Page 1

Operator’s

Manual

Engine Powered

Gasoline

Battery Electric

P/N 11447A

April 2003

Bi-Energy and Self Level

Page 2

LIMITED WARRANTY

Snorkel warrants each new machine manufactured and sold by it to be free from defectsin material and workmanship fora

periodofone(1)yearfrom dateofdelivery toaCustomeror forone yearafterthe machinehasbeen placedinfirstservicein a

Dealerrentalfleet, whichevercomes first.Any par t or par ts which, upon examinationbythe SnorkelService Department, are

foundtobe defective,willbe replaced or repaired,atthe sole discretion ofSnorkel,through its local Authorized Dealer atno

charge.

Snorkelfurther warrants the structural components;specifically, the mainframe chassis,turntable,boomsandscissorarms,

of each new machine manufactured by it to be freefrom defectsin material and workmanshipforanadditional period of four

(4) years.Any such part or parts which, upon examination by the SnorkelService Department, are found to be defective will

bereplaced or repairedbySnorkel throughitslocal AuthorizedDealerat nocharge;however,anylabor charges incurredasa

result of such replacement or repair will be the responsibility of the Customer or Dealer.

The Snorkel Service Depar tment must be notified within forty-eight (48) hours of anypossible warranty situation during the

applicable warranty period.Personnel performing warranty repair or replacement must obtain specific approval by Snorkel

Service Department prior to performing any warranty repair or replacement.

Customer and Dealer shall not be entitled to the benefits of this warranty and Snorkel shall haveno obligations hereunder

unless the “Pre-Delivery and Inspection Report” has been properly completed and returned to the Snorkel Service

Department within ten (10) days after delivery of the Sorkel product to Customer or Dealer’s rental fleet. Snorkel must be

notified, in writing, within ten (10) days,of any machine sold to a Customer from a Dealer’s rental fleet during the warranty

period.

At the direction of the Snorkel Service Department, any component par t(s) of Snorkel products to be replaced or repaired

underthiswarrantyprogram must be returned freight prepaid to the Snor kel ServiceDepartmentforinspection. Allwarranty

replacement parts willbeshipped freight prepaid (standard ground) fromtheSnorkel Service Department or from Snorkel’s

Vendor to Dealer or Customer.

REPLACEMENT PARTS WARRANTY

Any replacement or service part made or sold by Snorkel is not subject to the preceding Limited Warranty beyond the

normal warranty per iod of the machine upon which the part was installed.

THIS WARRANTY EXCLUDES AND SNORKEL DOES NOT WARRANT:

1. Engines, motors, tires and batteries whichare manufactured by suppliers to Snorkel, whofurnish their own warranty.

Snorkelwill, however,tothe extentpermitted,passthroughany suchwarrantyprotectiontothe CustomerorDealer.

2. AnySnorkelproduct whichhasbeenmodified or altered outside Snorkel’sfactory without Snorkel’swritten approval,if

suchmodification or alteration, in thesolejudgment of Snorkel’sEngineering and/or ServiceDepartments, adversely

affects the stability, reliability or service life of the Snorkel product or any component thereof.

3. AnySnorkelproductwhich hasbeensubjectto misuse,improper maintenanceoraccident.“Misuse”includesbutisnot

limited to operation beyond the factory-rated load capacity and speeds.“Improper maintenance” includes but is not

limited to failure to follow the recommendations contained in the Snorkel Operation, Maintenance, Repair Parts

Manuals.Snorkelis not responsiblefornormal maintenance, service adjustments andreplacements,including but not

limited to hydraulic fluid, filters and lubrication.

4. Normalwearofany Snorkel componentpart(s).Normalwear of componentparts mayvarywiththe type application or

type of environment in which the machine may be used;such as, but not limited to sandblasting applications.

5. Any Snorkel product that has come in direct contact with any chemical or abrasive material.

6. Incidental or consequential expenses,losses, or damages related to any part or equipment failure, including but not

limited to freight cost to transport the machine to a repair facility, downtime of the machine, lost time for workers,lost

orders, lost rental revenue, lost profits or increased cost.

This warrantyisexpresslyinlieuofallother warranties,representationsorliabilitiesof Snorkel, either expressedor implied,

unless otherwise amended in writing by Snorkel’s President, Vice President-Engineer ing, Vice President-Sales or Vice

President-Marketing.

SNORKEL MAKES NO WARRANTIESWHICH EXTEND BEYONDTHE DESCRIPTION OF THIS LIMITED WARRANTY.

SNORKEL MAKES NO IMPLIED WARRANTYOF MERCHANTABILITYOR FITNESS FOR A PARTICULARPURPOSE

AND DISCLAIMS ALL LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT

LIMITED TO INJURY TO PERSONS OR PROPERTY.

The Customer shall make all warranty claims through its local AuthorizedDealer and shouldcontact the Dealerfrom whom

the Snorkel product was purchased for warranty service. Or, if unable to contact the Dealer, contact the Snorkel Service

Department for further assistance.

Effective July 1995

Page 3

■

Electrical Hazard Warning

THE SNORKELIFT AERIAL WORK PLATFORM

IS NOT ELECTRICALLY INSULATED.

Electrical Hazard

DANGER

If the platform, booms, or any other conductive part of a Snorkelift contacts a high-voltage electrical con

ductor, the result can be SERIOUS INJURY or DEATH for persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH DISTANCES

(M.S.A.D) - AS OUTLINED IN TABLE 1. AND FIGURE 3.,

ON THE NEXT PAGE.

Be sure to allow for sag and sway in the wires and the work platform.

If a Snorkelift comes in contact with a live electrical conductor, the entire machine can be charged.

If that happens, you should remain on the machine and not contact any other structure or object within

reach. That includes the ground, adjacent buildings, poles, and any object not a part of the Snorkelift.

Suchcontact could makeyourbody aconductor to theother objectcreating an electricalshock hazardre-

sulting in SERIOUS INJURY or DEATH.

DO NOT attempt to enter or leave the Snorkelift until you are sure the electricity has been turned off.

If aSnor kelift is in contactwith a liveconductor, the platform operator MUST warn others on the ground in

the vicinity of the Snorkelift to STAY AWAY from the machine, since their bodies can also form a path for

electricity to ground thus creating an electrical shock hazard with possible ELECTROCUTION and

DEATH.

-

DONOTattempttooperatetheSnorkeliftground controls whentheplatform,booms,oranyother conduct

ingpartofa Snorkeliftisincontact with electricalwiresorifthereisanimmediatedangerofsuchcontact.

Regard all conductors as energized.

Personnel working on or near a Snorkelift must be continuously aware of electrical hazards, recognizing

that SERIOUS INJURY or DEATH can result if contact with an electrical wire does occur.

MHP12/34J – 11447A page - i

-

Page 4

Electrical Hazard

p

■

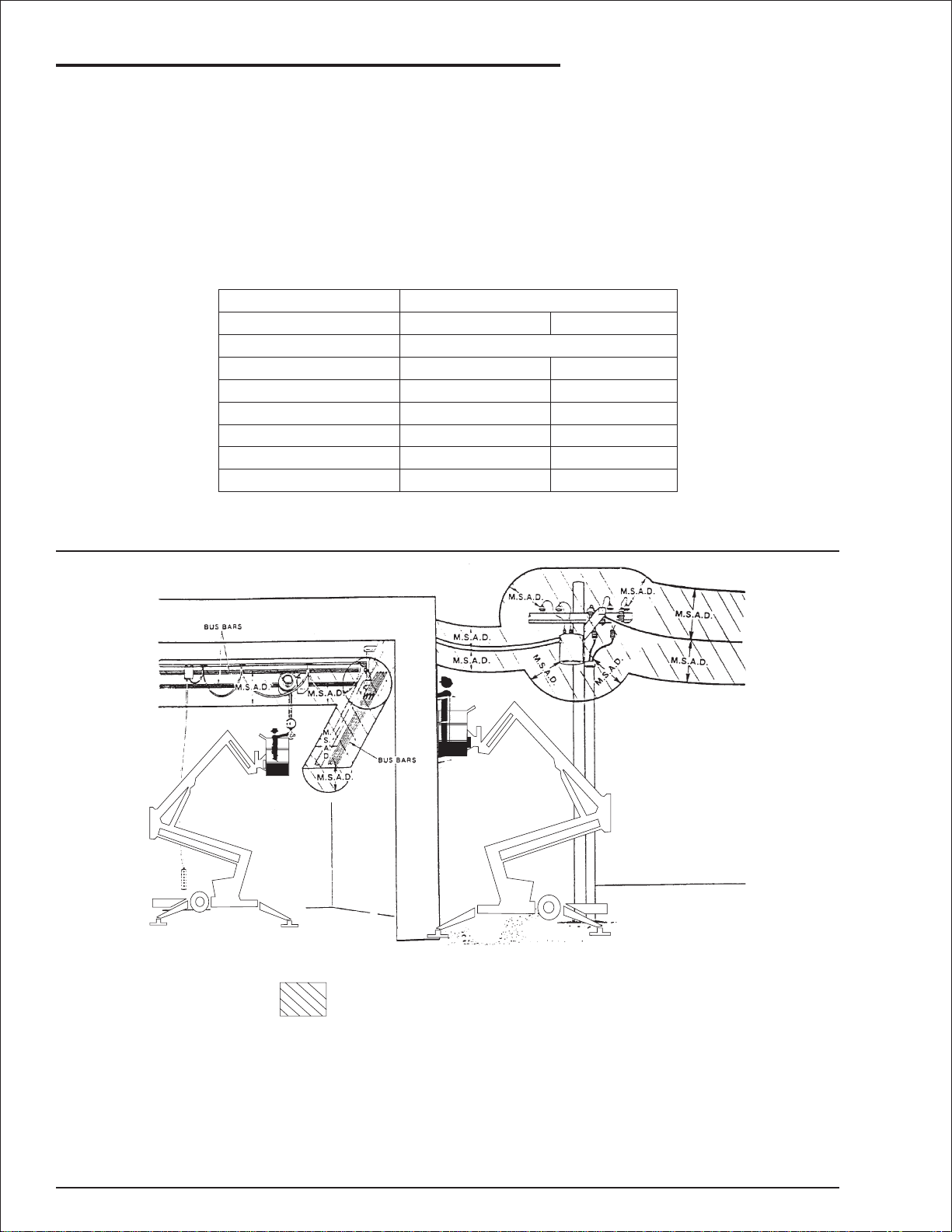

Minimum Safe Approach Distance

TheSnorkeliftis anallmetal boom,NOTELECTRICALLY INSULATED, aerialworkplatform.DO NOTop

erateit nearELECTRICAL conductors.Regard all conductors as beingenergized.Usethe tableand illus

trationbelowtodetermine safeclearance from electricalconductors.(Table1andFigure 3, below,arefrom

ANSI/SIA A92.5–1992 Standard, reprinted with permission of Scaffold Industry Association.)

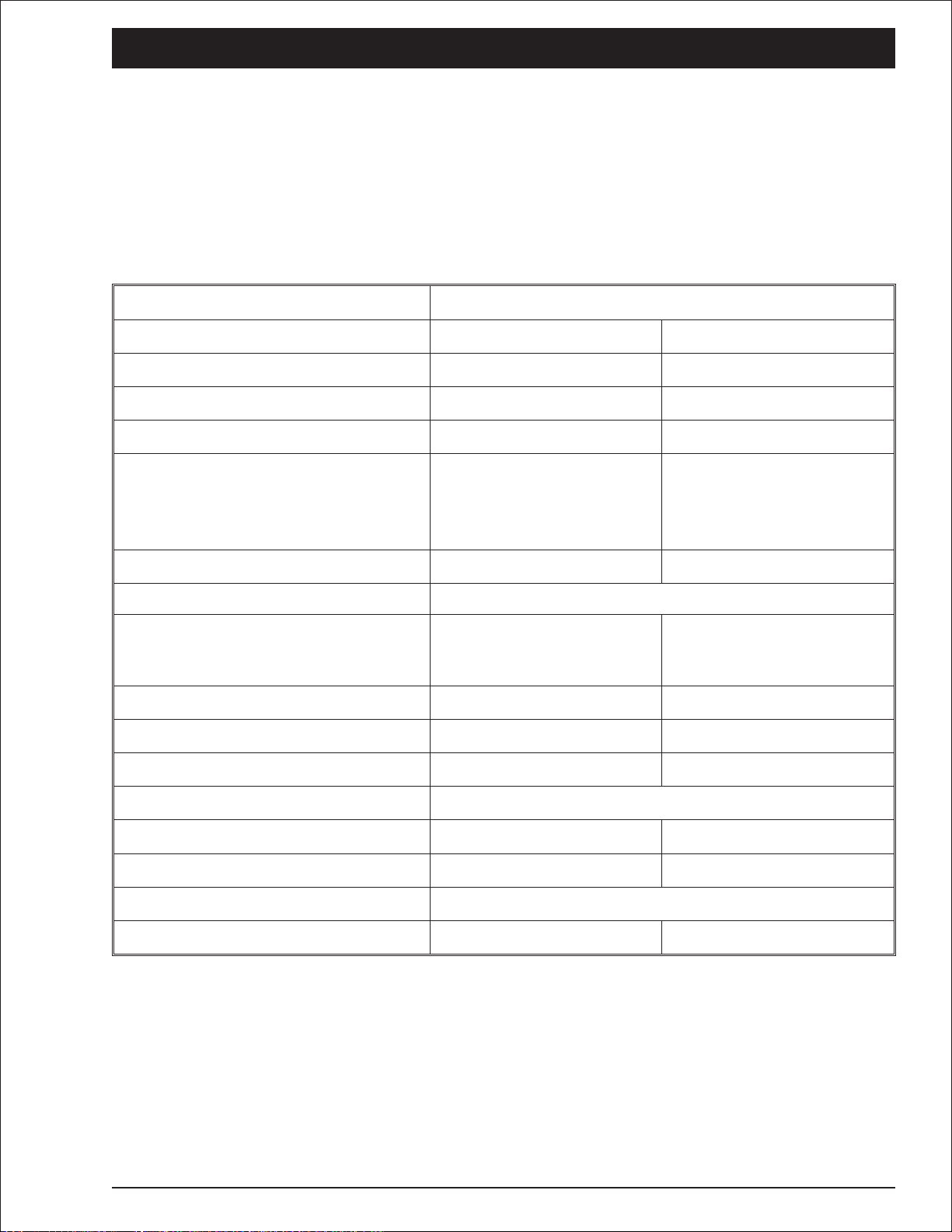

Table 1 - (M.S.A.D.)

❑

Minimum Safe Approach Distance

to energized (exposed or insulated power lines)

Voltage range Minimum safe approach distance

(phase to phase)

0 to 300V

over 300v to 50kv

over 50kv to 200kv

over 200kv to 350kv

over 350kv to 500kv

over 500kv to 750kv

over 750kv to 1000kv

(Feet) (Meters)

Avoid contact

10

15

20

25

35

45

3.05

4.60

6.10

7.62

10.67

13.72

-

-

Figure 3 - (M.S.A.D.)

❑

Denotes prohibited zone

Danger:

Caution:

page - ii MHP12/34J – 11447A

- Do not allow machine personnel or conductive

materials inside prohibited zone.

- Maintain M.S.A.D. From all energised lines and parts

as well as those shown.

- Assume all electrical parts and wires are energised

unless known otherwise.

- Diagrams shown are only for purposes of illustrating

M.S.A.D. Work

ositions, not all workpositions.

Page 5

Introduction

The most important chapter in this manual is

"Safety" chapter 1. Take time, now, to study it

closely. The information in chapter 1, might save

your life or prevent serious injury.

■

Signs

The following three conventionsare used through

out this manual.

1. Danger sign

DANGER

means:Attention! Become alert! Yoursafety

is involved.

2. Caution sign

CAUTION

meansone oftwothings:(1) an action,about

to be performed, is potentially hazardous

and might result in minor personal injury if

not done correctly,or (2) an action, about to

be performed, can harm the Snorkelift if not

done correctly.

3. Note sign

NOTE

means: The information following is to assist you

in either the proper steps to take for an action or

as additional information concerning your present

situation, but does not indicate a dangerous

condition to either you or the Snorkelift unit.

■

Qualified operators

TheSnorkeliftaer ial platformhasbuiltin safetyfea

tures and has been factory tested for compliance

withSnor kel specificationsand industry standards.

However,anypersonnelliftingdevicecanbepoten

tially dangerous in the hands of untrained or care

less operators.

Training is vitally important andMUST be done un

derthe direction ofa QUALIFIEDperson.You must

displayproficiency in knowledge and actual opera

tion of the Snorkelift.

Before operation of the Snorkelift you must read

and understand the operating instructions in this

manual as well as the decals, warnings, and in

structions on the machine itself.

Before operating the Snorkelift you must be

AUTHORIZED by the person in charge to do so.

■

Operation rules

The following rules will help ensure the safety of

personnelandhelppreventneedlessdowntimebe

cause of damaged equipment.

1. Only TRAINED and AUTHORIZED operators

shall be permitted to operate the equipment.

-

2. All manufacturer’s operating instructions and

safety rules and all employers’ safety rules

and all OSHA and other government safety

rules must be strictly adhered to.

3. Repairs and adjustments shall be made only

by QUALIFIED TRAINED maintenance

personnel.

4. No modification shall be made to the

equipment without prior wr itten consent of

the Snorkel Engineering Department.

5. You must make a pre-start inspection of the

Snorkelift at the beginning of each shift. A

malfunctioning machine must not be used.

6. You must make an inspection of the work

place to locate possible hazards before

operating the Snorkelift.

DANGER

DO NOT operate this equipment unless you

are TRAINED and AUTHORIZED and have

read and thoroughly understand all of the

information given in this Operator’s Manual

and on all DANGER and CAUTION signs on

the machine. Misuse of this machine can

result in DEATH or SERIOUS INJURY.

■

-

-

-

-

-

-

Maintenance

Every personwho maintains, inspects,tests, or re

pairs these machines, and every person supervis

ing any of these functions, MUST be properly

trained.

This Operator’s Manualprovides a dailyinspection

procedure that will help youkeep your Snorkelift in

good operating condition. DO NOT perform other

maintenance unless you are a TRAINED me

chanic, QUALIFIED to work on the Snorkelift. Call

QUALIFIED maintenance personnel if you find

problems or malfunctions.

DO NOT modify this machine without written ap

proval from the Engineering Department of Snor

kel.

Informationcontainedin thismanualconcerns only

current Snorkelift's, and the right is reserved to

make changes at any time without obligation.

-

-

-

-

-

-

MHP12/34J – 11447A page - iii

Page 6

Introduction

■

Responsibilities of parties

It is imperative that all owners and users of the

Snorkelift read, understand, and conform to all ap

plicableregulations.Ultimate compliance to OSHA

regulations is the responsibility of the employerus

ing the equipment.

DANGER

ANSI Standard A92.2-1992 clearly identifies

requirements of all parties who might be

involved with Boom-Supported Elevating

Work Platforms.

AUSTRALIAN / NZ STANDARD 2550-10

1994 Also identifies the requirements of all

parties who might be involved with

Boom-Supported Elevating Work

Platforms.

A reprint of the “Manual of Responsibilities for

Dealers, Owners, Users, Operators, Lessors and

Lessees of ANSI/SIA A92.5-1992 Boom Sup

ported Elevating Work Platforms” is available from

Snorkel dealers or from the factory upon request.

■

Additional information

For additional information, contact your local

dealer.

-

Snorkel

2/26 Redfern Street

Wetherill Park NSW 2164

Australia

Snorkel

PO Box 1041

Levin 5500

New Zealand

-

CopiesarealsoavailablefromtheScaffoldIndustry

Association, Inc., 14039 Sherman Way, VanNuys,

CA 91405-2599.

■

Options

The use of optional equipment is discussed in the

“Options” chapter 11.

The options you will find discussed there are:

1. Bi-Energy

2. Self Levelling Stabiliser

3. Air line to platform

4. Dual fuel

5. Work lights.

6. Sandblast protection kit.

7. RCD/ELCB AC outlet.

8. Flashing light.

9. Platform rotator.

page - iv MHP12/34J – 11447A

Page 7

Table of Contents

Electrical Hazard

Electrical Hazard Warning . . . . . . . . . . . . . . . . . . i

Minimum Safe Approach Distance . . . . . . . . . . . ii

Table 1 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . . ii

Figure 3 - (M.S.A.D.). . . . . . . . . . . . . . . . . . . . . ii

Introduction

Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Qualified operators. . . . . . . . . . . . . . . . . . . . . . . iii

Operation rules. . . . . . . . . . . . . . . . . . . . . . . . . . iii

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Responsibilities of parties . . . . . . . . . . . . . . . . . iv

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Additional information. . . . . . . . . . . . . . . . . . . . . iv

1. Safety

Safe Operation. . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pre-start Inspection. . . . . . . . . . . . . . . . . . . . 1-1

Work Place Inspection and Practices . . . . . . 1-1

Electrocution . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tipover and Falling Hazards . . . . . . . . . . . . . 1-1

Crushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General Safety Precautions. . . . . . . . . . . . . . . 1-2

Personnel Precautions . . . . . . . . . . . . . . . . . 1-2

Operator General Precautions . . . . . . . . . . . 1-2

Mounting and Dismounting Precautions . . . . 1-2

Starting and Stopping Precautions . . . . . . . . 1-2

Operating Precautions . . . . . . . . . . . . . . . . . 1-2

Operator Maintenance Precautions . . . . . . . 1-3

Fuel Handling Precautions . . . . . . . . . . . . . . 1-3

Safety Decals and Placards . . . . . . . . . . . . . . 1-3

Safety Placards and Decals Location . . . . . . . 1-4

2. Safety Devices

Safety Device Information . . . . . . . . . . . . . . . . 2-1

Emergency Stop Switches. . . . . . . . . . . . . . . . 2-1

At ground control box . . . . . . . . . . . . . . . . . . 2-1

At platform control box . . . . . . . . . . . . . . . . . 2-1

Other Safety Devices. . . . . . . . . . . . . . . . . . . . 2-1

Lanyard anchor points. . . . . . . . . . . . . . . . . . 2-1

Gravity gate. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Foot switch . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Bubble level. . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

RCD/ELCB AC outlet . . . . . . . . . . . . . . . . . . 2-3

Flashing light. . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3. Specifications

General Specifications. . . . . . . . . . . . . . . . . . . 3-1

Engine Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Overall Dimensions - MPH12/34J . . . . . . . . . . 3-3

Working Envelope - MHP12/34J . . . . . . . . . . . 3-4

Booms identification . . . . . . . . . . . . . . . . . . . 3-5

Nomenclature And Serial Numbers. . . . . . . . . 3-5

Right side view of machine . . . . . . . . . . . . . . 3-5

Left side view of machine . . . . . . . . . . . . . . . 3-6

Serial number location, chassis . . . . . . . . . . 3-6

4. Gauges

Hourmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Level Bubble . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Hydraulic Oil Level. . . . . . . . . . . . . . . . . . . . . . 4-1

5. Automatic Shut-offs and Circuit Breakers

RCD/ELCB Outlet (option). . . . . . . . . . . . . . . . 5-1

Main Circuit Breaker . . . . . . . . . . . . . . . . . . . . 5-1

Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6. Controls

Controls Description . . . . . . . . . . . . . . . . . . . . 6-1

Controls and Control Decals Locations. . . . . 6-1

Ground Control Box. . . . . . . . . . . . . . . . . . . . . 6-2

Ground Control Box Controls . . . . . . . . . . . . 6-3

Platform Control Box . . . . . . . . . . . . . . . . . . . . 6-4

Platform Control Box Controls. . . . . . . . . . . . 6-5

7. Daily Inspection and Maintenance

Daily Inspection and Maintenance Table. . . . . 7-1

Engine Fuel Level . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel Tank Cap . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Engine Oil Level. . . . . . . . . . . . . . . . . . . . . . . . 7-2

Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . 7-2

Battery Terminals. . . . . . . . . . . . . . . . . . . . . . . 7-3

Battery Fluid Level. . . . . . . . . . . . . . . . . . . . . . 7-3

Hydraulic Oil Level. . . . . . . . . . . . . . . . . . . . . . 7-3

Hydraulic Oil Leaks . . . . . . . . . . . . . . . . . . . . . 7-3

Bolts and Fasteners. . . . . . . . . . . . . . . . . . . . . 7-4

Wheels and Tyres . . . . . . . . . . . . . . . . . . . . . . 7-4

Structural Damage and Welds. . . . . . . . . . . . . 7-4

Lanyard Anchor Points . . . . . . . . . . . . . . . . . . 7-5

Platform Gravity Gate . . . . . . . . . . . . . . . . . . . 7-5

Platform Guardrails . . . . . . . . . . . . . . . . . . . . . 7-5

Flashing Light (option). . . . . . . . . . . . . . . . . . . 7-5

Ground Control Switches. . . . . . . . . . . . . . . . . 7-6

Emergency Lower . . . . . . . . . . . . . . . . . . . . . . 7-6

Lower control box . . . . . . . . . . . . . . . . . . . . . 7-6

Upper control box . . . . . . . . . . . . . . . . . . . . . 7-6

Platform Control Switches . . . . . . . . . . . . . . . 7-6

AC Outlet RCD/ELCB (option). . . . . . . . . . . . . 7-7

Placards and Decals . . . . . . . . . . . . . . . . . . . . 7-7

Standard placards and decals. . . . . . . . . . . . 7-7

Inspection drawing . . . . . . . . . . . . . . . . . . . . 7-8

8. Operation

Operating Procedures . . . . . . . . . . . . . . . . . . . 8-1

MHP12/34J – 11447A page - v

Page 8

Table of Contents

Control Stations. . . . . . . . . . . . . . . . . . . . . . . . 8-1

Emergency Stopping . . . . . . . . . . . . . . . . . . . . 8-1

Operation Considerations . . . . . . . . . . . . . . . . 8-2

Starting From Ground Control Box . . . . . . . . . 8-2

Stabilizer Operation. . . . . . . . . . . . . . . . . . . . . 8-2

Starting From Platform Control Box. . . . . . . . . 8-3

Moving The Platform . . . . . . . . . . . . . . . . . . . . 8-4

From Ground Control Box. . . . . . . . . . . . . . . 8-4

From Platform Control Box . . . . . . . . . . . . . . 8-5

Securing for Day . . . . . . . . . . . . . . . . . . . . . . . 8-5

9. Emergency Operation

Emergency Operation Procedures . . . . . . . . . 9-1

Operation From Platform Control Box. . . . . . 9-1

Operation From Ground Control Box . . . . . . 9-2

10. Stowing and Transporting

Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

The correct stowed position is shown here. 10-1

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Trailering . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Upper boom lock pin . . . . . . . . . . . . . . . . . . 10-1

Lower boom lock pin . . . . . . . . . . . . . . . . . . 10-1

Securing to a Transport Vehicle . . . . . . . . . 10-2

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Forklift points. . . . . . . . . . . . . . . . . . . . . . . . 10-2

11. Options

Bi-Energy. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

DC motor operation. . . . . . . . . . . . . . . . . . . 11-1

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Battery charger . . . . . . . . . . . . . . . . . . . . . . 11-1

Self Levelling Stabiliser . . . . . . . . . . . . . . . . . 11-2

Self levelling stabiliser operation. . . . . . . . . 11-2

Air Line To Platform . . . . . . . . . . . . . . . . . . . . 11-2

Dual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Work Lights . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . 11-2

RCD/ELCB AC Outlet . . . . . . . . . . . . . . . . . . 11-2

Sandblast Protection Kit . . . . . . . . . . . . . . . . 11-2

Platform Rotator . . . . . . . . . . . . . . . . . . . . . . 11-3

12. Fire Fighting and Chemical Containment

Hazardous Components . . . . . . . . . . . . . . . . 12-1

Battery, Lead/Acid (UN 2794) . . . . . . . . . . . 12-1

Gasoline (UN 1203) . . . . . . . . . . . . . . . . . . 12-2

Hydraulic Oil (UN 1270) . . . . . . . . . . . . . . . 12-3

Motor Oil (UN 1270) . . . . . . . . . . . . . . . . . . 12-4

13. Operator's Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 13-1

Operator Troubleshooting Chart . . . . . . . . . 13-1

page - vi MHP12/34J – 11447A

Page 9

■

Safe Operation

The followingsafety information is vitally important

for safeoperation of the MHP12/34J.Failure to fol

low these instructions can result in personal injury

or DEATH.

Pre-start Inspection

❑

Atthe start ofeachwork shift,the MHP12/34Jshall

be given a visual inspection and function test. See

the “Daily Inspection and Maintenance” chapter 7,

inthismanualfora list ofitems to inspectand test.

1. Safety

When moving the platform, check the clearance

around theMHP12/34J to avoidcontact with struc

tures or other hazards.Alwayslook in the direction

of motion.

Keep ground personnel from under the platform

when the platform is raised.

Secureallaccessories,containers,tools,and other

materials inthe platformto preventthem from acci

dentally falling or being kicked off the platform.

DONOTengage inanyformof“horseplay”or“stunt

driving” while operating the MHP12/34J.

-

-

CAUTION

DO NOT operate the MHP12/34J unless you

are trained and authorized, understand the

operation characteristics of the MHP12/34J,

and have inspected and tested all functions

to be sure they are in proper working order.

Work Place Inspection and Practices

❑

Donotuse theMHP12/34Jas a groundforwelding.

Ground to the work piece.

Before the MHP12/34J is used, and during use,

check the area in which the MHP12/34J is to be

used for possible hazards such as, but not limited

to:

1. Drop-offs or holes.

2. Side slopes.

3. Bumps and floor obstructions.

4. Debris.

5. Overhead obstructions and electrical

conductors.

6. Hazardous locations.

7. Inadequate surface and support to withstand

all load forces imposed by the aerial platform

in all operating configurations.

8. Wind and weather conditions.

9. Presence of unauthorized persons.

10. Other possible unsafe conditions.

Before the MHP12/34J is used, determine the haz

ardclassification of anyparticular atmosphere or lo

cation according to ANSI/NFPA 505-1987.

Any MHP12/34J operated in a hazardous location

must be approved and of the type required by

ANSI/NFPA 505-1987.

A recommended safety practice is to have

personnel that are trained in the operation of the

emergency controls working in theimmediate area

ofthe MHP12/34J to assist theplatform operatorin

the event of an emergency.

DO NOT permit riders on the machine anyplace

other than on the platform.

Remove all loose objects stored in or on the ma

chine, particularly in the platform. Remove all ob

jects which do not belong in or on the machine.

When other moving equipment is in the area, take

special precautions to comply with local regula

tions regarding warnings.

Never steady the platform by positioning it against

another platform.

DO NOT operate an MHP12/34J that is not functioning properly, or has been damaged, until the

machine has been repaired by a qualified maintenance person.

DO NOToperate a MHP12/34J that does not have

all its decals and placards attached and legible.

Watchforbystandersand neverallow anyonetobe

under, or to reach through, the machine and its

equipment while operating.

Use the recommended transport device when

loading the machine.

❑

Electrocution

The MHP12/34J is an all metal boom,

NON-INSULATED, aerial work platform.

DO NOT operateit nearELECTRICAL conductors.

Regard all conductors as being energized.

DO NOT operate outside during a thunderstorm.

-

-

❑

Tipover and Falling Hazards

DONOToperatetheMHP12/34Jfroma position on

trucks, trailers, railway cars, floating vessels, scaf

folds,orsimilar equipmentunless theapplication is

approved in writing by Snorkel.

If the platform or elevating assembly becomes

caught, snagged, or otherwise prevented from

normal motion by an adjacent structure or other

obstacles such that control reversal does not free

the platform, remove all personnel from the

-

-

-

-

MHP12/34J – 11447A page 1 - 1

Page 10

1. Safety

platform before attempts are made to free the

platform using ground controls.

Under normal working conditions it is best not to

transfer from the platform to another structure or

vice versa, unless that is the safest way to do the

job.Each situation must be judged separately tak

ing the work environment into account.The follow

ing guidelines apply:

1. Where possible, place the work platform over

a roof or walking structure to do the transfer.

2. Transfer your anchorage from one structure

to another before you step across.

3. Remember, you might be departing the work

platform to a structure where fall arrest is

required.

4.

DO NOT climb the rails. Use the entrance.

All platform occupants MUST wear and use fallre

straint.Attach fall restraints to the platform lanyard

anchor points.

DO NOT exceedthe unrestricted platformcapacity

asindicatedonthecapacity placard attheentrance

to the platform.

ENSURE all four stabilizer foot plates are in firm

contact with the ground as laid out on page 1-1

“Work Place Inspection and Practices”. DO NOT

raise the boom if the MHP12/34J is on soft ground.

Operatethe boom onlyon afirm surfacecapableof

withstanding all load forces imposed by the aer ial

work platform in all operating conditions.

Do Not carry loads from any point outside of the

platform.

Care shall be taken to prevent rope, electric cords,

and hoses, etc., from becoming entangled in the

aerial platform.

Raise the platform only whenthe MHP12/34J ison

level ground.

Maintain a fir m footing on the platform floor.

Climbing on the guardrails is prohibited.

DO NOT use ladders, planks, or other devices to

extendorincrease yourworkpositionfrom theplat

form.

DO NOT jerkthe controls.Movethecontrols slowly

and deliberately to avoid jerky and erratic opera

tion.Alwaysstop thecontrols in theneutral, off,po

sition before going in the opposite direction.

DO NOT use the boom for any purpose other than

to position personnel, their tools, and materials.

DO NOT use the MHP12/34J as a crane, hoist, or

jack.

DO NOToperate the MHP12/34J in winds,or wind

gusts, of 28 mph 12.5 m/s) or more.

DO NOT add anything to the MHP12/34J that will

increase the wind loading (banners, flags, etc.).

-

-

-

-

-

-

Crushing

❑

Always look in the direction of travel. Avoid over

head obstructions.

Nevercover the floor grating or otherwise obstruct

your view below.

Make sure the area below the platform is free of

personnel before lowering.

■

General Safety Precautions

Personnel Precautions

❑

If you encounter any suspected malfunction of the

aerial platform, or any hazard or potentially unsafe

condition relatingto capacity, intendeduse, or safe

operation, cease operation and seek assistance

from management.

Operator General Precautions

❑

Makesure that all protectiveguards, cowlings,and

doors are in place and secure.

Be sure the guardrail system, including the gate, is

in place and secure.

❑

Mounting and Dismounting Precautions

Use three points of support when getting on or off

theplatform(twohandsand one footor a similarset

of points). Keep the platform clean.

DO NOT jump off the machine.

DO NOT dismount while the boom is in motion.

❑

Starting and Stopping Precautions

DO NOT start until all personnel are clearly away

from the machine.

Beforeleavingthe operator’s station,place thema

chine in the stowed position.

When leaving the machine parked or unattended,

remove the starter key from the Master Key

Switch.

❑

Operating Precautions

DO NOT modify the MHP12/34J in any way.

Whenpar ts orcomponentsare replaced,theyshall

be identical or equivalent to original Snorkel parts

or components.

-

-

page 1 - 2 MHP12/34J – 11447A

Page 11

1. Safety

DO NOT override any of the safety features of the

MHP12/34J.

Operator Maintenance Precautions

❑

CAUTION

DO NOT use your hand to search for

hydraulic oil leaks. High pressure hydraulic

oilcaneasilycut and penetrate yourskin —a

very serious injury that requires immediate

attention by a medical specialist trained in

that type of injury. Use a piece of cardboard

or wood to search for hydraulic oil leaks.

DO NOT attempt repairs unless you are

trained. Refer to manuals and experienced

repair personnel for help.

Fuel Handling Precautions

❑

DONOTsmokeor permitopenflames while fueling

or near fueling operations.

Neverremove the fuel cap or refuel a gasoline engine while the engine isrunning or hot.Neverallow

fuel to spill on hot machine components.

part. See your Snorkel dealer for new decals

and placards.

NOTE

Refer to Placards and Decals Inspection Chart

and Drawing in the “Daily Inspection and

Maintenance” chapter 7, for part numbers,

location, and required quantities of all placards

and decals.

Maintain control of the fuel filler nozzle when filling

the tank.

DO NOT fillthe fuel tankto capacity.Allowroom for

expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely.If the fuel cap is

lost, replace it with an approved cap from Snorkel.

Use of a non-approved cap without proper venting

may result in pressurization of the tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

■

Safety Decals and Placards

There are several safety decals and placards on

the MHP12/34J. Their locations and descriptions

areshowninthissection.Taketime to studythem.

CAUTION

Be sure that all the safety decals and

placards on the MHP12/34J are legible.

Clean or replace them if you cannot read the

wordsor see the pictures.Clean with soap &

water and a soft cloth. Do not use solvents.

You MUST replace a decal or placard if it is

damaged, missing, or cannot be read. If it is

on a part that is replaced, make sure a new

decal or placard is installed on the replaced

MHP12/34J – 11447A page 1 - 3

Page 12

1. Safety

■

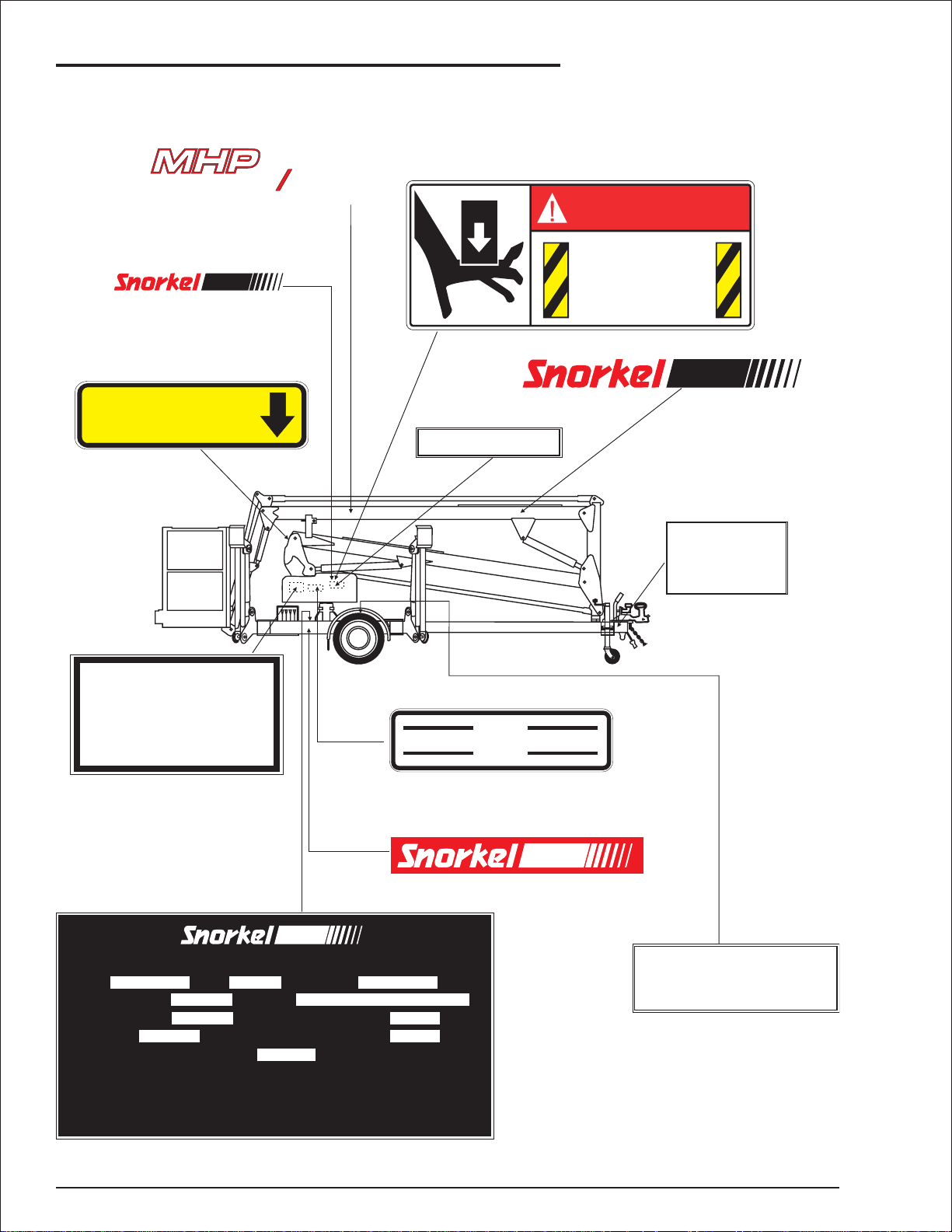

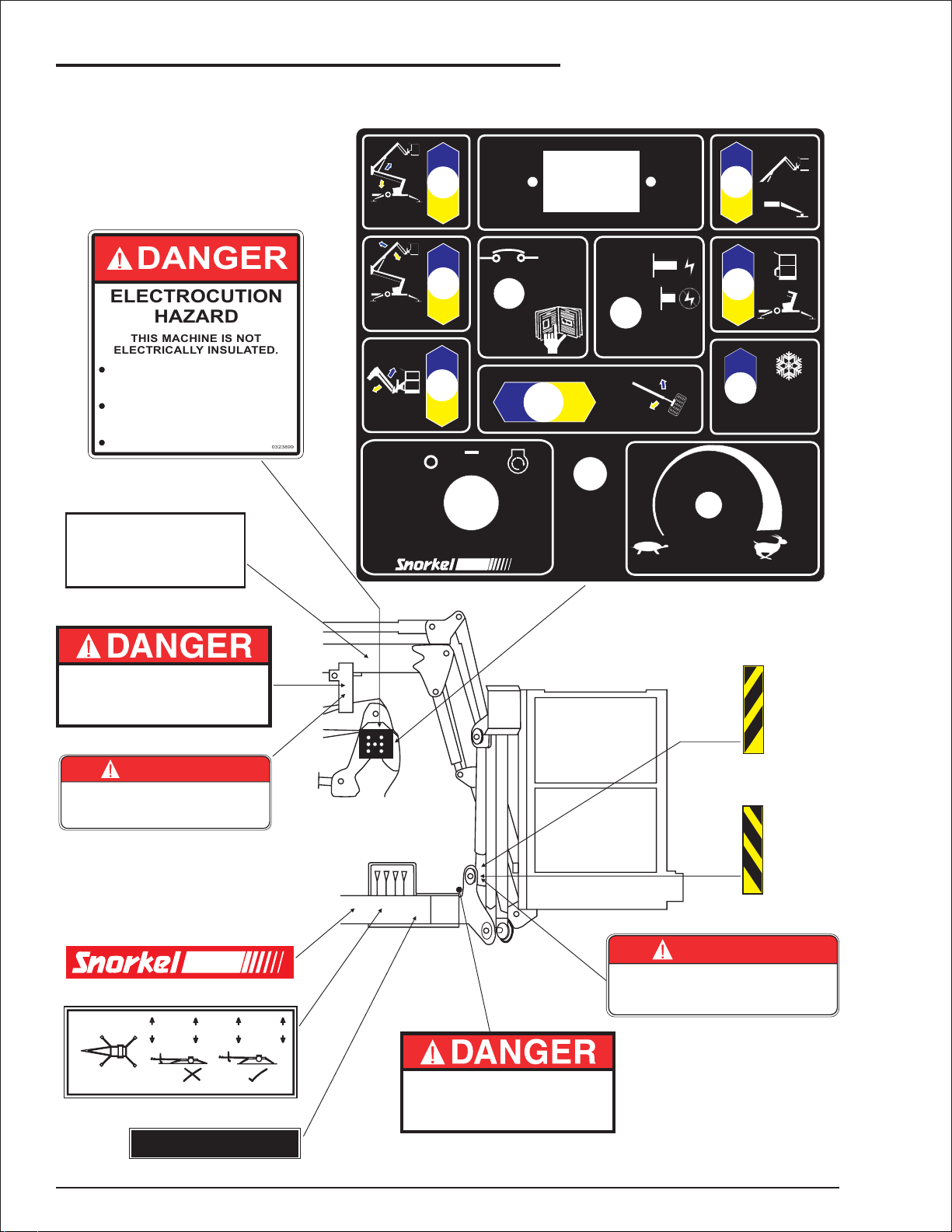

Safety Placards and Decals Location

1

234J

10817-4

11227-34

DANGER

PINCH POINT

Keep hands

clear.

302559

EMERGENCY BLEED

DOWN VALVE

0070420

FLUID

HYDRAULIC

CHECK FLUID LEVEL WITH PLATFORM LOWERED

USE PREMIUM HYDRAULIC OIL

GRADE 10W40

VISCOSITY AT 100 F (38 C)

320 SUS (SAYBOLT)

POUR POINT: -35 F (-37 C)

DO NOT OVERFILL

LEVEL

OO

OO

45177-6

HYDRAULIC OIL

FULL

ADD

560239

9207

kmh

SPEED

MAXIMUM

7855

TOWING

80

302950

10812-2

THIS TRAILOR WAS MANUFACTURED TO COMPLY WITH THE INDICATED DESIGN CODES

MODEL

MHP

DATE OF MANUFACTURE

GROSS TRAILER MASS

TYRE SIZE

RECOMMENDED COLD INFLATION PRESSURE

THE TYRES FITTED TO THIS VEHICLE SHALL HAVE A SPEED CATEGORY NOT LESS THAN “L” (120 KWH)

THE SUM OF THE LOAD CARRYING CAPACITIES OF THE TYRES FITTED TO ANY AXLE OR AXLE GROUP OF THIS

VEHICLE SHALL NOT BE LESS THAN THE RELEVANT LOAD SHOWN ABOVE

36 BRUCE RD LEVIN NEW ZEALAND

165 SR 13

S.W.L.

SERIAL NUMBER

VIN NUMBER

AXLE LOAD CAPACITY

310 KPA

RIM SIZE

1250 KG

5X13

DESIGN CODES EN 280

AS 141B.10

TYRE

45

9999

PRESSURE

p.s.i.

310

kPa

COLD

7856-45

page 1 - 4 MHP12/34J – 11447A

Page 13

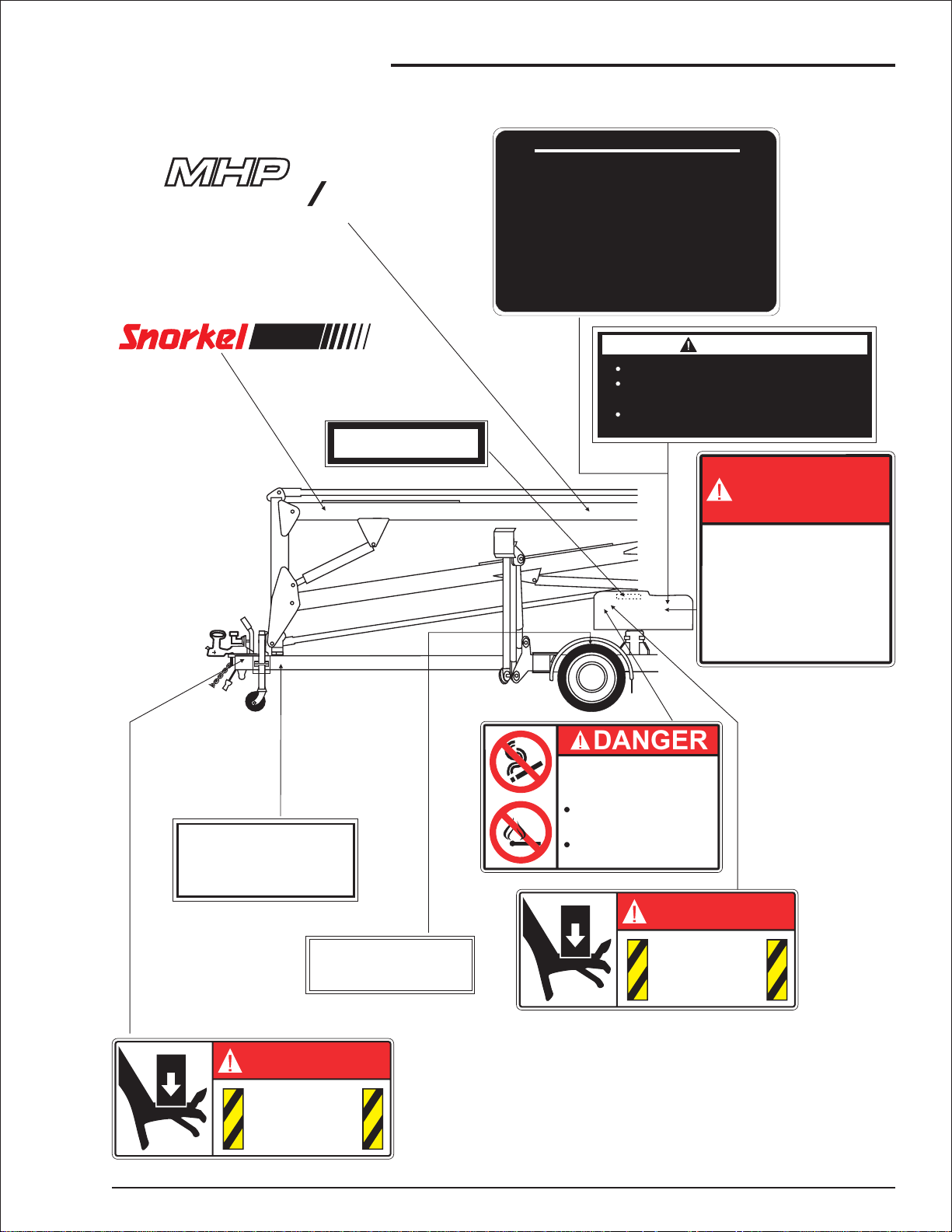

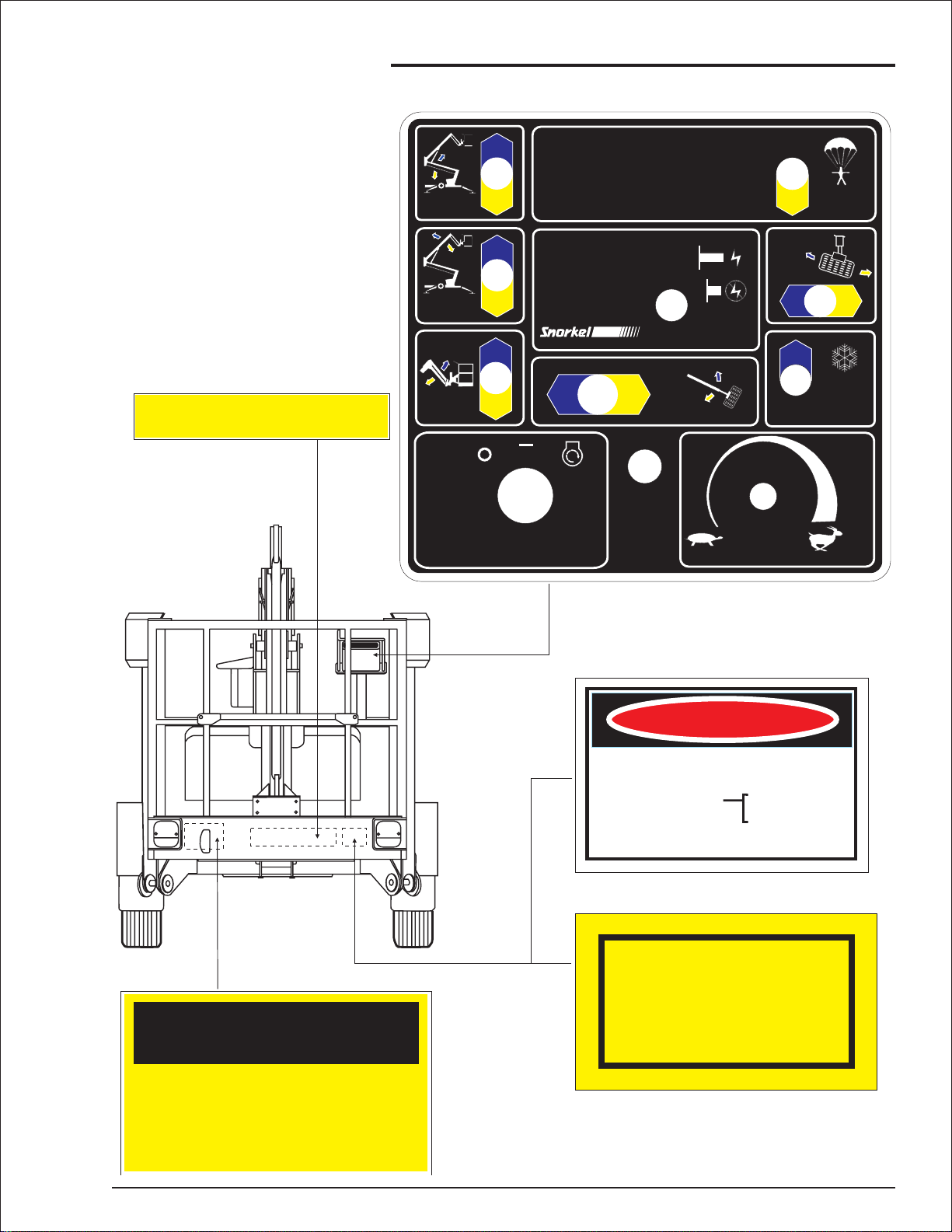

1

234J

11227-34

OPERATORS CHECKLIST

INSPECT AND/OR TEST THE FOLLOWING DAILY

OR AT THE BEGINNING OF EACH SHIFT

1. OPERATING AND EMERGENCY CONTROLS.

2. SAFETY DEVICES.

3. PERSONAL PROTECTIVE DEVICES.

4. HOSES, FITTINGS AND VALVES FOR LEAKS.

5. CABLES AND WIRING HARNESS.

6. LOOSE OR MISSING PARTS.

7. TYRES AND WHEELS.

8. PLACARDS, WARNINGS, CONTROL MARKINGS

AND OPERATING MANUAL(S).

9. GUARDRAIL SYSTEM.

10.OIL LEVELS.

11.BATTERY FLUID LEVEL.

300699

1. Safety

560239

FIT BOOM CRADLE LOCK PIN

FOR TRAVELLING.

1772-002K

GASOLINE

0071925

Death or serious injury could occur from tipover.

All outriggers must be extended onto firm level surface

before elevating or before entering platform.

Do not exceed platform capacity.

DANGER

EXPLOSIVE FUMES

Death or serious injury might result

from fire or explosion.

Do not smoke or permit open

flames while fueling or near

fueling operations.

Clean up spilled fuel

immediately.

WARNING

0130025

DANGER

YOU MUST NOT OPERATE THIS DEVICE UNLESS:

1.

YOU HAVEBEEN TRAINED IN THE SAFEOPERATION OF THIS

DEVICE AND HHHH

2.

YOU KNOW AND FOLLOW THE SAFETY AND OPERATING

RECOMMENDATIONSCONTAINED IN THE MANUFACTURER'S

MANUALS, YOUR EMPLOYER'S WORK RULES, AND APPLICABLE GOVERNMENTAL REGULATIONS. HHHHHHHH

AN UNTRAINED OPERATOR SUBJECTSHIMSELF AND OTHERS TO

476706

DEATH OR SERIOUS INJURY.

0323897

DANGER

TYRE

45

p.s.i.

PRESSURE

310

kPa

COLD

7856-45

302559

PINCH POINT

Keep hands

clear.

DANGER

PINCH POINT

Keep hands

302559

MHP12/34J – 11447A page 1 - 5

clear.

Page 14

1. Safety

DANGER

LOWER

BOOM

BOOMS

STABILISER

PLATFORM

ELECTROCUTION

HAZARD

THIS MACHINE IS NOT

ELECTRICALLY INSULATED.

Death or serious injury can result from

contact or inadequate clearance to

electrical power lines and apparatus.

Maintain 10 feet minimum clearance

from electrical power lines and

apparatus.

Allow for sway, rock, and sag.

FIT BOOM CRADLE LOCK PIN

FOR TRAVELLING.

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

1772-002K

0150602

0323899

UPPER

BOOM

JIB

BOOM

LIFT

ENABLE

11420

SLEW

SPEED CONTROL

ALL FOUR

STABLIZERS

BASE

CHOKE

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

ALL FOUR

STABLIZERS

DANGER

10817-2

2

4

1

3

2

1

4

3

10968-1

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

V.I.N.

8945

page 1 - 6 MHP12/34J – 11447A

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

ALL FOUR

STABLIZERS

0150602

451986

Page 15

LOWER

BOOM

UPPER

BOOM

EMERGENCY LOWER

TO LOWER PLATFORM, OPERATE EMERGENCY

1.

LOWER SWITCH.

TO SLEW BOOM, OPERATE ‘EMERGENCY

2.

LOWER’ & ‘SLEW’ SWITCHES TOGETHER.

1. Safety

EMERGENCY

ROTATE

PLATFORM

LOWER

SWL

200

KG

2025-200

JIB

BOOM

SLEW

LIFT

ENABLE

11420 - 1

SPEED CONTROL

DANGER

BEWARE OF ELECTRICAL HAZARDS

(a) Minimum approach of an appliance

to live electrical apparatus.

(b) Inspection of the work site for

electrical hazards before

commencing to use the appliance.

(c) Constant vigilance and an observer required

whilst working or travelling the appliance

in the vicinity of live electrical apparatus.

REGULATION 133A OF THE

CONSTRUCTION SAFETY ACT 1912 REQUIRES

3m. for voltages up to 132,000

6m. for voltages above 132,000

and up to 330,000

8m. for voltages above 330,000

CHOKE

(Australia Only)

WARNING

KEEP LINESCLEAR POWEROF

CAUTION

Unless the Electrical Supply Authority has advised

the clearance between any live overhead

power line and any part of this machine or

in writing otherwise;

load carried is required to beby law

AT LEAST 4 METRES

This is a requirement of regulation 93 of the

Electrical Supply Regulations 1984

in the interests of safe working.

SAFETY BELTS WITH

SHOULDER STRAPS OR

(New Zealand Only)

SAFETY HARNESS ARE

TO BE USED

MHP12/34J – 11447A page 1 - 7

9928

Page 16

1. Safety

page 1 - 8 MHP12/34J – 11447A

Page 17

2. Safety Devices

■

Safety Device Information

Foremergencyoperation controls andprocedures,

see the “Emergency Operation” chapter 9, in this

manual.

The devices listed in this chapter are safety de

vices.

They are on the MHP12/34J to increase safety in

the workplace forboth the operatorand other peo

ple near the MHP12/34J.

CAUTION

DO NOT by pass, disable, modify, or ignore

anyofthesedevices.Checkthem carefully at

the start of each work shift to see that they

are in working order (see “Daily Inspection

and Maintenance”chapter 7). If any is found

to be defective, remove the MHP12/34J from

service immediately until a qualified service

technician can make repairs.

■

Emergency Stop Switches

At platform control box

❑

-

-

Figure 2.2 - Emergency Stop Switch at

Platform Control Box

At ground control box

❑

Figure 2.1 - Emergency Stop Switch at

Ground Control Box

PresstheEMERGENCY STOPswitchcoverdown,

at any time, under any conditions and the entire

machine stops, and nothing moves. This emergency stop switch covermust be up and the switch

turnedonforanythingontheMHP12/34Jtowork.

NOTE:

The ground control box is designed to override

the platform control box. If the platform control

box EMERGENCY STOP switch is down (off) the

ground control box can still be used to start and

operate the MHP12/34J.

■

Other Safety Devices

❑

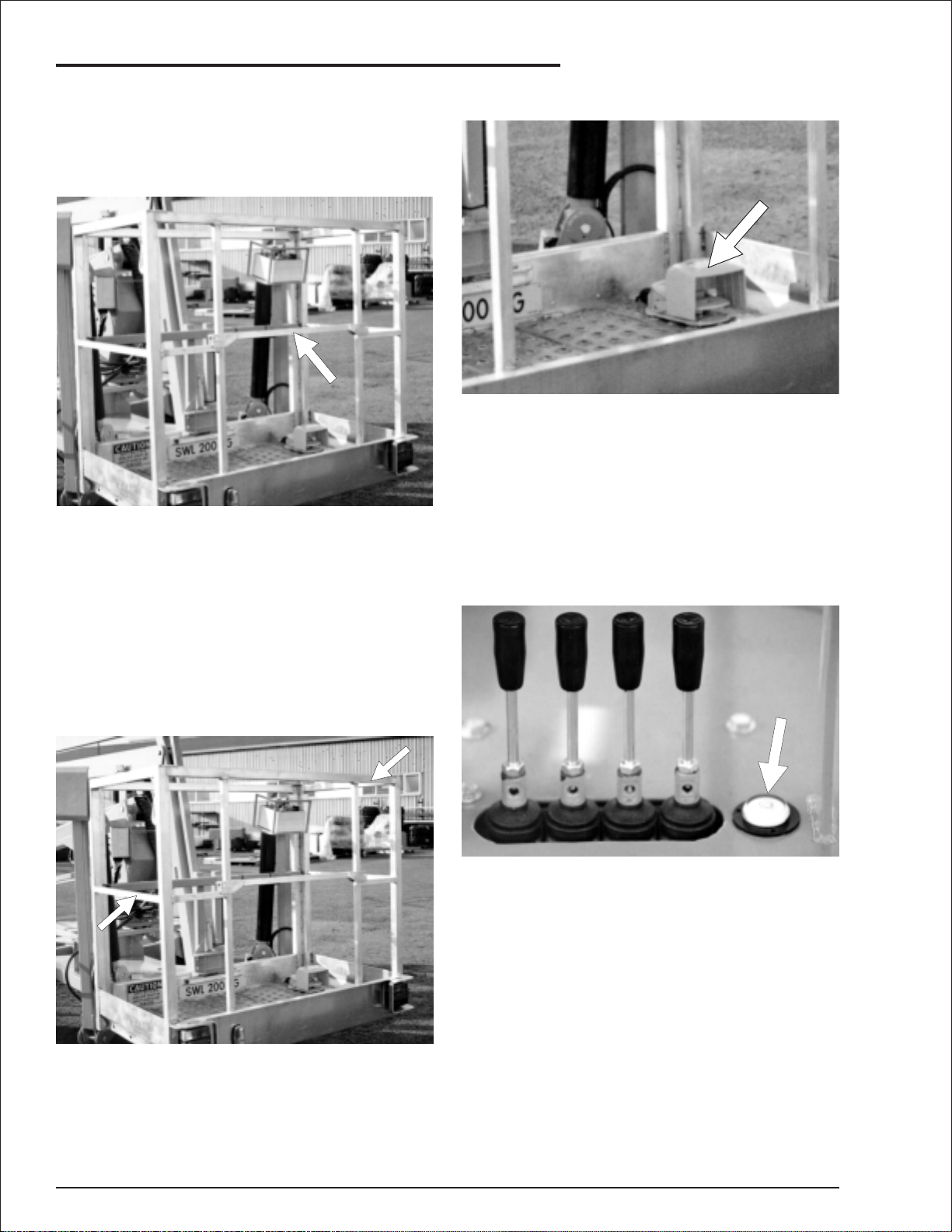

Lanyard anchor points

PresstheEMERGENCY STOPswitchcoverdown,

at any time, under any conditions and the entire

machine stops, and nothing moves. This emer

gency stop switch covermust be up and the switch

turnedonforanythingontheMHP12/34Jtowork.

MHP12/34J – 11447A page 2 - 1

-

Figure 2.3 - Lanyard Anchor Points

Page 18

2. Safety Devices

Allpersonnel on theplatformshould attachtheirfall

restraint lanyards to one of the lanyard anchor

points.

Gravity gate

❑

Figure 2.4 - Gravity Gate

The gravitygate is the place in the platform guardrail system where you should enter and leave the

platform.Raise the gate and step under it onto the

platform. Once you have entered the platform and

attached your fall restraint lanyard to an anchor

point, check to see that the gravity gate has fallen

back into place.

Foot switch

❑

Figure 2.6 - Foot Switch

Thefootswitchpreventstheplatformfrommovingif

something accidentally pushes one of the plat

form-moving controls on the platform control box.

Steppingonthefootswitchisanactionthatmustbe

performed, at the same time as another action, to

make the platform move.

Bubble level

❑

-

❑

Guardrails

Figure 2.5 - Guardrails

The guardrails help protect you from falling off the

platform. Be sure the guardrails are properly in

stalled and that the gravity gateor swinging gate is

in place.

Figure 2.7 - Bubble Level

A bubblelevel is located on the trailer side rail, be

side the outrigger controls. Watch the bubble level

while you set the outriggers. Lower the outriggers,

one at a time, just enough to center the bubble in

the circle on top of the guage. When the bubble is

centered the platform is level and can be safely

raised.

-

-

page 2 - 2 MHP12/34J – 11447A

Page 19

RCD/ELCB AC outlet

❑

RCD

Power Outlet

At Platform

Power Input

Connector

Figure 2.8 - RCD/ELCB AC Outlet

The RCD (Residual Current Device) is located at

the base and will protect against short circuits to

earth. When there is a short circuit the RCD will

shutdownthe230vACpowertotheplatformoutlet.

2. Safety Devices

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the

base.

If the problempersists call atrained service technician.

❑

Flashing light

Figure 2.9 - Flashing Light

The flashing light alerts people that the

MHP12/34J is moving. The light flashes at about

one flash per second any time the MASTER KEY

switch is on. There is no ON/OFF switch for the

flashing light, it cannot be turned off while the

MHP12/34J is running.

MHP12/34J – 11447A page 2 - 3

Page 20

2. Safety Devices

page 2 - 4 MHP12/34J – 11447A

Page 21

3. Specifications

The Snorkelift MHP12/34J is a boom supported elevating wor k platform built to conform to all applicable

OSHA, ANSI or CSA standards as previously outlined.

OSHA Paragraph 1910.67 Title 29, C.F.R.,Vehicle-MountedElevating and Rotating Work Platforms - La

bour.

OSHA Paragraph 1926.556 Title 29, C.F.R., Aerial Lifts - Construction.

Australian Standard AS1418-10 1996 Elevating Work Platforms.

■

General Specifications

SPECIFICATIONS MHP12/34J

Nominal working height

Maximum height to basket floor

Maximum outreach

Maximum outreach height

Maximum width of base

Outriggers retracted

Outriggers extended

Safe working load (unrestricted)

12.4m 40’8”

10.4m 34’1”

5.4m 17’9”

5.65m 18’6”

1.55m

3.50m

200kg 440lbs

5’1”

11’5”

-

Standard colour Orange base/boom grey platform

Platform size

Travelling height

Overall length

Maximum towing speed

Turntable rotation

Trailer tongue weight

Maximum rated axle capacity

Insulation rating

Weight

1200 x 760 x 1100mm

Aluminum

2.04m 6’8”

5.71m 18’8”

80km/h 50m/h

550 degrees non-continuous

75kg 165lbs

1200kg 2645lbs

Nil

1160kg 2609lbs

4’x 2’ 6” x 3’ 7”

Aluminum

MHP12/34J – 11447A page 3 - 1

Page 22

3. Specifications

■

Engine Data

Engine Make Honda (gasoline)

Model GX 160

Engine type 4-stroke, over head valve, 1 cylinder

Displacement 163 cm3(9.9 cu-in)

Bore x Stroke 68 x 45 mm (2.7 x 1.8 in)

Max. output 4 kW/4,000 rpm

Max. torque 1.1 kg-m (8.0 ft-lb)/ 2500 rpm

Fuel gasoline

Fuel Grade automotive gasoline (unleaded or lowleaded preferred)

Fuel consumption 230 g/PSh

Cooling system Forced air

Ignition system Transistor magneto

PTO shaft

rotation

Oil Capacity 0.60 litres (0.60 US qt, 0.53 Imp qt)

Oil Grade SAE 10W-30

Counterclockwise

page 3 - 2 MHP12/34J – 11447A

Page 23

3. Specifications

(

)

(

)

■

Overall Dimensions - MPH12/34J

6’ 8”

20”

525mm

2040mm

(16.5”)

420mm

35mm

(1.3”)

3370mm

5710mm

(18’ 8”)

1550mm

(5’ 1”)

MHP12/34J – 11447A page 3 - 3

Page 24

3. Specifications

S

FEET

■

Working Envelope - MHP12/34J

15

14

METER

13

12

50

45

40

11

35

10

9

30

8

25

7

6

5

4

3

2

1

METERS

0

6

METERS

20

15

10

5

FEET

0

5

4

3

2

1

0

1

2

3

4

5

6

20

FEET

page 3 - 4 MHP12/34J – 11447A

15

10

5

0

5

10

15

20

Page 25

■

Nomenclature And Serial Numbers

Right side view of machine

❑

3. Specifications

Jockey

wheel

To w

coupling

Draw bar

Engine

cover

Outriggers (4)

Column

Trailer

Ground

controls

Outrigger

controls

Platform

controls

Platform

❑

Booms identification

Levelling

turret

Lower

boom

Upper boom

Jib

boom

VIN Number

MHP12/34J – 11447A page 3 - 5

Page 26

3. Specifications

Left side view of machine

❑

Jib Cylinder

Upper

cylinder

Lower cylinder

Hand

brake

Oil tank

cover

❑

Serial number location, chassis

Outrigger cylinder

Serial number

plate

page 3 - 6 MHP12/34J – 11447A

Page 27

4. Gauges

■

Hourmeter

Figure 4.1 - Hourmeter

The hour meter is basically an electric clock. It ac

cumulates time when the master key switch is

turnedon.The hourmetercannotbereset.AnMHP

qualifiedservicetechnician canuse itto tellwhen it

is time for the periodic maintenance listed in the

maintenance manual.

■

Hydraulic Oil Level

Figure 4.3 - Hydraulic Oil Level

Thehydraulicoil levelguageis on thesideofthehy

-

draulicoil tank.It showsthe actuallevelof oilinside

thetank.Readit onlywhen thebooms are fullylow

eredandoutriggers areraisedinthe travelposition.

Theoillevelshouldbe within +or -6mm (1/4”)of the

line.

-

-

■

Level Bubble

Figure 4.2 - Level Bubble

A level bubble is located beside the outrigger con

trol valve, mounted on the trailer base. Watch the

bubblewhile you set the outriggers.Lower the out

riggers,front onesfirst,one atatime justenough to

center the bubble in the circle on top of the guage.

When the bubbleis centralthe platform is leveland

the platform can be safely raised.

-

-

MHP12/34J – 11447A page 4 - 1

Page 28

4. Gauges

page 4 - 2 MHP12/34J – 11447A

Page 29

5. Automatic Shut-offs and Circuit Breakers

■

RCD/ELCB Outlet (option)

Figure 5.1 - RED/ELCB Outlet

The RCD (Residual Current Device) is located at

the base and will protect against short circuits to

earth. When there is a short circuit the RCD will

shutdownthe230vACpowertotheplatformoutlet.

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the

base.

■

Outriggers

Figure 5.3 - Outriggers

The MHP12/34J cannot beraised unless the outrig

gersareloweredand theliftenablelighton thelower

controlboxislit.Oncethe boomsareraisedfrom the

stowedposition theoutriggers become disabledun

til the booms are stowed in the travel position.

-

-

If the problempersists call atrained service technician.

■

Main Circuit Breaker

Figure 5.2 - Main Circuit Breaker

There is only one circuit breaker, on a standard

MHP12/34J, that is accessible to the operator. Its

purpose is to protect the electrical circuits from

electrical overloads.When the circuit breaker trips

(pops out) push it back in then attempt to use the

MHP12/34J. If the circuit breaker trips a second

time, take the MHP12/34J out of service and refer

the problem to a qualified trained service techni

cian for repair.

-

MHP12/34J – 11447A page 5 - 1

Page 30

5. Automatic Shut-offs and Circuit Breakers

page 5 - 2 MHP12/34J – 11447A

Page 31

■

Controls Description

This chapter explains what each control does.

This chapter DOES NOT explain how to use the

controls to produce useful work, refer to the “Oper

ation” chapter 8-1 for that after you have read this

chapter.

For optional equipment controls, see the “Options”

chapter.11-1

Seethe “Emergency Operation”chapter 9-1 for the

location of the emergency bleed down control and

for correct emergency bleed down procedures.

Controls and Control Decals Locations

❑

BOOMS

LOWER

BOOM

STABILISER

PLATFORM

6. Controls

ThemainoperatingfunctionsofanMHP12/34Jcan

be controlled from the ground control box or from

the platform control box.

-

UPPER

BOOM

JIB

BOOM

LIFT

ENABLE

11420

SLEW

SPEED CONTROL

Ground Controls

BASE

CHOKE

Platform Controls

LOWER

BOOM

UPPER

BOOM

EMERGENCY LOWER

TOLOWER PLATFORM, OPERATE EMERGENCY

1.

LOWER SWITCH.

TO SLEW BOOM, OPERATE‘EMERGENCY

2.

LOWER’ & ‘SLEW’ SWITCHES TOGETHER.

ROTATE

PLATFORM

EMERGENCY

LOWER

JIB

BOOM

LIFT

ENABLE

11420- 1

SLEW

SPEED CONTROL

CHOKE

MHP12/34J – 11447A page 6 - 1

Page 32

6. Controls

■

Ground Control Box

Controls for operating the MHP12/34J from the

ground, are located on the right side of the turnta

ble.

NOTE

The number of each control below corresponds to

the control’s call out on the control box illustration.

1.

Emergency Stop: Press the EMERGENCY

STOP switch cover down, at any time, under

any conditions, and the entire machine stops,

and nothing moves. This emergency stop

switch cover must be up and the switch

turned on for anything on the MHP12/34J to

work.

2.

Platform/Ground Selector : Must be in the

GROUND position (down) for the ground

control box to work. The switch MUST be in

the PLATFORM position (up) for the platform

control box to work.

3.

Choke/Cold Start: Hold the switch UP while

you start an engine that is at ambient air

temperature (a "cold" engine). This will choke

the engine.

4.

Master Key Switch: This switch works like

an automobile ignition switch. Hold it at

START until the engine starts, then release it

to ON. (-) Turn the Master Key Switch to

OFF (O) if the platform is to stay in one

position for a long time, that will turn the

engine off and save fuel.

5.

Boom Speed: This control determines how

fast the booms move.Set it to SLOW (turtle)

until you are very familiar with the way the

machine works or if the platform is working in

dangerous or cramped surroundings.

6.

Stablizer / Boom Selector Switch:

Must be in Stablizer (outrigger) position

(down) for the outriggers to wor k. Once

outriggers are down and set the switch must

be placed in the boom (up) position for the

booms to work.

Control switches 7 through 10 are the platform

movingswitches.Each isa three position,momen

tary contact, normally OFF switch.

9.

Jib Boom: UP raises the jib boom. DOWN

lowers the jib boom.

10.

-

-

Slew: LEFT rotates the entire turntable and

boom to the left. RIGHT rotates the entire

turntable and boom to the right.

11.

Lift Enable: The platform can only be raised

when this light is lit. When this light is not lit

the platform will not raise because the

outriggers are not proper ly set.

NOTE

(See “Nomenclature and Serial Numbers” in the

“Specifications” chapter 3, for boom

identification.)

7.

Lower Boom : UP raises the lower boom.

DOWN lowers the lower boom.

8.

Upper Boom: UP raises the upper boom.

DOWN lowers the upper boom.

page 6 - 2 MHP12/34J – 11447A

Page 33

Ground Control Box Controls

❑

6. Controls

1

BOOMS

7

6

LOWER

BOOM

8

STABILISER

PLATFORM

2

UPPER

BOOM

9

JIB

BOOM

4

SLEW

LIFT

BASE

3

CHOKE

5

ENABLE

11420

10 11

MHP12/34J – 11447A page 6 - 3

SPEED CONTROL

Page 34

6. Controls

■

Platform Control Box

Controls for operating the MHP12/34J from the

platform are located on the platform control box,

with the exception of the footswitch which is on the

platform floor.

NOTE

The number of each control below corresponds to

the control’s call out on the control box illustration.

1.

Emergency Stop: Press the EMERGENCY

STOP switch cover down, at any time, under

any conditions, and the entire machine stops,

and nothing moves. This emergency stop

switch cover must be up and the switch

turned on for anything on the MHP12/34J to

work.

2.

Choke/Cold Start: Hold the switch UP while

you start an engine that is at ambient air

temperature (a "cold" engine). This will choke

the engine.

3.

Anti-Restart: This switch works like an

automobile ignition switch.Hold it at START

until the engine starts, then release it to ON

(-). If the engine dies in ON, the key must be

turned to OFF (O) before it will go back to

START. Turn the switch to OFF if the platform

is to stay in one position for a long time, that

will tur n the engine off and save fuel.

4.

Boom Speed: This control determines how

fast the booms move.Set it to SLOW (turtle)

until you are very familiar with the way the

machine works or if the platform is working in

dangerous or cramped surroundings.

5.

Emergency Lower: If the engine stops and

cannot be restarted, hold the switch down

and this will lower the upper and lower

booms (not the jib boom). To slew during

emergency lower operate emergency lower

and slew switches together.

8.

Upper Boom: UP raises the upper boom.

DOWN lowers the upper boom.

9.

Jib Boom: UP raises the jib boom. DOWN

lowers the jib boom.

10.

Slew: LEFT rotates the entire turntable and

boom to the left. RIGHT rotates the entire

turntable and boom to the right.

11

Lift Enable: The platform can only be raised

when this light is lit. When this light is not lit

the platform will not raise because the

outriggers are not proper ly set.

12.

Foot Switch: You must step down on the foot

switch, and hold it down when you use any

platform control that causes the platform to

move.

Items 6 through 10 are the platform moving

switches.Each isa threeposition, momentary con

tact, normally OFF switch.

NOTE

(See “Nomenclature and Serial Numbers” in the

“Specifications” chapter 3, for boom

identification.)

6.

Platform Rotate: (Option) LEFT rotates the

platform left. RIGHT rotates the platform

right.

7.

Lower Boom: UP raises the lower boom.

DOWN lowers the lower boom.

page 6 - 4 MHP12/34J – 11447A

-

Page 35

Platform Control Box Controls

❑

6. Controls

10

1

EMERGENCY LOWER

TO LOWER PLATFORM, OPERATE EMERGENCY

1.

7

LOWER

BOOM

8

UPPER

BOOM

9

JIB

BOOM

LOWER SWITCH.

TO SLEW BOOM, OPERATE ‘EMERGENCY

2.

LOWER’ & ‘SLEW’ SWITCHES TOGETHER.

SLEW

RO TATE

PLATFORM

EMERGENCY

LOWER

CHOKE

5

6

2

11

3

LIFT

4

ENABLE

11420 - 1

SPEED CONTROL

12

MHP12/34J – 11447A page 6 - 5

Page 36

6. Controls

page 6 - 6 MHP12/34J – 11447A

Page 37

7. Daily Inspection and Maintenance

At the start of each work day (or 8 hour shift), an

MHP12/34J qualified operator must perform the

Daily Inspection and Maintenance as listed in the

table below.

The purpose of the Daily Inspection and Mainte

nance isto keep the MHP12/34Jin proper working

condition and to detect signs of malfunction at the

earliest possible time.

The MHP12/34J should be in the STOWED

POSITION and the Master KeySwitch set to OFF

before you begin this inspection.

■

Daily Inspection and Maintenance Table

Item Service Required

Engine fuel level Look to see that the fuel tank is full

Fuel tank cap Check to see that the cap is tight

Engine oil level Check oil level (between dipstick lines)

Fuel leaks Visually inspect (hoses and connections)

Engine coolant Check that grills are not blocked

Wiring harnesses Visually inspect (installation, condition)

Battery terminals Visually inspect (no corrosion)

Battery fluid level Check fluid level (1/4" or 6 mm below filler neck)

Hydraulic oil level Visually inspect level (between lines on gauge)

Hydraulic oil leaks Visually inspect (hoses, tubes)

Tires and wheels Visually inspect (condition)

Bolts and fasteners Visually inspect (condition)

Structural damage and welds Visually inspect (weld cracks, dents)

Lanyard anchor points Visually inspect (condition)

Platform gravity gate Check condition and operation

Platform guardrails Visually inspect (condition)

Flashing light (option) Visually inspect (operation)

Ground control switches Actuate and inspect for proper operation

Level sensor (option) Check operation

Emergency lower Check operation (causes correct motion)

Platform control box switches Actuate and inspect for proper operation

RCD/ELCB AC outlet (option) Check operation

Platform work lights (option) Check operation

Placards and decals Visually inspect (installation, condition)

Defective par ts and/or equipment malfunctions

jeopardizethe safetyof theoperator andother per

sonnel, and can cause damage to the machine.

-

DONOToperatean MHP12/34J that isknown

to be damaged or malfunctioning.

Repair all equipment damage or

malfunctions,before placing the MHP12/34J

into service.

DANGER

-

MHP12/34J – 11447A page 7 - 1

Page 38

7. Daily Inspection and Maintenance

Therest of thischapter shows howtoperformthe in

spection and maintenance required for each item in

the Daily Inspection and Maintenance Table.

■

Engine Fuel Level

Figure 7.1 - Engine Fuel Level

Visually check to see that the gasoline tank is full.

See the “Specifications” chapter 3, fuel for octane

and grade.

■

Fuel Tank Cap

Visually inspect the Honda fuel tank and the entire

length of the fuel line, from the engine to the fuel

tank, for leaks.

■

Engine Oil Level

COMBINED OIL FILLER

CAP AND DIPSTICK

OIL LEVEL FILLED TO

TOP OF FILLER NECK

OIL LEVEL

Figure 7.4 - Engine Oil Level

Remove the oil filler cap and wipe the dipstick

clean. Insert the dipstick into the oil filler neck, but

do not screw it in.

If the level is low, fill to the top of the oil filler neck

with the recommended oil.

See the “Specifications” chapter 3, for the correct

engine oil grade and weight.

Figure 7.2 - Fuel Tank Cap

Check to see that the tank cap is in place and is

tight.

■

Fuel Leaks

■

Wiring Harnesses

Figure 7.5 - Wiring Harnesses

Figure 7.6 - Wiring Harnesses

Inspect all the wiring harnesses, on the machine,

for loose connections, broken wires, and frayedin

Figure 7.3 - Fuel Leaks

page 7 - 2 MHP12/34J – 11447A

sulation.

-

Page 39

■

Battery Terminals

Figure 7.7 - Battery Terminals

Battery terminals should be tight, clean and free of

dirt and corrosion.

■

Battery Fluid Level

7. Daily Inspection and Maintenance

Figure 7.9 - Hydraulic Oil Level

The hydraulic oil level should be between the two

marks on the decal.

DANGER

Batteries emit hydrogen and oxygen,

elements that can combine explosively.

DO NOT smoke or permit open flames or

sparks when checking batteries.

Figure 7.8 - Battery Fluid Level

Remove the caps from the battery and visually

checkto seethat thebattery fluidis 1/4”(6 mm) be

low the bottom of the filler neck inside each hole.

Figure 7.10 - Hydraulic Oil Filler Cap

If necessary, add hydraulic oil at the filler cap.See

the“Specifications”chapter 3,fortype and gradeof

hydraulic oil.

■

Hydraulic Oil Leaks

DANGER

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds

(if under high pressure).Do not search for

leaks with your hand. Have a qualified

trained maintenance person repair all

hydraulic fluid leaks before you operate an

MHP12/34J.

-

■

Hydraulic Oil Level

To check the hydraulic oil level:

Completely lowerthe booms and ensure the stabi

lizers are in the stowed position.

MHP12/34J – 11447A page 7 - 3

-

Figure 7.11 - Hydraulic Oil Leaks

Page 40

7. Daily Inspection and Maintenance

Hydraulic oil leaks are easily visible and can show

up anyplace.

Visuallyinspect theentire machine forhydraulicoil.

Checkthe groundunderthemachine forleakedoil.

Carefully inspect the ends of the upper and lower

booms. Oil can run down inside of the booms and

drip out the end.

■

Bolts and Fasteners

Visually inspect all fasteners to see that none is

missing or obviously loose.

Figure 7.14 - Tyre Condition

Check each wheel for obvious damage that could

cause a blowout.

Figure 7.12 - Critical Pin Retainer Bolts

Critical pin retainer bolts have locktab washers fitted, theyshould allbe presentand not damaged in

any way.

Figure 7.13 - Wheel Nuts

Pay particular attention to all of the wheel nutsand

bolts.

None should be visibly loose, missing, or de

formed.

Figure 7.15 - Location of Tyre Pressure Decal

Ensuretyre pressures aremaintained accordingto

the decal attached to the chassis behind the mud

guard (fender).

■

Structural Damage and Welds

Visually inspect all welds for cracks, all structural

members for deformity.

-

-

■

Wheels and Tyres

TheMHP12/34J relies onit’styresfortowing stabil

ity.

page 7 - 4 MHP12/34J – 11447A

-

Figure 7.16 - Chassis Welds

Page 41

7. Daily Inspection and Maintenance

Pay particular attention to the chassis welds

Figures 7.17 - Boom Welds

Closely inspect boom welds all the way around, for

cracks.

■

Lanyard Anchor Points

■

Platform Guardrails

Figure 7.20 - Platform Guardrails

Visually inspect the platform guardrails to see that

none of the tubing has been cut out, removed, or

deformed in any way.

Visually checkthe guardrail welds to see thatnone

is cracked nor ground down.

■

Flashing Light (option)

Figure 7.18 - Lanyard Anchor Points

Visuallycheckthelanyardanchor points toseethat

they are not deformed or cut off.

■

Platform Gravity Gate

Figure 7.19 - Platform Gravity Gate

Figure 7.21 - Flashing Light

Visuallychecktheoptionalflashinglight,to see that

thelightflashes atapproximatelyoneflashper sec

ond when the motor key switch is turned on.

-

MHP12/34J – 11447A page 7 - 5

Page 42

7. Daily Inspection and Maintenance

■

Ground Control Switches

Figure 7.22 - Ground Control Switches

With the Ground/Platform Selector set to

ground:

Check that each of the platform moving switches

( through to ) cause the MHP12/34J to move

the way it should.

Check both positions of each switch.

For correct operating procedures see the “Opera-

tion” chapter 8.

NOTE

Pay particular attention to the Emergency Stop

switch to see that it tur ns the MHP12/34J

engine off when the red cover is struck.

With the booms raised open the Emergency

Lower Valve on the top of the manifold valve.

Theboomsshouldbegintolower.Therateoflower

ing can be regulated by the amount the valve is

opened.

To check the slew function when using the manual

emergency lower valve the Master Key Switch

and Emergency Stop switch must be on and the

Platform/groundSelector mustbesettoground.

To slew(withthemanual emergency lowervalveal

ready open) select the required direction on the

slew toggle switch .

NOTE

The manual emergency lower valve must be

closed after the test to ensure proper boom

operation.

For correct emergency lowering operating proce

dures see “Emergency Operation” chapter 9.

Upper control box

❑

Emergency lower from the upper control box is

achievedbyturning the uppercontrol to onand depressing thefoot switchwhilst operatingthe Emer-

gency Lower switch

To slew the unit select thedirection required on the

slew toggle switch at the same time. For correct

emergency lowering operating procedures see

“Emergency Operation” chapter 9.

■

Platform Control Switches

-

-

-

■

Emergency Lower

❑

Lower control box

Figure 7.23 - Emergency Lower Valve

page 7 - 6 MHP12/34J – 11447A

Figure 7.24 - Platform Control Switches

Page 43

7. Daily Inspection and Maintenance

On the ground control box set the Ground/Plat

form Selector to platform.

Check that each of the platform moving switches

( through to ) cause the platform to move the

way it should.

Check both positions of each switch.

For correct operating procedures see the ”Opera

tion” chapter 8.

NOTE

Pay particular attention to the Emergency Stop

switch to see that it turns the MHP12/34J

engine off when struck.

Pay particular attention to the platform foot switch

to see that it deactivates the platform moving

switches when the foot switch is not stepped on.

■

AC Outlet RCD/ELCB (option)

-

Standard placards and decals

❑

Seepage7-8forthefollowing items.

No Part No Description Req

-

9999 Serial number plate

1

451776 Decal - Hydraulic fluid level

2

108172 Decal - Snorkel

3

302950 Decal - Hydraulic oil level

4

7856-45 Decal - Tyre pressure

5

7855 Decal - Towing speed

6

9207 Decal - Hydraulic oil

7

0070420 Decal - Emergency lower

8

560239 Decal - Snorkel

9

302559 Decal - Pinch point

10

10817-4 Decal - Snorkel

11

1

1

2

1

2

1

1

1

2

2

2

Figure 7.25 - AC Outlet RCD/ELCB

If the MHP12/34J has this option fitted check the

RCD works by connecting a power source to the

base inlet and an appliance to the platform outlet.

Push the test button on the RCD/ELCB device and

the power outlet at the platform should not work.

CAUTION

RCD/ELCB devices should only be replaced

by a qualified electrician.

■

Placards and Decals

Looktoseethat all placardsanddecalsarein place

and legible. Replace any missing or illegible plac

ardsordecalsbeforeplacingtheSnorkeliftinto ser

vice for the daily work shift.

Decalandplacard kitsfortheMHP12/34Jare avail

able from Snorkel dealers.

11227-34 Decal - MHP12/34J

12

007-1925 Decal - Gasoline

13

300699 Decal - Operator checklist

14

0130025 Decal - Warning

15

0323897 Decal - Danger

16

476706 Decal - Danger explosive gas

17

11420 Decal - Lower control box

18

0323899 Decal - Electrocution hazard

19

0150602 Decal - Descending boom

20

451986 Decal - Limit switches

21

9223-3 Decal - Chevron

22

10968-1 Decal - Outrigger control

23

8945 Decal - Vin plate

24

11420-1 Decal - Upper controls

25

2025-200 Decal - Safe working load

26

99228 Decal - Caution

27

1772-002K Decal - Boom lock pin

28

-

29

-

11287-3 Decal - Chevron

30

-

9428 Decal-Danger(AustraliaOnly)

31

1843 Decal - Warning (NZ Only)

2

1

1

1

1

1

1

1

4

5

4

1

1

1

1

1

2

4

1

1

MHP12/34J – 11447A page 7 - 7

Page 44

7. Daily Inspection and Maintenance

Inspection drawing

❑

11

1

20

12

9

10

28

20

3

7,4,2

9

6

5

(X4), 30 (X4)

22

11

(x4)

21

12

5

21,20

13

25

23

28

28

18

19

8

3

24

10

14,15,16,17

27

26

31

page 7 - 8 MHP12/34J – 11447A

Page 45

■

Operating Procedures

This chapter explains howto properly start andop

erate an MHP12/34J.Read and understand all the

previous chapters in this manual before you begin

to operate an MHP12/34J.

CAUTION

IfyouusetheMHP12/34Jforpaintingbesure

the optional sandblast protection kit is

installed to protect the hydraulic cylinder

rodsfrom paint.Donot leavethe MHP12/34J

enginerunningif youare sandblasting.Sand

drawn into the air intake can erode engine

parts.

■

Control Stations

An MHP12/34J can be operated from the ground

control box or from the platform control box.There

are basically two differencesbetween ground con

troland platformcontroloperations, both aresafety

related:

1. The ground control box can override the

platform control box at any time.If a person

operating the machine from the platform

becomes incapacitated, a person on the

ground can always take over machine control.

2. The outriggers can only be selected from the

ground control box and only when the

booms are in the stowed position.

8. Operation

-

-

Figure 8.1 - Ground Control Box Emergency

Stop Switch Location.

DANGER

TheMHP12/34JisnotElectricallyInsulated.

Death or Serious Injury to operating

personnel, can occur if the machine should

come into contact with energized electrical

wires during operation.

DO NOT attempt to operate the MHP12/34J

ground controls if the platform, booms, or

any other conducting part of an MHP12/34J

is in contact with energized electrical wires

or if there is an immediate danger of such

contact.

NOTE

See the "Electrical Hazard" section, in this

manual for a complete explanation of the hazards

concerning electricity.

■

Emergency Stopping

To stop an MHP12/34J, press the Emergency

Stop switch cover down on either of the two

EMERGENCY STOP switches at the ground con

trol box or at the platform control box.

Figure 8.2 - Platform Control Box Emergency

Stop Switch Location.

NOTE

For a complete discussion of the Emergency

Stop switches, see “Controls” chapter 6, in this

manual.

-

MHP12/34J – 11447A page 8 - 1

Page 46

8. Operation

■

Operation Considerations

To use this chapter, firstdecide whether youwill be

starting and operating the MHP12/34J from the

ground control box or the platform control box.

Beginat thesectionentitled "Starting FromGround

Control Box", if you intend to start and run the

MHP12/34J from the ground station.