Page 1

Operator’s

Manual

P/N 0172094

February,2001

Page 2

DANGER

The aerial platform is not electrically insulated. Death or serious injury can result

from contact with,or inadequate clearance from,an energized conductor.

Do not go closer than the minimum safe approach distance as defined by the Mini

mum Safe Approach Distance section in Chapter 3–Safety.

Regard all conductors as energized.

Allow for electrical wire sag and aerial platform sway.

If the platform, booms, or any part of the aerial platform contacts a high-voltage electrical

conductor, the entire machine can become electrically charged.

Ifthathappens,remain onthe machineand donot contactanyotherstructure orobject.This

includestheground, adjacentbuildings,poles,andany otherobjectsthat are notpartofthe

aerial platform.

Such contact could make your body a conductor to the other object, creating an electrical

shock hazard resulting in death or serious injury.

If an aerial platform is in contact with an energized conductor the platform operator must

warn groundpersonnelinthevicinityto stay away.Theirbodies can conduct electricity creating an electrical shock hazard resulting in death or serious injury.

Do not approach or leave the aerial platform until the electricity has been turned off.

Donot attempttooperatethe lowercontrolswhentheplatform,booms,oranypartof theae

rial platform isincontactwitha high-voltage electrical conductor or ifthereisanimmediate

danger of such contact.

Personnel on or near an aerial platform must be continuously aware of electrical hazards,

recognizingthat deathor seriousinjurycanresultfromcontactwithanenergizedconductor.

-

-

Battery posts, terminals and related accessories contain

lead and lead components, chemicals knownto the State

of California to cause cancer and birthdefects or other

reproductive harm. Wash hands after handling.

TB37 – 0172094

Page 3

Table of Contents

Chapter 1. Introduction

Aerial Platform Features. . . . . . . . . . . . . . . . . . . . . 1-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operator’s Manual . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual of Responsibilities . . . . . . . . . . . . . . . . . . . 1-2

Additional Information. . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2. Specifications

Component Identification . . . . . . . . . . . . . . . . . . . . 2-1

Working Envelope. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General Specifications . . . . . . . . . . . . . . . . . . . . . . 2-3

Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . 2-4

Engine Oil Viscosity. . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3. Safety

Electrocution Hazards . . . . . . . . . . . . . . . . . . . . . . 3-1

Minimum Safe Approach Distance . . . . . . . . . . 3-1

Prestart Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Work Place

Inspection and Practices . . . . . . . . . . . . . . . . . . . . 3-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Tip-Over and Falling Hazards. . . . . . . . . . . . . . . . . 3-2

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Engine and Fuel

Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . 3-3

Placards and Decals. . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4. Safety Devices

Emergency Stop Controls. . . . . . . . . . . . . . . . . . . . 4-1

Emergency Power System . . . . . . . . . . . . . . . . . . . 4-1

Emergency Lowering Knob . . . . . . . . . . . . . . . . . . 4-1

Ground Controls Switch . . . . . . . . . . . . . . . . . . . . . 4-2

Platform Foot Switch. . . . . . . . . . . . . . . . . . . . . . . . 4-2

Guardrails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Lanyard Anchors. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Ground Fault Circuit Interrupter . . . . . . . . . . . . . . . 4-2

Tilt Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Engine Protection Systems . . . . . . . . . . . . . . . . . . 4-2

High Engine Temperature Alarm . . . . . . . . . . . . 4-3

Low Oil Pressure Alarm. . . . . . . . . . . . . . . . . . . 4-3

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Drive Motion Alarm. . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Driving Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Platform Work Lights . . . . . . . . . . . . . . . . . . . . . . . 4-3

Chapter 5. Gauges and Displays

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine Temperature Gauge. . . . . . . . . . . . . . . . . . 5-1

Ammeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine Air Filter Gauge . . . . . . . . . . . . . . . . . . . . . 5-1

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Hydraulic Fluid Filter Gauge. . . . . . . . . . . . . . . . . . 5-2

Fluid Level and

Temperature Gauge . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chapter 6. Controls

Battery Disconnect Switch . . . . . . . . . . . . . . . . . . . 6-1

Lower Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Start Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Emergency Stop Switch . . . . . . . . . . . . . . . . . . 6-1

Controls Switch . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Ground Controls Switch. . . . . . . . . . . . . . . . . . . 6-1

Rotation Switch . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Boom Elevation Switch . . . . . . . . . . . . . . . . . . . 6-2

Boom Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Platform Level Switch . . . . . . . . . . . . . . . . . . . . 6-2

Platform Rotator Switch. . . . . . . . . . . . . . . . . . . 6-2

Engine/Emergency Power Switch . . . . . . . . . . . 6-2

Throttle Switch. . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Fuel Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Circuit Breaker Reset Buttons . . . . . . . . . . . . . . . . 6-2

Upper Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Anti-Restart Master Switch . . . . . . . . . . . . . . . . 6-3

Emergency Stop Button. . . . . . . . . . . . . . . . . . . 6-3

Speed Knob. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Swing Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Boom Up/Down Switch . . . . . . . . . . . . . . . . . . . 6-3

Boom Extend/Retract Switch. . . . . . . . . . . . . . . 6-4

Level Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Steer Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Drive Joystick. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Drive Range Switch. . . . . . . . . . . . . . . . . . . . . . 6-4

Engine/Emergency Power Switch . . . . . . . . . . . 6-4

Throttle Switch. . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Platform Rotator Switch. . . . . . . . . . . . . . . . . . . 6-4

Horn Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Platform Foot Switch. . . . . . . . . . . . . . . . . . . . . . . . 6-4

Machine/Generator Switch . . . . . . . . . . . . . . . . . . . 6-5

Dual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Driving and Platform Work Lights. . . . . . . . . . . . . . 6-5

Chapter 7. Prestart Inspection

Operator’s Manual . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Oil Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Fuel Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Charging System . . . . . . . . . . . . . . . . . . . . . . . 7-2

Cold Weather Start Kit—Block Heater . . . . . . . 7-3

TB37 – 0172094

Page 4

Table of Contents

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Emergency Power Battery. . . . . . . . . . . . . . . . . 7-3

Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . . 7-3

Battery Terminals. . . . . . . . . . . . . . . . . . . . . . . . 7-3

Cables and Wiring Harness. . . . . . . . . . . . . . . . 7-3

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Fluid Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Hoses, Tubes, and Fittings . . . . . . . . . . . . . . . . 7-4

Tires and Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Air Filled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Foam Filled . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Lower Control Station. . . . . . . . . . . . . . . . . . . . . . . 7-5

Operating Controls. . . . . . . . . . . . . . . . . . . . . . . 7-5

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Emergency Power . . . . . . . . . . . . . . . . . . . . . . . 7-5

Emergency Lowering . . . . . . . . . . . . . . . . . . . . . . . 7-6

Level Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Sandblast Protection Kit. . . . . . . . . . . . . . . . . . . . . 7-6

Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Weldments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Slide Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Upper Control Station. . . . . . . . . . . . . . . . . . . . . . . 7-7

Guardrail System. . . . . . . . . . . . . . . . . . . . . . . . 7-7

Lanyard Anchors . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Operating Controls. . . . . . . . . . . . . . . . . . . . . . . 7-8

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Emergency Power . . . . . . . . . . . . . . . . . . . . . . . 7-8

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Electrical Power Outlet . . . . . . . . . . . . . . . . . . . 7-8

Drive Motion Alarm . . . . . . . . . . . . . . . . . . . . . . 7-9

Driving and Work Lights . . . . . . . . . . . . . . . . . . 7-9

Platform Control Cover . . . . . . . . . . . . . . . . . . . 7-9

Tow Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Placards and Decals. . . . . . . . . . . . . . . . . . . . . . . . 7-9

Prestart Inspection Check List . . . . . . . . . . . . . . . 7-13

Chapter 8. Operation

Cold Weather Start-Up. . . . . . . . . . . . . . . . . . . . . . 8-1

Engine Cold Weather Start Kit . . . . . . . . . . . . . 8-1

Ford—Block Heater . . . . . . . . . . . . . . . . . . . 8-1

Deutz—Manifold Preheater . . . . . . . . . . . . . 8-1

Hydraulic System

Cold Weather Warm-Up . . . . . . . . . . . . . . . . . . 8-1

Preparing for Operation . . . . . . . . . . . . . . . . . . . . . 8-2

Lower Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Upper Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Boom Operation. . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Driving and Steering . . . . . . . . . . . . . . . . . . . . . 8-3

Drive Speeds . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Four-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Electrical Power Outlet . . . . . . . . . . . . . . . . . . . . . . 8-4

AC Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Dual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Driving Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Platform Work Lights . . . . . . . . . . . . . . . . . . . . . . . 8-5

Chapter 9. Stowing and Transporting

Stowing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Hoisting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Securing for Transport. . . . . . . . . . . . . . . . . . . . 9-3

Chapter 10. Emergency Operation

Emergency Power System . . . . . . . . . . . . . . . . . . 10-1

Lower Controls. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Upper Controls. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Emergency Lowering . . . . . . . . . . . . . . . . . . . . . . 10-2

Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Chapter 11. Troubleshooting

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . 11-1

Appendix A. Glossary

TB37 – 0172094

Page 5

Chapter 1. Introduction

Aerial Platform Features

The aerial platform is a boom-supported elevating work

platform used to raise personnel, their tools, and mate

rial to the workstation. The booms are raised and low

ered with hydraulic cylinders. Hydraulic motors on the

drivewheels providepowerto movetheaerialplatform.

The standard machine includes the following features.

●

Proportional drive control

●

Pneumatic tires

●

Gasoline liquid cooled engine

●

High engine temperature shut down

●

Low oil pressure shut down

●

Hour meter

●

Ammeter

●

Coolant temperature gauge

●

Hydraulic oil level and temperature gauges

●

Battery operated emergency power system

●

Manual lowering valve

●

Tilt alar m

●

360° continuous turntable rotation

●

Tie-down lugs

●

Lifting lugs

●

AC electrical outlet with GFCI at platform

●

5′ steel 600 lb capacity platform

●

Gravity gate

●

Five year warranty

The aerial platform has been manufacturedtoconform

toallapplicablerequirements of the followingorganiza

tions.

●

Occupational Safety and Health Administration

(OSHA)

●

American National Standards Institute (ANSI)

●

Canadian Standards Association (CSA)

Options

Thefollowingoptionsmaybeprovidedonthe machine.

●

Four-wheel drive

●

Road tread tires

●

Foam filled tires

●

Drive motion alarm

●

Diesel air cooled engine

●

Dual fuel with 12 gallon gasoline tank

●

Dual fuel with 20 gallon gasoline tank

●

Flashing light

●

-

-

Driving lights

●

Platform work lights-flood or halogen

●

Horn

●

Platform control cover

●

Swinging platform gate

●

8′ aluminum 600 lb capacity platform

●

8′ aluminum 600 lb capacity platform with

guardrails

●

8′ steel 500 lb capacity platform

●

5′ aluminum 650 lb platform

●

5′ steel 600 lb platform

●

Sandblast protection kit

●

Cold weather start kit

●

Tow kit

●

AC generator

Operator’s Manual

This manual provides information for safe and proper

operationofthe aerial platform.Because it coversmore

than one model,somefiguresmayonly represent what

isactuallyon themachine.Readand understandtheinformation in this Operator’s Manual before operating

the aerial platform on the job.

Additional copies of this manual may be ordered from

Snorkel. Supply the model and manual part number

from the front cover to assure that the correct manual

will be supplied.

All information in this manual is based on the latest

-

product information at the time of publication. Snorkel

reserves the right to makeproductchangesat any time

without obligation.

Safety Alerts

A safetyalert symbol is used throughout this manual to

indicate danger and caution instructions.Follow these

instructions to reduce the likelihood of personal injury

andpropertydamage.Thetermsdanger andcaution in

dicate varying degrees of personal injury or property

damagethat canresult iftheinstructionis notfollowed.

DANGER

Indicates asituationwhich if not avoided canresult

in death or serious injury.

CAUTION

Indicates asituationwhich if not avoided canresult

in minor injury or property damage.

-

TB37 – 0172094 page 1 - 1

Page 6

Chapter 1. Introduction

Notes

Notes are used to provide special information or helpful

hints to assist in aerial platform operation, but do not indi

cate a hazardous situation.

Operation

The aerial platform has built-in safety featuresand has

beenfactorytested forcompliancewith Snorkel specifi

cations and industr y standards. However, any person

nellifting aerialplatformcanbepotentiallydangerousin

the hands of untrained or careless operators.

DANGER

The potential for an accident increases when the

aerial platform is operated by personnel who are

not trained and authorized. Death or serious injury

can result from such accidents. Read and under

stand the information in this manual and on the

placards and decals on the machine before operat

ing the aerial platform on the job.

Training is essentialandmustbe performed by a quali

fiedperson.Becomeproficientin knowledgeandactual

operation before using the aerial platform on the job.

Youmustbetrainedandauthorizedtoperformanyfunctions of the aer ial platform. Operation of the aerial platform must be within the scope of the machine

specifications.

The operator bears ultimate responsibility for following

all manufacturer’s instructions and warnings, regulationsandsafetyrulesoftheir employerand/orany state

or federal law.

Maintenance

Every person who maintains, inspects,tests,orrepairs

the aerial platform must be qualified to do so.Following

the daily prestart inspection in this Operator’s Manual

will help keep the aerial platform in optimum working

condition. Other maintenance functions must be per

formed by maintenance personnel who are qualified to

work on the aerial platform.

Do not modify this aerial platform without prior written

consent of the Snorkel Engineering Department.Modi

ficationmayvoid thewarranty, adverselyaffectstability,

or affect the operational characteristics of the aerial

platform.

-

-

Manual of Responsibilities

All owners and users of the aerial platform must read,

understand, and comply with all applicable regulations.

Ultimate compliance to OSHA regulations is the re

sponsibility of the user and their employer.

ANSI publications clearly identify the responsibilities of

all personnel who may be involved with the aerial plat

form. A reprint of the “Manual of Responsibilities for

-

Dealers, Owners, Users, Operators, Lessors and Les

sees of ANSI/SIA A92.5-1992 Boom-Supported Ele

-

vating Work Platforms” is available from Snor kel

dealers or from the factory upon request.

Copies are also available from:

Scaffold Industry Association

20335 Ventura Blvd. Suite 310

Woodland Hills, CA 91364-2471 USA

Additional Information

For additional information contact your local dealer or

Snorkel at:

Snorkel Inter national, Inc.

P.O.Box 1160

St. Joseph, MO 64502-1160 USA

816-364-0317

http://www.snorkelusa.com

-

-

-

-

-

-

page 1 - 2 TB37 – 0172094

Page 7

Chapter 2. Specifications

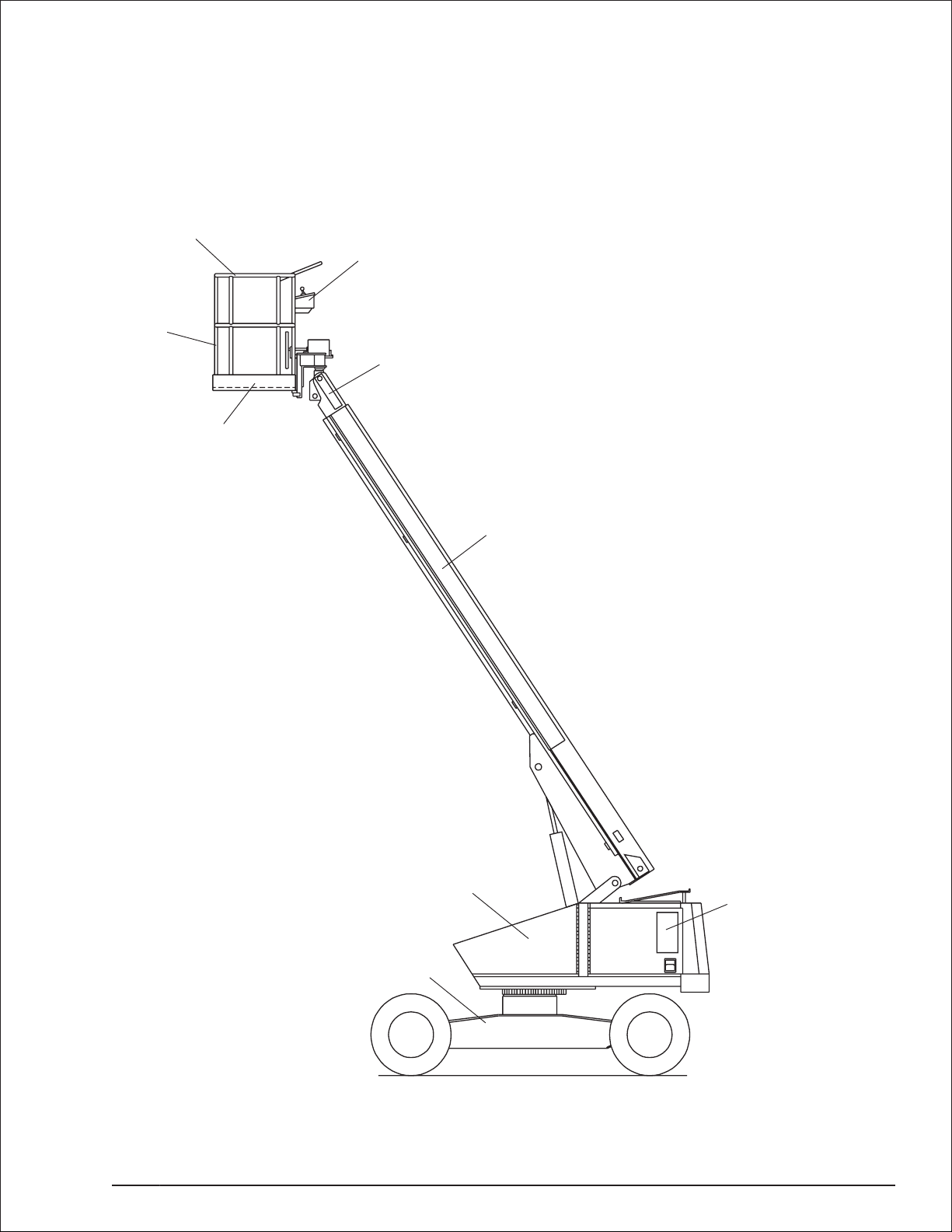

Component Identification

Guardrails

Upper Controls

latform

Toeboards

Tip Boom

Main Boom

Turntable

Chassis

Rear

TB37 – 0172094 page 2 - 1

Front (Steer)

Lower Controls

Page 8

Chapter 2. Specifications

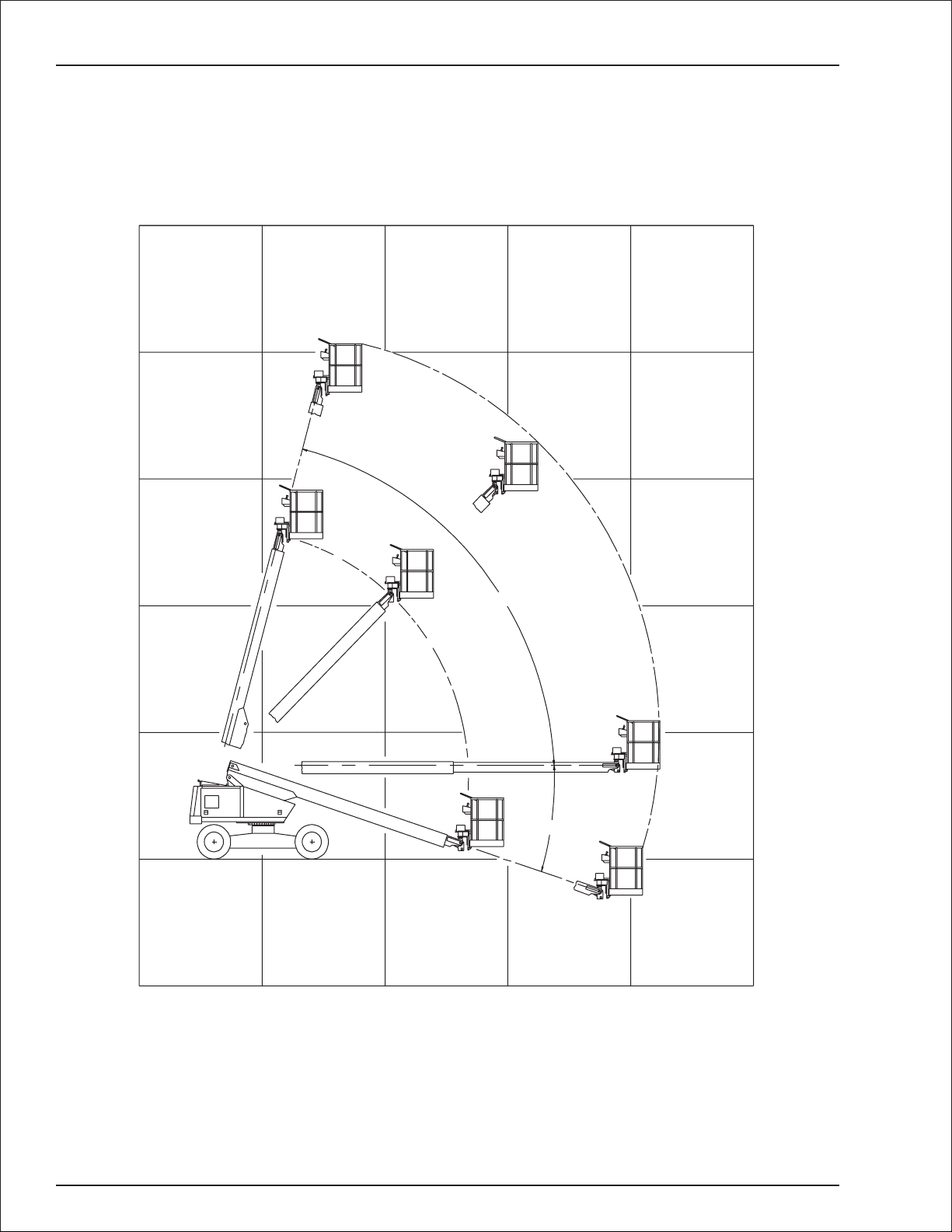

Working Envelope

50

(15.2)

40

(12.2)

30

(9.1)

20

(6.1)

10

(3.0)

0

10

(3.0)

010

(3.0)

75°

20

(6.1)

18°

30

(9.1)

Feet

(Meters)

page 2 - 2 TB37 – 0172094

Page 9

General Specifications

Chapter 2. Specifications

Aerial Platform

Working height 43′ (13.1 m)

Maximum platform height 37′ (11.3 m)

Horizontal reach 32′ (9.8 m)

Main boom

Articulation -18° to +75°

Extension 12′ (3.6 m)

Turntable rotation 360° continuous

Turning radius, inside 5′ 2″ (1.6 m)

Wheelbase 8′ (2.4 m)

Ground clearance 10″ (25 cm)

Maximum wheel load 5,500 lbs (2,495 kg)

Maximum ground pressure 54 psi (3.8 kg/cm²)

Weight, GVW

Approximate 10,500 lbs (4,763 kg)

Stowed width 7′ 11.5″ (2.4 m)

Stowed length 26′ 2″ (8 m)

Stowed height 7′ 6″ (2.3 m)

Platform

Dimensions

Standard 30″ x60″ (76 cm x 152 cm)

Optional 30″ x96″ (76 cm x 244 cm)

Guardrail height 30″ x96″

Rated work load

Standard 600 lb (272 kg)

Optional 500 lb (227 kg)

Optional 650 lb (295 kg)

Rotation 180°

Maximum number of occupants 2 people

Optional AC generator 120 V, 17.4 amp

Function Speed

Turntable rotation 90 to 100 seconds

Main boom

Up 40 to 45 seconds

Down 40 to 45 seconds

Extend 35 to 45 seconds

Retract 30 to 40 seconds

Platform rotation 16 to 20 seconds

Drive

High, booms stowed 3.0 mph (4.8 km/h)

Low, booms elevated 1.0 mph (1.6 km/h)

Drive System

Standard 2-wheel dr ive

Optional 4-wheel dr ive

Gradeability 25%

Tires, 10 ply

Pneumatic 12″ x 16.5″ (30 cm x 42 cm)

Flotation 15″ x 19.5″ (38 cm x 50 cm)

Foam filled Pneumatic or Flotation

Electrical System

Voltage 12 V DC negative chassis ground

Source

Gas engine 1 -12 V 600 CCA battery

Diesel engine 2 - 12 V 600 CCA batteries

Fluid recommended distilled water

Hydraulic System

Maximum pressure 2,500 psi (17,237 kPa)

Reservoir capacity 16.5 US gal (62.4 l)

System capacity 20 US gal (75.7 l)

Maximum operating temperature 200°F (93°C)

Hydraulic fluid recommended

Above 10°F (-13°C) Mobil DTE-13M

(ISO VG32)

Below 10°F (-13°C) Mobil DTE-11M

(ISO VG15)

Engine

Gasoline and/or LPG Ford VSG-413

Diesel Deutz F3L-1011

Fuel Tank Capacity

Gasoline or diesel 20 US gal (75.7 l)

LPG 43.5 lbs (19.7 kg)

Dual fuel gasoline 20 US gal (75.7 l)

12 US gal (45.4 l)

Ambient Air Temperature Operating Range

Fahrenheit 0°F to 110°F

Celsius -18°C to 43°C

Maximum Wind Speed

Gust or steady 28 mph (45 km/h)

TB37 – 0172094 page 2 - 3

Page 10

Chapter 2. Specifications

Engine Specifications

Ford VSG-413

Ford VSG-413

Fuel type Gasoline LPG Diesel

Deutz F3l-1011

Deutz F3l-1011

Fuel grade Unleaded gasoline 87

octane

Do not use gasoline

blends with more than 5%

methanol by volume, or

blends that do not contain

cosolvents and corrosion

inhibitors.

Commercial LP gas

DIN 51 601 (February 1986)

•

BS 2869: A1 and A2 (with A2

•

refer to Deutz manual about

sulfur content)

ASTM D 975-88: 1-D and 2-D

•

CEN EN 590 or DIN EN 590

•

NATO Code F-54 and F-75

•

For operating temperatures

•

below 32°F (0°C) use winter

grade diesel.

Displacement 79.3 cu. in.(1,300 cc) 125 cu. in. (2,049 cc)

Coolant 50% water/50% anti-freeze (ethelene glycol) Air

Operating temperature 160°F (71°C) to 190°F (88°C) 172°F (78°C) to 203°F (95°C)

Oil capacity 3.5 qt USA (3.25 l) 1.59 U.S. gal.(6.0 l)

Oil grade API: SG, SG/CC or SG/CD API: CD grades or higher

Oil viscosity See Engine Oil Viscosity

Running time One full tank of gas, diesel, or LPG will last for eight hours under normal working

conditions.

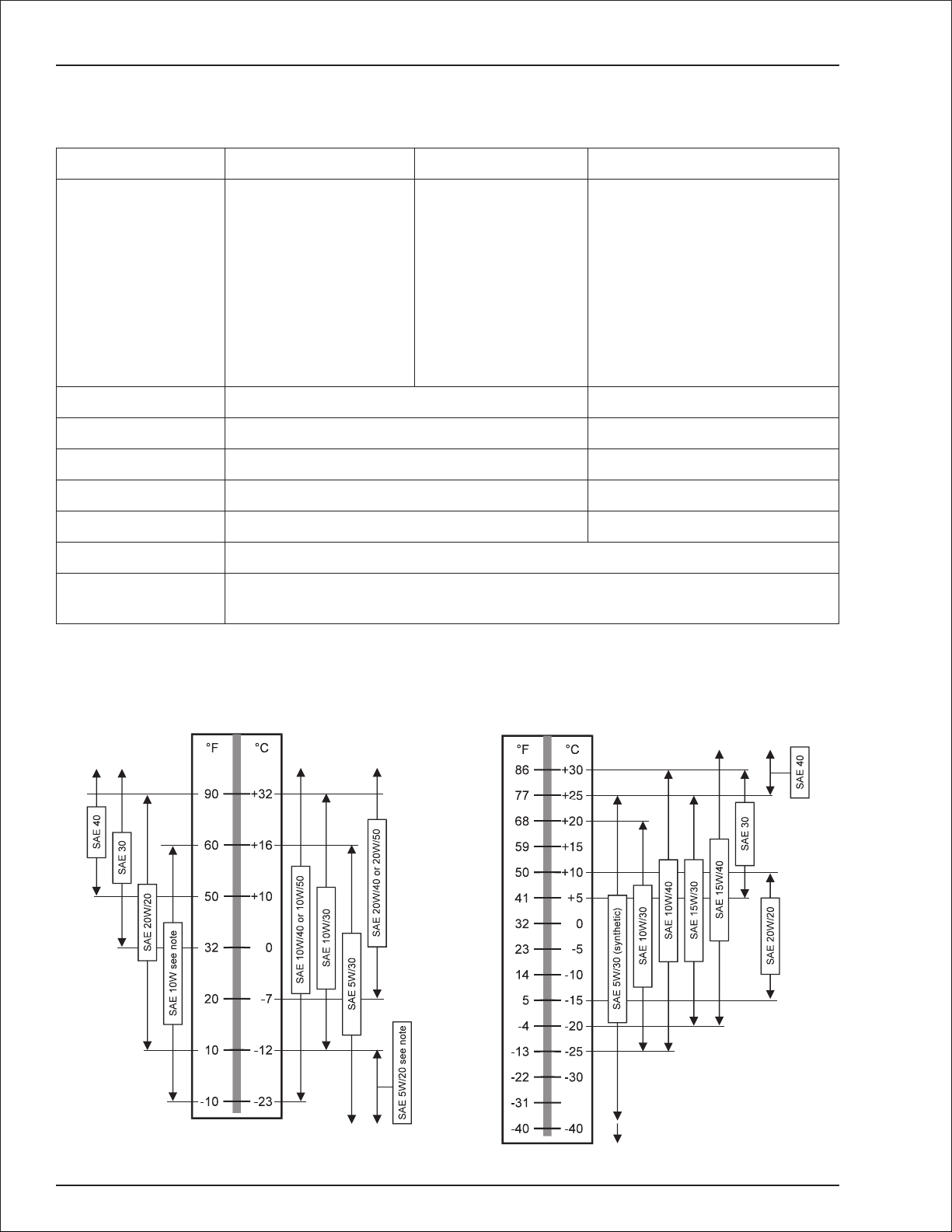

Engine Oil Viscosity

Ford VSG-413

Deutz F3l-1011

Single Viscosity Multi Viscosity

Note:

Not recommended for severe service, including high

RPM operation.

page 2 - 4 TB37 – 0172094

Only with engine oil preheating.

Page 11

Chapter 3. Safety

Knowledgeoftheinformationinthismanual,andproper

training, provide a basis for safely operating the aerial

platform.Know the location of all controls and howthey

operatetoactquicklyandresponsiblyin anemergency.

Safety devices reduce the likelihood of an accident.

Never disable, modify, or ignore any safety device.

Safety alerts in this manual indicate situations where

accidents may occur.

If any malfunction, hazard or potentially unsafe condi

tionrelatingtocapacity,intended use, orsafeoperation

is suspected, stop aerial platform operation and seek

assistance.

The operator bears ultimate responsibility for following

all manufacturer’s instructions and warnings, regula

tionsandsafetyrulesoftheir employerand/orany state

or federal law.

Electrocution Hazards

Theaerialplatform ismadeof metalcomponentsand is

not insulated. Regard all conductors as energized. Do

not operate outside during a thunderstorm.

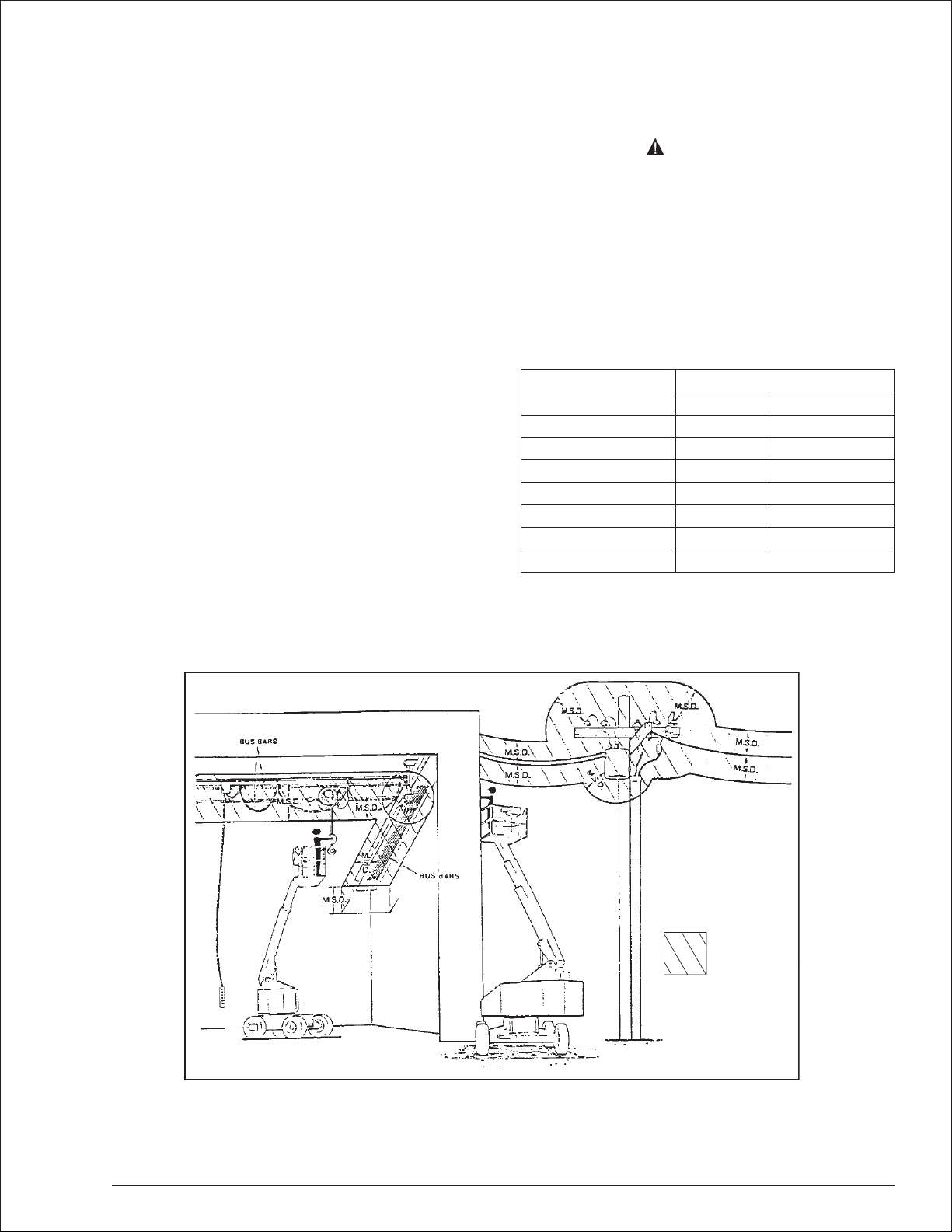

Minimum Safe Approach Distance

Minimum safe approach distances to energized power

linesandtheir associatedpartsmustbeobservedwhile

operating the aerial platform.

DANGER

The aerial platform is not electrically insulated.

Deathor seriousinjurycan resultfromcontactwith,

or inadequate clearance from, an energized con

ductor.Do not go closer than the minimumsafeap

proach distance as defined by ANSI.

ANSI publications define minimum distances that must

be observed when working near bus bars and ener

gized power lines. Table 1 and Figure 3 are reprinted

courtesy of Scaffold Industry Association, ANSI/SIA

A92.5, page 23.

-

Voltage range

(phase to phase)

0 to 300V

Over 300V to 50kV

Over 50kV to 200kV

Over 200kV to 350kV

Over 350kV to 500kV

Over 500kV to 750kV

Over 750kV to 1000kV

Table 1—Minimum Safe Approach Distance

Minimum safe approach distance

(Feet) (Meters)

Avoid contact

10

15

20

25

35

45

-

-

-

3.05

4.60

6.10

7.62

10.67

13.72

Denotes

prohibited

zone

Figure 3—Minimum Safe Approach Distance

TB37 – 0172094 page 3 - 1

Page 12

Chapter 3. Safety

Prestart Inspection

Perform a prestart inspection before each shift as de

scribed in Chapter 7. Do not use the aerial platform on

thejob unlessyouaretrainedandauthorizedto doso.

Work Place

Inspection and Practices

Do not use the aerial platform as a ground connection

when welding. The welding ground clamp must be at

tachedtothe same structure thatisbeing welded.Elec

trical current flowcan be very intense, causingserious

internal damage to some components.

Inspect the area beforeand during aerial platform use.

Thefollowingaresomepotentialhazards thatmaybein

the work place.

●

Debris

●

Slopes

●

Drop-offs or holes

●

Bumps and floor obstructions

●

Overhead obstructions

●

Unauthorized persons

●

High voltage conductors

●

Wind and weather conditions

●

Inadequate surface and support to withstand load

forcesappliedby theaerialplatformin all operating

configurations

Beforeusing the aerial platforminany hazardous (classified) location, make certain it is approved and of the

typerequiredbyANSI/NFPA 505foruse in thatparticu

lar location.

Know and understand the job site traffic-flow patterns and

obey the flagmen, road signs, and signals.

While operatingtheaerialplatform,agoodsafety prac

ticeistohavequalifiedpersonnelinthe immediatewor k

area to:

●

Help in case of an emergency

●

Operate emergency controls as required

●

Watch for loss of control by platform operator

●

Warn the operator of any obstructions or hazards

that may not be obvious to them

●

Watch for soft terrain, sloping surfaces, drop-offs,

etc. where stability could be jeopardized

●

Watchfor bystandersandnever allowanyonetobe

under, or to reach through the booms while

operating the aerial platform

-

Pinch points may exist between moving compo

DANGER

nents. Death or serious injury can result from be

coming trapped between components, buildings,

structures, or other obstacles. Make sure there is

sufficient clearance around the machine before

moving thechassis,booms, or platform.Allow suffi

cient roomandtimetostop movement to avoidcon

-

tact with structures or other hazards.

Always look in the direction of movement. Drive with

careandat speeds compatiblewith the workplacecon

ditions.Usecautionwhendrivingoverrough ground,on

slopes,andwhenturning.Do not engage inanyform of

horseplay or permit riders any place other than in the

platform.

Secureallaccessories,containers,tools,and otherma

terials in the platform to preventthemfromaccidentally

falling or being kicked off the platform. Remove all ob

jects that do not belong in or on the aerial platform.

Never steady the platform by positioning it against an

other platform.Do not use boards, or other temporary

means to support or level the aerial platform.

Donotoperate the aerialplatformif it isdamagedor not

functioning properly. Qualified maintenance personnel

must correct the problembeforeputting the aerial platform back into service.

Operation

Usethreepoints of support whenenteringorexitingthe

platform. For example, use two hands and one foot

-

when climbing into the platform.

Never cover the platform floor grating or otherwise ob

struct your view below. Make sure the area below the

platform is free of personnel before lowering.

-

Keep both feet positioned firmly on the platform floor.

Operate the controls slowly and deliberately to avoid

jerky and erratic operation. Always stop the controls in

neutral before going in the opposite direction.

Donotdismount while theaerialplatformis in motionor

jump off the platform.

Properly stow the aerial platform and secure it against

unauthorizedoperationat theendof eachworkday,be

fore transporting, or if it is left unattended.

Tip-Over and Falling Hazards

Operatetheaer ial platform onlyona firm, flat, level sur

facecapableof withstanding all load forcesimposedby

the aerial platform in all operatingconditions.Raise the

boomsonly whenthe aerialplatform isonlevelground.

-

-

-

-

-

-

-

-

-

-

-

page 3 - 2 TB37 – 0172094

Page 13

Chapter 3. Safety

DANGER

The aerial platformcan tip over if it becomesunstable.

Death or serious injury can result from a tip-overacci

dent.Donotdriveorpositiontheaerialplatf ormforele

vateduse nearan ydrop-off,hole,slope,softor uneven

ground, or other tip-over hazard.

Allplatf ormoccupantsmustwearafallrestraintdevicecon

nected to a lanyard anchor point.

It isbestnotto transfer fromtheplatformtoanother struc

tureorfrom the structuretotheplatform, unlessthatis the

safest way to do the job.Judge each situation separately

takingthe workenvironment intoaccount.If itisnecessary

to transf er from the platform to another structure the fol

lowing guidelines apply:

1. Where possible, place the platform over a roof or

walking structure to do the transfer.

2. Transfer your anchorage from one structure to the

other before stepping across.

3. Remember that you might be transf erring to a struc

ture where

4. Use the platform entrance, do not climb over the

guardrails.

personal fall arrest

is required.

Electrical System

Charge the batteries in a well-ventilated area free of

flame, sparks, or other hazards that might cause fire or

-

explosion.

-

Donotoperateanyoftheaerialplatform functionswhile

the battery charger is plugged in.

-

Batteries give off hydrogen and oxygen that can

combineexplosively.Deathor seriousinjury canre

-

sult from a chemical explosion. Do not smoke or

permit open flames or sparks when checking the

batteries.

-

Battery acidcan damage theskinand eyes.Serious

infection orreactioncan result if medical treatment

is not given immediately. Wearfaceandeye protec

tion when working near the batteries.

Batteries contain sulfuric acid that can damage your

eyes or skin on contact. Wear a face shield, rubber

gloves, and protective clothing when wor king around

batteries. If acid contacts your eyes, flush immediately

with clear water and get medical attention. If acid contacts your skin, wash off immediately with clear water.

DANGER

-

-

Donotoperatetheaerial platforminwindyorgusty conditions. Do not add anything to the aerial platform that

will increase the wind loading such as billboards, banners, flags, etc.

Never operate the aerial platform without all parts of the

guardrail system in place and the gate closed.Makesure

that all protective guards, cowlings, and doors are securely fastened.

Donotexceed theplatformcapacity as indicatedonthe

platform rating placard on the platform. Do not carry

loads that extend beyond the platform guardrails without

prior written consent from Snorkel.

Do not operate the aerial platform from trucks, trailers,

railway cars, floating vessels, scaffolds, or similar

equipment unless the application is approvedinwriting

by Snorkel.

Do not usetheaerialplatformasacrane, hoist, jack,or

for anypurpose other than to position personnel, tools,

and materials.

Donotclimb ontheguardrails oruseladders, planks,or

other devices to extend or increase the work position

from the platform.

Take caretopre v entrope, electrical cords,andhoses, etc.,

from becoming caught in or on the aerial platform. If the

platform or booms becomes caught on an adjacent struc

tureorotherobstacleandispreventedfrom normalmotion,

reverse the control to free the platform. If control reversal

doesnotfreethe platform,ev acuatethe platform beforeat

tempting to free it.

Hydraulic System

The hydraulic system contains hoses with hydraulic

fluid under pressure.

DANGER

Hydraulic fluid escaping under pressure can have

enough force to inject fluid into the flesh. Serious

infection orreactioncan result if medical treatment

is notgivenimmediately.In caseofinjuryby escap

inghydraulic fluid,seekmedical attentionat once.

Do not place yourhandoranypart of yourbodyinfront

of escaping hydraulicfluid.Use a piece of cardboard or

wood to search for hydraulic leaks.

Engine and Fuel

Handling Precautions

Refer to the engine manufacturer’s Operator’s Manual

for complete information on safe engine operation,

maintenance, and specifications.

DANGER

Engine exhaust contains carbon monoxide, a poi

sonous gas that is invisible and odorless.

Breathing engine exhaust fumes can cause death

or serious illness. Do not run the engine in an en

-

closed area or indoors without adequate ventila

tion.

-

Operate dual fuel machines on LPG fuel when indoors

to reduce exhaust fumes and carbon monoxide.

-

-

-

-

TB37 – 0172094 page 3 - 3

Page 14

Chapter 3. Safety

Be careful not to run the diesel fuel tank empty. Bleed

the fuel system if air enters the lines between the tank

and the injection pump.

Allowtheengine to return to idle beforeshutting the en

gine off.

Do not smoke or permit open flames while fueling or

near fueling operations.

Never removethe fuel cap or fill the fuel tank while the

engine is running orhot.Never allow fuel to spillon hot

machine components.

Maintain control of the fuel filler nozzle when filling the

tank. Spilled fuel is a potential fire hazard.

Donotfillthefueltankto capacity.Allow roomforexpan

sion.

Clean up spilled fuel immediately.

Tighten the fueltankcapsecurely.Ifthefuelcap is lost,

replace it with an approved cap from Snorkel.Use of a

non-approved cap without proper venting may result in

pressurization of the tank.

Never use fuel for cleaning pur poses.

Fordiesel engines,use thecorrectfuel gradefor theop

erating season.

CAUTION

Enginecoolantescaping underpressure cancause

serious burns.Shut theengine off and letitcool be

fore removing the radiator cap.

Letthe engineand radiatorcoolbeforeaddingcoolant.

-

Placards and Decals

The aerial platform is equipped with placards and de

cals that provide instruction for operation and accident

prevention. Do not operate the aerial platform if any

placards or decals are missing or not legible.

-

-

-

page 3 - 4 TB37 – 0172094

Page 15

Chapter 4. Safety Devices

This aerial platform is manufactured with safety de

vices, placards, and decals to reduce the likelihood of

an accident. For the safety of all personnel, do not dis

able,modify,orignoreanysafetydevice.Safetydevices

are included in the daily prestart inspection.

DANGER

Thepotentialfor anaccidentincreases whensafety

devices do not function properly. Death or serious

injury can result from such accidents. Do not alter,

disable, or override any safety device.

If any safety devices are defective, remove the aerial

platform from service until qualified maintenance per

sonnel can make repairs.

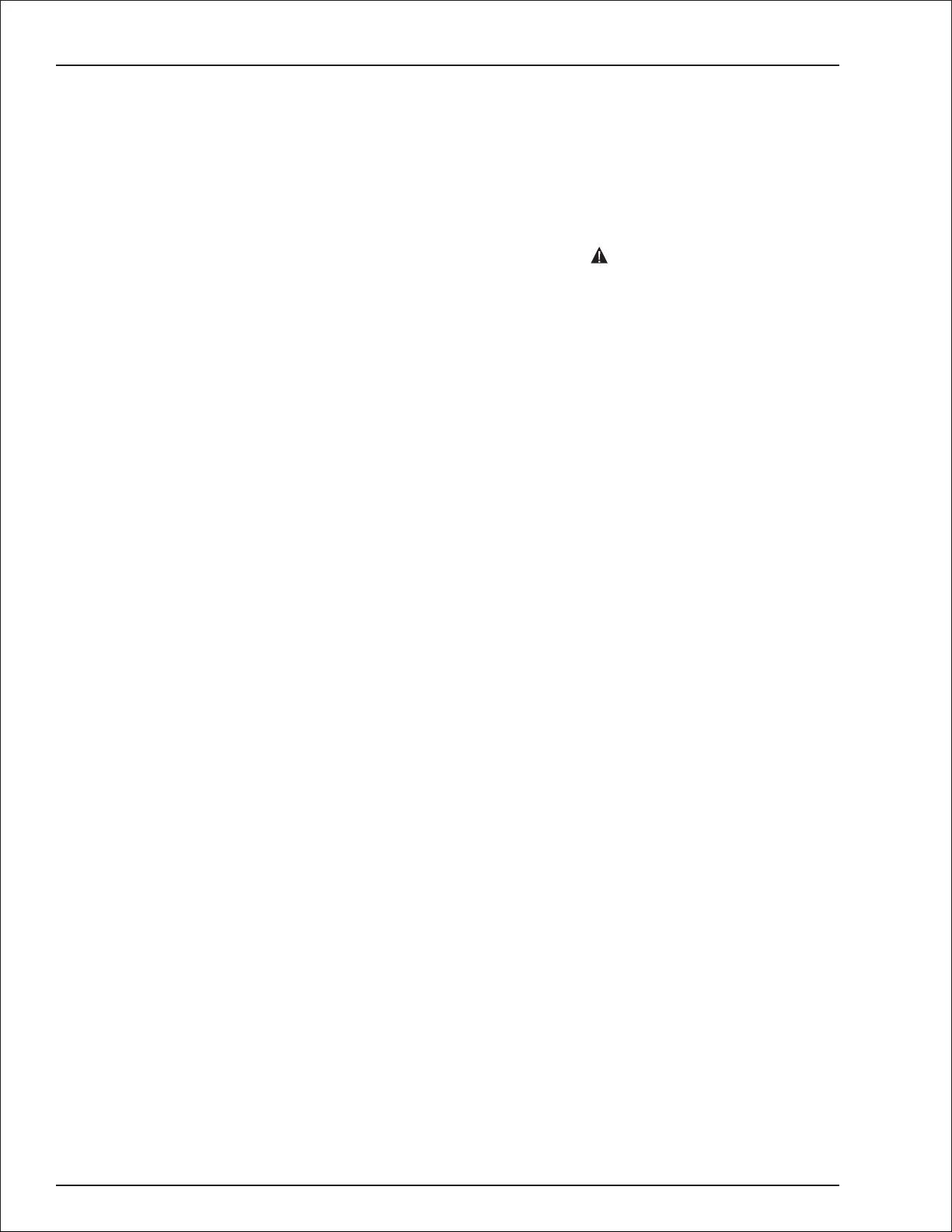

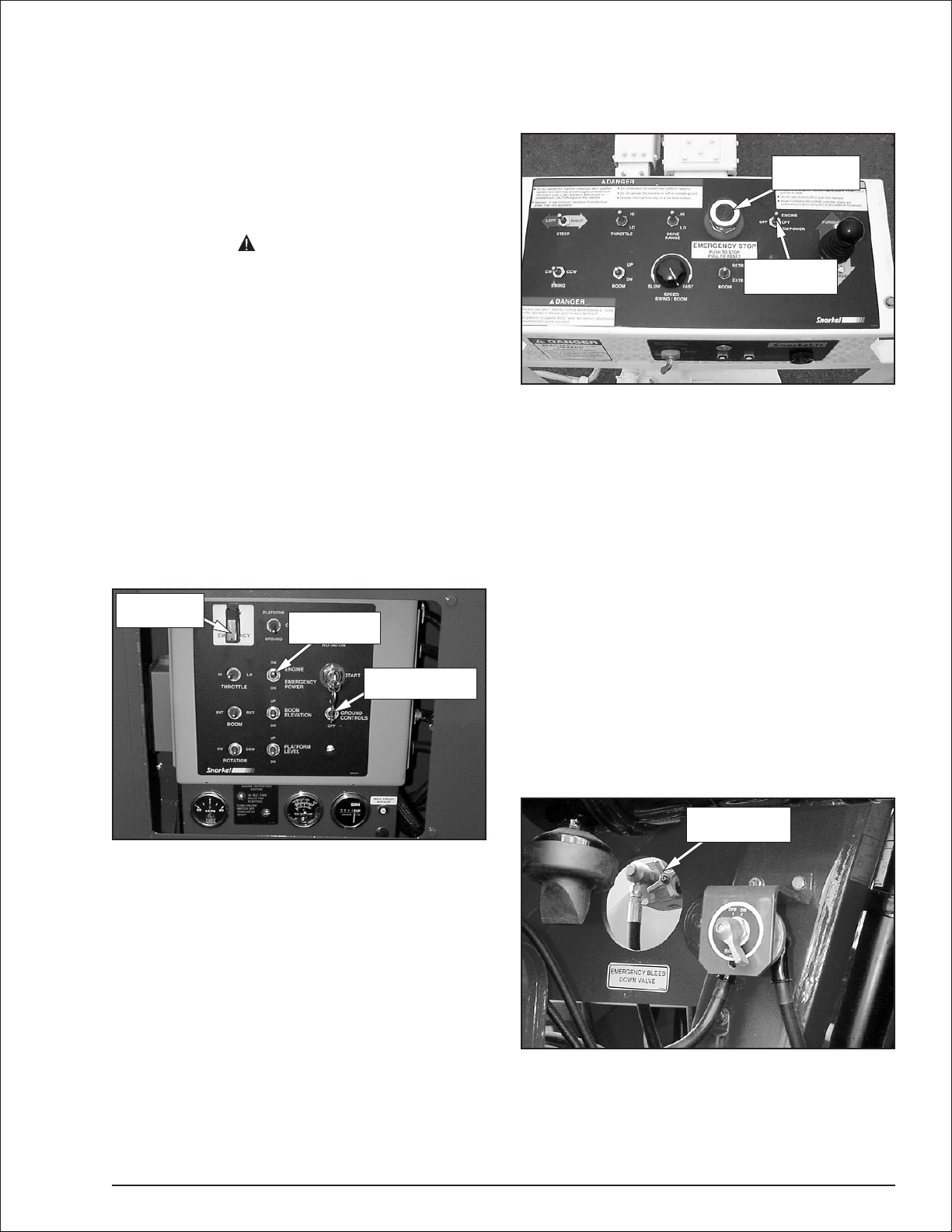

Emergency Stop Controls

Thereisan emergencystopcontrol atthelowerandup

per controls.

At the lower controls, the emergency stop is a

two-positiontoggleswitch with aredsafety guard (refer

to Figure 4.1). Push the guard down over the toggle

switchtodisconnect power toallcontrolcircuits.Lift the

guard and push the toggle switch up to restore power.

Emergency

Stop Switch

Emergency

Power Switch

Ground Controls

Switch

-

-

-

Figure 4.2—Upper Controls

Emergency

Stop Button

Emergency

Power Switch

Emergency Power System

-

The emergency power system includes a back-up

pump, motor, and battery. Use this system to operate

theboomand turntablefunctionsto lowertheplatform if

the main powersystemfails due to engineorpumpfailure.

Hold the emergency power switch (refer to Figure 4.1

and4.2) downtoactivatetheemergency powersystem.

The length of time the pump can be operated depends

on the capacity of the battery.

Emergency Lowering Knob

Theemergencyloweringknobmaybeusedtolowerthe

booms if the engine will not start and the emergency

powersystem willnot work.Theknobis onthe baseend

of the main boom lift cylinder and can be accessed

through the hole to the left of the battery disconnect

switch (refer to Figure 4.3).

Emergency

Lowering Knob

Figure 4.1—Lower Controls

Note

The lower controls override the upper controls. If the

upper control emergency stop button is engaged, the

lower controls can still be used to operate the aerial

platform.

At the upper controls, the emergency stop is a

two-position push button (refer to Figure 4.2).

Pushtheemergency stopbuttonin todisconnectpower

toall controlcircuits.Pullthebuttonouttorestorepower.

Figure 4.3—Emergency Lowering Knob

The knob may be turned to open the cylinder bleed

down valve for emergency lowering.

TB37 – 0172094 page 4 - 1

Page 16

Chapter 4. Safety Devices

Ground Controls Switch

The ground controls switch (refer to Figure 4.1) pre

vents boom and platform movement if a control switch

on the lower control panel is accidentally moved.

Holdtheswitchinthe controlson positiontooperate the

machine from the lower controls.

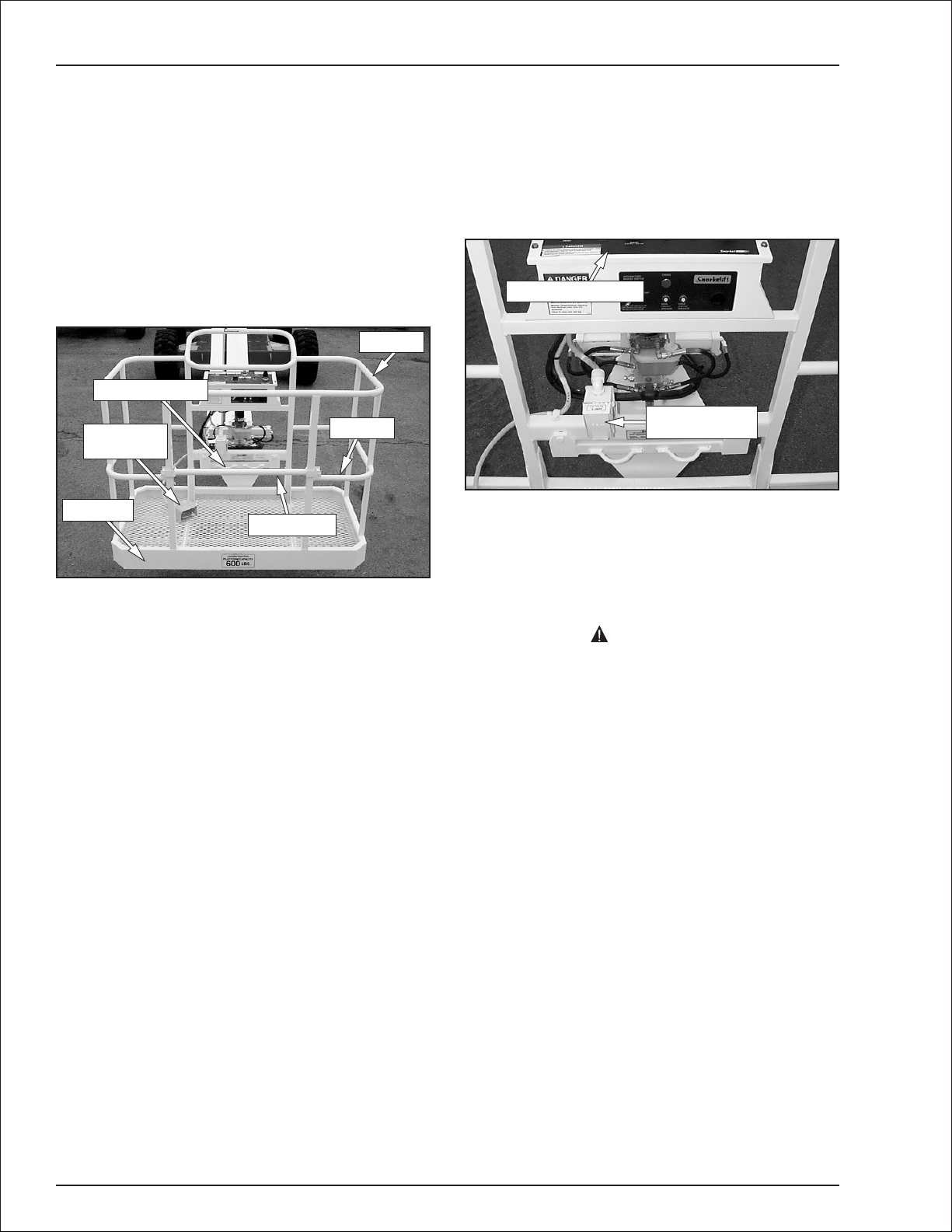

Platform Foot Switch

The platform foot switch (refer to Figure 4.4) prevents

boom and platform movement if a control on the upper

control panel is accidentally moved.

Top Rail

Lanyard Anchor

Platform

Foot Switch

T oeboar d

Gravity Gate

Figure 4.4—Platform

Step down on the platform foot switch to activate the

boom and platform controls.

Mid Rail

Guardrails

The guardrail system includes a top rail, mid rail, and

toeboardsaroundthesides of theplatform(refer toFig

ure 4.4).

Agravitygate oranoptionalswinginggateallowsforac

cesstotheplatform.The gatesclose automaticallyafter

entering or exiting the platform. The gate is part of the

guardrail system and must be securely fastened after

entering the platform.

Lanyard Anchors

Two lanyardanchorsforfallrestraintanchoragearepro

vided below the upper controls at the front of the plat

form (refer to Figure 4.4).

Note

The lanyard anchors are not for lifting or tying the

machine down.

All personnel in the platform must connect their fall re

straintdevicetoalanyardanchorbeforeraisingtheplat

form. Do not use the aerial platform for

arrest

-

anchorage.

Ground Fault Circuit Interrupter

The electrical power outlet (refer to Figure 4.5), at the

platform contains a ground fault circuit interrupter

(GFCI)to helppreventaccidental conductorgrounding.

Upper Control Panel

Electrical Power

Outlet

Figure 4.5—Electrical Power Outlet

Tilt Alarm

If the aerial platform chassis is out of level more than

fivedegrees whenthe mainboomisraisedorextended,

an alar m will sound.

DANGER

The aerialplatformcan tip over ifitbecomesunstable. Death or serious injury can result from a

tip-overaccident.Do notdriveor position the aerial

-

platform for elevated use near any drop-off, hole,

slope, soft or uneven ground,or other tip-over haz

ard.

Completely lower and retract the main boom and then

drive to a level surface when the tilt alarm sounds.

Thetiltalarm isforaddedprotection anddoesnotjustify

operating on anything other than firm, flat, level sur

faces.

-

Engine Protection Systems

-

A constant tone alarm will sound to warn against high

engine temperature or low oil pressure.

The engine will shut-down if the operatingtemperature

exceedsa preset levelor if theoilpressure is toolowfor

safe operation. An engine temperature gauge is below

-

the lower control panel (refer to Figure 4.6).

-

personal fall

-

-

page 4 - 2 TB37 – 0172094

Page 17

Chapter 4. Safety Devices

Drive Motion Alarm

An optional drive motion alarm may be provided on the

machine. When the drive/steer control is moved out of

neutral,thealarm sounds towarn personnelinthe work

area to stand clear.

Tem perature

Gauge

Figure 4.6—Engine Gauges

High Engine Temperature Alarm

If the coolant in a Ford engine exceeds 220°F (140°C)

an alar m will sound and the engine will shut off.

If the oil in a Deutz engine exceeds 230°F (110°C) an

alarm will sound and the engine will shut off. Any time

there is no alternator current being produced, an alar m

will sound and the engine will shut off. This prevents

high engine temperature if the fan belt breaks.

Donotrestarttheengine until theconditionthatcaused

the overheating has been corrected.

Low Oil Pressure Alarm

The low oil pressure alarm sounds when the engine oil

pressure is near the lower limit for safe engine operation. If the alarm sounds, lower the platform to the

ground and then turn the engine off. Do not restart the

engine until the condition that caused the low oil pres

sure has been corrected.

If the engine oil pressure falls below a safe operating

value the engine will shut off. The engine can be re

started with low oil pressure, but it will only run a few

seconds before it shuts off again.

Flashing Light

An optional red or amber flashing light may be located

onthetop oftheboom (refertoFigure 4.7).The flashing

light warns personnel that the aerial platform is in the

area.

Figure 4.7—Flashing Light

The light flashes at about one flash per second when

the engine is running.

Driving Lights

Optional headlights and blinking tail lights may be installed on the machine. The headlights are located on

-

the top of the front cowling. The tail lights are mounted

on the sides of the rear cowling.

Drivinglightshelp improvevisibility whiledrivingthe ae

-

rial platformandhelp othersseeit too.Driving lightsare

not for driving on public roadways.

-

Horn

The optional horn may be used to warn personnel on

the ground. The horn is operational when the machine

is set up for operation from the upper controls.

TB37 – 0172094 page 4 - 3

Optional platformworklightsmaybe located on the top

railof theplatform, oneon eachside ofthe uppercontrol

panel.

Use the platform lights to improve visibility while work

ing aloft in dimly lit areas.Do not use theplatform work

lights to drive on public roadways.

Platform Work Lights

-

Page 18

Chapter 5. Gauges and Displays

The aerial platform is equipped with several gauges to

monitor the condition of the machine before and during

operation.

Hour Meter

The hour meter is located below the lower controls (re

fer to Figure 5.1).It measures the accumulated engine

operating time.

Tem perature Gauge

Ammeter Hour Meter

Figure 5.1—Lower Controls

Engine Temperature Gauge

The temperaturegaugeislocatedbelow the lower control panel (refer to Figure 5.1).

On liquid cooled engines it shows the temperature of

the water and antifreeze mixture in the engine block.

The gauge on air cooled engines shows the temperature of the engine oil as the oil leaves the filter.

Air Filter Gauge

-

Figure 5.2—Air Filter Gauge

Whentheareainsidethe clearsection oftheindicatoris

red, it’s time to change the filter element.

Fuel

Thefuelgauge islocatedon topofthe tank(refertoFig

ure 5.3). The gauge indicates the fluid level in fractions-of-a-full-tank.

Fuel Gauge

-

Ammeter

The ammeter is located below the lower control panel

(refer to Figure 5.1).The ammeter displays the level of

current flow from the alternator to the batteries.

Aftertheenginehas been running fora fewminutesun

dernormaloperatingconditions,theammetergaugein

dicator should read “0.”

-

-

Engine Air Filter Gauge

Theairfilter gauge (referto Figure 5.2)islocated above

the lower control panel on the air cleaner. The gauge

measures theairpressurebetweenthe intake manifold

and the air filter.

TB37 – 0172094 page 5 - 1

Figure 5.3—Gasoline or Diesel Fuel Tank

Note

Do not r un a diesel fuel tank empty. Air in the fuel line

makes the engine hard to start.

LPG tanks have a fuel gauge that has two scales.One

scalemeasuresthefuel levelwhenthe tank is mounted

vertical and theotherisusedwhenthe tank is mounted

horizontal (refer to Figure 5.4).

Page 19

Chapter 5. Gauges and Displays

Horizontal Scale

Figure 5.4—LPG Fuel Gauge

The LPG tank is mounted horizontally at the rear of the

turntable. Read the horizontal scale to determine the

fuel level.

Engine Oil

The engineoillevelismeasured with a dipstick(referto

Figure 5.5).Oil sump and filter capacities inthe engine

specificationchartsareapproximate.Thedipstickis the

only way to accurately determine the engine oil level.

The engine oil level should always be between the add

and full marks on the dipstick.

Dipstick

Hydraulic Fluid Filter Gauge

The fluid filter gauge (refer to Figure 5.6) is located on

thereturnlinefilteron top the reservoir.Thereservoiris

behind the door on the right side of the turntable.The

gauge indicates the condition of the filter. When the

needle on the gauge is in the red zone, it is time to

change the filter.

Filter Gauge

Figure 5.6—Fluid Filter Gauge

Fluid Level and

Temperature Gauge

A gauge on the end of the reservoir displays the level

and temperature of the hydraulic fluid (refer to Figure

5.7).

Figure 5.5—Engine Oil Dipstick

The dipstick is visible behind the lower control panel.

Level andTemperature Gauge

Figure 5.7—Hydraulic Reservoir

If the temperature rises above 200°F (93°C) stop ma

chine operation and let the fluid cool before resuming

operation.

-

page 5 - 2 TB37 – 0172094

Page 20

Chapter 6. Controls

Controlstoposition the platformarelocatedon the lower

control panel on the turntable and on the upper control

panel in the platform. Drive controls are located on the

upper control panel only.

Battery Disconnect Switch

The battery disconnect is located behind the door on

the right side oftheturntableabove the battery (referto

Figure 6.1).

Figure 6.1—Battery Disconnect Switch

The battery disconnect removes electrical power from

all electrically controlled functionswhen in the off position. Place the switch in the on position to electr ically

connect the battery to the electrical system.

CAUTION

Only authorized personnel should operate the

aerial platform. Unqualified personnel may cause

injury to coworkers or property damage. Lock the

battery disconnect switchintheoffpositionbefore

leaving the aerial platform unattended.

Turn the batter y disconnect switch off to prevent unau

thorized use of the aerial platform.

●

Platform level switch

●

Platform rotator switch

●

Engine/emergency power switch

●

Throttle switch

●

Fuel switch

Figure 6.2—Lower Controls

Start Switch

The start switch works like an automobile ignition

switch. Hold it at start until the engine starts, then release it to on.If the engine dies, the key mustbeturned

to off before it will go back to start.

An alarm sounds when the switch is turned on to warn

others that the machine engine is being started.

Emergency Stop Switch

Theemergencystopisa two-positiontoggle switchwith

aredsafetyguard.Pushthered safetyguard downover

the toggle switch to disconnect power to all control cir

cuits.Lift theguardandpush the toggle switchupto the

on position to restore power.

-

Lower Controls

The lower controls (refer to Figure 6.2) are located on

the left side of the turntable. Boom and platform func

tions can be operated from the lower controls.The fol

lowing are located on the lower control panel.

●

Start switch

●

Emergency stop switch

●

Controls switch

●

Ground controls switch

●

Rotation switch

●

Boom elevation switch

●

Top boom switch

●

Boom switch

TB37 – 0172094 page 6 - 1

Controls Switch

Use the controls switch to select between lowercontrol

andupper controloperation.Place theswitchintheplat

formpositiontooperate the aerial platform fromtheup

percontrols andin thegroundpositionforlowercontrols

operation.

Ground Controls Switch

Hold the switch in the on position to operate the ma

chine from the lower controls.

This switch is spring returned to the off position.

-

-

-

Page 21

Chapter 6. Controls

Rotation Switch

The rotation switch is used to rotate the turntable in a

clockwise or counterclockwise direction. The switch is

spring returned to the center off position.

Hold the switchtotheright to rotate the turntable coun

terclockwise. Hold the switch to the left to rotate the

turntable clockwise.

Boom Elevation Switch

The boom elevation switchis used to raise or lower the

main boom. The switch is spring returned to the center

off position.

Hold the switch up to raise the main boom. Hold the

switch down to lower the main boom.

Boom Switch

The boom switch is used to extend or retract the tip

boom.The switchis springreturnedtothe centeroffpo

sition.

Hold the switch to the left to extend the tip boom.Hold

the switch to the right to retract the tip boom.

Place the switch in the low position fornormal machine

operationand inthe highposition forengineorhydraulic

system warm-up.

Fuel Switch

Engines on machines with the dual fuel option can be

operated using gasoline or liquefied petroleum gas

(LPG).Dual fuel machines haveagasolinetank behind

the door on the right side of the turntable and an LPG

tank at the rear of the turntable.

The fuel switch (refer to Figure 6.2) may be used to se

lect between gasoline and LPG operation.

Place the switchuptooperateon LPG and down to op

erate the engine using gasoline.

Circuit Breaker Reset Buttons

The lower control panel electrical system has a circuit

breakerfor themain, throttle,andrun circuits.Thereisa

reset button for each circuit breaker below the lower

control panel (refer to Figure 6.3).

-

-

Platform Level Switch

The platform level switch is used to level the platform

floor withrespecttotheground.Theswitch is spring returned to the center off position.

Hold the switch up to tilt the platform floor upward or

away from the ground. Hold the switch down to tilt the

platform floor downward or toward the ground.

Platform Rotator Switch

Theplatformrotatorswitchisused torotate theplatform

relative to the end of the tip boom. The switch is spring

returned to the center off position.

Hold the switch to the right to rotate the platform coun

terclockwise.Holdthe switchtothelefttorotate theplat

form clockwise.

Engine/Emergency Power Switch

Hold the emergency power switch down to operate ae

rial platform functions using the emergency power sys

tem. Release the switch to disengage the emergency

power system.

Note

The emergency power system is for lowering the

platform during an emergency and is not intended for

normal machine operation.

If the engine is running, it will stop when the switch is

placed in the emergency power position.

Main

Throttle

Run

Figure 6.3—Lower Control Gauge Panel

The upper control panel has a circuit breaker for the

-

main and drive circuits.The circuit breakers are on the

-

front of the upper control panel (refer to Figure 6.4).

-

-

Anti-Restart

Master Switch

Main Drive

Throttle Switch

Figure 6.4—Upper Control Panel Front

The throttle switch is used to set the engine throttle

speed to either low or high idle.

page 6 - 2 TB37 – 0172094

Page 22

Chapter 6. Controls

The circuit breakers protect the electrical wiring and

components from electrical overload in case of a short

circuit or other fault.

CAUTION

A tripped circuit breaker indicates a malfunction in

the electrical system. Component damage can re

sult ifthecause of the malfunctionisnot corrected.

Do not operate the aerial platform if the circuit

breaker trips repeatedly.

Push the button to reset the circuit breaker.

Upper Controls

The upper controls (refer to Figure 6.5) are located on

the control panel at the platform. Boom, platform, and

drivefunctions canbeoperatedfrom theuppercontrols.

The following controls are located on the upper control

panel.

●

Anti-restart master switch

●

Emergency stop button

●

Speed knob

●

Swing switch

●

Boom up/down switch

●

Boom extend/retract switch

●

Level switch

●

Steer switch

●

Drive joystick

●

Drive range switch

●

Engine/emergency power switch

●

Throttle switch

●

Platform rotator switch

This switch is similar to an automobile ignition switch.

Turn the switch to start until the engine starts, then re

lease it to on. If the engine dies, the switch must be

turned to off before it can be turned back to start.

An alarm sounds when the switch is turned on to warn

others that the machine engine is being started.

-

Note

Onsomemachines itmaybe necessary topauseabout

threesecondsinthe on positionbeforegoing to start so

the starter can engage.

Turnthe switchtooff to turn theengineoff and savefuel

iftheplatform is tostay inaparticularpositionfor a long

time.

Emergency Stop Button

The emergency stop is a two-position, red push button

onthetopof the upper control panel.Push the buttonin

to disconnect power to all control circuits at the upper

controls.Pull the button out to restore power.

Note

The lower controls override the upper controls. If the

upper control emergency stop button is engaged the

lower controls can still be used to operate the aerial

platform.

Pushtheemergencystopbuttoninwhentheuppercontrolsarenotinuse toprotectagainstunintentionaloperation.

Speed Knob

Use the boom speed control knob to control the speed

of the following boom functions.

●

Turntable swing clockwise/counterclockwise

●

Main boom raise/lower

Set the knob to slow when beginning a boom move

ment. The speed may be increased by slowly rotating

the knob toward fast. For smooth operation, rotate the

knob to slow when ending boom movement.

-

-

Swing Switch

The swing switch is used to rotate the turntable in a

clockwise or counterclockwise direction. The switch is

spring returned to the center off position.

Hold the switchtotheright to rotate the turntable coun

terclockwise. Hold the switch to the left to rotate the

turntable clockwise.

Figure 6.5—Upper Control Panel

Anti-Restart Master Switch

The machine engine can be started from the platform

using the anti-restart master switch on thefrontoftheup

per control panel (refer to Figure 6.4).

TB37 – 0172094 page 6 - 3

Boom Up/Down Switch

The boom up/down switchis used to raiseor lower the

main boom. The switch is spring returned to the center

off position.

Hold the switch up to raise the main boom. Hold the

switch down to lower the main boom.

-

Page 23

Chapter 6. Controls

Boom Extend/Retract Switch

The boom extend/retractswitch is used to extendorre

tract the tip boom. The switch is spring returned to the

center off position.

Hold the switch down to extend the tip boom. Hold the

switch up to retract the tip boom.

Level Switch

Thelevelswitchis usedtoleveltheplatform floorwithre

spect to the ground. The switch is spring returned to the

center off position.

Hold theswitchup to tilt theplatformfloorupward or awa y

from the ground.Hold the switch down to tilt the platform

floor downward or toward the ground.

Steer Switch

The steer switch is used to steer right and left. The

switch is spring returned to the center off position.The

steering and drive functions may be operated simulta

neously.

Note

The steering wheels are not self-centering. Set the

steeringwheelsstraightaheadaftercompleting aturn.

Hold the switchtothe right to turnrightandtotheleft to

turn left as indicated by the directional arrows on the

chassis.

powersystem.Place theswitchintheoff positiontodis

engage the emergency power system.

-

Note

The emergency power system is for lowering the

platform during an emergency and is not intended for

normal machine operation.

If the engine is running, it will stop when the switch is

placed in the emergency power position.

-

Throttle Switch

The throttle switch is used to set the engine throttle

speed to either low or high idle.

Place the switch in the low position fornormal machine

operation and in high to drive at maximum speed.

Platform Rotator Switch

The platform rotator switch (refer to Figure 6.6)is used

to rotatetheplatform relative totheendofthe tip boom.

Theswitchisspringreturnedto thecenteroffposition.

-

-

Drive Joystick

Thedrivejoystickisusedto controlforwardandreverse

motion of the aerial platform.

Holdthejoystickforwardtomovetheaerialplatform for

ward and backward to move in reverse as indicated by

the directional arrows on the chassis.

Drive Range Switch

The driverangeswitch has twopositionstoselectdrive

wheel operation:

●

HI—high speed and low torque operation.

●

LO—low speed and high torque operation.

Engine/Emergency Power Switch

Place the switch in the engine position for aerial plat

form engine operation.

Placetheswitchinthe emergencypowerposition toop

erate aerial platform functions using the emergency

-

Figure 6.6—Upper Control Panel Side

Hold the switch to the right to rotate the platform coun

terclockwise.Holdthe switchtothelefttorotate theplat

form clockwise.

Horn Button

Theoptionalhorn buttonison therightside oftheupper

control panel. Press the button to sound the horn.

Platform Foot Switch

-

The upper controls are interlocked through the platform

footswitch(refertoFigure6.7).Step downon andholdthe

platform foot switch to activate the drive and boom func

tions from the upper controls.

-

-

-

page 6 - 4 TB37 – 0172094

Page 24

Platform

Foot Switch

Figure 6.7—Platform

Machine/Generator Switch

The switch for the optional generator is located on the

upper front of the control panel (refer to Figure 6.8).

Chapter 6. Controls

Machine functions willnotoperatewhiletheswitch is in

the generator position.

Dual Fuel

Engines on machines with the dual fuel option can be

operated using gasoline or liquefied petroleum gas

(LPG).Dual fuel machineshave agasolineandan LPG

tank on the left side of the chassis.

The switch to select between gasoline and LPG opera

tion is on the lower control panel (refer to Figure 6.9).

-

Machine/Generator Switch

Figure 6.8—Upper Control Panel Front

Withtheengine running, placetheswitchinthe genera

tor position to provide electrical power to the electrical

outlet at the platform.

Dual Fuel

Switch

Figure 6.9—Lower Controls

Place the switchuptooperateon LPG and down to operate the engine using gasoline.

Driving and Platform Work Lights

The control for the optional driving lights is on the back

ofeachlight.Placetheswitch intheonposition to operate the driving lights.

Thecontrolfortheoptionalplatformwork lightsison the

-

back of each light.

TB37 – 0172094 page 6 - 5

Page 25

Chapter 7. Prestar t Inspection

Potentialservice and safetyproblemsmay be detected

byinspectingtheaerialplatform. This chapter includes

information on properly inspecting the aerial platform

and includes a prestart inspection checklist at the end

of the chapter to ensure that no areas are overlooked.

DANGER

The potential for an accident increases when oper

atinganaerial platformthat is damagedor malfunc

tioning. Death or serious injury can result from

suchaccidents.Donot operate theaerial platformif

it is damaged or malfunctioning.

Perform a prestart inspection at the beginning of each

shift, beforeusingtheaerialplatform on the job.The in

spection site must have a smooth and level surface.

Operator’s Manual

The manual holder is located in the engine compart

ment(refertoFigure7.2)on theleftsideofthe machine.

Make cer tain it is securely fastened in place.

Coolant

Fordenginesareliquid cooled.Whenthe engineis cold,

there should be about 1″(2.5 cm) of coolant in thebot

tom of the reservoir (refer to Figure 7.2).

CAUTION

Enginecoolantescaping underpressure cancause

-

serious burns.Shut theengine off and letitcool be

-

fore removing the radiator cap.

Add coolant, if necessary, when the engine is cold and

notrunning.Whenrunning atoperatingtemperaturethe

coolant should be at the Hot level.

Deutzenginesare air cooled.Visually inspecttheairin

-

takeand fan(refertoFigure 7.3)tobe suretheyare free

of obstructions thatcouldstopor slow the flowofair.In

spect the fan belt to see that it is in place and not

cracked.

-

Fan

-

-

-

-

Coolant

Reservoir

Figure 7.2—Operator’s Manual Holder

Checkto see thattheproper Operator’sManualis inthe

holder.The manual should be complete with all pages

intact and in readable condition.

Manual Holder

Engine

Open the engine compartment doors on both sides of

the machine and visually inspect the engine and its

components with the engine off.

Oil Level

Check the engine oil level before starting the engine so

the oilhasdrainedtothe pan. Theproperoillevel isbe

tween the add and full marks on the dipstick.

The distance between the top and bottom dipstick

marks corresponds toabout 1 quar t US (1 l). Add oil, if

necessary, before starting the engine.

Fan Belt

Figure 7.3—Deutz Air Intake

Radiator

Inspect the radiator hoses and clamps for wear, leak

age, or damage (refer to Figure 7.4). Make sure the

hoses are not hardened, cracked, or feelspongy. Make

sure the cap is in place and tight.

Hose

-

Figure 7.4—Radiator

-

Cover

Cap

TB37 – 0172094 page 7 - 1

Page 26

Chapter 7. Prestar t Inspection

Coolant leaks are easily visible on the ground. Check

under the chassis for coolant that has leaked.

Makesure theradiatorcoreandventilationopeningson

the cover are free of bugs, dirt, or foreign material that

might restrict airflow.

Fuel Tank

Check the fuel level (refer to Figure 7.5)and add fuel if

necessary. Make sure the cap is securely fastened on

gasoline or diesel tanks.

Cap

Fuel Line

Fuel Gauge

Fuel Line

Fuel Gauge

7. Connect the fuel line and open the shutoff valve.

Fuel Line

Visuallyinspecttheentire length ofthefuel line.Startat

thefueltankandtrace theline (referto Figure7.5)tothe

engine inspecting for leaks and damage.

Air Filter

Theairfiltergauge (refer toFigure7.7)has an indicator

to show when the filter needs replaced.

Air Filter Gauge

Figure 7.5—Gasoline or Diesel Tank

Use the following procedure to change the LPG tank.

1. Close the shutoff valve (refer to Figure 7.6).

Shutoff Valve

Latch

Quick Disconnect

Fitting

Slot

Pin

Figure 7.6—LPG Tank

2. Remove the fuel line from the tank using the quick

disconnect fitting.

3. Pulluponeachlatchtoreleasethestraps from the

tank.

4. Carefully lift the tank from the cradle.

5. Placea fulltankin thecradlemakingsurethe slotin

the tank aligns with the pin.

6. Latch both straps to secure the tank.

Figure 7.7—Air Filter

To inspect the air filter:

1. Turn thebatterydisconnectswitch onandclose the

cowling door.

2. On dual fuel machines, set the fuel switchtoeither

LPG or gasoline.

3. At the lower controls, place the emergency stop

switch in the on position.

4. Insert the key into the master switch and turn the

engine on.

5. Checktheclearzoneafter runningtheenginefor30

seconds.

●

If the indicator is red, replace the filter.

●

If the indicator is clear, the filter is OK.

6. Shut off the engine.

Charging System

When the engine is running, the ammeter needle (refer

to Figure 7.8) should be to the right of “0.” Left of the “0”

is discharging.

page 7 - 2 TB37 – 0172094

Page 27

Chapter 7. Prestar t Inspection

Ammeter

Tem perature Gauge

Figure 7.8—Ammeter

Hour Meter

Cold Weather Start Kit—Block Heater

Ifthemachineisequipped withan optionalengineblock

heater, visually inspect the heater and power cord. In

spectforleaks around theheaterand fordamagetothe

power cord.

Electrical System

Electrical powerissupplied from either oneortwo, 335

amp, 12 volt batteries. These batteries supply 12 volt

DC electrical power to operate the aerial platform electrical and electrohydraulic components.

Machines with gasoline engines have one battery and

machines with diesel engines have two batteries.

DANGER

Batteries give off hydrogen and oxygen that can

combineexplosively.Deathor seriousinjury canre

sult from a chemical explosion. Do not smoke or

permit open flames or sparks when checking the

batteries.

CAUTION

Even with low voltage electrical systems, severe

arcing can occur. Electrical shock or component

damage can result from contact with energized

conductors. Use caution when working with any

electrical device.

Thebatteriesarebehindthe dooron therightsideofthe

turntable.

Caps

Terminals

Figure 7.9—Emergency Power Battery

Include the emergency power battery when inspecting

and servicing the electrical system.

-

Battery Fluid Level

Remove the caps from each batter y (refer to Figure

7.9).Visually check the battery fluid level. If the level is

not within

side each hole,add distilled water.

Replace the caps on the batteries.The caps must be in

place and tight during machine operation.

1

/4″ (6 mm) of the bottom of the filler neck in

Battery Terminals

Check the top of the batteries, the terminals,andcable

ends(refertoFigure7.9).Theyshouldbecleanandfree

of corrosion and dirt. Clean the top of the batteries if

necessary. Clean the terminals and cable ends with a

wirebrushor terminal cleaningtool.Allcable endsmust

-

be securely fastened to the terminals.

Cables and Wiring Harness

Inspect all cables and wiring for wear and/or physical

damage such as loose connections, broken wires, and

frayed insulation. Check the wiring in areas where a

change in routing direction maycausethemtobecome

pinched(refertoFigure7.10).Makesurethecablesand

wires are properly routed to avoid sharp edges, pinch

ing, and scuffing.

-

-

Emergency Power Battery

Theemergency powerbattery (refertoFigure7.9)isbe

hind the door on the right side of the chassis. The bat

tery is automatically charged when the engine is

running.

TB37 – 0172094 page 7 - 3

-

-

Page 28

Chapter 7. Prestar t Inspection

Figure 7.10—Cables and Wiring Harness

Hydraulic System

Hydraulic powerissuppliedfrom an engine dr iven vari

able displacement piston pump.

CAUTION

Not all hydraulic fluid is suitable to use in the hy

draulicsystem.Somehave poorlubricating charac

teristics and can increase component wear. Only

use hydraulic fluid as recommended.

If necessary, remove the filler cap and add fluid of the

proper type.Referto Chapter 2 for the proper type and

gradeof hydraulicfluidtouse.Theneedtoregularlyadd

fluid indicates a leak that should be corrected.

The sight glass on the reservoir has an internal ther

mometertomeasurethefluid temperature.Thetemper

ature should be less than 200°F (93°C).

Fluid Filter

Checkingtheconditionof the hydraulicfluidfilter is par t

of the machine maintenance schedule and should not

be performed by the operator.

-

-

-

-

DANGER

Hydraulic fluid escaping under pressure can have

enough force to inject fluid into the flesh. Serious

infection orreactioncan result if medical treatment

is notgivenimmediately.In caseofinjuryby escapinghydraulic fluid,seekmedical attentionat once.

The hydraulic reservoir is behind the door on the left

side of the turntable.The pump is mounted on the engine.

Fluid Level

Check the hydraulic reservoir fluid level with the aerial

platform stowed on a level surface.Thefluid levelmust

be between the full and add marks as viewed on the

sight glass (refer to Figure 7.11).

Full

Add

Figure 7.11—Fluid Level Indicator

Hoses, Tubes, and Fittings

Inspect all hydraulic hoses, tubes, and fittings for wear,

leakage, or damage (refer to Figure 7.12). Make sure

the hoses are properly routed to avoid sharp edges,

kinking, and scuffing. Inspect the tubes for dents or

other damage that may restrict fluid flow.Makesure all

hoses and tubes are held firmly in their support brackets.

Figure 7.12—Hose, Tubes, and Fittings

Hydraulic fluid leaks are easily visible on the ground.

Check under the chassis for fluid that has leaked.

Tires and Wheels

Visually inspect the tires and wheels (refer to Figure

7.13) to make sure theyare suitable for service.Check

the wheel lug nuts to see that none are missing, dam

aged, or loose.

-

page 7 - 4 TB37 – 0172094

Page 29

Chapter 7. Prestar t Inspection

Emergency

Stop Switch

Emergency

Power Switch

Ground Controls

Switch

Figure 7.13—Tires and Wheels

The aerial platform may have air or foam filled tires.Air

filled tires have a tire pressure decal near the valve