Page 1

Models TB66J/TB66JRT

Replaces 0083740 March 2014

OPERATOR’S

MANUAL

Part Number 0083740

May 2014

Page 2

The aerial platform is not electrically insulated. Death or serious injury will result from contact

with, or inadequate clearance from, an energized conductor.

Do not go closer than the minimum safe approach distance as dened by the Minimum Safe

Approach Distance section in Chapter 3 – Safety.

Regard all conductors as energized.

Allow for electrical wire sag and aerial platform sway.

If the platform, booms, or any part of the aerial platform contacts a high-voltage electrical conductor,

the entire machine can become electrically charged.

If that happens, remain on the machine and do not contact any other structure or object. This includes

the ground, adjacent buildings, poles, and any other objects that are not part of the aerial platform.

Such contact could make your body a conductor to the other object, creating an electrical shock

hazard resulting in death or serious injury.

If an aerial platform is in contact with an energized conductor the platform operator must warn ground

personnel in the vicinity to stay away. Their bodies can conduct electricity creating an electrical shock

hazard resulting in death or serious injury.

Do not approach or leave the aerial platform until the electricity has been turned off.

Do not attempt to operate the lower controls when the platform, booms, or any part of the aerial

platform is in contact with a high-voltage electrical conductor or if there is an immediate danger of

such contact.

Personnel on or near an aerial platform must be continuously aware of electrical hazards, recognizing that death or serious injury can result from contact with an energized conductor.

California

Proposition 65 Warning

Battery posts, terminals and related accessories contain lead

and lead components, a chemical known to the State of California to cause cancer and birth defects or other reproductive

harm. Wash hands after handling.

California

Proposition 65 Warning

Diesel and gasoline engine exhaust and some of its constituents are known by the State of California to cause cancer, birth

defects and other reproductive harm.

Page 3

Table of Contents

Electrical Danger ............................ Inside Front Cover

California Proposition 65 ................ Inside Front Cover

Chapter 1 – Introduction

Aerial Platform Features ...........................................1

Options .....................................................................1

Operator’s Manual ....................................................1

Safety Alerts .............................................................1

Operation ..................................................................2

Maintenance .............................................................2

Manual of Responsibilities ........................................2

Additional Information ...............................................2

Chapter 3 – Specications

Component Identication ..........................................3

Working Envelope ....................................................4

General Specications..............................................5

Engine Specications ...............................................6

Engine Oil Viscosity ..................................................8

Chapter 3 – Safety

Electrocution Hazards ............................................11

Minimum Safe Approach Distance .........................11

Prestart Inspection..................................................12

Work Place Inspection and Practices .....................12

Operation ................................................................12

Tip-Over and Falling Hazards .................................13

Electrical System ....................................................13

Hydraulic System....................................................13

Engine and Fuel Handling Precautions ..................14

Placards and Decals...............................................14

Chapter 4 – Safety Devices

Emergency Stop Controls.......................................15

Emergency Power System .....................................15

Emergency Lowering Knob ....................................16

Ground Operation Switch .......................................16

Platform Foot Switch ..............................................16

Guardrails ...............................................................16

Lanyard Anchors.....................................................16

Ground Fault Circuit Interrupter ..............................17

Tilt Alarm .................................................................17

Engine Protection Systems ....................................17

High Engine Temperature Alarm .........................17

Low Oil Pressure Alarm .......................................17

Horn ........................................................................18

All Motion Alarm......................................................18

Flashing Light .........................................................18

Driving Lights .......................................................... 18

Platform Work Lights ..............................................18

Bump Guard System ..............................................18

Chapter 5 – Gauges and Displays

Hour Meter..............................................................19

Engine Temperature Gauge ...................................19

Ammeter – Cummins, Deutz and Ford Engines .....19

Voltmeter – General Motors Engines......................19

Engine Air Filter Gauge ..........................................19

Fuel Gauge .............................................................19

Engine Oil ...............................................................20

Hydraulic Fluid Filter Gauge ...................................20

Fluid Level and Temperature Gauge ......................20

Chapter 6 – Controls

Battery Disconnect Switch ...................................... 21

Lower Controls .......................................................21

Emergency Stop Button ......................................21

Control Selector Switch .......................................21

Start Switch .........................................................21

Ground Operation Switch ....................................22

Rotation Switch ...................................................22

Boom Elevation Switch .......................................22

Boom Extend/Retract Switch ..............................22

Jib Articulation Switch .........................................22

Boom Speed Knob .............................................23

Platform Level Switch ..........................................23

Platform Rotation Switch .....................................23

Engine/Emergency Power Switch .......................23

Throttle Switch ....................................................23

Fuel Switch ..........................................................23

Hydraulic System Warm-up Switch .....................23

Circuit Breaker Reset Buttons ................................24

Upper Controls .......................................................24

Start Switch .........................................................25

Emergency Stop Button ......................................25

Drive Joystick ......................................................25

Drive Range Switch .............................................26

Boom Joystick .....................................................26

Boom Extension Switch ......................................26

Jib Articulation Switch .........................................26

Platform Level Switch ..........................................26

Platform Rotation Switch .....................................26

Boom Speed Knob ..............................................26

Throttle Switch ....................................................26

Engine/Emergency Power Switch .......................27

Platform Foot Switch ..............................................27

Machine/Generator Switch .....................................27

Hydraulic System Warm-up Switch ........................27

Driving and Platform Work Lights ...........................28

Horn Button ............................................................28

TB66J – 0083740

Page 4

Table of Contents

Chapter 7 – Prestart Inspection

Operator’s Manual ..................................................29

Engine ....................................................................29

Oil Level ..............................................................29

Coolant ................................................................29

Radiator ...............................................................30

Fuel Tank .............................................................30

Fuel Line .............................................................31

Air Filter ...............................................................31

Charging System ................................................31

Cold Weather Start Kit ........................................31

Electrical System ....................................................32

Battery Fluid Level ..............................................32

Battery Terminals .................................................32

Cables and Wiring Harness .................................... 32

Hydraulic System....................................................32

Fluid Level ...........................................................32

Fluid Filter ...........................................................33

Hoses, Tubes, and Fittings ..................................33

Tires and Wheels ....................................................33

Lower Control Station .............................................34

Operating Controls ..............................................34

Emergency Stop ..................................................34

Emergency Power ...............................................34

Emergency Lowering .............................................. 34

Level Sensor...........................................................35

Flashing Light .........................................................35

Sandblast Protection Kit .........................................36

Structures ...............................................................36

Weldments ..........................................................36

Slide Pads ...........................................................36

Wire Ropes .........................................................36

Fasteners ............................................................37

Upper Control Station .............................................37

Guardrail System ................................................37

Lanyard Anchors .................................................38

Operating Controls ..............................................38

Emergency Stop ..................................................38

Emergency Power ...............................................38

Horn ....................................................................39

Electrical Power Outlet ........................................39

All Motion Alarm......................................................39

Air Line to Platform .................................................39

Driving and Platform Work Lights ...........................39

Tow Kit ....................................................................40

Platform Glazier Package ....................................... 40

Platform Control Cover ...........................................40

Placards and Decals...............................................40

Prestart Inspection Checklist ..................................47

Chapter 8 – Operation

Cold Weather Start Up ...........................................49

Engine Cold Weather Start Kit ................................49

Cummins, Kubota and Ford – Block Heater ........49

Cummins – Ether Injection ..................................49

Deutz – Manifold Preheater ................................50

GM – Radiator Hose In-Line ...............................50

Hydraulic System Cold Weather Warm-Up ............50

Hydraulic System Warm-up Switch .....................50

Manually Warming The Hydraulic System ..........50

Preparing for Operation ..........................................50

Lower Controls .......................................................50

Upper Controls .......................................................51

Boom Operation ..................................................52

Driving and Steering ............................................52

Drive Speeds .......................................................53

Motion Warning Alarm .........................................53

Four Wheel Drive....................................................53

Gradeability ............................................................53

Percent vs. Degree of Slope ...............................54

Driving on a Slope ...............................................54

Calculating Percent Grade ..................................54

Machine Gradeability ..........................................55

All Motion Alarm......................................................55

Four Wheel Drive....................................................55

Electrical Power Outlet ...........................................55

AC Generator .........................................................55

Dual Fuel ................................................................56

Air Line ...................................................................56

Driving Lights .......................................................... 56

Platform Work Lights ..............................................56

Platform Glazier Package ....................................... 57

Platform Capacity ................................................57

Bump Guard System ..............................................57

Chapter 9 – Stowing and Transporting

Stowing ...................................................................59

Transporting ...........................................................59

Driving .................................................................59

Winching .............................................................60

Hoisting ...............................................................60

Securing for Transport .........................................61

Chapter 10 – Emergency Operation

Emergency Power System .....................................63

Lower Controls ....................................................63

Upper Controls ....................................................63

Emergency Lowering .............................................. 64

Towing ....................................................................65

Chapter 11 – Troubleshooting

Troubleshooting Chart ............................................67

Appendix A – Glossary

Limited Warranty

TB66J – 0083740

Page 5

Chapter 1 – Introduction

Aerial Platform Features

The aerial platform is a boom-supported elevating work

platform used to raise personnel, tools and materials to

the workstation. The booms are raised and lowered with

hydraulic cylinders. Hydraulic motors on the drive wheels

provide power to move the aerial platform.

The standard machine includes the following features.

Proportional boom lift, swing and drive control

180 degree hydraulic platform rotation

360 degree continuous turntable rotation

6′ articulating jib boom

39″ x 96″ (99 cm x 243 cm) steel

500 lb (227 kg) capacity platform

Platform gravity gate

Drivable at full height

Two safety lanyard attachments

Manual lowering valve at chassis

Hydraulic oil level and temperature gauges

Tie-down/lifting lugs

Battery operated emergency power system

Engine anti-restart

High engine temperature shut down

Low oil pressure shut down

Tilt alarm

Hour meter

Ammeter – Cummins, Deutz, Ford engines

Voltmeter – GM engine

Coolant temperature gauge

Spark arrestor mufer – GM engines

Foam lled tires

Four wheel drive

Five year limited warranty

The machine may be powered with one of the following

engines.

Cummins B3.3 – Diesel

Deutz F4L-1011F – Diesel

Deutz F4L-2011F – Diesel

Kubota V2403-M-T – Diesel

Ford LRG 425 – Gasoline, LPG or dual fuel

Ford LRG 423 – Gasoline, LPG or dual fuel

General Motors 2.4L – Gasoline, LPG or dual fuel

The aerial platform has been manufactured to conform

to all applicable requirement of the following organizations.

Occupational Safety and Health Administration

(OSHA)

American National Standards Institute (ANSI)

Options

The following options may be provided on the machine.

Lower control cover

Platform work lights – ood lights

Flashing light

Driving lights – two headlights and two rear lights

Platform swinging gate

Side entry gravity gate

Sandblast protection kit

Cold weather start kit

Hydraulic system cold weather warm-up kit

AC generator – hydraulic powered, 110 V, 2000 W

AC generator – hydraulic powered, 220 V, 50Hz

All motion alarm

Airline to platform

Tow kit

30″ x 96 (76 cm x 244 cm) aluminum 500 lb

(272 kg) capacity platform

30″ x 96″ (76 cm x 244 cm) steel 500 lb

(227 kg) capacity platform

30″ x 60″ (76 cm x 152 cm) aluminum 600 lb

(272 kg) capacity platform

Horn

Two wheel drive

Platform glazier package

Platform welder package

Spark arrestor mufer – Deutz engines

Dual fuel with 20 gallon gasoline tank

Tilt warning light

Flotation tires

Highway tread tires

Non-marking tires

Canadian Standards Association (CSA)

Operator’s Manual

This manual provides information for safe and proper

operation of the aerial platform. Some information in

this manual refers to options that may or may not be on

your machine. Read and understand the information

in this Operator’s Manual before operating the aerial

platform on the job.

Additional copies of this manual may be ordered from

Snorkel. Supply the model and manual part number

from the front cover to assure that the correct manual

will be supplied.

All information in this manual is based on the latest

product information at the time of publication. Snorkel

reserves the right to make product changes at any time

without obligation.

Safety Alerts

A safety alert symbol is used throughout this manual to

indicate danger, warning and caution instructions. Follow

these instructions to reduce the likelihood of personal

injury and property damage. The terms danger, warning

TB66J – 0083740 1

Page 6

Chapter 1 – Introduction

and caution indicate varying degrees of personal injury

or property damage that can result if the instruction is

not followed.

Danger

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word is to be used in the most extreme

situations.

Warning

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Caution

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

Notes

Notes are used to provide special information or helpful

hints to assist in aerial platform operation, but do not

indicate a hazardous situation.

Operation

The aerial platform has built-in safety features and has

been factory tested for compliance with Snorkel specications and industry standards. However, any personnel

lifting aerial platform can be potentially dangerous in the

hands of untrained or careless operators.

Warning

The potential for an accident increases when the

aerial platform is operated by personnel who are not

trained and authorized. Death or serious injury can

result from such accidents. Read and understand

the information in this manual and on the placards

and decals on the machine before operating the

aerial platform on the job.

Maintenance

Every person who maintains, inspects, tests, or repairs

the aerial platform must be qualied to do so. Following

the daily prestart inspection in this Operator’s Manual will

help keep the aerial platform in optimum working condition. Other maintenance functions must be performed

by maintenance personnel who are qualied to work on

the aerial platform.

Caution

Welding current can be very intense. Damage to electronic components may result. Connect the ground

clamp as close as possible to the area being welded.

Disconnect battery cables and any microprocessors

and engine control modules before welding on the

machine.

If it becomes necessary to weld aerial platform components as a method of repair, take all precautions to

prevent damage to electronic circuitry and devices on

the machine. This includes, but may not be limited to,

disconnecting battery cables and electronic devices.

Do not modify this aerial platform without prior written con-

sent of the Snorkel Engineering Department. Modication

may void the warranty, adversely affect stability, or affect

the operational characteristics of the aerial platform.

Manual of Responsibilities

All owners and users of the aerial platform must read,

understand, and comply with all applicable regulations.

Ultimate compliance to OSHA regulations is the responsibility of the user and their employer.

ANSI publications clearly identify the responsibilities

of all personnel who may be involved with the aerial

platform. A reprint of the “Manual of Responsibilities for

Dealers, Owners, Users, Operators, Lessors and Lessees of ANSI/SIA A92.5-2006 Boom-Supported Elevating Work Platforms” is available from Snorkel dealers or

from the factory upon request.

Training is essential and must be performed by a quali-

ed person.

Become procient in knowledge and actual operation

before using the aerial platform on the job.

The operator must be trained and authorized to

perform any functions of the aerial platform.

Operation of the aerial platform must be within the

scope of the machine specications.

The operator bears ultimate responsibility for following

all manufacturer’s instructions and warnings, regulations

and safety rules of their employer and/or any state or

federal law.

2 TB66J – 0083740

Copies are also available from:

Scaffold Industry Association, Inc.

P.O. Box 20574

Phoenix, AZ 85036-0574 USA

Additional Information

For additional information contact your local dealer or

Snorkel at:

Snorkel International

P.O. Box 1160

St. Joseph, MO 64502-1160 USA

1-800-255-0317

http://www.snorkelusa.com

Page 7

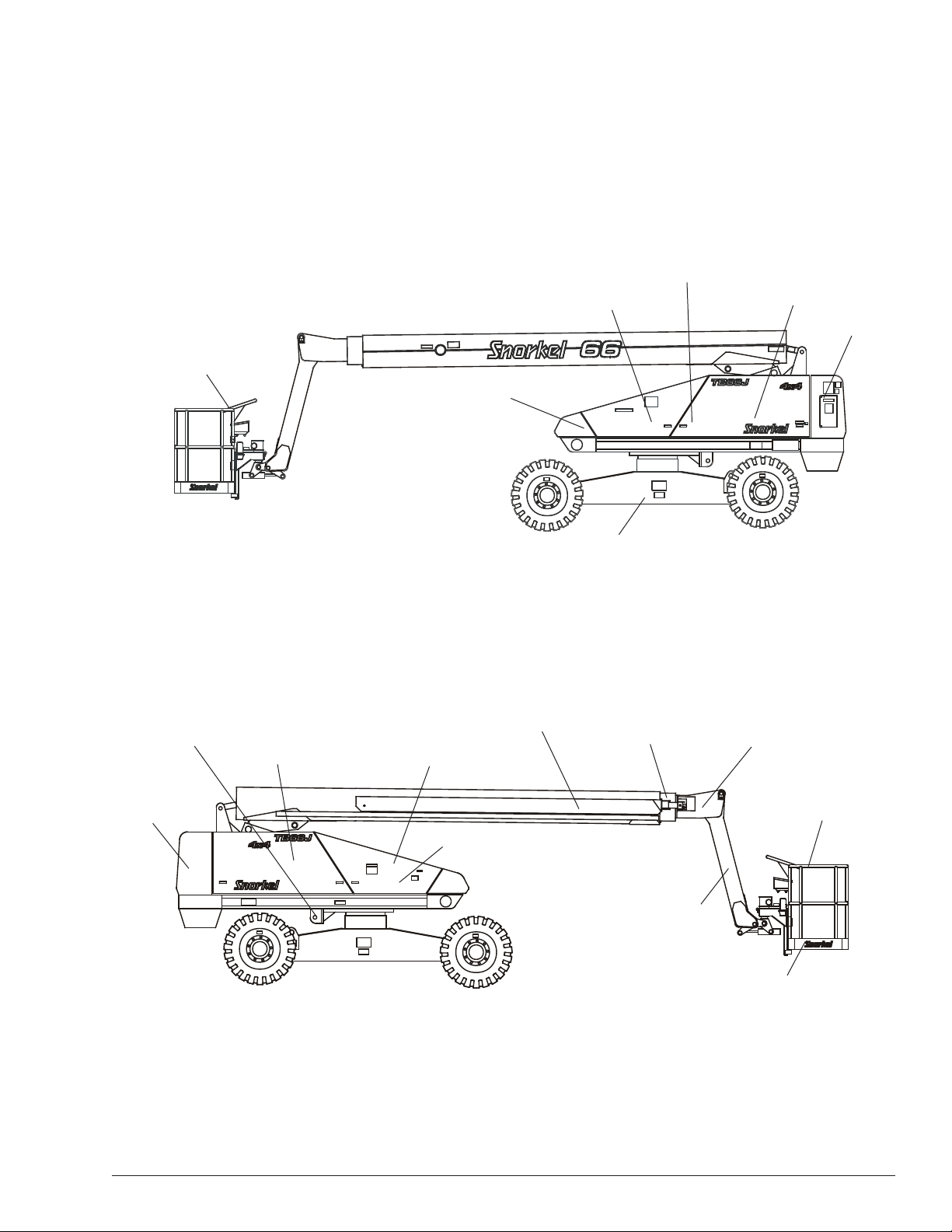

Component Identication

Upper Controls

Chapter 3 – Specications

Fuel Tank

LP Fuel Tank

Operator’s

Manual

Wiring Box

Lower Controls

Emergency

Lowering

Valve

Engine

Hydraulic Fluid Tank

And Filter

Steer Wheels

Right Side

Battery Disconnect Switch

Batteries

Main Boom

Chassis

Intermediate

Boom

Jib Boom

Steer Wheels

Tip Boom

Platform

Platform

Foot Switch

Left Side

TB66J – 0083740 3

Page 8

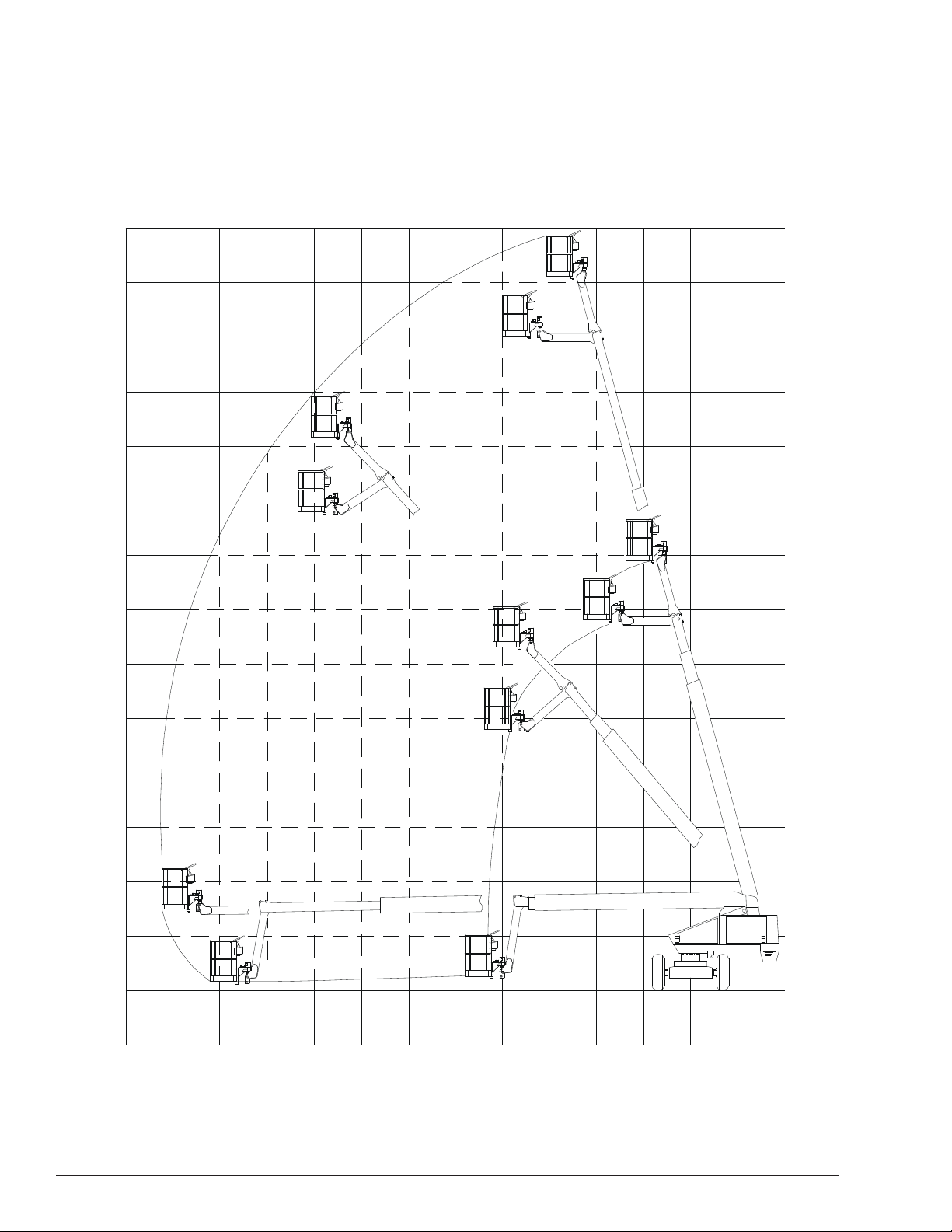

Chapter 2 – Specications

Working Envelope

Feet

(Meters)

70

(21.3)

60

(18.3)

50

(15.2)

40

(12.2)

30

(9.1)

20

(6.1)

10

(3)

0

5

(1.5)

60

(18.3)

4 TB66J – 0083740

50

(15.2)

40

(12.2)

30

(9.1)

20

(6.1)

(3)

010

10

(3)

Page 9

General Specications

Chapter 2 – Specications

Aerial Platform

Working height 72′ (21.9 m)

Maximum platform height 66′ (20.1 m)

Horizontal reach 56′ (17.1 m)

Main boom

Articulation -1° to +72°

Extension 0 to 27′ 4″ (0 to 8.33 m)

Turntable rotation 360° continuous

Turning radius, inside 15′ 5″ (4.7m)

Wheelbase 10′ (3 m)

Ground clearance 13″ (33 cm)

Maximum wheel load 13,360 lbs (6060 kg)

Maximum ground pressure 80 psi (552 kPa)

Weight, GVW

Approximate 26,220 lbs (11,916 kg)

Stowed width 7′ 11.5″ (2.4 m)

Stowed length 33′ (10 m)

Stowed height 8′ 9″ (2.7 m)

Platform

Dimensions

Standard steel 39″ x 96″ (99 cm x 243 cm)

Rated work load 500 lb (227 kg)

Optional aluminum 30″ x 60″ (76 cm x 152 cm)

Rated work load 600 lb (272 kg)

Optional aluminum 30″ x 96″ (76 cm x 244 cm)

Rated work load 500 lb (227 kg)

Optional steel 30″ x 96″ (76 cm x 244 cm)

Rated work load 500 lb (227 kg)

Rotation 90° CW to 80° CCW

Maximum number of occupants 2 people

Optional AC generator 125 VAC

Optional AC generator 220 VAC, 50 Hz

Function Speed

Turntable rotation, 360 degrees 85 to 95 seconds

Main boom

Up 40 to 50 seconds

Down 40 to 50 seconds

Extend 60 to 70 seconds

Retract 35 to 50 seconds

Jib

Up 7 to 13 seconds

Down 7 to 13 seconds

Platform rotation, 170 degrees 16 to 20 seconds

Drive

High, booms stowed 3.0 mph (4.8 km/h)

Low, booms elevated 1.0 mph (1.6 km/h)

Drive System

Standard Four-wheel drive

Gradeability 30%

Optional Two-wheel drive

Gradeability 25%

Tires

Foam Fillled

Highway tread,14 ply 15″ x 19.5″ (38 cm x 50 cm)

Bar lug, 4x4 12 ply 15″ x 19.5″ (38 cm x 50 cm)

Flotation, 4x4 40″ x 19-19.5″ (101.6 cm x 50 cm)

Air Fillled

Flotation 40″ x 19-19.5″ (101.6 cm x 50 cm)

Electrical System

Voltage 12 V DC negative chassis ground

Source 12 V 550 CCA battery

Fluid recommended distilled water

Hydraulic System

Maximum pressure 2,500 psi (17,250 kPa)

Reservoir capacity 26.1 US gal (99 l)

System capacity 35 US gal (132 l)

Maximum operating temperature 200°F (93°C)

Hydraulic uid recommended

Above 10°F (-12°C) Mobil DTE-13M (ISO VG32)

Below 10°F (-12°C) Mobil DTE-11M (ISO VG15)

Engine

Diesel Cummins B3.3

Deutz F4L-1011F

Deutz F4L-2011F

Kubota V2403-M-T

Gasoline and/or LPG Ford LRG 423

Ford LRG 425

General Motors 2.4L

Fuel Tank Capacity

Diesel or gasoline 40 US gal (151 l)

LPG 43.5 lbs (19.7 kg)

Dual fuel gasoline 20 US gal (76 l)

Ambient Air Temperature Operating Range

Fahrenheit 0°F to 110°F

Celsius -18°C to 43°C

Maximum Wind Speed

Gust or steady 28 mph (12.8 m/s)

TB66J – 0083740 5

Page 10

Chapter 2 – Specications

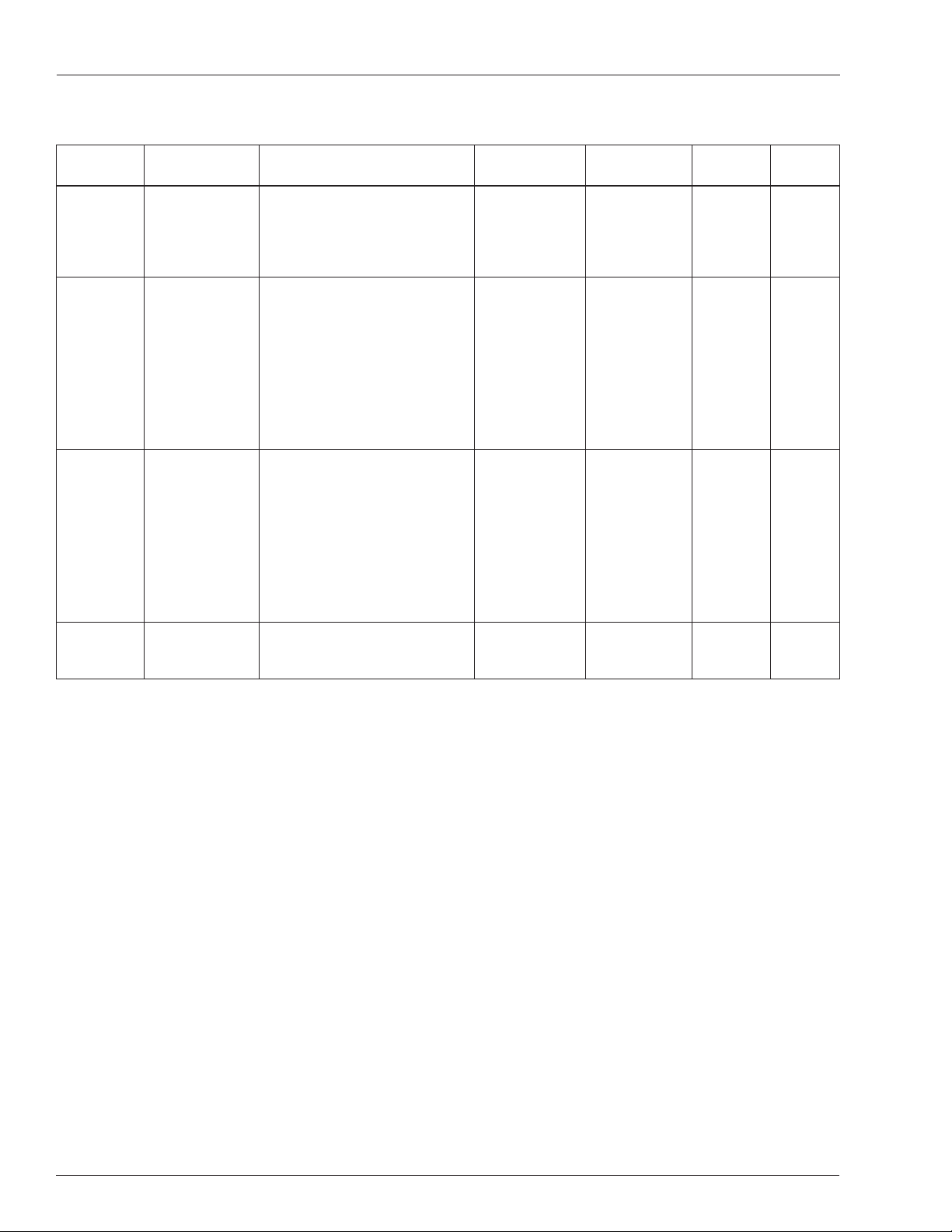

Engine Specications

Engine Displacement Fuel Grade Coolant

Diesel

Cummins

B3.3

Deutz

F4L-1011F

Deutz

F4L-2011F

Kubota

V2403-M-T

199 cu. in.

(3.26 liter)

190 cu. in.

(3.11 liter)

190 cu. in.

(3.11 liter)

148.5 cu. in.

(2.43 liter)

ASTM No. 2D fuel with a mini-

mum Cetane no. of 40.1 For op-

erating temperature below 0°C

(32°F) use winterized No. 2D.

Diesel

DIN 51 601 (February 1986).

BS 2869: A1 and A2 (with A2

refer to Deutz manual about

sulfur content)

ASTM D 975-88: 1-D and 2-D

3

CEN EN 590 or DIN EN 590

NATO Code F-54 and F-75

For operating temperatures

1

below 0°C (32°F) use winter

grade diesel.

Diesel

DIN 51 601 (February 1986).

BS 2869: A1 and A2 (with A2

refer to Deutz manual about

sulfur content)

ASTM D 975-88: 1-D and 2-D

CEN EN 590 or DIN EN 590

NATO Code F-54 and F-75

For operating temperatures

1

below 0°C (32°F) use winter

grade diesel.

Diesel

Diesel Fuel No. 2-D

ASTM D975

50% Water

50% Antifreeze

1

1

50% water

1

50% Antifreeze

Air

Air

Operating

Temperature

140°F to 212°F

2

60°C to 100°C

172°F to 203°F

78°C to 95°C

172°F to 203°F

78°C to 95°C

2

NA

Oil

Capacity

2 US gal

(7.5 liter)

2.75 US

gal (10.4

liter)

2.75 US

gal (10.4

liter)

2.51 gal

(9.5 liter)

Grade

15W-40

3

CH4/SG

API: CD

higher

API: CD

higher

CF grade

or higher

Oil

SAE

3

API

or

3

or

3

API:

3

Note 1: Refer to the engine manufacturers manual for specic fuel recommendations and specications.

Note 2: Refer to the engine manufacturers manual for specic coolant recommendations and specications.

Note 3: Refer to the engine manufacturers manual for specic lubricating oil recommendations and specications.

6 TB66J – 0083740

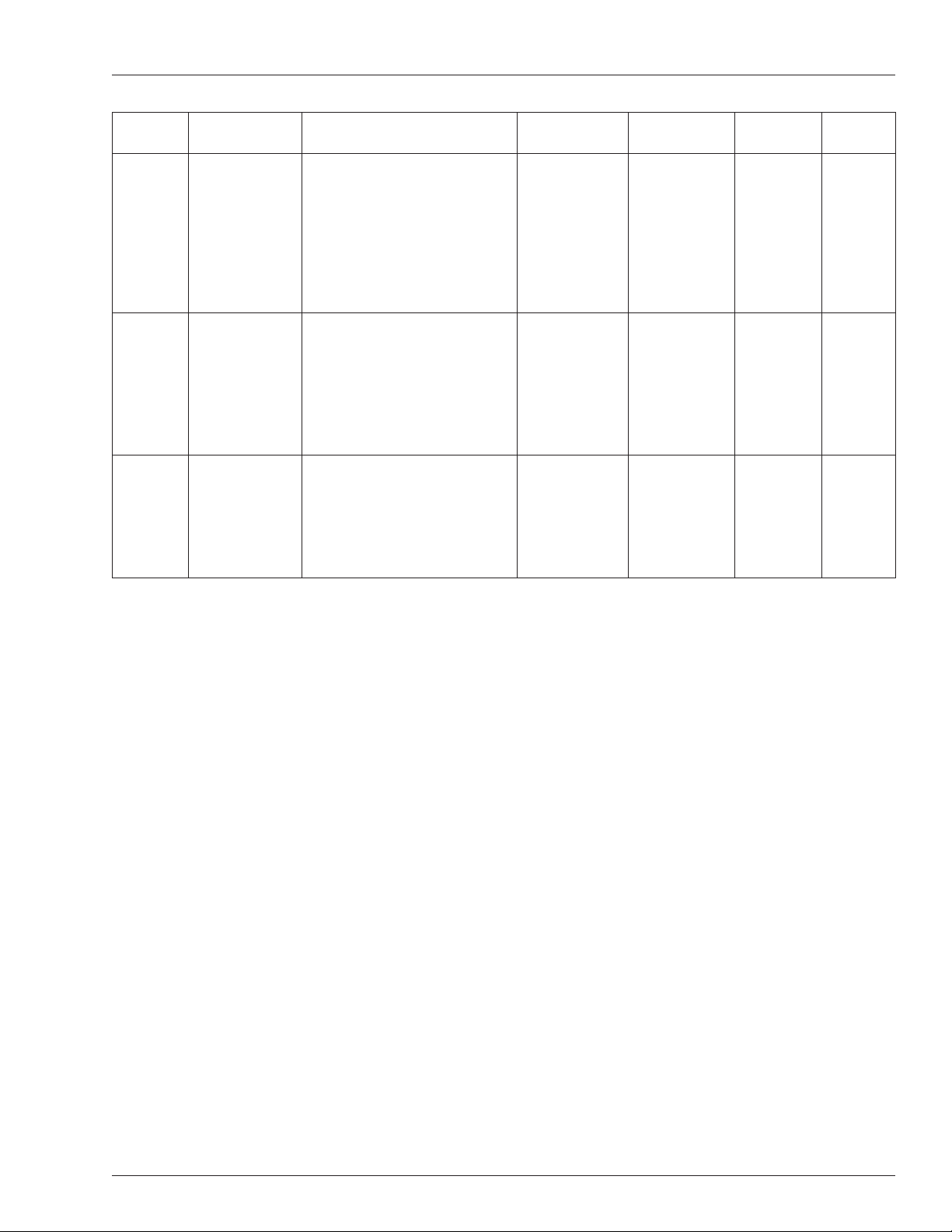

Page 11

Chapter 2 – Specications

Engine Displacement Fuel Grade Coolant

Ford

LRG 425

Ford

LRG 423

GM

2.4L

153 cu. in.

(2.5 liter)

140 cu. in.

(2.3 liter)

150 cu. in.

(2.4 liter)

Gasoline

Unleaded 87 or 89 octane.

Do not use gasoline blends with

more than 10% ethanol by

volume octane index of 87 or 89.

3

LPG

HD-5 USA

EN589 European

Gasoline

Unleaded gasoline 85 octane

(motor method).

LPG

Gas Processors Association

Standard 2140

Category: special duty propane

Gasoline

Unleaded 87 octane

LPG

HD-5

1

1

1

50% Water

50% Antifreeze

1

50% Water

50% Antifreeze

1

50% Water

50% Antifreeze

Operating

Temperature

195°F to 220°F

3

91°C to 104°C

160°F to 190°F

3

71°C to 88°C

176°F to 183°F

5

80°C to 84°C

Oil

Capacity

4.5 US qt

(4.26 liter)

4 US qt

(3.8 liter)

With lter:

1.12 US gal

(4.5 liter)

W/o lter:

1.18 US gal

(4.25 liter)

Grade

API: SH

3

Gasoline

API: SH

SG only if

SH is not

available

SG or SH

ILSAC

Oil

or SJ

LPG

GF-4

2

2

4

Note 1: Refer to the engine manufacturers manual for specic fuel recommendations and specications.

Note 2: Refer to the engine manufacturers manual for specic lubricating oil recommendations and specications.

Note 3: Refer to the Ford LRG 425 Operator Handbook for specic coolant recommendations and specications.

Note 4: API Starburst symbol on GF-4 oils reads “API Service SM.”

Note 5: Refer to the engine manufacturers manual for specic coolant recommendations and specications.

TB66J – 0083740 7

Page 12

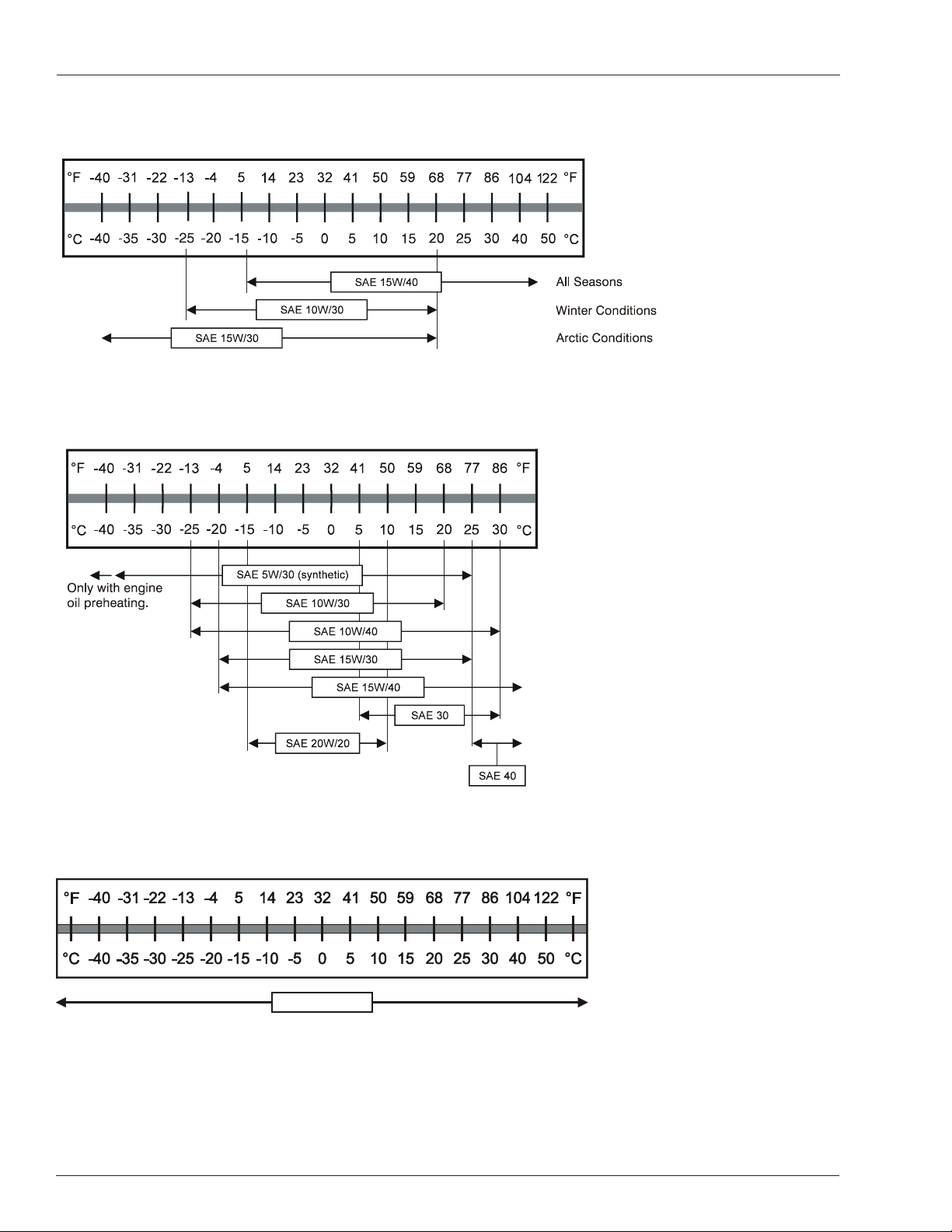

Chapter 2 – Specications

S AE 1 5W /4 0

Engine Oil Viscosity

Cummins B3.3

Deutz F4L-1011F

Deutz F4L-2011F

Kubota V2403-M-T

8 TB66J – 0083740

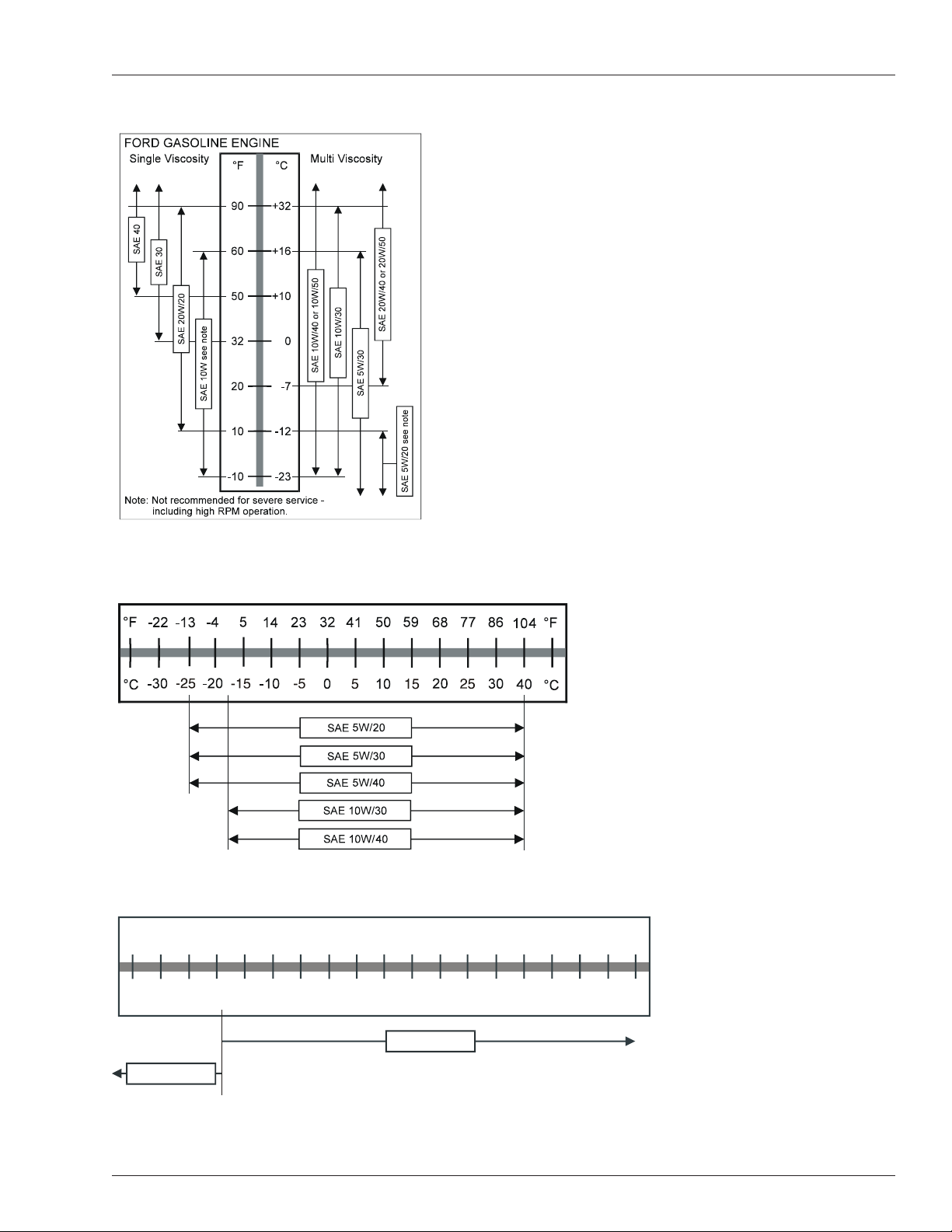

Page 13

Ford LRG 423

°F

°F

-4 0

-3 1

-2 2

-1 3

-4

5

14

23 32

41

50 59 6 8 7 7 8 6 104

122

°C

°C

-4 0

-3 5

-3 0 -2 5 -2 0 -15 -1 0

-5

0

10

15 2 0 25

30

40 5 0

5

S AE 5 W /3 0

S AE 0 W /3 0

Chapter 2 – Specications

Ford LRG 425

General Motors 2.4L

Note

No straight weight oils and no specialized diesel oils are

to be used in GM engines.

TB66J – 0083740 9

Page 14

Chapter 2 – Specications

10 TB66J – 0083740

Page 15

Chapter 3 – Safety

D enotes

pro h ib ited

zon e

Knowledge of the information in this manual, and

proper training, provide a basis for safely operating the

aerial platform. Know the location of all controls and

how they operate to act quickly and responsibly in an

emergency.

Safety devices reduce the likelihood of an accident.

Never disable, modify, or ignore any safety device.

Safety alerts in this manual indicate situations where

accidents may occur.

If any malfunction, hazard or potentially unsafe condition

relating to capacity, intended use, or safe operation is suspected, stop aerial platform operation and seek assistance.

The operator bears ultimate responsibility for following

all manufacturer’s instructions and warnings, regulations

and safety rules of their employer and/or any state or

federal law.

Electrocution Hazards

The aerial platform is made of metal components and is

not insulated. Regard all conductors as energized. Do

not operate outside during a thunderstorm.

Minimum Safe Approach Distance

Minimum safe approach distances to energized power

lines and their associated parts must be observed while

operating the aerial platform.

Danger

The aerial platform is not electrically insulated.

Death or serious injury will result from contact

with, or inadequate clearance from, an energized

conductor. Do not go closer than the minimum safe

approach distance as dened by ANSI.

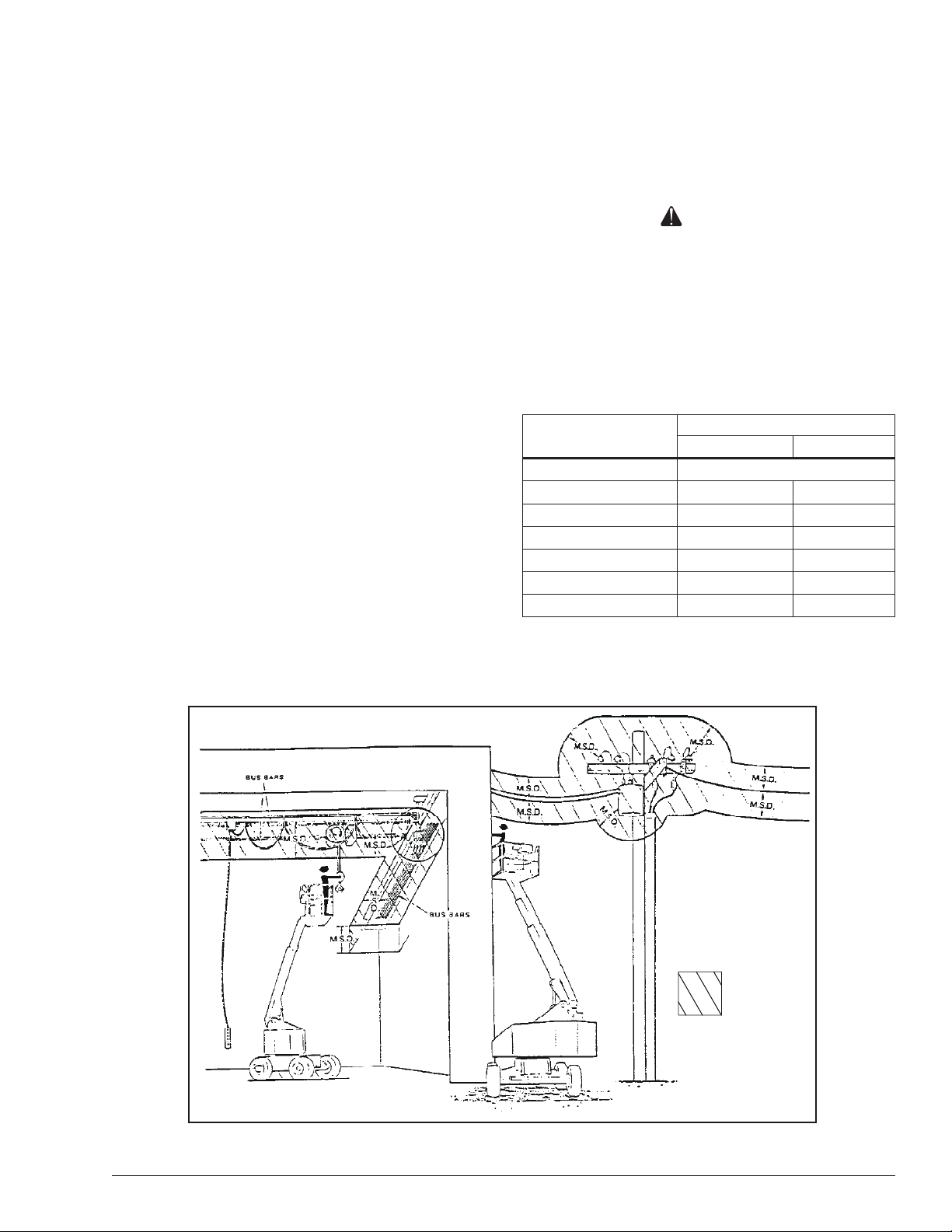

ANSI publications dene minimum distances that must

be observed when working near bus bars and energized

power lines. Table 1 and Figure 3 are reprinted courtesy

of Scaffold Industry Association, ANSI/SIA A92.5.

Voltage Range

(Phase to Phase)

0 to 300V Avoid Contact

Over 300V to 50kV 10 3.05

Over 50kV to 200kV 15 4.60

Over 200kV to 350Kv 20 6.10

Over 350kV to 500kV 25 7.62

Over 500kV to 750kV 35 10.67

Over 750kV to 1000kV 45 13.72

Minimum Safe Approach Distance

Feet Meters

Table 1 – Minimum Safe Approach Distance

Figure 3 – Minimum Safe Approach Distance

TB66J – 0083740 11

Page 16

Chapter 3 – Safety

Prestart Inspection

Perform a prestart inspection before each shift as described in Chapter 7. Do not use the aerial platform on

the job unless you are trained and authorized to do so.

Work Place Inspection and Practices

Do not use the aerial platform as a ground connection

when welding.

The welding ground clamp must be attached to the

same structure that is being welded.

Electrical current ow can be very intense, causing

serious internal damage to some components.

Inspect the area before and during aerial platform use.

The following are some potential hazards that may be

in the work place.

• Debris

• Slopes

• Drop-offs or holes

• Bumps and oor obstructions

• Overhead obstructions

• Unauthorized persons

• High voltage conductors

• Wind and weather conditions

• Inadequate surface and support to withstand load

forces applied by the aerial platform in all operating

congurations

Before using the aerial platform in any hazardous

(classied) location, make certain it is approved and

of the type required by ANSI/NFPA 505 for use in that

particular location.

booms, or platform. Allow sufcient room and time

to stop movement to avoid contact with structures

or other hazards.

Always look in the direction of movement.

Drive with care and at speeds compatible with the

work place conditions.

Use caution when driving over rough ground, on

slopes and when turning.

Do not engage in any form of horseplay or permit

riders any place other than in the platform.

Secure all accessories, containers, tools, and other

materials in the platform to prevent them from accidentally falling or being kicked off the platform. Remove all

objects that do not belong in or on the aerial platform.

Never steady the platform by positioning it against another platform.

Warning

The potential for an accident increases when operating an aerial platform that is damaged or malfunctioning. Death or serious injury could result from

such accidents. Do not operate the aerial platform

if it is damaged or malfunctioning.

Do not operate the aerial platform if it is damaged or not

functioning properly. Qualied maintenance personnel

must correct the problem before putting the aerial platform back into service.

Know and understand the job site trafc-ow patterns

and obey the agmen, road signs and signals.

While operating the aerial platform, a good safety

practice is to have qualied personnel in the immediate

work area to:

• Help in case of an emergency

• Operate emergency controls as required

• Watch for loss of control by platform operator

• Warn the operator of any obstructions or hazards

that may not be obvious to them

• Watch for soft terrain, sloping surfaces, drop-offs,

etc. where stability could be jeopardized

• Watch for bystanders and never allow anyone to be

under, or to reach through the booms while operating the aerial platform

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure there is sufcient clearance around the machine before moving the chassis,

Operation

Use three points of support when entering or exiting

the platform. For example, use two hands and one foot

when climbing into the platform.

Never cover the platform oor grating or otherwise obstruct your view below. Make sure the area below the

platform is free of personnel before lowering.

Keep both feet positioned rmly on the platform oor.

Operate the controls slowly and deliberately to avoid

jerky and erratic operation.

Always stop the controls in neutral before going in

the opposite direction.

Do not dismount while the aerial platform is in motion

or jump off the platform.

Properly stow the aerial platform and secure it against

unauthorized operation at the end of each work day,

before transporting, or if it is left unattended.

12 TB66J – 0083740

Page 17

Chapter 3 – Safety

Tip-Over and Falling Hazards

Operate the aerial platform only on a rm, at, level

surface capable of withstanding all load forces imposed

by the aerial platform in all operating conditions. Refer to

the General Specications chart for the maximum wheel

load and ground pressure. Raise the booms only when

the aerial platform is on level ground.

Danger

The aerial platform can tip over if it becomes unstable. Death or serious injury will result from a tip-over

accident. Do not drive or position the aerial platform

for elevated use near any drop-off, hole, slope, soft

or uneven ground, or other tip-over hazard.

All platform occupants must wear a fall restraint device

connected to a lanyard anchor point.

It is best not to transfer from the platform to another

structure or from the structure to the platform, unless

that is the safest way to do the job. Judge each situation

separately taking the work environment into account. If

it is necessary to transfer from the platform to another

structure the following guidelines apply:

1. Where possible, place the platform over a roof or

walking structure to do the transfer.

2. Transfer your anchorage from one structure to the

other before stepping across.

3. Remember that you might be transferring to a structure where personal fall arrest is required.

4. Use the platform entrance, do not climb over or

through the guardrails.

Do not operate the aerial platform in windy or gusty

conditions. Do not add anything to the aerial platform

that will increase the wind loading such as billboards,

banners, ags, etc.

Never operate the aerial platform without all parts of the

guardrail system in place and the gate closed. Make

sure that all protective guards, cowlings and doors are

securely fastened.

Do not climb on the guardrails or use ladders, planks or

other devices to extend or increase the work position

from the platform.

Take care to prevent rope, electrical cords, and hoses,

etc., from becoming caught in or on the aerial platform.

If the platform or booms becomes caught on an ad-

jacent structure or other obstacle and is prevented

from normal motion, reverse the control to free the

platform.

If control reversal does not free the platform, evacu-

ate the platform before attempting to free it.

Electrical System

Charge the batteries in a well-ventilated area free of

ame, sparks or other hazards that might cause re or

explosion.

Do not operate any of the aerial platform functions while

the battery charger is plugged in.

Warning

Batteries give off hydrogen and oxygen that can

combine explosively. Death or serious injury could

result from a chemical explosion. Do not smoke or

permit open ames or sparks when checking the

batteries.

Battery acid can damage the skin and eyes. Serious

infection or reaction can result if medical treatment

is not given immediately. Wear face and eye protection when working near the batteries.

Batteries contain sulfuric acid that can damage your

eyes or skin on contact.

Wear a face shield, rubber gloves, and protective

clothing when working around batteries.

If acid contacts your eyes, ush immediately with

clear water and get medical attention.

If acid contacts your skin, wash off immediately with

clear water.

Do not exceed the platform capacity as indicated on

the platform rating placard on the platform. Do not carry

loads that extend beyond the platform guardrails without

prior written consent from Snorkel.

Do not operate the aerial platform from trucks, trail-

ers, railway cars, oating vessels, scaffolds or similar

equipment unless the application is approved in writing

by Snorkel.

Do not use the aerial platform as a crane, hoist, jack or

for any purpose other than to position personnel, tools

and materials.

TB66J – 0083740 13

Hydraulic System

The hydraulic system contains hoses with hydraulic uid

under pressure.

Danger

Hydraulic uid escaping under pressure can have

enough force to inject uid into the esh. Serious

infection or reaction will result if medical treatment

is not given immediately. In case of injury by escaping hydraulic uid, seek medical attention at once.

Page 18

Chapter 3 – Safety

Do not place your hand or any part of your body in front

of escaping hydraulic uid. Use a piece of cardboard or

wood to search for hydraulic leaks.

Engine and Fuel Handling Precautions

Refer to the engine manufacturer’s Operator’s Manual

for complete information on safe engine operation,

maintenance and specications.

Danger

Engine exhaust contains carbon monoxide, a poisonous gas that is invisible and odorless. Breathing

engine exhaust fumes will cause death or serious

illness. Do not run the engine in an enclosed area

or indoors without adequate ventilation.

Operate dual fuel machines on LPG fuel when indoors

to reduce exhaust fumes and carbon monoxide.

Be careful not to run the diesel fuel tank empty. Bleed

the fuel system if air enters the lines between the tank

and the injection pump.

Allow the engine to return to idle before shutting the

engine off.

Do not smoke or permit open ames while fueling or

near fueling operations.

Never remove the fuel cap or ll the fuel tank while the

engine is running or hot. Never allow fuel to spill on hot

machine components.

Maintain control of the fuel ller nozzle when lling the

tank. Spilled fuel is a potential re hazard.

Do not overll the fuel tank. Allow room for expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap is lost,

replace it with an approved cap from Snorkel. Use of a

non-approved cap without proper venting may result in

pressurization of the tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for the

operating season.

Caution

Engine coolant escaping under pressure may cause

serious burns. Shut the engine off and let it cool

before removing the radiator cap.

Let the engine and radiator cool before adding coolant.

Placards and Decals

The aerial platform is equipped with placards and decals that provide instruction for operation and accident

prevention. Do not operate the aerial platform if any

placards or decals are missing or not legible.

14 TB66J – 0083740

Page 19

Chapter 4 – Safety Devices

This aerial work platform is manufactured with safety

devices, placards, and decals to reduce the likelihood

of an accident.

For the safety of all personnel, do not disable, modify,

or ignore any safety device.

On older machines the emergency stop is a two-

position toggle switch with a red safety guard.

Push the guard down over the toggle switch to dis-

connect power to all control circuits. Lift the guard

and push the switch up to restore power.

Safety devices are included in the daily prestart

inspection.

Warning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury could result from such accidents. Do not alter,

disable, or override any safety device.

If any safety devices are defective, remove the aerial

platform from service until qualied maintenance personnel can make repairs.

Emergency Stop Controls

There is an emergency stop control at the lower and

upper controls.

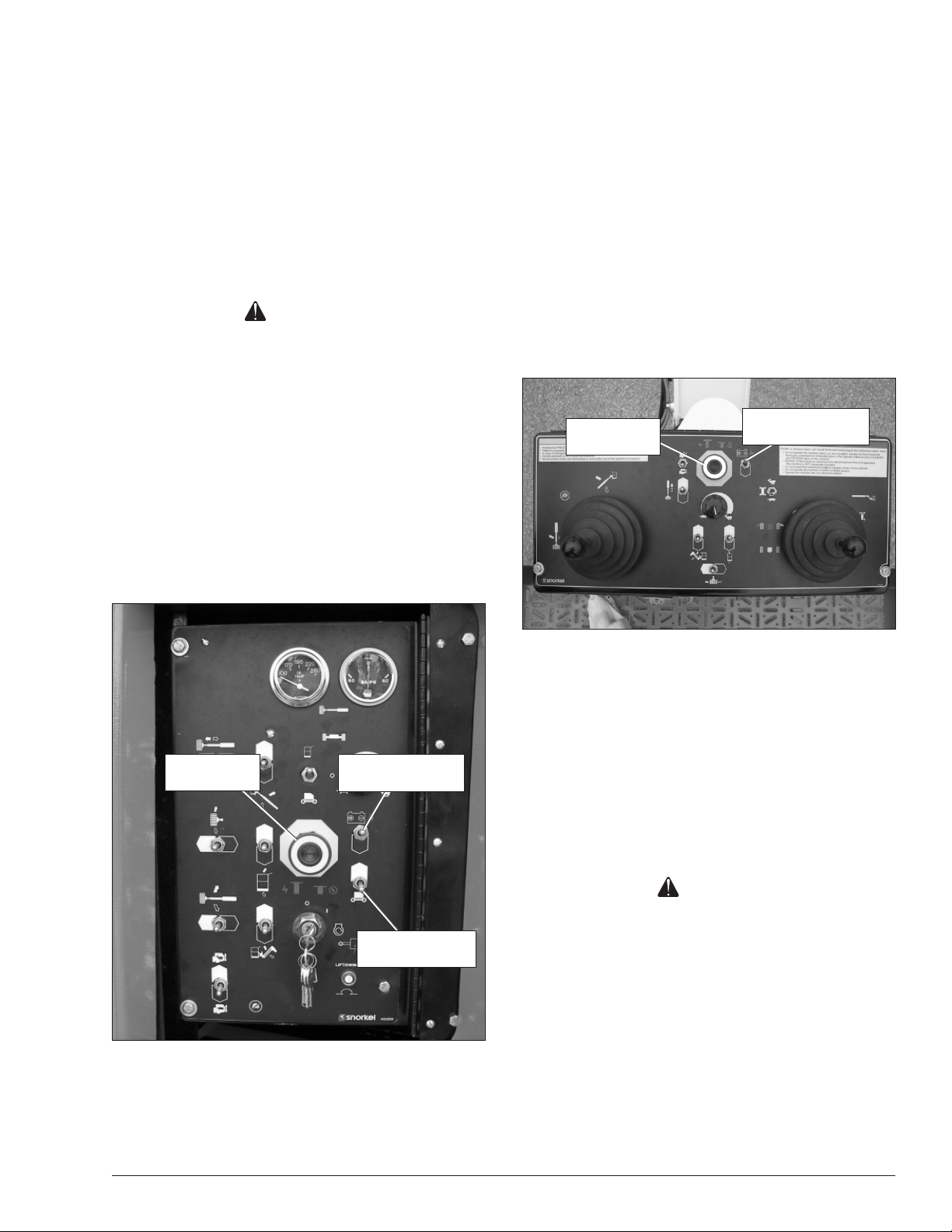

At the lower controls, the emergency stop button is a

two-position push button (refer to Figure 4.1).

Note

The lower controls override the upper controls. If the upper control emergency stop button is engaged, the lower

controls can still be used to operate the aerial platform.

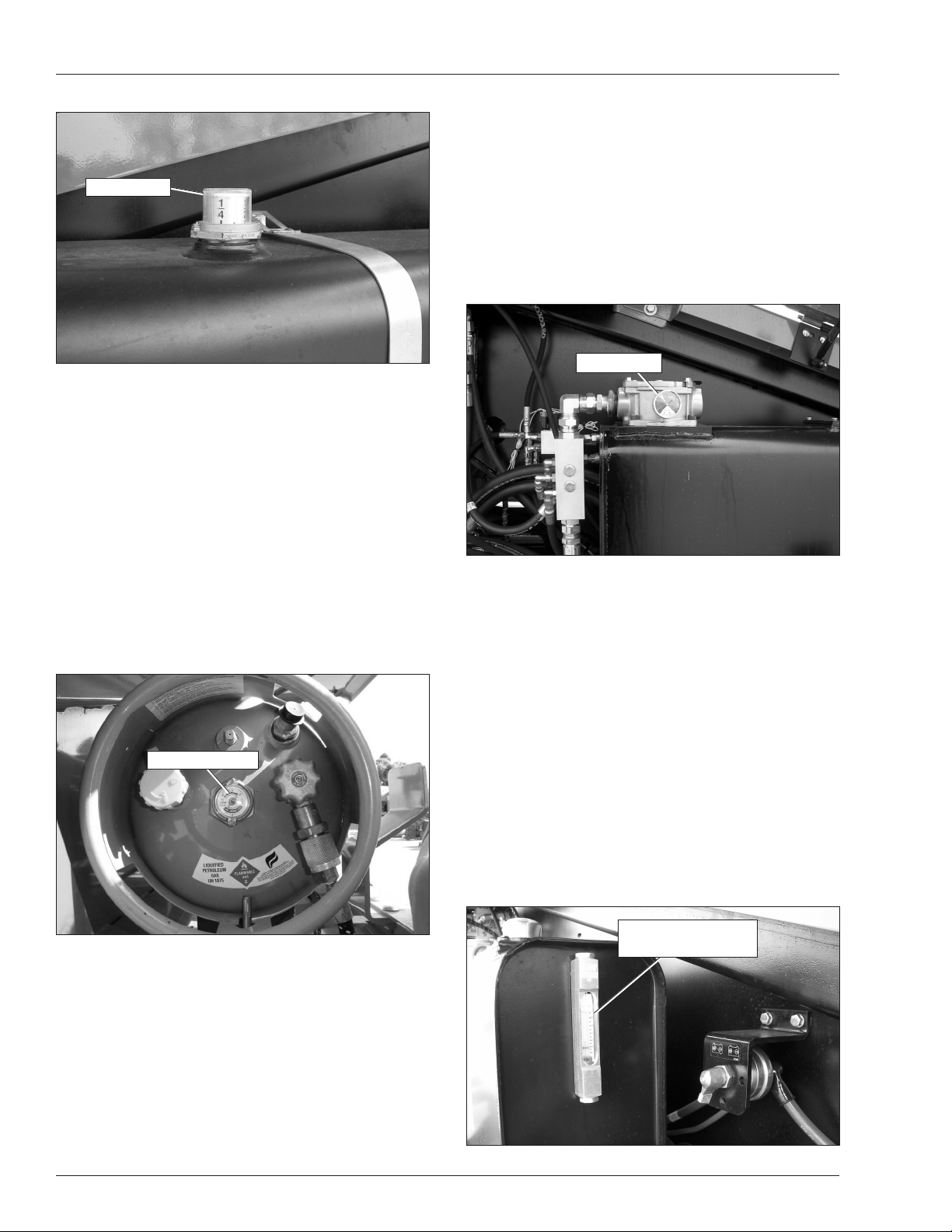

At the upper controls, the emergency stop is a two-posi-

tion push button (refer to Figure 4.2).

Emergency

Stop Button

Engine/Emergency

Power Switch

Figure 4.2 – Upper Controls

Push the emergency stop button inward to discon-

nect power to the upper control circuits.

Emergency

Stop Button

Engine/Emergency

Power Switch

Ground Operation

Switch

Figure 4.1 – Lower Controls

Push the emergency stop button inward to discon-

nect power to all control circuits.

Pul l the bu tto n ou twa rd to r estore po wer.

Pull the button outward to restore power.

Emergency Power System

The emergency power system includes a back-up pump,

motor, and battery. Use this system to operate the boom

and turntable functions to lower the platform if the main

power system fails due to engine or pump failure.

Caution

The emergency power system is for emergency

lowering and stowing only. The length of time the

pump can be operated depends on the capacity

of the battery. Do not use this system for normal

operation.

Hold the engine/emergency power switch (refer to

Figure 4.1 and 4.2) downward to activate the emergency power system.

Release the switch to disengage the emergency

power system.

The length of time the pump can be operated de-

pends on the capacity of the battery.

TB66J – 0083740 15

Page 20

Chapter 4 – Safety Devices

Emergency Lowering Knob

The emergency lowering knob may be used to lower

the booms if the engine will not start and the emergency

power system will not work.

The knob is on the base end of the main boom lift

cylinder (refer to Figure 4.3) under the left side of the

turntable.

Emergency

Lowering Knob

Figure 4.3 – Emergency Lowering Knob

Guardrails

The guardrails (refer to Figure 4.5) help protect personnel from falling off the platform.

The guardrail system includes:

A top rail

A mid rail

A gravity gate or optional swinging gate

Optional side entry gravity gate

Toeboards around the sides of the platform.

The gravity gate(s) allow for access to the platform and

close automatically after entering or exiting the platform.

After entering the platform check to make sure the gates

are fully lowered and even with the mid rail.

The optional swinging gate (refer to Figure 4.5) allows

for access to the platform. The gate must be securely

latched except when personnel are entering or leaving

the platform.

Ground Operation Switch

The ground operation switch (refer to Figure 4.1) prevents boom and platform movement if a control switch

on the lower control panel is accidentally moved.

Hold the switch up to operate the machine from the

lower controls.

Platform Foot Switch

Step down on the platform foot switch (refer to Figure

4.4) to activate the upper controls.

Top Rail

Lanyard

Anchors

Platform Foot

Switch

Figure 4.4 – Platform

The foot switch must be engaged and a control must be

moved to operate the boom, drive and/or platform from

the upper controls.

Gravity

Gate

Mid Rail

Toeboard

Figure 4.5 – Platform Swing Gate

Lanyard Anchors

Two lanyard anchors for fall restraint anchorage are

provided below the upper controls at the front of the

platform (refer to Figure 4.4).

Note

The lanyard anchors are not designed for lifting or tying

the machine down.

All personnel in the platform must connect their fall

restraint device to a lanyard anchor before raising

the platform.

Attach only one fall restraint device to each lanyard

anchor.

Do not use the aerial platform for personal fall arrest

anchorage.

16 TB66J – 0083740

Page 21

Ground Fault Circuit Interrupter

The electrical power outlet at the platform (refer to Figure

4.6) contains a ground fault circuit interrupter (GFCI) to

provide protection for personnel.

Electrical

Power Outlet

Figure 4.6 – Electrical Outlet

Tilt Alarm

If the aerial platform chassis is out of level more than

ve degrees when the main boom is raised or extended,

an alarm will sound. The tilt alarm is located under the

upper control panel.

Chapter 4 – Safety Devices

Engine

Temperature

Gauge

Figure 4.7 – Lower Control Panel

Danger

The aerial platform can tip over if it becomes unstable. Death or serious injury will result from a tip-over

accident. Do not drive or position the aerial platform

for elevated use near any drop-off, hole, slope, soft

or uneven ground, or other tip-over hazard.

Completely retract and lower the main boom and then

drive to a level surface when the tilt alarm sounds.

The tilt alarm is for added protection and does not

justify operating on anything other than rm, at, level

surfaces.

Engine Protection Systems

A constant alarm will sound to warn against high engine

temperature or low oil pressure.

The engine will shut-down

if the operating temperature exceeds a preset level

or if the oil pressure is too low for safe operation.

An engine temperature gauge is on the lower control

panel (refer to Figure 4.7).

High Engine Temperature Alarm

If the coolant in a Cummins or GM engine exceeds the

engine operating temperature an alarm will sound and

the engine will shut off.

If the oil in a Deutz engine exceeds 230°F (110°C) an

alarm will sound and the engine will shut off. Any time

there is no alternator current being produced, an alarm

will sound and the engine will shut off. This prevents

high engine temperature if the fan belt breaks.

Do not restart the engine until the condition that caused

the overheating has been corrected.

Low Oil Pressure Alarm

The low oil pressure alarm sounds when the engine oil

pressure is near the lower limit for safe engine operation.

If the alarm sounds, lower the platform to the ground

and then turn the engine off.

If the engine oil pressure falls below a safe operating

value the engine will shut off.

The engine can be restarted with low oil pressure,

but it will only run for a few seconds before it shuts

off again.

Do not restart the engine until the condition that

caused the low oil pressure has been corrected.

TB66J – 0083740 17

Page 22

Chapter 4 – Safety Devices

Horn

An optional horn may be used to warn personnel on

the ground. The horn button is on the right side of the

upper control box.

The horn is operational when the emergency stop button and the start switches are both on, at the lower and

the upper controls.

All Motion Alarm

An optional all motion alarm may be provided on the

machine. The alarm sounds, in short beeps, anytime the

machine functions are being operated. The alarm is used

to warn personnel in the work area to stand clear.

Flashing Light

An optional amber ashing light may be located on

the top of the boom near the base end (refer to Figure

4.8). The ashing light warns personnel that the aerial

platform is in the area.

Flashing Light

Driving Lights

The optional headlights and blinking tail lights may be

used to help improve visibility while driving the aerial

platform and help others see it too.

The headlights are located on the top of the front

cowling.

The tail lights are mounted on the sides of the rear

cowling.

Do not use the driving lights to drive on public

roadways.

Platform Work Lights

The optional platform work lights may be used to help

improve visibility while working aloft in dimly lit areas.

The platform work lights are located on the top rail of

the platform, one on each side of the upper control

panel (refer to Figure 4.9).

Do not use the platform work lights to drive on public

roadways.

Figure 4.8 – Flashing Light

The light ashes at about one ash per second when

the engine is running.

Light Switch

Figure 4.9 – Platform Work Lights

Bump Guard System

The optional bump guard system is a spring mounted

padded railing below the platform. There are two infrared

lights mounted along the bottom of the platform next

to two infrared sensitive switches. The lights shine on

reectors on the bump guard system and are reected

back to the switches.

If the bump guard comes into contact with a stationary

object, the bump guard moves and one or both of the

light beams is broken, immediately stopping all platform

movement.

18 TB66J – 0083740

Page 23

Chapter 5 – Gauges and Displays

The aerial platform is equipped with several gauges to

monitor the condition of the machine before and during

operation.

Hour Meter

The hour meter is located on the wiring box on the left

side of the lower controls (refer to Figure 5.1). It measures the accumulated engine operating time.

Hour

Meter

Figure 5.1 – Wiring Box

Engine Temperature Gauge

The temperature gauge is located on the lower control

panel (refer to Figure 5.2).

Ammeter – Cummins, Deutz and Ford Engines

The ammeter is located on the lower control panel (refer

to Figure 5.2). The ammeter displays the level of current

ow from the alternator to the batteries.

After the engine has been running for a few minutes

under normal operating conditions, the ammeter

gauge indicator should read “0.”

Machines with Kubota engines do not have an engine

ammeter gauge.

Voltmeter – General Motors Engines

The voltmeter is located on the engine gauge panel

above the lower controls. The voltmeter displays battery voltage.

After the engine has been running for a few minutes

under normal operating condition, the voltmeter

should indicate between 12.5 and 14 volts.

Engine Air Filter Gauge

The air lter gauge (refer to Figure 5.3) is located on the

engine gauge panel above the lower controls.

Air Filter

Gauge

Machines with Kubota engines do not have an engine

temperature gauge.

Engine

Temperature

Gauge

Ammeter – Cummins, Deutz,

and Ford Engines

Voltmeter – General Motors Engines

Figure 5.2 – Lower Controls

The gauge on liquid cooled engines shows the

temperature of the water and antifreeze mixture in

the engine block.

The gauge on air cooled engines shows the temper-

ature of the engine oil as the oil leaves the lter.

Reset Button

Figure 5.3 – Air Filter Gauge

The air lter gauge measures the air pressure between

the intake manifold and the air lter.

The yellow indicator disk inside the sight glass stays

at its highest level when the engine is turned off.

When the yellow indicator disk reaches the red area,

it’s time to change the lter element.

After changing the lter, press the reset button to reset

the indicator disk to the bottom of the sight glass.

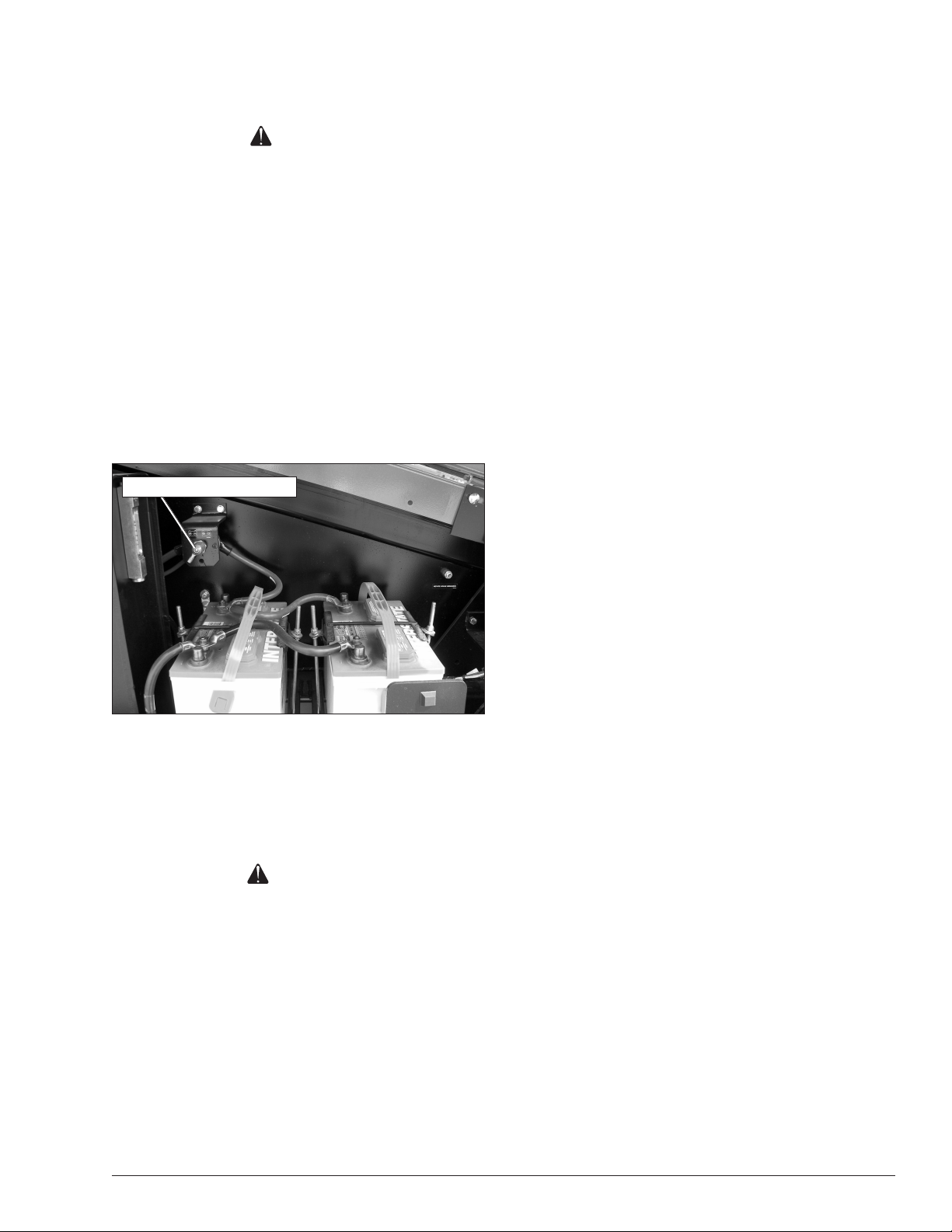

Fuel Gauge

The fuel gauge is located on top of the diesel or gasoline

tank (refer to Figure 5.4). Access the gauge by opening

the door on the right side of the chassis.

TB66J – 0083740 19

Page 24

Chapter 5 – Gauges and Displays

Fuel Gauge

Hydraulic Fluid Filter Gauge

The uid lter gauge (refer to Figure 5.6) is located on the

return line lter on the top of the reservoir. The reservoir

is behind the door on the left side of the turntable.

During high pump ow situations, the gauge indi-

cates the condition of the lter.

When the needle on the gauge is in the red zone,

its time to change the lter.

Figure 5.4 – Fuel Tank

Read the fuel gauge at the line in the clear plastic

window.

The gauge indicates the fuel tank level in fractions

of a full tank.

Note

Do not run a diesel fuel tank empty. Air in the fuel line

makes the engine hard to start.

LPG tanks have a fuel gauge that has two scales. One

scale measures the fuel level when the tank is mounted

vertical and the other is used when the tank is mounted

horizontal (refer to Figure 5.5).

Horizontal Scale

Filter Gauge

Figure 5.6 – Hydraulic Fluid Filter Gauge

Fluid Level and Temperature Gauge

A sight gauge on the right side of the hydraulic reservoir

displays the level and temperature of the hydraulic uid

(refer to Figure 5.7). The reservoir is behind the door on

the left side of the machine.

Only read the uid level when the aerial platform is in the

stowed position, booms completely down and retracted.

Otherwise, the cylinders act as large reservoirs for hy-

draulic uid making the level appear too low.

The fluid should be between the minimum and

maximum lines.

If the temperature rises above 200°F (93°C) stop

machine operation and let the uid cool before resuming operation.

Fluid Level and

Figure 5.5 – LPG Tank

The LPG tank is mounted horizontally behind the

Temperature Gauge

rear cowling door on the right side of the machine.

Read the horizontal scale to determine the fuel level.

Engine Oil

The engine oil level is measured with a dipstick. The

dipstick is the only way to accurately determine the

engine oil level. The engine oil level should always be

between the add and full marks on the dipstick.

20 TB66J – 0083740

Figure 5.7 – Hydraulic Fluid Filter Gauge

Page 25

Chapter 6 – Controls

Danger

Pinch points may exist between moving components. Death or serious injury can result from being

trapped between components, buildings, structures,

or other obstacles. Make sure all personnel stand

clear while operating the aerial platform.

Controls to position the platform are located on the

lower control panel on the turntable and on the upper

control panel in the platform.

Controls to drive the aerial platform are located on

the upper control panel only.

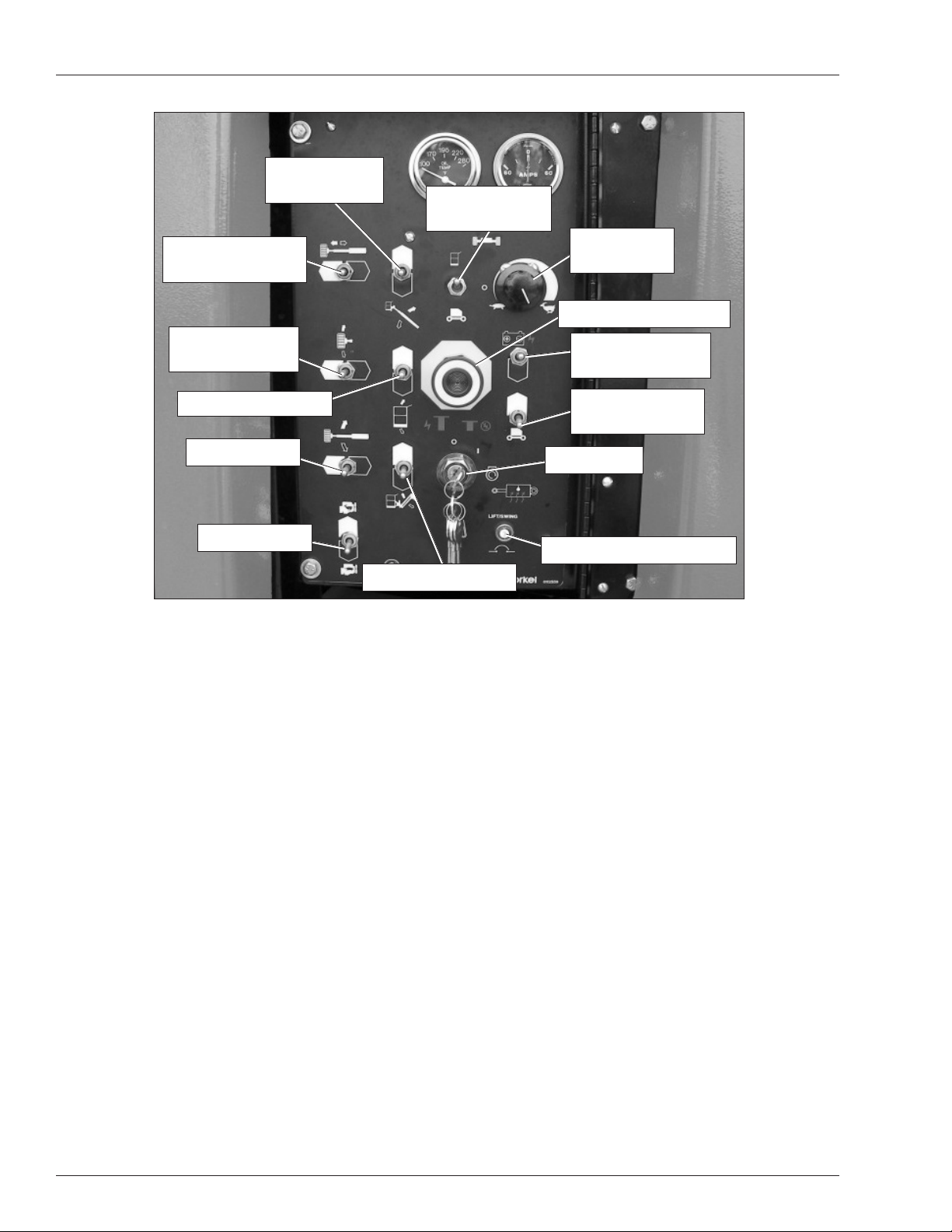

Battery Disconnect Switch

The battery disconnect is located behind the door on

the left side of the turntable above the batteries (refer

to Figure 6.1).

Battery Disconnect Switch

The following are located on the lower control panel.

• Emergency stop button

• Control selector switch

• Start switch

• Ground operation switch

• Rotation switch

• Boom elevation switch

• Boom extend/retract switch

• Jib articulation switch

• Boom speed knob

• Platform level switch

• Platform rotation switch

• Engine/emergency power switch

• Throttle switch

• Fuel switch (dual fuel machines)

Emergency Stop Button

The emergency stop button

two-position, red push button.

Push the button inward to disconnect power to all

(refer to Figure 6.2)

is a

control circuits.

Pull the button outward to restore power.

On older machines, the emergency stop is a two-position

toggle switch with a red safety guard.

Figure 6.1 – Battery Disconnect Switch

The battery disconnect removes electrical power from all

electrically controlled functions when in the off position.

Place the switch in the on position to electrically

connect the battery to the electrical system.

Caution

Only authorized personnel should operate the aerial

platform. Unqualied personnel may cause injury

to coworkers or property damage. Lock the battery

disconnect switch in the off position before leaving

the aerial platform unattended.

Turn the battery disconnect switch off to prevent

unauthorized use of the aerial platform.

Lower Controls

The lower controls (refer to Figure 6.2) are located on the

right side of the turntable. Boom and platform functions

can be operated from the lower controls.

Push the guard down over the toggle switch to dis-

connect power to all control circuits

Lift the guard and push the toggle switch up to re-

store power.

Control Selector Switch

Use the control selector switch (refer to Figure 6.2)

to select between the lower control and upper control

operation.

Push the switch upward to operate the aerial platform

from the upper controls.

Push the switch downward to operate the aerial

platform from the lower controls.

Start Switch

The start switch (refer to Figure 6.2) works like an automobile ignition switch.

Hold the switch in the start position until the engine

starts, then release it to on.

If the engine dies, the switch must be turned to off

before it can be turned back to start.

An alarm sounds, when the switch is turned on, to warn

others that the machine engine is being started.

TB66J – 0083740 21

Page 26

Chapter 6 – Controls

Boom Extend/Retract

Switch

Boom Elevation

Switch

Control Selector

Switch

Boom Speed

Knob

Emergency Stop Button

Platform Rotation

Switch

Platform Level Switch

Rotation Switch

Throttle Switch

Jib Articulation Switch

Figure 6.2 – Lower Controls

Note

On some machines it may be necessary to pause about

three seconds in the on position before going to start so

the starter can engage.

If the platform is to stay in a particular position for a long

time, turn the start switch to off to shut off the engine

and save fuel.

Engine/Emergency

Power Switch

Ground Operation

Switch

Start Switch

Circuit Breaker Reset Button

Boom Elevation Switch

The boom elevation switch (refer to Figure 6.2) is used

to raise or lower the main boom. The switch is spring

returned to the center off position.

Hold the switch up to raise the main boom.

Hold the switch down to lower the main boom.

Ground Operation Switch

The ground operation switch (refer to Figure 6.2) is used

to operate the machine from the lower controls. The

switch is spring returned to the off position.

Hold the ground operation switch upward continually

Boom Extend/Retract Switch

The boom extend/retract switch (refer to Figure 6.2) is

used to extend or retract the booms. The switch is spring

returned to the center off position.

Hold the switch to the left to extend the tip boom.

to operate the machine from the lower controls.

Hold the switch to the right to retract the tip boom.

The engine speed increases when the switch is

held upward.

Jib Articulation Switch

The jib switch (refer to Figure 6.2) is used to raise or

Rotation Switch

The rotation switch (refer to Figure 6.2) is used to ro-

lower the jib. The switch is spring returned to the center

off position.

tate the turntable in a clockwise or counterclockwise

direction. The switch is spring returned to the center

Hold the switch up to raise the jib.

off position.

Hold the switch down to lower the jib.

Hold the switch to the right to rotate the turntable

counterclockwise.

Hold the switch to the left to rotate the turntable

clockwise.

22 TB66J – 0083740

Page 27

Chapter 6 – Controls

Boom Speed Knob

The boom speed knob (refer to Figure 6.2) is used to

control the speed of the following boom functions:

Main boom raise/lower

Jib boom raise/lower

Boom extend/retract

Platform level up/down

Turntable rotation clockwise/counterclockwise

Set the knob to slow when beginning a movement. The

speed may be increased by slowly rotating the knob

toward fast. For smooth operation, rotate the knob to

slow when ending movement.

Platform Level Switch

The platform level switch (refer to Figure 6.2) is used to

level the platform oor with respect to the ground. The

switch is spring returned to the center off position.

Hold the switch upward to tilt the platform oor up-

ward or away from the ground.

Hold the switch downward to tilt the platform oor

downward or toward the ground.

Platform Rotation Switch

The platform rotation switch (refer to Figure 6.2) is used

to rotate the platform relative to the end of the tip boom.

The switch is spring returned to the center off position.

Hold the switch to the right to rotate the platform

counterclockwise.

Hold the switch to the left to rotate the platform

clockwise.

Engine/Emergency Power Switch

The engine/emergency power switch (refer to Figure 6.2)

is used to operate turntable, boom, and platform functions using the emergency power system. The switch is

spring returned to the engine position for aerial platform

engine operation.

Caution

The emergency power system is for emergency

lowering and stowing only. The length of time the

pump can be operated depends on the capacity

of the battery. Do not use this system for normal

operation.

Hold the engine/emergency power switch downward

to activate the emergency power system.

If the engine is running, it will stop when the switch is

placed in the emergency power position.

Throttle Switch

The throttle switch (refer to Figure 6.2) is used to set the

engine throttle speed to either low or high idle.

Place the switch in the low position before starting

the engine.

Place the switch in the high position for machine

operation and for engine and/or hydraulic system

warm-up.

The engine has a two speed throttle operation from the

lower controls.

Place the throttle switch is in the low position to idle

the engine.

Place the switch in the high position to increase the

engine speed to mid-range.

Placing the ground controls switch in the on position

also increase the engine speed to mid-range

Fuel Switch

Engines on machines with the dual fuel option can be

operated using gasoline or liqueed petroleum gas

(LPG). Dual fuel machines have a gasoline tank and

an LPG tank behind the door on the right side of the

turntable.

The fuel switch may be used to select between gasoline

and LPG operation.

Place the switch downward to operate the engine

using gasoline.

Place the switch upward to operate the engine us-

ing LPG.

Hydraulic System Warm-up Switch

The optional hydraulic uid warm-up switch is used to

warm the hydraulic uid when the ambient temperature

is below 32°F (0°C) and boom movement is sluggish

because of cold uid.

Caution

Not all hydraulic uid is suitable to use in the hydraulic system. Some have poor lubricating char-

acteristics and may increase component wear. Only

use hydraulic uid as recommended.

Release the switch to disengage the emergency

power system.

Note

The emergency power system is for lowering the platform during an emergency and is not intended for normal

machine operation.

TB66J – 0083740 23

Use cold weather hydraulic oil as recommended in the

machine General Specications in temperatures of 10°F

(-12°C) or below.

The toggle switches for the warm-up system are on

the lower control panel and on the front of the upper

control panel.

Page 28

Chapter 6 – Controls

Note

Machine functions are not operational while using the

hydraulic warm-up system.

To warm-up the hydraulic uid from the lower controls:

1. Start the engine from the lower controls.

2. Place the hydraulic uid warm-up switch in the on

position.

The engine throttle speed will increase to warm

the hydraulic uid.

The engine throttle speed will decrease and return

to idle once the hydraulic uid reaches a preset

temperature.

If the warm-up switch is left on the engine speed

will continue to increase and decrease to keep the

hydraulic uid at a preset temperature.

3.

When the engine throttle speed returns to idle, place

the hydraulic uid warm-up switch in the off position.

Circuit Breaker Reset Buttons

The wiring box has a circuit breaker for the main and run

circuits. There is a reset button for each circuit breaker

on the front of the wiring box (refer to Figure 6.3).

Circuit Breaker Reset Buttons

Start Switch

Figure 6.4 – Upper Control Panel Front

The electrical power outlet at the platform has a 15 amp

circuit breaker. The reset button is on the right side of

the electrical box (refer to Figure 6.5).

Circuit Breaker Reset Button

Circuit Breaker Reset Buttons

Figure 6.3 – Wiring Box

The upper control panel has a circuit breaker for the

swing (turntable rotation), lift, drive and main control

circuits. The circuit breakers are on the front of the up-

per control panel (refer to Figure 6.4).

Figure 6.5 – Electrical Power Outlet

The circuit breakers protect the electrical wiring and

components from electrical overload in case of a short

circuit or other fault.

Caution

A tripped circuit breaker indicates a malfunction in

the electrical system. Component damage can result

if the cause of the malfunction is not corrected. Do

not operate the aerial platform if the circuit breaker

trips repeatedly.

Push the button to reset the circuit breaker.

Upper Controls

The upper controls (refer to Figure 6.6) are located on the

control panel at the platform. Boom, platform, and drive

functions can be operated from the upper controls.

24 TB66J – 0083740

Page 29

Chapter 6 – Controls

The following controls are located on the upper control

panel.

• Start switch

• Emergency stop button

• Boom joystick

• Boom extension switch

• Jib articulation switch

• Boom speed knob

• Drive joystick

• Drive range switch

• Platform level switch

• Platform rotate switch

• Engine/emergency power switch

• Throttle switch

• Hydraulic system warm-up (option)

Start Switch

The engine can be started from the platform using the

anti-restart master switch on the front of the upper con-

trol panel (refer to Figure 6.6). This switch is similar to

an automobile ignition switch.

Turn the switch to start until the engine starts, then

release it to on.

If the engine dies, the switch must be turned to off

before it can be turned back to start.

An alarm sounds when the switch is turned on to warn

others that the machine engine is being started.

Note

On some machines it may be necessary to pause about

three seconds in the on position before going to start so

the starter can engage.

If the platform is to stay in a particular position for a

long time, turn the switch to off to shut off the engine

and save fuel

Emergency Stop Button

The emergency stop is a two-position, red push button on

the top of the upper control panel (refer to Figure 6.6).

Push the button inward to disconnect power to all

control circuits at the upper controls.

Pull the button outward to restore power.

Note

The lower controls override the upper controls. If the upper control emergency stop button is engaged the lower

controls can still be used to operate the aerial platform.

Push the emergency stop button inward when the

upper controls are not in use to protect against unintentional operation.

Drive Joystick

The drive joystick (refer to Figure 6.6) is used to control

forward and reverse motion of the aerial platform. It is

also used to steer the machine. The steering and drive

functions may be operated simultaneously.

Boom Joystick

Emergency Stop

Throttle

Switch

Boom Extension Switch

Jib Articulation Switch

Start Switch

Figure 6.6 – Upper Controls

Button

Engine/Emergency

Power Switch

Drive Range

Switch

Drive Joystick

Boom Speed Knob

Platform Level

Switch

Platform Rotation

Switch

TB66J – 0083740 25

Page 30

Chapter 6 – Controls

Note

The distance the joystick is moved is proportional to the

speed of the function.

To move the aerial platform forward, hold the joystick