STIHL SR 420, SR 340 Owner's Manual

STIH)

STIHL SR 340, 420

Instruction Manual Manual de instrucciones

Warning!

For safe operation follow all safety precautions in Instruction Manual - improper use can cause serious injury.

Advertencia!

Para su seguridad durante el manejo de este producto, siga siempre las precauciones de seguridad dadas en el manual de instrucciones - el uso indebido puede causar lesiones graves.

Contents

05.fm |

|

Guide to Using this Manual .............. |

2 |

|

|

Safety Precautions and |

|

||

007 01_ |

|

Working Techniques ......................... |

3 |

|

|

Assembling the Machine ................ |

14 |

||

004_ |

|

Harness .......................................... |

16 |

|

|

Fuel |

17 |

||

_ |

|

|||

_SE |

|

Fueling |

18 |

|

BA |

|

|||

|

Information Before You Start |

18 |

||

|

|

|||

|

|

Starting / Stopping the Engine ........ |

19 |

|

|

|

Calculating Required Quantity |

|

|

|

|

of Solution ...................................... |

22 |

|

|

recycled. |

Metering Unit .................................. |

23 |

|

|

Filling the Container |

25 |

||

|

|

|||

|

|

Mistblowing ..................................... |

25 |

|

|

can be |

Cleaning the Air Filter ..................... |

26 |

|

|

Motor Management ........................ |

27 |

||

|

paper |

Adjusting the Carburetor ................ |

27 |

|

|

Spark Arresting Screen |

|

||

|

oils; |

|

||

|

in Muffler ......................................... |

29 |

||

paper.free-chlorineon vegetablecontaininks |

Checking the Spark Plug |

29 |

||

|

|

|||

|

|

Replacing Starter Rope and |

|

|

|

|

Rewind Spring ................................ |

30 |

|

|

|

Storing the Machine ........................ |

33 |

|

|

|

Maintenance Chart ......................... |

34 |

|

Printed |

Printing |

Parts and Controls .......................... |

35 |

|

Specifications |

37 |

|||

|

|

|||

|

|

Special Accessories ....................... |

38 |

|

|

|

Maintenance and Repairs ............... |

38 |

|

|

|

STIHL Incorporated |

|

|

|

USA |

Federal Emission Control |

|

|

|

Warranty Statement |

39 |

||

2006KG,Co.& |

etniPr..6PMd in |

|||

Trademarks |

41 |

|||

|

|

|||

© ANDREAS STIHL AG 40 58738 2 621A J..M0,8 |

STIHl |

|

||

English / USA

Allow only persons who understand this Manual to operate your mistblower.

To receive maximum performance and satisfaction from your STIHL mistblower, it is important that you read and understand the maintenance and safety precautions, starting on page 3, before using your mistblower.

Contact your STIHL dealer or the STIHL distributor for your area if you do not understand any of the instructions in this Manual.

!Warning!

Because a mistblower is a tool for spraying chemicals, some special safety precautions must be observed as with any other power tool to reduce the risk of personal injury.

Careless or improper use may cause serious or even fatal injury.

STIHL's philosophy is to continually improve all of its products. As a result, engineering changes and improvements are made from time-to-time. If the operating characteristics or the appearance of your mistblower differs from those described in this Manual, please contact your STIHL dealer for information and assistance.

SR 340, SR 420 |

1 |

English / USA

Guide to Using this Manual

Pictograms

All the pictograms attached to the machine are shown and explained in this manual.

The operating and handling instructions are supported by illustrations.

Symbols in text

The individual steps or procedures described in the manual may be marked in different ways:

:A bullet marks a step or procedure without direct reference to an illustration.

A description of a step or procedure that refers directly to an illustration may contain item numbers that appear in the illustration.

Example:

Loosen the screw (1) Lever (2) ...

In addition to the operating instructions, this manual may contain paragraphs that require your special attention. Such paragraphs are marked with the symbols described below:

Warning where there is a risk of an accident or personal injury or

serious damage to property.

Caution where there is a risk of damaging the machine or its individual components.

Caution where there is a risk of damaging the machine or its individual components.

Note or hint which is not essential for using the machine, but may improve the operator’s understanding of the situation and result in better use of the machine.

Note or hint which is not essential for using the machine, but may improve the operator’s understanding of the situation and result in better use of the machine.

Note or hint on correct procedure in

Note or hint on correct procedure in

order to avoid damage to the environment.

order to avoid damage to the environment.

Equipment and features

This instruction manual may refer to several models with different features. Components that are not installed on all models and related applications are marked with an asterisk (*). Such components may be available as special accessories from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually improve all of its products. As a result, engineering changes and improvements are made from time to time. If the operating characteristics or the appearance of your machine differ from those described in this manual, please contact your STIHL dealer for assistance.

Therefore some changes, modifications and improvements may not be covered in this manual.

2 |

SR 340, SR 420 |

Safety Precautions and

Working Techniques

Because the mistblower is a tool for spraying chemicals, special safety

precautions must be observed to reduce the risk of personal injury.

It is important that you read, fully understand and observe the following general safety precautions and warnings. Read the

instruction manual and the safety precautions periodically. In addition, read and follow the chemical manufacturer’s instructions for the chemical products being applied. Since such products may vary greatly in handling/application requirements and risks, the product label is normally your best guide for safe and effective use.

!Warning!

Read the label each time before mixing or using the chemical and before storing or disposing of it. Do not trust your memory. Careless or improper use may cause serious or fatal injury.

Have your STIHL dealer show you how to operate your power tool. Observe all applicable local safety regulations, standards and ordinances.

All operating and servicing personnel should be trained and familiarized with the proper handling procedures for the chemical products being used, as well as with first aid/emergency care, and liquid chemical disposal regulations.

!Warning!

Do not lend or rent your power tool without the instruction manual. Be sure that anyone using it understands the information contained in this manual.

!Warning!

The chemicals sprayed with your power tool may contain toxic and/or caustic substances. Such chemicals can be dangerous and cause serious or fatal injury to persons and animals and/or severe damage to plants and the environment.

Avoid direct contact with chemicals. Follow the chemical manufacturer’s instructions with respect to any contact with its product.

Use your power tool for spraying chemicals and other liquids to control pests and weeds in fruit, flower and vegetable gardens, on trees and bushes and on other plants, such as coffee, tobacco and cotton. It is also useful in the maintenance of young trees, controlling the bark beetle and other plant diseases.

English / USA

!Warning!

Do not use it for other purposes, since misuse may result in personal injury or property damage, including damage to the machine.

!Warning!

Minors should never be allowed to use this power tool. Bystanders, especially children, and animals should not be allowed in the area where it is in use.

!Warning!

To reduce the risk of injury to bystanders and damage to property, never let your power tool run unattended. When it is not in use (e.g. during a work break), shut it off and make sure that unauthorized persons do not use it.

Most of these safety precautions and warnings apply to the use of all STIHL mistblowers. Different models may have different parts and controls. See the appropriate section of your instruction manual for a description of the controls and the function of the parts of your model.

Safe use of a mistblower involves

1.the operator

2.the power tool

3.the use of the power tool

4.the handling of the chemicals to be sprayed.

SR 340, SR 420 |

3 |

English / USA

THE OPERATOR Physical Condition

You must be in good physical condition and mental health and not under the influence of any substance (drugs, alcohol, etc.) which might impair vision, dexterity or judgment. Do not operate this machine when you are fatigued.

!Warning!

Be alert – if you get tired, take a break. Tiredness may result in loss of control. Working with any power tool can be strenuous. If you have any condition that might be aggravated by strenuous work, check with your doctor before operating this machine.

!Warning!

Prolonged use of a power tool (or other machines) exposing the operator to vibrations may produce whitefinger disease (Raynaud's phenomenon) or carpal tunnel syndrome.

These conditions reduce the hand's ability to feel and regulate temperature, produce numbness and burning sensations and may cause nerve and circulation damage and tissue necrosis.

All factors which contribute to whitefinger disease are not known, but cold weather, smoking and diseases or physical conditions that affect blood vessels and blood transport, as well as high vibration levels and long periods of exposure to vibration are mentioned as factors in the development of whitefinger disease. In order to reduce the risk of whitefinger disease and carpal tunnel syndrome, please note the following:

–Most STIHL power tools are available with an anti-vibration (“AV”) system designed to reduce the transmission of vibrations created by the machine to the operator's hands. An AV system is recommended for those persons using power tools on a regular or sustained basis.

–Wear gloves and keep your hands warm.

–Keep the AV system well maintained. A power tool with loose components or with damaged or worn AV buffers will tend to have higher vibration levels.

–Maintain a firm grip at all times, but do not squeeze the handles with constant, excessive pressure. Take frequent breaks.

All the above-mentioned precautions do not guarantee that you will not sustain whitefinger disease or carpal tunnel syndrome. Therefore, continual and regular users should closely monitor the condition of their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

!Warning!

The ignition system of the STIHL unit produces an electromagnetic field of a very low intensity. This field may interfere with some pacemakers. To reduce the risk of serious or fatal injury, persons with a pacemaker should consult their physician and the pacemaker manufacturer before operating this tool.

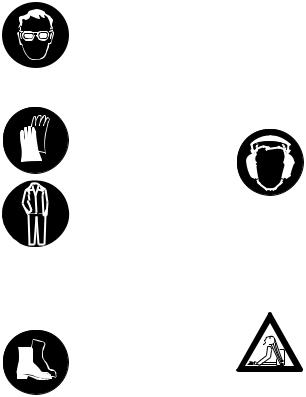

Proper Clothing

!Warning!

To reduce the risk of injury when working with chemical agents, the operator should wear proper protective apparel when filling, using and cleaning the power tool. Always follow all of the chemical manufacturer’s instructions with respect to proper eye, skin, nose and mouth protection. They may differ from and exceed the following precautions.

4 |

SR 340, SR 420 |

English / USA

!Warning!

To reduce the risk of injury to your eyes you may

need to wear protective goggles when operating your power tool. Check the product label for the

chemical you are spraying.

Always wear rubber/ chemical-resistent gloves when handling the power tool.

For some chemicals it is advisable to wear

impermeable coveralls or an impermeable work

apron. Check the product label. If you are spraying overhead or if the spray may reach head

apron. Check the product label. If you are spraying overhead or if the spray may reach head

height, wear a wide brim hat or other suitable head covering. Do not wear shorts, sandals or go barefoot.

Wear rubber/chemicalresistent boots.

!Warning!

When working with toxic chemicals, the operator and any bystanders may need to wear a properly fitted respirator approved by NIOSH/MSHA for the chemical being used. Consult the product label. Breathing toxic chemicals can cause serious or fatal injury.

!Warning!

Power tool noise may damage your hearing.

Wear sound barriers (ear plugs or ear mufflers) to

help protect your hearing. Continual and regular

users should have their hearing checked regularly.

Be particularly alert and cautious when wearing hearing protection because your ability to hear warnings (shouts, alarms, etc.) is restricted.

Avoid loose-fitting jackets, scarfs, neckties, jewelry,

flared or cuffed pants, unconfined long hair or anything that could become caught on

branches, brush or the moving parts of the unit. Secure hair so it is above shoulder level.

!Warning!

Mistblowers may usually also be used in greenhouses that are well ventilated if the operator can protect himself or herself from any harmful effects through the use of proper eye, skin, nose and mouth protection. Such work may require special precautions.

SR 340, SR 420 |

5 |

English / USA

THE POWER TOOL

For illustrations and definitions of the power tool parts see the chapter on “Main Parts and Controls.”

!Warning!

Never modify this power tool in any way. Only attachments supplied by STIHL or expressly approved by STIHL for use with the specific STIHL model are authorized. Although certain unauthorized attachments are useable with STIHL power tools, their use may, in fact, be extremely dangerous.

If this tool is subjected to unusually high loads for which it was not designed (e.g. heavy impact or a fall), always check that it is in good condition before continuing work. Check in particular that the fuel system is tight (no leaks) and that the controls and safety devices are working properly. Do not continue operating this machine if it is damaged. In case of doubt, have it checked by your STIHL servicing dealer.

!Warning!

An electrostatic charge may be created in the extension tube and nozzle area when applying dry materials (e.g. dusts) with the dusting and spreading attachment (special accessory). This is especially true in low humidity conditions. Check the label and/or material safety data sheet for the chemical you are applying. To reduce the risk of severe or fatal injury, do not use your mistblower to apply substances that may create a combustible or explosive dust cloud. For instance, never use your mistblower to apply sulfur or sulfur compounds, since they may be highly explosive and have relatively low melting and ignition points.

!Warning!

To reduce the risk of sparking when applying any dry substance, make sure that the discharge system (conductive wire in the mistblower connected to a metal chain) is completely and properly mounted to the machine, and that the discharge chain is making contact with the ground. It is essential to follow the fitting instructions supplied with the dusting and spreading attachment.

HANDLING OF CHEMICALS

!Warning!

Chemicals can be harmful to individuals, animals and the environment if improperly used. In addition, some chemicals that are caustic, corrosive or poisonous should not be used in your mistblowers.

Carefully read the labels on chemical containers prior to use. Chemicals are classified into categories of toxicity.

Pesticides regulated by the EPA, for instance, use signal words to indicate the product’s potential to make you sick. “Caution“ appears on pesticides found to be least harmful to humans. “Warning“ indicates a product that is more poisonous than those in the “Caution“ group. Pesticides with the signal word “Danger“ on the label are very poisonous or irritating. They should be used with extreme care. Finally, pesticides labeled “Danger – Poison“ are for restricted use only and generally must be used under the supervision of a certified applicator. Each category will have unique handling characteristics. Familiarize yourself with the characteristics for the category you are using.

!Warning!

Mix only compatible pesticides. Wrong mixtures can produce toxic fumes.

6 |

SR 340, SR 420 |

English / USA

When handling chemicals and when spraying, make sure you are operating in accordance with local, state, and federal environmental protection rules and guidelines. Do not spray in windy conditions.To help protect the environment, use only the recommended dosage – do not overuse.

!Warning!

Do not eat, drink, or smoke while handling chemicals or while you are spraying. Never blow through nozzles, valves, pipes or any other component by mouth. Always handle chemicals in a well ventilated area while wearing appropriate protective clothing and safety equipment. Do not store or transport chemicals with food or medicines, and never reuse a chemical container for any other purpose.

Do not transfer spray materials to other containers, especially food and/or drink containers.

!Warning!

In case of accidental contact or ingestion of chemicals or in case of contamination of clothing, stop work and immediately consult the chemical manufacturer’s instructions. If in doubt as to what to do, consult a poison control center or doctor without delay. Have the product’s label available to read to or show the persons you consult.

Clean all chemical spills immediately. Dispose of any residue in accordance with state or federal laws and regulations.

!Warning!

Keep chemicals out of reach of children, other unauthorized people or animals. When not in use, store chemicals in a safe place. Follow the manufacturer’s recommendations for proper storage.

THE USE OF THE POWER TOOL Transporting the Power Tool

Always switch off the engine before taking the machine off your back and putting it down. Empty container when transporting it in a vehicle; properly secure it to prevent turnover, fuel spillage and damage to the unit.

Fuel

Your STIHL power tool uses an oilgasoline mixture for fuel (see the chapter on “Fuel” of your instruction manual).

!Warning!

Gasoline is an extremely flammable fuel. If spilled and ignited by a spark or

other ignition source, it can cause fire and serious burn injury or property

damage. Use extreme caution when handling gasoline or fuel mix.

Do not smoke or bring any fire or flame near the fuel or the power tool. Note that combustible fuel vapor may escape from the fuel system.

SR 340, SR 420 |

7 |

English / USA

Fueling Instructions

!Warning!

To reduce the risk of serious injury from burns, never attempt to refuel the unit until it has been completely removed from the operator.

!Warning!

Fuel your power tool in well-ventilated areas, outdoors. Always shut off the engine and allow it to cool before refueling. Gasoline vapor pressure may build up inside the fuel tank depending on the fuel used, the weather conditions and the tank venting system.

In order to reduce the risk of burns and other personal injury from escaping gas vapor and fumes, remove the fuel filler cap on your power tool carefully so as to allow any pressure build-up in the tank to release slowly. Never remove the fuel filler cap while the engine is running.

Select bare ground for fueling and move at least 10 feet (3 m) from the fueling spot before starting the engine. Wipe off any spilled fuel before starting your machine.

!Warning!

Check for fuel leakage while refueling and during operation. If fuel leakage is found, do not start or run the engine until the leak is fixed and any spilled fuel has been wiped away. Take care not to get fuel on your clothing. If this happens, change your clothing immediately.

Different models may be equipped with different fuel caps.

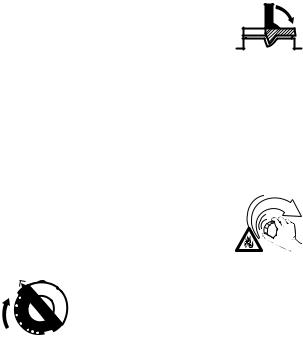

Cap with grip

!Warning!

In order to reduce the risk of fuel spillage and fire from an improperly tightened fuel cap, correctly position and tighten the fuel cap in the fuel tank opening.

To do this with this STIHL

cap, raise the grip on the

top of the cap until it is

upright at a 90° angle. Insert the cap in the fuel tank opening with the

triangular marks on the grip of the cap and on the fuel tank opening lining up. Using the grip, turn the cap firmly clockwise as far as it will go (approx. a quarter turn).

Fold the grip flush with the top of the cap. If the grip

does not lie completely flush with the cap and the detent on the grip does not fit in the

corresponding recess in the filler opening, the cap is not properly seated and tightened and you must repeat the above steps.

Screw cap

!Warning!

Unit vibrations can cause an improperly tightened

fuel filler cap to loosen or

come off and spill

quantities of fuel. In order to reduce the risk of fuel spillage and fire, tighten the fuel filler cap

quantities of fuel. In order to reduce the risk of fuel spillage and fire, tighten the fuel filler cap

by hand as securely as possible.

8 |

SR 340, SR 420 |

English / USA

Filling the Container

!Warning!

Tighten all connections and check to be sure the hose is securely attached and in good condition. Keep the stop cock closed.

Before using the power tool with chemicals, fill it with fresh water to assure that you have it properly assembled and practice spraying. Also, check for any leaks at this time. When thoroughly familiar with the power tool operation, follow normal operating procedures.

Fill your power tool in well-ventilated areas, outdoors.

!Warning!

Do not use:

–flammables in the mistblower, which can explode causing serious or fatal injury;

–caustic or corrosive materials in the mistblower, which could result in damage to the unit;

–liquids with a temperature above 120° F (50° C) to avoid scalding and damage to the unit.

To fill the power tool, place it on a level surface. To reduce the risk of contaminating the surrounding environment, be careful not to overfill the container with chemical solution.

If you fill the container with a hose attached to a central water supply, be sure the end of the hose is out of the solution to reduce the risk of backflow, i.e. the chemicals being sucked into the water supply in the case of a sudden vacuum.

Calculate the correct amount of chemical solution so that it is used up at one time, with no extra solution left in the tank.

!Warning!

Check for leakage while refilling and during operation. A leak from the container or a loose fitting could soak your clothing and come into contact with your skin.

Before Starting

!Warning!

Always check your power tool for proper condition and operation before starting, particularly the throttle trigger, setting lever and stop switch. The throttle trigger must move freely and always spring back to the idle position. Never attempt to modify the controls or safety devices.

!Warning!

To reduce the risk of leakage and skin contact with chemicals, check that the cap and all connections are tight, and be sure the hose is securely attached and in good condition. Keep the stop cock closed.

!Warning!

Never use a power tool that is damaged or not properly maintained.

!Warning!

Check that the spark plug boot is securely mounted on the spark plug – a loose boot may cause arcing that could ignite combustible fumes and cause a fire.

Keep the handles clean and dry at all times; it is particularly important to keep them free of moisture, pitch, oil, fuel mix, grease or resin in order for you to maintain a firm grip and properly control your power tool.

SR 340, SR 420 |

9 |

English / USA

!Warning!

To reduce the risk of injury from thrown parts, check the fan housing for damage (cracks, nicks, chipping). If any damage is found, stop using the unit and contact your STIHL dealer for repair.

Starting

Start the engine at least 10 feet (3 meters) from the fueling spot, outdoors only.

!Warning!

Your power tool is a one-person machine. To reduce the risk of eye or other injury from thrown objects, insure that by-standers are at least 50 feet (15 m) away during use. Stop operation immediately if you are approached.

For specific starting instructions, see the appropriate section of your manual. Place the power tool on firm ground or other solid surface in an open area. Maintain good balance and secure footing.

!Warning!

When you pull the starter grip, do not wrap the starter rope around your hand. Do not let the grip snap back, but guide the starter rope to rewind it properly. Failure to follow this procedure may result in injury to your hand or fingers and may damage the starter mechanism.

The assistance of another person may be needed in placing the unit on your back after starting. In order to reduce the risk of injury to the assistant from thrown objects, chemical spray/dust or from contact with hot exhaust fumes, the engine should be kept at idle speed during this brief period, and your assistant should not stand in the area of the outlet nozzle or exhaust. Otherwise, the unit should be started and operated without assistance.

During Operation

Holding and controlling the power tool

372BA019 KN

The mistblower is designed for singlehanded operation with the right hand on the control handle. It should be carried as a backpack with the straps of the harness over both shoulders.

!Warning!

To reduce the risk of loss of control, never carry the unit with the strap(s) over one shoulder.

Wrap your fingers tightly around the handle, keeping the control handle cradled between your thumb and forefinger. Keep your hand in this position to have your machine under control at all times.

10 |

SR 340, SR 420 |

English / USA

!Warning!

Adjust carrying harness to suit your size before starting work.

In an emergency, you may slip out of the harness and throw off the machine quickly. Try slipping out of the harness a number of times before using the machine in order to become accustomed to it. Do not throw off the machine while practicing as it could damage the machine.

!Warning!

In order to keep the container upright and reduce the risk of spillage, do not bend at the waist. Bend only at the knees and support yourself as required to ensure proper balance.

Remember that a mistblower filled with liquid has a significant amount of weight. Use caution when bending, leaning or walking.

!Warning!

Do not overreach. Keep proper footing and balance at all times. Special care must be taken in slippery conditions (wet ground, snow) and in difficult, overgrown terrain. Watch for hidden obstacles such as tree stumps, roots and ditches to avoid stumbling. For better footing, clear away fallen branches, scrub and cuttings. Be extremely cautious when working on slopes or uneven ground.

To reduce the risk of stumbling and loss of control, do not walk backward while operating the machine.

!Warning

To reduce the risk of injury from loss of control, never work on a ladder, in a tree or on any other insecure support.

Working conditions

Operate and start your power tool only outdoors in a well ventilated area. Operate it under good visibility and daylight conditions only. Work carefully.

!Warning!

As soon as the engine is running, this product

generates toxic exhaust fumes containing chemicals, such as unburned hydrocarbons

(including benzene) and carbon monoxide, that are known to cause respiratory problems, cancer, birth defects, or other reproductive harm. Some of the gases (e.g. carbon monoxide) may be colorless and odorless. To reduce the risk of serious or fatal injury/illness from inhaling toxic fumes, never run the machine indoors or in poorly ventilated locations.

!Warning!

Inhalation of chemicals can cause susceptible persons to have an allergic or asthmatic reaction. Substantial or repeated inhalation of certain chemicals may cause respiratory disease, cancer, birth defects or other reproductive harm. Control the chemical spray/dust at the source where possible. Use good work practices, such as operating the unit so that the wind or operating process does not blow the chemical spray/dust back on the operator. Follow the recommendations of EPA/OSHA/ NIOSH and occupational and trade associations with respect to proper usage. When the inhalation of the chemical spray/dust being applied cannot be avoided, the operator and any bystanders may need to wear a respirator approved by NIOSH/MSHA for the type of chemical encountered. Consult the label of the chemical product being used.

SR 340, SR 420 |

11 |

English / USA

!Warning!

If you are unfamiliar with the risks associated with the particular chemical at issue, review the product label and/or material safety data sheet for that substance and/or consult the material manufacturer/supplier. You may also consult your employer, governmental agencies such as the EPA, OSHA and NIOSH and other sources on hazardous materials. The state of California and some other authorities, for instance, have published lists of substances known to cause cancer, reproductive toxicity, etc.

Operating instructions

!Warning!

In the event of an emergency, switch off the engine immediately – move the slide control / stop switch to 0 or STOP.

!Warning!

Never spray in the direction of humans, animals or property which might be injured or damaged by spray formula.

Pay attention to the direction of the wind, i.e., do not work against the wind. When spraying, stand so that the wind does not blow towards you or bystanders.

Keep children and pets away from areas that have just been sprayed. After the use of some chemicals, especially agricultural pesticides, a notice must be posted on the treated area that a “Restricted Entry Interval“ (REI) is in effect. See the product’s label and any applicable governmental regulations.

Danger!

Your power tool is not insulated against electric shock. To reduce the risk of electrocution, never

operate this power tool in the vicinity of any wires or cables (power, etc.) which may be carrying electric current. Do not spray on or near electrical installations.

!Warning!

To reduce the risk of personal injury, do not direct air blast towards bystanders, since the high pressure of the air flow could injure eyes and could blow small objects at great speed.

!Warning!

Always shut off the engine before cleaning or servicing the unit or replacing parts.

!Warning!

The blower fan between the air intake and output openings rotates whenever the engine is running.

Never insert any foreign object into the air intake of the machine or into the nozzle of the blower. It will damage the fan wheel and may cause serious injury to the operator or bystanders as a result of the object or broken parts being thrown out at high speed.

Do not place the blower on the ground when operating at high speed, because small objects such as sand, grass, dust, etc. may be pulled into the air intake and damage the fan wheel.

!Warning!

The muffler and other parts of the engine (e.g. fins of the cylinder, spark plug) become hot during operation and remain hot for a while after stopping the engine. To reduce risk of burns do not touch the muffler and other parts while they are hot.

12 |

SR 340, SR 420 |

English / USA

!Warning!

To reduce the risk of fire and burn injury, keep the area around the muffler clean. Remove excess lubricant and all debris such as pine needles, branches or leaves. Let the engine cool down sitting on concrete, metal, bare ground or solid wood (e.g. the trunk of a felled tree) away from any combustible substances.

!Warning!

Never modify your muffler. The muffler could be damaged and cause an increase in heat radiation or sparks, thereby increasing the risk of fire and burn injury. You may also permanently damage the engine. Have your muffler serviced and repaired by your STIHL servicing dealer only.

After Finishing Work

Always wash thoroughly with soap and water after spraying or handling chemicals. Shower immediately, and wash all protective clothing separately from other items. Follow any additional recommendations of the chemical manufacturer.

Always clean dust and dirt off the power tool.

!Warning!

Empty, rinse and clean container and assembly after each use. This helps to prevent the solution from crystallizing, which could later cause clogging and chemical damage to the unit. In addition; residual chemicals may have undesirable effects during subsequent spraying with a different type of chemical (e.g., residual herbicide may damage or kill plants being sprayed with a pesticide).

Disposal of contaminated rinse should be in accordance with applicable ordinances. Observe the precautionary instructions of the chemical manufacturer.

Do not store the mistblower with spray solution in the container.

MAINTENANCE, REPAIR AND STORING

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. However, if you make a warranty claim for a component which has not been serviced or maintained properly or if nonapproved replacement parts were used, STIHL may deny coverage.

!Warning!

Use only identical STIHL replacement parts for maintenance and repair. Use of non-STIHL parts may cause serious or fatal injury.

Strictly follow the maintenance and repair instructions in the maintenance chart near the end of the instruction manual.

!Warning!

Always stop the engine and make sure that the fan is stopped before doing any maintenance or repair work or cleaning the power tool.

SR 340, SR 420 |

13 |

English / USA

!Warning!

Do not attempt any maintenance or repair work not described in your instruction manual. Have such work performed by your STIHL servicing dealer only.

!Warning!

Use the specified spark plug and make sure it and the ignition lead are always clean and in good condition. Always press spark plug boot snugly onto spark plug terminal of the proper size. (Note: If terminal has detachable SAE adapter nut, it must be securely attached.) A loose connection between spark plug terminal and the ignition wire connector in the boot may create arcing that could ignite combustible fumes and cause a fire.

Assembling the Machine

!Warning!

Never test the ignition system with the spark plug boot removed from the spark plug or with a removed spark plug, since uncontained sparking may cause a fire.

!Warning!

Do not operate your power tool if the muffler is damaged, missing or modified. An improperly maintained muffler will increase the risk of fire and hearing loss. If your muffler was equipped with a spark-arresting screen to reduce the risk of fire, never operate your power tool if the screen is missing or damaged. Remember that the risk of forest fires is greater in hot or dry weather.

Tighten all nuts, bolts and screws, except the carburetor adjustment screws, after each use.

For any maintenance of the emission control system please refer to the maintenance chart and to the limited warranty statement near the end of the instruction manual.

Store the power tool in a dry and high or locked location out of reach of children. Before storing for longer than a few days, always empty the fuel tank. See chapter "Storing the machine" in this manual.

The throttle cable is already connected and must not be kinked during assembly.

The throttle cable is already connected and must not be kinked during assembly.

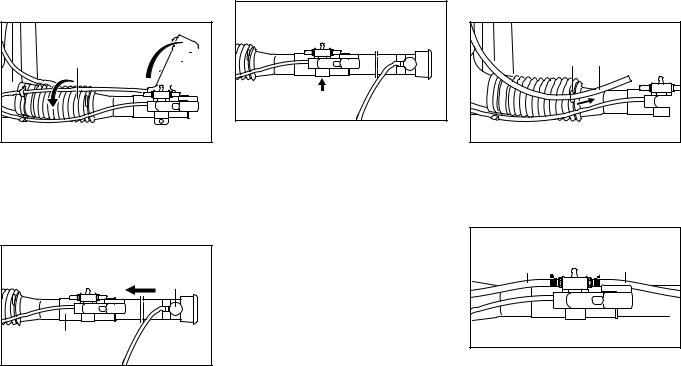

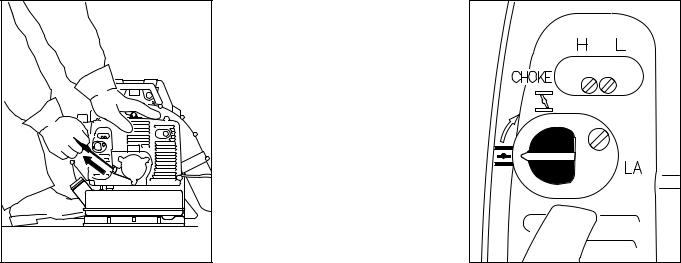

Mounting the elbow

2

3 |

|

KN |

1 |

372BA023 |

|

The combination wrench and carburetor screwdriver are stowed on the underside of the machine.

:Line up the stops on the elbow and stub and push the elbow (1) into the stub (2) as far as it will go.

:Fit the nut (3) in the hexagon recess in the stub.

:Insert the screw in the nut from the other side and tighten moderately – the elbow must still turn.

14 |

SR 340, SR 420 |

English / USA

Mounting the extension tube

1

2

2

372BA024 KN

:Rotate the pleated hose (1) as far as stop.

:Turn the control handle (2) so that it is horizontal.

|

4 |

|

|

3 |

|

1 |

KN |

|

372BA025 |

||

|

:Push the extension tube (3) into the pleated hose (1) as far as it will go.

:The metering unit (4) must point in the same direction as the control handle.

|

KN |

5 |

372BA026 |

|

:Tighten down the clamp screw (5) (see “Adjusting the control handle”).

Fitting the liquid hose

2 |

1 |

|

372BA027 KN |

: Secure liquid hose (1) from the container to the pleated hose with the retainer (2).

1 |

4 |

4 |

3 |

|

|

|

372BA028 KN |

:Use hose clips (4) to secure hose (1) and hose (3) to the stubs on the stop cock.

:Close the stop cock (move lever to vertical position).

:Fill up with water and check all hose connections for leaks.

SR 340, SR 420 |

15 |

English / USA

Adjusting the control handle

|

2 |

1 |

372BA029 KN |

:Put the machine on your back.

:Loosen the clamp screw (1).

:Slide the control handle (2) along the tube to the most comfortable position.

:Tighten down the clamp screw (1) firmly.

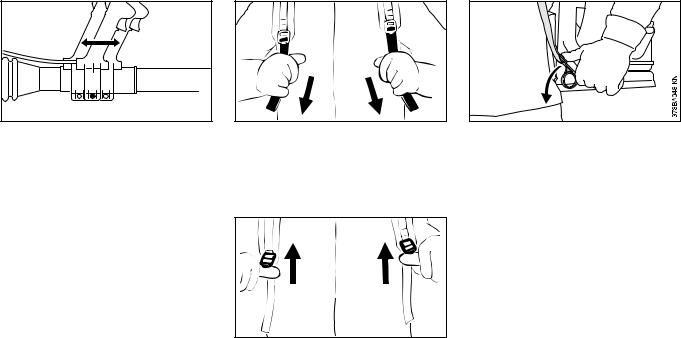

Harness

Adjusting the Harness

373BA003 KN

:Pull the ends of the straps downward to tighten the harness.

Loosening the Harness

373BA004 KN

:Lift the tabs of the sliding adjusters.

:Adjust the straps so that the backplate is held firmly and comfortably against your back.

Throwing Off Backpack

Before using the machine, make yourself familiar with how to release and throw off the backpack.

In an emergency, quickly throw the machine off your back as follows:

:Open the quick-release fastener on the waist belt (special accessory).

:Open the strap hook on the backplate by snapping it forwards (arrow).

:Throw the machine to the rear.

16 |

SR 340, SR 420 |

Fuel

This engine is certified to operate on unleaded gasoline and the STIHL twostroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of highquality gasoline and quality two-stroke air cooled engine oil.

Use mid-grade unleaded gasoline with a minimum octane rating of 89 (R+M/2). If the octane rating of the mid-grade gasoline in your area is lower, use premium unleaded fuel.

Fuel with a lower octane rating may increase engine temperatures. This, in turn, increases the risk of piston seizure and damage to the engine.

The chemical composition of the fuel is also important. Some fuel additives not only detrimentally affect elastomers (carburetor diaphragms, oil seals, fuel lines, etc.), but magnesium castings and catalytic converters as well. This could cause running problems or even damage the engine. For this reason STIHL recommends that you use only nationally recognized high-quality unleaded gasoline!

English / USA

Use only STIHL two-stroke engine oil or equivalent high-quality two-stroke engine oils that are designed for use only in air cooled two-cycle engines.

We recommend STIHL 50:1 two-stroke engine oil since it is specially formulated for use in STlHL engines.

Do not use BIA or TCW rated (twostroke water cooled) mix oils or other mix oils that state they are for use in both water cooled and air cooled engines (e.g., outboard motors, snowmobiles, chainsaws, mopeds, etc.).

Take care when handling gasoline. Avoid direct contact with the skin and avoid inhaling fuel vapor. When filling at the pump, first remove the canister from your vehicle and place the canister on the ground before filling. Do not fill fuel canisters that are sitting in or on a vehicle.

The canister should be kept tightly closed in order to avoid any moisture getting into the mixture.

The machine‘s fuel tank and the canister in which fuel mix is stored should be cleaned as necessary.

Fuel mix ages

Only mix sufficient fuel for a few days work, not to exceed 3 months of storage. Store in approved fuel-canisters only. When mixing, pour oil into the canister first, and then add gasoline. Close the canister and shake it vigorously by hand to ensure proper mixing of the oil with the fuel.

Gaso- |

Oil (STIHL 50:1 or |

line |

equivalent high-quality oils) |

US gal. |

US fl.oz |

1 |

2.6 |

2 1/2 |

6.4 |

5 |

12.8 |

Dispose of empty mixing-oil canisters only at authorized disposal locations.

SR 340, SR 420 |

17 |

English / USA |

|

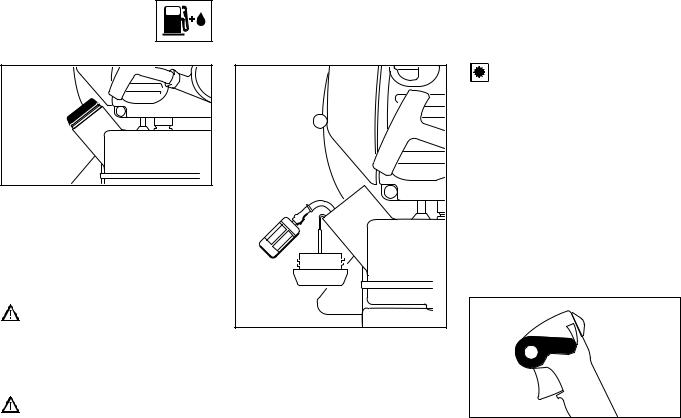

Fueling |

Information |

|

Before You Start |

373BA030 KN

Before fueling, clean the filler cap and the area around it to ensure that no dirt falls into the tank.

Always thoroughly shake the mixture in the canister before fueling your machine.

In order to reduce the risk of burns or other personal injury from

escaping gas vapor and fumes, remove the fuel filler cap carefully so as to allow any pressure build-up in the tank to release slowly.

After fueling, tighten fuel cap

as securely as possible by hand.

373BA007 KN |

Change the fuel pick up body every year.

Before storing your machine for a long period, drain and clean the fuel tank and run engine until carburetor is dry.

With the engine stopped and before starting, check the air intakes between the backplate and powerhead for blockages and clean if necessary.

With the engine stopped and before starting, check the air intakes between the backplate and powerhead for blockages and clean if necessary.

A protective screen is available as a special accessory to keep the air intakes clear.

The throttle cable disconnects itself from the throttle trigger if the engine is not shut off in the idle position.

The throttle cable reconnects itself automatically when the setting lever is moved to the idle position.

373BA037 KN

:Move the setting lever to the idle position.

18 |

SR 340, SR 420 |

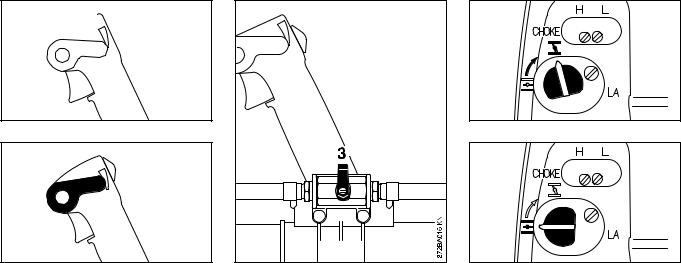

Starting / Stopping

the Engine

1

1

373BA008 KN

2

373BA009 KN

: Observe safety precautions – see chapter on “Safety Precautions and Working Techniques”.

: Slide the stop switch (1) to #

: Move the setting lever (2) to the center position – this is the starting throttle position

The setting lever can be used to select any throttle opening between idle speed (lower stop) and full throttle (upper stop).

Set the lever to the idle position before switching off the engine.

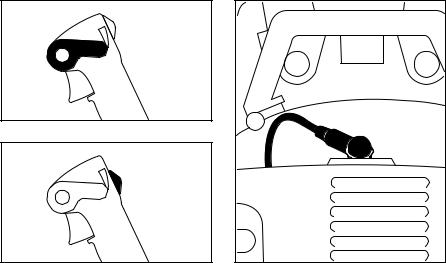

Before starting

:Move stop cock lever (3) to upright position.

English / USA

373BA010 KN

373BA011 KN

:If the engine is cold, turn the choke knob to g

:If the engine is warm, turn the choke lever to e

Also use this position if the engine has been running but is still cold.

SR 340, SR 420 |

19 |

English / USA

373BA012 KN |

:Pull the starter grip slowly with your right hand until you feel it engage and then give it a brisk strong pull. Do not pull the starter rope out all the way as it might otherwise break.

:Do not let the starter grip snap back.

:Guide it slowly back into the housing so that the starter rope can rewind properly.

373BA013 KN |

:Put the unit on the ground. Check that bystanders are well clear of the general work area and the nozzle.

:Make sure you have a firm footing: Hold the unit with your left hand on the housing and put one foot against the base plate to prevent it slipping.

When engine begins to fire:

:If engine is cold:

Turn choke knob to eand continue cranking until engine runs.

:If engine is warm:

Continue cranking until engine runs.

20 |

SR 340, SR 420 |

English / USA

2 |

|

373BA014 KN |

|

1 |

|

373BA015 KN |

373BA016 KN |

:Fit the spark plug and reconnect the spark plug boot.

:Move the stop switch to #

:Turn the choke knob to e even if the engine is cold.

:Now start the engine.

Fuel tank run until dry and then refueled

:Pull the starter rope several times to prime the fuel line.

As soon as engine runs:

:Move the setting lever (2) to the lower stop so that the engine settles down to idle speed.

To shut down the engine:

:Move the stop switch (1) to 0 or

STOP.

At very low outside temperatures: Allow engine to warm up

As soon as engine runs:

:Move the setting lever to the lower stop – the engine settles down to idle speed.

:Open throttle slightly – warm up engine for a short period.

If the engine does not start:

If you did not turn the choke knob to e quickly enough after the engine began to fire, the combustion chamber is flooded.

:Pull off the spark plug boot.

:Unscrew and dry off the spark plug.

:Move the stop switch to 0 or STOP.

:Open the throttle wide.

:Pull the starter rope several times to clear the combustion chamber.

SR 340, SR 420 |

21 |

English / USA

Calculating Required

Quantity of Solution

Step 1:

Determine surface area (m2)

In the case of ground crops, multiply the length of the field by its width.

The surface area of high-growing plants is calculated approximately by multiplying the length of the rows by the average height of the foliage. The result is multiplied by the number of rows and then by two if both sides have to be treated.

The area in hectares is obtained by dividing the number of square meters by 10,000.

Example:

A field 120 meters long and 20 meters wide has to be treated with a pesticide.

Area:

120 m x 30 m = 3,600 m2

3,600 / 10,000 = 0.36 ha

Step 2:

Determine quantity of active ingredient

Refer to the instructions supplied with the active ingredient to determine:

:Required quantity of active ingredient for 1 hectare (ha) and the

:concentration of active ingredient (mix ratio)

Multiply the required quantity of active ingredient for 1 ha by the area determined in Step 1. The result is the quantity of active ingredient required for the area to be treated.

Example:

According to the maker’s instructions, 0.4 liters of active ingredient are required per hectare to obtain a concentration of 0.1%.

Quantity of active ingredient:

0.4 (l/ha) x 0.36 (ha) = 0.144 l

Step 3:

Determine quantity of solution

The required quantity of solution is calculated as follows:

TW

–––– x 100 = TB K

Where:

TW = Quantity of active ingredient in l K = Concentration in %

TB = Required quantity of solution in l

Example:

In Step 2 the quantity of active ingredient required was calculated to be 0.144 l. According to the maker’s instructions, the concentration is 0.1%.

Quantity of solution:

0.144 l

––––– x 100 = 144 l 0.1%

22 |

SR 340, SR 420 |

Step 4:

Determine walking speed

Carry out a trial run with the machine fueled and the container filled with water. Operate the spray tube (swing it back and forth) as it will be during the real run described below. Determine the distance walked in one minute.

Also use the trial run to check the selected working width. In the case of low-growing crops, the best working width is 4-5 m. The working width should be marked with stakes.

Dividing the distance in meters by the time in minutes gives you the walking speed in meters per minute (m/min).

Example:

The distance covered in one minute is 10 meters.

Walking speed:

10 m

––––– = 10 m/min 1 min

Step 5:

Determine discharge rate

The setting of the metering knob is calculated as follows:

Va (l) x vb (m/min) x b(m)

–––––––––––––––––––––– = Vc (l/min)

A (m2)

Va = Quantity of solution vb = Walking speed

Vc = Discharge rate b = Working width A = Area

Example:

The values determined in Steps 1-4 and a working width of 4 m produce the following discharge rate (setting of metering knob):

144 l x 10 (m/min) x 4 m

–––––––––––––––––––– = 1.6 l/min 3,600 m2

Hectares (ha) have to be converted into m2 (ha x 10,000 = m2).

English / USA

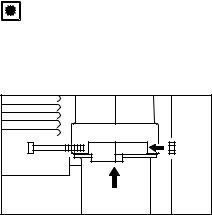

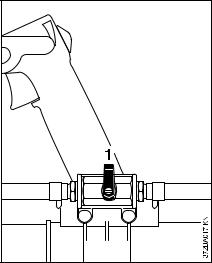

Metering Unit

:The stop cock (1) is closed when the lever is upright.

:The stop cock (1) is open when the lever is parallel to the hose.

:Adjust the discharge rate with the metering knob – not the stop cock.

SR 340, SR 420 |

23 |

English / USA

|

1 |

2 |

|

2 |

4 |

6 |

|

3 |

|

5 |

4 |

|

||

|

|

|

|

|

|

|

3 |

|

372BA005 KN |

|

|

|

|

:The discharge rate can be infinitely varied by turning the metering knob (2) on the nozzle (3).

:Position 1 = minimum flow rate

:Position 6 = maximum flow rate

The required number on the metering knob must be lined up with the molded lug (4) under the knob.

Discharge rate without pressure pump1)

Knob |

Discharge rate (l/min) |

|

position |

SR 340 |

SR 420 |

1 |

0.08 |

0.12 |

2 |

0.41 |

0.44 |

3 |

0.85 |

0.86 |

4 |

1.28 |

1.27 |

5 |

1.59 |

1.58 |

6 |

1.81 |

1.81 |

Discharge rate without pressure |

||

pump, with ULV nozzle1) |

|

|

ULV nozzle |

Discharge rate (l/min) |

|

|

SR 340 |

SR 420 |

0.5 |

0.03 |

0.03 |

0.65 |

0.06 |

0.07 |

0.8 |

0.10 |

0.10 |

1)Table shows the mean discharge rates at full throttle with spray tube at 0° and 30° to horizontal.

Discharge rate with pressure pump (special accessory)

Metering |

Discharge rate (l/min) |

|

nozzle |

SR 340 |

SR 420 |

1.0 |

0.57 |

0.64 |

1.6 |

1.70 |

1.88 |

2.02.90 3.13

Discharge rate with pressure pump (special accessory) and ULV nozzle

ULV nozzle |

Discharge rate (l/min) |

||

|

|

SR 340 |

SR 420 |

|

0.5 |

0.10 |

0.10 |

0.65 |

0.16 |

0.20 |

|

0.8 |

0.28 |

0.42 |

|

24 |

SR 340, SR 420 |

Checking metering unit

:Place the machine on the ground.

:Remove the baffle screen and pressure pump.

:Fill the container with water up to 10 liter mark.

:Set the metering knob to “6”

:Start the machine.

:Hold the spray tube horizontally, run the engine at full throttle, spray the contents of the container down to the 5 liter mark and note the time taken.

The time required to spray 5 liters fluid should be between 140 and 170 seconds.

In case of deviations:

:Check the metering unit for contamination and clean it if necessary.

:Check engine setting and correct if necessary.

If no there is no improvement, contact your dealer for assistance.

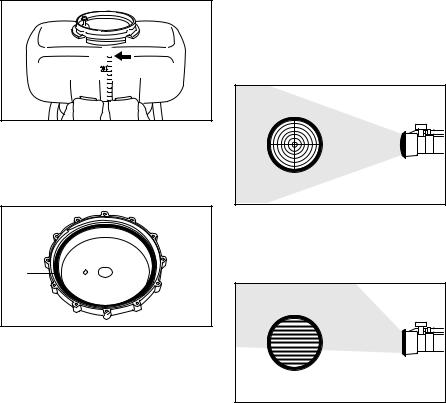

Filling the Container

:Stand the machine on a level surface.

:Close the stop cock.

372BA029 KN

:Fill up with thoroughly mixed spray solution – do not exceed maximum level of 13 liters (arrow).

English / USA

Mistblowing

:Always use full throttle when mistblowing.

:Stop cock must be fully open while mistbllowing – do not vary the flow rate via the stop cock.

Different baffle screens enable the shape of the spray jet to be varied.

Tapered baffle screen

372BA006 KN |

1

372BA021 KN

:The gasket (1) in the cap must always be lubricated with grease.

:Fit the cap and screw it down tightly.

Spray is finely atomized – short, broad and dense spray pattern.

Deflector baffle screen

372BA007 KN |

Diverts spray jet at an angle – for underleaf treatment of low-growing crops.

SR 340, SR 420 |

25 |

Loading...

Loading...