Page 1

FOR MORE INFORMATION

USA Local Distributor:

Operator Manual

TEL: (1) 209-891-5200

FAX: (1) 209-896-9012

PARTSFAX: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPE

TEL: (353) 1-202-4100

FAX: (353) 1-285-1710

Pottery Road, Dun Laoire, Ireland

ÉTATS-UNIS Distributeur local :

TÉL. : (1) 209-891-5200

TÉLÉC. : (1) 209-896-9012

TÉLÉC. (PIÈCES) : (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPE

TÉL : (353) 1-202-4100

TÉLÉC. : (353) 1-285-1710

Pottery Road, Dun Laoire, Ireland

USA Inr Ortsveitrieb:

TEL: (1) 209-891-5200

FAX: (1) 209-896-9012

Fax für Ersatzteile: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPA

TEL: (353) 1-202-4100

FAX: (353) 1-285-1710

Pottery Road, Dun Laoire, Ireland

Guide de l’opérateur

Betriebsanleitung

Manual del operador

LX Electric & BiEnergy

LX Electric & BiEnergy

All personnel shall carefully read, understand and follow all safety rules, and

operating instructions before performing maintenance on or operating any

Refer to page 2 for the English language version of this Operator Manual.

Tout le personnel doit lire attentivement et respecter toutes les consignes de

sécurité avant d’entretenir ou d’utiliser une plate-forme élévatrice UpRight.

Reportez-vous à la page 12 pour la version française de ce guide de l’opérateur

LX-SERIES

SERIAL NO. 1879 TO CURRENT

WARNING

UpRight aerial work platform.

AVERTISSEMENT

USA Distribudor local:

TÉLÉFONO: (1) 209-891-5200

FACSÍMIL : (1) 209-896-9012

FACSÍMIL PARA REPUESTOS: (1) 209-896-9244

1775 Park St., Selma, CA 93662

http://www.upright.com

EUROPA

TÉLÉFONO: (353) 1-202-4100

FACSÍMIL : (353) 1-285-1710

Pottery Road, Dun Laoire, Ireland

48

067449-020

9901 .1 D

Revised 10-99

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Bedienungsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten

ausführen oder diese in Betrieb nehmen.

Bezüglich der deutschsprachigen Ausgabe dieser Betriebsanleitung siehe Seite 22.

ADVERTENCIA

Todo el personal debe leer atentamente, entender y respetar todas las reglas de

seguridad, las instrucciones de operación antes de efectuar trabajos de

mantenimiento o manejar cualquier plataforma aérea de trabajo UpRight.

Referirse a la página 32 para la versión en español de este manual del operador.

1

Page 2

English Language Section

SAFETY RULES

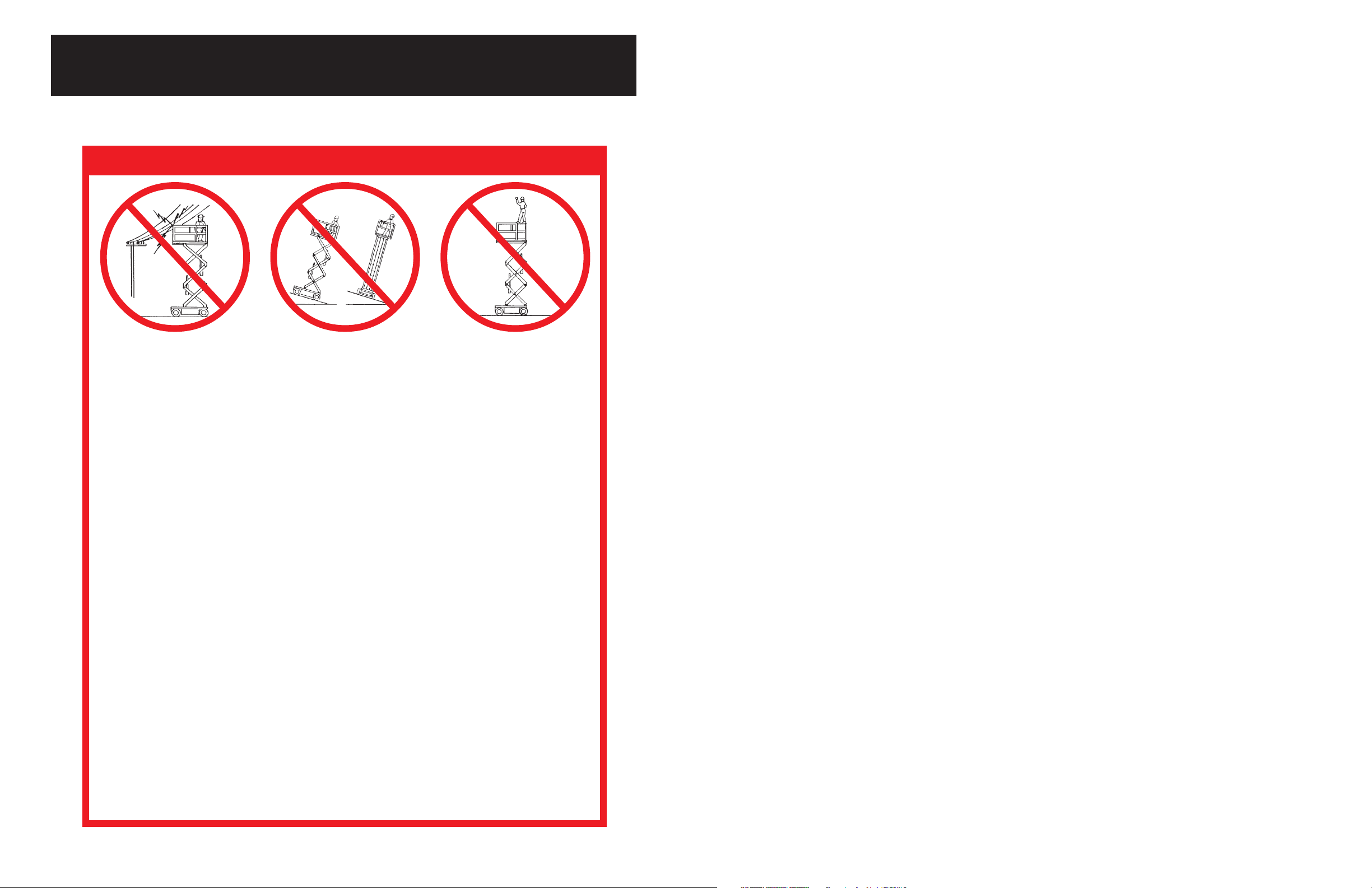

NEVER operate the machine

within 3 m (10 ft) of power

lines. THIS MACHINE IS NOT

INSULATED.

NEVER operate the machine without first surveying the work area for surface hazards such as

holes, drop-offs, bumps and debris.

NEVER operate the machine if all guardrails are not properly in place and secured with all fasten-

ers properly torqued.

SECURE and lock gate after mounting platform.

KEEP all body parts clear of outriggers when extending or retracting (outrigger equipped machines

only).

NEVER use ladders or scaffolding on the platform.

NEVER attach overhanging loads or increase platform size.

MAINTAIN tire pressure at 3.4 bars (50 psi). Check daily.

LOOK up, down and around for overhead obstructions and electrical conductors.

DISTRIBUTE all loads evenly on the platform. See the back cover for maximum platform load.

NEVER use damaged equipment. (Contact UpRight for instructions. See toll-free phone number on

back cover.)

NEVER change operating or safety systems.

INSPECT the machine thoroughly for cracked welds, loose hardware, hydraulic leaks, damaged

control cable, loose wire connections and wheel bolts.

NEVER climb down elevating assembly with the platform elevated.

NEVER perform service on machine while platform is elevated without blocking elevating assem-

bly.

NEVER recharge battery near sparks or open flame; batteries that are being charged emit highly

explosive hydrogen gas.

AFTER USE secure the work platform against unauthorized use by turning key switch off and

removing key.

NEVER replace any component or part with anything other than original UpRight replacement parts

without the manufacturer's consent.

NEVER elevate or drive elevated

on uneven slopes or soft ground

or elevate the platform unless the

platform is level.

NEVER sit, stand or climb

on guardrail or midrail.

2

47

Page 3

UPRIGHT ELECTRICAL SCHEMATIC LX ELECTRIC

PART NO. 067447-003

ENGLISH

CONTROLLER CONTRÔLEUR Steuergerät CONTROLADOR

PLUG NUMBERS NUMÉROS DE FICHE Steckernummern NUMERACÍÓN CONECTOR

DRIVE ENABLE LIGHT TÉMOIN, MODE DE DÉPLACEMENT Fahrbereitschaftsleuchte LUZ DE HABILITACIÓN DE

560 OHM 560 ohms 560 Ohm 560 OHM

TRIGGER IMPULSION DE DÉCLENCHEMENT Triggerschalter GATILLO

ROCKER ARMATURE Wippenschalter BALANCÍN

IGNITION ALLUMAGE Zündung ARRANQUE

EMERGENCY STOP ARRÊT D’URGENCE Notaus-Taster PARADA DE EMERGENCIA

DRIVE DÉPLACEMENT Fahren TRANSMISIÓN

LIFT LEVAGE Heben ELEVACIÓN

HIGH/LOW HAUT/BAS Hochdruck/Niederdruck ALTO/BAJO

EMERGENCY STOP SECTIONNEUR Notaustaster-Schutzschalter FUSIBLE DE PARADA

CIRCUIT BREAKER D’ARRÊT D’URGENCE DE EMERGENCIA

CHASSIS/PLATFORM CHÂSSIS/PLATE-FORME Fahrwerk/Arbeitsbühne CHASIS/PLATAFORMA

DOWN ABAISSÉE abwärts ABAJO

UP LEVÉE aufwärts ARRIBA

LIFT SWITCH SÉLECTEUR DE MODE Hubschalter INTERRUPTOR DE ELEVACIÓN

FONCTIONNEMENT, LEVAGE

LOWER CONTROLS COMMANDES D’ABAISSEMENT untere Bedienorgane CONTROLES INFERIORES

POWER RELAY RELAIS D’ALIMENTATION Stromrelais RELE DE ENERGÍA

DRIVE/LIFT DÉPLACEMENT/LEVAGE Fahren/Heben TRANSMISIÓN/ELEVACIÓN

LEVEL SENSOR CAPTEUR DE NIVEAU Niveausensor SENSOR DE NIVEL

51.7 (750 PSI) 51,7 bars (750 lb/po²) 51,7 bar (750 psi) 51,7 BAR (750 lb/plg2)

TILT ALARM ALARME D’INCLINAISON Neigungswarnung ALARMA DE INCLINACIÓN

DOWN ALARM ALARME D’ABAISSEMENT Senkwarnung ALARMA ABAJO

STEER RIGHT DIRECTION À DROITE Lenkung rechts DIRECCIÓN DERECHA

STEER LEFT DIRECTION À GAUCHE Lenkung links DIRECCIÓN IZQUIERDA

PUMP START DÉMARRAGE, POMPE Pumpenanlauf ARRANQUE DE LA BOMBA

BRAKE FREIN Bremsen FRENO

UP LIMIT LIMITE SUPÉRIEURE Hochfahrbegrenzer LÍMITE SUPERIOR

DOWN ALARM ALARME, ABAISSÉE Senkwarnung ALARMA INFERIOR

BRAKE N.O. FREIN, N.O. Bremse (Schließer) FRENO (ABIERTO)

BRAKE N.C. FREIN, N.F. Bremse (Öffner) FRENO (CERRATO)

RESISTOR PACK BLOC, RÉSISTANCES Widerstandssatz RESISTENCIA

INTERFACE MODULE MODULE D’INTERFACE Schnittstellenmodul MÓDULO DE INTERFASE

PUMP/TRACTION POMPE/TRACTION Pumpe / Traktion BOMBA/TRACCIÓN

LEFT GAUCHE links IZQUIERDA

RIGHT DROITE rechts DERECHA

ARMATURE INDUIT Anker INDUCIDO

FIELD CHAMP Feld CAMPO

POWER UNIT BLOC D’ALIMENTATION Antriebseinheit UNIDAD DE ENERGÍA

PUMP OVERDRIVE SURMODULATION, POMPE Pumpenschnellgang SOBREMARCHA DE LA BOMBA

BATTERY CHARGER CHARGEUR DE BATTERIES Batterieladegerät CARGADOR DE BATERÍA

MAIN POWER ALIMENTATION PRINCIPALE Hauptspannung ENERGÍA PRINCIPAL

CONTROL MODULE MODULE DE COMMANDE Steuergerät MÓDULO DE CONTROL

300 AMP 300 A 300 A 300 AMP

FRANÇAIS GERMAN

LA TRANSMISIÓN

SPANISH

Introduction

This manual covers Electric and BiEnergy of the LX

Series Work Platforms. This manual must be stored on

the machine at all times.

Pre-Operation and Safety

Inspection

Carefully read, understand and follow all safety rules,

labels, and operating instructions, then perform the

following steps each day before use.

Perform a complete visual inspection of the entire unit

prior to operating. Check the following areas for discrepancies:

1. Open panels and check hydraulic components and

hoses for damage or leaks. Check electrical components and wiring for damage or loose connections.

2. Inspect chassis, axles, hubs, and steering linkage for

damage, deformation, buckled paint, loose or missing

hardware, and cracked welds.

3. With platform fully lowered, check the hydraulic oil

level sight gauge on the hydraulic tank . Add ISO #46

hydraulic oil if necessary.

4. Check that fluid level in all batteries is correct (See

Battery Maintenance, Page 9).

5. Check the engine oil level and fuel level (BiEnergy

model).

6. Check that all guardrails are in place. Insure that gate

operates freely and latches securely.

7. Check tires for damage. Check tire pressure; 5.2 bar

(75 psi) if equipped with pneumatic tires.

8. Carefully inspect the entire work platform for damage

such as cracked welds or structural members, loose

or missing parts, oil leaks, damaged cables or hoses,

and loose connections.

9. BiEnergy models - While the engine is cool check the

engine coolant level.

NEVER remove the cap from a hot radiator. Hot

coolant can cause severe burns.

System Function Inspection

STAND CLEAR of the work platform while

performing the following checks.

Before operating the work platform survey the

work area for surface hazards such as holes,

drop-offs, bumps and debris.

Check in ALL directions, including above the

work platform, for obstructions and electrical

conductors.

Protect control console cable from possible

damage while performing checks.

1. Unhook controller from front guardrail. Firmly grasp

controller handle in such a manner that the interlock

lever can be depressed, while performing the

following checks from the ground.

NOTE: BiEnergy machine may be powered by

batteries or by engine. To power the machine by

engine, press the engine start button to crank the

engine. Release button when engine starts. If engine

is cold: press the glow plug button for six seconds

prior to starting.

IMPORTANT: BiEnergy models - If starting engine

from platform be sure engine switch on chassis is set

to "RUN".

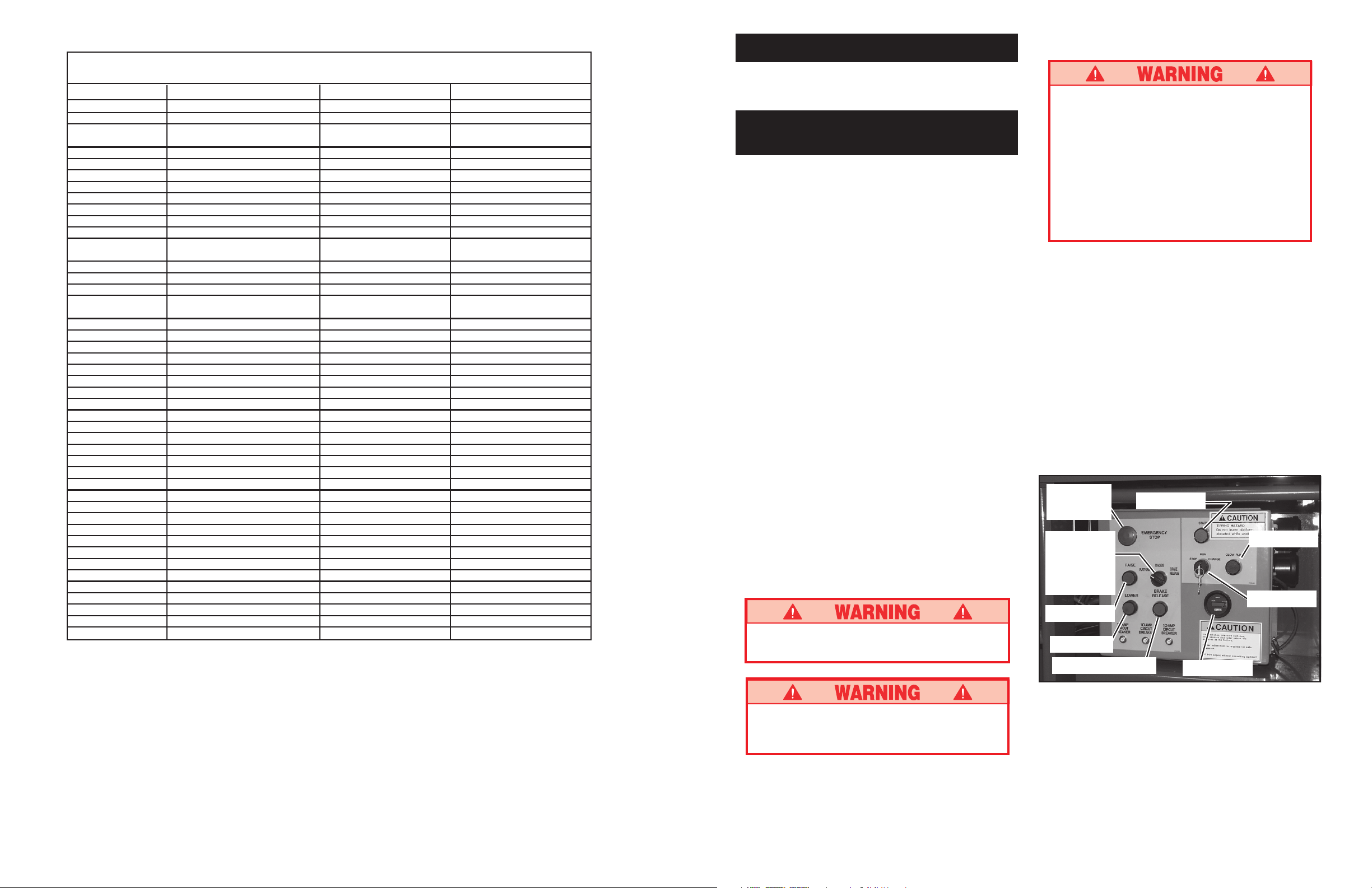

Emergency

Stop

Button

Platform/

Chassis/

Brake

Release

Switch

Raise

Lower

Brake Release

Start

Glow Plug

Key Switch

Hour Meter

46

Figure 1: Chassis, Left Side

DO NOT use a machine that is damaged or

malfunctioning. Tag and remove the unit from

service until it is repaired.

3

Page 4

2. Turn controller key switch clockwise to ON.

3. Position drive/lift switch to DRIVE position. Drive

enable indicator will be illuminated.

4. With the speed range switch first in LOW SPEED

and then again in HIGH SPEED depress the interlock

lever and slowly push the control lever to FORWARD

then REVERSE positions to check for speed and

directional control. The farther you push or pull the

control lever the faster the machine will travel.

5. Push steering switch RIGHT then LEFT to check for

steering control.

6. Hook controller on guardrail in original position.

7. Turn the platform/chassis switch to

8. From lower controls, push chassis raise button to

elevate platform while pushing the tilt sensor (Figure 3)

off of level. The platform should only partially elevate

and the tilt alarm should sound. If the platform continues to elevate and/or there is no alarm STOP and

remove the machine from service until it is repaired.

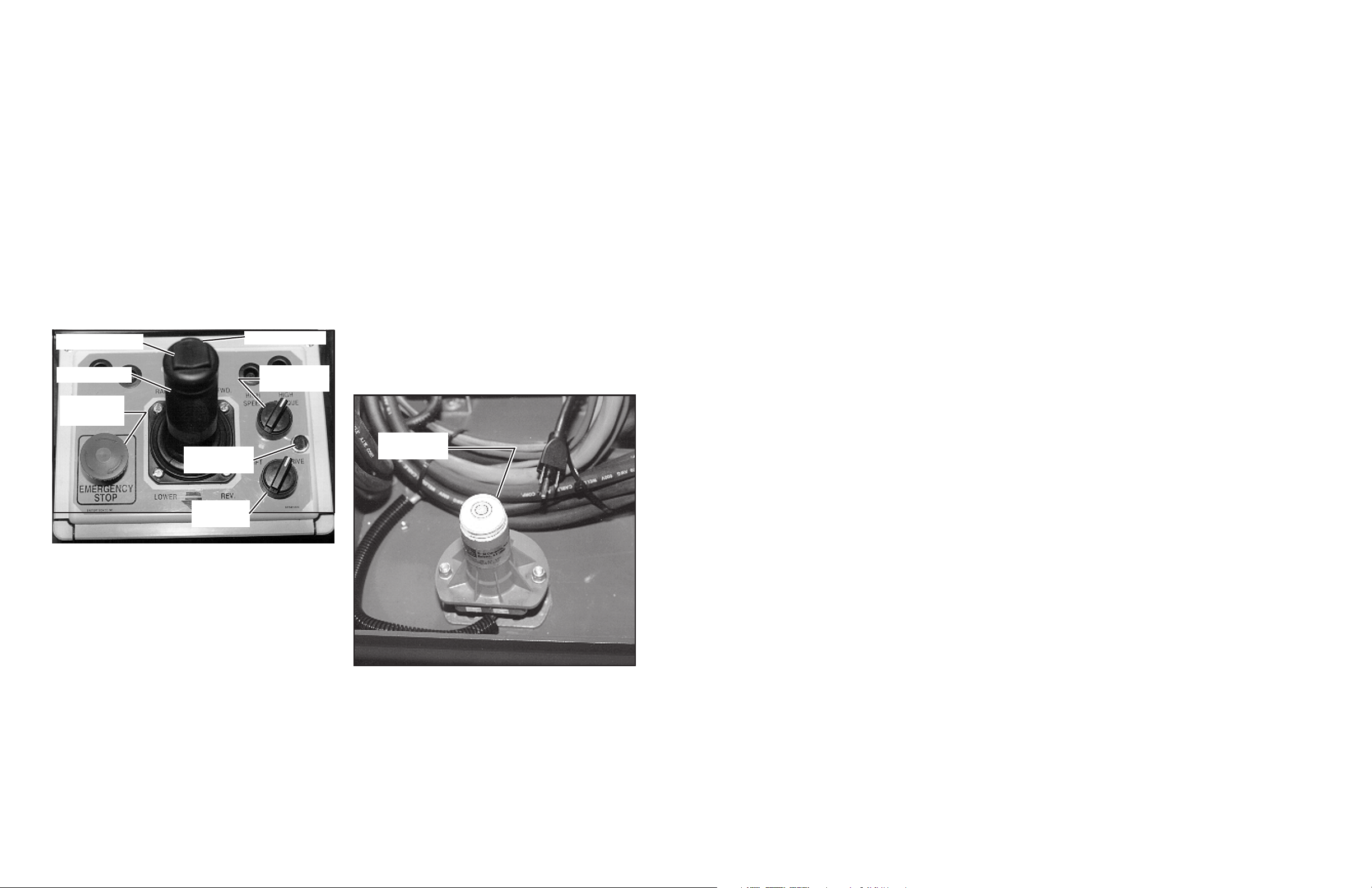

Steering Switch

Control Lever

Emergency

Stop Switch

CHASSIS.

Interlock Lever

Speed Range

Switch

9. Release the tilt sensor and fully elevate platform.

10. Visually inspect the elevating assembly, lift cylinder,

cables and hoses for damage or erratic operation.

Check for missing or loose parts.

11. Lower the platform partially by pushing in on the

chassis lower switch, and check operation of the

audible lowering alarm.

12. Open the chassis emergency lowering valve

(Figure 4) to check for proper operation by pulling

and holding the knob out. Once the platform is fully

lowered, close the valve by releasing the knob.

13. Turn the platform/chassis switch to

14. Mount the platform making sure the gate is latched.

15. Position drive/lift switch to LIFT.

16. Depress the interlock lever and slowly push the

control lever to RAISE to raise the platform, fully

actuate the control lever to check proportional lift

speed. Elevate the platform to 3.7 m (12 feet).

17. Slowly pull control lever to DOWN position to lower

platform. Check that lowering alarm sounds.

18. Turn controller key switch to OFF, push the emergency

stop button and dismount the platform.

19. Close and secure module covers.

PLATFORM.

Drive Enable

Indicator

Lift/Drive

Switch

Figure 2: Controller

Tilt Sensor

Figure 3: Tilt Sensor

4

45

Page 5

UPRIGHT ELECTRICAL SCHEMATIC LX BI-ENERGY

PART NO. 067447-002

ENGLISH

CONTROLLER CONTRÔLEUR Steuergerät CONTROLADOR

PLUG NUMBERS NUMÉROS DE FICHE Steckernummern NUMERACIÓN CONECTOR

DRIVE ENABLE LIGHT TÉMOIN, MODE DE Fahrbereitschaftsleuchte LUZ DE HABILITACIÓN DE LA

DÉPLACEMENT TRANSMISIÓN

560 OHM 560 ohms 560 Ohm 560 OHM

TRIGGER IMPULSION DE DÉCLENCHEMENT Triggerschalter GATILLO

ROCKER ARMATURE Wippenschalter BALANCÍN

IGNITION ALLUMAGE Zündung ARRANQUE

EMERGENCY STOP ARRÊT D’URGENCE Notaus-Taster PARADA DE EMERGENCIA

DRIVE DÉPLACEMENT Fahren TRANSMISIÓN

LIFT LEVAGE Heben ELEVACIÓN

HIGH/LOW HAUT/BAS Hockdruck/Niederdruck ALTO/BAJO

START 12 VOLTS DÉMARRAGE, 12 V Starter 12 V ARRANQUE 12 VOLTIOS

BATTERY 12 VOLTS BATTERIE, 12 V Batterie 12 V BATERÍA 12 VOLTIOS

NEGATIVE NÉGATIF Minuspol NEGATIVO

POSITIVE POSITIF Pluspol POSITIVO

BATTERY CABLE CÂBLE DE BATTERIE Batteriekabel CABLE DE BATERÍA

RECTIFIER REDRESSEUR Gleichrichter RECTIFICADOR

DYNAMO DYNAMO Dynamo DÍNAMO

STARTER RELAY RELAIS DE DÉMARREUR Starterrelais RELÉ DE ARRANQUE

GLOW PLUG RELAY RELAIS DE BOUGIE Glühkerzenrelais RELÉ DE BUJÍA

DE PRÉCHAUFFAGE INCANDESCENTE

KUBOTA GLOW PLUG BOUGIE DE PRÉCHAUFFAGE Kubota-Glühkerze BUJÍA INCANDESCENTE

KUBOTA KUBOTA

12 VOLT CIRCUIT BREAKER SECTIONNEUR, 12 V Schutzschalter 12 V DISYUNTOR DE 12 VOLTIOS

POWER CIRCUIT BREAKER SECTIONNEUR DE PUISSANCE Hauptstrom-Schutzschalter DISYUNTOR DE ENERGÍA

CHARGE CHARGE Ladung CARGA

STARTER DÉMARREUR Starter ARRANCADOR

GLOW PLUG BOUGIE DE PRÉCHAUFFAGE Glühkerze BUJÍA INCANDESCENTE

ENGINE RUN MOTEUR, MARCHE Motorlauf MARCHA DEL MOTOR

EMERGENCY STOP SECTIONNEUR, ARRÊT Notaustaster-Schutzschalter FUSIBLE DE PARADA DE

CIRCUIT BREAKER D’URGENCE EMERGENCIA

CHASSIS/PLATFORM CHÂSSIS/PLATE-FORME Fahrwerk/Arbeitsbühne CHASIS/PLATAFORMA

DOWN ABAISSÉ abwärts ABAJO

UP LEVÉ aufwärts ARRIBA

LIFT SWITCH SÉLECTEUR DE MODE Hubschalter INTERRUPTOR DE

FONCTIONNEMENT, LEVAGE ELEVACIÓN

LOWER CONTROLS COMMANDES D’ABAISSEMENT untere Bedienorgane CONTROLES INFERIORES

POWER RELAY RELAIS D’ALIMENTATION Stromrelais RELÉ DE ENERGIA

DRIVE/LIFT DÉPLACEMENT/LEVAGE Fahren/Heben TRANSMISIÓN/ELEVACIÓN

LEVEL SENSOR CAPTEUR DE NIVEAU Niveausensor SENSOR DE NIVEL

51.7 (750 PSI) 51,7 bars (750 lb/po²) 51,7 bar (750 psi) 51,7 BARS (750 lb/plg2)

TILT ALARM ALARME D’INCLINAISON Neigungswarnung ALARMA DE INCLINACIÓN

DOWN ALARM ALARME D’ABAISSEMENT Senkwarnung ALARMA ABAJO

STEER RIGHT DIRECTION À DROITE Lenkung rechts DIRECCIÓN DERECHA

STEER LEFT DIRECTION À GAUCHE Lenkung links DIRECCIÓN IZQUIERDA

PUMP START DÉMARRAGE, POMPE Pumpenanlauf ARRANQUE DE LA BOMBA

BRAKE FREIN Bremsen FRENO

UP LIMIT LIMITE SUPÉRIEURE Hochfahrbegrenzer LÍMITE ARRIBA

DOWN ALARM ALARME, ABAISSEMENT Senkwarnung ALARMA ABAJO

BRAKE N.O. FREIN, N.O. Bremse (Schließer) FRENO (ABIERTO)

BRAKE N.C. FREIN, N.F. Bremse (Öffner) FRENO (CERRADO)

RESISTOR PACK BLOC DE RÉSISTANCES Widerstandssatz RESISTENCIA

INTERFACE MODULE MODULE D’INTERFACE Schnittstellenmodul MÓDULO DE INTERFASE

PUMP/TRACTION POMPE/TRACTION Pumpe/Traktion BOMBA/TRACCIÓN

LEFT GAUCHE links IZQUIERDA

RIGHT DROITE rechts DERECHA

ARMATURE INDUIT Anker INDUCIDO

FIELD CHAMP Feld CAMPO

POWER UNIT BLOC D’ALIMENTATION Antriebseinheit UNIDAD DE ENERGÍA

PUMP OVERDRIVE SURMODULATION, POMPE Pumpenschnellgang SOBREMARCHA DE LA BOMBA

BATTERY CHARGER CHARGEUR DE BATTERIES Batterieladegerät CARGADOR DE BATERÍA

MAIN POWER ALIMENTATION PRINCIPALE Hauptspannung ENERGÍA PRINCIPAL

CONTROL MODULE MODULE DE COMMANDE Steuergerät MÓDULO DE CONTROL

300 AMP 300 A 300 A 300 AMP

FRANÇAIS GERMAN SPANISH

Operation

Before operating work platform, ensure that the pre-

operation and safety inspection has been completed, any

deficiencies have been corrected and the operator has

been thoroughly trained on this machine.

NOTE: BiEnergy machine may be powered by batteries or by engine. To power the machine by engine,

press engine start button to crank the engine. Release button when engine starts. If engine is cold,

press the glow plug button on chassis control box

for six seconds prior to starting.

IMPORTANT: If starting engine from platform be sure

engine switch on chassis is set to "RUN".

Travel With Platform Lowered

1. Verify chassis emergency stop switch is in the ON

position (pulled out), the drive enable indicator is on,

and that the platform/chassis switch is on PLAT-

FORM.

Note: If the drive enable indicator is off, verify that

the platform is fully lowered.

2. After mounting platform, close and latch gate. Check

that guardrails are in position and properly assembled

with fasteners properly torqued.

3. Check that route is clear of persons, obstructions,

holes and drop-offs and surface is capable of supporting the wheel loads.

4. Check clearances above, below and to the sides of

the platform.

5. Pull controller emergency stop button out to ON

position.

6. Set the speed range switch to LOW SPEED.

7. Grasp the control lever so the interlock lever is

depressed (releasing the interlock lever cuts power to

controller). Slowly push or pull the control lever to

FORWARD or REVERSE to travel in the desired

direction. The farther you push or pull the control

lever from center the faster the machine will travel.

8. While moving, push the speed range switch to HIGH

SPEED for travel on level surfaces or to LOW

SPEED for climbing grades or traveling in confined

areas.

Steering

1. Push the steering switch RIGHT or LEFT to turn the

wheels. Observe the tires while maneuvering to

insure proper direction.

Note: Steering is not self-centering. Wheels must be

returned to the straight ahead position by operating

the steering switch.

Raising and Lowering the Platform

1. Position the drive/lift switch to LIFT.

2. While holding the control lever so the interlock lever

is depressed, push the control lever slowly to UP to

raise the platform. Pushing the control lever farther

increases the lift speed.

3. When the work task is completed, position the drive/

lift switch to LIFT and lower the platform by pulling

back on the control lever until the platform is fully

lowered.

44

5

Page 6

Travel with Work Platform Elevated

Travel with platform elevated ONLY on firm and level

surfaces.

Note: The work platform will travel at reduced speed

when in the elevated position, and then only when

the front axle is parallel with the rear axle.

1. Check that the route is clear of persons, obstructions, holes and drop-offs, surface is level and

capable of supporting the wheel loads.

2. Check clearances above, below and to the sides of

platform.

3. Position the drive/lift switch to the DRIVE position.

4. Push the control lever to FORWARD or REVERSE

for the desired direction of travel.

If the machine quits driving and the tilt alarm

sounds, immediately lower the platform and move

the machine to a level location before re-elevating the

platform.

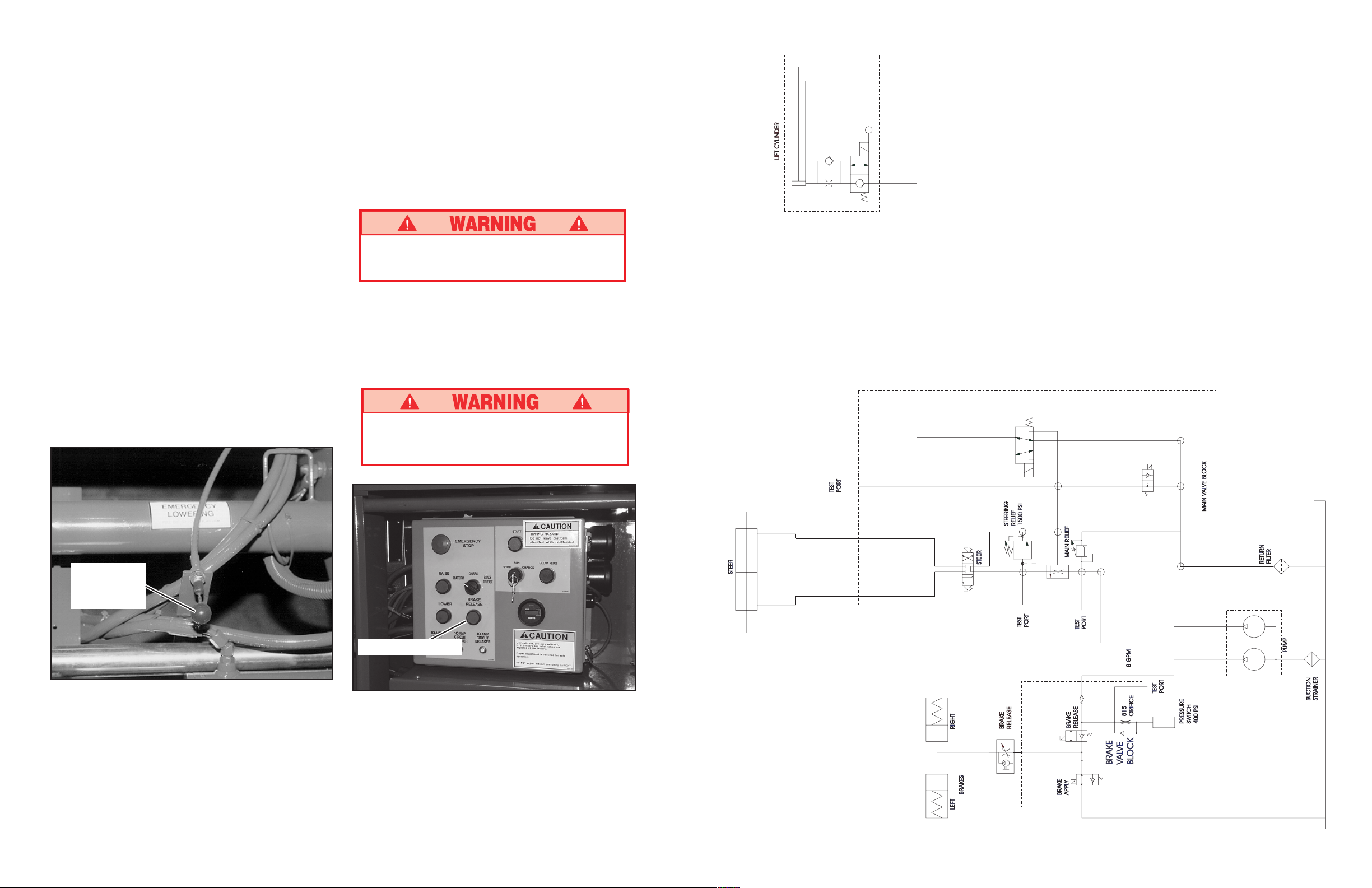

Emergency Lowering

The emergency lowering knob is located at the front

of the machine at the base of the scissor assembly

(Figure 4).

1. Open the emergency lowering valve by pulling on the

knob and holding it.

2. Once the platform is fully lowered, release the knob

to close the valve.

After Use Each Day

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under

cover, secure against vandals, children or unauthorized operation.

3. Turn the key switch to OFF and remove the key to

prevent unauthorized operation.

Parking Brake Release (Figure 5)

Perform the following only when the machine will not

operate under its own power and it is necessary to move

the machine or when winching onto a trailer to transport.

Never release brakes if machine is on a slope.

Hook machine to towing vehicle before releasing

brakes.

1. Turn the Platform/Chassis/Brake Release switch to

Brake Release position. Alarm will sound.

2. Momentarily push brake release button.

3. The machine will now roll when pushed or pulled.

4. For normal operation, turn Platform/Chassis/Brake

Release switch to platform.

Never operate work platform with the parking

brakes released. Serious injury or damage could

result.

Emergency

Lowering

Knob

Figure 4: Emergency Lowering Knob

Hydraulic Schematic: LX Electric & BiEnergy - Euro - 067446-000

Brake Release

Figure 5: Parking Brake Release

6

43

Page 7

UPRIGHT HYDRAULIC SCHEMATIC LX ELECTRIC & BI-ENERGY

PART NO. 67446-000

ENGLISH

BRAKES FREINS Bremsen FRENOS

815 ORIFICE ORIFICE 815 Blende 815 ORIFICIO 815

LEFT GAUCHE links IZQUIERDA

RIGHT DROITE rechts DERECHA

SUCTION STRAINER CRÉPINE D’ASPIRATION Ansaugsieb FILTRO DE ASPIRACIÓN

TEST PORT PRISE D’ESSAI Prüfanschluß PUERTO DE PRUEBA

STEER DIRECTION Lenkung DIRIGIR

BRAKE RELEASE DESSERRAGE DES FREINS Bremsbetätigung QUITAR EL FRENO

BRAKE APPLY SERRAGE DES FREINS Bremse anziehen COLOCAR EL FRENO

BRAKE VALVE BLOCK BLOCAGE DE SOUPAPE DE FREIN Bremsventilblock BLOQUE DE VÁLVULA DE FRENO

PRESSURE SWITCH MANOSTAT Druckschalter INTERRUPTOR DE PRESIÓN

27.6 BARS (400 PSI) 27,6 bars (400 lb/po²) 27,6 bar (400 PSI) 27,6 bars (400 lb/plg2)

PUMP POMPE Pumpe BOMBA

MAIN RELIEF DÉCHARGE, PRINCIPALE Überdruck-Hauptventil ALIVIO PRINCIPAL

MAIN VALVE BLOCK BLOCAGE, SOUPAPE PRINCIPALE Hauptventilblock BLOQUE DE LA VÁLVULA

RETURN FILTER FILTRE DE RETOUR Rücklauffilter FILTRO DE RETORNO

STEERING RELIEF DÉCHARGE, DIRECTION, Lenkentlastung ALIVIO DE LA DIRECCIÓN

103 BARS (1500 PSI) 103 bars (1500 lb/po²) 103 bar (1500 PSI) 103 bars (1500 lb/plg2)

LIFT CYLINDER VÉRIN DE LEVAGE Hubzylinder CILINDRO DE ELEVACIÓN

FRANÇAIS GERMAN SPANISH

PRINCIPAL

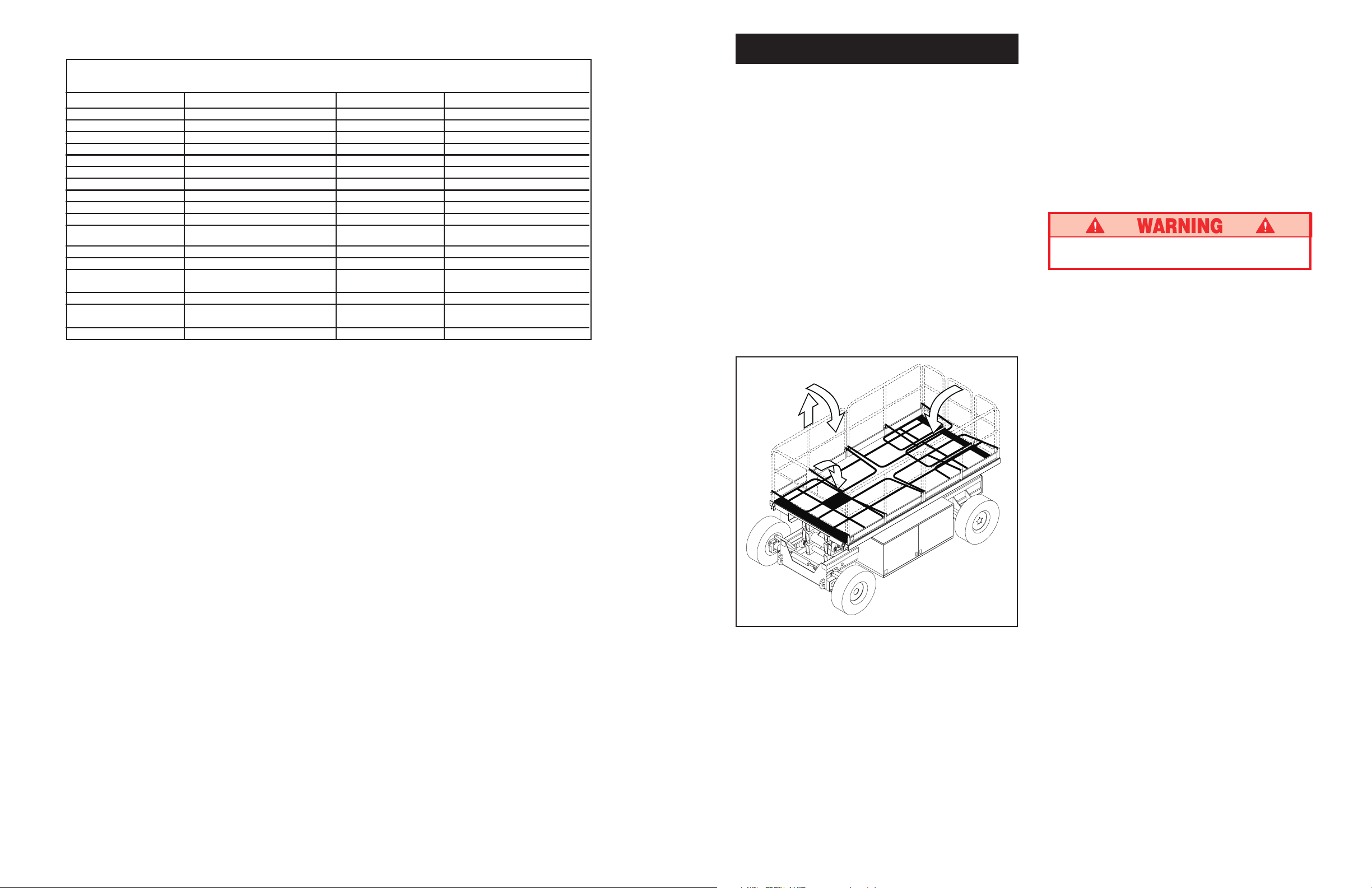

Fold Down Guardrails

This procedure is only for passing through doorways.

Guardrails must be returned to proper position before

using the machine.

Fold Down Procedure (Figure 6)

Note: When performing the following procedures

retain all fasteners.

1. Place controller on platform.

2. Starting at the front of the platform, remove nuts,

bolts and washers from the top of the front guardrail.

Fold the front guardrail down onto the platform.

3. Close and latch the gate.

4. Remove nuts, bolts and washers from the top of the

rear guardrail. Fold the rear guardrail down onto the

platform being careful to keep gate latched at all

times.

5. Remove nuts, bolts and washers from the top of the

side guardrails and from the slideout deck midrail. Lift

up and fold one side guardrail in so it rests on the

deck. Repeat with other side guardrails.

Erection Procedure

1. Raise side guardrails making sure each is pushed

down to secure the guardrail in the vertical position.

2. Install bolts, washers and nuts between the side

guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes and

install bolts, washers and nuts. Tighten securely.

4. Raise front guardrail, aligning holes and install bolts,

washers and nuts. Tighten securely.

5. Hang controller from front guardrail.

6. Before operating work platform check that all fasteners are in place and properly torqued.

Before operating machine, guardrails must be

securely fastened in their proper position.

Double Deck Fold Down Procedure

(Figure 7)

NOTE: When performing the following procedures

retain all fasteners.

1. Place controller on platform.

2. Starting at the front; slide out deck, remove hardware

from top front corners of guardrails. Remove hardware

from the slide out deck side guardrail midrails. Also

remove hardware from the top of the sockets that

hold the slide out deck side guardrails to the deck.

Fold the side guardrails down onto the platform.

3. Follow step 2 to fold the front side guardrails on the

rear slide out deck.

4. Unlatch the gate so the left side guardrails can be

folded down in two separate pieces. Also remove the

hardware opposite the gate latch on the right side

guardrail so it can be separated into two pieces.

5. Lift up and fold side guardrails in so they rest on the

deck.

6. Lift up and fold front guardrail in so it rests on the

deck. Repeat for rear guardrail.

42

Figure 6: Fold Down Guardrails

7

Page 8

Double Deck Erection Procedure

1. Raise front guardrail making sure it is pushed down to

secure the guardrail in the vertical position. Repeat

for rear guardrail.

2. Raise guardrails making sure each is pushed down to

secure the guardrail in the vertical position. Align

holes and install hardware. Tighten securely.

3. Raise one of the four slide out deck side guardrail

assemblies. Align holes and install hardware. Tighten

securely. Repeat this procedure for the other three

slide out deck side guardrails.

4. Hang controller from front guardrail.

5. Before operating work platform, check that all fasteners are in place and properly torqued.

step 6

step 2

step 5

step 3

Note: Illustration above is shown with decks

extended for clarity. Perform this procedure with

decks retracted.

Figure 7: Fold Down Guardrails (Double Deck)

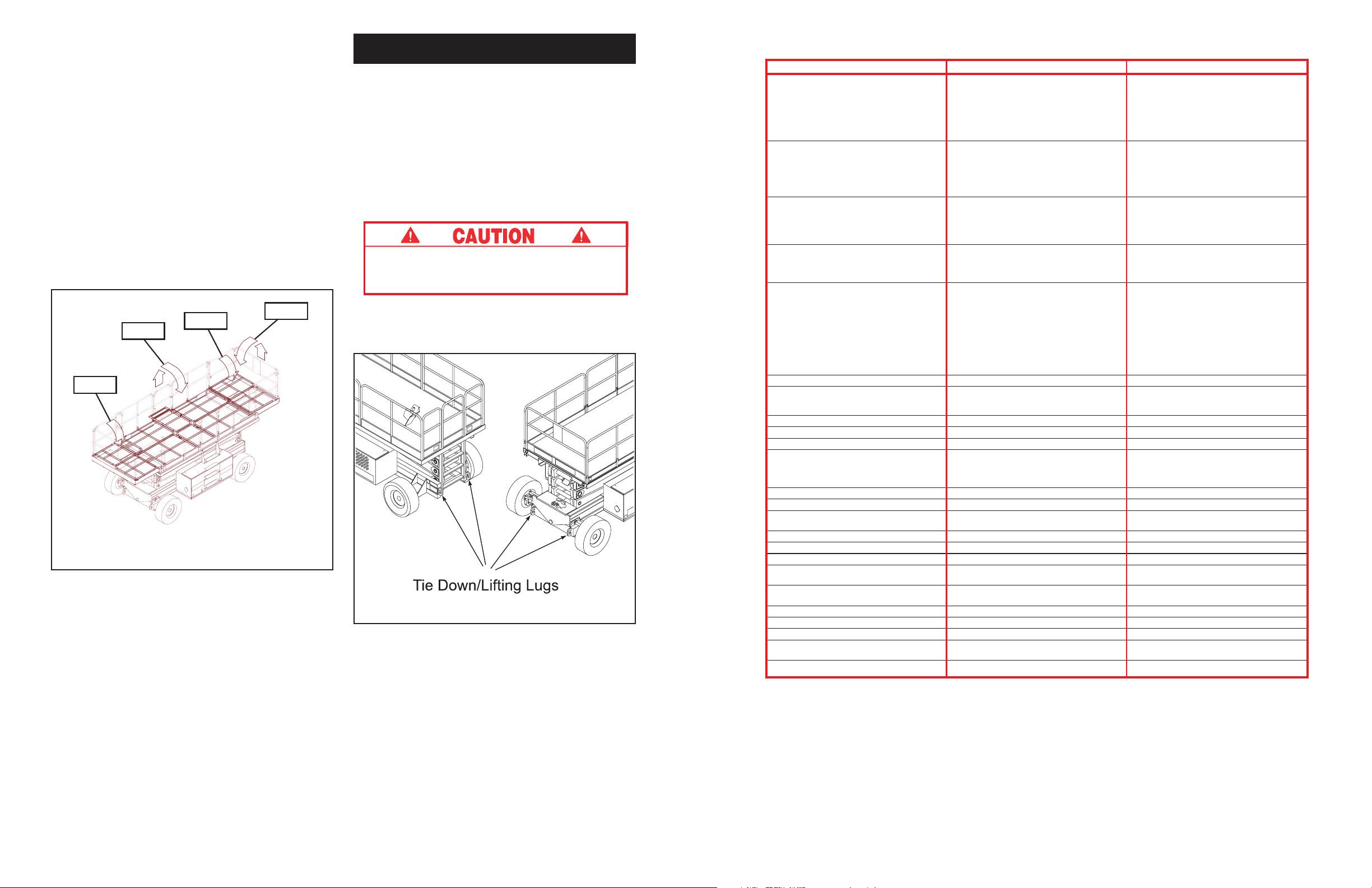

Transporting Work Platform

By Crane

1. Secure straps to chassis tie down/lifting lugs only

(Figure 8).

By Truck

1. Maneuver the work platform into transport position

and chock wheels.

2. Secure the work platform to the transport vehicle with

chains or straps of adequate load capacity attached

to the chassis tie down/lifting lugs (Figure 8).

Overtightening of chains or straps through tie

down lugs may result in damage to work platform.

Figure 8: Transporting Work Platform

Especificaciones*

LX31 LX41ÍTEM

Tamaño de plataforma

(dentro de banda de protección)

Estándar 3,64 m x 1,78 m [143,38 plg x 70 plg] 3,64 m x 1,78 m [143,38 plg x 70 plg]

Con extensión 4,56 m x 1,73 m [179,38 plg x 68 plg] 4,56 m x 1,73 m [179,38 plg x 68 plg]

Modelos de doble cubierta

Con las cubiertas retraídas 3,96 m x 1,73 m [156 plg x 68 plg] 3,96 m x 1,73 m [156 plg x 68 plg]

Con las cubiertas extendidas 5,79 m x 1,73 m [228 plg x 68 plg] 5,79 m x 1,73 m [228 plg x 68 plg]

Capacidad máxima de plataforma

Estándar 907 kg [2 000 lb] 680 kg [1 500 lb]

Con extensión 907 kg [2 000 lb] 680 kg [1 500 lb]

Sobre extensión 227 kg [500 lb] 227 kg [500 lb]

Modelos de doble cubierta 795 kg [1 750 lb] 567 kg [1 250 lb]

en Extensión (solo un extremo) 227 kg [500 lb] 227 kg [500 lb]

Ocupantes, máximo

Estándar 8 personas 6 personas

Sobre extensión 2 personas 2 personas

Modelos de doble cubierta 8 personas 6 personas

en Extensión (solo un extremo) 2 personas 2 personas

Altura

Altura de trabajo 11,28 m [37 pies] 14,33 m [47 pies]

Altura máxima plataforma 9,45 m [31 pies] 12,34 m [40 pies, 6 plg]

Altura mínima plataforma 1,43 m [56,3 plg] 1,66 m [65,3 plg]

Dimensiones

Peso, Eléctrica 2WD: 4 477 kg [9 870 lb]; 2WD: 5 085 kg [11 210 lb]

Peso, Energía doble 2WD : 4 568 kg [10 070 lb] 4WD: 5 176 kg [11 410 lb]

Peso, Eléctrica con extensión2WD: 4 672 kg [10 300 lb] 2WD: 5 280 kg [11 640 lb]

Peso, Energía doble 2WD : 4 763 kg [10 500 lb] 4WD: 5 371 kg [11 890 lb]

Peso, Eléctrica doble cubierta 2WD: 4 866 kg [10 728 lb] 2WD: 5 474 kg [12 068 lb]

Peso, Energía doble 2WD : 4 957 kg [10 928 lb] 4WD: 5 565 kg [12 268 lb]

Ancho total 2,29 m [90 plg] 2,29 m [90 plg]

Altura total 2,53 m [99,75 plg] 2,76 m [108,75 plg]

Largo total, estándar 4,08 m [160,5 plg] 4,08 m [160,5 plg]

Altura de movimiento 9,45 m [31 pies] 12,34 m [40 pies, 6 plg]

Velocidad de avance

Plataforma abajo 0 a 5,0 km/h [0 a 3,1 mph] 0 a 5,0 km/h [0 a 3,1 mph]

Plataforma arriba 0 a 0,48 km/h [0 a 0,3 mph] 0 a 0,48 km/h [0 a 0,3 mph]

Voltaje 48 volts, corriente continua 48 volts, corriente continua

Capacidad estanque hidráulico 107,13 L [28,3 galones EE.UU.] 107,13 L [28,3 galones EE.UU.]

Presión hidráulica máxima 206,8 bars [3 000 lb/plg2] 206,8 bars [3 000 lb/plg2]

Fluido hidráulico

Uso normal (sobre 0 oC [32 oF]) ISO #46 ISO #46

Baja temperatura

(-23 a 0 oC [-10 a 32 oF]) 5W-20 aceite motor 5W-20 aceite motor

Sistema de levante Un cilindro de elevación de una etapa Un cilindro de elevación de una etapa

Velocidad de levante Levante, 45 seg./ Bajada, 65 seg. Levante, 45 seg./ Bajada, 60 seg.

Fuente de potencia Ocho baterías 6V360 AH (doble Ocho baterías 6V360 AH (doble

energía) Una Kubota 12 CV Diesel energía) Una Kubota 12 CV Diesel

Control de tracción Proporcional Proporcional

Sistema de control Palanca manual simple suave Palanca manual simple suave

Tracción horizontal Dos motores de ruedas eléctricos Dos motores de ruedas eléctricos

Neumáticos - estándar 10-16,5 NHS 8 capas 10-16,5 NHS 8 capas

Neumát cos - opcional 3,4 bars [50 lb/plg2] Relleno de poli 3,4 bars [50 lb/plg2) Relleno de poli

Frenos de estacionamiento Dos, por resorte, desenganche Dos, por resorte, desenganche

Radio de giro (interno) 1,22 m [48 plg] 1,22 m [48 plg]

Inclinación máxima 2WD: 30% [16,7o]2WD: 30% [16,7o]

Base de ruedas 2,94 m [115,75 plg] 2,94 m [115,75 plg]

Barandas 1,1 m [43,5 plg] de alto, plegar con 1,1 m [43,5 plg] de alto, plegar con

Banda de protección 152 mm [6 plg] de alto 152 mm [6 plg] de alto

hidráulico, discos múltiples hidráulico, discos múltiples

compuerta de cierre automático compuerta de cierre automático

* Las especificaciones pueden cambiarse sin aviso previo.

Vea en el Manual de mantenimiento la lista completa de repuestos

e información de servicio.

Cumple o excede todos los requisitos apropiados de OSHA y ANSI A92.6-1990.

8

41

Page 9

Mantenimiento de rutina

Use la tabla siguiente como guía para mantenimiento de

rutina. Sólo personal entrenado y que sepa los

procedimientos eléctricos y mecánicos de la

máquina debe inspeccionarla y mantenerla. Consulte

en el Manual de mantenimiento las instrucciones

completas de mantenimiento.

Fotocopie esta página y úsela como hoja de verificación

de mantenimiento de rutina.

Clave de la tabla

Intervalo

Diario = cada turno (cada día) o cada ocho horas

D = cada mes (30 días) o cada cincuenta horas

30

3M = cada 3 meses o cada 125 horas

6

M = cada 6 meses o cada 250 horas

1Y = cada año o cada 500 horas

2Y = cada dos años o cada 1000 horas

S = Si/aceptable

N = No/No aceptable

R = Reparada/Aceptable

Maintenance

Upper Scissor

Center Pivot

Never perform service on the work platform in

the elevating assembly area while platform is

elevated without first blocking the elevating

assembly.

DO NOT stand in elevating assembly area while

deploying or storing brace.

Tabla de mantenimiento de rutina

COMPONENTE INSPECCIÓN O ACTIVIDAD INTERVALO S N R

Aceite motor Verifique nivel y condición Diario

modelos de Verifique goteos Diario

doble energia Cambie filtro y aceite 100 hr

Sistema com- Verifique nivel combustible Diario

bustible motor Verifique goteos Diario

modelos de Cambie filtro combustible 100 hr

doble energia Inspeccione depurador del aire Diario

Batería Verifique nivel electrólito Diario

principal Verifique gravedad específica 30D

Limpie exterior 6M

Inspeccione condición cables Diario

Limpie terminales 6M

Sistema Verifique nivel electrólito Diario

batería Verifique gravedad específica 30D

motor Limpie exterior 6M

modelos de Inspeccione condición cables Diario

doble energia Limpie terminales 6M

Refrigerante Verifique nivel (motor frío) Diario

motor Cambie refrigerante 2Y

Aceite Verifique nivel Diario

hidráulico Cambie filtro 6M

Cambie aceite 2Y

Sistema Verifique goteos Diario

hidráulico Inspeccione conexión de mangueras 30D

Inspeccione desgaste mangueras 30D

Sistema Abra la válvula de bajada de emergencia

hidráulico de e inspeccione condición Diario

emergencia

Contralor Inspeccione operación conmutador Diario

Cable de Inspeccione exterior cable por daños

control

Baranda Verifique par de torsión pernos Diario

y piso Inspeccione soldaduras Diario

plataforma Inspeccione condición de piso Diario

Neumáticos Inspeccione condición Diario

Verifique presión 5,2 bars (75 lb/plg2) Diario

Verifique tensión tuercas 205 Nm (150 lbs.-pies) 30D

Bomba Limpiado exterior 30D

hidráulica Examine fugas por junturas 30D

Verifique goteos conectores mangueras Diario

Verifique par de torsión de pernos 30D

Motores Inspeccione operación y goteos

hidráulicos

Sistema de Verifique par de torsión de pernos y conectores 6M

dirección Lubrique puntos pivotes 30D

Verifique goteos y par de torsión de cilindro

de dirección

Diario

Diario

30D

COMPONENTE INSPECCIÓN O ACTIVIDAD INTERVALO S N R

Mecanismo Verifique integridad estructura Diario

de tijera Inspeccione desgaste pivotes 30D

Verifique par de torsión de pernos de

pasadores pivotes

Inspeccione dobladuras de brazos de tijeras 6M

Engrase pasadores de tijeras 30D

Chasis Inspeccione mangueras por

estrangulaciones o roces

Verifique par de torsión de componentes

de montaje

Verifique integridad de soldaduras Diario

Cilindro de Verifique condición vástago 30D

levante Verifique par de torsión de pernos de

pasadores

Revise sellos por fugas 30D

Inspeccione desgaste de puntos pivote 30D

Verifique par de torsión de conectores 30D

Cilindro Verifique condición vástago 30D

del eje Verifique par de torsión de pernos

de pasadores

Revise sellos por fugas 30D

Inspeccione desgaste de puntos pivote 30D

Verifique par de torsión de conectores 30D

Unidad Revise y repare daños de colisión Diario

completa Verifique par de torsión de pernos 3M

Inspeccione por corrosión; limpie y pinte 6M

Lubricar 30D

Calcomanías Reemplace las dañadas, ilegibles o sueltas Diario

30D

Diario

6M

30D

30D

Informe de mantenimiento

Fecha:

Dueño:

Modelo No.: No. serie:

Mecánico:

Intervalo:

Blocking Elevating Assembly

(Figure 9)

Installation

1. Park the work platform on firm level ground.

2. Verify platform emergency stop switch is ON.

3. Turn platform/chassis switch to CHASSIS.

4. Elevate platform far enough to allow brace to be

lowered.

5. From the left side of the machine, disengage the

locking pin securing the brace. Rotate the scissor

brace counterclockwise until it is vertical and between

the two scissor center pivots.

6. Slowly lower platform until brace is supporting the

platform.

Removal

1. Using chassis controls, raise platform until the

scissors brace clears the two scissor center pivots.

2. Rotate scissors brace clockwise until the locking pin

engages.

3. Lower platform completely.

Brace

Locking Pin

Lower Scissor

Center Pivot

Figure 9: Blocking Elevating Assembly

Battery Maintenance

Hazard of explosive gas mixture. Keep sparks,

flame and smoking materials away from batteries.

Always wear safety glasses when working with

batteries.

Battery fluid is highly corrosive. Rinse away any

spilled fluid thoroughly with clean water.

Always replace batteries with UpRight batteries

or manufacturer approved replacements weighing

54.4 kg (120 lbs.) each.

Check battery fluid level daily, especially if work platform

is being used in a warm, dry climate.

If electrolyte level is lower than 10 mm (3/8 in.) above

plates add distilled water only. DO NOT use tap water

with high mineral content it will shorten battery life.

Keep terminals and tops of batteries clean.

Refer to the Service Manual to extend battery life and for

complete service instructions.

40

9

Page 10

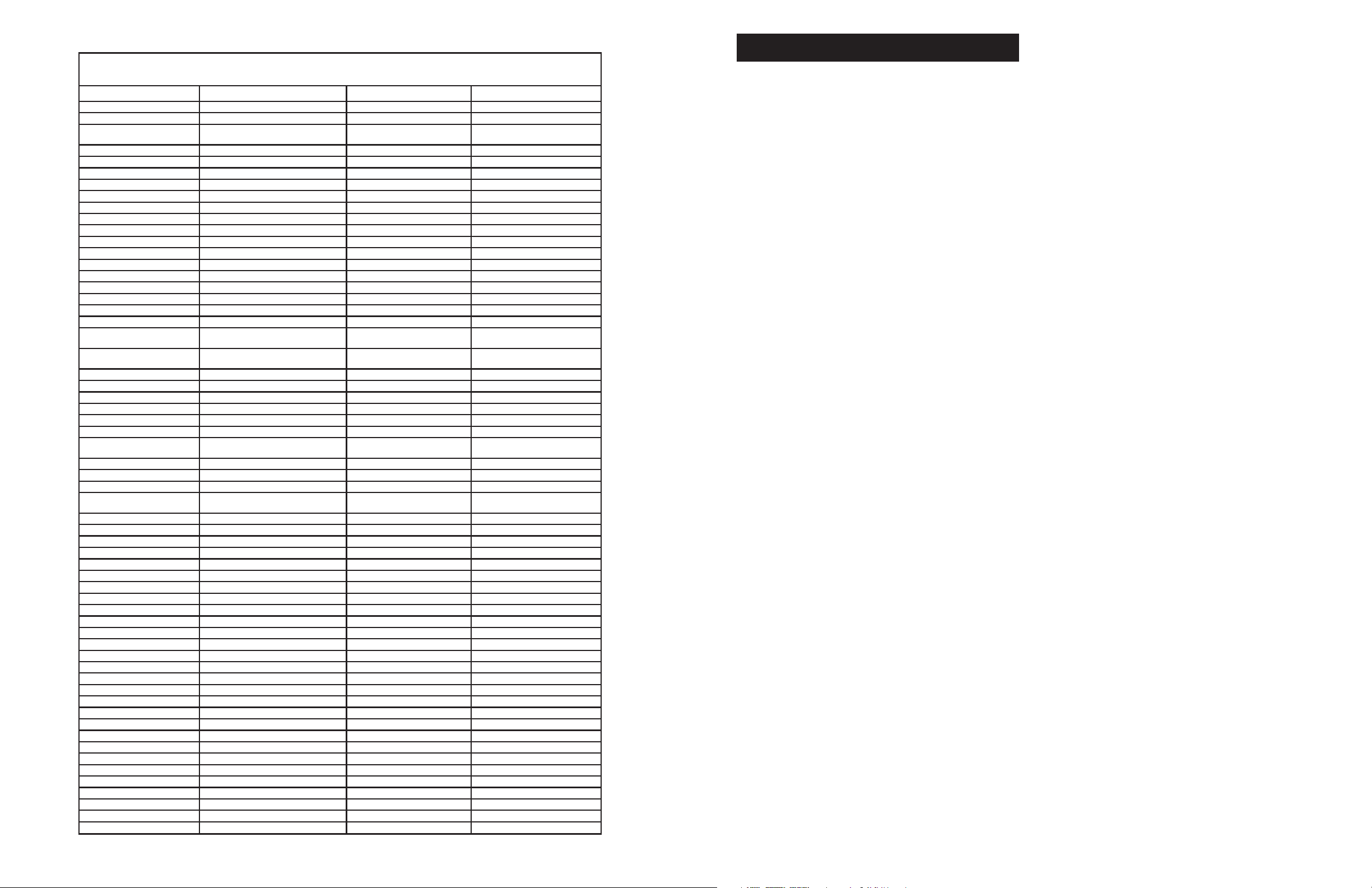

Routine Service

Use the following table as a guide for routine maintenance. Inspection and maintenance shall be

performed by personnel who are trained and familiar

with mechanical and electrical procedures. Refer to

the Service Manual for complete service instructions.

Please copy this page and use the Routine Service

Table as a checklist when inspecting a machine for

service.

Routine Service Table Key

Interval

Daily=each shift (every day) or every eight hours

30D=every month (30 days) or every 50 hours

3M=every 3 months or 125 hours

6M=every 6 months or 250 hours

1Y=every year or 500 hours

Y=every 2 years or 1000 hours

2

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Mantenimiento

Jamás mantenga el mecanismo de tijera de la

plataforma de trabajo con la plataforma

levantada sin haber bloqueado antes ese

mecanismo.

NO se pare en el área del mecanismo de tijera al

instalar o guardar el puntal.

Pivote central

de tijera

superior

Routine Service Table

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Engine Oil Check level and condition Daily

BiEnergy Check for leaks Daily

Models Change oil & filter 100HOURS

Engine Fuel Check fuel level Daily

System Check for leaks Daily

BiEnergy Replace fuel filter 100 HOURS

Models Check air cleaner Daily

Main Check electrolyte level Daily

Battery Check specific gravity 30D

Pack Clean exterior 6M

Engine Check electrolyte level Daily

Battery Check specific gravity 30D

System Clean exterior 6M

BiEnergy Check battery cable condition Daily

Models Clean terminals 6M

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 2Y

Hydraulic Check oil level Daily

Oil Change filter 6M

Hydraulic Check for leaks Daily

System Check hose connections 30D

Emergency Open the emergency lowering valve and

Hydraulic check for serviceability Daily

System

Controller Check switch operation Daily

Control Check the exterior of the cable

Cable for pinching, binding or wear

Platform Check fasteners for proper torque Daily

Deck and Check welds for cracks Daily

Rails Check condition of deck Daily

Tires Check for damage Daily

Hydraulic Wipe clean 30D

Pump Check for leaks at mating surfaces 30 D

Drive Motors Check for operation and leaks Daily

Steering Check hardware & fittings

System for proper torque

Check battery cable condition Daily

Clean terminals 6M

Drain and replace oil 2 Y

Check hoses for exterior wear 30D

Daily

Check air pressure 5.2 bars (75 psi) Daily

Check lug nuts (torque to 205 Nm [150 ft. lbs.]) 30D

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30D

6M

Oil all pivot points 30D

Check steering cylinder for leaks &

mounting bolts for proper torque

30D

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Elevating Inspect for structural cracks Daily

Assembly Check pivot points for wear 30D

Check pivot pin mounting bolts

for proper torque

Check scissor arms for bending 6M

Grease scissor pins 30D

Chassis Check hoses for pinch or rubbing points Daily

Check component mounting for proper torque 6M

Check welds for cracks Daily

Lift Check the cylinder rod for wear 30D

Cylinder Check pivot pin mounting bolts for proper torque 30D

Check seals for leaks 30D

Inspect pivot points for wear 30D

Check fittings for proper torque 30D

Axle Check the cylinder rod for wear 30D

Cylinder Check mounting pin pivot bolts for proper torque 30D

Check seals for leaks 30D

Inspect pivot points for wear 30D

Check fittings for proper torque 30D

Entire Check for and repair collision damage Daily

Unit Check fasteners for proper torque 3M

Check for corrosion-remove and repaint 6M

Lubricate 30D

Labels Check for peeling, missing, or unreadable

labels & replace

30D

Daily

Service Report

Date: ________________

Owner: _________________

Model No: ____________ Serial No: _____________

Serviced By: ____________

Service Interval: _________

Bloqueando el mecanismo de tijera

(figura 9)

Instalación

1. Estacione la plataforma de trabajo en piso horizontal

firme.

2. Verifique que el interruptor de paradas de

emergencia esté conectado “ON”.

3. Gire el conmutador plataforma/chasis a chasis

“CHASSIS”.

4. Eleve la plataforma lo más lejos posible para permitir

que la abrazadera baje.

5. Desde el lado izquierdo de la máquina, saque el

pasador de enganche que asegura el brazo. Gire el

brazo de las tijeras contra las manecillas del reloj

hasta que esté vertical y entre los dos pivotes de las

tijeras.

6. Baje la plataforma lentamente hasta que la

abrazadera sostenga la plataforma.

Remoción

1. Desde los controles del chasis levante la plataforma

hasta que el puntal de las tijeras salga de los dos

pivotes centrales.

2. Gire el puntal en el sentido de los punteros del reloj

hasta que el pasador de enganche encaje.

3. Baje completamente la plataforma.

Puntal

Pasador de

enganche

Pivote central de

tijera inferior

Figura 9: Bloqueo del mecanismo de tijera

Mantenimiento de la batería

Peligro de mezcla de gases explosiva. Mantenga

las baterías lejos de chispas, llamas o de

cigarrillos.

Cuando trabaje con baterías, use siempre

anteojos de seguridad.

Los electrólitos son muy corrosivos. Lave bien

los derrames con agua limpia.

Use siempre baterías UpRight de repuesto o

aquellas aprobadas por el fabricante como tales

y que pesen 54,4 kg (120 lb) c/u.

Inspeccione el nivel de electrólito diariamente,

especialmente si la plataforma de trabajo se usa en un

clima seco y cálido.

Si el electrólito está a menos de 10 mm (3/8 plg) del

tope de las placas agregue sólo agua destilada. NO use

agua potable con alto contenido de minerales para no

acortar la vida de la batería.

Mantenga los terminales y las baterías limpias.

Consulte en la Manual de mantenimiento como

incrementar la vida de la batería y las instrucciones

completas de mantenimiento.

10

39

Page 11

Procedimiento de elevación para

modelos de doble cubierta

1. Levante la baranda delantera y empújela hacia abajo

para asegurar la baranda en posición vertical. Repita

la operación para la baranda trasera.

2. Levante las barandas laterales y empújelas hacia

abajo para asegurarlas en posición vertical, alínee

los orificios e instale los pernos, arandelas y

tuercas. Asegúrelos firmemente.

3. Levante uno de los cuatro ensamblados de las

barandas laterales de la cubierta de deslizamiento.

Alinee los orificios e instale los elementos de

montaje. Asegúrelos firmemente. Repita este

proceso para las otras tres barandas laterales de la

cubierta de deslizamiento.

4. Cuelgue el contralor en la baranda delantera.

5. Antes de operar la plataforma de trabajo verifique que

los pernos estén en su lugar y apretados al par de

torsión correcto.

paso 6

paso 2

paso 5

paso 3

Nota: La illustración de arriba muestra las cubiertas

extendidas con el propósito de clarificar. Realice

este procedimiento con las cubiertas retrídas.

Figura 7: Plegar la baranda (doble cubierta)

Transportar la plataforma

de trabajo

Por grúa

1. Asegure las correas sólo a los anillos de amarre o

levante (fig. 8).

Por camión

1. Mueva la plataforma de trabajo a la posición para

transporte y acuñe las ruedas.

2. Asegure la plataforma de trabajo al vehículo de

transporte con cadenas o correas, de resistencia

adecuada para la carga, desde los anillos de

amarre (fig. 8).

Sobreestirar cadenas o correas desde los

anillos puede dañar la plataforma de trabajo.

Anillos de amarre para asegurar o levantar

Figura 8: Transportando la plataforma de trabajo

ITEM

Platform Size (Inside Toeboards)

Standard

w/ Extension

Double Deck Models

w/ Decks Retracted

w/ Decks Extended

Max. Platform Capacity

Standard

w/ Extension

on Extension

Double Deck Models

on Extension (one end only)

Max. No. of occupants

Standard

on Extension

Double Deck Models

on Extension (one end only)

Height

Working Height

Max. Platform Height

Min. Platform Height

Dimensions

Weight, Electric

Overall Width

Overall Height

Overall Length, Standard

Driveable Height

Surface Speed

Platform Lowered

Platform Raised

System Voltage

Hydraulic Tank Capacity

Maximum Hydraulic System Pressure

Hydraulic Fluid

Normal Use (> 0 °C [32 °F])

Low Temp. Use

(-23 to 0 °C [-10 to 32 °F])

Lift System

Lift Speed

Power Source

Drive Control

Control System

Horizontal Drive

Tires Standard

Parking Brakes

Turning Radius (inside)

Maximum Gradeability

Wheel Base

Guardrails

Toeboard

BiEnergy

Electric w/ Extension

BiEnergy

Electric Double Deck

BiEnergy

Optional

LX31

3.64 m x 1.78 m [143.38 in. x 70 in.]

4.56 m x 1.73 m [179.38 in. x 68 in.]

3.96 m x 1.73 m [156 in. x 68 in.]

5.79 m x 1.73 m [228 in. x 68 in.]

907 kg [2000 lbs.]

907 kg [2000 lbs.]

227 kg [500 lbs.]

795 kg [1750 lbs.]

227 kg [500 lbs.]

8 people

2 people

8 people

2 people

11.28 m [37 ft.]

9.45 m [31 ft.]

1.43 m [56.3 in.]

2WD: 4,477 kg [9,870 lbs.]

2WD: 4,568 kg [10,070 lbs.]

2WD: 4,672 kg [10,300 lbs.]

2WD: 4,763 kg [10,500 lbs.]

2WD: 4,866 kg [10,728 lbs.]

2WD: 4,957 kg [10,928 lbs.]

2.29 m [90 in.]

2.53 m [99.75 in.]

4.08 m [160.5 in.]

9.45 m [31 ft.]

0 to 5.0 km/h [0 to 3.1 mph]

0 to .48 km/h [0 to 0.3 mph]

48 Volt DC

107.13 l [28.3 Gallons]

206.8 bar [3000 psi]

ISO #46

5W-20 Motor Oil

One Single Stage Lift Cylinder

Raise, 40 sec./Lower, 60 sec.

Eight 6V 350 AH Batteries

(BiEnergy) One Kubota 12 HP Diesel

Proportional

Smooth one hand Joystick

Two Electric Wheel Motors

10-16.5 NHS 8 Ply, 3.4 bar [50psi]

Poly Filled

Two, Spring Applied, Hydraulic Release,

Multiple Disc

1.22 m [48 in.]

2WD: 30% [16.7º]

2.94 m [115.75 in.]

1.1 m [43.5 in.] high, Fold Down with Self

Closing Gate

152 mm [6 in.] High

LX41

3.64 m x 1.78 m [143.38 in. x 70 in.]

4.56 m x 1.73 m [179.38 in. x 68 in.]

3.96 m x 1.73 m [156 in. x 68 in.]

5.79 m x 1.73 m [228 in. x 68 in.]

680 kg [1,500 lbs.]

680 kg [1,500 lbs.]

227 kg [500 lbs.]

567 kg [1,250 lbs]

227 kg [500 lbs.]

6 people

2 people

6 people

2 people

14.33 m [47 ft.]

12.34 m [40 ft. 6 in. ]

1.66 m [65.3 in. ]

2WD: 5,085 kg [11,210 lbs.]

4WD: 5,176 kg [11,410 lbs.]

2WD: 5,280 kg [11,640 lbs.]

4WD: 5,371 kg [11,890 lbs.]

2WD: 5,474 kg [12,068 lbs.]

4WD: 5,565 kg [12,268 lbs.]

2.29 m [90 in.]

2.76 m [108.75 in.]

4.08 m [160.5 in.]

12.34 m [0 ft. 6 in.]

0 to 5.0 km/h [0 to 3.1 mph]

0 to .48 km/h [0 to 0.3 mph]

48 Volt DC

107.13 l [28.3 Gallons]

206.8 bar [3000 psi]

ISO #46

5W-20 Motor Oil

One Single Stage Lift Cylinder

Raise, 40 sec./Lower, 60 sec.

Eight 6V 350 AH Batteries

(BiEnergy) One Kubota 12 HP Diesel

Proportional

Smooth one hand Joystick

Two Electric Wheel Motors

10-16.5 NHS 8 Ply, 3.4 bar [50psi]

Poly Filled

Two, Spring Applied, Hydraulic Release,

Multiple Disc

1.22 m [48 in.]

2WD: 30% [16.7º]

2.94 m [115.75 in.]

1.1 m [43.5 in.] high, Fold Down with Self

Closing Gate

152 mm [6 in.] High

38

* Specifications subject to change without notice.

Refer to Service Manual for complete parts and service information.

Meets or exceeds all applicable requirements of OSHA and ANSI A92.6-1990

11

Page 12

Version française

RÈGLES DE SÉCURITÉ

NE JAMAIS utiliser la machine

à moins de 3 mètres (10 pi) de

lignes d’énergie électrique.

CETTE MACHINE N’EST PAS

ISOLÉE.

NE JAMAIS utiliser la machine sans avoir d’abord vérifié si la surface de la zone de travail ne

présente pas de dangers, tels que des trous, des dénivellations, des bosses et des débris.

NE JAMAIS utiliser la machine sans que tous les garde-corps soient bien montés en place et

fixés solidement au moyen de toutes les pièces de fixation serrées au bon couple.

REFERMER et verrouiller le portillon après être monté sur la plate-forme.

NE PAS s’approcher des stabilisateurs au moment d’élever ou d’abaisser la plate-forme. (Ma-

chines équipées de stabilisateurs seulement).

NE JAMAIS dresser d’échelle ni d’échafaudage sur la plate-forme.

NE JAMAIS agrandir la surface de la plate-forme, ni y fixer une charge qui la déborde.

MAINTENIR la pression des pneus à 3,4 bars (50 lb/po2) . Vérifier chaque jour.

REGARDER en haut, en bas et tout autour de la machine afin de s’assurer qu’il n’y a aucun

conducteur électrique ou autre obstacle aux alentours.

RÉPARTIR également toutes les charges sur la plate-forme. Pour connaître la capacité

maximale de cette dernière, voir la fiche technique à la page couverture arrière.

NE JAMAIS utiliser une machine endommagée. (Si la machine est endommagée, communiquer

avec UpRight en composant le numéro sans frais inscrit à la page couverture arrière.)

NE JAMAIS modifier les éléments assurant le fonctionnement de la machine, ni les dispositifs de

sécurité.

VÉRIFIER la machine de fond en comble en s’assurant que toutes les soudures et tous les

câbles électriques ou de commande sont en bon état, que toutes les pièces de fixation sont bien

serrées, y compris les boulons de fixation des roues, que le circuit hydraulique ne présente

aucune fuite et que tous les fils électriques sont bien branchés.

NE JAMAIS descendre par le dispositif d’élévation lorsque la plate-forme est élevée.

NE JAMAIS effectuer des travaux d’entretien dans la zone du dispositif d’élévation d’une plate-

forme élevée sans avoir d’abord bloqué ce dernier au moyen d’un étai.

NE JAMAIS recharger la batterie d’accumulateurs près d’une flamme ou d’une source d’étincelles :

au moment du rechargement, les batteries dégagent de l’hydrogène gazeux hautement explosif.

APRÈS AVOIR UTILISÉ la plate-forme élévatrice, tourner la clé de l’interrupteur à la position

d’arrêt « OFF », puis la retirer afin de prévenir l’utilisation de la plate-forme par toute personne

non autorisée.

NE JAMAIS remplacer quelque élément ou quelque pièce que ce soit par autre chose qu’une

pièce d’origine UpRight, sans le consentement du fabricant.

NE JAMAIS élever la plate-forme

sur des pentes de surface inégale

ou sur un sol mou, ni déplacer la

machine en pareilles conditions,

ni élever la plate-forme si celle-ci

n’est pas de niveau.

12

NE JAMAIS s’asseoir, monter

ou se mettre debout sur les

rampes du garde-corps de la

plate-forme.

Abatiendo barandas

Use este procedimiento sólo para pasar por puertas.

Vuelva las barandas a su posición correcta antes de

usar la máquina.

Procedimiento para abatir (figura 6)

Nota: Cuando ejecute este procedimiento guarde los

pernos, tuercas y arandelas.

1. Coloque el contralor en la plataforma.

2. Empezando por el frente, saque los pernos, tuercas

y arandelas de encima de la baranda delantera.

Abata la baranda delantera sobre la plataforma.

3. Cierre la puerta con pestillo.

4. Saque los pernos, tuercas y arandelas de encima de

la baranda trasera. Abata la baranda sobre la

plataforma cuidando mantener la puerta con pestillo

todo el tiempo.

5. Saque los pernos, tuercas y arandelas de encima de

las barandas laterales y del eje medio de la

plataforma deslizante. Levante y voltee la baranda

de un lado dejándola sobre la plataforma. Repítalo

con la baranda opuesta.

Figura 6: Abatiendo barandas

Procedimiento de elevación

1. Levante las barandas laterales y empújelas hacia

abajo para asegurarlas en la posición vertical.

2. Instale pernos, arandelas y tuercas entre las

barandas laterales y apriételos bien.

3. Levante el ensamble de la baranda trasera, alinee

hoyos e instale pernos, arandelas y tuercas.

4. Levante la baranda delantera, alinee agujeros e

instale pernos, arandelas y tuercas. Apríetelos bien.

5. Cuelgue el contralor en la baranda delantera.

6. Antes de operar la plataforma de trabajo verifique

que los pernos estén en su lugar y apretados al par

de torsión correcto.

Antes de operar la máquina, las barandas deben

estar aseguradas en su posición correcta.

Procedimiento de plegado para los

modelos de doble cubierta (figura 7)

Nota: Cuando se realiza el siguiente procedimiento

guardar todos los sujetadores.

1. Coloque el controlador sobre la plataforma

2. Comenzando desde el frente de la máquina, la

cubierta de deslizamiento, quite los elementos de

montaje de los extremos superiores delanteros de

las barandas. Quite los elementos de montaje de la

baranda lateral de la cubierta de deslizamiento.

También quite los elementos de montaje de la parte

superior de los soportes que unen la baranda lateral

de la cubierta de deslizamiento con la cubierta.

Doble las barandas laterales sobre la plataforma.

3. Siga el paso 2 para plegar la baranda lateral sobre la

cubierta de deslizamiento trasera.

4. Destrabe la compuerta de modo que se pueda plegar

la baranda lateral izquierda en dos piezas separadas.

También quite los elementos de montaje que se

encuentran frente al pestillo de la compuerta en la

baranda lateral derecha, para poder separarla en dos

piezas.

5. Levante y pliegue la baranda lateral hacia adentro de

modo que quede sobre la cubierta.

6. Levante y pliegue la baranda delantera hacia adentro

de modo que quedesobre la cubierta. Repita la

peración con la baranda trasera.

37

Page 13

Traslado con la plataforma elevada

Traslade la plataforma elevada SÓLO en superficies

firmes y horizontales.

Nota: La máquina se moverá a velocidad reducida

con la plataforma elevada, y sólo cuando ambos ejes

están paralelos.

1. Cersiórese de que no haya personas, obstrucciones,

hoyos y desniveles en el camino y que la superficie

sea capaz de resistir la carga de las ruedas.

2. Verifique el espacio libre sobre, debajo y en los lados

de la plataforma.

3. Coloque el conmutador manejo/levante en la

posición de manejo “DRIVE”.

4. Empuje la palanca de control a avance

“FORWARD” o retroceso “REVERSE” según la

dirección de movimiento deseada.

Si la máquina se detiene y la alarma de inclinación

suena, baje la plataforma de inmediato y mueva la

máquina a un lugar horizontal antes de levantar la

plataforma de nuevo.

Bajada de emergencia

La válvula de bajada de emergencia se encuentra en

el frente de la máquina en la base del mecanismo de

tijera (fig. 4).

1. Abra la perilla de bajada de emergencia tirando y

sosteniendo la manilla.

2. Cuando la plataforma esté abajo, suelte la manilla

para cerrar la válvula.

Manilla de

bajada de

emergencia

Figura 4: Manilla de bajada de emergencia

Después de cada uso diario

1. Cerciórese que la plataforma esté totalmente abajo.

2. Estacione la máquina en piso horizontal, de

preferencia bajo techo, asegurada contra vándalos,

niños o usos no autorizados.

3. Apague el motor y saque la llave “OFF” para

prevenir usos no autorizados.

Desenganche del freno de

estacionamiento (figura 5)

Ejecute lo siguiente sólo cuando la máquina no opere por

si misma y es necesario moverla, o al tirarla sobre un

remolque para transporte.

Nunca suelte los frenos cuando la unidad està

en una pendiente. Enganche la unidad a un

vehìculo de remolque antes de soltar los frenos.

1. Coloque el interruptor de desenganche del freno/

plataforma/ chasis, en la posición de desenganche

del freno. La alarma sonará.

2. Apriete por un momento el botón de desenganche del

freno.

3. Las ruedas de la máquina girarán al empujarla o

tirarla.

4. Para la operación normal, coloque el interruptor

plataforma/chasis, desenganche del freno en

plataforma.

Jamás opere la plataforma de trabajo sin los

frenos de estacionamiento enganchados. Ello

puede resultar en lesiones o daños serios.

Desenganche del

freno

Introduction

Ce manuel se rapporte à l'utilisation des modèles

électrique et bi-énergie de plate-formes élévatrices de

travail appartenant à la série LX. On veillera à le garder

sur la machine en tout temps.

Vérification préliminaire

de sécurité

Lire d’abord attentivement toutes les règles de

sécurité, les étiquettes et le mode d’emploi, en

s’assurant de les comprendre et de s’y conformer.

Chaque jour avant d’utiliser la machine, exécuter les

tâches suivantes.

Effectuer une inspection visuelle complète de la machine

avant de l’utiliser.

1. Ouvrir les panneaux, et vérifier que les composants des

circuits hydrauliques/les tuyaux ne présentent pas de

fuites ni de dommages. Vérifier qu’aucun composant

ou filage électrique ne présente de dommages ni de

connexions ayant du jeu.

2. Vérifier à fond le châssis, les essieux, les moyeux et la

timonerie de direction pour s’assurer qu’ils ne

présentent pas de dommages, de déformations, de

peinture gondolée, de pièces de fixation ayant du jeu ou

qui manquent, ni de soudures fissurées.

3. La plate-forme étant complètement abaissée, vérifier

la jauge de niveau du réservoir d’huile hydraulique.

Faire l’appoint d’huile hydraulique ISO no 46, au

besoin.

4. S’assurer que le niveau d’électrolyte de toutes les

batteries est correct. (Voir « Entretien de la batterie »,

à la page 19.)

5. Vérifier le niveau d'huile du moteur et le niveau de

carburant (modèles bi-énergie).

6. S’assurer que tous les garde-corps sont en place.

Veiller à ce que le portillon fonctionne librement et

s’enclenche fermement.

7. Vérifier si les pneus ne sont pas endommagés.

Vérifier la pression des pneus; elle doit être de

5,2 bars (75 lb/po2), si la machine est équipée de

pneumatiques.

8. Vérifier la plate-forme élévatrice de fond en comble

en s’assurant que les soudures et toutes les pièces –

comme les éléments porteurs, les câbles électriques,

les tuyaux flexibles et les pneus – sont en bon état,

que toutes les pièces sont fixées solidement en place

et qu’aucune d’elles ne manque, qu’il n’y a aucune

fuite d’huile et que tous les fils électriques sont bien

branchés.

9. Modèles bi-énergie - Une fois le moteur refroidi,

vérifier le niveau de liquide de refroidissement.

NE PAS utiliser la machine si elle est endommagée ou en mauvais état de fonctionnement.

Apposer une étiquette volante sur la machine et la

retirer du service jusqu’à ce qu’elle ait été réparée.

Essai de fonctionnement des

éléments

S’ÉLOIGNER de la plate-forme de travail au

moment d’effectuer les essais décrits ci-après.

Avant d’utiliser la plate-forme de travail, vérifier

si la surface de la zone de travail ne présente

pas de dangers à l’utilisateur, tels que des trous,

des dénivellations, des bosses et des débris.

REGARDER en haut, en bas et tout autour de la

machine afin de s’assurer qu’il n’y a aucun

conducteur électrique ou autre obstacle aux

alentours.

En effectuant les essais, protéger le câble du

pupitre de commande contre tout dommage

éventuel.

1. Décrocher le boîtier de commande du garde-corps

avant. Saisir fermement la poignée du boîtier de

commande, de façon à pouvoir actionner le levier

d’enclenchement solidaire au moment d’effectuer les

essais au sol décrits ci-après.

NOTA : L’engin bi-énergie peut être mû par batteries

d’accumulateurs ou par moteur. Pour mouvoir

l’engin par moteur, enfoncer le bouton de démarrage

du moteur pour lancer celui-ci; relâcher le bouton

lorsque le moteur démarre. Si le moteur est froid :

enfoncer le bouton de préchauffage, et le maintenir

enfoncé pendant 6 secondes avant d’essayer de

démarrer.

Bouton

d’arrêt

d’urgence

Sélecteur de

châssis/

plate-forme/

desserrage

des freins

Élever

Abaisser

Démarrer

Bougie de

préchauffage

Interrupteur

à clé

Figura 5: Desenganche del freno de estacionamiento

36

NE JAMAIS ôter le bouchon d’un radiateur

chaud. Le liquid de refroidissement chaud peut

causer de graves brûlures.

Desserrage des freins

13

Horomètre

Figure 1 : Châssis, côté gauche

Page 14

2. Régler l’interrupteur à clé du boîtier de commande à

la position « ON ».

3. Régler le sélecteur de mode de fonctionnement à la

position de déplacement « DRIVE ». Le témoin du

mode de déplacement sera alors allumé.

4. Le sélecteur de plage de vitesses étant réglé d’abord

à la position de basse vitesse « LOW SPEED », puis

à la position de grande vitesse « HIGH SPEED »,

vérifier les commandes de vitesse et de direction.

Pour ce faire, appuyer sur le levier d’enclenchement

solidaire et déplacer progressivement le levier de

commande à la position de marche avant

« FORWARD », puis à la position de marche arrière

« REVERSE ». La vitesse de déplacement de la

machine augmentera à mesure que le levier de

commande s’éloigne de la position neutre.

5. Vérifier la commande de direction en déplaçant le

bouton de commande de direction d’abord vers la

DROITE, puis vers la GAUCHE.

6. Accrocher le boîtier de commande du garde-corps

dans sa position initiale.

7. Régler le sélecteur de châssis/plate-forme à la

position « CHASSIS ».

8. Appuyer sur le bouton d’élévation situé sur le tableau

de commande du châssis, puis déplacer le détecteur

d’inclinaison (figure 3) de sa position de nivelage en

le poussant. La plate-forme devrait arrêter avant

d’atteindre sa hauteur maximale, et l’alarme du

détecteur d’inclinaison devrait sonner. Si la plateforme continue à s’élever ou que l’alarme ne sonne

pas, ARRÊTER la machine et la faire réparer avant

de l’utiliser à nouveau.

Bouton de commande

de direction

Bouton de

commande de

stabilisateur

Bouton d'arret

d'urgence

Témoin du mode

de déplacement

Levier d'enclenchement

solidaire

Sélecteur de plage

de vitesses

9. Relâcher le détecteur d’inclinaison, et élever la plateforme à la hauteur maximale.

10. Vérifier le bon état et le bon fonctionnement des

éléments suivants : le dispositif d’élévation, le vérin,

les câbles et les tuyaux flexibles. S’assurer que les

pièces sont fixées solidement en place et qu’aucune

d’elles ne manque.

11. Abaisser partiellement la plate-forme au moyen du

bouton d’abaissement situé sur le tableau de

commande du châssis, puis vérifier le fonctionnement de l’alarme sonore d’abaissement.

12. Au châssis, vérifier le bon fonctionnement de la

soupape d’abaissement de secours (figure 4). Pour

ce faire, l’ouvrir en tirant sur sa tirette de commande

et la maintenir dans la position ouverte. Une fois la

plate-forme abaissée à fond, fermer la soupape en

relâchant la tirette.

13. Régler le sélecteur de châssis/plate-forme à la

position « PLATFORM ».

14. Monter sur la plate-forme et fermer le portillon au

loquet.

15. Régler le sélecteur de mode de fonctionnement à la

position d’élévation « LIFT ».

16. Appuyer sur le levier d’enclenchement solidaire et

déplacer progressivement le levier de commande à

la position d’élévation « RAISE » pour élever la

plate-forme. Ce faisant, actionner le levier sur toute

sa course afin de vérifier la vitesse d’élévation

proportionnelle. Élever la plate-forme jusqu’à une

hauteur de 3,7 mètres (12 pi).

17. Déplacer progressivement le levier de commande à la

position d’abaissement « DOWN », pour abaisser la

plate-forme. S’assurer que l’alarme d’abaissement

sonne.

18. Tourner la clé du boîtier de commande à la position

« OFF », rentrer le bouton d’arrêt d’urgence et

descendre de la plate-forme.

19. Fermer les modules en s’assurant que les couvercles

sont fixés solidement en place.

Operación

Antes de operar la plataforma de trabajo asegúrese que

se completó la inspección de pre-operación y seguridad,

que cualquiera deficiencia ha sido corregida y que el

operador ha sido entrando en la máquina.

NOTA: Las máquinas de doble energía pueden ser

accionadas por baterías o motor. Para accionar la

máquina a motor, presione el botón de arranque del

motor para arrancar el motor. Libere el botón cuando

la máquina arranque. Si el motor está frío, presione

el botón de la bujía incandescente en la caja de

control del chasis, durante seis segundos antes del

arranque.

IMPORTANTE: Si arranca el motor desde la plataforma, asegúrese de que el interruptor del motor en

el chasis esté en la posición de “RUN” (marcha).

Traslado con la plataforma abajo

1. Verifique que el interruptor de parada de emergencia

del chasis se encuentre en la posición ON

(encendido) (hacia afuera), que el indicador de

habilitación de la transmisión esté encendido y que el

interruptor de la plataforma/chasis se encuentre en

PLATFORM (plataforma).

Nota: Si el indicador de habilitación de la ransmisión está apagado, verifique que la plataforma esté

completamente abajo.

2. Suba a la plataforma y cierre la puerta con pestillo.

Verifique que las barandas estén bien ensambladas

y colocadas con los tornillos bien apretados.

3. Cersiórese de que no haya personas, obstrucciones,

hoyos y desniveles en el camino y que la superficie

sea capaz de resistir la carga de las ruedas.

4. Verifique el espacio libre sobre, abajo y a los lados

de la plataforma.

5. Tire el botón de detención de emergencia a la

posición de contacto “ON”.

6. Coloque el interruptor de promedio de velocidad en

“LOW SPEED” (velocidad baja).

7. Coja la palanca de control de tal manera que presione

la palanca de enganche (soltando la palanca de

enganche interrumpe la corriente al contralor).

Suavemente mueva la palanca de control a avance

“FORWARD” o retroceso “REVERSE” para

trasladarse en la dirección deseada. Mientras más

empuja o tira la palanca de control de su centro, más

rápido se moverá la máquina.

8. En movimiento, coloque el interruptor de velocidades

en la posición de HIGH SPEED (alta velocidad) para

desplazarse sobre superficies niveladas o en la

posición de LOW SPEED (baja velocidad) para subir

pendientes o desplazarse en áreas limitadas.

Dirección

1. Empuje el cambiode dirección a DERECHA o

IZQUIERDA para mover las ruedas. Mientras

maniobre verifique que las ruedas giren en la

dirección requerida.

Nota: La dirección no es auto-centrante. Las ruedas

deben volverse al sentido derecho moviendo el

cambio de dirección.

Subir y bajar la plataforma

1. Coloque el conmutador manejo/levante en levante

“LIFT”.

2. Mientras sostenga la palanca de control para

presionar la palanca de enganche, empuje la palanca

de control lentamente a arriba “UP” para levantar la

plataforma. Al empujar más la palanca de control se

aumenta la velocidad de levante.

3. Al completar la tarea coloque el conmutador manejo/

levante en levante “LIFT” y baje la plataforma

tirando hacia atrás la palanca de control hasta que la

plataforma esté totalmente abajo.

Selecteur de

mode de

fonctionnement

Figure 2 : Boîtier de commande

14

Capteur de degré

d'inclinaison

Figure 3 : Capteur de degré d'inclinaison

35

Page 15

2. Gire la llave del contralor hacia la derecha a contacto

“ON”.

3. Coloque el conmutador manejo/levante en la posición

de manejo “DRIVE”. El indicador de habilitación de

la transmisión se iluminará.

4. Con el selector de velocidades, primero en par de

torsión alto “LOW SPEED” (baja velocidad) y luego

en alta velocidad “HIGH SPEED” (alta velocidad)

presiones la palanca de enganche y lentamente

empuje la palanca de control a avance “FORWARD”

y luego a retroceso “REVERSE” para verificar la

velocidad y control direccional. Mientras más empuje

o tire la palanca de control más rápido se moverá la

máquina.

5. Empuje el cambio de dirección hacia la derecha

“RIGHT” y luego a la izquierda “LEFT” para verificar

el control de dirección.

6. Enganche el controlador en la barandilla en la

posición original

7. Gire el conmutador plataforma/chasis a chasis

“CHASSIS”.

8. En los controles de bajada. Empuje el botón de

levante en el chasis para levantar la plataforma

mientras empuja el sensor de inclinación fuera de

nivel (fig. 3). La plataforma debería elevarse sólo

parcialmente y la alarma de inclinación sonar. Si la

plataforma continúa subiendo y / o la alarma no

suena, pare “STOP” y retire la máquina del servicio

hasta que esté reparada.

Conmutador de

dirección

Palanca de

control

Interruptor para

parar de

emergencia

Indicador de

enganche para

manejar

Conmutador

manejo/levante

Palanca de

interconexión

Conmutador de

rango de

velocidades

9. Suelte el sensor de inclinación y levante la

plataforma totalmente.

10. Inspeccione visualmente el mecanismo y cilindro de

levante, los cables y mangueras cerciorándose que

no estén dañados y que funcionen bien. Verifique

que no falten partes o que estén sueltas.

11. Baje la plataforma parcialmente, empujando el botón

de bajada en el chasis y verifique el funcionamiento

de la alarma audible de bajada.

12. Abra la válvula de bajada de emergencia del chasis

(fig. 4) para verificar el funcionamiento adecuado

tirando y sosteniendo la perilla. Cuando la

plataforma esté totalmente abajo cierre la válvula

soltando la perilla.

13. Gire el conmutador plataforma/chasis a plataforma

“PLATFORM”.

14. Suba a la plataforma y cierre la puerta con pestillo.

15. Gire el conmutador manejo/levante a levante “LIFT”.

16. Presione la palanca de enganche y, lentamente,

empuje la palanca de control a arriba “RAISE” para

levantar la plataforma, mueva totalmente la palanca

de control para verificar la velocidad proporcional de

levante. Levante la plataforma 3,70 m (12 pies).

17. Suavemente, mueva la palanca de control a abajo

“DOWN” para bajar la plataforma. Verifique que la

alarma suene.

18. Saque la llave de partida del contralor “OFF”, empuje

el botón de detención de emergencia y bájese de la

plataforma.

19. Cierre y asegure las cubiertas del módulo.

Sensor de

inclinación

Mode d’emploi

Avant d’utiliser la plate-forme élévatrice de travail,

effectuer la vérification préliminaire de sécurité et réparer

toute défectuosité relevée. S’assurer également que

l’opérateur a reçu une formation pratique qui lui a permis

de bien connaître l’utilisation de la machine.

NOTA : L’engin bi-énergie peut être mû par batteries

d’accumulateurs ou par moteur. Pour mouvoir

l’engin par moteur, enfoncer le bouton de démarrage

du moteur pour lancer celui-ci; relâcher le bouton

lorsque le moteur démarre. Si le moteur est froid :

enfoncer le bouton de préchauffage, et le maintenir

enfoncé pendant 6 secondes avant d’essayer de

démarrer.

IMPORTANT : Pour faire démarrer le moteur à partir

de la plate-forme, s’assurer que l’interrupteur du

moteur monté sur le châssis est bien réglé sur la

position « RUN ».

Déplacement – plate-forme abaissée

1. Au tableau de commande du châssis, régler le

bouton d’arrêt d’urgence à la position « ON »

en le tournant dans le sens inverse des aiguilles

d’une montre. S’assurer que le témoin du mode de

déplacement s’allume, et régler le sélecteur de

châssis/plate-forme à la position « PLATFORM ».

Nota : Si le témoin du mode de déplacement ne

s’allume pas, s’assurer que la plate-forme est abaissée

à fond.

2. Monter sur la plate-forme et fermer le portillon au

loquet. S’assurer que les garde-corps sont bien

montés en place et que leurs pièces de fixation sont

toutes bien serrées.

3.

Vérifier la voie de passage en s’assurant qu’elle est

libre de personnes, d’obstacles, de trous et de

dénivellations, et que la surface est capable de

supporter les charges des roues.

4. Vérifier l’espace disponible de chaque côté de la