Star Manufacturing 39 Series, 86 Series Operation Manual

<![endif]>® JetStar® JetStar® JetStar

JetStar®

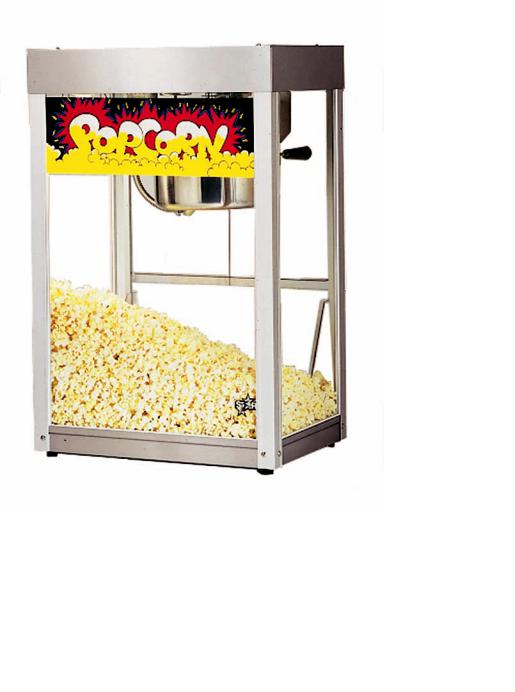

COUNTER POPCORN POPPER

MODEL

39 & 86 Series

Installation and

Operation

Instructions

2M-Y8397 Rev. O 7/12/10

86-S

<![endif]>etStar

SAFETY SYMBOL

These symbols are intended to alert the user to the presence of important operating and maintenance instructions in the manual accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Star reserves the right to change specifications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the specifications contained in this sheet are subject to change without notice. While Star Manufacturing exercises good faith efforts to provide information that is accurate, we are not responsible for errors or omissions in information provided or conclusions reached as a result of using the specifications. By using the information provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record

the model number, serial number, voltage and purchase date in the area below and have it ready when you call to ensure a faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent Listing

Reference the listing provided with the unit or

for an updated listing go to:

Website: |

www.star-mfg.com |

Service@star-mfg.com |

|

Telephone: |

(800) 807-9054 Local (314) 781-2777 |

Service Help Desk

Business |

8:00 am to 4:30 p.m. Central Standard Time |

|

Hours: |

|

|

Telephone: |

(800) 264-7827 |

Local (314) 781-2777 |

Fax: |

(800) 396-2677 |

Local (314) 781-2714 |

Parts@star-mfg.com |

||

|

Service@star-mfg.com |

|

|

Warranty@star-mfg.com |

|

Website: |

www.star-mfg.com |

|

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

SPECIFICATIONS: 39 SERIES

Capacity: |

135 one ounce servings per hour |

|

Electrical: |

120 volt, |

1197 watts, 9.98 amps |

|

230 volt, |

1197 watts, 5.20 amps |

Cord Length - 6 ft.

Plug NEMA Spec - NEMA 5-15P (120V Models)

Dimensions: |

CEE7-7 (230V Models) |

Weight |

lbs. |

(kg) |

|

||||

39-A - Yellow |

19 1/2" W x 14-1/4" D x 25 1/8" H |

Installed |

45 |

(20.41) |

|

(49.5 cm W x 36.2 cm D x 63.8 cm H) |

Shipping |

56 |

(25.4) |

39D-A - Wood Grain |

21" W x 14-1/4" D x 25 1/8" H |

Installed |

45 |

(20.41) |

|

(53.3 cm W x 36.2 cm D x 63.8 cm H) |

Shipping |

56 |

(25.4) |

39R-A - Antique |

19 1/2" W x 14-1/4" D x 25 1/8" H |

Installed |

45 |

(20.41) |

|

(49.5 cm W x 36.2 cm D x 63.8 cm H) |

Shipping |

56 |

(25.4) |

39S-A - Stainless Steel |

19 1/2" W x 14-1/4" D x 25 1/8" H |

Installed |

45 |

(20.41) |

ACCESSORY |

(49.5cm W x 36.2 cm D x 63.8 cm H) |

Shipping |

56 |

(25.4) |

|

|

|

|

|

Cart for 39 and J4R Popcorn Machines |

|

|

|

|

Dimensions: |

|

Weight |

lbs. |

(kg) |

JPC-4/6 |

13 1/2" W x 19 1/4" D x 35" H |

Installed |

42 |

(19.1) |

|

(34.3 cm W x 48.9 cm D x 88.9 cm H) |

Shipping |

50 |

(22.7) |

86 SERIES

Capacity: |

170 one ounce servings per hour |

|

Electrical: |

120 volt, |

1197 watts, 10.0 amps |

|

230 volt, |

1100 watts, 4.8 amps |

Cord Length - 6 ft.

Plug NEMA Spec - NEMA 5-15P (120V Models)

Dimensions: |

CEE7-7 (230V Models) |

Weight |

lbs. |

(kg) |

|

||||

86S & 86SS |

19 1/2" W x 14-1/4" D x 30 1/2" H |

Installed |

54 |

(24.5) |

|

(49.5 cm W x 36.2 cm D x 77.5 cm H) |

Shipping |

65 |

(29.5) |

This equipment is designed and sold for commercial use only by personnel trained and experienced in its operation and is not sold for consumer use in and around the home nor for use directly by the general public in

CAUTION food service locations. For equipment to be used by the general public, please contact the factory.

Before using your new equipment, read and understand all the instructions & labels associated with the unit prior to putting it into operation. Make sure all people associated with its use understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If equipment is received in damaged condition, either apparent or concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a request for inspection of concealed damage must be made with carrier within 15 days. Be certain to retain all contents plus external and internal packaging materials for inspection. The carrier will make an inspection and will supply

necessary claim forms.

GENERAL INSTALLATION INSTRUCTIONS

Each machine has been properly wired and inspected at the factory for operation on the voltage and type of

WARNING current specified on the nameplate.

DO NOT CONNECT TO ANY OTHER TYPE OF CURRENT OR THE MACHINE WILL BE SERIOUSLY DAMAGED.

120 VOLT MACHINES

Machines with a nameplate stamped 120V are equipped for operation on 120 volt 60 hertz AC single phase service and must be connected to a 3 wire grounded, polarized receptacle.

230 VOLT MACHINES

Machines with a nameplate stamped 230CE are equipped for operation on 230 volt 50 hertz AC single phase service and must be connected to a 3 wire grounded receptacle.

DISPLAY SIGN

The display sign is shipped inside the cabinet. It can be located on the front glass or on the rear doors. If installed on the rear doors, cut the sign after installation to allow the doors to open.

GENERAL OPERATING INSTRUCTIONS

The motor air intake hole located on top of the machine must be clear of any obstructions.

CAUTION DO NOT COVER THIS AIR VENT HOLE AS SERIOUS MOTOR DAMAGE WILL RESULT.

Make sure the corn drawer is in place on the machine before starting the popping cycle. With all switches in the "OFF" (0) position, proceed in the following sequence to pop corn:

1.Turn "ON" (1) the corn warming switch / lamp.

2.Turn "ON" (1) the kettle / motor switch. Allow six or seven minutes to pre-heat the kettle. Thermostat adjustments should not be necessary as it has been preset at the factory for the correct popping temperature.

3.Corn and oil measuring cups are supplied with your machine. Pour a level measuring cup of oil (two ounces) in kettle. Add 6 ounces of raw corn for the 39 Series models or 8 ounces of raw corn for the 86S Series models and 1/2 teaspoon of popcorn salt. Vary the amount of salt and oil to suit taste. If desired, salt may be added after the corn is popped.

4.When the corn stops popping (about 2 1/2 minutes), dump the kettle immediately by turning the handle clockwise approximately 90 degrees to release latch. Recharge as quickly as possible. Screen out unpopped kernels over the perforated section of the corn pan.

5.Turn the kettle switch off (0) when the desired amount of popping is completed.

DO NOT LEAVE THE KETTLE SWITCH "ON" (1) WHEN THE MACHINE IS NOT IN USE.

DO NOT IMMERSE KETTLE IN WATER OR ALLOW WATER TO COME IN CONTACT WITH CAUTION THE HEATING ELEMENT.

DO NOT IMMERSE KETTLE IN WATER OR ALLOW WATER TO COME IN CONTACT WITH CAUTION THE HEATING ELEMENT.

POPPING CORN IN DRY KETTLE IS NOT RECOMMENDED.

KEEPING THE POPPING UNIT CLEAN

After each popping period, wipe the inside and outside of the kettle while it is warm (not hot) with a clean cloth. This is important to keep salt, seasoning, oil from forming a carbonized material which not only lowers popping efficiency but can cause excessive smoking or damage the kettle. For retaining the high luster on the stainless steel kettle shell and lids, use a non-abrasive standard stainless steel cleaner when the kettle is cold. Use a

damp cloth and a warm mild soap solution to clean the clear glass and plastic surfaces.

TO REMOVE KETTLE:

Allow kettle to cool or use heat insulated gloves to remove a hot kettle. Turn off the kettle switch. Disconnect the twist lock cap at the end of the kettle conduit, turn kettle handle clockwise 90 degrees to unlatch the kettle. Remove the hitch pin clip from the kettle hinge pin, hold the kettle and pull out the hinge pin. The kettle can now

be removed from the unit. Do not place the kettle in water as this will damage the electrical assembly.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local service company for service or required maintenance.

Loading...

Loading...