HCD-SB500W

SERVICE MANUAL

Ver. 1.1 2005.01

HCD-SB500W is the amplifier, super audio CD/DVD

system and tuner section in DAV-SB500W.

SPECIFICATIONS

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

Mechanism T ype CDM77A-DVBU20

Optical Traverse Unit Name DBU-1

Amplifier section

Stereo mode (ra ted) 65 W+65 W (4 ohms at

Surround mode (reference)

*Depending on the sound field settings and the source,

there may be no sound output.

Inputs VIDEO (AUDIO IN):

Phones Accepts low-and high-

Super Audio CD/DVD system

Laser

Signal format system NTSC or NTSC/PAL

Frequency response (at 2 CH STEREO mode)

1kHz, DIN)

Front: 96 W+96 W

(with SS-TS11)

Center: 96 W

(with SS-CT11)

Subwoofer: 170 W

(with SS-WS11)

Sensitivity: 250 mV

Impedance: 50 kilohms

SAT (AUDIO IN):

Sensitivity: 450 mV

Impedance: 50 kilohms

impedance headphones.

Semiconductor laser

(S

uper Audio CD/DVD:

λ = 650 nm)

(CD: λ = 780 nm)

Emission duration:

continuous

DVD (PCM): 2 Hz to 22

kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0

dB)

Tuner section

System PLL quartz-locked digital

synthesizer system

FM tuner section

Tuning range 87.5 − 108. 0 MHz (50 kHz

step)

antenna (aerial) FM wire antenna (aerial)

antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 531 − 1,602 kHz (with the

interval set at 9 kHz)

530 − 1,710 kHz (with the

interval set at 10 kHz)

antenna (aerial) AM loop antenna (aerial)

Intermediate frequency 450 Hz

Video section (exept AEP, UK models)

Outputs Video: Vp-p 75 ohms

S video:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

Video section (EURO AV) (AEP,UK models)

Outputs Video: 1 Vp-p 75 ohms

SUPER AUDIO CD/DVD RECEIVER

General

System

Power requirements 220 − 240 V AC, 50/60 Hz

Power consumption 90 W (220-240 V AC)

0.3 W (220-240 V AC) ( at

the Power Saving Mode)

Dimensions (approx.) 430 × 70 × 393 mm

(w/h/d) incl. projecting

parts

Mass (approx.) 4.4 kg

Design and specifications are subject to change

without notice.

9-879-015-02

2005A05-1

© 2005.01

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

HCD-SB500W

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This System Can Play the

Following Discs

Format of

discs

DVD VIDEO

Super Audio

CD

VIDEO CD

Audio CD

Format of

discs

CD-R/CD-RW

(audio data)

(MP3 files)

(JPEG files)

Disc logo

Disc logo

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

The “DVD VIDEO” logo is a trademark.

Terms for Discs

• Title

The longest section of a pi ct ur e or m usic

feature on a DVD, movie, etc., in video

software, or the entire album in audio

software.

• Chapter

Section of a picture or a music piece that is

smaller than titles. A title is composed of

several chapters. Depending on the disc, no

chapters may be r ecorded.

• Album

Section of a music piece or an image on a data

CD containing MP3 audio tracks or JPEG

files.

• Track

Section of a picture or a music piece on a

VIDEO CD, Super Audio CD, CD, or MP3.

• Index (Super Audio CD, CD) / Video

Index (VIDEO CD)

A number that divides a track into sections to

easily locate the point you want on a VIDEO

CD or Super Audio CD. Depending on the

disc, no indexes may be recorded.

• Scene

On a VIDEO CD with PBC functions, the

menu screens, moving pictures and still

pictures are divided into sections called

“scenes.”

• File

Section of a picture on a data CD containing

JPEG image files.

2

HCD-SB500W

Note on PBC (Playback Control)

(VIDEO CDs)

This system conforms to Ver. 1. 1 and Ver. 2.0 of

VIDEO CD standards. You can enjoy two kinds

of playback depending on the disc type.

About Multi Session CD

• This system can play Mul ti Session CDs when

an MP3 audio track is contained in the first

session. Any subsequent MP3 audio tracks

recorded in lat er sessions can also be played

back.

• This system can play Mul ti Session CDs when

a JPEG image file is contained in the first

session. Any subsequent JPEG image files

recorded in lat er sessions can also be played

back.

• If audio tracks and images in music CD format

or video CD format are recorded in the first

session, only th e fi rst session wi ll be played

back.

Region code

Your system has a regio n code printed on the

back of the unit and will only play DVDs labeled

with the same region code.

DVDs labeled will also play on this system.

If you try to play any other DVD, the message

[Playback prohibited by area limitations.] wi ll

appear on the TV screen. Depending on the

DVD, no region code indication may be given

even though playing the DVD is prohibited by

area restrictio ns.

Examples of discs that the system

cannot play

The system cannot play the following discs:

• CD-ROMs (except for extension “.MP3,”

“.JPG,” or “.JPEG”)

• CD-Rs/CD-RWs other than those record ed in

the followin g formats:

− audio CD format

− video CD format

− MP3/JPEG format that conforms to

ISO9660* Level 1/Level 2, or its extended

format, Joliet

Data part of CD-Extras

• DVD-ROMs

• DVD Audio discs

• DVD-RAMs

• DVD-RWs in VR (Video Recording) mode

• Progressive JPEG file

*A logical format of files and folders on CD-ROMs,

defined by ISO (International Organiza tion for

Standardization)

Do not load the following discs:

• A DVD with a different region code.

• A disc that is neither standard nor circular

(e.g., card, heart , or star shape).

• A disc with paper or stickers on it.

• A disc that has adhesive or cellophane tape still

left on it.

Disc type You can

VIDEO CDs

without PBC

functions

(Ver. 1.1 discs)

Enjoy video playback (moving

pictures) as well as music.

VIDEO CDs

with PBC

functions

(Ver. 2.0 discs)

Play interactive software using

menu screens displayed on the

TV screen (PBC Playback), in

addition to the video playback

functions of Ver. 1.1 discs.

Moreover, you can play highresolution still pictures, if they

are included on the disc.

DVD

structure

VIDEO CD,

Super

Audio CD

or CD

structure

MP3

structure

Disc

Disc

Disc

Title

Chapter

Track

Index

Album

Track

JPEG

structure

Disc

Album

File

ALL

Notes about CD-R/CD-RW/DVD-R/DVD-RW

(Video mode)/DVD+R/DVD+RW

In some cases, CD-R/CD-RW/DVD-R/DVD-RW

(Video mode)/DVD+R/DVD+RW cannot be played

on this player due to the recording quality or physical

condition of the disc, or the characteristics of the

recording device and authoring software.

The disc will not play if it has not been correctly

finalized. For more information, see the operating

instructions for the recording device.

Note that discs created in the Packet Write format

cannot be played.

Music discs encoded with copyright protection

technologies

This product is designed to play back discs that

conform to the Compac t D is c (CD ) st an dard.

Recently, various music discs encoded with copyright

protection technologies are m arke ted by some record

companies. Please be aware that among those discs,

there are some that do not conform to the CD standard

and may not be playable by this product.

Note on playback operations of

DVDs and VIDEO CDs

Some playback operations of DVDs and VIDEO

CDs may be intentionally set by software

producers. Since this system plays DVDs and

VIDEO CDs according to the disc contents the

software producers designed, some p layback

features may no t be available. Also, refer t o the

instructions supplied with the DVDs or VIDEO

CDs.

Copyrights

This product incorporates copyright protec t io n

technology that is protected by U.S. patents and

other intellectual property rights. Use of this

copyright protection technology must be

authorized by Macrovision, an d is in tended for

home and ot her limited viewing uses only unless

otherwise authorized by Macrovis i on. Re verse

engineering or disas se m bl y i s pr ohibited.

This system incorporates with Dolby* Digital

and Dolby Pro Logic (II ) ad aptive matrix

surround decoder and the DTS** Digi t al

Surround System.

*Manufactured under license from Dolby

Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are

trademarks of Dolby Laboratories.

**Manufactured under license from Digital Theater

Systems, Inc.

“DTS” and “DTS Digital Surround” are trademark s

of Digital Theater Systems, Inc.

On handling discs

• To keep the disc clean, handle the disc by its

edge. Do not touc h the surface.

• Do not stick paper or tape on the disc.

• Do not expose the disc to direct sunlight or

heat sources such as hot air ducts, or leave it in

a car parked in direct sunlight as the

temperature may rise considerably inside the

car.

• After playing, store the disc in its ca se.

On cleaning

• Before playing, clean the disc with a cleaning

cloth.

Wipe the disc from the centre out.

• Do not use solvents such as benzi ne, thinner,

commercially available cleane rs, or anti -stat ic

spray intended for vinyl LPs.

This system can only play back a standard

circular disc. Using neit her standa rd nor circul ar

discs (e.g., card, heart, or st ar shape) may cause

a malfunction.

Do not use a disc that has a commercially

available accessory attached, such as a label or

ring.

Notes about the Discs

3

HCD-SB500W

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 5

2. GENERAL ................................................................... 7

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 9

3-2. Case ................................................................................. 9

3-3. Front Panel Block ............................................................ 10

3-4. DVD Mechanism Deck ................................................... 10

3-5. IO Board .......................................................................... 11

3-6. MAIN Board.................................................................... 11

3-7. Tray (AU) ........................................................................ 12

3-8. Optical Pick-up Block, Chuck Cam ................................ 12

3-9. Optical Traverse Unit (DBU-1) ....................................... 13

3-10. DC Motor (Loading) (M001) .......................................... 13

4. TEST MODE.............................................................. 14

5. ELECTRICAL ADJUSTMENTS ......................... 23

6. DIAGRAMS

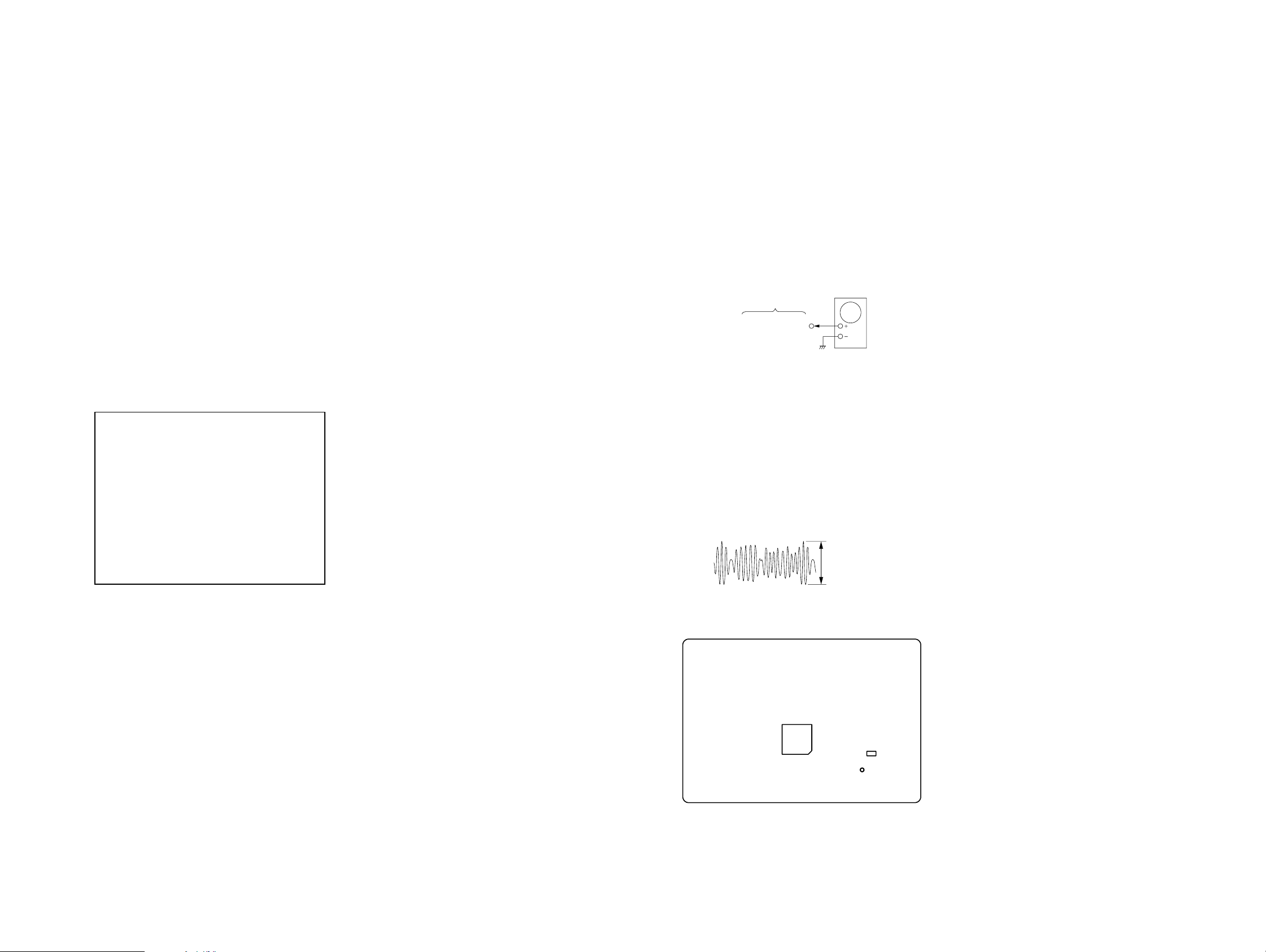

6-1. Block Diagram – RF SERVO Section – ......................... 24

6-2. Block Diagram – DVD DSP Section –........................... 25

6-3. Block Diagram – AUDIO Section – ............................... 26

6-4. Block Diagram – AMP, PANEL Section –..................... 27

6-5. Block Diagram – POWER SUPPLY Section – .............. 28

6-6. Printed Wiring Board – RF Board – ............................... 30

6-7. Schematic Diagram – RF Board –.................................. 31

6-8. Printed Wiring Board

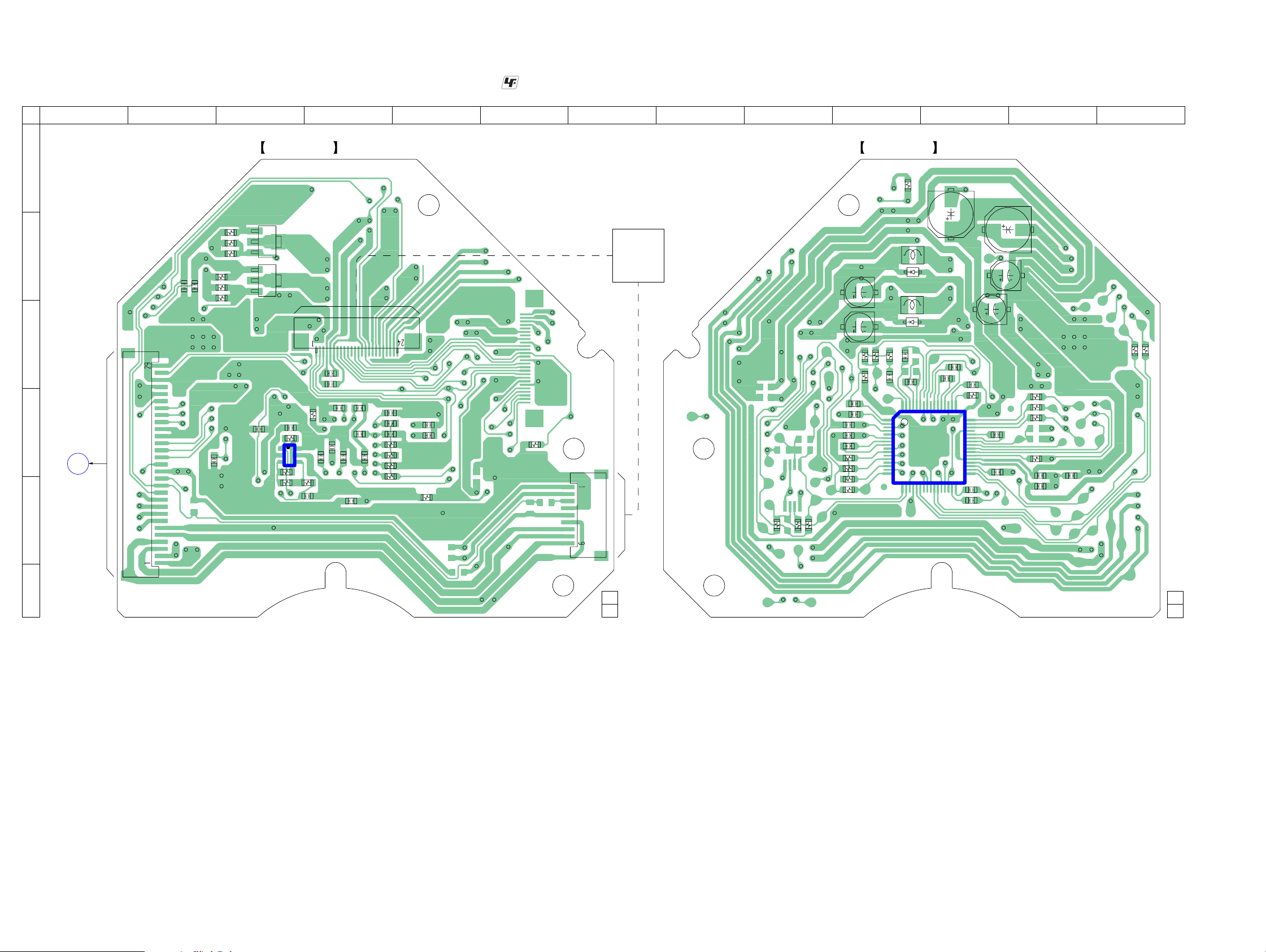

– DMB07 Board (Component Side) –............................. 32

6-9. Printed Wiring Board

– DMB07 Board (Conductor Side) – .............................. 33

6-10. Schematic Diagram – DMB07 Board (1/9) –................. 34

6-11. Schematic Diagram – DMB07 Board (2/9) –................. 35

6-12. Schematic Diagram – DMB07 Board (3/9) –................. 36

6-13. Schematic Diagram – DMB07 Board (4/9) –................. 37

6-14. Schematic Diagram – DMB07 Board (5/9) –................. 38

6-15. Schematic Diagram – DMB07 Board (6/9) –................. 39

6-16. Schematic Diagram – DMB07 Board (7/9) –................. 40

6-17. Schematic Diagram – DMB07 Board (8/9) –................. 41

6-18. Schematic Diagram – DMB07 Board (9/9) –................. 42

6-19. Printed Wiring Board – IO Board –................................ 44

6-20. Schematic Diagaram – IO Board –................................. 45

6-21. Printed Wiring Board

– AMP Board (Component Side) – ................................. 46

6-22. Printed Wiring Board

– AMP Board (Conductor Side) – ................................... 47

6-23. Schematic Diagaram – AMP Board (1/4) –.................... 48

6-24. Schematic Diagaram – AMP Board (2/4) –.................... 49

6-25. Schematic Diagaram – AMP Board (3/4) –.................... 50

6-26. Schematic Diagaram – AMP Board (4/4) –.................... 51

6-27. Printed Wiring Board – DIAT SPK Board – .................. 52

6-28. Schematic Diagram – DIAT SPK Board – ..................... 53

6-29. Printed Wiring Board – DIAT TRANSMIT Board – ..... 54

6-30. Schematic Diagram – DIAT TRANSMIT Board – ........ 55

6-31. Printed Wiring Board

– MAIN Section (Component Side) – ............................. 56

6-32. Printed Wiring Boards

– MAIN Section (Conductor Side) –............................... 57

6-33. Schematic Diagram – MAIN Section (1/2) – ................. 58

6-34. Schematic Diagram – MAIN Section (2/2) – ................. 59

6-35. Printed Wiring Boards – PANEL Section –.................... 60

6-36. Schematic Diagaram – PANEL Section –...................... 61

6-37. Printed Wiring Board – FL Board – ............................... 62

6-38. Schematic Diagram – FL Board – .................................. 63

6-39. Printed Wiring Boards – POWER SUPPLY Section...... 64

6-40. Schematic Diagarm – POWER SUPPLY Section – ....... 65

7. EXPLODED VIEWS

7-1. Front Panel Section ......................................................... 87

7-2. Back Panel Section .......................................................... 88

7-3. Chassis Section................................................................ 89

7-4. DVD Mechanism Deck Section (CDM77A-DVBU20) .. 90

8. ELECTRICAL PARTS LIST................................ 91

4

SECTION 1

SERVICING NOTES

HCD-SB500W

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

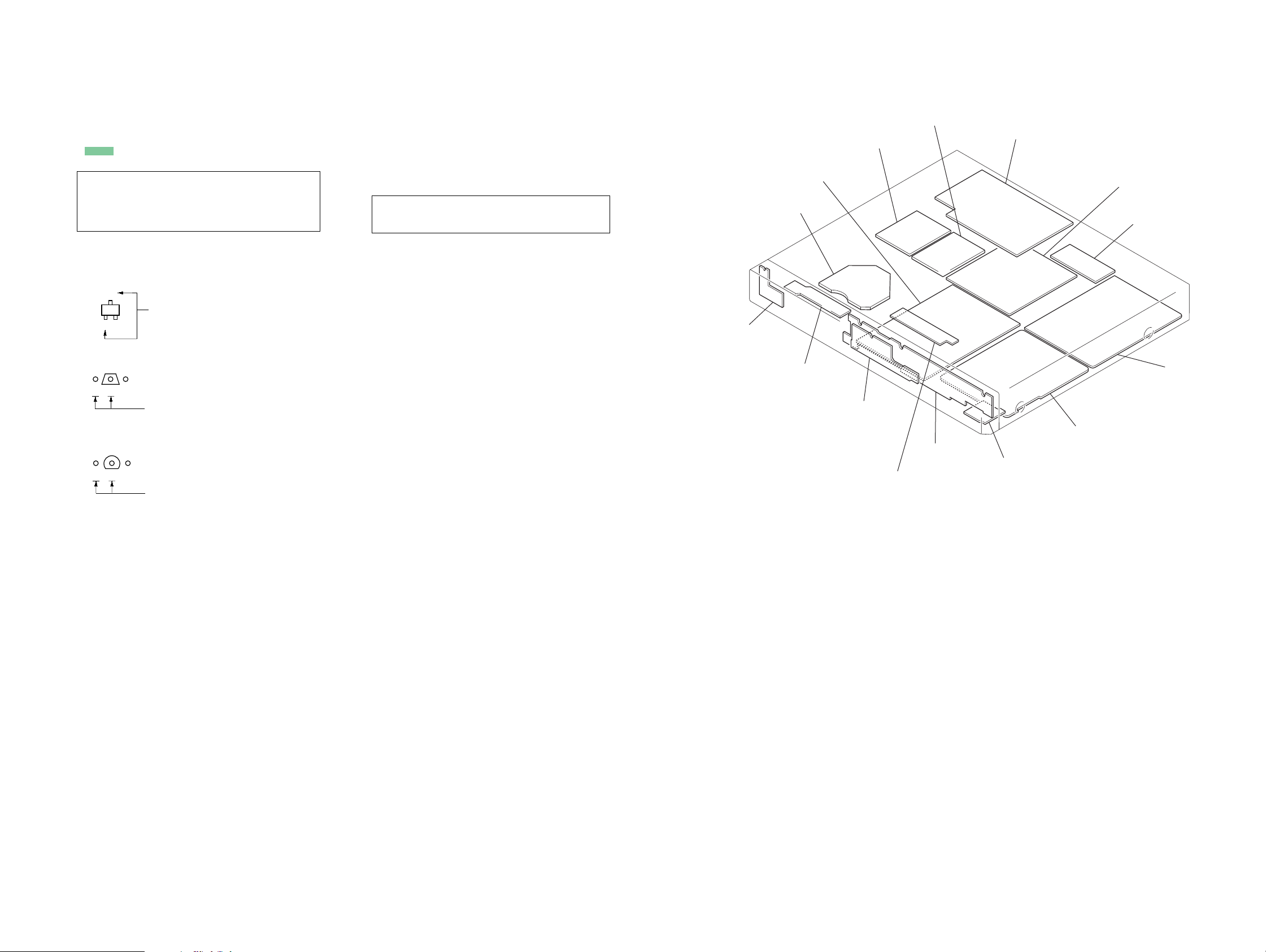

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

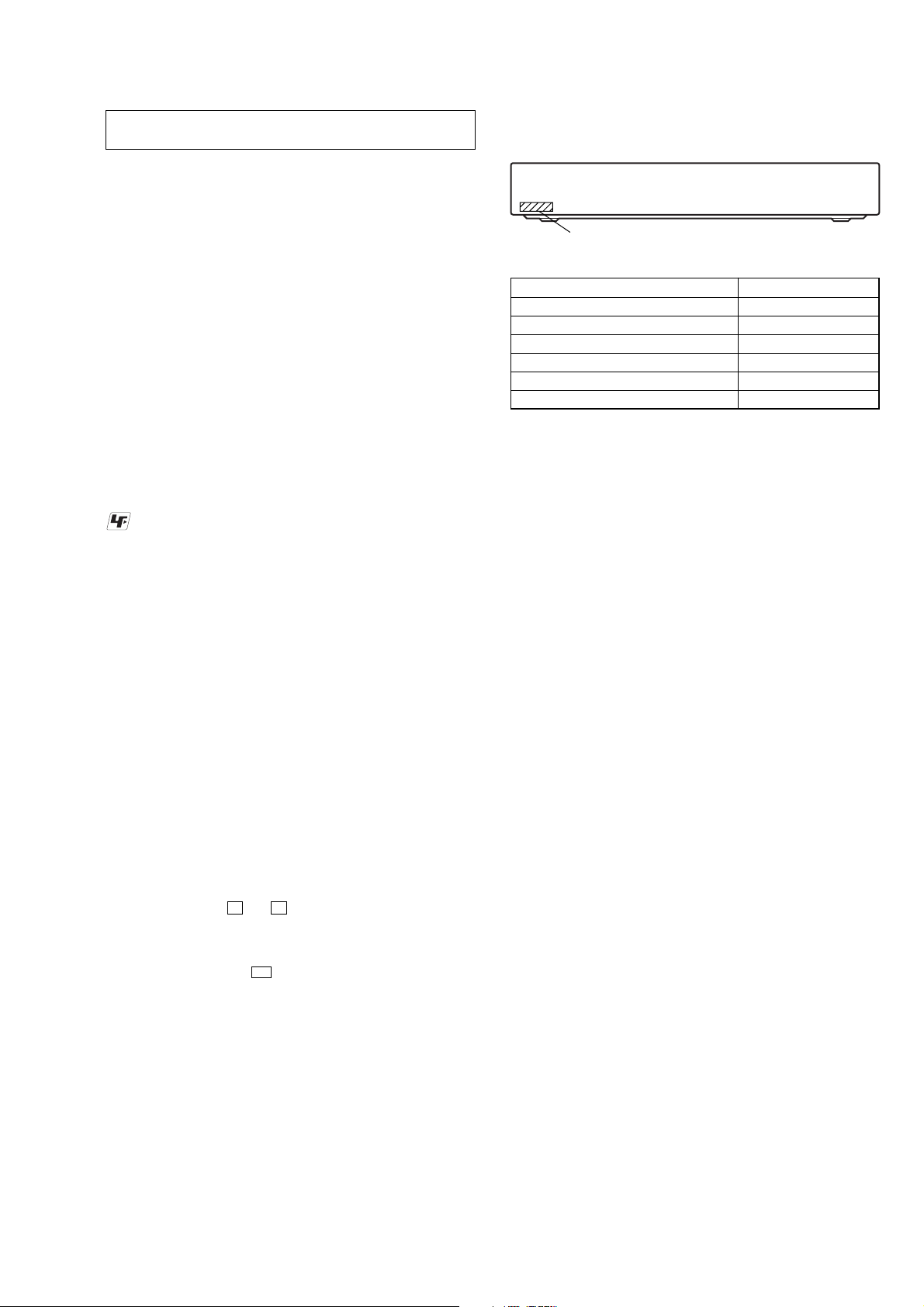

• MODEL IDENTIFICATION

– Back Panel –

PART No.

MODEL PART No.

AEP, UK models 2-067-992-0[]

Korean model 2-067-992-1[]

Singapore model 2-067-992-2[]

Hong Kong model 2-067-992-3[]

Australian model 2-067-992-4[]

Russian model 2-067-992-5[]

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure :

Press two buttons of

The message “UNLOCKED” is displayed and the tray is unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by turning

power on/off with the I/1 button.

NOTE OF REPLACING THE DMB07 BOARD

When replacing the DMB07 board, since the adjustment value is

not set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 15)

2. Press the [2] ke y of the remote commander, and set the “DRIVE

MANUAL OPERATION”. (See page 18)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 20)

4. Press the [CLEAR] key of the remote commander , and initialize

Memory.

A and x simultaneously for five seconds.

5

HCD-SB500W

DECISION TO PASS OR FAIL OF THE OPTICAL

PICK-UP BLOCK

Connection:

oscilloscope

DMB07 board

1

3

pin

pin

CN901

CN901

Procedure:

1. Connect an oscilloscope to test point 1 pin and 3 pin of

CN901 on the DMB07 board.

2. Turn the power on.

3. Put the disc (LUV-P01) (Part No.: 4-999-032-01) (CD) in to

playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

5. Put the disc (TDV -520CSO) (P art No.: J-2501-236-A) (DVD)

is to playback.

6. Perform confirmation in the same manner as step 4.

Note: A clear RF signal waveform means that the shape “◊” can be clearly

distinguished at the center of the waveform.

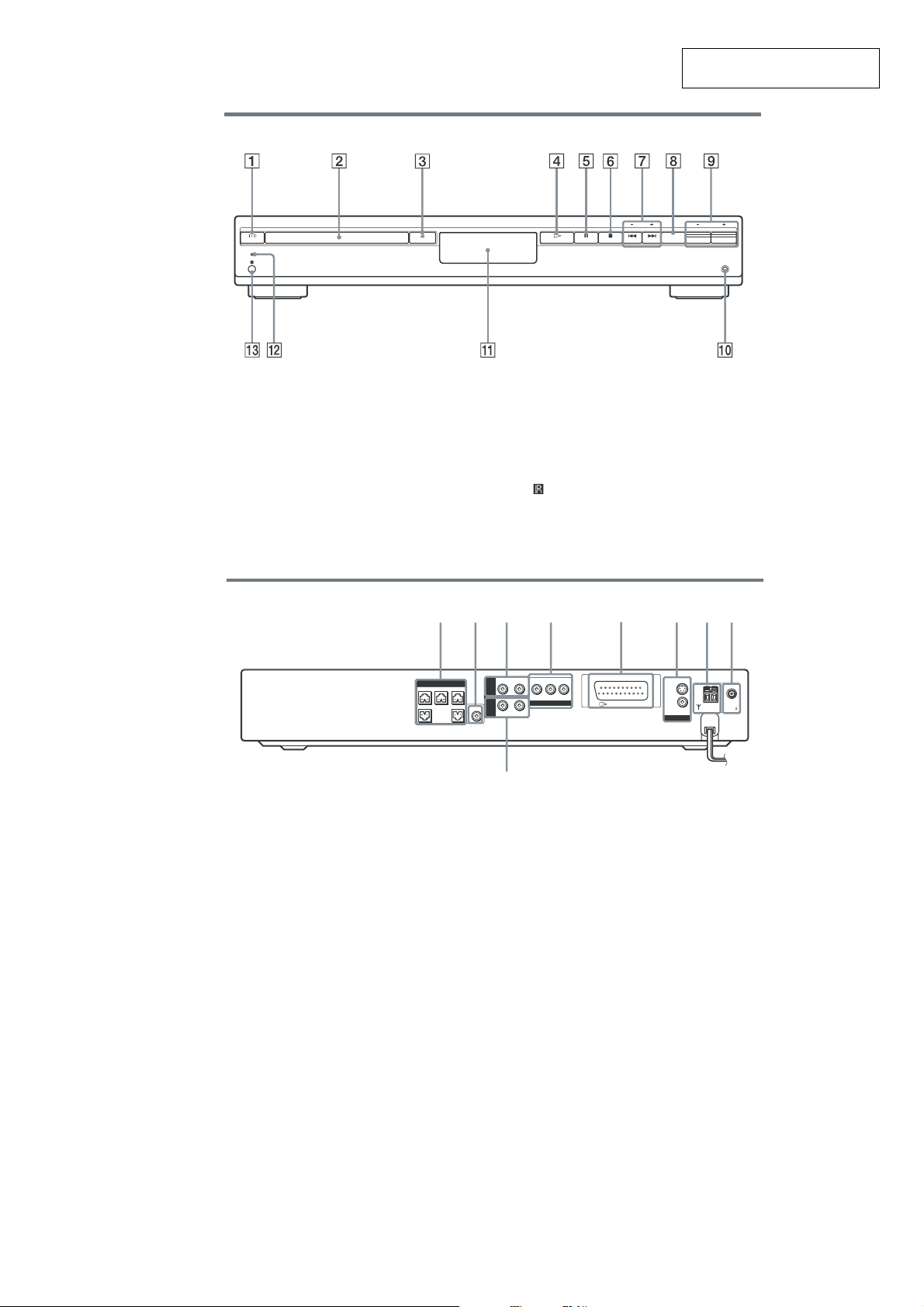

+

–

RF signal waveform

Checking Location:

– DMB07 Board (Component Side) –

IC801

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

±

CD: 1.05

DVD: 1.09 ± 0.2 Vp-p

0.2 Vp-p

IC207

IC701

CN901

7

1

6

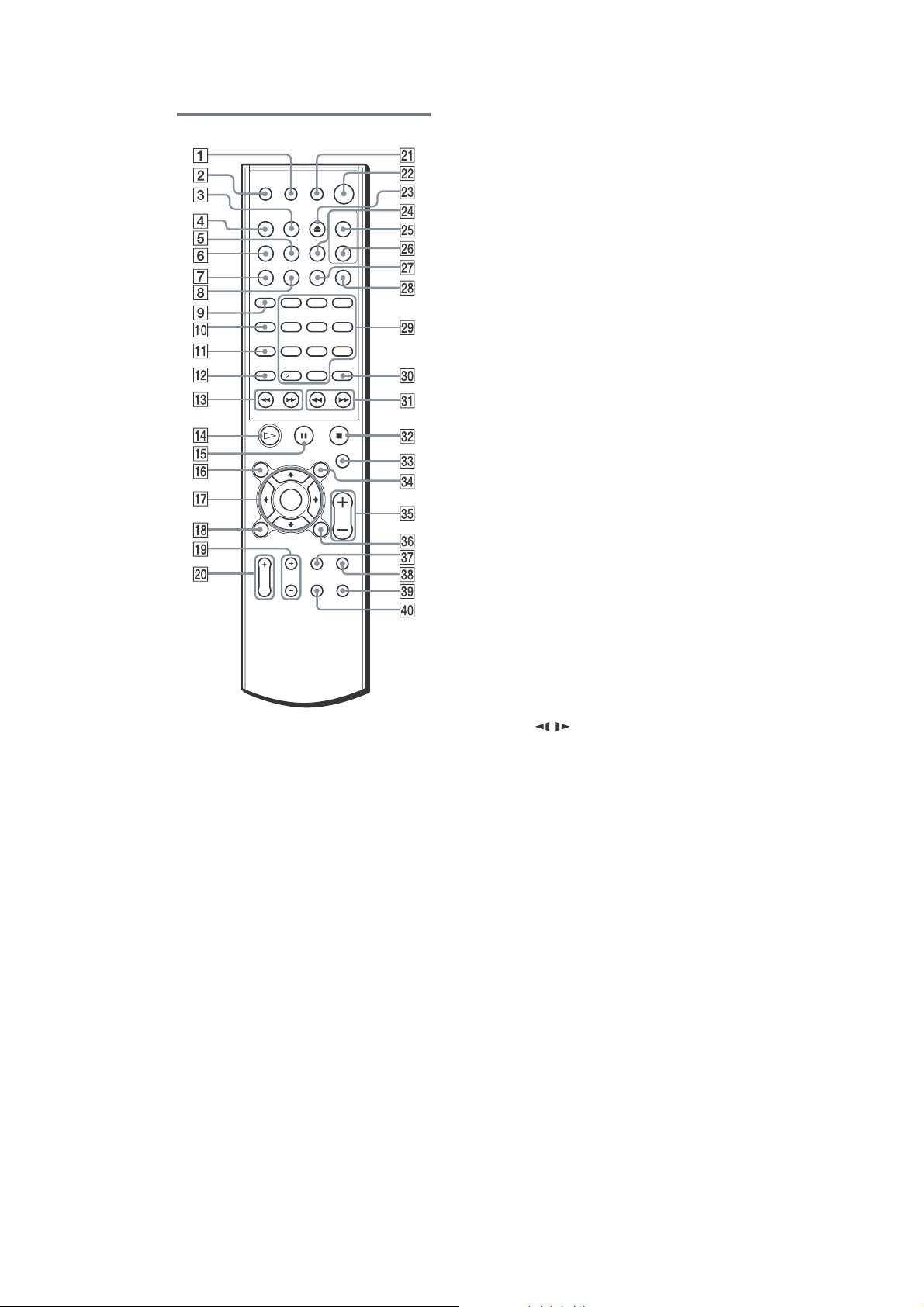

Front Panel

SECTION 2

GENERAL

HCD-SB500W

This section is extracted from

instruction manual.

STANDBY

A "/1 (power)

B Disc tray

C A (open/close)

D H (play)

E X (pause)

F x (stop)

G ./>, PRESET –/+

Rear Panel

1

H FUNCTION

I VOLUME –/+

J PHONES jack

K Front panel display

L STANDBY indicator

M (remote sensor)

4

3

2

5

PRESET

FUNCTION

6

7

VOLUME

PHONES

8

FRONT R

WOOFER

1 SPEAKER jacks

2 DIR-T1 jack

3 VIDEO AUDIO IN L/R jacks

4 COMPONENT VIDEO OUT jacks

(except AEP, UK models)

5 EURO AV OUTPUT (TO TV ) jack

(AEP, UK models only)

SPEAKER

CENTER

FRONT L

WOOFER

AUDIO IN

YPB/CBPR/C

L

R

VIDEO

SAT

DIR-T1

AUDIO IN

R

COMPONENT VIDEO OUT

L

EURO AV

R

OUTPUT(TO TV)

S VIDEO (DVD ONLY)

MONITOR OUT

9

6 MONITOR OUT (VIDEO/S VIDEO) jacks

(except AEP, UK models)

7 AM terminals

8 FM 75 COAXIAL jack

9 SAT AUDIO IN L/R jacks

COAXIAL

75

AM

FM

VIDEO

7

HCD-SB500W

Remote

123

45

7

10

6

8

9

0

A SONY TV DIRECT

B SLEEP

C TUNER/BAND

D MUTING

E TUNER MENU

F PLAY MODE

G REPEAT

H FM MODE

I TV

J AUDIO

K ANGLE

L SUBTITLE

M ./>, PRESET –/+

N H PLAY

O X PAUSE

P DVD TOP MENU/ALBUM–

Q C/X/x/c/ENTER

R DVD DISPLAY

S TV CH +/–

T TV VOL +/–

U TV [/1 (on/standby)

V "/1 (standby)

W Z (open/close)

X DSGX

Y AUTO FORMAT DIRECT

Z MODE

wj NIGHT MODE

wk FUNCTION

wl Number buttons

e; ENTER

ez m/M// SLOW, TUNING –/+

es x STOP

ed DISPLAY

ef DVD MENU/ALBUM+

eg VOLUME +/–

eh O RETURN

ej TV/VIDEO

ek CLEAR

el DIMMER

r; DVD SETUP

8

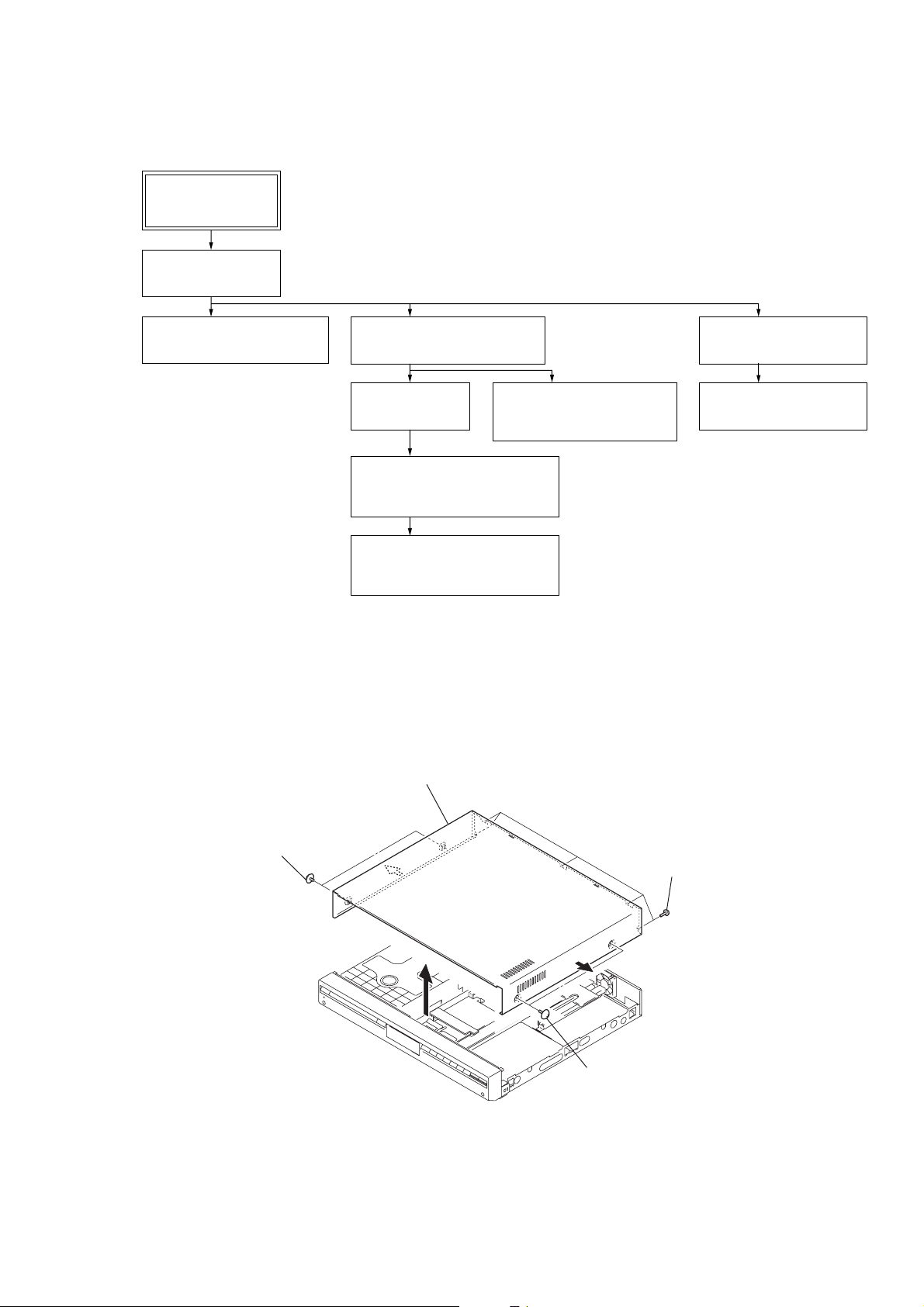

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. CASE

(Page 9)

HCD-SB500W

SECTION 3

DISASSEMBLY

3-3. FRONT PANEL BLOCK

(Page 10)

Note: Follow the disassembly procedure in the numerical order given.

3-4. DVD MECHANISM DECK

(Page 10)

3-7. TRAY (AU)

(Page 12)

3-8. OPTICAL PICK-UP BLOCK,

CHUCK CAM

(Page 12)

3-9. OPTICAL TRAVERSE UNIT

(DBU-1)

(Page 13)

3-2. CASE

4

case

3-10. DC MOTOR (LOADING)

(M001)

(Page 13)

3-5. IO BOARD

(Page 11)

3-6. MAIN BOARD

(Page 11)

2

two screws

(CASE3 TP2)

1

two screws

(CASE3 TP2)

3

five screws

(BVTP3

×

8)

9

HCD-SB500W

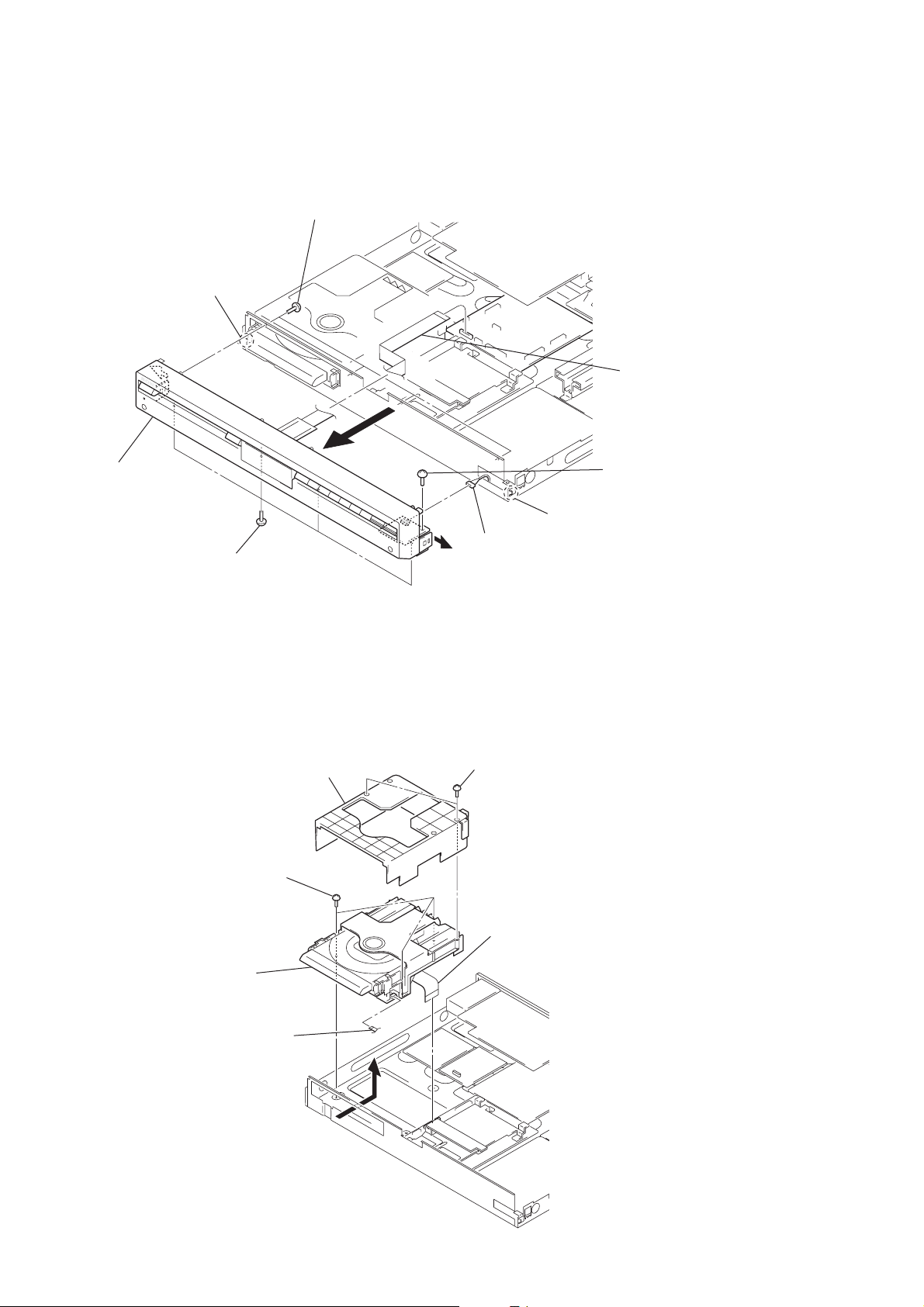

3-3. FRONT PANEL BLOCK

5

claw

2

four screws

(DIA.2.6

×

8)

1

wire (flat type)

(17 core) (CN503)

8

front panel

block

4

four screws

(BV3)

3-4. DVD MECHANISM DECK

4

three screws

(BV3)

2

cover (DVD)

6

7

connector

(CN04)

1

two screws

(DIA.2.6

3

screw

( BV3)

5

claw

×

8)

10

5

DVD mechanism

deck

3

wire (flat type)

(5 core) (CN001)

3

wire (flat type)

(29 core) (CN501)

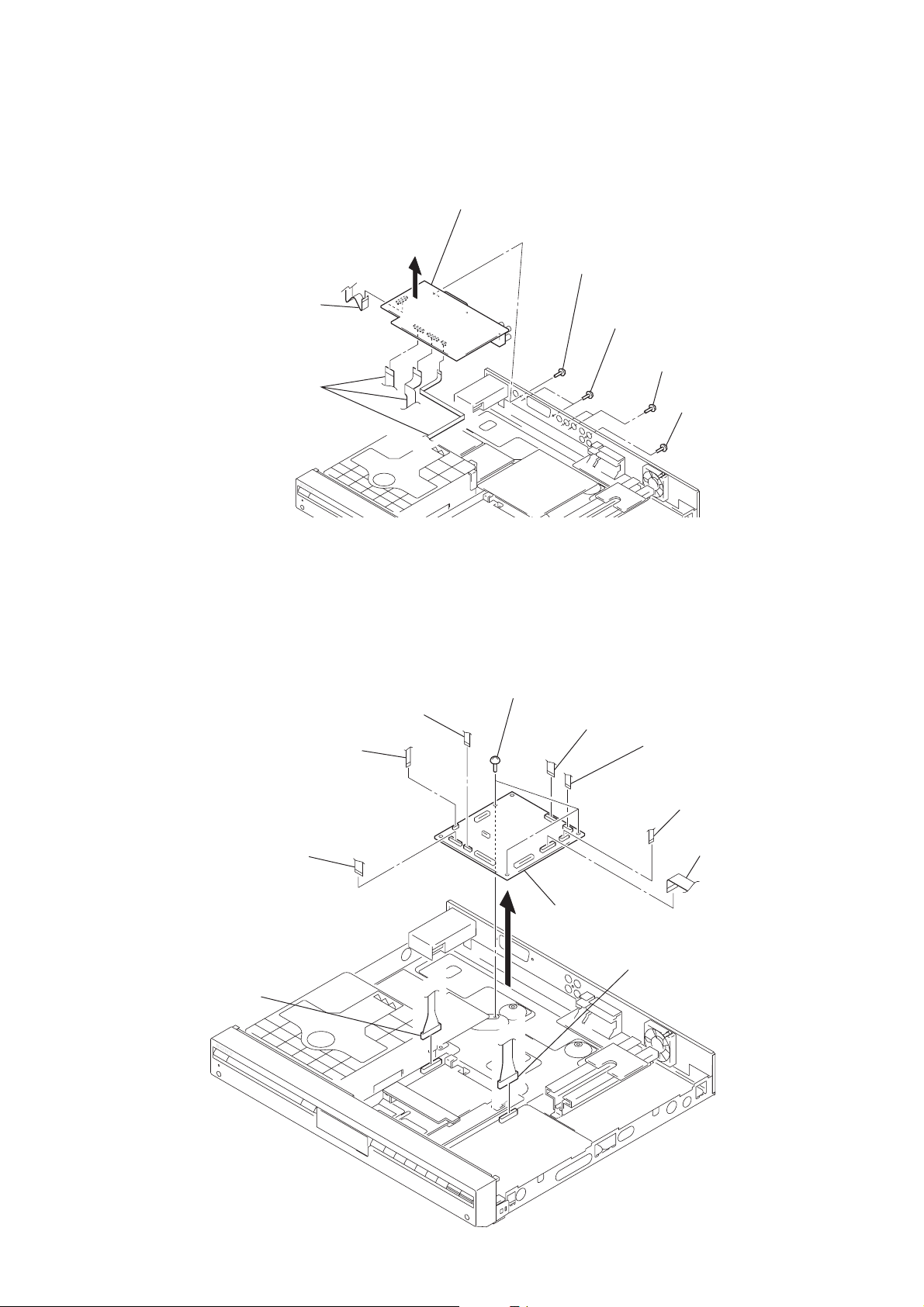

3-5. IO BOARD

)

• Abbreviation

RU: Russian model

I/O board

5

HCD-SB500W

4

wire (flat type)

(11 core) (CN200)

4

three wires (flat type)

(17 core: CN201,

15 core: CN202,

5 core: CN203)

3-6. MAIN BOARD

1

wire (flat type)

(5 core) (CN511)

3

1

wire (flat type)

(9 core) (CN505)

3

three screws

(BV3)

2

screw (DIA.2.6 × 8)

(except AEP, UK, RU)

2

1

wire (flat type)

(11 core) (CN508)

two screws (BV3)

(AEP, UK, RU)

2

two screws

(except AEP, UK, RU)

1

screw (BV3)

1

wire (flat type)

(9 core) (CN507)

1

wire (flat type)

(17 core) (CN503)

2

connector

(CN102)

4

MAIN board

1

wire (flat type)

(9 core) (CN512)

1

wire (flat type)

(17 core) (CN509

2

connector

(CN8)

11

HCD-SB500W

k

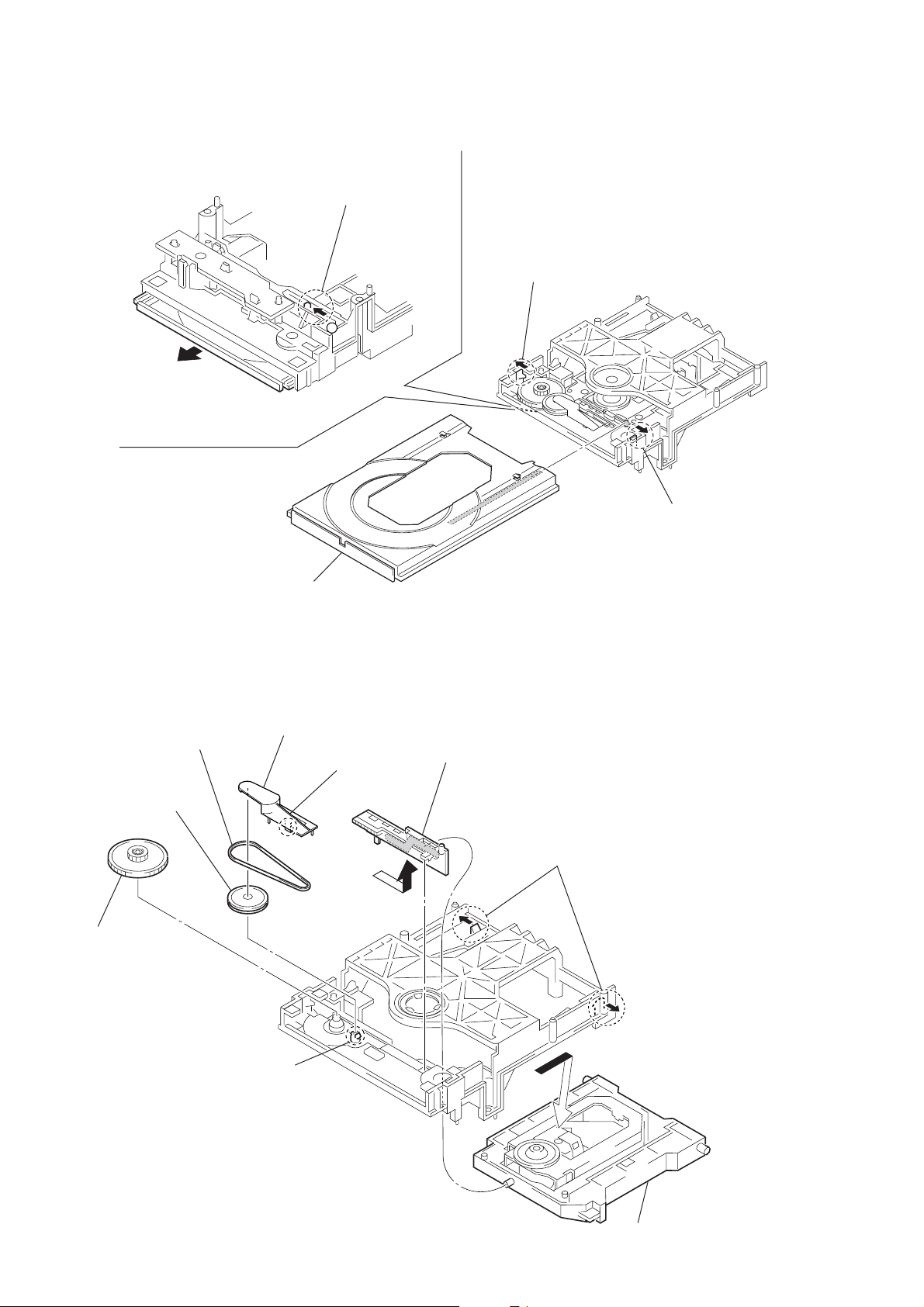

3-7. TRAY (AU)

2

1

Slide the chuck

cam in the direction

of arrow

A

A

.

3

claw

4

tray (AU)

3-8. OPTICAL PICK-UP BLOCK, CHUCK CAM

2

support

1

claw

6

gear

5

pulley

3

belt

9

chuck cam

7

two claws

3

claw

12

4

claw

8

optical pick-up bloc

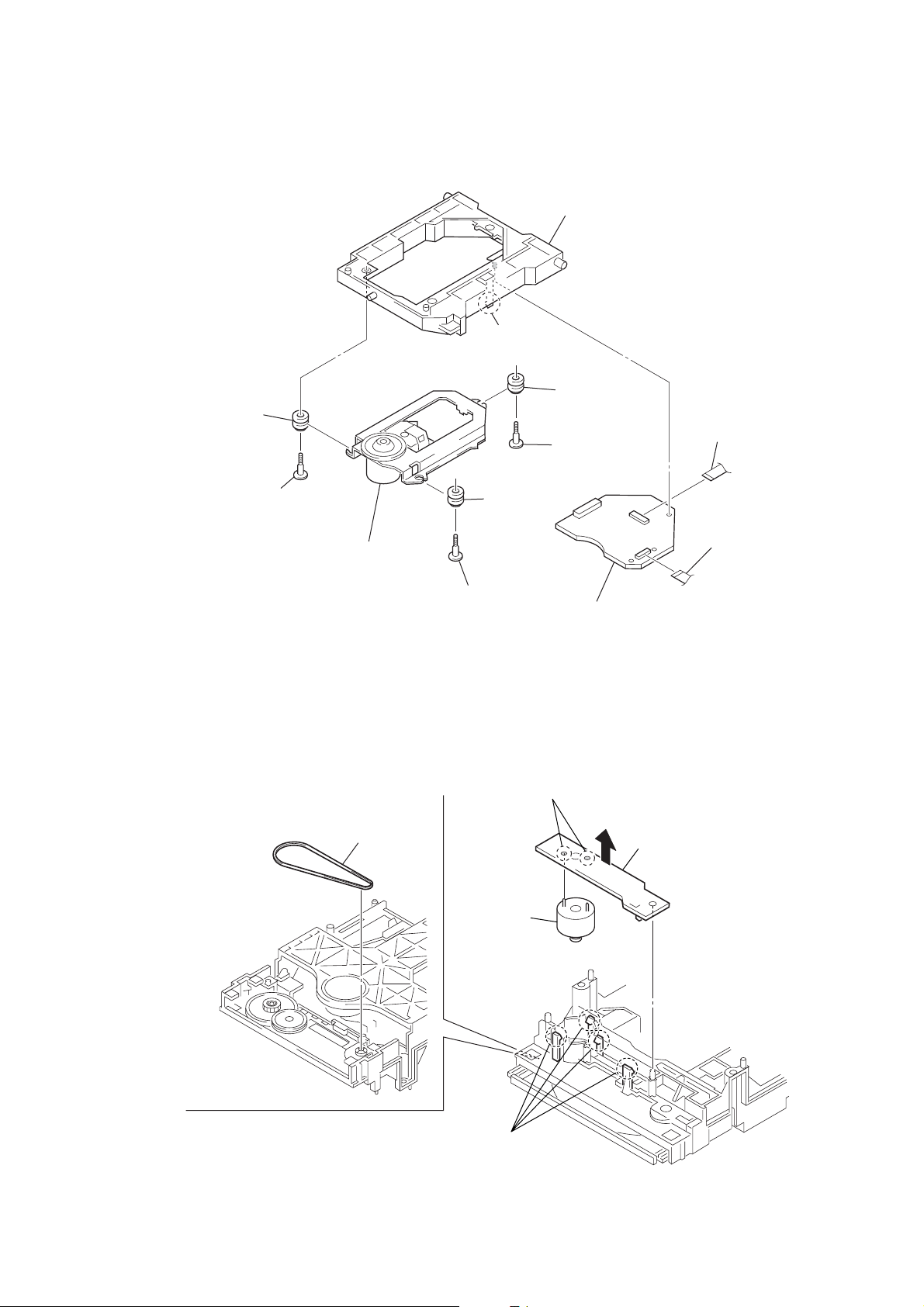

3-9. OPTICAL TRAVERSE UNIT (DBU-1)

7

insulator

1

claw

6

holder (DBU1)

7

insulator

5

step screw (M)

HCD-SB500W

3

w

ire (flat type)

(24 core) (CN001)

5

step screw (M)

8

optical traverse unit

(DBU-1)

3-10. DC MOTOR (LOADING) (M001)

1

belt

5

step screw (M)

5

7

insulator

4

Remove two solders.

DC motor

(loading)

(M001)

4

RF board

3

MS-128 board

2

flexible board

(CN003)

2

four claws

13

HCD-SB500W

SECTION 4

TEST MODE

COLD RESET

The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press three buttons of the > , X , and A simultaneously.

2. The message “ColdRESET” is displayed on the fluorescent

indicator tube, and the set is reset, then becomes standby mode.

VERSION DISPLAY

This mode is used to check the model and software version.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of the [VOL +], VOL – and A simultaneously for

five seconds. The software version and destination is displayed.

DISPLAY LED TEST

This mode is used to check the fluorescent indicator tube and FL

back light LED.

Procedure:

1. Press three buttons of the VOL – , . and A simultaneously.

2. All segments of fluorescent indicator tube and FL back light

LED are turned ON.

3. To release from this mode, press the I/1 button.

AUTO TUNING

This mode is used to auto tuning.

Procedure:

1. Press two buttons of the . and > simultaneously for

three seconds.

2. The message “AUTO 87.50” is displayed on the fluorescent

indicator tube. Then display repeats from automatic “AUTO

87.50” to “AUTO 108.00”.

3. To release from this mode, press the any buttons except the

VOLUME +/– buttons.

AMP TEST

This mode is used to check the function of the amplifier.

Procedure:

1. Press three buttons of the VOL – , . and [FUNCTION]

simultaneously.

2. Each time the [AUTO FORMAT] or [MODE] key on the remote

commander is pressed, output change as following order.

Display Function

SWAP F2S FRONT L-ch/R-ch input is outputted also

to SURROUND L-ch/R-ch speakers.

SWAP F2CW L-ch input is outputted to CENTER speaker,

and R-ch input is outputted to WOOFER

speaker.

SWAP Full L-ch/R-ch input is outputted all speakers.

EQ MAX 6dB of levels of the bus and treble is upped.

EQ MIN 6dB of levels of the bus and treble is downed.

SRAH CHECK Not used

3. Each time the [DSGX] key on the remote commander is pressed,

DSGX on/off are changed over.

4. Each time the [NIGHT MODE] key on the remote commander

is pressed, NIGHT MODE on/off are changed over.

5. Each time the VOLUME +/– key on the remote commander is

pressed, the message “VOLUME MIN”, “VOLUME 21” or

“VOLUME MAX” is displayed in this order on the fluorescent

indicator tube.

6. To release from this mode, press the I/1 button.

KEY TEST

This mode is used to check the front panel keys.

Procedure:

1. Press three buttons of the VOL – , [VOL +] and [FUNCTION]

simultaneously.

2. the fluorescent indicator tube displays “KEY XX”. Each time

a button is pressed, “KEY” value increases.

However, once a button is pressed, it is no longer taken into

account.

3. To release from this mode, perform same manner as step 1.

ROBBERY PREVENTION LOCK

This mode is used to unable to take sample disc out of set in the

shop.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press two buttons of the x and A simultaneously for five

seconds.

4. The message “LOCKED” is displayed on the fluorescent

indicator tube and the disc tray is locked. (Even if pressing

the A button, the message “LOCKED” is displayed on the

liquid crystal display and the disc tray is locked)

5. To release from this mode, press two buttons of the x and

the A simultaneously for five seconds again.

6. The message “UNLOCKED” is displayed on the liquid crystal

display and the disc tray is unlocked.

SHIP MODE

This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press three buttons the > , . and A simultaneously.

4. The message “MECHA LOCK” is displayed on the liquid

crystal display and the ship mode is set, then becomes power

off.

REPEAT 5 TIMES CANCEL

The number of repeat for DVD playback is 5 times when the repeat

mode is “REPEAT”. This mode enables DVD to repeat playback

for limitless times.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press three buttons of the > , [VOL +] and A simultaneously.

4. Repeat 5 times limit is canceled.

AM TUNING INTERVAL CHANGE-OVER

(Except AEP, UK, Russian models)

A step of AM channels can be changed o ver between 9 kHz and 10

kHz.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “AM”.

3. Press the I/1 button to turn the power off.

4. Press two buttons of the VOL – and I/1 simultaneously.

5. AM step 9 kHz and 10 kHz are changed over.

14

HCD-SB500W

Ver. 1.1

DVD DEBUG MODE

This mode is used to unable to reset for performing the debug of

DVD.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press three buttons of the > , [VOL +], and [FUNCTION]

simultaneously.

4. DVD debug mode is set.

COLOR SYSTEM CHANGE-OVER

(Singapore and Australian models)

This mode is used to changed over color system.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press the I/1 button to turn the power off.

4. Press two buttons of X and I/1 simultaneously.

5. The message “COLOR NTSC” or “COLOR P AL” is displayed

on the liquid crystal display, and the color system is changed

over NTSC or PAL.

COMPULSION INTERLACE

This mode is used to changed over video output into interlace.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to select “DVD”.

3. Press two buttons of . and [FUNCTION] simultaneously.

4. Video output is changed over interlace.

VACS DISPLAY

This mode is used to display of VACS (Variable Attenuation Contr ol

System) states.

Procedure:

1. Press the

2. Press three buttons of the x , [FUNCTION] and X

simultaneously.

3. When VACS is on, “VACS O” is displayed. When VACS is

off, “VACS OFF” is displayed.

I/1 button to turn the power on.

VACS ON/OFF

This mode is used to switch on or off the VA CS (V ariable Attenuation

Control System).

Procedure:

1. Press the I/1 button to turn the power on.

2. Press three buttons of the > , [FUNCTION] and X

simultaneously.

3. VACS on/off are changed over.

DVD SECTION

DVD TEST MODE GENERAL DESCRIPTION

The T est Mode allows you to make diagnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

• Test Disc List

Use the following test disc on test mode.

TDV-520CSO (DVD-SL): Part No. J-2501-236-A

LUV-P01 (CD) : Part No. 4-999-032-01

TDV-540C (DVD-DL) : Part No. J-2501-235-A

Note: Do not use existing test disc for DVD.

STARTING DVD TEST MODE

1. Press the I/1 button to turn the power ON.

2. Press the [FUNCTION] button to select “DVD”.

4. Press three buttons of the x , A and [VOLUME +]

simultaneously.

5. The message “SERVICE IN” is display ed on the fruorescent

indicator tube, and the Test Mode Menu is display ed on the

monitor screen as follows. (At the bottom of the menu screen,

the model name and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :DAV-SB500W

Revision :x.xx

6. To execute each function, select the desired menu and press

its number on the remote commander (RM-SP240).

7. To release from test mode, press the

power off.

I/1 button and turn the

PRODUCT OUT

This mode is used to performed COLD RESET and SHIP MODE

simultaneously.

Procedure:

1. Press the three buttons of the x , . , and [FUNCTION]

simultaneously.

2. The message “ColdRESET” is displayed on the fluorescent

indicator tube, and the set is reset, then becomes standby mode.

15

HCD-SB500W

OPERATING DVD TEST MODE

0. Syscon Diagnosis

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

7. Audio

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

Example display

### Syscon Diagnosis ###

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below .

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Version

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-7. Audio Check

0-2. Version

0-2-2. Version

The revision number of ROM (IC204) that the program for

the DVD system processor (IC207) is stored.

(4 digits hexadecimal number)

0-2-3. ROM Check Sum

The revision number of ROM (IC204) tha t the program for

the DVD system processor (IC207) is stored.

0-2-4. Model Type

Model name is displayed.

0-2-5. Region

Model destination code is displayed. (2 digits number)

Diag All Check

No.2 Version

2-2. Version

ROM Reversion = X.XX

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM check, the check sum calculated by the syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the > button to go to the next item,

or press the . button to repeat the same operation again.

To quit the diagnosis and return to Check Menu screen, press the

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the [RETURN] key on the remote commander to quit the

diagnosis, or press the . button to repeat the same check where

an error occurred, or press the > button to continue the check

from the item next to faulty item.

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-1. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error .

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC207)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and MPEG

decoder (IC207).

0-6. Video Check

Output the color bars for video level adjustment.

0-7. Audio Check

Output the test signal (1kHz sine wave) for 2 CH test.

16

HCD-SB500W

1. Drive Auto Adjustment

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

Exit: RETURN

Normally, [0] is selected to adjust D VD (single layer), CD and DVD

(dual layer) in this order. But, individual items can be adjusted for

the case where adjustment is suspended due to an error. In this mode,

the adjustment can be made easily through the operation following

the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [0] key on the remote commander, and the servo set data

in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD disc

and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. Y ou can finish the adjustment

by pressing the [RETURN] button on the remote commander.

1-1. DVD-SL (single layer)

Press the [1] key on the r emote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto focus offset adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto track gain adjust

21. All servo stop

22. EEP copy loop filter offset

1-2. CD

Press the [2] key on the remote commander and insert a CD disc

following the message. Then the adjustment will be made through

the steps, then adjusted values will be written to the EEPROM.

Note: During adjustment of each disc, the measurement for disc type

judgment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

CD Adjustment Steps:

1. Sled rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Sled ON

16. Check CLV on

17. Auto focus offset adjust

18. Auto focus gain adjust

19. Auto focus offset adjust

20. EQ boost adjust

21. Auto track gain adjust

22. All servo stop

17

HCD-SB500W

1-3. DVD-DL (dual layer)

Press the [3] key on the remote commander and insert a DVD dual

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps:

1. Sled reset

2. Disc check memory DL

3. Wait 500 msec

4. Set disc type DL

5. LD on

6. Spindle start

7. Wait 1 sec

Layer 1 Adjust

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 500 msec

14. Sled on

15. Check CLV lock

16. Auto focus adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto Track Gain Adjust

Layer 0 Adjust

21. Focus jump (L1 → L0)

22. Auto track offset adjust L0

23. CLVA on

24. Wait 500 msec

25. Tracking on

26. Wait 500 msec

27. Sled on

28. Check CLV lock

29. Auto Focus Adjust

30. Auto focus gain adjust

33. Auto focus offset adjust

34. EQ boost adjust

35. Auto track gain adjust

37. All servo stop

2. Drive Manual Operation

Note: This mode is used for design, and not used in service fundamentally.

On the Test Mode Menu screen, press the [2] key on the remote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can be

executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, exit the manual operation menu immediately

to stop the servo operation, and press the I/1 button to turn the

power off.

Basic operation:

(controllable from front panel or remote commander)

I/1 :Power off (release the test mode)

Z : Stop and eject/loading

[RETURN] : Return to Operation Menu or Test Mode Menu

. , > :Transition between sub modes of menu

[0] to [9] : Selection of menu items

Cursor o / O : Increase/Decrease in manually adjusted value

18

HCD-SB500W

2-1. Disc Type

Disc Type

Disc Type Select

1. Disc Type Auto Check

2. Set Disc Type DVD

3. Set Disc Type CD

4. Set Disc Type Hybrid

Exit: RETURN

2-1-1. Disc Type Auto Check

1. Press the [1] key on the remote commander to display the Disc

Type Auto Check screen.

2. Insert a disc and press the [ENTER] key on the remote

commander.

3. It judges the type of inserted disc automatically and displays

the disc type and so on as below.

Disc Type Auto Check

Disc Type xx

Layer xx

Mirr Time xx

Mirr Count xx

FZC Count xx

PI Reference xx

PI Peak xx

2-1-3. Disc Type CD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: CD disc (normal speed, 12 cm)

[2]: CD disc (double speed, 12 cm)

[3]: CD disc (normal speed, 8 cm)

[4]: CD disc (double speed, 8 cm)

[5]: CD-RW disc (normal speed, 12 cm)

[6]: CD-RW disc (double speed, 12 cm)

[7]: CD-RW disc (normal speed, 8 cm)

[8]: CD-RW disc (double speed, 8 cm)

2-1-4. Disc Type Hybrid

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: SACD Hybrid disc (SACD layer, 12 cm)

[2]: SACD Hybrid disc (CD layer, normal speed, 12 cm)

[3]: SACD Hybrid disc (CD layer, double speed, 12 cm)

[4]: SACD Hybrid disc (SACD layer, 8 cm)

[5]: SACD Hybrid disc (CD layer, normal speed, 8 cm)

[6]: SACD Hybrid disc (CD layer, double speed, 8 cm)

2-2. Servo Control

Note: Be sure to perform the disc type setup before performing this item.

Servo Control

1. LD off R.Sled FWD

2. Focus off L.Sled REV

3. SPDL off U.Sled Reset

4. CLVA off D.Sled Limit

5. Trk. off

6. Sled off

7. Fcs.Srch off

ENTER.Execute

Exit: RETURN

Disc Type : CD, DVD or Hybrid (SACD)

Layer : SINGLE, DUAL or HYBRID

Mirr Time : Mirror time of between disc surface and record

surface when disc type judgment. (hexadecimal

number)

Mirr Count : The number of times which mirror counts between

disc surface and record surface when disc type

judging.

FZC Count : The number of times which focus zero cross points

of each layer when lens down.

PI Reference : The average of PI reference voltage. (hexadecimal

number)

PI Peak : PI peak level voltage. It performs only when disc

type judgment is successful. (hexadecimal number)

2-1-2. Disc Type DVD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: DVD single layer disc (12 cm)

[2]: DVD dual layer disc (0 layer, 12 cm)

[3]: DVD dual layer disc (1 layer, 12 cm)

[4]: DVD-RW disc (12 cm)

[5]: DVD single layer disc (8 cm)

[6]: DVD dual layer disc (0 layer, 8 cm)

[7]: DVD dual layer disc (1 layer, 8 cm)

[8]: DVD-RW disc (8 cm)

0. All Servo Off

Exit: RETURN

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system is

faulty or RF is not present. In such a case, do not operate CLVA.

[1] LD : Turn on/off the laser.

[2] Focus : Search the focus and turn on the focus.

[3] SPDL : Turn on/off the spindle.

[4] CLVA : Turn on/off normal servo of spindle servo.

[5] Trk. : Turn on/off the tracking servo.

[6] Sled : Turn on/off the sled servo.

[7] FCS. Srch : Turn on/off the focus search.

[0] : All servo off.

[R] Sled FWD (right cursor) : Move the sled forward.

[L] Sled REV (left cursor) : Move the sled reverse.

[U] Sled FWD (up cursor) : Reset the sled.

[D] Sled REV (down cursor) : Limit in the sled.

19

HCD-SB500W

2-3. Track/Layer Jump

Track/Layer Jump

1. 1Tj FWD R.Lj L0>L1

2. 1Tj REV L.Lj L1>L0

3.500Tj Fine FWD U.Fj L0>L1

4.500Tj Fine REV D.Fj L1>L0

5.10kTj Dirc FWD

6.10kTj Dirc REV

7.20kTj Dirc FWD

8.20kTj Dirc REV

0.All Servo Off

Exit: RETURN

On this screen, track jump, etc. can be performed. Only for the DVD

dual layer disc, the focus jump and layer jump are displayed in the

right field

[1] 1Tj FWD : 1 track jump forward.

[2] 1Tj REV : 1 track jump reverse.

[3] 500Tj FWD : 500 track jump (fine search)forward.

[4] 500Tj REV : 500 track jump (fine search) reverse.

[5] 10kTj FWD : 10k track jump (direct search) forward.

[6] 10kTj REV : 10k track jump (direct search) reverse.

[7] 20kTj FWD : 20k track jump (direct search) forward.

[8] 20kTj REV : 20k track jump (direct search) reverse.

[0] : All servo off.

[R] LjL0 t L1 (right cursor) : Layer jamp L0 t L1

[L] LjL1 t L0 (left cursor) : Layer jamp L1 t L0

[U] FjL0 t L1 (up cursor) : Focus jamp L0 t L1

[D] FjL1 t L0 (down cursor) : Focus jamp L1 t L0

2-4. Non EEPROM Write Adjust

Non EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. Trk. Offset Fine

5. Trk. Gain

6. EQ Boost

0. All Servo Off

2-5. EEPROM Write Adjust

EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. ------------

5. Trk. Gain

6. EQ Boost

0. All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number [1] to [0] from the remote commander, and selected

item is adjusted automatically. Thus value is stored in the EEPR OM.

[1] Focus Offset : Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset Coarse : Adjusts tracking offset of the RF

amplifier (IC001) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of

equalizer.

[0] : All servo off.

2-6. Memory Check

Display images are shown as follows, and all two screens are able

to switch by the O key (UP) or o key (DW).

EEPROM Data 1/2 CD SL L0 L1

Focus Gain xx xx xx xx

Trk. Gain xx xx xx xx

Focus Offset xx xx xx xx

Trk. Offset xx xx xx xx

EQ. Boost xx xx xx xx

PI Level xx xx -- -Fcs. Balance -- xx -- -Jitter xx xx xx xx

Mirror Time xx xx xx -FE Level -- xx -- -Traverse Lv1. -- xx -- -Next:DW Default:CLR Exit:RET

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number [1] to [10/0] from the remote commander , and current

setting for the selected item will be displayed, then increase or

decrease numeric value with the O key or o key. If CLV has been

applied, the jitter is displayed for reference for the adjustment.

[1] Focus Offset : Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset Coarse : Adjusts tracking offset of the RF

amplifier (IC001) side.

[4] TRK. Offset Fine : Adjusts tracking offset of the DSP

(IC401) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of

equalizer.

[0] : All servo off.

20

EEPROM Data 2/2 CDRW DVDRW

Focus Gain xx xx

Trk. Gain xx xx

Focus Offset xx xx

Trk. Offset xx xx

EQ. Boost xx xx

Prev:UP Default:CLR Exit:RET

On this screen, current servo adjusted data stored in the EEPROM

are displayed. The adjusted data are initialized by pressing the

[CLEAR] key, but be careful that they are not recoverable after

initialization.

Before clearing the adjusted data, make a note of the set data.

HCD-SB500W

2-7. Disc Check Memory

Disc Check Memory

1. SL Disc check

2. CD Disc check

3. DL Disc check

Exit: RETURN

On this screen, measure the mirror time of chucked disc, and write

to the EEPROM.

2-8. Error Rate Display

Error Rate Display

UC CR Address

PI1 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PI2 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PO Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

3. Mecha Aging

On the T est Mode Menu screen, selecting [3] executes the aging of

the mechanism deck.

### Aging Test MENU ###

** Pls use over 40min.CD **

Operation Menu

1. Open/Close Test

Exit: RETURN

1. Set over-40-min. CDs.

2. On the Aging Test MENU screen, press the [1] key on the

remote commander to display the Open/Close Test screen.

3. Insert discs and press the [ENTER] key on the remote

commander.

4. Is starts the aging.

During aging, the disc number, operating status and repeat

cycle are displayed. Aging can be aborted at any time by

pressing the [RETURN] key. After the operation is stopped,

press the [RETURN] key to return to the Aging Test MENU.

Exit: RETURN

On this screen, measure and display the error rate.

UC : Incorrect value

CR : Correct value

2-9. SACD Water Mark Check

SACD Water Mark Check

PSP AMP

PSN

Start: ENTER Stop: RETURN

On this screen, measure the PSP AMP v alue and PSN value of SACD

water mark.

21

HCD-SB500W

4. Emergency History

On the Test Mode Menu screen, selecting [4] displays the

information such as servo emergency history.

The history information from last 1 up to 10 can be scrolled with

the O key or o key. Also, specific information can be displayed

by directly entering that number with ten keys.

### EMG. History ###

Laser Hours CD xxxxhxxm

DVD xxxxhxxm

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

Select:1-9 Scroll:UP/DOWN

(1.Latest EMG.) Exit: RETURN

xxxxhxxm : The laser on total hours. Data below minutes are

omitted.

a. : Error number.

bb : Error code.

xx : Not used.

• Clearing History Information

Clearing laser hours:

Press the [DVD DISPLAY] and [CLEAR] keys in this order.

Then both CD and DVD data are cleared.

Clearing emergency history:

Press the [DVD TOP MENU] and [CLEAR] keys in this order.

Initializing EEPROM data:

Press [DVD MENU] and [CLEAR] keys in this order.

The data have been initialized when “EEPROM Initialize

Finished. ” message is displayed, press the [RETURN] key to return

to the EMG. History screen.

• Code list of Emergency History

10: Communication to RF amplifier (IC001) failed.

11: Each servo for focus, tracking, and spindle is unlocke d.

12: Check sum error of EEPROM (IC204).

14: Communication to servo DSP (IC509) failed, or servo DSP

(IC509) is faulty.

15: Communication to DVD decoder (IC701) failed, or DVD

decoder (IC701) is faulty.

16: Communication to DSD decoder (IC801) failed, or DSD

decoder (IC801) is faulty.

20: Initialization of sled servo failed. It is not placed in the initial

position.

23: Sled servo operation error.

24: Made a request to move the sled servo to wrong position.

30: Tracking balance adjustment error.

31: Tracking gain adjustment error.

33: Focus bias adjustment error.

34: Focus gain adjustment error.

35: Equalizer adjustment error.

40: Focus servo does not operate.

41: With a DVD dual layer disc, focus jump failed.

50: CLV (spindle) servo does not operate.

51: Spindle does not stop.

60: Made a request to seek nonexistent address.

61: Seek error of retry more than regulated times.

70: Control data could not be read.

80: Disc reading failed.

5. Mecha Error History

On the Test Mode Menu screen, selecting [5] displays the

information of mechanism deck error history.

The history information from last 1 up to 8 can be scrolled with

the O key or o key.

### Mecha Error History ###

1. aa bb cc dd ee xx xx xx

2. aa bb cc dd ee xx xx xx

3. aa bb cc dd ee xx xx xx

4. aa bb cc dd ee xx xx xx

5. aa bb cc dd ee xx xx xx

6. aa bb cc dd ee xx xx xx

7. aa bb cc dd ee xx xx xx

8. aa bb cc dd ee xx xx xx

Scroll:UP/DOWN

(1.Latest Err.) Exit: RETURN

aa : Initialization is completed or not.

FF : Complete the initializing. (normal operation)

11 : Stocker movement (to chucking position) fail-

ing in the midst of initializing the mechanism

deck.

12 : Stocker movement (to chucking position) fail-

ing in the midst of initializing the mechanism

deck.

1x : Initializing the mechanism deck.

2x : Initializing the mechanism deck.

3x : Initializing the mechanism deck.

41 : Disc eject failing in the midst of initializing

the mechanism deck.

4x : Initializing the mechanism deck.

50 : Disc eject failing in the midst of initializing

the mechanism deck.

5x : Initializing the mechanism deck.

A2 : Disc eject failing in the midst of initializing

the mechanism deck.

Ax : Initializing the mechanism deck.

D3 : Disc eject failing in the midst of initializing

the mechanism deck.

Dx : Initializing the mechanism deck.

Ex : Initializing the mechanism deck.

bb : Operating status of mechanism deck at an error occurred.

(lod sq jcp)

00 : Initializing.

10 to 15 : Open operating.

16 to 19 : Kicking cause open failed.

1A to 1F : Open operating.

20 to 27 : Complete the open operation.

28 : No disc and complete the open operation.

29 to 2F : Complete the open operation.

30 to 3F : Close requesting.

40 to 4F : Open requesting.

50 to 5F : Close operating.

60 to 6F : Complete the chucking operation.

80 to 8F : Complete the release operation.

(BU is home position)

90 to 9F : BU down operating.

A0 to AF : Opening/closing the shutter. Or stationary state

in open/close the shutter is enablement.

B0 to BF : BU up requesting.

C0 to CF : BU down requesting.

D0 to DF : BU upping.

E0 to EF : No disc checking in disc loading.

22

SECTION 5

p

TP815

(RF AMP OUT)

DIA T TRANSMIT

board

oscilloscope

ELECTRICAL ADJUSTMENTS

HCD-SB500W

cc : Operating status of table at an error occurred.

(tbl sq jcp)

13 : The rotation stop position determination error

of a table.

11 to 12 : The loading position determination error of a

table.

dd : Operating status of mechanism deck at an error occurred.

(lod op jcp)

00 : Complete the operation.

10 to 1F : Open operating.

20 to 2F : Close operating.

30 to 3F : Release operating.

60 to 6F : Chucking operating.

70 to 7F : Kicking operating.

80 to 8F : Returning the BU to home position. (after

kicking)

ee : The status of table operation. (“n” is unfixed)

(tbl op cp)

1n : Rotating in the direction of a forward.

2n : Rotating in the direction of a reverse.

6. Version Information

On the Test Mode Menu screen, selecting [6] displays the ROM

version and region code.

The parenthesized hexadecimal number in version field is checksum

value of ROM.

## Version Information ##

IF con. Ver.x. xxx

SYScon. Ver.x. xx (xxxx)

Model DAV-SB500W

Region xx

Config xxxxxxxx

Front End Ver.x.xx

About the dicision to pass or fail of the optical pick-up block,

refer to “DICISION TO P ASS OR FAIL OF THE OPTICAL PICKUP BLOCK” (see page 6)

AUTO SERVO ADJUSTMENT

After parts related to the servo circuit (RF amplifier (IC001), DSP

(IC509), motor driver (IC501), EEPROM (IC903) so on) are replaced, re-adjusting the servo circuit is necessary . Select “ALL” at

“1. DRIVE AUTO ADJUSTMENT” (Refer to page 17 in TEST

MODE) and adjust DVD-SL (single layer), CD and D VD-DL (dual

layer).

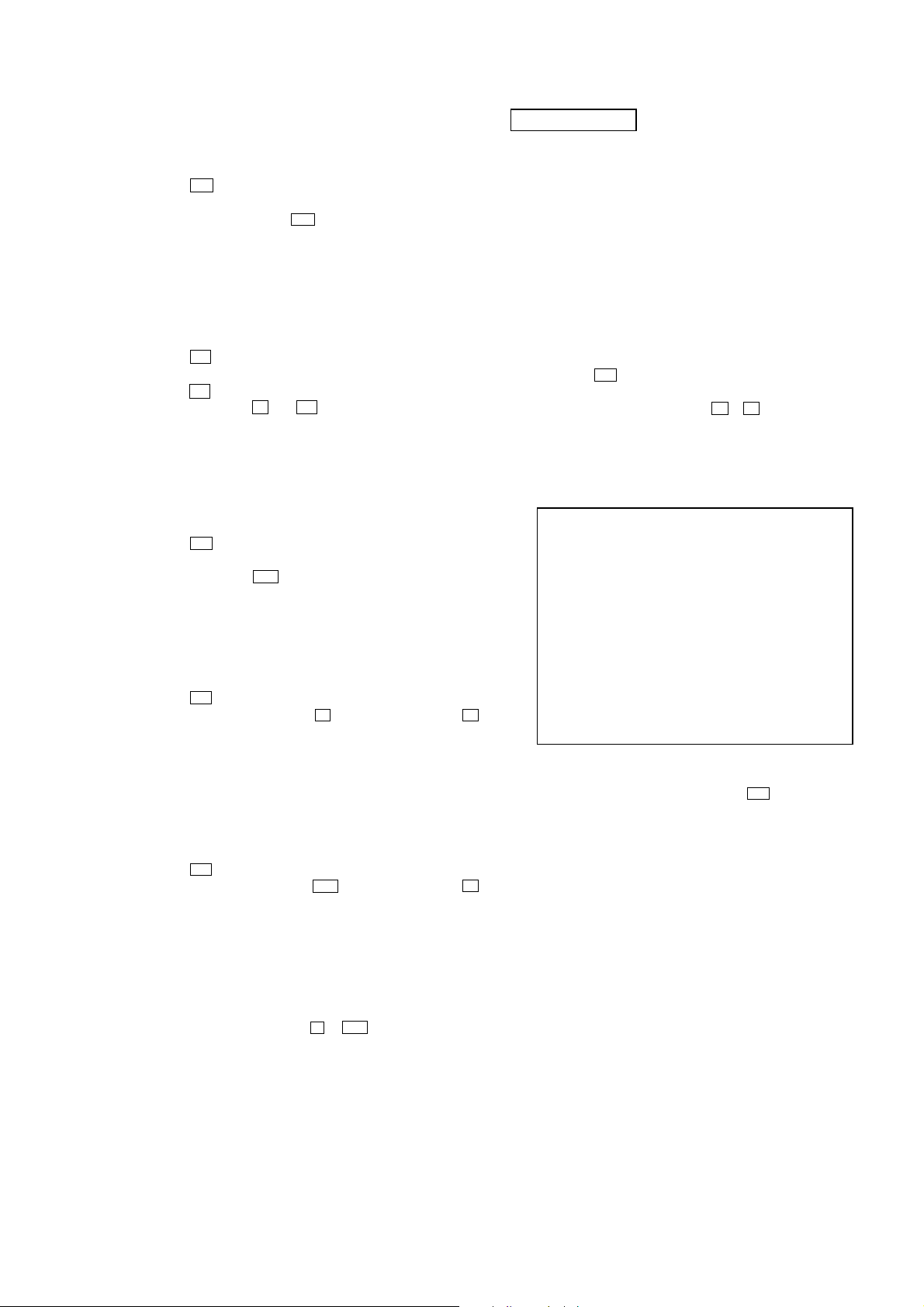

DIAT SIGNAL RF LEVEL ADJUSTMENT

This adjustment is performed in order to adjust the transmission

distance of RF signal for DIAT communication.

Connection:

Procedure:

1. Connect the oscilloscope to TP815 (RF AMP OUT) and GND

on the DIAT TRANSMIT board.

2. Connect DIR-T1 to DIR-T1 jack (J301).

3. Adjust RV801 on the DIAT TRANSMIT board so that the

center of waveform becomes 1.0 Vp-p.

4. Confirm trigger is locked.

5. Adjust RV801 on the DIAT TRANSMIT board so that the

center of waveform becomes 2.2 to 2.4 Vp-p.

RF Signal Reference Waveform

VOLT/DIV : 500mV

TIME/DIV : 500ns

Exit: RETURN

IF con. : The version of system controller (IC101).

SYScon. : The version of DVD system processor (IC207).

Front End : The version of mechanism controller (IC901).

7. Video Level Adjustment

On the T est Mode Menu screen, selecting [7] displays color bars for

video level adjustment. During display of color bars, OSD disappears

but the menu screen will be restored if pressing the [RETURN] key.

level : 2.2 to 2.4 Vp-

Adjustment Location:

– DIAT TRANSMIT Board (Component Side) –

IC804

IC805

TP815

(RF AMP OUT)

HCD-SB500W

2323

HCD-SB500W

SECTION 6

DIAGRAMS

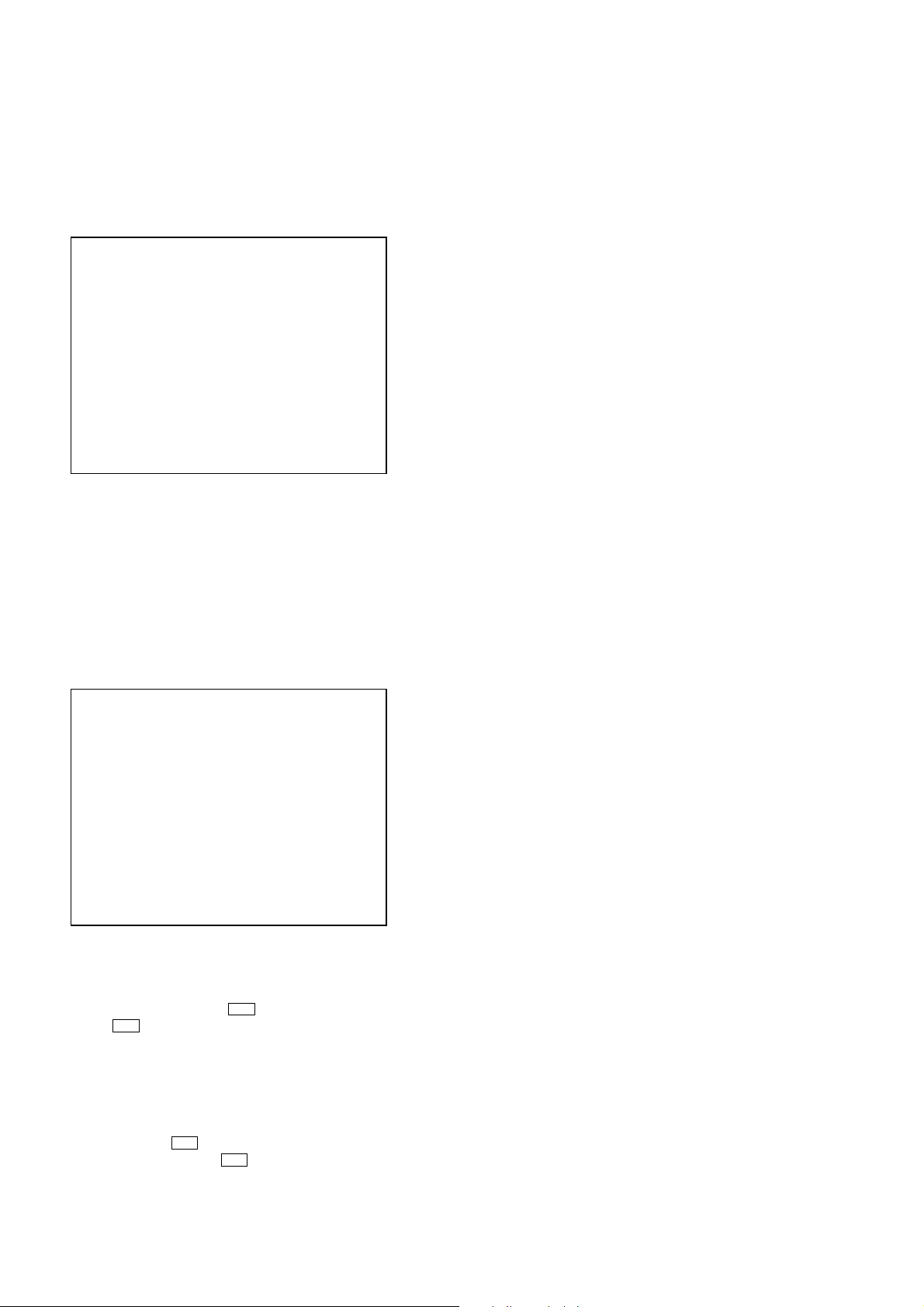

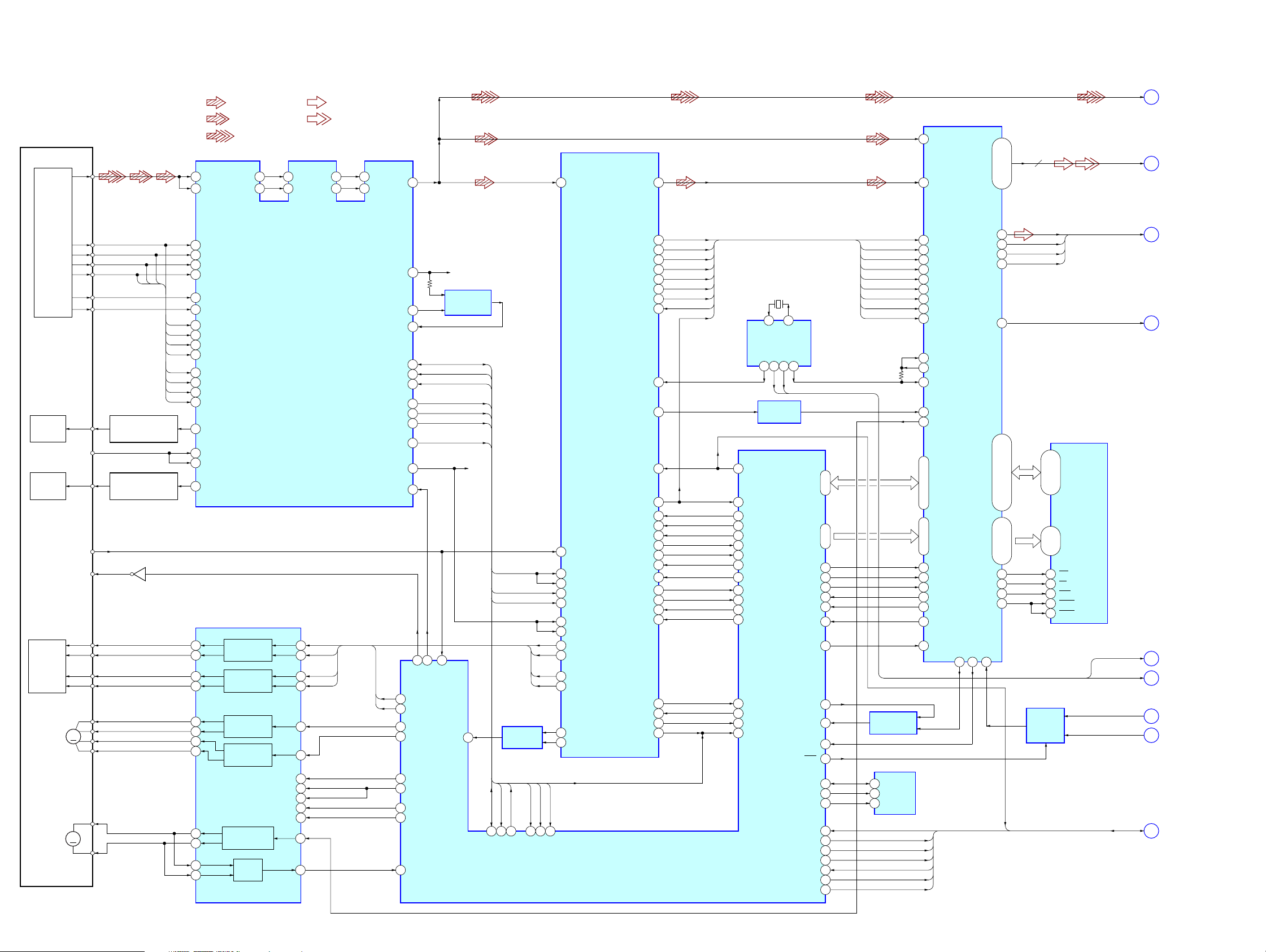

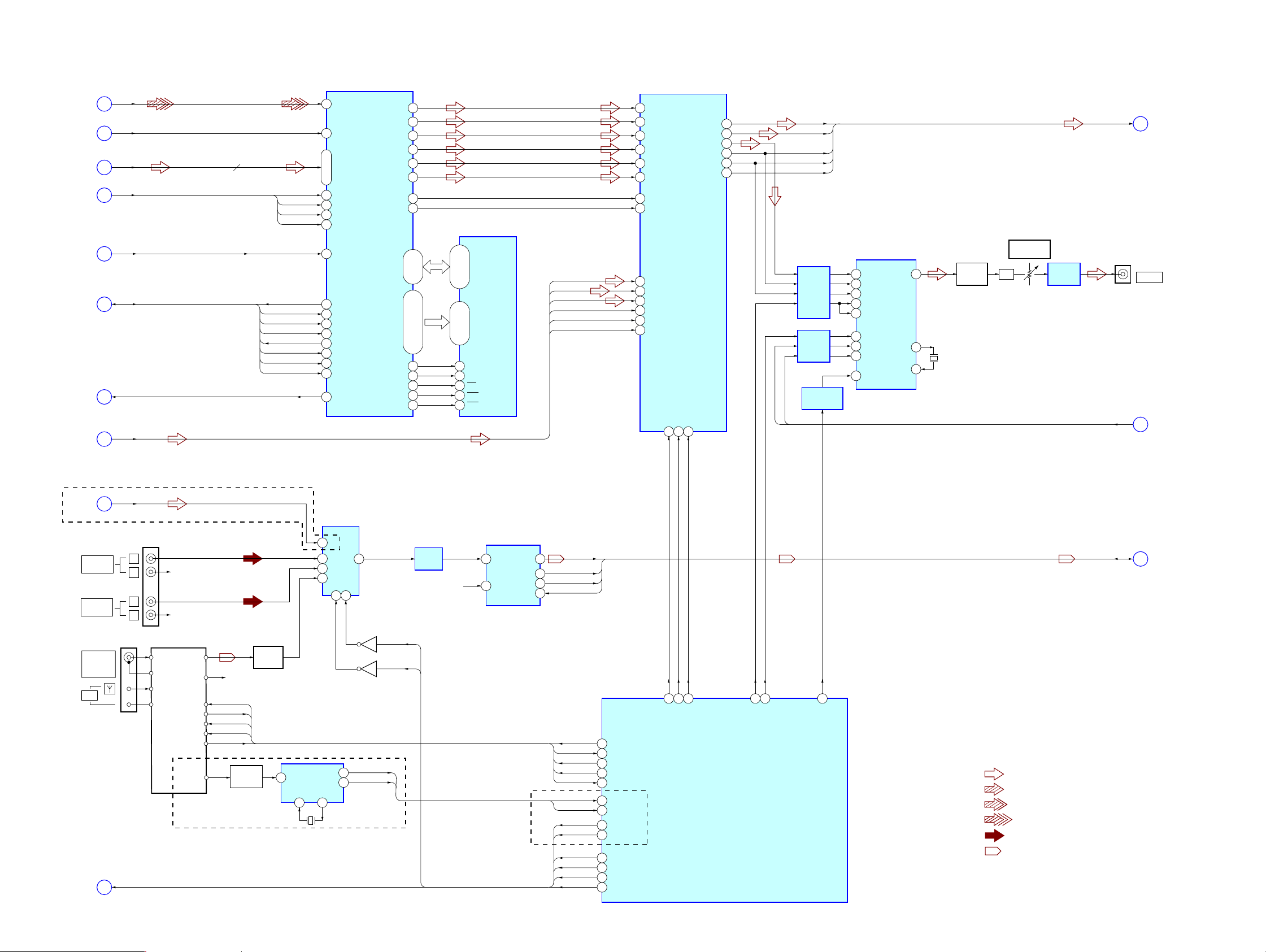

6-1. BLOCK DIAGRAM – RF SERVO Section –

• SIGNAL PATH

: CD PLAY

: DVD PLAY

: SACD PLAY

DETECTOR

OPTICAL PICK-UP

BLOCK

(DBU-1)

LASER

CD LD

DIODE

(FOR CD)

LASER

DVD LD

DIODE

(FOR DVD)

INLIM

FCS+

FCS–

2AXIS

DEVICE

FOCUS/

TRACKING

(SPINDLE)

COIL

M2

(SLED)

M1

TRK+

TRK–

MM

MM

SW

RF

A

B

C

D

F

E

PD

CBA

D

Q002

AUTOMATIC POWER

CONTROL (FOR CD)

Q001

AUTOMATIC POWER

CONTROL (FOR DVD)

DVDRFP

1

RFSIN

63

A2

3

B2

4

C2

5

D2

6

18

CD E

17

CD F

B

12

A

A

11

B

D

10

C

C

9

D

B

16

CD A

A

15

CD B

D

14

CD C

C

13

CD D

22

CDLD

24

CDPD

DVDPD

23

DVDLD

21

Q901

FOCUS/TRACKING COIL DRIVER,

SPINDLE/SLED MOTOR DRIVER

36 48

37 1

34 3

35 4

32

31

30

29

27

28

47

46

ATOP

62

ATON

61

IC501

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SLED MOTOR

DRIVE

POWER SAVE

SPINDLE MOTOR

DRIVE

BUFFER

: AUDIO

: VIDEO

FNP

AIP

59

AIN

60

CD/DVD/SACD RF AMP,

FOCUS/TRACKING ERROR AMP

10

39

19

MUTE12

20

MUTE34

21

MUTE5

22

TSD-M

13

45

535254

FNN

IC001

FF

FR

TF

TR

7

RF_AC

A

(Page 26)

117

RFIN

8

DIP

55

DIN

RFAC

MEVO

MIN

SDATA

SCLK

SDEN

MIRR

VI25

LDON

FF

FR

VC

TE

FE

7

8

44

43

97

60

63

73

62

57

20

32

31

47

46

48

39

40

38PI

27

36

26

28

76 31

LDON

LDSEL

FCS_JMP_1

FCS_JMP_2

SLED_B

SLED_A

DSAVE

MUTE_2D

SP_ON

TSD-M

FG

VC

IC003

COMPARATOR

DATA_RF

CLK_RF

SDEN

TE

FE

PI

MIRR

AVC

INLIM

61

SLED

TE

FE

PI

CLK_RF

DATA_RF

82

83

SDCLK_RF

SDATA_RF

IC503

SDEN

2

SDEN

AMP

50

RFAC

IC509

CD DECODER,

DIGITAL SERVO PROCESSOR

SSTP

26

41

TE

40

SE

FE

39

43

RFDC

VC

38

CE

42

FF

33

FFDR

FR

34

FRDR

TF

31

TFDR

TR

32

TRDR

SFDR

29

SRDR

30

MIRR

PI

FE

TE

67PI66

65

FE

TE

IC901 (1/2)

MECHANISM

CONTROLLER

PCMD

BCK

LRCK

C2PO

WDCK

DFCT

WFCK

SBSO

EXCK

XTAI

MDP

MD2

SCOR

DATA

CLOK

XLAT

SENS

SQSO

SQCK

XRST

LOCK

GFS

MUTE

XTSL

COUT

SCLK

FOK

MIRR

66

BCLK

67

LRCK

65

C2PO

14

GSCOR

17

DFCT

21

WFCK

10

SBSO

79

EXCK

80

SCOR

IC906

CLOCK

GENERATOR

13 3

71

3

26

49

50

27

9

52

54

98

75

71

59

10

30

72

74

29

IC703 (1/2)

DOCTR/

ISBTEST

SCOR

DATA_CD

CLOK_CD

LAT_CD

SENS_CD

SQSO

SQCK

XDRST

LOCK_CD

GFS_CD

MUTE_CD

CDSP2

COUT_CD

SCLK_CD

FOK_CD

MIRR

25

63

15

4

6

5

7

76

77

2

24

13

3

69

19

8

22

20

7 8

XTI

SO1

SO3

MO1

9 10

27M

768FS

BUFFER

XCS_DVD

INT0_DVD

INT1_DVD

GFS_DVD

XRST_1882

SCK_DSD

SACD/DVD

SDIN_DSD

SDOUT_DSD

MSCK_SAMBA

READY_DSD

MUTE_DSD

XRST_2753

X902

27MHz

XTO

SO2

XRD

XWR

MNT1

SDA_EEP

SCL_EEP

WP_EEP

XMSLAT

JIT

14-21

D0 – D7

89-96

A0 – A7

85

84

12

22

23

58

25

45

64

6

77

5

100

99

47

46

24

51

48

53

4

BCLK

LRCK

C2PO

GSCOR

DFCT

WFCK

SBSO

EXCK

SCOR

IC703 (2/2)

COMPARATOR

5

SDA

6

SCL

7

WP

MSDATO

MSDATI

MSCK

XMSLAT

SHRRDY

SHRMUT

XRST_DSD

160

MDAT

158

BCLK

163

LRCK

155

C2PO

146

GSCOR

145

DFCT

151

WFCK

148

SBIN

147

EXCK

150

SCOR

DVD DECODER

167

XTAL

169

XTL2

170

XTL1

137

MDIN2

135

SPO

D0 – D7

172-176, 1, 2, 4

A0 – A7

5, 7, 9-14

17

XRD

18

XWR

19

XCS

20

XINT0

21

XINT1

107

GFS

164

XRST

IC903

EEPROM

IC701

AEP0

109

XMWR

92

32, 30, 27, 24

HDB0 – HDB7

44, 41, 39, 35,

SDEF

26

HDRQ

46

XHWR

48

XHRD

49

MNT2

93

MDB0 – MDB9,

MDBA – MDBF

99, 101, 102, 104-106

66-69, 71, 73-75, 96, 97,

89, 91

MA0 – MA9

79, 80, 82-87,

76

94

XMOE

78

XRAS

95

XCAS

XHAC

MNT1

53

ISBTEST

SDEF

XSAK

XDCK

XSHD

2-5, 7-10,

I/O0 – I/O15A0 – A9

41-44, 46-49

IC706

16Mbit

D-RAM

27-32

21-24,

17

WE

33

OE

18

RAS

34

UCAS

35

LCAS

IC257

SACD/DVD

SELECT

MSDATO, MSDATI, MSCK,

XMSLAT, SHRRDY, SHRMUT,

SD0 – SD7

SDEF, XDCK,

XSAK, XSHD

WPK

768FS

27M

XSRQ

XSRQ-ZIVA

ISBTEST, XRST_DSD

B

(Page 25)

C

(Page 25)

D

(Page 26)

(Page 26)

E

F

(Page 25)

(Page 26)

H

I

(Page 25)

J

(Page 26)

HCD-SB500W

2424

HCD-SB500W

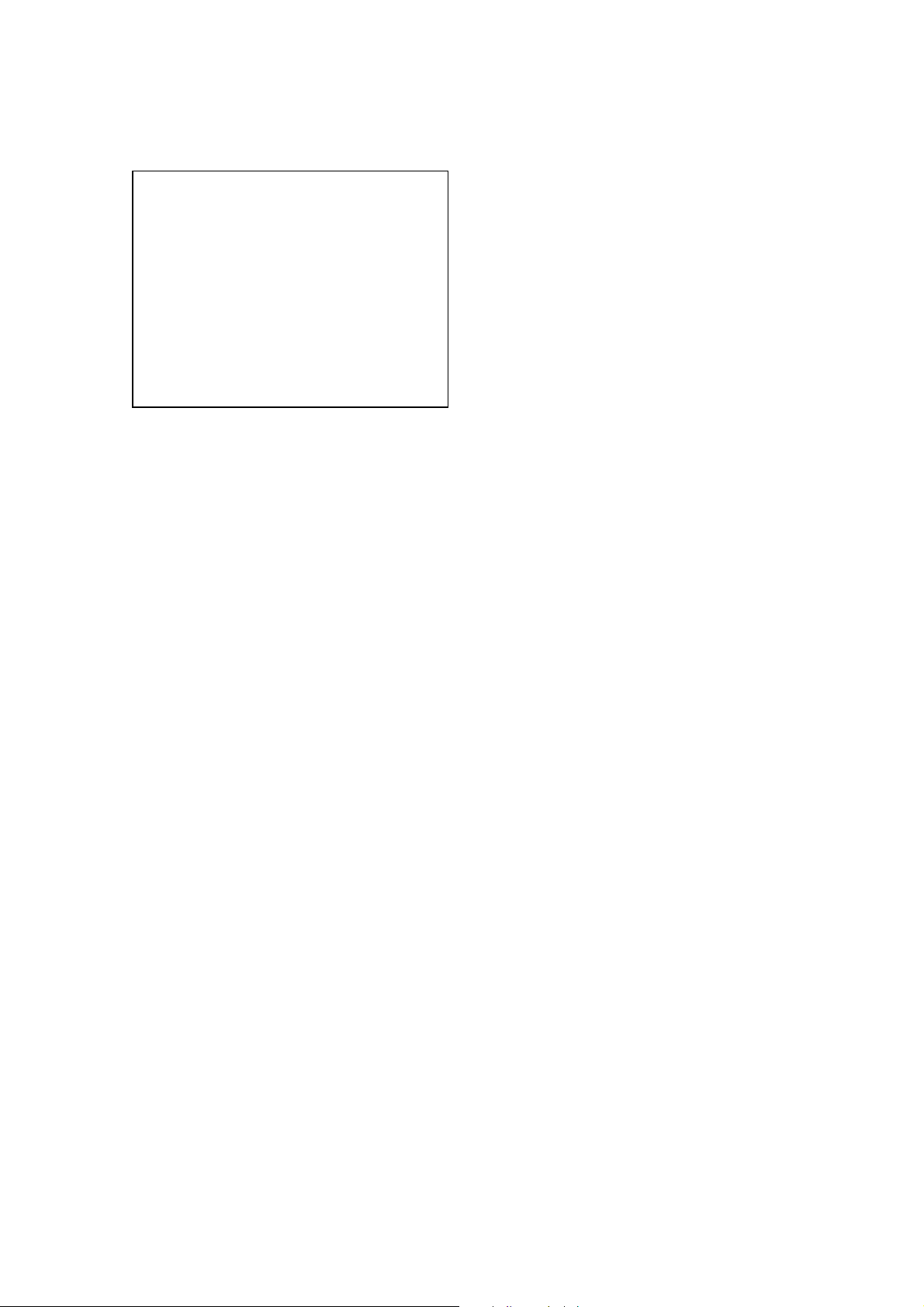

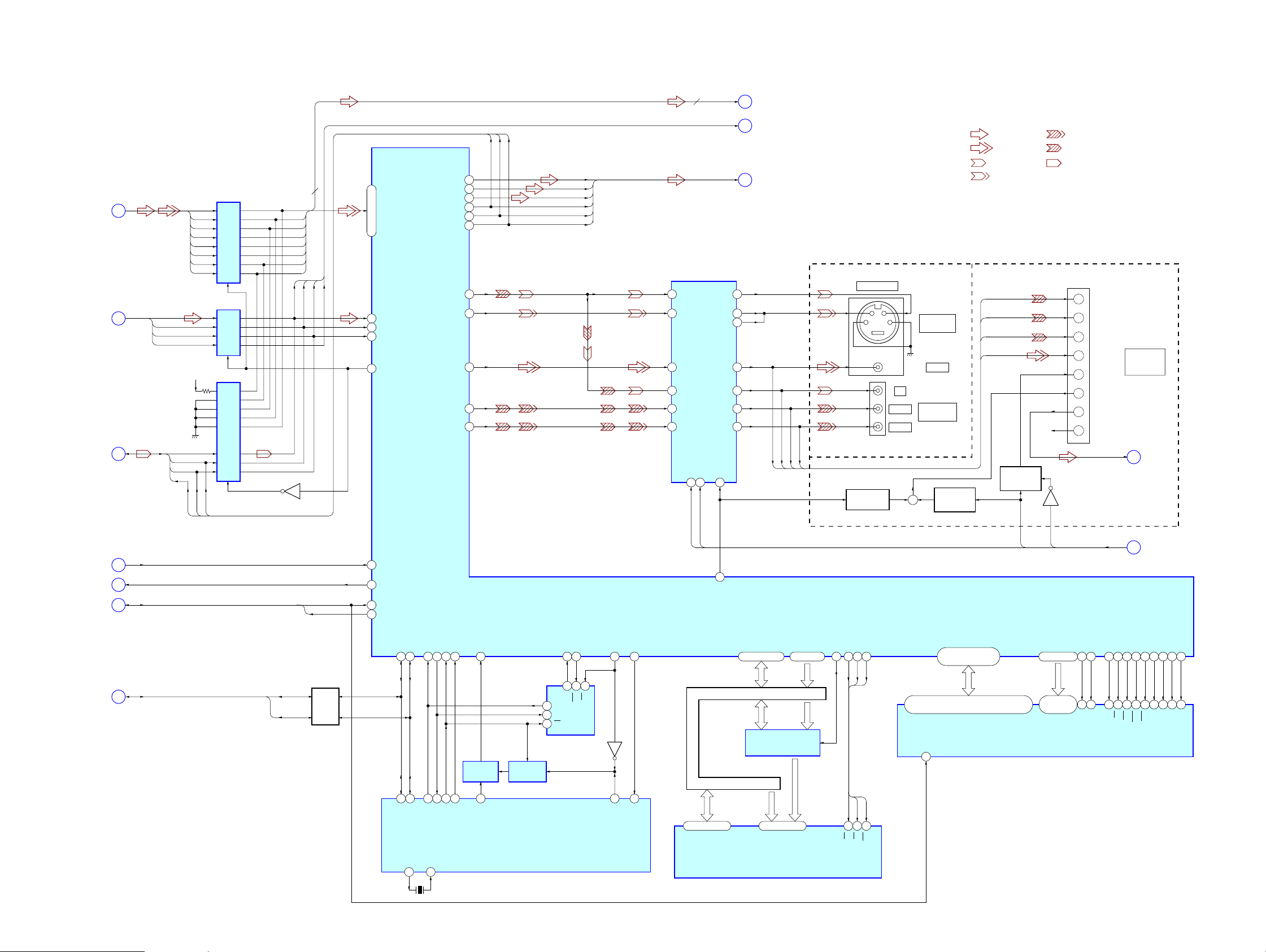

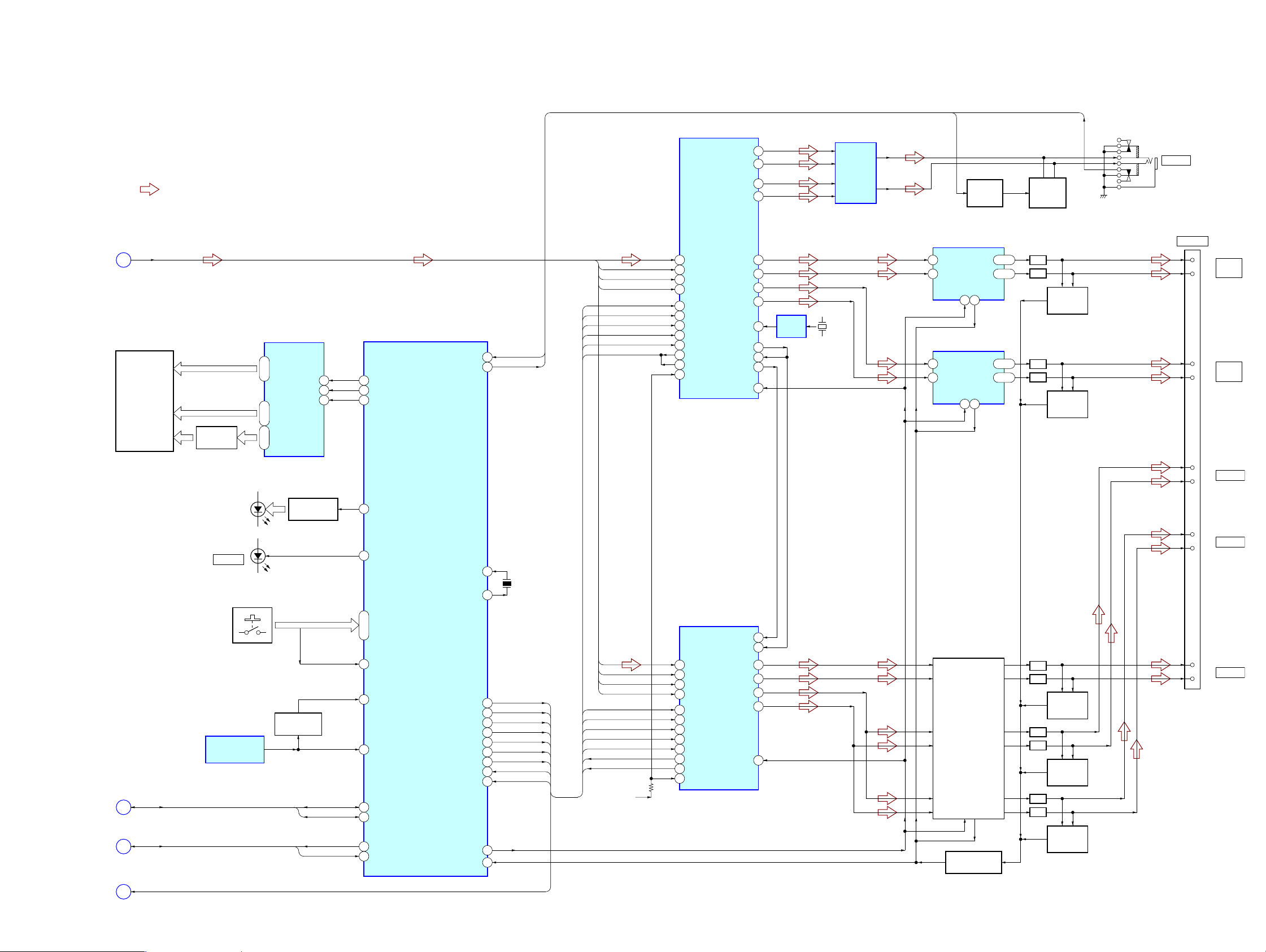

6-2. BLOCK DIAGRAM – DVD DSP Section –

8

Q201

I2CDATA

I2CCLK

AV0

AV1

AV2

AV3

AV4

AV5

AV6

AV7

SDEF#

XDCK#

SYS RESET

MUTE REQ

(Page 24)

(Page 24)

(Page 26)

(Page 24)

(Page 24)

(Page 27)

(Page 27)

B

C

N

27M

F

XSRQ_ZIVA

I

SYS RESET, MUTE REQ

S

I2CDATA, I2CCLK

R

SDEF

XDCK

XSAK

XSHD

D3V

ADC_DATA

BCK

LRCK

XCK

XCK

SD0

SD1

SD2

SD3

SD4

SD5

SD6

SD7

LRCK

BCK

IC256

LATCH

IC258

LATCH

IC259

LATCH

XSAK#

IC111

LEVEL

SHIFT

XSHD#

177-174, 171-168

SDDATA0 – SDDATA7

SDERROR

182

SDCLK

183

SDEN

179

INT/EXT

192

XIN

139

SDREQ

178

RESET

202

MREQ

110

161

78

I2C_DA

I2C_CL

160

79

I2C_SIO

I2C_SCL

EXTAL

41 40

DATA1(FLR)

DATA2(SLR)

DATA3(CSW)

VDAC_2

VDAC_1

VDAC_0

VDAC_3

VDAC_4

DRVTX

DRVRX

186

187

185

34

33

35

SI_ZIVA

SO_ZIVA

XTAL

X901

20MHz

LRCK

BCK

XCK

DRVCLK

HIRQ1

184

36

DRVIRQ

SCK_ZIVA

BCK

LRCK

151

154

155

148

149

147

125

128

131

122

119

DRVRDY

188

IC904

FLIP-FLOP

37

DRVRDY

MECHANISM CONTROLLER

XCK

IC902

SWITCHING

IC901 (2/2)

6

5

4

LRCK-ZIVA

BCK-ZIVA

116

1 8

DO

DI

SK

IC204

EEPROM

DATA1

DATA2

DATA3

XCK1

HIRQ2

WRITE_CTRL(ZIVA_E2P)

165

R/B

162

3

CS

WC

Q202

32

RST_SPC

CS_(ZIVA_E2P)

191

38

RST

CS_ZIVA

AV0 - AV7

8

XSAK#, SDEF#,

XDCK#, XSHD#

DATA1 – DATA3,

LRCK-ZIVA,

BCK-ZIVA, XCK1

IC201

VIDEO AMP, 75Ω DRIVER

6

YIN

2

CIN

S-DC OUT

4

CVBS IN

CVBS OUT

10

CYIN

12

CBIN

14

CRIN

MUTE125S1

MUTE2

3

13

AV SEL3

AV SEL1

DVD SYSTEM PROCESSOR

DATA & ADDRESS BUS

HAD0 – HAD15

DQ0 – DQ15

(Page 26)

K

(Page 26)

L

(Page 26)

O

21

YOUT

26

COUT

27

23

20

CYOUT

18

CBOUT

16

CROUT

CYOUT

VOUT

107

VS

IC207

22, 19-14, 11-3 2, 207, 206

HAD0 – HAD15 HA1 – HA3

DATA & ADDRESS BUS

HAD0 – HAD15 HA1 – HA2

IC231 – 233

ADDRESS LATCH

HA1 –

HA3

11 – 2, 34 – 4315 – 22, 24 – 31

A0 – A20

IC205

PROGRAMMABLE ROM

CBOUT

HA1 – HA3HAD0 – HAD15

CROUT

190

HA4 –HA22

ADDRESS BUS

WIDE SWITCH

ALE

HCS0

195

27

CEWEOE

CE

OE

12

14OE1

CE

J105

MONITOR OUT

34

Q204

WEH.UDS

HREAD

25

WE

WE

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

(AEP, UK, Russian)(EXCEPT AEP, UK, Russian)

S VIDEO

(DVD ONLY)

12

VIDEO

Y

J201

COMPONENT

PB/CB

VIDEO OUT

PR/CR

Q205, 206

FUNCTION

+

2,4,5,7,8,10,11,13,74,76,77,79,80,82,83,85,31,

33,34,36,37,39,40,42,45,47,48,50,51,53,54,56

SWITCH

MD0 – MD31

57-60, 64-71, 75-78,

81-84, 88-95, 99-102

DQ0 – DQ31 A0 – A11

CKE

69

: AUDIO

: VIDEO

: Y

: CHROMA

CBOUT

CYOUT

CROUT

VOUT

Q207, 208

BLANKOUT

SWITCH

DVD

SEL

128Mbit SD-RAM

R-CH

RGB

SEL

MA0 – MA11

42-33, 45, 46

25-27,

60-66,24,21

IC203

: COMPONENT VIDEO

: R, G, B

: TUNER

J202

B OUT

7

G OUT

11

15

R/C OUT

19

V/Y OUT

BLANK

16

OUT

FUNCTION

8

SW

6

A (L) IN

A (R) IN

2

A (L) IN

Q210

AV SEL1, AV SEL3,

RGB SEL, DVD SEL

BA0

BA1

56

48

47

68

22

23

BS0

BS1

(Page 26)

MCLK

MCS0

49

53

20

17

CS

CLK

EURO AV

T OUTPUT

(TO TV)

T

(Page 26)

M

MWE

MRAS

MCAS

51

52

62

19

18

16

WE

CAS

RAS

MDQM0

MDQM1

73

71

DQM0

DQM1

MDQM2

86

28

DQM2

MDQM3

97

59

DQM3

HCD-SB500W

2525

HCD-SB500W

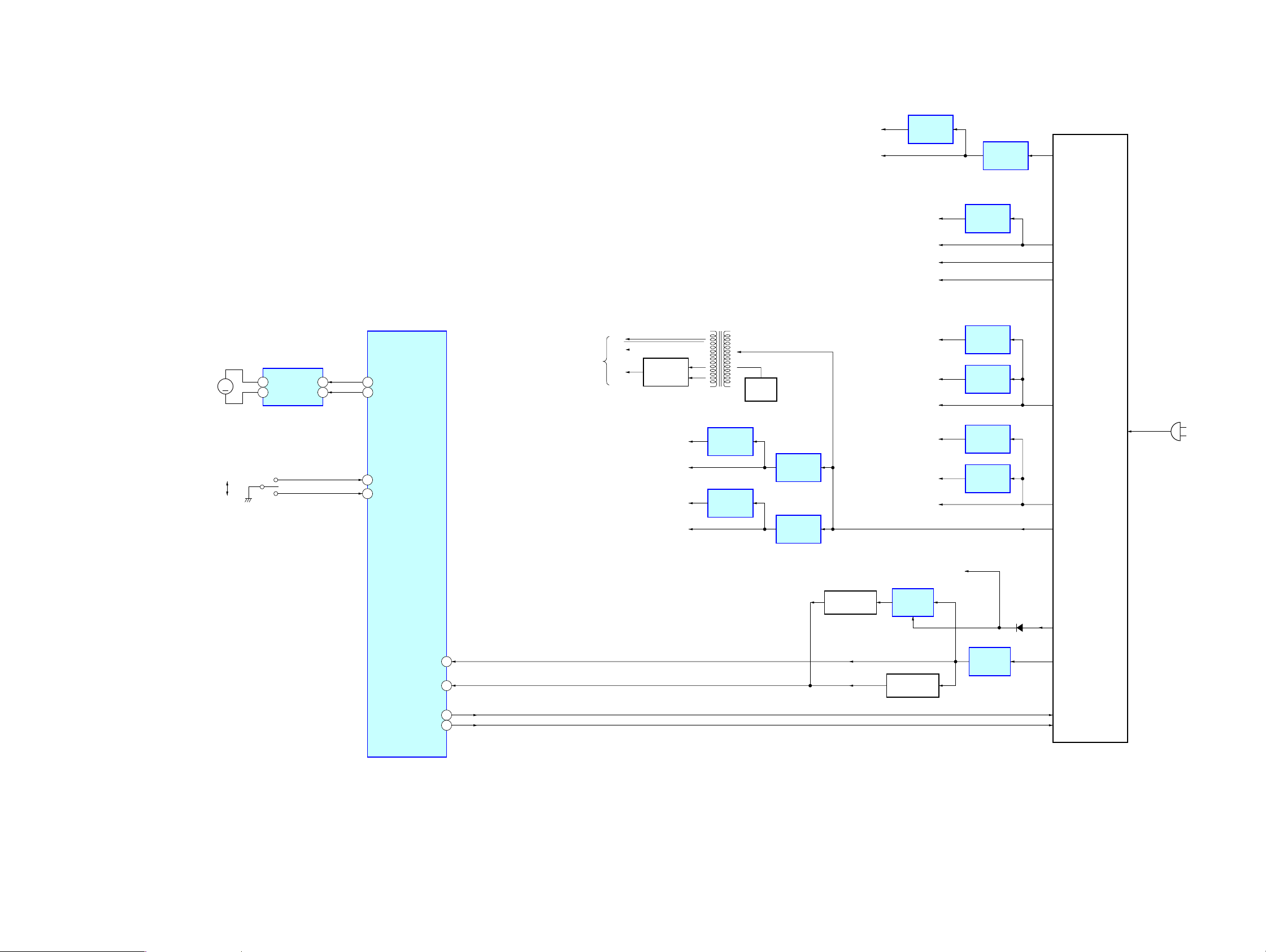

6-3. BLOCK DIAGRAM – AUDIO Section –

(Page 24)

(Page 24)

(Page 25)

(Page 25)

(Page 24)

(Page 24)

(Page 24)

(Page 25)

RF_AC

A

WPK

D

AV0 – AV7

K

SDEF#, XSHD#,

XDCK#, XSAK#

L

768FS

E

MSDATO, MSDATI, MSCK,

XMSLAT, SHRRDY, SHRMUT,

ISBTEST, XRST_DSD

J

XSRQ

H

DATA1 – DATA3,

LRCK-ZIVA,

BCK-ZIVA, XCK1

O

126

WARFI

123

WCK

8

169 – 176

XDCK#

XSAK#

SDEF#

XSHD#

MSDATO

MSDATI

MSCK

XMSLAT

SHRRDY

SHRMUT

ISBTEST

XRST_DSD

166

167

168

165

11

6

4

3

2

7

10

115

9

164

SD0 – SD7

SDCK

XSAK

SDEF

XSHD

DSD DECODER

MCKI

MSDATO

MSDATI

MSCK

XMSLAT

MSREADY

SMUTE

TESTI

XRST

XSRQ

IC801

DSAL

DSAR

DSAC

DSALFE

DSALS

DSARS

BCKAO

EXCKO1

DCLK

DCKE

XWE

XRAS

XCAS

64

66

69

71

74

76

60

13

134-131

139-136,

DQ0 – DQ7A0 – A11

162-159, 157-154,

152, 151, 149, 148

141

142

143

145

144

9, 11, 12

DQ0 – DQ7

2, 3, 5, 6, 8,

IC808

16Mbit

SD-RAM

20, 19

A0 – A11

21-24, 27-32,

35