Star Manufacturing HPD1, HPD1SHP, HPD1H Parts List

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Installation

and

Operating

Instructions

Phone: (314) 781-2777

Fax: (314) 781-3636

2M-Z4671 Rev. G 4/24/07

HEATED PERISTALTIC DISPENSER

HPD1, HPD1H, HPD1P, HPD1HP

HPD2, HPD2H, HPD2P, HPD2HP

1

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

SPECIFICATIONS

HPD1, HPD1H, HPD1P, HPD1HP

Capacity: Two 6 pound bags (Two 2.7 KG Bags)

Electrical: 120V, 60 hertz, single phase, 800 Watts; 7.10 amps

230V, 50/60 hertz, single phase, 800 Watts; 3.75 amps

Cord: 6 ft. length

Plug: 120V - NEMA 5-15P

230V - CEE7-7

Dimensions: 9 7/16" W x 20 7/16" D x 26 13/16" H (23.97 W x 51.91 D x 68.10 H cm)

Net Weight: 36 lbs. (16.34 KG)

HPD2, HPD2H, HPD2P, HPD2HP

Capacity: Four 6 pound bags (Four 2.7 KG Bags)

Electrical: 120V, 60 hertz, single phase, 950 Watts; 9 amps

230V, 50/60 hertz, single phase, 950 Watts; 4.75 amps

Cord: 6 ft. length

Plug: 120V - NEMA 5-15P

230V - CEE7-7

Dimensions: 14 5/16" W x 20 7/16" D x 26 13/16" H (36.35 W x 51.91 D x 68.10 H cm)

Net Weight: 50 lbs. (22.7 KG)

3

CAUTION

This equipment is designed and sold for commercial

use only by personnel trained and experienced in its

operation and is not sold for consumer use in and

around the home nor for use directly by the general

public in food service locations.

-IMPORTANT-

Read this manual completely before attempting

installation.

INSTALLATION

This peristaltic dispenser is equipped for the voltage

and wattage indicated on the nameplate mounted

on the back of the unit, and is designed for use on

alternating current (AC) only.

NOTE: The peristaltic dispenser should not be installed

without the four-inch (10cm) legs provided with the

machine. The legs screw into the nuts on the bottom

of the dispenser.

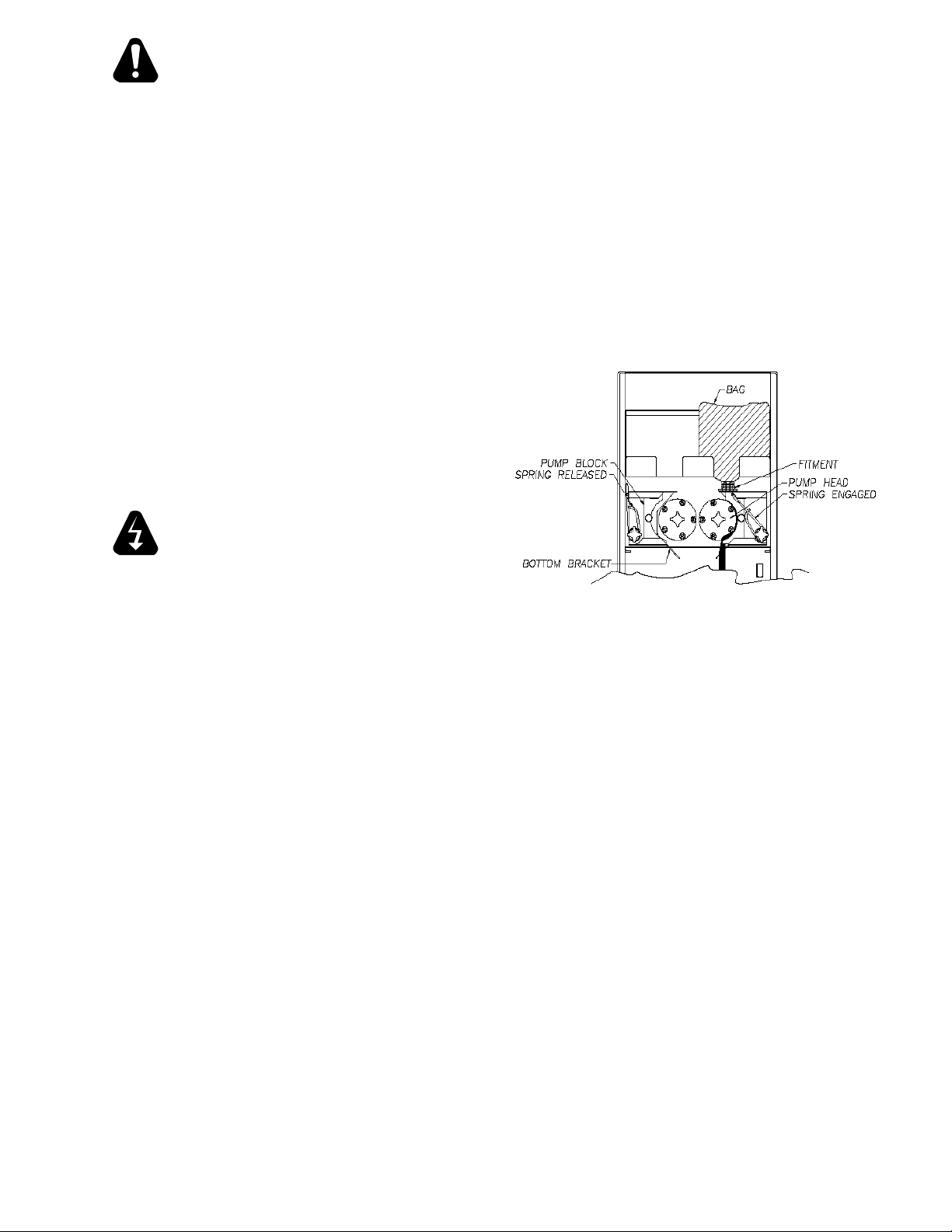

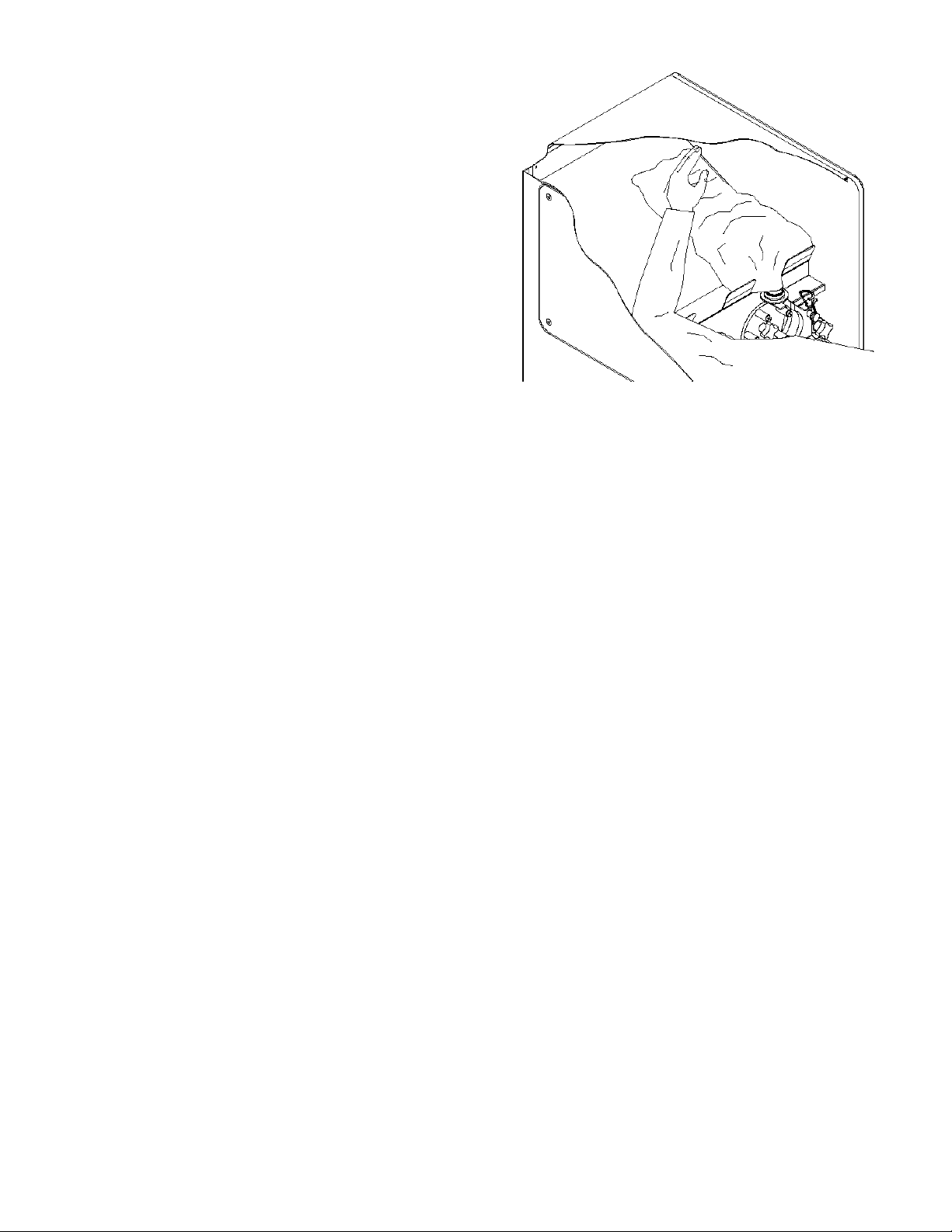

4. Insert the new bag into tray making sure the fi tment

rests on the block track and route the tube around

the rollers.

(Note: Make sure tube is not twisted)

5. Place the end of the tube in the slot of the bottom

bracket.

6. Slide the pump block towards the pump head.

7. Hook the tension spring onto the catch.

8. Route the tube through the hole in the tube cover

leaving 1/2" of the tube below the cover.

9. Dispense a small amount of product to insure

the tube is seated correctly, and the product is

fl owing.

WARNING

DO NOT CONNECT TO DIRECT CURRENT

(DC).

GENERAL OPERATING INSTRUCTIONS

This heated dispenser is designed to be used with a

9” x 18” (22.8 x 45.7cm) poly bag with a 1 inch (2.5cm)

outlet fi tment. The peristaltic dispenser is designed

to be used with 1/4 inch ID (.6cm) to

1/2 inch id. (1.3cm) tubing with 1/16 inch (.16cm) wall

thickness.

The dispenser is designed with a preset non-adjustable

thermostat. It is designed to maintain a product

temperature of 155°F +/- 10°F, This is not to be

confused with the thermometer temperature which

will be different.

Loading Product:

1. Turn the dispenser OFF.

2. Unhook the tension spring from the catch.

3. Slide the pump block away from the pump head.

PORTION CONTROL

This dispenser is supplied with a portion control

timer. This portion control is based on a time setting.

Variations in product temperature and consistency will

affect the dispensed amount. To insure a consistent

portion, use product that is at the correct temperature

(145°F to 160°).

To set portion:

1. Load preheated product bag into dispenser.

2. Dispense product until there is a steady fl ow.

3. Dispense the product into a clean container,

and measure the product to verify the dispensed

amount.

4. Using a small screwdriver, turn the control dial

located on the back panel clockwise for more

product and counter-clockwise for less product.

5. Repeat steps 3 and 4 until the desired amount is

reached.

4

Operation Notes:

The product should be preheated according to the

manufacturer's instructions. The product should be

a minimum of 140°F before dispensing.

The dispenser will not function correctly if the product

is not at the correct temperature.

CHECKING PRODUCT TEMPERATURE

The dispenser should be plugged in and turned on

with product in the dispenser for a least 5 hours.

1. Dispense at least 3 inches of product into an

insulated cup.

2. Without hesitation, insert the thermometer to the

bottom of the cup and stir the product gently with

the stem of the thermometer.

3. Position the tip of the thermometer in the center

of the product mass.

4. The temperature should read between 140°F and

165°F.

The dispenser is designed to operate 24 hours a day.

Once the product is placed in the dispenser it should

not be removed until the bag is empty, or the holding

period of the product has expired.

Note: To increase the evacuation, open the dispenser

and pull the product towards the outlet fi tment once

or twice during operation.

If the pump drips, or does not dispense product, check

to make sure the tube is routed correctly, the spring

is latched onto the catch.

NOTE: The tube cover must be in place for

proper operation.

CLEANING INSTRUCTIONS

To clean the peristaltic dispenser:

The stainless steel body is corrosion resistant, but

may corrode if not cleaned properly. The dispenser

should be cleaned with a soft cloth with mild soap and

water and wiped dry. Do not use detergents, strong

abrasives, or metal scouring pads on the stainless

steel panels.

The pump mechanism should not need cleaning during

normal use. If product should spill onto the pump

head, it can be removed for easy cleaning. Clean the

parts in a solution of mild soap and water using a soft

cloth. Dry parts before reassembling.

The spring can also be removed for cleaning by

removing the knob and retaining washer.

5

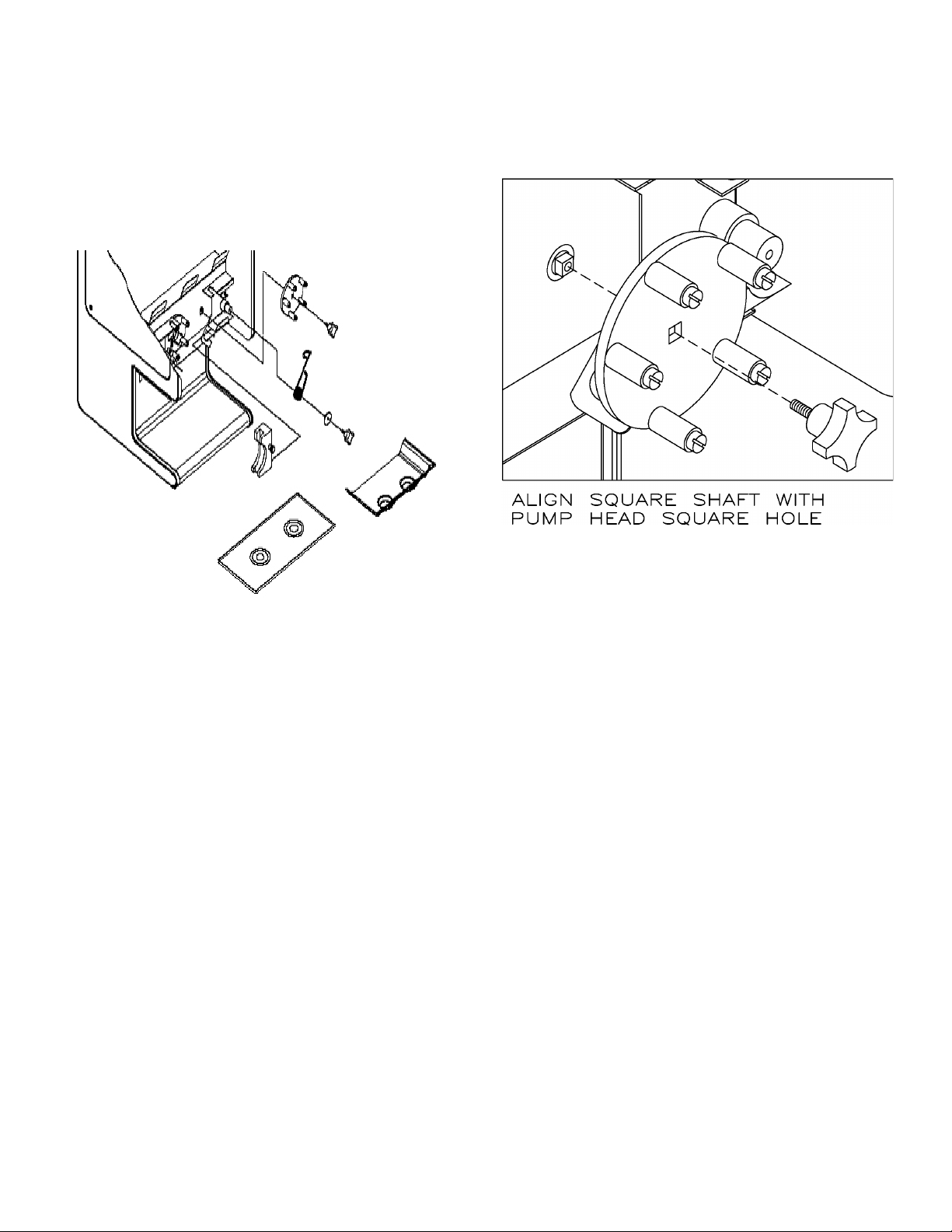

To remove and clean the pump head:

1. Open the door.

2. Remove the bag according to the instructions.

3. Unscrew the knob from the pump head.

4. Remove the pump head.

5. Slide the pump block out of the track.

6. If needed the rollers can also be disassembled

for cleaning.

Note: When installing the pump head onto the drive

shaft, make sure the pump head is fully seated onto

the square end of the drive shaft before installing

the knob.

WARNING: The drive shaft and pump head

could be damaged if the pump head is installed

incorrectly.

6

Loading...

Loading...