Page 1

X26-32

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Der zweite Abschnitt von dieser Betriebsanleitung ist die Deutsche version.

Guide d’opérateur

La troisième section de ce manuel d'opérateurs est la version de langue Française.

WARNING

The X32 Machine has been re-assessed to ensure

compliance to the Machinery Directive (2006/42/EC).

The Machine rating has been changed from:

Windspeed rating of 12.5 m/s (Beaufort 6)

To

Windspeed rating of 7 m/s (Beaufort 4)

Please attach to the front cover of

your X32 manual

(EN) Manual part number 504155-001 for serial numbers 50064 to current.

510329-000

(DE) Bestellnummer 504165-001 ab Seriennummer 50064 fortlaufend.

(FR) Manuel Pièce numéro 504165-001 pour numéro série 50064 à présent.

Page 2

Page 3

X Series

Serial Numbers 50000 – Current

ENGLISH

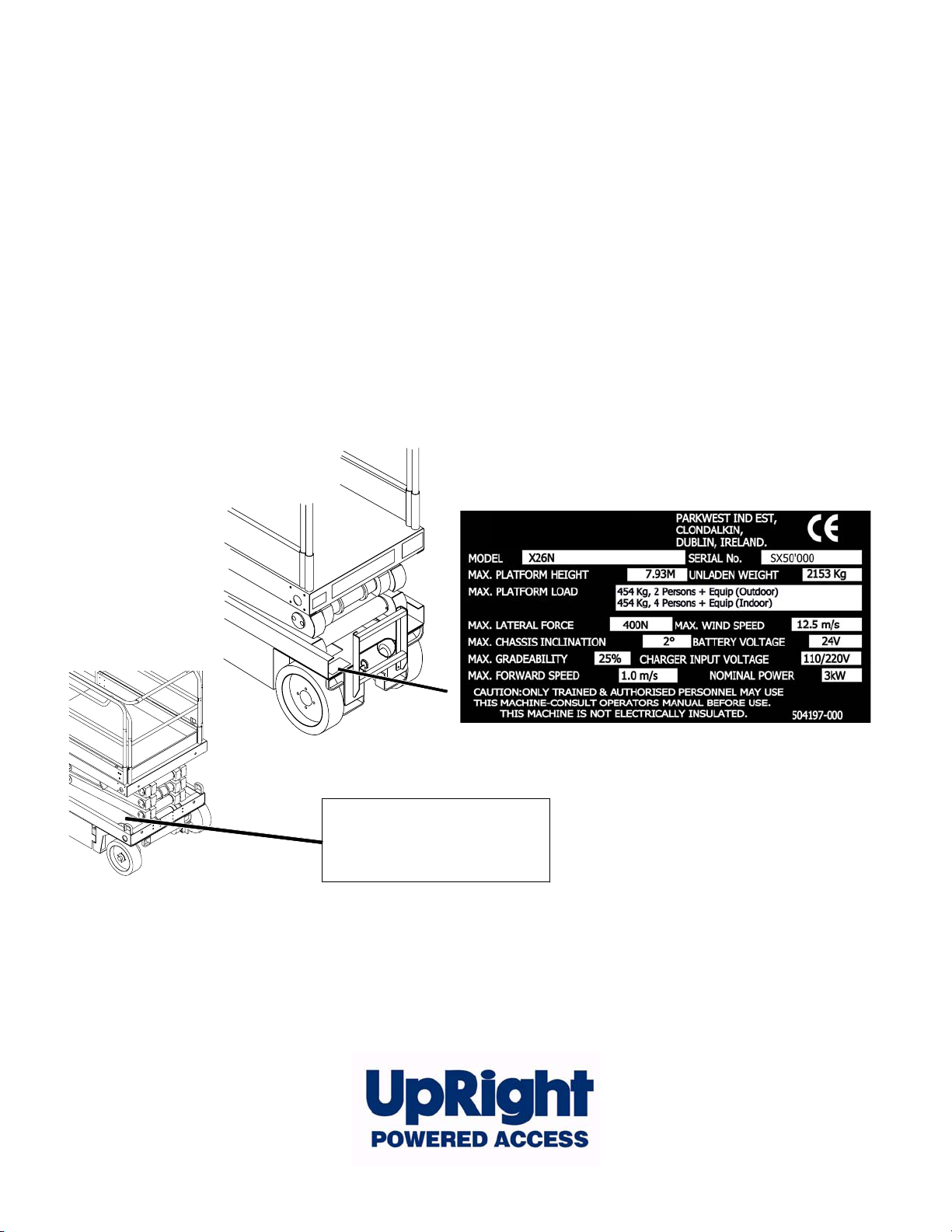

When contacting Ui for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis above the

front axle pivot.

FRANÇAIS

Lors des communications avec Ui pour des informations au sujet de l’entretient ou des pièces, ne pas oublier d’inclure les

NUMÉROS DE MODÈLE et de SÉRIE inscrits sur la plaque signalétique. Si la plaque signalétique manque, le NUMÉRO

DE SÉRIE est également estampé sur le dessus du châssis, au-dessus de l’axe pivot avant.

DEUTSCH

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben, wenn Sie sich mit

Ui bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzten. Sollte das Typenschild fehlen, finden Sie die

SERIENNUMMER auch auf dem Fahrwerk über der vorderen Schwenkachse.

Stamped Serial Number

Estampille de numéro de série

Eingestanzte Seriennummer

Page 4

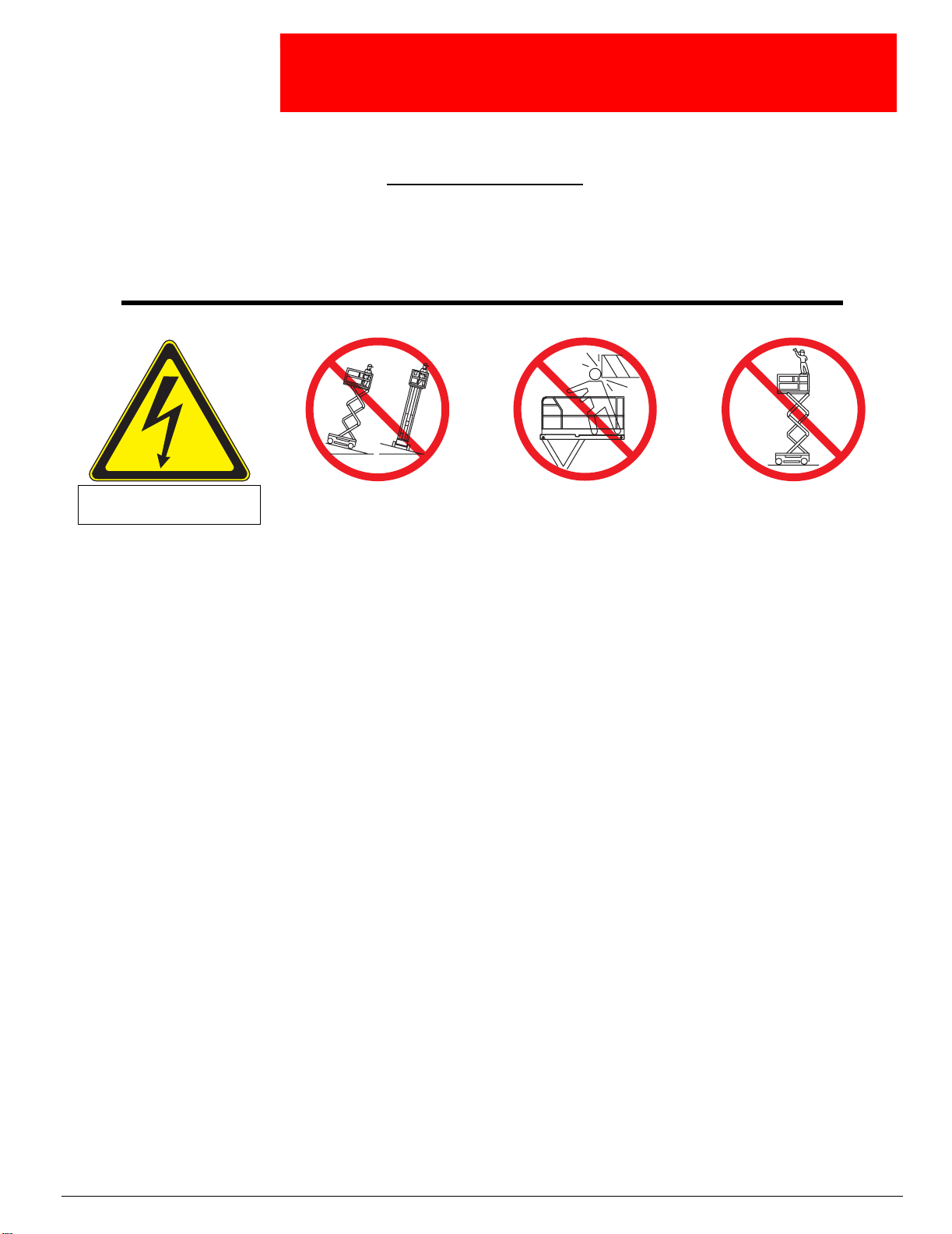

OPERATION MANUAL

C

WA RN IN G

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any Ui aerial work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All oth er uses of t he aerial work platform are proh ibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the m achin e withou t first surve y ing th e w ork area f or su rf a ce ha zards such as h oles , dro p-offs , b um ps , curb s, or deb ris;

and avoiding them.

OPERATE machine on ly on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the r ailing of the pla tf orm, standi ng on o r st epping from th e platform onto buildings , st eel or pref a b conc rete s tructures , etc.,

is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain t hat the swing gate is closed and securely

locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, l oos e wire connections, and da ma ged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are pr oh ibite d or permissible only at the approval by

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

ollision Hazard Fall Hazard

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

Ui.

NEVER climb, stand, or sit on

platform guardrails or midrail.

Page 1

Page 5

504165-001

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Platform Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Lowered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Elevating the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lowering the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

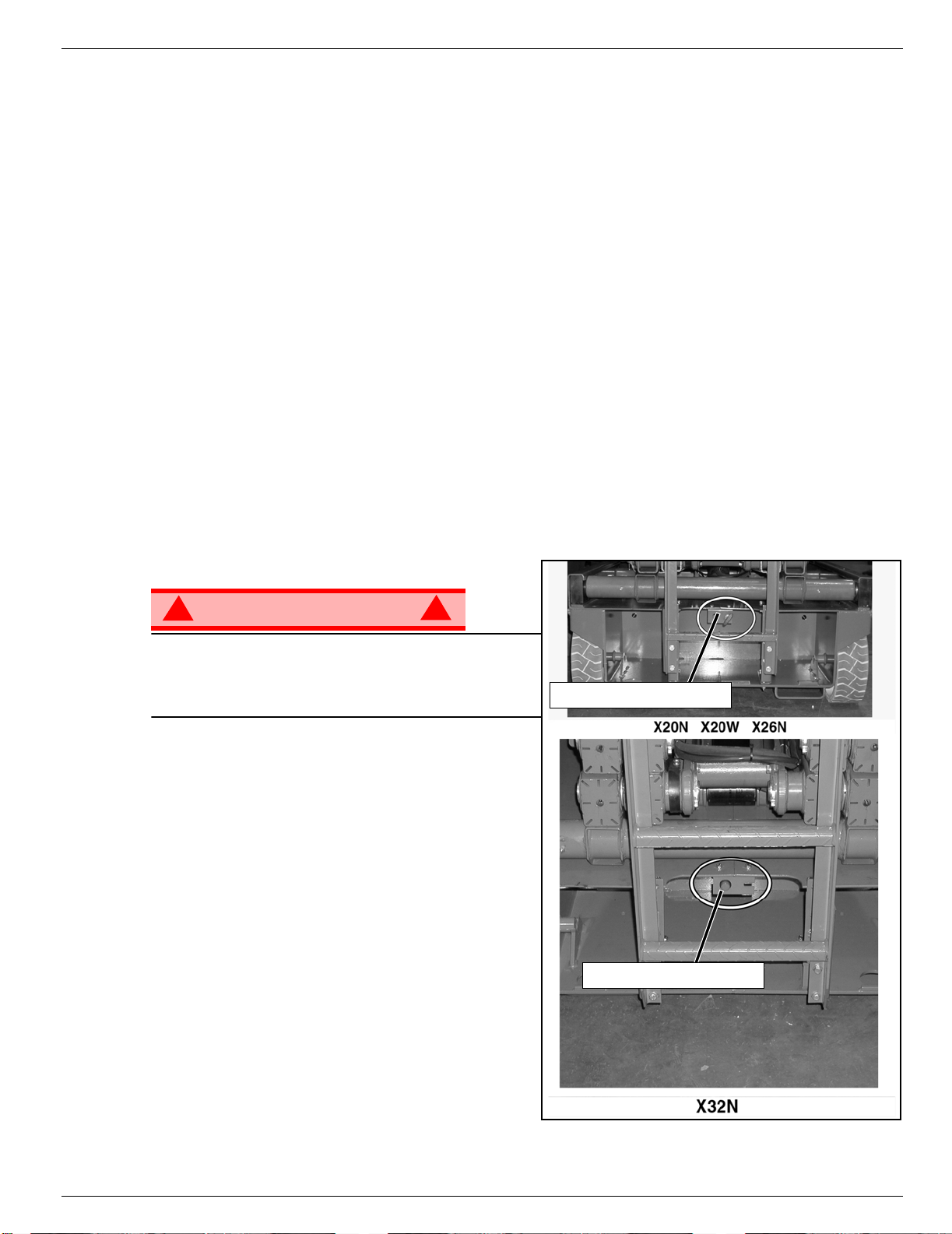

X20N, X20W and X26N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X32N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lower the Guardrails, X26N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lowering Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Raising Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fold Down guardrails, X32N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fold Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Erection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parking Brake Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting the Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting By Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

By Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driving or Winching onto a Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blocking The Elevating Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Stowage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspection and Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Daily Preventative Maintenance Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

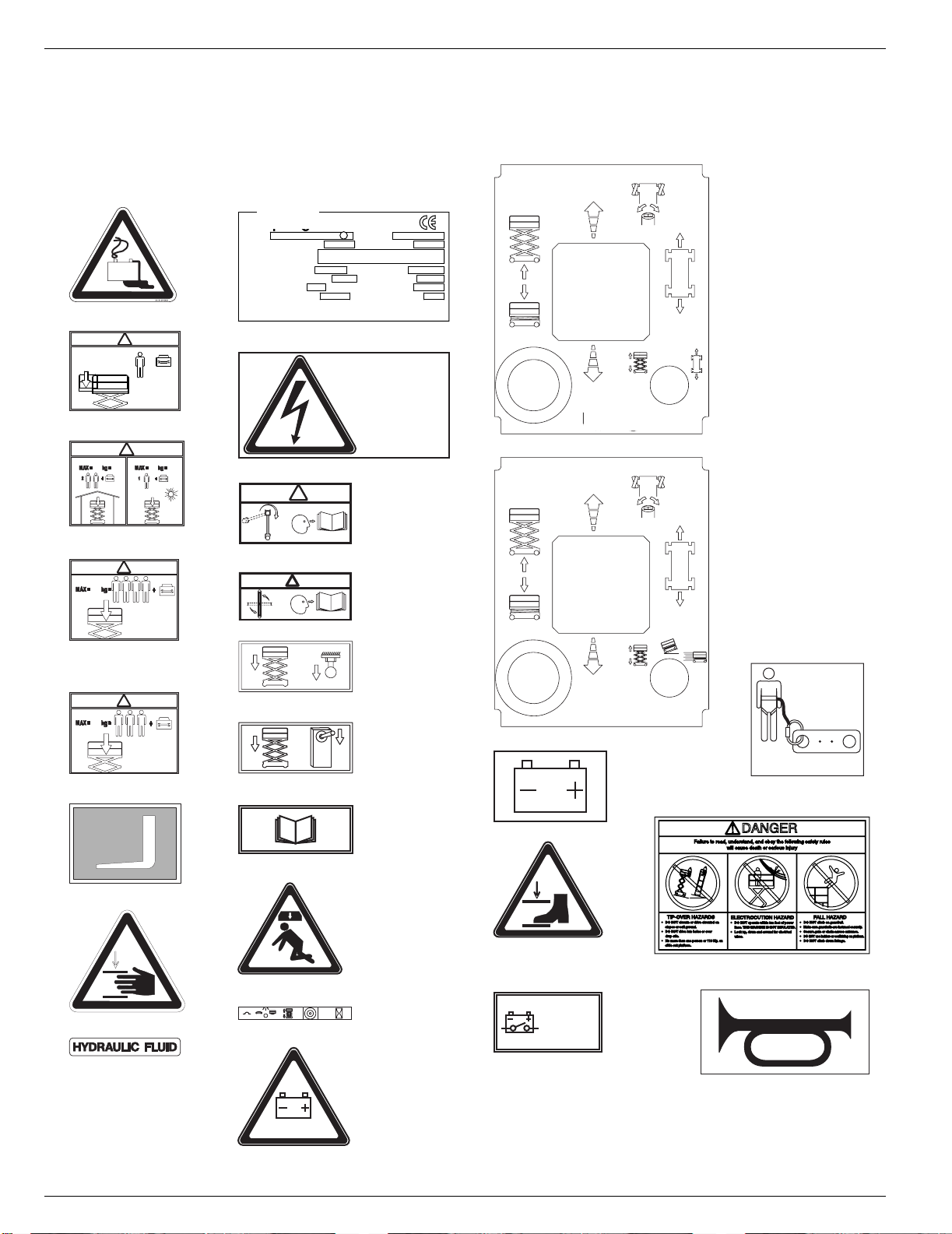

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Page 2 Operation Manual

Page 6

Introduction 504165-001

I

NTRODUCTION

This manual covers operation of the X Series Self-Propelled Work Platforms. This manual must be

stored on the machine at all times.

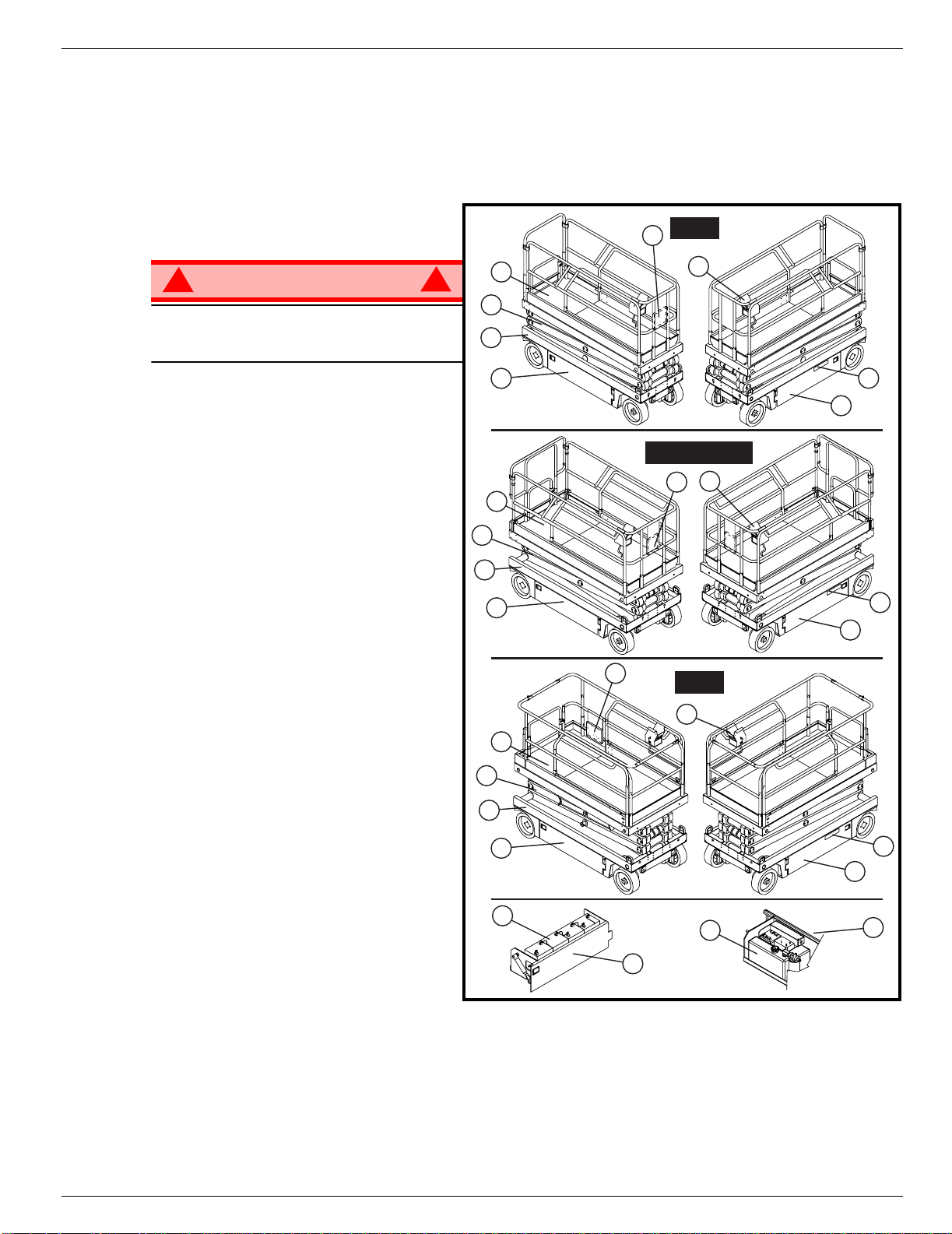

G

ENERAL

D

ESCRIPTION

1. Platform

7

Figure 1: X Series

X20N

!

WARNING

DO NOT use the maintenance platform

without guardrails properly assembled

and in place

2. Elevating Assembly

3. Chassis

4. Power Module

5. Control Module

6. Platform Controls

7. Manual Case

8. Chassis Controls

9. Hydraulic Fluid Reservoir

10. Batteries

1

6

!

2

3

4

X20W & X26N

6

7

1

2

3

4

7

X32N

6

8

5

8

5

1

2

3

4

10

9

4

8

5

5

Operation Manual Page 3

Page 7

504165-001 Special Limitations

S

PECIAL

L

IMITATIONS

Travel with the platform raised is limited to creep speed range.

Elevating the Work Platform is limited to firm, level surfaces only.

DANGER

! !

The elevating function shall ONLY be used when the work platform is level and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

P

LATFORM

The maximum capacity for the MACHINE, including occupants is determined by model and options, and

is listed in “Specifications” on page 20.

DANGER

! !

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

M

ANUAL

Manual force is the force applied by the occupants to objects such as walls or other structures outside the

work platform.

F

C

APACITY

ORCE

The maximum allowable manual force is limited to 200 N (45 lbs.) of force per occupant, with a maximum

of 400 N (90 lbs.) for two or more occupants.

DANGER

! !

DO NOT exceed the maximum amount of manual force for this machine.

B

EAUFORT

Never operate the machine when wind speeds exceed 25 km/h (15 mph) [Beaufort scale 4].

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

m/s km/h ft/s mph

L

IFT

O

If a load equivelent to 90% of safe working load is lifted a fault code “03” will be displayed on the digital

display on the platform control box. If a load which is greater than the safe working load is present in the

basket all machine functions will cease to operate and an acoustic warning will sound. In order to return to

normal operation a load equal to or less than the safe working load must be present in the basket and the

power must be re-cycled, power can be re-cycled by pushing the emergency stop button and releasing it

again.

S

CALE

WIND SPEED

VERLOAD

A

GROUND CONDITIONS

LARM

DANGER

! !

Never operate the machine with a platform load greater than the rated capacity.

Page 4 Operation Manual

Page 8

Controls and Indicators 504165-001

C

ONTROLS AND INDICATORS

Figure 2: Controls and Indicators

Platform Controls

4

6

3

1

1 Drive Selectors

2. Horn Button

3. Lift/Lower Button

4. Emergency Stop Button

5. Display

6. Joystick

1

2

Chassis Controls

2

5

34

1. Keyswitch

2. Enable Button

3. Toggle Switch (Up & Down)

4. Emergency Stop Switc h

Operation Manual Page 5

Page 9

504165-001 Pre-Operation Safety Inspection

P

RE

-O

PERATION

NOTE: Carefully read, understand and follow all safety rules, operating instructions, labels and National Safety

Instructions/Requirements. Perform the following steps each day before use.

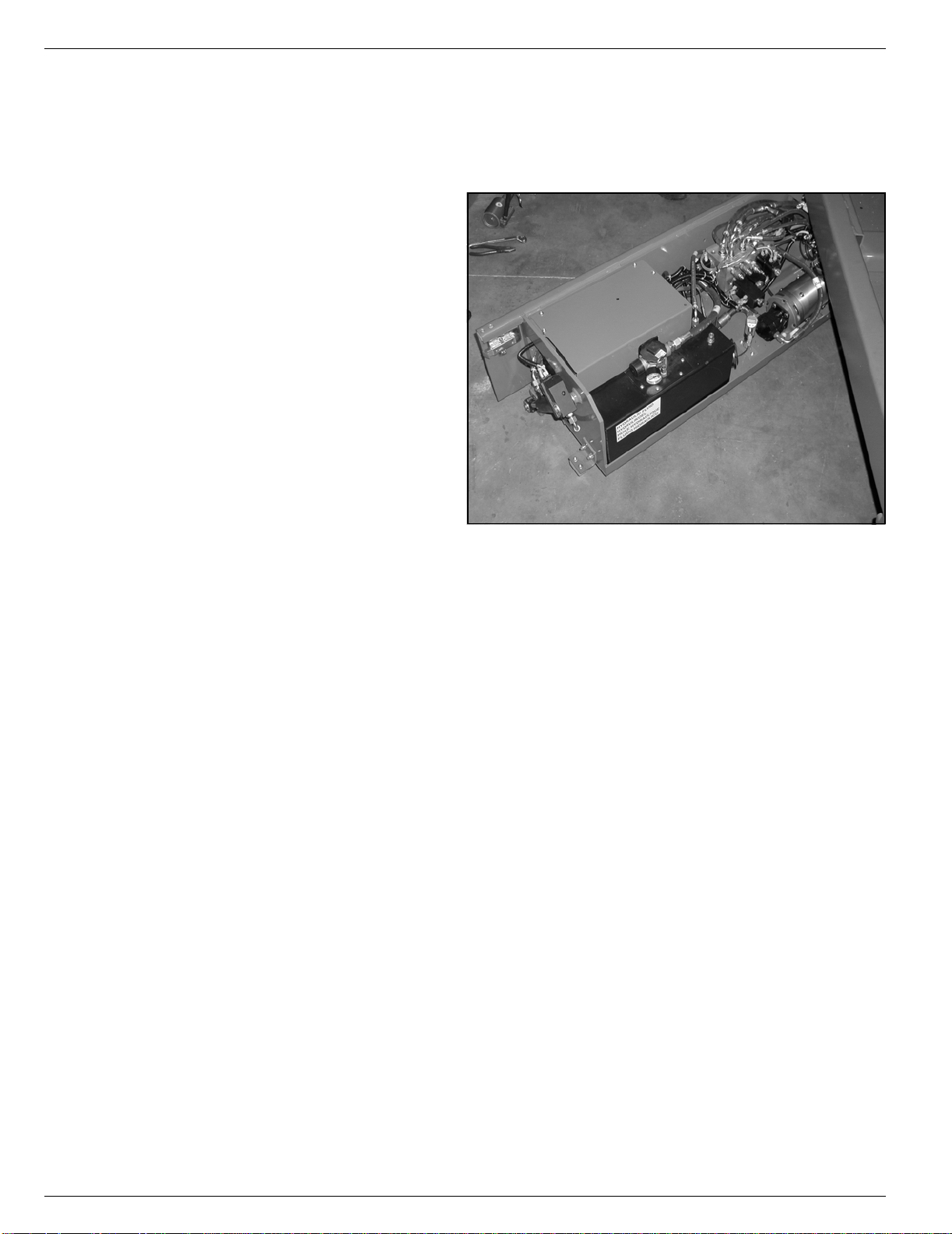

1. Open modules and inspect for damage, fluid leaks or missing parts.

2. Check the level of the hydraulic fluid with

the platform fully lowered. The hydraulic

reservoir is located in the Control Module Door. The fluid level must be

between the MIN and MAX lines. Add

hydraulic fluid if necessary.

3. Check that fluid level in the batteries is

correct.

4. Verify that batteries are charged.

5. Check that A.C. extension cord has

been disconnected from the plug in the

rear of the machine.

6. Check that all guardrails are in place

and all fasteners are properly tightened.

7. Inspect the machine thoroughly for

cracked welds and structural damage,

loose or missing hardware, hydraulic

leaks, damaged control cable, loose wire connections and wheel bolts.

S

AFETY

I

NSPECTION

Figure 3: Hydraulic Tank

Page 6 Operation Manual

Page 10

System Function Inspection 504165-001

S

YSTEM

F

UNCTION INSPECTION

Refer to Figure 2 for the locations of various controls and indicators.

!

WARNING

STAND CLEAR of the work platform while performing the following checks.

Before operating the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in ALL directions, including above the work platform, for obstructions and electrical conductors.

Protect the control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Pull Chassis Emergency Stop Switch to the ON position.

3. Pull Platform Emergency Stop Switch to the ON position.

4. Turn and hold the Chassis Key Switch to the ON position. Push the Chassis Lift/Lower Switch to the UP

position and raise the platform approximately 2,1 m (7 feet). BLOCK THE ELEV ATING ASSEMBLY AS

DESCRIBED ON PAGE 9.

5. Visually inspect the elevating assembly, lift cylinder, cables, and hoses for cracked welds and structural

damage, loose hardware, hydraulic leaks, loose wire connections, and erratic operation. Check for missing or loose parts.

6. Verify that the Depression Mechanism Supports have rotated into position under the machine. REMOVE

THE SCISSOR BRACE AS DESCRIBED ON page 14.

7. Push the Chassis Lift/Lower Switch to the UP position and fully elevate the platform.

8. Partially lower the platform by pushing Chassis Lift/Lower Switch to LOWER, and check for proper operation of the audible lowering alarm.

9. Open the Emergency Lowering Valve (see Figure 5) by pulling the knob out to check for proper operation. When the platform is lowered, release the knob.

10. Push the Chassis Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Chassis Emergency Stop Switch to resume.

11. Check that the route is clear of obstacles (persons, obstructions, holes, and drop-offs, bumps and

debris), is level, and is capable of supporting the wheel loads.

12. Mount the platform and properly close the entrance.

13. Mount the platform and select DRIVE mode.

!

NOTE: Use both HI and LOW drive (if applicable) when performing the following step.

14. While engaging the Interlock Switch, move the Control Handle to FORWARD, then REVERSE, to check

for speed control.

15. Push the Steering Switch RIGHT, then LEFT, to check for steering control.

16. Select LIFT mode. Grasp the Control Handle, engaging the Interlock Switch, and push it forward to

check platform lift controls. Raise the platform to full elevation.

17. Pull back on the Control Handle. The platform should descend and the audible lowering alarm should

sound.

18. Push the Platform Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Platform Emergency Stop Switch to resume.

Operation Manual Page 7

Page 11

504165-001

O

PERATION

Before operating the work platform, ensure that the Pre-Operation Safety Inspection has been completed

and that any deficiencies have been corrected. Never operate a damaged or malfunctioning machine.

The operator must be thoroughly trained on this machine.

P

LATFORM

1. Mount the platform and properly close the entrance.

2. Depress the foot lever located at the rear of the platform

extension. Push the platform extension forward until the

pin engages the front stop.

3. To retract the platform extension, depress the foot lever

and pull the platform extension toward the rear of the

machine until the pin engages the rear stop.

T

RAVEL

OWERED

L

1. Check that the route is clear of obstacles (persons,

obstructions, holes, drop-offs, bumps, and debris), is level,

and is capable of supporting the wheel loads.

2. Verify that the Chassis Key Switch is turned to ON and the

Chassis Emergency Stop Switch is ON (pulled out).

3. Mount the platform and properly close the entrance.

4. Check clearances above, b elow, and to the sides of platform.

5. Pull the Platform Emergency Stop Switch out to the ON position.

6. Select DRIVE mode.

E

W

ITH THE

XTENSION

P

LATFORM

Figure 4: Platform Extension

NOTE: Choose between standard drive and extra torque depending on the gradient.

7. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from center the Control

Handle is moved.

S

TEERING

1. Turn the Drive/Lift Switch to DRIVE.

2. While engaging the Interlock Switch, push the Steering Switch to RIGHT or LEFT to turn the wheels in

the desired direction. Observe the tires while maneuvering the work platform to ensure proper direction.

NOTE: Steering is not self-centering. Wheels must be returned to the straight ahead position by operating the Steering

Switch.

E

LEVATING THE

1. Select a firm, level surface.

2. Select LIFT mode.

3. While engaging the Interlock Switch, push the Control Handle forward.

4. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm level surface before

attempting to re-elevate the platform.

NOTE: Depression Mechanism supports will deploy automatically as the platform elevates and will retract after the

platform has been lowered completely and has been driven.

P

LATFORM

Page 8 Operation Manual

Page 12

Operation 504165-001

T

RAVEL

NOTE: The machine will travel at reduced speed when the platform is elevated.

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, b elow, and to the sides of platform.

3. Select DRIVe mode.

4. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from center the Control Handle is moved.

5. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm, level surface before

attempting to re-elevate the platform.

L

OWERING THE

1. Select LIFT mode.

2. Check around the base of the platform to ensure that no one is in contact with the machine. Engage the

Interlock Switch and pull back on the Control Handle to lower the platform.

3. The platform will stop when it reaches the PPE cutout height. Inspect around the machine to ensure no

one is in contact with the machine. After a four-second time delay, lower the platform as in step 2.

W

ITH THE

P

P

LATFORM

LATFORM

E

LEVATED

E

MERGENCY

!

WARNING

If the platform should fail to lower, NEVER climb

down the elevating assembly.

Stand clear of the elevating assembly while operating

the Emergency Lowering Valve Knob.

X20N, X20W

The Emergency Lowering Valve for the X20N,

X20W, and X26N is located at the rear of the

machine, above the charger.

1. Open the Emergency Lowering Valve by pulling

and holding the knob.

2. To close, release the knob. The platform will not

elevate if the Emergency Lowering Valve is open.

L

OWERING

AND

X26N

!

X32N

The emergency lowering control switch is located at

the rear of the machine.

Figure 5: Emergency Lowering Valve

Emergency Lowering Knob

Emergency Lowe r i ng Button

1. Open the emergency lowering valve by pushing

down on the toggle switch and holding it.

2. Once the platform is fully lowered, release the

toggle switch to close the valve. The platform will

not elevate if the Emergency Lowering Valve is

open.

Operation Manual Page 9

Page 13

504165-001 Operation

L

OWER THE

This procedure applies only to the X26N model for the purpose of passing through a standard double

doorway. Guardrails must be returned to proper position before using the machine.

L

OWERING PROCEDURE

1. Ensure that the slide-out deck extension is fully retracted and the deck pin is locked. Place the Platform

Control s on the floor of the platform.

2. Remove and retain the set screws from the side guardrails and the slide-out deck guardrails.

3. Lower the slide-out deck guardrail completely.

4. Lower the rear guardrail until it rests on the stop screws.

5. Lower the side guardrails completely.

6. Raise the rear guardrail until the retaining pins engage. Remove and retain the stop screws and nuts

from the rear guardrail.

7. Pull the two retaining pins and lower the rear guardrail completely.

R

AISING PROCEDURE

1. Raise the rear guardrail until the retaining pins engage.

2. Install the stop screws and nuts on the rear guardrail and torque to 42 N-m (31 ft. lbs).

3. Pull the two retaining pins and lower the rear guardrail until it rests on the stop screws.

4. Raise the side guardrails until the tops are level with the rear guardrail.

• Install the set screws

5. Raise the slide-out deck guardrail until the top is level with the side guardrails.

• Install the set screws

6. Hang the controller on the slide-out deck guardrail.

7. Torque all set screws to 42 N-m (31 ft. lbs).

G

UARDRAILS

, X26N

!

WARNING

Before operating machine, guardrails must be securely fastened in their proper position.

!

Page 10 Operation Manual

Page 14

Operation 504165-001

F

OLD

F

OLD

1. Unhook the controller from the side guardrail and place it on the floor of the platform.

2. Pull the retaining pin on the front guardrail and rotate inwards.

3. Pull the retaining pin on the rear guardrail and rotate inwards.

4. Starting with the slide-out deck guardrails and then the outer guardrails, lift up on each guardrail and fold

E

RECTION

1. Starting with the outer guardrails and then the slide-out deck guardrails, raise each guardrail and drop it

2. Rotate the front and rear upper guardrails outward and secure them to the opposite side guardrails,

3. Hang the controller on the side guardrail.

D

OWN GUARDRAILS

This procedure applies only to the X32N model for the purpose of passing through a standard double doorway. Guardrails must be returned to proper position before using the machine.

D

OWN PROCEDURE

inward.

P

ROCEDURE

down, securing it in the vertical position.

using the retaining pins.

, X32N

Operation Manual Page 11

Page 15

504165-001 Towing or Winching

T

OWING OR

W

INCHING

Perf orm the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting the Work Platform” on

page 13).

CAUTION

DO NOT tow or winch the machine faster than 0,3 m/s (1 ft./s). Faster speeds will damage drive

components and void the warranty.

!

WARNING

Never tow faster than 0,3 m/sec. (1 ft./sec.).

Never operate the work platform with the parking brakes released. Serious injury or damage could

result.

A

FTER

1. Ensure that the platform is fully lowered.

2. Park the machine on a firm level surface, preferably under cover, secure against vandals, children and

3. Turn the Chassis Key Switch to OFF and remove the key to prevent unauthorized operation.

H

OUR

To access the hour meter function perform the following steps.

1. Climb into the basket (with the machine powered up)

2. Push the platform emergency stop button.

3. Hold down the following buttons, Jib and Upper Boom Lift.

4. While holding the buttons twist the emergency stop button to return power to the machine.

5. “hr” will now be displayed on the readout, Pressing the right turn button will scroll through the accumulated hours two digits at a time. For example, if pressing the right turn button once displays “20”, pressing

it a 2nd time displays “58”, and pressing it a 3rd time displays “hr”, the elapsed time of operation is 2058

hours.

U

SE

E

ACH

unauthorized operation.

M

ETER

D

!

AY

Page 12 Operation Manual

Page 16

Transporting the Work Platform 504165-001

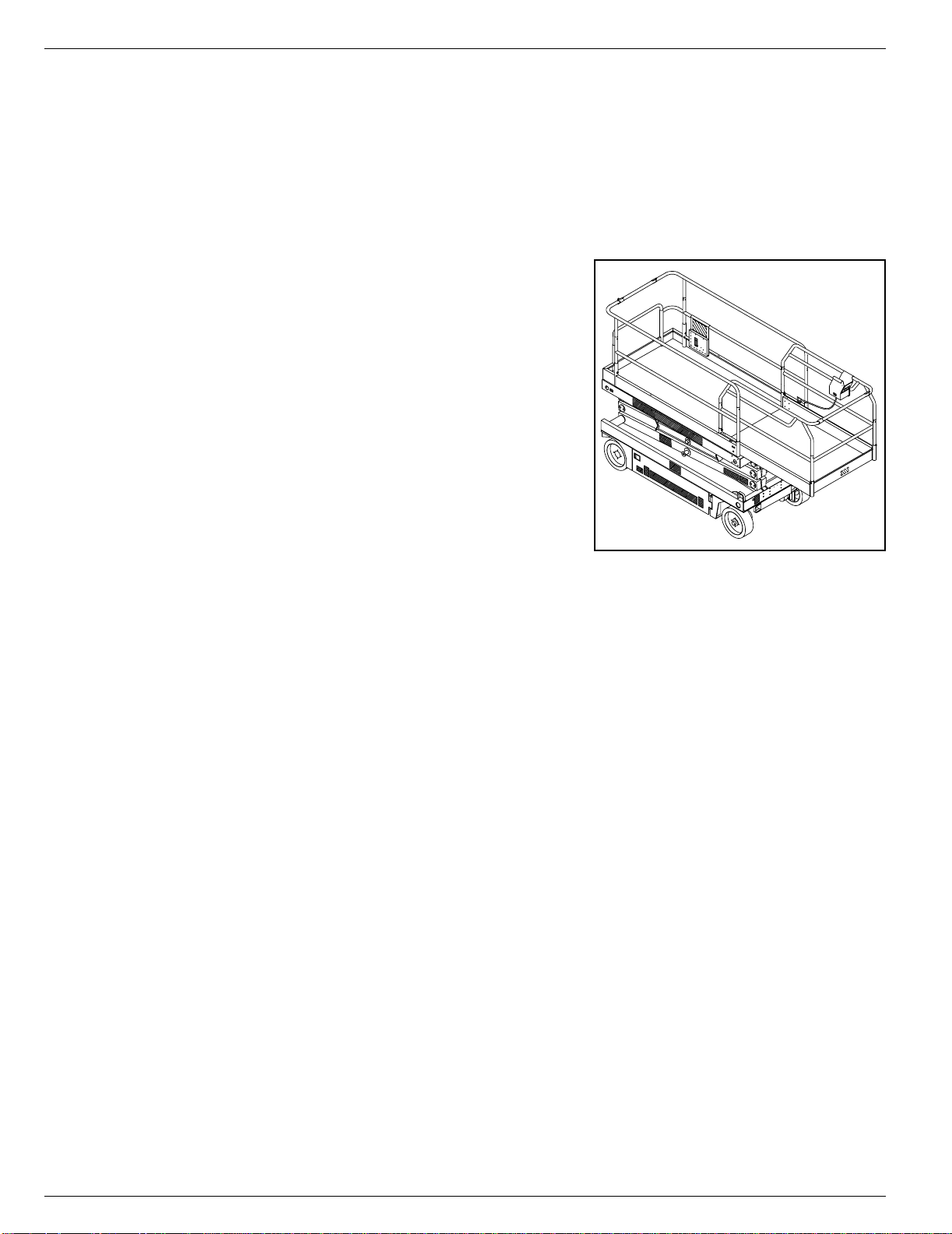

T

RANSPORTING THE

P

REPARATION FOR

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage to the frame.

L

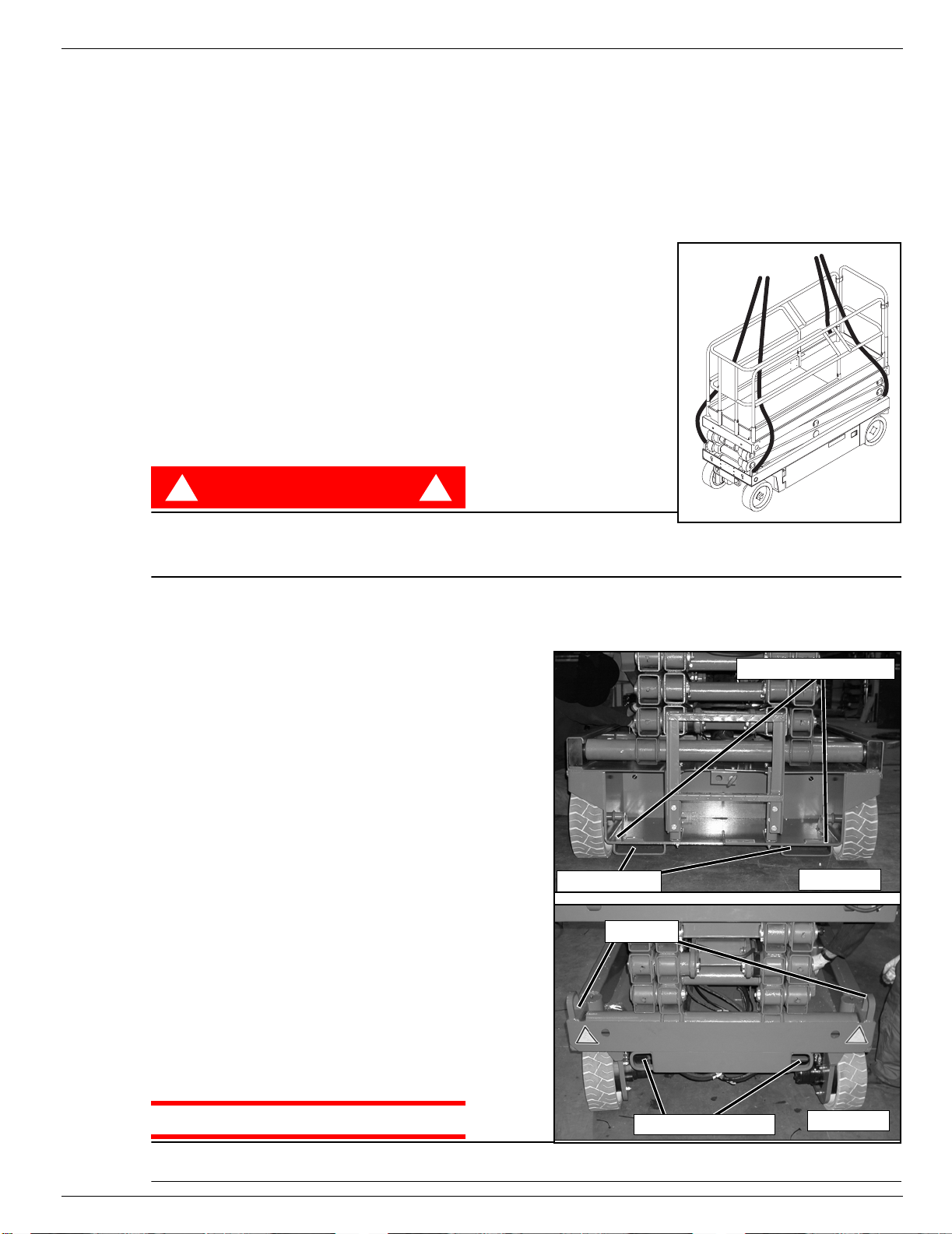

IFTING

1. Secure straps to chassis tie down/lifting lugs only.

2. Place the platform onto the transport vehicle in transport position.

3. Chock the wheels.

4. Secure the work platform to the transport vehicle with chains or straps

of adequate load capacity attached to the chassis tie down/lifting lugs.

BY C

W

ORK

RANE

P

S

HIPMENT

LATFORM

Figure 6: Secure Crane Straps

BY F

Forklifting is for transport only.

See specifications for weight of work platform and be certain that forklift is of adequate capacity to lift

the work platform.

D

RUCK OR

T

NOTE: Do not winch faster than 0,3 m/s (1 ft/s).

1. Move the machine onto the truck or trailer;

2. Secure the work platform to the transport vehicle

ORKLIFT

DANGER

! !

Forklift from the rear of the machine using the forklift pockets provided. If necessary, the machine may be

forklifted from the side by lifting under the Chassis Modules.

Figure 7: Transporting the Work Platform

RIVING OR

A. To Drive the machine onto the transport vehicle:

a. Move the work platform up the ramp and into

transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

B. To Winch the machine onto the transport vehicle:

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting lugs.

c. Release the parking brakes (refer to “Towing or

Winching” on page 12).

d. Winch the platform into transport position

e. Chock the wheels.

with chains or straps of adequate load capacity

attached to the chassis tie down/lifting lugs.

W

T

RAILER

INCHING ONTO A

Forklift Pockets

Lift Lugs

Rear Tie Down/Lift Lugs

REAR

CAUTION

Overtightening of the chains or straps attached to the

Tie Down/Lifting Lugs may result in damage to work platform.

Operation Manual Page 13

Front Tie Down Lugs

FRONT

Page 17

504165-001 Maintenance

M

AINTENANCE

!

WARNING

Never perform service while the platform is elevated without first blocking the elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

SSEMBLY

A

S

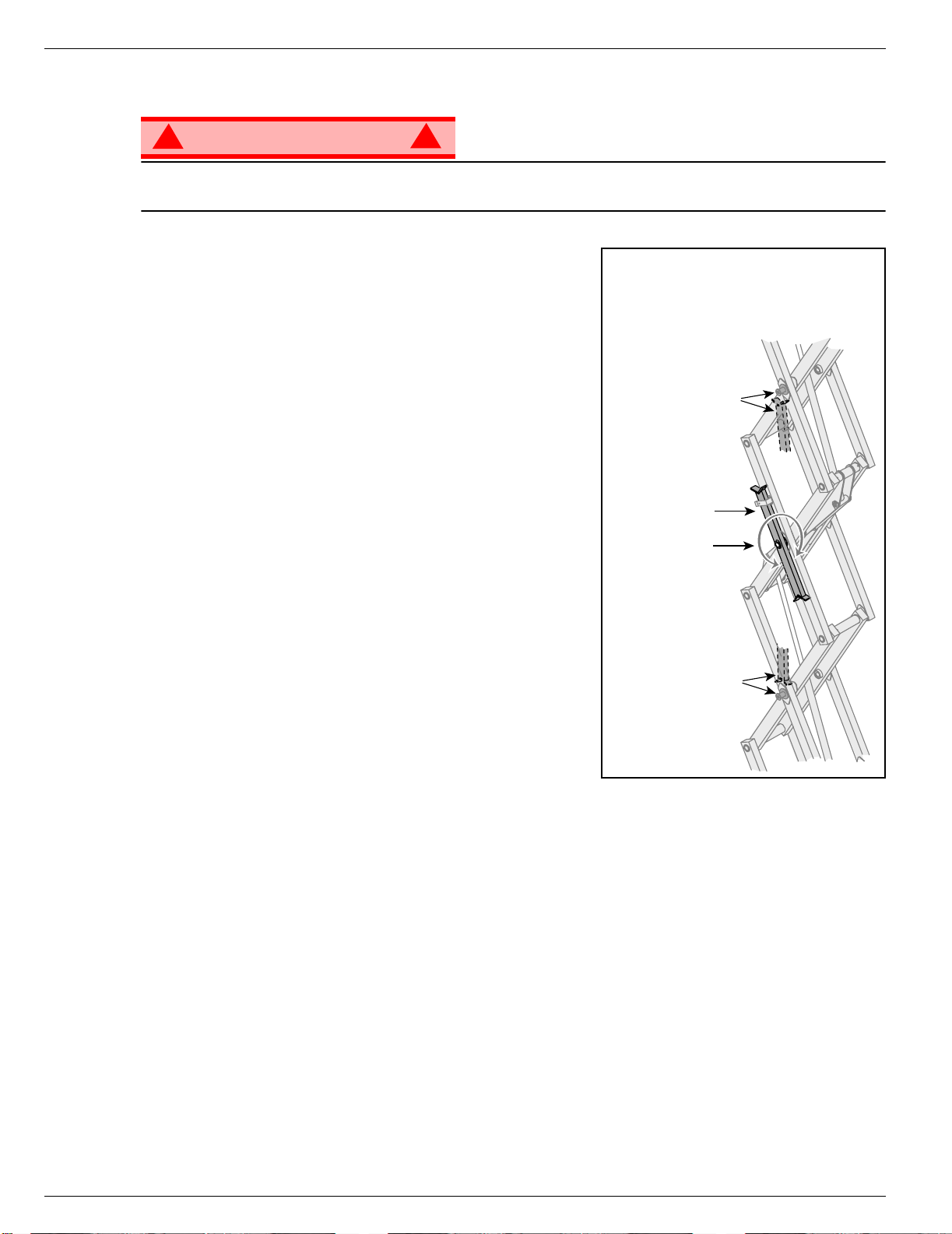

CISSOR BRACE INSTALLATION

1. Park the work platform on a firm, level surface.

2. Pull Chassis EMERGENCY STOP Switch to the ON position.

3. Pull Platform EMERGENCY STOP Switch to the ON position.

4. Turn and hold the Chassis Key Switch to CHASSIS.

5. Push the Chassis Lift/Lower Switch to LIFT to elevate the

platform until the Scissor Brace can be rotated to the vertical

position.

6. X20N, X20W, and X26N – From the rear of the machine, lift

the Scissor Brace from its stowed position. Rotate upward

and outward, then down until it is hanging vertically below its

attachment point.

7. X32N – From the left side of the machine, pull the locking

pin securing the brace. Rotate the Scissor Brace counterclockwise until it is in the vertical posit ion .

8. Lower the platform by pushing the Chassis Lift/Lower Switch

to LOWER and gradually lower the platform until the Scissor

Brace is supporting the platform.

T

HE

E

LEVATING

!

Figure 8: Scissor Brace

X20N, X20W, and X26N

Pin Rests on Brace

when in Blocking

Position

Scissor Brace in

Rest Position

Brace Rotates to

Blocking Position

Brace Rests on Pin

when in Blocking

Position

X32N

S

CISSOR BRACE

1. Using the Chassis Controls, gradually elevate the platform until the Scissor Brace is clear.

2. X20N, X20W, and X26N – Rotate the Scissor Brace outward and upward over its mounting point until it

rests in the stowed position.

3. X32N – Rotate the Scissor Brace clockwise until the locking pin engages.

4. Lower the platform by pushing the Chassis Lift/Lower Switch to LOWER to completely lower the platform.

Page 14 Operation Manual

S

TOWAGE

Page 18

Maintenance 504165-001

B

ATTERY

M

AINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with Ui batteries or manufacturer approved replacements weighing 26,3 kg

(58 lbs.) each.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

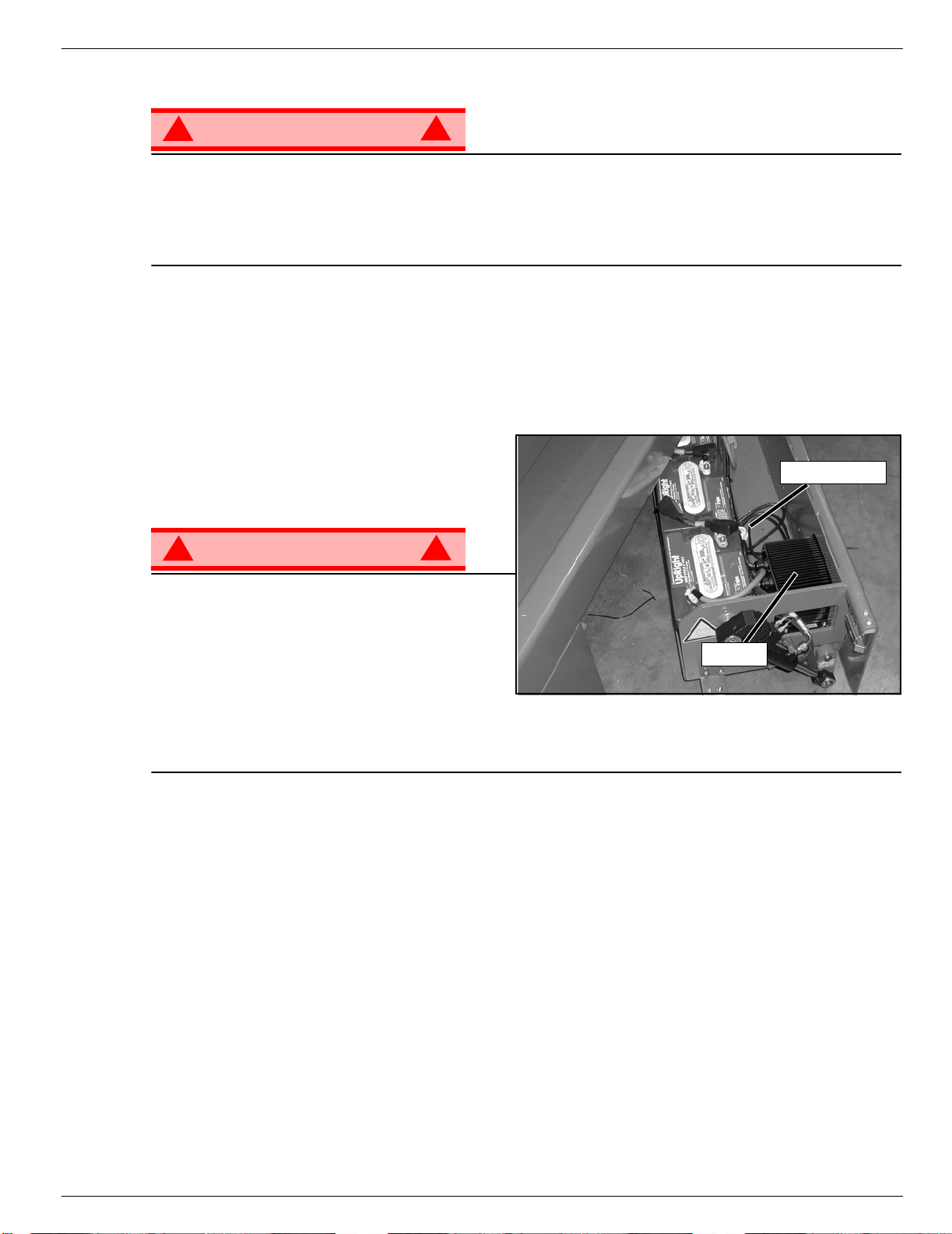

ATTERY CHARGING

Charge the batteries at the end of each work

shift or sooner if the batteries have been discharged.

!

WARNING

Charge the batteries in a well ventilated area.

Do not charge the batteries when the work

platform is near a source of sparks or flames.

Permanent damage to the batteries will result if

the batteries are not immediately recharged after

discharging.

Never leave the battery charger operating for more than two days.

Never disconnect the cables from the batteries when the charger is operating.

Keep the charger dry.

!

3

(

/

in.) above the plates add distilled water only. DO NOT use

8

Figure 9: Battery Charger

Charger Plug

!

Charger

3

(

/

1. Check the battery fluid level. If the battery fluid level is lower than 10 mm

distilled water only.

2. Connect an appropriate extension cord to charger outlet plug in Left Module Door. Plug the extension

cord into a properly grounded outlet of proper voltage and frequency.

3. The charger turns on automatically after a short delay. The LED charge indicator will illuminate. After

completion of the charge cycle the LED will blink, indicating that the charger is in a continuing maintenance mode. DO NOT leave the charger plugged in for more than 48 hours, as permanent damage to

the batteries may occur.

NOTE: The battery charger circuit must be used with a GFI (Ground Fault Interrupt) outlet.

NOTE: DO NOT operate the machine while the charger is plugged in.

Operation Manual Page 15

in.) above the plates add

8

Page 19

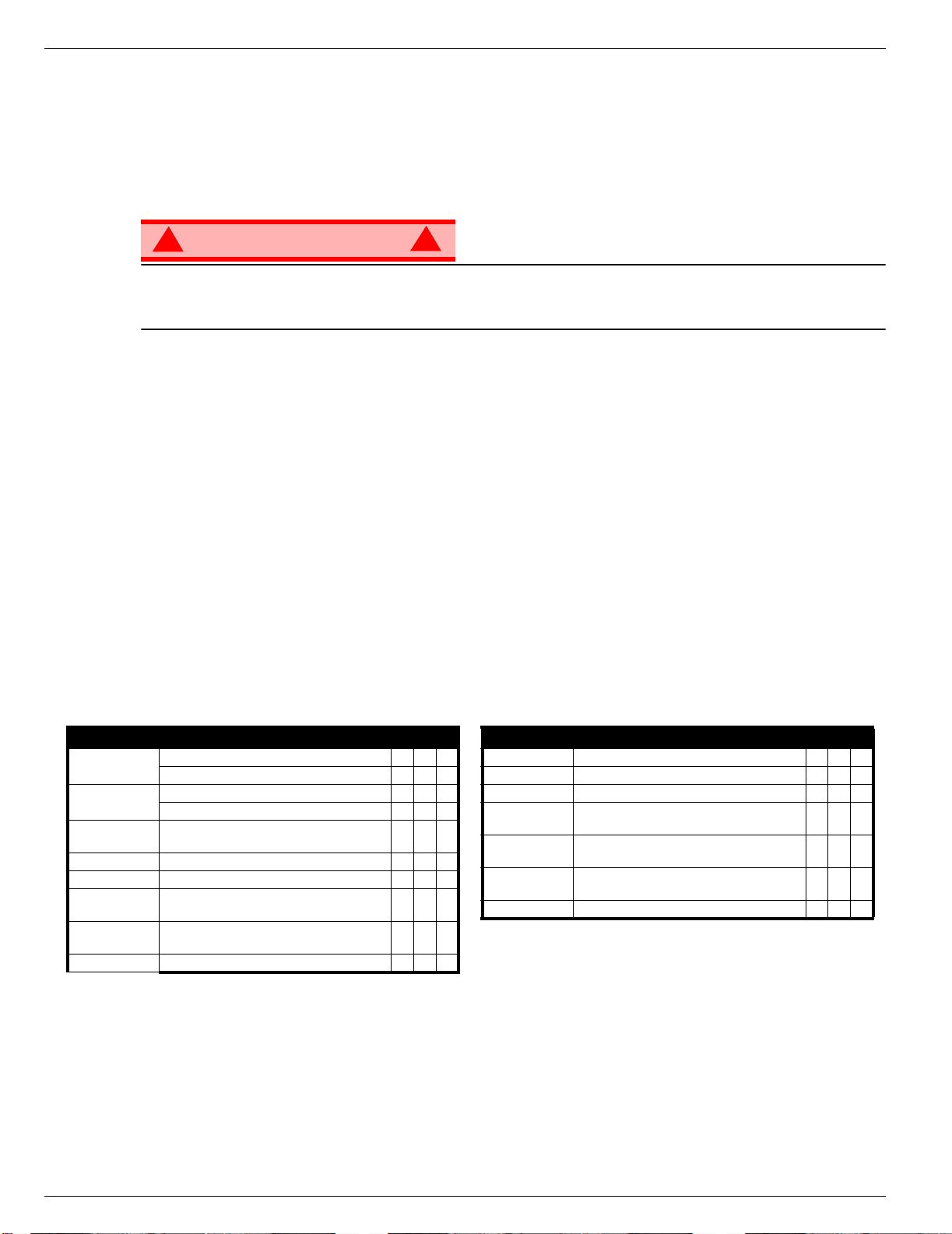

504165-001 Inspection and Maintenance Schedule

I

NSPECTION AND

M

AINTENANCE

S

CHEDULE

The Complete Inspection consists of periodic visual and operational checks, along with periodic minor

adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. Inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical procedures.

D

AILY

M

AINTENANCE

!

WARNING

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform maintenance while the

platform is elevated.

The daily preventative maintenance checklist has been designed for machine service and maintenance.

Please photocopy this page and use the checklist when inspecting the machine.

P

REVENTATIVE

T

ABLE KEY

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

!

M

AINTENANCE

C

HECKLIST

P

REVENTATIVE MAINTENANCE

R

EPORT

Date:_______________________________________

Owner: _____________________________________

Model No:___________________________________

Serial No: ___________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Battery

Chassis

Control Cable

Controller Check switch operation.

Drive Motors Check for operation and leaks.

Elevating

Assembly

Emergency

Lowering System

Entire Unit Check for and repair collision damage.

Check electrolyte level.

Check battery cable condition.

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check the exterior of the cable for pinching,

binding or wear.

Inspect for structural cracks.

Operate the emergency lowering valve and check

for serviceability.

Serviced By:_________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Hydraulic Fluid Check fluid level.

Hydraulic Pump Check for hose fitting leaks.

Hydraulic System Check for leaks.

Labels

Platform Deck

and Rails

Platform Deck

and Rails

Tyres and Wheels Check for damage.

Check for peeling, missing, or unreadable labels

& replace.

Check welds for cracks.

Check condition of deck.

Page 16 Operation Manual

Page 20

Daily Preventative Maintenance Checklist 504165-001

N

OTES

:

Operation Manual Page 17

Page 21

504165-001 Labels

MAX = 113 kg =

066561-902

067195-001

454Kg,2Persons+Equip(Outdoor)

CLONDALKIN,

DUBLIN,IRELAND.

PARKWESTINDEST,

THISMACHINECONSULTOPERATORSMANUALBEFOREUSE.

CAUTION:ONLYTRAINED&AUTHORISEDPERSONNELMAYUSE

CHARGERINPUTVOLTAGE

MAX.WINDSPEED

UNLADENWEIGHT

SERIALNo.

UpRight

MAX.CHASSISINCLINATION

MAX.LATERALFORCE

MAX.PLATFORMLOAD

MAX.PLATFORMHEIGHT

NOMINALPOWER

MODEL

X26N

400N

3kW

2∞

5.8m

110/220V

12.5m/s

BATTERYVOLTAGE

24V

2153Kg

MAX.GRADEABILITY

MAX.FORWARDSPEED

1.0m/s

25%

504197000

454Kg,4Persons+Equip(Indoor)

L

ABELS

These labels shall be present and in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

11 504197-000

15 100102-900

THIS PLATFORM IS

NOT INSULATED

DIESE ARBEITSBÜHNE

IST NICHT ISOLIERT

CETTE PLATEFORME

N'EST ISOLEE

100102-900

31 X20N 101222-904

4 101210-000

!

1

MAX = 113 kg =

+

5 066551-950

!

340

340

066551-950

!

066557-951

066557-930

6 X20N 066557-930

!

454

066557-951

066557-954

16 X20N, 20W, 26N 066561-900

!

16 X32N 066561-902

066561-900

066561-902

6 X20W, 26N

066557-957

!

340

17 X20N, 20W, 26N 005223-906

005223-906

31 X20W, 26N, 32N 101222-905

066557-951

066557-950

6 X32N 066557-950

17 X32N 005223-908

005223-908

36 068635-001

066522-900

32 066522-900

010076-901

014222-903

20 010076

7 014222-903

33 501453-000

37 067195-001

25 066556-900

9 503724-000

10 060197-001

26 503721-000

INSIDE

INNSEITIG

L'INTERIEUR

107051-900

34 503723-000

40 107053-000

26,3 kg +

29 062562-951

Page 18 Operation Manual

Page 22

Labels 504165-001

Operation Manual Page 19

Page 23

504165-001 Specifications

S

PECIFICATIONS

ITEM X20N X20W X26N X32N

Platform Size w/ Extension

Max. Platform Capacity

Standard 340 kg [750 lbs.] 454 kg [1000 lbs.] 454 kg [1000 lbs.] 340 kg [750 lbs.]

on Extension 110 kg [250 lbs.] 113 kg [250 lbs.] 113 kg [250 lbs.] 113 kg [250 lbs.]

Max. No. of occupants

Standard (total) 3 people indoor

on Extension 1 person 1 person 1 person 1 person

Height

Working Height 8.1 m [26.58 ft.] 8.1 m [26.58 ft.] 9.93 m [32.58 ft.] 11.6 m [38.1 ft.]

Max. Platform Height 6.1 m [20 ft.] 6.1 m [20 ft.] 7.93 m [26 ft.] 9.75 m [32 ft.]

Min. Platform Height 0.96 m [38 in.] 0.96 m [38 in.] 1.09 m [43 in.] 1.22 m [48 in.]

Dimensions

Weight 1736 kg [3828 lbs.] 1938 kg [4273 lbs.] 2153 kg [4747 lbs.] 2486 kg [5481 lbs.]

Overall Width 0.82 m [32.5 in.] 1.22 m [48 in.] 1.22 m [48 in.] 1.22 m [48 in.]

Overall Height 2.06 m [78.5 in.] 2.06 m [78.5 in.] 2.19 m [83.5 in.] 2.32 m [88.5 in.]

Overall Height, Rails Lowered N/A N/A 1.98 m [78 in.] 1.88 m [74 in.]

Overall Length, Extension In 2.35 m [92.5 in.] 2.35 m [92.5 in.] 2.35 m [92.5 in.] 2.35 m [92.5 in.]

Overall Length, Extension Out 3.26 m [128.5 in.] 3.26 m [128.5 in.] 3.26 m [128.5 in.] 3.26 m [128.5 in.]

Drivable Height 6.1 m [20 ft.] 6.1 m [20 ft.] 7.93 m [26 ft.] 9.75 m [32 ft.]

Drive Speed

Platform Lowered 0 to 3,2 km/h [0 to 2.0 mph]

Platform Raised 0 to 1 km/h [0 to 0.62 mph]

Energy Source 24 Volt Battery Pack (4-220 A Hour, 6 Volt Batteries, min. wt. 28.12 kg [62 lbs.] each)

Motor 24 Volt 4 Horse Power DC Electric Motor

System Voltage 24 Volt DC

Battery Charger 25 A, 110/220 V AC

Battery Duty Cycle 25% for 8 Hours

Hydraulic Tank Capacity 15 L [4 US Gallons] 15 L [4 US Gallons] 15 L [4 US Gallons] 19 L [5 US Gallons]

Maximum Hydraulic Pressure 207 bar [3000 psi]

Hydraulic Fluid

Normal Temperature (>32° F [0° C])

Low Temperature (<32° F [0° C])

Extreme Temperature (<0° F [-17° C])

Lift System

Lift Speed Raise, 35 sec./Lower 30 sec. Raise, 40 sec./Lower 30 sec. Raise, 45 sec./Lower 40 sec. Raise, 65 sec./Lower 40 sec.

Control System

Drive System Dual Front Wheel Hydraulic Motors

Tires 381 mm [15 in.] Diameter Solid Rubber, non-marking

Parking Brake Dual Spring Applied, Hydraulic Release

Turning Radius 203 mm [8 in.] Inside

Maximum Gradeability 13° [23%] 13° [23%] 12° [22%] 12° [22%]

Wheel Base 1.9 m [74.75 in.]

Guardrails 1.02 m [40 in.] High

Noise Level

0.71 m x 2.21 m

[28 in. x 87 in.]

1 person outdoor

One Single Stage

Lift Cylinder

Proportional Control Handle with Interlock Switch, Rotary Drive/Lift Switch,

1.12 m x 2.21 m

[44 in. x 87 in.]

4 people

ISO #46

ISO #32

ISO #15

One Single Stage

Lift Cylinder

and Red Mushroom EMERGENCY STOP Switch

1.17 m x 2.21 m

[44.25 in. x 87 in.]

4 people

2 people outdoor

One Single Stage

Lift Cylinder

1.17 m x 2.21 m

[44 in. x 87 in.]

3 people

Two Single Stage

Lift Cylinders

*Specifications are subject to change without notice. Hot weather or heavy use may affect performance.

Refer to the Service Manual for complete parts and service information.

This machine meets or exceeds all applicable CE and GS machinery directive requirements.

Page 20 Operation Manual

Page 24

Page 25

Serie X

Seriennummern 50000 – aktuell

DEUTSCH

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben, wenn Sie sich

mit Ui bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzen. Sollte das Typenschild fehlen, finden Sie

die SERIENNUMMER auch auf dem Fahrwerk über der vorderen Schwenkachse.

USA

TEL: +1 800-926-5438 oder

+1 559-662-3900

FAX: +1 559-673-6184

PARTS FAX: +1 800-669-9884

801 South Pine Street

Madera, California 93637 USA

http://www.upright.com

Stamped Serial Number

Estampille de numéro de série

Eingestanzte Seriennummer

Ui

Unit S1

Friel Avenue

Parkwest Industrial Park ,

Nangor Road

Dublin 12

Irland

TEL: +353 1 6209300

FAX: +353 1 6209301

Page 26

Page 27

BETRIEBSANLEITUNG

S

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner Ui-Hocharbeitsbühne Wartungsarbeiten

ausführen oder die Arbeitsbühne in Betrieb nehmen.

Sicherheitsregeln

Elektroschockgefahr Kippgefahr Kollisionsgefahr

DIESE MASCHINE IST NICHT

ISOLIERT!

EINSATZ DER HOCHARBEITSBÜHNE: Diese Hocharbeitsbühne dient dazu, Personen und Werkzeuge sowie die für die jeweilige Arbeit

erforderlichen Materialien zu transportieren. Sie wurde speziell für Reparatur- und Montagearbeiten sowie für Einsatzbereiche konzipiert, die

sich oberhalb der Mita rbe ite r be finden, sodass die Mitar bei t er nac h oben gerichtet arbeiten m üssen (z. B. Decken, Krän e, Dachstrukturen,

Gebäude etc.). Jede andere Verwendung der Hocharbeitsbühne ist st rik t ve rb ot en!

DIESE HOCHARBEITSBÜHNE IST NICHT ISOLIERT! Aus diesem Grund muss zwingend ein Sicherheitsabstand zu al len le i tfäh ig en Teilen

der elektrischen Ausrüstung eingehalten werden!

Die angegebene zulässige Höchstlast darf nicht überschritten werden!Nähere Informationen hierzu finden Sie im Abschnitt “Beschränkungen”

auf Seite 4.

Es ist strikt verboten, die Ho charbeitsbühne als Hub w er kzeug oder Kran einzuset ze n (d. h. um Lasten von unten n ach oben oder von oben

nach unten zu beförde rn ).

Die für diese Maschine zu lä ss ig e m anuelle Kraft NIEMALS überschreiten.Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Lasten immer gleichmäßig auf der Plattform VERTEILEN.

Vor Inbetriebnahme der M aschine IMMER ZUERST die Aufstellfläche im Arb eit sbereich auf Gefahren wie Bo denlöcher, ausgelaufen e

Flüssigkeiten, Bodenerhebungen, Kanten od er Sc hutt untersuchen und dies e umgehen bzw. beseitigen.

Maschine nur auf Oberf lächen IN BETRIEB NEHMEN, die die zuläss igen Radlasten aufnehmen können.

Maschine NIEMALS in Betrieb nehmen, wenn die tatsächliche Windgeschwin d i gkeit höher ist als die Windgeschwindigkeit, für die di e

Maschine ausgelegt ist. Nähere Informationen hierzu finden Sie im Abschnitt “Beaufort-Skala” auf Seite 4.

IM NOTFALL NOT-AUS-Schalter drücken, um alle strombetriebenen Funktionen zu deaktivieren.

WENN EIN ALARM ERTÖNT, während die Plattform ausgefahren wird, Plattfo rm ANH ALTEN und vorsichtig einfahren (absenken). Masc hi ne

auf feste, ebene Oberflä che fahren.

Auf das Schutzgeländer der P lat tfor m zu kl ettern, auf Gebäuden , Stah l- oder vorgefertigten Beto nst r ukt ur en zu stehen oder von d er Pl at tform

aus darauf zu klettern et c. ist verboten!

Das Schwingtor oder an der e Komponenten des Sch ut zge l änders zu demontieren ist verboten! Vergewissern Sie sich immer, dass das

Schwingtor geschlossen und sicher verriegel t ist!

Es ist verboten, das Schwingtor geöffnet zu halte n (z . B. m it Befestigungsgurten), wen n di e Ar beitsplattform ausgefa hr en wi r d!

Die Höhe oder Reichweite der Plattform d urch An bring en von Leitern, Gerü sten oder ähnlichen Vorrichtungen zu verg röß ern

IMMER ZUERST die Hubvorrichtung blocki er en, be vor bei ausgefahrener Pla ttf or m Wartungs- oder Insta ndh al t ungsarbeiten an der Maschine

durchgeführt werden.

Maschine vor jedem Ge brauch sorgfältig auf Riss e an Schweißstellen, lose oder fehlende Beschläg e, Leckagen in der Hydraulikv orrichtung,

gelöste Kabelverbindu ngen und beschädigte Kabe l od er S chläuche UNTERSUCHEN.

Vor Gebrauch SICHERSTELLEN, dass alle Bezeichnung sschilder ordnungsge m äß angebracht und volls tä ndig lesbar sind.

NIEMALS eine Maschine benutzen, die beschädigt is t , nich t o rd nungsgemäß funktion ie rt oder deren Bezeichnungs schilder Beschädigu ngen

aufweisen oder sogar gan z f ehl en.

Sicherheitseinrichtungen zu umgehen ist verboten und stellt eine Gefahr für alle Personen dar, die sich auf der Hocharbeitsbühne und in deren

Arbeitsbereich befinden.

Batterien NIEMALS in der Nähe von Funkenquellen oder of fenen Flammen aufladen. Bei m Auf l ade n von Batterien wird explosives

Wasserstoffgas freigesetzt.

Änderungen an der Hocharbeitsbühne sind verbot en bzw. nur mit ausdrückl i che r G e nehmigung von

NACH GEBRAUCH ist die Hocharbeitsbühne gegen unbefugten Gebrauch durch Dritte zu sichern. Hierzu müssen beide Schlüsselschalter auf

“Aus” gestellt und die Schl üssel abgezogen werde n.

NIEMALS die Plattform ausfahren

oder die Maschine mit ausgefahrener

Plattform fortbewegen, wenn sich die

Maschine nicht auf einer festen,

ebenen Fläche befindet.

Plattform NIEMALS in Position

bringen, ohne vorher sicherzustellen,

dass der Bereich über der Plattform

frei von Hindernissen und anderen

Gefahren ist.

Ui zulässig.

des Plattformgeländers klettern

und auch nicht darauf stehen

turzgefahr

NIEMALS auf das obere

oder mit tlere Gestänge

oder sitzen.

ist verboten

!

Seite 1

Page 28

504165-001

I

NHALT

Einführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Allgemeine Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Beschränkungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Tragfähigkeit der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manuelle Kraft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort-Skala. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Überlastalarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bedienelemente und Anzeigen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sicherheitsprüfung vor Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Überprüfung der Systemfunktionen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Bedienung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Plattformverlängerung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fahren mit eingefahrener Plattform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lenken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ausfahren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fahren mit ausgefahrener Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Einfahren der Plattform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notfallabsenkung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X20N, X20W und X26N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X32N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Absenken des Schutzgeländers, X26N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Absenken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Anheben. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Einklappen des Schutzgeländers, X32N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Einklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ausklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Schleppen oder Anheben . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Lösen der Parkbremse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Nach dem täglichen Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Betriebsstundenzähler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transport der Arbeitsbühne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Vorbereitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Anheben per Kran. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Per Gabelstapler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fahren oder Heben auf einen LKW oder Anhänger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instandhaltung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blockieren der Hubvorrichtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation der Scherenverstrebung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Verstauen der Scherenverstrebung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instandhaltung der Batterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Aufladen der Batterien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspektions- und Instandhaltungsplan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Checkliste der täglichen präventiven Instandhaltungsmaßnahmen . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Bezeichnungsschilder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Seite 2 Betriebsanleitung

Page 29

Einführung 504165-001

E

INFÜHRUNG

Dieses Handbuch beschreibt Einsatz und Bedienung der selbstfahrenden Arbeitsbühnen der Serie X.

Das Handbuch muss immer bei der Maschine aufbewahrt werden.

A

LLGEMEINE

1. Plattform

B

ESCHREIBUNG

7

Abbildung 1: Serie X

X20N

WARNUNG

!

Hocharbeitsbühne NICHT ohne korrekt

montiertes und angebrachtes

Schutzgeländer ve rwe nde n.

2. Hubvorrichtung

3. Fahrwerk

4. Leistungsmodul

5. Steuermodul

6. Plattform-Bedienelemente

7. Handbuchfach

8. Fahrwerk-Bedienelemente

9. Behälter für Hydraulikflüssigkeit

10. Batterien

1

6

!

2

3

4

X20W & X26N

6

7

1

2

3

4

7

X32N

6

8

5

8

5

1

2

3

4

10

9

4

8

5

5

Betriebsanleitung Seite 3

Page 30

504165-001 Beschränkungen

B

ESCHRÄNKUNGEN

Bei ausgefahrener Plattform kann die Maschine nur im Schleichgang gefahren werden.

Die Arbeitsplattform kann nur auf festen, ebenen Oberflächen ausgefahren werden.

GEFAHR

! !

Die Hubfunktion darf NUR verwendet werden, wenn die Hocharbeitsbühne nivelliert ist und auf einer

festen Oberfläche steht.

Die Hocharbeitsbühne ist NICHT dafür ausgelegt, auf unebenem, grobem oder weichem Gelände

gefahren zu werden.

T

RAGFÄHIGKEIT DER

Die maximale Tragfähigkeit der MASCHINE, einschließlich Personen, hängt vom Modell und verschiedenen

Optionen ab; Sie fi nden eine entspr echende Liste im Absc hnitt “Technische Daten” auf Seite 20.

GEFAHR

! !

Maximale Tragfähigkeit der Plattform oder maximal zulässige Personenzahl für diese Maschine NICHT

überschreiten.

P

LATTFORM

M

ANUELLE

Unter manueller Kraft versteht man die Kraft, die die Personen auf der Plattform auf Objekte wie Wände

oder andere Strukturen außerhalb der Arbeitsplattform ausüben.

Die maximal zulässige manuelle Kraft ist auf 200 N (45 lbs.) pro Person beschränkt, d. h. maximal 400 N

(90 lbs.), wenn sich zwei oder mehr Personen auf der Plattform befinden.

GEFAHR

! !

Die für diese Maschine maximal zulässige manuelle Kraft NICHT überschreiten.

B

EAUFORT

Niemals die Maschine in Betrieb nehmen, wenn die Windgeschwindigkeit mehr als 25 km/h (15 mph)

[Beaufort-Skala 4] beträgt.

BEAUFORT-WERT

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papier und dünne Zweige bewegen sich, Fahnen wehen.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Staub und Papier wird aufgewirbelt und kleine Zweige schaukeln.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Ganze Bäume schwanken. Es ist schwierig, gegen den Wind zu gehen.

m/s km/h ft/s mph

Ü

BERLASTALARM

Wenn eine Last angehoben wird, die 90 % der Nennlast ausmacht, erscheint im digitalen Display des

Bedienpultes an der Plattform der Fehlercode “03”. Befindet sich im Fahrkorb eine Last, die höher als die

Nennlast ist, werden alle Maschinenfunktionen blockiert und eine akustische Warnung ertönt. Damit der

normale Betrieb wieder aufgenommen werden kann, muss die Last im Fahrkorb verringert werden,

sodass sie gleich oder niedriger als die Nennlast ist, und die Stromzufuhr zur Maschine muss aus- und

wieder eingeschaltet werden. Das Aus- und wieder Einschalten der Stromversorgung kann durch

Drücken und anschließendes Lösen des Not-Aus-Tasters erfolgen.

WINDGESCHWINDIGKEIT

K

-S

RAFT

KALA

BODEN-/UMGEBUNGSBEDINGUNGEN

Sträucher mit Blättern beginnen zu schaukeln. In Teichen, Sümpfen oder anderen Gewässern

erscheinen Wellenkämme.

Zweige und Äste von Bäumen bewegen sich. Stromleitungen pfeifen. Regenschirme können nur mit

Mühe geöffnet werden.

GEFAHR

! !

Niemals die Maschine in Betrieb nehmen, wenn sich auf der Arbeitsplattform eine Last befindet, die

die angegebene Tragfähigkeit überschreitet.

Seite 4 Betriebsanleitung

Page 31

Bedienelemente und Anzeigen 504165-001

B

EDIENELEMENTE UND

A

NZEIGEN

Abbildung 2: Bedienelemente und Anzeigen

Plattform-Bedienelemente

4

6

3

1

1 Aus wahltasten zum Fahren

2. Taste für die Hupe

3. Taste zum Aus-/Einfahren

4. Not-Aus-Taster

5. Display

6. Joystick

1

2

Fahrwerk-Bedienelemente

2

5

34

1. Schlüsselschalter

2. Freigabetaste

3. Umschalter (Auf & Ab)

4. Not-Aus-Schalter

Betriebsanleitung Seite 5

Page 32

504165-001 Sicherheitsprüfung vor Inbetriebnahme

S

ICHERHEITSPRÜFUNG VOR INBETRIEBNAHME

HINWEIS: Lesen Sie sich alle Sicherheitsregeln, Betriebsanleitungen, Bezeichnungsschilder und nationalen

Sicherheitsanweisungen/-anforderungen sorgfältig durch, stellen Sie sicher, dass Sie sie vollständig verstanden

haben und halten Sie sie ein. Gehen Sie jeden Tag vor Inbetriebnahme der Maschine wie folgt vor.

1. Öffnen Sie die Module, und untersuchen Sie sie auf Beschädigungen, Leckagen oder fehlende Teile.

Abbildung 3: Hydraulikbehälter

2. Überprüfen Sie bei vollständig

abgesenkter Plattform die Füllstandshöhe

der Hydraulikflüssigkeit.

Der Hydraulikbehälter befindet sich

in der Tür des Steuermoduls.

Die Füllstandshöhe der Flüssigkeit muss

zwischen den Strichen für MIN und MAX

liegen. Füllen Sie bei Bedarf

Hydraulikflüssigkeit nach.

3. Stellen Sie sicher, das s die

Batterieflüssigkeit die korrekte

Füllstandshöhe aufweist.

4. Vergewissern Sie sich, dass

die Batterien aufg eladen sind.

5. Vergewissern Sie sich, dass das

AC-Verlängerungskabel vom Anschluss

auf der Rückseite der Maschine

abgezogen wurde.

6. Überprüfen Sie, ob alle Komponenten der Schutzgeländer angebracht und sämtliche

Befestigungselem ente ordnungsgemäß festge zog en si nd.

7. Untersuchen Sie die Maschine sorgfältig auf Risse an Schweißstellen und Schäden an der Struktur,

lose oder fehlende Beschläge, Leckagen in der Hydraulikvorrichtung, Beschädigungen am Steuerkabel

sowie lose Kabelverbindungen und Radbolzen.

Seite 6 Betriebsanleitung

Page 33

Überprüfung der Systemfunktionen 504165-001

Ü

BERPRÜFUNG DER

Die Positionen der verschiedenen Bedienelemente und Anzeigen sehen Sie in Abbildung 2.

S

YSTEMFUNKTIONEN

WARNUNG

!

HALTEN SIE AUSREICHENDEN ABSTAND zur Arbeitsplattform, während Sie die nachfolgenden

Überprüfungen durchführen.

Untersuchen Sie vor Inbetriebnahme der Hocharbeitsbühne die Aufstellfläche im Arbeitsbereich auf

Gefahren wie Bodenlöcher, ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt.

Prüfen Sie in ALLE Richtungen, einschließlich im Bereich über der Arbeitsplattform, ob irgendwelche

Hindernisse und elektrische Leitungen vorhanden sind.

Schützen Sie das Kabel des Bedienpultes vor möglichen Beschädigungen, während Sie diese

Prüfungen durchführen.

1. Fahren Sie die Maschine ggf. in einen Bereich ohne Hindernisse, um die Hubvorrichtung vollständig

auszufahren.

2. Ziehen Sie den Not-Aus-Schalter des Fahrwerks in die Position EIN.

3. Ziehen Sie den Not-Aus-Schalter der Plattform in die Position EIN.

4. Drehen Sie den Schlüsselschalter des Fahrwerks in die Position für EIN, und halten Sie ihn in dieser

Position. Drücken Sie den am Fahrwerk befindlichen Schalter zum Aus-/Einfahren in die Position für

AUFWÄRTS, und fahren Sie die Arbeitsplattform etwa 2,1 m (7 ft) aus. BLOCKIEREN SIE DIE

HUBVORRICHTUNG WIE AUF SEITE 9 BESCHRIEBEN.

5. Führen Sie eine Sichtprüfung an Hubvorrichtung, Hubzylinder, Kabeln und Schläuchen durch. Stellen

Sie sicher, dass keine Risse an Schweißstellen und Schäden an der Struktur, lose Beschläge, Leckagen

in der Hydraulikvorrichtung oder gelösten Kabelverbindungen vorliegen und dass die Maschine fehlerfrei

arbeitet. Vergewissern Sie sich, dass keinerlei Teile fehlen oder gelöst sind.

6. Vergewissern Sie sich, dass sich die Stützen des Absenkmechanismus unter der Maschine in Position

gedreht haben.

7. Drücken Sie den am Fahrwerk befindlichen Schalter zum Aus-/Einfahren in die Position für AUFWÄRTS,

und fahren Sie die Arbeitsplattform vollständig aus.

8. Fahren Sie die Arbeitsplattform anschließend teilweise wieder ein, indem Sie den Fahrwerkschalter

zum Aus-/Einfahren in die Position für ABWÄRTS drücken, und überprüfen Sie, ob der akustische

Absenkalarm korrekt arbeitet.

9. Öffnen Sie das Ventil zur Notfallabsenkung (siehe Abbildung 5) durch Herausziehen des Knopfes, um

zu überprüfen, ob es korrekt arbeitet. Wenn die Plattform eingefahren wird, lassen Sie den Knopf los.

10. Drücken Sie den Not-Aus-Schalter des Fahrwerks, um zu überprüfen, ob er korrekt arbeitet. Alle

Maschinenfunktionen sollten jetzt deaktiviert sein. Ziehen Sie den Not-Aus-Schalter am Fahrwerk

heraus, um den Betrieb wieder aufzunehmen.

11. Prüfen Sie, ob der Verfahrweg frei von Hindernissen (Personen, sonstige Hindernisse, Bodenlöcher und

ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlast en tragen kann.

12. Besteigen Sie die Plattform, und schließen Sie die Eingangspforte ordnungsgemäß.

13. Besteigen Sie die Plattform, und wählen Sie den Modus FAHREN.

ENTFERNEN SIE DIE SCHERENVERSTREBUNG WIE AUF Seite 14 BESCHRIEBEN.

!

HINWEIS: Ve rwenden Sie ggf. beide Antriebe (AUF und AB), wenn Sie die folgenden Schritte ausführen.

14. Rasten Sie den Verriegelungsschalter ein, und bewegen Sie den Bedienhebel dabei VORWÄRTS und

dann RÜCKWÄRTS, um die Drehzahlregelung zu überprüfen.

15. Drücken Sie den Lenkschalter nach RECHTS, dann nach LINKS, um zu überprüfen, ob die Lenkung

ordnungsgemäß funktioniert.

16. Wählen Sie den Modus AUSFAHREN. Greifen Sie den Bedienhebel, während Sie dabei den

Verriegelungsschalter einrasten, und schieben Sie ihn nach vorn, um die Bedienelemente zum

Ausfahren der Arbeitsplattform zu überprüfen. Fahren Sie die Arbeitsplattform vollständig aus.

17. Ziehen Sie den Bedienhebel zurück. Die Plattform sollte nun einfahren und der akustische Absenkalarm

ertönen.

18. Drücken Sie den Not-Aus-Schalter der Plattform, um zu überprüfen, ob er korrekt arbeitet. Alle

Maschinenfunktionen sollten jetzt deaktiviert sein. Ziehen Sie den Not-Aus-Schalter der Plattform

heraus, um den Betrieb wieder aufzunehmen.

Betriebsanleitung Seite 7

Page 34

504165-001 Bedienung

B

EDIENUNG

Vor Inbetriebnahme der Hocharbeitsbühne müssen Sie sicherstellen, dass sämtliche vorbereitenden

Sicherheitsprüfungen durchgeführt und eventuelle Defekte behoben wurden. Nehmen Sie niemals eine

beschädigte oder nicht ordnungsgemäß arbeitende Maschine in Betrieb. Der Bediener muss

umfassend auf dieser Maschine geschult worden sein.

P

LATTFORMVERLÄNGERUNG

Abbildung 4: Plattformverlängerung

1. Besteigen Sie die Plattform, und schließen Sie

die Eingangspforte ordnungsgemäß.

2. Drücken Sie den Fußhebel auf der Rückse ite der

Plattformverlängerung herunter. Schieben Sie die

Plattformverlängerung nach vorn, bis der Zapfen

im vorder en An schl ag einr a ste t.

3. Um die Plattformverlängerung wieder einzufahren,

drücken Sie den Fußhebel herunter und ziehen die

Plattformverlängerung zur Rückseite der Maschine,

bis der Zapfen im hinteren Anschlag einrastet.

F

AHREN MIT EINGEFAHRENER

LATTFORM

P

1. Prüfen Sie, ob der Verfahrweg frei von Hindernissen

(Personen, sonstige Hinderni sse, Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen und

Schutt) und eben ist und die Radlasten tragen kann.

2. Vergewissern Sie sich, dass sowohl der Schlüsselsch alter des Fahrwerks a l s auch der Not-AusSchalter des Fahrwerks auf EIN stehen (der Not-Aus-Schalter muss herausgezogen sein).

3. Besteigen Sie die Plattform, und schließen Sie die Eingangspforte ordnungsgemäß.

4. Überprüfen Sie den Bereich über, unter und an den Seiten der Plattform.

5. Ziehen Sie den Not-Aus-Schalter der Plattform heraus in die Position EIN.

6. Wählen Sie den Modus FAHREN.

HINWEIS: Wählen Sie – je nach Steigung – zwischen dem Standardantrieb und einem zusätzlichen Drehmoment.

7. Rasten Sie den Verriegelungsschalter ein, und bewegen Sie den Bedienhebel VORWÄRTS oder

RÜCKWÄRTS, um in die gewünschte Richtung zu fahren. Die Geschwindigkeit der Maschine hängt

davon ab, wie weit der Bedienhebel von der Mittelstellung wegbewegt wird.

L

ENKEN

1. Drehen Sie den Schalter für Fahren/Ausfahren in die Stellung für FAHREN.

2. Drücken Sie, während Sie den Verriegelungsschalter einrasten, den Schalter für die Lenkung nach

RECHTS oder LINKS, um die Räder in die gewünschte Richtung zu lenken. Beobachten Sie beim

Manövrieren der Arbeitsplattform die Reifen, um sicherzustellen, dass die Richtung korrekt ist.

HINWEIS: Die Lenkung ist nicht selbstzentrierend. Die Räder müssen mithilfe des Schalters für die Lenkung wieder

geradeaus gestellt werden.

A

USFAHREN DER

1. Wählen Sie eine feste, ebene Oberfläche.

2. Wählen Sie den Modus AUSFAHREN.

3. Schieben Sie, während Sie den Verriegelungsschalter einrasten, den Bedienhebel vorwärts.

4. Wenn die Maschine nicht nivelliert ist, ertönt der Kippalarm; in diesem Fal l fährt die Maschine weder die

Plattform aus noch lässt sie sich selbst fahren.

eingefahren (abgesenkt) und die Maschine auf eine feste, ebene Oberfläche gefahren werden,

bevor Sie erneut versuchen können, die Arbeitsplattform au szufahren.

P

LATTFORM

Wenn der Kippalarm ertönt, muss d ie Arbeitsplattform

HINWEIS: Die Stützen des Absenkmechanismus klappen beim Ausfahren der Arbeitsplattform automatisch aus und

klappen wieder ein, sobald die Plattform komplett eingefahren wurde und die Maschine anfährt.

Seite 8 Betriebsanleitung

Page 35

Bedienung 504165-001

F

AHREN MIT AUSGEFAHRENER

HINWEIS: Wenn die Arbeitsplattform ausgefahren ist, fährt die Maschine mit gedrosselter Geschwindigkeit.

1. Prüfen Sie, ob der Verfahrweg frei von Hi ndernissen (Personen, sonstige Hinderniss e, Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen und Schutt) und eben ist und die Radlast en tragen kann.

2. Überprüfen Sie den Bereich über, unter und an den Seiten der Plattform.

3. Wählen Sie den Modus FAHREN.

4. Rasten Sie den Verriegelungsschalter ein, und bewegen Sie den Bedienhebel VORWÄRTS oder

RÜCKWÄRTS, um in die gewünschte Richtung zu fahren. Die Geschwindigkeit der Maschine hängt

davon ab, wie weit der Bedienhebel von der Mittelstellung wegbewegt wird.

5. Wenn die Maschine nicht nivelliert ist, ertönt der Kippalarm; in diesem Fal l fährt die Maschine weder die

Plattform aus noch lässt sie sich selbst fahren.

eingefahren (abgesenkt) und die Maschine auf eine feste, ebene Oberfläche gefahren werden,

bevor Sie erneut versuchen können, die Arbeitspl attform aus zufahre n.

E

INFAHREN DER

1. Wählen Sie den Modus AUSFAHREN.

2. Überprüfen Sie den Bereich rund um den Plattformsockel, um sicherzustellen, dass keine Personen

oder Hindernisse mit der Maschine in Kontakt sind. Rasten Sie den Verriegelungsschalter ein, und

ziehen Sie den Bedienhebel zurück, um die Arbeitsplattform einzufahren (abzusenken).

3. Die Arbeitsplattform stoppt, sobald sie die Höhe den persönlichen Schutzausschnitt erreicht hat.

Vergewissern Sie sich, dass rund um die Maschine keine Personen oder Hindernisse mit der Maschine

in Kontakt sind. Fahren Sie dann nach einer zeitlichen Verzö gerung von vier S ekunden die Arbeitsplat tform

wie in Schritt 2 beschrieben ein.

P

LATTFORM

P

LATTFORM

Wenn der Kippalarm ertönt, muss d ie Arbeitsplattform

N

OTFALLABSENKUNG

WARNUNG

!

Falls sich die Plattform nicht einfahren lassen sollte,

AUF KEINEN FALL an der Hubvorrichtung

herunterklettern.

Halten Sie Abstand zur Hubvorrichtung, und

betätigen Sie den Ventilknopf zur Notfallabsenkung.

X20N, X20W

Das Ventil zur Notfallabsenkung befindet sich bei

den Modellen X20N, X20W und X26N auf der

Rückseite der Maschine, über dem Ladegerät.

1. Öffnen Sie das Ventil zur Notfallabsenkung, indem

Sie den Knopf herausziehen und gezogen halten.

2. Zum Schließen lassen Sie den Knopf einfach los.

Die Plattform fährt nicht aus, wenn das Ventil zur

Notfallabsenkung geöffnet ist.

UND

X26N

!

X32N