STIHL RE 108 PLUS, RE 118 PLUS, RE 128 PLUS User Manual [fr]

{

STIHL RE 108, 118, 128 PLUS

Instruction Manual Notice d’emploi

GInstruction Manual 1 - 23

FNotice d’emploi 25 - 49

Contents

|

|

Guide to Using this Manual |

2 |

|

|

|

Safety Precautions and Working |

|

|

|

|

Techniques |

2 |

|

Manual |

|

Assembling the Unit |

6 |

|

|

Transporting the Unit |

7 |

||

Instruction |

|

Fitting, removing high-pressure |

8 |

|

|

|

Fitting, removing spray lance |

||

Original |

|

hose |

8 |

|

|

Connecting the water supply |

9 |

||

|

|

Connecting to a pressureless water |

|

|

|

recycled.be |

supply |

10 |

|

|

Switching On |

11 |

||

|

|

Connecting to Power Supply |

10 |

|

|

can |

Working |

11 |

|

|

oils, paper |

Adding detergent |

12 |

|

|

Switching Off |

13 |

||

chlorineon-free paper containinksvegetable |

Storing the Machine |

13 |

||

storage |

15 |

|||

|

|

Maintenance and Care |

14 |

|

|

|

Maintenance |

15 |

|

Printed |

Printing |

First use after long periods of |

|

|

Main Parts |

16 |

|||

|

|

|||

|

|

Specifications |

17 |

|

|

|

Special Accessories |

19 |

|

|

|

Troubleshooting |

21 |

|

2011 |

|

Maintenance and Repairs |

23 |

|

|

Disposal |

23 |

||

© ANDREAS STIHL AG & Co. KG, |

0458-650-8221. M999.A11.TP. 0000004010_001_GB |

{ |

|

|

English

Dear Customer,

Thank you for choosing a quality engineered STIHL product.

This machine has been built using modern production techniques and comprehensive quality assurance.

Every effort has been made to ensure your satisfaction and troublefree use of the machine.

Please contact your dealer or our sales company if you have any queries concerning your machine.

Your

Hans Peter Stihl

RE 108, RE 118, RE 128 PLUS |

1 |

English

Guide to Using this Manual

Pictograms

All the pictograms attached to the machine are shown and explained in this manual.

Symbols in text

Warning where there is a risk of an accident or personal injury or

serious damage to property.

Caution where there is a risk of damaging the machine or its

individual components.

Engineering improvements

STIHL's philosophy is to continually improve all of its products. For this reason we may modify the design, engineering and appearance of our products periodically.

Therefore, some changes, modifications and improvements may not be covered in this manual.

Safety Precautions and

Working Techniques

The high water pressure generated and the power connection are particular sources of danger.

It is important that you carefully read the entire Instruction Manual before using the machine for the first time and keep it in a safe place for future reference. Non-compliance with the Instruction Manual may cause serious or even fatal injury.

Warning!

–This appliance is not intended for use by children and other persons whose physical, sensory, or mental capabilities or lack of experience and knowledge prevents them from using the appliance safely without supervision or instruction by a responsible person.

–Minors should never be allowed to use the high-pressure cleaner – except for young trainees over the age of 16 when working under supervision.

–Children should be supervised by responsible person to ensure that they do not play with the appliance.

–The machine should only be provided or loaned to people familiar with this model and its operation. The instruction manual should always be handed over with the machine.

–Do not use the machine if anyone not wearing protective clothing is in the working area.

–Before starting any work on the machine, e. g., cleaning, servicing, replacement of parts – unplug the power plug!

Observe the national safety regulations issued, for example, by the employers' liability insurance association, social security institutions, occupational safety and health authorities or other organizations.

When not using the machine, it must be put down in such a way that it does not endanger anyone. Ensure that the machine cannot be used without authorization, unplug the power cord.

The user is responsible for accidents or risks involving third parties or their property.

If using the machine for the first time: Have your STIHL dealer or another expert show you how to use it safely.

In some countries, operation of machines that emit noise may be restricted by municipal regulations. Observe national regulations.

Unsuitable extension cords may be dangerous. When working outdoors, use only extension cords that are approved for this use and correspondingly marked and have a sufficient cross-section.

2 |

RE 108, RE 118, RE 128 PLUS |

Never touch the power plug, power cord and extension cord and electrical plug connections with wet hands.

Always check that the machine is in good working order before starting work. Pay particular attention to the power cord, mains plug, high-pressure hose, spray attachment and safety mechanisms.

Never operate the machine with a defective high-pressure hose – ensure that it is replaced immediately.

The machine may only be used when all parts are in perfect working order.

The high-pressure hose must not be driven over, pulled, buckled or twisted.

Never pull the high-pressure hose or the power cord in order to move the machine.

The high-pressure hose must be approved for the permissible excess pressure of the machine.

The permissible excess pressure, the maximum permitted temperature and the date of manufacture are stated on the cladding of the high-pressure hose. The permissible pressure and date of manufacture are specified on the fittings.

Accessories and spare parts

Warning!

–High-pressure hoses, fittings and couplings are important for machine safety. Only high-pressure hoses, fittings, couplings and other accessories which have been approved by STIHL for this machine

RE 108, RE 118, RE 128 PLUS

or technically equivalent parts may be mounted on the machine. Contact a servicing dealer if in doubt. Use only high-quality accessories, in order to avoid the risk of accidents or damage to the machine.

–STIHL recommends the use of genuine STIHL parts and accessories. These have been optimized for the product and the user's requirements.

Never modify the machine in any way, as this could be extremely dangerous. STIHL excludes all liability for personal injury and damage to property caused while using unauthorized attachments.

Physical suitability

The machine may only be operated by people who are fit, in good physical health and in good mental condition. If you have any condition that might be aggravated by strenuous work, check with your doctor before operating a machine.

Anyone who has consumed alcohol, medicines affecting their ability to react or drugs must not operate the machine.

Applications

The high-pressure cleaner can be used to clean motor vehicles, machines, tanks, facades or stables and to remove rust without dust or sparks.

Other uses are not permitted and may lead to accidents or damage to the machine.

English

Clothing and equipment

Wear shoes with non-slip soles.

Wear goggles and protective clothing. STIHL recommends that a boilersuit be worn in order to reduce the risk of injury due to accidental exposure to the highpressure jet.

Transporting the machine

When transporting the machine in or on a vehicle, it must be secured, e.g. with straps, so that it cannot slip or tip over.

Antifreeze is recommended if the machine and accessories are to be transported at temperatures near or below 0° C (32 °F) – see “Storing the Machine".

3

English

Detergents

Warning!

–Unsuitable detergents can cause damage to health, as well as to the machine and the object to be cleaned. Contact a servicing dealer if in doubt.

–STIHL recommends the use of genuine STIHL detergents. Follow the instructions for use.

–Chemical detergents may contain physiologically harmful (toxic, caustic, irritant), flammable or explosive substances. In the event of skin or eye contact with detergent, flush the affected body parts with plenty of clean water immediately. If detergent is swallowed, seek medical attention immediately. Note the manufacturer's safety data sheets!

Detergents should always be used in the proportions specified by the manufacturer.

Before starting work

Do not connect the highpressure cleaner directly to the drinking water main.

Only connect the high-pressure cleaner to the drinking water main in conjunction with a backflow preventer – see "Special accessories".

Warning!

–If drinking water has passed through the backflow preventer, it can no longer be regarded as drinking water.

Do not use the machine with dirty water.

If there is a risk that dirty water will occur (e. g., flowing sand), an appropriate water filter must be used.

Inspecting the high-pressure cleaner

Warning!

–The high-pressure cleaner should only be used if it is in full working order – risk of accident!

–It must be possible to move the switch to the 0 position easily

–The switch must be in the 0 position

–Inspect the high-pressure hose, spray attachment and safety mechanisms for damage

–High-pressure hose and spray attachment in good condition (clean, moving easily) and correctly assembled

–For good control of the machine, the handles should be clean and dry with no oil or dirt on them

–Never attempt to modify the controls or safety devices

Electrical connection

Warning!

Minimize the risk of electrical shock:

–Voltage and frequency of the machine (see rating plate) must match the voltage and frequency of the mains supply

–Examine the power cord, power plug and extension cord for damage. Damaged cords, couplings and plugs or power cords that do not comply with the regulations must not be used

–Only connect the machine to a correctly installed power socket

–The insulation on the power cord and any extension cord, the plug and the coupling must be fully intact

Warning!

Route the power cord and extension cord properly:

–Observe the minimum cross-section of the individual cords – see "Connecting the machine to the power supply"

–Route and mark the power cord so that it cannot become damaged and no one is endangered – danger of stumbling!

–The connector and coupling of the extension cord must be waterproof or routed in such a way that they cannot come into contact with water

– the connector and coupling of the extension cord must not lie in water

–don't let the cord rub against edges or pointed or sharp objects

–don't squeeze the cord under doors or windows

4 |

RE 108, RE 118, RE 128 PLUS |

–if cords become snarled – unplug the power plug and unsnarl the cord

–always unroll the power cord from the cable drum completely to avoid risk of fire due to overheating

During work

Warning!

–Never draw in fluids containing solvents or undiluted acids and solvents (e. g., gasoline, heating oil, paint thinner or acetone). These substances damage the materials used in the machine. The spray is highly combustible, explosive and poisonous.

Never direct the highpressure jet or water hose against the machine itself or against other electrical appliances and equipment – danger of short-circuiting!

Never direct the highpressure jet or water hose against electrical equipment, connections and power cords – danger of short-circuiting!

Never direct the highpressure jet against yourself or other people, not even to clean clothing or shoes – risk of injury!

Ensure you always have a firm and safe footing.

Beware of slipping on ice, water, snow or uneven ground!

Keep the high-pressure cleaner as far away as possible from the object being cleaned.

The machine may only be operated in an upright position. Do not cover the machine and ensure adequate motor ventilation.

The plug must be disconnected immediately if the cord is damaged – danger of electrocution!

Do not direct the high-pressure jet against animals.

Do not direct the high-pressure jet onto places you cannot see.

Children, animals and bystanders must remain at a distance.

Hazardous substances (e. g., asbestos or oil) must not be allowed to escape into the environment unchecked when working with the machine. The applicable environmental regulations must be observed without fail.

Surfaces of asbestos cement must never be cleaned with a high-pressure jet. Hazardous, breathable asbestos fibers may be released in addition to the dirt. The danger is greatest when the washed surface has dried.

Delicate parts made of rubber, fabric or similar materials must not be cleaned with a pencil jet, e. g., from the rotary nozzle. Maintain a sufficient distance between the high-pressure hose and the surface when cleaning to avoid any damage to the surface being cleaned.

English

The trigger on the spray gun must move easily and automatically return to its starting position when released.

Hold the spray attachment firmly with both hands in order safely to withstand the kickback force and additional torque produced when using spray attachments with angled spray lance.

Ensure that the power cord and the highpressure hose are not damaged by being driven over, squashed or pulled; protect them against heat and oil.

Do not touch the power cord with the high-pressure jet.

If the machine is subjected to unusually high loads for which it was not designed (e.g., heavy impact or a fall), always check that it is in good condition before continuing work - refer also to the chapter "Before starting work". Also make certain that the safety mechanisms are working properly. Never continue using a machine that is not in perfect working order. Consult a servicing dealer if in doubt.

Before leaving the machine: Switch off the machine – unplug the power cord.

Safety equipment

When the safety equipment is activated, excessive pressure is returned to the intake side of the pump via a safety valve. This safety feature has been set by the manufacturer and must not be adjusted.

RE 108, RE 118, RE 128 PLUS |

5 |

English

After finishing work

Switch off the machine before leav-

Switch off the machine before leav-

ing it!

ing it!

–Unplug the power plug from the socket

–Disconnect water intake hose between machine and water supply

Never unplug the power plug by pulling on the cord: always grip the plug itself.

Maintenance and repairs

Warning!

Before starting any work on the machine: always disconnect the machine from the mains power supply.

–Use only high-quality spare parts. in order to avoid the risk of accidents or damage to the machine. Contact a servicing dealer if in doubt.

–If the supply cord is damaged, it must be replaced by authorized STIHL dealers or qualified electricians in order to avoid a hazard.

Clean plastic parts with a cloth. Harsh detergents can damage the plastic.

Cleaning ventilation slots in motor housing as needed.

The machine must be serviced regularly. Do not attempt any maintenance or repair work not described in the Instruction Manual. All other work should be carried out by a servicing dealer.

STIHL recommends the use of genuine STIHL spare parts. Such parts have been optimized for the machine and the user's requirements.

STIHL recommends that maintenance and repair work be carried out only by authorized STIHL dealers. STIHL dealers receive regular training and are supplied with technical information.

Assembling the Unit

The following accessory parts must be fitted before using the machine for the first time.

Connector on water inlet

1 |

1 |

|

650BA003 KN |

NAttach the connector (1) to the water inlet and tighten it by hand

RE 108, 118

Handle

2

1

1

650BA000 KN

NPress the handle (1) onto the telescopic shafts from above and fasten it with the two bolts (2) and nuts

6 |

RE 108, RE 118, RE 128 PLUS |

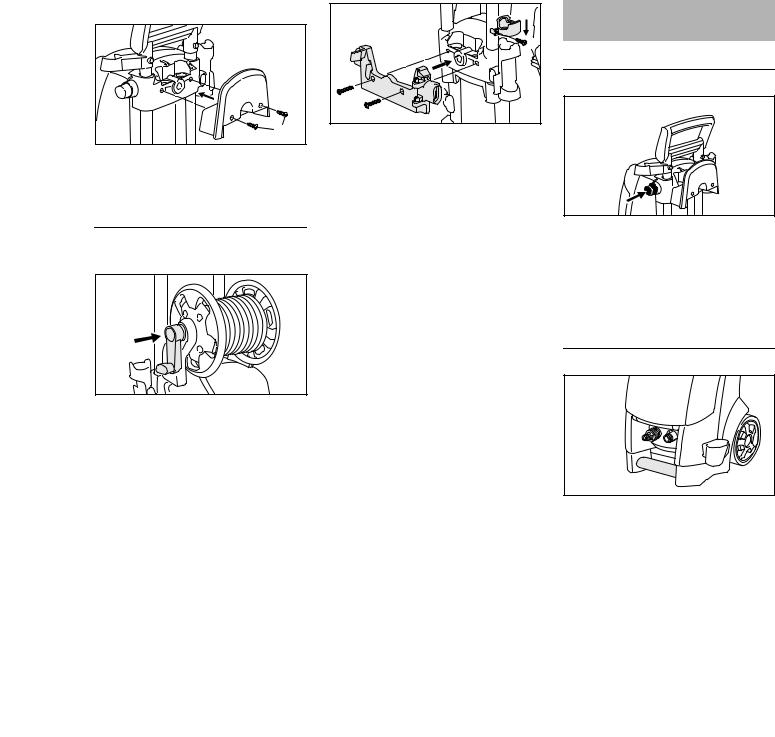

Holder for high-pressure hose

1

2 |

650BA001 KN |

NPosition the holder (1) for the highpressure hose on the adjuster and fasten it with the screws (2)

RE 128 PLUS

Crank for hose reel

650BA022 KN

N Engage crank handle in hose reel

Holder for flat hose cassette

A flat hose cassette is available as special accessory.

The holder for the flat hose cassette is included and can be installed as needed.

1 |

2 |

650BA029 KN |

NSlide the locking ring (1) over the spray attachment holder

NFasten the holder (2) for the flat hose cassette with the included screws

English

Transporting the Unit

Height adjustable handle

2

1 |

650BA004 KN |

NPress button (1) and pull handle (2) upward as far as it will go

NRelease button and pull/push on the handle again until the telescopic shafts engage

Transport handle (RE 118, 128 PLUS only)

650BA023 KN

The machine can be carried using the transport handle.

RE 108, RE 118, RE 128 PLUS |

7 |

English

Fitting, removing spray lance

Spray lance

Removing

NPress the safety latch (4) and pull out the nozzle (3)

2 1

650BA012 KN

NPress the spray lance (1) into the mount on the spray gun (2), turn it by 90° so that it engages

Removing

NPress the spray lance (1) into the mount on the spray gun (2), turn it by 90° and pull it out of the mount

Nozzle

4 3

+

-

666BA014 KN

NInsert nozzle (3) in spray lance until the safety latch (4) engages – at which point the safety latch button will spring out again – the adjustable fan jet nozzle has an anti-twist device; orient this according to the groove on the spray lance

8

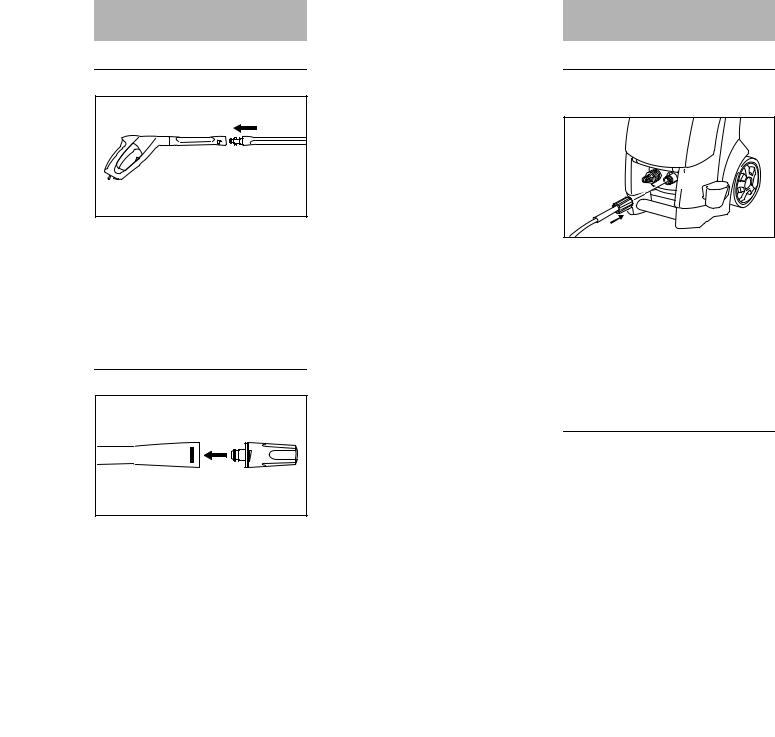

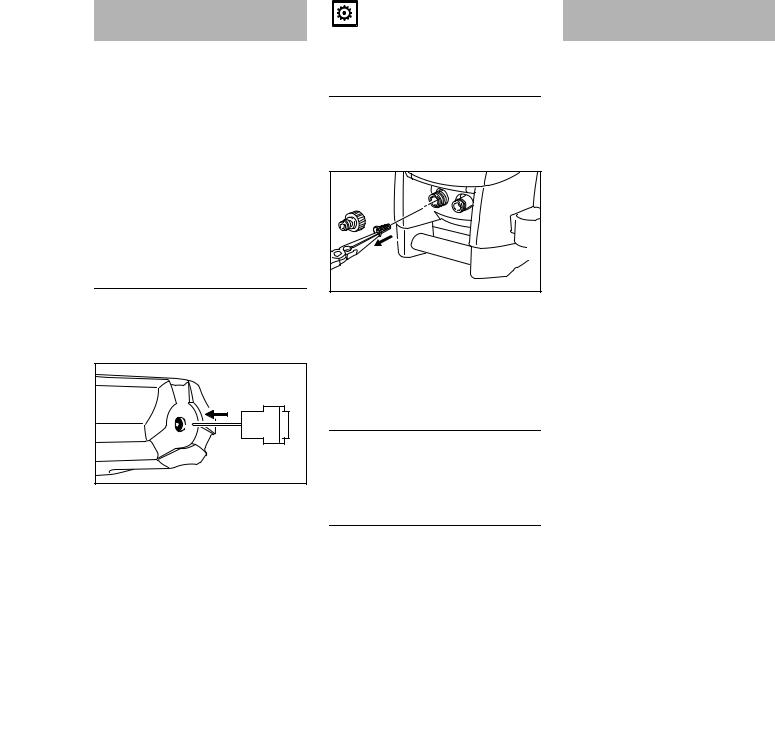

Fitting, removing highpressure hose

RE 108, RE 118

Connecting the high-pressure hose

1 |

2 |

KN |

|

|

650BA024 |

NPush high-pressure hose onto the connector (2)

NAttach union nut (1) and screw it on and tighten by hand

Disconnecting the high-pressure hose

N Unscrew the union nut (1)

NPull high-pressure hose off of connector (2)

RE 128 PLUS

The high-pressure hose is already connected.

RE 108, RE 118, RE 128 PLUS

Disconnecting the high-pressure hose

2 |

1 |

|

650BA006 KN |

NPull out the spring clip (1) and pull the high-pressure hose (2) out of the connector

Connecting the high-pressure hose

NPush the high-pressure hose (2) onto the connector of the hose reel

NPush the spring clip (1) into the connector

Connecting the high-pressure hose to the spray gun

Fitting

|

4 |

5 |

KN |

3 |

650BA013 |

|

NPush the connector of the highpressure hose (3) into the mount on the spray gun (4) – until it engages

Removing

NActuate the safety catch (5) and pull the high-pressure hose (3) out of the mount on the spray gun

High-pressure hose extension

As a rule, always use only one highpressure hose extension – see "Special accessories"

English

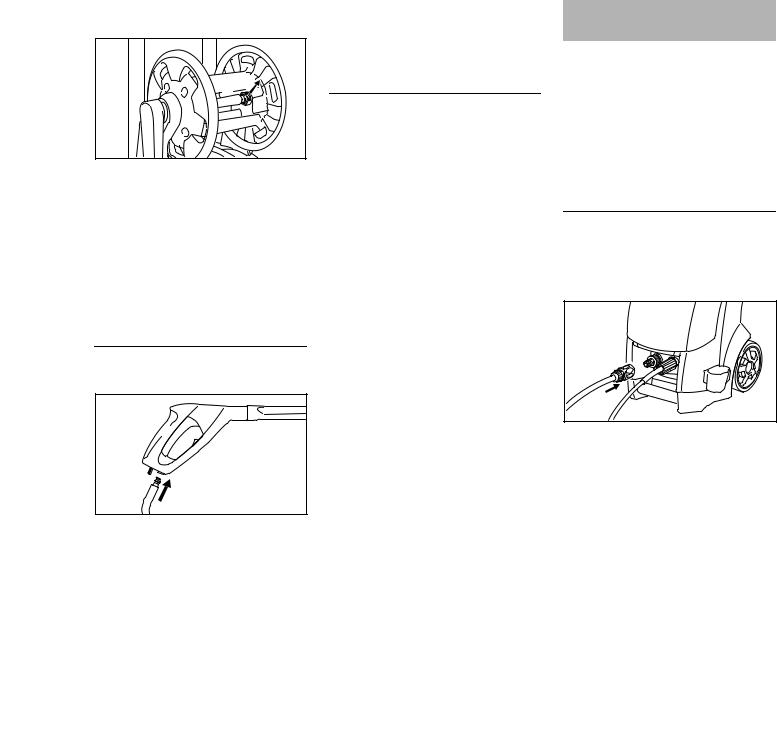

Connecting the water supply

In suction operation, the machine can also be connected to rivers, lakes, cisterns and tanks, etc. – see "Connecting to a pressureless water supply".

Briefly rinse out the hose before connecting it to the machine to prevent sand and other particles from entering the machine.

Connect hose

NConnect hose to water supply (1/2" diameter, length at least 10 m to absorb pressure surges. Maximum length 25 m)

1 |

2 |

|

650BA025 KN |

NPush the coupling (1) on to the hose connector (2)

N Turn on water supply

RE 108, RE 118, RE 128 PLUS |

9 |

English

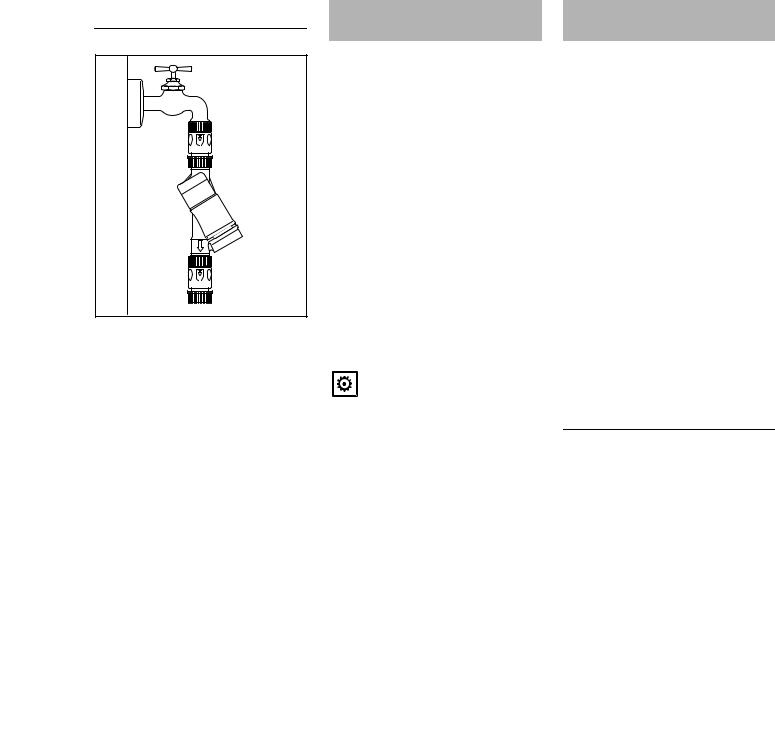

Connection to the drinking water main

003BA003 KN

When hooking up to the drinking water main, a backflow preventer (Type BA in accordance with EN 60335-2-79) must be installed between the water tap and the hose.

If drinking water has passed through the backflow preventer, it can no longer be regarded as drinking water.

Follow the rules laid down by the local water supply company to prevent water flowing back from the high-pressure cleaner into the drinking water main.

Connecting to a pressureless water supply

NConnect the machine to the pressurized water supply and start it up briefly in accordance with the Instruction Manual

N Switch off machine

NDisconnect the spray attachment from the high-pressure hose

NReplace water intake hose with suction hose (special accessory)

Always use the connecting element supplied with the intake hose to connect the hose. The standard connecting elements are watertight only when used with a pressurized water supply and for this reason are not suitable for suction operation.

NFill the suction hose with water and immerse the suction cup of the suction hose in the water tank – do not use dirty water

As a rule, it is advisable to use a water filter.

NHold down the high-pressure hose by hand

N Switch on the machine

NWait until a steady jet exits the highpressure hose

N Switch off machine

N Connect spray attachment

NSwitch on the machine with the spray gun open

NActuate the spray gun several times briefly in order to bleed the air out of the machine as quickly as possible

Connecting to Power Supply

The voltage and frequency of the machine (see rating plate) must match the voltage and frequency of the power connection.

The minimum fuse protection of the power connection must comply with the specifications – see "Specifications".

The machine must be connected to the power supply via an earth-leakage circuit breaker to disconnect the power supply if the differential current to earth exceeds 30 mA for 30 ms.

The power connection must correspond to IEC 60364-1 and relevant national regulations.

When the machine is switched on, voltage fluctuations that occur under unfavorable mains conditions (high power line impedance) may negatively affect other connected electrical appliances. Trouble is not anticipated at power line impedances less than

0.15 ohms.

Extension Cords

Make sure your electrical cord set is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized extension cord may cause a drop in line voltage resulting in loss of power and overheating. The table below shows the correct size (AWG) to use for your machine (Cord types SJW or SJTW) depending on cord length and

10 |

RE 108, RE 118, RE 128 PLUS |

nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Cord length (ft) |

Wire gage (AWG) |

50 |

16 |

100 |

14 |

150 |

12 |

Appropriate extension cords are available in special stores for electrical equipment or from your STIHL dealer.

Connection to the power supply socket

Before connection to the power supply, check that the machine is switched off – see "Switching off the machine"

1607BA035 KN

1607BA035 KN

NSwivel the lower holder upward and remove the power cord

NPlug the power cord or extension cord into a properly installed outlet

Switching On

N Turn on water supply

The machine may only be  switched on when the water intake hose is connected and the water supply has been turned on. Otherwise the machine may be damaged due to lack of water.

switched on when the water intake hose is connected and the water supply has been turned on. Otherwise the machine may be damaged due to lack of water.

NCompletely unroll the high-pressure hose

1607BA011 KN

NTurn the master switch to I – now the machine is in standby mode

English

Working

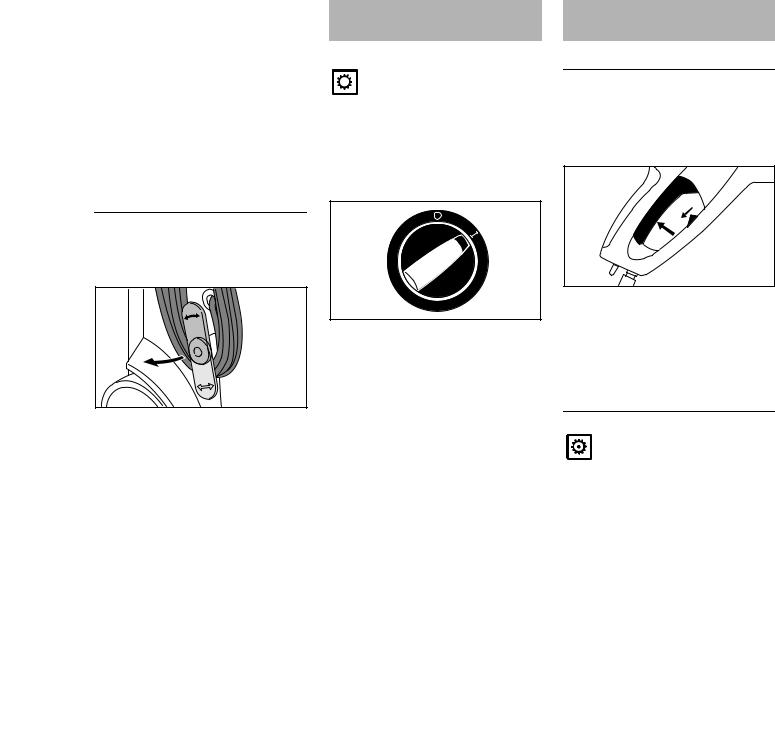

Actuating the spray gun

NPoint the spray gun at the object to be cleaned – never at persons!

NPoint the rotary nozzle downwards when starting (if fitted)

650BA014 KN

NPress the safety latch (2) downward

– the lever (1) is unlatched

N Squeeze the lever (1)

The motor stops when the lever is released.

Standby mode

The machine must not be operated in standby mode for more than 5 minutes. If work is interrupted for more than 5 min., during breaks or if the machine is left unattended, switch off the machine at the master switch – see "Switching off the machine".

RE 108, RE 118, RE 128 PLUS |

11 |

English

High-pressure hose |

|

Storage compartment for nozzles |

Do not buckle or loop the highpressure hose.

Do not place any heavy objects on the high-pressure hose, and do not drive any vehicles over it.

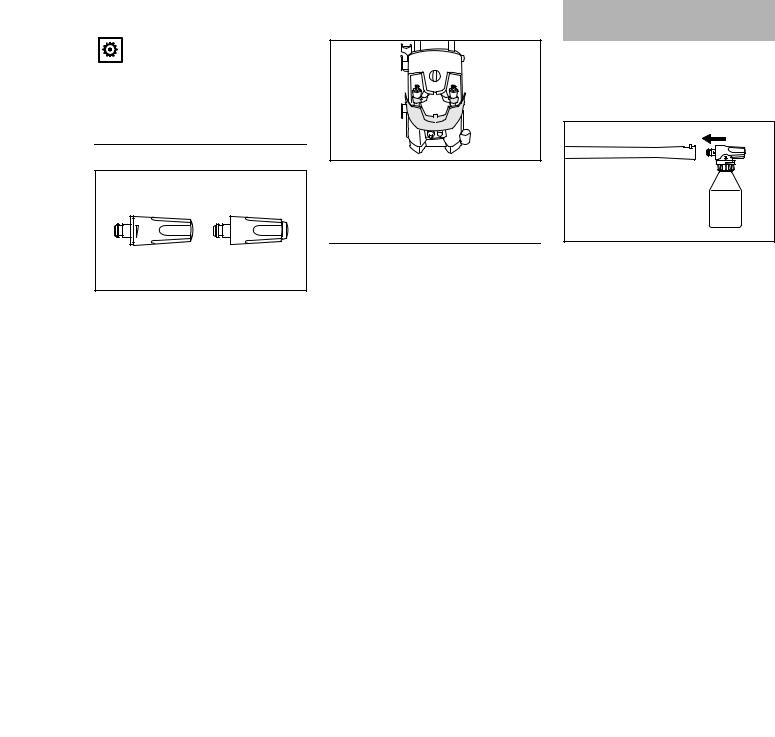

Nozzles

1 2

+

-

666BA015 KN

Fan-jet nozzle (1)

The operating pressure can be infinitely adjusted at the nozzle.

Jet angle 15°, maximum effect at a distance of approx. 7 cm.

N Turn nozzle sleeve

Rotary nozzle (2)

Nozzle with rotating jet for stubborn dirt on hard surfaces. Maximum effect at a distance of 10 cm.

The spray attachment can also be used without nozzles at low pressure, e.g., for rinsing with a large flow of water.

650BA026 KN

NOpen the flap – the rotary nozzle and fan jet nozzle can be stored in the holders

Storing accessories

Spray gun, spray lance, detergent bottle and cleaning pin can be stored directly on the machine – see "Main Parts".

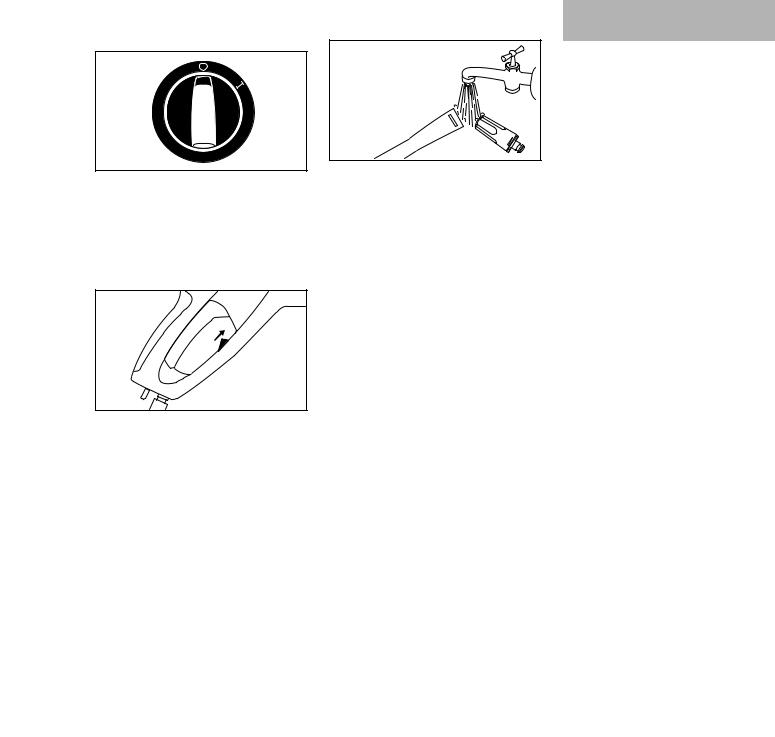

Adding detergent

Detergent must not be allowed to dry on the object to be cleaned.

NRemove nozzle from spray lance – see "Fitting, removing spray lance"

1 |

|

4 |

|

3 |

KN |

|

666BA016 |

|

|

|

NInstall spray set (3) on spray

lance (1) – the spray set has an antitwist device; orient this according to the groove on the spray lance

Fill the container of the spray set with STIHL detergent diluted as directed (approx. 0.5 liters).

NUse the adjusting ring (4) to set the quantity of detergent to be added

NWhen applying detergent, start at the bottom and work upwards

Maximum effect at a distance of 1 m.

12 |

RE 108, RE 118, RE 128 PLUS |

|

|

After use |

||

Switching Off |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1607BA018 KN

NTurn the master switch to 0 and turn off the water supply

NActuate the spray gun until water only drips from the spray head (the machine is now depressurized)

N Release trigger

|

|

KN |

|

- |

666BA017 |

+ |

|

|

NRinse the connection latches of the spray lance and nozzle with water so that no deposits form

NRoll the high-pressure hose and power cable up on the holders provided for this purpose – see "Main Parts"

650BA015 KN

NPress the safety latch upward – the spray gun is locked to prevent inadvertent operation

NUnplug the power plug from the socket

NDisconnect hose from the water supply and from the machine

English

Storing the Machine

Store the machine in a dry room where it is protected from frost.

If protection from frost cannot be guaranteed, draw glycol-based antifreeze – like that used in motor vehicles – into the pump:

NInsert water intake hose in container with antifreeze

NInsert spray gun without spray lance in the same container

NSwitch on the machine with the spray gun open

NActuate the spray gun until a uniform jet emerges

NKeep leftover antifreeze in a sealed container

RE 108, RE 118, RE 128 PLUS |

13 |

English

Maintenance and Care

The following maintenance intervals apply in normal operating conditions. The spec- |

|

|

|

|

|

|

ified intervals must be shortened accordingly for longer daily working hours. If the |

|

at the end of work and/or daily |

|

|

|

|

machine is only used occasionally, the intervals can be extended accordingly. |

|

|

|

|

||

|

|

before starting work |

monthly |

if damaged |

as required |

|

|

|

|

|

|

|

|

Complete machine |

visual inspection (condition, leaks) |

X |

|

|

|

|

|

|

|

|

|

|

|

clean |

|

X |

|

|

X |

|

|

|

|

|

|||

|

|

|

|

|

|

|

Connectors on high-pressure hose |

clean |

|

X |

|

|

X |

|

|

|

|

|

|

|

grease |

|

|

|

|

X |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Plug-type coupling of the spray lance and |

clean |

X |

|

|

|

X |

the coupling sleeve of the spray gun |

|

|

|

|

|

|

Water intake screen in the high-pressure |

clean |

|

|

X |

|

X |

inlet |

|

|

|

|

|

|

replace |

|

|

|

X |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

High pressure nozzle |

clean |

|

X |

|

|

|

|

|

|

|

|

|

|

replace |

|

|

|

X |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Ventilation openings |

clean |

|

|

|

|

X |

|

|

|

|

|

|

|

Machine supports |

check |

|

|

|

|

X |

|

|

|

|

|

|

|

replace |

|

|

|

X |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

14 |

RE 108, RE 118, RE 128 PLUS |

Maintenance

Always unplug the power cord before servicing or cleaning the machine.

In order to ensure trouble free operation, we recommend carrying out the following steps whenever the machine is used:

NRinse the water hose, highpressure hose, spray lance and accessories with water before fitting them

NRemove all dust and sand from the couplings

N Rinse out the spray set after use

Cleaning the nozzle

Since the pump pressure increases if the nozzle is clogged, it must be cleaned immediately.

666BA018 KN |

N Switch off machine

NActuate the spray gun until water merely drips from the spray head – the machine is now depressurized

N Remove the nozzle

NClean the nozzle with the cleaning pin

Always remove the nozzle before cleaning it

NRinse the nozzle with water from the front

Cleaning the water intake screen

The water intake screen must be cleaned once per month or more often if necessary.

650BA027 KN

N Unscrew the hose connection

NCarefully remove the screen with pliers and rinse it with water

NBefore refitting the screen, ensure that it is undamaged and replace if necessary

Cleaning the ventilation openings

The machine must be kept clean so that cooling air can flow freely through the openings in the machine.

Greasing couplings

The couplings on the spray gun for connecting the high-pressure hose and the spray lance must be greased as required.

English

First use after long periods of storage

During long periods of storage, mineral residue from the water may be deposited in the pump. This may cause the motor to start with difficulty or not at all.

NConnect the machine to the water supply and flush thoroughly with tap water, leave the power cord unplugged while doing so

NPlug the power plug into the wall socket

NSwitch on the machine with the spray gun open

RE 108, RE 118, RE 128 PLUS |

15 |

Loading...

Loading...