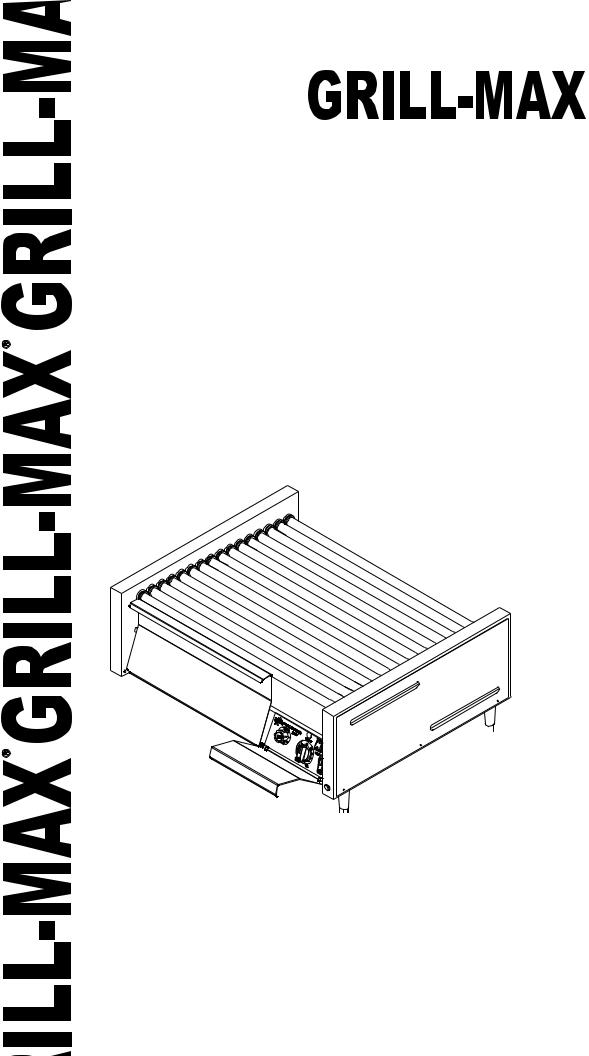

Star Manufacturing 50SCHDM, 45SCHDEP, 50SCHDEP, 50SCHDEM, 75SCHDEM Operation Manual

®

ROLLER GRILLS

MODELS

30SCHDM-120V, 50SCHDM-120V

Ininite Controls

& Heated Bun Drawer

45SCHDEP-120V, 50SCHDEP-120V

50SCHDEM-120V, 75SCHDEM-120V

Electronic Controls

& Heated Bun Drawer

Installation and

Operation

Instructions

2M-Z11808 REV. B 9/1/11

IL1541

SAFETY SYMBOL

These symbols are intended to alert the user to the presence of important operating and maintenance instructions in the manual accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Star reserves the right to change speciications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the speciications contained in this sheet are subject to change without notice. While Star International Holdings Inc., Company exercises good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions reached as a result of using the speciications. By using the information provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when you call to ensure a faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent Listing

Reference the listing provided with the unit

or |

|

for an updated listing go to: |

|

Website: |

www.star-mfg.com |

Service@star-mfg.com |

|

Service Help Desk |

|

Business |

8:00 am to 4:30 p.m. Central Standard Time |

Hours: |

|

Telephone: |

(314) 678-6303 |

Fax: |

(314) 781-2714 |

Parts@star-mfg.com |

|

|

Service@star-mfg.com |

|

Warranty@star-mfg.com |

Website: |

www.star-mfg.com |

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2 2

TABLE OF CONTENTS

|

PAGE NUMBER |

GENERAL SAFETY INFORMATION |

3 |

GENERAL INSTALLATION INFORMATION |

4 |

Connection Load |

4 |

GENERAL OPERATING INSTRUCTIONS |

|

Bun Box |

5 |

Ininite Controls |

5 |

Electronic Controls |

6 |

Cleaning |

7 |

WARRANTY |

|

Outside the United States |

8 |

United States |

9 |

WIRING DIAGRAM |

8 |

EXPLODED VIEW |

10 - 11 |

PARTS LIST |

|

50 MODEL SERIES |

12 - 13 |

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and experienced in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

CAUTION Before using your new equipment, read and understand all the instructions & labels associated with the unit prior to putting it into operation. Make sure all people associated with its use understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If equipment is received in damaged condition, either apparent or concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a request for inspection of concealed damage must be made with carrier within 15 days. Be certain to retain all contents plus external and internal packaging materials for inspection. The carrier will make an inspection and will supply necessary claim forms.

3

GENERAL INSTALLATION INFORMATION

The grill should be connected to a wall type receptacle, a direct line or individual branch circuit. An individual branch circuit is preferred. If connected to an overloaded circuit the grill will not operate properly. The unit should be level when installed. Models equipped with bun boxes must be level to utilize the self-closing feature of the bun drawer. Adjustable 4-inch legs are standard on the 75 series and available for all other models.

This grill is equipped for the voltage shown on the nameplate. It will operate on alternating current only, however, the speciied voltage must be applied.

CONNECTION LOAD:

INFINITE CONTROL

MODEL SERIES |

WATTAGE |

30SCHDM |

1380 |

50SCHDM |

1885 |

50SCHDEP |

1565 |

DO NOT CONNECT TO DIRECT CURRENT (DC).

WARNING IMPORTANT

UNLEVEL UNITS COULD RESULT IN HAVING PRODUCT TRAVEL FROM ONE SIDE TO THE NEXT, OVER A PERIOD OF TIME.

4

GENERAL OPERATING INSTRUCTIONS

BUN WARMER

Operating the bun drawer requires illing the pan with fresh buns and removing the stale buns as required. The heated bun drawer is not meant to toast the buns and the temperature should be at 122°F (50°C). To determine the correct setting, set the Bun Box Knob to #3, using a thermometer, adjust until the correct setting is reached. NO WATER IS REQUIRED OR RECOMMENDED.

All units are equipped with an easily removed bun pan which can be removed by lifting out of the open bun drawer. This makes daily cleaning of the pan easy. It is necessary to remove the bun drawer before attempting to remove the drip tray when access to the rear of the unit is obstructed. To remove the bun drawer, irst allow the unit to cool, remove bun pan, then grab the drawer by both sides and pull it out all the way. Lift the front to unhook the drawer slide from rear drawer roller. Pull the drawer the remainder of the way out. Use caution not to drop the drawer when reaching the end of the drawer slide travel. To reinsert the drawer, irst hook the drawer slide over the irst right side roller then push the drawer in until the second roller drops in, doing one side at a time. Repeat for left side rollers. Reinsert bun pan. Do not operate the grill without the drip tray in place.

OPERATING PROCEDURES FOR INFINITE CONTROL GRILLS

The main switch located on the control panel controls all the power to the unit. With the main switch on, the rollers will turn, heat will be supplied to the bun box, but no heat will be supplied to the rollers unless the heat controls are turned on. The switch is lighted to indicate when the unit is turned on.

For lexibility the heating section of the grill is divided into two individually controlled heat sections. The right control regulates the heat to the rear section and the left control regulates the heat to the front section. On Ininite control grills a signal light is provided above each heat control and indicates when the heated section is on. An additional light is provided on the end housing of the unit that indicates the position of the main power switch.

|

|

|

IL1540 |

|

Bun Warmer |

Front |

Power |

Rear |

|

Control |

Switch |

Control |

||

|

COOKING

The heat controls provide an ininite range of settings for a wide variety of food products and installation conditions. The size, content and shape of the product and the installation of any sanitary food shields or sneeze guards will determine the proper heat setting. The National Sanitation Foundation requires that perishable foods be kept at 60°C or above during serving periods. Do

not keep the food product on a low setting for more than two hours. The product should be kept refrigerated until ready for use. Cooking time will vary depending on the starting temperature and the quality of the product. For best results when cooking hot dogs use a hot dog made for grilling.

5

OPERATING PROCEDURES FOR ELECTRONIC GRILLS

START-UP

When initially turning on power to the electronic controlled grill, it will be in the HOLD mode. The displays will lash until the setpoint temperature is reached, heat will be supplied to the bun box. The grill will beep once when it is up to temperature. Ininite controlled grills have no notiication when operating temperature is reached.

HEATING

Thesize,content,andshapeoftheproductandtheinstallation of any sanitary food shields or sneeze guards will determine the proper heat setting. The National Sanitation Foundation requires that all perishable foods be kept at 140°F or above during serving periods.

The product should be kept refrigerated until ready to use. Heating times vary depending on the starting temperature and the qualities of the product. For best results, use a hot dog or products that arer made for grilling.

Beforecookingfortheirsttime,washtherollerswithmildsoap and water using a soft cloth. When the electronic controled grills are initially turned on, the displays will lash the HOLD temperature until the grill reaches that setpoint.

With the grill preheated to the hold temperature, load with the desired product and press the HEAT button. The grill will then go into the heat mode and the displays will lash until the HEAT temperature is reached. After the heating cycle, the grill will beep four times and the food product will be at the serving temperature. The grill will automatically return to the HOLD temperature.

NOTE: Based on the product being heated, some experimentation is required to ind the optimal HEAT temperature and HEAT time to bring the product up to

temperature in an acceptable amount of time.

PROGRAMMING

The electronic controls provide programmable HEAT and HOLD settings for a variety of food products and installation

conditions.

To program the electronic roller grill:

1.With the grill on, push and hold the  and

and  on the side you wish to program together for three seconds until the alarm beeps once and the display blanks.

on the side you wish to program together for three seconds until the alarm beeps once and the display blanks.

2.To set the heat temperature and/or heat time, push the heat button. The last saved heat time will be displayed and the HEAT LED will lash and HEAT TIME indicator will be ON. Use the  and

and  buttons to adjust to the desired time, then press the HEAT button again. The HEAT TIME LED indicator will turn off and the HEAT TEMP LED indicator will now be lit. When programming the HEAT temperature is complete, push the HEAT button one more time to exit the programming mode.

buttons to adjust to the desired time, then press the HEAT button again. The HEAT TIME LED indicator will turn off and the HEAT TEMP LED indicator will now be lit. When programming the HEAT temperature is complete, push the HEAT button one more time to exit the programming mode.

3.To set the hold temperature, repeat step 1 above then push the HOLD button. The last saved hold temperature will be displayed and HOLD LED will be ON. Use the  and

and  buttons to adjust to the desired temperature, then press the HOLD button again to exit programming mode.

buttons to adjust to the desired temperature, then press the HOLD button again to exit programming mode.

4.To turn the heat off to the front or rear section, press and hold the  for that section for 3 seconds. "OFF" will be displayed. To turn the section back on, press the HEAT or HOLD button.

for that section for 3 seconds. "OFF" will be displayed. To turn the section back on, press the HEAT or HOLD button.

LED

IL2010

Bun Box |

Front Control |

Rear Control |

Power Switch |

Electronic Controls

6

USE ONLY PLASTIC OR COATED UTENSILS FOR HANDLING THE FOOD PRODUCT. METAL WILL SCRATCH THE ROLLER COATING AND AFFECT THE

CAUTION ABILITY TO CLEAN THE ROLLERS.

INTERNAL DRAWER COMPONENTS & DRAWER CAVITY ARE HEATED. ALLOW THE DRAWER & CAVITY TO COOL DOWN BEFORE SERVICING OR CLEANING.

DO NOT USE STEEL WOOL OR ABRASIVE CLEANERS ON THE ROLLERS. SCRAPES ON ROLLERS CAUSED BY ABUSE WILL VOID THE WARRANTY.

USE CAUTION WHEN CLEANING WHILE HOT TO PREVENT BURNS OR BODILY INJURY.

CLEANING

Before cooking for the irst time, wash the rollers with mild soap and water using a soft cloth. Do not use metal utensils when cooking. Scratches and scrapes will hamper the ability to easily clean the rollers. Never use steel wool or abrasive cleaners on the rollers. This will damage the inish and the roller bearings. The rollers clean most easily when hot. Use caution when cleaning to prevent burns and bodily injury. Clean the rollers with a clean wet cloth. Wipe from the ends to the center to prevent forcing debris into the roller seals. Do not allow the food product to build up and bake onto the roller surface. The exterior of the unit should be cleaned using a mild detergent or non-abrasive cleaner. Clean the entire unit daily to insure long life and satisfactory performance as well as to maintain an attractive appearance. Do not clean with water jet equipment.

When cleaning the interior bun drawer compartment, remove the bun drawer (see General Operating Instructions on page 5) and clean with mild detergent and warm water.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local service company for service or required maintenance. Replacement cord sets must be purchased from Star Manufacturing International, Inc.

7

INTERNATIONAL ONE (1) YEAR EQUIPMENT WARRANTY

All workmanship and materials in “STAR” products are warranted for a period of one year from the date shipped from the factory or one year from the date shown on the proof of purchase of the end-user when purchased through an authorized “STAR” dealer/distributor in a commercial foodservice location.

“STAR’s” obligation under this warranty is limited to the replacement of the defective part(s) only without charge. This warranty is void if damage occurs from improper installation, misuse or abuse, disassembly or tampering of unit for any purpose other than repair by a qualified service agent, wrong voltage, incorrect or fluctuating voltage conditions, wrong gas, improper gas or gas conditions, operated contrary to the installation and operating instructions, operated in an application for which the unit is not suited, or if the unit is not maintained and/or cleaned in a suitable manner.

Any expense in connection with installation, or any cost of making adjustments on a unit to conform to electric or gas service at the point of installation, are not covered by this warranty.

*The warranty period for the JetStar series six (6) ounce popcorn machines is two (2) years.

*The warranty period for the Chrome-Max Griddles is five (5) years on the griddle surface. See detailed warranty provided with unit.

*The warranty period for Teflon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to Teflon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners. This warranty does not apply to the “non-stick” properties of such materials.

*This warranty is not valid on Conveyor Ovens unless a “start-up/check-out has been performed by a Factory Authorized Technician.

In order to make a claim under this warranty; a warranty report must be filed with Star Manufacturing International Inc. in St. Louis, Missouri, U.S.A. by the dealer/distibutor through which product was purchased. All details, including serial number and model number of the defective unit, must be included. Failure to file a claim within a 120 Day time period may result in the claim being refused.

“STAR” may forego the necessity of returning the part for inspection dependent upon the expense involved. However, “STAR” requires defective parts to be held in the claimant’s possession for a period of ninety (90) days for possible inspection by a “STAR” representative or designated inspector .

The foregoing warranty is lieu of any and all other warranties, expressed or implied, and constitutes the entire warranty.

PARTS WARRANTY

Parts that are sold for out-of-warranty repair are warranted for a period of ninety days. The part only is warranted; no labor.

SERVICES NOT COVERED BY WARRANTY

1.Labor

2.Mileage and/or travel time

3.Installation and/or adjustment of equipment

4.Operation contrary to the installation and operating instructions

5.Cleaning of equipment

6.Seasoning of griddle plates

7.Voltage conversions/adjustments

8.Gas conversions

9.Pilot light conversion/adjustments

10.Thermostat calibration/adjustments

11.Resetting of circuit breakers or safety controls

12.Replacement of bulbs/lamps

13.Replacement of fuses

14.Damages due to improper installation

15.Damages from abuse or misuse

16.Damage created by acts of God, Acts of War, or Civil Disturbance

08-05 RMS

8

Loading...

Loading...