitthewheel sothatthearrowon the wheel points in the direction of the rotation of the spindle.

THE USE OF THE POWER TOOL

Transporting the STIHL Cutquik

WARNING

WARNING

To reduce the risk of injury from unintended activation and/or contact with a moving wheel, always stop the engine before putting a cut-off machine down or carrying it. The abrasive wheel continues to rotate (coast down) for a short while after the throttle trigger is released (flywheel effect). Bring the wheel to a stop by lightly contacting the bottom of the wheel with a hard surface or wait until the wheel comes to a completestoponitsown.Carryingacutoff machine with the engine running is extremely dangerous. Accidental accelerationoftheenginecancausethe wheel to rotate. Avoid touching the hot muffler.

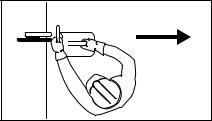

By hand: When carrying your cut-off machine by hand, the engine must be stopped and the cut-off machine must be in the proper position. Grip the front handle and place the muffler at the side away from the body with the cutting attachment to the rear.

WARNING

WARNING

Always protect the cutting wheel from hitting the ground or any other objects. Damaged wheels may shatter and cause serious or fatal injury.

TS 700, TS 800

By vehicle: Properly secure your cut-off machine to prevent turnover, fuel spillage and damage to the cut-off machine. Never transport with cutting wheel mounted. A wheel damaged duringtransportationmayshatterduring operation and cause serious personal injury.

Fuel

Your STIHL power tool uses an oilgasoline mixture for fuel (see the chapter on "Fuel" of your instruction manual.)

WARNING

WARNING

Gasoline is an extremely flammable fuel. If spilled and ignited by a spark or other ignition source, it can cause fire and seri-

ous burn injury or property damage. Use extreme caution when handling gasoline or fuel mix. Do not smoke or bring any fire or flame near the fuel or the power tool. Note that combusti- ble fuel vapor may escape from the fuel system.

WARNING

WARNING

Dust may collect on the powerhead, especially around the carburetor, and mayabsorbgasolineresultinginariskof fire. Clean dust from the powerhead regularly.

Fueling Instructions

WARNING

WARNING

Fuel your power tool in well-ventilated areas, outdoors. Always shut off the engine and allow it to cool before refueling. Gasoline vapor pressure may build up inside the fuel tank depending on the fuel used, the weather conditions and the tank venting system.

In order to reduce the risk of burns and other personal injury from escaping gas vapor and fumes, remove the fuel filler caponyourpowertoolcarefullysoasto allow any pressure build-up in the tank to releaseslowly.Neverremove thefuel filler cap while the engine is running.

Selectbare groundforfuelingandmove at least 10 feet (3 m) from the fueling spot before starting the engine. Wipe off any spilled fuel before starting your machine.

WARNING

WARNING

Check for fuel leakage while refueling and during operation. If fuel leakage is found, do not start or run the engine until the leak is fixed and any spilled fuel has been wiped away. Take care not to get fuel on your clothing. If this happens, change your clothing immediately.

English

WARNING

WARNING

If fuel gets spilled on clothes, especially trousers, it is very important to change clothes immediately. Do not rely upon evaporation. Flammable quantities of fuel may remain on clothes after a spill for longer than expected. Cutting metal with a cut-off machine when clothes are wet or damp from gasoline is extremely dangerous, as the operator's clothes might catch fire and cause serious or fatal injury.

WARNING

WARNING

An improperly tightened fuel cap can loosenor comeoff andspill quantities of fuel.

Different cut-off machines may be equipped with different fuel filler caps:

Bayonet Fuel Filler Cap

Never use a tool to open or close the bayonet fuel filler cap, as this could damage the cap and cause fuel to leak out.

The bayonet fuel filler cap must be securely closed after refuelling.

TS 700, TS 800 |

7 |

English

Fuel Filler Cap with Screw Thread

Tighten the fuel filler cap as securely as possible

after refuelling.

after refuelling.

This reduces the risk of the cap working loose due to engine vibrations and fuel leaking out.

WARNING

WARNING

Never attempt to force the cap open by using a tool. It may damage the cap and allow fuel to leak.

WARNING

WARNING

Before use, make sure that the fuel cap has been completely and properly tightened and any spilled fuel wiped away. Check for fuel leakage while refueling and during operation. If a fuel leak is suspected, do not start or run the engine until the leak is fixed and spilled fuel has been wiped away.

Before Starting

For wheel installation, follow the procedure described in the appropriate sections of your instruction manual.

WARNING

WARNING

Check fuel system for leaks, especially the visible parts, e.g., filler cap, hose connections,manual fuelpump (onlyfor powertoolsequippedwithamanualfuel pump). Do not start the engine if there are leaks or damage – risk of fire! Have the machine repaired by a servicing dealer before using it.

8

WARNING

WARNING

Never operate a cut-off machine if it is damaged, improperly adjusted or maintained, or not completely or securely assembled. Check machine that it is ready for proper operation.

Keep the handles dry, clean and free of oil and fuel.

WARNING

WARNING

Before operation of your cut-off machine, be sure the controls (e.g. throttle trigger, throttle trigger lockout, stop switch) and the safety devices are workingproperly,thecarburetoridleand maximum speed are correctly adjusted, the wheel is properly mounted, and the wheel guard is in place and securely fastened to your unit. All wheels should becarefullyinspectedforgoodcondition before mounting.

Adjust the wheel guard so that sparks, dust and cut material are deflected

away from the operator, and cannot reach flam- mable surroundings. See section "Operating Instructions" of your instruction manual.

WARNING

WARNING

Check that the spark plug boot is securely mounted on the spark plug – a loose boot may cause arcing that could ignite combustible fumes and cause a fire.

Proper tensioning of the ribbed V-belt is important. In order to avoid an incorrect setting, the tensioning procedure must

be followed as described in your manual. Always make sure the hexagonal collar nuts for the cast arm are tightened securely.

Checkribbed belttensionafteronehour of operation and correct if necessary.

Starting

002BA058 KN

WARNING

WARNING

Your cut-off machine is a one-person tool. Do not allow other persons to be near a running cut-off machine. Start and operate your cut-off machine without assistance. For specific starting instructions,seethe appropriate section of your instruction manual.

Do not drop start. This method is very dangerous because you may lose control of the cut-off machine. Place the cut-off machine on firm ground or other solid surface in an open area. Maintain good balance and secure footing. Be

TS 700, TS 800

absolutely sure that the cutting wheel is clear of you and all other obstructions andobjects,includingtheground.When the engine starts at starting-throttle, engine speed will be fast enough for the clutch to engage the belt pulley and turn the wheel.Neverattemptto startthe cutoff machine when the abrasive wheel is in a cut.

Once the engine has started, immediately blip the throttle trigger, whichshouldreleasethestartingthrottle lock and allow the engine to slow down to idle.

WARNING

WARNING

When you pull the starter grip, do not wrap the starter rope around your hand. Do not allow the grip to snap back, but guide the starter rope slowly back to permit the rope to rewind properly. Failure to follow this procedure may result in injuries to hand or fingers and may damage the starter mechanism.

Important Adjustments

At correct idle speed, the wheel should not turn. For directions to adjust idle speed, see the appropriate section of your instruction manual.

WARNING

WARNING

Do not use a cut-off machine with incorrect idle speed adjustment. The rotating wheel may cause injury. If you cannot obtain the correct setting, have your STIHL dealer check your cut-off machine and make proper adjustments or repairs.

Working Conditions

Operatethecut-offmachineundergood visibility and daylight conditions only.

Wearing of hearing protection reduces sound perception. Be alert not to miss voice signals from co-workers. Keep within calling distance to other persons who may assist in case of emergency.

WARNING

WARNING

As soon as the engine is running, this product gen- erates toxic exhaust

fumes containing chemi- cals, such as unburned hydrocarbons (including benzene) and carbon monoxide, that are known to cause respira- tory problems, cancer, birth defects, or other reproductive harm. Some of the gases (e.g. carbon monoxide) may be color- less and odorless. To reduce the risk of serious or fatal injury/illness from inhaling toxic fumes, never run the machine indoors or in poorly venti- lated locations. Ensure proper ventilation when working in trenches or other confined areas.

WARNING

WARNING

Use of this product to cut masonry, concrete, metal and other materials can generate dust and fumes containing chemicals known to cause serious or fatalinjuryorillness,such asrespiratory

English

disease, cancer, birth defects or other reproductive harm. If you are unfamiliar with the risks associated with the particular material being cut, review the materialsafetydatasheetand/orconsult your employer, the material manufacturer/supplier, governmental agencies such as OSHA and NIOSH and other sources on hazardous materials. California and some other authorities, for instance, have published lists of substances known to cause cancer, reproductive toxicity, etc. Control dust and fumes at the source where possible.

In this regard use good work practices and follow the recommendations of the manufacturer/supplier, OSHA/NIOSH, and occupational and trade associations. A water attachment kit is provided with your cut-off machine and shouldbeusedtoreducedustwhenever wet cutting is feasible. For dust suppression purposes, the flow rate should be at least 0.6 liters (20 fl.oz) of water per minute. If wet cutting at the recommended flow rate is not utilized, the operator and any bystanders should always wear a respirator approved by NIOSH/MSHAforthematerialbeingcut. See the section on "Respiratory Protection" in the chapter "Sample Applications" in the instruction manual. Even if wet cutting at the recommended flow rate, an operator who is actively cutting for more than two hours in one day should wear at least a NIOSHapproveddisposablerespirator.Consult and follow any federal, state or local laws or regulations with respect to dry and wet cutting.

TS 700, TS 800 |

9 |

English

WARNING

WARNING

Cutting masonry, concrete and other materials with silica in their composition may give off dust containing crystalline silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable crystalline silica as a substance known to cause cancer. When cutting such materials, always follow the respiratory precautions mentioned above.

WARNING

WARNING

Breathing asbestos dust is dangerous and can cause severe or fatal injury, respiratory illness or cancer. The use and disposal of asbestos-containing products have been strictly regulated by OSHAandtheEnvironmentalProtection Agency.Donotuseyourcut-offmachine to cut or disturb asbestos, asbestoscontainingproducts,orproductssuchas pipes which are wrapped or covered withasbestosinsulation.Ifyouhaveany reason to believe that you might be cutting asbestos, immediately contact your employer or a local OSHA representative.

002BA549 AM

WARNING

WARNING

Your STIHL cut-off machine is designed for hand-held use or operation on a cutoff machine cart. Cutting with your cutoff machine resting on the ground or othersurfacecancauseexcessivewear to the bracket designed to protect the bottom of the tank housing. Loss of fuel and personal injury from fire may result. Replace damaged or badly worn brackets immediately.

Grip:Neverusethecut-offmachinewith one hand. Always hold the cut-off machinefirmlywithbothhandswhenthe engine is running. Place your left hand on front handle bar and your right hand on rear handle and throttle trigger. Lefthanded users should follow this instruction too.

Wrap your fingers tightly around the handles, keeping the handles cradled between your thumbs and forefingers. Makesureyourcut-offmachinehandles and grip are in good condition and free of moisture, pitch, oil, fuel mix or grease.

Never touch a rotating wheel with your hand or any part of your body.

WARNING

WARNING

Clear the area where you are working. Avoidstumblingonobstaclesandwatch out for holes or ditches. Be extremely cautious when working on slopes or uneven ground. Take extreme care in wet and freezing weather (rain, snow, ice.)

WARNING

WARNING

Never operate the cut-off machine with thestarting-throttlelockengagedas this does not permit proper control of the speed of the unit and may lead to serious injury.

WARNING

WARNING

Sparks from cutting metal can burn or cause cloth- ing to catch fire. Always

direct sparks away from the operator or any flam- mable surroundings.

Never cut metal while standing on a flammable surface, such as wood or tar paper. Where there is a risk of fire, have appro- priate fire extinguishing equipment readily available.

WARNING

WARNING

To reduce the risk of injury from fire, do not cut into any pipe, drum or other container without first ensuring that it does not contain a volatile or flammable substance.

10 |

TS 700, TS 800 |

WARNING

WARNING

Whencuttingintoexistingwalls,floorsor similar structures, be alert for hidden hazards such as electrical cables, water and gas pipes and flammable substances. Make sure that power, water and gas have been shut off and pipes drained before starting to cut.

Operating Instructions

002BA550 AM

002BA550 AM

WARNING

WARNING

The wheel guard is adjustable. It is extremely important that the wheel guard is in place and set to suit the type of work and your stance. The guard should always be adjusted so that the user is not endangered by particles of the material being cut, sparks or pieces of damaged wheels either directly or by ricochet.Failuretofollowthis instruction could result in serious or fatal injury.

WARNING

WARNING

Your cut-off machine is equipped with a wheel guard limit stop that restricts the positioning of the wheel guard. To reduce the risk of injury from wheel contact and/or reactive forces and to avoid damaging the guarding system, never attempt to pull the adjusting lever past the limit stop.

TS 700, TS 800

WARNING

WARNING

Always check the wheel before use and after unintentionally striking any object; frequently check it during use when it is stopped.Lookforcracksand makesure that it is undamaged and in good condition and that no pieces have broken off. See sections on "Abrasive Wheels" and "Reactive Forces" in this manual. Check the wheel guard for cracks. If you discover any breaks or cracks, fit a new guard before further use.

WARNING

WARNING

It is essential to determine the exact direction of the cut before applying the abrasive wheel to the work. Wheels are constructed for radial pressure only. Lateral pressure must be avoided. Hold the cut-off machine steady. To reduce the risk of serious or fatal injury, do not changethedirectionofthecutduringthe cut as this may produce a high torsional load on the abrasive wheel and may cause it to bind, break or shatter. A binding of the wheel can also result in reactive forces. See section on "Reactive Forces."

WARNING

WARNING

Do not use abrasive wheels for rough grinding. Large bending stresses occur during such work, which may cause abrasive wheels to shatter or break and result in serious or fatal injury.

WARNING

WARNING

To reduce the risk of injury from shattered abrasive wheels:

English

1.Do not exceed the maximum operating speed marked on the wheel.

2.Do not use a wheel that has been dropped.

3.Test each new wheel immediately after installation for approximately one minute at maximum speed withoutcutting,makingsuretokeep bystanders away.

4.Donotcutanymaterialforwhichthe abrasive wheel is not authorized.

5.Do not grind on the side of the abrasive wheel.

6.Do not twist, thrust, knock or drop the machine. This can cause damage to the wheel.

To achieve a clean and efficient cut, pull the abrasive wheel across the work or move it "to and fro" in the cutting direction. Do not use force to push the abrasive wheel into the work.

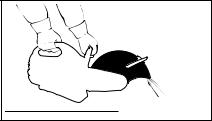

Insertthewheelintothematerialonlyas deep as necessary to make the cut. To reduce the amount of dust created, do not cut all the way through stone and concrete materials – leave a thin piece uncut. For most such materials, this piece can be easily broken afterwards. Do not cock, jam or wedge the wheel in the cut.

Always stop the engine and be sure the wheel has stopped rotating before setting down the cut-off machine.

If a cut-off machine cart is used, sweep debris from the path of the wheels, as debris under one of the cart’s wheels maycauseflexingoftheabrasivewheel. This could result in high frictional forces and thus greatly reduce the engine

11

English

power available for the actual cutting work. It could also damage the abrasive wheel.

STIHL recommends the use of the cart for longer cuts in a straight line.

Wet Cutting with Abrasive Wheels

Before wet cutting, make sure water will not damage the floor or building.

WARNING

WARNING

Toreducetheriskofelectrocutiontoyou or bystanders, do not allow water or sludge to contact live electric wires.

WARNING

WARNING

To reduce the risk of injury from wheel breakage when wet cutting with any composite wheel:

1.Makecertainwaterdoesnotflowon awheelthatisnotrunning,sincethe wheel will absorb water, which will affect wheel balance.

2.Be certain water is applied to both sides of wheel, since uneven distribution can cause "one sided" wear.

3.After finishing work, run the cutting wheelatnormaloperatingspeedfor about 3 to 6 seconds without water so that the remaining water is flung off.

WARNING

WARNING

To reduce the risk of injury from wheel breakage when wet cutting with a composite wheel that is not specifically designedforwetcutting,neverstoreand

reuse such a wheel that has been used with water. Use these wheels up the same day.

Reactive Forces including Kickback

WARNING

WARNING

Reactive forces may occur at any time the cut- ting wheel on a cut-off machine is rotating.

Thepowerfulforceusedtocutthrougha workpiece can be reversed and work against the operator. If the wheel is slowed or stopped by frictional contact with any solid object or by a pinch or binding, reactive forces can occur instantly and may result in the operator losing control of the cut-off machine, which, in turn, may result in serious or fatal injury.

Anunderstandingofthecausesofthese reactive forces may help you avoid loss ofcontrol.Reactiveforcesareexertedin a direction opposite to the direction in whichthewheelismovingatthepointof contact or of pinching/binding. If the wheel is slowed solely by frictional contact with a solid object, such as the workpiece, the resulting reactive forces are normally moderate and readily controllable by an operator who is holding the machine properly. If, however,thewheelisabruptlyslowedor stopped by a pinch or severe bind, the reactive forces may be substantially greater. The greater the force generated, the more difficult it will be for the operator to control the cut-off machine. Loss of control can result in severe personal injury or death.

Pull-away, Climbing, Pinching and

Rotational Kickback Forces

002BA553 AM |

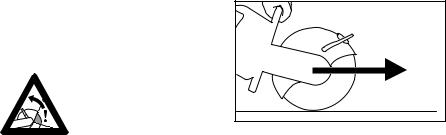

The most common reactive forces are pull-away and climbing. If the contact is at the bottom of the wheel, a cut-off machine will try to pull away from the operator (pull-away.) If the contact is at the front of the wheel, the wheel may attempt to climb the object being cut (climbing.)

Pinching occurs when the piece being cut closes on the wheel. A severe binding may also occur if the wheel is substantially sideloaded in the kerf or if animproperordamageddiamondwheel beginsorceasestowobblein thekerf.If the wheel is severely pinched or bound intheupperquadrant,thewheelmaybe instantly thrown up and back towards the operator with great force in a rotational kickback motion. Such kickback situations can and should always be avoided. Pinching of the wheel can be prevented by proper support of the workpiece. (See below.) Severe binding of the wheel can be prevented by proper cutting techniques, e.g., not sideloading the wheel, and by the use of properly designed, manufactured and maintained wheels.

12 |

TS 700, TS 800 |

Reducing the Risk of Kickback Injury

002BA582 ST |

WARNING |

To reduce the risk of kickback injury, avoid cutting with the upper quadrant of the wheel where possible. Be especially cautious for a pinching or binding of the wheel in this area, which can cause severe reactive forces in a rotational kickback motion.

002BA146 KN |

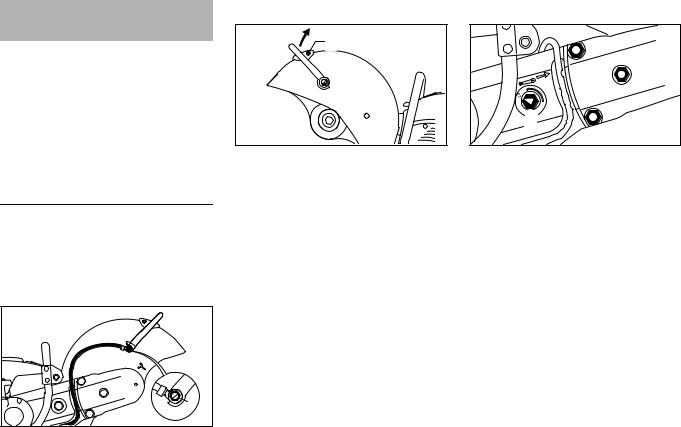

Avoid wedge action. The severed part must not bind the abrasive wheel.

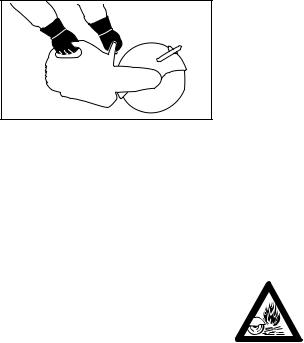

Be alert to potential movement of the workpiece or anything else that could cause the cut to close and pinch the wheel. In order to reduce the risk of pinching, support the workpiece in such a way that the cut remains open during the cutting process and when the cut is finished (see illustration). Never make a cut that results in a binding of the wheel. If you cannot properly support the workpiece, do not use a cutting-off machine to make the cut; select another tool or cutting technique that is not subject to kickback.

Where there is a possibility of a pinch, you can leave an uncut part that prevents the kerf from closing and pinching the wheel, which can later be broken manually. If you are making a complete cut, make sure that the final, separating cut is made at the top of the workpiece with the bottom of the wheel. In this way, if there is any residual pinching, it will be at the bottom of the wheel, where it may result in pull-away, but not in kickback. Be alert for pullaway.

Objects to be cut must therefore be properlysupportedandmustbesecured against rolling away, slipping or vibrations.

English |

002BA603 KN |

Support an exposed pipe in a trench so that it is stable and capable of bearing weight. If the ends of the pipe are firmly in the ground, the ground may act as a supportwherethepipeemergesintothe open. Additional support will be needed closer to the cut, however, to prevent sagging (see illustration). Be alert for pipe that is under stress that may cause it to shift when cut; pipe in the ground maybe understressbecauseofuneven surfaces.

Make sure any section of pipe to be removed is also properly supported and will not shift. After the first cut, you may need to move the supports or add additional support for the second cut so that both sides of that cut are fully supported, including the section to be removed. That section can also be supported by means of a strap from above,e.g.,suspendedfromabackhoe. It must be evenly supported and properlytensioned,however,sothatthe section remains in its position and does not tend to go up or down as a whole or on one side when separated.

Always pay attention in subgrade/subsurface work areas – supportingmaterialcan crumbleorslide away.

TS 700, TS 800 |

13 |

English

WARNING

WARNING

Be particularly alert when cutting a workpiece such as a pipe with a belled end or cutting out a section of pipe in a trench that, if not properly supported, can sag or drop upon completion of the cut, creating a pinch not where you are actuallycuttingbut,rather,atornearthe topoftheworkpiece.Ifthepinchisinthe upper quadrant of the abrasive wheel, kickback can result.

WARNING

WARNING

Use wet-cutting whenever feasible, since the water can act as a lubricant in a pinch situation and thus reduce the likelihood of reactive forces occurring and the energy of any such forces that do occur, making it easier to maintain control of the machine.

WARNING

WARNING

Only STIHL branded cutting attachments are recommended. Use of certain non-STIHL branded wheels may be extremely dangerous. Many substandard diamond wheels, for instance, are available in the market. If they are not manufactured with the proper quality steel in their core, if they are not properly tensioned, or if other design or manufacturing defects exist, they may, e.g., begin to wobble during use, lose segments or exhibit other operational problems that can substantially increase the risk of personal injury or death. If a diamond wheelbeginsorceasestowobblewithin the kerf, the change in the behavior of the wheel may cause a severe binding that can lead to loss of control and/or

14

kickback. If the wheel you are using begins to wobble or has ever wobbled, discard it immediately. Although such a wheelmaytemporarilyceasetowobble, e.g., if run without load, it will always be prone to wobble again under certain conditions.

WARNING

WARNING

Some other non-STIHL branded diamond wheels are manufactured with abrasive material on their sides. Do not use such wheels, since the abrasive material may lead to substantially increased reactive forces in a pinch or sideloading situation.

WARNING

WARNING

Never use chipped abrasive wheels or circular saw blades, carbide-tipped blades,rescuebladesorwood-cuttingor toothedbladesofanynatureonacut-off machine. The use of such wheels or blades will greatly increase the risk of loss of control and severe personal injury or death from reactive forces, sincethe chippedsection ofanabrasive wheel or the teeth of a saw blade may catch in the material being cut and generate substantially greater reactive forces, including rotational kickback.

Cut-off machines are designed for use with abrasive wheels in good condition only. Machines designed for use with wood-cutting or other toothed blades use different types of guarding systems thatprovidetheprotectionnecessaryfor those types of blades. Machines, such as a cut-off machine, that are designed for use with abrasive wheels require a different guarding system, which is not designed to provide protection against

all dangers presented by circular saw blades, carbide-tipped blades, rescue blades or wood-cutting or toothed blades of any nature.

WARNING

WARNING

To reduce the risk of injury from loss of control from reactive forces, including kickback:

1.Hold the cut-off machine firmly with both hands.

2.Maintain good balance and footing at all times. Never cut while standing on a ladder.

002BA554 AM

3.Position the cut-off machine in such a way that your body is clear of the cutting attachment. Avoid standing in direct line with the wheel (See illustration.) Never bend over the cuttingattachment,especiallywhen theguardispulledbacktowardsthe top and there is a risk of reactive forces. Ensure sufficient freedom of movement, especially in trenches. Make sure there is sufficient space for the user and the fall of the severed part.

4.Do not cut above shoulder height.

TS 700, TS 800

5.Only STIHL branded diamond and composite abrasive wheels are recommended. The use of nonSTIHL branded wheels can be extremely dangerous. Never work with a diamond wheel that wobbles or that has ever wobbled or that is manufactured with abrasive material on its sides.

6.Do not cut wood or any other material for which the abrasive wheel is not authorized.

7.Never use circular saw blades, carbide-tipped blades, rescue blades, wood-cutting blades or toothed blades of any nature. Their use increases the risk of injury from blade contact, thrown tips and reactive forces, including kickback.

8.Begin cutting and continue at full throttle.

9.Do not overreach.

10.Never sideload a wheel in the kerf.

11.Use your cut-off machine for cutting only. It is not designed for prying or shoveling away any objects.

12.Be especially alert for reactive forces, including kickback, when cutting with the front and upper quadrant of the wheel. Never pull the top of the wheel guard back beyond the limit stop.

13.Be alert to shifting of the workpiece or anything that could cause the cut to close and pinch the wheel, especially in the upper quadrant. Support the workpiece in such a way that the cut remains open. Never make a cut that results in a binding of the wheel.

TS 700, TS 800

14.Use wet-cutting whenever feasible. Inapinchsituationthewatercanact as a lubricant and reduce the energy of reactive forces.

15.Release the pressure on the cut-off machineasyoureachtheendofthe cut. Too much pressure may cause the operator to lose control of the cut-off machine when the abrasive wheel completes the cut. The abrasive wheel may contact the operator or strike some foreign object and shatter.

16.Use extreme caution when reentering a cut and do not turn the wheelatanangleorpushthewheel into the cut as this may result in a binding of the wheel.

Gyroscopic Forces

Be alert for gyroscopic forces that are caused by the rapid spinning of the cutoff wheel. These forces result in opposition to directional change, e.g., when the operator attempts to move the machine in a sideways direction.

Maintenance, Repair and Storing of the

Cut-Off Machine

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. However, if you make a warranty claimforacomponentthathas not been serviced or maintained properly or if nonapproved replacement parts were used, STIHL may deny warranty coverage.

English

Never operate a cut-off machine that is damaged, improperly adjusted or not completely or securely assembled.

Follow the maintenance and repair instructions in the appropriate sections of your instruction manual.

WARNING

WARNING

Use only STIHL replacement parts for maintenance and repair. Use of parts manufactured by others may cause serious or fatal injury.

WARNING

WARNING

Alwaysstopthemachineandmakesure that the wheel is stopped before doing any maintenance or repair work or cleaning the cut-off machine. Do not attempt any maintenance or repair work notdescribedinyourinstructionmanual. Have such work performed only at your STIHL servicing dealer.

Clean off grinding dust after finishing work. Tighten all nuts, bolts and screws except the carburetor adjustment screws after each use.

Do not clean your machine with a pressure washer. The solid jet of water may damage parts of the machine.

WARNING

WARNING

Nevertesttheignitionsystemwithspark plug boot removed from spark plug or with an unseated spark plug, since uncontained sparking may cause a fire.

WARNING

WARNING

Toreducetheriskoffireandburninjury, use only spark plugs authorized by STIHL. Always press spark plug boot

15

English

snugly onto spark plug terminal of the proper size. (Note: If terminal has a detachable SAE adapter nut, it must be attached.) A loose connection between spark plug terminal and ignition wire connector in the boot may create arcing that could ignite combustible fumes and causeafire.Keepsparkplug clean,and make sure ignition lead is in good condition.

WARNING

WARNING

Do not operate your cut-off machine if the muffler is damaged, missing or modified. An improperly maintained muffler will increase the risk of fire and hearing loss. Never touch a hot muffler or spill fuel or other flammable liquid over it. Burn injuries or fire will result. If your muffler was equipped with a sparkarrestingscreentoreducetheriskoffire (e. g. in the USA, Canada and Australia), never operate your cut-off machine if the screen is missing or damaged.

In California, it is a violation of § 4442 or § 4443 of the Public Resources Code to use or operate gasoline-powered tools on forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a complying spark arrester that is maintained in effective working order. The owner/operator of this product is responsible for properly maintaining the spark arrester. Other states or governmentalentities/agencies,suchas the U.S. Forest Service, may have similar requirements. Contact your local fire agency or forest service for the laws or regulations relating to fire protection requirements.

For any maintenance please refer to the maintenance chart and to the warranty statementneartheendoftheinstruction manual.

Store wheels on a flat surface in a dry place, preferably at a constant temperature, where there is not a risk of frost.Donotstoreacut-offmachinewith a wheel mounted on the machine. Store cut-off machine in a high or locked place, away from children.

Empty the fuel tank before storing for longerthanafewdays.Storefuelonlyin correctly labeled and approved containers.Avoiddirectskincontactand do not inhale the gas vapors.

Sample applications

Water connection

–A water attachment kit is mounted onthemachineforusewithalltypes of water supply.

–A pressurized 2.6 gallons (10 liter) water tank is available from STIHL for wet cutting.

–A water tank for mounting on the Cutquikcartisalsoavailableforwet cutting.

Most diamond cutting wheels are suitable for wet cutting

Wet cut whenever feasible. It increases the service life and cutting speed of diamond cutting wheels.

Ensure that the cutting wheel is generously supplied with water.

Wet cutting helps to suppress dust. The water binds the dust.

The cutting wheel must be supplied with at least 20 fl. oz (0.6 liters) water per minute.

Wet cutting can reduce the energy of reactive forces. In a pinch situation, the water can act as a lubricant.

16 |

TS 700, TS 800 |

Compositeresinwheelscanbeusedfor dry cutting of metals or for wet or dry cutting of concrete, stone or masonry.

Composite resin wheels designed for dry cutting

Special procedures must be followed when wet cutting with a composite nondiamond wheel designed for dry cutting. See the section entitled "Wet Cutting with Abrasive Wheels" in the safety precautions of this manual. Wet cutting is generally not suitable for cutting metals.

Composite resin wheels designed for wet cutting

Adjust water flow rate during cutting so it is suf- ficient to bind all the dust that occurs (at least

20 fl. oz (0.6 L/min)).

If the water flow rate is too high, the cutting wheel may skim on the water surface in the cut and greatly reduce cutting performance. To avoid this, do not exceed a water flow rate of about 135 fl. oz (4 L/min).

Use water properly:

1.Be certain water is applied to both sides of wheel, since uneven distribution can cause one sided wear with possible wheel breakage.

2.Makecertainwaterdoesnotflowon wheel that is not running, since the wheelwillabsorbwater and that will affect wheel balance.

3.After finishing work, run the cutting wheelatnormaloperatingspeedfor about 3 to 6 seconds without water so that the remaining water is flung off.

Respiratory protection

WARNING

WARNING

When wet cutting at the recommended flow rate is not utilized, the operator and any bystanders should always wear a respirator approved by NIOSH/MSHA for the material being cut. Even if wet cutting, an operator who is actively cutting for more than two hours a day should wear at least a NIOSH-approved disposable respirator.

Points to be noted with diamond and composite cutting wheels

Object to be cut

–Must be fully supported

–Must be secured so that it cannot roll or slip away

–Must be protected against vibration

English

The cutting sequence

The cutting sequence is important when cutting openings and recesses, etc. The last cut must always be made in such a way that the cutting wheel cannot become bound and so that the user is not at risk of being injured by the part that has been cut off or out.

If applicable, leave small ridges of uncut material to hold the severed part in position.Theseridgescansubsequently be broken through.

A number of points must be decided before the part is finally severed:

–How heavy is the part?

–In which direction can it move after being severed?

–Is it under tension?

Helpers must not be put at risk of injury when the part is broken off or out.

Cutting in several passes

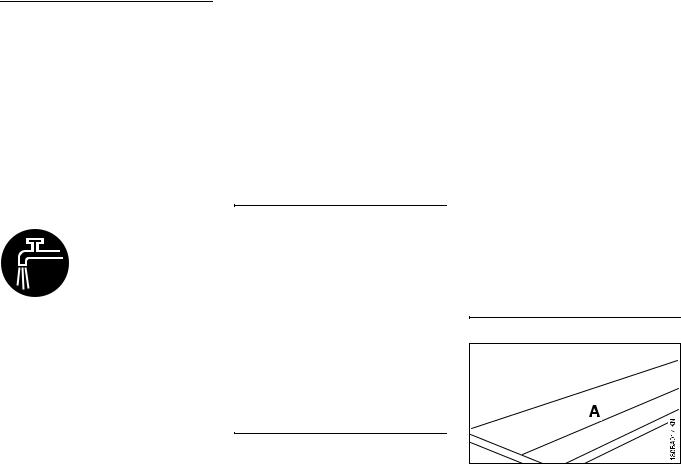

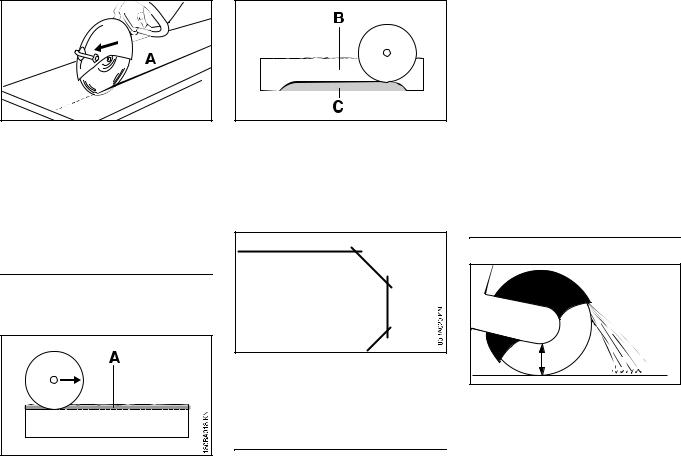

N Mark cutting line (A).

TS 700, TS 800 |

17 |

English |

180BA027 AM |

NWork along the cutting line. If corrections are necessary, always reposition the cutting wheel, taking care to ensure that it is not wedged. The cutting depth per pass should not exceed 5 to 6 cm (2“ to 2 1/2“). Thicker material must be cut in several passes.

Cutting slabs

NSecure the slab (e. g. on a non-slip surface, sandbed).

NCut a guiding groove (A) along the marked line.

180BA028 AM |

N Cut deeper into the parting cut (B). N Leave a ridge (C) of uncut material.

NCut through the slab at the ends so the material does not chip.

N Then break the slab.

NCurves must be cut in several straight passes, taking care to ensure that the cutting wheel does not become wedged.

Cutting pipes, round and hollow bodies

NSecure pipes, round and hollow bodies against vibrations, slipping and rolling away.

NNote direction of fall and weight of the severed part.

NDetermineandmarkthecuttingline; avoid metal reinforcement to the extent possible, especially in the direction of the severing cut.

NDetermine sequence of severing cuts.

NGrind a guide groove along the line marked.

NMake cuts deeper along the guide groove – observe recommended cutting depth on each pass. For smallcorrectionsofdirection,donot tilt the abrasive wheel, but always position it anew instead. If necessary, leave small ridges that hold the part that is to be separated in position. Break these ridges manually after the last cut.

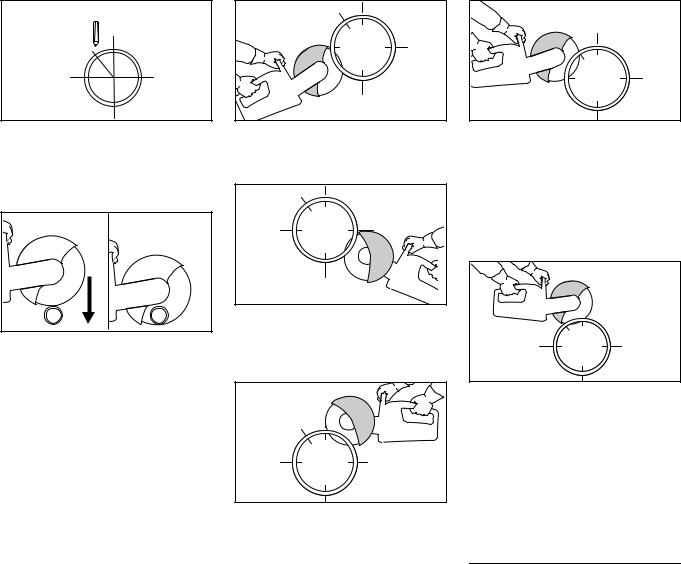

Cutting concrete pipe

A |

AM |

|

002BA557 |

||

|

The procedure is dependent on the outer diameter of the pipe and the maximum possible cutting depth of the abrasive wheel (A).

NSecure pipe against vibrations, slipping and rolling away.

NNote weight, tension and direction of fall of the part to be severed.

18 |

TS 700, TS 800 |

English

002BA528 AM

N Determineandmarkdirectionofcut. N Determine sequence of cuts.

Outer diameter of pipe is smaller than the maximum cutting depth

002BA558 AM

NMake one cut from the top to the bottom

Outer diameter of pipe is greater than the maximum cutting depth

Plan first, then cut. Several cuts are needed – correct sequence is important.

N Turn guard to rear stop.

TS 700, TS 800

002BA560 AM

NAlways start at the bottom, use the front and upper part of the abrasive wheel for cutting.

002BA561 AM

NUse the front and upper part of the abrasive wheel for cutting the opposite lower side. Make sure that the cut at the bottom is complete.

002BA562 AM

NNext, make a first lateral cut on the top half of the pipe, connecting with the kerf from the bottom half.

002BA563 AM

NA second lateral cut is then made in the marked area. To keep the pipe from pinching during this cut, never cut into the area of the final cut.

Only make the final top cut once all bottom and lateral cuts have been completed and connect with one another.

002BA559 AM

NAlways make the final separating cutfromthetop(approx.15 %ofthe pipe circumference). If the workpiece is properly supported, it should not pinch when the cut is completed. If there is any residual pinching, however, it will be at the bottom of the wheel, where it may result in pull-away, but not in kickback. Be alert for pull-away.

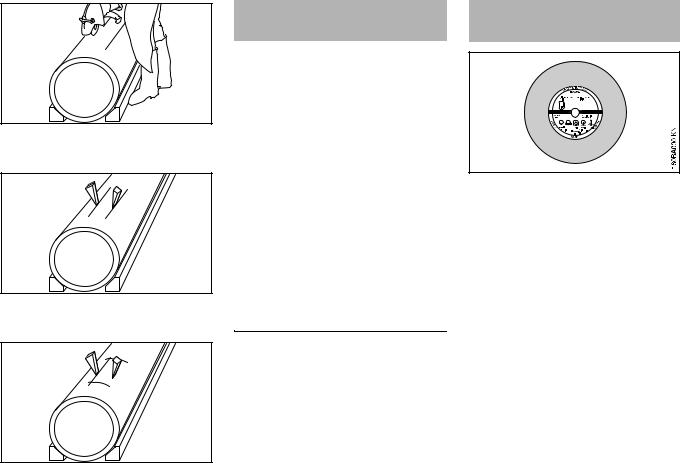

Concrete pipe – cut recess

Sequence of cuts (1 to 4) is important: N First, cut hard-to-reach areas.

19

English

1

2

2

180BA024 AM

NAlways make severing cuts so that the abrasive wheel is not pinched.

180BA025 AM

NUse wedges and/or leave ridges that are broken after cutting.

4

3

180BA026 AM

NIf the severed part remains in the recessaftercutting(due towedges, ridges used), do not make any further cuts – break the severed part.

Cutting wheels

Cutting wheels are exposed to extremely high loads especially during hand-held cutting.

Only use abrasive whhels that comply withANSI B 7.1forhand-heldmachines and are correspondingly labeled. Note that the maximum permissible speed of the cutting wheel must be higher than the maximum spindle speed listed on the wheel guard label.

The cutting wheels that have been developed for STIHL by well-known manufacturersofabrasivewheelsareof high quality and tailored precisely to the respective intended use as well as the engine performance of the cut-off machine.

Transport and storage

–Do not expose cutting wheels to direct sunshine or other thermal stresses during transport and storage.

–Avoid jolting and impacts.

–Stack cutting wheels flat on a level surface in the original packaging in a dry place where the temperature is as constant as possible.

–Do not store cutting wheels in the vicinity of aggressive fluids.

–Store cutting wheels in a frost-free place.

Composite resin cutting wheels

Types:

–for dry applications

–for wet applications

Economic benefit is improved and premature wear can be avoided by choosing and using the correct compositeresincuttingwheel.Theshort name (e.g. “asphalt“, “concrete“)

–on the label and

–on the packaging (table with recommended uses)

can help to ensure the correct choice.

STIHL composite resin cutting wheels are suitable, depending on the version, for cutting the following materials:

–Asphalt

–Concrete

–Stone

–Ductile cast pipes

–Steel; STIHL composite resin cuttingwheelscannotbeusedtocut railway tracks.

Do not cut any other materials – risk of accident!

20 |

TS 700, TS 800 |

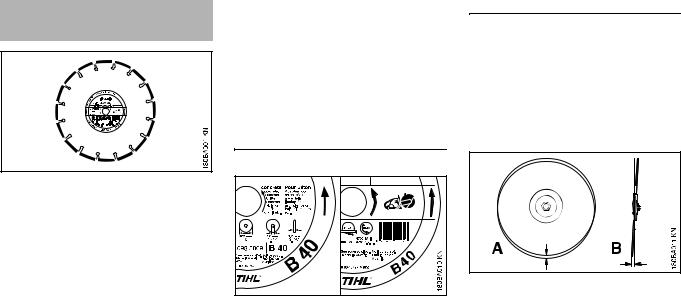

Diamond cutting wheels

For wet applications.

Economic benefit is improved and premature wear can be avoided by choosingand using thecorrectdiamond cutting wheel. The short name (see following explanation)

–on the label and

–on the packaging (table with recommended uses)

can help to ensure the correct choice.

STIHL diamond cutting wheels are suitable, depending on the version, for cutting the following materials:

–Asphalt

–Concrete

–Stone (hard rock)

–Abrasive concrete

–Green concrete

–Clay bricks

–Clay pipes

–Ductile iron

–Structural steel up to 10 mm thick

Do not cut any other materials. Cut-off machines are not suitable for cutting certain metals and other substances.

Never use diamond abrasive wheels with abrasive material on their sides, sinceinapinchsituation,theycanresult in extreme kickback – Risk of severe or fatal injury.

Short names

The short name is a combination of letters and numerals with up to four digits:

–Thelettersindicatethemainareaof use for the cutting wheel.

–The numerals indicate the performance class of the STIHL diamond cutting wheel.

Letter |

Main area of use |

AAsphalt

BConcrete

BA |

Concrete, Asphalt |

SStone (rock)

SB* |

Rock, Concrete |

*) |

can be used for structural steel up |

|

to10 mmthickandductileiron–not |

|

suitable for continuous cutting of |

|

such materials |

English

Radial and axial run-out

A correctly mounted spindle bearing on the cut-off machine is essential for a long service life and efficient operation of the diamond cutting wheel.

Using a cutting wheel on a cut-off machine with defective spindle bearing can lead to axial and radial run-out.

Excessive radial run-out (A) causes individual diamond segments to be overloaded and to overheat. This can in turn lead to stress cracking in the wheel core or to softening of individual segments.

Axial run-out or spindle wobble (B) results in higher thermal stress and wider cuts.

TS 700, TS 800 |

21 |

English

Troubleshooting

Cutting wheel |

|

|

|

|

|

Problem |

Cause |

Remedy |

Frayed edges or tears, cut wanders out |

Radial or axial run-out |

Consult a dealer1) |

of line, increased wear at the sides of the |

|

|

segments |

|

|

|

Cutting wheel wobbles |

Use a new cutting wheel |

Frayed edges, cut wanders out of line, lit- |

Cutting wheel is blunt; built-up edges on cut- |

Dress the cutting wheel for stone by |

tle or no cutting performance, sparking |

ting wheels for stone |

briefly cutting in abrasive material; use a |

|

|

new cutting wheel for cutting asphalt |

Poor cutting performance, high level of |

Cutting wheel rotates in the wrong direction |

Mount the cutting wheel with correct |

segment wear |

|

direction of rotation |

Chipping or cracking in the wheel core |

Overload |

Replace immediately with a new cutting |

and segments |

|

wheel |

Undercutting |

Cutting in a material for which the wheel is |

Use a new cutting wheel; note the differ- |

|

not rated |

ent cutting layers in different materials |

1)STIHL recommends that a STIHL servicing dealer be consulted.

22 |

TS 700, TS 800 |

Undercut

Undercutting is a wearing away of the steel core at or just below the diamond segments. When cutting road surfaces, do not cut through into the more abrasive ballast (gravel, crushed rock) below, as indicated by a light colored dust. This can cause excessive undercutting, resulting in wheel breakage and/or thrown segments.

WARNING

WARNING

Immediately replace a diamond wheel if the core has been severely undercut.

Built-up edges, dressing

Built-up edges are identified by a pale grey deposit on the top of the diamond segments that clogs and blunts the segments.

Built-up edges can form:

–when cutting extremely hard material, such as granite,

–as a result of incorrect handling, such as applying excessive feed force.

Built-up edges increase vibrations, reduce cutting performance and cause sparking.

Diamond cutting wheels must be "dressed" at the first sign of built-up edges. For this purpose, briefly cut a more abrasive material, such as sandstone, aerated concrete or asphalt.

Wet cutting helps to prevent the formation of built-up edges.

If you continue to use a cutting wheel with blunt segments, the segments may soften as a result of excessive heat built up. The wheel core will also overheat and lose its mechanical strength. This can lead to considerable stress, as clearly indicated by stress cracks and/or a wobbling movement of the cutting wheel.

English

WARNING

WARNING

Such cutting wheels may break apart or throwoffsegmentsduring useor lead to significant reactive forces, causing serious or fatal injury. Replace them immediately.

TS 700, TS 800 |

23 |

English

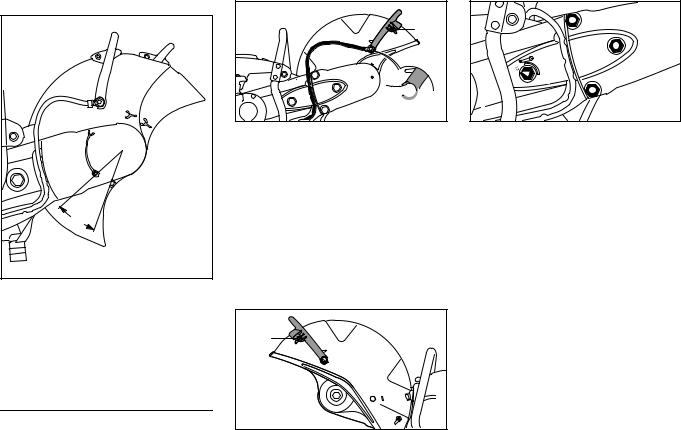

Assembling the bearing and guard

The "support with guard" is mounted on the inboard side by the manufacturer.

The "support with guard" can also be mounted on the outboard side depending on requirements.

Assembly on the inboard side is recommended for freehand cutting on account of the better balance.

Outboard mounting (TS 700)

NDisassemble the abrasive wheel (see “Fitting / replacing an abrasive wheel”)

Removing the water attachment

1 |

3 |

|

|

|

|

|

1 |

KN |

|

376BA079 |

|

|

|

NUnscrew the banjo bolt (1) with the combination wrench – in the process, remove the square nut fromtheinsideoftheguardfromthe guide

NRemove the water hose (2) with connector from the adjusting lever (3)

Removing the adjusting lever

3 |

2 |

|

|

|

1 |

|

376BA080 KN |

NUnscrew the banjo bolt (1) with the combination wrench and remove it together with the seal – in the process, remove the square nut fromtheinsideoftheguardfromthe guide

N Unscrew the screw (2)

NTurntheadjustinglever (3)upwards and remove

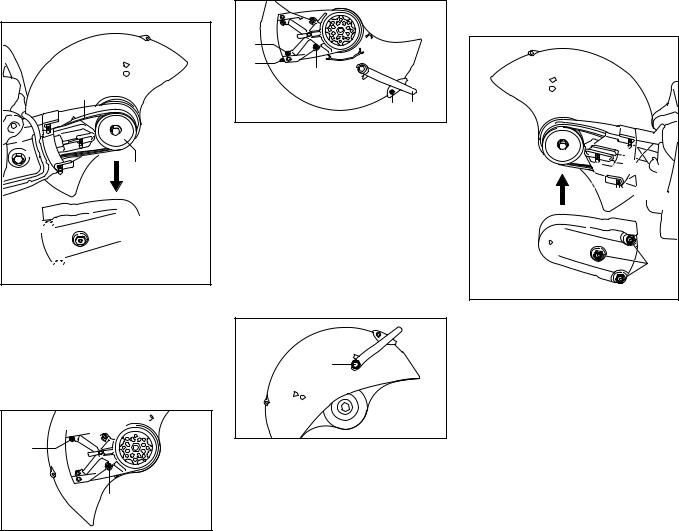

Slackening the V-belt

|

1 |

|

|

|

|

1 |

|

|

1 |

KN |

|

2 |

376BA091 |

||

|

|||

|

|

NTo relax the poly V-belt, loosen the nuts (1) – do not unscrew the nuts (1) from the studs

NTurn the tensioning nut (2) counterclockwise with the combination wrench – approx. 1/4 turn, as far as it will go = 0

NUnscrew nuts (1) from the studs – nuts (1) are fastened to the belt guard so that they are secured against loss

24 |

TS 700, TS 800 |

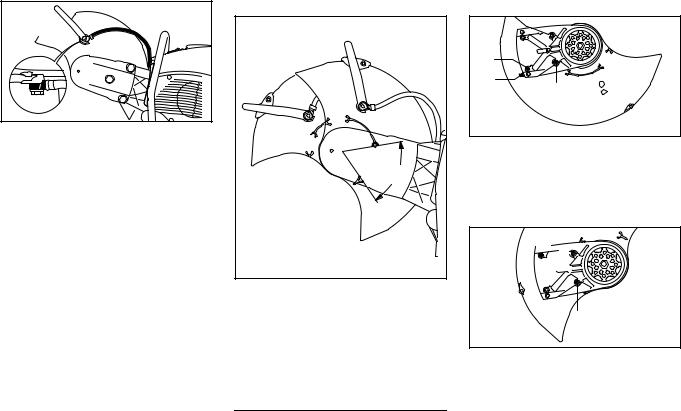

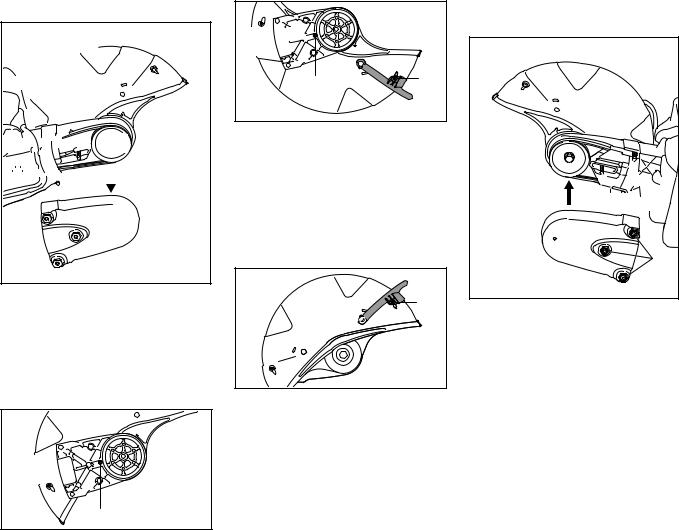

Removing the V-belt guard

4

2

3

1

1

KN376BA092

KN376BA092

NPull the V-belt guard (1) off and remove the V-belt (2) from the front pulley (3)

N Remove the"supportandguard" (4)

Preparing the "support with guard" for outboard mounting

2

1

3 |

KN |

|

376BA083 |

||

|

NUnscrew the screw (1) of the limit stop (2)

N Remove the limit stop (2)

N Unscrew the stop pin (3)

1 |

|

|

|

2 |

3 |

A |

KN |

|

|||

|

5 |

4 |

376BA084 |

NTurn the guard so that it is in the position shown (see picture)

N Screw in and tighten the stop pin (3)

NInsert limit stop (2) – align the hole in the limit stop with the hole in the bearing

N Insert and tighten the screw (1)

NMove the adjusting lever (4) to position A

N Insert and tighten the screw (5)

6

376BA085 KN

NTurn the "support with guard" so that the guard is on the outboard side

NInsert the square nut into the guide in the guard and hold it in place

NScrew in the shorter banjo bolt (6) and washer at the adjusting lever and tighten up with the combination wrench

English

Mounting "support with guard" – guard on the outboard side

1

3

2 |

KN |

|

4 |

||

376BA093 |

||

|

NFit the "support with guard" (1) on the outboard side of the cast arm - at the same time, guide the V-belt over the belt pulley

NOTICE

The belt action must run smoothly. N Position the V-belt guard (2)

NAlign studs (3) in support with nuts (4) in the V-belt guard

NScrew nuts (4) onto studs (3) – do not tighten them yet

TS 700, TS 800 |

25 |

English

Connecting the water connection

3

1

1

2 |

|

KN |

1 |

376BA087 |

|

|

|

NInsert the longer banjo bolt (1) through the connector (2) of the water attachment – observe the position of the connector

NInsert the square nut into the guide in the guard and hold it in place

NFitthe supportwiththe longerbanjo bolt on the adjusting lever (3) – screw in the banjo bolt and tighten with the combination wrench

Checking the adjustment range of the

guard |

A |

376BA088 KN |

NRotate the guard forwards and backwards as far as possible – adjustment range (A) must be limited by the stop pin

Continue as described in the chapter “Tensioning the V-belt”.

Inboard mounting (TS 700)

NDisassemble the abrasive wheel (see “Fitting / replacing an abrasive wheel”)

N Remove the water attachment N Remove the adjusting lever N Slacken the V-belt

N Remove the V-belt guard

N Remove "support with guard"

Preparing the "support with guard" for inboard mounting

1 |

|

|

2 |

3 |

KN |

|

||

|

|

376BA089 |

NUnscrew the screw (1) of the limit stop (2)

N Remove the limit stop (2)

N Unscrew the stop pin (3)

2

1

1

3 |

KN |

|

376BA083 |

||

|

NTurn the guard so that it is in the position shown (see picture)

N Screw in and tighten the stop pin (3)

NInsert limit stop (2) – align the hole in the limit stop with the hole in the bearing

N Insert and tighten the screw (1) N Install the adjusting lever

NMount "support with guard" – guard on the inboard side

N Install the V-belt guard

N Connect the water connection

26 |

TS 700, TS 800 |

Checking the adjustment range of the

guard |

A |

376BA090 KN |

NRotate the guard forwards and backwards as far as possible – adjustment range (A) must be limited by the stop pin

Continue as described in the chapter “Tensioning the V-belt”.

Outboard mounting (TS 800)

NDisassemble the abrasive wheel (see “Fitting / replacing an abrasive wheel”)

TS 700, TS 800

Removing the water attachment

3 |

4 |

377BA013 KN

377BA013 KN

NUnscrew the banjo bolt (1) with the combination wrench – in the process, remove the square nut fromtheinsideoftheguardfromthe guide

NRemove the water hose (2) with connector from the adjusting lever (3)

N Unscrew the screw (4)

Removing the adjusting lever

3 |

2 |

1 |

4 |

377BA014 KN |

NUnscrew the banjo bolt (1) with the combination wrench and remove it together with the seal – in the process, remove the square nut fromtheinsideoftheguardfromthe guide

N Unscrew the screw (2)

NTurntheadjustinglever (3)upwards and remove

N Remove the sealing plug (4)

English

Slackening the V-belt

|

1 |

|

|

1 |

|

2 |

1 |

KN |

|

377BA015 |

|

|

|

NTo relax the poly V-belt, loosen the nuts (1) – do not unscrew the nuts (1) from the studs

NTurn the tensioning nut (2) counterclockwise with the combination wrench – approx. 1/4 turn, as far as it will go = 0

NUnscrew nuts (1) from the studs – nuts (1) are fastened to the belt guard so that they are secured against loss

27

English

Removing the V-belt guard

4

4

3

3

2

2

1

377BA016 KN

NPull the V-belt guard (1) off and remove the V-belt (2) from the front pulley (3)

N Remove the"supportandguard" (4)

Preparing the "support with guard" for outboard mounting

2

2

1 |

377BA017 KN |

N Unscrew the stop pin (1)

N Remove the sealing plug (2)

2

2

1 |

4 |

KN |

A |

|

377BA018 |

NTurn the guard so that it is in the position shown (see picture)

N Screw in and tighten the stop pin (1) N Insert the sealing plug (2)

NMove the adjusting lever (3) to position A

N Insert and tighten the screw (4)

4 |

5 |

2 |

KN |

|

377BA019 |

||

|

NTurn the "support with guard" so that the guard is on the outboard side

NInsert the square nut into the guide in the guard and hold it in place

NScrew in the shorter banjo bolt (5) and washer at the adjusting lever and tighten up with the combination wrench

N Insert the sealing plug (2)

N Insert and tighten the screw (4)

Mounting "support with guard" – guard on the outboard side

1

3

2 |

|

4 |

KN |

|

377BA020 |

NFit the "support with guard" (1) on the outboard side of the cast arm - at the same time, guide the V-belt over the belt pulley

NOTICE

The belt action must run smoothly. N Position the V-belt guard (2)

NAlign studs (3) in support with nuts (4) in the V-belt guard

NScrew nuts (4) onto studs (3) – do not tighten them yet

28 |

TS 700, TS 800 |

Loading...

Loading...