Page 1

DCR-TRV130E

RMT-814

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Level 1

Ver 1.0 2001. 01

SPECIFICATIONS

AEP Model

UK Model

M2000 MECHANISM

DIGITAL VIDEO CAMERA RECORDER

Page 2

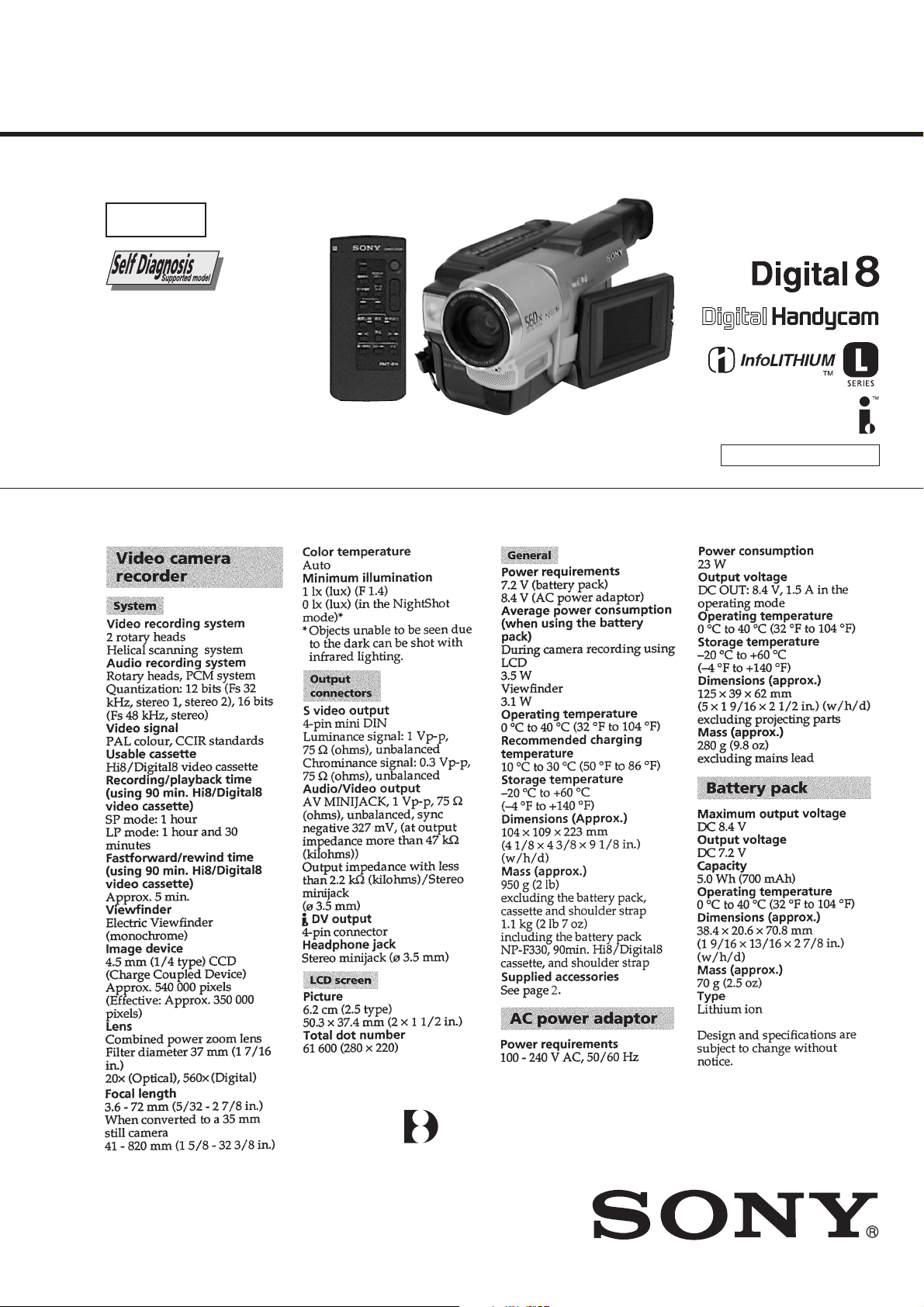

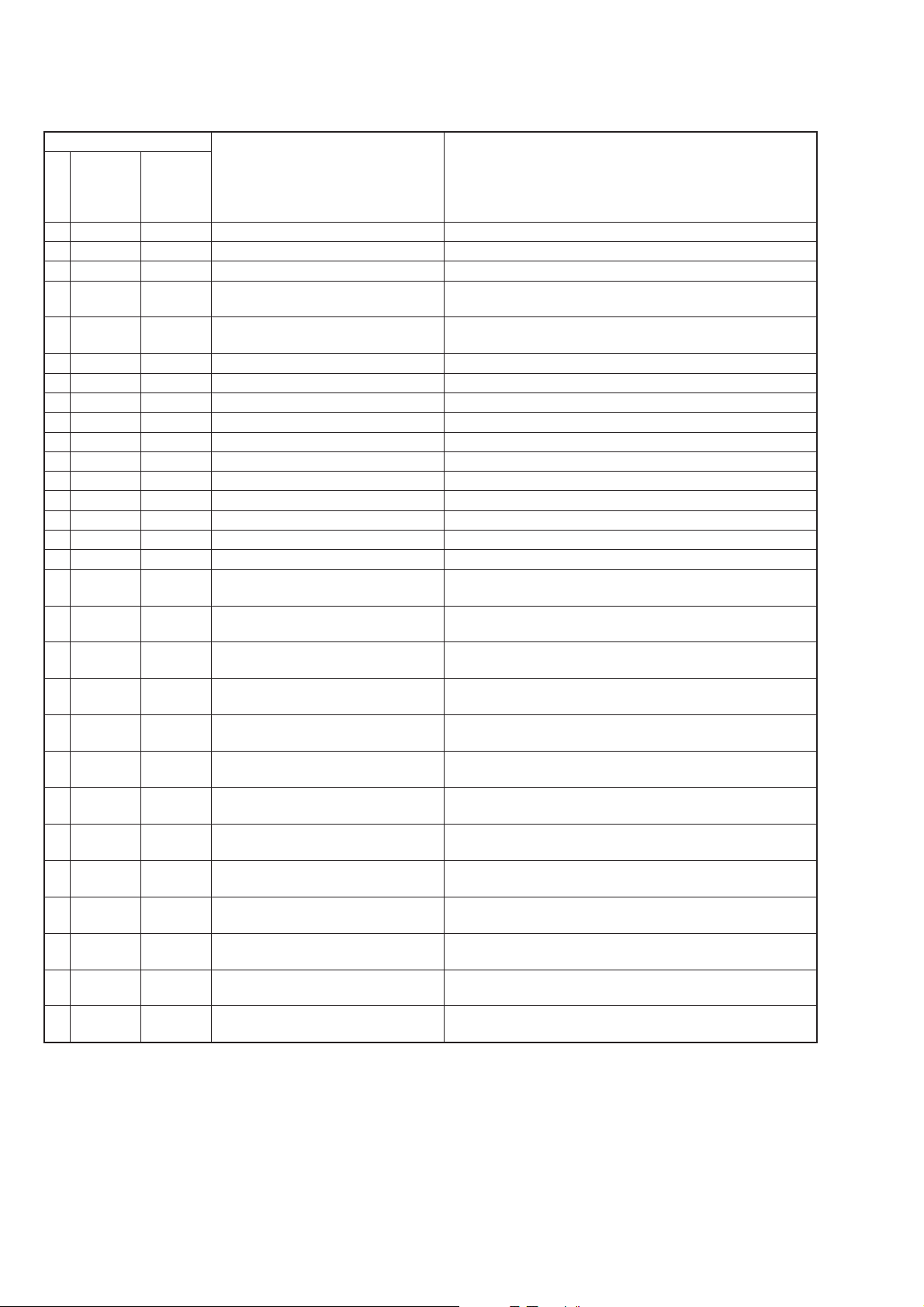

Checking supplied accessories.

Make sure that the following accessories are supplied with your camcorder.

Wireless Remote Commander (1)

RMT-814

1-475-141-61

A/V connecting cable (1.5m) (1)

1-765-080-11

AC-L10A/L10B/L10C

AC power adaptor (1)

0

1-475-599-11

Power cord (1) (AEP only)

0

1-769-608-11

Power cord (1) (UK only)

0

1-783-374-11

Shoulder strap (1)

3-987-015-01

Other accessories

3-065-652-11 OPERATING INSTRUCTIONS (ENGLISH/RUSSIAN)

3-065-652-21 OPERATING INSTRUCTIONS (FRENCH/GERMAN)(AEP)

3-065-652-31 OPERATING INSTRUCTIONS (ENGLISH/DUTCH)(AEP)

3-065-652-41OPERATING INSTRUCTIONS (SPANISH/PORTUGUESE)

3-065-652-51 OPERATING INSTRUCTIONS (ITALIAN/GREEK)(AEP)

(AEP)

NP-F330

battery pack (1)

(A-7094-141-A)

Lens cap (1)

X-3949-376-1

3-065-652-61 OPERATING INSTRUCTIONS (ENGLISH/SWEDISH)(AEP)

3-065-652-71 OPERATING INSTRUCTIONS (FINNISH/DANISH)(AEP)

3-065-652-81 OPERATING INSTRUCTIONS (POLISH/CZECH)(AEP)

3-065-652-91 OPERATING INSTRUCTIONS (SLOVAKIAN/HUNGARIAN)

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

21-pin adaptor (1)

1-573-291-11

Size AA (R6) battery for

Remote Commander (2)

(not supplied)

(AEP)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

TABLE OF CONTENTS

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS ·····························4

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ································································4

SELF-DIAGNOSIS FUNCTION

1. Self-diagnosis Function ······················································5

2. Self-diagnosis Display························································ 5

3. Service Mode Display ························································ 5

3-1. Display Method ·································································· 5

3-2. Switching of Backup No. ··················································· 5

3-3. End of Display···································································· 5

4. Self-diagnosis Code Table ·················································· 6

1. MAIN PARTS

1. ORNAMENTAL PARTS···················································· 8

2. DISASSEMBLY································································· 9

2-1. VIDEO LIGHT································································· 10

2-2. LCD SECTION (PD-131 BOARD) ································· 10

2-3. FRONT PANEL SECTION (MI-041 BOARD) ··············· 11

2-4. CABINET (L) SECTION················································· 11

2-5. CABINET (R) SECTION, CONTROL SWITCH

BLOCK (CF-1000)··························································· 12

2-6. EVF SECTION (VF-129 BOARD)·································· 13

2-7. BATTERY PANEL SECTION

(BATTERY TERMINAL BOARD) ································· 14

2-8. LENS SECTION ······························································ 14

2-9. VC-256 BOARD ······························································ 15

2-10. MECHANISM DECK······················································ 15

2-11. HINGE SECTION···························································· 16

3. REPAIR PARTS LIST······················································ 17

3-1. EXPLODED VIEWS ······················································· 17

3-1-1.OVERALL SECTION······················································ 17

3-1-2.CABINET (L) SECTION················································· 18

3-1-3.EVF SECTION································································· 19

3-1-4.LENS SECTION ······························································ 20

3-1-5.CABINET (R) SECTION ················································21

3-1-6.LCD SECTION ································································ 22

Superimposing a title ······························································ 36

Making your own titles ··························································· 36

Using the built-in light····························································37

Advanced Playback Operations

Playing back a tape with picture effects ································· 38

Playing back a tape with digital effects ·································· 38

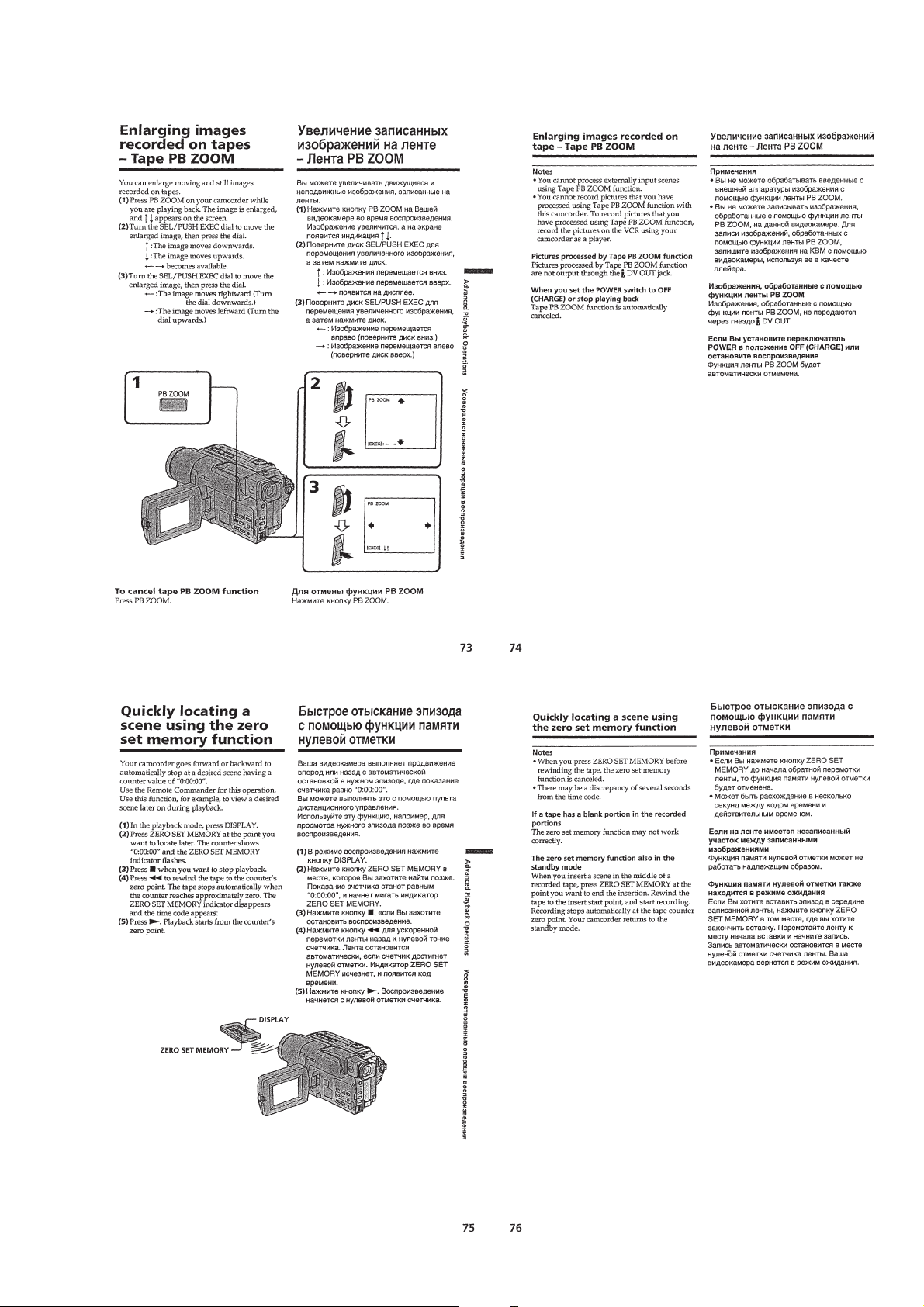

Enlarging images recorded on tapes –Tape PB ZOOM··········39

Quickly locating a scene using the zero set memory function ·····

Searching a recording by date –Date search··························· 40

Searching for a photo –Photo search/Photo scan···················· 40

Editing

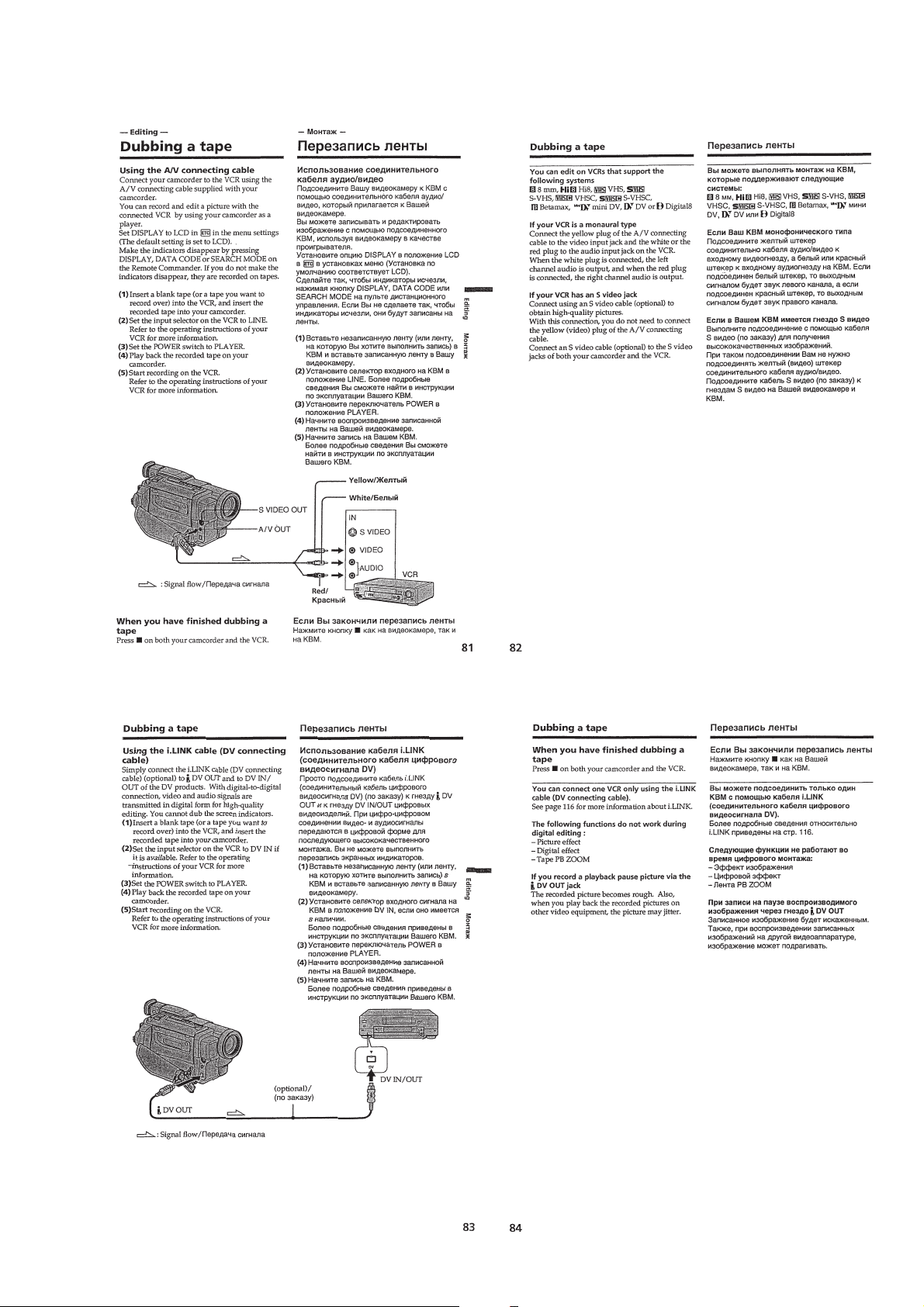

Dubbing a tape ········································································ 41

Customizing Y our Camcorder

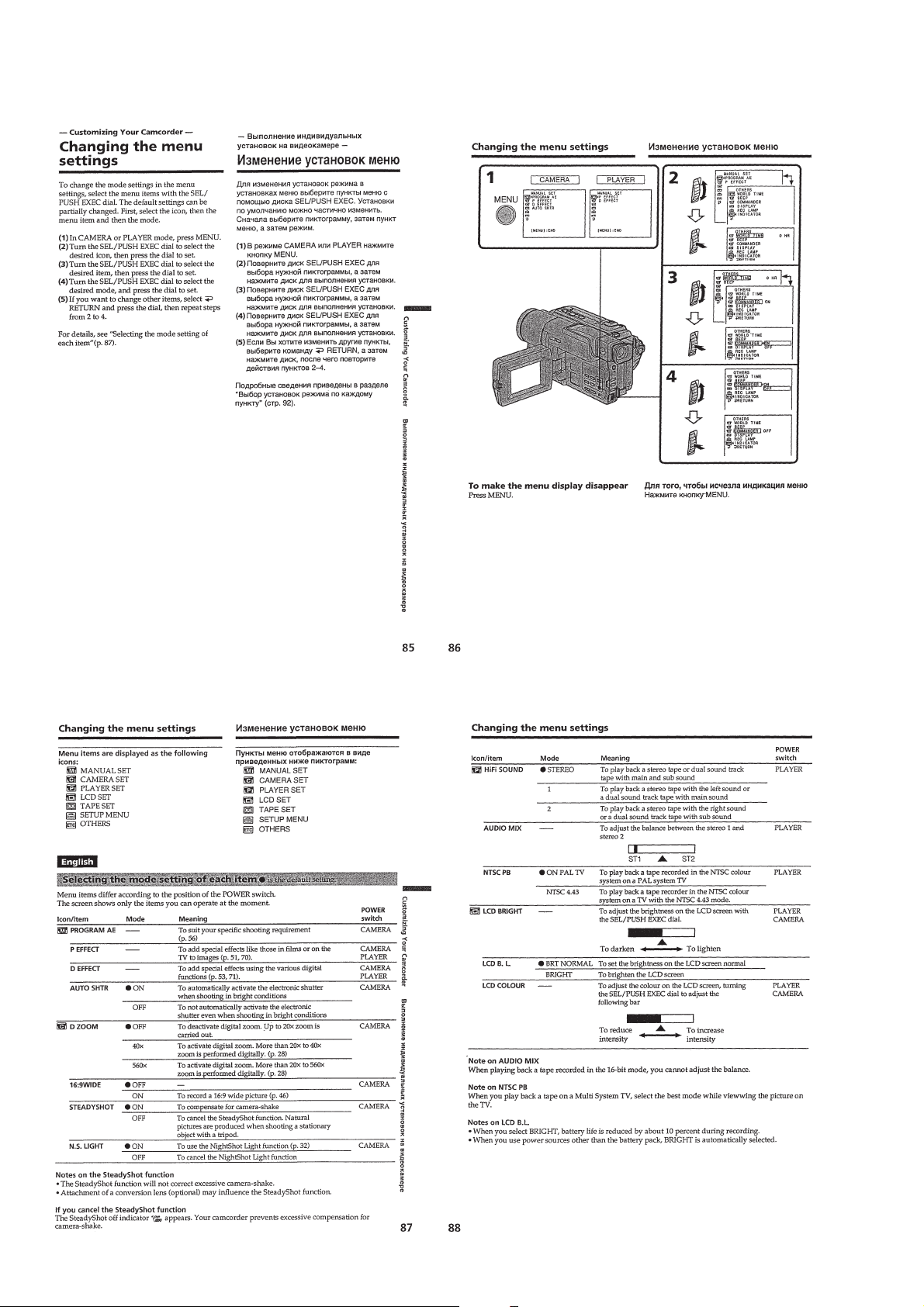

Changing the menu settings····················································42

Troubleshooting

Tupes of trouble and their solutions ······································· 43

Self-diagnosis display ····························································· 44

Warning indicators and messages ··········································· 45

Additional Information

About video cassettes ····························································· 45

About the “InfoLITHIUM” battery pack································ 46

About i.LINK·········································································· 46

Using your camcorder abroad················································· 47

Maintenance information and precautions······························ 47

Quick Reference

Identifying the parts and controls ··········································· 49

39

2. GENERAL

Checking supplied accessories ··················································· 23

Quick Start Guide ······································································· 23

Getting started

Using this manual ··································································· 23

Step 1 Preparing the power supply ········································· 24

Installing the battery pack····················································· 24

Charging the battery pack ····················································· 24

Connecting to the mains ······················································· 25

Step 2 Setting the date and time ············································· 25

Step 3 Inserting a cassette······················································· 26

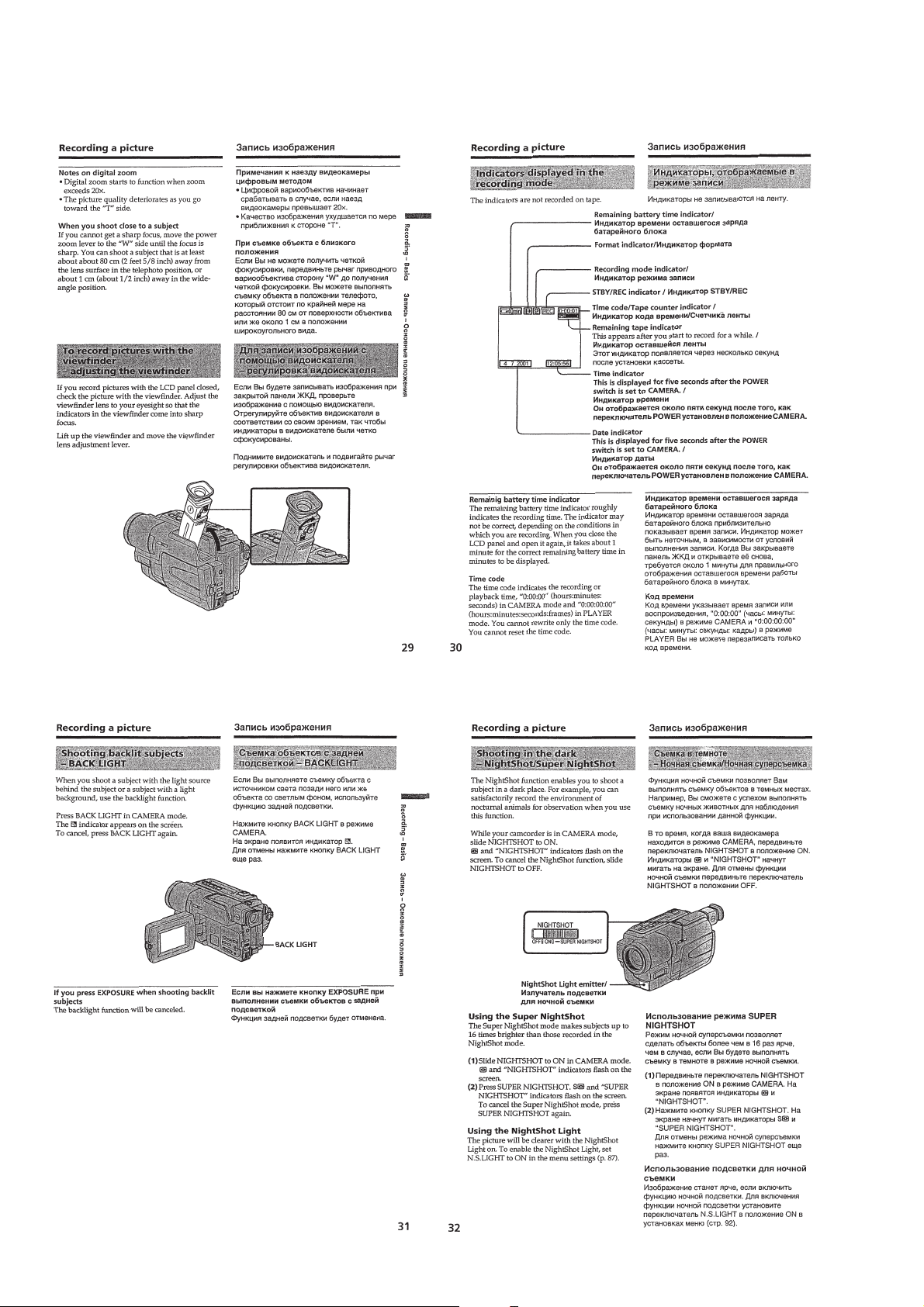

Recording –Basics

Recording a picture································································· 26

Shooting backlit subjects –BACK LIGHT ··························· 28

Shooting in the dark –NightShot/Super NightShot ·············· 28

Checking the recording –END SEARCH····························· 29

Playback –Basics

Playing back a tape ································································· 29

Viewing the recording on TV ················································· 31

Advanced Recording Operations

Recording a still image on a tape –Tape Photo recording ······ 31

Using the wide mode ······························································ 32

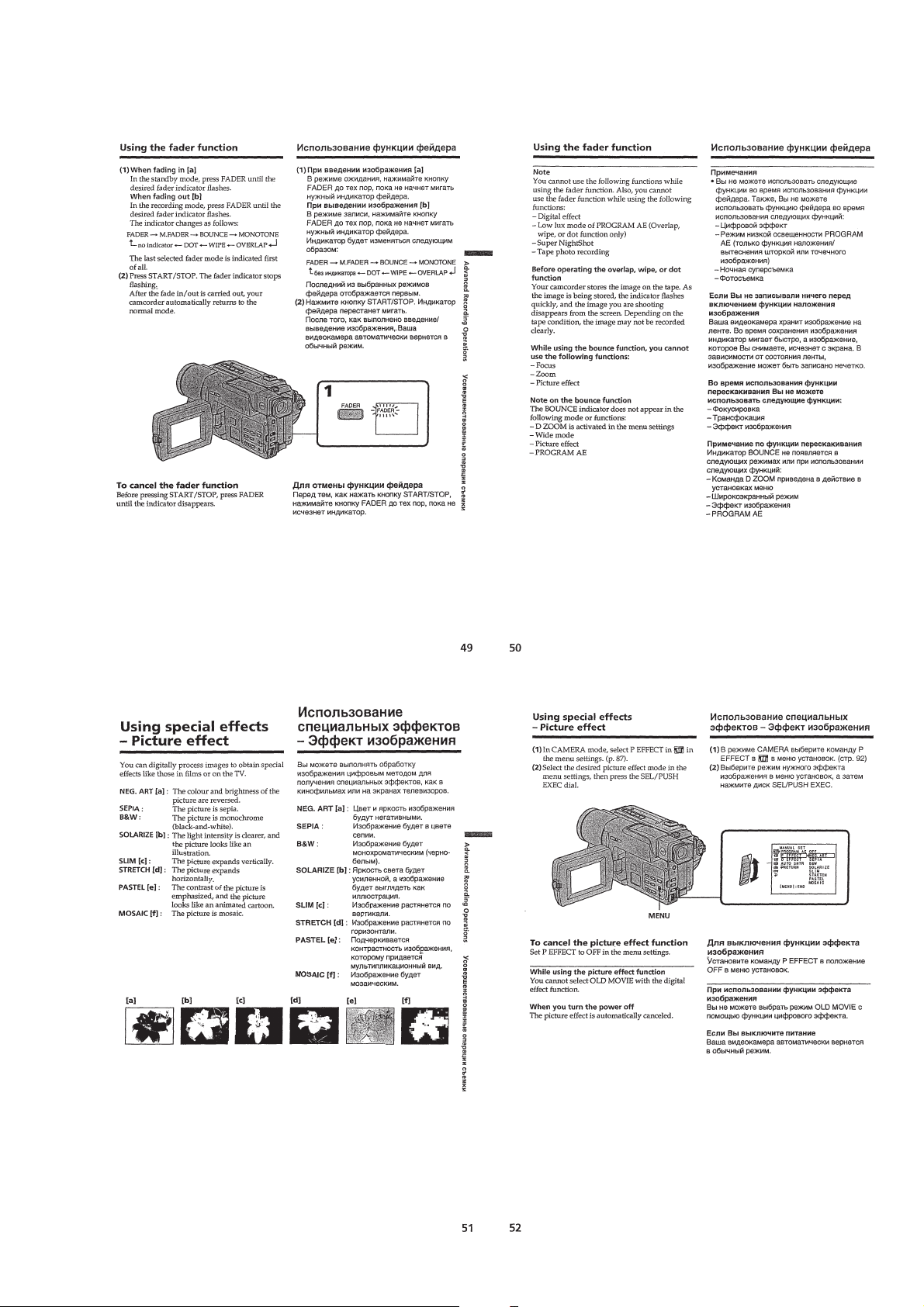

Using the fader function ························································· 32

Using special effects –Picture effect······································· 33

Using special effects –Digital effect·······································34

Using the PROGRAM AE function ········································ 34

Adjusting the exposure manually ··········································· 35

Focusing manually··································································35

— 3 —

Page 4

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied (8.4V) to the battery terminal using the service power code (J-6082-223-A), the power

is shut off so that the unit cannot operate.

These following two methods are available to prevent this. Take note of which to use during repairs.

Method 1.

Use the DC IN terminal. (Use the AC power adaptor.)

Method 2.

Connect the adjustment remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the HOLD switch to the “ADJ” side.

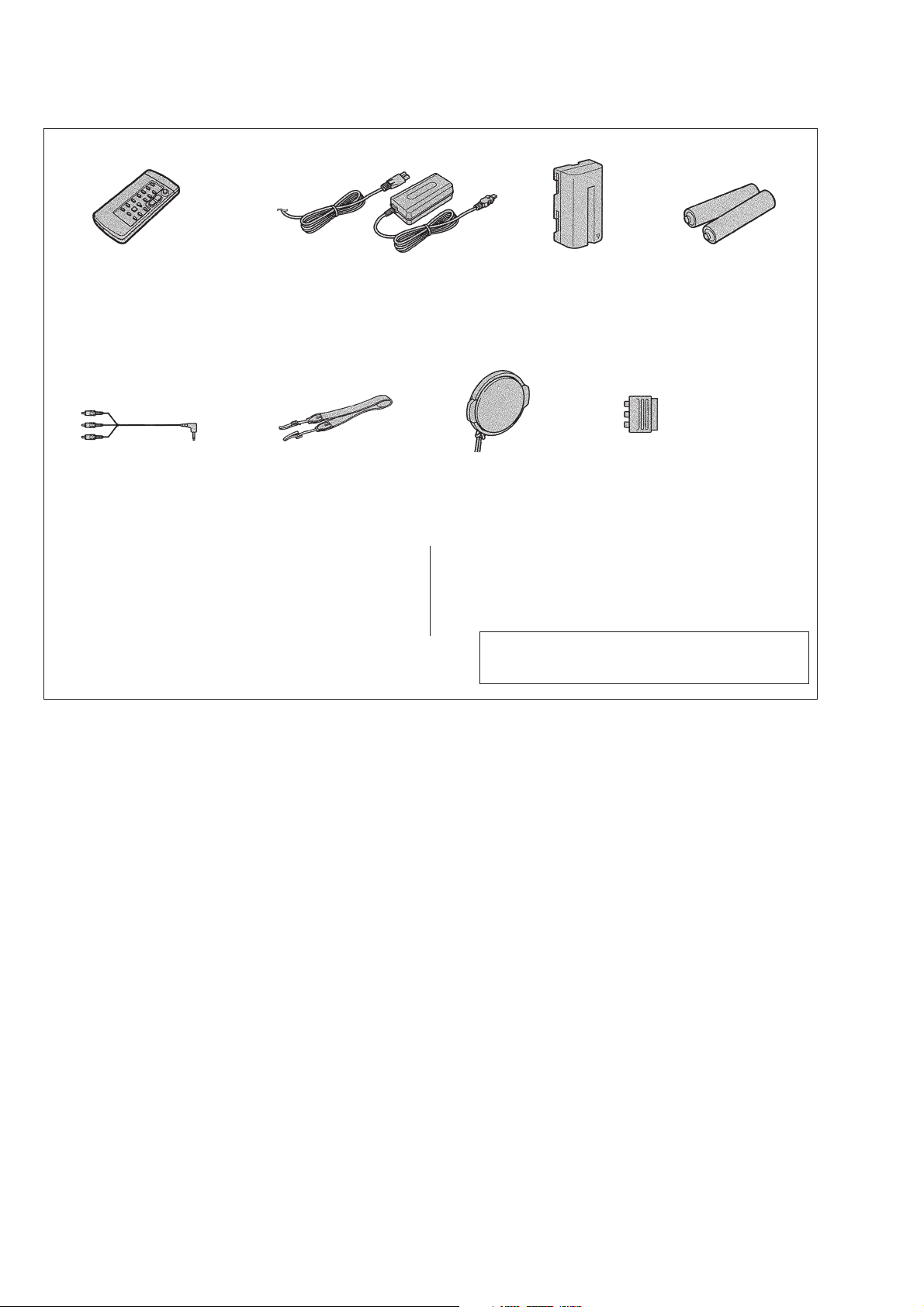

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-3. to remove the front panel section.

2 Refer to 2-4. to remove the cabinet (L) section.

3 Refer to 2-5. to remove the cabinet (R) section.

4 Open the control switch block (FK-1000).

5 Disconnect CN4401 (2P) of VC-256 board.

6 Add +5V from the DC POWER SUPPLY and unload with a pressing the cassette compertment.

7

Pull the timing belt in the direction of

arrow

the cassette compartment (take care

not to damage) to adjust the bending

of a tape.

A

Timing belt

Adjust the bending

of a tape

Loading

motor

A

with a pincette while pressing

Pincette

Timing belt

Press the cassette compartment not

to rise the cassette compartment

8

Let your hold the cassette

compartment and rise the cassette

compartment to take out a cassette.

DC power supply

(+5V)

Disconnect CN4401 of

VC-256 board

— 4 —

Page 5

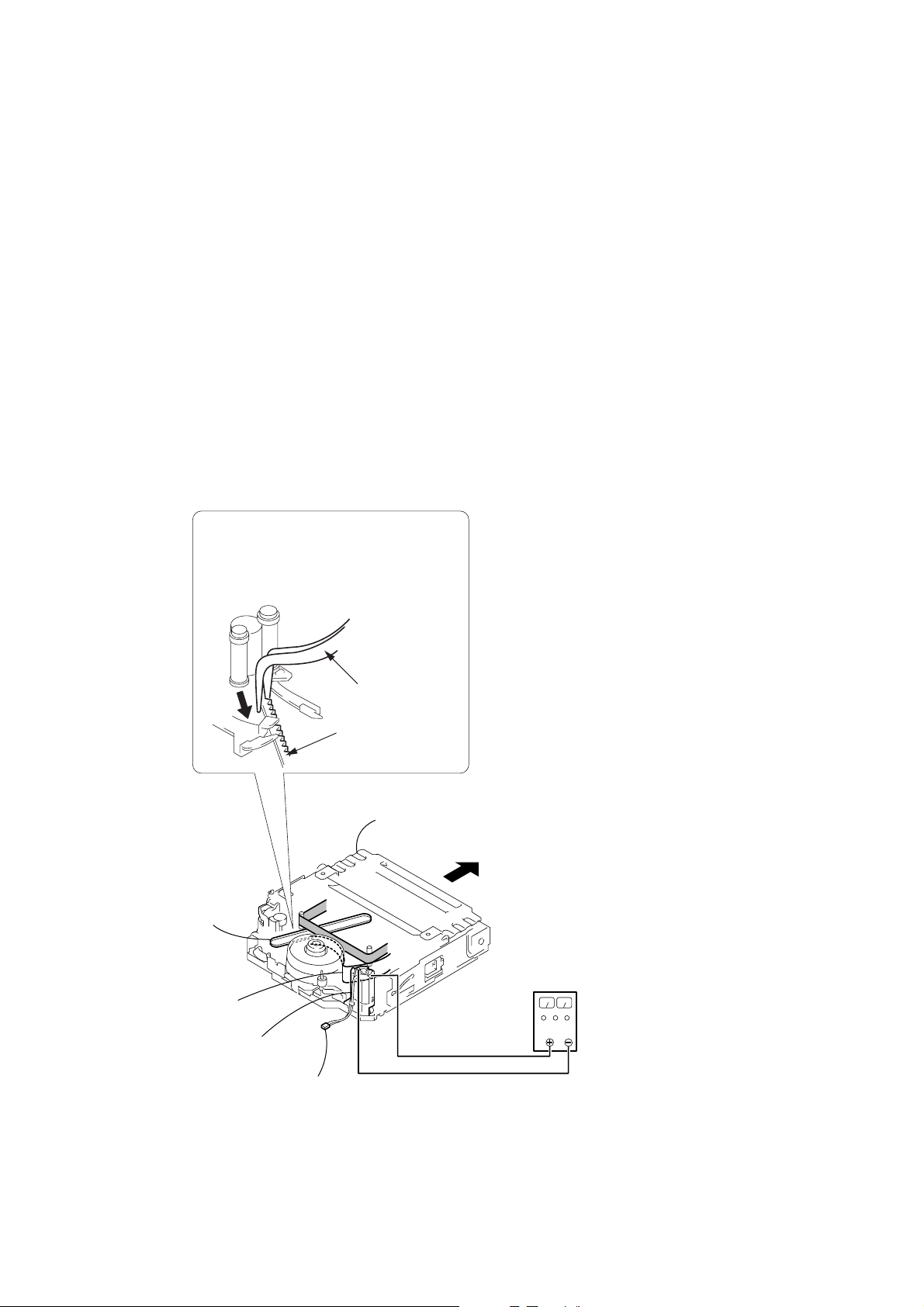

SELF-DIAGNOSIS FUNCTION

1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD or

Display window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD Display window

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tur n o n power again.

3 1

Block

1 1

C : 3 1 : 11

Detailed Code

Refer to page 6 and 7.

Self-diagnosis Code Table.

2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD or Display window shows a 4-digit display

consisting of an alphabet and numbers, which blinks at 3.2 Hz. This

5-character display indicates the “repaired by:”, “block” in which

the problem occurred, and “detailed code” of the problem.

Display window

3. Service Mode Display

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VCR or PLAYER”, and continue pressing the “STOP” key for 5 seconds

continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

Display window

3 C : 3 1 : 11

Control dial

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the built-in rechargeable lithium battery (CF-1000 block BT101).

When the cabinet (R) assembly is disconnected, the “self-diagnosis displa y” data will be lost by initialization.

— 5 —

Page 6

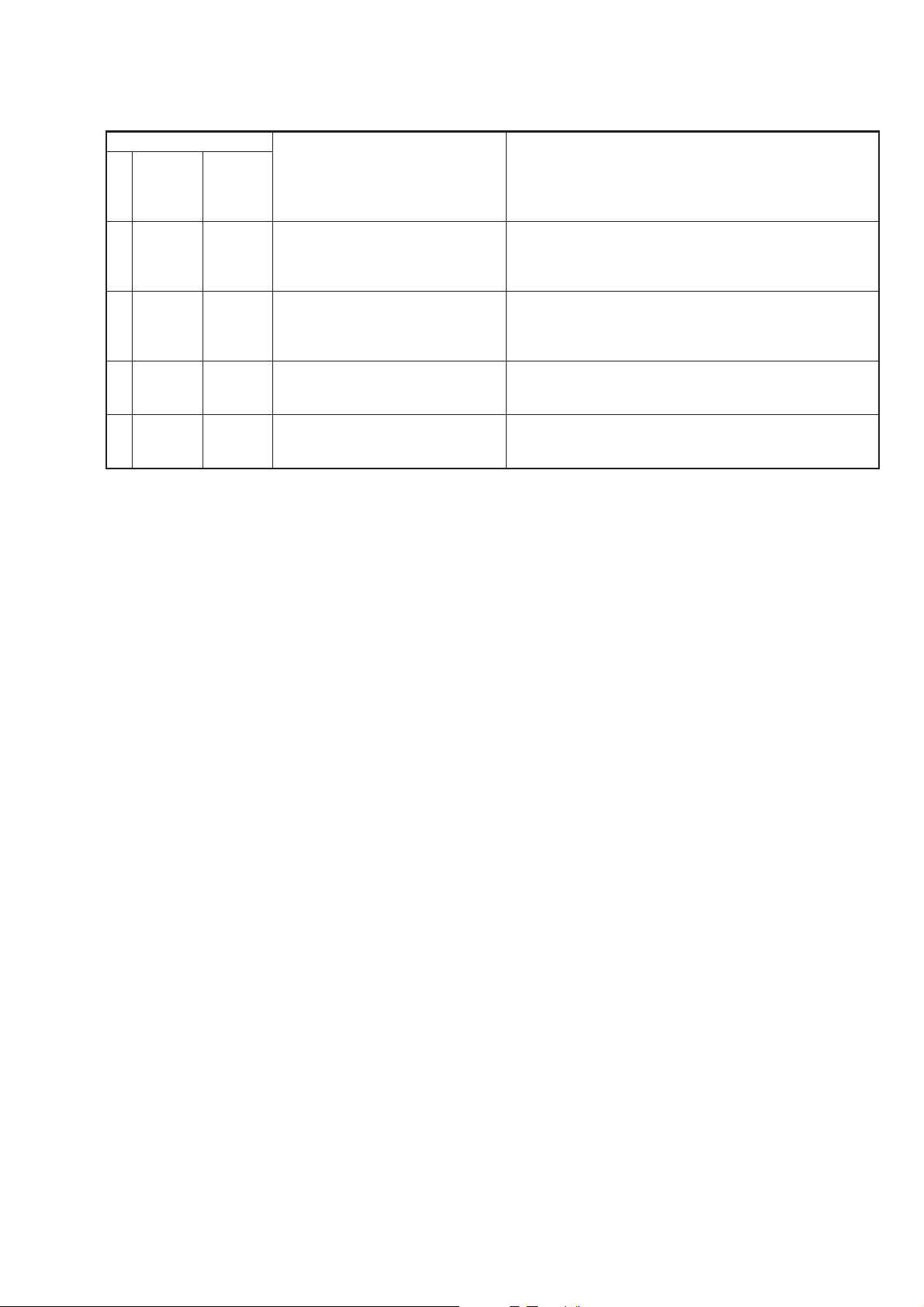

4. Self-diagnosis Code Table

Self-diagnosis Code

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum operations.

PG fault during normal drum operations.

Phase fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan

operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum

operations.

PG fault during normal drum

operations.

Phase fault during normal drum

operations.

Correction

Use the InfoLITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

— 6 —

Page 7

Self-diagnosis Code

Function

Repaired by:

E

E

E

E

Block

61

61

62

62

Detailed

Code

00

10

00

01

Symptom/State

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Handshake correction function does not

work well. (With pitch angular velocity

sensor output stopped.)

Handshake correction function does not

work well. (With yaw angular velocity

sensor output stopped.)

Correction

Inspect the lens block focus reset sensor (Pin qs of CN1551 of

VC-256 board) when focusing is performed when the control dial

is rotated in the focus manual mode and the focus motor drive circuit

(IC1551 of VC-256 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin qf of CN1551 of

VC-256 board) when zooming is performed when the zoom lens is

operated and the zoom motor drive circuit (IC1551 of VC-256

board) when zooming is not performed.

Inspect pitch angular velocity sensor (SE751 of MI-041 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE752 of MI-041 board)

peripheral circuits.

— 7 —

Page 8

DCR-TRV130E

)

1. MAIN PARTS

Note:

• Follow the disassembly procedure in the numerical order given.

• Items marked “*” are not stocked since they are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

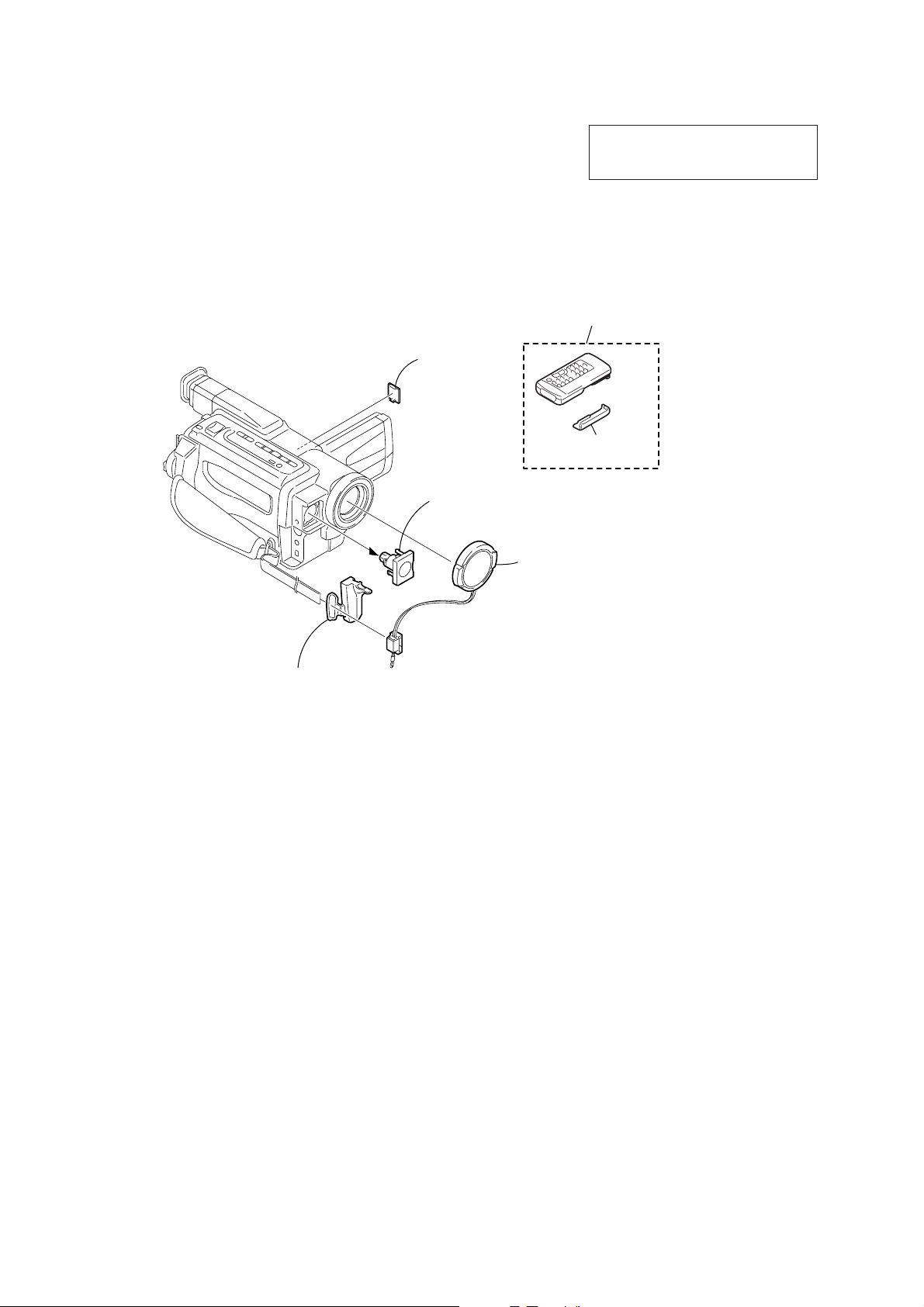

1. ORNAMENTAL PARTS

CPC lid

3-059-539-11

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Remote commander (RMT-814

1-475-141-61

Battery case lid

3-742-854-01

Jack cover

3-065-433-01

Video light

1-518-723-21

Lens cap assembly

X-3949-376-1

— 8 —

Page 9

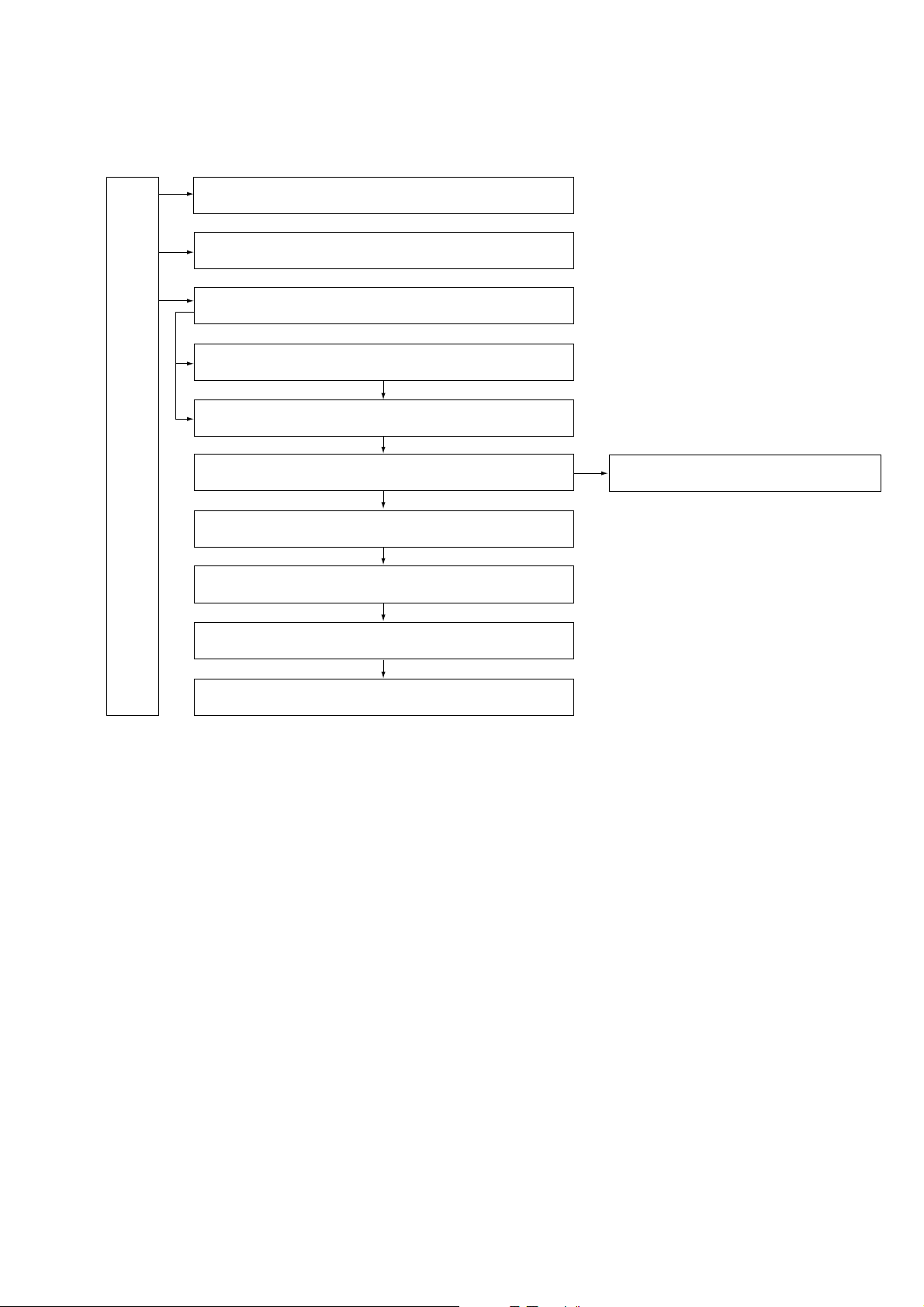

2. DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1. Video light

2-2. LCD section (PD-131 board)

2-3. Front panel section (MI-041 board)

2-4. Cabinet (L) section

2-5. Cabinet (R) section, Control switch block (CF-1000)

DCR-TRV130E

2-6. EVF section (VF-129 board)

2-7, Battery panel section (Battery terminal board)

2-8, Lens section

2-9. VC-256 board

2-10. Mechanism deck

2-11. Hinge section

— 9 —

Page 10

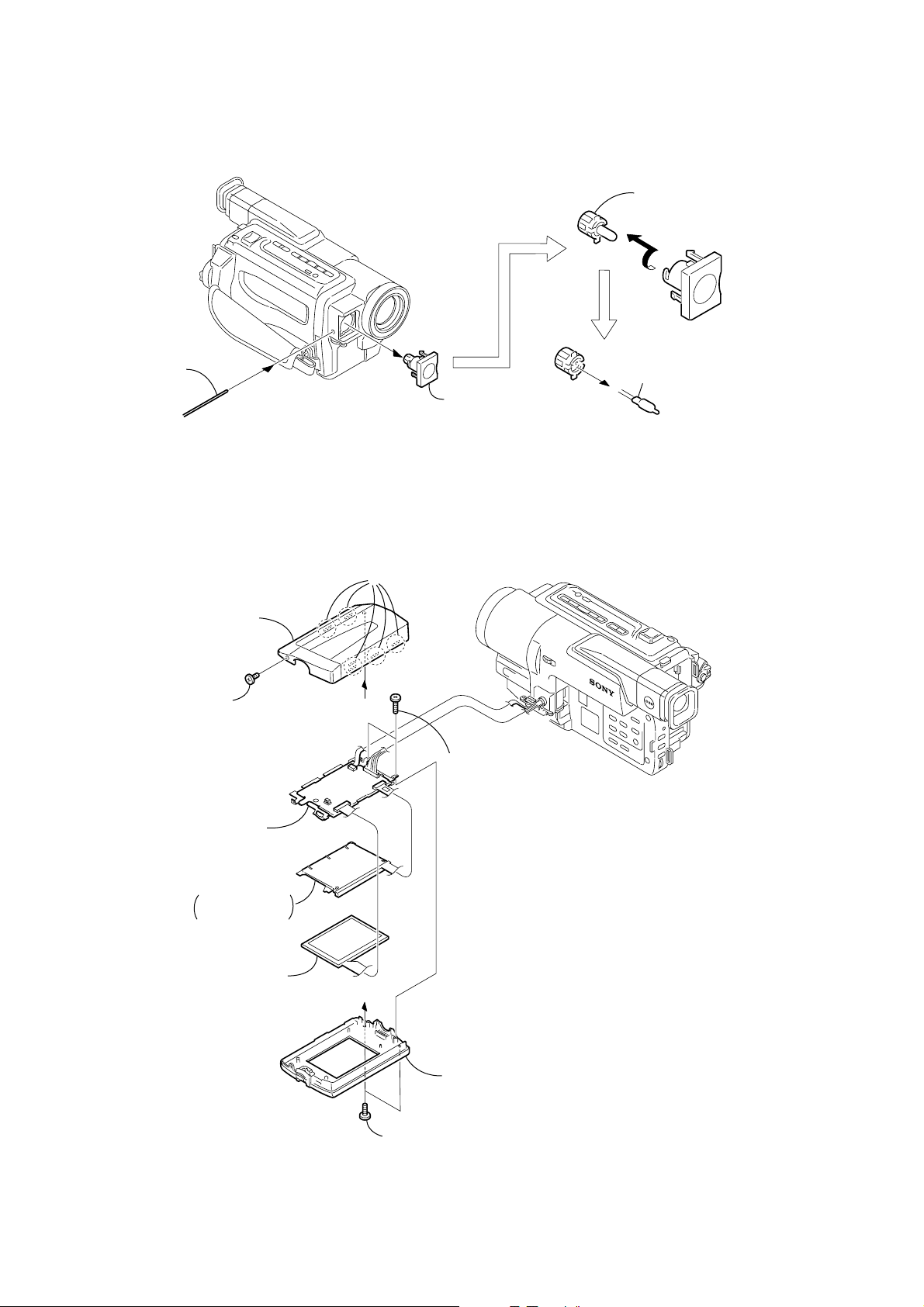

NOTE: F ollo w the disassembly procedure in the numerical order given.

n

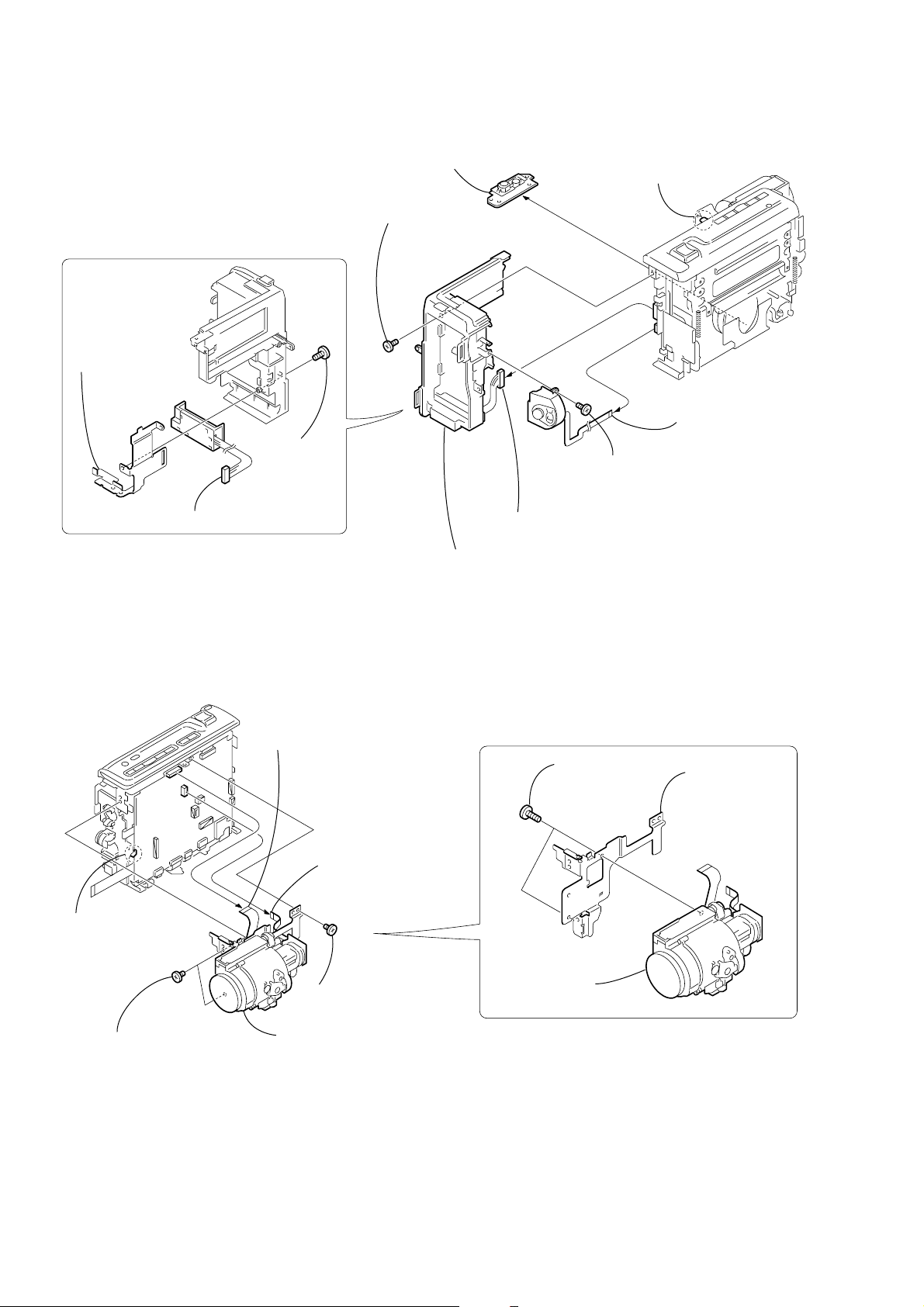

2-1. VIDEO LIGHT

1

Push in the dent

inside hole with

wire tip.

2

Video light

2-2. LCD SECTION (PD-131 BOARD)

3

Remove in the directio

of the arrow A.

A

4

Halogen lamp

4

P cabinet C

2

MI screw

(M2

×

4) (H)

9

PD-131 board,

Panel frame

8

Back light

Cold cathode

fluorescent tube

7

Liquid crystal

indicator module

PD-131

3

A

A

Five claws

5

T wo tapping

screws (B2

×

7)

6

1

T wo tapping

screws (B2

— 10 —

P cabinet M assembly

×

5)

Page 11

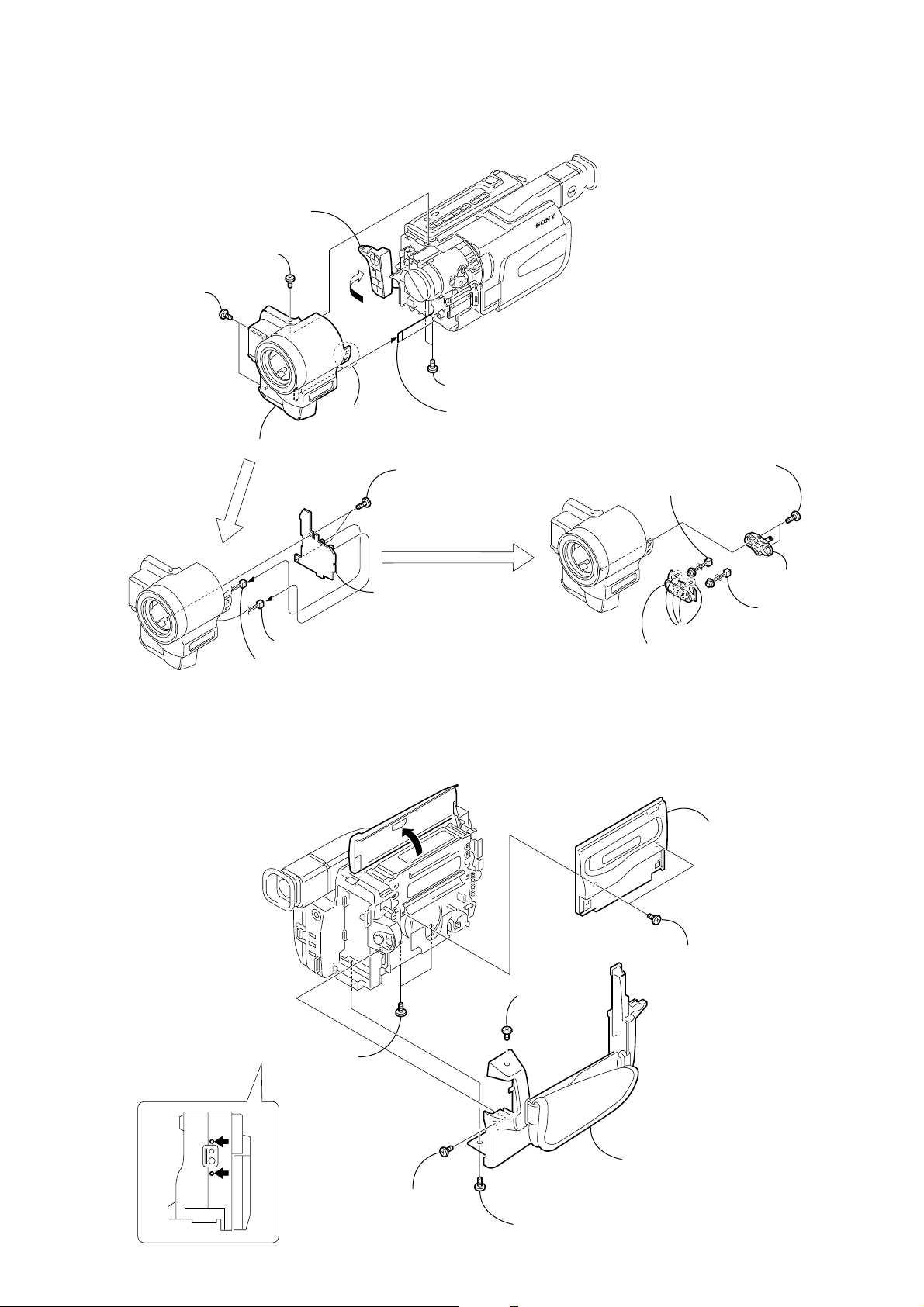

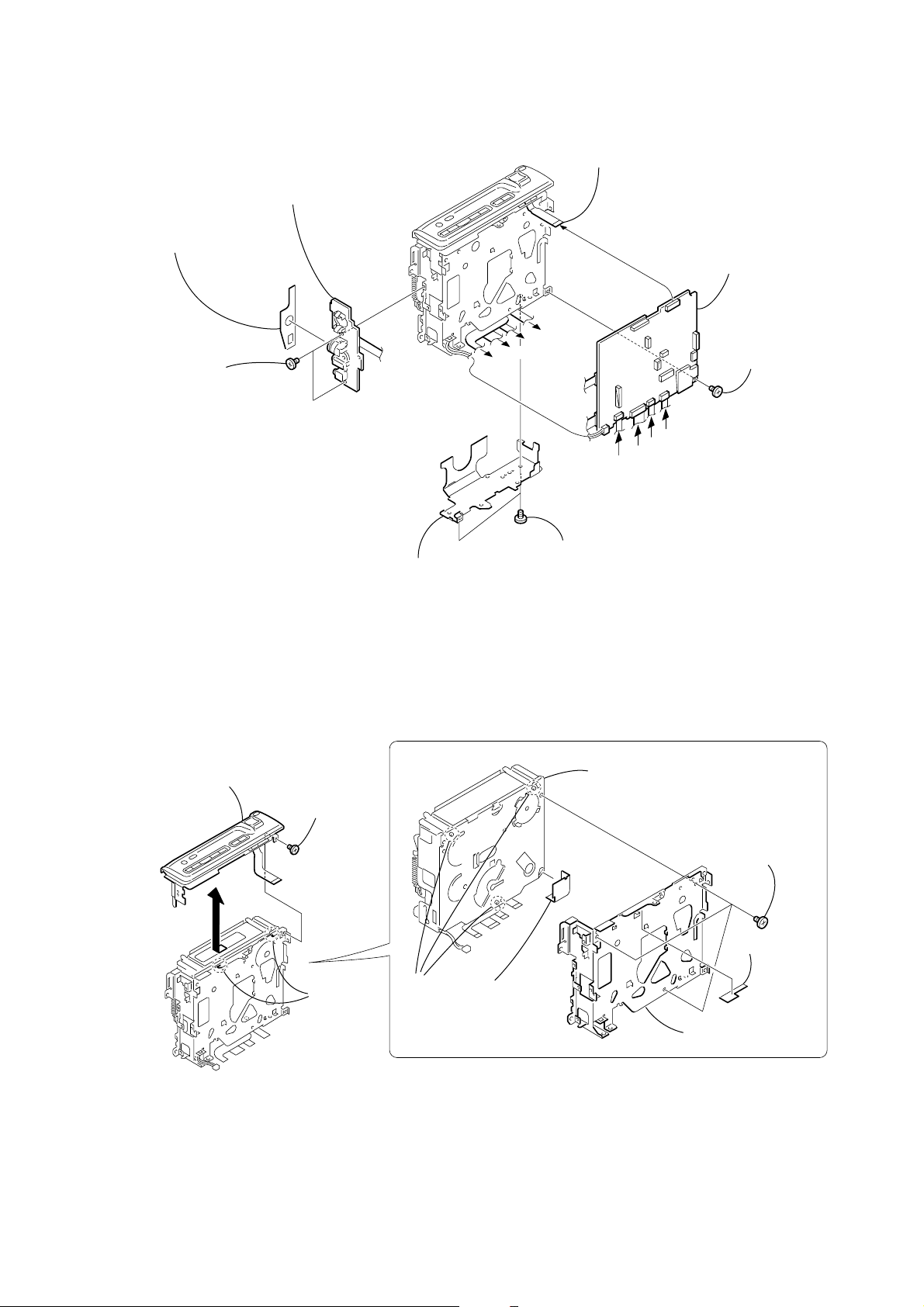

2-3. FRONT PANEL SECTION (MI-041 BOARD)

MI-041

Board

3

MI screw

(M2 × 4) (H)

1

Open the jack cover

2

Two MI screws

(M2 × 4) (H)

4

Two MI screws

(M2 × 4) (H)

5

Claw

2

Four claws

3

Microphone

retainer (rear)

4

Microphone

retainer (front)

7

Front panel section

6

FP-263 flexible

board (24P)

3

T wo tapping

screws (B2 × 5)

2

Microphone (Lch) (2P)

6

Microphone (Lch)

5

Microphone (Rch)

4

MI-041 board

1

T wo tapping

screws (B2 × 5)

1

Microphone (Rch) (2P)

2-4. CABINET (L) SECTION

6

Two MI screws

(M2

×

4) (H)

5

MI screw

(M2

1

×

4) (H)

— 11 —

4

MI screw

(M2

×

4) (H)

7

MI screw

(M2

×

4) (H)

3

2

Two MI screws

(M2

8

Cabinet (L) section

Cassette lid assembly

×

4) (H)

Page 12

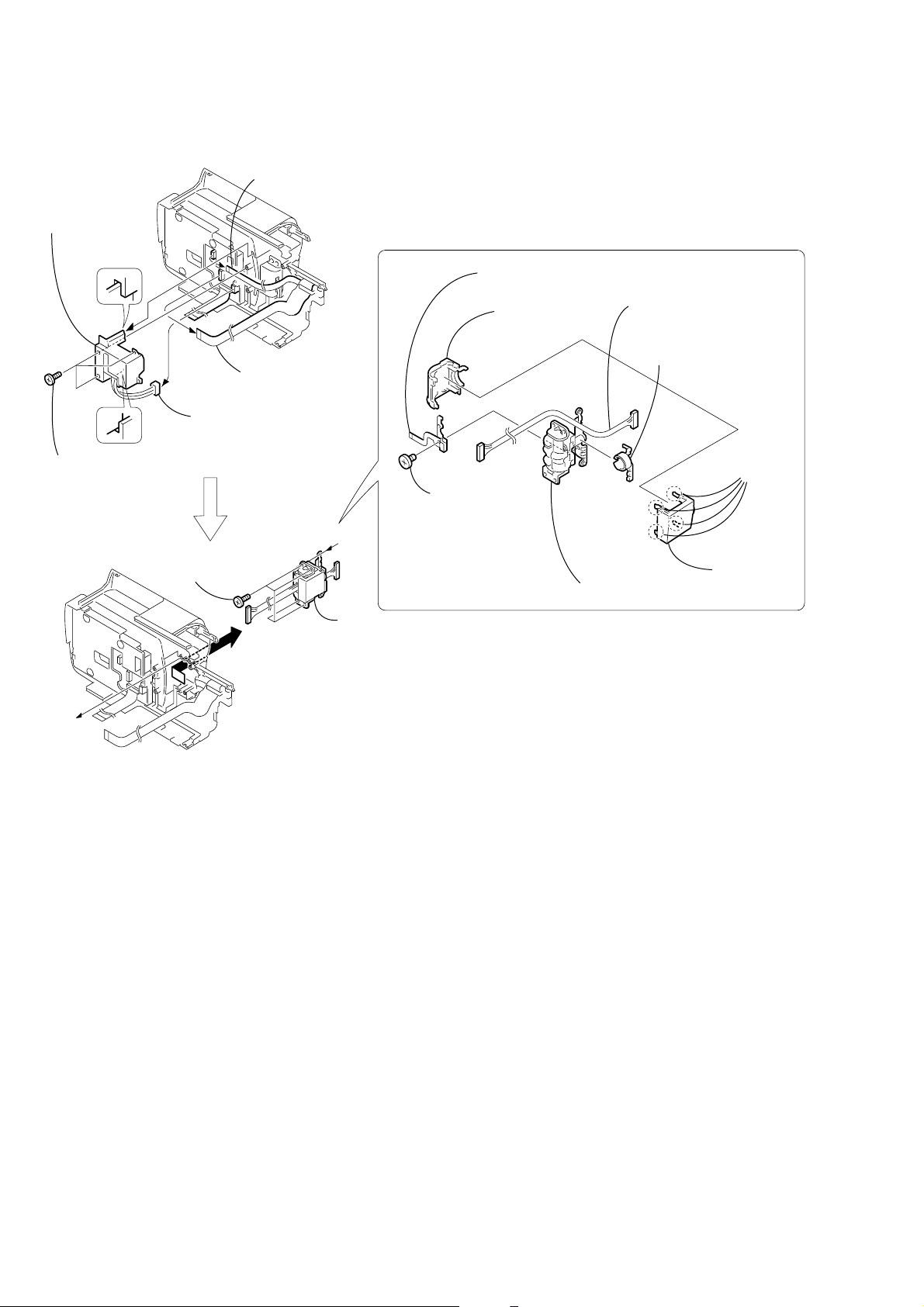

2-5. CABINET (R) SECTION, CONTROL SWITCH BLOCK (CF-1000)

1

MI screw

(M2

×

4) (H)

4

Claw

6

FFC-295 flexible

flat cable (24P)

5

Harness

(PD-110) (20P)

3

Three MI screws

(M2

2

MI screw

(M2

×

4) (H)

7

Cabinet (R) section

×

4) (H)

7

Remove the control switch block

(CF-1000) in the direction of the

arrow

Tape (A)

AB

.

B

A

5

Five tapping

screws (B2

1

×

5)

FFC-295 flexible flat cable (24P)

6

T ape (A)

8

Control switch block

(CF-1000)

2

FP-260 flexible board (16P)

4

Push switch (2P)

3

Electro luminous

element (4P)

— 12 —

Page 13

2-6. EVF SECTION (VF-129 BOARD)

1

FFC-289 flexible

flat cable (4P)

Finder (S) assembly

3

Rotate it in the direction of

the arrow B and remove it

in the direction of the arrow C.

C

B

4

2

Three tapping

screws (B2 × 5)

A

3

EVF section

1

F lock

screw (T)

2

Two loose

stopper screws

(M2 × 3)

4

1

T ape (A)

3

VF base B

PRECAUTION DURING

INSTALLATION

Tape (A)

FFC-289 flexible

flat cable

1

2

T wo tapping

screws (B2 × 5)

2

Slide the button in the

direction of the arrow A.

8

CRT assembly, VF-129 board,

FFC-289 flexible flat cable

3

Claw

5

(B2 × 5)

6

7

EVF cabinet lower B

1

VF hinge assembly

4

EVF cabinet

upper B assembly

2

T wo tapping

screws

(B2 × 5)

T apping screw

EVF tally

— 13 —

Page 14

2-7. BATTERY PANEL SECTION (BATTERY TERMINAL BOARD)

1

T ripod screw

4

MI screw

(M2 × 4) (H)

2

Strap sheet

metal (lower)

1

MI screw

×

4) (H)

(M2

3

Battery terminal board

6

Battery panel section

3

MI screw

(M2 × 4) (H)

2

Battery terminal board (7P)

5

Claw

7

Control switch block

(SS-1000) (5P)

2-8. LENS SECTION

VC-256

Board

5

Claw

4

T wo screws

(M2

×

lock ace, p2

3),

2

Flexible board

(from lens block)(24P)

1

FP-259 flexible

board (14P)

3

Screw

(M2

×

lock ace, p2

6

3),

1

screws (B2

3

Lens section

T wo tapping

2

×

5)

Lens frame

— 14 —

Page 15

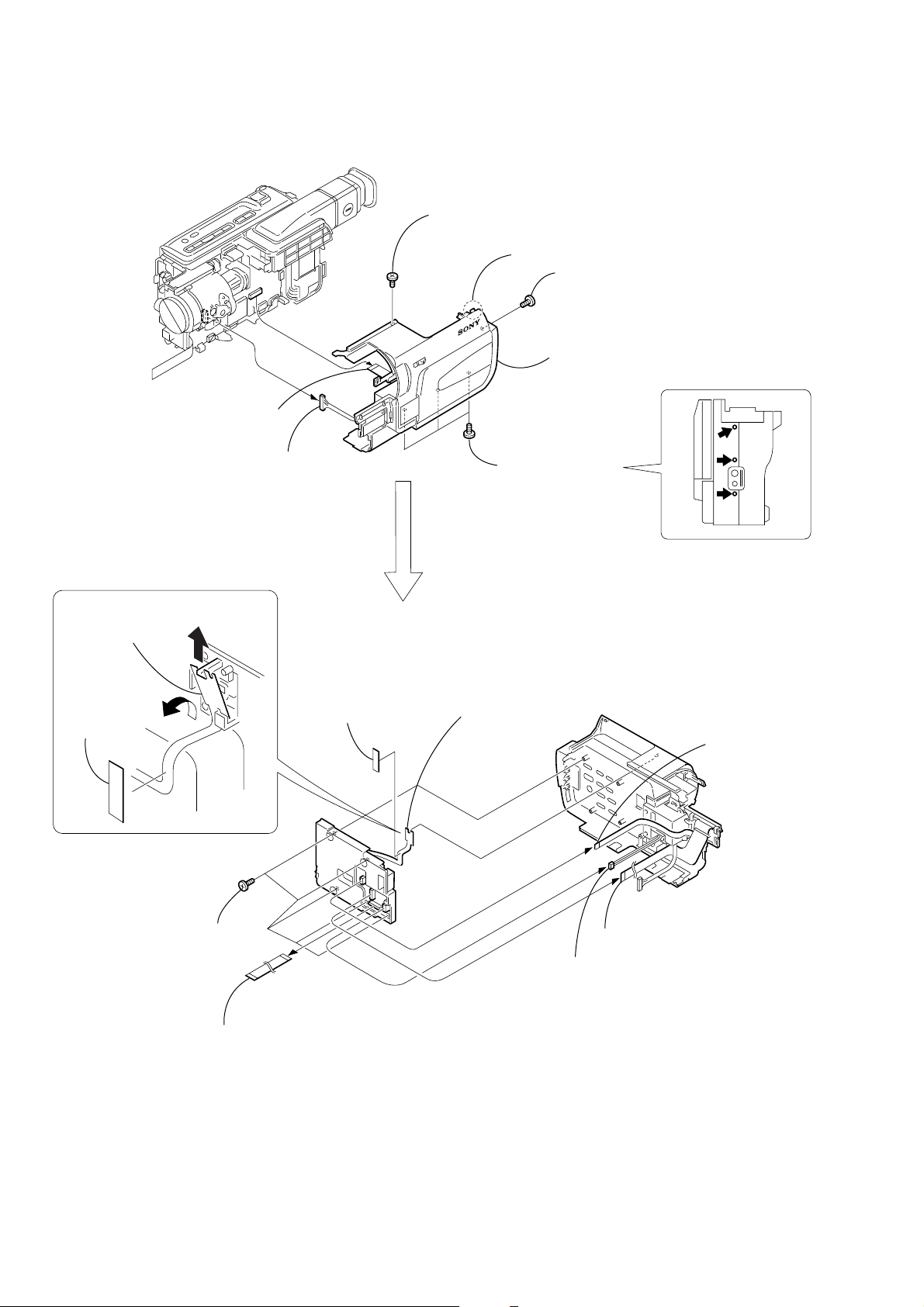

2-9. VC-256 BOARD

4

Jack cushion

3

T wo screws

(M2 × 3),

lock ace, p2

5

FP-258 flexible board

2

MD frame B

A

B

D

C

1

lock ace, p2

7

Control switch block

(FK-1000) (12P)

VC-256

Board

D

C

B

A

Two screws (M2 × 3),

8

VC-256 board

6

Screw (M2 × 3),

lock ace, p2

2-10. MECHANISM DECK

4

Control switch block

(FK-1000)

3

1

Screw

×

(M2

lock ace, p2

3),

2

Two claws

REMOVING THE MECHANISM DECK

6

Mechanism deck

3

Three

dowels

5

MD sheet

1

Three screws

(M1.7

4

MD frame A

×

2.5), p

2

absorbing

sheet

— 15 —

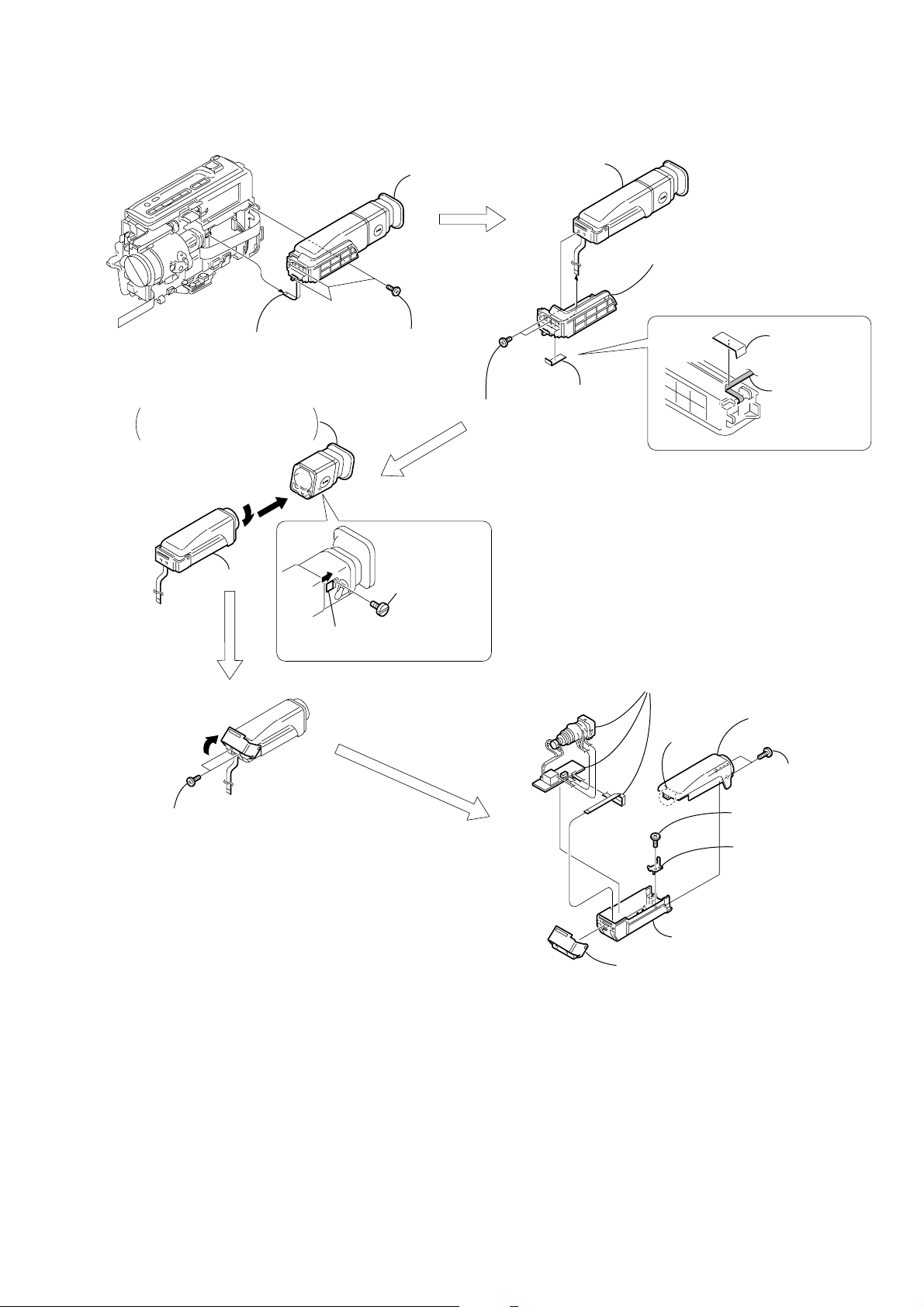

Page 16

2-11. HINGE SECTION

5

Hinge blind,

Push switch

2

4

Three tapping

screws (B2

×

5)

1

Four tapping

screws (B2

3

Electro luminous

element (4P)

1

FP-260 flexible

board (16P)

Push switch (2P)

×

5)

REMOVING THE HINGE ASSEMBLY

7

Control switch block

(PR-10000)

3

Hinge cover M

6

Screw

(M1.7

A

×

2.5), p

5

Harness (PD-110)

8

Hinge assembly

4

Harness clamp

2

cover C

1

claws

Hinge

Four

A

2

— 16 —

Page 17

3. REPAIR PARTS LIST

3-1. EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

3-1-1. OVERALL SECTION

• The mechanical parts with no reference number

in the exploded views are not supplied.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

11

A

10

9

8

LAMP, HALOGEN

XB-3D (HL6V/3W)

7

not

supplied

6

A

12

not supplied

6

5

B

14

not

supplied

1

6

13

1

19

6

Cabinet (L) section

(See page 18)

15

C

MIC901

3

MI-041

4

16

MIC902

B

Cabinet (R) section

6

(See page 21)

6

C

1

6

1

17

2

18

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-948-339-61 TAPPING

2 3-065-468-01 RETAINER (REAR), MICROPHONE

3 3-065-467-01 RETAINER (FRONT), MICROPHONE

* 4 3-065-470-01 CUSHION (10), MICROPHONE

5 X-3951-220-1 PANEL (10) ASSY, F

6 3-067-347-01 MI SCREW M2 (H)

7 1-518-723-21 LIGHT, VIDEO

8 X-3949-376-1 CAP (N) ASSY, LENS

9 3-065-433-01 COVER (10), JACK

10 X-3951-194-1 CABINET L (10) ASSY

11 3-052-815-01 BELT (ES), GRIP

* 12 3-065-455-01 STOPPER (FRONT) (10), BELT

* 13 3-065-457-01 PLATE REAR (10), L GROUND

14 3-058-622-01 STOPPER (REAR), BELT

15 not supplied MI-041 (S) BOARD, COMPLETE

16 3-987-717-01 SCREW, TRIPOD

17 1-475-141-61 REMOTE COMMANDER (RMT-814)

18 3-742-854-01 LID, BATTERY CASE (FOR RMT-814)

19 3-065-464-01 WINDOW (12), LCD

MIC901 1-542-452-11 MICROPHONE (Rch)

MIC902 1-542-452-11 MICROPHONE (Lch)

— 17 —

Page 18

3-1-2. CABINET (L) SECTION

58

57

Mechanism deck

66

53

F

55

H

E

53

D

53

68

B

A

C

71

61

not

supplied

54

67

Lens section

(See page 20)

59

51

70

65

53

53

E

52

H

58

I

BT901

56

VC-256

Board

D

C

B

A

63

62

J

K

F

53

I

J

not supplied

60

EVF section

(See page 19)

G

69

58

G

58

64

66

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 1-680-203-11 FP-263 FLEXIBLE BOARD

* 52 3-065-428-01 FRAME B (10), MD

53 3-968-729-51 SCREW (M2), LOCK ACE, P2

54 1-680-199-11 FP-258 FLEXIBLE BOARD

* 55 3-065-429-01 FRAME (10), LENS

56 4-974-725-01 SCREW (M1.7X2.5), P

57 X-3951-227-1 LID (12) ASSY, CASSETTE

58 3-067-347-01 MI SCREW M2 (H)

59 1-476-423-11 SWITCH BLOCK, CONTROL (FK-1000)

60 3-065-421-01 SHEET METAL (LOWER)(12), STRAP

61 3-066-169-01 SHEET, MD

62 1-476-424-41 SWITCH BLOCK, CONTROL (SS-1000)

63 X-3951-196-1 PANEL (12) ASSY, BATTERY

64 3-987-656-01 LID, JACK

65 not supplied VC-256 (IB-S) BOARD, COMPLETE (SERVICE)

66 3-948-339-61 TAPPING

67 1-680-200-11 FP-259 FLEXIBLE BOARD

68 3-065-662-01 LABEL, LS CAUTION

69 3-941-343-21 TAPE (A)

70 3-067-254-01 SHEET (10), ABSORBING

71 3-066-949-01 CUSHION (12), JACK

BT901 1-694-384-11 TERMINAL BOARD, BATTERY

— 18 —

Page 19

3-1-3. EVF SECTION

112

102

108

not

supplied

114

104

113

107

V901

105

111

103

109

110

103

106

103

101

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 3-061-794-01 SCREW, LOOSE STOPPER

102 3-065-481-01 BASE B (12), VF

103 3-948-339-81 TAPPING

104 X-3950-230-1 HINGE ASSY, VF

105 3-065-480-01 CABINET LOWER B (12), EVF

106 3-053-681-01 TALLY, EVF

107 1-792-454-11 CABLE, FLEXIBLE FLAT (FFC-289)

108 not supplied VF-129 (P) BOARD, COMPLETE

109 X-3951-202-1 CABINET UPPER B (12) ASSY, EVF

110 3-975-898-01 SCREW (T), F LOCK

111 X-3949-329-1 FINDER (S) ASSY

112 3-941-343-21 TAPE (A)

113 3-709-272-01 COVER, HIGH VOLTAGE (SERVICE)

114 3-709-273-01 MASK, CRT (SERVICE)

0 V901 not supplied CRT ASSY (M01KXX90WB)

— 19 —

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 20

3-1-4. LENS SECTION

163

161

160

162

IC191

155

154

152

159

M905

153

M906

not

supplied

158

157

155

156

154

152

153

151

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 not supplied DEVICE, LENS LSV-630A

152 not supplied IRIS FLEXIBLE ASSY 630

153 3-713-791-41 SCREW, TAPPING (M1.7X5), P2

154 3-713-791-51 SCREW, TAPPING (M1.7X3.5), P2

155 3-056-022-01 TAPPING (B1.7X3.5), HEAD

156 3-053-827-01 LEVER, IR

157 3-053-800-01 SPRING, RETAIN

158 3-053-799-01 GEA, IR

159 not supplied ADAPTOR (FK), CCD FITTING

160 not supplied FILTER BLOCK, OPTICAL

161 not supplied RUBBER (F), SEAL

162 not supplied CD-281 (X) BOARD,COMPLETE

163 3-318-203-11 SCREW (B1.7X6), TAPPING

IC191 not supplied CCD BLOCK ASSY (CCD IMAGER)

M905 not supplied MOTOR, STEPPING F630 (FOCUS)

M906 not supplied MOTOR, STEPPING Z600 (ZOOM)

— 20 —

Page 21

3-1-5. CABINET (R) SECTION

A

A

B

C

B

C

LCD section

(See page 22)

S901

LCD902

D901

201

201

201

202

201

201

207

208

203

209

204

205

206

: BT001 (Lithium battary) CF-1000 on the mount position.

The printed wiring board of the Control switch block (CF-1000) on which lithium battery is mounted, is not shown.]

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 3-948-339-61 TAPPING

202 3-065-436-01 BLIND (12), HINGE

203 1-476-425-21 SWITCH BLOCK, CONTROL (CF-1000)

204 X-3951-223-1 CABINET R (12) ASSY

205 3-059-539-11 LID (103P), CPC

206 3-065-451-01 HOLDER (12), LCD

207 1-680-201-11 FP-260 FLEXIBLE BOARD

208 1-757-397-21 CABLE, FLEXIBLE FLAT (FFC-295)

209 3-941-343-21 TAPE (A)

0 D901 not supplied ELEMENT, ELECTRO LUMINOUS

LCD902 not supplied DISPLAY PANEL, LIQUID CRYSTAL

S901 1-771-848-11 SWITCH, PUSH

— 21 —

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 22

3-1-6. LCD SECTION

265

255

256

254

257

266

253

259

258

260

252

C

A

251

261

262

PD-131

Board

263

B

ND901

C

264

LCD901

B

A

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

251 3-067-347-01 MI SCREW M2 (H)

252 3-065-474-01 CABINET C (12), P

* 253 3-058-672-01 CLAMP, HARNESS

254 3-948-339-31 SCREW, TAPPING

255 3-065-477-01 COVER C (12), HINGE

256 X-3951-206-1 HINGE (12) ASSY

257 1-960-975-11 HARNESS (PD-110)

258 3-065-478-01 COVER M (12), HINGE

259 4-974-725-01 SCREW (M1.7X2.5), P

— 22 —

260 1-418-802-11 SWITCH BLOCK, CONTROL (PR-10000)

261 not supplied PD-131 (XC-2.5) BOARD, COMPLETE

262 3-968-729-51 SCREW (M2), LOCK ACE, P2

263 3-065-475-01 FRAME (12), PANEL

264 X-3951-199-1 CABINET M (12) ASSY, P

265 3-948-339-81 TAPPING

266 not supplied PLATE (12), PANEL ORNAMENT

LCD901 not supplied INDICATOR MODULE LIQUID CRYST (SERVICE)

0 ND901 not supplied TUBE, FLUORESCENT, COLD CATHODE

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 23

2. GENERAL

DCR-TRV130E

This section is extracted

from instruction manual.

— 23 —

Page 24

— 24 —

Page 25

— 25 —

Page 26

— 26 —

Page 27

— 27 —

Page 28

— 28 —

Page 29

— 29 —

Page 30

— 30 —

Page 31

— 31 —

Page 32

— 32 —

Page 33

— 33 —

Page 34

— 34 —

Page 35

— 35 —

Page 36

— 36 —

Page 37

— 37 —

Page 38

— 38 —

Page 39

— 39 —

Page 40

— 40 —

Page 41

— 41 —

Page 42

— 42 —

Page 43

— 43 —

Page 44

— 44 —

Page 45

— 45 —

Page 46

— 46 —

Page 47

— 47 —

Page 48

— 48 —

Page 49

— 49 —

Page 50

— 50 —

Page 51

— 51 —

Page 52

DCR-TRV130E

9-929-860-41

Sony Corporation

Personal VIDEO Products Company

— 52 —

2001A1600-1

©2001.1

Published by Safety & Service Engineering Dept.

Page 53

Reverse

992986041.pdf

Revision History

Ver.

1.0

Date

2000.01

History

Official Release

Contents

—

S.M. Rev.

issued

—

Loading...

Loading...