Page 1

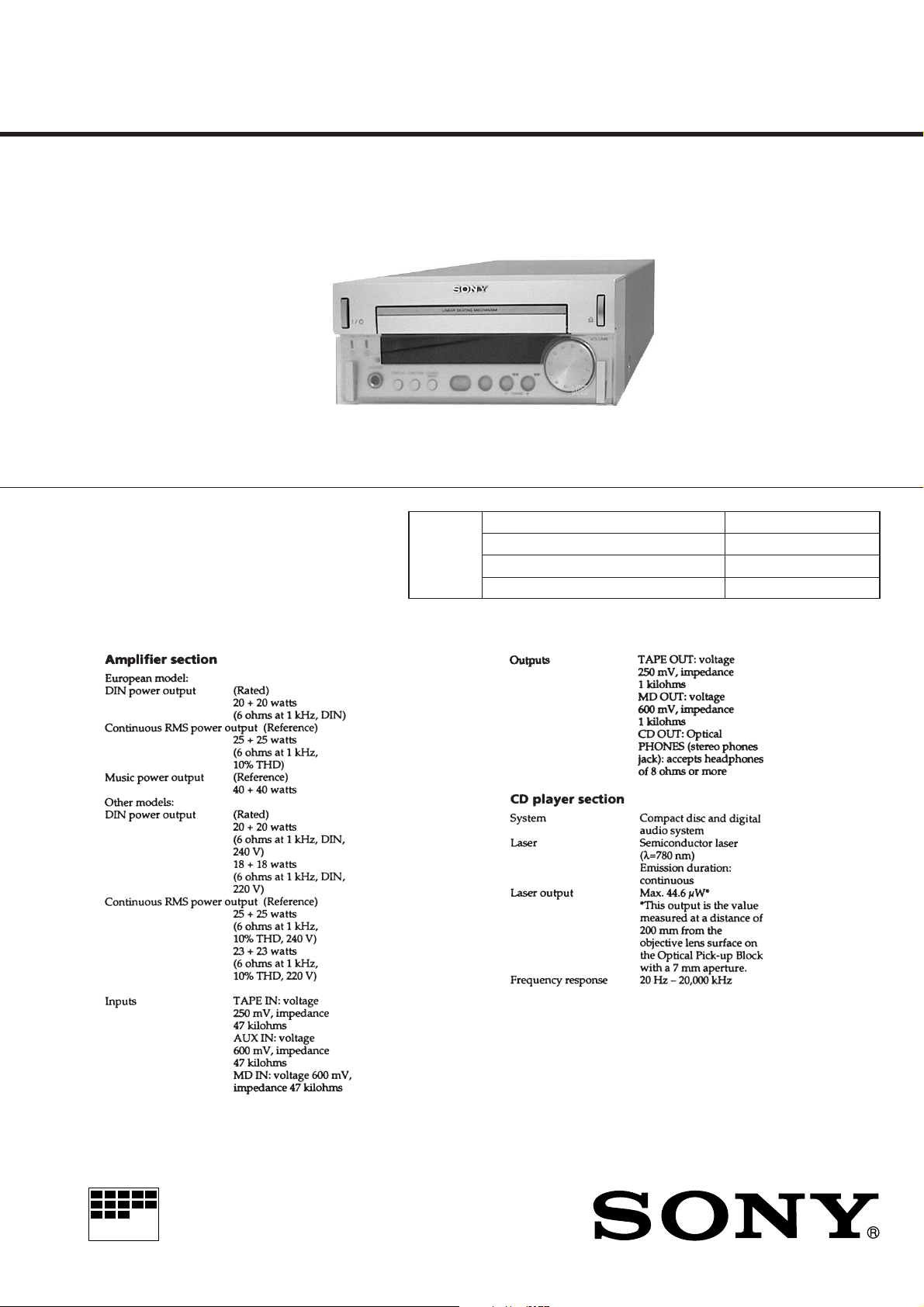

HCD-SD1

SERVICE MANUAL

HCD-SD1 is the amplifier, CD and

tuner section in CMT-SD1.

Model Name Using Similar Mechanism HCD-MD313

CD

SECTION

SPECIFICATIONS

Mechanism T ype CDM13B-5BD19

Base Unit Type BU-5BD19

Optical Pick-up Type KSS-213B/K-N

AEP Model

UK Model

E Model

MICROFILM

— Continued on next page —

COMPACT DISC RECEIVER

– 1 –

Page 2

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL IDENTIFICATION

– Specification Label –

MODEL NO. HCD-SD1

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

MODEL

AEP, UK model

SP, HK model

• Abbreviation

HK : Hong Kong model

SP : Singapore model

Parts No.

PARTS No.

4-212-711-0π

4-212-712-0π

Page 3

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 4

2. GENERAL ..........................................................................7

3. DISASSEMBLY

3-1. Loading Panel ....................................................................... 8

3-2. Glass ASSY...........................................................................8

3-3. Front Panel ........................................................................... 9

3-4. Main Board and Tuner Unit .................................................. 9

3-5. CD Mechanism Deck .......................................................... 10

3-6. Back Panel ......................................................................... 10

3-7. Disc Table .......................................................................... 11

3-8. Optical Pick-up ................................................................... 11

4. SERVICE MODE .............................................................12

5. TEST MODE ..................................................................... 13

6. ELECTRICAL ADJUSTMENTS ............................... 14

7. DIAGRAMS

7-1. Circuit Boards Location ...................................................... 16

7-2. Block Diagrams

• BD Section .......................................................................17

• Main Section .................................................................... 19

7-3. Schematic Diagram – BD Section – ................................... 23

7-4. Printed Wiring Board – BD Section –................................. 25

7-5. Schematic Diagram – Main (1/2) Section –........................ 27

7-6. Schematic Diagram – Main (2/2) Section – ........................ 29

7-7. Printed Wiring Board – Main Section – .............................. 31

7-8. Schematic Diagram – Sub Trans Section –.........................33

7-9. Printed Wiring Board – Sub Trans Section – ...................... 34

7-10. Schematic Diagram – Panel Section – ............................. 35

7-11. Printed Wiring Board – Panel Section –...........................37

7-12. Schematic Diagram – AMP Section –.............................. 39

7-13. Printed Wiring Board – AMP Section – ........................... 41

7-14. Schematic Diagram – Connector Section –...................... 43

7-15. Printed Wiring Board – Connector Section – ................... 45

7-16. Schematic Diagram – REG Section – .............................. 47

7-17. Printed Wiring Board – REG Section –............................ 49

7-18. IC Block Diagrams ........................................................... 51

7-19. IC Pin Functions ............................................................... 54

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output two times.

8. EXPLODED VIEWS

8-1. Front Panel Section ............................................................. 56

8-2. Chassis Section ................................................................... 57

8-3. Mechanism Deck Section (CDM13B-5BD19) ................... 58

8-4. Base Unit Section (BU-5BD19).......................................... 59

9. ELECTRICAL PARTS LIST ........................................ 60

– 3 –

Page 4

SECTION 1

SERVICING NOTE

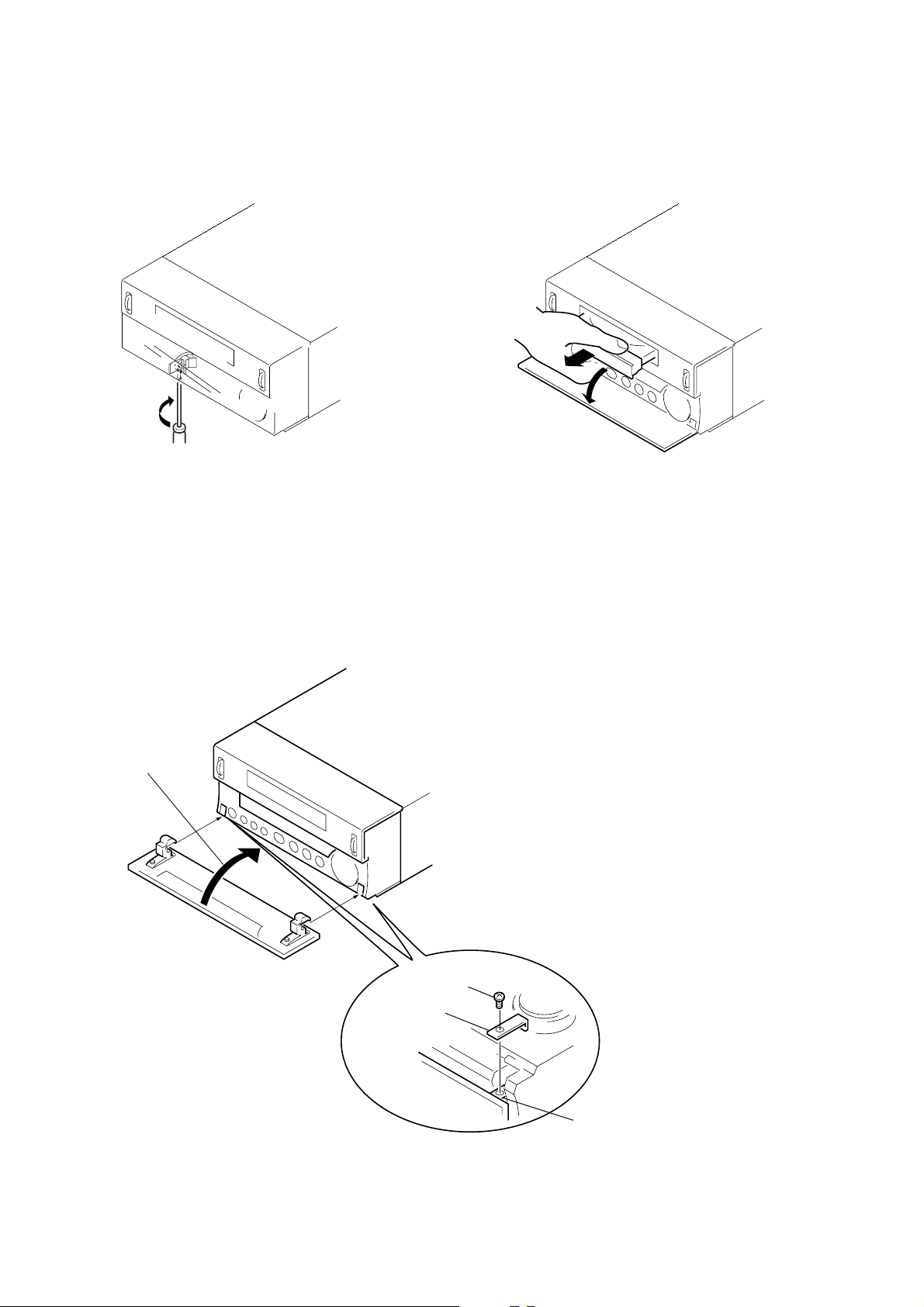

OPENING THE DISC TRAY WHEN POWER IS OFF

1

Using a thin screwdriver, rotate the internal cam

in the arrow direction completely.

2

Open the glass door, and pull out the loading panel.

ATTACHING THE GLASS ASSEMBLY

• Attach according to steps 1 to 4.

2

Pull up the glass door,

in the arrow direction.

1

1

3

Bracket (shaft)

4

Screw (PTP 2.6x6)

(Bottom side)

– 4 –

When securing this part, position at the

center to allow some play. Open and close

the glass window sever al times, and check

that the parts do not touch each other.

Page 5

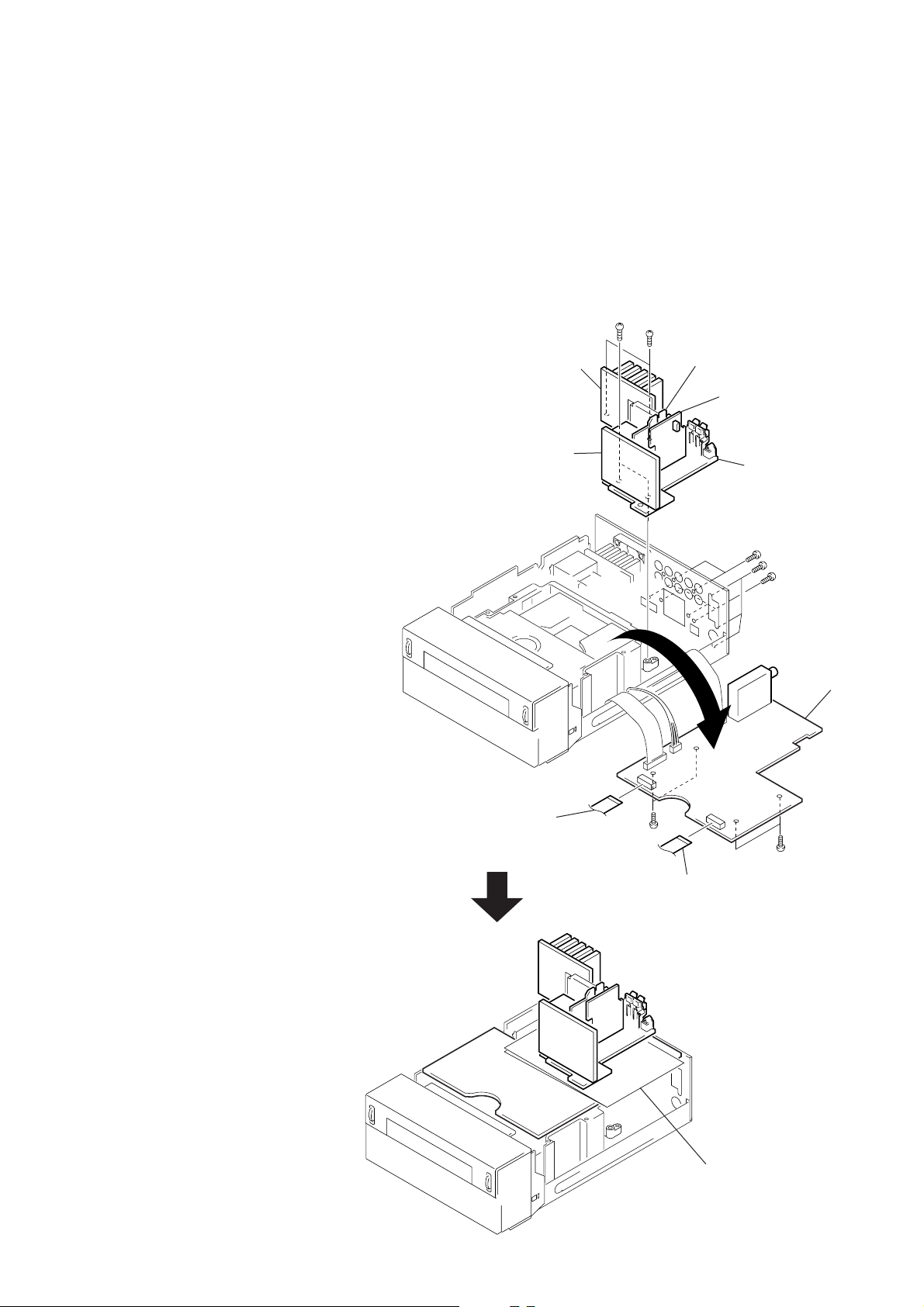

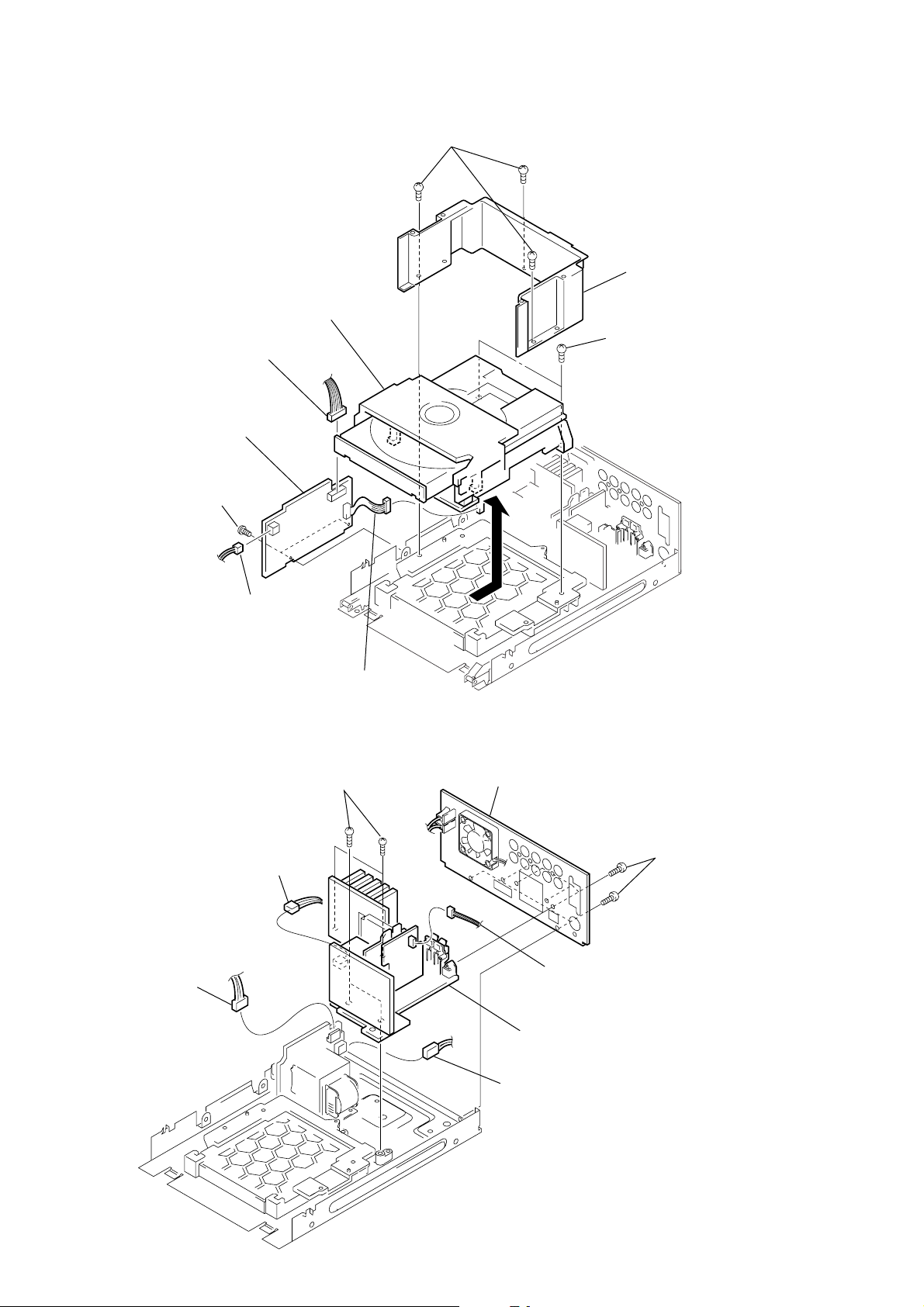

POSITIONS FOR SERVICING THE CONNECTOR

d

BOARD , SUB-TRANS BO ARD, CHEMI-CON BO ARD,

AND AMP BOARD

1 Remove the four screws securing the upper cover, and remove

the upper cover.

2 Remove the loading panel. (Refer to SECTION 3 DISASSEM-

BLY.)

3 Remove the four screws A securing the MAIN board, five screws

B securing the rear panel, two flat cables (CN701, CN702),

and open the MAIN board as shown in the figure.

4 Remove the two screws C securing the heat sink, and remove

the AMP board and CHEMI-CON board.

5 Remove the two screws D securing the SUB-TRANS board

and four screws E securing the CONNECTOR board, and remove the SUB-TRANS board and CONNECTOR board.

6 Return the MAIN board to its original position.

7 Insulate these boards and the MAIN board with paper, etc., and

assemble the CONNECTOR board, SUB-TRANS board,

CHEMI-CON board, and AMP board on these boards.

SUB-TRANS board

Heat sink

D

C

AMP board

CHEMI-CON board

CONNECTOR board

B

B

Flat type wire (CN701)

E

MAIN boar

A

A

Flat type wire (CN702)

– 5 –

Should be insulatable

with paper, etc.

Page 6

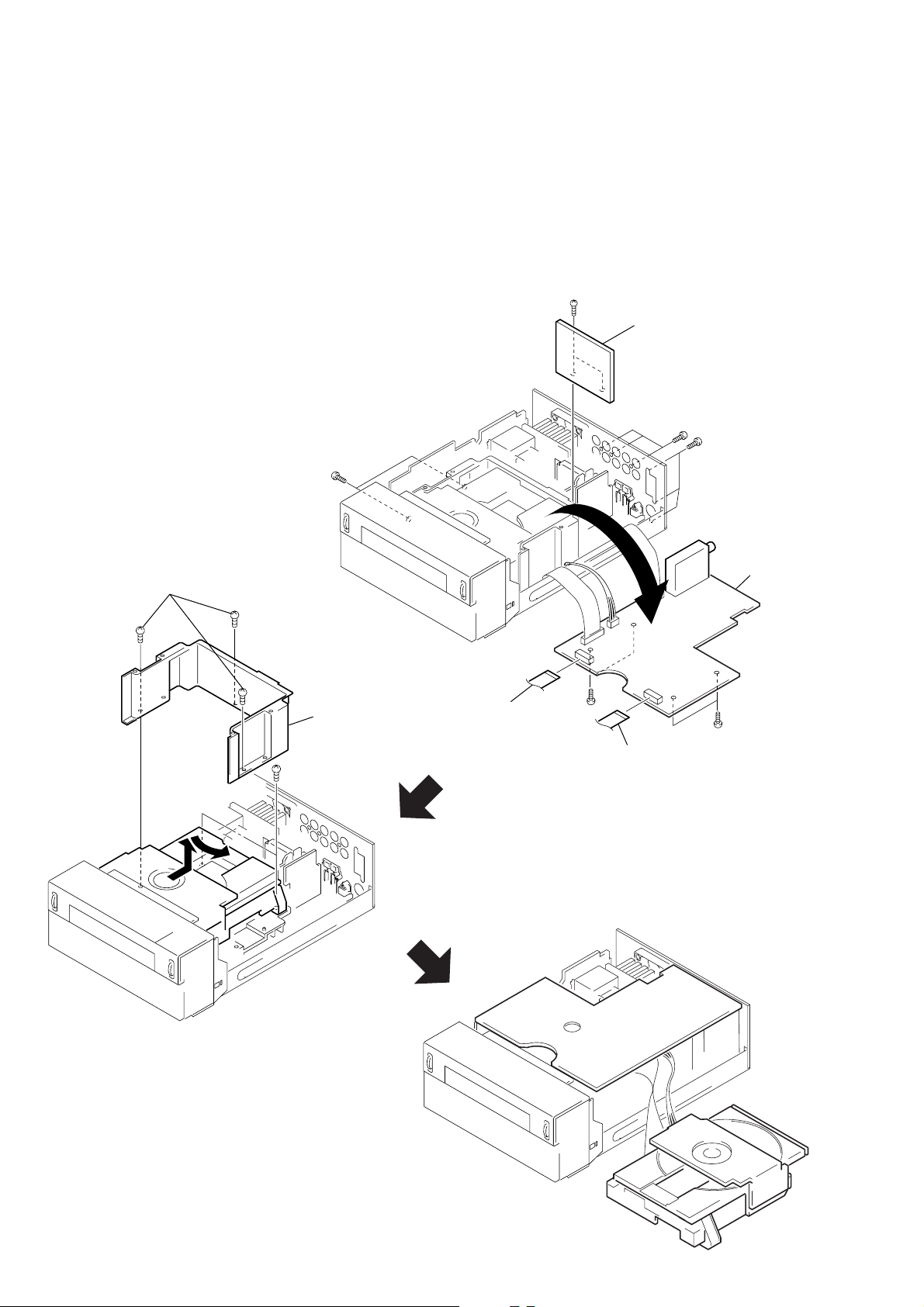

POSITION FOR SERVICING THE CD MECHANISM

r

DECK

1 Remove the four screws securing the upper cover, and remove

the upper cover.

2 Remove the loading panel. (Refer to SECTION 3 DISASSEM-

BLY.)

3 Remove the four screws A securing the MAIN board, five screws

B of the rear panel, and flat cables (CN701, CN702), and re-

move the MAIN board.

4 Remove the two screws D securing the SUB-TRANS board,

and remove the SUB-TRANS board.

5 Remove the two screws F securing the REG board.

6 Remove the three screws G securing the CDM cover, and re-

move the CDM cover.

7 Remove the two screws H securing the CDM, move the CDM

backwards by about 5 mm horizontally, and then lift upwards.

8 Rotate the CDM in the counterclockwise direction by about 30˚

to remove.

9 Return the MAIN and SUB-TRANS boards to their original

positions.

F

G

D

SUB-TRANS board

B

B

MAIN board

H

CDM cove

Flat type wire (CN701)

A

A

Flat type wire (CN702)

– 6 –

Page 7

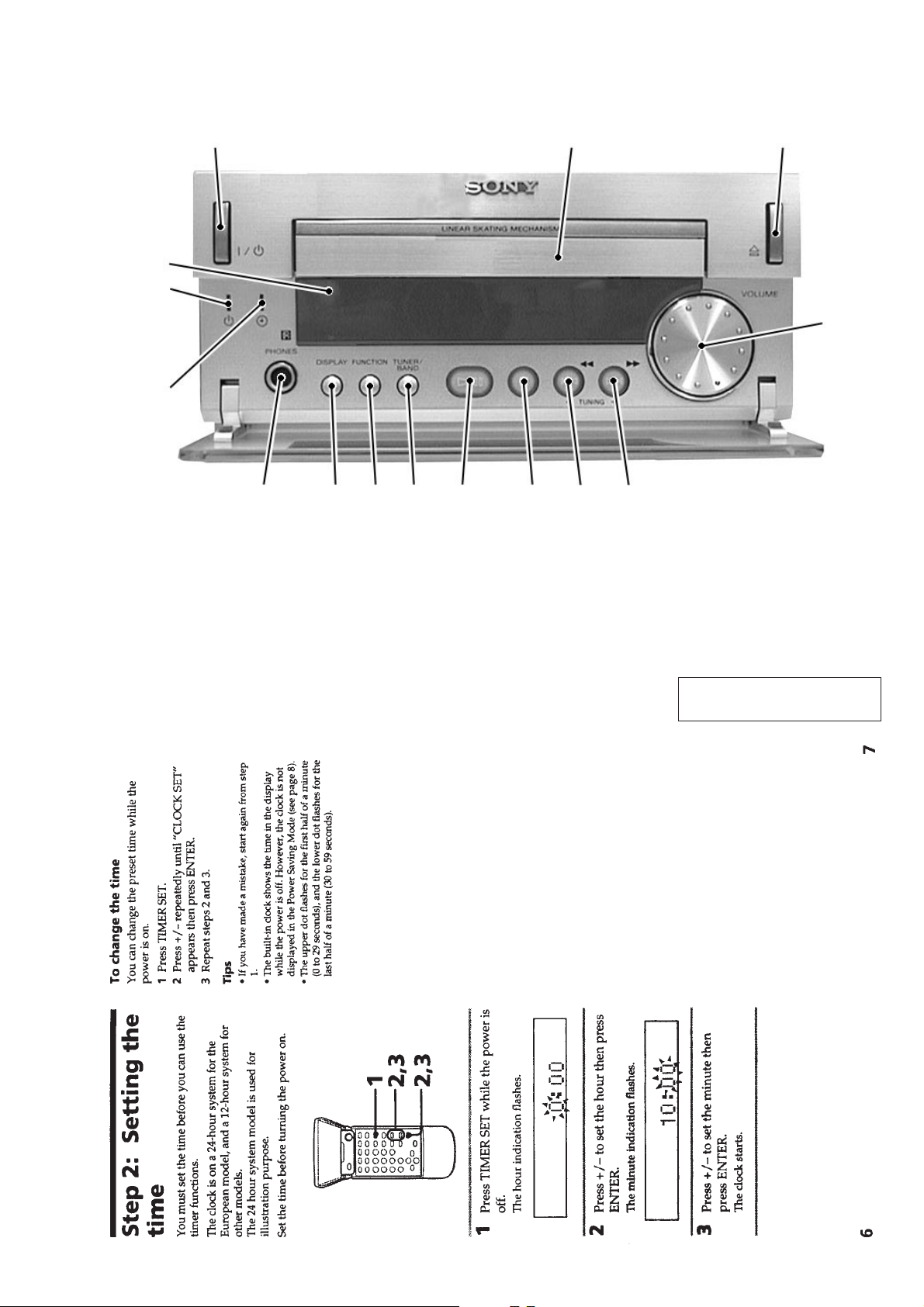

Front Panel

15

14

13

SECTION 2

GENERAL

1

2

3

4

12

Location of Parts and Controls

1 1/u (Power) button

2 CD disc tray

3 § button

4 VOLUME dial

5 ±/)/TUNING + button

11

6 ≠/0/TUNING – button

7 π button

8 fl button

9 TUNER/BAND button

10 FUNCTION button

78910

6

5

11 DISPLAY button

12 PHONES jack

13 t indicator

14 u indicator

15 Display window

This section is extracted from

instruction manual.

– 7 –

Page 8

SECTION 3

n

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

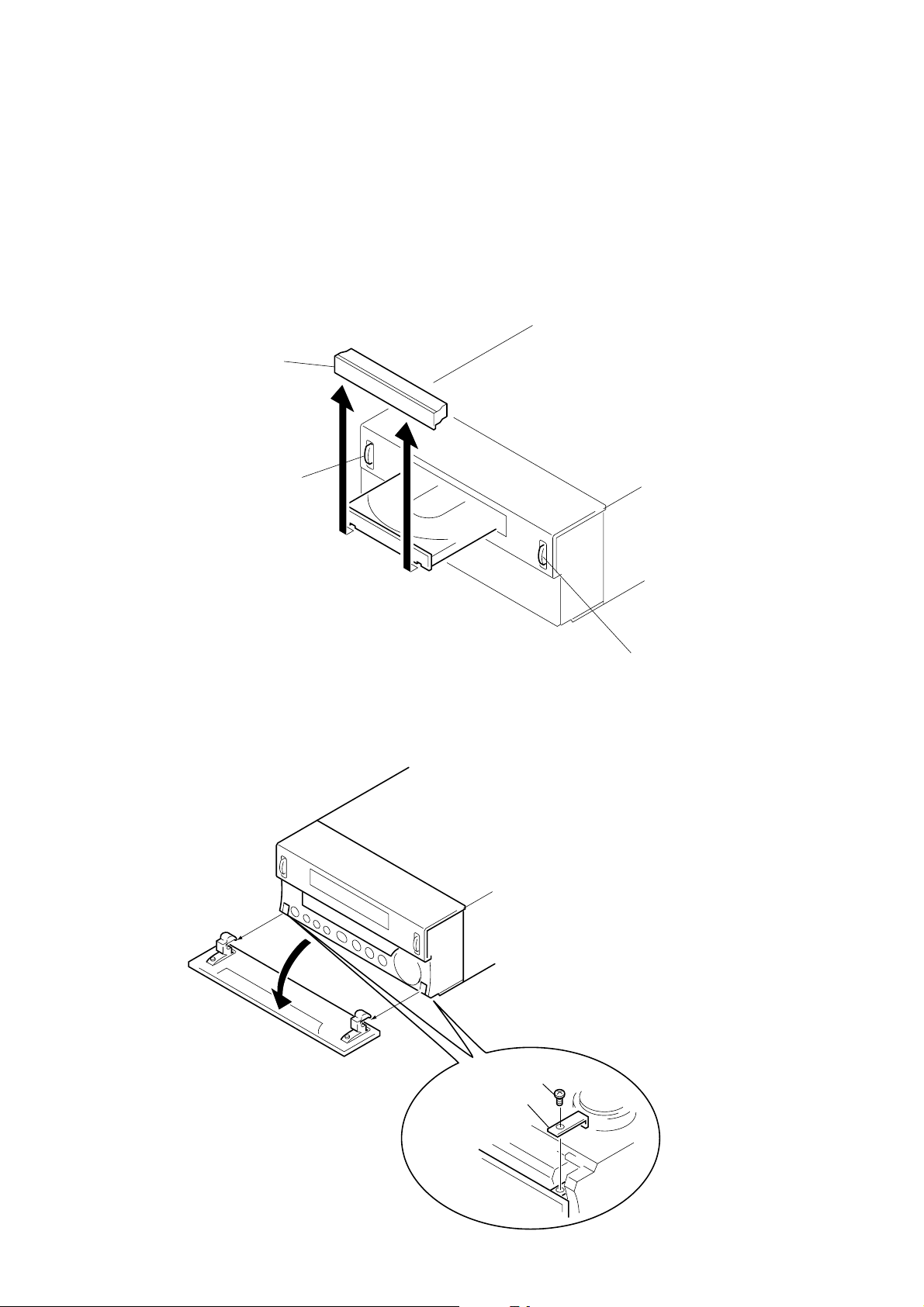

3-1. LOADING PANEL

1 Turn ON the power, and press the EJECT button to open the

tray.

2 Remove the loading panel in the arrow direction.

3 Press the EJECT button to close the tray.

• If the power cannot be turned ON, refer to “Opening the Disc

Tray When the Power is OFF” of “Service Note”, and open the

tray.

Loading panel

Power button

3-2. GLASS ASSY

4

3

4

1

Screw (PTP2.6x6)

2

Bracket (shaft)

Eject butto

– 8 –

(Bottom side)

Page 9

3-3. FRONT PANEL

2

Three claws

6

Front panel

4

Flat type wire (11core)

(CN702)

3

5

Flat type wire (13core)

(CN701)

3-4. MAIN BOARD AND TUNER UNIT

1

Four screws

(BVTP3x8)

4

Flat type wire (19core)

(CN301)

1

Three screws

(BVTP3x8)

3

7

MAIN board and Tuner unit

8

Connector (CN706)

5

Connector (CN351)

6

Flat type wire

(19core) (CN705)

2

Six screws

(BVTP3x8)

– 9 –

Page 10

3-5. CD MECHANISM DECK

r

3

Connector

(CN942)

5

REG board

1

T wo screws

(BVTP3x8)

9

CD mechanism deck

6

Three screws

(BVTP3x8)

7

Dust cove

8

T wo screws

(BVTP3x8)

3-6. BACK PANEL

3

Connector

(CN992)

2

Connector

(CN945)

5

Connector

(CN901)

4

Connector

(CN994)

2

Four screws

(BVTT3X8)

7

Back panel

6

Connector

(CN551)

8

PC board block

1

Six screws

(BVTP3X8)

– 10 –

4

Connector

(CN991)

Page 11

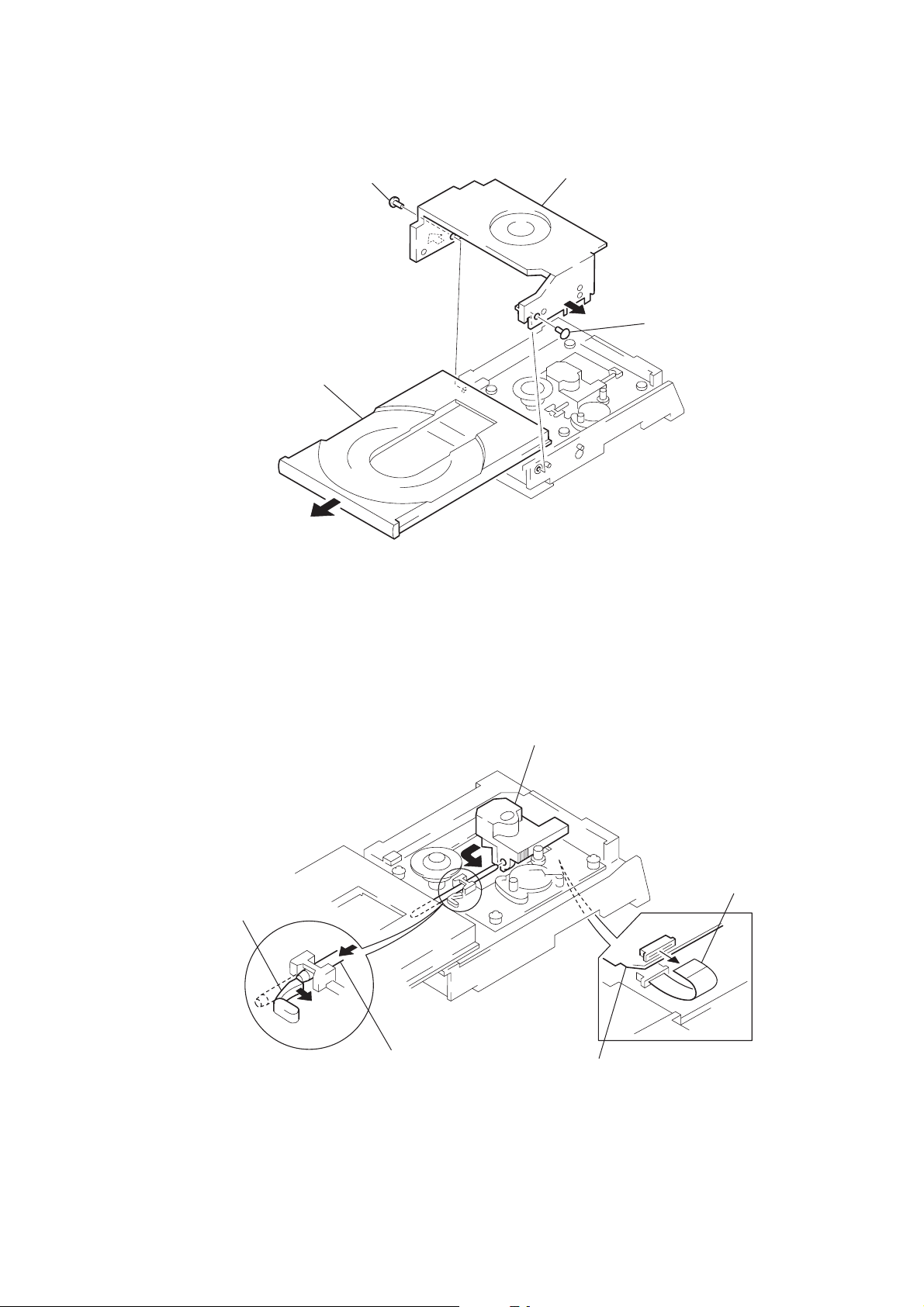

3-7. DISC TABLE

)

1

Screw (BV3x8)

4

Pull out the disc table.

3

Holder (MG) assembly

2

Screw (BV3x8

3-8. OPTICAL PICK-UP

1

Move the claw

in the arrow

A

direction.

4

Remove the optical pickup in the arrow direction C.

B

A

2

Remove the sled shaft in the

arrow direction

B

.

C

Flat type wire (16 core)

3

(CNU101)

BD board

– 11 –

Page 12

SECTION 4

SERVICE MODE

Key Check Mode for Complete Lighting of LED/Fluorescent Display Tube

• Perform this mode to analyze and check malfunctions such as display defects and when buttons do not work.

Procedure:

1. Press the 1/u button to turn on the power.

2. Press the DISPLAY button and ^ button together.

3. All LEDs and the fluorescent display tube will light up completely.

4. Pressing the FUNCTION button here will light the fluorescent display tube in the following order; Partial lighting 1 n Partial lighting

2 n Complete lighting n Partial lighting 1······

Turning the VOLUME dial will switch the lighting order of the LED.

To end without shifting to the key check mode, press the 1/u button to end.

5. Pressing the p button sets the key check mode.

6. During the key check mode, “KEY=0 JOG=0” will be displayed on the fluorescent display tube.

Pressing a button will increase the value of “KEY=”. However the value will not increase for buttons which have already been pressed

once.

Rotating the VOLUME knob in the clockwise direction increases the value of “JOG=” in the order of 1, 2, 3.... and rotating in the

counterclockwise direction decreases in order of 10, 9, and 8.

7. To end the check mode, press all buttons (8 buttons). “KEY-OK” will be displayed.

Then press any button, and disconnect the power cord from the outlet.

Checking the Sub-Clock

• Perform this mode to check clock operations.

Procedure:

1. Connect an oscilloscope and frequency counter between the pin (TP791) and ground of IC701 of the MAIN board.

2. Press the § and 1/u buttons together to display “91P = 32.768k” on the fluorescent display tube.

3. Check that the signal on the oscilloscope becomes a 32 kHz rectangular waveform and the reading of the frequency counter becomes

32.768 kHz.

4. Press the 1/u button to end.

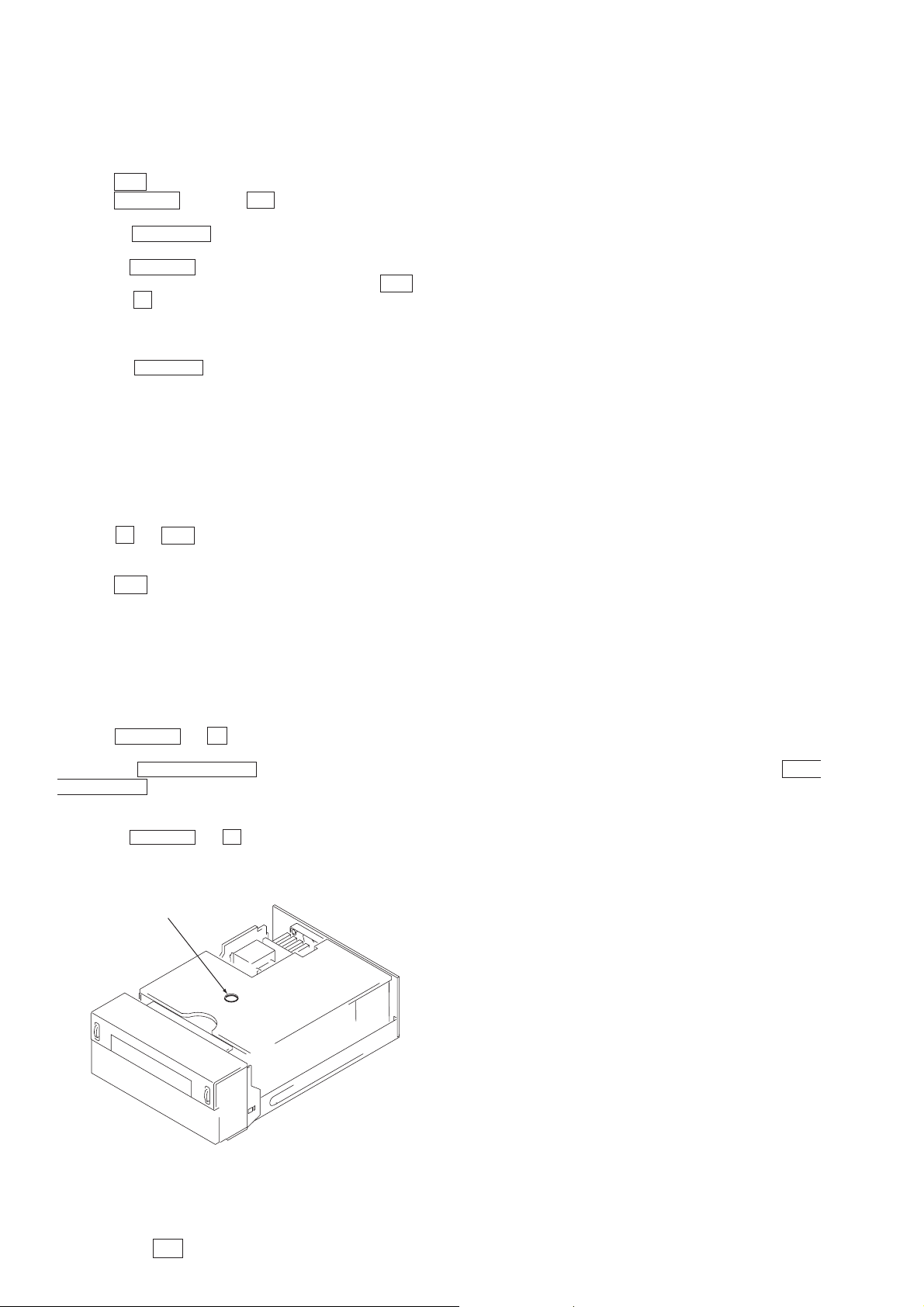

Sled Servo Mode

• In this mode, the CD sled motor can be operated freely.

Execute it when cleaning the pick-up.

Round holes can be seen on the topmost board when the case is opened. Move the pick-up and clean off the dirt in these round holes using

a cotton swab.

Procedure:

1. Press the DISPLAY and § buttons with the power of the unit OFF.

2. When the sled servo is set, “MANUAL” is displayed on the fluorescent display tube.

3. Pressing the +/TUNING/) button when the CD is in the stop state moves the pick-up to the outer track. Pressing the =/

TUNING/0 button moves it to the inner track.

4. To end this mode, perform the following steps.

1) Move the If not, the disc cannot be removed.

2) Press the DISPLAY and § buttons together.

Note:

• When ending this mode, be sure to move the pick-up to the innermost circumference. If not, the disc cannot be removed.

• Do not move the sled motor more than required as this will damage the gears.

Round holes for cleaning

Initializing (Forced Reset)

• Perform this mode when resetting the unit or when returning the unit to the customer.

• The preset frequency of the tuner, etc. will be the settings at shipment.

Procedure:

While pressing the 1/u button, insert the power cord into the outlet.

– 12 –

Page 13

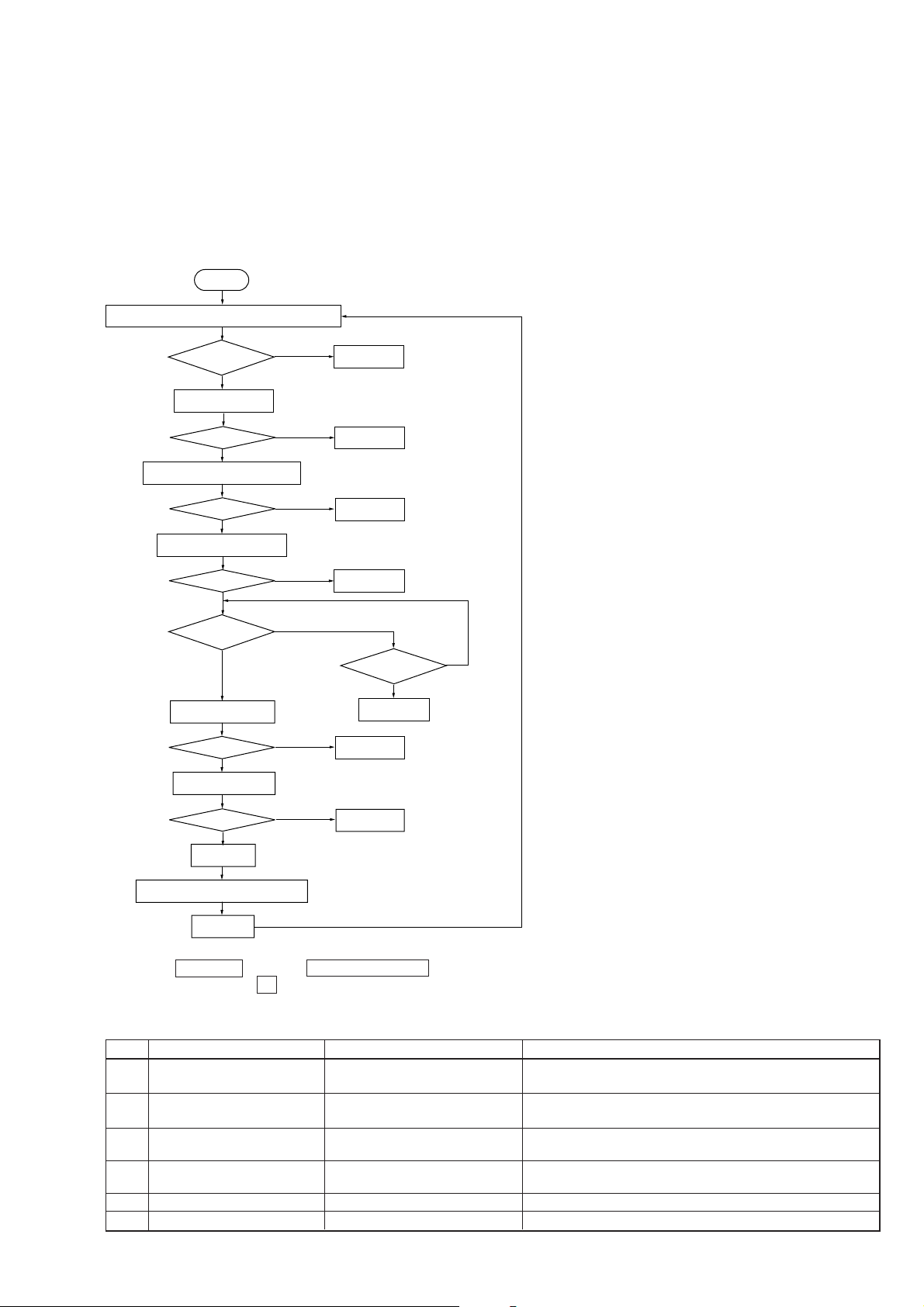

SECTION 5

TEST MODE

AGING MODE

This unit is equipped with an aging mode.

Use this mode for analyzing defects and for checks after completing repairs.

After repairs, perform aging 100 times and check that the unit is normal.

The aging mode is executed in the following sequence.

The aging mode will continue as long as the unit is normal.

If the unit becomes abnormal, it will display the state and number of cycles, and operations will stop. (Refer to Table 1.)

Sequence of Aging Mode:

Start

Sets the CD function and reads the CD TOC.

CD TOC OK?

YES

Pauses first song.

OK?

YES

Last song search paused state

OK?

YES

Starts last song playback

OK?

YES

End playback?

YES

Opens the CD tray

OK?

YES

Closes the CD tray

NO

NO

NO

NO

NO

NO

Message 1

Message 2

Message 3

Message 4

Is CD playing?

Message 4

Message 5

OK

NG

OK?

YES

Power OFF

Display of number of aging cycles

Power ON

NO

Message 6

Procedure:

1. Press the DISPLAY button and =/TUNING/0 button together.

2. To end aging, press the u button and end.

Table-1 Messages and Main Reasons for Stop of Aging

No

1

2

Error Messages

CD No Disc NG

CD Pause NG

Details of Error

Cannot read CD TOC.

Cannot set CD pause in

CD synchro mode.

3

4

5

6

CD Search NG

CD Play NG

CD Open NG

CD Close NG

Cannot search last track on CD.

Cannot play last track on CD.

Cannot open CD tray.

Cannot close CD tray.

Main Causes

Optical defect, spindle defect (including motor), cannot read

Q data, disc defect (scratches, etc.), bad focus, bad GFS, etc.

Disc defect (scratches, etc.), cannot read Q data, etc.

Optical defect, sled, tracking defect (including motor), cannot

read Q data, disc defect (scratches, etc.).

Optical defect, cannot read Q data, disc defect (scratches, etc.),

etc.

LOAD OUT SW defect

LOAD IN SW defect

– 13 –

Page 14

–

+

oscilloscope

BD (CD) board

TP (RF)

TP (VC)

SECTION 6

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with lens cleaning liquid

when the signal level is low than specified value with the following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

Perform this adjustment when the optical pick-up has been replaced

or repaired.

oscilloscope

BD (CD) board

TP (RF)

TP (VC)

Procedure:

1. Connect oscilloscope to test point TP (RF).

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.)

5. After adjustment, check the RF signal level.

• RF signal

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

+

–

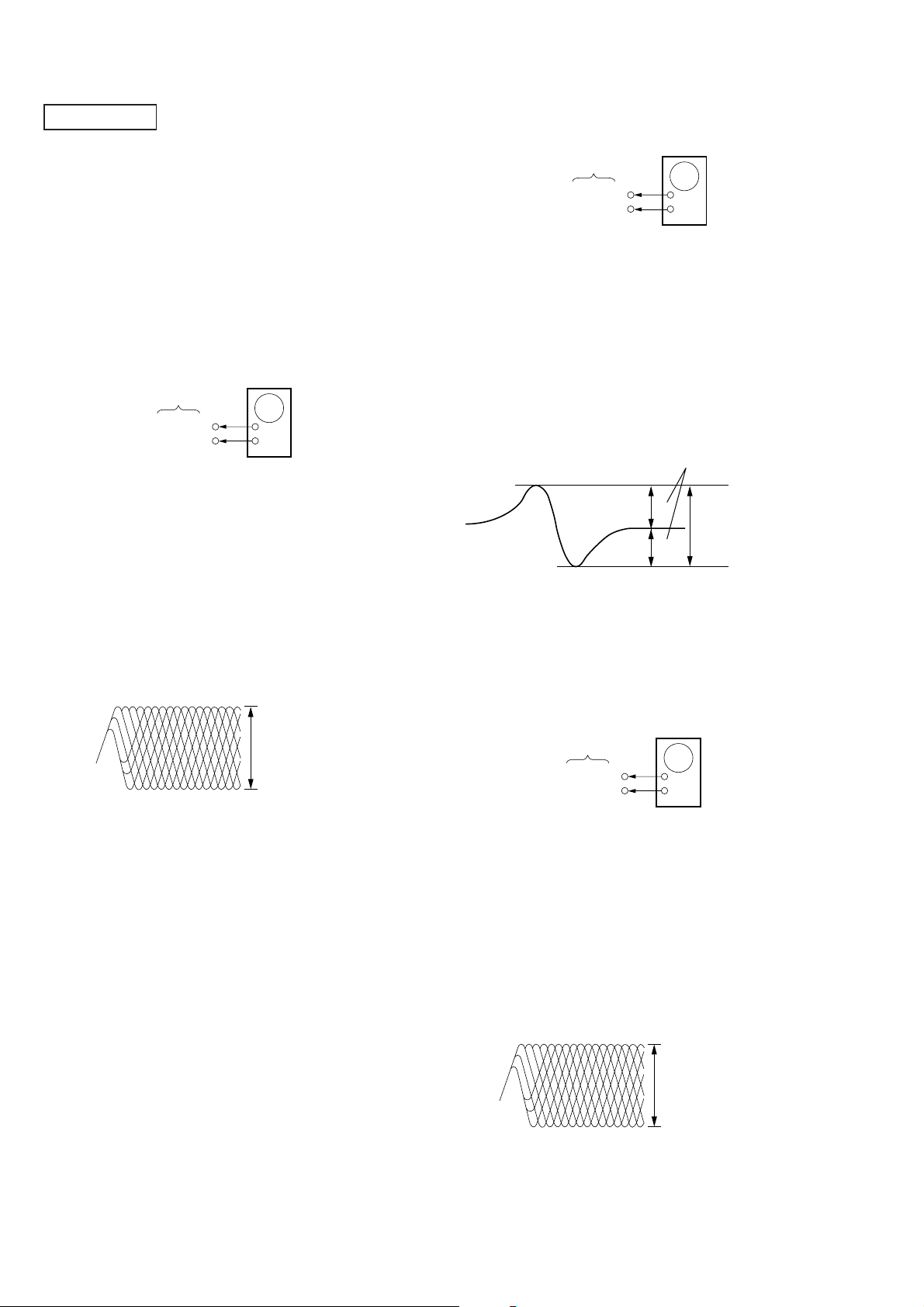

S Curve Check

oscilloscope

BD (CD) board

TP (FEO)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Chec k the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 2.4 ± 0.7

Vp-p.

S-curve waveform

symmetry

A

±

within 2.4

B

0.7 Vp-p

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

• Tak e sweep time as long as possible and light up the brightness to obtain best waveform.

RF Level Check

level : 1.3 ± 0.3 Vp-p

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

• RF signal

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level : 1.3 ± 0.3 Vp-p

– 14 –

Page 15

E-F Balance (1 Track Jump) Check

V

RF

RV101

(Focus Bias Adjust)

RV103

TEO

VC

FEO

RV102

TEI

FEI

FOK

IC101

IC104

GND

PCK

IC102

(Without remote commander)

oscilloscope

BD (CD) board

Adjustment Location:

[BD (CD) BOARD] — Component Side —

TP (TEO)

TP (VC)

+

–

Procedure :

1. Connect oscilloscpe to test point TP (TEO) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (P ause)” button. (Becomes the 1 track jump mode)

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0Vdc, and check this level.

1 track jump waveform

A

0

B

LEVEL : 300 ± 100 mVp-p

Specified level: • x 100 = less than ± 7%

A – B

2 (A + B)

• A + B = 300 ± 100 mVp-p

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

– 15 –

Page 16

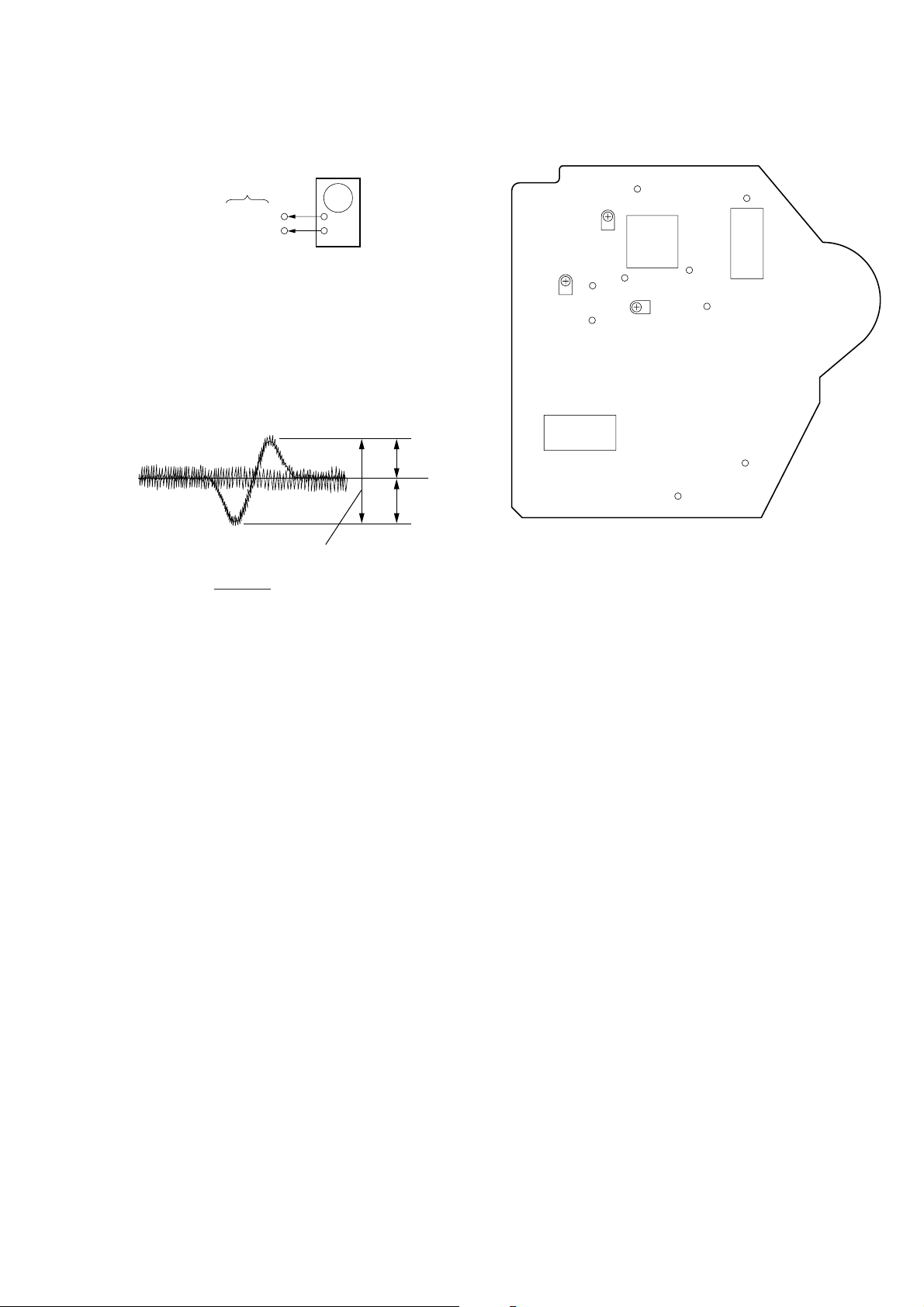

7-1. CIRCUIT BOARDS LOCATION

d

PANEL-SW board

SECTION 7

DIAGRAMS

TRANS board

MAIN board

PANEL board

SUB-TRANS board

BD board

LOADING board

AMP board

REG board

CHEMI-CON boar

HP board

CONNECTOR board

VOLUME board

– 16 –

Page 17

7-2. BLOCK DIAGRAMS

– BD SECTION –

OPTICAL PICK-UP

DETECTOR

E

A

B C

(KSS-213B)

B+

K

A

D

D

C

B

F

HCD-SD1

X101

22.5792 MHz

TRACKING/FOCUS SERVO,

RF AMP

IC101 (1/2)

1

4

2

5

10

6

RV102

FOCUS

GAIN

PD1

35

36

PD2

F

38

39

E

2

FEI

RFO

C.OUT

SENS

FE BIAS

31

30

RFI

23

24

RV101

FOCUS

BIAS

37

+5V

RF

14

DIGITAL SIGNAL PROCESSOR

CNIN

55

SEIN

54

DATAO56XLTO57CLKO59MDP3FOK1XLON

64

IC103

DATA51XLAT52CLOK53SCOR43SQSO46SQCK47SENS49XRST50D OUT

SPOD

63

34

39

XTAI

PCMD

LRCK

BCLK

4

5 • 6

•

XTI

XTO

CKO

DATA

21

20

2

LRCK

1

BCLK

322

LOUT

ROUT

DATA26MLAT28CLOK

27

16

13

DIGITAL FILTER

D/A CONVERTER

IC104

CD LOUT

MAIN

A

SECTION

(Page 19)

LASER

DIODE

PD LD

FOCUS

COIL

SLED/SPINDLE

MOTOR DRIVE

IC102 (2/2)

TRACKING

COIL

2-AXIS

DEVICE

RV103

TRACKING

GAIN

LD DRIVE

Q101, 102

T+

T–

F–

F+

1

FEO

42

TEO

44

TEI

33

LD

34

PHD

XRST

22

7

XRST

18

17

12

11

TRACKING

COIL DRIVE

TRACKING/FOCUS

COIL DRIVE

IC102 (1/2)

FOCUS

COIL DRIVE

SLED

SERVO

IC101 (2/2)

FE-O

FE-M

TA-M

TAO

DATA

XLT

CLK

FOK

FGD

6

7

12

13

21

20

19

25

4

19

9

FOCUS SW

Q103

S101

(LIMIT)

M904 (CD)

LOADING

MOTOR

D OUT

CLK

DATA

XRST

SCOR

SENS

SQCK

SQSO

DF LAT

XLAT

FOCUS SW

MOTOR

DRIVER

IC351

2

DRIVE

5

LOAD-OUT

M

10

DRIVE

6

LOAD-IN

MAIN

A

SECTION

(Page 19)

MAIN

A

SECTION

(Page 19)

M102

SLED MOTOR

M101

SPINDLE

MOTOR

09

• SIGNAL PATH

: CD

: Digital out

26

•

M

27

1

•

M

2

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

25

4

– 17 –

16

SLO

SL+

14

S291

(LOAD OUT)

S292

(LOAD IN)

OUT-SW

IN-SW

– 18 –

Page 18

HCD-SD1

– MAIN SECTION –

ANTENNA

AM

FM

75Ω

J101

(1/2)

L

IN

MD

R

J102

(1/2)

L

IN

CS/BS

R

L

IN

TAPE

R

FLUORESCENT INDICATOR TUBE

VF1

VF0

–VG

BUFFER

Q601

TUNER

UNIT

L-OUT

R-OUT R-CH

STEREO

TUNED

MUTING

FM-DET-OUT

R-CH

BS

R-CH

R-CH

R-CH

IN

4

FL601

56

51

ST

TUN

MUT

DO

DO

CL

CL

DI

DI

CE

CE

12

13

2

1

RDS DECODER

IC451

DATA

14

13

X601

4.3 MHz

5 – 50

VFL

DAT

G12

63 62 61 60

DISPLAY DRIVER

IC601

BUFFER

Q450

SWITCH

IC102

9 10 11

SWITCH

Q103

INT

16

2

CLKCSRST

14

15

R-CH

CD SECTION

(Page 18)

A

SIRCS

IC602

LOUT

R-CH

CD

TUNER

BS/CS

MD

CD

LAT

DAT

CLK

FOCUS SW

DF-LAT

IN SW

OUT SW

LOAD IN

LOAD OUT

D OUT

SOUND PROCESSOR

4

5

6

7

39

38

37

36

20

LATCH

DATA

21

CLOCK

22

90

DAT

65

CLK

66

LAT

67

ST

82

TUN

83

DO

84

DI

85

CL

86

CE

87

MUT

88

100

38

37

36

35

20

21

SCOR

22

SQSO

43

SQCK

45

52

SENS

53

CLK

57

DAT

58

59

XLAT

60

XRST

63

49

50

61

62

IC101(1/2)

• VOLUME

SIRCS

SDATA

SCLOCK

SLAT1

STEREO

TUNED

ST.IDATA

ST.ODATA

ST.CLOCK

ST.LATCH

ST.MUTE

V/T

FL.RST

FL.LAT

FL.SLK

FL.DAT

RDS.CLK

RDS.DAT

SCOR

SQSI

SQCK

FSW

SENS

CD-CLK

CD-DATA

DF-LAT

DSP-LAT

BD.RESET

IN SW

OUT SW

LOAD IN

LOAD OUT

TREBLE

IC701

SP RELAY SW

15

8

28

35

ON/XSRBY

FLDISP SW

2

I C.CLOCK

ENCODERB

ENCODERA

TIMER LED

STBY LED

PANEL SW

BD POWER

BASS/

AMP

MASTER CONTROL

DEFB SW

Q121

R-CH

R-CH R-CH

TC-MUT

99

MD-MUT

98

MUTE2

69

76

MUTE1

68

31

HPSW

81

75

HELP

51

2

55

I C.DAT

56

26

KEY2

25

KEY1

19

18

XT1

14

XT2

13

11

X2

X1

10

73

72

ON LED

70

64

LIGHT

8

AC CUT

15

RESET

2

1

+8dB AMP

IC103

3

5 7

MUTE SW

Q183

MUTE SW

Q182

MUTE SW

Q181

SWITCH

Q753

X702

32KHz

X701

5MHz

SWITCH

Q752

RESET

Q751

PANEL SW

S699

S621-625,631-634

R-CH

R-CH

1

KEY BOARD

SWITCH

2

1

3 1

SOUND PROCESSOR

IC101(2/2)

16

DBFB

27

MUTE

Q111

MUTE

Q112

SWITCH

Q793

SWITCH

Q791

VOLUME

S691

t

TIMER:RED

D605

D601-604

RESET

IC951

TO IC701 VDD

SWITCH

Q943

18

25

AMP

R-CH

R-CH

u

ON:GREEN

STANDBY:RED

D606

D601

)/±

D752

SWITCH

Q792

R-CH

J101(2/2)

J102(2/2)

D602

0/≠

STBY+5.6V

D751

+

C759 BACK UP

L

MD

OUT

R

L

TAPE

OUT

R

D603

MUTE

Q141

LY

LXSYSX

2

I C BUS

EXTENDER

IC791

D604

π

fl

POWER AMP

IC801

10

+

3

–

9

8

MUTE

Q505

HLP

DAT

76

CLK

23

R-CH

D881

RELAY SW

Q502,503

RELAY SW

Q501

A±7.5VREG

D±5V

M+7V

CDD+5V

ST12V

STBY+5.6V

VG SWITCH

VF SWITCH

Q965

Q966

R-CH

A±7.5VREG

Q941, 946

3

D+5VREG

M+7VREG

3

CDD+5V SW

ST 12V OUT

Q951,952

SPEAKER RELAY

RY501

RELAY DRIVE

Q504

±B

1

IC921

1

IC922

Q942

3 1

VG

VF1

VF0

RECT

D971

RECT

D941-944

RECTIFIER

D921,922

RECTIFIER

Q951,953

STBY+5.6V REG

IC901

VG SW

Q964

VF SW

Q962,963

R-CH

UG REG

Q961

T991

MAIN

TRANSFORMAER

RECT

D901-904

RECT

D961-964

R-CH

FAN-DRIVE

Q551–553

R-CH

DAT

HLP

CLK

RY901

STANDBY RELAY

T991

SUB

TRANSFORMER

• R ch is same as L ch

• SIGNAL PATH

: FM

BS

:BS/CS

TMB11

+

–

–

+

FAN

CN781

1

2

5

IC311

DOUT

AC IN

AC OUTLET

CN904

L

R

J667

PHONES

SYSTEM

CONTROL

DIGITAL

OPTICAL

SPEAKER

INPEDANCE

6-16Ω

: PB

: REC

: CD

: Digital out

: TAPE

– 19 –

– 20 –

Page 19

HCD-SD1

2.6 Vp-p

7.6 µs

5.1 Vp-p

136 µs

4.6 Vp-p

16.9344 MHz

Approx.

150 mVp-p

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• 2 : nonflammable resistor.

• 1 : fusible resistor.

• C : panel designation.

Note: The components identified by mark ! or dotted line

• S : B+ Line.

• T : B– Line.

• H : adjustment for repair.

• Voltages and wav ef orms are dc with respect to ground in

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

Signal path.

• Abbreviation

: internal component.

with mark ! are critical for safety.

Replace only with part number specified.

service mode.

Voltage var iations may be noted due to normal produc-

tion tolerances.

Voltage var iations may be noted due to normal produc-

tion tolerances.

F : FM

E : PB (MD)

m : PB (TAPE)

n : REC

J : CD

c : digital out

SP : Singapore model.

HK : Hong Kong model.

4

W or less unless otherwise

WAVEFORMS

– BD SECTION –

1

IC101 #¡ (RFO) (PLAY Mode)

500 mV/DIV, 500 ns/DIV

2

IC101 $¢ (TEI) (PLAY Mode)

50 mV/DIV, 1 µs/DIV

3

IC101 2 (FEI) (PLAY Mode)

50 mV/DIV, 1 µs/DIV

4

IC103 3 (MDP) (PLAY Mode)

5

IC103 @• (RFCK)

6

14 ns

IC103 @∞ (XPCK)

1.3 ± 0.3 Vp-p

Approx.

100 mVp-p

5.3 Vp-p

– MAIN SECTION –

1

4.3 Vp-p

5 MHz

IC701 !¡ (XI)

2

2.6 Vp-p

32 kHz

IC701 !¢ (XI)

For printed wiring boards.

Note:

• X : parts extracted from the component side

• p : parts mounted on the conductor side.

®

•

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

: Through hole.

¢

: internal component.

• Indication of transistor

C

Q

EB

These are omitted

C

EB

These are omitted

7

5 Vp-p

474 ns

IC103 @™ (BCLK)

8

5.1 Vp-p

22.8 µs

IC103 @º (LRCK)

9

IC104 6 (XTO)

– 21 – – 22 –

Page 20

HCD-SD1

7-3. SCHEMATIC DIAGRAM – BD SECTION –

• See page 22 for Waveforms.

• See page 51 for IC Block Diagrams.

Note on Schematic Diagram:

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : Stop

( ) : CD (PLAY)

* : Can not be measured.

(Page 29)

– 23 –

– 24 –

Page 21

7-4. PRINTED WIRING BOARD – BD SECTION –

• See page 16 for Circuit Boards Location.

HCD-SD1

• Semiconductor

Location

Ref. No. Location

IC103 C-1

Q101 B-3

Q103 C-3

• Semiconductor

Location

Ref. No. Location

IC101 B-1

IC102 B-1

IC104 C-3

Q102 B-1

OPTICAL PICK-UP

BLOCK

KSS-213BA/S-N

(Page 32)

– 25 – – 26 –

Page 22

HCD-SD1

7-5. SCHEMATIC DIAGRAM – MAIN (1/2) SECTION –

• See page 22 for Waveforms.

• See page 31 for Printed Wiring Board.

(Page 39)

(Page

29)

– 27 –

(Page

29)

– 28 –

Page 23

7-6. SCHEMATIC DIAGRAM – MAIN (2/2) SECTION –

• See page 22 for Waveforms.

• See page 31 for Printed Wiring Board.

• See page 53 for IC Block Diagrams.

• See page 54 for IC Pin Functions.

HCD-SD1

(Page

28)

(Page 43)

(Page 24)

(Page 43)

(Page 36)

(Page

28)

(Page 48)

(Page 35)

(Page 48)

– 29 – – 30 –

Page 24

HCD-SD1

• Semiconductor

Location

Ref. No. Location

D351 A-6

D751 G-5

D752 G-5

D753 G-6

D755 G-6

D791 B-5

D792 B-5

D793 B-5

IC101 C-3

IC102 D-2

IC103 A-1

IC351 A-5

IC701 C-6

IC791 B-6

IC951 G-6

Q103 D-2

Q111 B-1

Q112 C-1

Q121 D-4

Q141 C-4

Q181 D-4

Q182 D-4

Q183 D-4

Q211 B-1

Q212 C-1

Q222 B-3

Q241 B-4

Q751 G-7

Q752 B-7

Q753 C-6

Q781 F-8

Q782 F-8

Q783 F-8

Q791 B-6

Q792 B-6

Q793 C-6

7-7. PRINTED WIRING BOARD – MAIN SECTION –

• See page 16 for Circuit Boards Location.

R

OUT

L

R

IN

L

R

OUT

L

R

IN

L

R

IN

L

AEP, UK

(Page 45)

*1

JW734

JW735

R735

: MOUNT

: NO MOUNT

AEP, UK SP, HK

(Page 41)

(Page 46)

(Page 26)

(Page 37)

*1

X601

AEP, UK

– 31 – – 32 –

(Page 38)

(Page 50)(Page 50)

Page 25

HCD-SD1

7-8. SCHEMATIC DIAGRAM – SUB SECTION –

(Page 47)

11EQS04

11EQS04

11EQS04

11EQS04

11ES2-NTA2B

11ES2NTA2B

11ES2NTA2B

11ES2-NTA2B

DTC114ESA

DTA114ESA-TP

7-9. PRINTED WIRING BOARD – SUB SECTION –

• See page 16 for Circuit Boards Location.

(Page 49)

(Page 43)

DTA114ESA-TP

(Page 45)

• Semiconductor Location

Ref. No. Location

D901 B-2

D902 B-1

D903 B-1

D904 B-1

D905 C-2

D906 B-3

D961 B-2

D962 B-2

D963 B-2

D964 B-2

D965 C-2

Ref. No. Location

D966 C-1

IC901 C-2

Q901 B-3

Q961 C-2

Q962 B-3

Q963 C-3

Q964 C-3

Q965 C-2

Q966 C-2

– 33 –

– 34 –

Page 26

HCD-SD1

7-10. SCHEMATIC DIAGRAM – PANEL SECTION –

(Page 30)

(Page 30)

– 35 – – 36 –

Page 27

7-11. PRINTED WIRING BOARD – PANEL SECTION –

• See page 16 for Circuit Boards Location.

HCD-SD1

(Page 32)

(Page 32)

E

• Semiconductor

Location

Ref. No. Location

D601 C-3

D602 C-3

D603 C-4

D604 C-5

D605 B-7

AEP, UK

D606 B-7

IC601 B-5

IC602 B-2

Q601 C-3

– 37 –

– 38 –

Page 28

HCD-SD1

7-12. SCHEMATIC DIAGRAM – AMP SECTION –

(Page 47, 48)

(Page 28)

– 39 – – 40 –

(Page 43)

Page 29

7-13. PRINTED WIRING BOARD – AMP SECTION –

• See page 16 for Circuit Boards Location.

HCD-SD1

• Semiconductor

Location

Ref. No. Location

D553 A-5

D554 A-5

D971 A-5

D972 A-5

Q505 B-4

Q551 A-5

Q552 A-5

Q553 A-4

(Page 50)

(Page 31)

(Page 45)

– 41 –

– 42 –

Page 30

HCD-SD1

7-14. SCHEMATIC DIAGRAM – CONNECTOR SECTION –

(Page 30)

(Page 29)

(Page 40)

(Page 33)

– 43 – – 44 –

Page 31

7-15. PRINTED WIRING BOARD – CONNECTOR SECTION –

11

(11)

CN291

S291

(LOAD OUT)

1

2

3

4

5

M904

(LOADING

MOTOR)

M

LOADING BOARD

S292

(LOAD IN)

1-634-461-

(Page 32)

• See page 16 for Circuit Boards Location.

(Page 31, 32)

(Page 34)

DIGITAL

OPTICAL

CD AUX

HCD-SD1

• Semiconductor

Location

Ref. No. Location

D501 B-3

D556 B-3

D557 C-3

D881 D-2

IC311 B-5

Q501 B-2

Q502 B-2

Q503 B-3

Q504 B-3

(Page 42)

AEP, UK

SPEAKER

INPEDANCE

SYSTEM

CONTROL

– 45 –

– 46 –

Page 32

HCD-SD1

7-16. SCHEMATIC DIAGRAM – REG SECTION –

(Page 40)

(Page 29)

(Page 29)

(Page 33)

– 47 – – 48 –

Page 33

7-17. PRINTED WIRING BOARD – REG SECTION –

• See page 16 for Circuit Boards Location.

AC

OUTLET

MDS-SD1

ONLY

UNSWITCHED

200W MAX

HCD-SD1

NOT REPLACEABLE:

BUILT IN TRANSFORMER

(Page 34)

(Page 32)

(Page 32)

(Page 42)

• Semiconductor

Location

Ref. No. Location

D921 A-4

D922 A-4

D941 A-4

D942 A-4

D943 A-4

D944 A-4

D945 B-2

D946 B-1

D952 B-1

– 49 –

IC921 B-3

IC922 B-3

Q941 B-2

Q942 C-2

Q943 C-2

Q951 A-1

Q952 B-1

– 50 –

Page 34

HCD-SD1

A

7-18. IC BLOCK DIAGRAMS

• BD section

IC101 CXA1782BQ

PHD2

37FE BIAS

38F

39E

40EI

41VEE

42TEO

43LPFI

44TEI

45ATSC

46TZC

47TDFCT

48VC

PHD1

36

35 34

BAL1

TOG1

• WINDOW COMP

PHD

–

RF IV AMP1

RF IV AMP2

F IV AMP

E IV AMP

BAL2

TOG2

ATSC

–

+

+

–

APC

–

+

–

+

BAL3

TOG3

+

–

+

–

+

TE AMP

+

FE AMP

1

FEO

IC102 BA6397FP

GND

OUT4

OUT4B

IN4A

28

27

26

LD

33

–

+

RF M

32

–

+

–

+

LEVELS

+

–

FOK

TTL

IIL

FZC COMP

–

DFCT

3

2

FEI

FDFCT

DFCT

FS4

31

–

–

+

–

+

–

+

+

–

TZC COMP

RF O

–

+

RF I

30

–

+

+

+

–

MIRR

• IIL DATA RESISTOR • INPUT SHIFT RESISTOR

TOG1-3 FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

–

+

HPF COMP LPF COMP

• FCS PHASE

COMPENSATION

TM1

5

4

FLB

FGD

–

+

FS2

+

–

6

FE O

+

–

• ADDRESS DECODER

• OUTPUT DECODER

TG1

FS1

7

FE M

CB

29CP28

DFCT

• TRACKING

• PHASE

COMPENSATION

9

8

SRCH

TGU

–

TM7

TG2

+

TM6

TM5

TM4

TM3

CC126CC225FOK

27

–

+

24 SENS

IIL

TTL

23 C. OUT

22 XRST

TTL

21 DATA

20 XLT

IIL

19 CLK

18 VCC

IC103 CXD2507AQ

FOK

MON

MDP

• ISET

17 ISET

MDS

LOCK

TEST

FILO

–

16 SL 0

+

FILI

PCO

VSS

15 SL M

AVSS

CLTV

AVDD

TM2

14 SL P

+

1312TA O

–

RF

BIAS

ASYI

ASYO

ASYE

WDCK

• F SET

11

10

TG2

FSET

TA M

DRIVE

BUFFER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

DRIVE

BUFFER

1

OUT1A

2

OUT1B

SERVO AUTO

SEQUENCER

14

INTERFACE

DIGITAL

PLL

ASYMMETRY

CORRECTOR

5

SHIFT

LEVEL

DRIVE

BUFFER

XLON

CPU

LRCK

PCMD

BUFFER

LEVEL

THERMAL

SHUT DOWN

3

IN1A

SPOD

SPOC

16K

RAM

BCLK

DRIVE

SPOB

GTOP

IN4B

24

25

SHIFT

4

5

IN1B

TR-B

DD

SPOA

CLKO

V

5

SUB CODE

PROCESSOR

EFM

DEMODULATOR

3

ERROR

CORRECTOR

3

DD

V

XUGF

XPCK

XLTO

INTERFACE

GFS

VC

23

REGULATOR

6

REG 0

DATO

CNIN

4

D/A

RFCK

CZPO

V

SEIN

CLOK

DIGITAL

CLV

6

XROF

MNT3

CC

V

22

CC

7

XRST

52535455565758596061626364

32313029282726252423222120

XLAT

DIGITAL

MNT1

OUT

VCCIN3B

21

V

CC

8

GND

CLOCK

GENERATOR

20

9

IN2A

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

DRIVE

BUFFER

DATA

XRST

SENS

MUTE

SQCK

SQSO

EXCK

SBSO

SCOR

SS

V

WFCK

EMPH

DOUT

C4M

FSTT

XTSL

XTAO

XTAI

MNTO

IN3A

19

SHIFT

LEVEL

DRIVER MUTE

SHIFT

LEVEL

DRIVE

BUFFER

10

IN2B

OUT3B

18

11

OUT2A

OUT3AOP+

17

16

DRIVE

BUFFER

DRIVE

BUFFER

12

13

GND

OUT2B

OP–

15

14

OP-OUT

– 51 – – 52 –

Page 35

IC104 PCM1710U-R

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

V

VCC2R

GND2R

EXT1R

EXT2R

VOUTR

GND1

1

2

3

4

5

6

7

8

DD

9

10

11

12

13

14

INPUT

INTERFACE DIGITAL

TIMING

CONTROL

5-LEVEL DAC

RIGHT

LOW-PASS FILTER

RIGHT

3-STAGE AMP

RIGHT

FILTER

NOISE

SHAPER

MODE

CONTROL

5-LEVEL DAC

LEFT

LOW-PASS FILTER

LEFT

3-STAGE AMP

LEFT

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/DSD

MC/DM2

MD/DM1

MUTE

MODE

CKSL

DGND

DD

V

VCC2L

GND2L

EXT1L

EXT2L

VOUTL

V

CC1

– MAIN Section –

IC351 LB1641

T.S.D O.C.P

MOTOR

DRIVE

FWD/REV/STOP

CONTROL LOGIC

2 3

1

GND

DRIVE

MOTOR

NOISE

FILTER

5 6 7 8 9 10

4

VCC 1

FWD.IN

REV.IN

CLAMP

VCC 2

IC791 P82B715TD.118

NC

SDA

VCC

8

6

BUFFER

NC

5

1

LDA

7

NOISE

MOTOR

DRIVE

FILTER

DRIVE

MOTOR

SCL

3

BUFFER

4

GND

LCL

2

– 53 –

Page 36

7-19. IC PIN FUNCTIONS

• IC701 System Control (µPD780018AYGF-015-3BA) (MAIN Board)

Pin No.

1 BD POWER O CD power control pin, “H”:CD POWER ON

2 PANEL SW I Front cover open/close switch, “H”:Open glass door, “L”:Close glass door

3 to 7 – I Not used

8 AC.CUT I AC power connection signal, “L”:Power is disconnected

9 VPP – Normally connected to the ground pin

10 X2 O Main system clock output pin (5 MHz)

11 X1 I Main system clock input pin (5 MHz)

12 VDD1 – Positive power supply (+5V)

13 XT2 O Sub system clock output pin (32 kHz)

14 XT1 I Sub system clock output pin (32 kHz)

15 RESET I System reset input pin, “L”:RESET

16, 17 – I Not used

18 ENCODER A I Encoder input pin for jogging

19 ENCODER B I Encoder input pin for jogging

20 RDSCLK I RDS clock input pin (Not used)

21 RDSDAT I RDS data input pin (Not used)

22 SCOR I SCOR input pin

23 VDD0 – Positive power supply of port (+5V)

24 ADREF – Reference voltage of A/D converter (+5V)

25 KEY1 I Key input pin (Analog input)

26 KEY0 I Key input pin (Analog input)

27 to 30 – I Not used

31 HP-SW I Headphone detection SW, “L”:No HP, “H”:HP

32 – I Not used

33 AVSS – A/D converter ground potential

34 – I Not used

35 FL.DAT O Serial data output for FL tube control IC (MSM9202-02)

36 FL.CLK O Serial clock output for FL tube control IC (MSM9202-02)

37 FL.LAT O Chip select output for FL tube control IC (MSM9202-02)

38 FL.RST O Reset signal output for FL tube control IC (MSM9202-02)

39 – I Not used

40 VSS1 – Ground potential other than port and analog

41, 42 – I Not used

43 SQSI I CD sub code data input

44 – I Not used

45 SQCK O Clock output for reading CD sub code

46 to 48 – I Not used

49 IN-SW I CD tray close completion detection input, “L”:CLOSE

50 OUT-SW I CD tray open completion detection input, “L”:OPEN

51 HELP I Pin requesting power ON from the PC link adapter (optional), Normally “H”

52 FSW O Focus gain switch

53 SENSE I SENSE input pin

54 – I Not used

55 IIC DAT I/O System control communication data input/output pin

56 IIC CLOCK I/O System control communication clock input/output pin

57 CD-CLK O Serial clock for CD control

58 CD-DATA O Serial data for CD control

59 DF-LAT O Chip select signal for DA/DF

60 DSP-LAT O DSP IC and SSP IC chip select

Pin Name

I/O

Function

– 54 –

Page 37

Pin No.

61 LOAD IN O Tray loading motor control signal, “L”:Loading

62 LOAD OUT O Tray loading motor control signal, “L”:When OPEN

63 BD.RESET O IC reset signal for CD control, “L”:RESET

64 LIGHT O BLUE LED control port of front panel, “L”:LED ON

65 SDATA O Serial data for SOUND PROCESSOR IC101 (M62428AFP)

66 SCLOCK O Serial clock for SOUND PROCESSOR IC101 (M62428AFP)

67 SLAT1 O Chip select for SOUND PROCESSOR IC101 (M62428AFP)

68 MUTE1 O Audio mute signal, “H”:Power amplifier ICs (IC801, IC851) MUTE

69 MUTE2 O Audio mute signal, “L”:Line mute (Q141, Q241) MUTE

70 STANDBY LED O Signal controlling LED which lights when power is OFF, “L”:LED ON

71 VSS0 – Ground potential of port

72 ON LED O Signal controlling LED which lights when power is ON, “L”:LED ON

73 TIMER LED O Signal controlling LED which lights in timer standby, “H”:LED ON

74 – I Not used

75 FL DISP SW O Power ON/OFF signal for FL display, “H”:FL display ON

76 SP RELAY SW O Speaker relay control signal, “L”:Speaker relay ON

77 to 80 – I Not used

81 ON/XSTBY O System power control signal, “H”:Standby relay ON

82 STEREO I Tuner stereo signal, “L”:Stereo

83 TUNED I Tuner selection OK signal, “L”:TUNED

84 ST IDATA I Serial input data for tuner

85 ST ODATA O Serial output data for tuner

86 ST.CLOCK O Serial clock for tuner

87 ST LATCH O Chip select for tuner

88 ST MUTE O Tuner mute output

89 ST POWER O Tuner power signal (Not used)

90 SIRCS I SIRCS code input signal (Remote control signal input)

91 PCL I 32 KHz clock monitor out

92, 93 – I Not used

94 DEST1 I Destination differentiation signal (Fixed at “H”)

95 DEST2 I Destination differentiation signal (Fixed at “L”)

96 – I Not used

97 HP MUTE O HP mute signal output

98 MD-MUTE O MD REC OUT control signal “L”:MD REC OUT MUTE (“L” only for MD function)

99 TC-MUTE O REC OUT control signal of TAPE

100 V/T O Function control signal “H”:TAPE, “L”:CS/BS

Pin Name

I/O

32.768 kHz signal is output in the test mode (Refer to page 12.)

“L”:TAPE REC OUT MUTE (“L” only for TAPE function)

Function

– 55 –

Page 38

SECTION 8

EXPLODED VIEWS

NOTE:

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

• The mechanical parts with no reference number in

the exploded views are not supplied.

8-1. FRONT PANEL SECTION

not supplied

Supplied with J667

13

14

8

5

• Hardware (# mark) list and accessories and packing materials are given in the last of this parts list.

• Abbreviation

HK : Hong Kong model

SP : Singapore model

14

17

19

15

14

16

12

FL601

24

not supplied

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

20

18

19

1

4

7

2

6

#2

not supplied

3

2

3

22

23

14

Ref. No. Part No. Description Remark

1 X-4950-580-1 GLASS ASSY (CD)

2 4-212-584-01 BRACKET (SHAFT)

3 4-993-007-01 SCREW (M2.6X6), +P TAPPING

4 4-942-636-21 EMBLEM (NO.3.5), SONY

5 4-212-538-11 PANEL (AL-CD), FRONT

6 X-4950-364-1 KNOB (VOL) ASSY

7 4-212-542-11 RING (VOL)

8 X-4950-995-1 PANEL ASSY (CD), FRONT

9 4-212-580-11 SPRING (GLASS)

10 X-4950-999-1 BRACKET (R) ASSY

* 11 1-671-610-11 VOLUME BOARD

12 X-4950-998-1 BRACKET (L) ASSY

* 13 1-671-617-11 PANEL-SW BOARD

21

11

10

9

#1

Ref. No. Part No. Description Remark

14 4-951-620-01 SCREW (2.6X8), +BVTP

15 1-769-940-11 WIRE (FLAT TYPE) (11 CORE)

16 1-769-972-11 WIRE (FLAT TYPE) (13 CORE)

* 17 1-671-609-11 HP BOARD

* 18 A-4419-060-A PANEL BOARD, COMPLETE

19 3-363-099-51 SCREW (CASE 3 TP2)

* 20 4-212-561-31 CASE

21 4-212-540-11 PANEL (AL-CD), LOADING

22 4-212-541-11 PANEL (CD), LOADING

23 4-212-545-11 PLATE (CD), ORNAMENTAL

* 24 4-212-590-11 HOLDER (FL)

FL601 1-517-805-11 INDICATOR TUBE, FLUORESCENT

– 56 –

Page 39

8-2. CHASSIS SECTION

)

#2

51

CDM13B-5BD19

52

not supplied

#2

not supplied

66

67

54

#2

53

55

#1

#1

#1

not supplied

T991

#1

#1

not

supplied

not

supplied

#2

#2

#2

M551

#4

61

64

#4

#1

56

CN904

#5

57

60

65

58

(UK,HK

#2

#2

#2

59

62

#1

not supplied

#2

#2

63

not supplied

#2

63

#2

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 51 A-4419-059-A MAIN BOARD, COMPLETE (AEP,UK)

* 51 A-4419-070-A MAIN BOARD, COMPLETE (SP,HK)

* 52 A-4419-068-A REG BOARD, COMPLETE

53 1-790-305-11 WIRE (FLAT TYPE) (19 CORE)

54 1-693-408-11 TUNER

* 55 1-671-615-11 TRANS BOARD

* 56 A-4419-064-A CHEMI-CON BOARD, COMPLETE

! 57 1-575-651-91 CORD, POWER

* 58 3-703-244-00 BUSHING (2104), CORD

* 59 4-212-564-11 PANEL (CD), BACK

60 1-773-108-11 WIRE (FLAT TYPE) (19 CORE)(100mm)

* 61 A-4419-065-A SUB-TRANS BOARD, COMPLETE

* 62 1-671-614-11 CONNECTOR BOARD

63 X-4950-994-1 FOOT ASSY

* 64 1-671-611-11 AMP BOARD

! 65 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P (UK,HK)

66 3-531-576-01 RIVET

67 3-655-653-01 BAND (TAITON), BINDING

! CN904 1-526-794-11 OUTLET, AC

M551 1-698-997-21 FAN, D.C.

! T991 1-433-478-11 TRANSFORMER, POWER

– 57 –

Page 40

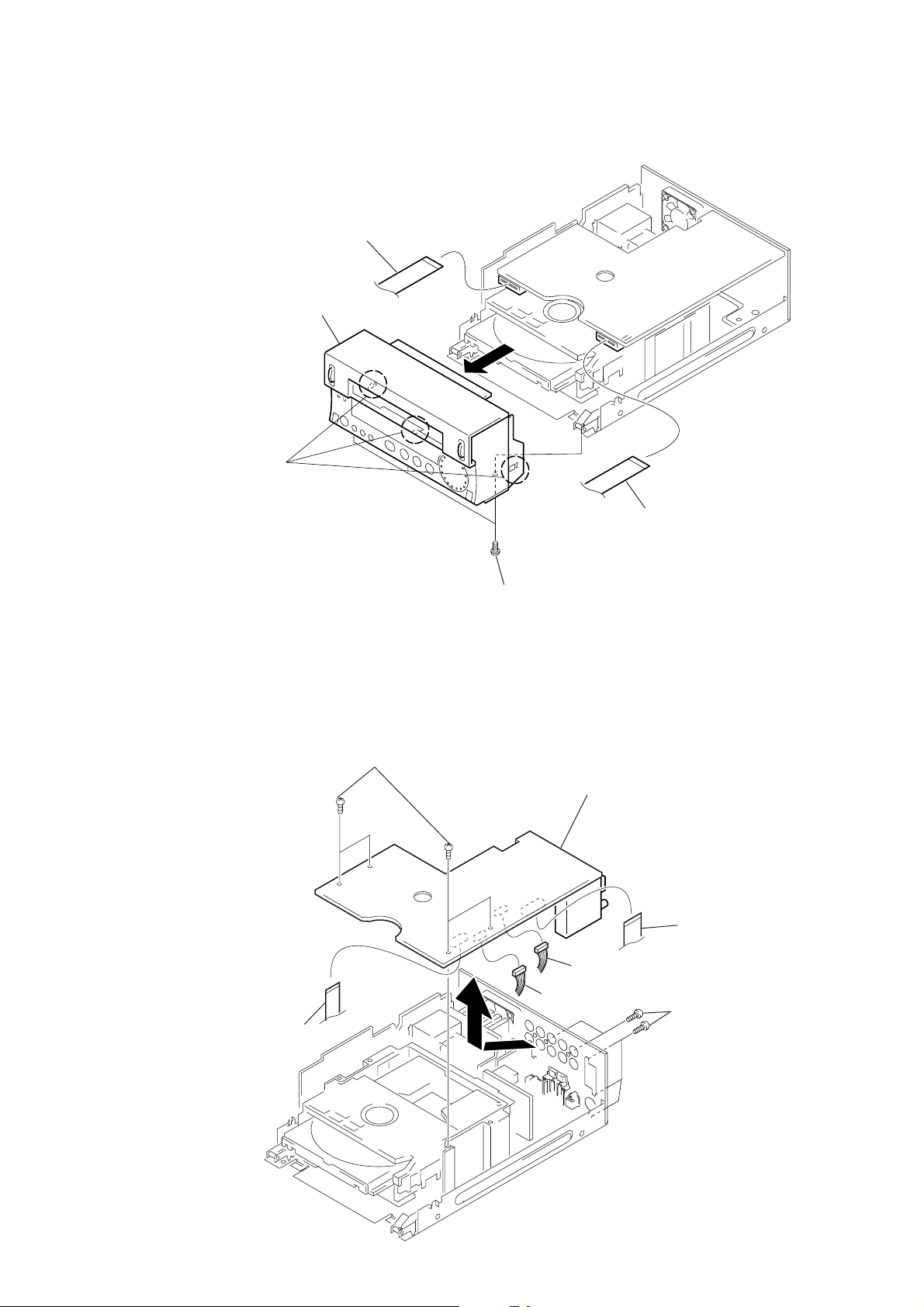

8-3. MECHANISM DECK SECTION (CDM13B-5BD19)

211

#2

#2

not supplied

212

#7

204

201

218

202

219

#2

205

#6

207

206

M904

210

203

216

215

#6

208

209

#8

213

#2

214

215

BU-5BD19

216

not supplied

217

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 201 1-634-461-11 LOADING BOARD

202 4-927-654-01 WASHER (LIMITER)

203 3-659-338-00 SPRING, COMPRESSION

204 4-929-764-01 SHAFT (TABLE GUIDE)

205 4-927-620-01 GEAR (P)

206 4-944-006-11 BEARING

207 4-927-628-01 GEAR (C)

208 4-927-649-01 BELT

209 4-929-724-01 PULLEY (B)

210 X-4947-265-1 ARM ASSY, SWING

211 4-944-012-01 TABLE, DISC

212 A-4604-752-A HOLDER (MG) ASSY

* 213 4-917-583-21 BRACKET, YOKE

214 X-4941-462-1 CHASSIS (MD) ASSY

215 4-933-134-01 SCREW (+PTPWH M2.6X6)

216 4-958-593-01 SPRING (BU), COMPRESSION

217 4-929-747-01 HOLDER (BU)

218 4-929-727-01 CAM (A)

219 4-929-729-01 CAM (B)

M904 A-4660-307-A MOTOR (L) ASSY (LOADING)

– 58 –

Page 41

8-4. BASE UNIT SECTION (BU-5BD19)

M101

255

256

259

257

253

M102

254

254

258

252

251

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

251 4-951-620-01 SCREW (2.6X8), +BVTP

* 252 A-4673-402-B BD BOARD, COMPLETE

253 4-917-565-01 SHAFT, SLED

254 4-951-940-01 INSULATOR (BU)

! 255 8-848-379-31 OPTICAL PICK-UP KSS-213B/S-N

256 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

257 4-917-567-01 GEAR (M)

258 4-917-564-01 GEAR (P), FLATNESS

259 3-713-786-51 SCREW +P 2X3

M101 X-4917-523-4 MOTOR ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 59 –

Page 42

SECTION 9

AMP

Note:

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board

name.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-671-611-11 AMP BOARD

C801 1-124-720-11 ELECT 4.7uF 20% 50V

C803 1-162-215-31 CERAMIC 47PF 5% 50V

C804 1-124-724-11 ELECT 47uF 20% 50V

C805 1-162-215-31 CERAMIC 47PF 5% 50V

C806 1-164-159-11 CERAMIC 0.1uF 50V

C807 1-164-159-11 CERAMIC 0.1uF 50V

C808 1-164-159-11 CERAMIC 0.1uF 50V

C809 1-163-038-91 CERAMIC 0.1uF 25V

C841 1-126-948-11 ELECT 100uF 20% 35V

C842 1-126-948-11 ELECT 100uF 20% 35V

C851 1-124-720-11 ELECT 4.7uF 20% 50V

C853 1-162-215-31 CERAMIC 47PF 5% 50V

C854 1-124-724-11 ELECT 47uF 20% 50V

C855 1-162-215-31 CERAMIC 47PF 5% 50V

C856 1-164-159-11 CERAMIC 0.1uF 50V

C857 1-164-159-11 CERAMIC 0.1uF 50V

IC801 8-759-331-41 IC LM3876TF

IC851 8-759-331-41 IC LM3876TF

R801 1-249-417-11 CARBON 1K 5% 1/4W F

R802 1-249-437-11 CARBON 47K 5% 1/4W

R803 1-249-417-11 CARBON 1K 5% 1/4W F

R804 1-249-437-11 CARBON 47K 5% 1/4W

R805 1-249-433-11 CARBON 22K 5% 1/4W

R806 1-249-389-11 CARBON 4.7 5% 1/4W F

R851 1-249-417-11 CARBON 1K 5% 1/4W F

R852 1-249-437-11 CARBON 47K 5% 1/4W

R853 1-249-417-11 CARBON 1K 5% 1/4W F

R854 1-249-437-11 CARBON 47K 5% 1/4W

R855 1-249-433-11 CARBON 22K 5% 1/4W

R856 1-249-389-11 CARBON 4.7 5% 1/4W F

**************************************************************

* A-4673-402-B BD BOARD, COMPLETE

BD

• Due to standardization, replacements in the parts list

• -XX, -X mean standardized parts, so they may have

• Items marked “*” are not stocked since they are

• RESISTORS

*********

< CAPACITOR >

< IC >

< RESISTOR >

******************

ELECTRICAL PARTS LIST

may be different from the parts specified in the

diagrams or the components used on the set.

some difference from the original one.

seldom required for routine service. Some delay

should be anticipated when ordering these items.

All resistors are in ohms

METAL: Metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F : nonflammable

C103 1-164-346-11 CERAMIC CHIP 1uF 16V

C105 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C106 1-164-690-91 CERAMIC CHIP 0.0022uF 5% 50V

C107 1-164-690-91 CERAMIC CHIP 0.0022uF 5% 50V

C108 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C109 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C110 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C111 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C112 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C113 1-164-690-91 CERAMIC CHIP 0.0022uF 5% 50V

C114 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-163-016-00 CERAMIC CHIP 0.0039uF 10% 50V

C117 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C118 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C119 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C120 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C121 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C122 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C123 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C124 1-126-607-11 ELECT CHIP 47uF 20% 4V

C125 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C126 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C127 1-164-690-91 CERAMIC CHIP 0.0022uF 5% 50V

C128 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

C129 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C130 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C131 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C132 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C133 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C134 1-164-346-11 CERAMIC CHIP 1uF 16V

C135 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C136 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C137 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C139 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C140 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C141 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C142 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C145 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C146 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C147 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C148 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C149 1-164-346-11 CERAMIC CHIP 1uF 16V

• SEMICONDUCTORS

In each case, u: µ , for example:

uA...: µ A..., uPA...: µPA..., uPB...: µ PB...,

uPC...: µ PC..., uPD...: µ PD...

• CAPACITORS

uF : µ F

• COILS

uH : µ H

• Abbreviation

HK : Hong Kong model

SP : Singapore model

< CAPACITOR >

C101 1-126-607-11 ELECT CHIP 47uF 20% 4V

C102 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C153 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C154 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

– 60 –

Page 43

BD CHEMI-CON

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< CONNECTOR >

CNU101 1-770-014-11 CONNECTOR, FFC/FPC 16P

CNU102 1-770-013-11 CONNECTOR, FFC/FPC 19P

R145 1-216-097-91 RES,CHIP 100K 5% 1/10W

R146 1-216-097-91 RES,CHIP 100K 5% 1/10W

R147 1-216-049-91 RES,CHIP 1K 5% 1/10W

R148 1-216-049-91 RES,CHIP 1K 5% 1/10W

< IC >

IC101 8-752-074-34 IC CXA1782BQ

IC102 8-759-291-06 IC BA6397FP

IC103 8-752-372-94 IC CXD2507AQ

IC104 8-759-185-29 IC PCM1710U-B

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-424-08 TRANSISTOR UN2111

Q103 8-729-421-22 TRANSISTOR UN2211

< RESISTOR >

R102 1-216-001-00 METAL CHIP 10 5% 1/10W

R103 1-216-049-91 RES,CHIP 1K 5% 1/10W

R104 1-216-097-91 RES,CHIP 100K 5% 1/10W

R105 1-216-093-91 RES,CHIP 68K 5% 1/10W

R106 1-216-093-91 RES,CHIP 68K 5% 1/10W

R107 1-216-093-91 RES,CHIP 68K 5% 1/10W

R108 1-216-093-91 RES,CHIP 68K 5% 1/10W

R109 1-216-097-91 RES,CHIP 100K 5% 1/10W

R112 1-216-083-00 METAL CHIP 27K 5% 1/10W

R113 1-216-083-00 METAL CHIP 27K 5% 1/10W

R114 1-216-101-00 METAL CHIP 150K 5% 1/10W

R115 1-216-101-00 METAL CHIP 150K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R117 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R118 1-216-049-91 RES,CHIP 1K 5% 1/10W

R119 1-216-089-91 RES,CHIP 47K 5% 1/10W

R120 1-216-089-91 RES,CHIP 47K 5% 1/10W

R121 1-216-114-00 RES,CHIP 510K 5% 1/10W

R122 1-216-097-91 RES,CHIP 100K 5% 1/10W

R123 1-216-099-00 METAL CHIP 120K 5% 1/10W

R124 1-216-091-00 METAL CHIP 56K 5% 1/10W

R125 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R126 1-216-063-91 RES,CHIP 3.9K 5% 1/10W

R127 1-216-089-91 RES,CHIP 47K 5% 1/10W

R128 1-216-105-91 RES,CHIP 220K 5% 1/10W

R129 1-216-049-91 RES,CHIP 1K 5% 1/10W

R130 1-216-079-00 METAL CHIP 18K 5% 1/10W

R131 1-216-079-00 METAL CHIP 18K 5% 1/10W

R132 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R133 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R149 1-216-049-91 RES,CHIP 1K 5% 1/10W

R150 1-216-037-00 METAL CHIP 330 5% 1/10W

R151 1-216-037-00 METAL CHIP 330 5% 1/10W

R152 1-216-037-00 METAL CHIP 330 5% 1/10W

R153 1-216-082-00 RES,CHIP 24K 5% 1/10W

R154 1-216-065-91 RES,CHIP 4.7K 5% 1/10W

R156 1-216-085-00 METAL CHIP 33K 5% 1/10W

R157 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R158 1-216-001-00 METAL CHIP 10 5% 1/10W

< VARIABLE RESISTOR >

RV101 1-223-587-11 RES, ADJ, CARBON 22K

RV102 1-223-587-11 RES, ADJ, CARBON 22K

RV103 1-223-587-11 RES, ADJ, CARBON 22K

< SWITCH >

S101 1-572-085-11 SWITCH, LEAF (LIMIT)

< VIBRATOR >

X101 1-579-280-11 VIBRATOR, CRYSTAL (16.9344MHz)

**************************************************************

* A-4419-064-A CHEMI-CON BOARD, COMPLETE

*************************

< CAPACITOR >

C503 1-126-948-11 ELECT 100uF 20% 35V

C551 1-128-131-11 ELECT 22uF 20% 50V

C553 1-126-933-11 ELECT 100uF 20% 16V

C554 1-164-159-11 CERAMIC 0.1uF 50V

C555 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C556 1-126-948-11 ELECT 100uF 20% 35V

C971 1-126-042-11 ELECT 3300uF 20% 35V

C972 1-126-042-11 ELECT 3300uF 20% 35V

C975 1-136-165-00 FILM 0.1uF 5% 50V

C976 1-136-165-00 FILM 0.1uF 5% 50V

< CONNECTOR >

* CN501 1-770-729-11 CONNECTOR, BOARD TO BOARD 10P

* CN551 1-564-506-11 PLUG, CONNECTOR 3P

< DIODE >

R134 1-216-065-91 RES,CHIP 4.7K 5% 1/10W

R135 1-216-065-91 RES,CHIP 4.7K 5% 1/10W

R136 1-216-073-00 METAL CHIP 10K 5% 1/10W

R137 1-216-065-91 RES,CHIP 4.7K 5% 1/10W

R138 1-216-049-91 RES,CHIP 1K 5% 1/10W

R139 1-216-033-00 METAL CHIP 220 5% 1/10W

R140 1-216-081-00 METAL CHIP 22K 5% 1/10W

R141 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R142 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R143 1-216-121-91 RES,CHIP 1M 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

D553 8-719-933-47 DIODE HZS7B2L

D554 8-719-933-39 DIODE HZS6C1L

D971 8-719-062-40 DIODE D4SBL20UF3

D972 8-719-024-99 DIODE 11ES2-NTA2B

< TRANSISTOR >

Q505 8-729-900-53 TRANSISTOR DTC114EK

Q551 8-729-620-05 TRANSISTOR 2SC2603-EF

Q552 8-729-620-05 TRANSISTOR 2SC2603-EF

Q553 8-729-026-68 TRANSISTOR 2SD2525(TP)

– 61 –

Page 44

CHEMI-CON

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

CONNECTOR

< RESISTOR >

HP

LOADING

L861 1-420-872-00 COIL, AIR-CORE

R505 1-216-097-91 RES,CHIP 100K 5% 1/10W

R506 1-216-085-00 METAL CHIP 33K 5% 1/10W

R551 1-216-049-91 RES,CHIP 1K 5% 1/10W

R552 1-216-097-91 RES,CHIP 100K 5% 1/10W

R553 1-247-887-00 CARBON 220K 5% 1/4W

R554 1-216-065-91 RES,CHIP 4.7K 5% 1/10W

R821 1-260-089-11 CARBON 150 5% 1/2W

R822 1-260-089-11 CARBON 150 5% 1/2W

R871 1-260-089-11 CARBON 150 5% 1/2W

R872 1-260-089-11 CARBON 150 5% 1/2W

**************************************************************

* 1-671-614-11 CONNECTOR BOARD

***************

< CAPACITOR >

C311 1-126-933-11 ELECT 100uF 20% 16V

C312 1-164-159-11 CERAMIC 0.1uF 50V

C501 1-126-933-11 ELECT 100uF 20% 16V

C502 1-126-948-11 ELECT 100uF 20% 35V

C781 1-164-159-11 CERAMIC 0.1uF 50V

C782 1-164-159-11 CERAMIC 0.1uF 50V

C785 1-164-159-11 CERAMIC 0.1uF 50V

C811 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C812 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C813 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C861 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C862 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C863 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

< CONNECTOR >

* CN781 1-566-856-11 SOCKET, CONNECTOR 5P

CN811 1-766-921-11 CONNECTOR, BOARD TO BOARD 10P

* CN961 1-774-813-11 CONNECTOR, BOARD TO BOARD 7P

CN962 1-695-342-31 PIN, CONNECTOR (PC BOARD) 19P

< DIODE >

< TRANSISTOR >

Q501 8-729-029-66 TRANSISTOR DTC114ESA

Q502 8-729-620-05 TRANSISTOR 2SC2603-EF

Q503 8-729-620-05 TRANSISTOR 2SC2603-EF

Q504 8-729-620-05 TRANSISTOR 2SC2603-EF

< RESISTOR >

R501 1-247-887-00 CARBON 220K 5% 1/4W

R502 1-249-389-11 CARBON 4.7 5% 1/4W F

R503 1-249-438-11 CARBON 56K 5% 1/4W

! R504 1-219-122-91 FUSIBLE 0.33 5% 1/4W F

R556 1-249-441-11 CARBON 100K 5% 1/4W

R557 1-249-441-11 CARBON 100K 5% 1/4W

R806 1-249-389-11 CARBON 4.7 5% 1/4W F

(AEP,UK)

R809 1-249-437-11 CARBON 47K 5% 1/4W

R811 1-260-076-11 CARBON 10 5% 1/2W

R856 1-249-389-11 CARBON 4.7 5% 1/4W F

(AEP,UK)

R859 1-249-438-11 CARBON 56K 5% 1/4W

R861 1-260-076-11 CARBON 10 5% 1/2W

R881 1-249-431-11 CARBON 15K 5% 1/4W

R882 1-249-431-11 CARBON 15K 5% 1/4W

R883 1-249-425-11 CARBON 4.7K 5% 1/4W F

< RELAY >

RY501 1-515-920-11 RELAY (24V)

< TERMINAL >

TM811 1-537-842-11 TERMINAL BOARD (SPEAKER)

**************************************************************

* 1-671-609-11 HP BOARD

********

< CAPACITOR >

C681 1-162-294-31 CERAMIC 0.001uF 10% 50V

C682 1-162-294-31 CERAMIC 0.001uF 10% 50V

C683 1-164-159-11 CERAMIC 0.1uF 50V

(AEP,UK)

C684 1-164-159-11 CERAMIC 0.1uF 50V

D501 8-719-911-19 DIODE 1SS119-25

D556 8-719-911-19 DIODE 1SS119-25

D557 8-719-911-19 DIODE 1SS119-25

D881 8-719-911-19 DIODE 1SS119-25

< FERRITE BEAD >

FB782 1-412-473-21 INDUCTOR 0UH

< IC >

IC311 8-749-923-04 IC TOTX178 (DIGITAL OPTICAL CD AUX)

< COIL >

L311 1-410-322-11 INDUCTOR 3.3uH

L801 1-420-872-00 COIL, AIR-CORE

< JACK >

J667 1-774-933-11 JACK (LARGE TYPE)(PHONES)

**************************************************************

* 1-634-461-11 LOADING BOARD

* CN291 1-564-498-11 PIN, CONNECTOR 5P

S291 1-571-924-11 SWITCH, LEAF (LOAD OUT)

S292 1-571-924-11 SWITCH, LEAF (LOAD IN)

**************************************************************

– 62 –

*************

< CONNECTOR >

< SWITCH >

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Page 45

MAIN

Ref. No. Part No. Description Remark

* A-4419-059-A MAIN BOARD, COMPLETE (AEP,UK)

********************

* A-4419-070-A MAIN BOARD, COMPLETE (SP,HK)

********************

* 4-212-590-11 HOLDER (FL)

< CAPACITOR >

C100 1-216-295-91 SHORT 0

C101 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C102 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C103 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C104 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C105 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C106 1-164-159-11 CERAMIC 0.1uF 50V

C107 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C121 1-126-022-11 ELECT 47uF 20% 10V

C122 1-130-475-00 MYLAR 0.0022uF 5% 50V

C123 1-126-964-11 ELECT 10uF 20% 50V

C126 1-126-963-11 ELECT 4.7uF 20% 50V

C127 1-126-963-11 ELECT 4.7uF 20% 50V

C128 1-126-963-11 ELECT 4.7uF 20% 50V

C129 1-126-964-11 ELECT 10uF 20% 50V

C130 1-136-165-00 FILM 0.1uF 5% 50V

C131 1-126-957-11 ELECT 0.22uF 20% 50V

C132 1-130-479-00 MYLAR 0.0047uF 5% 50V

C134 1-136-165-00 FILM 0.1uF 5% 50V

C135 1-136-165-00 FILM 0.1uF 5% 50V

C137 1-126-961-11 ELECT 2.2uF 20% 50V

C139 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C141 1-126-043-11 ELECT 0.47uF 20% 50V

C142 1-126-963-11 ELECT 4.7uF 20% 50V

C143 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C191 1-164-159-11 CERAMIC 0.1uF 50V

C192 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C193 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C194 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C195 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C196 1-162-294-31 CERAMIC 0.001uF 10% 50V

C197 1-124-995-11 ELECT 220uF 20% 10V

C198 1-164-159-11 CERAMIC 0.1uF 50V

C199 1-124-995-11 ELECT 220uF 20% 10V

C201 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C202 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C203 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C204 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C205 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C221 1-126-022-11 ELECT 47uF 20% 10V

C222 1-130-475-00 MYLAR 0.0022uF 5% 50V

C223 1-130-471-00 MYLAR 0.001uF 5% 50V

C224 1-104-664-11 ELECT 47uF 20% 16V

C226 1-126-963-11 ELECT 4.7uF 20% 50V

C227 1-126-963-11 ELECT 4.7uF 20% 50V

C228 1-126-963-11 ELECT 4.7uF 20% 50V

C229 1-126-964-11 ELECT 10uF 20% 50V

C230 1-136-165-00 FILM 0.1uF 5% 50V

C231 1-126-957-11 ELECT 0.22uF 20% 50V

C232 1-130-479-00 MYLAR 0.0047uF 5% 50V

Ref. No. Part No. Description Remark

C234 1-136-165-00 FILM 0.1uF 5% 50V

C235 1-136-165-00 FILM 0.1uF 5% 50V

C237 1-126-961-11 ELECT 2.2uF 20% 50V

C241 1-126-043-11 ELECT 0.47uF 20% 50V

C242 1-126-963-11 ELECT 4.7uF 20% 50V

C243 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C301 1-124-997-11 ELECT 470uF 20% 10V

C302 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C303 1-124-473-11 ELECT 1000uF 20% 10V

C304 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C305 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C306 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C351 1-104-664-11 ELECT 47uF 20% 16V

C352 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C353 1-162-306-11 CERAMIC 0.01uF 20% 16V

C354 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C401 1-162-294-31 CERAMIC 0.001uF 10% 50V

C402 1-162-294-31 CERAMIC 0.001uF 10% 50V

C403 1-162-306-11 CERAMIC 0.01uF 20% 16V

(AEP,UK)

C404 1-162-306-11 CERAMIC 0.01uF 20% 16V

(AEP,UK)

C405 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C451 1-126-961-11 ELECT 2.2uF 20% 50V

(AEP,UK)

C452 1-162-306-11 CERAMIC 0.01uF 20% 16V

(AEP,UK)

C453 1-162-291-31 CERAMIC 560PF 10% 50V

(AEP,UK)

C454 1-126-964-11 ELECT 10uF 20% 50V

(AEP,UK)

C455 1-162-306-11 CERAMIC 0.01uF 20% 16V

(AEP,UK)

C456 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

(AEP,UK)

C457 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

(AEP,UK)

C701 1-163-102-00 CERAMIC CHIP 24PF 5% 50V

C702 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C703 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C704 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C748 1-164-159-11 CERAMIC 0.1uF 50V

C751 1-124-589-11 ELECT 47uF 20% 16V

C752 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C753 1-126-925-11 ELECT 470uF 20% 10V

C754 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C755 1-124-589-11 ELECT 47uF 20% 16V

C756 1-164-159-11 CERAMIC 0.1uF 50V

C757 1-164-159-11 CERAMIC 0.1uF 16V

C758 1-164-159-11 CERAMIC 0.1uF 50V

C759 1-104-905-11 CAPACITOR 0.22F 5.5V

C791 1-163-038-91 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

* CN101 1-564-506-11 PLUG, CONNECTOR 3P

CN301 1-770-067-11 CONNECTOR, FFC/FPC 19P

* CN351 1-564-339-00 PIN, CONNECTOR 5P

CN401 1-774-289-11 PIN, CONNECTOR (PC BOARD) 15P

CN701 1-784-601-11 SOCKET, CONNECTOR (NON ZIF)13P

– 63 –

Page 46

MAIN

Ref. No. Part No. Description Remark

CN702 1-785-462-11 SOCKET, CONNECTOR (NON-ZIF)11P

CN703 1-770-380-11 CONNECTOR, BOARD TO BOARD 8P

CN704 1-770-380-11 CONNECTOR, BOARD TO BOARD 8P

CN705 1-695-342-31 PIN, CONNECTOR (PC BOARD) 19P

< DIODE >

D351 8-719-921-40 DIODE MTZJ-4.7C

D751 8-719-911-19 DIODE 1SS119-25

D752 8-719-024-99 DIODE 11ES2-NTA2B

D753 8-719-911-19 DIODE 1SS119-25

D755 8-719-911-19 DIODE 1SS119-25

D791 8-719-914-42 DIODE DA204K

D792 8-719-914-42 DIODE DA204K

D793 8-719-914-42 DIODE DA204K

< FERRITE BEAD >

FB301 1-412-473-21 INDUCTOR 0UH

FB791 1-500-445-21 FERRITE 0UH

FB792 1-500-445-21 FERRITE 0UH

< IC >

IC101 8-759-494-40 IC M62428AFP600C

IC102 8-759-300-71 IC HD14053BFP

IC103 8-759-100-96 IC UPC4558G2

IC351 8-759-822-09 IC LB1641

IC451 8-759-560-51 IC BU1924F (AEP,UK)

IC701 8-759-549-47 IC uPD780018AYGF-015-3BA

IC791 8-759-549-80 IC P82B715TD.118

IC951 8-759-635-63 IC M51943BSL