Page 1

0

Operator’s

Manual

267

Engine Powered

Diesel

Gasoline

P/N 11360A

July 1999

LPG Fuel

Page 2

LIMITED WARRANTY

Snorkel warrantseachnew machine manufactured and sold by it to be free from defects in mater ial and workmanship for a

periodofone(1)yearfromdateofdeliver y to a Customerorforone yearafterthemachinehas been placed infirstservice ina

Dealerrentalfleet,whichevercomesfirst.Any par t or partswhich,uponexaminationby the Snorkel Ser vice Department,are

foundto be defective,will be replaced or repaired, at the sole discretion of Snorkel, through its local Authorized Dealer at no

charge.

Snorkelfurther warrants the structural components;specifically, the mainframe chassis, tur ntable, booms and scissor arms,

of each new machine manufactured by it to be free from defects in material and workmanship for an additional per iod of four

(4) years.Any such part or parts which, upon examinationby the SnorkelService Department, are found to be defective will

bereplacedor repaired bySnorkelthroughitslocalAuthorized Dealeratnocharge;however,anylabor charges incurred asa

result of such replacement or repair will be the responsibility of the Customer or Dealer.

The Snorkel Service Department must be notified within forty-eight (48) hours of any possible warranty situation during the

applicable warranty period. Personnel performing warranty repair or replacement must obtain specific approval by Snorkel

Service Department prior to performing any warranty repair or replacement.

Customer and Dealer shall not be entitled to the benefits of this warranty and Snor kel shall have no obligations hereunder

unless the “Pre-Delivery and Inspection Report” has been properly completed and returned to the Snorkel Service

Department within t en (10) days after delivery of the Sorkel product to Customer or Dealer’s rental fleet. Snorkel must be

notified, in writing, within ten (10) days, of any machine sold to a Customer from a Dealer’s rental fleet during the warranty

period.

At the direction of the Snorkel Service Department, any component part(s) of Snorkel products to be replaced or repaired

underthiswarrantyprogrammustbe returned freightprepaid to the Snor kel ServiceDepartment for inspection. All warranty

replacement parts will be shipped freight prepaid (standard ground) from the Snorkel Service Department or from Snorkel’s

Vendor to Dealer or Customer.

REPLACEMENT PARTS WARRANTY

Any replacement or service part made or sold by Snorkel is not subject to the preceding Limited Warranty beyond the

normal warranty period of the machine upon which the part was installed.

THIS WARRANTY EXCLUDES AND SNORKEL DOES NOT WARRANT:

1. Engines, motors, tires and batteries which are manufactured by suppliers to Snorkel,who furnish their own warranty.

Snorkelwill, however,to the extentpermitted,passthrough anysuchwarrantyprotection totheCustomerorDealer.

2. AnySnorkelproduct which has been modified or altered outside Snorkel’sfactory without Snorkel’swrittenapproval,if

suchmodification or alteration, in thesole judgment of Snorkel’sEngineering and/or Service Departments, adversely

affects the stability, reliability or service life of the Snorkel product or any component thereof.

3. AnySnorkel productwhichhasbeensubject to misuse,impropermaintenance or accident.“Misuse”includesbut isnot

limited to operation beyond the factory-rated load capacity and speeds. “Improper maintenance” includes but is not

limited to failure to follow the recommendations contained in the Snorkel Operation, Maintenance, Repair Parts

Manuals.Snorkelisnotresponsiblefornormal maintenance, service adjustments and replacements, including but not

limited to hydraulic fluid, filters and lubrication.

4. NormalwearofanySnorkelcomponentpart(s).Normalwearofcomponentparts mayvarywiththetypeapplicationor

type of environment in which the machine may be used;such as, but not limited to sandblasting applications.

5. Any Snorkel product that has come in direct contact with any chemical or abrasive material.

6. Incidental or consequential expenses, losses, or damages related to any part or equipment failure, including but not

limited to freight cost to transport the machine to a repair facility,downtime of the machine, lost time for workers, lost

orders, lost rental revenue, lost profits or increased cost.

This warranty is expresslyinlieu of all other warranties,representations or liabilities of Snorkel, either expressed or implied,

unless otherwise amended in writing by Snor kel’s President, Vice President-Engineer ing, Vice President-Sales or Vice

President-Marketing.

SNORKEL MAKES NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THIS LIMITED WARRANTY.

SNORKEL MAKES NO IMPLIED WARRANTY OF MERCHANTABILITYOR FITNESS FOR A PARTICULAR PURPOSE

AND DISCLAIMS ALL LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT

LIMITED TO INJURY TO PERSONS OR PROPERTY.

The Customer shall make all warranty claims through its local Authorized Dealer and should contact the Dealer from whom

the Snorkel product was purchased for warranty service. Or, if unable to contact the Dealer, contact the Snorkel Ser vice

Department for further assistance.

Effective July 1995

Page 3

■

Electrical Hazard Warning

SRT ELEVATING WORK WORK PLATFORMS

ARE NOT ELECTRICALLY INSULATED.

Electrical Hazard

DANGER

Electrical Hazard

Iftheplatform, scissorsarmassembly,or anyotherconductivepartof anSRTcontactsa high-voltageelec

trical conductor, the result can be SERIOUS INJURY or DEATH for persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH DISTANCES

(M.S.A.D) - AS OUTLINED IN TABLE 1. AND FIGURE 3.,

ON THE NEXT PAGE.

Be sure to allow for sag and sway in the wires and the work platform.

If an SRT comes in contact with a live electrical conductor, the entire machine can be charged.

If that happens, you should remain on the machine and not contact any other structure or object within

reach. That includes the ground, adjacent buildings, poles, and any object not a part of the SRT.

Suchcontactcould makeyour body a conductor to the other object creating an electrical shock hazard re

sulting in SERIOUS INJURY or DEATH.

DO NOT attempt to enter or leave the SRT until you are sure the electricity has been tur ned off.

IfanSRTisincontactwithaliveconductor,theplatformoperatorMUST warnotherson thegroundinthe vi

cinity of the SRTto STAY AWAY from the machine, since their bodies can also form a path for electricity to

ground thus creating an electr ical shock hazard with possible ELECTROCUTION and DEATH.

-

-

-

DO NOT attempt to operate SRTground controls when the platform, scissors arm assembly, or any other

conductingpartof the SRTis in contactwith electr ical wires or ifthereis an immediatedangerof such con

tact.

Regard all conductors as energized.

Personnelworking on or near an SRT must be continuously awareof electrical hazards, recognizing that

SERIOUS INJURY or DEATH can result if contact with an electrical wire does occur.

SRT2670 – 11360A page - i

-

Page 4

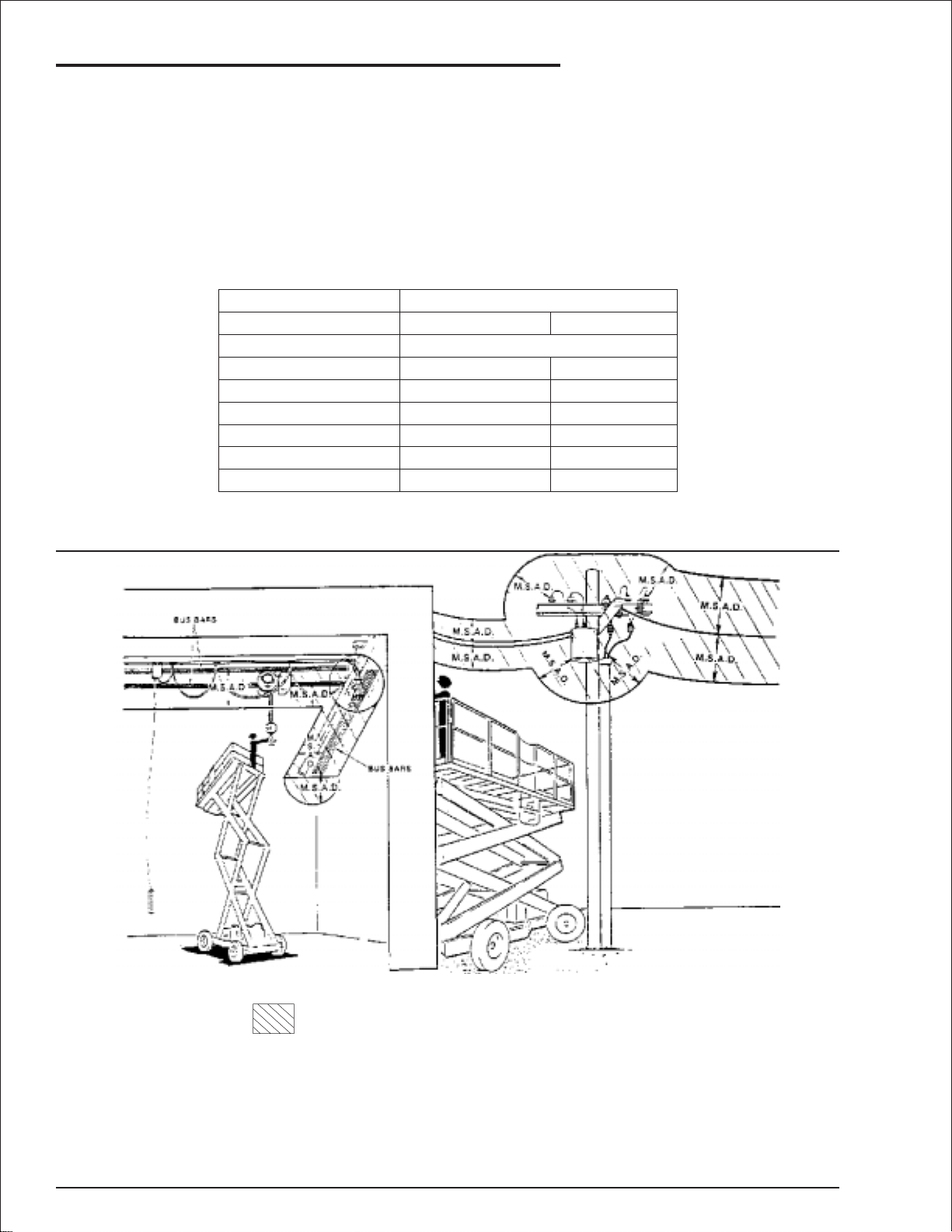

Electrical Hazard

p

■

Minimum Safe Approach Distance

An SRT is an all metal NOT ELECTRICALLY INSULATED, aerial work platform. DO NOT operate it near

ELECTRICAL conductors.Regard all conductors as being energized.Use the tableand illustration below

to determine safe clearance from electrical conductors. (Table 1 and Figure 3, below, are from ANSI/SIA

A92.6–1990 Standard, reprinted with permission of Scaffold Industry Association.)

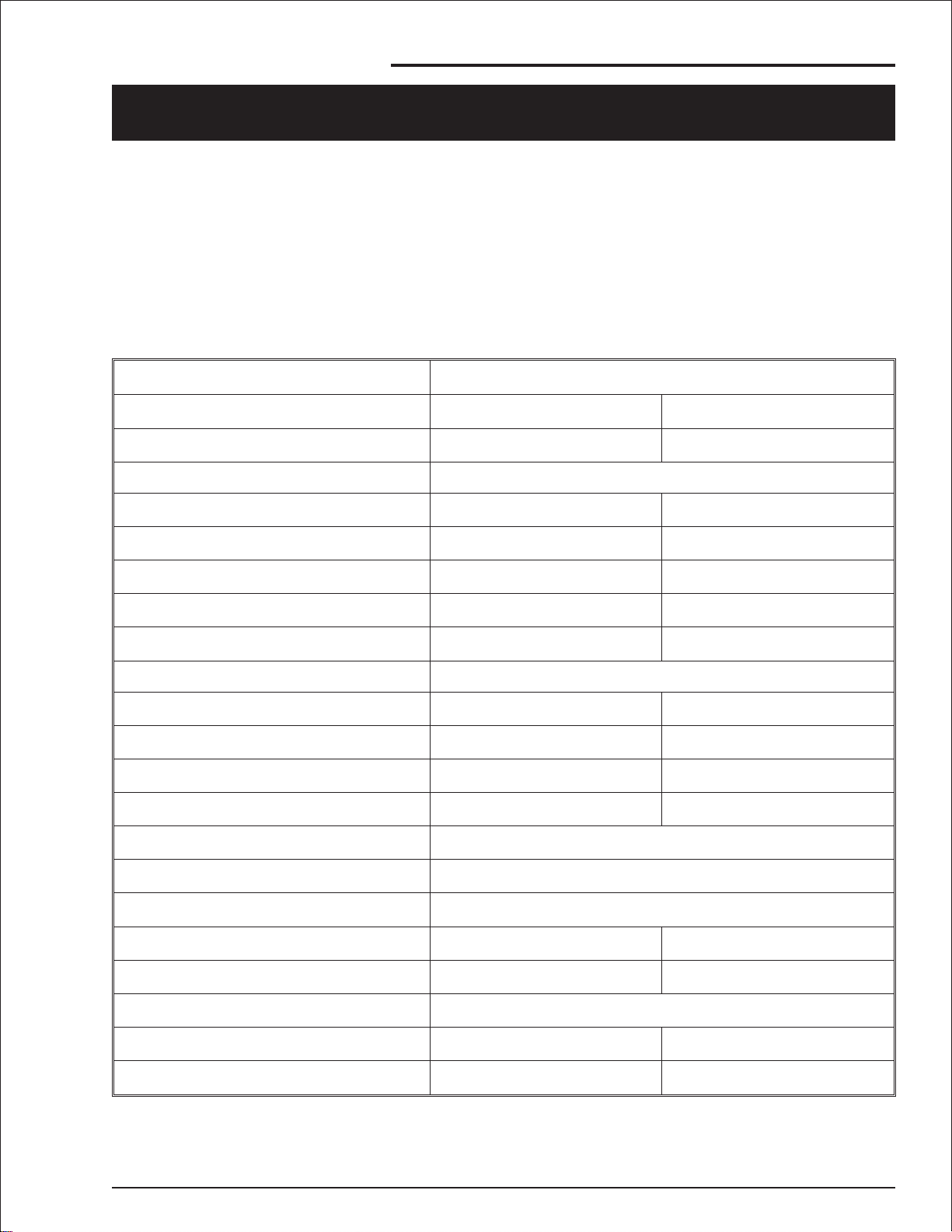

Table 1 - (M.S.A.D.)

❑

Minimum Safe Approach Distance

to energized (exposed or insulated power lines)

Voltage range Minimum safe approach distance

(phase to phase)

0 to 300V

over 300v to 50kv

over 50kv to 200kv

over 200kv to 350kv

over 350kv to 500kv

over 500kv to 750kv

over 750kv to 1000kv

(Feet) (Meters)

Avoid contact

10

15

20

25

35

45

3.05

4.60

6.10

7.62

10.67

13.72

Figure 3 - (M.S.A.D.)

❑

Denotes prohibited zone

Danger:

Caution:

- Do not allow machine personnel or conductive

materials inside prohibited zone.

- Maintain M.S.A.D. From all energised lines and parts

as well as those shown.

- Assume all electrical parts and wires are energised

unless known otherwise.

- Diagrams shown are only for purposes of illustrating

M.S.A.D. Work

ositions, not all workpositions.

page - ii SRT2670 – 11360A

Page 5

Introduction

The most important chapter in this manual is

"Safety" chapter 1. Take time, now, to study it

closely. The information in chapter 1, might save

your life or prevent serious injury.

■

Signs

The following three conventions are used through

out this manual.

1. Danger sign

DANGER

means: Attention! Become alert! Your safety is

involved.

2. Caution sign

CAUTION

means one of two things: (1) an action, about

to be performed, is potentially hazardous and

might result in minor personal injury if not

done correctly, or (2) an action, about to be

performed, can harm the SRT if not done

correctly.

3. Note sign

■

Operation rules

The following rules will help ensure the safety of

personnelandhelp preventneedlessdowntimebe

cause of damaged equipment.

1. Only TRAINED and AUTHORIZED

operators shall be permitted to operate

-

the equipment.

2. All manufacturer’s operating instructions

and safety rules and all employers’ safety

rules and all OSHA and other government

safety rules must be str ictly adhered to.

3. Repairs and adjustments shall be made

only by QUALIFIED TRAINED

maintenance personnel.

4. No modification shall be made to the

equipment without prior written consent of

the Snorkel Engineering Department.

5. You must make a pre-star t inspection of

the SRT at the beginning of each shift. A

malfunctioning machine must not be

used.

6. You must make an inspection of the work

place to locate possible hazards before

operating the SRT.

-

means: The information following is to assist

you in either the proper steps to take for an

action or as addition information concerning

your present situation, but does not indicate a

dangerous condition to either you or the SRT

unit.

■

Qualified operators

SRT aerial platforms have built in safety features

and have been factory tested for compliance with

Snorkel specifications and industry standards.

However,anypersonnelliftingdevicecanbe poten

tially dangerous in the hands of untrained or care

less operators.

Training is vitally important and MUST be done un

derthe direction of a QUALIFIEDperson.You must

displayproficiency in knowledge and actual opera

tion of the SRT.

Beforeoperation of the SRTyou must read and un

derstand the operating instructions in this manual

aswell asthe decals,warnings, andinstructionson

the machine itself.

Before operating an SRT you must be

AUTHORIZED by the person in charge to do so.

DANGER

DO NOT operate this equipment unless you

are TRAINED and AUTHORIZED and have

read and thoroughly understand all of the

information given in this Operator’s Manual

and on all DANGER and CAUTION signs on

the machine.Misuse of this machine can

result in DEATH or SERIOUS INJURY.

■

Maintenance

Every person who maintains, inspects, tests, or re

pairs these machines, and every person supervis

ing any of these functions, MUST be properly

trained.

This Operator’sManual provides a daily inspection

procedure that will help youkeep your SRTin good

operating condition. DO NOT perform other main

tenance unless you are a TRAINED mechanic,

QUALIFIED to work on the SRT. Call QUALIFIED

maintenancepersonnelifyoufind problemsormal

-

functions.

DO NOT modify this machine without written ap

proval from the Engineering Department of Snor

kel.

-

-

-

-

-

-

SRT2670 – 11360A page - iii

Page 6

Introduction

Informationcontained inthis manualconcernsonly

current SRT's, and the right is reserved to make

changes at any time without obligation.

■

Responsibilities of parties

Itis imperativethat all ownersand users oftheSRT

read, understand, and conform to all applicable

regulations.Ultimate compliance to OSHA regula

tions is the responsibility of the employer using the

equipment.

■

Additional information

For additional information, contact your local

dealer.

Snorkel

2/26 Redfern Street

Wetherill Park NSW 2164

Australia

DANGER

ANSI Standard A92.6-1990 clearly identifies

requirements of all parties who might be

involved with Self Propelled Elevating Work

Platforms.

AUSTRALIAN / NZ STANDARD AS2550-10

1994 Also identifies the requirements of all

parties who might be involved with Self

Propelled Elevating Work Platforms.

A reprint of the “Manual of Responsibilities for

Dealers, Owners, Users, Operators, Lessors

and Lessees of ANSI/SIA A92.6-1990 Self

Propelled Elevating Work Platforms” is

available from Snorkel dealers or from the

factory upon request.

Copies are also available from the Scaffold

Industry Association, Inc., 14039 Sherman

Way, Van Nuys, CA 91405-2599.

■

Options

The use of optional equipment is discussed in the

“Options” chapter 11.

Snorkel

PO Box 1041

Levin 5500

New Zealand

The options you will find discussed there are:

1. Operator Horn.

2. Outriggers.

3. RCD / ELCB Outlet.

4. Flashing Light.

5. Electrical Outlet.

6. Swinging Gate.

7. Spark Arrestor.

8. Lanyard Anchor Points.

page - iv SRT2670 – 11360A

Page 7

Table of Contents

Electrical Hazard

Electrical Hazard Warning . . . . . . . . . . . . . . . . . . i

Minimum Safe Approach Distance . . . . . . . . . . . ii

Table 1 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . . ii

Figure 3 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . ii

Introduction

Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Qualified operators. . . . . . . . . . . . . . . . . . . . . . . iii

Operation rules. . . . . . . . . . . . . . . . . . . . . . . . . . iii

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Responsibilities of parties . . . . . . . . . . . . . . . . . iv

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Additional information. . . . . . . . . . . . . . . . . . . . . iv

1. Safety

Safe Operation. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pre-start Inspection. . . . . . . . . . . . . . . . . . . . 1-1

Work Place Inspection and Practices . . . . . . 1-1

Electrocution . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tipover and Falling Hazards . . . . . . . . . . . . . 1-2

Crushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General Safety Precautions. . . . . . . . . . . . . . . 1-2

Personnel Precautions . . . . . . . . . . . . . . . . . 1-2

Operator General Precautions . . . . . . . . . . . 1-2

Mounting and Dismounting Precautions . . . . 1-3

Starting and Stopping Precautions . . . . . . . . 1-3

Operating Precautions . . . . . . . . . . . . . . . . . 1-3

Operator Maintenance Precautions . . . . . . . 1-3

Fuel Handling Precautions . . . . . . . . . . . . . . 1-3

Safety Decals and Placards . . . . . . . . . . . . . . 1-3

Safety Placards and Decals Location . . . . . . . 1-4

2. Safety Devices

Safety Device Information . . . . . . . . . . . . . . . . 2-1

Emergency Stop Switches. . . . . . . . . . . . . . . . 2-1

At platform control box . . . . . . . . . . . . . . . . . 2-1

At ground control box . . . . . . . . . . . . . . . . . . 2-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Platform control box . . . . . . . . . . . . . . . . . . . 2-1

Ground control box . . . . . . . . . . . . . . . . . . . . 2-2

Level sensor . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

High temperature . . . . . . . . . . . . . . . . . . . . . 2-2

Low oil pressure . . . . . . . . . . . . . . . . . . . . . . 2-2

Drive (reverse) . . . . . . . . . . . . . . . . . . . . . . . 2-2

Drive (forward). . . . . . . . . . . . . . . . . . . . . . . . 2-2

Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Swinging Gate (option) . . . . . . . . . . . . . . . . . . 2-3

Safety Control . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bubble Level (outrigger machines only) . . . . . 2-4

Operator Horn (option) . . . . . . . . . . . . . . . . . . 2-4

Outriggers (option). . . . . . . . . . . . . . . . . . . . . . 2-4

RCD/ELCB AC Outlet (option). . . . . . . . . . . . . 2-4

Flashing Light (option). . . . . . . . . . . . . . . . . . . 2-5

Lanyard Anchor Points (option) . . . . . . . . . . . 2-5

3. Specifications

General Specifications, Standard Machines . . 3-1

Engine Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Engine Oil Charts . . . . . . . . . . . . . . . . . . . . . . 3-2

WG750-G . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

D905-B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Nomenclature and Serial Numbers . . . . . . . . . 3-3

SRT2670 – 11360A

4. Gauges

Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fuel Level (option). . . . . . . . . . . . . . . . . . . . . . 4-2

Hydraulic Oil Level. . . . . . . . . . . . . . . . . . . . . . 4-2

Bubble Level (outrigger machines only) . . . . . 4-3

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Page 8

Table of Contents

5. Automatic Shut-offs and Circuit Breakers

Automatic Shut-offs . . . . . . . . . . . . . . . . . . . . 5-1

Level sensor . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine temperature. . . . . . . . . . . . . . . . . . . . 5-1

Engine oil pressure . . . . . . . . . . . . . . . . . . . . 5-1

Platform height vs.drive speed. . . . . . . . . . . 5-1

Parking brakes . . . . . . . . . . . . . . . . . . . . . . . 5-1

Dynamic brakes. . . . . . . . . . . . . . . . . . . . . . . 5-1

Alternator not charging . . . . . . . . . . . . . . . . . 5-2

Outriggers (option) . . . . . . . . . . . . . . . . . . . . 5-2

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main breaker . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

RCD / ELCB outlet (option). . . . . . . . . . . . . . 5-2

6. Controls

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Hydraulic Compartment. . . . . . . . . . . . . . . . . . 6-2

Ground Control Box. . . . . . . . . . . . . . . . . . . . . 6-2

Ground control box controls . . . . . . . . . . . . . 6-3

Platform Control Box . . . . . . . . . . . . . . . . . . . . 6-4

Platform control box controls. . . . . . . . . . . . . 6-5

7. Daily Inspection and Maintenance

Daily Inspection and Maintenance Table. . . . . 7-1

Fuel level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

(Option - LPG) . . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel filter (diesel engines only) . . . . . . . . . . . . 7-2

Fuel leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Engine coolant. . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Radiator cap . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Swinging gate (option). . . . . . . . . . . . . . . . . . . 7-3

Wiring harnesses and connectors. . . . . . . . . . 7-4

Battery terminals . . . . . . . . . . . . . . . . . . . . . . . 7-4

Hydraulic tank cap. . . . . . . . . . . . . . . . . . . . . . 7-4

Hydraulic oil level. . . . . . . . . . . . . . . . . . . . . . . 7-4

Hydraulic oil leaks . . . . . . . . . . . . . . . . . . . . . . 7-5

Tires and wheels . . . . . . . . . . . . . . . . . . . . . . . 7-5

Bolts and fasteners . . . . . . . . . . . . . . . . . . . . . 7-6

Structural damage & welds . . . . . . . . . . . . . . . 7-6

Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Lanyard anchorages (option) . . . . . . . . . . . . . 7-6

Bubble level (machines with outriggers) . . . . . 7-7

Guides, rollers, and slides . . . . . . . . . . . . . . . . 7-7

Charging system . . . . . . . . . . . . . . . . . . . . . . . 7-7

Level sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Ground controls. . . . . . . . . . . . . . . . . . . . . . . . 7-8

Emergency lowering . . . . . . . . . . . . . . . . . . . . 7-8

Platform controls . . . . . . . . . . . . . . . . . . . . . . . 7-8

Flashing light (option) . . . . . . . . . . . . . . . . . . . 7-8

RCD / ELCB (option). . . . . . . . . . . . . . . . . . . . 7-9

Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Safety prop . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Parking brakes. . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Placards and decals . . . . . . . . . . . . . . . . . . . 7-10

Standard placards and decals. . . . . . . . . . . 7-10

Inspection drawing . . . . . . . . . . . . . . . . . . . 7-11

8. Operation

Operating Procedures . . . . . . . . . . . . . . . . . . . 8-1

Control Stations. . . . . . . . . . . . . . . . . . . . . . . . 8-1

Emergency Stopping. . . . . . . . . . . . . . . . . . . . 8-1

Operation Considerations . . . . . . . . . . . . . . . . 8-2

Fuel type . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Operating From The Ground Control Box . . . . 8-2

Raising the platform . . . . . . . . . . . . . . . . . . . 8-4

Warming the hydraulic oil . . . . . . . . . . . . . . . 8-4

Operating From The Platform Control Box . . . 8-5

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Raising the Platform . . . . . . . . . . . . . . . . . . . 8-8

Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Setting the outriggers . . . . . . . . . . . . . . . . . . 8-8

To raise the outriggers: . . . . . . . . . . . . . . . . . 8-9

Extending The Multi-Position Platform . . . . . 8-10

page - vi SRT2670 – 11360A

Page 9

9. Emergency Operation

Emergency Operation Procedures . . . . . . . . . 9-1

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . 9-1

Emergency Bleed-Down . . . . . . . . . . . . . . . . . 9-1

Pushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

10. Stowing and Transporting

Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Trailering . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Securing to a Transport Vehicle . . . . . . . . . 10-3

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Pushing . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Winching Procedure . . . . . . . . . . . . . . . . . . 10-4

11. Options

Operator Horn . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

RCD / ELCB Outlet . . . . . . . . . . . . . . . . . . . . 11-1

Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . 11-2

Swinging Gate. . . . . . . . . . . . . . . . . . . . . . . . 11-2

Spark Arrestor . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Lanyard Anchor Points . . . . . . . . . . . . . . . . . 11-2

Table of Contents

12. Fire Fighting and Chemical Containment

Hazardous Components . . . . . . . . . . . . . . . . 12-1

Antifreeze (UN 1993) . . . . . . . . . . . . . . . . . 12-1

Battery, Lead/Acid (UN 2794) . . . . . . . . . . . 12-1

Diesel Fuel (NA 1993). . . . . . . . . . . . . . . . . 12-1

Foam In Tires . . . . . . . . . . . . . . . . . . . . . . . 12-2

Gasoline (UN 1203) . . . . . . . . . . . . . . . . . . 12-3

Hydraulic Oil (UN 1270) . . . . . . . . . . . . . . . 12-3

Liquefied Petroleum Gas (UN 1075). . . . . . 12-4

Motor Oil (UN 1270) . . . . . . . . . . . . . . . . . . 12-4

13. Operator's Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 13-1

Operator Troubleshooting Chart . . . . . . . . . 13-1

SRT2670 – 11360A

Page 10

Table of Contents

page - viii SRT2670 – 11360A

Page 11

■

Safe Operation

The followingsafetyinformation is vitally important

forsafeoperation ofthe SRT.Failuretofollowthese

instructionscanresult inpersonalinjuryorDEATH.

1. Safety

A recommended safety practice is to have person

nel that are trained in the operation of the emer

gencycontrolsworking intheimmediate areaofthe

SRT to assist the platform operator in the event of

an emergency.

-

-

Pre-start Inspection

❑

At the start of each work shift, the SRT shall be

givena visual inspection and function test.See the

“Daily Inspection and Maintenance” chapter 7, in

this manual for a list of items to inspect and test.

CAUTION

DO NOT operate the SRT unless you are

trained and authorized, understand the

operation characteristics of the SRT, and have

inspected and tested all functions to be sure

they are in proper working order.

Work Place Inspection and Practices

❑

Do not use the SRT as a ground for welding.

Ground to the work piece.

Before the SRT is used, and during use, check the

area in which the SRT is to be used for possible

hazards such as, but not limited to:

1. Drop-offs or holes.

2. Side slopes.

3. Bumps and floor obstructions.

4. Debris.

5. Overhead obstructions and electrical

conductors.

6. Hazardous locations.

7. Inadequate surface and support to

withstand all load forces imposed by the

aerial platform in all operating

configurations.

8. Wind and weather conditions.

9. Presence of unauthorized persons.

10. Other possible unsafe conditions.

Before the SRT is used, determine the hazard clas

sification of any particular atmosphere or location

according to ANSI/NFPA 505-1987.

AnySRT operatedinahazardous location must be

approved and of the type required by ANSI/NFPA

505-1987.

When moving the platform, check the clearance

around the SRT to avoid contact with structures or

other hazards. Always look in the direction of mo

tion.

Keep ground personnel from under the platform

when the platform is raised.

Secureallaccessories,containers,tools,andother

materials in the platform to preventthem from acci

dentally falling or being kicked off the platform.

DONOTengageinany formof“horseplay”or“stunt

driving” while operating the SRT.

DO NOT permit riders on the machine anyplace

other than on the platform.

Remove all loose objects stored in or on the machine, particularly in the platform. Remove all objects which do not belong in or on the machine.

When other moving equipment is in the area, take

special precautions to comply with local regulations regarding warnings.

Never steady the platform by positioning it against

another platform.

DO NOT operate an SRT that is not functioning

properly, or has been damaged, until the machine

has been repaired by a qualified maintenance per

son.

DO NOT operate a SRT that does not have all its

decals and placards attached and legible.

Drivethemachine withcare andatspeedscompat

iblewith conditions.Use extracaution when driving

over rough ground, on slopes, and when turning.

Know and understand the job site traffic-flow pat

terns and obey the flagmen, road signs, and sig

nals.

Watchforbystanders and neverallowanyone tobe

under, or to reach through, the machine and its

equipment while operating.

Use the recommended transport device when

loading the machine.

-

-

-

-

-

-

SRT2670 – 11360A page 1 - 1

Page 12

1. Safety

Electrocution

❑

The SRT is an all metal, NON-INSULATED, aerial

work platform.

DO NOToperate it near ELECTRICAL conductors.

Regard all conductors as being energized.

DO NOT operate outside during a thunderstorm.

Tipover and Falling Hazards

❑

On scissor lifts, like the SRT, personal fall protec

tion is not required by ANSI, Fedral OSHA,

AS1418-10-1996, NZ Code of Practice for Ele

vating Work Platforms, nor Snorkel. However, fall

restraint might be required by work regulations. If

so,theuser isresponsible forfitnessand method of

use.

DONOToperatethe SRTfroma positionontrucks,

trailers, railway cars, floating vessels, scaffolds, or

similar equipment unless the application is ap

proved in writing by Snorkel.

If the platform or elevating assembly becomes

caught,snagged, or otherwise preventedfrom normalmotion by anadjacentstructureor other obstacles such that control reversal does not free the

platform, remove all personnel from the platform

beforeattemptsare madeto freethe platformusing

ground controls.

Under normal working conditions it is best not to

transfer from the platform to another structure or

vice versa, unless that is the safest way to do the

job.Each situation must be judged separately taking the work environment into account. The following guidelines apply:

1. Where possible, place the work platform

next to a roof or walking structure to do

the transfer.

2. Transfer your anchorage from one

structure to another before you step

across.

3. Remember, you might be departing the

work platform to a structure where fall

arrest is required.

4.

DO NOT climb the rails. Use the entrance.

DO NOTexceed the platform capacity nor the plat

form-extensioncapacity asindicated on the capac

ity placards located at the entrance to the platform

and on the toeboard of the platform extension.

Care shall be taken to preventrope, electric cords,

and hoses, etc., from becoming entangled in the

aerial platform.

Maintain a fir m footing on the platform floor.

Climbing on the guardrails is prohibited.

DO NOT use ladders, planks, or other devices to

extendorincrease yourworkposition fromthe plat

form.

-

DO NOTjerk the controls.Movethe controlsslowly

and deliberately to avoid jerky and erratic opera

-

tion.Alwaysstop the controls in theneutral, off, po

sition before going in the opposite direction.

DO NOT use the platform for any purpose other

than to position personnel, their tools, and materi

als.

DO NOT use the SRT as a crane, hoist, or jack.

-

DONOToperatetheSRTinwinds,orwind gusts,of

28 mph 12.5 m/s) or more.

DO NOTadd anything to the SRT that will increase

the wind loading (banners, flags, etc.).

Crushing

❑

Always look in the direction of travel. Avoid overhead obstructions.

Nevercover the floor grating or otherwise obstruct

your view below.

Make sure the area below the platform is free of

personnel before lowering.

■

General Safety Precautions

❑

Personnel Precautions

If you encounter any suspected malfunction of the

aerial platform, or any hazard or potentially unsafe

condition relating to capacity,intended use, or safe

operation, cease operation and seek assistance

from management.

❑

Operator General Precautions

Makesure that all protective guards, cowlings,and

doors are in place and secure.

-

-

Be sure the guardrail system, including the gate, is

in place and secure.

-

-

-

-

DO NOT raise the platform if the SRT is on soft

ground.Operate the platform only onafirmsurface

capable of withstanding all load forces imposed by

the aerial platform in all operating conditions.

Do Not carry loads from any point outside of the

platform.

page 1 - 2 SRT2670 – 11360A

Page 13

1. Safety

Mounting and Dismounting Precautions

❑

Use three points of support when getting on or off

theplatform(two handsandone footora similarset

of points). Keep the platform clean.

DO NOT jump off the machine.

DONOTdismountwhilethemachineisinmotion.

Starting and Stopping Precautions

❑

DO NOT start until all personnel are clearly away

from the machine.

Beforeleavingtheoperator’sstation, place the ma

chine in the stowed position.

When leaving the machine parked or unattended,

removethe starter keyfrom the Key switchand set

the Battery switch to off.

Operating Precautions

❑

DO NOT modify the SRT in any way.

Whenpartsorcomponentsare replaced,theyshall

be identical or equivalent to original Snorkel parts

or components.

DO NOT override any of the safety features of the

SRT.

❑

Operator Maintenance Precautions

DO NOTfill the fuel tank tocapacity.Allow room for

expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap is

lost, replace it with an approved cap from Snorkel.

Use of a non-approved cap without proper venting

may result in pressurization of the tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

-

■

Safety Decals and Placards

There are several safety decals and placards on

the SRT. Their locations and descriptions are

shown in this section. Take time to study them.

CAUTION

Be sure that all the safety decals and placards

on the SRT are legible. Clean or replace them

if you cannot read the words or see the

pictures.Clean with soap & water and a soft

cloth. Do not use solvents.

You MUST replace a decal or placard if it is

damaged, missing, or cannot be read. If it is

on a part that is replaced, make sure a new

decal or placard is installed on the replaced

part. See your Snorkel dealer for new decals

and placards.

CAUTION

DO NOT use your hand to search for hydraulic

oil leaks.High pressure hydraulic oil can easily

cut and penetrate your skin—averyserious

injury that requires immediate attention by a

medical specialist trained in that type of injury.

Use a piece of cardboard or wood to search

for hydraulic oil leaks.

DO NOT attempt repairs unless you are

trained.Refer to manuals and experienced

repair personnel for help.

❑

Fuel Handling Precautions

DONOTsmokeorpermitopenflames whilefueling

or near fueling operations.

Neverremove the fuel cap or refuel a gasoline en

gine while the engine is runningor hot.Neverallow

fuel to spill on hot machine components.

Maintain control of the fuel filler nozzle when filling

the tank.

Refer to Placards and Decals Inspection Chart

and Drawing in the “Daily Inspection and

Maintenance” chapter 7, for part numbers,

location, and required quantities of all placards

and decals.

-

SRT2670 – 11360A page 1 - 3

Page 14

1. Safety

■

Safety Placards and Decals Location

page 1 - 4 SRT2670 – 11360A

Page 15

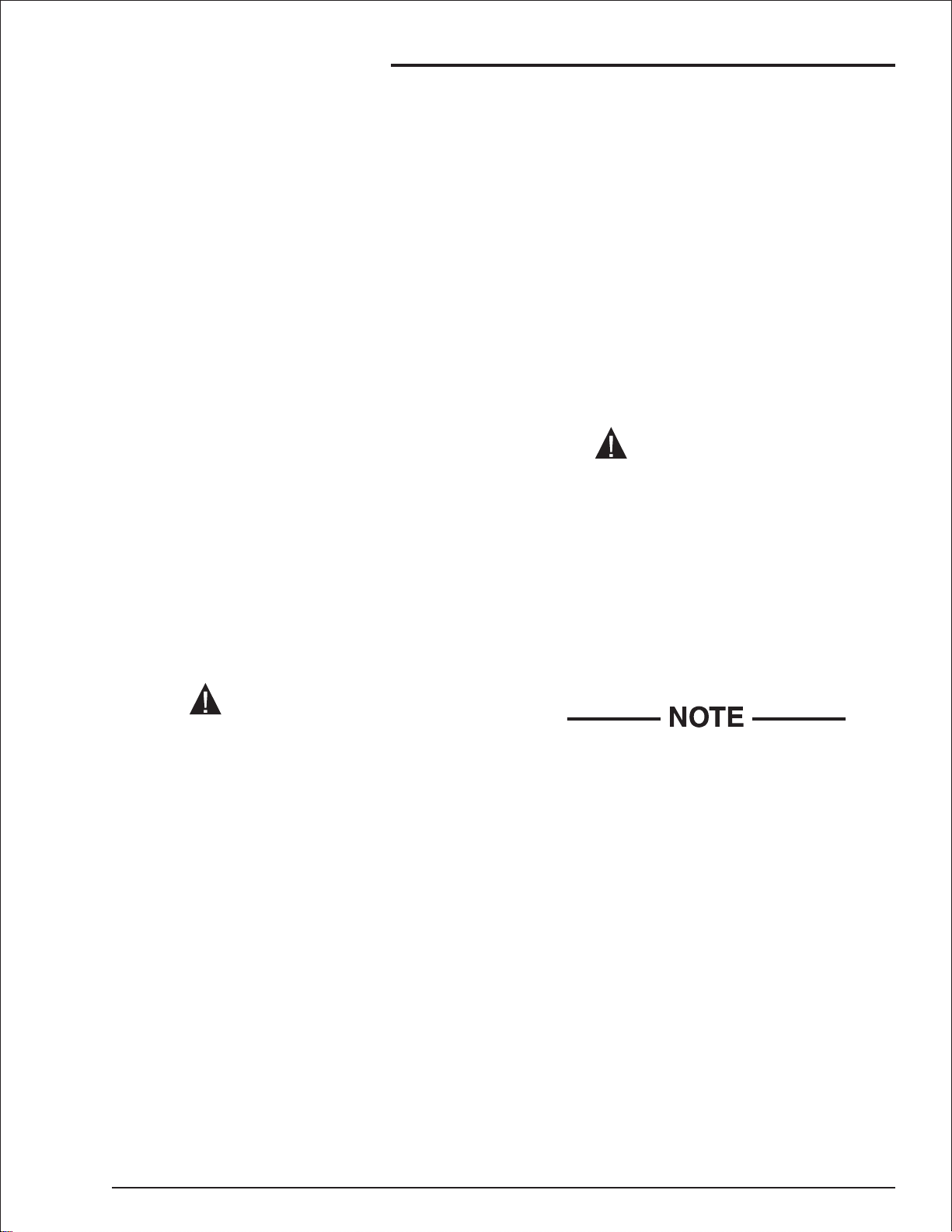

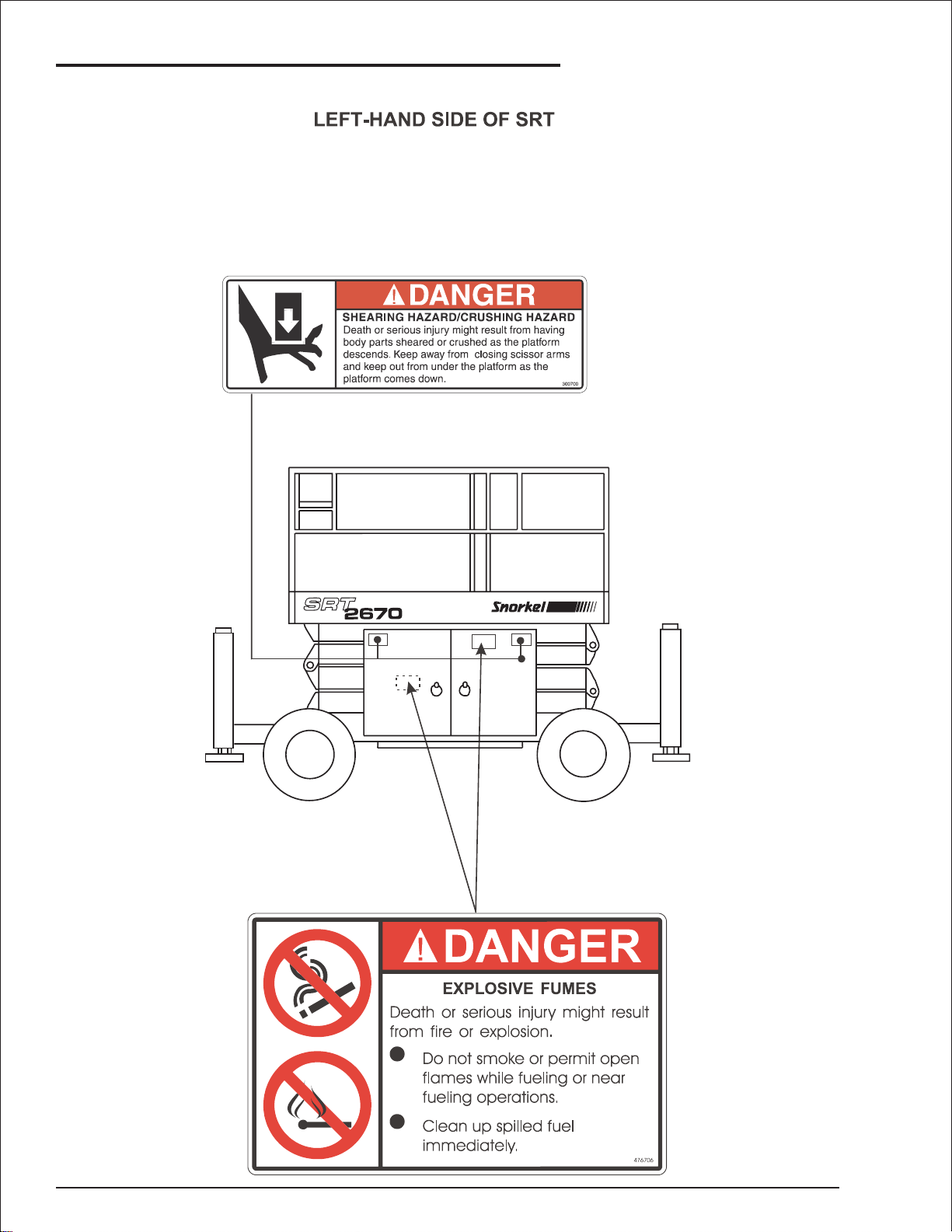

RIGHT-HAND SIDE OF SRT

1. Safety

SAFETY BAR

STORAGE POSITION

PROPER POSITION FOR USE

24”

SRT2670 – 11360A page 1 - 5

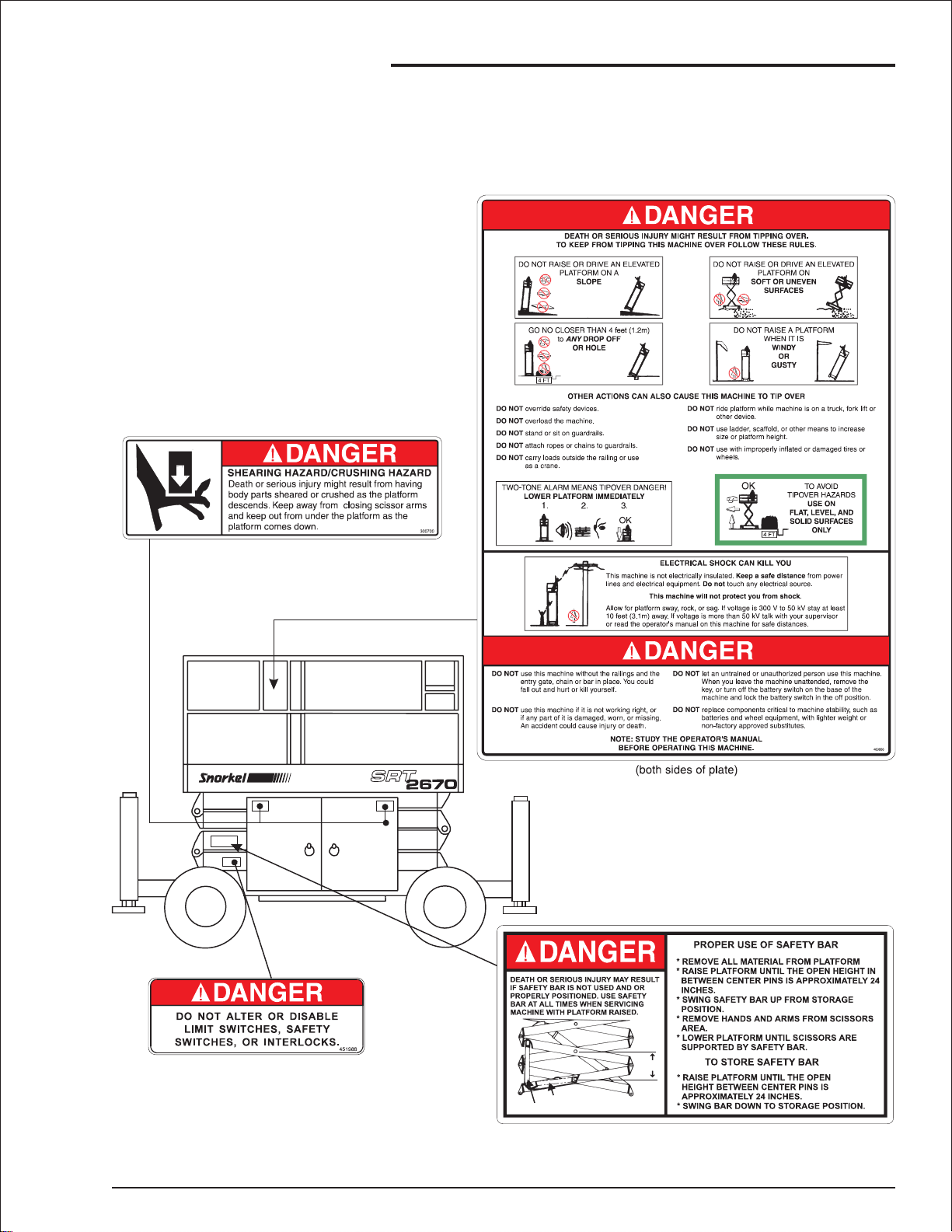

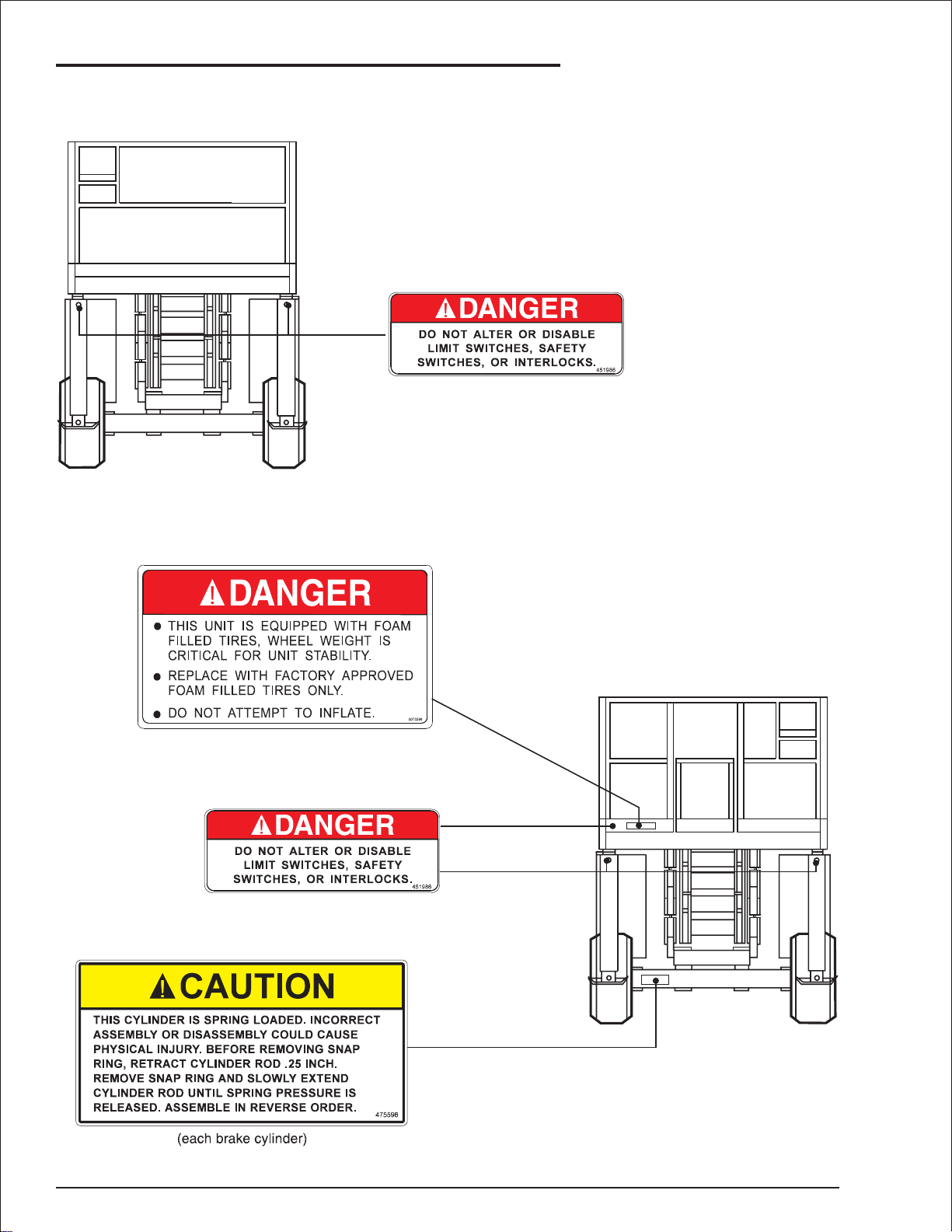

Page 16

1. Safety

FRONT END

REAR END

page 1 - 6 SRT2670 – 11360A

Page 17

2. Safety Devices

■

Safety Device Information

For emergency operation controls and procedures

see the “Emergency Operation” chapter 9, in this

manual.

The devices listed in this chapter are safety de

vices.

They are on an SRT to increase safety in the work

place for both the operator and other people near

the machine.

CAUTION

Do not by-pass, disable, modify, or ignore any

of these devices.Check them carefully at the

start of each work shift to see that they are in

working order (see “Daily Inspection &

Maintenance” chapter7). If any is found to be

defective, remove the SRT from service

immediately until a qualified service technician

can make repairs.

■

Emergency Stop Switches

❑

At platform control box

At ground control box

❑

-

Press the red EMERGENCY STOP switch cover

down, at any time, under any conditions, and the

entire machine stops, the engine turns off, and

nothing moves. the EMERGENCY STOP switch

must be up for anything on the SRT to work.

Press the large red EMERGENCY STOP button in

and the entire machine stops, the engine turns off,

and nothing moves.This switchmust be out (on) to

control the SRT from the platform (turn the switch

clockwise and it will pop out.

■

Alarms

❑

Platform control box

There are two alarms on an SRT.One is located in

the platform control box, the other is located in the

ground control box.

SRT2670 – 11360A page 2 - 1

Page 18

2. Safety Devices

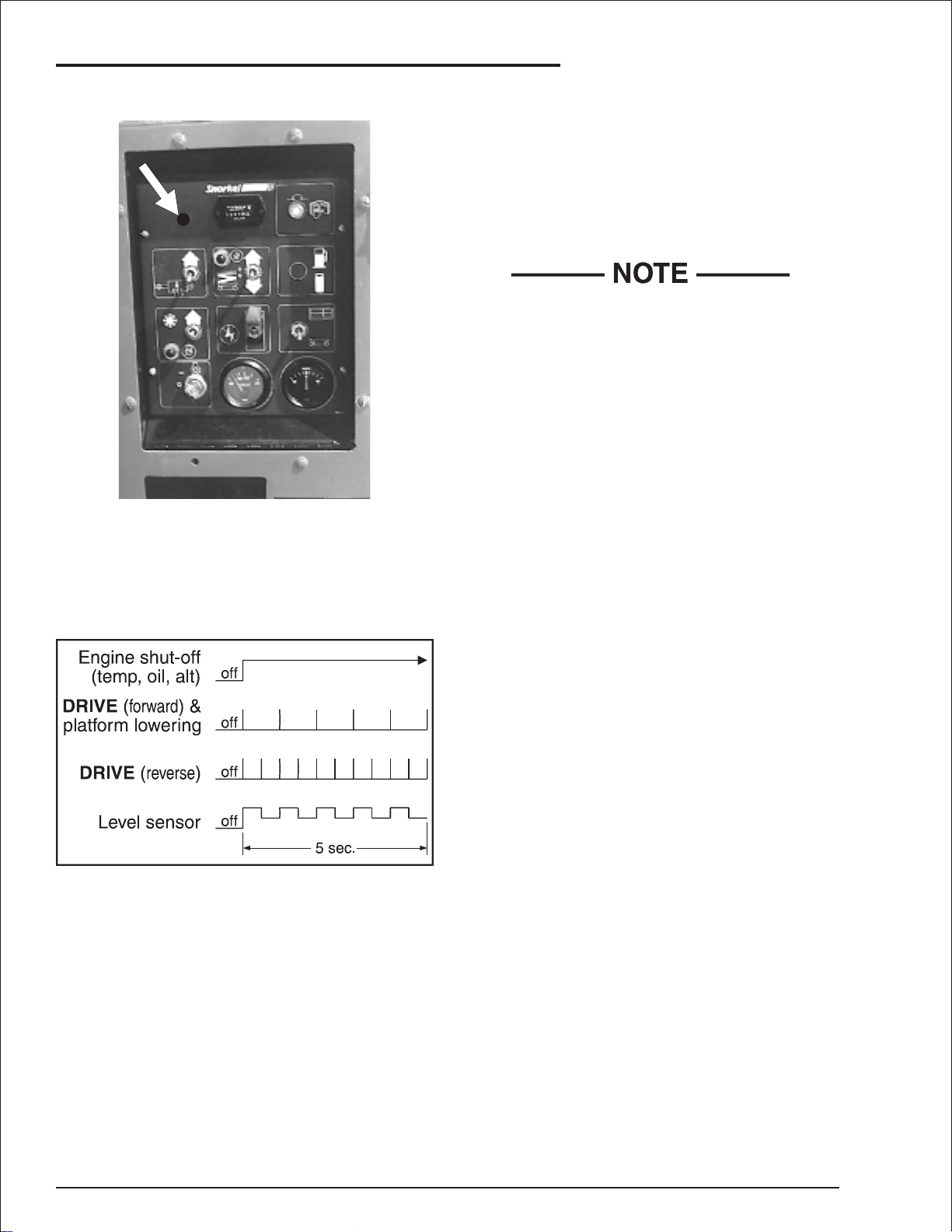

Ground control box

❑

The alarms are connected in parallel, they both

emit the same pattern of sound at the same time.

The different alarm sound patterns are shown in

the table immediately below and discussed below

the table.

Level sensor

❑

The level sensor alarm warns the SRT operator

that the SRT is not level. If the tilt continues to in

crease, the SRT will eventually tip over. When you

hear this alarm, immediately lower the platform

completely down. When the platform is completely

down, determine and correct the cause of the tilt

before raising the platform again.

While the alarm is sounding it is not possible

to drive the SRT nor raise the platform

Lowering

❑

Thelowering alarm warns people near an SRTthat

the platform is coming down and the scissor arm

assembly is closing.

High temperature

❑

Thehigh-temperature alarm warns youthat the engine is overheating. When the alarm sounds you

should immediately lower the platform completely

downthenturn theengineoff untilthecondition that

caused the overheating has been corrected. (See

“AutomaticShut-Offs & Circuit Breakers”chapter 5

for more information.)

-

The high-temperature, low oil-pressure, and alter

nator not-charging alar ms are each a continuous

tone.

The DRIVE (forward) and the platform-lowering

alarms beep at one beep per second. DRIVE (re

verse) beeps at two beeps per second. The level

sensor alarm is a high-low warbling sound.

❑

Low oil pressure

The low pressure alarm warns you that the engine

oilpressure isnear the lowerlimitfor safeoperation

of the engine. When the alarm sounds you should

immediately lower the platform completely down

then turn the engine off until the condition that

caused the low oil pressure has been corrected.

(See “Automatic Shut-Offs & Circuit Breakers”

chapter 5 for more information.)

❑

Drive (reverse)

The DRIVE (reverse) alarm alerts people that the

SRT is traveling backward along the ground. This

-

alarm beeps twice as fast as the DRIVE (forward)

alarm.

❑

Drive (forward)

-

The DRIVE (forward) alarm alerts people that the

SRT is traveling forward along the ground. This

alarm beeps half as fast as the DRIVE (reverse)

alarm.

page 2 - 2 SRT2670 – 11360A

Page 19

2. Safety Devices

■

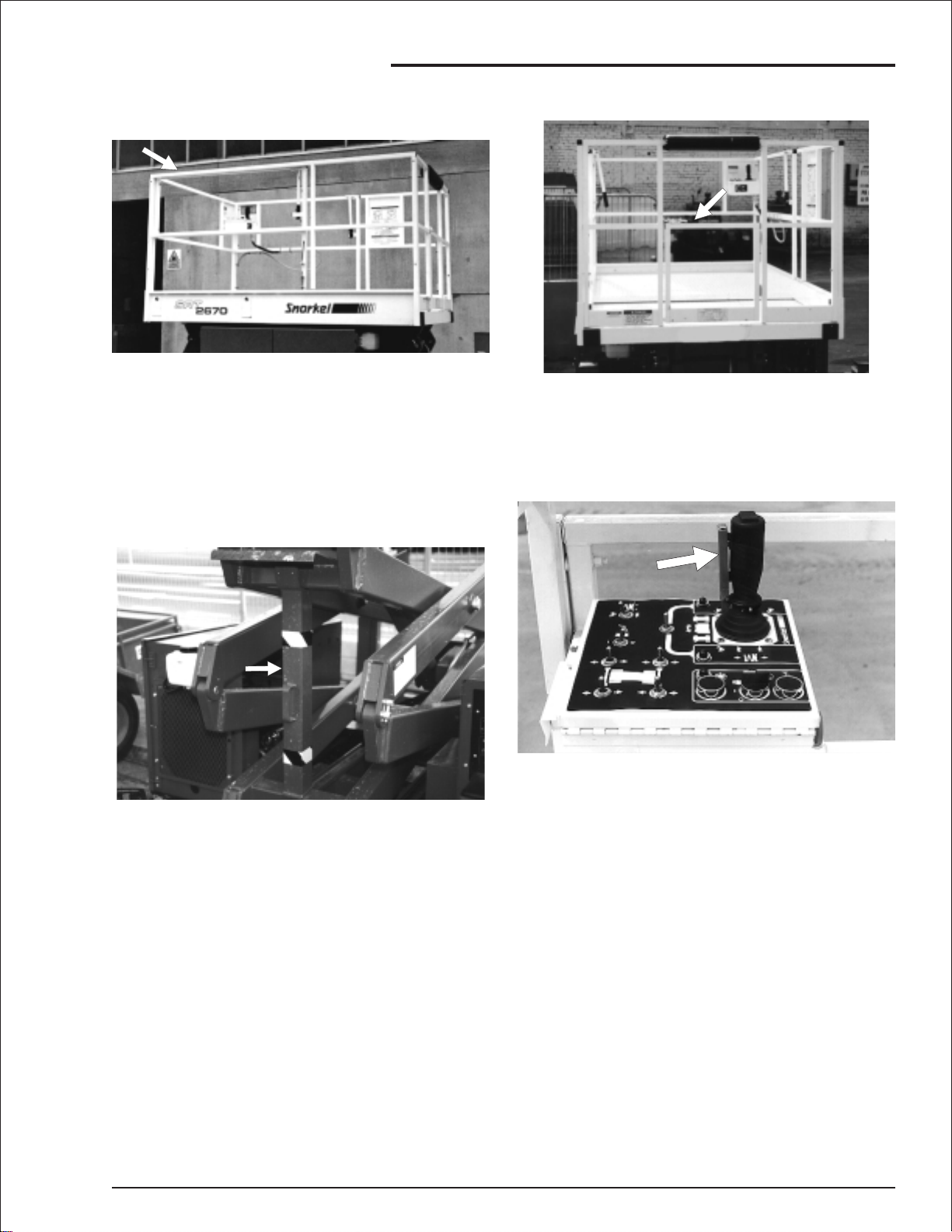

Guardrails

The guardrails help protect you from falling off the

platform. Be sure the guardrails are properly in

stalled and that the safety chain (or gate) and fas

teners are in place.

■

Safety Prop

■

Swinging Gate (option)

The swinginggate should be closed atall timesex

cept when someone is entering or leaving the plat

form.

-

■

Safety Control

-

-

The safety control must be squeezed and held to

activatethejoystick.Thesafetycontrolpreventsthe

joystickfrom movingtheplatform ifsomethingacci

Always raise the safety prop then lower the scis

sor-arm assembly onto the safety prop before

reachingintothe scissor-arm assemblyforanyrea

son.The safety chain should be closed at all times

except when someone is entering or leaving the

platform.

SRT2670 – 11360A page 2 - 3

-

dentally pushes the joystick. Do not disable the

safety control in any way.

-

-

Page 20

2. Safety Devices

■

Bubble Level (outrigger machines

only)

See the “Gauges”chapter 4 for a discussion of the

bubble level.

■

Operator Horn (option)

■

Outriggers (option)

The outr igger controls are on the upper left side of

theplatform control box.The outriggers are usedto

leveltheSRT(forcomplete outriggeroperatingpro

cedures see the “Operation” chapter 8).

CAUTION

The SRT must be on a firm surface capable of

withstanding all load forces imposed by the

aerial platform in all operation conditions

before the outriggers are used.

-

Theoperatorhornisused primarily toget theatten

tion of people on the ground when you are working

aloft.Forthe horn towork thefollowingswitches,on

the ground control box, must be set as indicated:

MAIN POWER........................ON

EMERGENCY STOP..............on (up)

SELECTOR............................PLATFORM

■

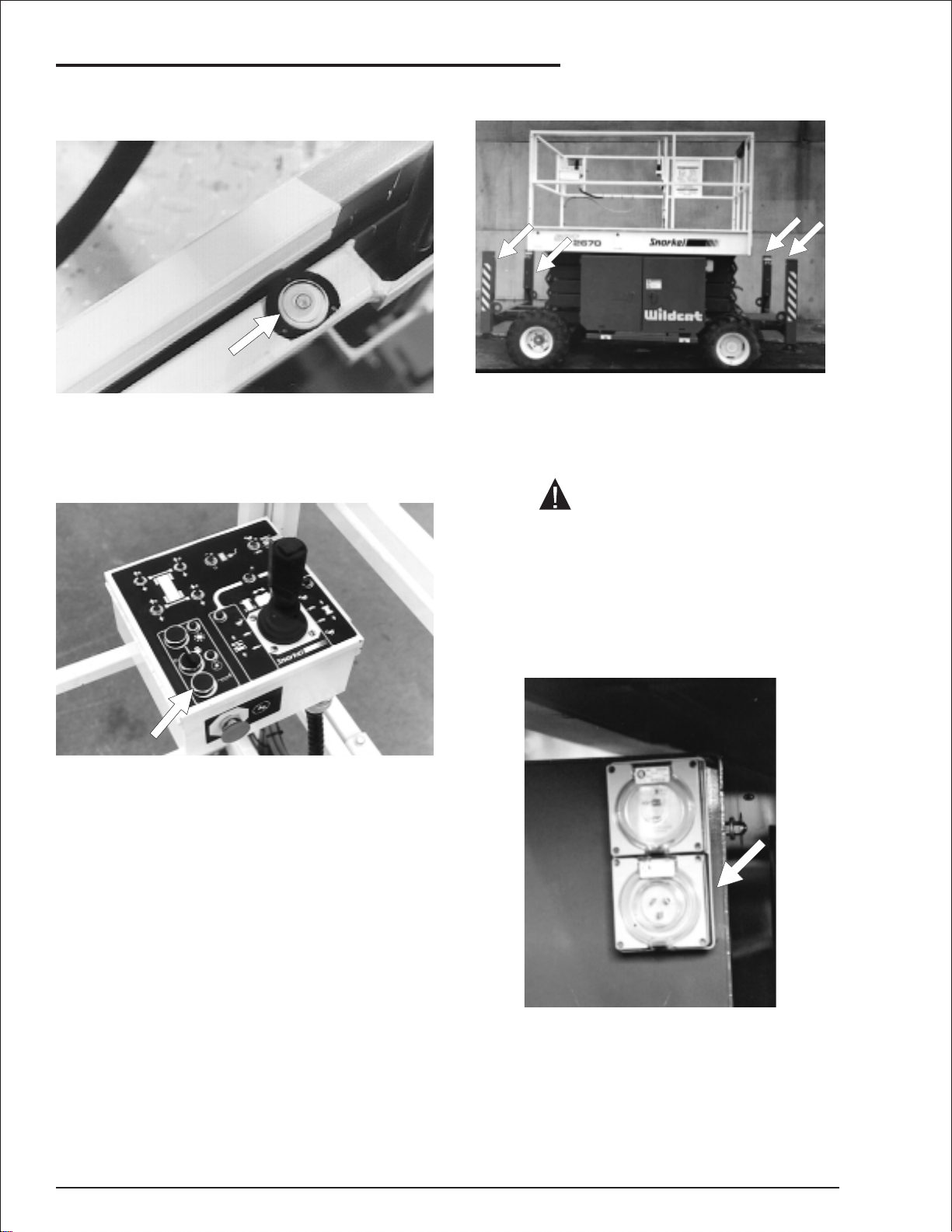

RCD/ELCB AC Outlet (option)

-

page 2 - 4 SRT2670 – 11360A

Page 21

The RCD (Residual Current Device) is located at

the ground and will protect against short circuits to

earth. When there is a short circuit the RCD will

shutdownthe 230vACpowerto theplatform outlet.

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the

ground.Ifthe problempersistscalla trainedservice

technician.

■

Flashing Light (option)

2. Safety Devices

The flashing light alerts people that the SRT is

present and that the SRT is moving. The light

flashes at about one flash per second any time the

SRTengine is running.There is no ON/OFF switch

for the flashing light, it cannot be turned off while

the SRT is running.

■

Lanyard Anchor Points (option)

There are four anchors on the floor of the platform,

one at the front of the roll-out deck, one at the back

of the platform, and one on each side of the plat

form.

These anchors are not for lifting or tying down

the machine.

Youshouldattachyourfallprotectionto theanchors

if work rules require it.

-

SRT2670 – 11360A page 2 - 5

Page 22

2. Safety Devices

page 2 - 6 SRT2670 – 11360A

Page 23

3. Specifications

3. Specifications

The SRT2670 series machines are scissor-supported elevatingwork platforms built to conform to the fol

lowing standards.

OSHA Paragraph1910.67 Title 29, C.F.R.,Vehicle-MountedElevating and Rotating Work Platforms - La

bour.

OSHA Paragraph 1926.556 Title 29, C.F.R., Aerial Lifts - Construction.

Australian Standard AS1418-10 1996 Elevating Work Platforms.

■

General Specifications, Standard Machines

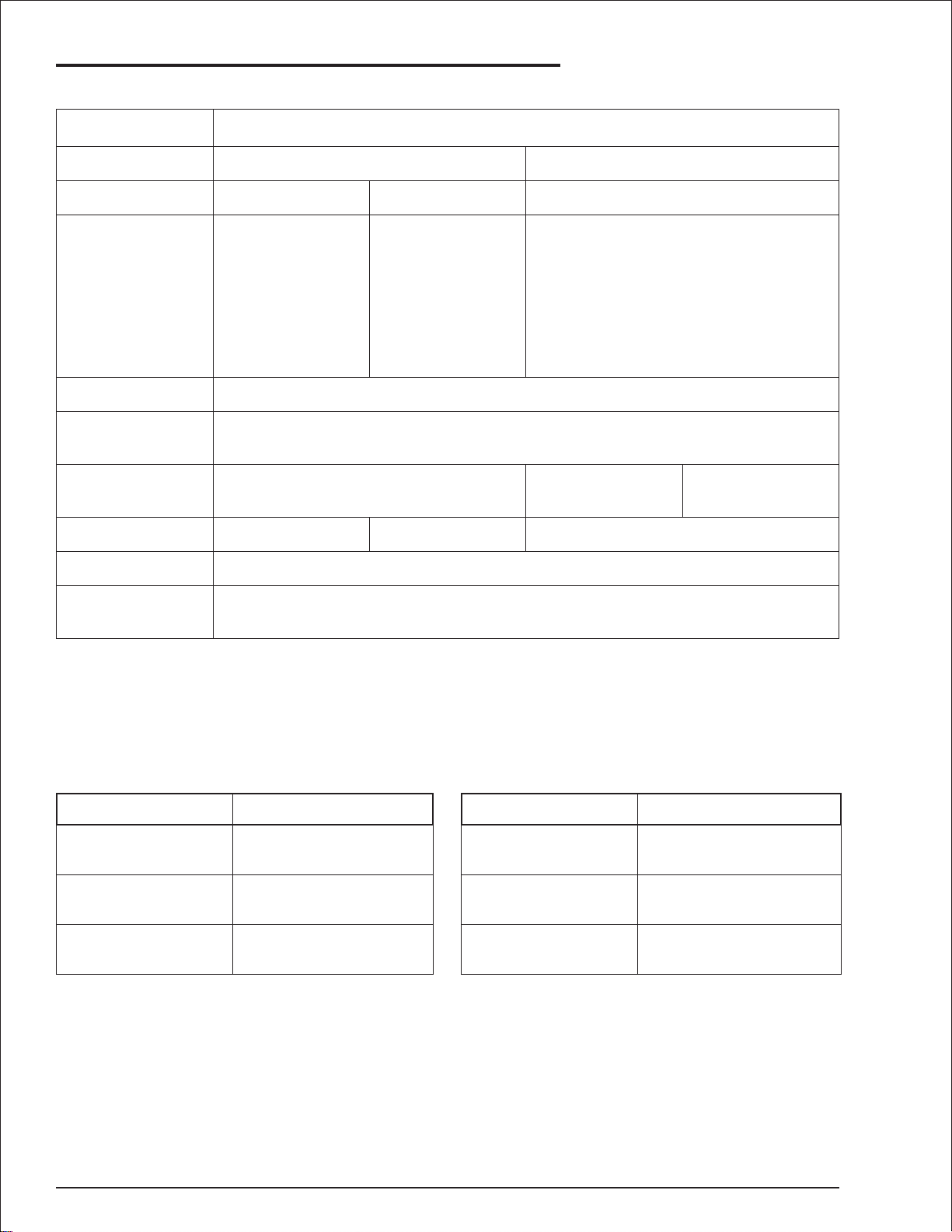

SPECIFICATIONS SRT 2670

Nominal working height

Maximum height to basket floor

Maximum outreach 1220mm with roll out deck

Speed (when raised)

Speed (maximum drive)

Maximum width of base

Safe working load (main deck)

9.9m 31’10”

7.9m 25’11”

0.72kph 0.45mph

6.2kph 3.9mph

1.8m 5’11”

390kg 858lbs

-

-

Safe working load (roll out deck)

Standard colour White platform. Orange scissors and base

Platform size*

Collapsed height

Overall length (without stabilizers)

Overall length (with stabilizers)

Gradeability

Lift time

Lower time

Turning radius (inner)

Turning radius (outer)

Insulation rating

Overall weight

Ground clearance

120kg 264lbs

1655 x 2200mm 5’5” x 7’ 4”

2525mm 8’1”

2680mm 8’ 10”

3325mm 10’10”

30%

22 seconds

45 seconds

2.56m 8’3”

4.3m 14’1”

Nil

2560kg 5632lbs

361mm 14.2”

* Four foot (1.2m) platfrom-extenuation retracted

SRT2670 – 11360A page 3 - 1

Page 24

3. Specifications

■

Engine Data

Engine Make Kubota

Model WG750-G D905-B

Fuel gasoline LPG Diesel number 2-D

Fuel grade Unleaded

HD5

ASTM number 2-D

85 octane

(motor method

Gas Processors

ASTM D975

Association

Do not use

gasoline blended

with methyl

alcohol.

Standard 2140

Category: special

duty propane

Centane number >44

(For operating temp. Below 32

use “winterized” number 2-D.)

Coolant 50% water + 50% ethylene glycol

Operating

180oF - 205oF (82oC-96oC)

temperature

Oil Capacity 3.5 qt USA

(3.25 liters)

5.2 qt USA

(5.1 liters)

Oil grade API: SF, SF/CD API: CC/CD/CE

Oil weight See chart below

Running time

(one tank of fuel)

A full tank of gasoline, or diesel, will last an entire eight hour shift, under normal

working conditions.It normally takes two tanks of LPG per eight hour shift.

4.2 qt USA

(4.0 liters)

o

F(0oC)

■

Engine Oil Charts

❑

WG750-G

Ambient temperature Engine oil weight

Above 77

o

32

Fto77oF

o

(0

C) to (25oC)

o

0

Fto32oF

(-17

o

F (25oC) SAE30 or 10W30

SAE20 or 10W30

o

C) to (0oC)

SAE10W or 10W30

❑

D905-B

Ambient temperature Engine oil weight

Above 77

o

F (25oC) SAE30 or 10W30

10W40

o

Fto77oF

32

o

(0

C) to (25oC)

Below 32

o

F(0oC) SAE10W or 10W30

SAE20 or 10W30

10W40

10W40

page 3 - 2 SRT2670 – 11360A

Page 25

■

Nomenclature and Serial Numbers

3. Specifications

SRT2670 – 11360A page 3 - 3

Page 26

3. Specifications

page 3 - 4 SRT2670 – 11360A

Page 27

■

Water

4. Gauges

Theindicator stays at its highestsetting, it does not

go to the bottom of the gauge when the engine is

turned off or the filter changed. After the filter is

changed, press the small reset button to reset the

indicator to the bottom of the gauge.

■

Amps

The water gauge is located on the ground control

box. It shows the temperature of the water-antifreezemixture in the engine block.The typical operating-temperature range for Kubota

enginesis 180°F to205°F (82°C to96°C), both diesel and gasoline.(See the “Automatic Shut-Offs &

Circuit Breakers ” chapter 5 for more information.)

■

Air Filter

The AMPS gauge shows the electric current from

the alternator to the battery. When the engine is

running, the needle in the AMPS gauge should not

be to the left of “0.” Under normal operating conditions, after the engine has been running for a few

minutes, the AMPS gauge should read “0.”

The air filter gauge is located between the air filter

and the intake manifold.The gauge measures the

vacuum(air pressure) between the intake manifold

and the air filter. As the filter clogs, the vacuum in

creases (pressure drops). As the vacuum in

creases, a red indicator raises toward the clear

area of the gauge.When you can see the indicator

inthecleararea ofthegauge,it’stimetochange the

air filter.

SRT2670 – 11360A page 4 - 1

-

-

Page 28

4. Gauges

■

Engine Oil

Engine oil levelis measured with a dipstick. Oil ca

pacities given in the “Specifications” chapter 3 are

approximate.True values will vary from machine to

machine due to slight variations or modifications

during production.

The oil dipstick is the only way to accurately

gauge if the engine oil level is correct.

Engine oil level should always be between the

lines on the dipstick - never above the top line

or below the bottom line.

Gasoline Diesel

The HOURS gauge is basically an electric clock.It

accumulates time only when the engine is running.

The HOURS gauge cannot be reset. An

SRT-qualifiedservicetechnician usesitto tellwhen

it is time for the periodic maintenance listed in the

Maintenance Manual.

■

Fuel Level (option)

LPGtanks havetwo fuel gauges (1) (2) ontop.One

measures correctly when the tank is standing on

end (VERTICAL) the other measures correctly

whenthe tank is layingdown (HORIZONTAL).Both

read in fractions-of-a-full-tank. SRT tanks are

mounted vertically. Therefore, you should read the

VERTICAL (1) scale.

■

Hours

■

Hydraulic Oil Level

The hydraulic-oil level gauge is on the side of the

hydraulic oil tank. It shows the actual level of oil in

side the tank. Read it only when the platform is

completely down. Otherwise, the lift cylinders be

come large reservoirs for hydraulic oil and the oil

level in the tank will be low.The oil level should be

within ( 0.25 inches (( 6.4 mm) of the line.

-

-

page 4 - 2 SRT2670 – 11360A

Page 29

■

Bubble Level (outrigger machines

only)

A bubble level is located on the platform side rail,

below the platform control box. Watch the bubble

levelwhile you set the outriggers.Lower the outrig

gers,oneata time,justenough tocenter thebubble

inthe circle ontop of thegauge.When thebubbleis

centered the platform is level and can safely be

raised.

4. Gauges

-

■

Coolant

The engine coolant reservoir is mounted on the

front of the engine tray.When the engine is at oper

atingtemperaturethe coolantshouldbe atthe HOT

line.When the engine is cold there should beabout

one inch (2.54 cm) of coolant in the bottom of the

reservoir.

-

SRT2670 – 11360A page 4 - 3

Page 30

4. Gauges

page 4 - 4 SRT2670 – 11360A

Page 31

5. Automatic Shut-offs and Circuit Breakers

■

Automatic Shut-offs

Level sensor

❑

When the levelsensor alarmsounds, automatic in

terlocksmakeitimpossibletodrivethe SRTorraise

the platform. For more complete information see

the “Level Sensor” subsection of the “Safety De

vices ” chapter.2

Engine temperature

❑

There is an oil pressure sensor in the engine. It

measures the engine oil pressure at the oil filter.If

the pressure falls below a safe operating value the

engine shuts off. The engine will restart with low

-

pressure but it will only run a few seconds before it

automatically shuts off again.

-

Platform height vs. drive speed

❑

When the platform is over 1.7m (5’ 6") above the

ground the drive speed is limited to its slowest

speed and the engine revs are also automatically

lowered.

Parking brakes

❑

Thereisatemperaturesensorinthe engine.Itmeasures the temperature of the antifreeze-water mixtureasthemixture leavesthetop oftheradiatorand

enters the top of the engine. If the temperature

reaches 210(F (99(C) an alarm sounds.If the temperature continues to rise, the engine shuts off

when the temperature reaches 230(F (110(C). The

engine will not restart until the temperature drops

below 210(F (99(C).

❑

Engine oil pressure

Whenthe JOYSTICKCONTROLLER is in the neutral position the SRT parking brakes are automatically set. The brakes automatically release when

youmovetheJOYSTICKCONTROLLERto drive.

❑

Dynamic brakes

When you drive an SRT down a slope, if the SRT

begins to coast (outrun the drive motors) the hy

draulicsystem“senses”thecoastingcondition.The

hydraulic drive motors then become hydraulic

brakesand the SRTis slowed.Thisaction prevents

SRTs from speeding down grades.

-

SRT2670 – 11360A page 5 - 1

Page 32

5. Automatic Shut-offs and Circuit Breakers

Alternator not charging

❑

When the fan belt breaks, or the alternator output

fallsbelowasafelevelforotherreasons,the engine

automatically shuts off and an alarm sounds. As

long as the SRT battery is charged you can lower

the platform, in the usual way, from the platform

control box or the ground control box without the

engine running.

Outriggers (option)

❑

The SRT cannot be driven unless the outriggers

arecompletely up.If youhavejustraised the outriggers but the SRT will not drive, double check to be

sure all four outriggers are completely up.

RCD / ELCB outlet (option)

❑

RESET

BUTTON

The RCD (Residual Current Device) is located at

the ground and will protect against short circuits to

earth. When there is a short circuit the RCD will

shutdownthe 230vACpowerto theplatform outlet.

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the

ground.

If the problempersists call a trained service technician.

■

Circuit Breakers

❑

Main breaker

There is only one circuit breaker, on a standard

SRT, that is accessible to the operator.Its purpose

is to protect the electrical circuits from electrical

overloads.Whenthe circuit breakertrips(pops out)

push it back in then attempt to use the SRT. If the

circuitbreakertrips asecondtime,takethe SRTout

of service and refer the problem to a qualified

trained service technician for repair.

page 5 - 2 SRT2670 – 11360A

Page 33

■

Controls

This chapter explains what each control does.

6. Controls

This chapter does not explain how to use the con

trolstoproduceuseful work,refertothe“Operation”

chapter8forthat,afteryouhavereadthischapter.

Foroptional-equipment controls, see the “Options”

chapter 11 .

The only optional-equipment controls discussed in

this chapter are the controls for: diesel engines,

dual-fuelengines,LP-onlyengines,andoutriggers.

See the “Emergency Operation” chapter 9 for the

location of the emergency bleed down control and

for correct emergency bleed down procedures.

The main operating functions of an SRT can be

controlled from the ground control box (1) or the

platform control box (2).

-

SRT2670 – 11360A page 6 - 1

Page 34

6. Controls

■

Hydraulic Compar tment

1.

Battery Switch: This must be ON for the

engine to start. When the battery switch is

OFF the positive side of the SRT battery

is disconnected from the electrical

system. Lock this switch OFF when the

SRT is left unattended.

■

Ground Control Box

Controls for operating an SRT from the ground are

located on the right side ofthe machine on the rear

of the hydraulic compar tment.

The number of each control below

corresponds to the control’s call-out on the

next page.

1.

Emergency Stop: Press the red

switch-cover down, at any time, under any

conditions, and the entire machine stops the engine turns off and nothing moves.

This switch must be up for anything on

the machine to work.

2.

Key Switch: This switch works like an

automobile ignition switch.Hold the key at

the start symbol (extreme clockwise

position) until the engine starts then

release it to the on position (bar

symbol).Turn the key to off (O) if the

platform is to stay in one position for a

long time.That will turn the engine off and

save fuel.

3.

Choke Indicator Light (gasoline engines

only): This light will be lit while you choke

the engine (see CHOKE below).

3.

Glow-Plug Indicator Light (diesel

engines only): This light will be on while

the glow plugs are on. Wait, about 30

seconds for the light to go out before you

try to start a diesel.

4.

Choke (gasoline engines only): Hold the

choke switch up anytime you start a

gasoline engine that is at ambient air

temperature (a “cold” engine).

4.

Glow Plug (diesel engines only): This is a

momentary contact switch. Press it up

then release it just before you start a

diesel engine that is at ambient air

temperature (a “cold” engine). This action

automatically causes glow plugs to come

on for 30 seconds to warm the inside top

of each cylinder, thus aiding combustion.

5.

Hydraulic Oil Warm-Up:When the

ambient air temperature is below 50°F

(10°C) and SRT movement is sluggish

because of cold hydraulic oil, turn the

warm-up switch on (up) for 5 to 10

minutes or until the hydraulic oil tank is

warm to the touch then turn the switch off

(down).For the warm-up system to work,

the engine must be running.

While the warm-up system is on, do not

attempt to move the SRT in any way.

6.

Lift Indicator Light: The platform can be

raised only when this light is lit. When this

light is not lit the platform will not rise

because: the platform is not level, or the

outriggers are not properly set.

7.

Platform Lift/Lower: Holding this switch

up causes the platform to rise. Pushing

this switch down causes the platform to

lower.

8.

Fuel (option): Before starting a dual-fuel

engine set the FUEL switch to gasoline

(up) or LP gas (down) depending on

which you want to use. If you select LP

gas, be sure to open the valve on top the

LP gas tank.

9.

Ground/Platform Selector: Must be

down for the ground control box to work.

Must be up for the platform control box to

work.

page 6 - 2 SRT2670 – 11360A

Page 35

Ground control box controls

❑

6

6. Controls

7

5

4

3

8

9

1

2

SRT2670 – 11360A page 6 - 3

Page 36

6. Controls

■

Platform Control Box

Controlsforoperatingan SRTfromthe platformare

located on the platform control box.

The number of each control below

corresponds to the control’s call-out on the

next page.

1.

Emergency Stop: Press the red button in

at any time, under any conditions, and the

entire machine stops - the engine turns

off and nothing moves. This switch must

be out (on) to start and run the SRT from

the platform control box, turn the switch

clockwise and it will pop out (on). Press

the switch in (off) if the platform is to stay

in one position for a long time. That will

turn the engine off and save fuel.

5.

Safety Control The SAFETY CONTROL

must be squeezed against the JOYSTICK

CONTROLLER to activate the joystick

controller.If the safety control is not

squeezed the joystick controller is

inoperative.

6.

Joystick Controller If the LIFT/DRIVE

SELECTOR is set to the left (lift function),

pushing the joystick controller forward

causes the platform to rise, pulling the

joystick controller backward causes the

platform to lower. If the LIFT/DRIVE

SELECTOR is set to the right (drive

function), pushing the joystick controller

forward causes the SRT to move forward,

pulling the joystick controller backward

causes the SRT to move backward.The

further you push or pull the controller the

faster the motion (except lowering-it

occurs at one speed only).

The EMERGENCY STOP switch on the

ground control box overrides the one on the

platform control box.If the one on the ground

control box is off the SRT will not start or run,

it does not make any difference whether the

one on the platform control box is on or off.

2.

Start Press and hold the switch in to start

the engine.As soon as the engine starts,

release the switch.

3.

Choke (gasoline engines only): Press

and hold the switch in anytime you start a

gasoline engine that is at ambient air

temperature (a “cold” engine).

3.

Glow-Plug (diesel engines only): This is a

momentary contact switch. Press it up

then release it just before you start a

diesel engine that is at ambient air

temperature (a “cold” engine). This action

automatically causes glow plugs to come

on for 30 seconds to warm the inside top

of each cylinder, thus aiding combustion.

4.

Choke Indicator Light (gasoline engines

only): This light will be lit while you choke

the engine.

4.

Glow-Plug Indicator Light (diesel

engines only): This light will be on while

the glow plugs are on. Wait for the light to

go out before you try to start a diesel.

Squeeze the SAFETY CONTROL anytime you

use the JOYSTICK CONTROLLER.

7.

Steering The rocker switch on top of the

JOYSTICK CONTROLLER turns the front

wheels left or right depending upon which

side of the switch you press.

The wheels do not return to straight ahead,

after a turn, the way automobile wheels do.

You must use the STEERING switch to

straighten the wheels after a turn.

8.

Lift/Drive Selector When this switch is

set to the left the JOYSTICK

CONTROLLER becomes a lift/lower

controller to raise or lower the platform.

When this switch is set to the right the

JOYSTICK CONTROLLER becomes a

drive controller to drive the SRT forward

or backward.The SRT will not drive and

lift at the same time.

9.

Speed Set the switch to turtle (slow)

when you are working in close quarters or

if you are new to the machine. Setting the

switch to rabbit (fast) doubles the top

speed of the SRT.

10.

AC Outlet Switch (option): This is an

on/off switch for the 230 V ac hydraulically

powered generator.When the switch is

on, the outlet box at the platform is

energized.

page 6 - 4 SRT2670 – 11360A

Page 37

6. Controls

11.

Lift Indicator Light The platform can be

raised only when this light is lit. When this

light is not lit the platform will not rise

because: the platform is not level, or the

outriggers are not properly set.

12.

Outriggers Each switch corresponds to

one of the outriggers. Pull a switch

backward to lower an outrigger, push it

forward to raise the outrigger.

Platform control box controls

❑

13.

Drive Indicator Light The platform can be

driven when this light is lit. When it is not lit

the platform will not drive because with the

platform raised the base is not level or with

the platform raised the axle switches are not

set.

SRT2670 – 11360A page 6 - 5

Page 38

6. Controls

page 6 - 6 SRT2670 – 11360A

Page 39

7. Daily Inspection and Maintenance

At the start of each work day (or 8 hour shift), an

SRT qualified operator must perform the Daily In

spection and Maintenance as listed in the table be

Defective par ts and/or equipment malfunctions

jeopardizethe safety of the operator and other per

sonnel, and can cause damage to the machine.

-

low.

The purpose of the Daily Inspection and Mainte

nance is to keep the SRT in proper working condi

tion and to detect signs of malfunction at the

earliest possible time.

Set the Key Switch set to OFF before you begin

this inspection.

■

Daily Inspection and Maintenance Table

-

-

DO NOT operate an SRT that is known to be

damaged or malfunctioning.

Repair all equipment damage or malfunctions,

before placing the SRT into service.

DANGER

Item Service Required

Fuel level Visually inspect

Fuel filter (diesel engines only) Visually inspect (condition)

Fuel leaks Visually inspect (hoses and connections etc)

Engine oil Check oil level (between dipstick lines)

Engine coolant Check fluid level and radiator hoses

Radiator cap Visually inspect installation)

Platform safety chain Visually inspect (operation)

Swinging gate Visually inspect (installation, operation)

Wiring harnesses and connectors Visually inspect (installation, operation)

Battery terminals Visually inspect (no corrosion)

Hydraulic tank cap Visually inspect installation)

Hydraulic oil level Check fluid level (at line on side of tank)

Hydraulic oil leaks Visually inspect (hoses,tubes)

Tires and wheels Visually inspect (condition)

Bolts and fasteners Visually inspect (looseness)

Structural damage and welds Visually inspect (welds, cracks, dents)

Guardrails Visually inspect (condition)

Lanyard anchorages (option) Visually inspect (condition)

Bubble level on platform (outrigger machines) Visually inspect (condition)

Guides, rollers and slides Visually inspect (condition)

START THE ENGINE FROM THE GROUND CONTROL BOX

Charging system Check condition (gauge)

Level sensor Check operation

Ground controls Actuate and visually inspect for operation

Emergency lowering Check operation (causes correct motion)

Platform controls Actuate and visually inspect for operation

Flashing light (option) Visually check (operation)

RCD / ELCB (option) Check operation

Air filter Check condition (gauge)

Safety prop Check operation

Parking brakes Check operation

Placards, decals, and Operators Manual Visually inspect (installation and condition)

-

SRT2670 – 11360A page 7 - 1

Page 40

7. Daily Inspection and Maintenance

The rest of this chapter shows how to perform the

inspectionand maintenance required for each item

in the daily inspection and maintenance table.

■

Fuel level

■

Fuel filter (diesel engines only)

Visually check to see that there is no water in the

bottom of the filter.

Remove the fuel tank cap. Visually Check to see

that the gasoline or diesel tank is full.

Replace the tank cap and tighten.

❑

(Option - LPG)

To check the fuel read the fuel meter (4) on top.

■

Fuel leaks

To replace an LPG tank: Close the valve (1).

Manually disconnect the fuel hose at the knurled

ring (2). Manually lift the tank (3) out.

page 7 - 2 SRT2670 – 11360A

Page 41

7. Daily Inspection and Maintenance

Visually inspect the entire length of the fuel line,

from the engine to the fuel tank, for leaks.

■

Engine oil

Keepthe oillevelbetweenthe markson thedipstick

(1).

The distance between the top and bottom dipstick

markscorresponds toabout1qt.(one liter).Add oil,

if needed at the cap (2) on top of the engine.

Turn the engine OFF at the ground control box box

KEYSWITCH.Removethecap(2) fromthecoolant

reservoir.Add coolant and replace cap.

■

Radiator cap

Visually check to see that the cap is in place and

tight.

■

Swinging gate (option)

See the “Specifications” chapter 3 for the

correct engine oil grade and weight.

■

Engine coolant

The Kubota engine is liquid cooled. At operating

temperatures the coolant should be at the HOT

level(1).When cold there should be approximately

1inch (2.5cm) of coolantin the bottomof the reser

voir.

Inspect the gate to see that it swingsfreely,latches

securely, and is not deformed in any way.

-

Thecoolantishalf waterandhalfethyleneglycol.

To add coolant:

SRT2670 – 11360A page 7 - 3

Page 42

7. Daily Inspection and Maintenance

■

Wiring harnesses and connectors

Inspect all the wiring harnesses, on the machine,

for loose connections, broken wires, and frayedin

sulation.

■

Battery terminals

Batteryterminalsshould beclean andfreeofcorro

sion — none of that greenish-white fuzzy stuff.

-

■

Hydraulic tank cap

-

Check to see that the cap is in place and is tight.

■

Hydraulic oil level

To check the hydraulic oil level:

Payparticular attentiontothe wiringharnessesthat

are attached to the scissor stack.

page 7 - 4 SRT2670 – 11360A

Completely lower the platform.

Page 43

The hydraulic oil level should be at the full level. If

necessary, add hydraulic oil at the Hydraulic oil

tankcap.Seethe “Specifications”chapter3fortype

and grade of hydraulic oil.

■

Hydraulic oil leaks

DANGER

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds (if

under high pressure). Do not tolerate hydraulic

oil leaks.They are dangerous.

Hydraulic oil leaks are easily visible and can show

up anyplace.

Visuallyinspect the entire machinefor hydraulicoil.

Checkthegroundunderthemachine forleakedoil.

7. Daily Inspection and Maintenance

Check for loose fittings at the valve.

Pay particular attention to the cylinders, check to

see that there is no oil leaking from the seal, also

check all hoses that run to the cylinders.

■

Tires and wheels

SRT tires are foam filled. Punctures of the type

causedby bolts, screws,or nails are not a problem.

Look for large holes or long cuts completely

through the tire body: holes or cuts where foam is

being forced or eroded out of the tire.Also look for

large imbedded objects, such as angle iron, that

can rip a tire body open under some conditions.

SRT2670 – 11360A page 7 - 5

Page 44

7. Daily Inspection and Maintenance

■

Bolts and fasteners

Visually inspect all fasteners to see that none are

missing or obviously loose.

Visually inspect all welds for cracks, all structural

members for deformity, and all sheet metal for

dents that could interfere with machine operation.

■

Guardrails

Pay particular attention to all of the wheel nuts.

None should be visibly loose, missing, or de

formed.

■

Structural damage & welds

Payparticular attentiontothe guardrails.Makesure

theguardrails areproperly installed, thatall the fas

teners are in place,and that the swinging gate is in

place and works properly.

■

Lanyard anchorages (option)

Check all four lanyard anchorages on the floor of

the platform to see that they are present, not de

formed, that they movefreely,and that they are se

curely attached to the platform.

-

-

-

page 7 - 6 SRT2670 – 11360A

Page 45

7. Daily Inspection and Maintenance

■

Bubble level (machines with

outriggers)

Visually check to see that the bubble level is not

damaged, that it is full of fluid, that the bubble does

not exceed the diameter of the center black circle,

and the surface on which the bubble level is

mounted is not deformed or bent out of level.

■

Guides, rollers, and slides

Visually check slides (1), and rollers (3) forwear or

damage.Be sure that the guides (2) are free of de

bris and allow the slides and rollers to move

smoothly.

■

Charging system

-

With the engine idling, the needle in the AMPS

gauge should not be to the left of “0" (left of ”0" is

discharging).

2

1

Leave the engine running for the next step

■

Level sensor

With the SRT engine running and scissors raised,

push the levelsensor to the side as faras possible.

The level sensor alarm should sound.

SRT2670 – 11360A page 7 - 7

Page 46

7. Daily Inspection and Maintenance

■

Ground controls

Checkthe Platform Lift/Lower switch(1) to see that

it is functioning properly by holding the switch up to

rise platform and pushing the switchdown to lower

the platform.

In cold temperatures (below 50(F/10(C ) check to

see that the Hydraulic Oil Warm-Up switch (2) is

functioning properly by turning the switch on (up)

for 5 to 10 minutes or until the hydraulic oil tank is

warmtothetouchthenturn theswitchoff(down).

Pay particular attention to the Emergency Stop

switch (3) to see that it turns the SRT engine off

when struck.

■

Emergency lowering

Then open the emergency bleed-downvalve(1) by

followingthe instructions on the emergency lower

ing decal (2). Screw the emergency bleed-down

valve (1) completely in after the platform is down.

■

Platform controls

Check all of the lift (1), drive (2), steer (3), and outrigger (4, if present) functions from the platform

control boxto see that theycause the SRT to move

the wayit should.(for correct operating procedures

see the “Operation” chapter 8).

Listen for the lowering alarm while the platform is

going down. Listen for the motion alarm while the

SRTis being drivenforward.Listen forthe back-up

alarm while the SRT is backing up.

Press the operator horn (5) to see that it works.

Pay particular attention to the Emergency Stop

switch (6) to see that it turns the engine off when

struck.

Payparticularattention to theSafety Control(7) to

see that it deactivates the Joystick Controller (8)

when the safety control (7) is released.

-

■

Flashing light (option)

To check the emergency lowering: Raise the plat

formand turnthe engine OFF at the ground control

box KEY SWITCH.

page 7 - 8 SRT2670 – 11360A

-

Page 47

7. Daily Inspection and Maintenance

Check to see that the light flashes approximately

once a second when the SRT engine is running.

■

RCD / ELCB (option)

The RCD (Residual Current Device) is located at

the ground and will protect against short circuits to

earth. When there is a short circuit the RCD will