qbkbl

pЙкобЕЙ=j~ем~д===== =

bеЦдблЬ

qbkbl

pЙкобЕЙ=j~ем~д===== =

bеЦдблЬ

IMPORTANT:

• In the case of faults which you are unable to eliminate with the

help of this manual, please contact our Customer Service Center.

• It is essential that you take this service manual and a service

laptop along with you on every customer call.

Furthermore, you must always have the spare parts list and wiring diagrams with you as well.

You can download this service manual in the dealer area of the Sirona

website.

Contents

1 Important information..................................................................................................... 1 – 1

1.1 Technical data.................................................................................................................................. 1 – 2

1.2 Warning and safety information ....................................................................................................... 1 – 3

1.3 Symbols ........................................................................................................................................... 1 – 4

1.4 Abbreviations ................................................................................................................................... 1 – 5

1.5 Where to save user-specific data in the TENEO.............................................................................. 1 – 6

1.6 Safety switches in the dental treatment center ................................................................................ 1 – 8

1.7 Removing the upholstery/arm rests from the patient chair............................................................... 1 – 9

1.8 Removing the cover panels of the patient chair...............................................................................1 – 10

1.9 Removing the cover panels of the support arm of the dentist element............................................ 1 – 11

1.10 Opening the dentist element ............................................................................................................ 1 – 12

1.11 Removing the user interface on the dentist element........................................................................ 1 – 13

1.12 Removing the NAK and NAB boards ............................................................................................... 1 – 14

1.13 Removing the NAR board for the X-ray viewer................................................................................ 1 – 15

1.14 Removing the cover panels of the support arm of the assistant element. ....................................... 1 – 16

1.15 Removing the cover panels of the assistant element....................................................................... 1 – 17

1.16 Removing the cover panels from the water unit...............................................................................1 – 18

2 Overview of modules and boards.................................................................................. 2 – 1

2.1 Locations of modules and boards.................................................................................................... 2 – 2

2.2 ... In the patient chair........................................................................................................................ 2 – 3

2.2.1 DCFU board - Motor control board................................................................................................................. 2 – 3

2.2.2 NSA board - Connection box ......................................................................................................................... 2 – 5

2.2.3 NSB board - Wireless base station ................................................................................................................ 2 – 8

2.2.4 NSC board - Seat connect ............................................................................................................................. 2 – 9

2.2.5 NSK board headrest....................................................................................................................................... 2 – 11

2.2.6 NSU board - USB connection to patient chair................................................................................................ 2 – 13

2.3 ... in the foot control.......................................................................................................................... 2 – 14

2.3.1 Wireless foot control....................................................................................................................................... 2 – 14

2.4 ... in the dentist element................................................................................................................... 2 – 15

2.4.1 CC board - instrument holder recognition in the dentist unit .......................................................................... 2 – 15

2.4.2 HF

2.4.3 NAC board - BL motor control ........................................................................................................................ 2 – 17

2.4.4 NAJ board - Dentist element control .............................................................................................................. 2 – 19

2.4.5 NAK board - User interface to dentist element baseboard and NAB board LED board................................. 2 – 21

2.4.6 NAL board - SL motor control ........................................................................................................................ 2 – 23

2.4.7 NAU board - USB connector to AE ................................................................................................................ 2 – 24

2.5 ... in the X-ray viewer ....................................................................................................................... 2 – 25

2.5.1 NAR board - X-ray viewer .............................................................................................................................. 2 – 25

2.6 ... in the assistant element ............................................................................................................... 2 – 26

2.6.1 NHE board - ASE control ............................................................................................................................... 2 – 26

2.6.2 NHT board - ASE user interface .................................................................................................................... 2 – 27

2.6.3 NOP board - 5 V power supply ...................................................................................................................... 2 – 28

2.7 ... in the water unit............................................................................................................................ 2 – 29

2.7.1 NWE board - Water unit control ..................................................................................................................... 2 – 29

2.7.2 NWM board - Automatic tumbler filling........................................................................................................... 2 – 32

+

board - Surgery module.......................................................................................................................... 2 – 16

bеЦдблЬ

3 Important information..................................................................................................... 3 – 1

3.1 Switching the dental treatment center ON/OFF............................................................................... 3 – 2

3.1.1 What happens when it is switched on?.......................................................................................................... 3 – 3

3.1.2 What happens when it is switched off?.......................................................................................................... 3 – 4

3.1.3 Signal path of the ON/OFF signal .................................................................................................................. 3 – 5

3.2 CAN BUS ......................................................................................................................................... 3 – 6

3.3 CAN BUS wiring diagram................................................................................................................. 3 – 7

3.4 Patient chair..................................................................................................................................... 3 – 8

3.4.1 Stand-alone installation function .................................................................................................................... 3 – 8

3.4.2 DCFU motor control ....................................................................................................................................... 3 – 8

3.4.3 Safety switches (For the locations of the safety switches see Section 1.6, Safety switches)........................ 3 – 8

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

I

Table of contents

4 Service area .................................................................................................................. 4 – 1

4.1 Service area of the user interface .................................................................................................... 4 – 2

4.2 Dental treatment center information................................................................................................. 4 – 3

4.2.1 Dentist element configuration INFO............................................................................................................... 4 – 3

4.2.2 Assistant element configuration INFO........................................................................................................... 4 – 4

4.2.3 Patient chair configuration INFO.................................................................................................................... 4 – 4

4.2.4 Water unit configuration INFO....................................................................................................................... 4 – 5

4.3 Reading out service codes............................................................................................................... 4 – 6

4.4 Maintenance display......................................................................................................................... 4 – 7

4.5 Service support with the PC............................................................................................................. 4 – 8

5 Points to observe when replacing ................................................................................. 5 – 1

5.1 ... Boards.......................................................................................................................................... 5 – 2

5.1.1 ... DCFU board in the patient chair ................................................................................................................ 5 – 2

5.1.2 ... NSA board in the patient chair................................................................................................................... 5 – 3

5.1.3 ... NSK board in the patient chair................................................................................................................... 5 – 3

5.1.4 ... HF

5.1.5 ... NAJ board in the dentist element............................................................................................................... 5 – 4

5.1.6 ... NHE board in the assistant element .......................................................................................................... 5 – 4

5.1.7 ... NWE board in the water unit...................................................................................................................... 5 – 4

5.1.8 ... NAR board in the RÖBI ............................................................................................................................. 5 – 5

+

board in the dentist element............................................................................................................... 5 – 4

6 PC connection / Networking .......................................................................................... 6 – 1

6.1 Connection of a dental treatment center to the practice network..................................................... 6 – 2

6.2 PC control via SIUCOM plus............................................................................................................ 6 – 3

6.2.1 Control of PC programs via the treatment center .......................................................................................... 6 – 3

6.2.2 Ethernet connection is required..................................................................................................................... 6 – 3

6.2.3 Third-party programs can also be controlled in this manner.......................................................................... 6 – 3

II D 3509.076.01.01.02 07.2008

61 94 448 D 3509

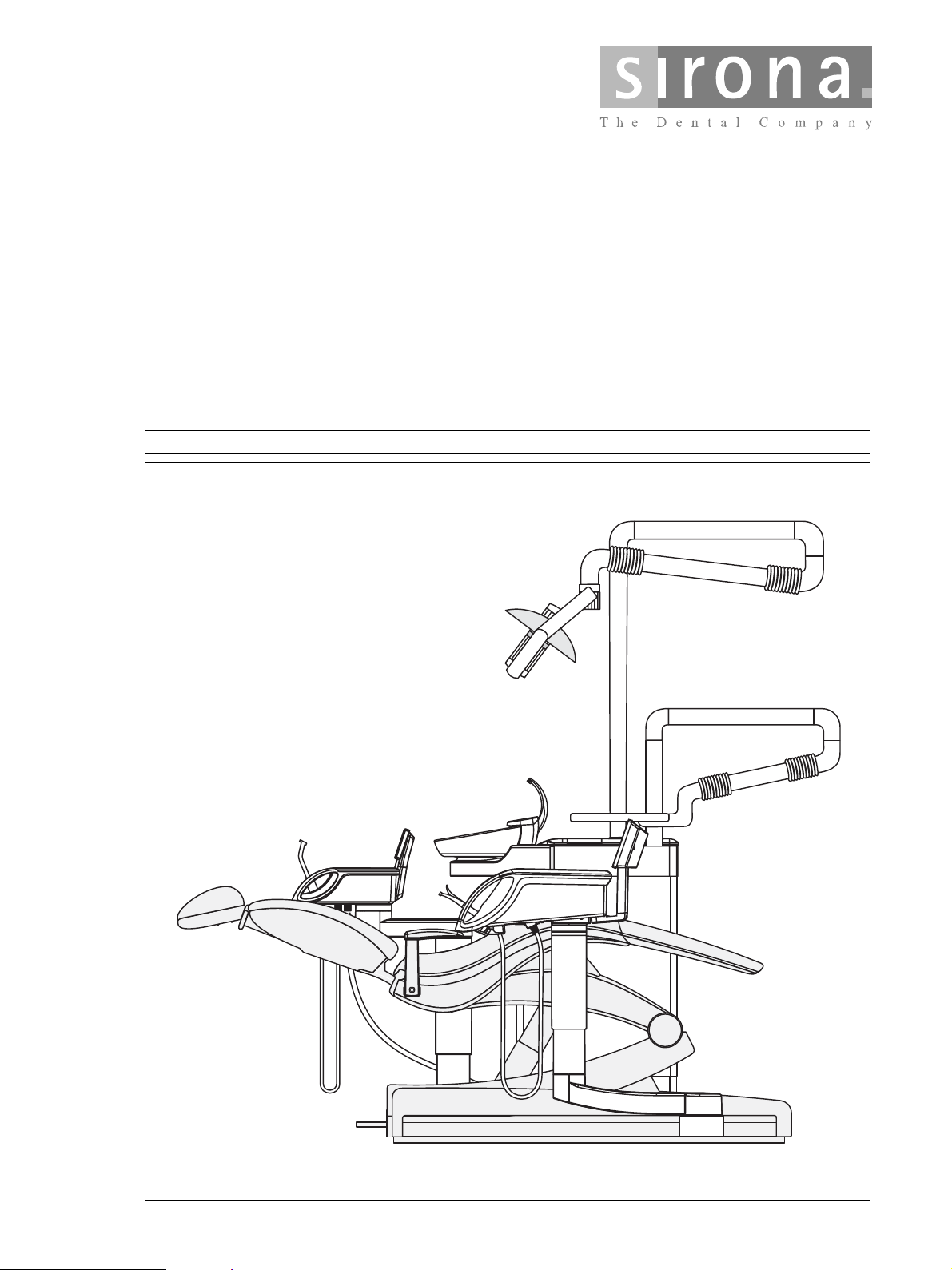

TENEO

1 Important information

1 Important information

1.1

Model designation TENEO

Power supply 100 - 230 V 50/60 Hz,

115 V∼ 50/60 Hz

Nominal current 230 V 4.8 A

115 V 9.6 A

100 V 11 A

Nominal power output: 1100 W

Technical data

1 – 2 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1 Important information

1.2 Warning and safety information

Caution! Prior to opening the unit, connecting a measuring instrument or replacing

parts, switch the treatment center OFF.

Protective ground connection The building water supply is at protective ground potential and must not touch

the fuse box of the chair.

Warning! If there is a protective ground contact, the patient or user may be exposed to

tension in the event of a fault - risk of electric shock!

Operational reliability To ensure operational reliability, the use of mobile wireless phones in practice

or hospital environments must be prohibited.

Troubleshooting: If you encounter difficulties, search in the error catalog first and proceed

according to the instructions given there.

CAUTION

When opening the unit:

Please observe the usual precautionary measures for

handling printed circuit boards (ESD).

Touch a ground point to discharge static electricity before handling any components. Use an ESD wrist band.

Connect it to the protective ground wire.

bеЦдблЬ

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 3

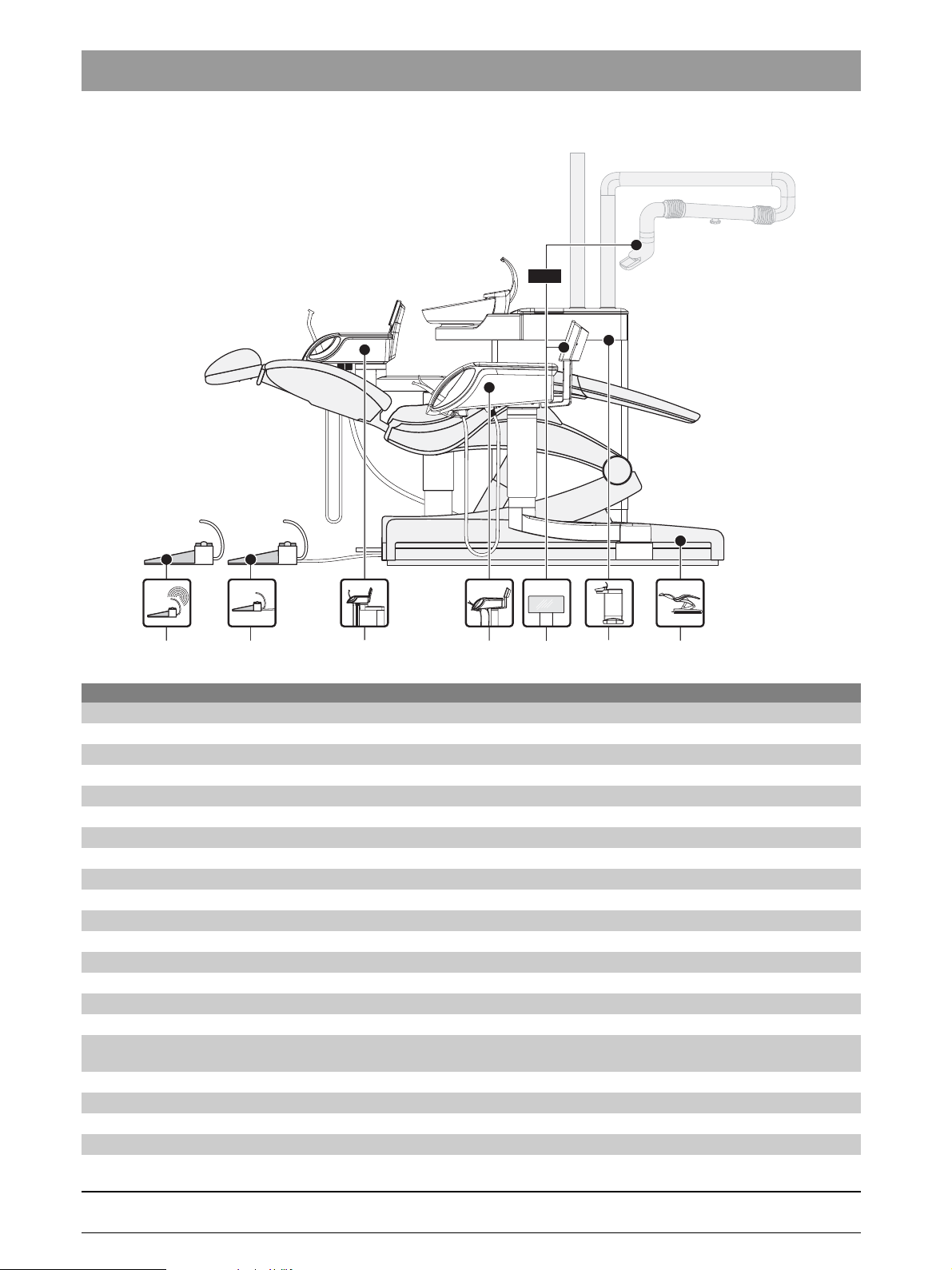

1 Important information

1.3

Dentist element

Assistant element

Foot control

Wireless foot control

Patient chair

Water unit

Symbols

1 – 4 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1 Important information

1.4 Abbreviations

AE Dentist element

AK Connection box

ASE Assistant element

BHE Dental treatment center

UI User interface

DNA Dürr wet suction system

PCB Printed circuit board

FS Foot control

FU Wireless foot control

GND Ground

HW Hardware

KS Four-way foot switch

LCable

LED Light emitting diode

LK Lumbar support cushion

MSBV Cuspidor valve

MV Solenoid valve

PC Personal computer

RÖBI X-ray image viewer

S Switch

SDI Sirona Dental Interface (electrical, pneumatic, hydraulic plug connection)

ST Patient chair

SW Software

VB Travel track

VDC DC voltage

WE Water unit

X Connector

bеЦдблЬ

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 5

1 Important information

Board

Part No.

NAK

61 86 626

Board

Part No.

NWE

61 15 567

1.5

Stored settings

PC configuration

Date of last maintenance performed:

Display brightness

Key click

Time format

Current user

Number of users

White screen, switchable

Cursor mode

Number of chair programs

Manual chair setting at top level

Slow travel, switchable

Current timer

All timer values

All values that must be stored in conjunction with implantology/endodontics:

Number of implantology levels

NaCl cooling

NaCl rinsing amount

Instrument light

Selected endodontic file system

Auto-reverse

Handpiece

Speed

Torque

Endodontic file

Stored settings

Flushing duration

Tumbler filling time

Tumbler heating on/off

Tumbler heater temperature

Sirolux brightness

Amalgam separator filling level

AmalgamMotor operating time

SepaMotor operating time

MSBV opening time

Sanitation data

Where to save user-specific data in the TENEO

1 – 6 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1 Important information

Board

Part No.

NHE

61 15 583

Board

Part No.

NSA

61 15 591

Stored settings

NHE heater on/off

Heater temperature

Sprayvit instrument light

Sprayvit instrument light lamp voltage

Hydrocolloid duration

Stored settings

Central error storage

Tumbler filling on/off in S program

Flushing on/off in S program

SIROLUX status with chair programs

# key (switch/button)

Chair program 0, S, 1, 2 for dental user A-F

IP address

DHCP activated/deactivated

Serial numbers of the motor controls

Packaging position

Travel track positions

bеЦдблЬ

Board

Part No.

NAJ

61 28 446

Board

Part No.

DCFU

61 83 193

Stored settings

Sprayvit ventilation, AE

Activation times (instrument /instrument holder-dependent)

Instrument settings

Example:

Cooling, cooling mode, light, light intensity, foot control mode, direction of rotation,

NaCl cooling, speed, HF intensity, HF modulation

Stored settings

Minimum and maximum value of the permissible range of motion. Determined based on the reference travel.

Motor parameters

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 7

1 Important information

X6

F1

F2

X29

X28

X30

X22

X21

X23

X24

X25

X15

X5

X27

X26

X18

X17

X16

X20

X19

X7

X4

X2

X1

X31

X13

F803

X14

X12

X19

X7X7

X4

X2

X11

X1

X3

X20

X13

X2

SDI

SS_MB

SS_HL

SS_HL

SS_AL

SS_RL

SS_HE

SS_HL

SS_HL

SS_HR

SS_HR

SS_HR

SS_SH

SS_HR

SS_FA

X9

X8

X14

X3

X10

X11

X13

X12

L218

S13

L332

L335

NWE

S8

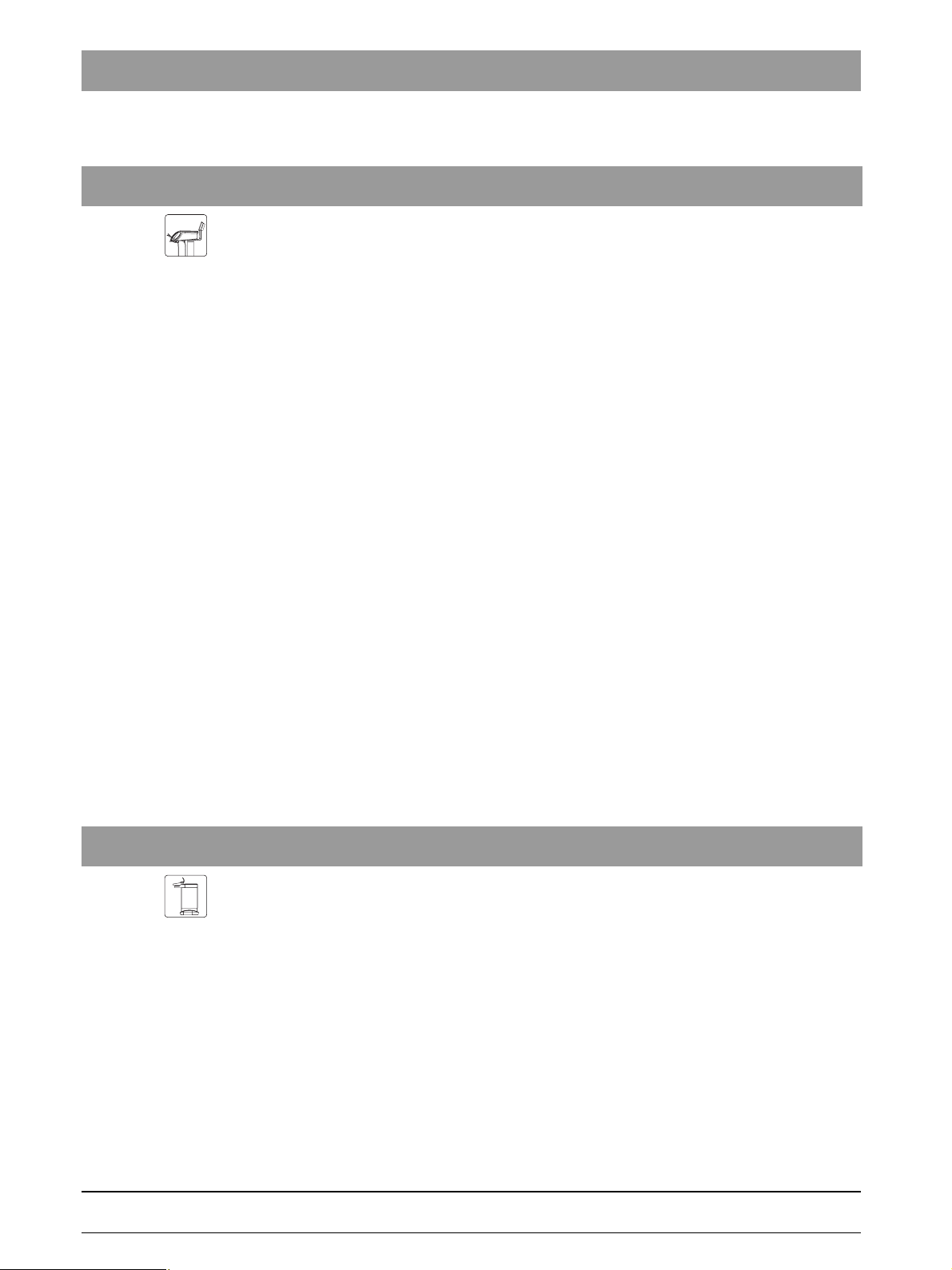

1.6

Safety switches in the dental treatment center

NSA

L317

L317

L334

L331

S6

S9

S4

S1

L332

L342

L331

L332

S11

L317

L316

L333

L316

S7

S5

S12

L333L235

S3

S2

S10

S14

1 – 8 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

4.

1 Important information

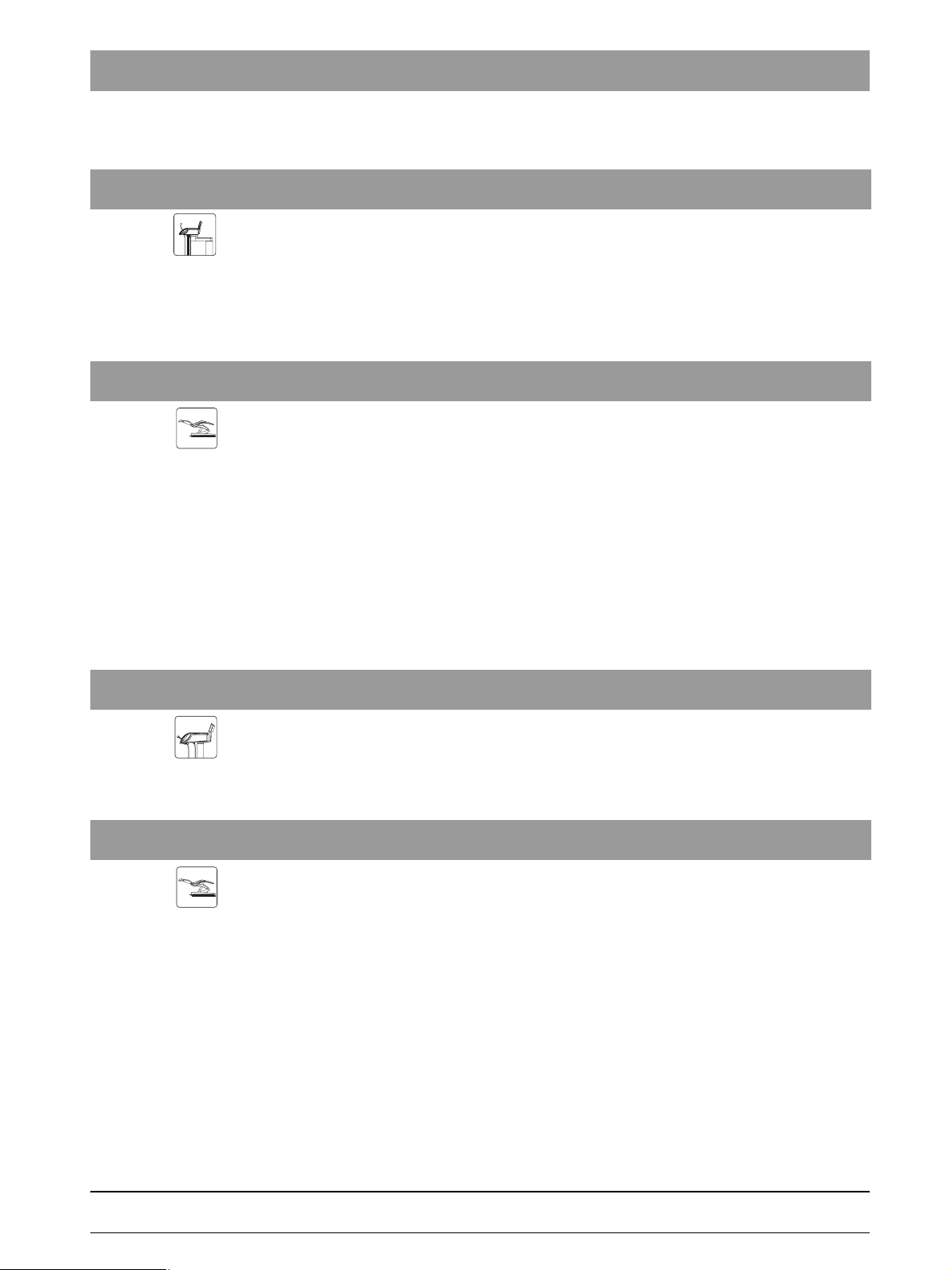

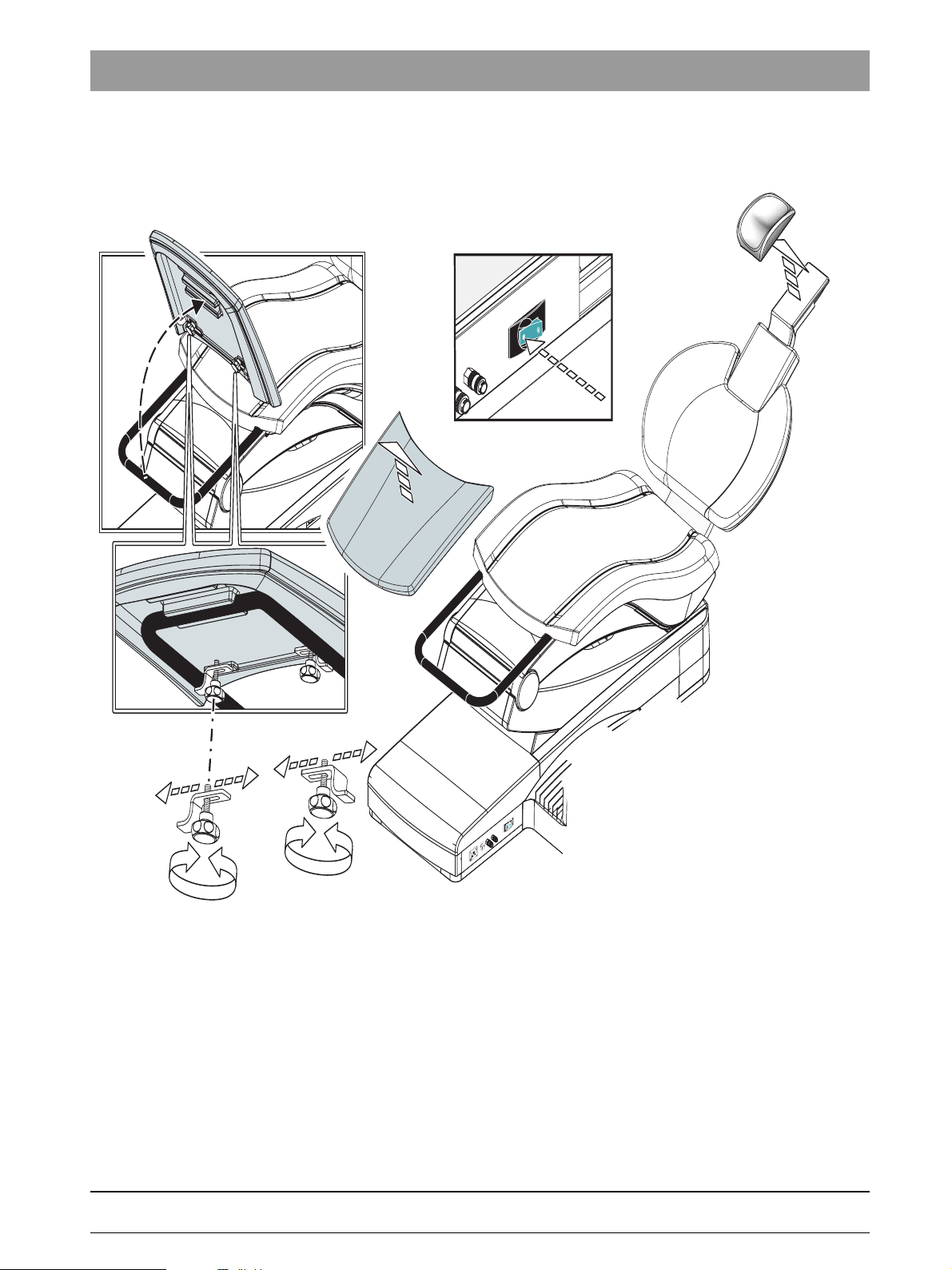

1.7 Removing the upholstery/arm rests from the patient

chair

bеЦдблЬ

2.

1.

AUS

4.

A

B

3.

B

A

1. Turn the mains power switch OFF.

2. Remove the upholstery on the headrest.

3. Loosen the screws and shift the retaining bracket B.

Remove the footrest.

4. Remove the seat upholstery.

5. Remove the backrest upholstery.

6. Pull off the backrest cover.

7. Press the release button on the armrest and pull out the armrest.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 9

1 Important information

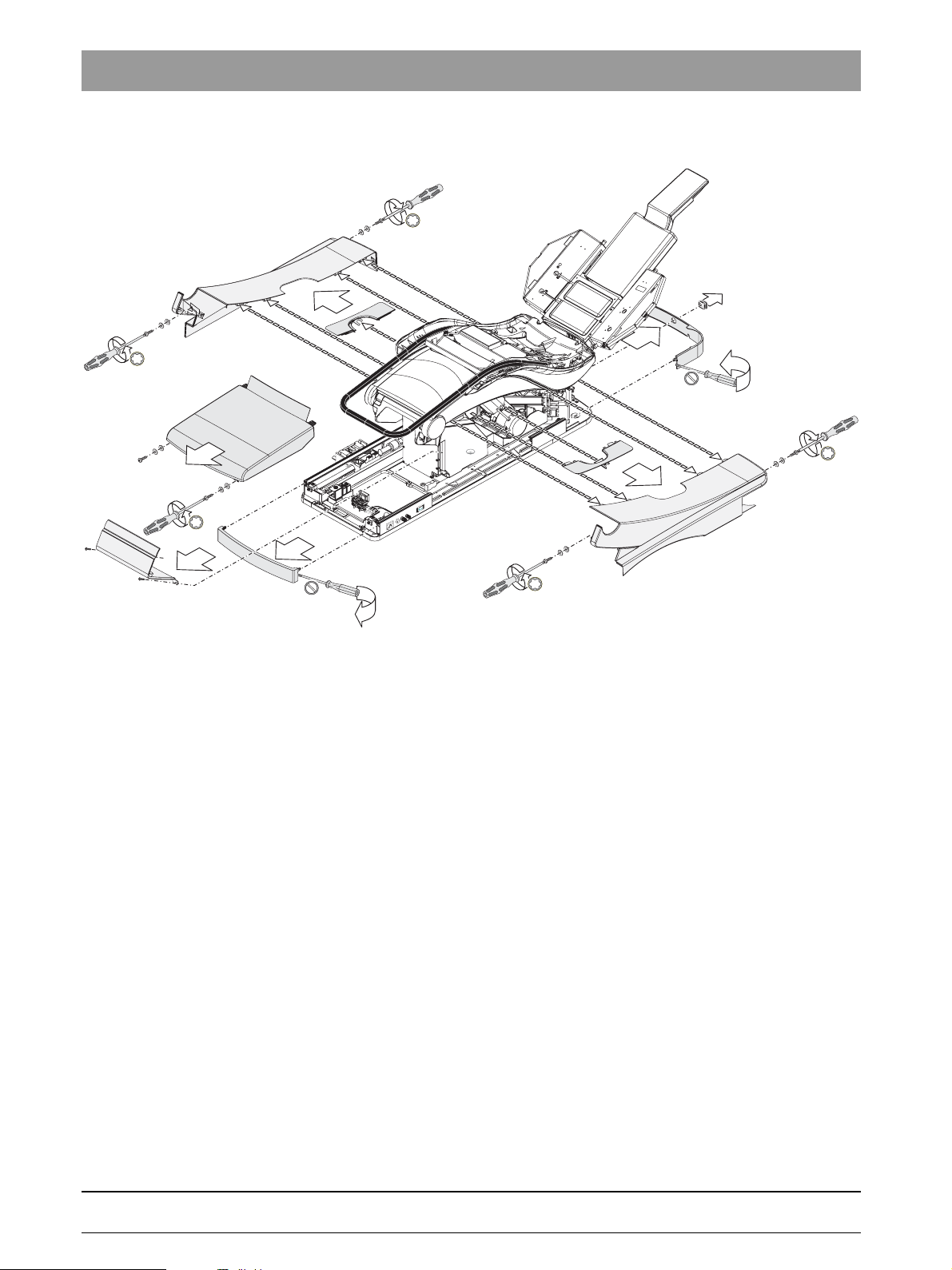

1.8

6.

6.

2.

3.

1.

7.

Removing the cover panels of the patient chair

4.

5.

6.

7.

6.

1. Remove the front faceplate of the base.

The faceplate is fitted on the lateral covers (if necessary, carefully pry

them apart with a screwdriver).

2. Unscrew the two screws (with washers) at the front of the cover.

Take off the cover.

3. Unscrew the two screws of the cover. Remove the cover (snap).

4. Pull off the small bellows from the four-way foot switch (if present).

5. Remove the rear faceplate of the base. The faceplate is fitted on the

lateral guide rails (if necessary, carefully pry them apart with a

screwdriver).

6. Remove the four screws of the side panels of the stand and remove the

covers.

7. Pull off the right and left covers.

1 – 10 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1 Important information

i

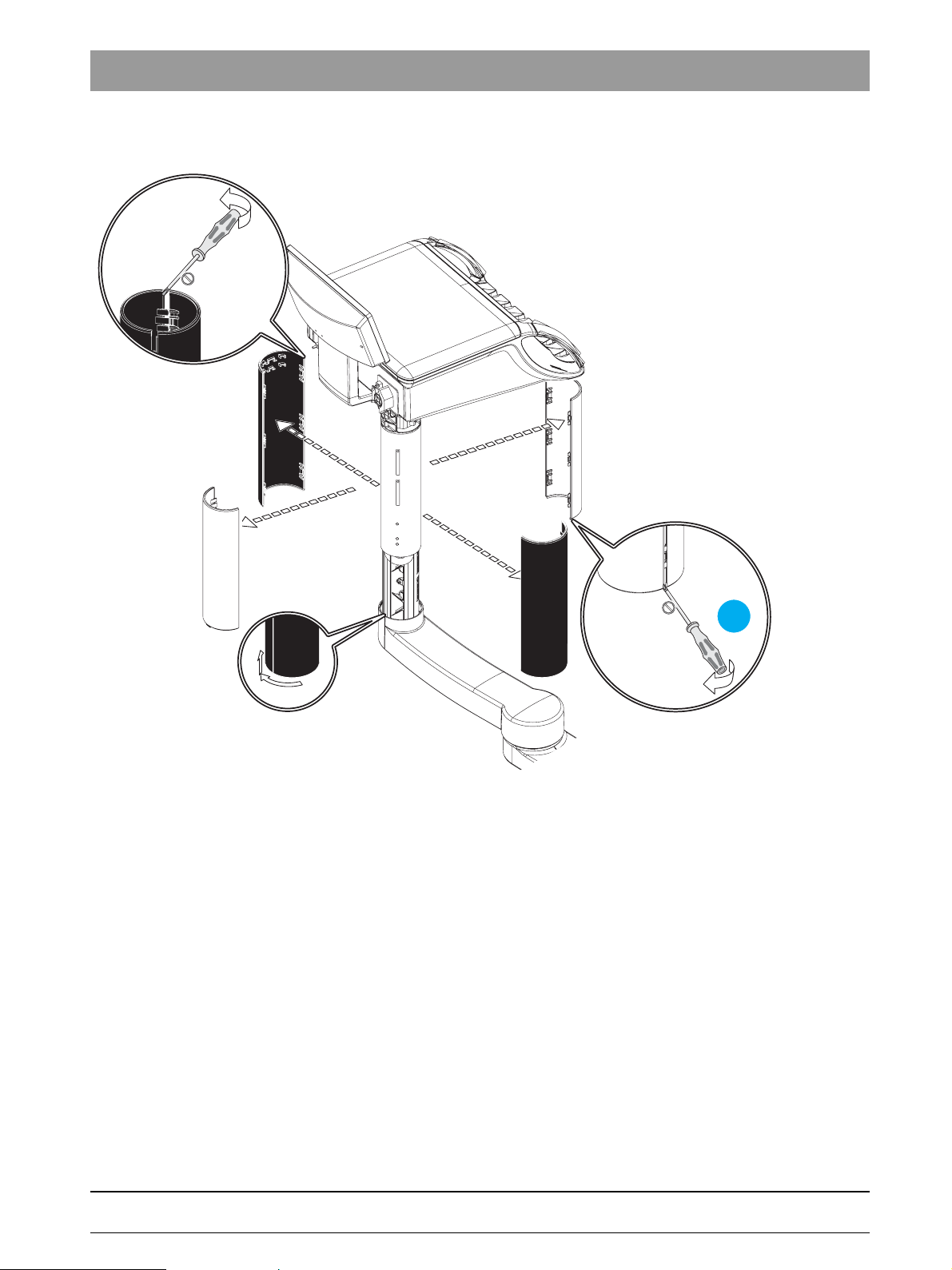

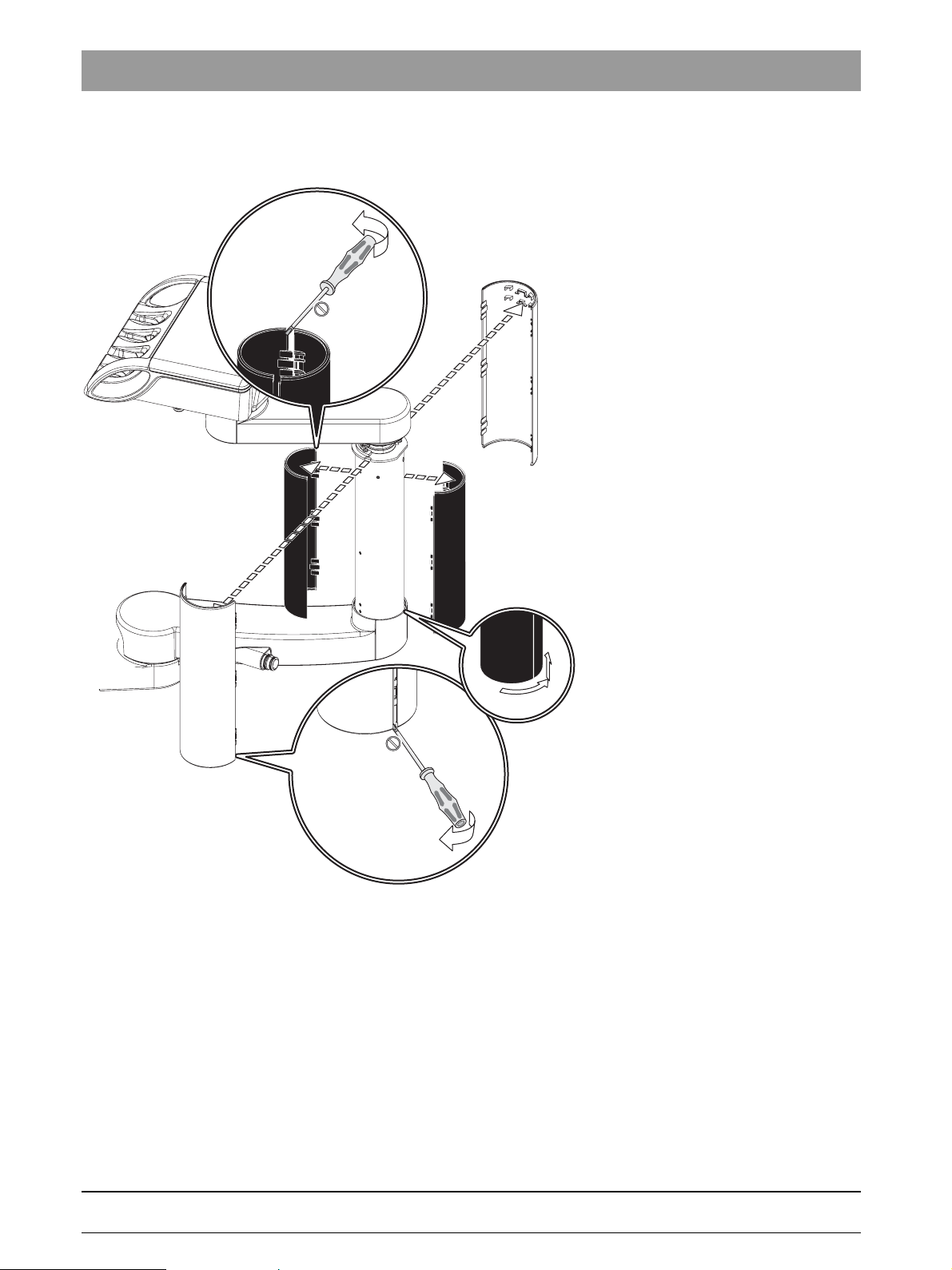

1.9 Removing the cover panels of the support arm of the

3.

1.

bеЦдблЬ

3.

1.

Dentist Element max.Assist.Element max.

3.

1.

2.

dentist element.

1. Remove the outer half-shell covers.

2. Detach the inner half-shell covers from the bayonet connector and move

them upward.

3. Remove the inner half-shell covers.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 11

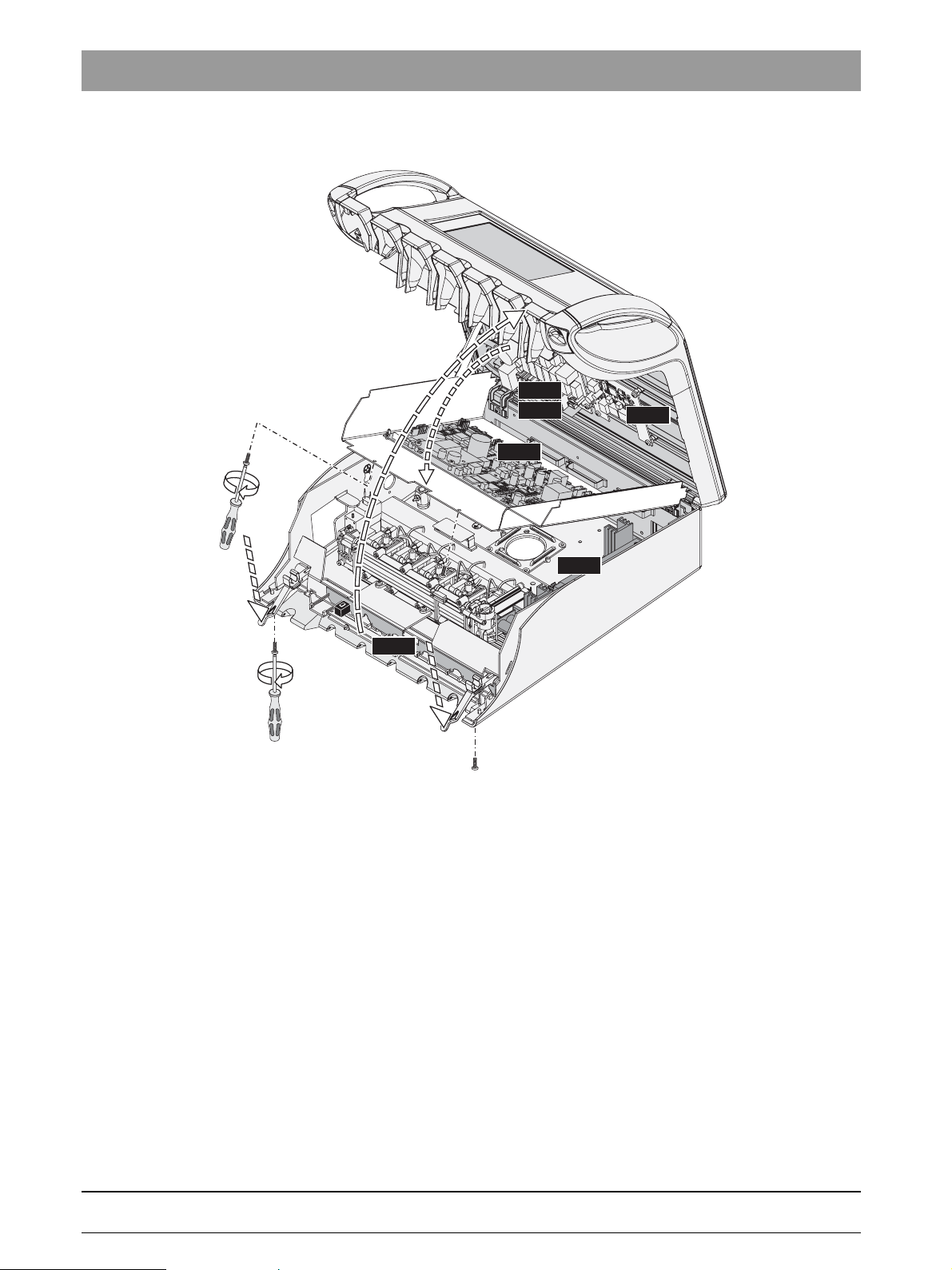

1 Important information

4.

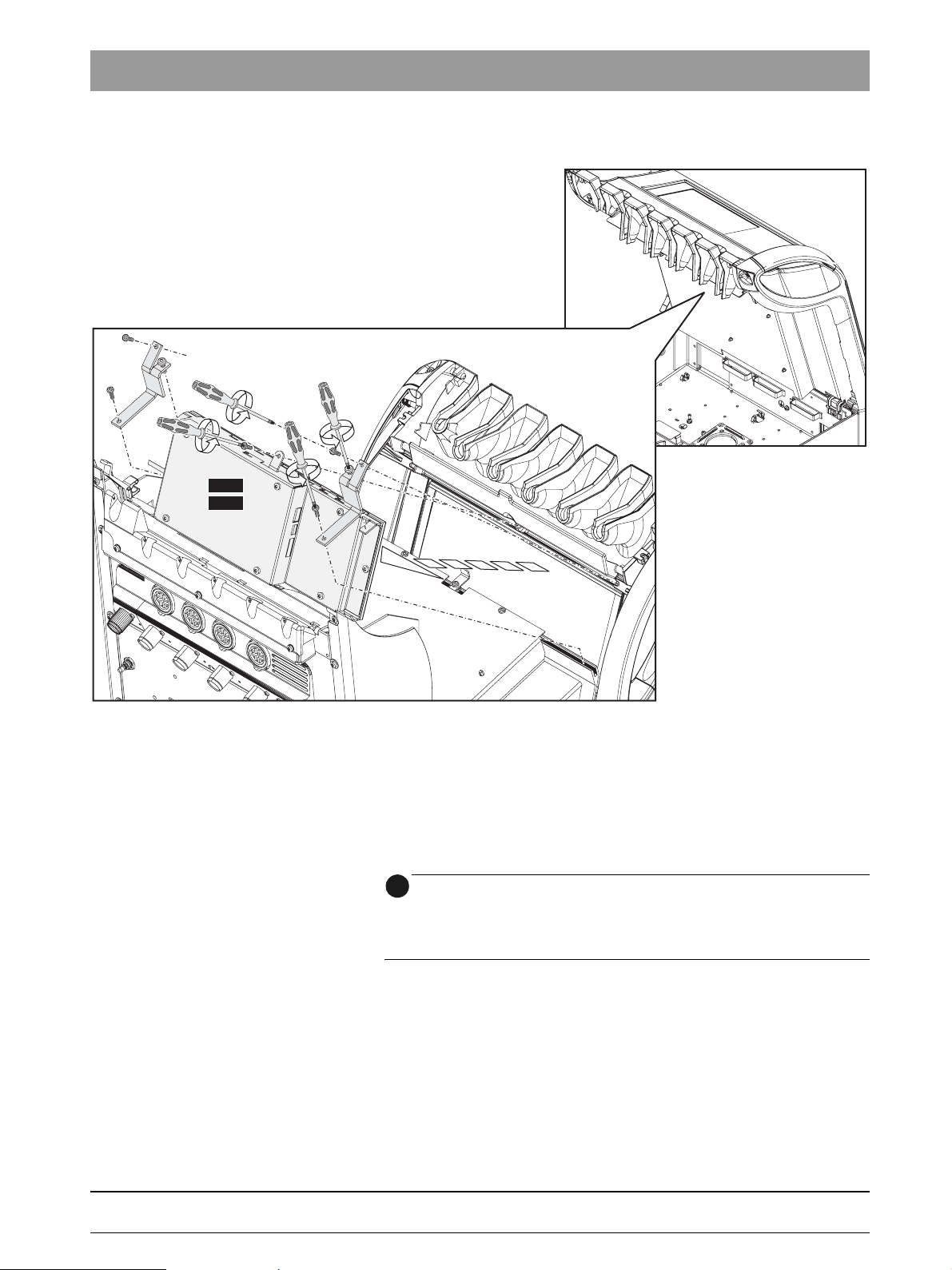

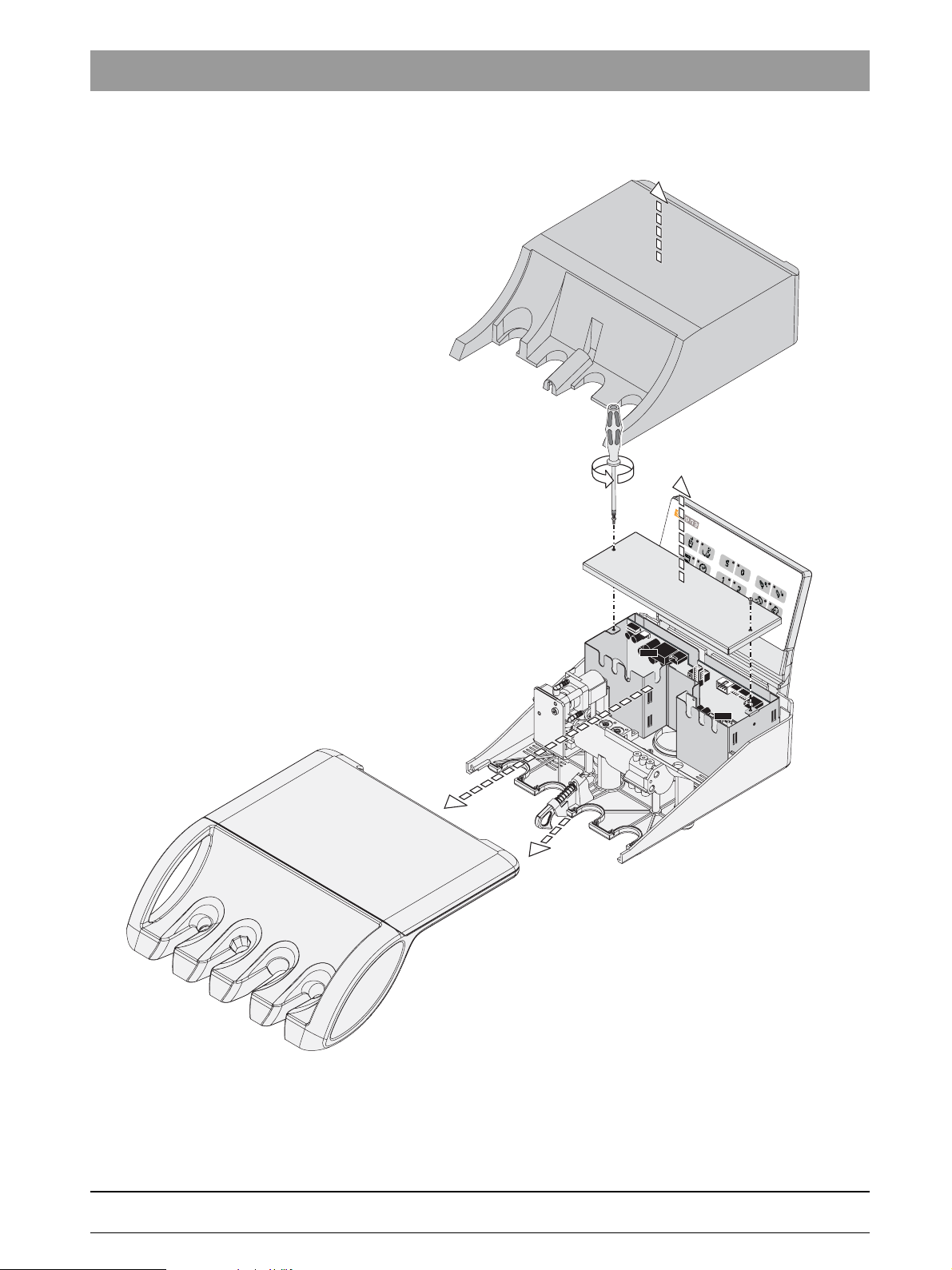

1.10

Opening the dentist element

3.

NAC

NAL

NAJ

NAU

5.

HF

2.

CC

1.

2.

1. Unscrew the two screws.

2. Press the locking bar.

3. Lift the cover upwards and let it lock it into the upright position.

4. Unscrew two screws and

5. fold down the PCB holder plate.

1 – 12 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1.

2.

2.

3.

NAB

NAK

1 Important information

1.11 Removing the user interface on the dentist element

bеЦдблЬ

1. Loosen the setscrew.

2. Unscrew the upper screws of the retaining bracket.

Loosen the lower screws of the retaining bracket.

Turn the right retaining bracket outwards to the right and the left retaining

bracket outwards to the left.

Pull the connector X1 off of the user interface.

3. Unscrew the screw and remove the user interface panel.

i

NOTE

When re-assembling the unit:

Tighten the setscrews 1 and 3 (these are not fastening screws) only until the

user interface panel is fixed in place.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 13

1 Important information

3.

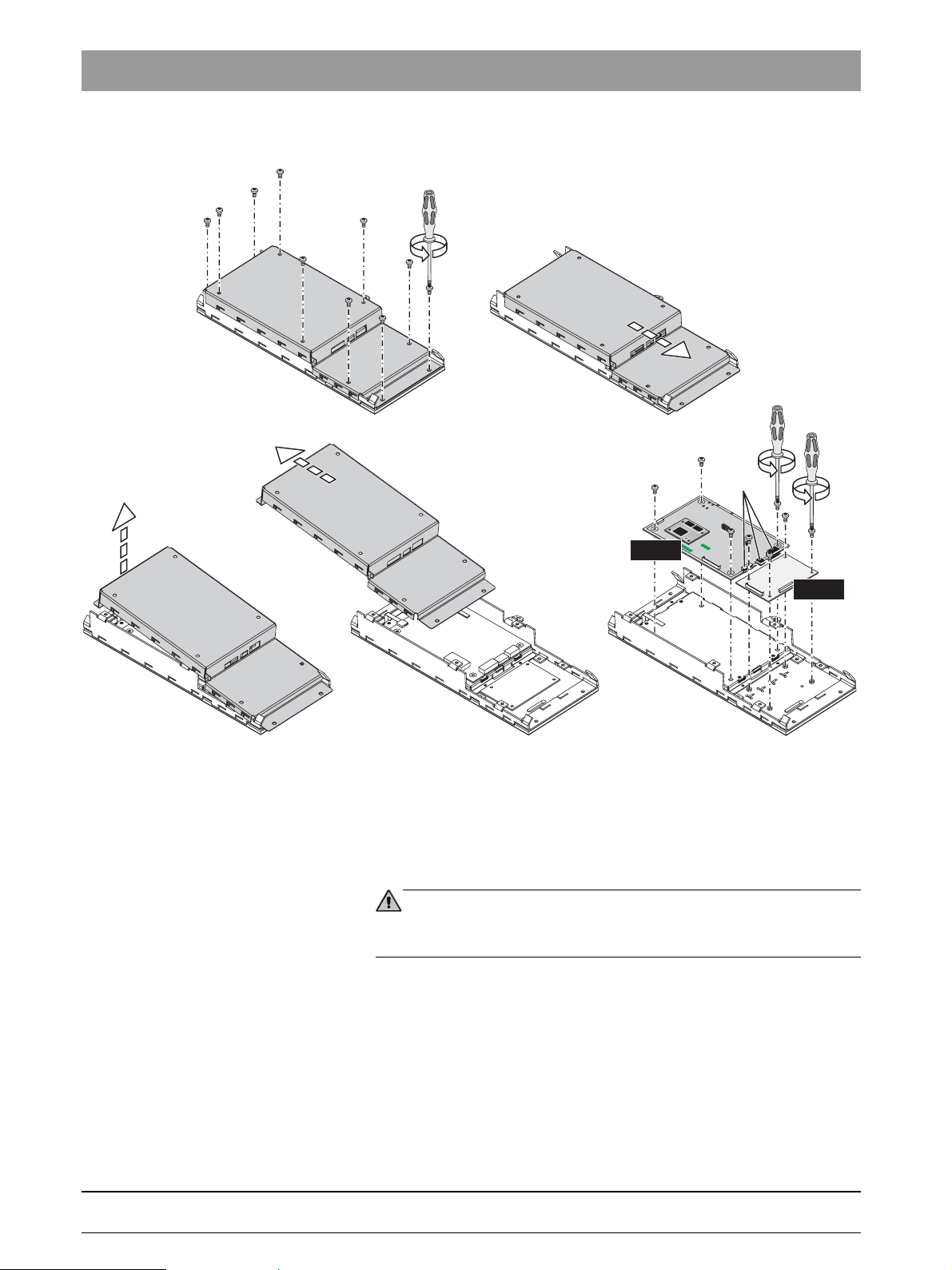

1.12

1.

Removing the NAK and NAB boards

2.

ca. 1cm

X1

X2

X3

4. 5.

NAK

NAB

1. Unscrew the ten screws.

2. Push the cover approximately 1 cm to the right.

3. Lift the left side of the cover and

4. Remove the cover diagonally to the left.

5. Unscrew the boards.

CAUTION

Pay attention to the connectors X1, X2 und X3 on the NAK board when putting

the cover back on!

61 94 448 D 3509

1 – 14 D 3509.076.01.01.02 07.2008

1 Important information

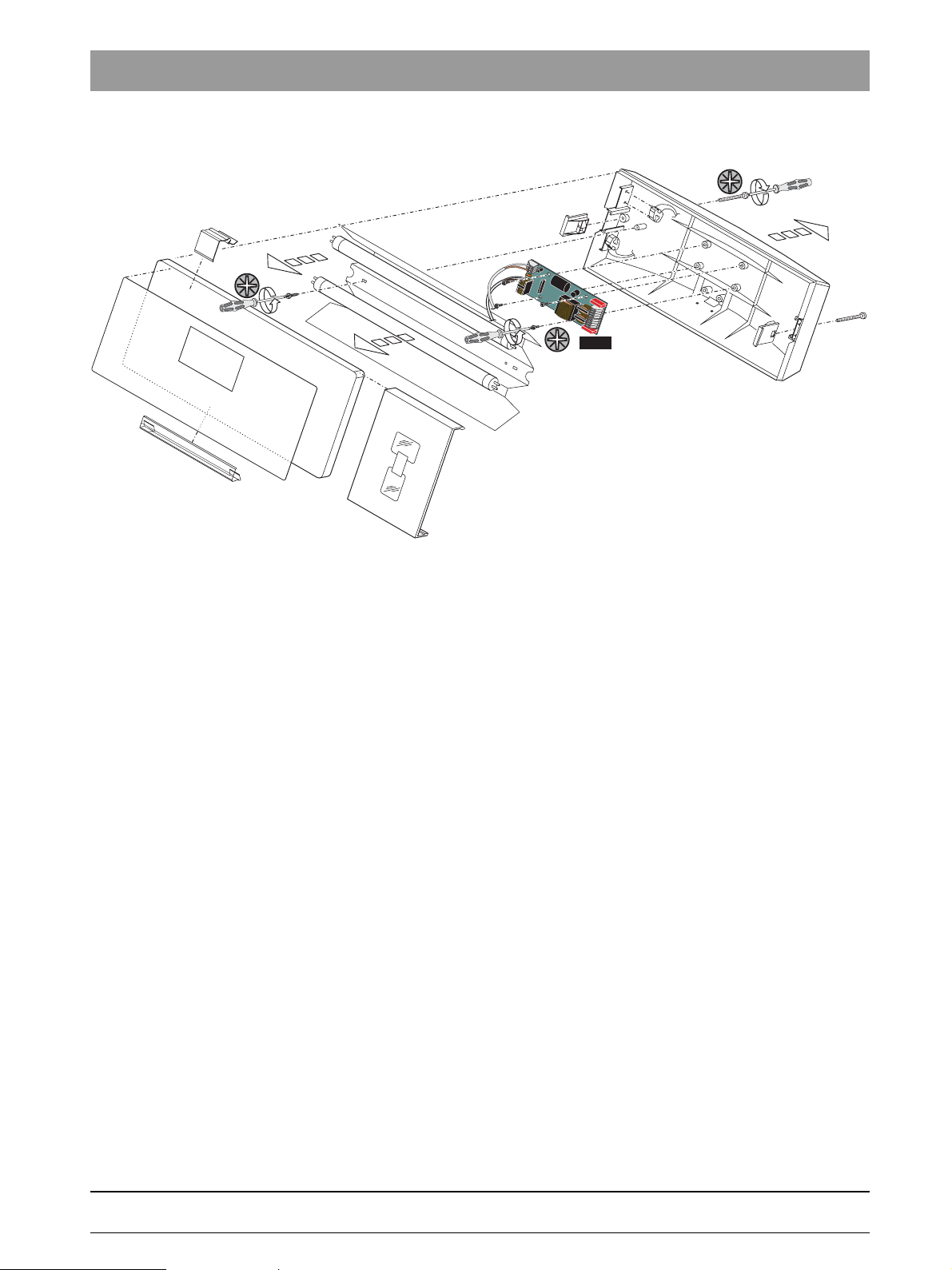

1.13 Removing the NAR board for the X-ray viewer

1.

bеЦдблЬ

3.

2.

1. Unscrew two screws and pull off the back wall.

2. Remove the fluorescent lighting tubes.

3. Unscrew two screws and take off the reflector.

4. Unscrew four screws and remove the NAR board.

4.

NAR

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1 – 15

1 Important information

3.

1.14

Removing the cover panels of the support arm of the

assistant element.

1.

3.

2.

1.

1. Remove the outer half-shell covers.

2. Detach the inner half-shell covers from the bayonet connector and move

them upward.

3. Remove the inner half-shell covers.

1 – 16 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

1 Important information

1.15 Removing the cover panels of the assistant element

1.

bеЦдблЬ

1.

1.

2.

2.

C

NHE

NOP

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

1. Pull the bar and remove the cover panels.

2. Unscrew two screws and remove the cover.

1 – 17

1 Important information

1.

3.

1.16

7.

Removing the cover panels from the water unit

6a.

8.

5.

A

4.

6.

3.

4

3

5

2

6

1

r

a

0

b

4

3

5

2

6

1

r

a

0

b

1.

3.

2.

1. Carefully pry apart the side panels.

Pull off the side panels.

2. Take off the service cover.

3. Unscrew the two screws on each of the covers, unhook and remove

covers.

4. Take off the cover.

5. Unscrew the four screws on the cover.

6. Remove the cover, 6a.. Remove the cover.

7. Unscrew the two screws on the cover and remove the cover.

8. Remove cover panel funnel.

Pay attention to snap-in nose A.

1 – 18 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

TENEO

2 Overview of modules and boards

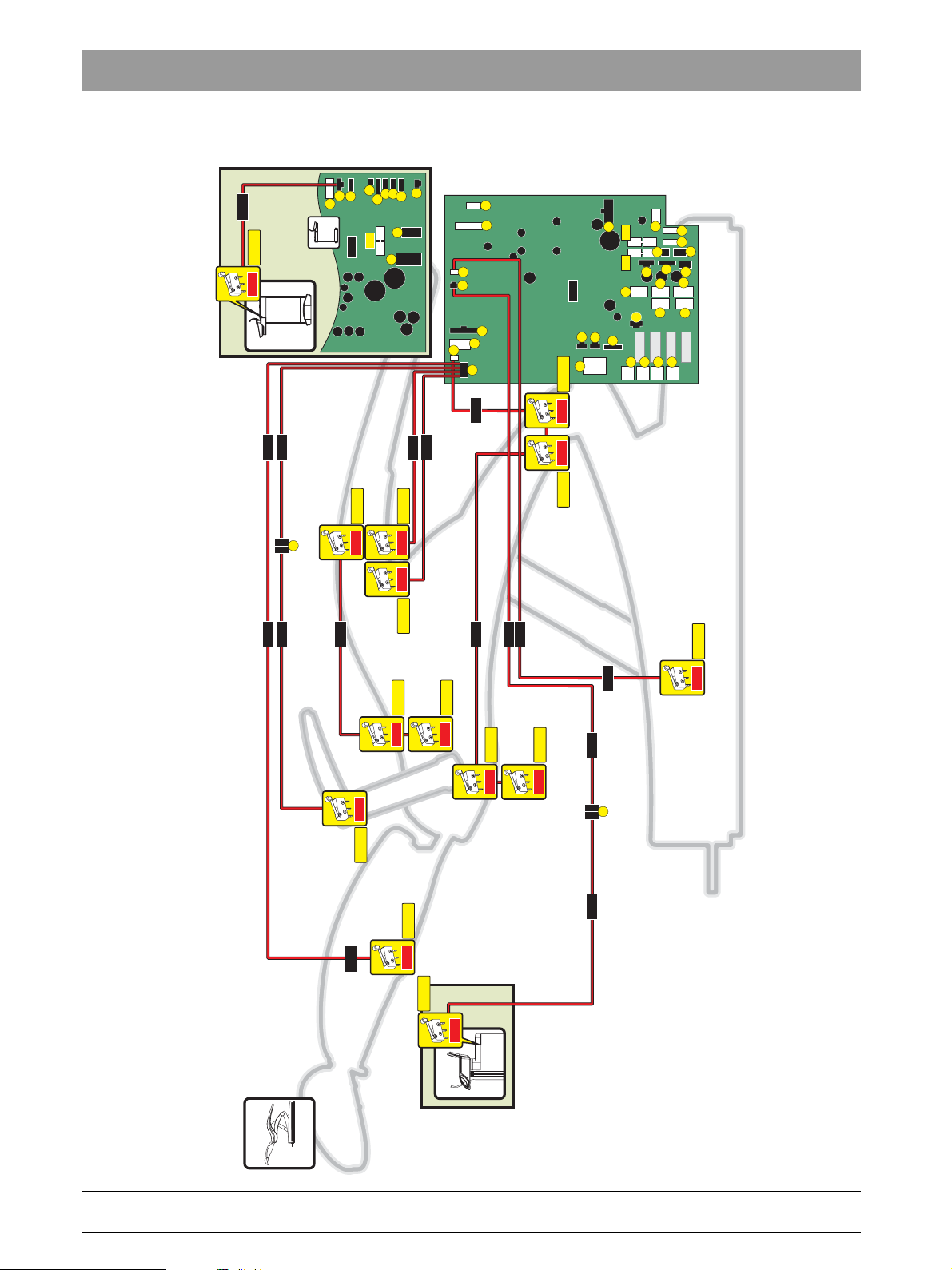

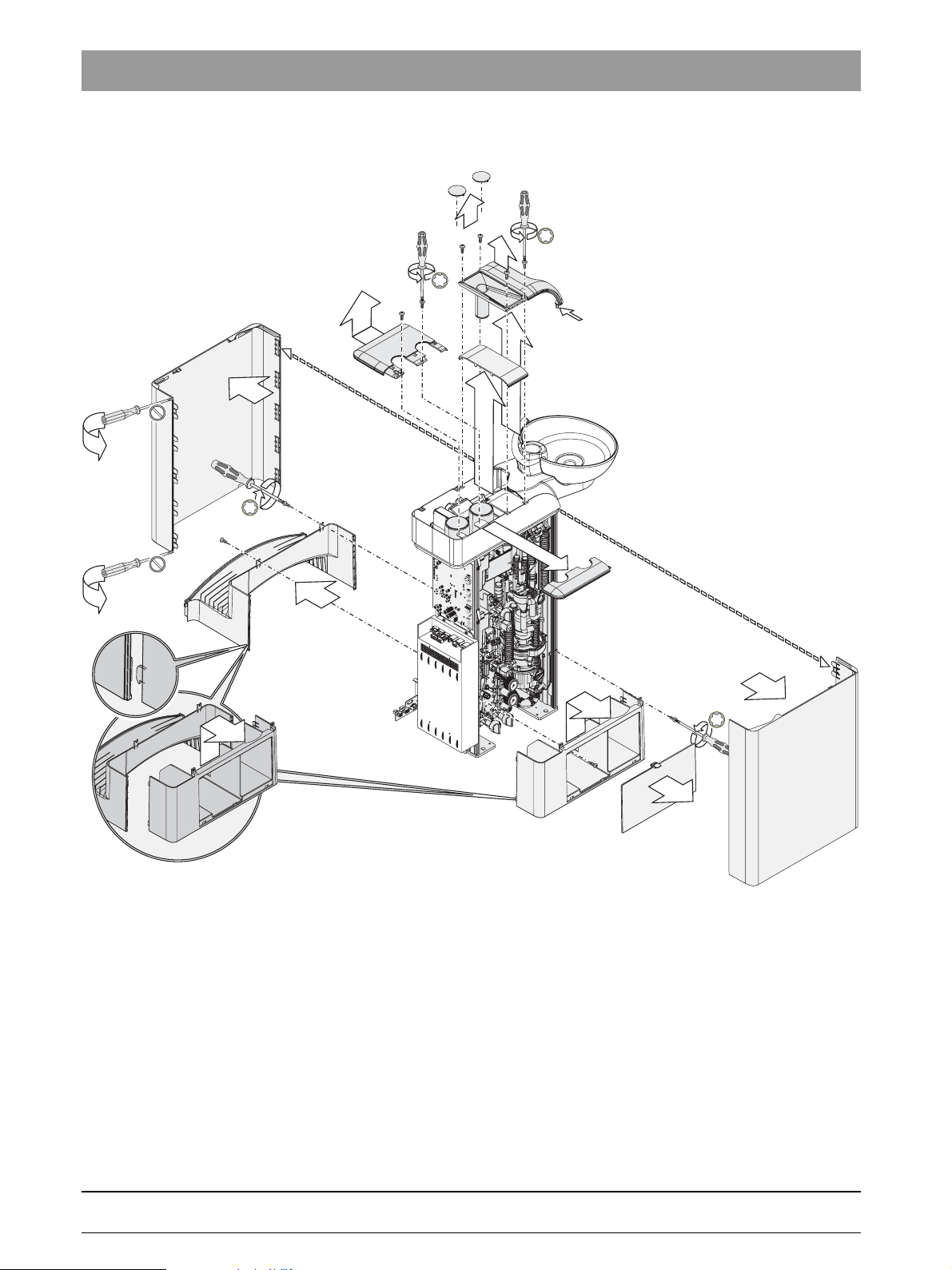

2.1 Locations of modules and boards

2.1

Locations of modules and boards

oder

ASEFSFU STAE WERÖBI

Component Board/module

ST Patient chair DCFU Motor control ( 3 units)

NSA Connection box

NSB Base station wireless foot control

NSC Seat connect

NSK Headrest

NSU USB connection to chair

FS Foot control

FU Wireless foot control NSF Wireless foot control

AE Dentist element CC instrument holder recognition AE (6 x)

RÖBI X-ray viewer

on the AE or tray support arm WE

ASE Assistant element NHE ASE control

WE Water unit NWE WE control

+

HF

NAB User interface AE LED board

NAC Motor control BL

NAJ AE control

NAK User interface AE baseboard

NAL Motor control SL

NAU USB connector to AE

NAR X-ray viewer board

NHT User interface ASE

NOP 5 V power supply

NWM Automatic tumbler filling

surgery module

2 – 2 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.2 ... In the patient chair

M3

M2

M1

2.2.1 DCFU board - Motor control board

DCFU für Rückenlehnenneigungs-Motor

2.2 ... In the patient chair

DCFU

X5

DCFU

V1

V2

DCFU für Rückenlehnen-Motor

Board Components on the board

DCFU Motor control

Backrest motor

V2 status LED (Yellow) Flashing 2 Hz > Motor running

M3

V3 36 V LED (Green)

X1 > L326 > X9 NSA Power supply

X2 > M3 Motor connection

X4 > L324 > X10 NSA Control line

X5 > L345 > Light barrier for reference travel and adjustment

X6 > Sensor Angular momentum sensor of motor

Board Components on the board

DCFU Motor control

Backrest inclination motor

V2 status LED (Yellow) Flashing 2 Hz > Motor running

M2

V3 36 V LED (Green)

X1 > L326 > X9 NSA Power supply

X2 > M2 Motor connection

X4 > L324 > X10 NSA Control line

X5 > L346 > Light barrier for reference travel and adjustment

X6 > Sensor Angular momentum sensor of motor

Board Components on the board

DCFU Motor control

Lift motor

V2 status LED (Yellow) Flashing 2 Hz > Motor running

M1

V3 36 V LED (Green)

X1 > L325 > X7 NSA Power supply

X2 > M1 Motor connection

DCFU

bеЦдблЬ

X4

X6

DCFU für Hub-Motor

X1

X2

DCFU

V3

ON > Motor idling

Flash code > Service message to NSA board

ON > Motor idling

Flash code > Service message to NSA board

ON > Motor idling

Flash code > Service message to NSA board

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 3

2.2 ... In the patient chair

M3

M2

M1

Board Components on the board

X4 > L308 > X29 NSA Control line

X5 > L344 > Light barrier for reference travel and adjustment

X6 > Sensor Angular momentum sensor of motor

V2 status LED (Yellow) Flashing 2 Hz > Motor running

Function of the DCFU board

Activated by the NSA board serially via CAN.

Control of the three-phase drives in the patient chair.

Acknowledgment of the motion via sensors in the motor.

Position recognition via counting of the pulses by the software of the DCFU board.

Communication of the motor position to the NSA board.

Motor locations

ON > Motor idling

Flash code > Service message to NSA board

2 – 4 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.2 ... In the patient chair

2.2.2 NSA board - Connection box

X14

X12

X3

X10

X13

V

V633

629

V

V623

618

V

X

X21

X

X26

X

X24

X

X22

5

0

V

3

5

0

V

8

4

1

V

1

4

0

V

1

4

0

V

3

4

V

3

0

V

6

3

0

V

1

3

0

3

V

1

1

V

0

1

2

1

V

0

1

1

1

0

0

18

27

25

23

17

X

31

X

5

X

4

X

939

X

V

X

1

X2

16

X

0

4

V

3

0

7

V

1

0

0

V

9

0

V

9

0

V

9

V

9

20

15

X

19

X

30

X

28

X

1

2

1

3

3

V

V209

5

7

4

V

V212

X11

0

2

4

1

6

509

V

V215

V

201

V

2

3

8

V

2

3

9

V743

X9

X8

NSA

V

744

V

745

V

7

4

0

X6

F1

F2

X29

X7

NSA

bеЦдблЬ

Board Components on the board

NSA Patient chair control F1 - T10AH 250V P Dentist element

F2 -T 10 AH 250 V P Assistant element

V201 - 36 V (Green)

V209 - 3.3 V (Green)

V212 - 5 V_Poti (Green)

V215 - 5 V (Green)

V238 - 36 V_AE (Green)

V239 - 36 V_HE (Green)

V503 - 3 V WDT (Green)

V303 - RESET (red) Lights up briefly after the unit is switched on

V508 - Safety Stop (red) ON > Locking of the motors, MVs, relay

> 1. Update software or

V901 - OC Track (red) ON > Overcurrent shutdown travel track

> Short circuit in motor 6 or in the line L309

V902 - OC Clutch (red) ON > Overcurrent shutdown travel track clutch

> Short circuit in the clutch or in line L309

V307 - ERROR (red) Flash code >

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2. Replace board

2 – 5

2.2 ... In the patient chair

Board Components on the board

V402 - SS Code (red) Flash code Active safety switch

V411 - Chair stop active (Yellow) ON > Motion lock by active instrument

V416 - HR_Stop (Yellow) ON > Motion lock by active instrument

V623 - Bell relay (Yellow)ON > Relay actuated

V629 - Auxiliary relay (Yellow)ON > Relay actuated

V633 - Suction relay (Yellow)ON > Relay actuated

V740 - 36 V M1 (Yellow) ON > 36 V Motor 1 enabled

V743 - 36V M2 (Yellow) ON > 36 V Motor 2 enabled

V744 - 36V M3 (Yellow) ON > 36 V Motor 3 enabled

V745 - 36 V NSC (Yellow) ON >NSC board enabled

V935 - Track (Yellow) ON > Move travel track close

V937 - Track (Yellow) ON > Move travel track away

V939 - Clutch (Yellow) ON > Travel track clutch activated

V1001 - FS active (Yellow) ON > Foot control pedal activated

V1100 - LAN Speed LED (Yellow) ON > 100 Mbit

V1101 - LAN Link/Activity (Yellow) ON > When connected

V1102 - LAN Full Duplex (Yellow) ON > If full duplex

X1 > L307 > SDI2 X1.1 - X1.10 > L248 > X22 NAJ

X2 > L305 > X6 > L205 > X5 NWE

X3 > L306 > X3 NSC

X4 > L340 > SDI2 X2.1 - X2.10 > L231 > X4 NHE

X5 > L311 > X5 NSB

X6 > L302 > X3 > L202 > X2 power supply

X7 > L325 > X1 DCFU M1 power supply

X8 > L303 > X1 NSC power supply

X9 > L326 > X1 DCFU M2 and DCU M3 power supply

X10 > L324 > X4 DCFU M2 and DCU M3 control line

X11 > L316 > S12 SS-SH

X12 > L317 > S1 - S4 SS-HR

X13 > L333 > SDI2 X2.12 - X2.13 > L235 > S14 SS_HE > L232 > X1 NHE

X14 > L331 > S5 - S8 SS_HL

> L334 > S9 SS_FA

> L332 > S10 SS_RL

> L335 > X13 > L342 > S11 SS_AL

X15 > L312 > 4-way foot switch

X17 > L309 > M6 4-way foot switch

X18 > L310 > X7 Poti 4 way foot switch

2x > Chair lift and cuspidor bowl

3x > Lifting frame

4x > Assistant element

5x > Handrail

6x > Footrest

7x > Backrest

8x > Armrest

9x >Malfunction in communication to user interface

10x > Total tilt implausible

1. Carry out reference travel

2. Replace NSC

11x > Chair stop active = LED 411

12x > Total tilt invalid

OFF > 10 Mbit

Flashes > During LAN data transmission

OFF> If half duplex

2 – 6 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

Board Components on the board

X19 > L313 > X8 / X9 > L314 C2+ foot control

X20 > L313 > X8 / X9 > L314 C2

X21 > RJ45 > L339 > RJ45 External PC Sivision

X26 > L328 > MVP1 - MVP3

X27 > MVAB

X28 > L341 > SDI2 X2.14 - X2.15

X29 > L308 > X4 DCFU M1 Control line

X30 > L315 > SDI2 X1.14 / X1.15 > L249 > X22 NAJ

+

foot control

Function of the NSA board

Travel track activation

Activation of the main input valves for air/water

Activation of the valve block for the media in the dentist element (SV and PV)

Enabling of wireless foot control (optional)

Evaluation of four-way foot switch

Evaluation C

System clock (RTC)

Evaluation of the position sensor on the NSC board

Communication with the user interface via S-CAN

Communication with the DCFU boards

Power supply for the DCFU boards

Communication with the NSC board

Communication via Ethernet with the PC

Power supply for the electronic circuit of the assistant element

Power supply for the electronic circuit of the dentist element

Evaluation of all safety switches

Software update via LAN / Implementation of the Ethernet protocol on S-CAN

+

of foot control

2.2 ... In the patient chair

bеЦдблЬ

i

NOTE

If the safety switch S12 is active (V402/SS code/Flashes 2x), the chair can only move upwards when the cuspidor bowl is

swiveled inwards.

Communication via CAN with the NSK board

Power supply of the NSK board

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 7

2.2 ... In the patient chair

2.2.3 NSB board - Wireless base station

V208

V209

V207

V21o

NSBNSB

V400

Board Components on the board

NSB Wireless foot control base

station

V207 - SP (Yellow) Pedal

V208 - CL (Yellow) Cursor right

V209 - CR (Yellow) Cursor left

V210 - CB (Yellow) Cursor down

V211 - CF (Yellow) Cursor up

V213 - Bat (Red) ON > Replace battery in wireless foot control

V214 - SL (Yellow) S / Spray

V216 - SR (Yellow) O / Chip blower

V221 - WDT (Red) ON > Cable foot control connected or no CAN

V300 - 36 V (Green)

V301 - 3.3 V (Green)

V308 - 2.5 V (Green)

V311 - 5 V (Green)

V400 - RUN (Green) Must flash with 1 - 2 Hz in normal status

V402 - BOOT (Yellow) Lights up briefly when booting

V403 - RESET (Red) Lights up briefly after the BHE is switched on

X5 > L311 > X5 NSA

V402

V308

V211

V214

V216

V213

V221

V300

X5

NSB

V403

V301

V311

communication or NSB board defective

Flashing > Overcurrent protection on foot control line active

> Flashing 1 Hz = Login procedure active

Function of the NSB board

Wireless base station for devices connected by wireless (e.g. wireless foot control).

Communication with the other boards via CAN.

Transmission frequency 2.4 GHz

61 94 448 D 3509

2 – 8 D 3509.076.01.01.02 07.2008

2.2.4 NSC board - Seat connect

X1

X5

X1

X1

X1

V9

V17

2.2 ... In the patient chair

V48

V39

V29

V24

V50

V30

V35

V31

V36

V37

V40

V41

bеЦдблЬ

V23

NSC

X2

X5

X4

X3

X1

Board Components on the board

NSC Seat connect V23 - 3.3 V (Green)

V24 - MVKP4 (Yellow)Deflate upper cushion Massage

V29 - MVKP3 (Yellow)Inflate upper cushion Massage

V39 - MVKP2 (Yellow)Deflate lower cushion Massage lumbar support

V48 - MVKP1 (Yellow)Inflate lower cushionMassage lumbar support

X1 > L303 > X8 NSA

X2 > L338 > X14 > Solenoid valves MVKP1 / MVKP2

X2 > L338 > X15 > Solenoid valves MVKP3 / MVKP4

X3 > L306 > X3 NSA

X4 > L322 > X10 > L323 > X4 NSK

NSC

Function of the NSC board

Activation with serial interface of NSA board with IIC bus.

Evaluation of the position sensor for the seating angle.

Forwarding of the CAN connection to the NSK board.

Activation of the solenoid valves for massage support.

For the active lumbar support support, only the lower cushion is inflated.

For massage, the lower and upper cushions are alternately inflated.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 9

2.2 ... In the patient chair

X14

X15

Solenoid valve for massage/active lumbar support

A58

A57

MVKP1

MVKP2

MVKP3

MVKP4

A55

Components

MVKP1 - Lumbar support inflation

MVKP2 - Lumbar support deflation

MVKP3 - Massage inflation

MVKP4 - Massage deflation

MVKP3 / MVKP4 > X14 > L338 > X2 NSC

MVKP1 / MVKP2 > X154 > L338 > X2 NSC

2 – 10 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.2.5 NSK board headrest

NSK

V523

V

405

V

502

V410

5

0

2

2

0

5

3

0

5

2

V

6

V

6

V

V

5

2

6

6

V

V

V307

V

301

V

303

V306

0

2

0

0

4

V

1

0

9

15

2

2

0

2

1

V

2

V

2

V

V

2.2 ... In the patient chair

bеЦдблЬ

X4

1

X

NSK

Board Components on the board

NSK Headrest V201 - 36 V ( Green)

V209 - 3.3 V ( Green)

V212 - 3.3V Poti (Green)

V215 - 5 V ( Green)

V301 - RUN (Green) Flashes in normal operation

V303 - RESET (Red) Lights up briefly after treatment center is switched on.

V306 - BOOT (Yellow)

V307 - ERROR (Red)

V402 - 3V_WDT (Green) ON > OK

V405 - Headrest stop M5 (Yellow)Directly connected with HR_Stop (V416) from NSA board

V410 - Safety Stop (Red) OFF > OK

V500 - OC_Headrest tilt M5 (Red) ON > Short circuit in tilting section of motor/line

V502 - Headrest tilt block M5 (Yellow)ON > Motor brake for tilt section active

V523 - Headrest tilt M5 (Yellow)Headrest backward

V525 - Headrest tilt M5 (Yellow)Headrest forward

V600 - OC_Headrest M4 (Red) ON > Short circuit in motor/line for size adjustment

V602 - OC_Headrest block M4(Yellow)ON > Motor brake size adjustment active

OFF > and V201 ON > Replace NSK board

OFF > and V201 OFF > Check line 36 V

ON > Motion locking via active instrument

ON > Check V405

ON > Motor control blocked by NSA board

OFF > Check RUN-LED

OFF > Update software

Flashing > Replace N>SK board

D 3509.076.01.01.02 07.2008

2 – 11

61 94 448 D 3509

2.2 ... In the patient chair

Board Components on the board

V623 - OC_Headrest M4 (Yellow)Extend motor for size adjustment

V625 - OC_Headrest M4 (Yellow)Retract motor for size adjustment

X1 > L327 > M5 tilt component

X1 > L337 > Poti tilt component

X1 > L321 > M4 size adjustment > Poti size adjustment

Function of the NSK board

Activation and evaluation of size adjustment

Activation and evaluation of overstretch.

Communication with the other boards via CAN.

Evaluation of the four-way switch in the headrest.

2 – 12 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.2.6 NSU board - USB connection to patient chair

NSU

2.2 ... In the patient chair

X11

X12

V12

NSU

bеЦдблЬ

V3

V4

X5

X1

V7

X2

X3

V11

V8

V9

Board Components on the board

NSU USB connection to patient

V3 - 5V (Green)

chair

V4 - 3V3 (Green)

V7 - X5 (Green) USB connection to external PC

V8 - X2 (Green) ON > If USB device on X2

V9 - X3 (Green) ON > If USB device on X3

V11 - X1 (Green) ON > If USB device on X1

V12 - 12V5 (Green)

X1 > L330 > X1 SDI

X5 > L348 > USB repeater > L343 > External PC

X11 > L320 > X4 > L203 > X6 Power supply

Function of the NSU board

In the patient chair it forms the interface between the PC connection and the USB applications in the dentist element.

The integrated power supply unit supplies a current of 2000 mA for the power supply of the USB connections.

The NSU board provides 12.5 V for the NAU board in the dentist element.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 13

2.3 ... in the foot control

S

0

NSF

2.3

... in the foot control

2.3.1 Wireless foot control

V4

Board Components on the board

NSF Wireless foot control

V4 - As long as the login procedure is running, the reflection of the green flashing LED is visble

on the step.

The flashing stops when the login has been successfully completed or after 30 seconds

without a login.

Battery status indicator during battery insertion:

10 sec ON > Battery usable

10 sec FLASHING > Replace battery

OFF > Battery empty or NSF board defective

61 94 448 D 3509

2 – 14 D 3509.076.01.01.02 07.2008

2.4 ... in the dentist element

2.4.1 CC board - instrument holder recognition in the dentist unit

CC

2.4 ... in the dentist element

bеЦдблЬ

V1

V11

X1

Board Components on the board

CC Instrument deposit

acknowledgment

V2

V12

V3

V13

V4

V14

V5

V15

V1 / V11 Sensor holder 1

V2 / V12 Sensor holder 2

V3 / V13 Sensor holder 3

V4 / V14 Sensor holder 4

V5 / V15 Sensor holder 5

V6 / V16 Sensor holder 6

X1> L260 > X12 NAJ

CC

V6

V16

Function of the CC board

Acknowledgment of instrument removal in the holder of the dentist element via infrared transmitter/receiver.

Not compatible with the C line.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 15

2.4 ... in the dentist element

2.4.2 HF+board - Surgery module

V9

V25

V26

X10

V24

V27

V23

X6

X7

X2

X4

X5

Board Components on the board

+

HF

Surgery module F1 - 4AM 36 V DC

X1

+

HF

R51 - Buzzer volume

V9 - Voltage in end phase (Green)

V23 - +5 V (Green)

V24 - Function check (Green)

V25 - HF active (Green)

V26 - CAN check (Green)

V27 - RESET (Red) Lights up briefly after treatment is switched on.

X1 > L252 > X32 NAJ 36 V DC power supply

X2 > L252 > X32 NAJ CAN / foot control

X4 > Flange_HF

X5 > Connection to ground wire

X6 > Flange_HF hose code

X7 > Code Pin 2 / Pin 3 must be connected

X10 > Jumper C1 / C2 must be connected at C1

R51

F1

HF

+

Function of the HF+ board

Generates the high frequency of the Sirotom handpiece.

The one pin of the high voltage is the tip of the handpiece, the other is the ground / casing.

Control via CAN.

Overheating guard at the end phase.

Generation of the operating tone with active HF.

The HF module is switched on for a few seconds after the dental treatment center is switched on. During this period the

HW/SW status is queried and the module carries out a self-test. Subsequently the module is switched off again. When the

HF handpiece is removed, the module is switched on again and carries out a brief self-test. When the handpiece is

returned to its place, the module is switched off again.

For operation in this dental treatment center, the code bridge X10 must be set to position "C1" and the code bridge at X7

must be connected to Pin 2 / Pin 3.

When HF is activated, the video circuit is shut off in the power pack and switched on again when the handpiece is

replaced. This is necessary so that no interference is visible on the screen when HF is active. When the video circuit is

switched off, the USB power supply and thus the USB camera are switched off.

61 94 448 D 3509

2 – 16 D 3509.076.01.01.02 07.2008

2.4.3 NAC board - BL motor control

2.4 ... in the dentist element

V204

V236

V205

V212

V301

V302

V303

V312

V311

V310

V304

V203

V901

X8

X6

NAC

X1

X5

X12

X13

X14

X15

X3

NAC

Board Components on the board

NAC BL motor control V203 - 3V3 (Green)

V204 - 3V3 (Green) analog

V205 - 5 V (Green)

V212 - 12 V (Green)

V236 - +36 V (Green)

V301 - RUN (Yellow) Flashes during standby 1 Hz

V302 - TEST 1 (Yellow) Lights up when foot control is activated

V303 - TEST 2 (Yellow) Lights up when motor controller J416 is in error status

V304 - BOOT (Yellow)

V310 - RESET (Red) Lights up briefly after unit is switched on

V311 - ERROR (Red)

V312 - CLAW (Yellow) Indicates the active instrument holder via flash code

V901 - 5V (Yellow) from NAJ

X1 > L248 > X1.16 / X1.17 AK

X3 > L251 > Flange_Scaler

X5 > Option_PK_Supply

X6 > Option_PK_Communication

X8 > L244 > X8 NAJ

X12 > L258 > Holder 2

X13 > L258 > Holder 3

X14 > L258 > Holder 4

X15 > L258 > Holder 5

bеЦдблЬ

Flashes when instrument is active 10 Hz

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 17

2.4 ... in the dentist element

Function of the NAC board

This board is integrated in the workstation via CAN and takes over the control of the brushless dental motors and turbines.

Supply for instrument light (halogen or LED).

2 – 18 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.4 ... in the dentist element

V600

V304

V303

V201

V212

2.4.4 NAJ board - Dentist element control

X6

X5

V719

X12

X20

X19

V405

X24

X21

X15

X8

V501

V102

X7

X22

X1

NAS

V212

V212

V201

NAJ

J11

J12

J13

S1

V600

V600

V304

V304

V303

V201

Board Components on the board

NAJ Dentist element control J11 > SW Option 1)

J12 > SW Option 2)

J13 > SW Option 3)

S1 > S1.1 ON > Ultrasound on instrument holder pos. 6

OFF > Ultrasound on holder pos. 5

S1.2 ON > Camera on external holder pos. 7

OFF > Camera on holder pos. 6

V102 - Chair Stop (Yellow)

V201 - 36 V (Green)

V211 - 26V5 (Green)

V212 - 5 V (Green)

V216 - 3V3 (Green)

V300 - HB (Green) Flashes during normal operation

V302 - BL (Yellow) Lights up briefly while booting

V303 - ERROR (Red) Flash code

V304 - RESET (Red) Lights up briefly after unit is switched on

V305 - User (Yellow) Lights up when at least one instrument has been removed

V405 - NaCl (Yellow) ON > NaCl pump switched on

V501 - 36V (Green) ON > Heater switched on

V600 - FPGA (Yellow) Flashing > OK (configuration is loaded)

V719 - P5V (Green) ON > Sprayvit removed Sprayvit supply on

V1002 - 36V_AUX (Green)

V1003 - 36V_HF (Green)

X1 > L246 > X1 NAP

X2 > L250 > Flange_Scaler

X5 > L256 > Holder 1 Sprayvit with light, air and water heater

X6 > L256 > Holder 1 Sprayvit with light, key and hose coding

X7 > L245 > Spray water heater

X8 > L244 > X8 NAL

X12 > L260 > X1 CC

V1002

V1003

NAJ

X32

NAS

X2

V216

V211

V305

V302

V300

Permanently ON > Connection to NSA board not present

or NAJ board is defective

Lit up> US scaler active

bеЦдблЬ

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 19

2.4 ... in the dentist element

Board Components on the board

X15 > L247 > X-ray viewer

X19 > MV_21_1 - MV_21_4 / MV_22_ZEG_Water / MV_23_ZEG_Air /

X21 > L248 > X1.14 / X1.15 AK

X21 > L248 > X1.14 / X1.15 AK

X21 > L248 > X1.14 / X1.15 AK

X21 > L248 > X1.14 / X1.15 AK

X22 > L249 > X1.1 - X1.10 AK

X24 > NaCl

X32 > L252 > X1.1 , X1.2 HF+

X2.1B, X2.2B HF+

X2.3B, X2.4B HF+

Function of the NAJ board

The NAJ board controls the dentist element functions.

The board is part of the basic equipment of the dentist element in the dental treatment center.

The following functions have been implemented:

- Control of the Sprayvit and ultrasound instruments and intraoral video camera

- Instrument removal acknowledgment

- Control of solenoid valve, med. solution, standard (water) heater, light barrier 5/6 on the instrument holder, NaCl pump

- Control and power supply for optional board for X-ray viewer

- Communication with the NAL instrument controls (for SL) and NAC (for BL motors)

- Interface to user interface

- Interfaces for 3 HW dongles (J11 / J12 / J13)

- Control and interface for optional HF and apex

MV_24_Sprayvit_Water / MV_25_Sprayvit_Air

S1 switch settings:

OFF ON

S1.1 Ultrasound

ON ON Ultrasound on instrument holder pos. 6 / Camera on external holder pos. 7

ON OFF Not permissible (ultrasound does not work)

OFF ON Ultrasound on instrument holder pos. 5 / Camera on external instrument holder pos. 7

OFF OFF Ultrasound on instrument holder pos. 5 / Camera on instrument holder pos. 6

S1.2 CAMERA

Function

2 – 20 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.4 ... in the dentist element

2.4.5 NAK board - User interface to dentist element baseboard and NAB board LED board

X21

X

14

GND

Keyb

Board Components on the board

NAK User interface to dentist

element baseboard

NAK

36V

3,3V

Run

Error

Reset

BackI

X11

LED 3V3 - (Green) Operating voltage

LED 36 V - (Green) Operating voltage

LED 5 V - (Green) Operating voltage

LED BackI - (Green) No function at present

LED Error - (Red) Lights up when there's an error on the PCB

LED Keyb - (Orange) Lights up during activation of the ext. Keyboard

LED Reset - (Red) Lights up briefly after the unit is switched on

LED Run - (Green) Flashes during normal operation

X1 > L246 > X1 > NAJ

X11 > NAB

X14 > Touch connection

X21 > Display connection

5V

X1

X11

bеЦдблЬ

NAB

X10

Function of the NAK board

Control of a 7" TFT display

Control of the user interface functions

Touch evaluation

CAN for BHE control

S-CAN for comfort functions

Communication with NAB via serial interface (keyboard/indicator LEDs)

Power supply 5 V, 3.3 V for operation of the user interface

Forwarding of the ON/OFF signal from the NAB PCB to the NAJ PCB

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 21

2.4 ... in the dentist element

Keyboard click

Control of the operation indicator derived directly from the operating voltage.

i

NOTE

In case of a fault during the warranty period, please replace the complete user interface.

Exception: During the warranty period the customer damaged the operating film and wants it replaced. This is not a warranty

case. However, in order to keep costs down, the front plate can be replaced. Please comply with the installation instructions for

the front plate.

NAB board LED board

Board Components on the board

NAB LED board X10 Connection of the ext. key matrix and ON/OFF button

X11 > Connector for the NAK board

Function of the NAB board

Evaluation of the ext. keyboard

Communication with NAK via serial interface

Control of the function and cursor LEDs

Forwarding of the ON/OFF signal

2 – 22 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.4.6 NAL board - SL motor control

2.4 ... in the dentist element

V300

V301

V308

V309

V305

V203

V207

V202

V901

X8

X6

X5

X1

X12

Board Components on the board

NAL SL motor control V202 - 36 V (Green)

X13

X14

NAL

X15

NAL

X3

V203 - 3V3 (Green)

V207 - 5V (Green)

V300 - RUN (Yellow) Flashes during standby 1 Hz

V301 - BOOT (Yellow)

V305 - RESET (Red) Lights up briefly after unit is switched on

V308 - ERROR (Red)

V309 - CLAW (Yellow)Indicates the active instrument holder pos. via flash code

V901 - 5V EK (Green)

X1 > L248 > X1.16 / X1.17 AK

X3 > L251 > Flange_Scaler

X5 > Option_PK_Supply

X6 > Option_PK_Communication

X8 > L244 > X8 NAJ

X12 > L258 > Holder 2

X13 > L258 > Holder 3

X14 > L258 > Holder 4

X15 > L258 > Holder 5

bеЦдблЬ

Flashing when instrument is active 10 Hz

Function of the NAL board

This board is integrated in the workstation via CAN and takes over the control of the brush dental motors and turbines.

Supply for instrument light (halogen or LED).

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 23

2.4 ... in the dentist element

V7

2.4.7 NAU board - USB connector to AE

NAU

V4

V7

V11

X5

X1

Board Components on the board

NAU USB connector to AE V4 - 3V3 (Green)

V8

X2

V7 - X1 (Green) ON > when connector X1 is occupied

V8 - X2 (Green) ON > when connector X2 is occupied

V11 - 12V5 (Green)

X1 > USB camera

X2 > USB device

X5 > L261 > X1.20 - X1.23 AK

NAU

Function of the NAU board

USB HUB for 2 USB connections

61 94 448 D 3509

2 – 24 D 3509.076.01.01.02 07.2008

2.5 ... in the X-ray viewer

2.5.1 NAR board - X-ray viewer

KL3

L247

+36V

GND

2.5 ... in the X-ray viewer

A

C

NAR

1

KL1

8

KL2

bеЦдблЬ

1

2

5

6

Board Components on the board

NAR X-ray viewer board KL3 -> L247 -> X15 NAJ or X15 NAW

Function of the NAR board

Control of the fluorescent tubes in the X-ray viewer

i

NOTE

The bridge at X15.A1 to X15.B1 on L247 is used to detect whether an RÖBI is present.

X-ray viewer on dentist element

NAJ board supplies operating voltage of 36 V with current limitation on output X15.A2.

The output on X15.B2 is switched against GND when the RÖBI is switched on.

X-ray viewer on tray

NWE board switches the current-limited operating voltage of +36V on at output X15.A2.

Connector X15.B2 is firmly connected to GND.

3

4

7

8

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 25

2.6 ... in the assistant element

X

2.6

... in the assistant element

2.6.1 NHE board - ASE control

NAS

NOP

NHE

6

X

5

X

1

S

101

X

14

X

12

S

100

X11

X4

X

NHE

V304

13

V300

X2

X

3

X

16

C

NAS

V200

V720

V203

V208

Board Components on the board

NHE ASE control V200 - 36 V (Green)

V203 - 3V3 (Green)

V208 - 5V (Green)

V300 - Heart (Yellow) Flashes once per second in normal operation

V304 - Error (Red) Flash code

V720 - P5V (Green) ON > Sprayvit removed Sprayvit supply ON

X1 > L323 > X2 (SDI) AK

X2 > MV31/32, MV36/38/39 KL1-4

X3 > L236 > X3 NOP (Option Mini LED)

X4 > L231 > X2 (SDI) AK

X5 > L237 > KL2 (Sprayvit / Light)

X6 > L237 > KL2 (Sprayvit / Light)

X12 > L233 > X12 NHT

X16 > L216 > MV44 (Hydrocolloid)

Function of the NHE board

The NHE board controls all TENEO assistant element functions that are installed as standard in the dental treatment

center. In addition, the optional mini-LED can also be connected to this board. A further interface for a future option such

as a new polylight is likewise provided.

Activation and analysis of the

- ASE keyboard

- Light barriers on the instrument holder (control of IR light barrier for the holder)

- Solenoid valve (Mv power stage)

- Sprayvit (Sprayvit CTRL and supply)

Communication with other components (communication part)

2 – 26 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

2.6.2 NHT board - ASE user interface

V2

V1

V4

V3

V6

V5

2.6 ... in the assistant element

bеЦдблЬ

V8

V10

V12

V11

V7

V9

X1

C

Board Components on the board

NHT ASE user interface V1 - Glass filling (Yellow)

V2 - Flushing (Yellow)

V3 - S-key (Yellow)

V4 - 0-key (Yellow)

V5 - Headrest UP (Yellow)

V6 - Headrest DOWN (Yellow)

V7 - X-ray viewer (Yellow)

V8 - Timer (Yellow)

V9 - Program 1 (Yellow)

V10 - Program 2 (Yellow)

V11 - Composite (Yellow)

V12 - Sirolux (Yellow)

X1 > L233 > X12 NHE

Function of the NHT board

The NHT board is controlled by the NHE board. The keyboard is evaluated with a key matrix and the LEDs are activated

directly.

The LEDs are always switched on by the NHE software when they receive the acknowledgment from the corresponding

component that the function has been activated.

There is no acoustic feedback when the key is activated.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 27

2.6 ... in the assistant element

2.6.3 NOP board - 5 V power supply

NAS

NHE

X3

X4

X2

NOP

Board Components on the board

NOP 5 V power supply V1 - +33V (Green)

C

V1

V2 - +5V (Green)

X2 > L238 > Mini LED

X3 > L236 > X3 NOP (Option Mini LED)

X4 > L238 > Mini LED

V2

Function of the NHT board

NOP

Universal 5V power supply (e.g. for the mini-LED

61 94 448 D 3509

2 – 28 D 3509.076.01.01.02 07.2008

2.7 ... in the water unit

X

2.7 ... in the water unit

2.7.1 NWE board - Water unit control

MV34

MV33

AA_95

AA_100

MV40.2

MV37

MV35

MV40.1

MV41

SIR_ON

MV44

MV1

MS_ON

MA_ON

V1_LED

R2_ON

MM_DIR1

MM_DIR2

ROE_OFF

MV_3

28V

POWER_FAIL

6

3V3

HEART BOOT

ERROR

ROE_ON

X28

NWE

CUPFILL

X22

X15

EK_90

FS

UNIT_ON

PK_90

PC_LIM

X5

CHAIR_STOP

PC_ON

DS32

DS41

TEMP_10

R2_DT

DN30

bеЦдблЬ

X25

X27

X26

NWE

X29

X9

X18

X10

X8

5V

NOT AUS

SS_SP

36V

F803

X3

S3

X1

Board Components on the board

NWE Water unit control F803 - 10AT - Main fuse for the water unit

LED 3V3- (Green)

LED 5 V - (Green)

LED 28 V - (Green)

LED 36 V - (Green)

LED BOOT - (Yellow) Lights up briefly while booting

Permanently ON > Connection to NSA board not present or

NAJ board is defective

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

X14

X20

X12

X13

X19

X7

X4

X2

X11

DS30

2 – 29

2.7 ... in the water unit

Board Components on the board

LED DS30 - (Yellow) ON > Filling level of Sepa tank OK

LED DS32 - (Yellow) ON > Disinfectant tank at lower filling level

LED DS41 - (Yellow) ON > Flushing tank at lower filling level

LED DN30 - (Yellow) ON > Waste water from cuspidor

LED FS - (Yellow) foot control active

LED HEART- (Yellow) Flashes once per second during normal operation

LED ERROR- (Yellow) Flash code

LED POWER_FAIL- (rot) ON > 36 V Operating voltage under 34V

LED R2_DT - (Yellow) ON > Tumbler heater present and ready for operation

LED R2_ON - (Yellow) ON > heater switched on

LED S3 - (rot) Safety switch AA S3

LED SS_SP- (Yellow) Safety switch cuspidor.

Power pack signal:

LED EK_90- (Red) ON > Power supply unit load > 90% in input circuit

LED TEMP_10- (Red) ON > Power supply unit overheating shutdown in 10 seconds

LED EMERGENCY OFF- (Red) Power supply unit switches off

LED PK_90- (Red) ON > Power supply unit load > 90% in patient circuit

LED PC_LIM- (Red) ON > PC video circuit in current limitation

LED PC_ON- (Yellow) ON > Video circuit switched on

LED UNIT_ON- (Yellow) ON > ON / OFF pressed on the dentist element user interface

OFF > Suction will be switched off

OFF > Heater active when LED_R2ON (Yellow) = ON

OFF > Video circuit switched off (Sirotom removed)

LED CUPFILL- (Yellow) ON > Morita > Switch on MV34 (tumbler filling)

LED CHAIR_STOP(Yellow) ON > Motion lock via active instrument

LED MM_DIR1- (Yellow) ON > Cuspidor motor rotary direction 1

LED MM_DIR2- (Yellow) ON > Cuspidor motor rotary direction 2

LED MV3- (Yellow) ON > Disinfectant dosage valve switched on

LED SIR_ON- (Yellow) ON > Sirolux switched on

LED ROE_ON- (Yellow) ON > X-ray viewer switch-on signal

LED ROE_OFF- (Yellow) ON > X-ray viewer switch-off signal

LED MS_ON- (Yellow) ON > Sepa motor switched on

LED MA_ON- (Yellow) ON > Amalgam separator switched on

LED V1_LED- (Yellow) ON > Light barrier signal when amalgam separator is running

LED MV40.1- (Yellow) ON > Right chamber of the water pump is active

LED MV40.2- (Yellow) ON > Left chamber of the water pump is active.

LED MV41- (Yellow) ON > Filling valve for rinsing tank is switched on

LED MV44- (Yellow) ON > Hydrocolloid valve switched on

LED MV1- (Yellow) ON > Filling valve for mixing tank is switched on

LED MV34- (Yellow) ON > Filling valve for tumbler is switched on

LED MV33- (Yellow) ON > Location selection valve for suction is switched on

LED AA95- (Yellow) ON > Filling level of amalgam rotor is > 95%

LED AA100- (Yellow) ON > Filling level of amalgam rotor is 100%

LED MV 37- (Yellow) ON > Water cover of drain to amalgam separator is open

LED MV35- (Yellow) ON > Flushing is switched on

X1 > L207 > X1 Power supply

If water is removed, then the

LED MV40.1 and MV40.2 flash alternately

2 – 30 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

Board Components on the board

X2 > Centrifuge_motor amalgam separator

X3 > L206 > X3 Power supply

X4 > Amalgam separator

X5 > L205 > X6 > L305 > X2 NSA

X6 > Sirolux F

X7 > S3 Amalgam separator

X8 > L217 > Water detector - MV37 and DN30

X9 > L219 > MV35 Flushing

X10 > DNA float switch

X11 > L221 > MV34 Cup fill

X12 > MV33 Automatic separator

X13 > DS30 Automatic separator

X14 > Heater

X15 > L215 > X-ray viewer

X18 > DNA Cuspidor valve

X19 > M8 Automatic separator

X20 > L18 > M9 Motor / S13 Cuspidor

X22 > L220 > CN1 / CN3 Morita PCB

X25 > L208 > Sensor1 HS1 / Sensor2 HS2 Pump > MV40.1 / MV40.2 Pump

X26 > L224 > MV3 Disinfection

> DS32 Disinfection

X27 > L223 > MV1 Disinfection > DS31.1 / DS31.2 Disinfection

X29 > L201 > MV41 Flushing vessel > DS41 Flushing vessel

2.7 ... in the water unit

bеЦдблЬ

Function of the NWE board

The NWE board controls all functions listed below

Cleaning system

Chemical disinfection system

Hydropneumatic pump

Standard tumbler filling with heater

Automatic tumbler filling

Swivel unit for cuspidor

Automatic separation

Amalgam separator with water alarm

Wet suction with cleaning button

Flushing

X-ray viewer on the tray

Hydrocolloid solenoid valve

Sirolux examination light

Communication with other components of the dental treatment center

Central power supply

Acoustic signal sensor for amalgam alarm, programming confirmation, etc.

Filling level detection via magnetically closing reed contacts:

- Mixing tank with upper (DS31.1) and lower (DS31.2) filling level sensor

- Disinfection tank only with lower filling level sensor (DS41)

The position of the pistons of the water pump is recorded magnetically analog via Hall sensors.

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

2 – 31

2.7 ... in the water unit

2.7.2 NWM board - Automatic tumbler filling

CN1

CN2

LED1

CN3

CN4

CN7

LED2

CN5

LED1

LED2

LED3

LED3

CN8

MWM

MWM

CN6

Board Components on the board

NWM Automatic tumbler filling LED1 - +15 V - Operating voltage (Green)

LED2 - Cup - Cup recognized (Yellow)

LED3 - Water level - Filling level achieved (Red)

CN1 > L220 > X22 NWE (Power supply)

CN3 > L220 > X22 NWE (Relay output)

CN4 > Potential filling level

CN5 > Light barrier

CN6 > Filling sensors

CN4 >

CN5 > Photo IC / IR LED

CN6 >

NWE

Function of the NWM board

Automatic tumbler filling (option only for Japan)

61 94 448 D 3509

2 – 32 D 3509.076.01.01.02 07.2008

TENEO

3 Important information

3 Important information

Switching the dental treatment center ON/OFF

3.1

After switching on the operating power supply, the boot loader is started on all boards. The software of the NSA board checks

all components to see whether they are up-to-date.

If they are not, an update is started (this can be done after a board is replaced).

If the software is up-to-date, it will be given approval to start, the corresponding booting LEDs go out and the application

software is loaded.

The green LED on the user interface is electronically coupled directly to the 36 V operating voltage.

If the dental treatment center is switched off at the user interface, the water unit emits a short beep to confirm the shutdown.

If the DNA option is installed, the DNA tank is emptied before the dental treatment center is really switched off. In rare cases

this may take up to 15 seconds. After the unit is switched off via the user interface, the treatment center can switched on

again via the user interface if it has not been switched off at the main power switch.

3 – 2 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

3.1.1 What happens when it is switched on?

Switch on the dental

treatment center

3 Important information

Switch on the dental treatment center at the main

Does the power supply unit

ja

switch

Relay in the user

interface switches on

audibly

Yes

switch on?

No

Activate the ON/OFF button on

the user interface

Replace power

supply unit

ja

bеЦдблЬ

3

No

ja

Was the power supply unit disconnected

from the mains voltage for 5 minutes?

Was the power supply unit

switched off for less than 20 seconds?

No

Is the WU X1 / {PSU X1 (L207) connector

Is clinic mode switched on?{(X1.A5. is not

plugged in?

ja

allocated)

Disconnect the power supply unit

No

No

No

from the mains for 5 minutes

Switch off the power supply unit at

ja

the main switch. Wait more than 20

Establish the connection WU X1 /

In sequence:{Replace power

supply unit -> test Replace NWE ->

test

seconds

Switch off the main switch.

{PSU X1 (L207)

Does the power supply unit

switch on?

ja

The operating power LED lights up

on the user interface

During activation of the ON/OFF button on the user interface,

Dental treatment center correctly

switched on

No

On the NWE, disconnect connector X1

Power supply switches on The operating

power LED lights up on the user interface

ja

the "Unit_On" LED lights up on the NWE PCB

ja

No

No

Replace power supply unit

Check signal path Unit_ON/OFFja

In sequence:{Check/replace L207 ->

test{Replace power supply unit -> test

Replace NWE -> test

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

3 – 3

3 Important information

3.1.2 What happens when it is switched off?

Switch off the dental

treatment center

Press the ON/OFF key on the user

interface for more than 2 seconds

Is the acoustic signal from the

WU as confirmation of shutoff

audible?

ja

DWSS integrated?

ja

Do not search for errors Replace

Is the key click of the user interface as

a confirmation of key activation

No

audible?

entire user interface

ja

ja

Check the Unit_ON/OFF signal

within the user interface as well.

Is the user interface still

under warranty?

Unit_ON/OFF is not grounded.

No

Is there a key click for other key

inputs of the user interface?

User interface cannot generate a

signal sound. {(Example: Signal

sensor defective but no impact on

function)

No

ja

No

Empty DWSS tank. Max.

15 seconds

No

The power supply unit

switches to standby mode

ja

Switch off completely

using the main switch if

required

User interface correctly

shut off

During activation the LED "Unit_On" lights up on

the NWE PCB

No

ja

Is the L207 NWE/

PSUline connected?

No

No

Check the wiring of Unit_ON/OFF from the

user interface to the NWE PCB.

In sequence: Check signal "Power supply

unit ON_OFF“{Check/replace L207 ->

ja

test{Replace PSU -> test Replace NWE ->

test

Re-establish the NWE/PSU connection

3 – 4 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

3.1.3 Signal path of the ON/OFF signal

3 Important information

Unit ON/OFF

NAB NAKTastatu r

X10 X11 X11 X1

9

10

9

9

55

B5 B5RD

L246

NAJ

X1

SDI

X1

X22

10 10 10WH

10

WH

L249

L307

Unit_ON/OFF: (keyboard to NWE) Power supply unit_ON/OFF: (NWE to NT)

Switching on Approx. 8-10 V when ON/OFF key is not pressed

0 V when the ON/OFF key is pressed

Switching off Approx. 28 V when the ON/OFF key is not pressed

Approx. 0.1 V when the ON/OFF key is pressed

NSA

X1 X2

VT10

L305

ST/WE

X6X1

B4 B4X6WH

NWE

X5 X1

Unit_ON/OFF

10

L205

Logik

Unit_On

Yellow

NetzteilON/OFF

Approx. 8-10 V when the ON/OFF key is not pressed

Approx. 0.5 V when the ON/OFF key is pressed

Approx. 8-10 V when the ON/OFF key is not pressed

Approx. 0.5 V when the ON/OFF key is pressed

B1 B1

BN

L207

NT

X1

bеЦдблЬ

3

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

3 – 5

3 Important information

Clean

Setup

CAN BUS

3.2

In the treatment center there are several CAN networks.

Thestandard CAN runs all of the control units for the treatment center, software updates and service support.

The S CAN runs only PC software functions for the user interface.

The motor CAN runs all commands for controlling the motorsM1 / M2 / M3 from theNSA board to the three DCFU boards.

After the treatment center is switched on, all components and software are queried and displayed in the set-up dialog. If the

connection fails during operation, the unit must be switched on again.

SET-UP key

C

> 2s

If an installed component is missing here, this board and the CAN connection to the user interface (NAKboard) must be

checked.

Each node that loses its standard CAN connection to the central error memory in the NSA board flashes cyclically 2x at its

error LED. -> Check the CAN bus.

In each CAN network there are 2x 120-Ohm resistors, that, measured in parallel on the CAN line, result in 60 Ohms. If you

measure 120 Ohms on the CAN line with an Ohm meter (when the dental treatment unit is switched off), there is a disruption

in the line.

In the case of a disruption, measure the connections between the connectors.

For example:

Check CAN

+

: NSA board, X1.5 to NAJboard X22.5:

0 - 3 Ohm = OK

00 Ohm = line disruption

240 Ohm = line disruption CAN+ but CAN- is OK

3 – 6 D 3509.076.01.01.02 07.2008

61 94 448 D 3509

3 Important information

3.3 CAN BUS wiring diagram

Standard CAN

3 33

5 45

NHE

CAN + CAN + CAN + CAN +

120

W

CAN - CAN - CAN - CAN -

SDI SDI

X4

YE YE YE YE YE YERD

GN GN GN GN GN GNBU

NSA NSC

X3X3 X1 X1 X1X22X4

A3

5 5 A3 A35555

A23 3 A2 A23333

B3

X4

B3

X4

X3 X3

A5 9

A4 7

A3

BU

A3

NSK NWE NSB HF

5

X2

YE

5

X16

YE

5

5

X32

Speed CAN

X31 X15 X31

NSA NAJ NAK

120

W

3

GN

3

GN

3

3

3

5

X5

YE BU OG

GN RD GNGY

3

5

X5

X6

X8

X8

4

3

4 mm Isolation

NAC / NAL

3

4

3

4

3

5

X32

B1

B2

X2

+

bеЦдблЬ

3

NSA

120

CAN +

W

CAN -

X1

RD RDPK

BK BUGY

SDI

NAJ NAK

X1X1X22

A5A5999

A4A4777

Motor CAN

NSA

DCFU

Motor-CAN + Motor-CAN + Motor-CAN +

RD YE

BU GN

Motor-CAN - Motor-CAN - Motor-CAN -

22

120

W

33

X10

2

3

7

120

W

6

120

W

DCFU

Motor-CAN +

2

3

Motor-CAN -

DCFU

2

3

M2

X4

YE

GN

X4X29X4

M3M1

61 94 448 D 3509

D 3509.076.01.01.02 07.2008

3 – 7

3 Important information

Patient chair

3.4

3.4.1 Stand-alone installation function

To operate the chair in stand-alone mode, the installation connector must be connected to the SDI connector of the assistant

element (on the chair). This connector closes off the CAN, simulates the safety switch in the assistant element and a bridge

lets the NSA board detect the connector.