Page 1

SR2684SL

SR3084SL

Operator Manual

This first section of the Operator manual is the English language version.

Manuel Utilisateur

La troisième section de ce manuel est la version en langue Française.

Manual del Usuario

El apartado cuarto de este manual del usuario corresponde a la versión en Españo.

(EN) Manual part number 505562-100 for serial numbers 50001 to current.

(FR) Manuel Pièce numéro 505562-100 pour numéro série 50001 jusqu'au

numéro courant.

(ES) El número de referencia para el manual es el 505562-100 para la

números de serie del 50001 hasta el actual.

Page 2

Page 3

SR-2684/3084-SL

Serial Numbers 50001 – Current

ENGLISH

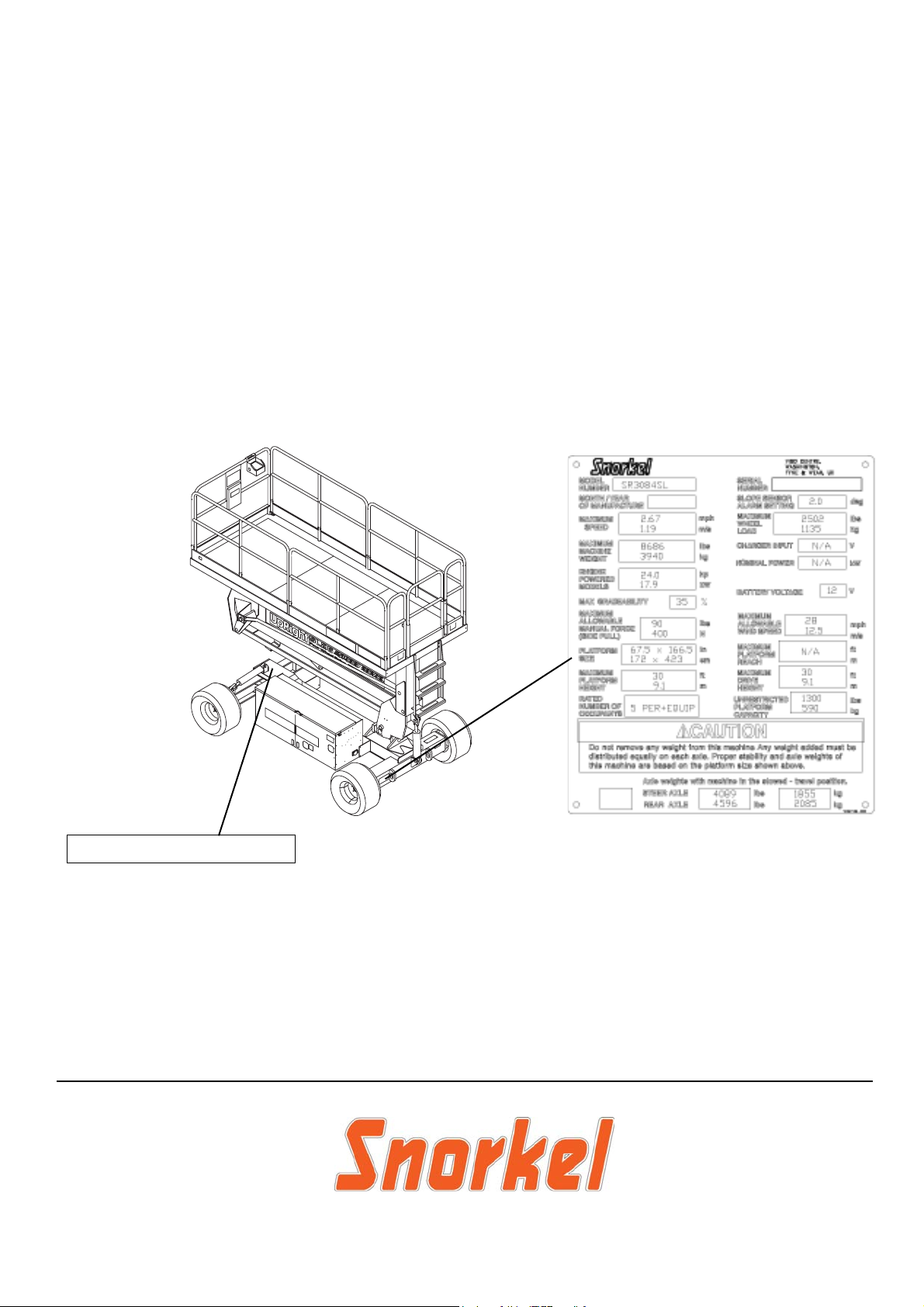

When contacting Snorkel for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the

equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis

above the front axle pivot.

Stamped Serial Number

TEXT FOR ILLUSTRATION PURPOSE ONLY

www .snorkelusa.com

Page 4

Page 5

OPERATION MANUAL

C

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any Snorkel work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assemb ly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing gate is closed and securely

locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

ollision Hazard Fall Hazard

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

Snorkel.

NEVER climb, stand, or sit on

platform guardrails or midrail.

Page 1

Page 6

505562-100

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Platform Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Lowered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Elevating the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Levelling the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fold Down guardrails, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fold Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Erection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parking Brake Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting the Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting By Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

By Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driving or Winching onto a Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blocking The Elevating Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Stowage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspection and Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Daily Preventative Maintenance Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 2 SR2684SL & SR3084SL

Page 7

Introduction 505562-100

I

NTRODUCTION

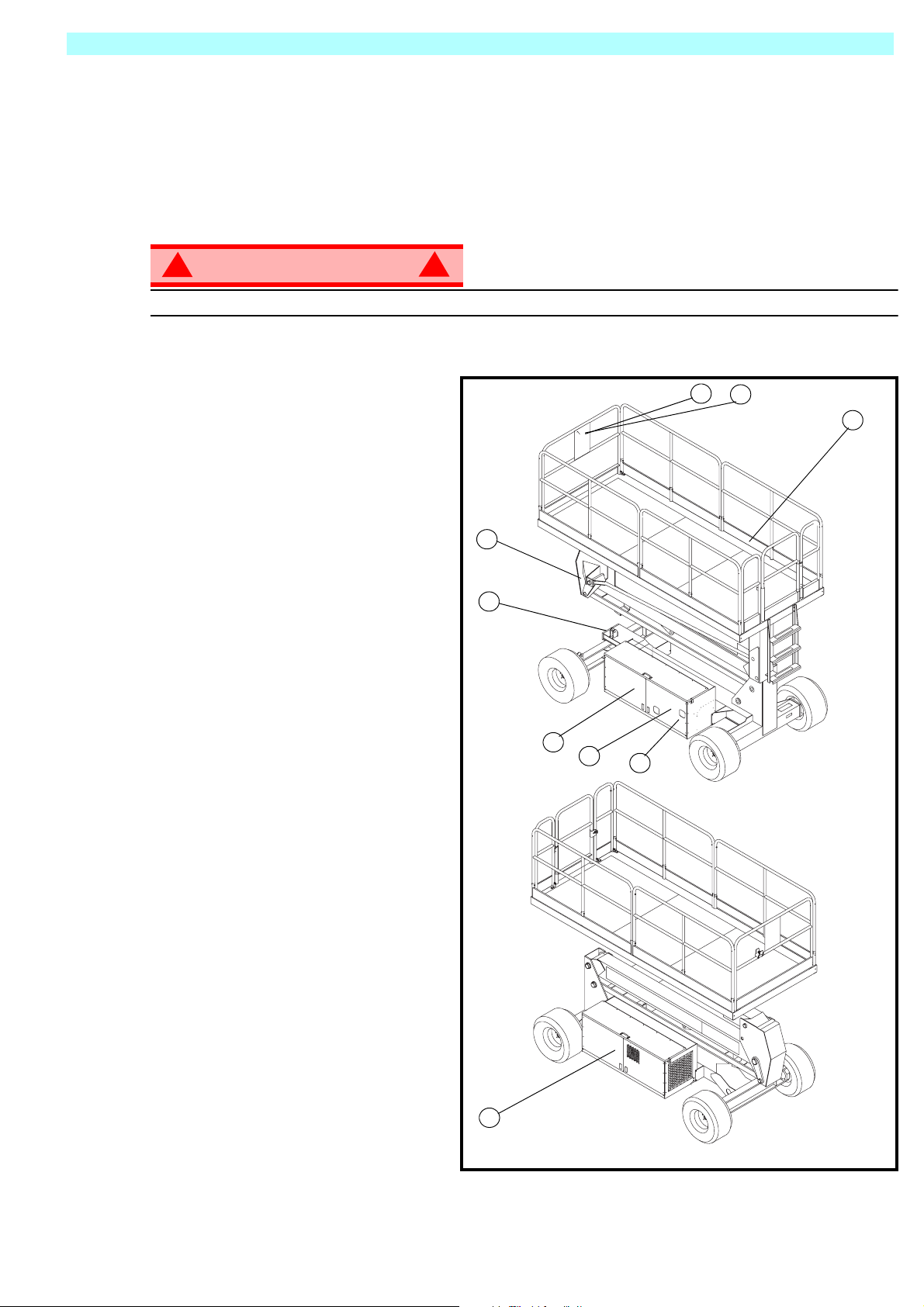

This manual covers operation of the SR2684SL & SR3084SL Series Self-Propelled Work Platforms.

This manual must be stored o n the machine at all times.

G

ENERAL

D

ESCRIPTION

!

WARNING

DO NOT use the maintenance platform without guardrails properly assembled and in place

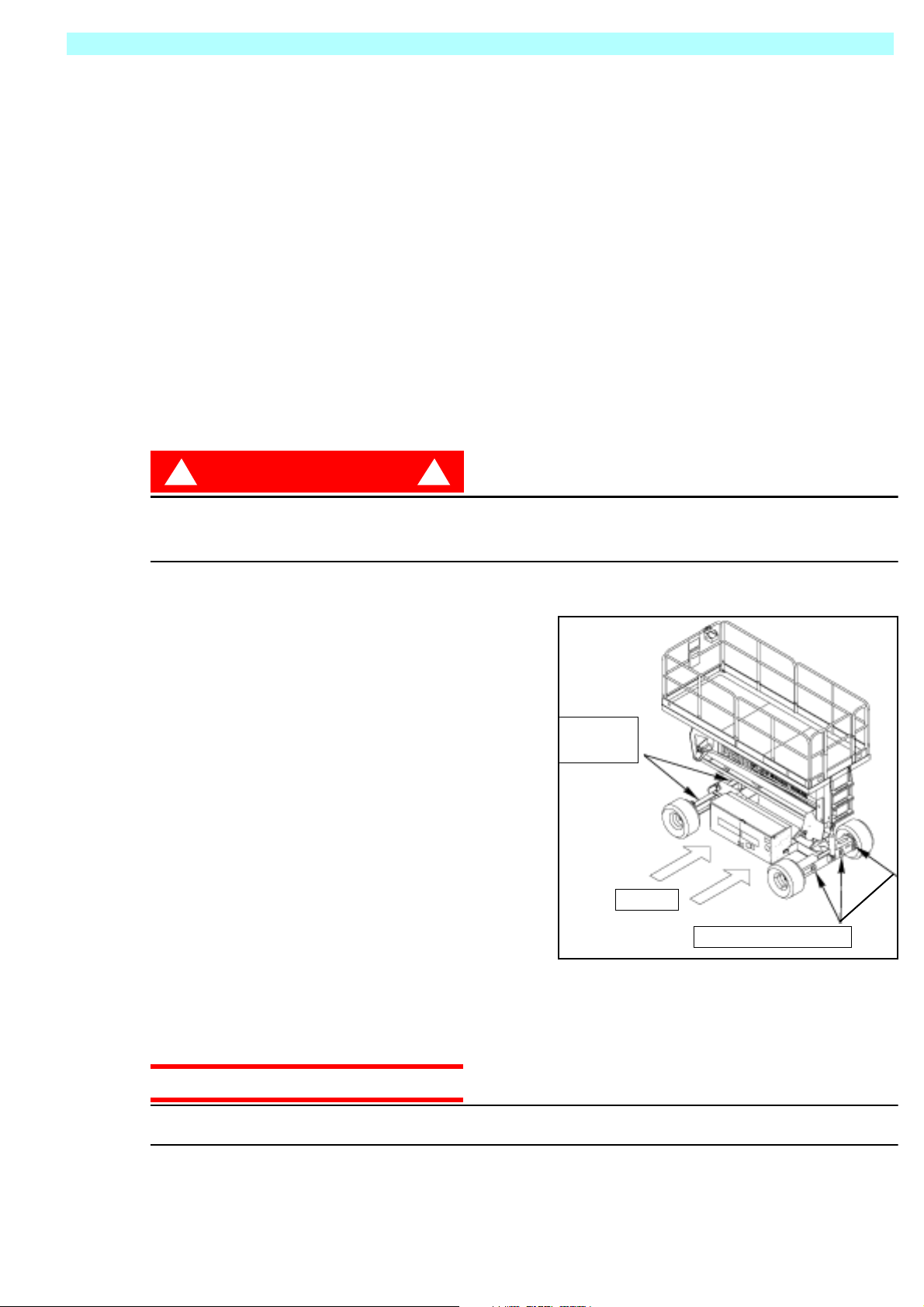

1. Platform

2. Elevating Assembly

3. Chassis

4. Power Module

5. Control Module

6. Platform Controls

7. Manual Case

8. Chassis Controls

9. Hydraulic Fluid Reservoir

!

Figure 1: SR2684SL & SR3084SL

7

6

2

3

1

5

8

4

9

SR2684SL & SR3084SL Page 3

Page 8

505562-100 Special Limitations

S

PECIAL

P

M

L

IMITATIONS

Travel with the platform raised is limited to creep speed range.

Elevating the Work Platform is limited to firm, level surfaces only.

DANGER

! !

The elevating function shall ONLY be used when the work platform is leveled and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

LATFORM

The maximum capacity for the MACHINE, including occupants is determined by model and options, and

is listed in “Specifications” on page 18.

DANGER

! !

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

ANUAL

Manual force is t he force applied by the o ccupant s to object s such as w alls or oth er structures outside the

work platform .

F

C

APACITY

ORCE

The maximum allowable manual for ce is limited to 200 N ( 45 lb s.) of force per occupant , with a ma ximum

of 400 N (90 lbs.) for two or more occupants.

DANGER

! !

DO NOT exceed the maximum amount of manual force for this machine.

B

EAUFORT

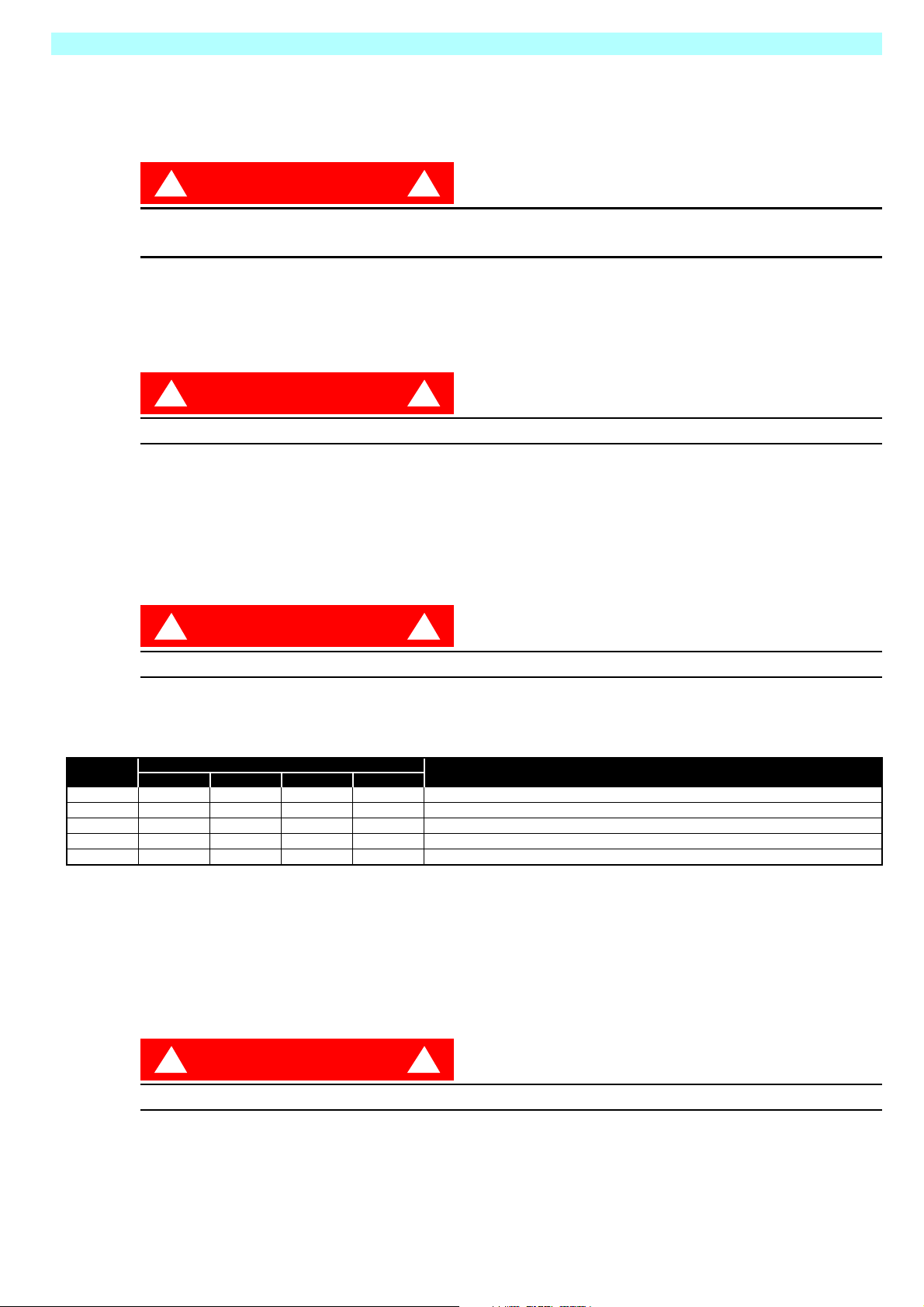

Never operate the machine when wind speeds exceed 12.5m/s (28 mph) [Beaufort scale 6].

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

m/s km/h ft/s mph

L

IFT

O

If a load equivelent to 90% of safe working load is lifted a fault code “03” will be displayed on the digital

display on the platform control box. If a load which is greater than the safe working load is present in the

basket all machine functions will cease to operate and an acoustic warning will sound. In order to return to

normal operation a load equal to or less than the saf e w orking load must be present in the bask e t and the

power must be re-cycled, power can be re-cycled by pushing the emergency stop button and releasing it

again.

WIND SPEED

VER L OA D

S

CALE

A

LARM

GROUND CONDITIONS

DANGER

! !

Never operate the machine with a platfo rm load greater than the rated capacity.

Page 4 SR2684SL & SR3084SL

Page 9

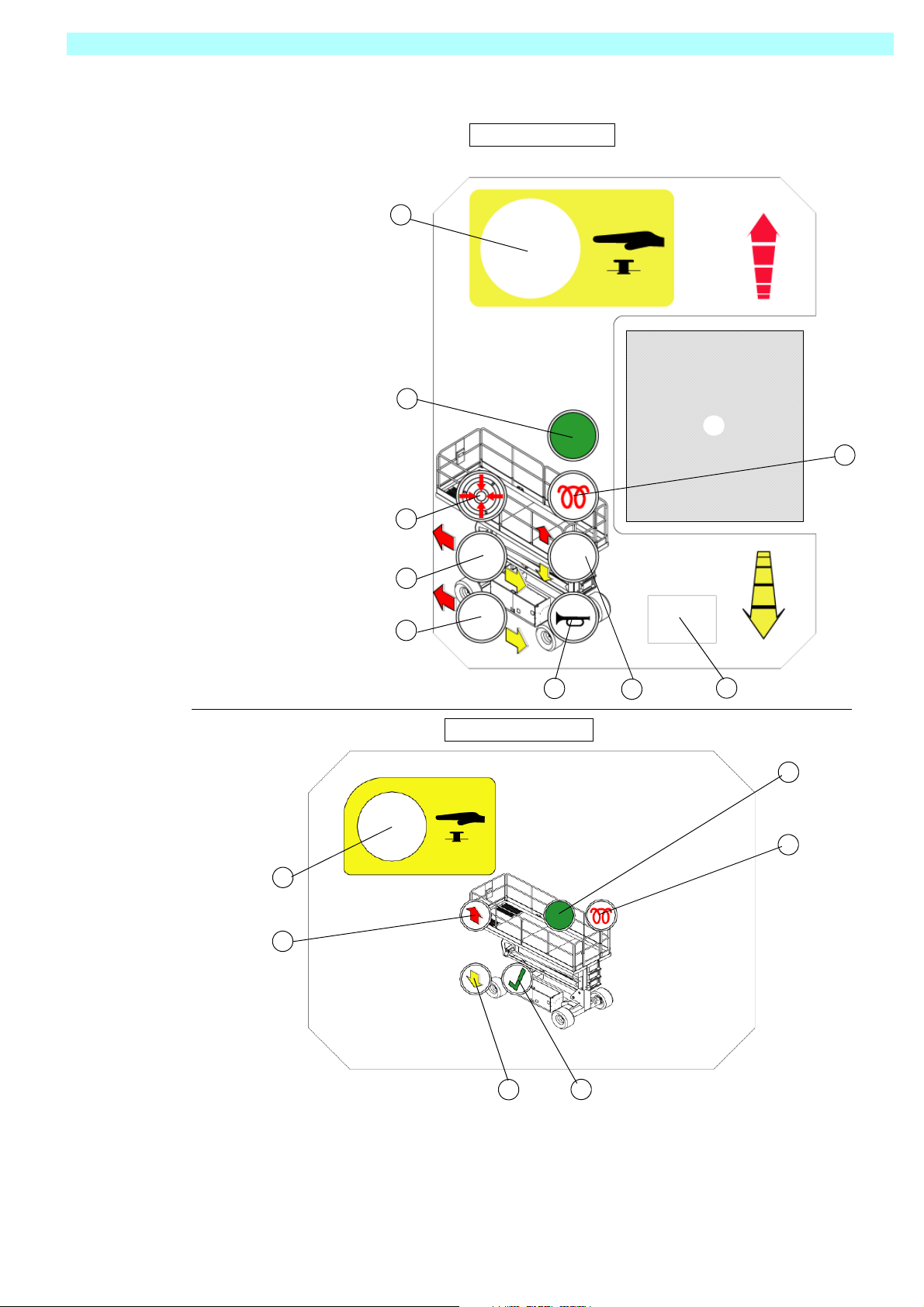

Controls and Indicators 505562-100

C

ONTROLS

AND

I

NDICATORS

Figure 2: Controls and Indicators

Platform Controls

8

7

10

6

1 Drive (Hi Speed)

2. Drive (Low Speed)

3. Level

4. Horn Button

5. Lift/Lower Button

6. Glow Plug

7. Engine Start

8. Emergency Stop Button

9. Display

10. Joystick

1

2

3

2

1

4

Chassis Controls

5

9

6

5

1. Emergency Stop

2. Elevate

3. Descend

4. Enable

5. Glow Plug

6. Start

3

4

SR2684SL & SR3084SL Page 5

Page 10

505562-100 Pre-Operation Safety Inspection

P

RE

-O

PERATION

NOTE: Carefully read, understand and follow all safety rules, operating instructions, labels and

National Safety Instructions/Requirements. Perform the following steps each day before use.

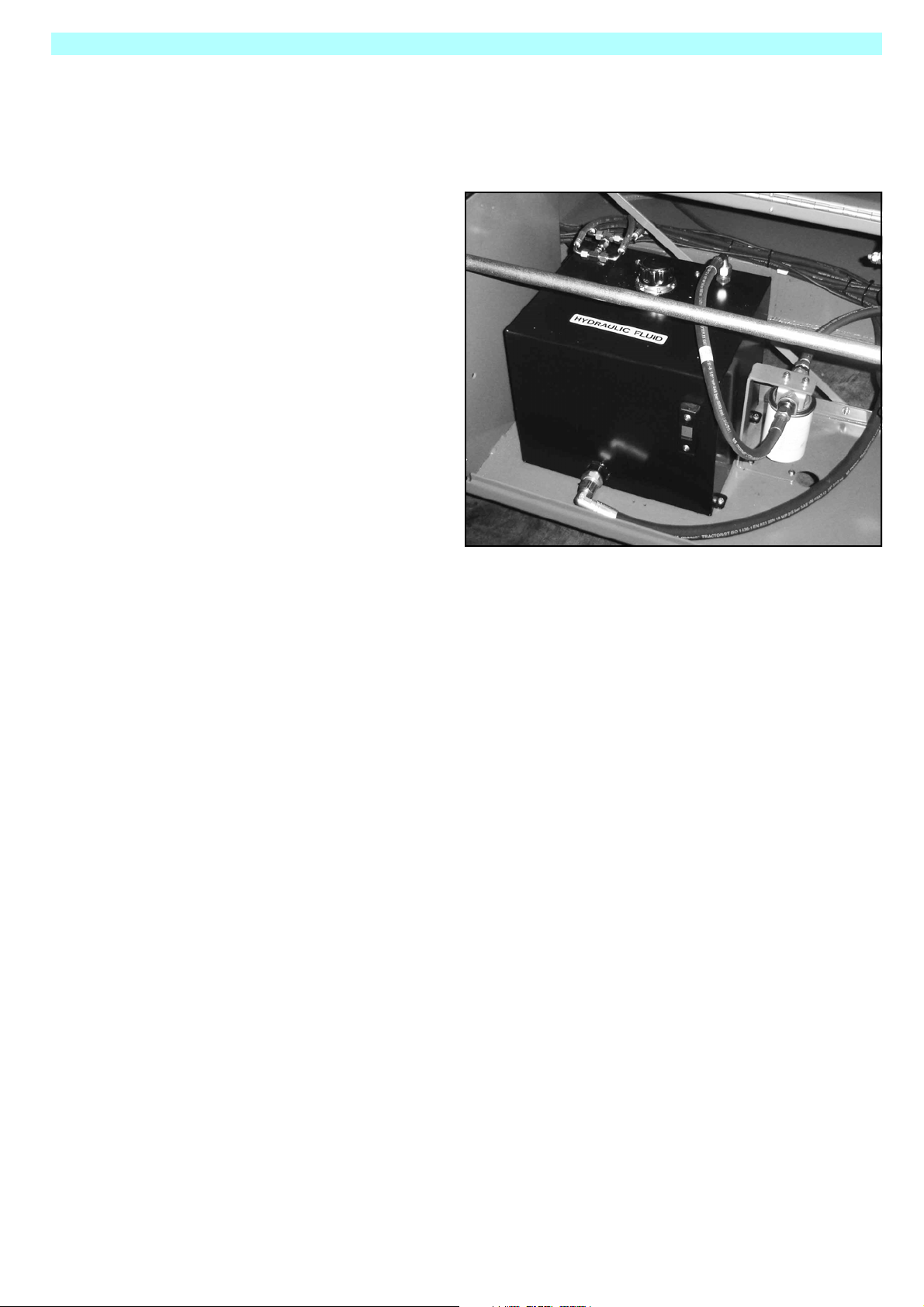

1. Open modules and inspect for damage, fluid leaks or missing parts.

2. Check the leve l of the h ydraulic fluid with

the platform fully lowered. The hydraulic

reservoir is located in the Control Module Door. The fluid level must be

between the MIN and MAX lines. Add

hydraulic fluid if necessary.

3. Check that fluid level in the starter battery is correct.

4. Check the level of the Diesel fuel with

the engine switched off. The fuel tank is

located in the Power Module. Add fuel

as required.

5. Check that all guardrails are in place

and all fasteners are properly tightened.

6. Inspect the machine thoroughly for

cracked welds and structural damage,

loose or missing hardware, hydraulic

leaks, damaged control cable, loose

wire connections and wheel bolts.

S

AFETY

I

NSPECTION

Figure 3: Hydraulic Tank

Page 6 SR2684SL & SR3084SL

Page 11

System Function Inspection 505562-100

S

YSTEM

F

UNCTION

Refer to Figure 2 (Page 5) for the locations of various controls and indicators.

I

NSPECTION

!

WARNING

STAND CLEAR of the work platform while performing the following checks.

Before operat ing the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in ALL directions, including above the work platform, for obstructions and electrical cond u cto rs.

Protect the control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Twist Chassis Emergency Stop Switch to the ON position.

3. Twist Platform Emergency Stop Switch to the ON position.

4. Turn the Key Switch to the ON position.

5. Visually inspect the elevating assembly, lift cylinder, cables, and hoses for cracked welds and structural

damage, loose hardware, hydraulic leaks, loose wire connections, and erratic operation. Check for missing or loose parts.

6. Push the Chassis ELEVATE and ENABLE buttons and fully elevate the platform.

7. Partially lower the platform by pushing Chassis DESCEND and ENABLE buttons, and check for proper

operation of the audible lowering alarm.

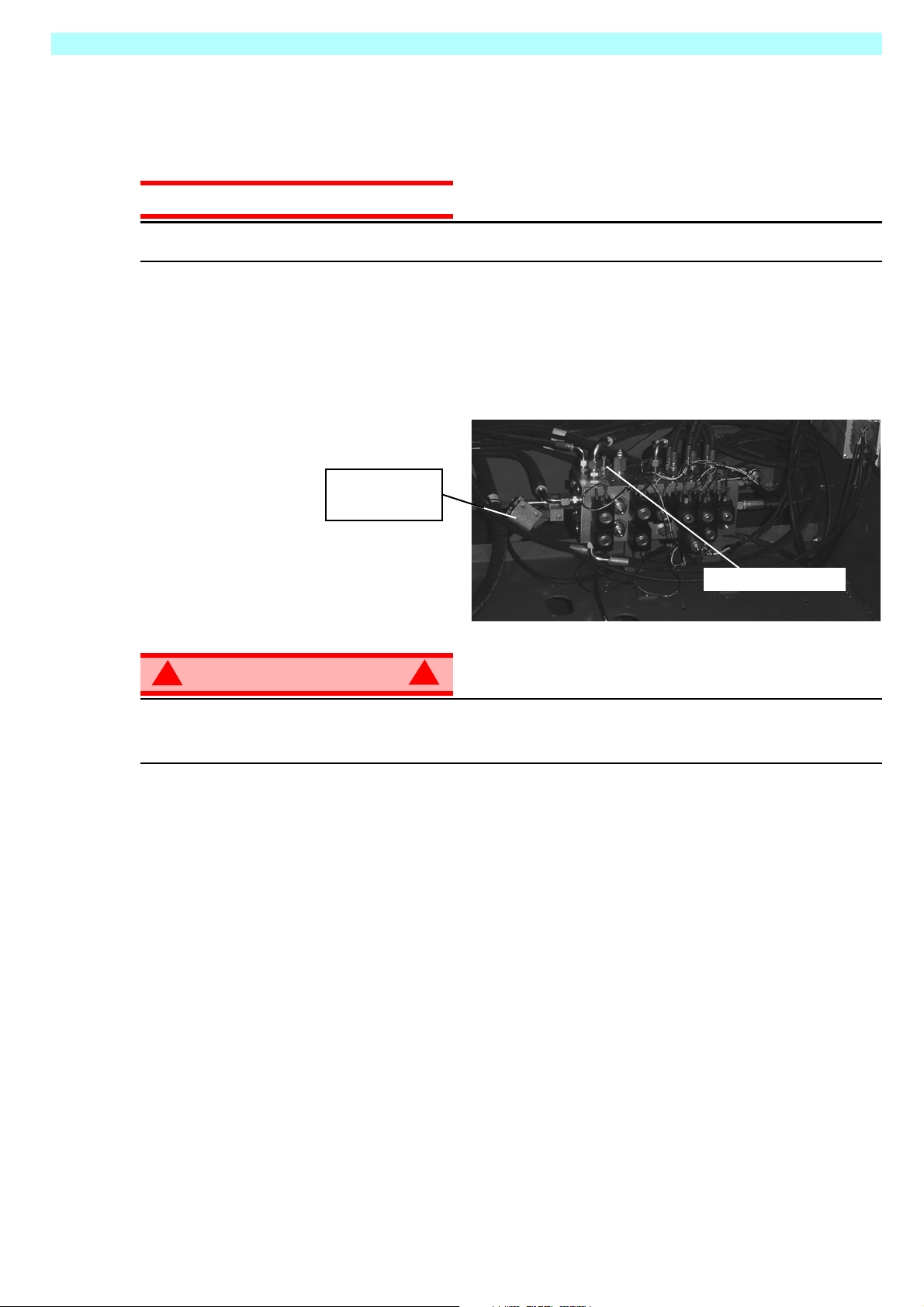

8. Open the Emergency Lowering Valve (see Figure 4) by pulling the knob out to check for proper operation. When the platform is low ered, release the knob.

9. Push the Chassis Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Twist the Chassis Emergency Stop Switch to resume.

10. Check that the route is clear of obstacles (persons, obstructions, holes, and drop-offs, bumps and

debris), is level, and is capable of supporting the wheel loads.

11. Mount the platform and properly close the entrance.

12. Select DRIVE mode.

!

NOTE: Use both HI and LOW drive (if applicable) when performing the following step.

13. While engaging the Safety Interlock Trigger , mo ve the Joystick to FORWARD, then REVERSE, to check

for speed control.

14. Push the Steering Switch RIGHT, then LEFT, to check for steering control.

15. Select LIFT mode. Grasp the Joystick, engaging the Safety Interlock Trigger, and push it forward to

check platform lift controls. Raise the platform to full elevation.

16. Pull back on the Joystic k. The platform should descend and the audible lowering alarm should sound.

17. Push the Platform Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Platform Emergency Stop Switch to resume.

SR2684SL & SR3084SL Page 7

Page 12

505562-100 Operation

O

PERATION

Before operating t he wo rk platform, ensure that the Pre-Operation Saf ety Inspe ction has bee n comple ted

and that any deficiencies ha v e been cor rected. Ne ver opera te a dama ged or malfunctioning mac hine.

The operator must be thoroughly tr ained on this machine.

S

TARTING THE

1. Mount the platform and properly close the entrance.

2. Depress and hold the GLOW PLUG button for approximately 5 seconds.

3. Press green START button.

T

RAVEL

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and debris),

is level, and is capable of supporting the wheel loads.

2. Verify that the Engine is started and the Chassis Emergency Stop Switch is ON (pulled out).

3. Mount the platform and properly close the entrance.

4. Check clearances above, below, and to the sides of platform.

5. Twist the Platform Emergency Stop Switch out to the ON position.

6. Select DRIVE mode.

W

ITH THE

E

NGINE

P

LATFORM

L

OWERED

NOTE: Choose between standard drive and extra torque depending on the gradient.

7. Engage the Safety Interlock Trigger and move the Joystick to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from center the Joystick is

moved.

S

TEERING

1. Turn the Drive/Lift Switch to DRIVE.

2. While engaging the Safety Interlock Trigger, push the Steering Switch to RIGHT or LEFT to turn the

wheels in the desired direction. Observe the tires while maneuvering the work platform to ensure proper

direction.

NOTE: Steering is not self-centering. Wheels must be returned to the straight ahead positi on by

operating the Steering Switch.

E

LEVATING

1. Select a firm, level surface.

2. Select LIFT mode.

3. While engaging the Safety Interlock Trigger, push the Joystick forward.

4. If the machine is not level the tilt alarm will sound and the machine will not lift or drive.

5. If the tilt alarm sounds the platform must first be fully lowered, then elevate the platform approximately

600mm (2ft), stop, press and hold the LEVEL button until the tilt alarm is silenc ed . On ly the n can you

elevate fully. If the platform is not levelled correctly the tilt alarm will continue to sound and lift functions

will be cut at a height of approximately 2m (6ft).

THE

P

LATFORM

Page 8 SR2684SL & SR3084SL

Page 13

Operation 505562-100

T

RAVEL

NOTE: The machine will travel at reduced speed when the platform is elevated.

1. Check that the route is clear of obstacles (persons , obstructions , holes, drop-offs , bump s, and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of platf orm.

3. Select DRIVE mode.

4. Engage the Safety Interlock Trigger on the Joystick and move to FORWARD or REVERSE to travel in

the desired direction. The speed of the machine will vary depending on how far from center the Joystick

is moved.

5. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm, level surface before attempting

to re-elevate the platform.

L

OWER ING THE

1. Select LIFT mode.

2. Check around the base of the platf orm to ensure that no one is in cont act with the mach ine . Engag e the

Safety Interlock Trigger and pull back on the Joystick to lower the platform.

3. The platform will stop when it reaches the PPE cutout height. Inspect around the machine to ensure no

one is in contact with the machine. After a four-second time delay, lower the platform as in step 2.

W

ITH THE

P

P

LATFORM

LATFORM

E

LEVATED

L

EVELLING

The AUTO LEVEL feature is designed to level the platform in a situation where the ground has no more

than a 13 degree slope side to side and 9 degr ees fore and aft, if the slope is gr eater tha n 13 deg rees side

to side and 9 degrees fore and aft the AUTO LEVEL feature will not function.

The tilt alarm will continue to sound until the platform is level

1. Check that the route is clear of obstacles (persons , obstructions , holes, drop-offs , bump s, and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of platf orm.

3. Elevate the platform approximately 600mm (2ft).

4. Press and hold the AUTO LEVEL and Engage the Safety Interlock Trigger until the platform is level and

the tilt alarm is silenced.

5. In this condition only the ELEVATE and DESCEND functions will work.

6. If you need to drive you must descend and return the platform to it’s normal inclanation.

THE

P

LATFORM

SR2684SL & SR3084SL Page 9

Page 14

505562-100 Operation

E

MERGENCY

L

OWER ING

Figure 4: Emergency Lowering Valve

!

WARNING

If the platform should fail to lower, NEVER

climb down the elevating assembly.

Stand clear of the elevating assembly while

operating the Emergency Lowering Valve

Knob.

!

Emergency Lowering Knob

SR2684SL & SR3084SL

The Emergency Lowering Valve for the

SR2684SL & SR3084SL is located in the

control module of the machine and is

accessable through an opening in the control module door.

1. Open the Emergency Lowering Valve by pulling and holding the handle.

2. To close, release the knob. The platform will not elevate if the Emergency Lowering Valve is open.

Page 10 SR2684SL & SR3084SL

Page 15

Operation 505562-100

F

OLD

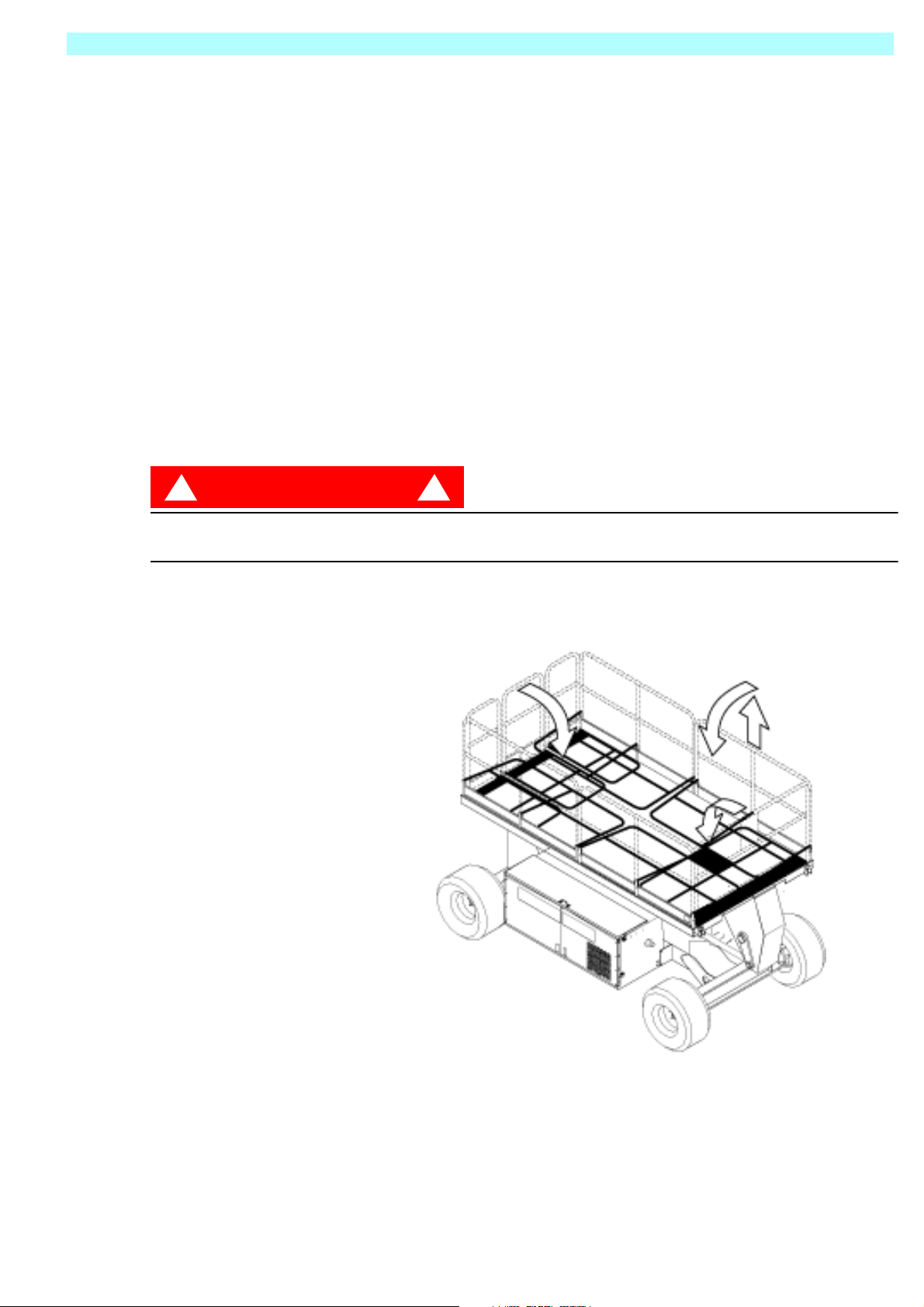

This procedure applies only to the SR2684SL & SR3084SL models for the purpose of passing through a

standard double doorway. Guardrails must be returned to proper position before using the

F

OLD

1. Unhook the controller from the side guardrail and place it on the floor of the platform.

2. Starting at the front of the platform, remove nuts, bolts and washers from the top of the front guardrail.

Fold the front guardrail down onto the platf orm.

3. Close and latch gate.

4. Remove nuts, bolts and washers from the top of the rear guardrail. Fold the rear guardrail down onto the

platform being careful to keep latched at all times.

5. Remove nuts, bolts and washers from the top of the side guardrails. Lift up and fold one side guardrail in

so it rests on the deck. Repeat with other side guardrails.

E

RECTION PROCEDURE

D

OWN GUARDRAILS

D

OWN PROCEDURE

1. Raise side guardrails, making sure each is pushed down to secure the guardrail in the vertical

position.

2. Install bo lts, washers and nuts between the side guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes and install bolts, washers and nuts. Tighten securely.

DANGER

! !

Before entering platform, guardrails must be securely fastened in their proper position.

SR2684SL & SR3084SL Page 11

Page 16

505562-100 Towing or Winching

T

OWIN G OR

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting the Work Platform” on

page 13).

W

INCHING

CAUTION

DO NOT tow or winch the machine faster than 0,3 m/s (1 ft./s). Faster speeds will damage drive

components and void the w arranty.

B

RAKE

Perform the following only when the machine will not operate under it’s own power and it is necessary to

move the machine or when towing the machine up a grade or onto a trailer to transport.

1. Close the needle valve by turning the allen screw clockwise.

2. Pump the Brake Release Pump until the Parking Brake Cylinder Rod clears the wheel rotor.

3. The machine will now roll when pushed or pulled.

4. Open needle valve and verify that the

cylinder rod has extended before the

machine is operated.

R

ELEASE

P

UMP

Hand Pump

Needle Valve

!

WARNING

Never tow faster than 0,3 m/sec. (1 ft./sec.).

Never op erate the work platform with the parking brakes released. Serious injury or damage could

result.

A

FTER

1. Ensure that the platform is fully lowered.

2. Park the machine on a firm level surface, pre ferably under cover, secure against vandals, children and

unauthorized operation.

3. Turn the Chassis Key Switch to OFF and remove the key to prevent unauthorized operation.

H

OUR

To access the hour meter function perform the following steps.

U

M

SE

ETER

E

ACH

!

D

AY

1. Climb into the basket (with the machine powered up)

2. Push the platform emergency stop button.

3. Hold down the following buttons, Horn & Lift.

4. While holding the buttons twist the emergency stop button to return power to the machine.

5. “hr” will now be displayed on the readout, Pressing the right turn button will scroll through the accumulated

hours two digits at a time. For example, if pressing the right turn button once displays “20”, pressing it a

2nd time displays “58”, and pressing it a 3rd time displays “hr”, the elapsed time of operation is 2058

hours.

Page 12 SR2684SL & SR3084SL

Page 17

Transporting the Work Platform 505562-100

T

RANSPORTING

P

REPARATION FOR

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage t o the frame.

L

IFTING

1. Secure straps to chassis tie down/lifting lugs only.

2. Place the platform onto the transport vehicle in transport position.

3. Chock the wheels.

4. Secure the work platform to the transport vehicle with chains or straps of adequate loa d capacity

attached to the chassis tie down/lifting lugs.

B

Y

THE

C

W

RANE

ORK

S

HIPMENT

P

LATFORM

BY F

! !

Forklifting is for transport only.

See specifications for weight of work platform and be certain that forklift is of adequate capacit y to lift

the work platform.

Forklift from the side by lifting under the Chassis Modules.

D

RIVING OR

ONTO

RAILER

T

NOTE: Do not winch faster than 0,3 m/s (1 ft/s).

1. Move the machine onto the truck or trailer;

A. To Drive the machine onto the transport vehicle:

B. To Winch the machine onto the transport vehicle:

2. Secure the work platform to the transport vehicle with chains or straps of adequate loa d capacity

ORKLIFT

DANGER

W

INCHING

A T

a. Move the work platform up the ramp and into

transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting lugs.

c. Release the parking brakes (refer to “Towing or

Winching” on page 12).

d. Winch the platform into transport position

e. Chock the wheels.

attached to the chassis tie down/lifting lugs.

RUCK OR

Front Tie

Down and

Lifting Lugs

Figure 5: Transporting the Work Platform

Forklift

Rear Tie Down/Lift

CAUTION

Overtightening of the chains or straps attached to the Tie Down/Lifting Lugs may result in damage to

work platform .

SR2684SL & SR3084SL Page 13

Page 18

505562-100 Maintenance

M

AINTENANCE

!

WARNING

Never pe rform service while the platform is elevated without first blockin g the elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

LEVATING

E

T

HE

A

SSEMBLY

!

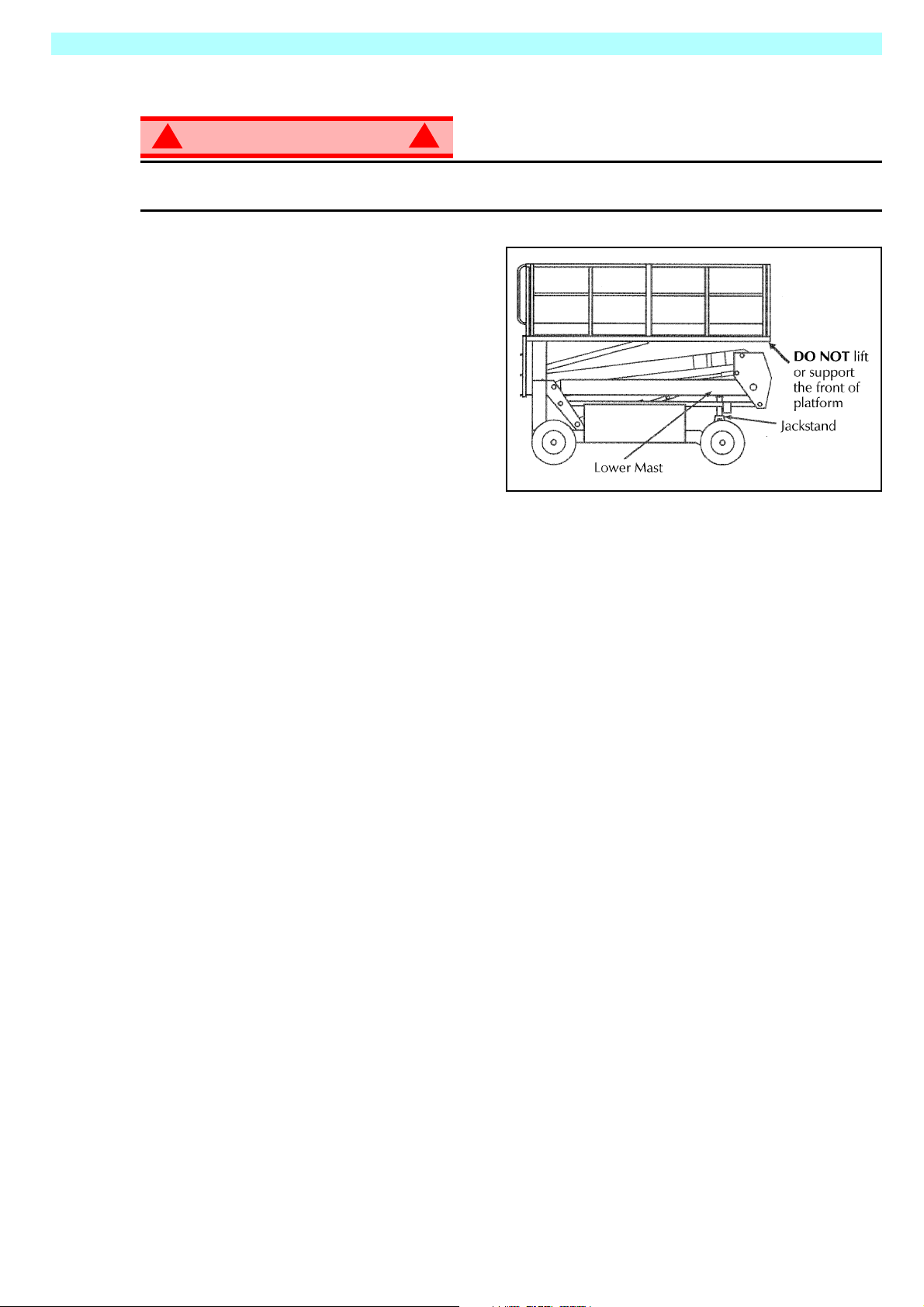

Figure 6: Scissor Brace

INSTALLATION

1. P ark the work platform on firm, level ground and

leave the engine running.

2. Ensure the Chassis Emergency Stop Button is

twisted to the ON position.

3. Press and hold the Chassis LIFT and ENABLE

buttons to elevate the platform approximately

305 mm (12 inches).

4. Place a jackstand with a minimum rating of

1814 kg (4000 lbs.) between the lower mast and chassis, just behind the front axle.

5. Press and hold the Chassis DESCEND and ENABLE buttons to lower the platform until jackstand is

secured tightly between lower mast and Chassis.

REMOVAL

1. Press and hold the Chassis LIFT and ENABLE buttons to elevate the platform until the jackstand can

be removed.

2. Remove jackstand.

3. Press and hold the Chassis DESCEND and ENABLE buttons to completely lower the platform.

Page 14 SR2684SL & SR3084SL

Page 19

Maintenance 505562-100

B

ATTERY

M

AINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with Snorkel batteries or manufacturer approved replacements.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY CHARGING

The battery is charged while the engine is running.

!

3

(

/

in.) above the plates add distilled water only. DO NOT use

8

SR2684SL & SR3084SL Page 15

Page 20

505562-100 Maintenance

F

AULT

01 - SYSTEM INIT ERROR

02 - SYSTEM PLATFORM COM ERROR

03 - PLATFORM OVERLOAD

04 - SYSTEM LOWER PANEL COM ERROR

05 - OIL PRESSURE LOW

06 - COOLANT TEMP HOT

21 - PLATFORM START ON

22 - PLATFORM LEFT TURN SW ON

23 - PLATFORM RIGHT TURN SW ON

24 - PLATFORM LIFT SW ON

25 - PLATFORM HISPEEDDRIVE SW ON

26 - PLATFORM GLOWLP SW ON

27 - PLATFORM LOSPEEDDRIVE SW ON

28 - PLATFORM AUTOLEVEL SW ON

29 - PLATFORM JOYSTICK ENABLE SW ON

C

ODES

31 - PLATFORM JOYSTICK NOT NEUTRAL

34 - GROUND PANEL ENABLE SW ON

37 - GROUND PANEL DOWN SW ON

38 - GROUND PANEL UP SW ON

43 - GROUND PANEL START SW ON

45 - GROUND PANEL GLOWLP SW ON

51 - Coil Fault HiSpeed1

52 - Coil Fault HiSpeed2

55 - Coil Fault LiftUp

56 - Coil Fault LiftDown

57 - Coil Fault TiltLeft

58 - Coil Fault TiltRight

59 - Coil Fault SteerRight

61 - Coil Fault SteerLeft

62 - Coil Fault TiltRear

63 - Coil Fault TiltForward

66 - Coil Fault Forward

67 - Coil Fault Reverse

71 - Coil Fault CushionValve

72 - Coil Fault AxleFloat

73 - Coil Fault SteerDump

68 – LOW BATTERY FAULT

Page 16 SR2684SL & SR3084SL

Page 21

Inspection and Maintenance Schedule 505562-100

I

NSPECTION

The Complete Inspection consists of periodic visual and operational checks, along with periodic minor

adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. Inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical proced u re s.

AND

M

AINTENANCE

S

CHEDULE

D

AILY

M

AINTENANCE

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

!

WARNING

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform maintenance while the

platform is elevated.

The daily preventative maintenance checklist has been designed for machine service and maintenance.

Please photocopy this page and use the checklist when inspecting the machine.

P

REVENTATIVE

T

ABLE KEY

!

M

AINTENANCE

P

Date:_______________________________________

Owner: _____________________________________

Model No:___________________________________

Serial No: ___________________________________

REVENTATIVE

C

M

AINTENANCE

HECKLIST

R

EPORT

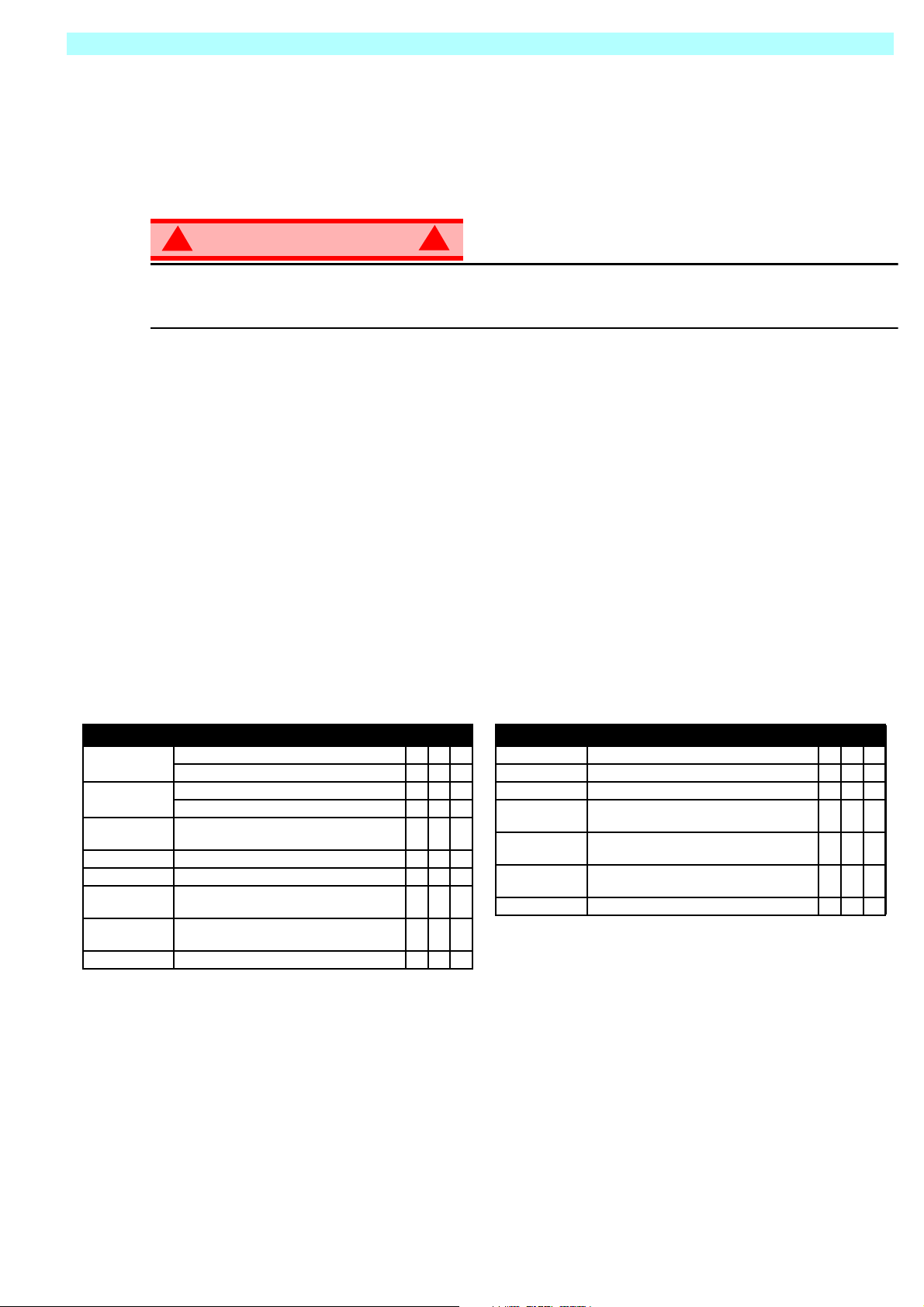

COMPONENT INSPECTION OR SERVICES Y N R

Battery

Chassis

Control Cable

Controller Check switch operation.

Drive Motors Check for operation and leaks.

Elevating

Assembly

Emergency

Lowering System

Entire Unit Check for and repair collision damage.

Check electrolyte level.

Check battery cable condition.

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check the exterior of the cable for pinching,

binding or wear.

Inspect for structural cracks.

Operate the emergency lowering valve and check

for serviceability.

Serviced By:_________________________ ________

COMPONENT INSPECTION OR SERVICES Y N R

Hydraulic Fluid Check fluid level.

Hydraulic Pump Check for hose fitting leaks.

Hydraulic System Check for leaks.

Labels

Platform Deck

and Rails

Platform Deck

and Rails

Tires and Wheels Check for damage.

Check for peeling, missing, or unreadable labels

& replace.

Check welds for cracks.

Check condition of deck.

SR2684SL & SR3084SL Page 17

Page 22

505562-100 Specifications

S

PECIFICATIONS

ITEM

Platform Size (Inside Toeboards)

Standard 1,71 m x 4,22 m [67.5 in. x 166.5 in.] 1,71 m x 4,22 m [67.5 in. x 166.5 in.]

Slide Out Deck Extended 1,71 m x 4,61 m [67.5 in. x 181.5 in.] N/A

Max. Platform Capacity

Standard 680kg [1,500 lbs.] 590 kg [1,300 lbs.]

w/ Extension 680kg [1,500 lbs.] N/A

On Extension 227g [500 lbs.] N/A

Max. No. of occupants

Standard 5 people 5 people

on Extension 2 people N/A

Height

Working Height 9.75 m [32 ft.] 10.97 m [36 ft.]

Max. Platform Height 7.93m [26 ft.] 9,14 m [30 ft.]

Min. Platform Height 1.5 m [59 in.] 1.5 m [59 in.]

Max. Drive Height 7.93 m [26 ft.] 9.14 m [30 ft.]

Dimensions

Weight Diesel: 3,216 kg [7,090 lbs.] Diesel: 3.216 kg [7,090 lbs.]

Overall Width, Standard 2,13 m [84 in.] 2,13 m [84 in.]

Overall Height 2,6 m [102.5 in.] 2,6 m [102.5 in.]

Overall Length, Standard 3.79 m [149 in.] 4,39 m [173 in.]

Surface Speed

Platform Lowered 0 to 5.0 km/h [0 to 3.1 m.p.h.] 0 to 5.0 km/h [0 to 3.1 m.p.h.]

Platform Raised 0 to 0.8 km/h [0 to 0.5 m.p.h.] 0 to 0.8 km/h [0 to 0.5 m.p.h.]

System Voltage 12 Volt DC 12 Volt DC

Hydraulic Tank Capacity 74 l [19.5 US Gallons] 74 l [19.5 US Gallons]

Maximum Hydraulic System Pressure 210 bar [3000 psi] 210 bar [3000 psi]

Hydraulic Fluid

Above 32° f [0° c]) ISO #46 ISO #46

Normal use, below 32° f [0° c]) ISO #32 ISO #32

Below 0° f [-17° c] ISO #15 ISO #15

Lift System One Single Stage Lift Cylinders One Single Stage Lift Cylinders

Lift Speed Raise, 48 sec./Lower, 40 sec. Raise, 48 sec./Lower, 40 sec.

Platform Leveling 13° side to side, 9° Fore and Aft 13° side to side, 9° Fore and Aft

Power Source 20 HP (Diesel) 20 HP (Diesel)

Drive Control Proportional Proportional

Control System Joystick Controller with Safety

Interlock Trigger and Thumb Rocker

Horizontal Drive Four Wheel, Hydraulic Motors Four Wheel, Hydraulic Motors

Tyres (Standard) 26 x 12.00 - 12 NHs Super Terra-grip

ANSI Spec. Pneumatic Tire Pressure Do Not Exceed 57 PSI Do Not Exceed 57 PSI

Parking Brakes Dual Spring Applied, Hydraulic

Turning Radius (inside) 3,96 m [13 ft.] 3,96 m [13 ft.]

Maximum Gradeability 35% [19°] 35% [19°]

Wheel Base 2,54 m [100 in.] 2,54 m [100 in.]

Guardrails 1,11 m [43.5 in.] high, Fold Down with

Toe board 152 mm [6 in.] High 152 mm [6 in.] High

Fuel Tank Capacity 45.5 l [12 US Gallons] 45.5 l [12 US Gallons]

SR2684SL SR3084SL

Joystick Controller with Safety

Interlock Trigger and Thumb Rocker

Steering, Toggle Selector and

Emergency Stop Switches

with Trac Seal

Release, multi-disc

gate.

Steering, Toggle Selector and

Emergency Stop Switches

26 x 12.00 - 12 NHs Super Terra-grip

Dual Spring Applied, Hydraulic

1,11 m [43.5 in.] high, Fold Down with

with Trac Seal

Release, multi-disc

gate.

*Specifications are subject to change without notice. Hot weather or he avy use may affect performance.

Refer to the Service Manual for complete parts and service information.

This machine meets or exceeds all applicable requirements of OSHA and ANSI A92.6-1999.

Page 18 SR2684SL & SR3084SL

Page 23

Specifications 505562-100

SR2684SL & SR3084SL Page 19

Page 24

Page 25

Série SR-2684/3084-SL

Numéros de série 50001 – actuel

FRANÇAIS

Lorsque vous contactez Snorkel pour des informations sur l'entretien ou les pièces, indiquez le MODÈLE ou le NUMÉRO

DE SÉRIE donné sur la plaque signalétique. En cas d'absence de plaque signalétique, le NUMÉRO DE SÉRIE est

également estampé sur le dessus du châssis, au-dessus du pivot d'essieu avant.

Numéro de série estampé

www.snorkelusa.com

Page 26

Page 27

MANUEL DE L'UTILISATEUR

AVERTISSEMENT

T out le per sonnel de vra lire soign eusement, comprendre et r especter toutes les règles de sécurité

et les instructions d'utilisation a vant d 'utiliser ou d'eff ectuer des trav aux de maint enance sur une

plate-forme de travail aérien Snorkel.

Règles de sécurité

Risque d'électrocution Risque de basculement Risque de collision Risque de chute

CETTE MACHINE N'EST

PASISOLÉE!

UTILISA TION DE LA PLATE-FORME DE TRAVAIL AÉRIEN : Cette plate-forme est destinée à lever le personnel et ses outils ainsi que

les matériaux utilisés pour effectuer le travail. Elle est conçue pour les travaux de répar ation et de montage situés en hauteur (plafonds,

grues, toitures, bâtiments, etc.). Toute autre utilisation de cette plate-forme de travail aérien est interdite !

CETTE PLATE-FORME DE TRAV AIL AÉRIEN N'EST PAS ISOLÉE ! Pour cette raison, il est impératif de maintenir une distance de

sécurité entre la plate-forme et les parties sous tension de l'équipement électrique !

Tout dépassement de la charge maximum admissible spécifiée est interdit ! Voir “Restrictions spéciales” page 4 pour plus de détails.

L'utilisation de cette plate-forme de travail aérien comme appareil de levage ou comme grue (levage de charge du bas vers le haut ou

du haut vers le bas) est interdite !

NE JAMAIS dépasser la force manuelle autorisée pour cette machine. Voir “Restrictions spéciales” page 4 pour plus de détails.

RÉPARTIR de façon égale toutes les charges sur la plate-forme.

NE JAMAIS utiliser la machine sans avoir auparavant vérifié sur la surface de travail l'absence de trous, dénivellations, bosses, bords

de trottoir ou débris afin de les éviter .

UTILISER la machine uniquement sur des surfaces capables de supporter les charges par roue.

NE JAMAIS utiliser la machine quand la vitesse du vent dépasse la résistance nominale au vent de la machine. Voir “Échelle de

Beaufort” page 4 pour plus de détails.

EN CAS D'URGENCE, appuyer sur le bouton d'ARRÊT D'URGENCE pour désactiver toutes les fonctions en marche.

SI L'ALARME RETENTIT pendant que la plate-forme est en position haute, ARRÊTER la plate-forme et l'abaisser avec précaution.

Déplacer la machine sur une surface ferme et de niveau.

Escalader le garde-corps de la plate-forme, l'enjamber pour passer de la plate-forme sur des bâtiments ou des structures en acier ou

béton préfabriqué, etc., est interdit !

Le démontage de la porte pivotante ou d'autres composants des garde-corps est interdit ! Toujours s'assurer que la porte pivotante est

fermée et correctement verrouillée !

Il est interdit de maintenir la porte pivotante en position ouverte (maintenue ouverte avec des sangles) quand la plate-forme est levée !

Augmenter la hauteur ou la portée de la plate-forme en y plaçant des échelles, échafaudages ou dispositifs similaires est interdit !

NE JAMAIS effectuer de réparations sur la machine pendant que la plate-forme est levée sans bloquer l'ensemble de levage.

INSPECTER soigneusement la machine avant toute utilisation pour vérifier qu'il n'y a pas de soudures fissurées, pièces de fixation

desserrées ou manquantes, fuites hydrauliques, connexions de câblage desserrées et câbles ou tuyaux endommagés.

VÉRIFIER que toutes les étiquettes sont en place et lisibles avant toute utilisation.

NE JAMAIS utiliser une machine endommagée, qui ne fonctionne pas correctement ou dont les étiquettes sont endommagées ou

manquantes.

La neutralisation de tout équipement de sécurité est interdite et présente un danger pour les personnes se tenant sur la plate-forme

de travail aérien et dans sa zone d'activité.

NE JAMAIS charger les batteries près d'étincelles ou d'une flamme nue. De l'hydrogène explosif est émis lors de la charge des

batteries.

Les modifications de la plate-forme de travail aérien sont interdites ou autorisées seulement après approbation d'Snorkel.

APRÈS UTILISATION, empêcher toute utilisation non autorisée de la plate-forme de travail en coupant le contact aux deux

interrupteurs et en retirant la clé.

NE JAMAIS élever la plate-forme ou

déplacer la machine avec la plateforme élevée sauf sur une surface

ferme et de niveau.

NE JAMAIS positionner la plate-

forme sans vérifier au préalable qu'il

n'existe pas d'obstructions ou d'autres

risques au-dessus de celle-ci.

NE JAMAIS grimper, se tenir

debout ou assis sur les garde-

corps ou la rampe intermédiaire

de la plate-forme.

Page 1

Page 28

505562-100

T

ABLE DES

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Description générale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Restrictions spéciales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Commandes et indicateurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Contrôle de sécurité avant utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Vérification des fonctions des systèmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Remorquage ou treuillage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Transport de la plate-forme de travail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Liste de vérification quotidienne de maintenance préventive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

MATIÈRES

Capacité de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Force manuelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Échelle de Beaufort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Alarme de surcharge de levage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Extension de la plate-forme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Déplacement avec la plate-forme abaissée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Élévation de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Déplacement avec la plate-forme élevée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Abaissement de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mise de niveau de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Abaissement d'urgence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Garde-corps rabattables,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Procédure pour rabattre les garde-corps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Procédure pour remonter les garde-corps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Desserrage du frein de stationnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Après chaque utilisation au quotidien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Horomètre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Préparation pour expédition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Levage avec une grue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Avec un chariot élévateur à fourche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conduite ou treuillage sur un camion ou une remorque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Blocage de l'ensemble de levage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Déploiement du bras articulé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rangement du bras articulé. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance des batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Charge des batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Codes de défaut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programme de contrôle et de maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Page 2 Manuel de l'utilisateur

Page 29

Introduction 505562-100

I

NTRODUCTION

Le présent manuel couvre l'utilisation des plates-formes de travail automotrices SR2684SL & SR3084SL.

Il doit être rangé sur la machine en permanence.

D

ESCRIPTION

GÉNÉRALE

!

AVERTISSEMENT

NE PAS utiliser la plate-forme de maintenance sans les garde-corps correctement montés et en place

1. Plate-forme

2. Ensemble de levage

3. Châssis

4. Module d'alimentation

5. Module de commande

6. Commandes de la plate-forme

7. Boîte pour le manuel

8. Commandes du châssis

9. Réservoir de liquide hydraulique

!

Figure 1: SR2684SL & SR3084SL

7

6

1

2

3

5

8

4

Manuel de l'utilisateur Page 3

9

Page 30

505562-100 Restrictions spéciales

R

ESTRICTIONS

Tout déplacement avec la plate-forme levée doit s'effectuer à des vitesses très lentes uniquement.

L'éléva tion de la plate-forme de travail est possible uniquement sur des surfaces fermes et de niveau.

DANGER

! !

La fonction d'élévation sera utilisée SEULEMENT quand la plate-forme de travail est de niveau et sur une

surface ferme.

La plate-forme de travail N'EST PAS conçue pour être déplacée sur un terrain inégal, non nivelé ou

mou.

C

APACITÉ

La capacité maximale de la MACHINE, occupants inclus, est fonction du modèle et des options ; celle-ci

est indiquée dans les “Caractéristiques” page 18.

DANGER

! !

NE PAS dépasser la capacité maximale de la plate- forme ni le nombre limite d'occupants pour cette

machine.

SPÉCIALES

DE LA PLATE

-

FOR M E

F

ORCE

La force manuelle est la force appliquée par les occupants aux objets tels que les murs ou autres

structures extérieures à la plate-forme de travail.

La force manuelle maximale admissible est limitée à 200 N de force par occupant, avec un maximum

de 400 N pour deux occupants ou plus.

! !

NE PAS dépasser la valeur maximale de force manuelle pour cette machine.

É

CHELLE

Ne jamais utiliser la machine lorsque la vitesse du vent dépasse 45 km/h (force 6 sur l'échelle de

Beaufort).

ÉCHELLE DE

BEAUFORT

3 3,4~5,4 12,25~19,4 11,5~17,75 7,5~12 Les feuilles et les rameaux sont sans cesse agités ; les drapeaux légers se déploient.

4 5,4~8 19,4~28,8 17,75~26,25 12~18 Le vent soulève la poussière, les feuilles et les morceaux de papier, il agite les petites branches.

5 8~10,8 28,8~38,9 26,25~35,5 18~24,25 Les arbustes en feuilles commencent à se balancer. Des vaguelettes se forment sur les plans d'eau.

6 10,8~13,9 38,9~50 35,5~45,5 24,5~31

7 13,9~17,2 50~61,9 45,5~56,5 31~38,5 Les arbres sont agités en entier. La marche contre le vent devient pénible.

m/s km/h ft/s mi/h

A

LARME DE SURCHARGE

Si une charge équivalente à 90 % de la charge de travail admissib l e est soul evée, un code de d éfaut “03”

s'inscrit sur l'affichage numérique du boîtier de commande de la plate-forme. Si la nacelle contient une

charge supérieure à la charge de travail admissible, toutes les fonctions de la machine deviennent

inopérantes et une alarme sonore retentit. Pour revenir à un fonctionnement normal, la nacelle doit

contenir une charge inférieure ou égale à la charge de travail admissible et l'alimentation électrique doit

être coupée puis rétablie en appuyant sur le bouton d'arrêt d'urgence et en le relâchant.

MANUELLE

DANGER

DE

VITESSE DU VENT

B

EAUFORT

CONDITIONS AU SOL

Les grandes branches sont agitées. Les fils des lignes électriques font entendre un sifflement.

L'utilisation des parapluies devient difficile.

DE LEVAGE

DANGER

! !

Ne jamais utiliser la machine avec une charge supérieure à la capacité nominale sur la plate-forme.

Page 4 Manuel de l'utilisateur

Page 31

Commandes et indicateurs 505562-100

C

OMMANDES

ET INDICATEURS

Figure 2: Commandes et indicateurs

Commandes de la plate-forme

8

7

10

6

1 Déplacement (vitesse rapide)

2. Déplacement (vitesse lente)

3. Niveau

4. Bouton d'avertisseur sonore

5. Bouton de levage/abaissement

6. Bougie de préchauffage

7. Démarrage du moteur

8. Bouton d'arrêt d'urgence

9. Affichage

10. Manette

1

2

3

2

1

4

Commandes du châssis

5

9

6

5

1. Arrêt d'urgence

2. Monter

3. Descendre

4. Activation

5. Bougie de préchauffage

6. Démarrage

3

4

Manuel de l'utilisateur Page 5

Page 32

505562-100 Contrôle de sécurité avant utilisation

C

ONTRÔLE

NOTE: Lire soigneusement, comprendre et respecter toutes les règles de sécurité, instructions

d'utilisation, étiquettes et instructions/exigences nationales de sécurité. Exécuter les étapes

suivantes chaque jour avant d'utiliser la machine.

1. Ouvrir les modules et vérifier l'absence de dommages, de fuites de liquides ou de pièces manquantes.

2. Vérifier le niveau de liquide hydraulique

lorsque la plate-forme est complètement

abaissée. Le réservoir hydraulique est

situé dans la porte du module de

commande. Le niveau de liquide doit

être situé entre les lignes MIN et MAX.

Si nécessaire, ajouter du liquide

hydraulique.

3. Vérifier que le niveau de liquide dans

la batterie de démarrage est corre ct.

4. Contrôler le niveau de gazole lorsque

le moteur est coupé. Le réservoir de

carburant se trouve dans le module

d'alimentation. Si nécessaire, ajouter

du gazole.

5. Vérifier que t ous les garde-corps sont en

place et que toutes les fixations

correctement serrées.

6. Inspecter soigneusement la machine pour vérifier l'absence de soudures fissurées et dommages

structurels, pièces de fixation desserrées ou manquantes, fuites hydrauliques, câble de commande

endommagé, connexions de câblage et boulons de roue desserrés.

DE SÉCURITÉ AVANT UTILISATION

Figure 3: Réservoir hydraulique

Page 6 Manuel de l'utilisateur

Page 33

Vérification des fonctions des systèmes 505562-100

V

ÉRIFICATION

Se référer à la Figure 2 (page 5) pour les emplacements des commandes et indicateurs.

DES

FONCTIONS

DES

SYSTÈMES

!

AVERTISSEMENT

SE TENIR À L'ÉCART de la plate-forme de travail pour effectuer les vérifications suivantes.

Avant d'utiliser la plate-forme de travail, v érifier sur la surface de travail l'absence de trous, dénivellations,

bosses ou débris.

Vérifier dans TOUTES les directions, y compris au-dessus de la plate-forme de travail, l'absence

d'obstructions et conducteurs électriques.

Protéger le câble de console de commande de tout dommage possible pendant les vérifications.

1. Si nécessaire, déplacer la machine dans une zone dégagée pour po uv oir monter complèt ement la plateforme.

2. Tourner le bouton d'arrêt d'urgence du châssis en position de marche.

3. Tourner le bouton d'arrêt d'urgence de la plate-forme en marche de marche.

4. Mettre le contact.

5. Inspecter visuellement l'ensemble de levage, le vérin de levage, les câbles et tuyaux pour déceler les

soudures fissurées et dommages structures, les pièces de fixation desserrées, les fuites de liquide

hydraulique, les connexions de câblage desser rées et tout fonctionnement irrégulier. Vérifier l'absence

de pièces manquantes ou desserrées.

6. Pousser les boutons MONTER et ACTIVATION du châssis et élever la plate-forme au maximum.

7. Pousser les boutons DESCENDRE et ACTIVATION pour abaisser un peu la plate-forme et vérifier que

l'alarme sonore de descente fonctionne bien.

8. Ouvrir la soupape d'abaissement d'urgence (voir Figure 4) en tirant sur le bouton afin de vérifier son

fonctionnement. Une fois la plate-forme abaissée, relâcher le bouton.

9. Appuyer sur le bouton d'arrêt d'urgence du châssis pour vérifier son fonctionnement. Toutes les

fonctions de la machine d e vraient êt re inopérante s. Tourner le bouton d'arrêt d'urgence pour une reprise

des fonctions.

10. Vérifier que la voie ne comporte pas d'obstacles (personnes, obstructions, trous, dénivellations, bosses

ou débris), est de niveau et capable de supporter les charges par roue.

11. Monter la plate-forme et fermer correctement l'entrée.

12. Sélectionner le mode de DÉPLACEMENT.

!

NOTE: Utiliser les modes de déplacement RAPIDE et LENT (le cas échéant) pendant l'exécution

de l'étape suivante.

13. T out en appuyant sur la gâchette de sécurité, placer la manette sur MARCHE AVANT, puis sur MARCHE

ARRIÈRE pour vérifier la commande de vitesse.

14. Pousser le commutateur de direction DROITE, puis GAUCHE, afin de vérifier la commande de direction.

15. Sélectionner le mode LEVAGE. Saisir la manette en appuyant sur la gâchette de sécurité et la pousser

vers l'avant pour vérifier les commandes de levage de la plate-forme. Lever complèt ement la plateforme.

16. Tirer la manette vers l'arrière. La plate-forme devrait descendre et l'alarme sonore de descente devrait

retentir.

17. Appuyer sur le bouton d'arrêt d'urgence de la plate-forme pour vérifier son fonctionnement. Toutes les

fonctions de la machine devraient être inopérantes. Tirer sur le bouton d'arrêt d'urgence de la plateforme pour une reprise des fonctions.

Manuel de l'utilisateur Page 7

Page 34

505562-100 Utilisation

U

TILISATION

Avant d'utiliser la plate-forme de travail, s'assurer que le contrôle de sécurité avant utilisation a été

effectué et que les défaillances ont été corrigés. Ne jamais utiliser une machine endommagée ou qui

fonctionne mal. L'utilisateur doit être parfaitement formé à l'utilisation de la machine.

D

ÉMARRAGE DU MOTEUR

1. Monter la plate-forme et fermer correctement l'entrée.

2. Maintenir enfoncé le bouton de la BOUGIE DE PRÉCHAUFFAGE pendant 5 secondes environ.

3. Appuyer sur le bouton vert de démarrage.

D

ÉPLACEMENT AVEC LA PLATE

1. Vérifier que la voie ne comporte pas d'obstacles (personnes, obstructions, trous, dénivellations, bosses

ou débris), est de niveau et capable de supporter les charges par roue.

2. Vérifier q ue le moteur est bien démarré et que le bouton d'arrê t d'urgence du châssis est activé (sorti).

3. Monter sur la plate-forme et fermer correctement l'entrée.

4. Vérifier qu'il n'y a pas d'obstacles au-dessus, en dessous et sur les côtés de la plate-forme.

5. Tourner le bouton d'arrêt d'urgence de la plate-forme en position de marche.

6. Sélectionner le mode de DÉPLACEMENT.

-

FOR M E ABAISSÉE

NOTE: Choisir entre le déplacement standard et avec couple supplémentaire en fonction de la pente.

7. Appuyer sur la gâchette de sécurité et déplacer la manette sur MARCHE AVANT ou MARCHE

ARRIÈRE pour déplacer la machine dans le sens souhaité. La vitesse de la machine dépend

de la position de la manette par rapport à son centre.

D

IRECTION

1. Tourner le commutateur de déplacement/levage sur DÉPLACEMENT.

2. Tout en appuyant sur la gâchette de sécurité, pousser le commutateur de direction à DROITE ou

GAUCHE pour tourner les roues dans la direction so uhaitée. Observer les roues pendant la manœuvre

de la plate-forme de travail pour vérifier qu'elles se déplacent d ans la bonne direction.

NOTE: La direction n'est pas autocentrée. Il est nécessaire de remettre les roues droites en

utilisant le commutateur de direction.

É

LÉVATION

1. Choisir une surface ferme et de niveau.

2. Sélectionner le mode LEVAGE.

3. Tout en appuyant su r la gâchette de sécurité, pousser la manette vers l'avant.

4. Si la machine n'est pas de niveau, l'alarme d'inclinaison retentit et la plate-f orme ne monte pas ou ne se

déplace pas.

5. Si l'alarme d'inclinaison retentit, abaisser d'abord complètement la plate-forme, puis l'élever d'environ

600 mm, arrêter et maintenir enfoncé le bouton NIVEAU jusqu'à ce que l'alarme s'éteigne. La plateforme pourra alors être élevée au maximum. Si la plate-forme n'est pas mise de niveau, l'alarme

d'inclinaison continuera de retent ir et la plate-forme ne pourra pas être élevée au-delà de 2 mètres

environ.

DE LA PLATE

-

FOR M E

Page 8 Manuel de l'utilisateur

Page 35

Utilisation 505562-100

D

ÉPLACEMENT AVEC LA PLATE

NOTE: La machin e se déplace à vitesse réduite quand la plate-forme est élevée.

1. Vérifier que la voie ne comporte pas d'obstacles (personnes, obstructions, trous, dénivellations, bosses

ou débris), est de niveau et capable de supporter les charges par roue.

2. Vérifier qu'il n'y a pas d'obstacles au-dessus, en dessous et sur les côtés de la plate-forme.

3. Sélectionner le mode de DÉPLACEMENT.

4. Appuyer sur la gâchette de sécurité et déplacer la manette sur MARCHE AVANT ou MARCHE

ARRIÈRE pour déplacer la machine dans le sens souhaité. La vitesse de la machine dépend de

la position de la manette par rapport à son centre.

5. Si la machine n'est pas de niveau, l'alarme d'inclinaison retentit et la plate-forme ne monte pas et

ne se déplace pas. Si l'alarme d'inclinaison retentit, la plate-forme doit être abaissée et la machine

déplacée sur une surface ferme et de niveau avant d'essayer de nouveau d'élever la plate-forme.

A

BAISSEMENT

1. Sélectionner le mode LEVAGE.

2. S'assurer que personne n'est en contact avec la machine autour de la base de la plate-forme. Appuyer

sur la gâchette de sécurité et tirer la manette vers l'arrière pour abaisser la plate-forme.

3. La plate-forme s'arrête quand elle atteint la hauteur de découpe de l'équipement de protection

individuelle. V érifier autour de la machine que personne n'est en contact a vec celle-ci. Après un délai de

quatre secondes, abaisser la plate-forme comme indiqué à l'étape 2.

DE LA PLATE

-

-

FOR M E ÉLEVÉE

FOR M E

M

ISE DE NIVEAU

La fonction « mise de niveau automatique » (AUTO LEVEL) sert à mettre de niveau la plate-forme lorsque

le degré d'inclinaison de la pente est inf érieur ou égal à 13 degrés dans le sens de la largeur et à 9 degrés

dans le sens de la longueur de la plate-fo rme ; si le degré d'inclinaison de la pente est supérieur

à 13 degrés dans le sens de la largeur et à 9 degrés dans le sens de la longueur de la plate-forme, cette

fonction ne marchera pas.

L'alarme d'inclinaison continuera de retentir jusqu'à ce que la plate-forme soit mise de niveau

1. Vérifier que la voie ne comporte pas d'obstacles (personnes, obstructions, trous, dénivellations, bosses

ou débris), est de niveau et capable de supporter les charges par roue.

2. Vérifier qu'il n'y a pas d'obstacles au-dessus, en dessous et sur les côtés de la plate-forme.

3. Élever la plate-forme d'environ 600 mm.

4. Maintenir enfoncé le bouton de « mise de niveau automatique » et appuyer sur la gâchette de sécurité

jusqu'à ce que la plate-forme soit de niveau et que l'alarme d'inclinaison s'éteigne.

5. Dans ce cas, seules les fonctions MONTER et DESCENDRE marcheront.

6. Pour déplacer l'ensemble, abaisser la plate-forme et la remettre à son inclinaison normale.

DE LA PLATE

-

FOR M E

Manuel de l'utilisateur Page 9

Page 36

505562-100 Utilisation

A

BAISSEMENT

D'

URGENCE

Figure 4: Soupape d'abaissement d'urgence

!

AVERTISSEMENT

Si la plate-forme ne s'abaisse pas,

NE JAMAIS descendre de l'appareil

de levage en l'escaladant.

Se tenir à l'écart de l'ensemble de levage

tout en actionnant le bouton de la soupape

d'abaissement d'urgence.

!

Bouton d'abaissement d'urgence

SR2684SL & SR3084SL

La soupape d'abaissement d'urgence

de la SR2684SL & SR3084SL se trouve

dans le module de commande de la

machine et est accessible par une

ouverture dans la porte du module de commande.

1. Ouvrir la soupape d'abaissement d'urgence en tirant sur le bouton et en le maintenant dans cette

position.

2. Pour la fe rmer, relâcher le bouton. La plate-forme ne s'élève pas si la soupape d'abaissement

d'urgence est ouverte.

Page 10 Manuel de l'utilisateur

Page 37

Utilisation 505562-100

G

ARDE

Cette procédure s'applique seulement au modèle SR2684SL & SR3084SL et a pour but de passer une

porte à deux vantaux standard. Les garde-corps doivent être remis en position normale avant d'utili-

ser la machine.

P

ROCÉDURE POUR RABATTRE LES GARDE-CORPS

1. Décrocher la télécommande du garde-corps latéral et la placer sur le plancher de la plate-forme.

2. Commen cer par l'avant de la plate-forme : enlever les écrous, boulons et rondelles du haut du gardecorps avant. Rabattre le garde-corps avant sur la plate-forme.

3. Fermer et verrouiller la porte.

4. Enlever les écrous, boulons et rondelles du haut du garde-corps arrière. Rabattre le garde-corps arrière

sur la plate-forme en faisant attention à ce qu'il soit verrouillé en permanence.

5. Enlever les écrous, boulons et rondelles du haut des garde-corps latéraux. Soulever et rabattre un

garde-corps latéral sur le plancher. Répéter la même action avec les autres garde-corps latéraux.

P

ROCÉDURE POUR REMONTER LES GARDE-CORPS

1. Relever les garde- corps latéraux, en vérifiant que chaque garde-corps est bien enfoncé de manière

à ne pas pouvoir sortir de sa position.

2. Remettre en place les écrous, boulons et rondelles entre les garde-corps latéraux, bien les serrer.

3. Relever le garde-corps arrière, aligner les trous et remettre en place les écrous, boulons et rondelles.

Bien les serrer.

-

CORPS RABATTABLES

DANGER

! !

Avant de monter sur la plate-forme,

vérifier que les garde-corps sont

bien montés et fixés.

Manuel de l'utilisateur Page 11

Page 38

505562-100 Remorquage ou treuillage

R

EMORQUAGE

Exécuter la procédure suivante seulement quand la machine ne fonctionne pas avec sa propr e

alimentation et s'il est nécessaire de la déplacer ou de la treuiller sur un véhicule de transport

(voir « Transport de la plate-forme de travail » page 13).

OU TREUILLAGE

ATTENTION

NE PAS remorquer ni treuiller la machine à une vitesse supérieure à 0,3 m/s. Des vitesses plus

rapides endommageront les éléments de propulsion et annuleront la garantie.

P

OMPE

Exécuter la procédure suivante seulement quand la machine ne fonctionne pas avec sa propre

alimentation et s'il est nécessaire de la déplacer ou de la remorquer, que ce soit sur un plan incliné

ou sur une remorque pour la transporter.

1. Fermer le pointeau en tournant la vis à 6 pans à tête creuse dans le sens des aiguilles d'une

montre.

2. Actionner la pompe hydraulique de desserrage des freins jusqu'à ce que les freins libèrent le

tambour des roues.

3. La machine peut maintenant rouler quand elle est poussée ou tirée.

4. Veiller à ouvrir le pointeau et vérifier que la tige de commande s'est déplacée avant d'utiliser

la machine.

HYD RA U LI Q U E DE DESSERRAGE DES FREINS

Pompe manuelle

Pointeau

!

AVERTISSEMENT

Ne jamais remorquer la machine à une vitesse supérieure à 0,3 m/s.

Ne jamais utiliser la plate-forme de travail avec les freins de stationnement desserrés. Cela pourrait

causer des blessures ou des dommages graves.

A

PRÈS

1. S'assurer que la plate-forme est complètement abaissée.

2. Stationner la machine sur une surface ferme et de niveau, de préférence à l'abri, protégée contre les

vandales, les enfants et toute utilisation non autorisée.

3. Couper le contact dans le châssis et retirer la clé pour empêcher toute utilisation non autorisée.

H

OROMÈTRE

Pour accéder à la fonction d'horomètre, suivre les étapes ci-dessous.

1. Monter dans la nacelle (avec la machine sous tension)

2. Appuyer sur le bouton d'arrêt d'urgence de la plate-forme.

3. Maintenir enfoncés les boutons d'avertisseur sonore et de levage.

4. Tout en maintenant enfoncés ces boutons, tourner le bouton d'arrêt d'urgence pour rétablir l'alimentation électrique de la machine.

5. La mention « hr » apparaît sur l'affichage ; appuyer sur le bouton rotatif de droite fait défiler le nombre

d'heures d'utilisation de la machine, en montrant les chiffres deux par deux. Par exemple, si le fait

d'appuyer une première fois sur le bouton rotatif de droite affiche “20”, la deuxième fois “58”, et la

troisième fois “hr”, le temps d'utilisation est de 2058 heures.

CHAQUE

!

UTILISATION

AU QUOTIDIEN

Page 12 Manuel de l'utilisateur

Page 39

Transport de la plate-forme de travail 505562-100

T

RANSPORT DE LA PLATE

P

RÉPARATION POUR

1. Abaisser complètement la plate-forme.

2. Débrancher le câble négatif (-) de la borne des batteries.

3. Attacher la télécommande au garde-corps avant.

4. Attacher la tringlerie de levage au châssis.

L

EVAG E AVEC UNE

1. Fixer les sangles uniquement aux anneaux de levage/d'arrimage du châssis.

2. Placer la plate-forme sur le véhicule de transport en position de transport.

3. Caler les roues.

4. Attacher la plate-forme de travail au véhicule de transport avec des chaînes ou des sangles

de résistance adaptée et fixées aux anneaux de levage/ d'arrimage du châssis.

A

VEC UN CHARIOT ÉLÉVATEUR

DANGER

! !

Utiliser un chariot élévateur à fourche pour le transport seulement.

Voir les caractéristiques pour le poids de la plate-forme de travail et vérifier que le chariot élévateur

à fourche a une capacité suffisante pour soulever la plate-forme.

-

FORME DE TRAVAIL

L'

EXPÉDITION

GRUE

À

FOURCHE

Avec le chariot à fourche, soulever la machine par le côté, en passant la fourche sous les modules

de châssis.

Figure 5: Transport de la plate-forme de travail

C

ONDUITE

TREUILLAGE

UN CAMION

OU

SUR

OU UNE

REMORQUE

NOTE: Ne pas treuiller à une vitesse supérieure

à0,3m/s.

1. Déplacer la machine sur le camion ou la remorque ;

A. Pour déplacer la machine sur le véhicule de

transport :

a. Faire monter la rampe à la plate-forme de travail

et la placer à sa position de transport.

b. Placer les roues droites et arrêter la machine.

c. Caler les roues.

B. Pour treuiller la machine sur le véhicule de

transport :

a. Faire monter la rampe à la plate-forme de travail.

b. Fixer le câble du treuil aux anneaux de

levage/d'arrimage.

c. Desserrer les freins de stationnement (se reporter à « Remorquage ou treuillage » page 12).

d. Treuiller la plate-forme dans sa position de transport.

e. Caler les roues.

2. Attacher la plate-forme de travail au véhicule de transport avec des chaînes ou des sangles

de résistance adaptée et fixées aux anneaux de levage/ d'arrimage du châssis.

Anneaux

de levage/

d'arrimage

avant

Chariot

élévateur

Anneaux de

ATTENTION

Le fait de trop serrer les chaînes ou sangles fixées aux anneaux de levage/ d'arrimage peut

endommager la plate-forme de travail.

Manuel de l'utilisateur Page 13

Page 40

505562-100 Maintenance

M

AINTENANCE

!

AVERTISSEMENT

Ne jamais effectuer de répar ations lorsque que la plate-forme est levée sans avoir bloqué au préalable

l'ensemble de levage.

NE PAS rester à proximité de l'ensemble de levage pendant le déploiement ou le r angement du bras.

B

LOCAGE

DE L'ENSEMBLE