Operator Manual

X Series

Serial No. 15020 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules,

operating instructions, and the Scaffold Industry Association’s MANUAL

OF RESPONSIBILITIES

performing maintenance on any UpRight Aerial Work Platform.

of ANSI A92.6-1999

Safety Rules

before operating or

Safety Rules and Operating Instructions

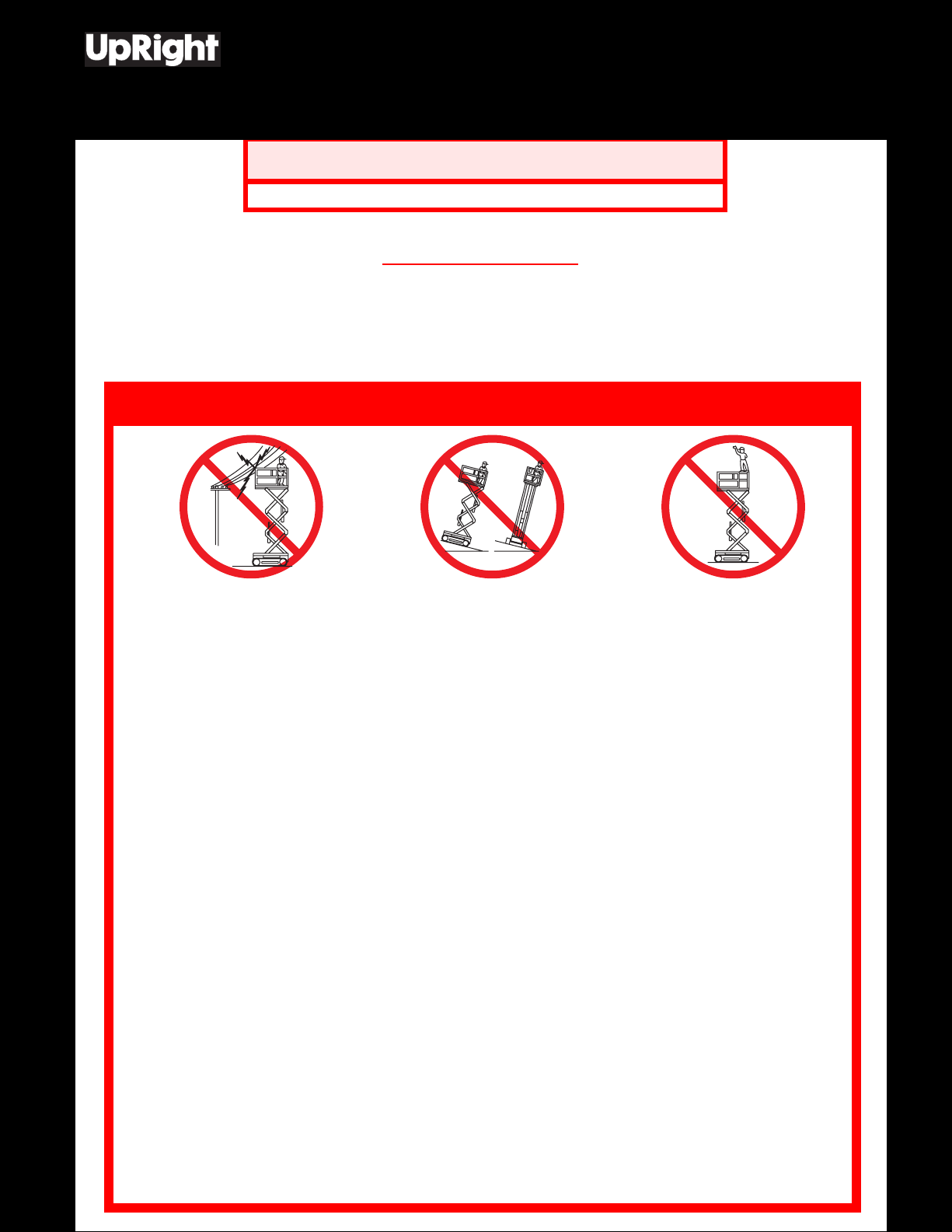

NEVER operate the machine within

ten feet of power lines.

THIS MACHINE IS NOT INSULATED

NEVER

drop-offs, bumps and debris.

NEVER

erly torqued.

SECURE

NEVER

NEVER

LOOK up

DISTRIBUTE

NEVER

cover.)

NEVER

INSPECT

cable, loose wire connections and wheel bolts.

NEVER

NEVER

NEVER

sive hydrogen gas.

AFTER USE

key.

NEVER

out the manufacturer’s consent.

operate the machine without first surveying the work area for surface hazards such as holes,

operate the machine if all guardrails are not properly in place and secured with all fasteners prop-

chain or gate across entrance after mounting platform.

use ladders or scaffolding on the platform.

attach overhanging loads or increase platform size.

, down and around for overhead obstructions and electrical conductors.

all loads evenly on the platform. See the back cover for maximum platform load.

use damaged equipment. (Contact UpRight for instructions. See toll-free phone number on back

change operating or safety systems.

the machine thoroughly for cracked welds, loose hardware, hydraulic leaks, damaged control

climb down elevating assembly with the platform elevated.

perform service on machine while platform is elevated without blocking elevating assembly.

recharge batteries near sparks or open flame; batteries that are being charged emit highly explo-

secure the work platform against unauthorized use by turning key switch off and removing

replace any component or part with anything other than original UpRight replacement parts with-

NEVER elevate the platform or drive

the machine while elevated unless

the machine is on firm level surface.

NEVER sit, stand or climb on

guardrail or midrail.

Safety Rules and Operating Instructions

I

NTRODUCTION

PRE-O

This manual covers operation of the X Series Self Propelled Work Platforms.

be stored on the machine at all times.

PERATION AND SAFETY INSPECTION

Carefully read, understand and follow all safety rules, operating instructions, labels, and the Scaffold Industry Association’s MANUAL OF RESPONSIBILITIES. Perform the following steps each

day before use.

1. Open module covers and inspect for damage, oil leaks, or missing parts.

2. Check the level of the hydraulic oil with the platform fully lowered. Open the Left Module and

remove the reservoir cap. Oil should be visible in the filler screen. Add hydraulic fluid if necessary.

3. Check that fluid level in the batteries is correct (See “Battery Maintenance” on page 11.).

4. Verify that batteries are charged.

5. Check that A.C. extension cord has been disconnected from charger.

6. Check that all guardrails are in place with all fasteners properly tightened.

7. Check that the slide out deck extension is secured with the pin.

8. Inspect the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks,

damaged control cable, loose wire connections and wheel bolts.

9. Close and secure module covers.

10. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

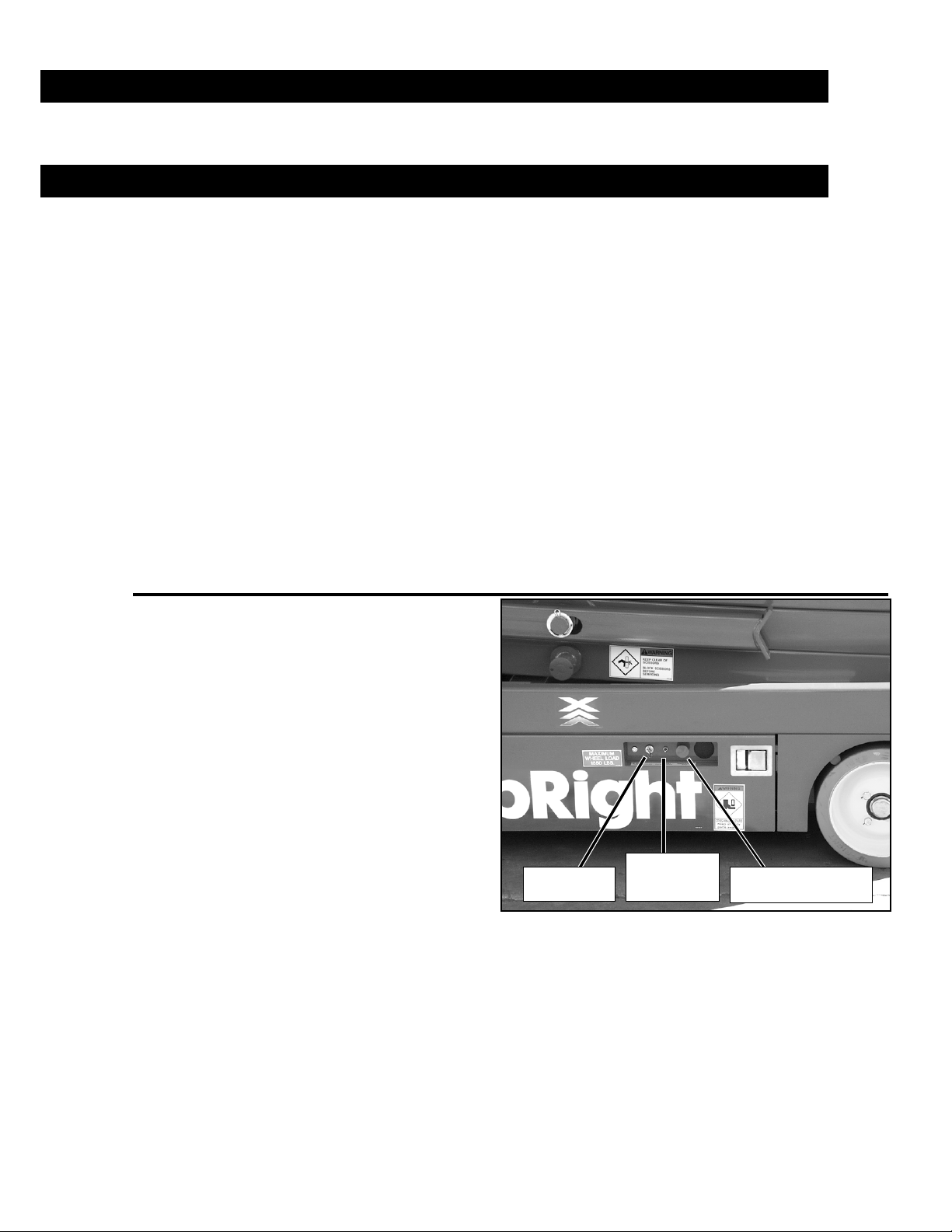

11. Pull Chassis EMERGENCY STOP Switch to the ON position.

12. Pull Platform EMERGENCY STOP Switch to the ON position.

This manual must

Figure 1:

13. Turn and hold the Chassis Key

Switch to CHASSIS.

14. Push the Chassis Lift/Lower Switch

to LIFT to elevate the platform until

the Scissor Brace can be rotated to

the vertical position. Block the elevating assembly as described on

page 10.

15. Visually inspect the elevating

assembly, lift cylinder, cables and

hoses for cracked welds, loose

hardware, hydraulic leaks, loose

wire connections and erratic operation. Check for missing or loose

parts.

16. Verify that the depression mechanism has deployed into position

under each module. Remove the

scissor brace as described on

page 10.

17. Push the Chassis Lift/Lower Switch to LIFT and fully elevate the platform.

18. Partially lower the platform by pushing the Chassis Lift/Lower Switch to LOWER, and check

operation of the audible lowering alarm.

Chassis Key

Switch

Chassis

LIFT/LOWER

Switch

Chassis Controls

Chassis EMERGENCY

STOP Switch

Page 2 X Series

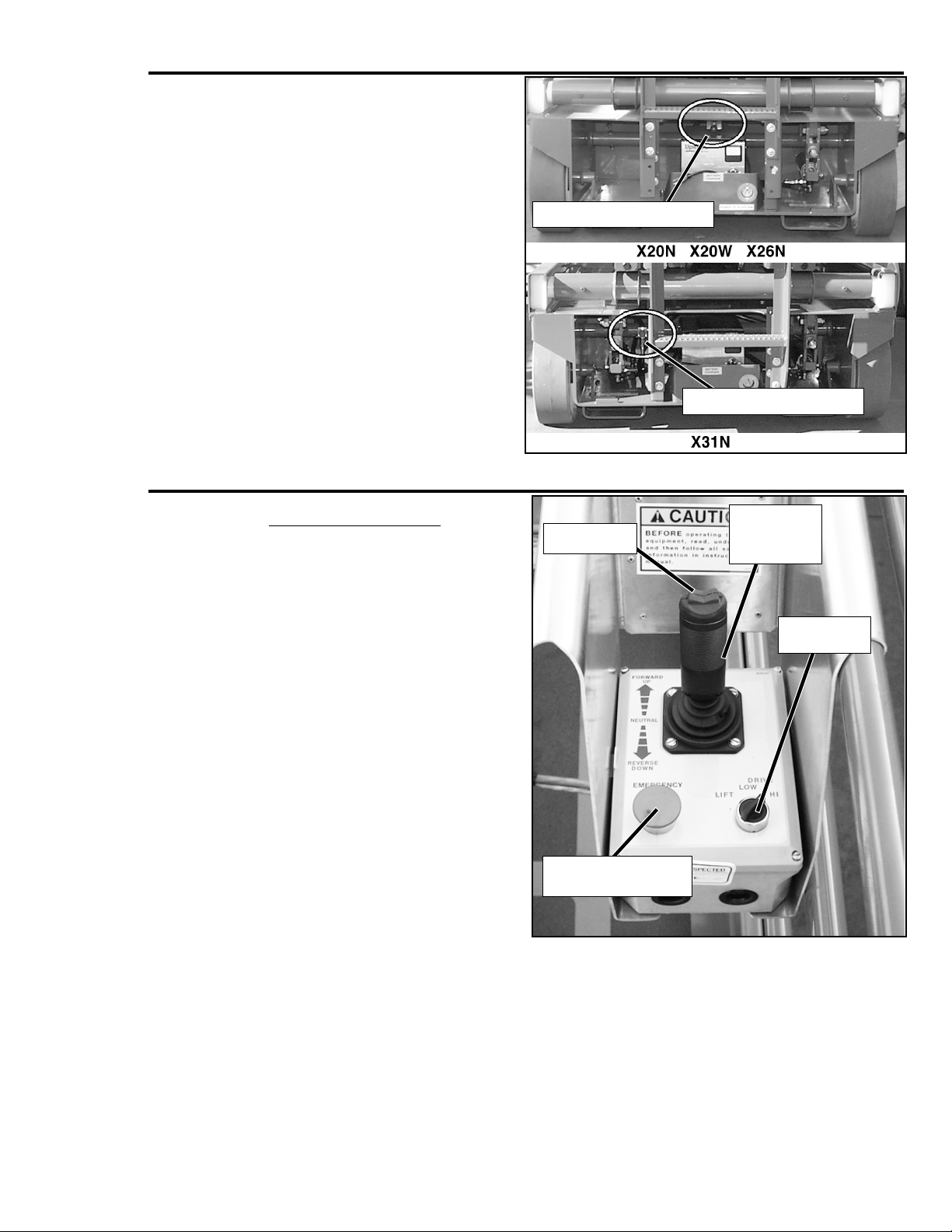

19. Pull out on the Emergency Lowering

Emergency Lowering Knob

Emergency Lowering Knob

Control

Handle with

Interlock

Switch

LIFT/ DRIVE

Switch

Platform EMERGENCY

STOP Switch

Steering

Switch

Knob to check for proper operation.

Once the platform has lowered,

release the knob.

20. Push the Chassis EMERGENCY

STOP Switch to check for proper

operation. All the machine functions

should be disabled. Pull out the

EMERGENCY STOP Switch to

resume.

21. Turn the Chassis Key Switch to

DECK.

22. Check that the route is clear of

obstacles (persons, obstructions,

holes, drop-offs, bumps, and

debris), is level, and capable of supporting the wheel loads.

23. Mount the platform and properly

close the entrance.

Figure 2:

Emergency Lowering

24. PLATFORM CONTROLS

, Turn Lift/

Drive Switch to DRIVE.

NOTE: Use both HI and LOW drive (if

applicable) when performing

the following step.

25. Engage the Interlock Switch and

move the Control Handle FORWARD, then REVERSE, to check for

speed control.

26. Push the Steering Switch RIGHT,

then LEFT, to check for steering control.

27. Turn the Lift/Drive Switch to LIFT.

28. Engage the Interlock Switch and

move the Control Handle forward to

check platform lift controls. Raise the

platform to full elevation.

29. Pull back on the Control Handle. The

platform should descend and the

audible lowering alarm should sound.

30. Lower the platform completely.

31. Push the Platform EMERGENCY

STOP Switch to check for proper

operation. All the machine functions

should be disabled. Pull out the Platform EMERGENCY STOP Switch to resume.

Figure 3:

Platform Controls

Page 3X Series

O

PERATION

Before

operating work platform, ensure that the pre-operation safety inspection has been com-

pleted, and that any deficiencies have been corrected.

tioning machine.

understand, and follow this Operator Manual and Scaffold Industry Association’s Manual of

Responsibilities of ANSI A92.6-1999.

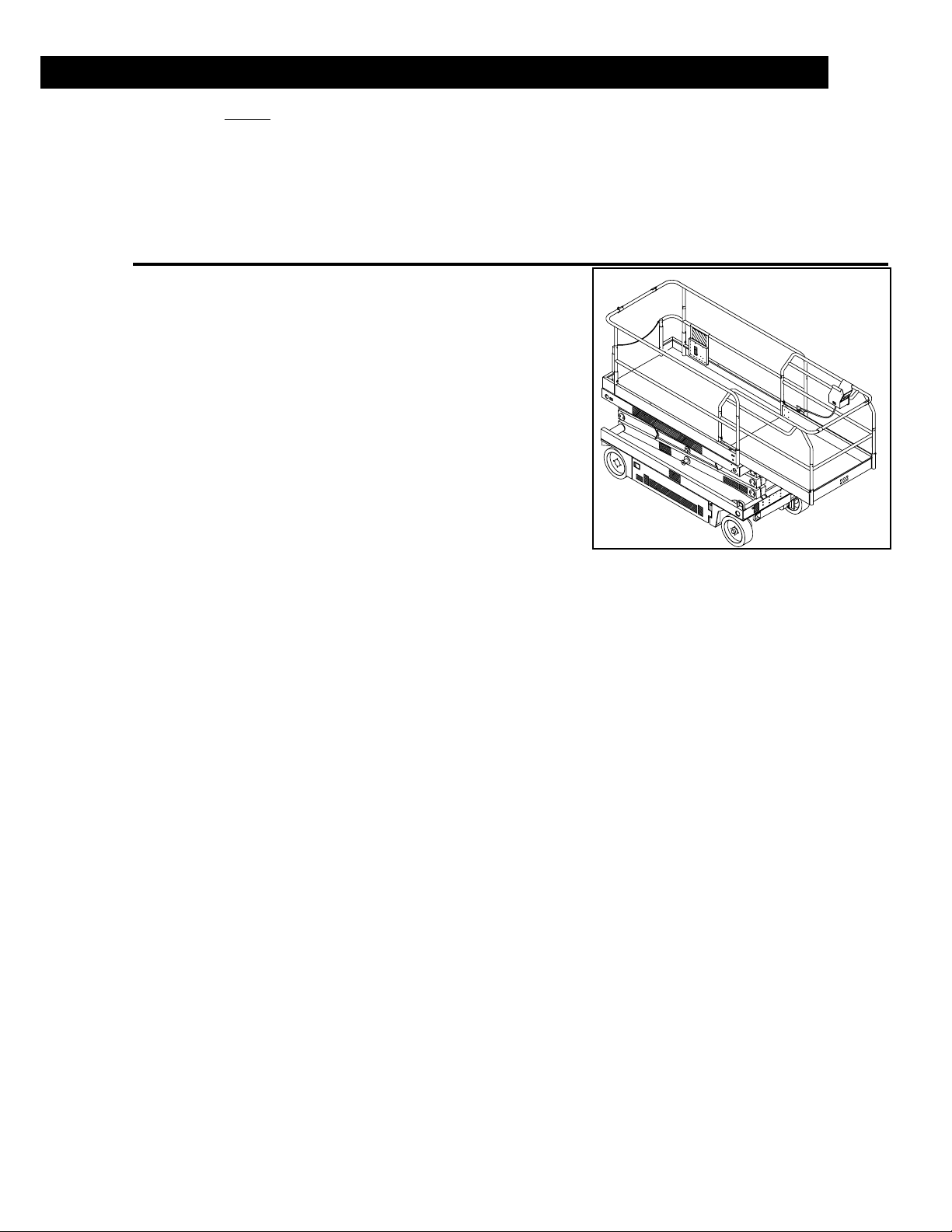

LATFORM EXTENSION

P

The operator must be thoroughly trained on this machine, and must read, fully

Never operate a damaged or malfunc-

Figure 4:

1. Mount the platform and properly close the

entrance.

2. Depress the foot lever located at the rear of the

platform extension. Push the platform extension

forward until the pin engages the front stop.

3. To retract the platform extension, depress the

foot lever and pull the platform extension toward

the rear of the machine until the pin engages the

rear stop.

RAVEL WITH PLATFORM LOWERED

T

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and

debris), is level, and capable of supporting the

wheel loads.

2. Turn the Chassis Key Switch to DECK.

3. Pull Chassis EMERGENCY STOP Switch to the ON position.

4. Mount the platform and properly close the entrance.

5. Check clearances above, below and to the sides of platform.

6. Pull Platform EMERGENCY STOP Switch to the ON position.

7. Turn Lift/Drive Switch to DRIVE.

NOTE: Turn Lift/Drive Switch to HI (if applicable) for traveling on level ground, or to LOW

8. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to

when extra torque is required for climbing grades.

travel in the desired direction. The speed of the machine will vary depending on how far from

center the Control Handle is moved.

Platform Extension

Page 4 X Series

TEERING

S

1. Turn the Lift/Drive switch to DRIVE.

2. Engage the Interlock Switch, push the Steering Switch RIGHT or LEFT to turn the wheels in

the desired direction. Observe the tires while operating the machine to ensure proper direction.

NOTE: Steering is not self-centering. Wheels must be returned to the straight ahead

LEVATING THE PLATFORM

E

1. Select a firm, level surface.

2. Turn the Lift/Drive Switch to LIFT.

3. Engage the Interlock Switch and push the Control Handle forward.

4. If the machine is not level the tilt alarm will sound and the machine will not lift or drive.

RAVEL WITH WORK PLATFORM ELEVATED

T

NOTE: The machine will travel at reduced speed when the platform is elevated.

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and

2. Check clearances above, below and to the sides of platform.

3. Turn the Lift/Drive Switch to DRIVE.

4. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to

5. If the machine is not level, the tilt alarm will sound and the machine will not lift or drive.

position by operating the Steering Switch.

If the

tilt alarm sounds the platform must be lowered and the machine moved to a firm level

surface before attempting to re-elevate the platform.

debris), is level, and capable of supporting the wheel loads.

travel in the desired direction. The speed of the machine will vary depending on how far from

center the Control Handle is moved.

If the

tilt alarm sounds, the platform must be lowered and the machine moved to a firm level

surface before attempting to re-elevate the platform.

OWERING THE PLATFORM

L

1. Turn the Lift/Drive Switch to LIFT.

2. Engage the Interlock Switch and pull back on the Control Handle to lower the platform.

Page 5X Series

Loading...

Loading...